Patents

Literature

399results about How to "Improve paint quality" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Production paint shop design

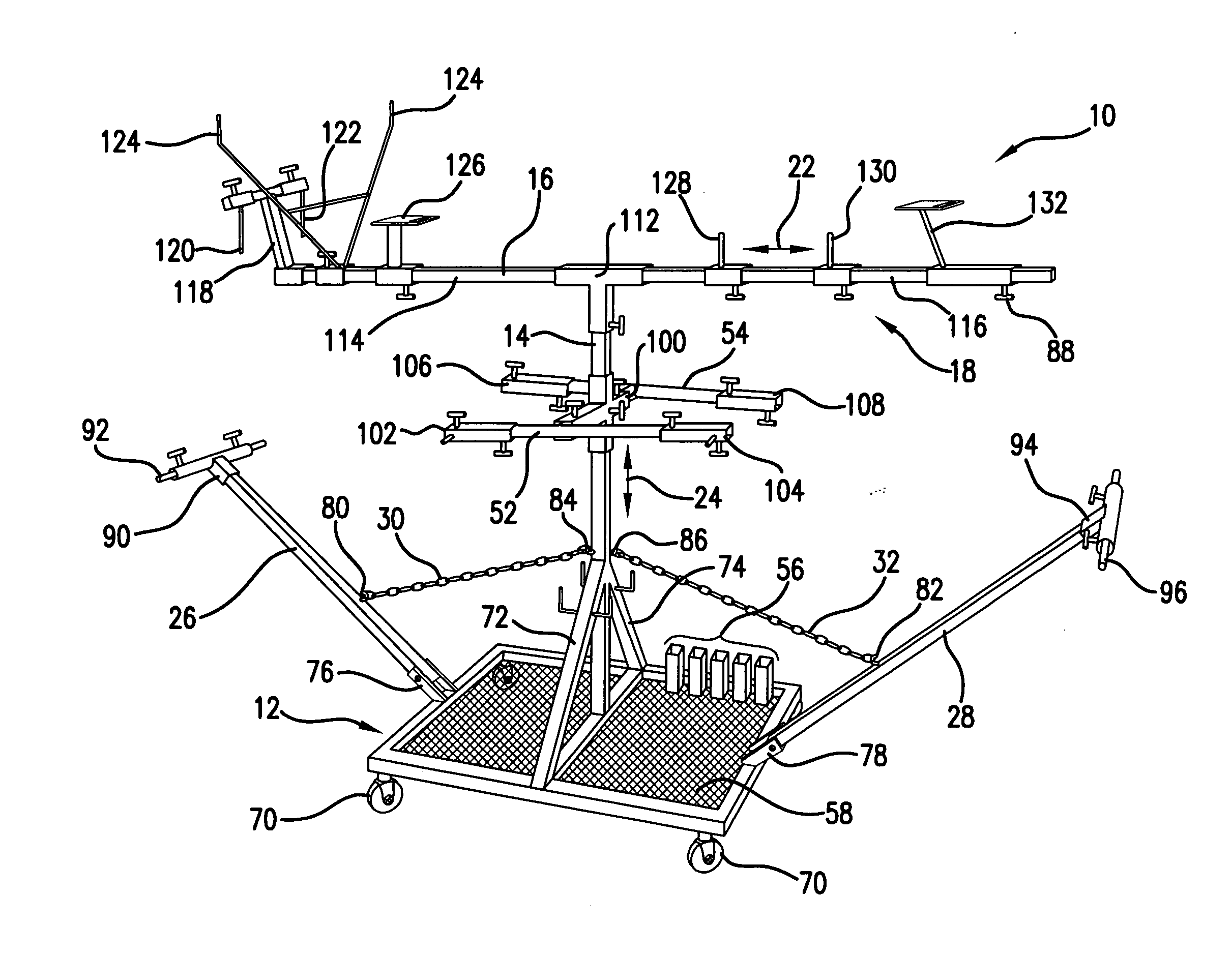

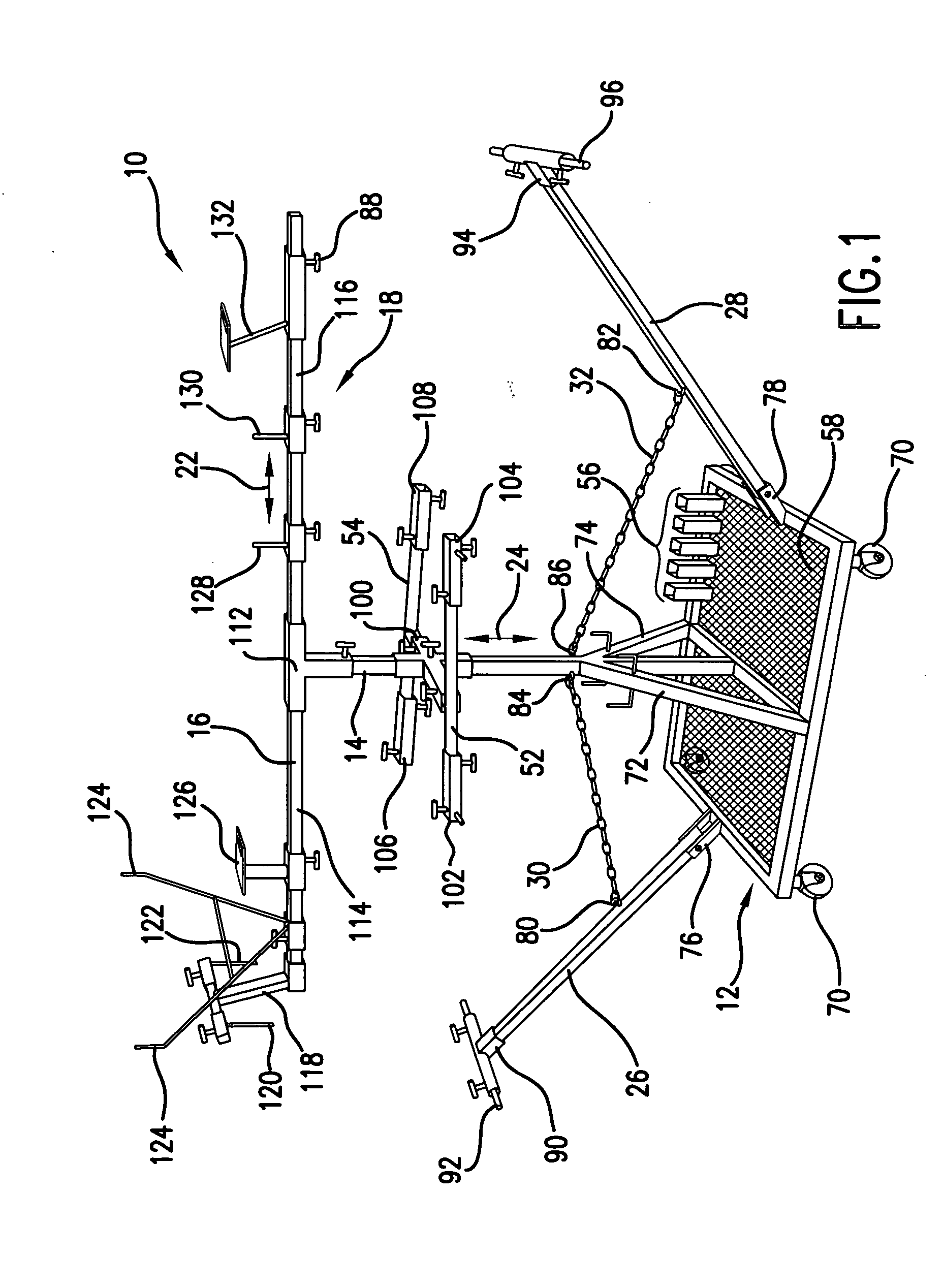

InactiveUS20060068094A1Improve paint qualityReduce flow rateConveyorsSpray nozzlesMotorized vehicleMechanical engineering

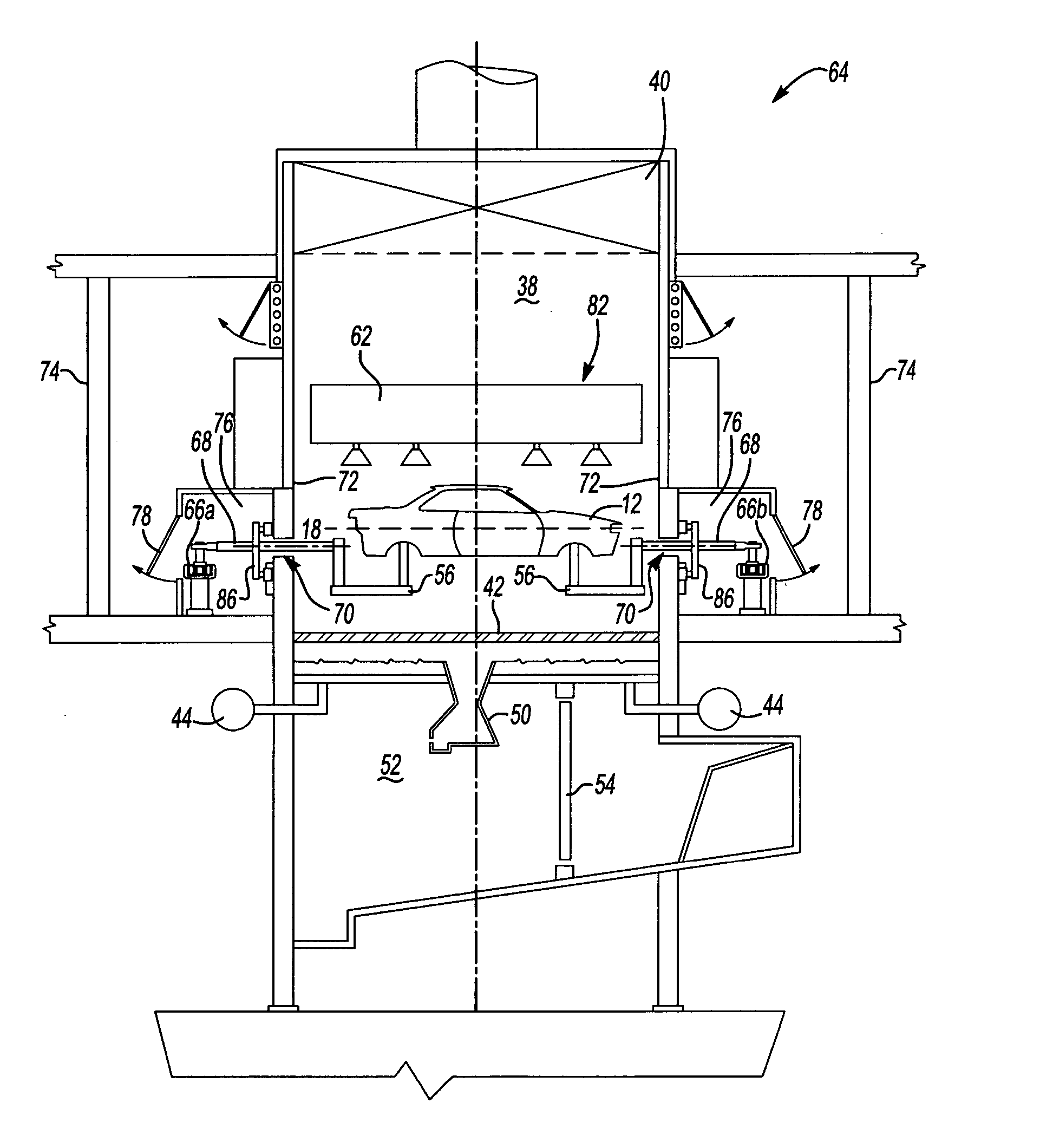

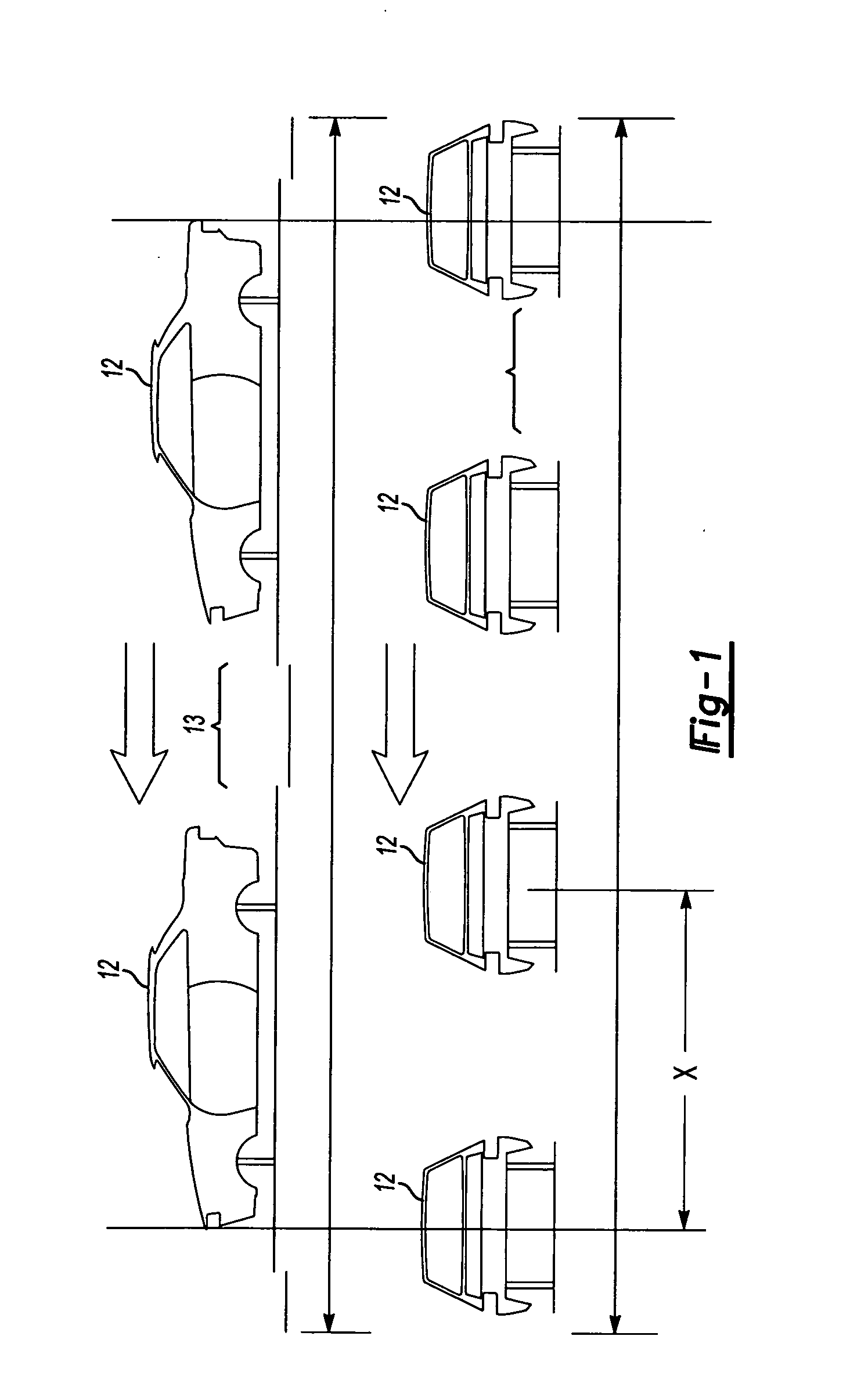

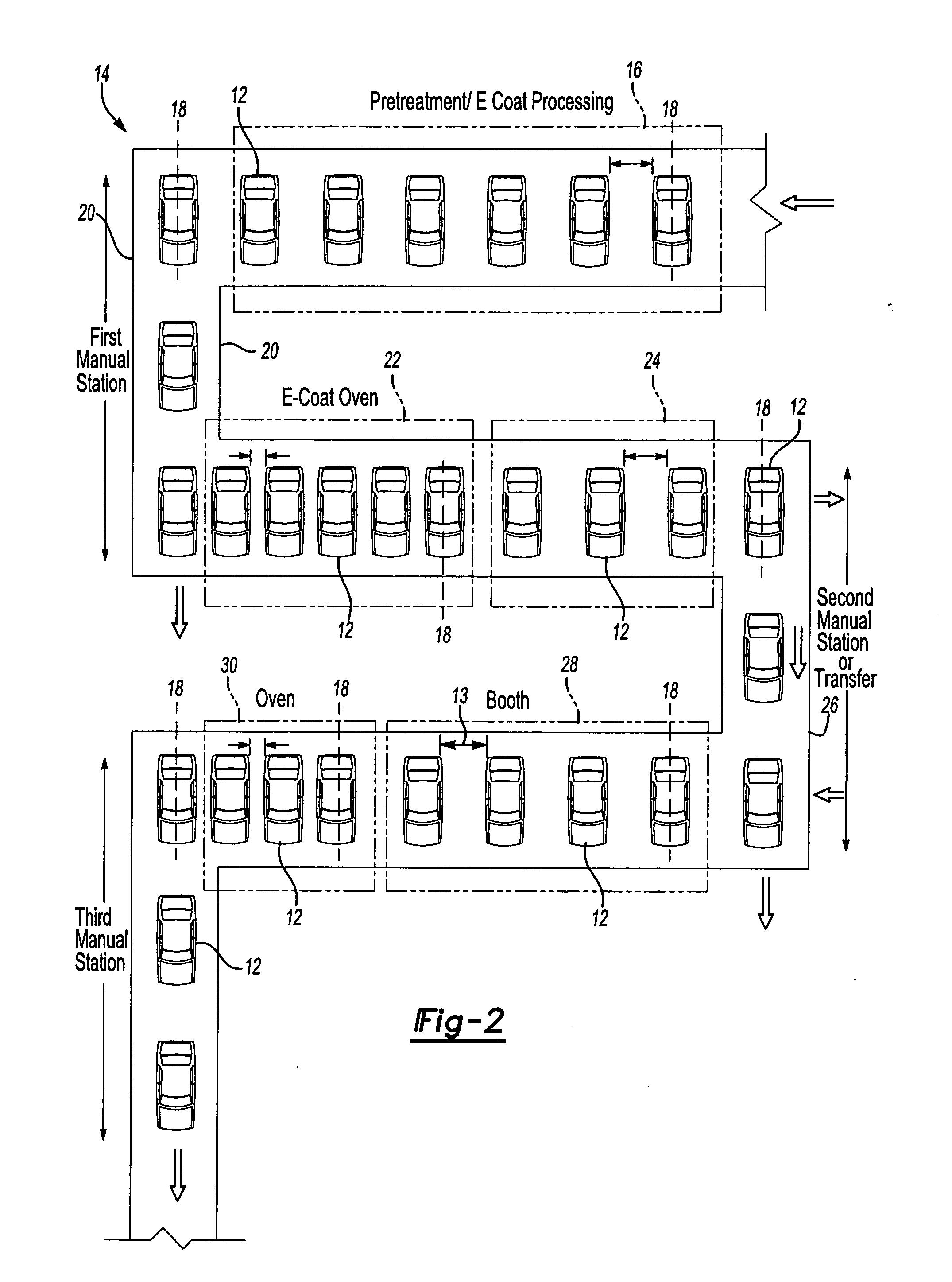

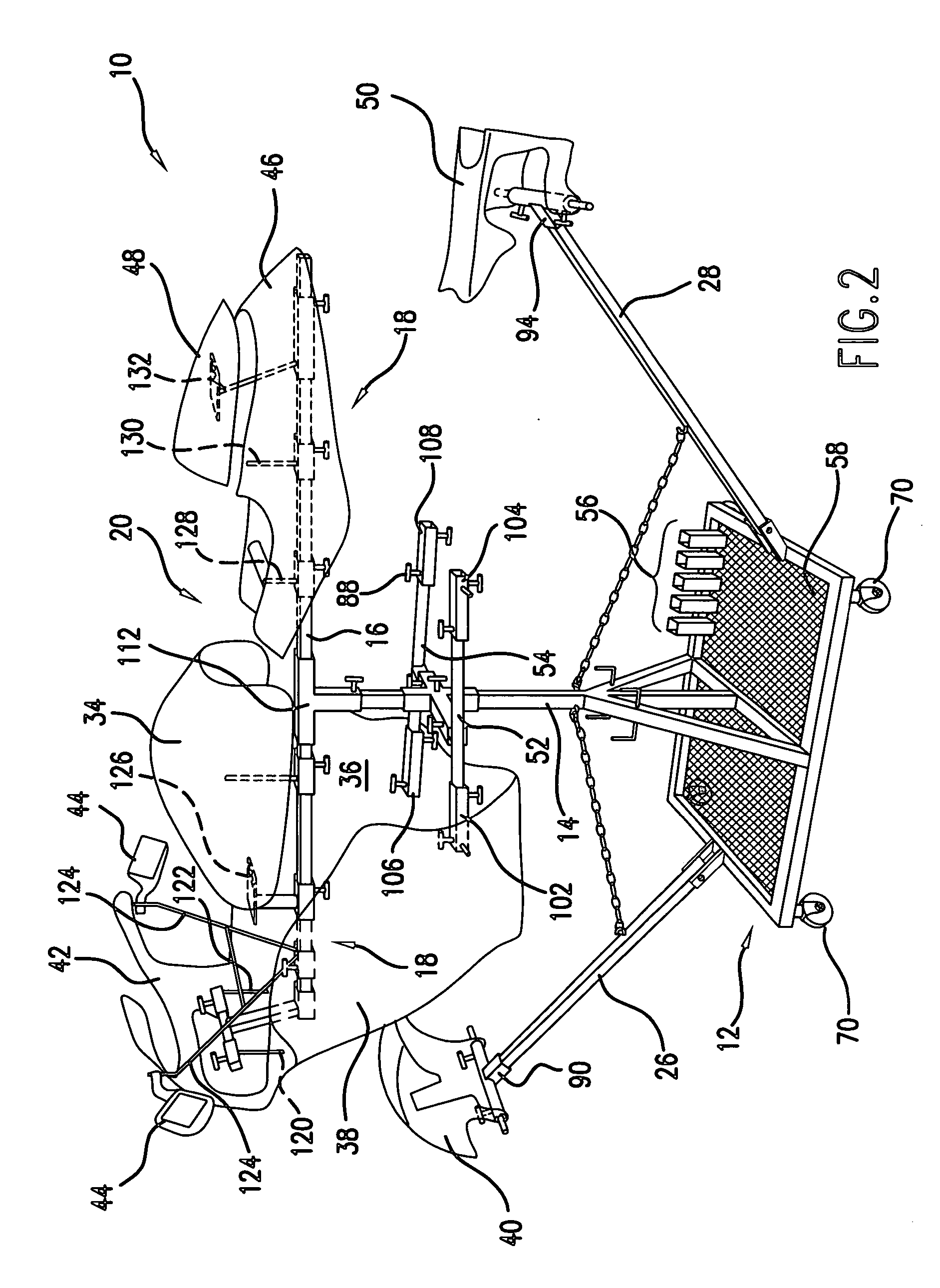

A paint application facility including a paint booth assembly for applying paint to automotive vehicles each defining a longitudinal axis includes a carrier adapted to serially move a plurality of automotive vehicles through the booth assembly in a direction generally perpendicular to the longitudinal axis of the vehicle.

