Environment-friendly and efficient UV paint spraying line and technology thereof

A painting line, high-efficiency technology, applied in the direction of painting booths, spraying devices, devices for coating liquid on the surface, etc., can solve the problems of not easy to scratch, low surface hardness, easy to scratch, etc., to improve cleanliness, durability Good abrasiveness, the effect of increasing the hardening speed of spray paint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

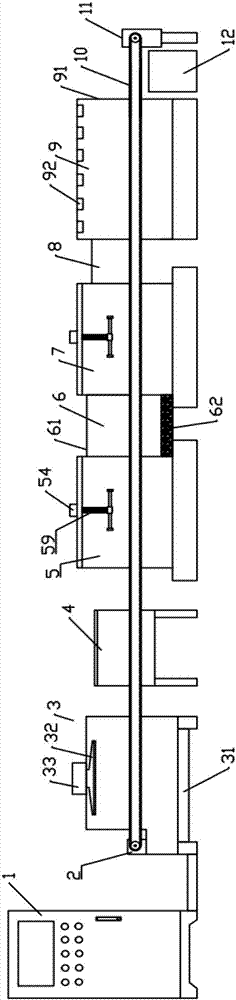

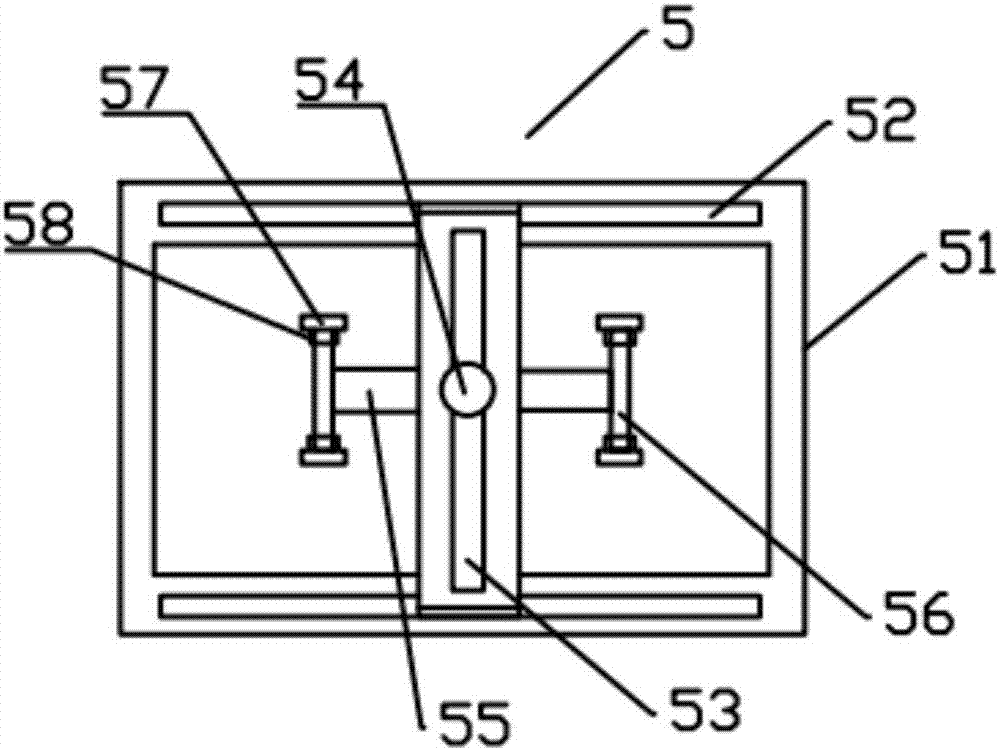

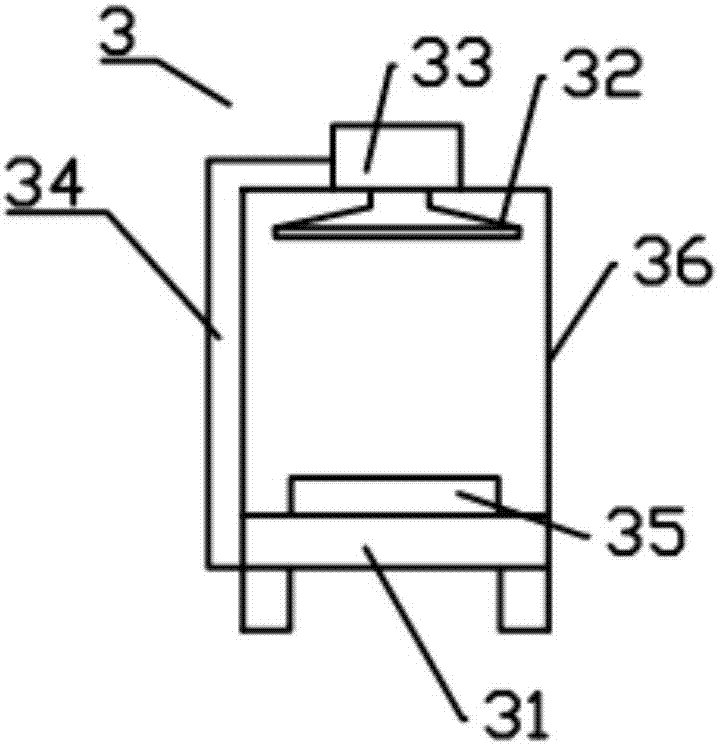

[0038] Such as figure 1 The environmentally friendly and efficient UV painting line and its process shown include electric control cabinet 1, first motor 2, automatic dust removal device 3, preheating device 4, UV primer spraying device 5, first tunnel 6, UV topcoat spraying Device 7, second tunnel 8, UV curing device 9, material transmission belt 10, second motor 11 and material storage box 12, the first motor 2, automatic dust removal device 3, preheating device 4, UV primer spraying device 5 , the first tunnel 6, the UV topcoat spraying device 7, the second tunnel 8, the UV curing device 9 and the second motor 11 are electrically connected to the electric control cabinet 1, and the material transmission belt 10 is arranged on the first motor 2 and the second motor Between the motors 11, the automatic dust removal device 3, the preheating device 4, the UV primer spraying device 5, the first tunnel 6, the UV topcoat spraying device 7, the second tunnel 8 and the UV curing dev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com