Owner:FUJIFILM HEALTHCARE CORP +1

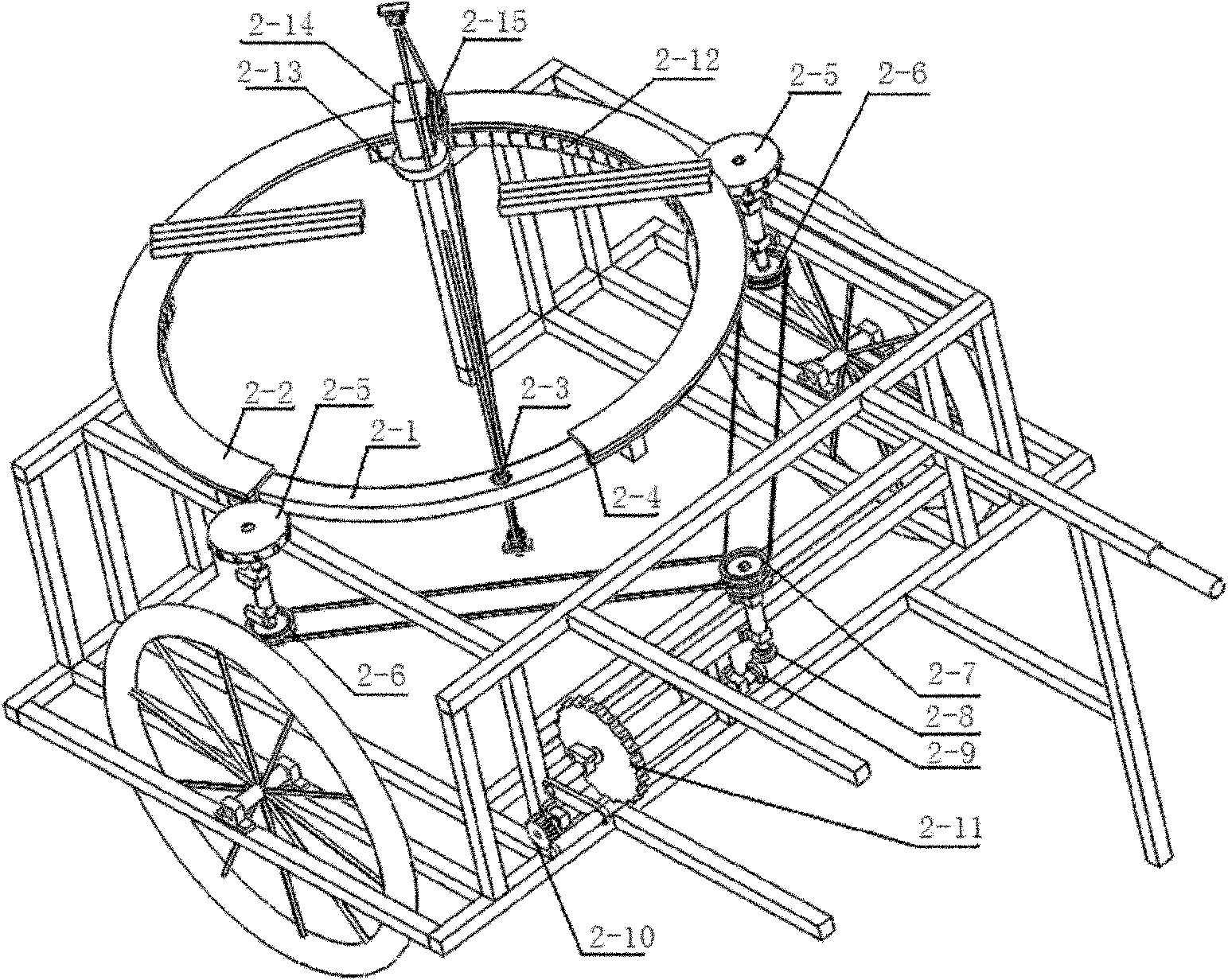

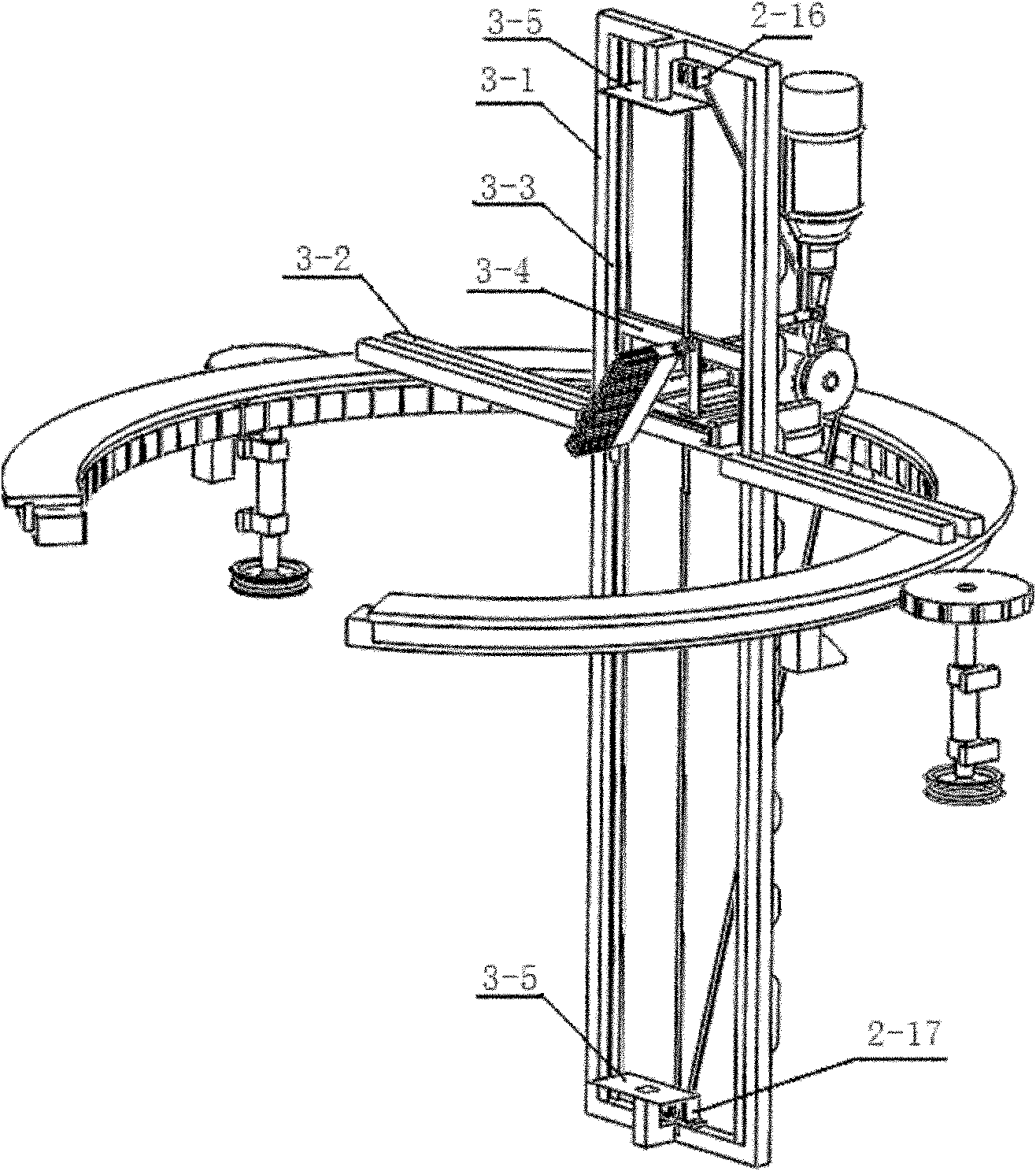

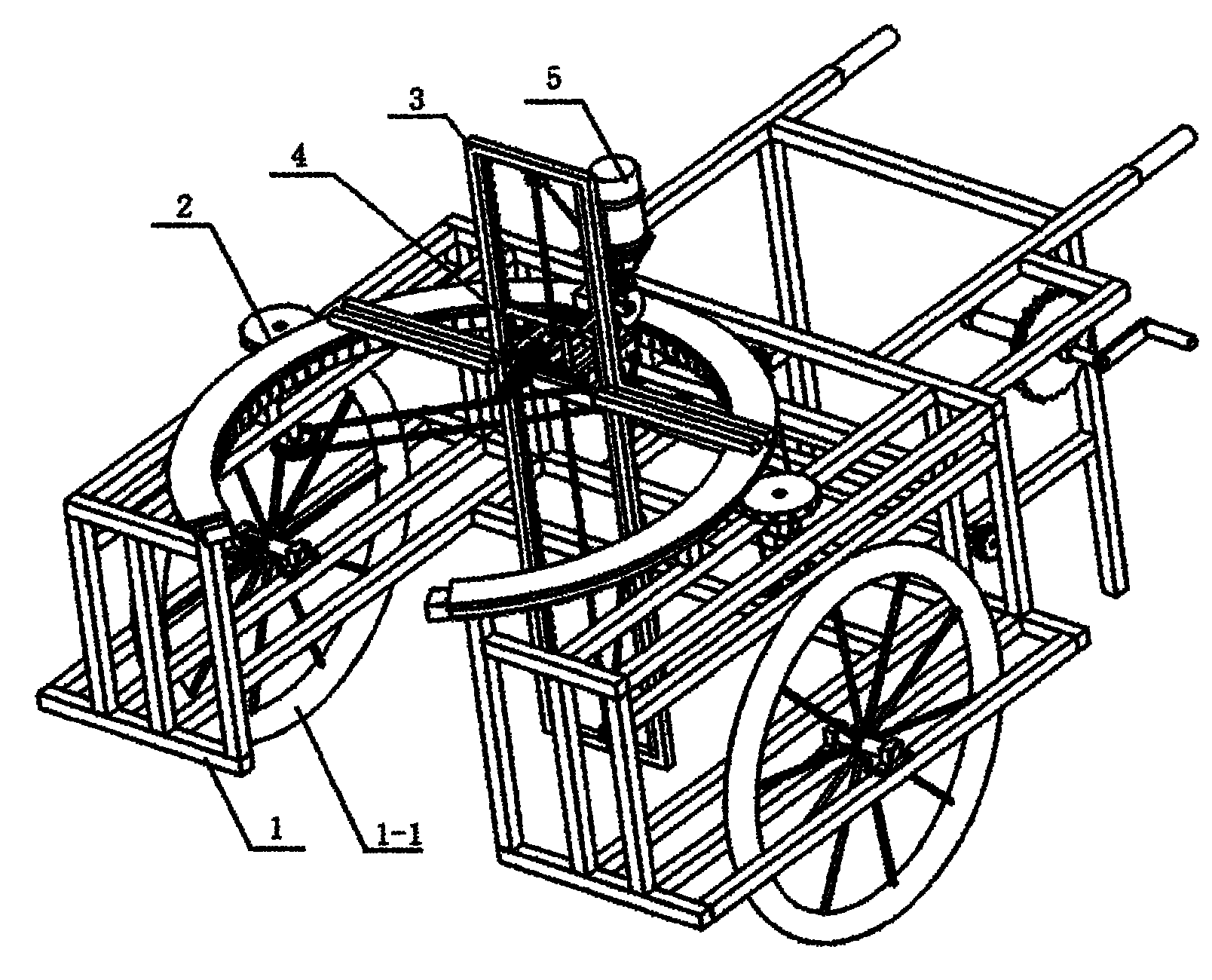

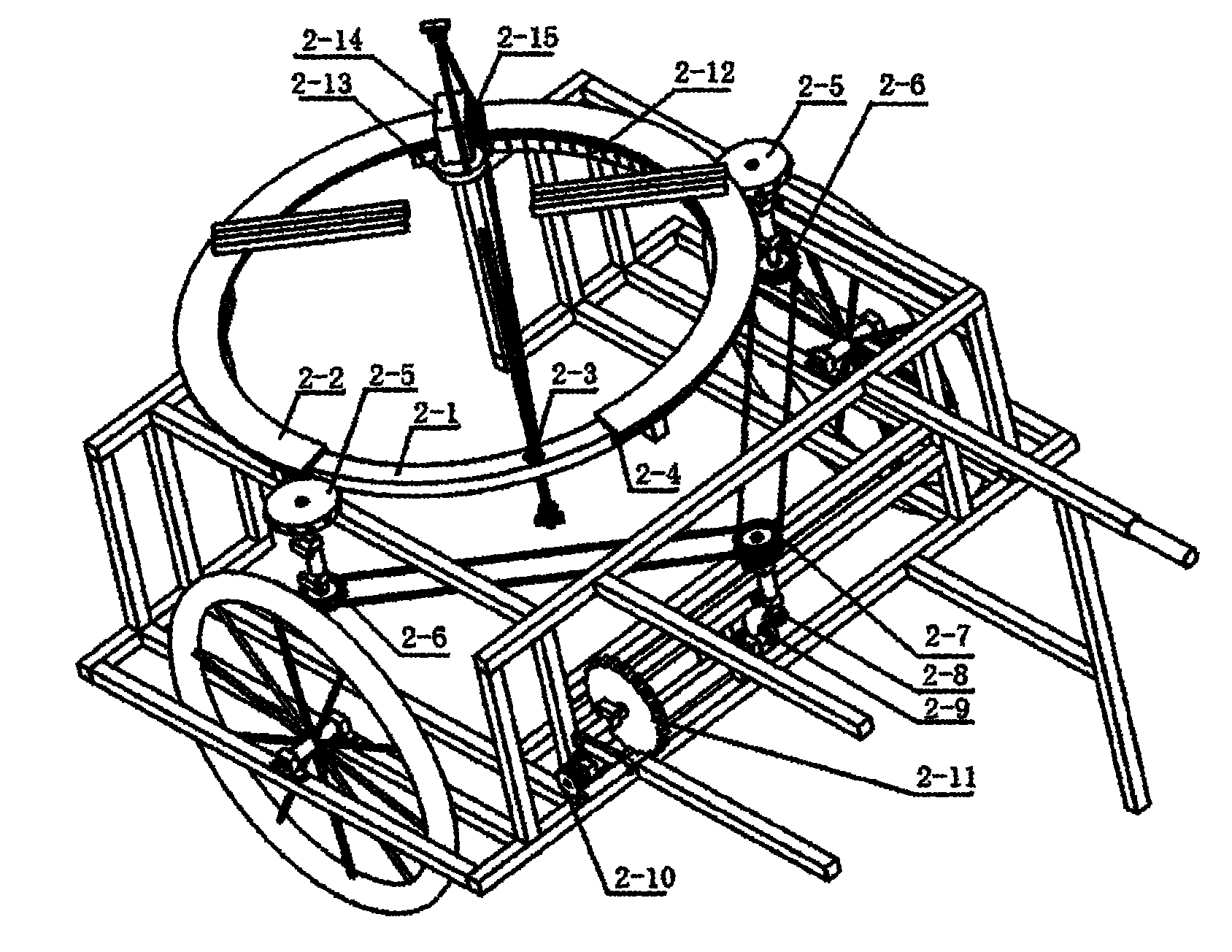

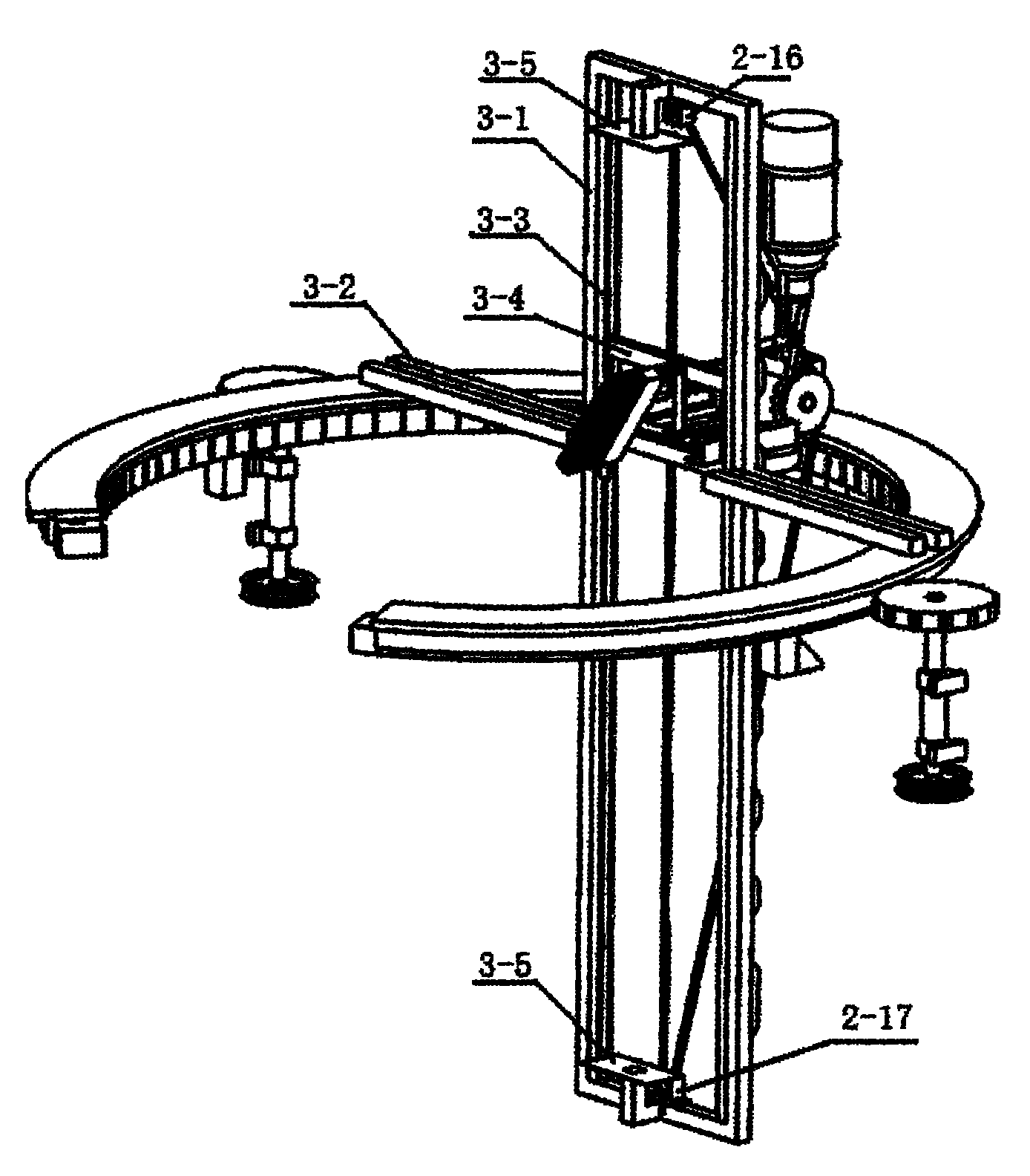

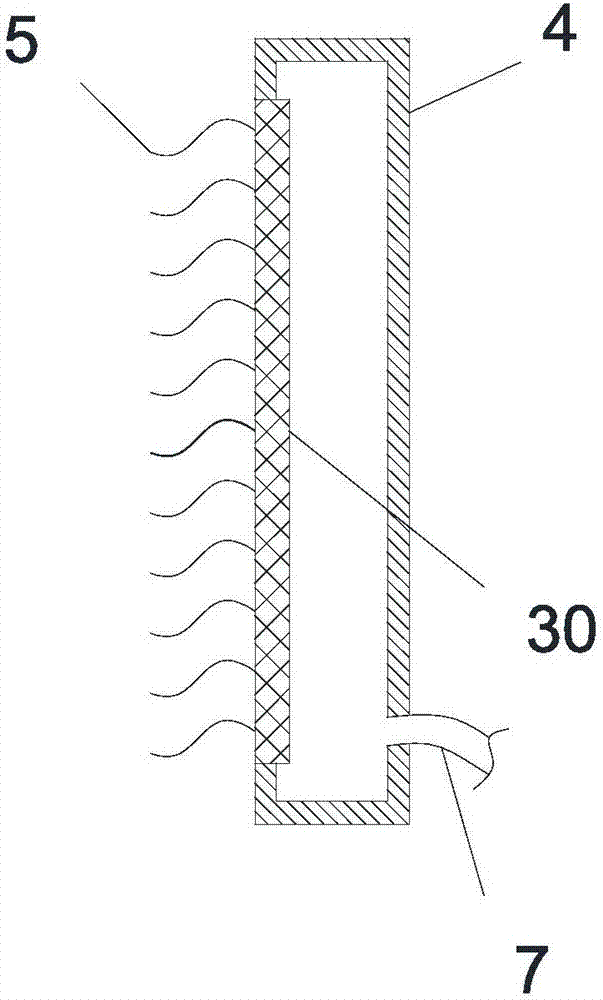

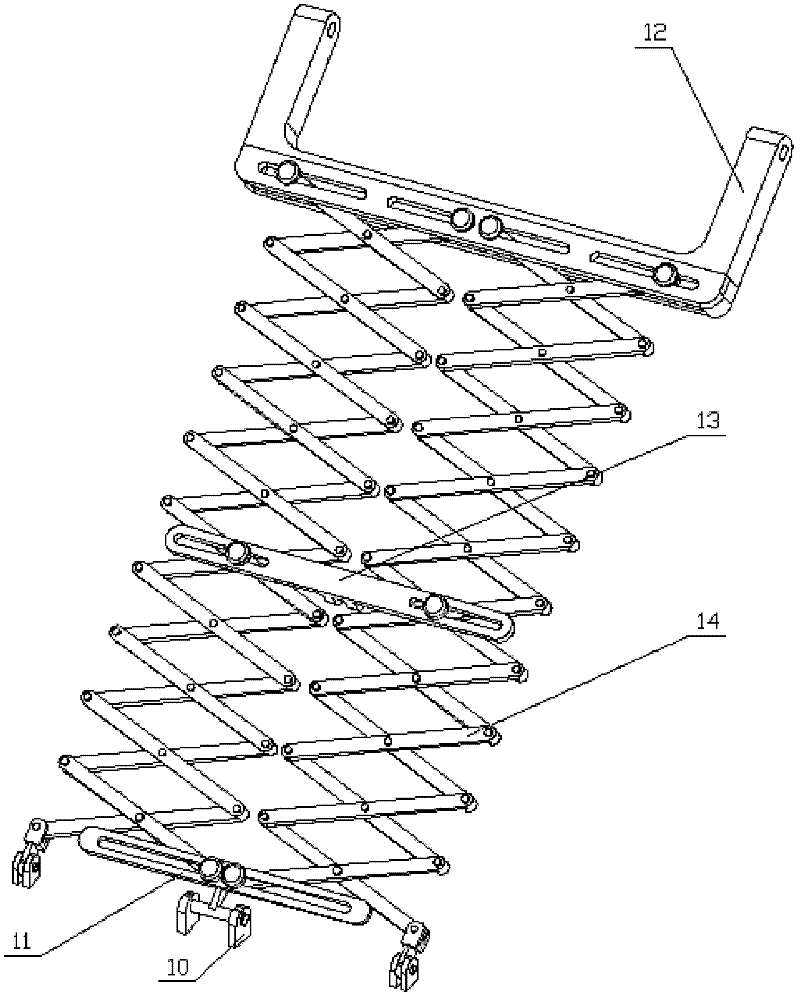

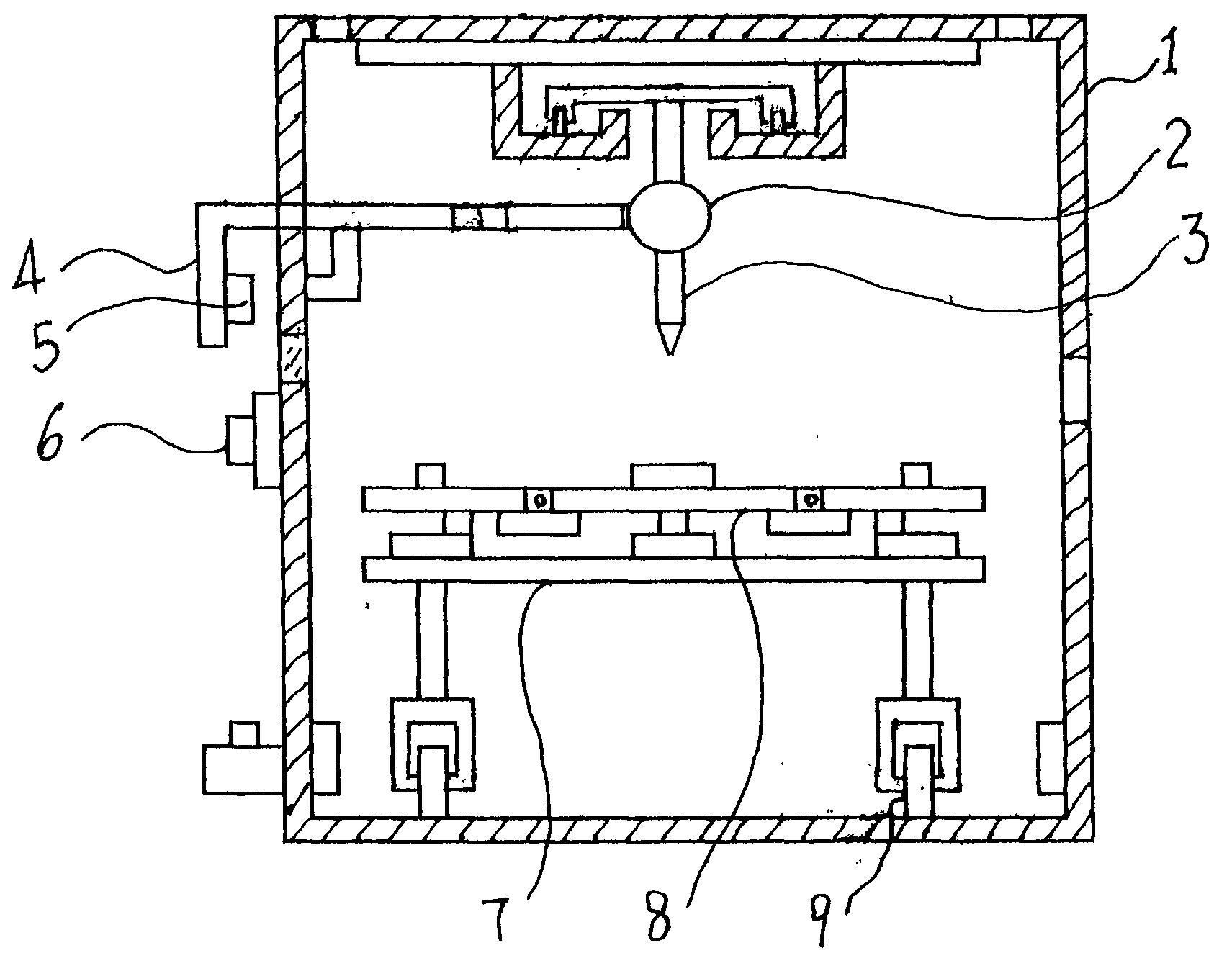

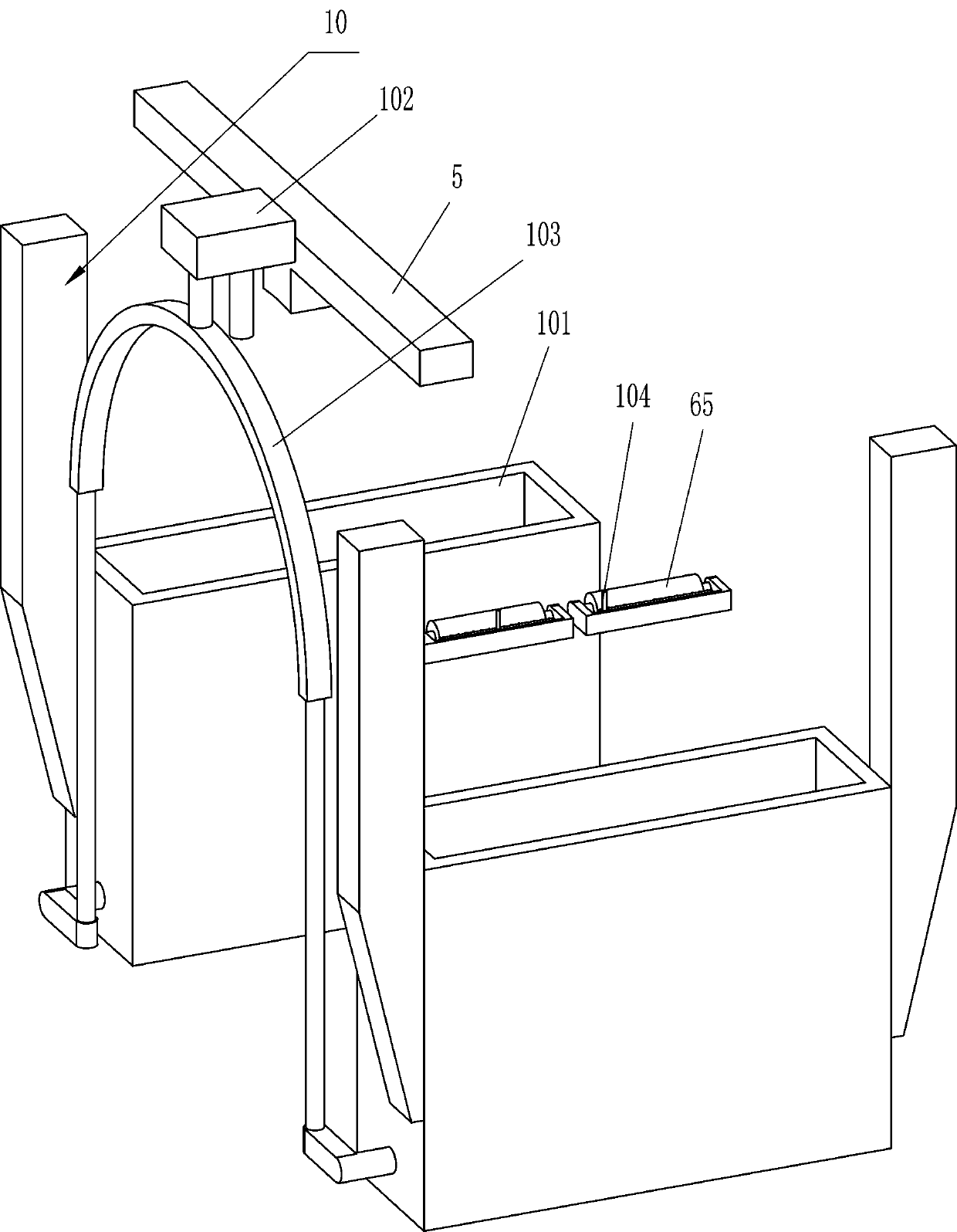

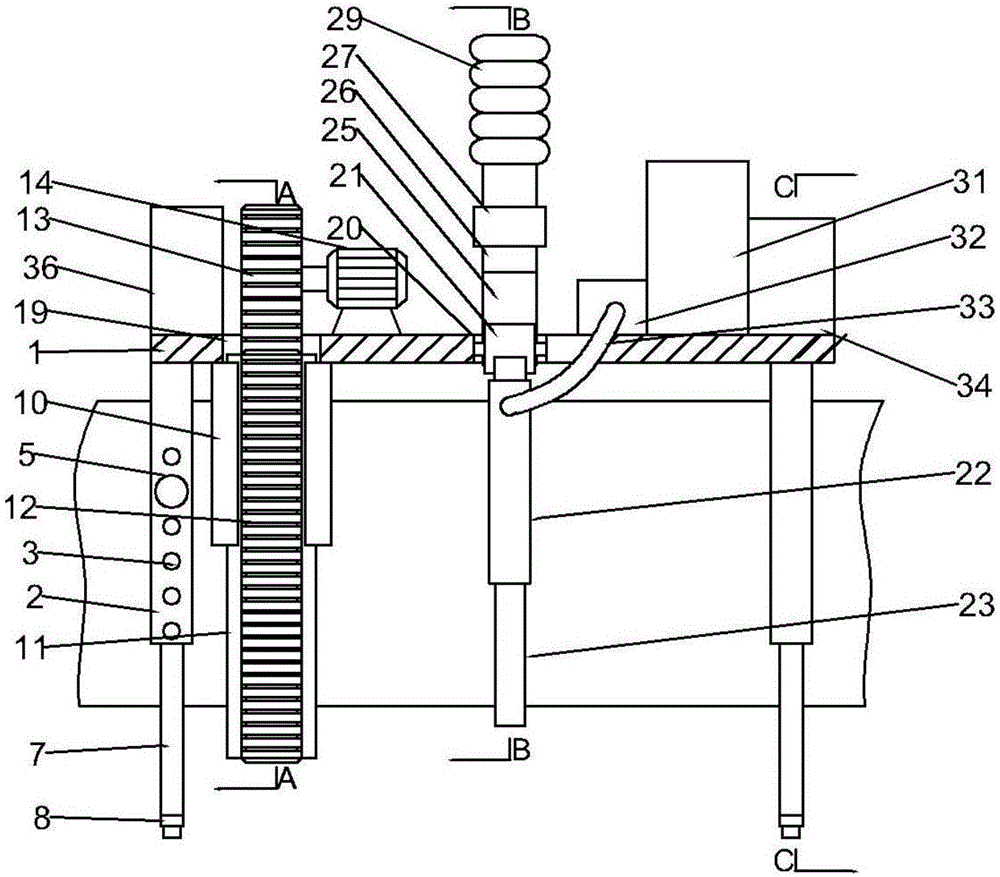

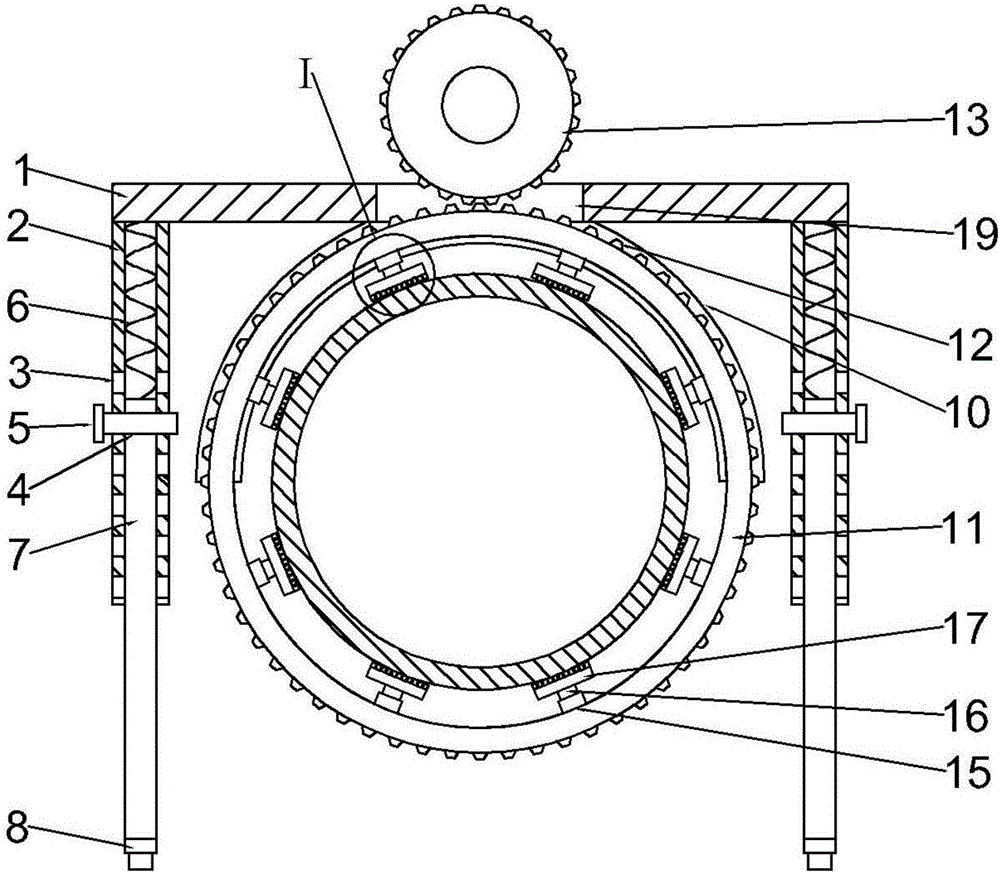

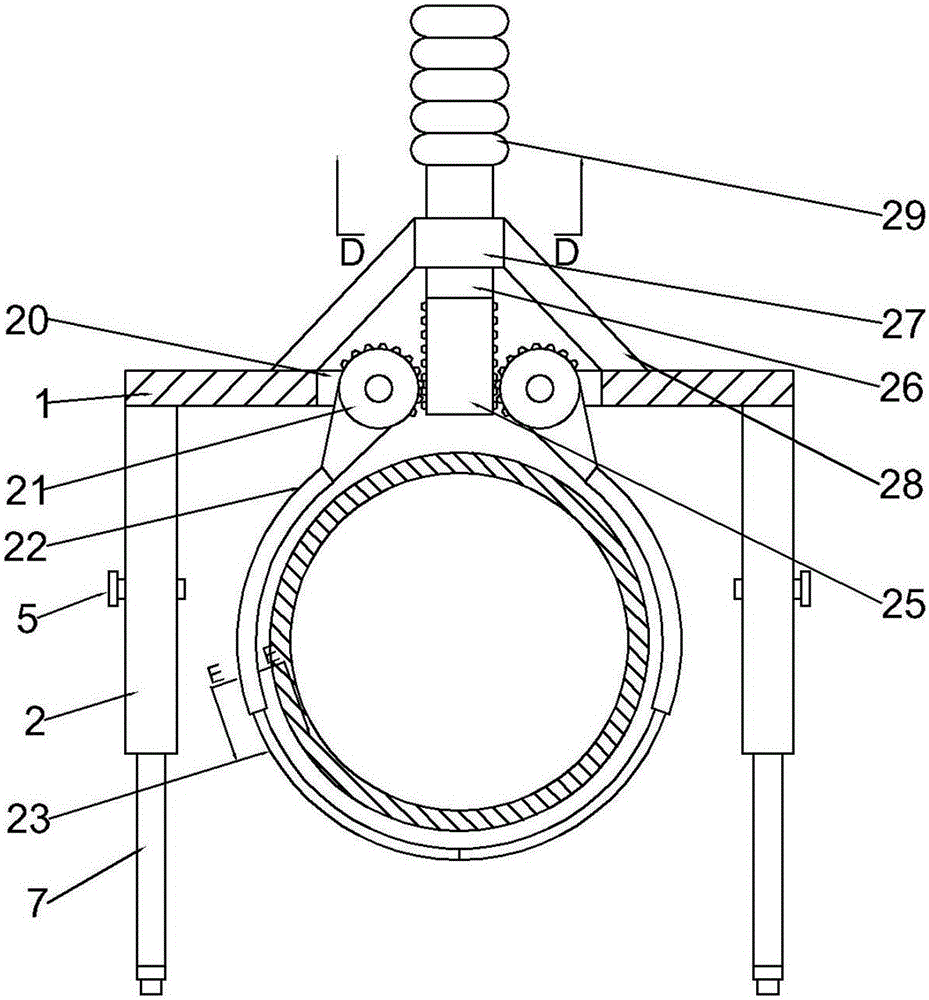

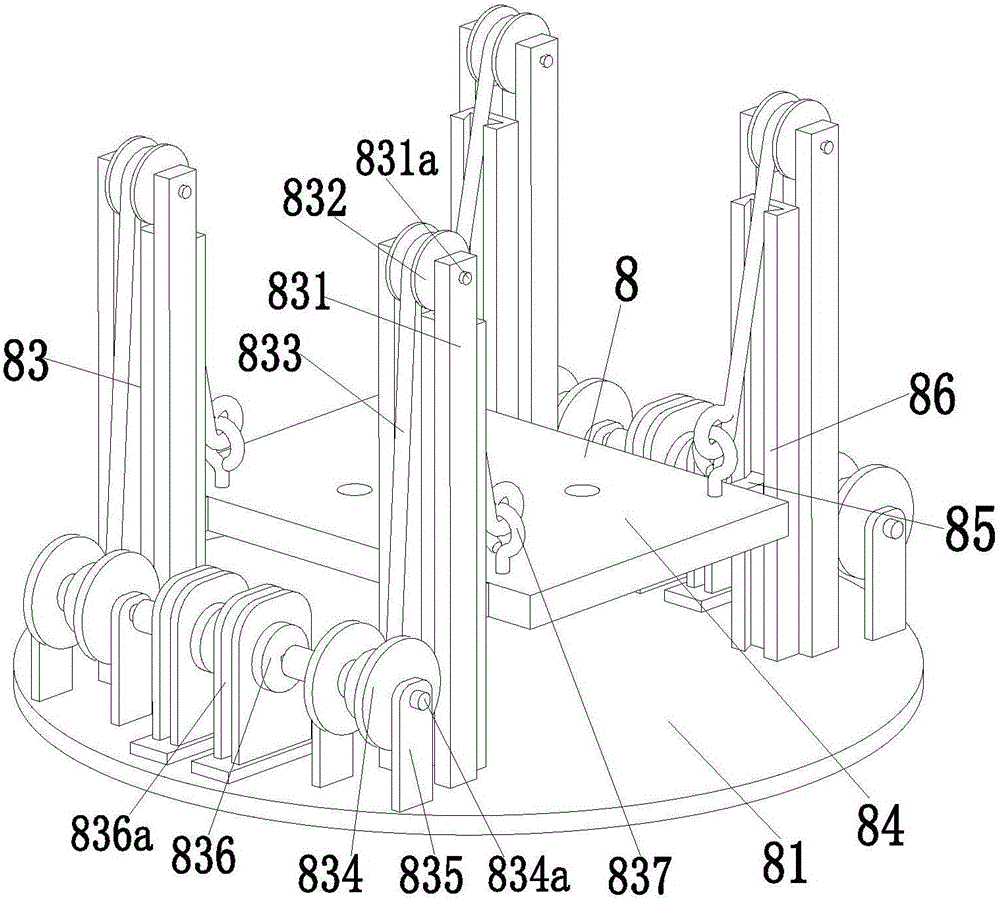

Novel tree whitewashing machine

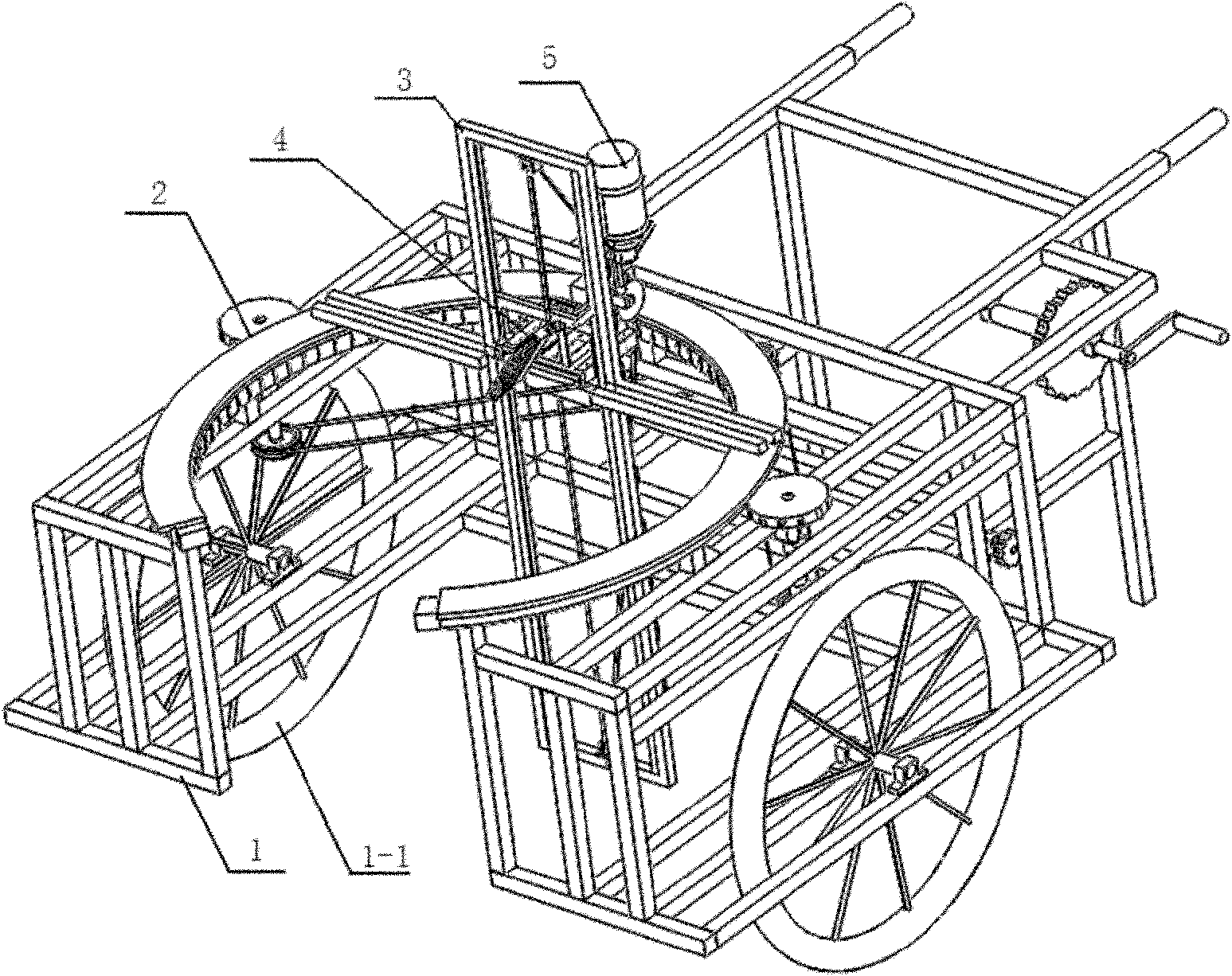

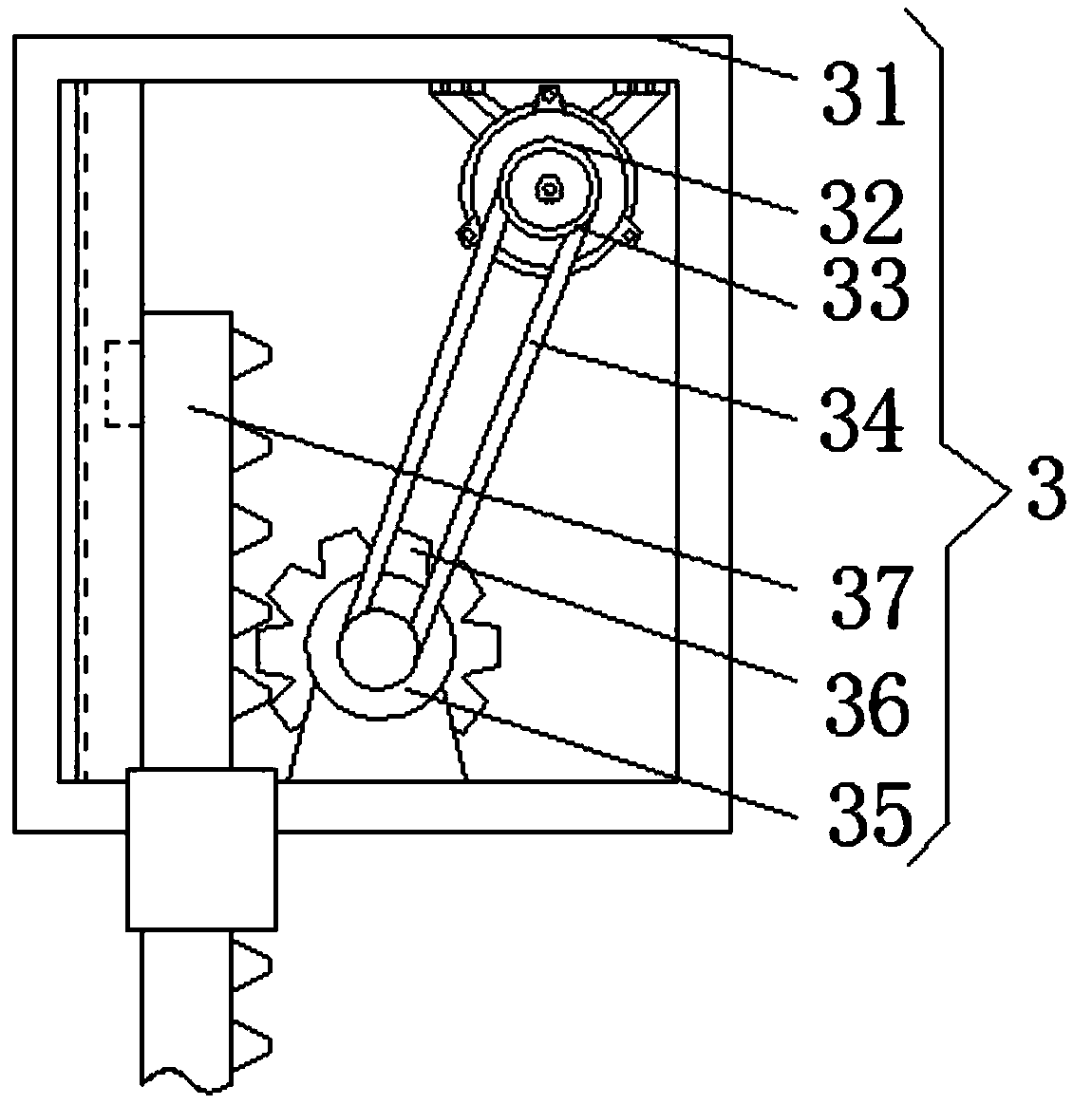

ActiveCN102172187AEliminate working dead endsImprove paint qualityPlant protectionGear wheelFixed frame

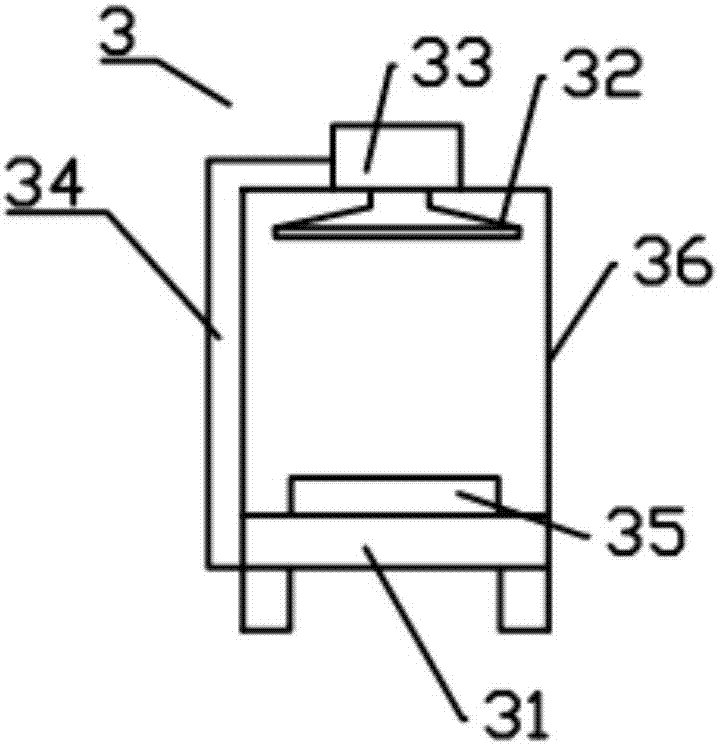

The invention relates to a novel tree whitewashing machine which comprises a frame, a rotating transmission mechanism, a brush mechanism and a liquid feed mechanism. A guide pipe of the liquid feed mechanism is arranged on the brush mechanism; a fixed opening ring is installed on the frame; a rotation opening ring is rotatably installed outside the fixed opening ring in a winding manner; the outer side of the rotation opening ring is provided with a chain with a K-shaped accessory; the chain and a first chain wheel are in engaged transmission; the first chain wheel is in transmission connection with a manual handle through a transmission element; the inner side of the fixed opening ring is provided with an internal rack with an arc opening; a speed reducing commutator is fixed on the rotation opening ring; gears are installed on an input shaft of the speed reducing commutator; an output shaft of the speed reducing commutator is provided with a wire rope pulley; an external framework is fixed on the rotation opening ring through a fixed frame; guide grooves are installed at a left inner side and a right inner side of the external framework; a lifting block is installed on the guide grooves in a vertically-moving manner; and an upper fixed pulley and a lower fixed pulley are respectively fixed on the external framework. The novel tree whitewashing machine can be used for effectively eliminating dead angles and improving painting quality.

Owner:海宁市黄湾镇资产经营有限公司

Autocycle universal stand

InactiveUS20070022950A1Improve paint qualityEasy to viewLiquid surface applicatorsWash-standsMechanical engineering

Owner:LIVINGSTON WILLIAM A

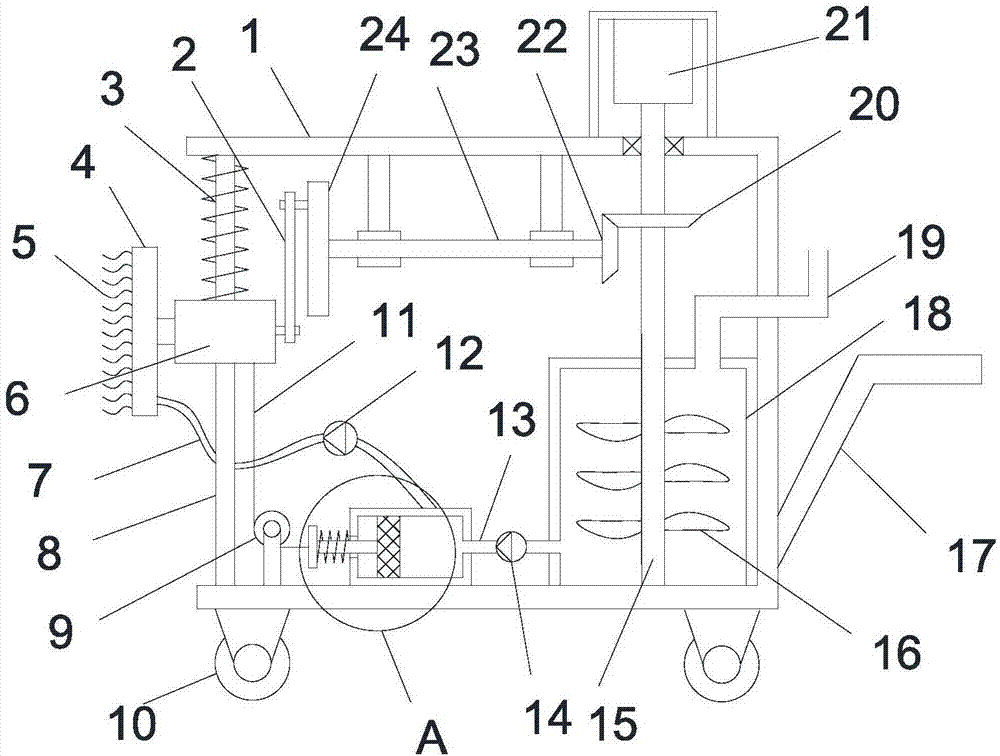

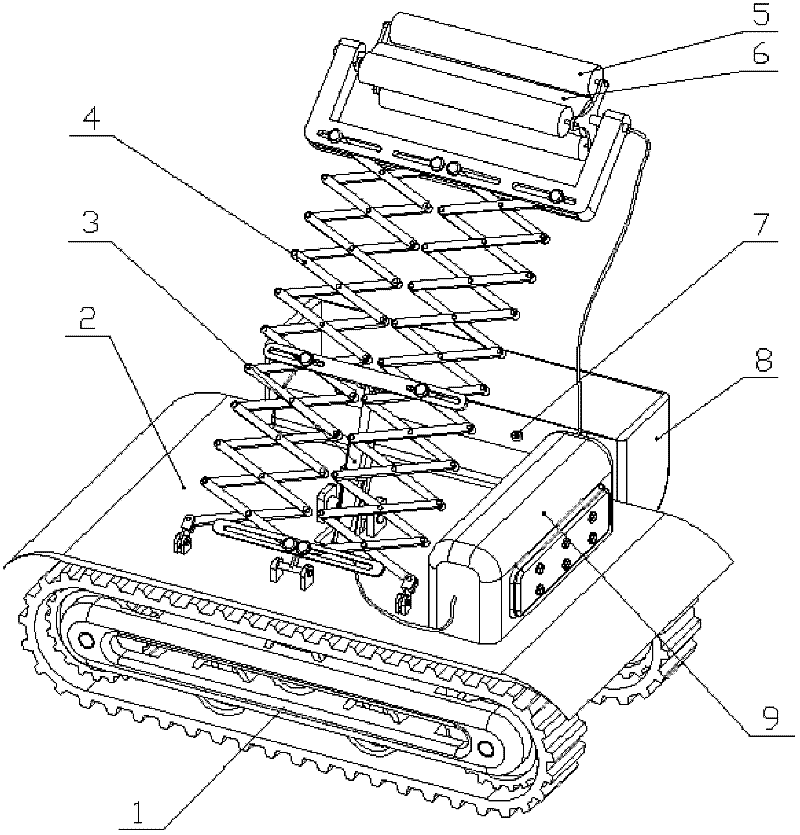

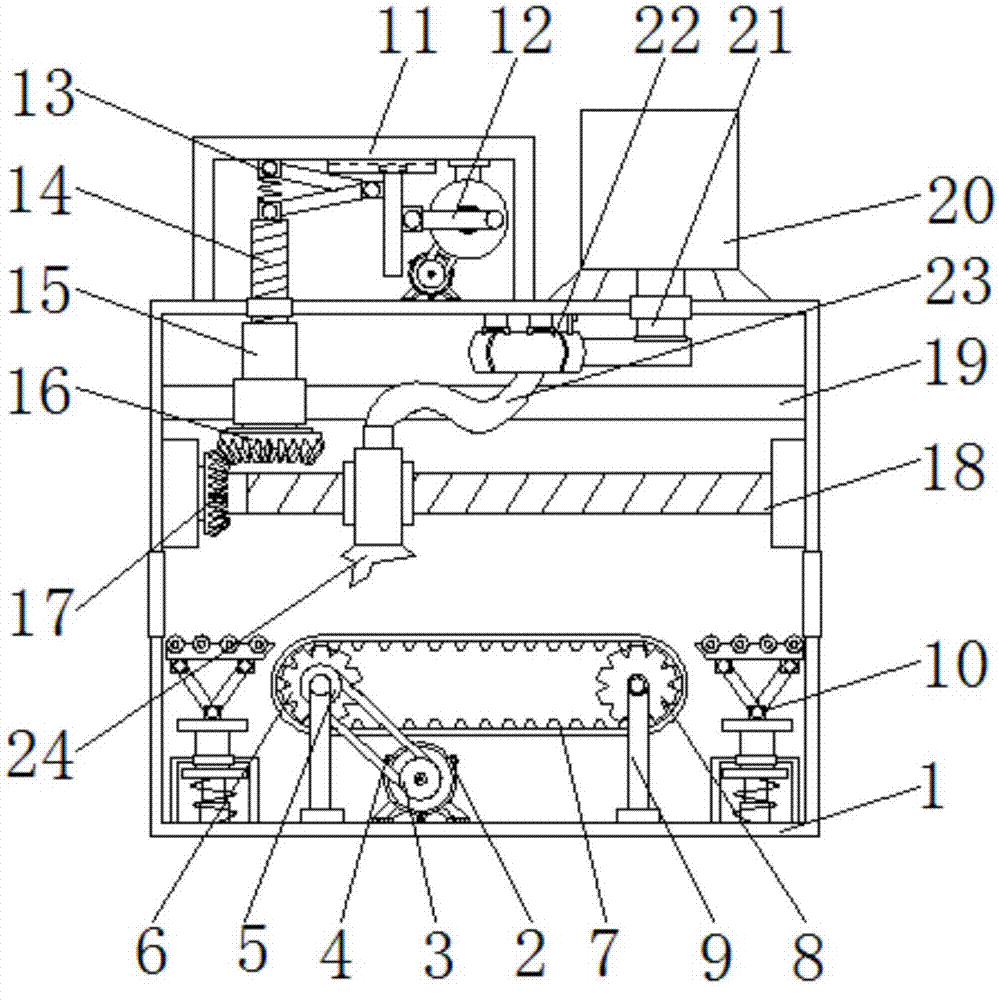

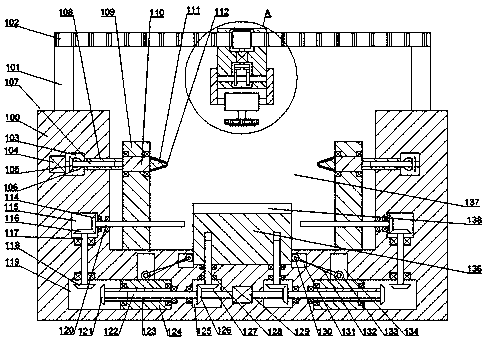

Full-automatic multifunctional wall plastering machine

InactiveCN102011482AEasy to operateHumanized operationBuilding constructionsWorking environmentEngineering

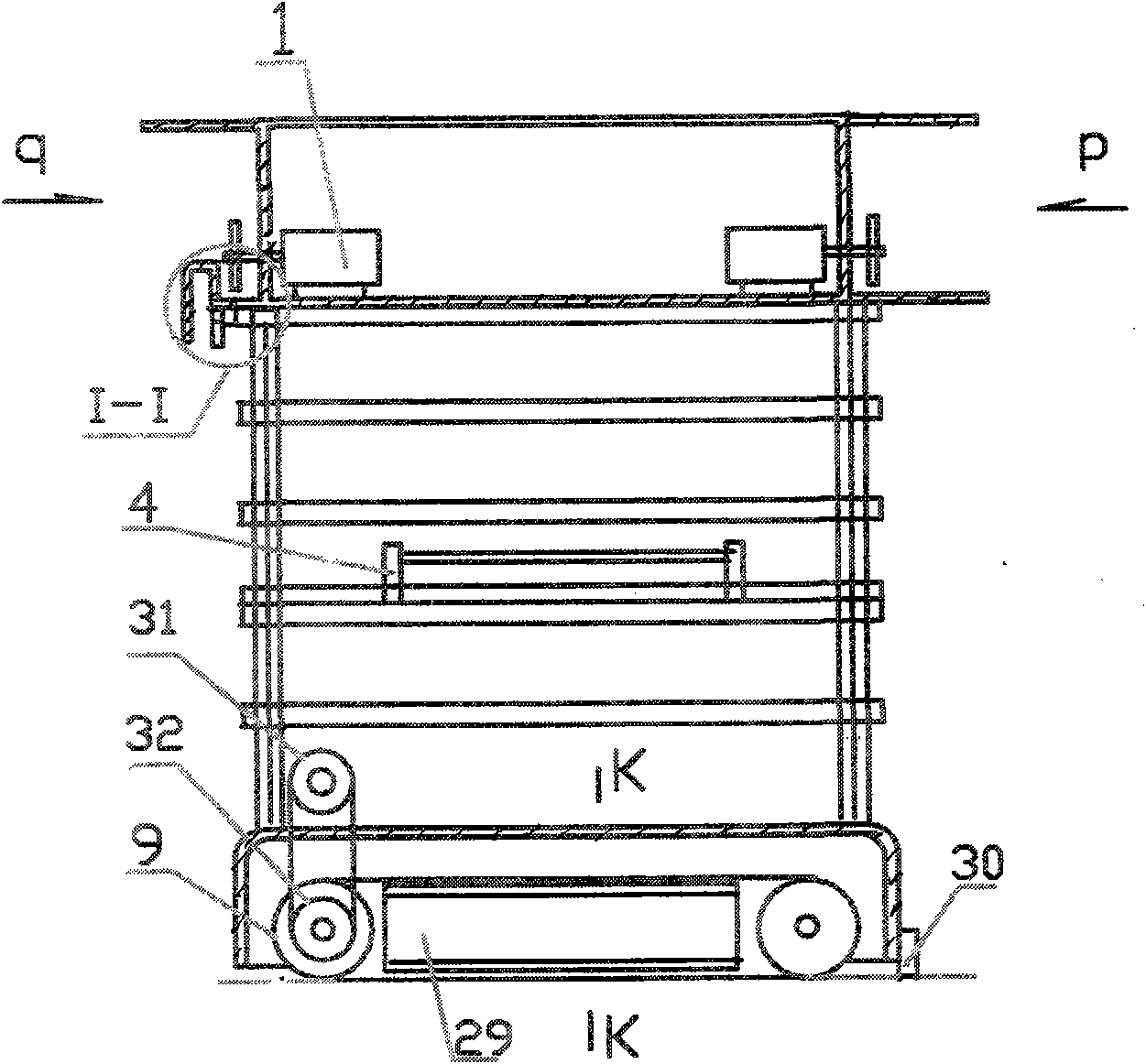

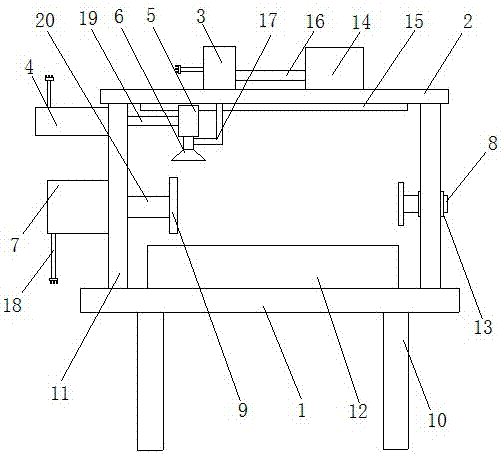

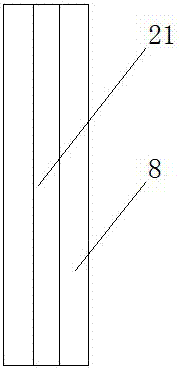

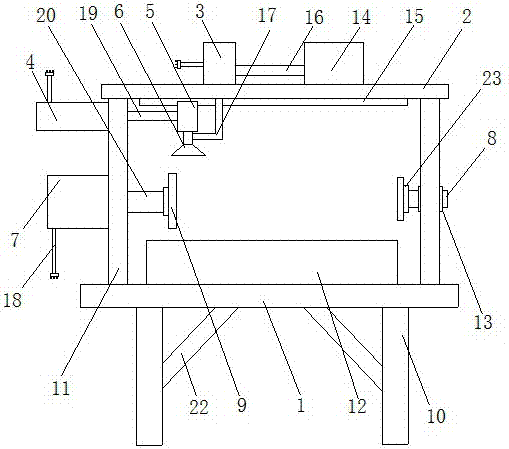

The invention discloses a full-automatic multifunctional wall plastering machine comprising a control mechanism, a power mechanism, a transmission mechanism, a lifting mechanism, a working mechanism and a crawler-type traveling positioning mechanism, wherein the crawler-type traveling positioning mechanism can enable the working mechanism to realize horizontal and vertical synchronous movement positioning; the crawler-type traveling positioning mechanism comprises a horizontal crawler (9) and a longitudinal crawler (10), wherein the horizontal crawler (9) can synchronously travel, and the longitudinal crawler (10) can synchronously travel, lift and veer; and a wall corner plastering roller (21) capable of plastering a wall corner, a wall surface plastering wheel (18) and a roof plastering roller (24) capable of plastering an indoor roof are arranged below the top surface of the working mechanism. The invention can not only save the non-operation time and enhance the wall plastering work efficiency, but also ensure a plastered wall surface to be flat, thereby enhancing the plastering quality of the wall surface; the wall plastering machine has the advantages of compact and reasonable structure, convenience in operation, good work environment, low work labor intensity, strong applicability and high use safety and automation degree, can not only fast plaster the wall surface, but also plaster the wall corners, pillars, the roofs and outer walls with certain height.

Owner:何干清

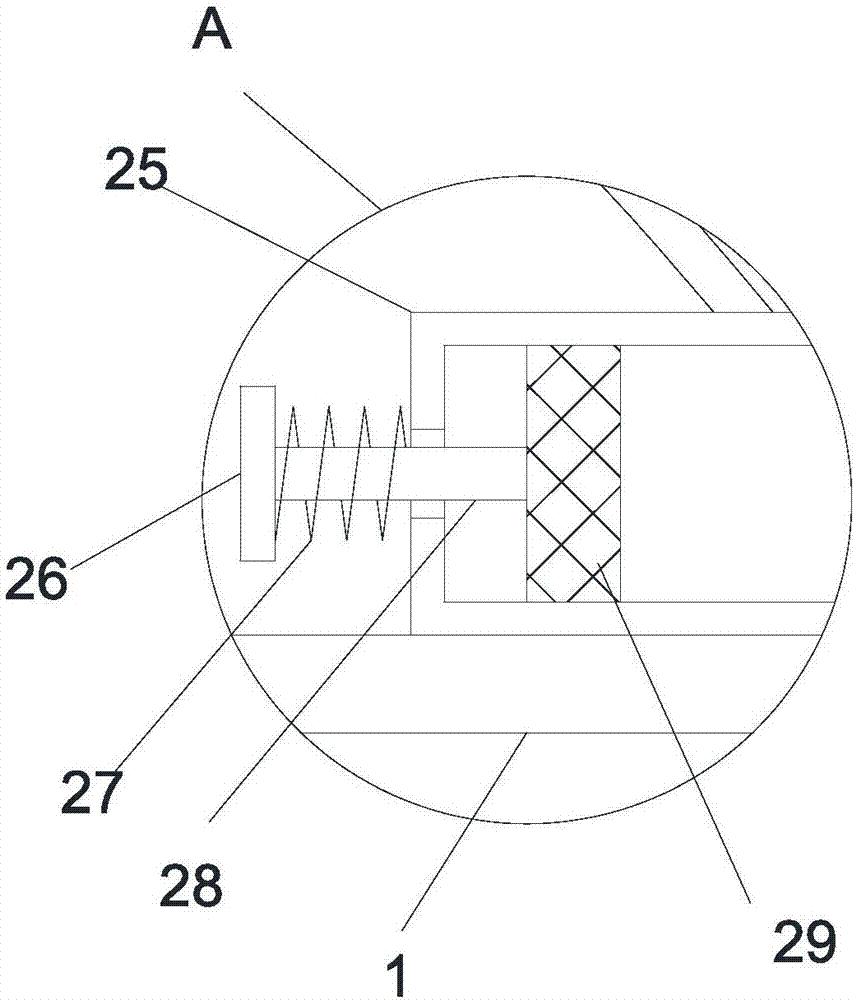

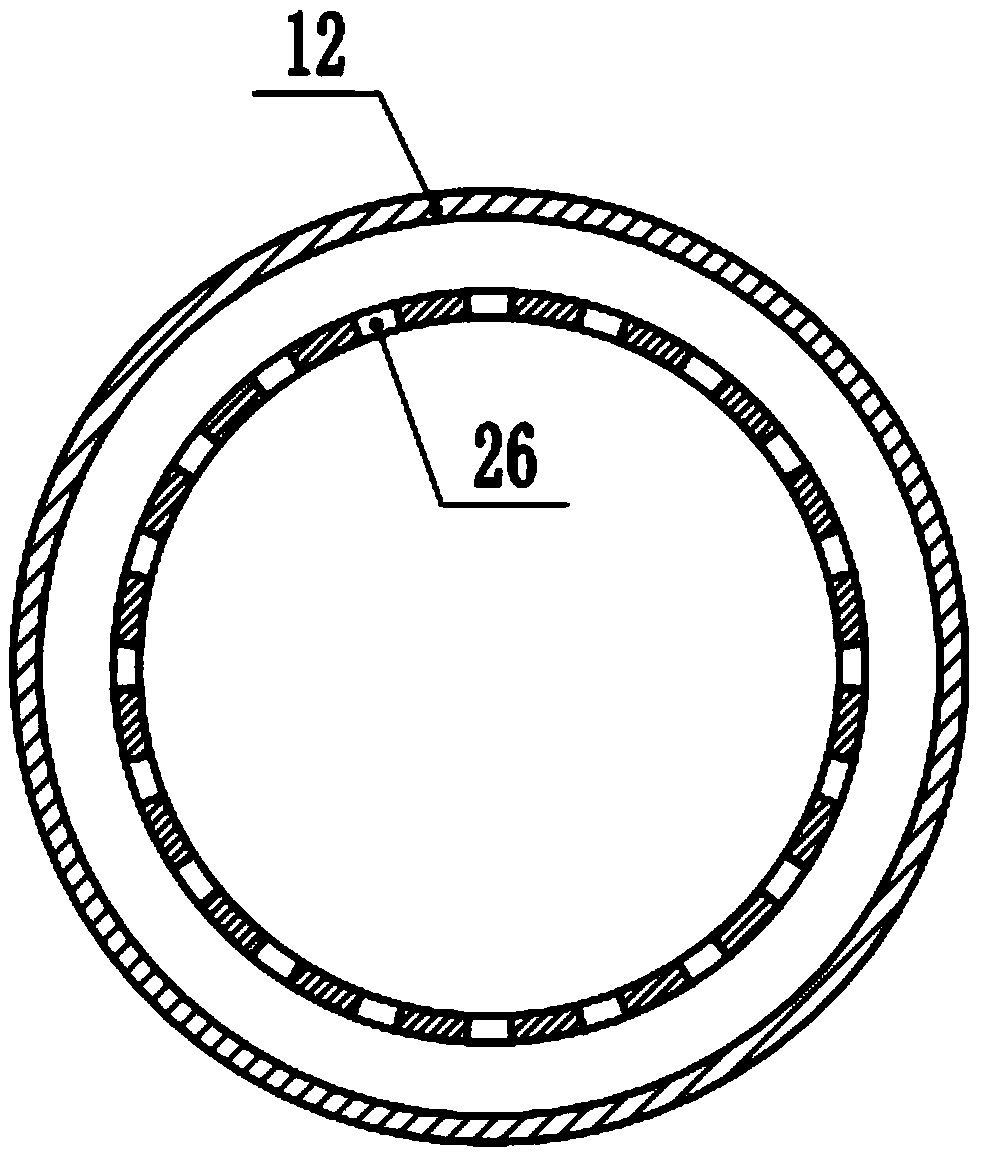

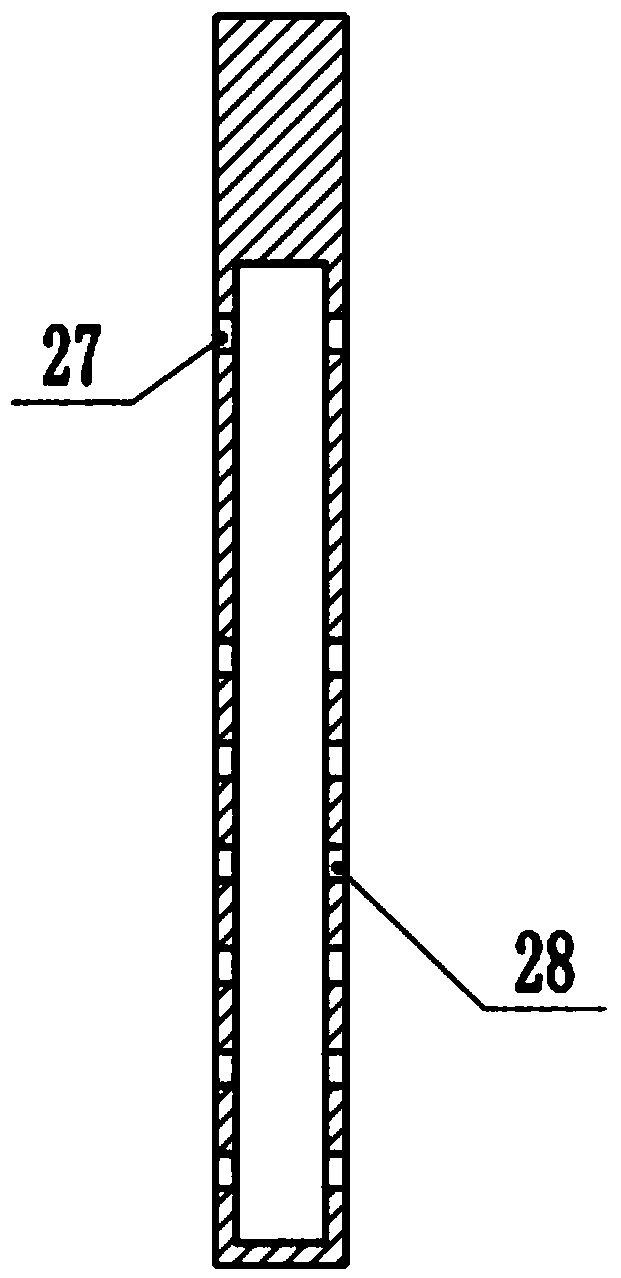

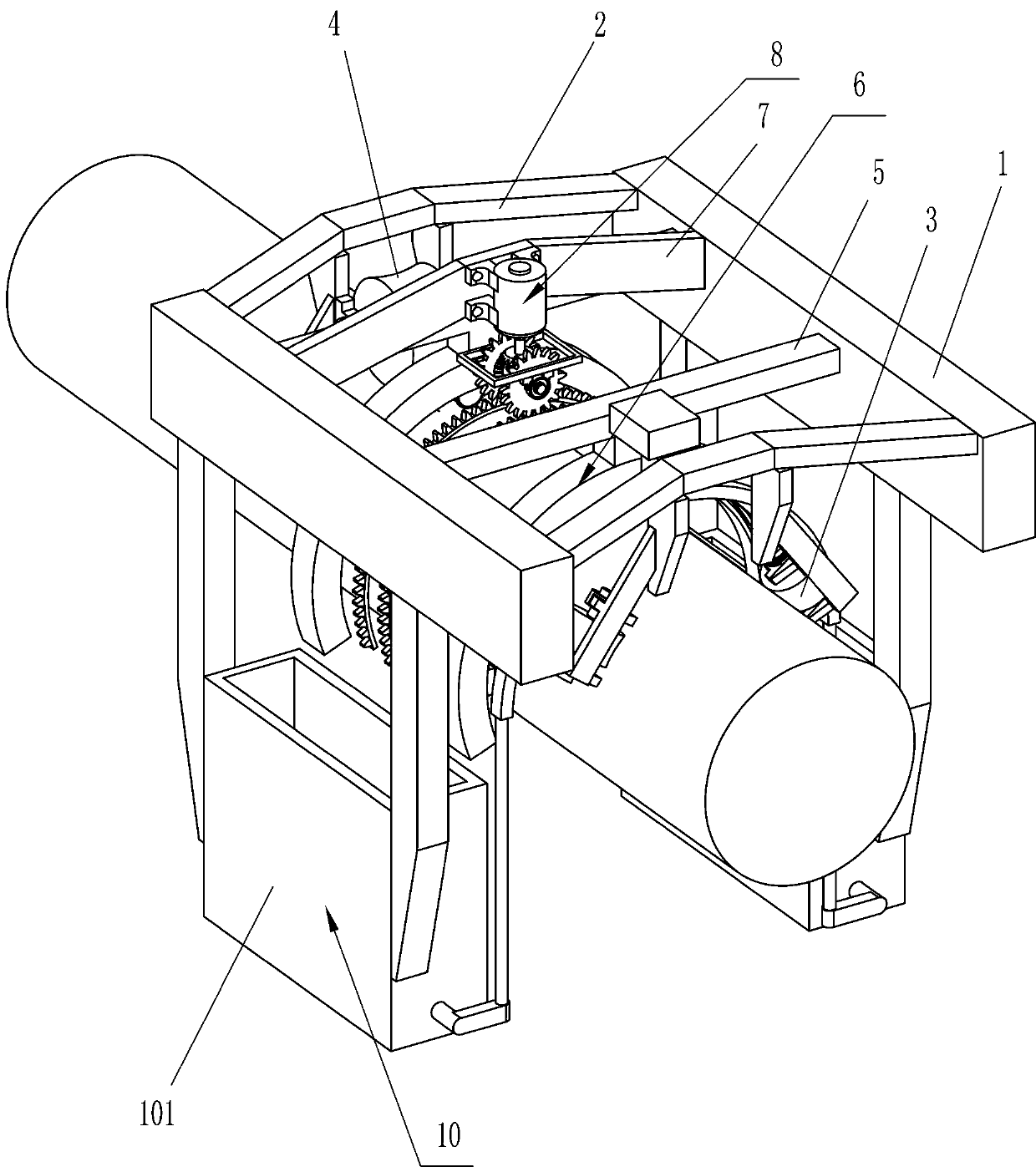

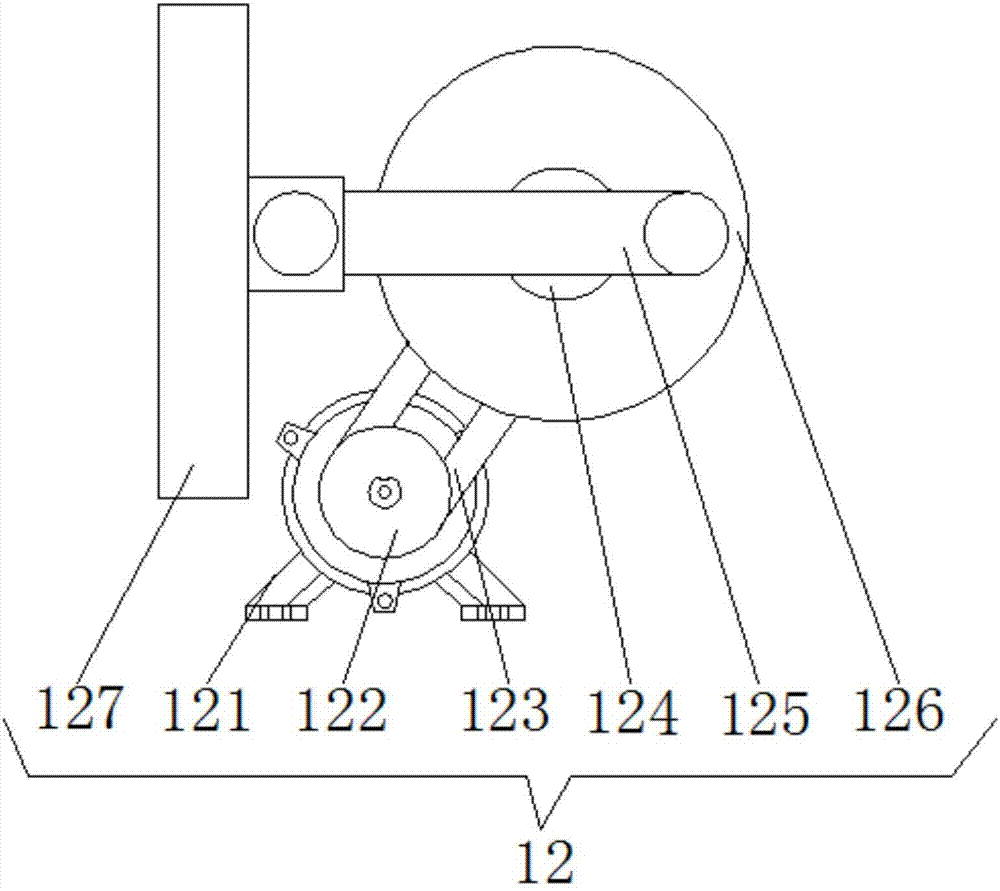

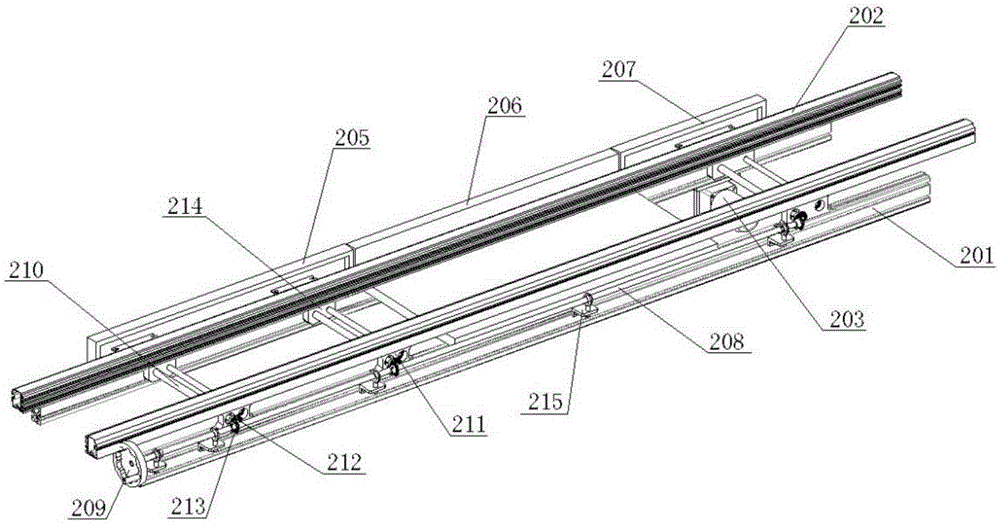

Rotary transmission mechanism of tree white-coating machine

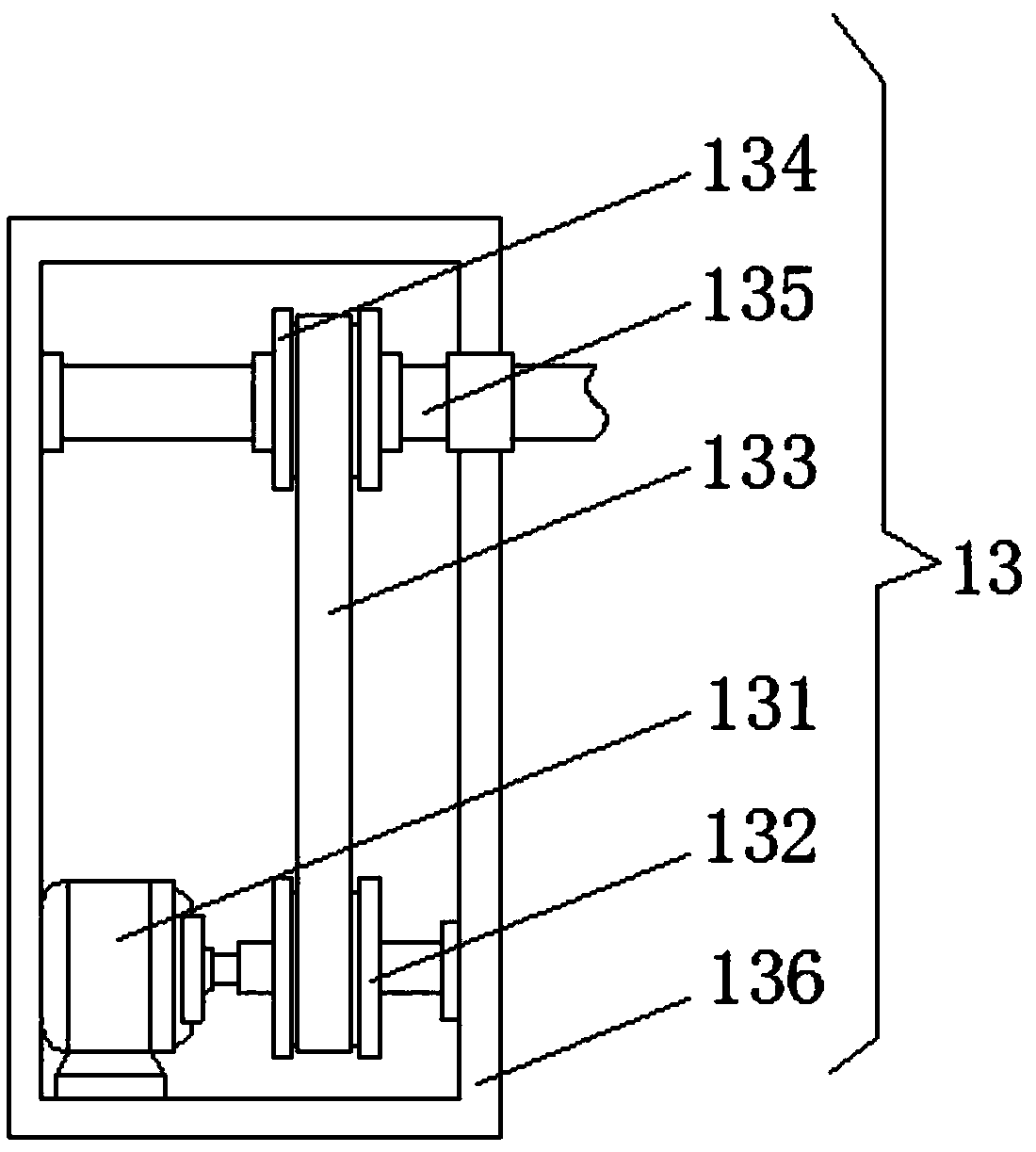

InactiveCN102101092AEliminate working dead endsImprove painting qualityLiquid surface applicatorsGearingVehicle frameSprocket

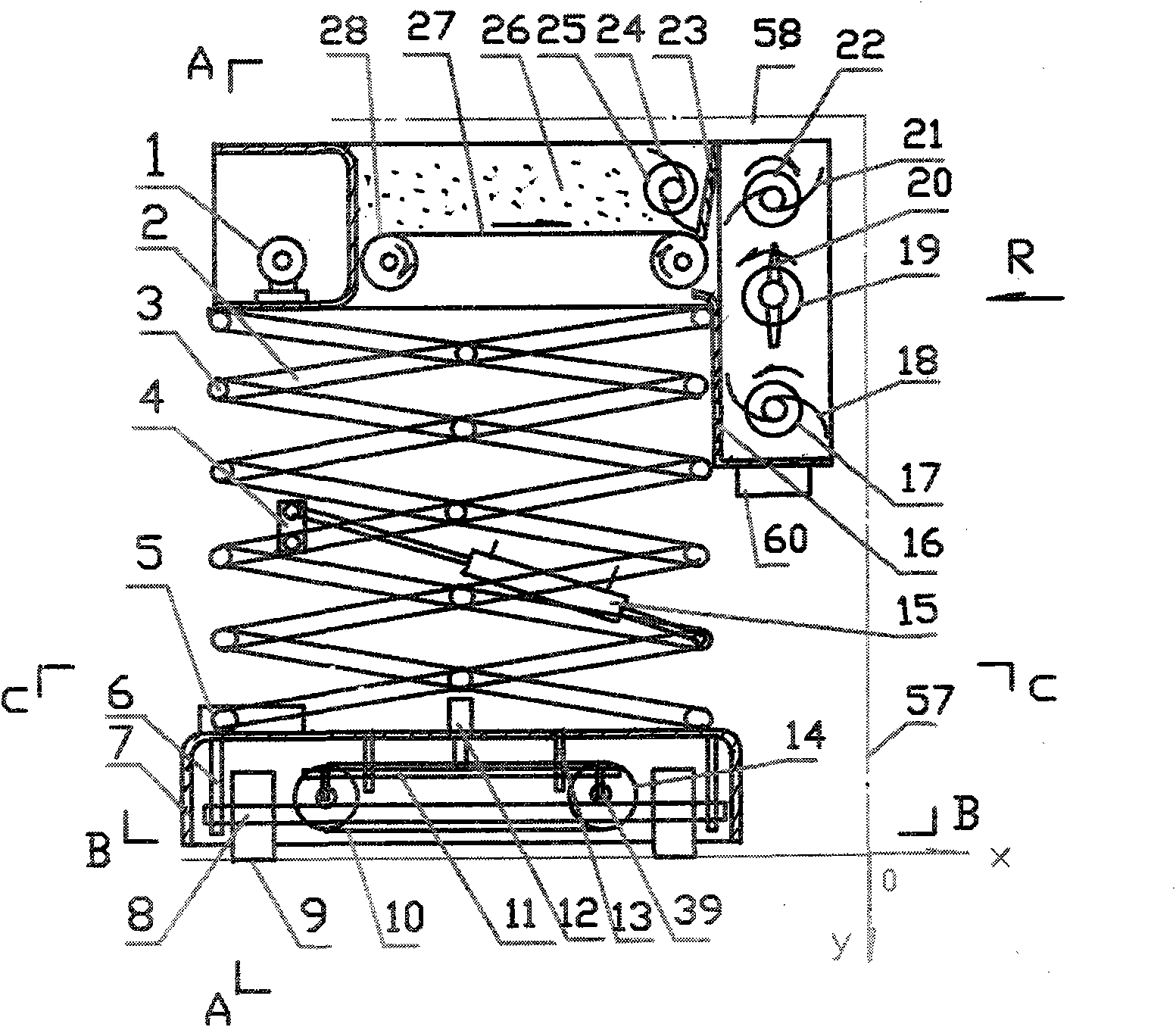

The invention relates to a rotary transmission mechanism of a tree white-coating machine. The rotary transmission mechanism of the tree white-coating machine comprises a vehicle frame, wherein a fixed opening ring is arranged on the vehicle frame; a rotary opening ring is rotationally arranged outside the fixed opening ring; a chain with K-shaped attachments is arranged outside the rotary opening ring; the chain is in mesh type transmission with a first sprocket; an inner rack with an arc-shaped opening is arranged on the inner side of the fixed opening ring; a speed-reducing commutator is fixed on the rotary opening ring; a gear is arranged on an input shaft of the speed-reducing commutator and is in mesh type transmission with the arc-shaped inner rack; a steel wire rope wheel is arranged on an output shaft of the speed-reducing commutator; a steel wire rope is sleeved on the steel wire rope wheel and is sleeved on an upper fixed pulley and a lower fixed pulley; an outer frame is fixed on the rotary opening ring through a fixed frame; a guide groove is arranged on the left inner side and the right inner side of the outer frame; a lifting block is arranged on the guide groove in an up and down movement mode; and the upper fixed pulley and the lower fixed pulley are fixed at the upper end and the lower end of the outer frame respectively. The rotary transmission mechanism of the tree white-coating machine can effectively eliminate a working dead angle and can improve coating quality.

Owner:ZHEJIANG UNIV OF TECH

Paint brushing device for surface of building wall

InactiveCN107965130ABrush evenly and efficientlyAvoid stickingBuilding constructionsLacquerReciprocating motion

The invention discloses a painting device for the surface of a building wall, which comprises a vehicle body, the vehicle body is fixedly installed on the right side wall of the vehicle body, and the output shaft of the driving motor is fixedly installed with a stirring shaft extending into the paint bucket in a rotating manner. , the right end of the driven shaft is sleeved with a driven bevel gear that meshes with the driving bevel gear, the left end of the driven shaft is coaxially fixed with a runner, the left side wall of the runner is eccentrically hinged with a connecting rod, and the piston A discharge hose is connected between the sleeve and the brush plate, and a first one-way valve is installed on the discharge hose; a fixed pulley is arranged in the car body; the present invention drives the sponge plate to reciprocate up and down through the sleeve block together with the brush plate Movement, and then realize the up and down reciprocating movement of the brush on the wall, paint brushing is more uniform and efficient, the paint is injected into the brush plate intermittently, and there is no need to manually dip the paint, which improves the efficiency of wall painting, and the stirring shaft drives the stirring The leaves rotate and stir the paint to avoid the adhesion of the paint, improve the fineness of the paint, and improve the quality of painting.

Owner:季元吉

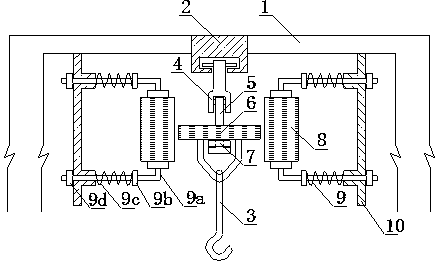

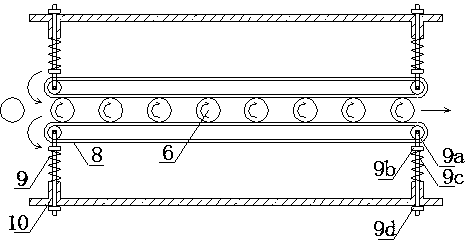

Automatic rotating paint-spraying suspension device

InactiveCN104209210ASmooth rotationHarm reductionSpraying apparatusClassical mechanicsStructural engineering

The invention discloses an automatic rotating paint-spraying suspension device and belongs to the field of paint spraying. The device comprises a bracket, a guide rail and a pothook, wherein the guide rail is connected with the pothook through a rotating mechanism; a driving belt, a spring adjusting rod and a lateral plate are arranged on each of two sides of the rotating mechanism; the driving belts are fixed on the lateral plates through the spring adjusting rods; the lateral plates are fixed on the bracket. The rotating mechanism is connected between the pothook and the guide rail and the driving belts are used for rubbing the rotating mechanism to rotate, so that the paint-spraying pothook is rotated at a uniform speed, the paint-spraying efficiency and the paint-spraying quality are increased, and the harm to a human body caused by near-distance paint-spraying is reduced.

Owner:ANQING TIANRUN ENG MACHINERY

Multi-functional automatic wall plastering machine

InactiveCN102418413AAchieve large-scale movementReduce labor intensityBuilding constructionsElectrical controlAtmospheric pressure

The invention provides a multi-functional automatic wall plastering machine. The multi-functional automatic wall plastering machine consists of a travelling support mechanism, a lifting mechanism and a working device, wherein the lifting mechanism consists of a pneumatic cylinder and a cantilever crane and realizes the movement of the working device; and the working device consists of a main hopper, a rotating beam barrel, a plastering hopper, a scrapping plate, a whitewashing roller and an electrical control part, and realizes full automatic plastering, scrapping and coating whitewashing actions.

Owner:杨岳

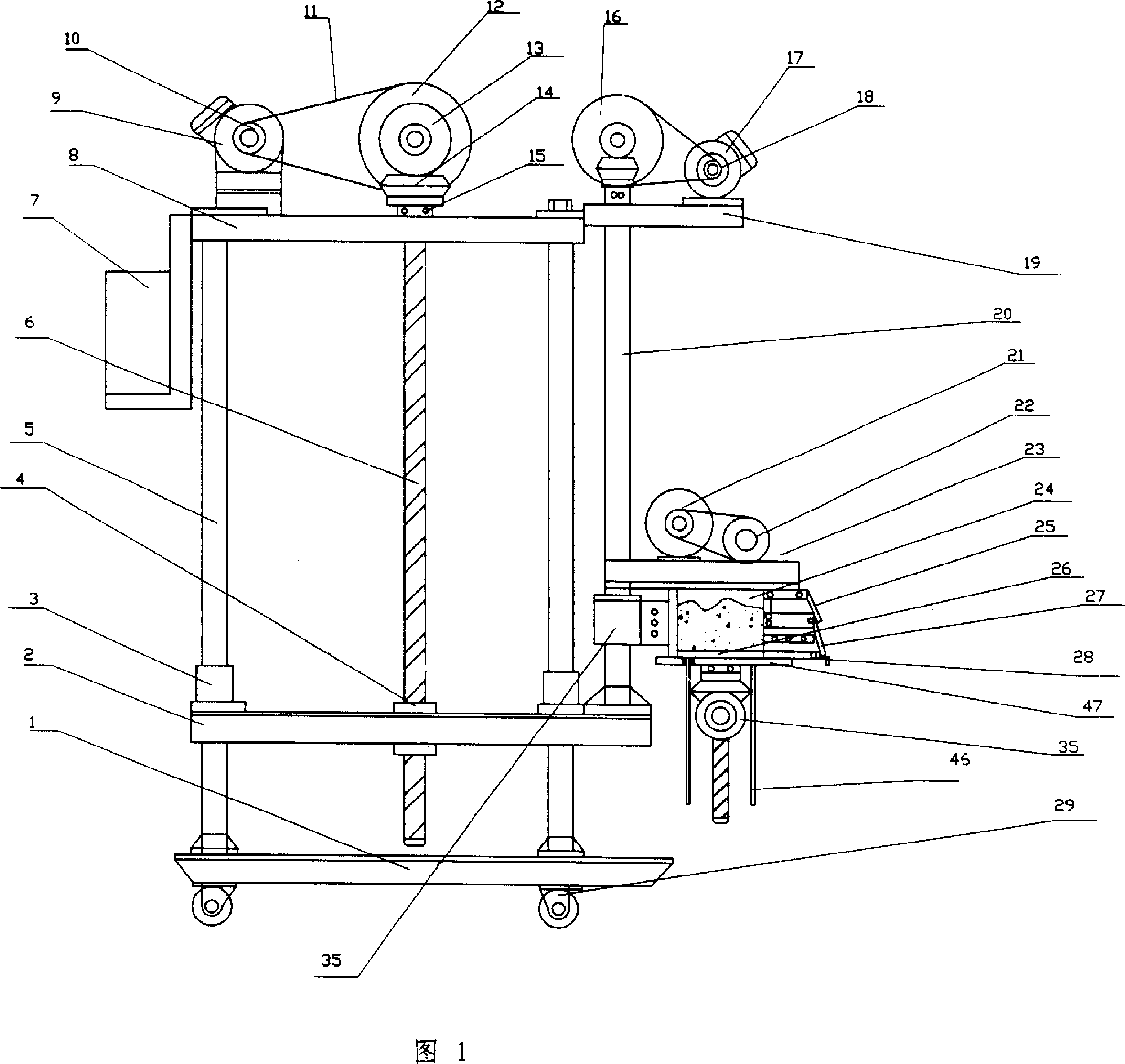

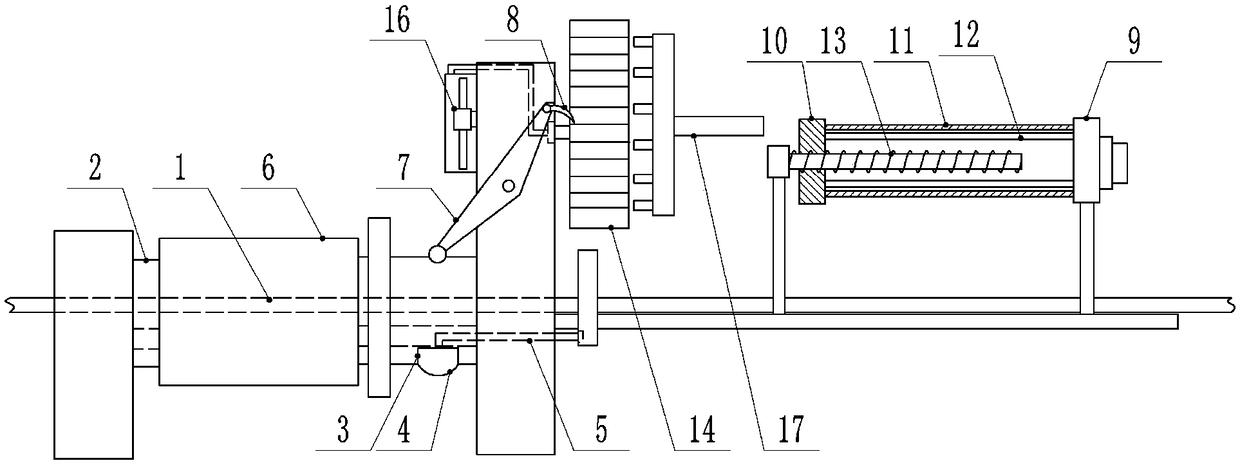

Synchronously and uniformly automated painting device for inner and outer walls of tubular member

The invention discloses a synchronously and uniformly automated painting device for inner and outer walls of a tubular member, and belongs to the technical field of automation equipment. The synchronously and uniformly automated painting device includes a fixing base, wherein guide frames are arranged on both sides of the upper end of the fixing base; a top plate is arranged on the upper ends of the guide frames; a paint feeding tank is arranged in the middle of the top plate; the upper end of the top plate is connected with a fixing plate through top frames; the middle of the upper end of thefixing plate is provided with a rotating motor; an output shaft at the lower end of the rotating motor is connected with a rotating shaft; a driving belt pulley is arranged at the middle of the upperend of the rotating shaft; both ends of the driving belt pulley are connected with driven belt pulleys through belts; rotating rods are arranged at the middles of the driven belt pulleys; the upper ends of the rotating rods pass through the fixing plate and are connected with rotating cams; the middles of the rotating rods pass through the top plate and are connected with reciprocating blocks through reciprocating thread areas; the bottom end of one rotating rod pass through the fixing base and is connected with a rotating belt pulley; and the right end of the rotating belt pulley is connected with a drive belt pulley through a belt. According to the synchronously and uniformly automated painting device, the synchronous painting of the inner and outer walls of the tubular member is ensured, the painting efficiency and the painting quality are improved, and the practicability is high.

Owner:宁波众创智能科技有限公司

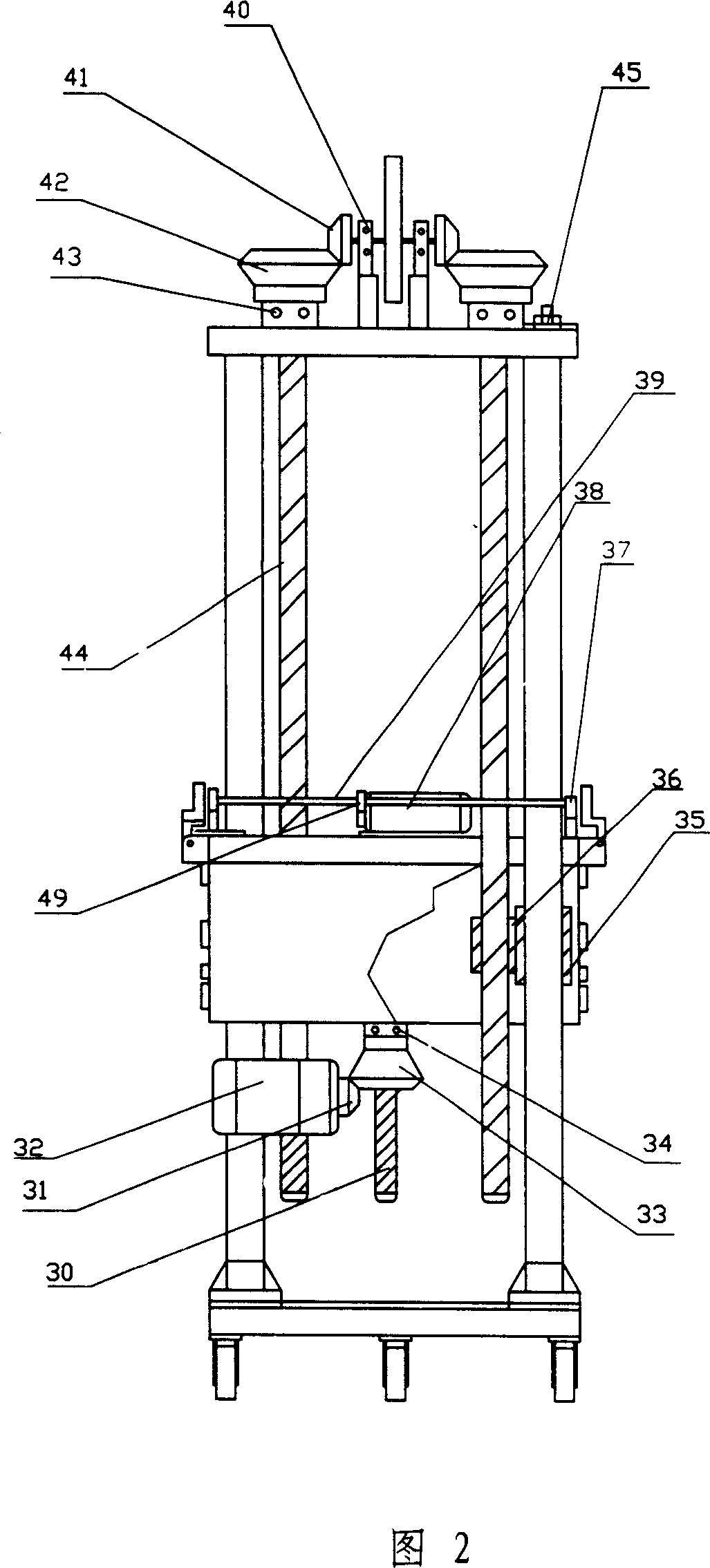

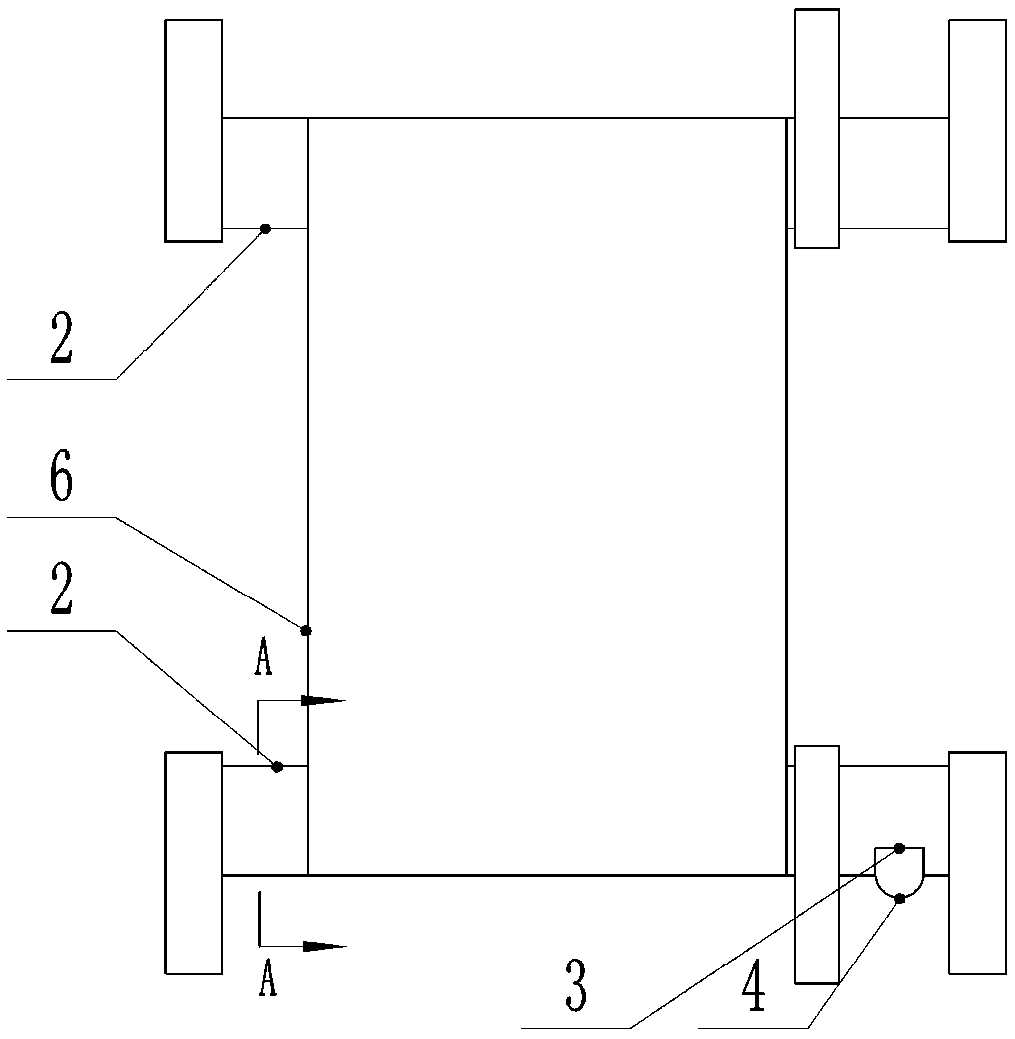

Wall plastering apparatus

InactiveCN1966909AImprove painting qualityImprove work efficiencyBuilding constructionsFixed frameEngineering

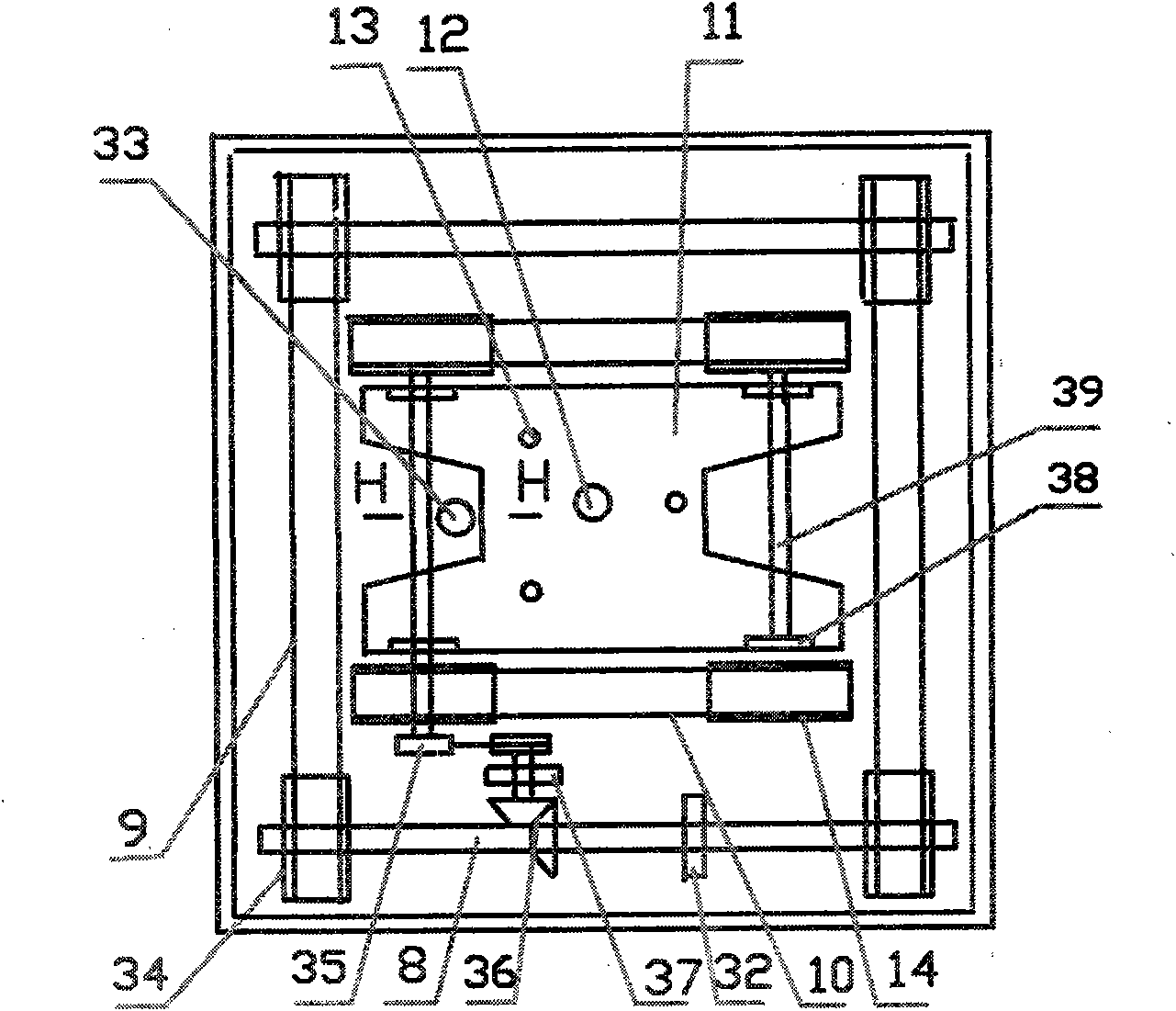

A wall plaster for construction comprises a fastening frame made of bottom and top plates, and four studs, a lift device made of a lift bracket moving up and down along the stud, and a guide screw and silk braid formed two level elevator, and a wall plastering device made of feed box, lift bottom plate, plastering plate, sleeve and pusher with the side fastened to the sleeve on the stud of the two level lift device. It is efficient with reduced labor requirement.

Owner:卢济桴

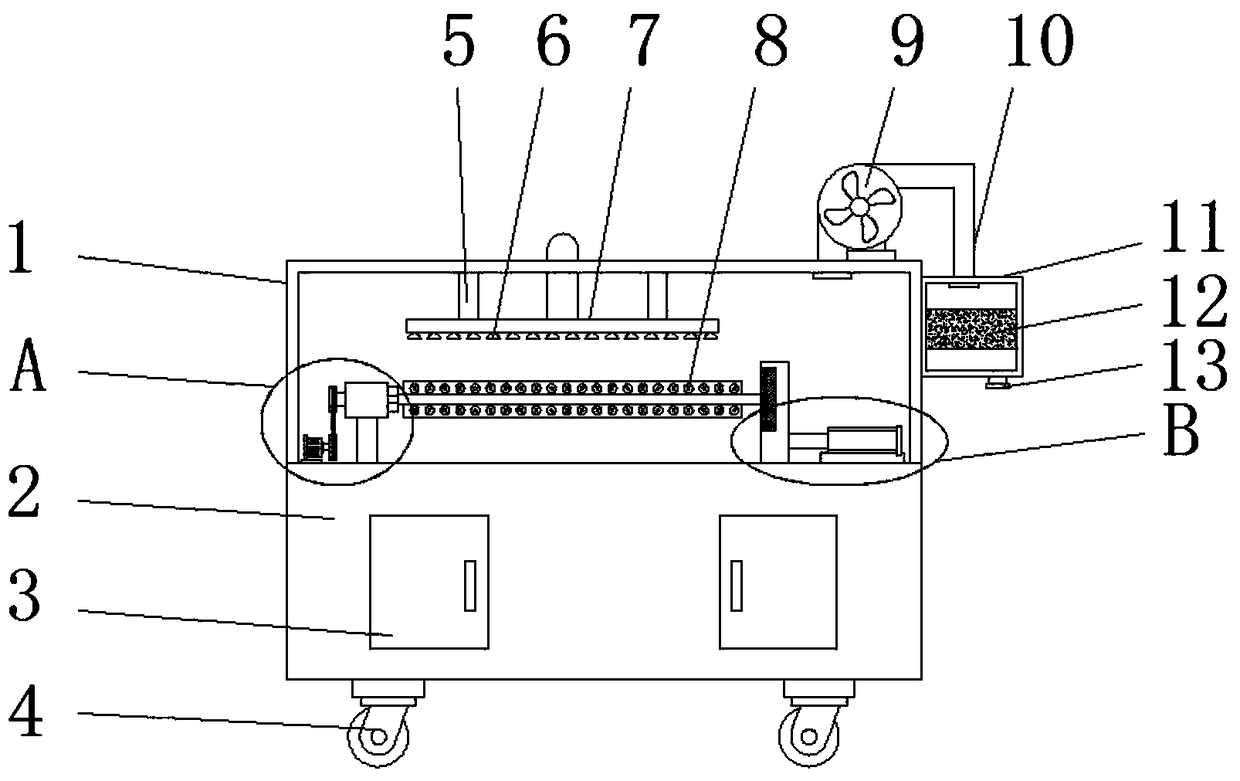

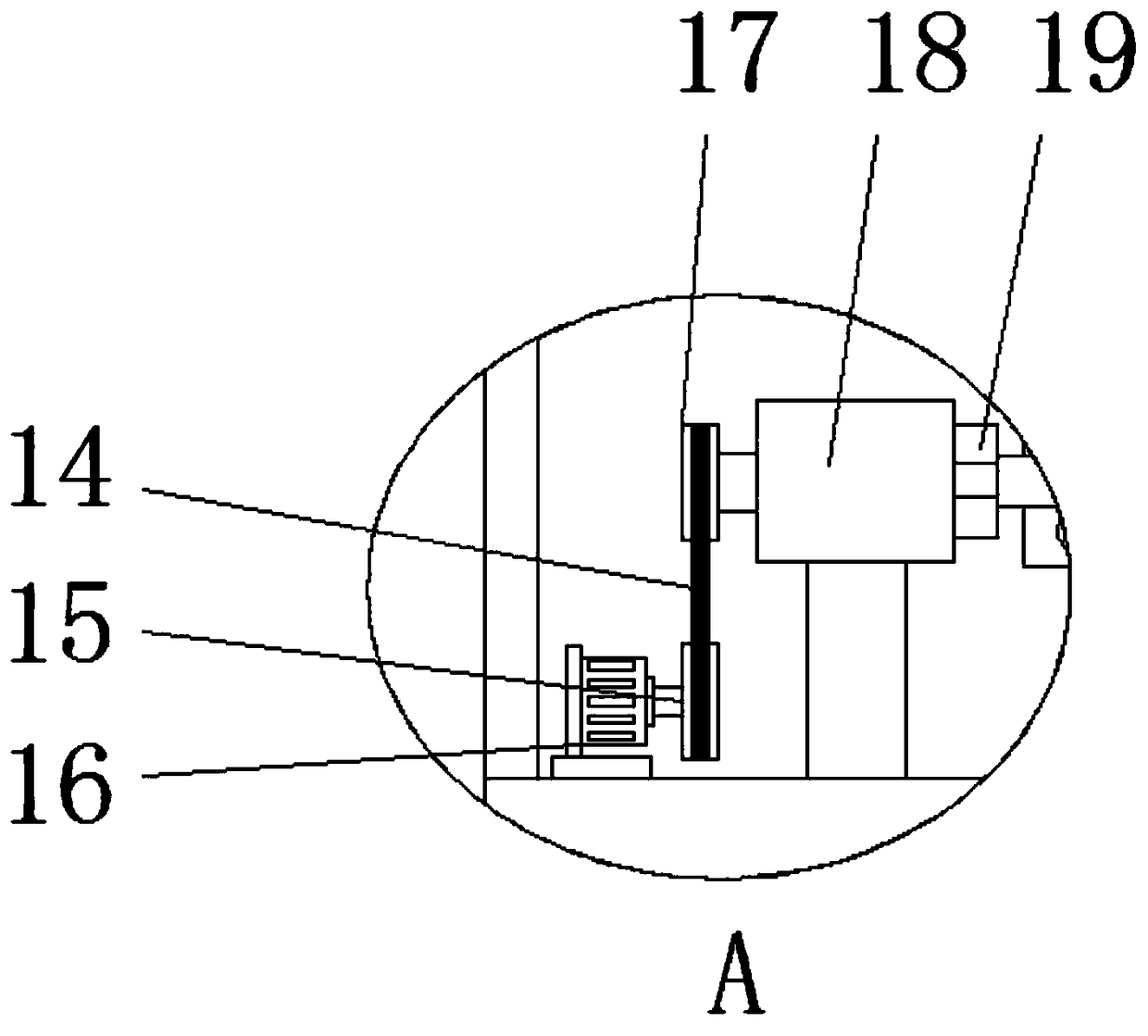

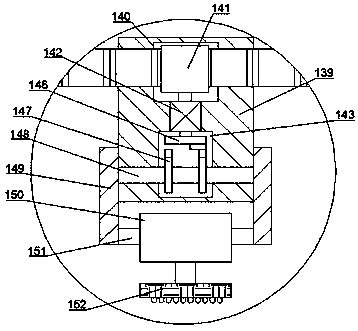

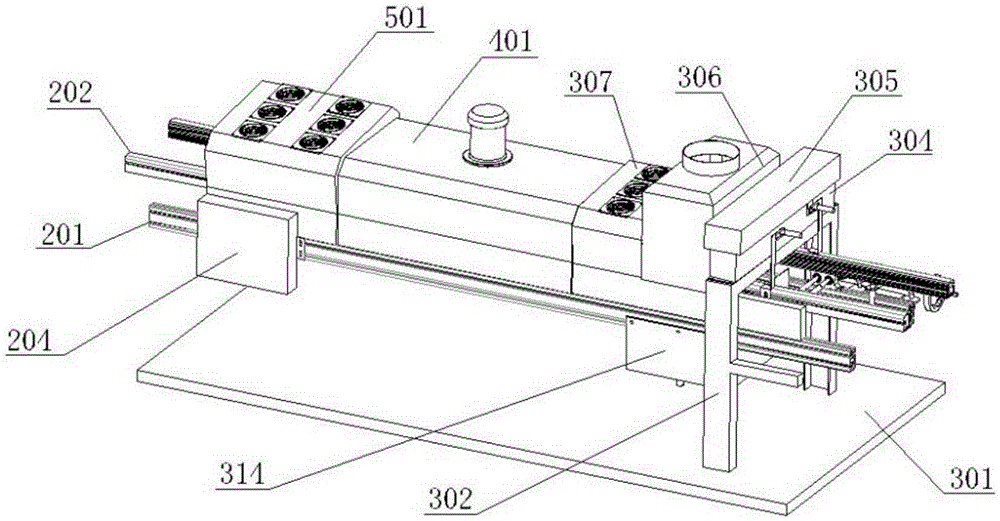

Environment-friendly, safe and efficient paint spraying device

InactiveCN103567105AImprove paint qualityReduce painting costsLiquid surface applicatorsCoatingsEngineeringMechanical engineering

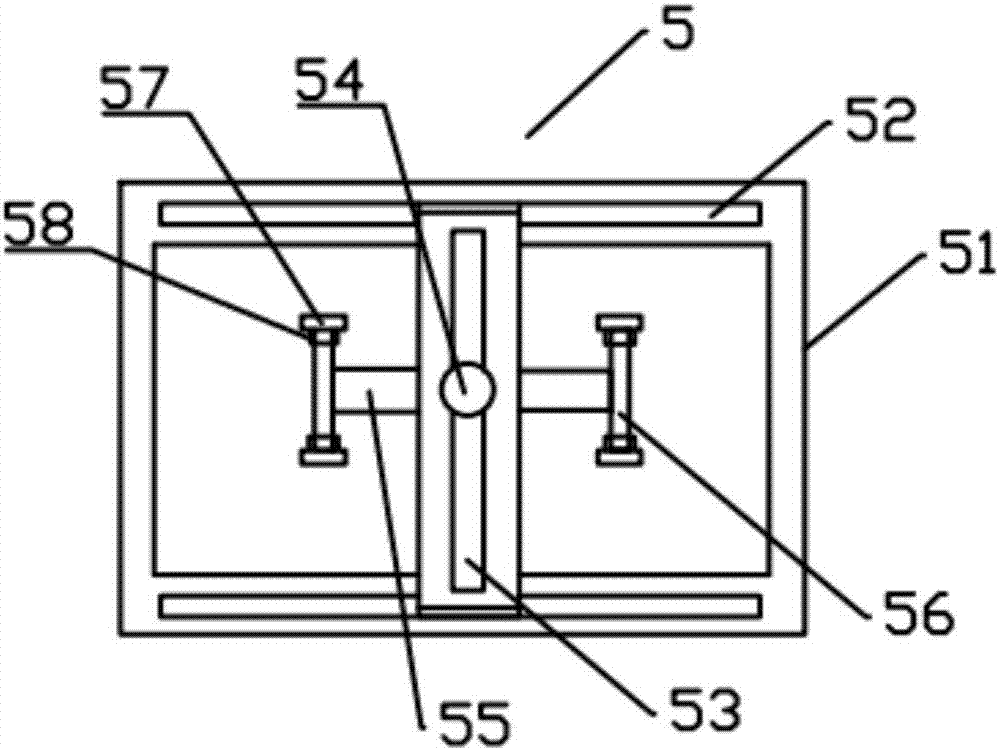

The invention discloses an environment-friendly, safe and efficient paint spraying device to overcome deficiencies that the work efficiency is affected and the like due to the poor operation environment of prior paint spraying devices. A paint spraying mechanism comprises an operation mechanism capable of displacing and rotating the paint spraying mechanism. The operation mechanism comprises a paint spraying switch and an operation handle which stretches out of a paint spraying case and is capable of controlling the rotation of the paint spraying mechanism. A shelf capable of holding an object to be sprayed is arranged in the paint spraying case and comprises moving rollers. A supporting plate is arranged in the shelf and is composed of a rotation mechanism, a lifting mechanism and a supporting plate folding mechanism. The paint spraying case comprises a controller for controlling the displacement rotation of the paint spraying mechanism and the shelf. The device is used for environment-friendly, safe and efficient paint spraying of furniture and other objects, and paint spraying workers can operate the paint spraying mechanism to spray paint through the operation handle or the controller on the outside of the case and perform appearance judgment, so that the work efficiency is improved by 10%, and the paint spray efficiency is improved by 15%.

Owner:会同县康奇瑞竹木有限公司

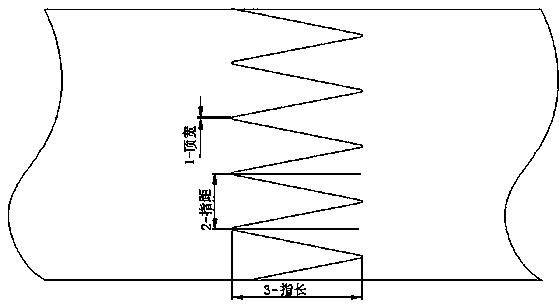

Manufacturing method for gum wood finger-joined floors

ActiveCN103753661AReduce wasteSolve roughnessWood veneer joiningWood dampingAdhesive glueWood machining

The invention belongs to the technical field of wood processing, and particularly discloses a manufacturing method for gum wood finger-joined floors. The manufacturing method comprises the following steps of drying, selecting, improvement of machining properties, humidifying, connection and combination, treatment of grooves and tongues, sanding, painting and the like. By using the manufacturing method for the gum wood finger-joined floors, the problems that in production of fast-growing gum wood finger-joined floors, sanding cost is high, loss of materials is high, the using amount of glue is high, tree laces crack, the moisture content of a portion between each two gum wood finger-joint floors is not uniform, finger joining is difficult, and the like are solved. The manufacturing method for the gum wood finger-joined floors has the advantages of low production cost, high product quality and the like.

Owner:丰胜(广州)建材有限公司

Furniture board machining equipment

PendingCN108636644AEfficient removalQuality assuranceBelt grinding machinesLiquid spraying apparatusSlagEngineering

The invention relates to the field of board painting devices, and discloses furniture board machining equipment. The furniture board machining equipment comprises a conveying mechanism and a paintingmechanism; and the conveying mechanism comprises a conveying belt. The furniture board machining equipment further comprises a polishing mechanism; the polishing mechanism comprises a first rotating roller and a second rotating roller arranged in parallel; a sleeve rod sleeves the first rotating roller; the sleeve rod is provided with a long hole for enabling the first rotating roller to penetratethrough; the long hole is positioned in the eccentric position of the sleeve rod, and is parallel to the axial direction of the sleeve rod; the second rotating roller is the same in structure with the first rotating roller; a polishing belt is sleeved between the first rotating roller and the second rotating roller; the polishing belt comprises an upper-layer belt and a lower-layer belt; and a conveying belt penetrates between the upper-layer belt and the lower-layer belt. The furniture board machining equipment can solve the problem of influence on the board surface painting quality by burrsor slag on the surfaces of boards.

Owner:四川三虎家居有限公司重庆分公司

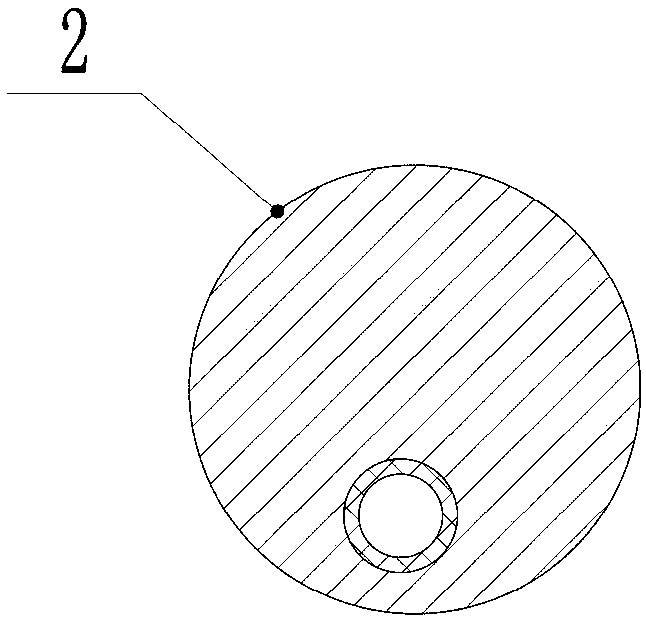

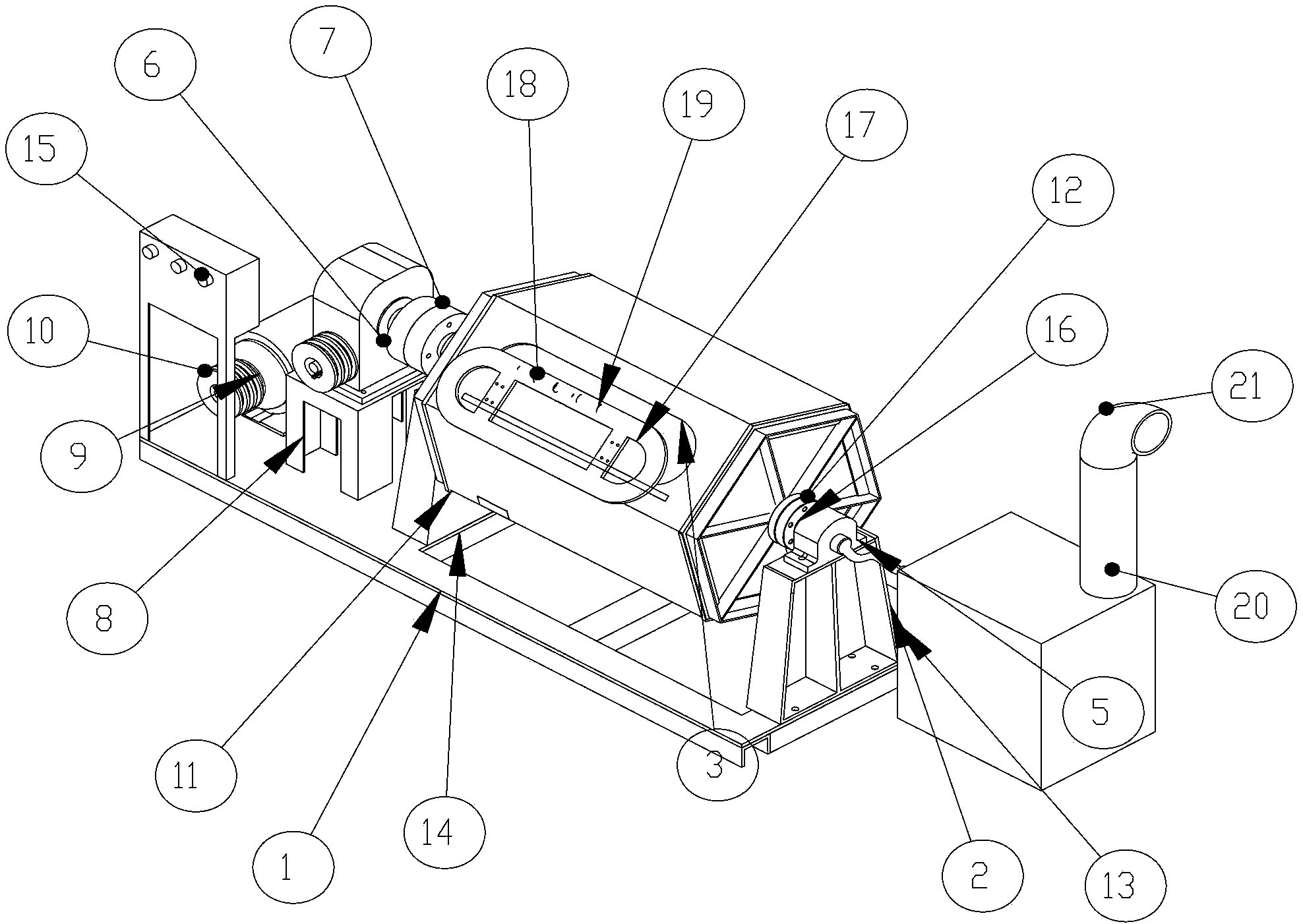

Small-part sand rolling machine capable of automatically removing dust

InactiveCN103433829AImprove paint qualityIncrease productivityEdge grinding machinesPolishing machinesSurface finishingHuman health

The invention relates to a small-part sand rolling machine capable of automatically removing dust. The small-part sand rolling machine comprises a driving device, a dust removing device and a roller, wherein the driving device drives the roller to rotate; parts to be derusted are stored in a roller cavity containing a rust remover; the roller is communicated with the dust removing device. The invention provides the small-part sand removing machine capable of automatically removing the dust; according to the small-part sand removing machine, the surface treatment is thorough, the working efficiency is high, and the pollution to the environment and the harm to human health can be avoided.

Owner:XI AN RAILWAY TRANSPORTATION EQUIP

Paint spraying device for steel bar for truss and application method thereof

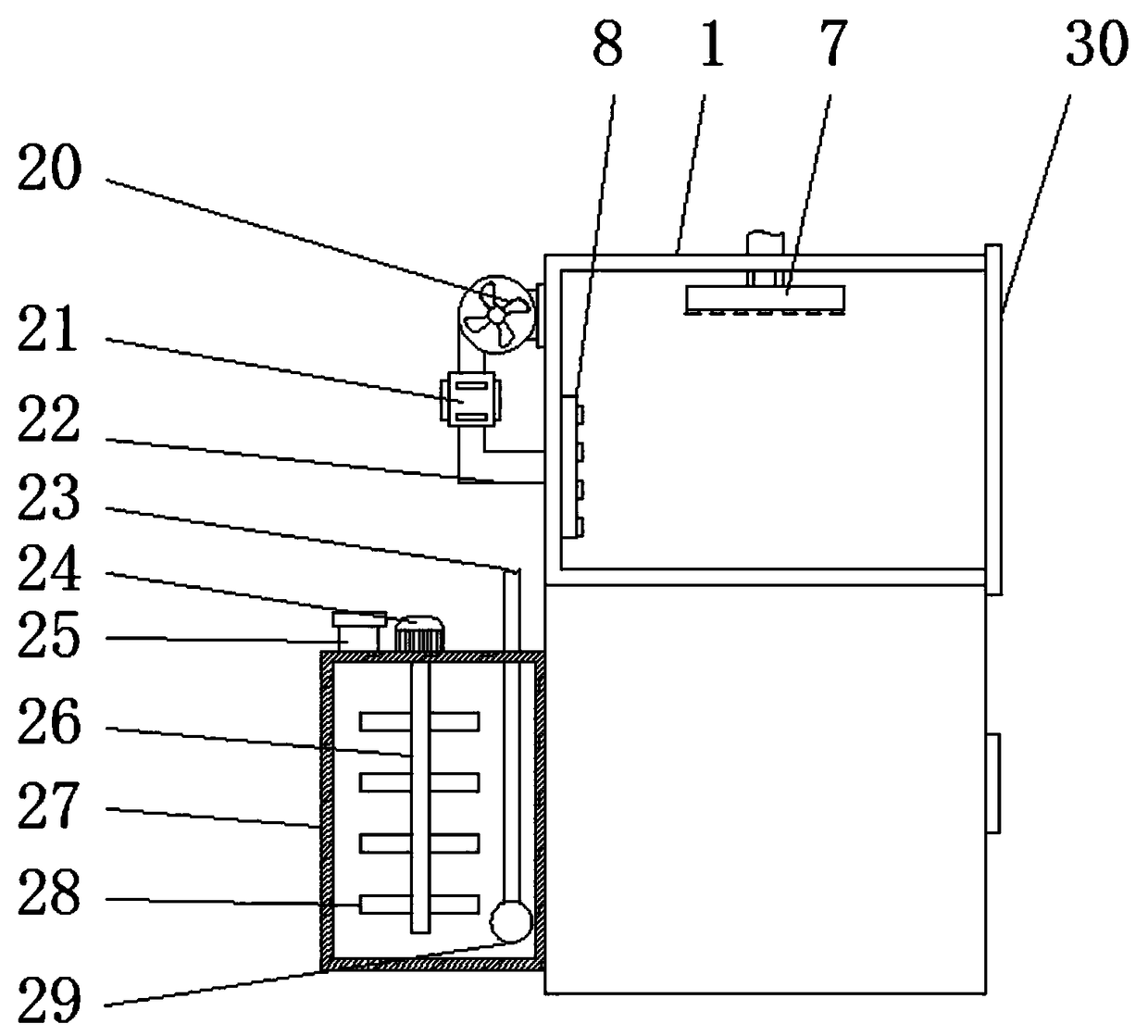

PendingCN108816581AHigh speedImprove paint qualityPretreated surfacesLiquid spraying apparatusActivated carbonMental health

The invention discloses a paint spraying device for a steel bar for a truss and an application method thereof. The paint spraying device comprises a base. The paint spraying device sprays paint in a protective cover, and smelly gas in the protective cover is sent into a box body through an induced draft fan and a gas guide tube. After the peculiar smell of the smelly gas is removed through an activated carbon layer in the box body, the gas is exhausted through a gas exhaust tube. Thus, by the operation of removing the peculiar smell in the paint spraying process, harmful substances generated in the paint spraying process are effectively adsorbed and collected. Therefore, the health of staff and the good working environment are ensured, and the physical and mental health of staff is helped.The paint spraying device works through an air blower and an air heater, so that hot air is blown out from an air outlet of an air knife so as to dry the paint-sprayed steel bar, therefore the steelbar does not need a drying process and can be used immediately, and thus the efficiency is greatly improved. Moreover, the steel bar does not need to be moved and rotated, and therefore the influenceon a paint surface in the movement and rotation process is effectively avoided.

Owner:鸿志远科技股份有限公司

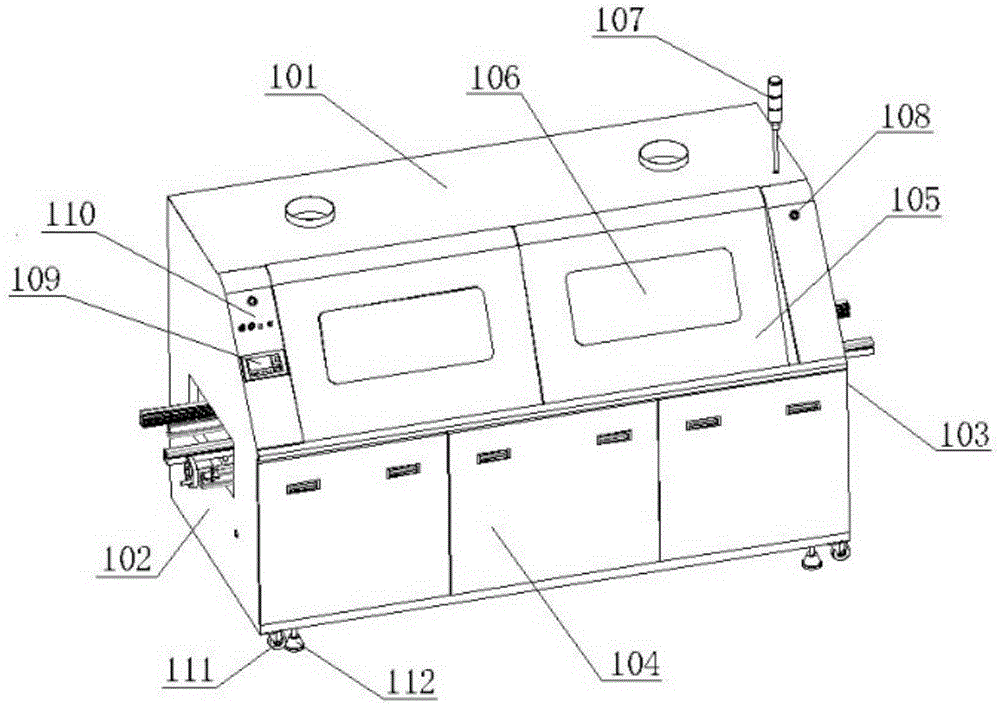

Automatic painting device of wooden door

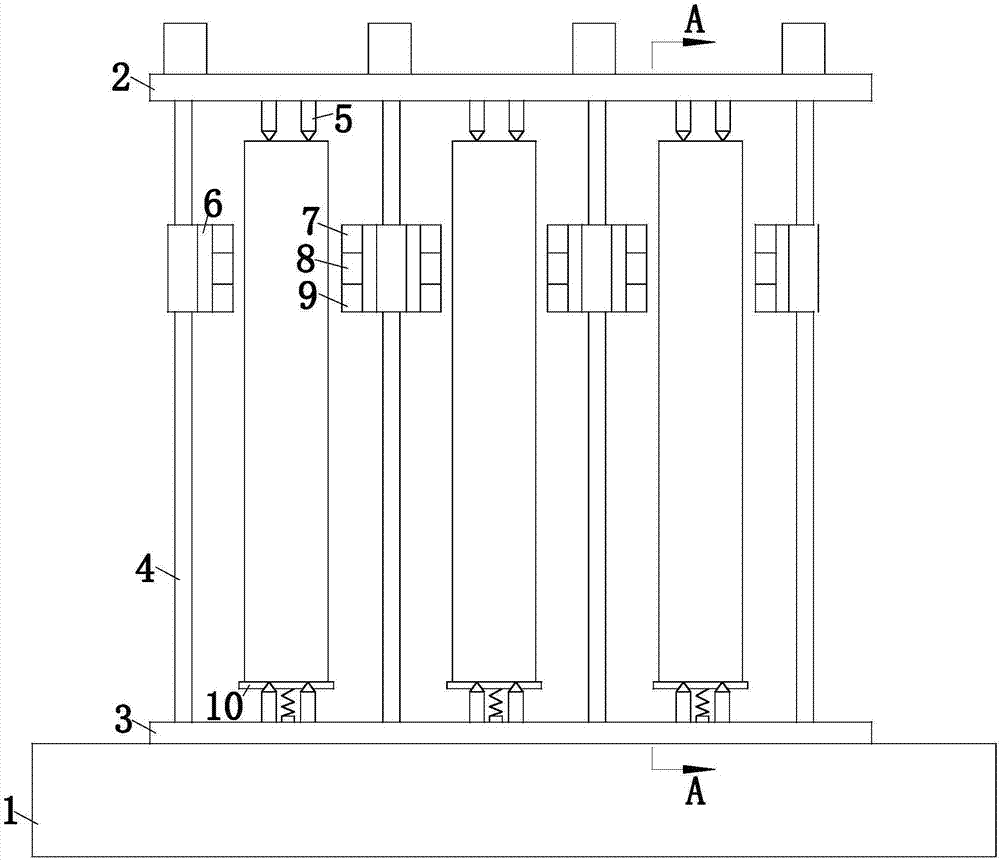

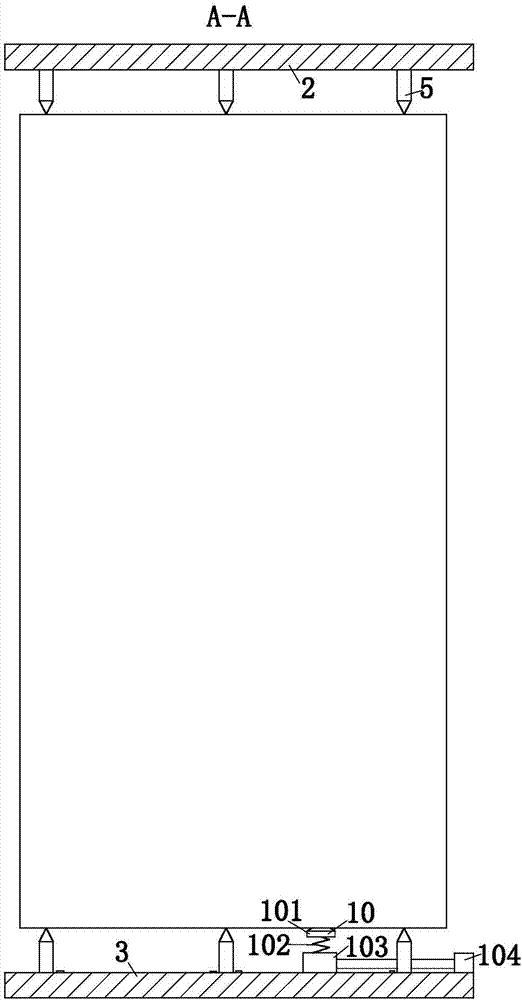

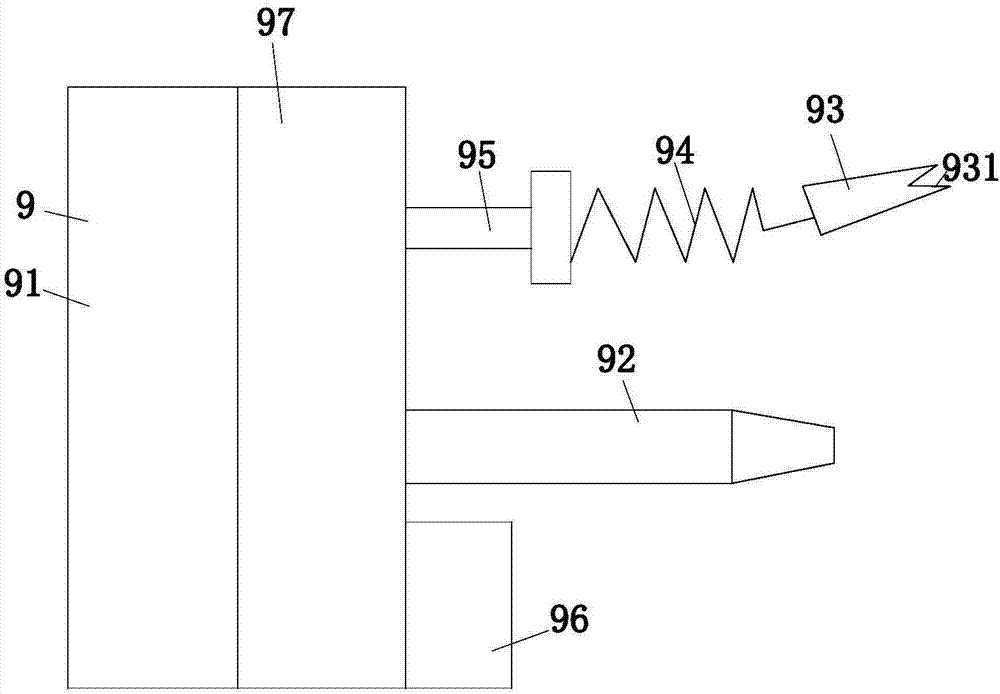

ActiveCN107344156AImprove paint qualityIncrease batchPretreated surfacesLiquid spraying apparatusEngineeringAutomation

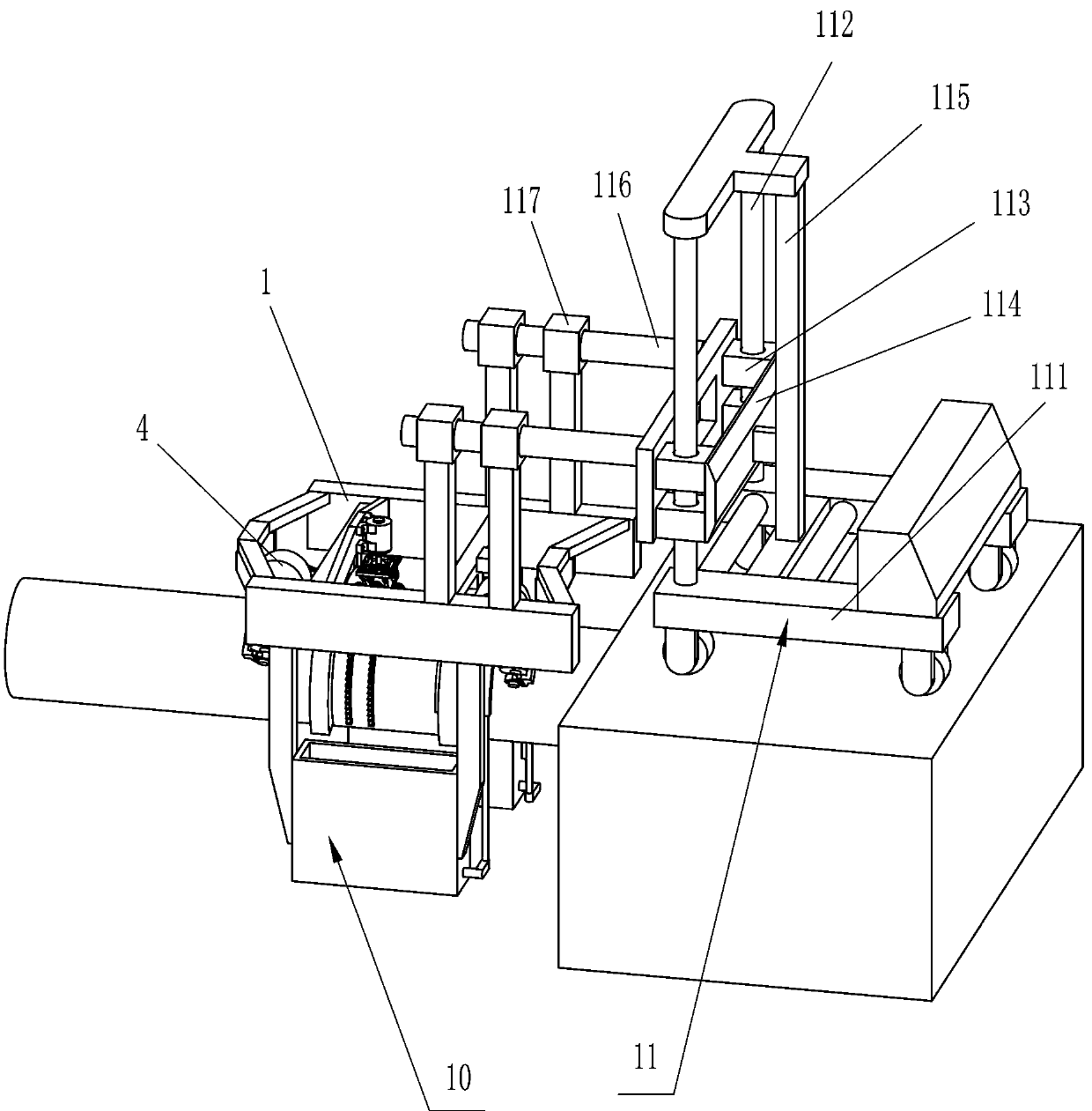

The invention relates to the field of automatic spraying equipment, in particular to an automatic painting device of a wooden door. The automatic painting device of the wooden door comprises a paint tank, a top plate, a baseplate, vertical transmission mechanisms, support modules, slide bases, detecting modules, drying modules, vertical painting modules, bottom surface painting modules and a controller; the paint tank is mounted on the ground; the baseplate is mounted in the paint tank; the top plate is positioned rightly above the baseplate; the top plate and the baseplate are connected through the vertical transmission mechanisms; multiple vertical transmission mechanisms are provided; the support modules are mounted on the top plate and the baseplate; the slide bases are mounted on the vertical transmission mechanisms; the detecting modules, the drying modules and the vertical painting modules are mounted on the slide bases in sequence from top to bottom; and the bottom surface painting modules are mounted on the support modules. The automatic painting device of the wooden door is used for automatically painting, drying and detecting the door, improves the painting quality and batch, and achieves automation.

Owner:LIUZHOU LIUCHENG HONGSEN FURNITURE MFG

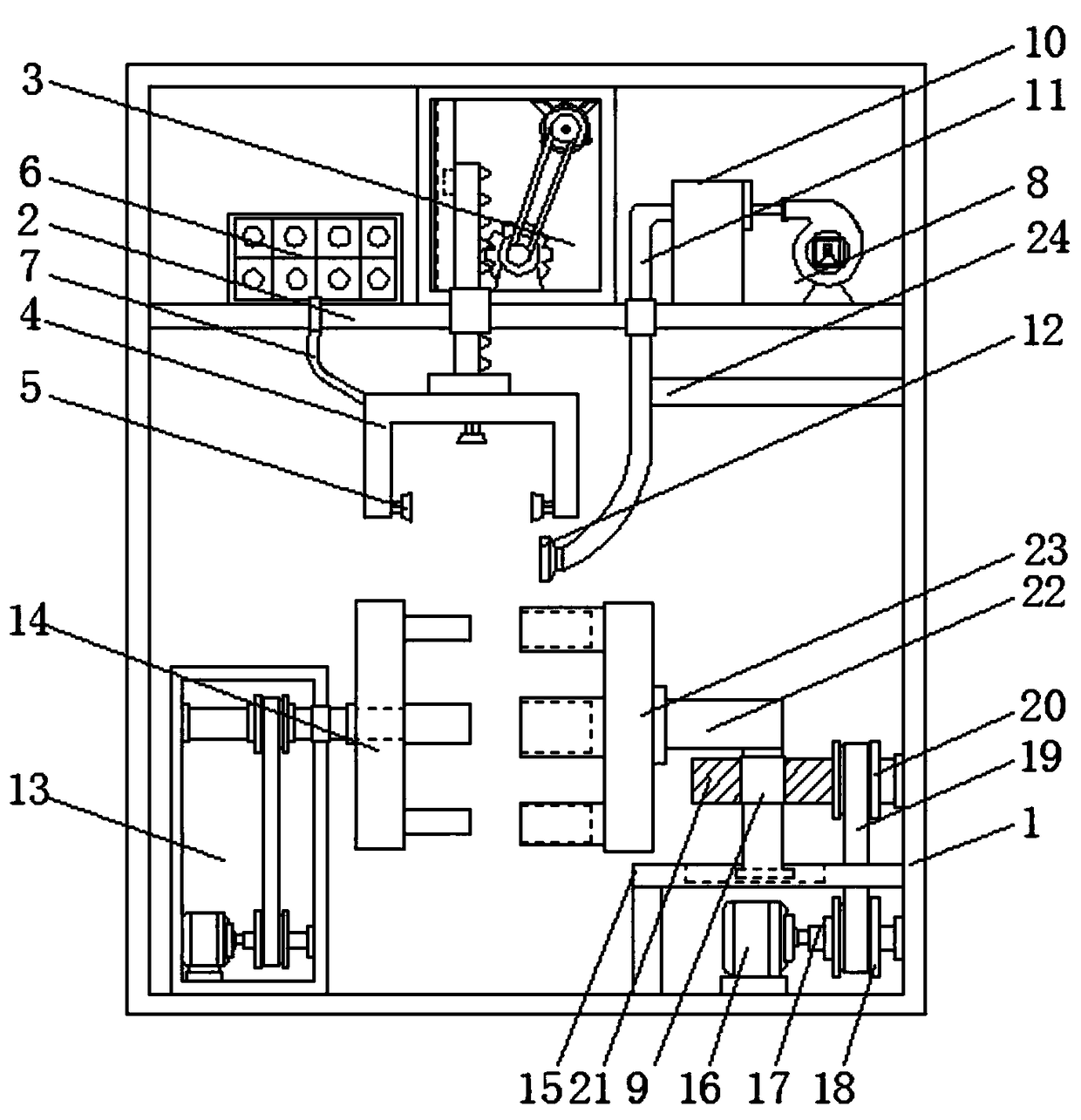

Environment-friendly and efficient UV paint spraying line and technology thereof

InactiveCN107470073AImprove cleanlinessFast hardeningPretreated surfacesCoatingsUV curingEngineering

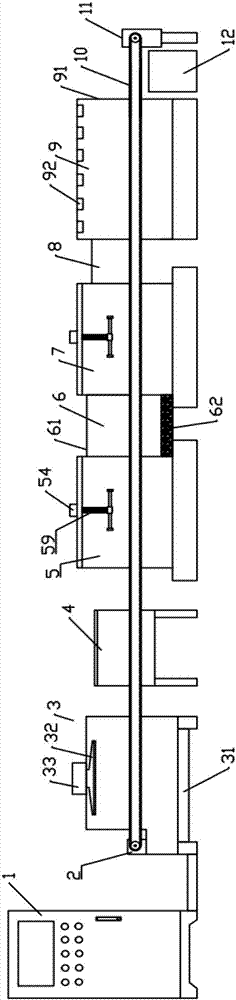

The invention discloses an environment-friendly and efficient UV paint spraying line. The environment-friendly and efficient UV paint spraying line comprises an electric control cabinet, a first motor, an automatic dust removing device, a preheating device, a UV primer paint spraying device, a first tunnel, a UV finish paint spraying device, a second tunnel, a UV curing device, a material driving belt, a second motor and a material storing box; and the first motor, the automatic dust removing device, the preheating device, the UV primer paint spraying device, the first tunnel, the UV finish paint spraying device, the second tunnel, the UV curing device and the second motor are electrically connected with the electric control cabinet, the material driving belt is arranged between the first motor and the second motor, and the automatic dust removing device, the preheating device, the UV primer paint spraying device, the first tunnel, the UV finish paint spraying device, the second tunnel and the UV curing device are sequentially arranged from left to right and connected through the material driving belt. According to the environment-friendly and efficient UV paint spraying line and a technology thereof, UV paint is sprayed to a workpiece, and then a product which is high in surface hardness, wear resistance and glossiness is obtained.

Owner:太仓市众翔精密五金有限公司

Automatic painting equipment for surface of outdoor pipeline

ActiveCN111558496AAvoid dangerHigh degree of automationLiquid surface applicatorsCoatingsStructural engineeringCounter rotation

Owner:台州伟兴科技有限公司

Building construction plate paint spraying device

InactiveCN107457120AEasy feedingEasy dischargeLiquid spraying apparatusTransmission beltArchitectural engineering

The invention discloses a panel painting device for building construction, which comprises an outer frame, a paint bucket fixed on the top of the outer frame, and a paint spraying head installed inside the outer frame, a transmission belt is fixedly installed in the middle of the bottom of the inner wall of the outer frame, and Both sides are fixedly installed with stabilizing devices; the top of the outer frame is fixedly connected with a power box, the bottom of the inner wall of the power box is fixedly connected with a rotating device, and the left side of the rotating device is fixedly connected with a transmission device; The two ends of the screw rod are respectively rotatably connected with the two sides of the inner wall of the outer frame. The invention relates to the technical field of plate painting devices. The plate painting device for building construction does not require manual feeding and manual spraying, reduces the burden on workers, improves the stability of the plate during painting, improves the quality of painting, protects the health of workers, and is convenient for painting. , Improve painting efficiency.

Owner:钟晓梅

Vehicle outer shell paint spraying equipment

The invention provides vehicle outer shell paint spraying equipment. The equipment comprises a main machine body; left and right symmetrical support rods are fixedly arranged on the top end surface ofthe main machine body; the support rods extend up; a cross beam rack is fixedly arranged between the left and right symmetrical support rods; a paint spraying mechanism is slidingly arranged on the cross beam rack; a working cavity extending down is formed in the top end surface of the main machine body; a worktable is slidingly arranged in the bottom wall of the working cavity; and a top cavityis formed in the main machine body on the left side of the working cavity. The invention designs equipment for paint spraying of small shells; and through design of multiple sets of support plate mechanisms, the paint spraying work of multiple sets of shells can be realized, the paint spraying time is shortened, the working efficiency is improved, the large-batch shell paint brushing demands are met, the manpower is saved, and the cost is saved.

Owner:江苏铭利达科技有限公司

Wheel hub paint spraying method for new energy vehicle production and achieving convenient fixing

The invention discloses a wheel hub paint spraying method for new energy vehicle production and achieving convenient fixing. A device comprises a box body. A long plate is fixedly connected between the two sides of the inner wall of the box body. A moving device is fixedly connected with the top of the long plate, the top of the moving device is fixedly connected with the top of the inner wall ofthe box body, and the bottom of the moving device penetrates through the long plate and extends to the bottom of the long plate. A paint spraying box is fixedly connected with the end, located at thebottom of the long plate, of the moving device. The invention relates to the technical field of new energy vehicles. By the adoption of the wheel hub paint spraying method for new energy vehicle production and achieving convenient fixing, a wheel hub is conveniently fixed, paint spraying is conveniently conducted on the wheel hub, the paint spraying quality of the wheel hub is improved, and manualoperation is not required in the wheel hub spraying process; and spray nozzles and the wheel hub can be kept at the optimal positions in the practical spraying process, the wheel hub can be timely dried after spraying is accomplished, follow-up machining can be conveniently and timely conducted on the wheel hub, the time is saved, and the working efficiency is improved.

Owner:海宁鼎合工程技术开发有限公司

Full-automatic paint spraying machine

ActiveCN105289927AEvenly heatedImprove drying effectPretreated surfacesCoatingsControl systemSprayer

The invention discloses an automatic paint spraying machine. The automatic paint spraying machine comprises a guide rail transportation system, a paint spraying system, a drying system, a cooling system and a control system, wherein the paint spraying system, the drying system and the cooling system are mounted on the guide rail transportation system in sequence; and the paint spraying system comprises a paint sprayer and an induction device. The automatic paint spraying machine automatically transports PCBs into the paint spraying system through the guide rail transportation system; the paint spraying system realizes automatic paint spraying through the induction of the induction device; after the paint spraying is finished, the PCBs enter the drying system; the drying system sets the temperature for drying according to the sizes and the humidity of the boards; and after the drying is finished, the PCBs enter the cooling system for cooling to room temperature. The automatic paint spraying machine has such advantages as high production efficiency, automatic production, reduction of labor intensity, uniform paint coating, high paint spraying quality, uniform heating of the PCBs and good drying effect.

Owner:安徽广晟德自动化设备有限公司

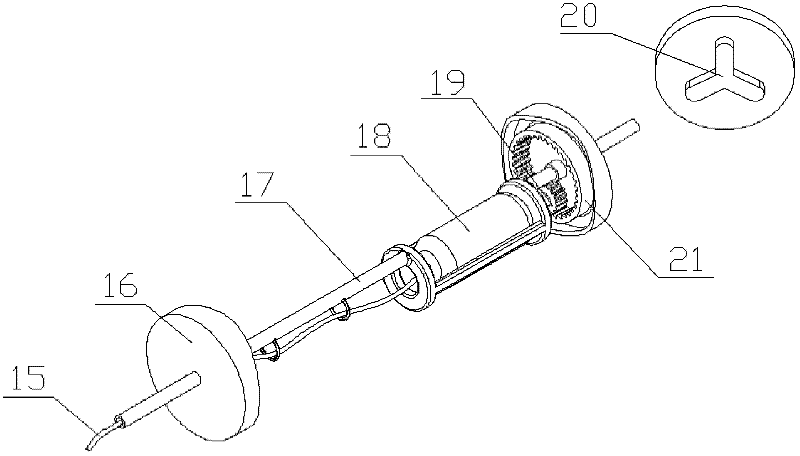

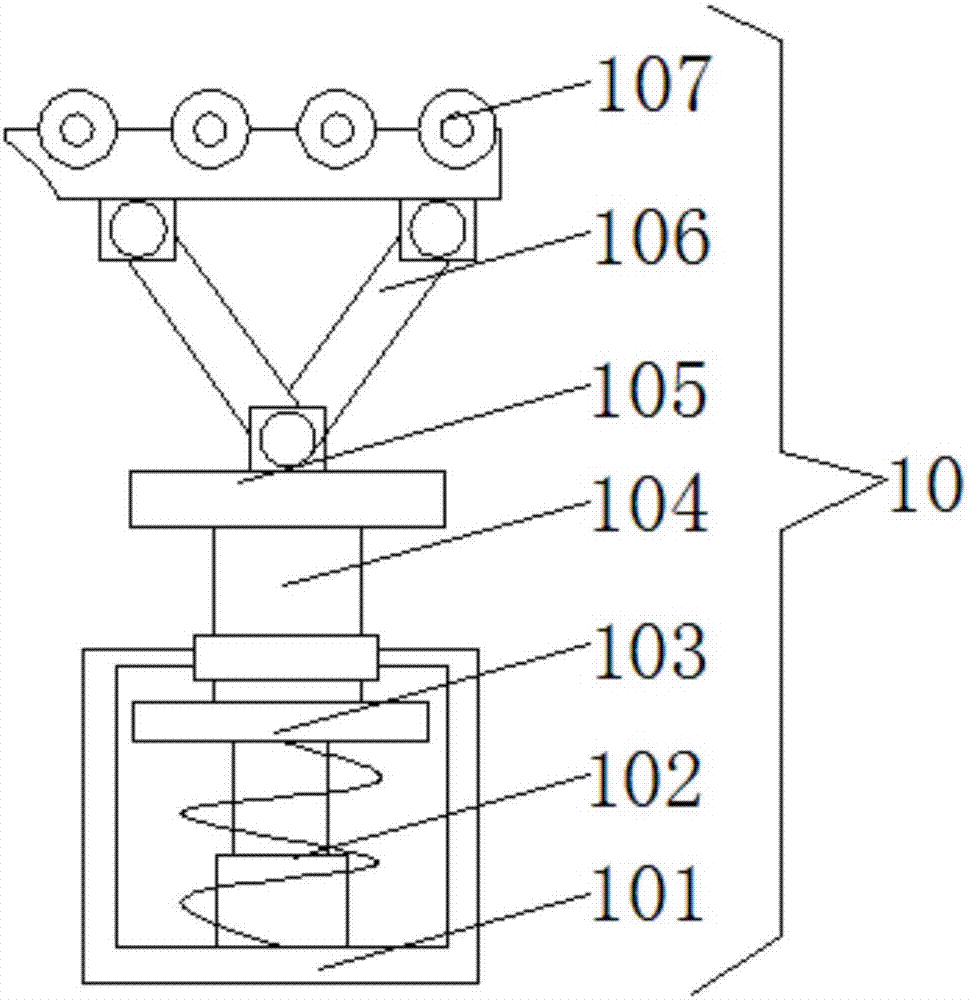

Anti-corrosion paint spraying maintenance device applicable to oil transferring pipelines of multiple specifications

InactiveCN106583089AImprove uniformityImprove paint qualityPretreated surfacesCleaning using toolsCoil springSurface cleaning

The invention discloses an anti-corrosion paint spraying maintenance device applicable to oil transferring pipelines of multiple specifications. The anti-corrosion paint spraying maintenance device comprises an installing plate. A pair of sleeves is fixedly connected with the left side of the lower portion of the installing plate. A landing leg column is arranged in each sleeve, wherein the top end of the landing leg column is connected into the sleeve through a first spiral spring, and a plurality of first fixing pin holes are formed in the side wall of the sleeve. By adoption of the anti-corrosion paint spraying maintenance device, the oil transferring pipelines can be subjected to outer surface cleaning, anti-corrosion paint spraying and drying in sequence, anti-corrosion paint sprayed on the outer surfaces of the oil transferring pipelines is good in uniformity, and the paint spraying quality is improved; and the anti-corrosion paint spraying maintenance device is applicable to the oil transferring pipelines of the different specifications, and the applicability is high.

Owner:合肥图腾龙企业管理事务所(有限合伙)

Ecological and environment-friendly coating and preparation method thereof

InactiveCN105524528AImprove purification effectImprove antibacterial propertiesAntifouling/underwater paintsPaints with biocidesWater basedOxygen ions

The invention discloses an ecological and environment-friendly coating and a preparation method thereof. The coating is prepared from raw materials in parts by weight as follows: 0.05-0.15 parts of a pH regulator, 0.3-0.8 parts of a dispersant, 10-15 parts of a hydroxyethyl cellulose solution, 0.1-0.4 parts of a wetting agent, 0.1-0.4 parts of an antifoaming agent, 1-10 parts of negative oxygen ion powder, 10-20 parts of titanium dioxide, 0.05-0.2 parts of a molecular sieve silver-loaded antibacterial agent, 0.1-0.4 parts of a preservative, 2-10 parts of quartz / nano-titanium dioxide compound slurry, 10-20 parts of superfine quartz powder slurry, 15-40 parts of a water-based acrylic emulsion, 0.2-1.0 part of a thickening agent and 20-30 parts of deionized water. The coating has good performance, the formaldehyde purification rate is higher than 95%, the formaldehyde purification durability is longer than 90%, the antibacterial effect is higher than 90%, and the negative oxygen ion release amount is larger than 8000 per cubic centimeter.

Owner:GUIZHOU LIANHE NEW BUILDING MATERIAL

High-reactivity polyurethane compositions containing uretdione groups and comprising carbonate salts

InactiveUS20160017179A1Improve paint qualityPolyureas/polyurethane adhesivesSynthetic resin layered productsGramIsocyanate

A high-reactivity polyurethane composition useful in coatings and adhesives, contains the following components A)-D): A) 5 to 98.7 wt %, based on the total mass of the components, of at least one compound containing an uretdione group, and a free NCO content of less than 5 wt %, and an uretdione content of 2 to 25 wt %, based on i) aliphatic and / or (cyclo)aliphatic and / or cycloaliphatic polyisocyanates and ii) compounds containing hydroxyl groups; B) 0.2 to 5 wt %, based on the total mass of the components, of at least one catalyst selected from the group consisting of a substituted carbonate salt having a quaternary ammonium counterion, a substituted carbonate salt having a quaternary phosphonium counterion and mixtures thereof; C) 0.1 to 10 wt %, based on the total mass of the components, of at least one cocatalyst having at least one epoxide group; D) 1 to 90 wt %, based on the total mass of the components, of at least one polymer containing a hydroxyl group and having an OH number of between 20 and 1000 mg KOH / gram; wherein a sum of all components A)-D) is 100 wt %.

Owner:EVONIK DEGUSSA GMBH

Surface paint-spraying device suitable for plank

InactiveCN107321535AImprove work efficiencyImprove paint qualitySpraying apparatusDrive shaftEngineering

The invention discloses a surface paint-spraying device suitable for a plank. The device comprises an operation platform, a fixed plate, a liquid conveying pump, an air cylinder, a sliding block, an atomizing nozzle, a motor, a driven shaft and a bearing block; the device is characterized in that the operation platform is arranged on brackets, the fixed plate is arranged on vertical plates, and the liquid conveying pump is arranged on the fixed plate; the air cylinder is arranged on one vertical plate, the sliding block is arranged on a sliding rail, and the atomizing nozzle is arranged on the sliding block; a motor is arranged on the other vertical plate, and the driven shaft is arranged in a bearing. According to the surface paint-spraying device suitable for the plank, the sliding block is arranged on the sliding rail of the fixed plate and connected with a piston rod of the air cylinder, the atomizing nozzle is arranged on the sliding block, and the air cylinder can drive the sliding block to move back and forth on the sliding rail, so that the atomizing nozzle can be driven to move back and forth to spray paint on different positions of the surface of the plank, and thus, not only can the working efficiency of paint spraying for the plank be improved, but also the quality of paint spraying for the plank is improved.

Owner:吴桂丽

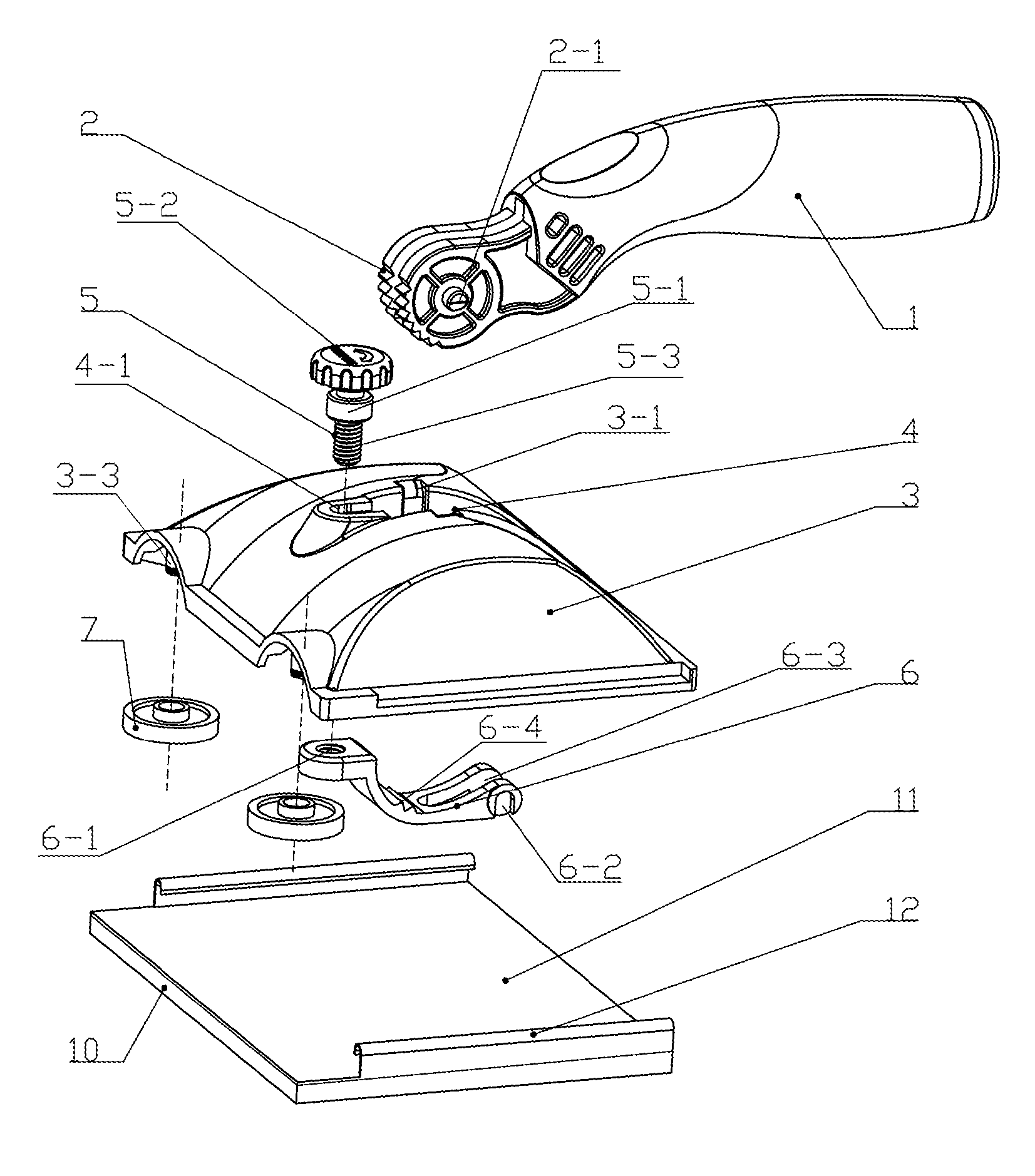

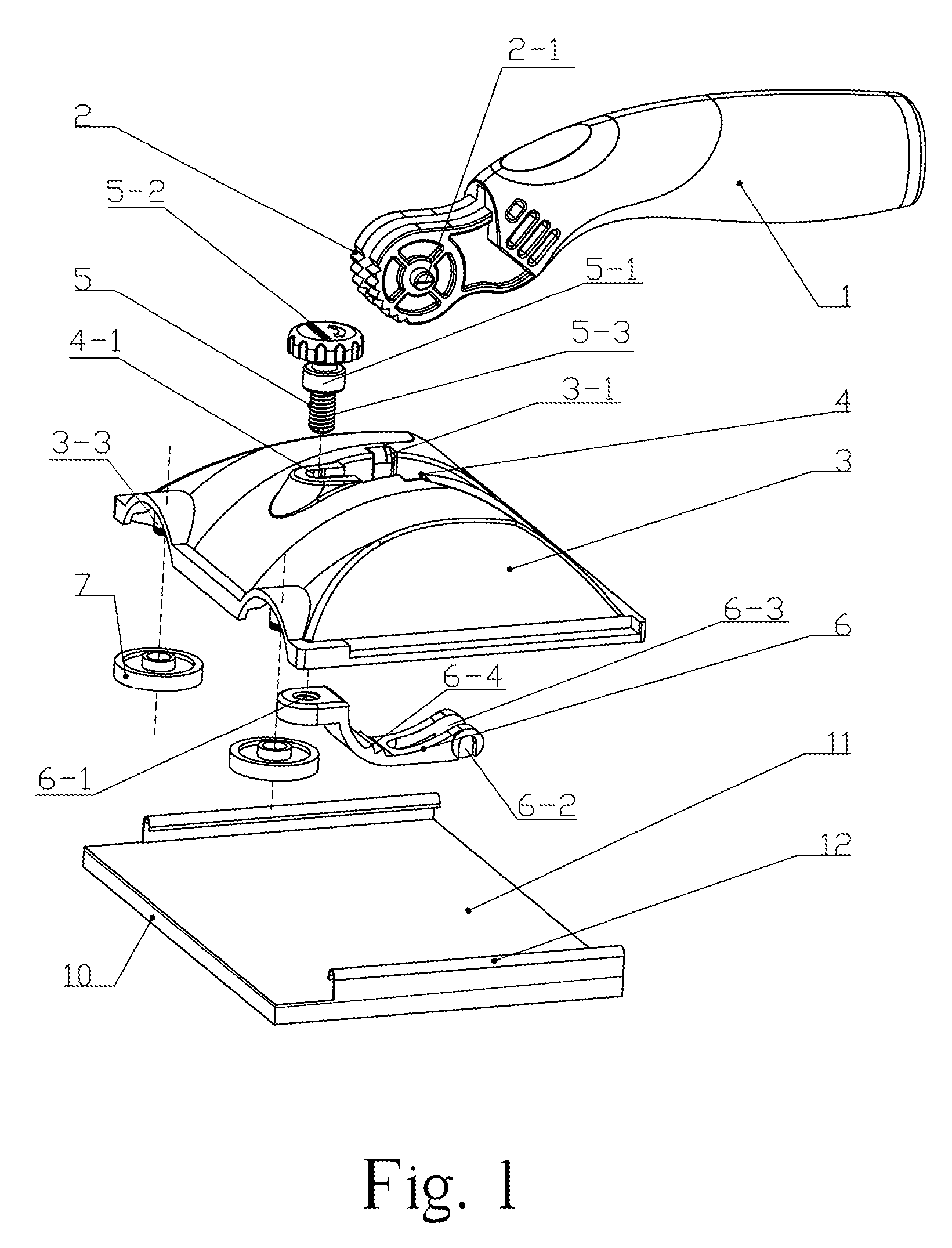

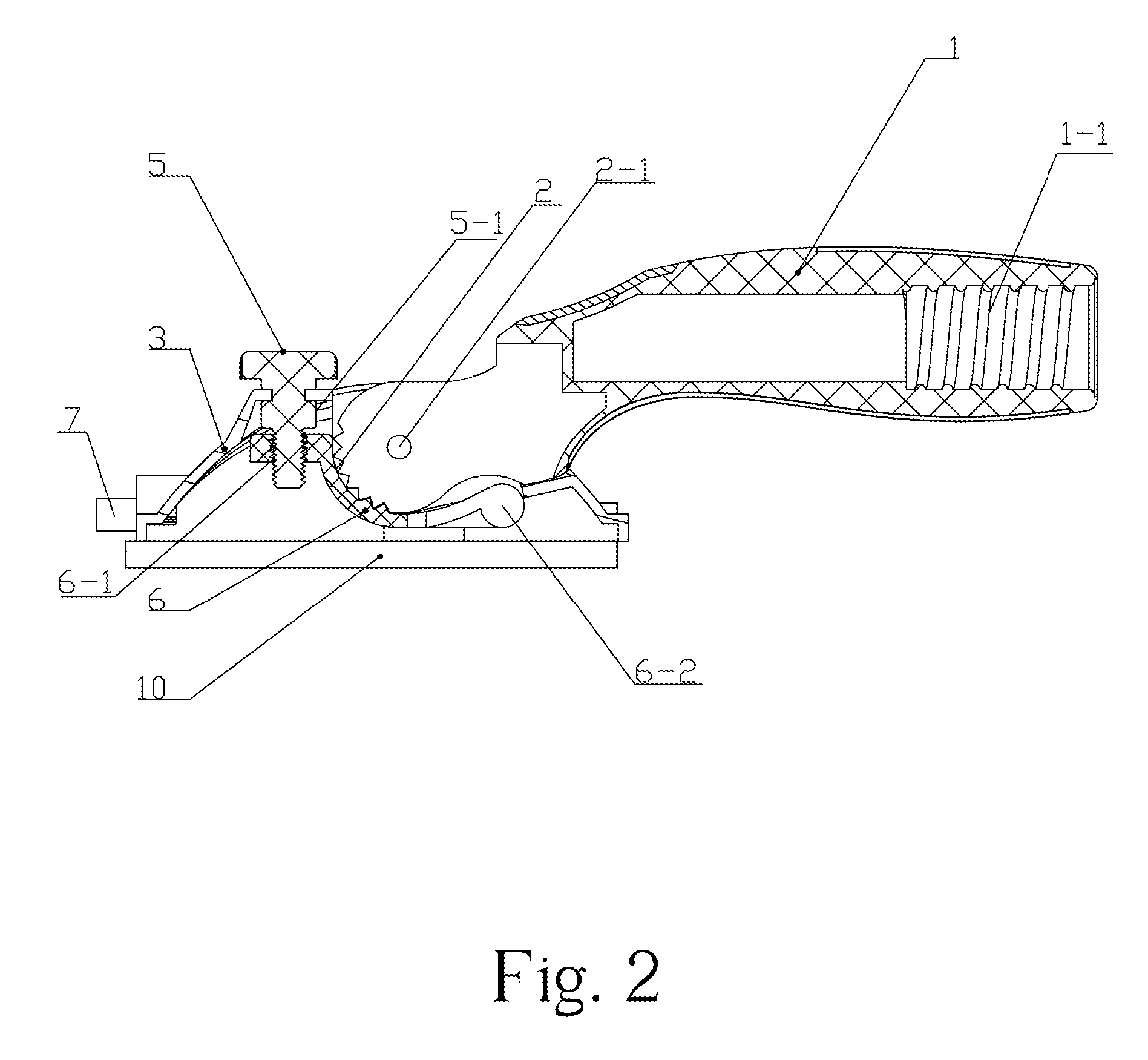

Paint pad with adjustable handle

InactiveUS7854037B2Easy to operateEasy for operator to eraseBoard cleaning devicesLiquid surface applicatorsEngineeringGasket

A paint pad with adjustable handle belong to painting tool field, includes a handle; a pad unite that includes a pad support body and a pad holder plate, the pad holder plate is connected to the bottom of the pad support body; wherein the pad support body has a handle groove on the top; a orientation part is under the groove, its up surface has a plurality of orientation teeth; the handle with plurality of adjusting teeth at the end of handle is located in the groove; a knob on the top of the pad support body can adjust the relationship between the orientation teeth and adjusting teeth. The conventional paint pad is fallible and instable for keeping stable angle between the handle and pad unite, it influences the painting route and uniformity, and reduces painting quality. The paint pad of the present invention allows the handle to have up & down vertically pivotal movement but not left & right swing; though the knob to adjust the engaging force between teeth, therefore, keep the right needed angle for stable operation. The new paint pad possesses advantages of easy in changing working situation, comfortable holding, big amount of absorbing paint, speedy painting, high quality in painting of corner wall areas and area with different colors and exchangeable of paint pad.

Owner:LU JIANXIN

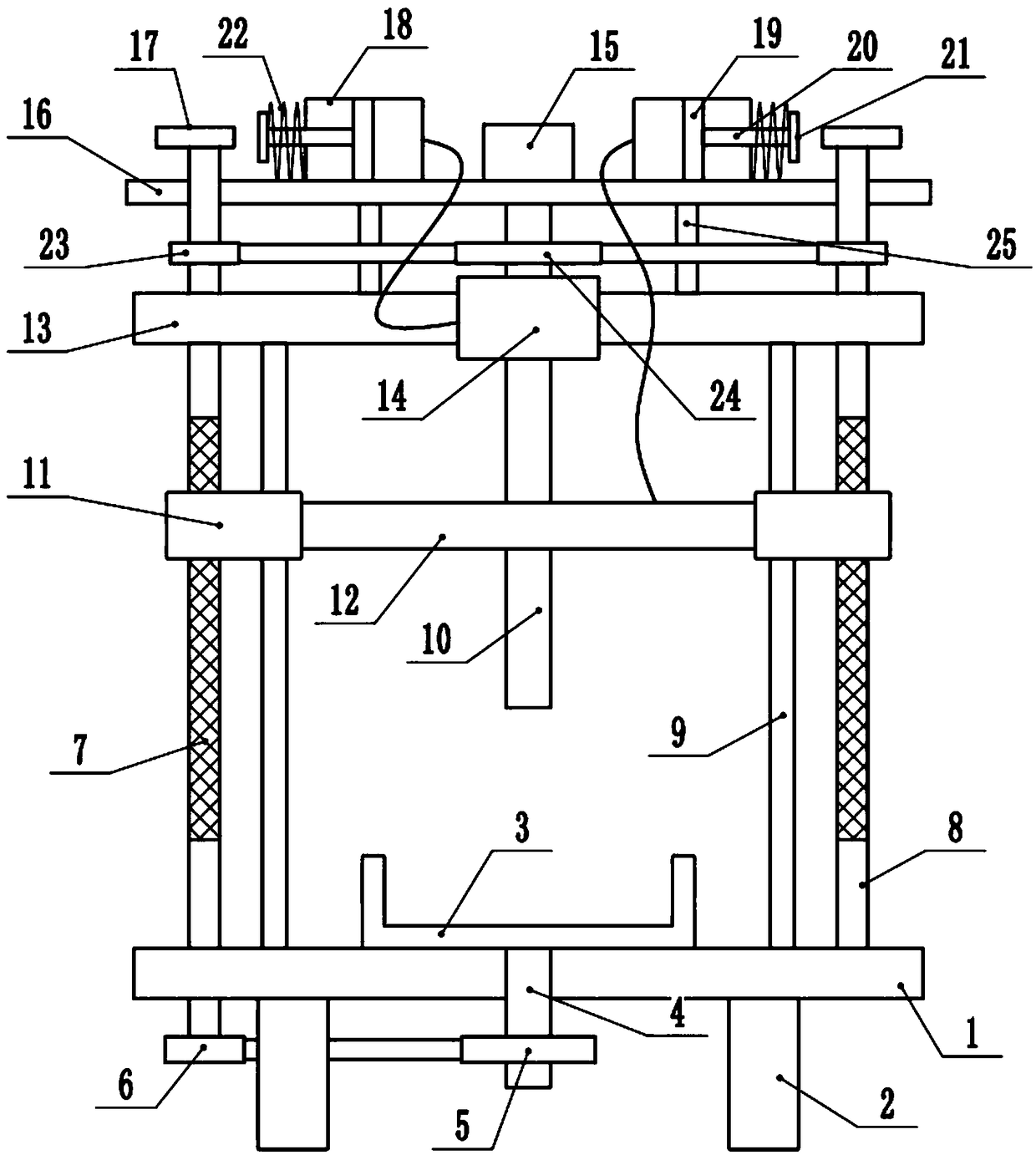

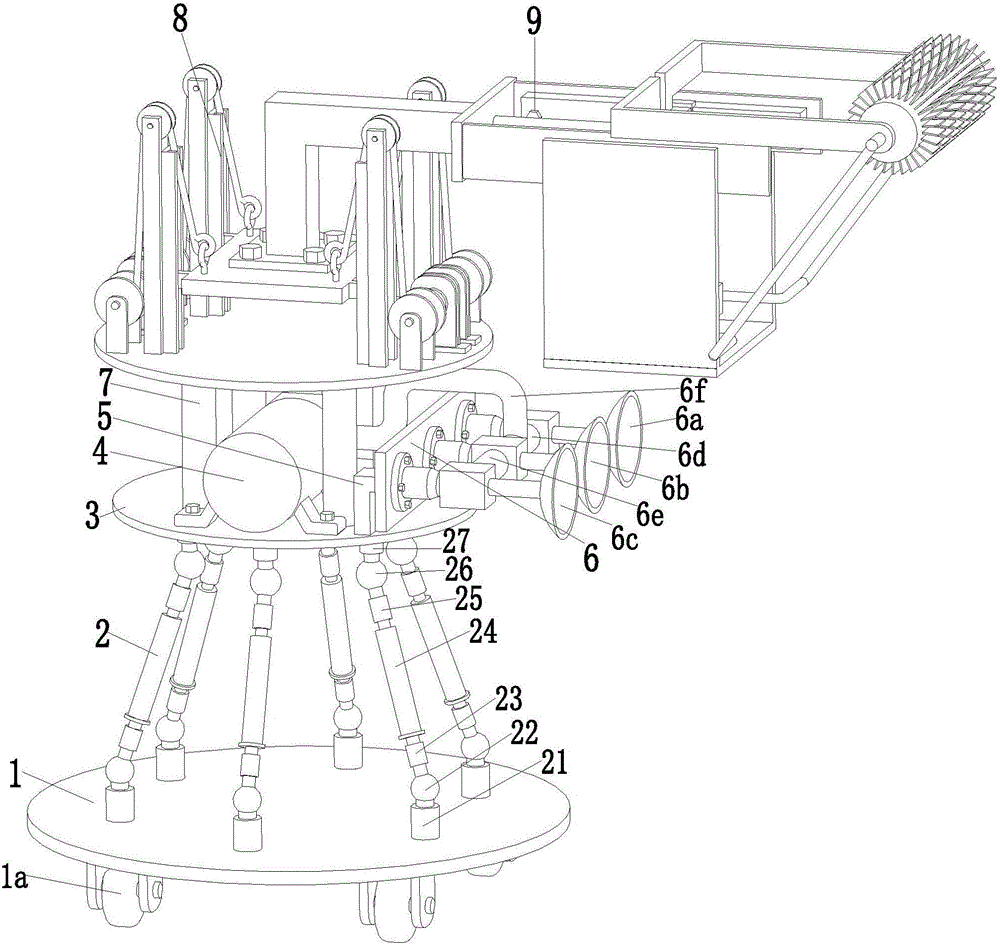

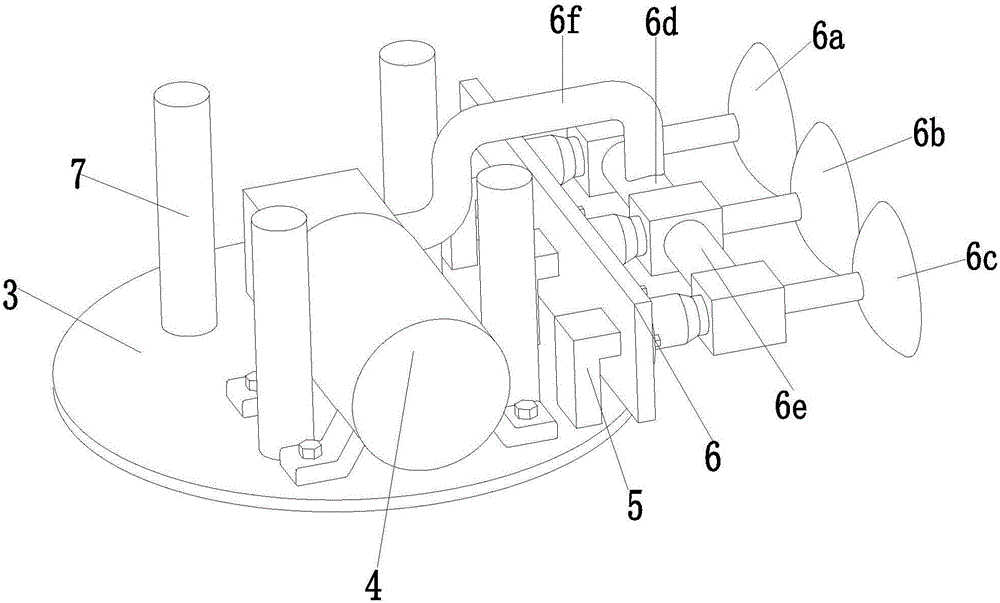

Intelligent whitewashing robot used for indoor building wall decoration

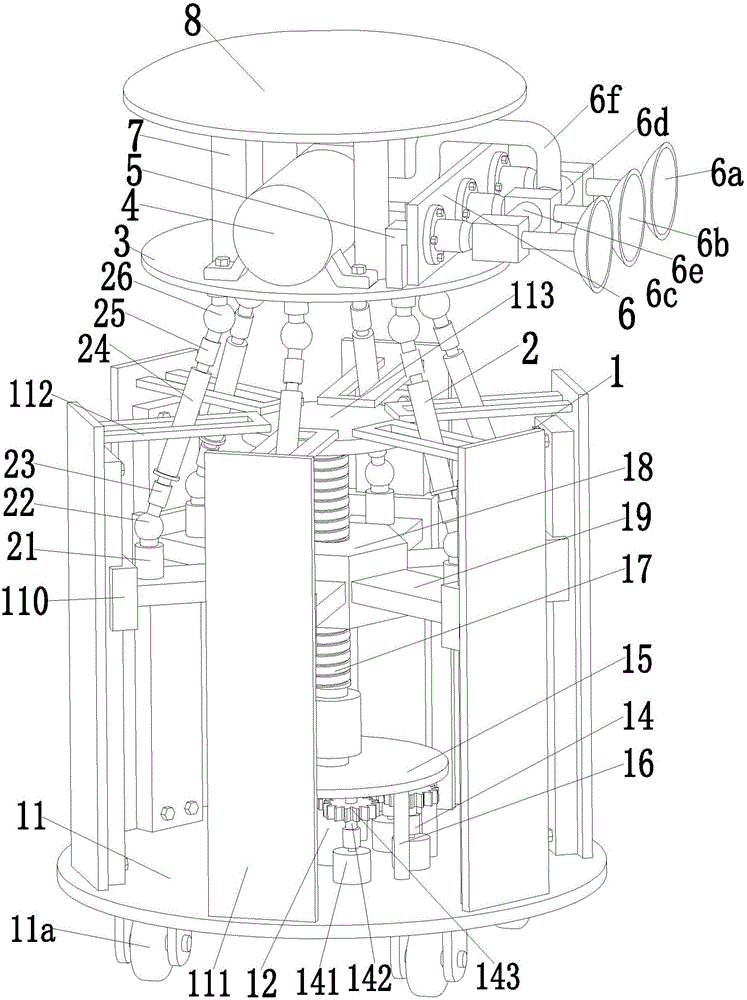

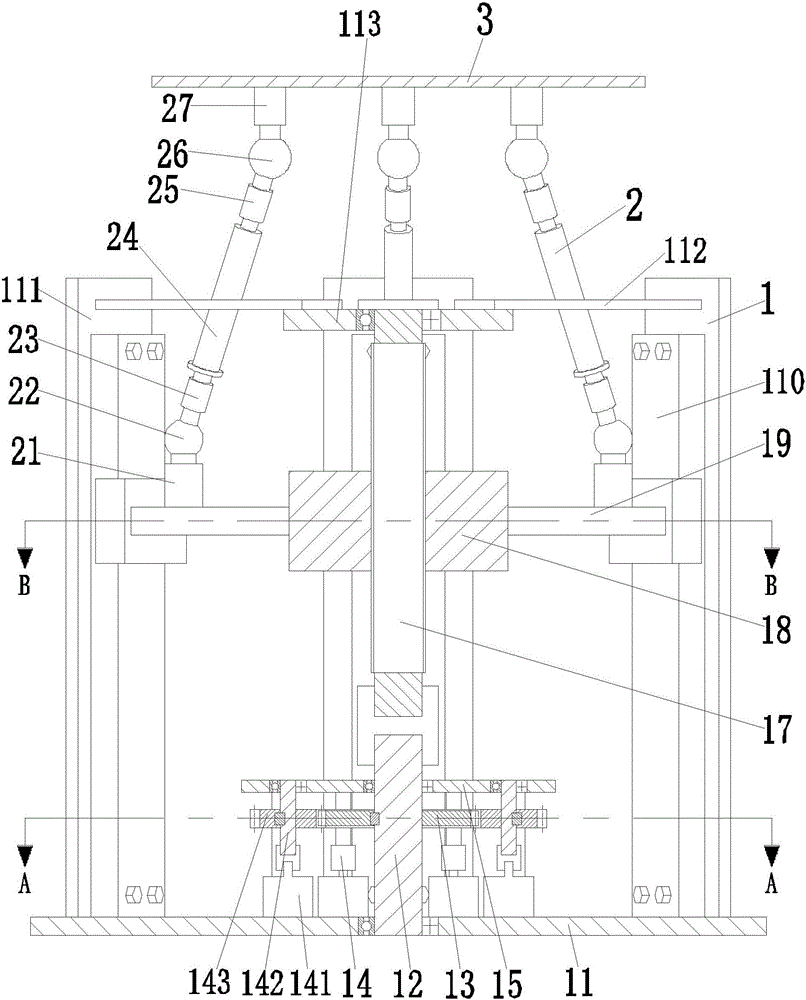

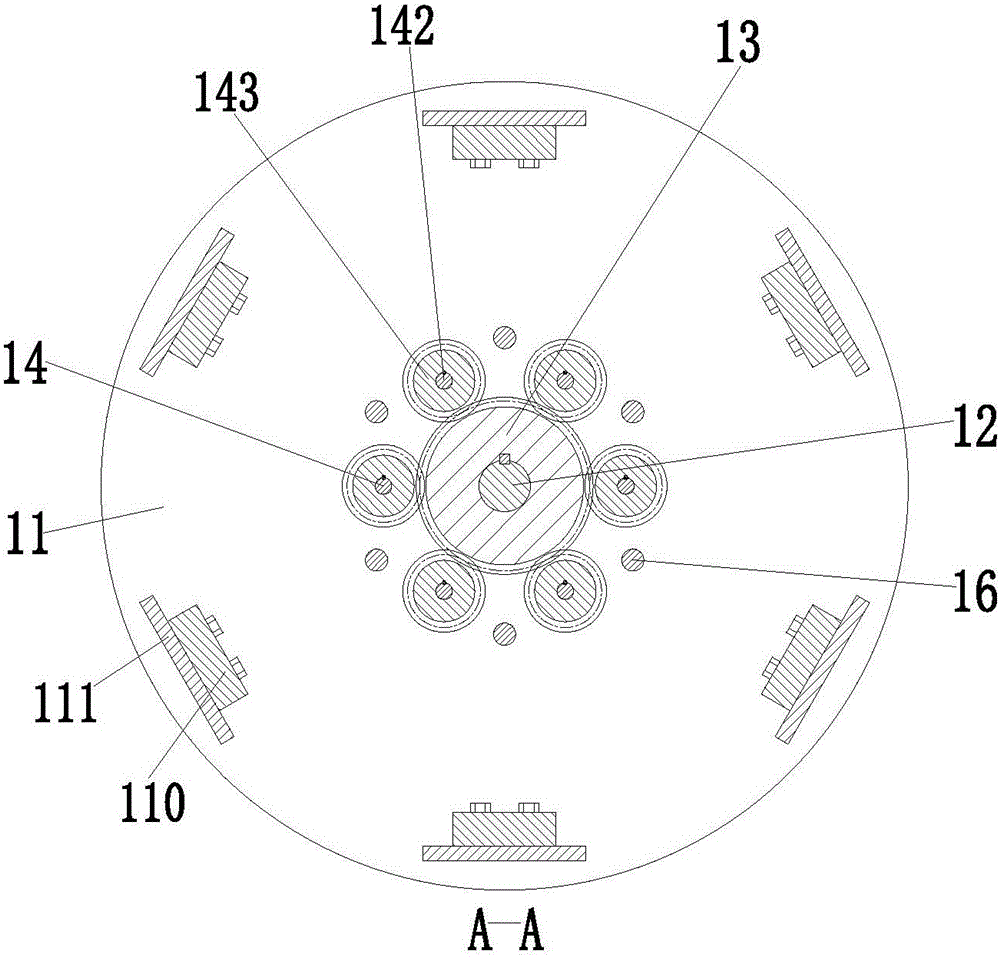

ActiveCN105952118AImprove work efficiencyEliminate jitter conditionsBuilding constructionsEngineeringManipulator

The invention relates to an automatic coating-pouring-type whitewashing robot used for indoor building wall decoration. The automatic coating-pouring-type whitewashing robot comprises a lower platform, the lower end surface of which is provided with four universal wheels symmetrically. By means of the four universal wheels, the automatic coating-pouring-type whitewashing robot can move at will to below a to-be-whitewashed wall surface. The lower platform is uniformly provided with six parallel branched chains. Upper ends of the six parallel branched chains are uniformly installed on an upper platform. The middle part of the upper end surface of the upper platform is equipped with an air extracting pump through screws. The right side of the upper end surface of the upper platform is uniformly welded with three L-shaped support columns, tail ends of which are welded with air extracting support boards. Inner walls of the air extracting support boards are respectively equipped with a first sucker, a second sucker and a third sucker through screws. The upper end surface of the upper platform is symmetrically welded with four air extracting top columns. The upper end surfaces of the four air extracting top columns are welded with an elevating table, the upper end of which is equipped with a whitewashing manipulator through screws. The intelligent whitewashing robot used for the indoor building wall decoration has functions of stably elevating and automatically whitewashing. A new way for mechanically and automatically whitewashing wall surfaces is provided.

Owner:闻天地装饰科技有限公司

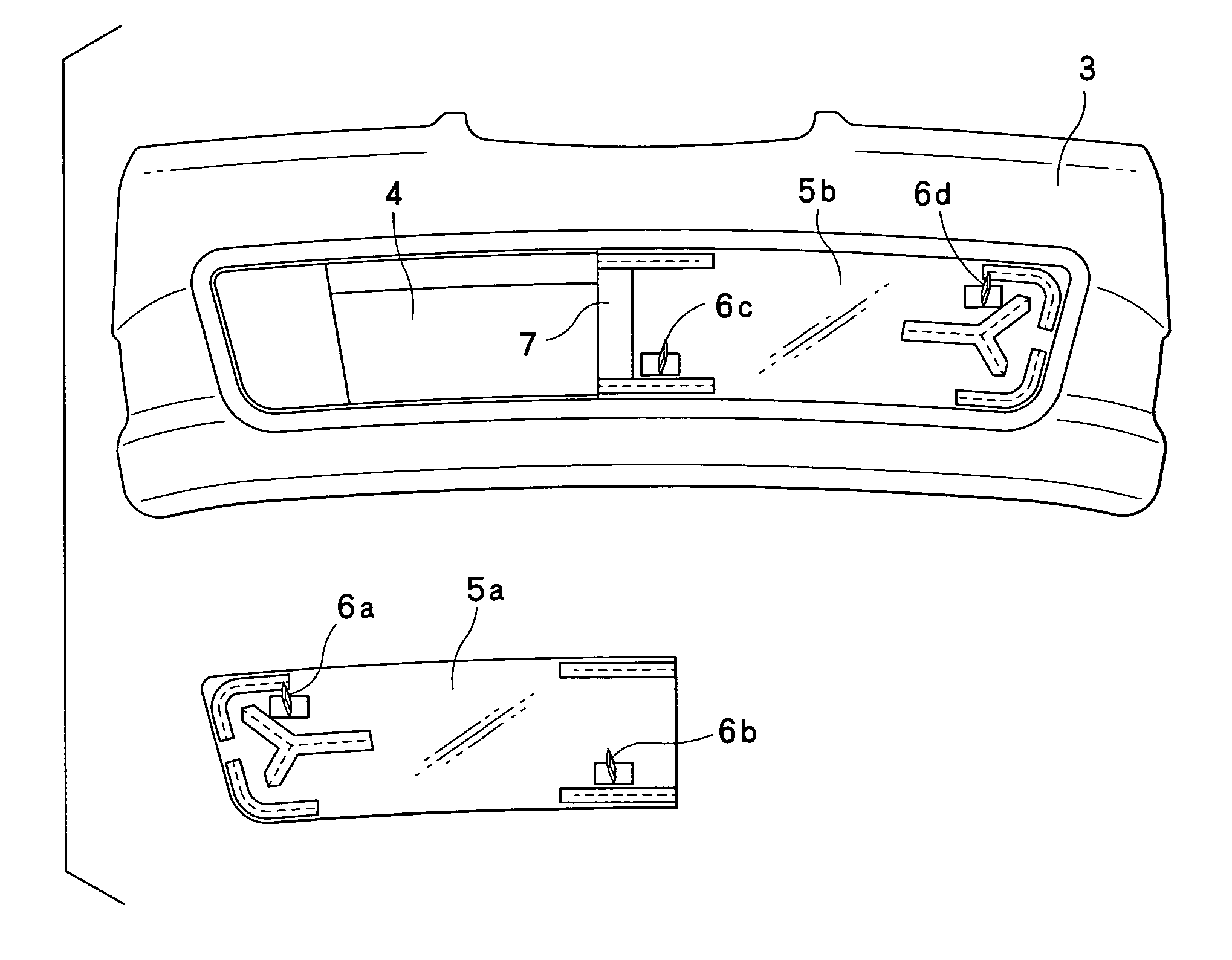

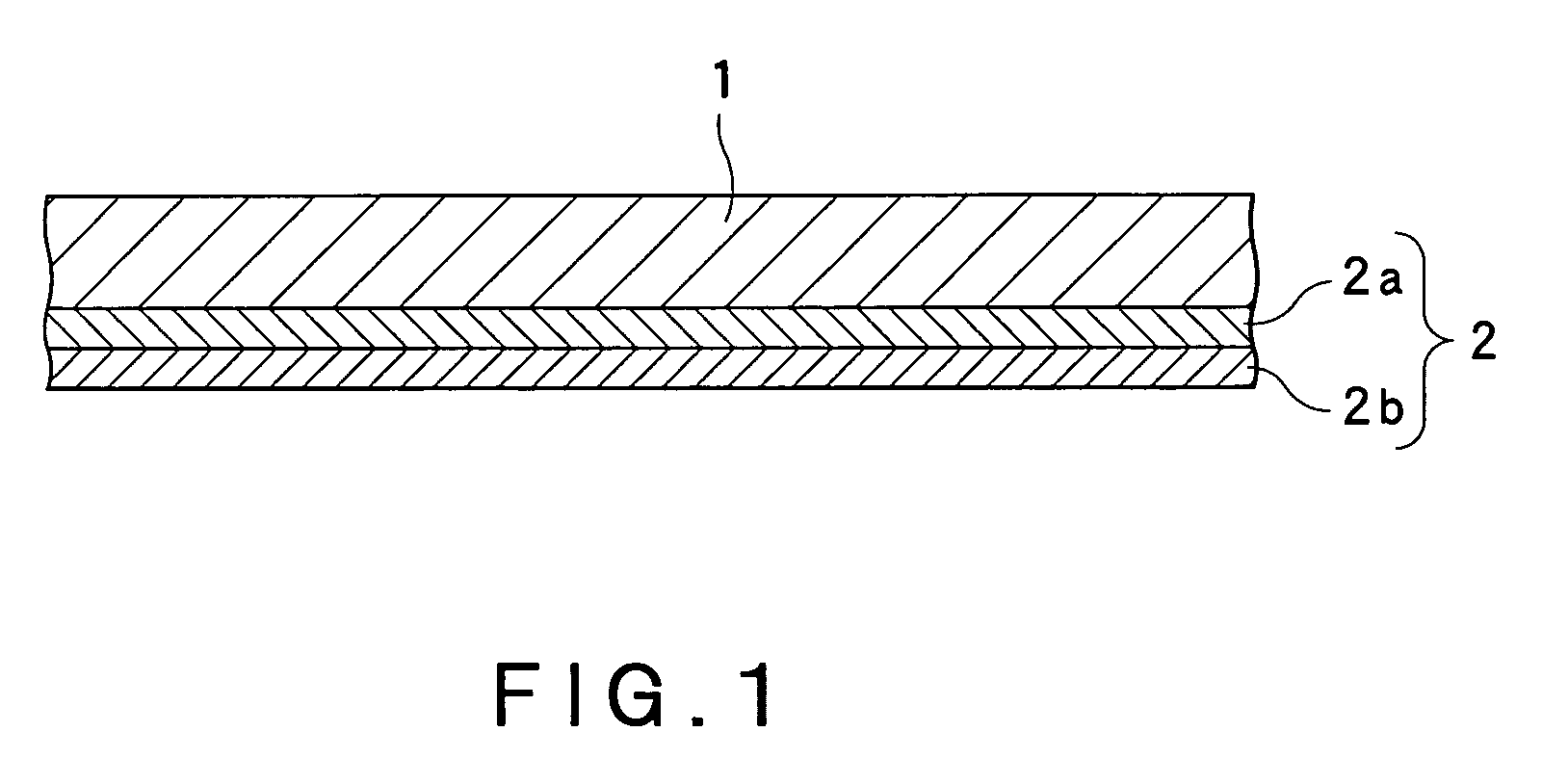

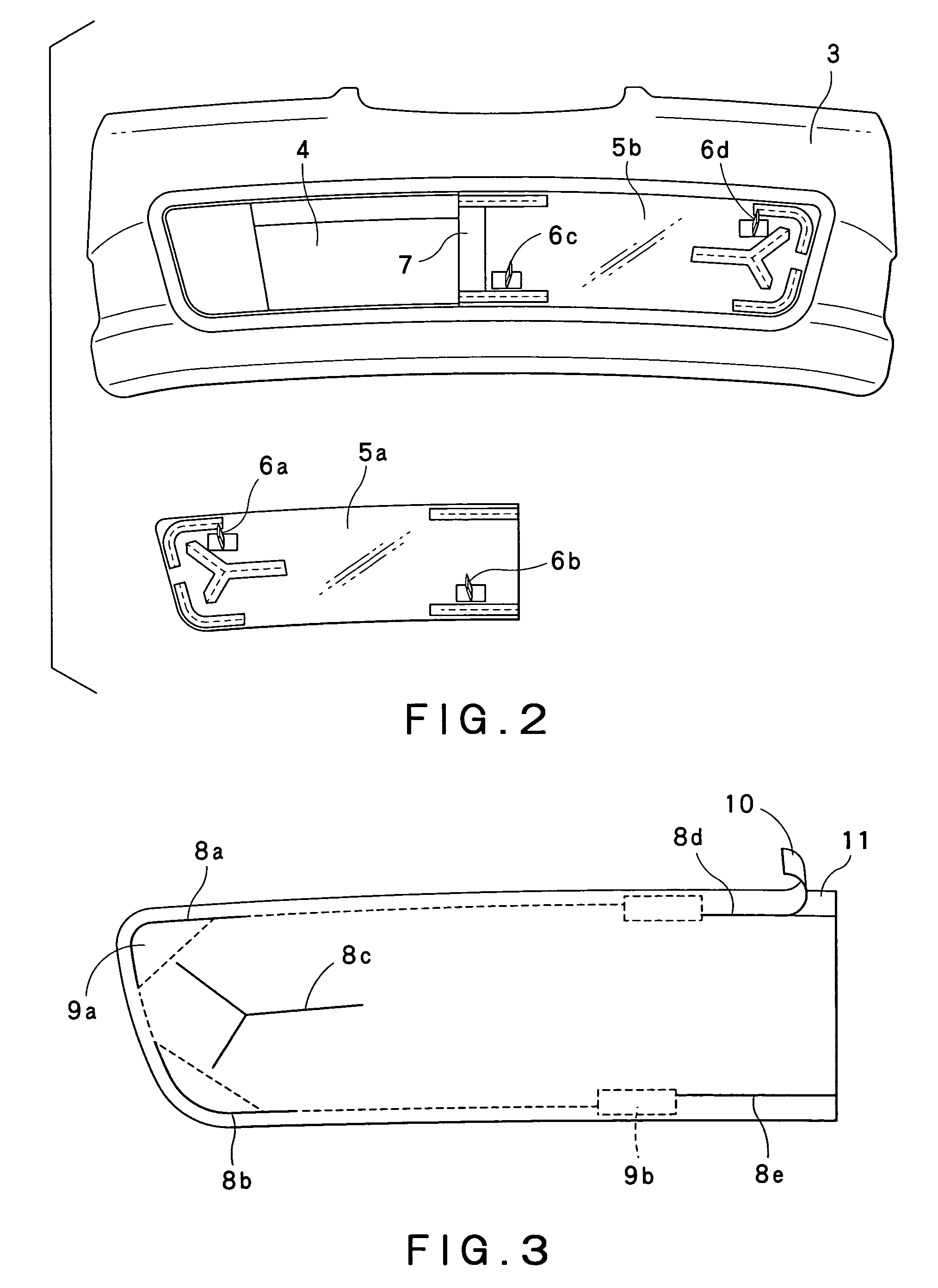

Masking material for painting

The present invention is a masking material for painting for masking a surface to be unpainted, comprising: a masking material body for painting made of a carton having a shape conformed to the surface to be unpainted; a double-sided tape provided on the whole rear surface of the masking material body for painting; an incision formed in both the masking material body for painting and the double-sided tape; and a piece of thin paper that covers the incision.

Owner:YAMATO

Interior decoration fixing equipment for negative pressure type building

InactiveCN105804374AIncrease stiffnessEliminate jitter conditionsLifting framesBuilding constructionsEngineering

The invention relates to interior decoration fixing equipment for a negative pressure type building. The interior decoration fixing equipment comprises a fixing rack, wherein six parallel-connected branched chains are respectively arranged on the fixing rack, and the upper ends of the six parallel-connected branched chains are uniformly arranged on an upper platform; a sucking pump is arranged in the middle of the upper end surface of the upper platform through screws, and three L-shaped pillars are uniformly welded at the right side of the upper end surface of the upper platform; the tail ends of the three L-shaped pillars are welded with a sucking supporting plate, and a first sucking disc, a second sucking disc and a third sucking disc are respectively arranged on the inner wall of the sucking supporting plate through screws; the first sucking disc is connected with the second sucking disc through a first connecting air pipe, and a sucking pipe is connected onto a sucking opening of the sucking pump; the sucking pipe is communicated with the first connecting air pipe, and the upper end surface of the upper platform is symmetrically welded with four sucking support pillars; the upper end surfaces of the four sucking support pillars are welded with a lifting platform, and an existing automatic painting device is arranged in the middle of the lifting platform. The interior decoration fixing equipment for the negative pressure building provided by the invention can achieve a stable fixed support function, and provides a new way to fixedly support the existing automatic painting device.

Owner:浙江磐石建设有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com