Furniture board machining equipment

A technology for processing equipment and boards, applied in the field of processing equipment for furniture boards, can solve problems such as affecting the quality of wood surface painting, and achieve the effects of promoting processing quality, simplifying dust removal work, and increasing the degree of polishing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in further detail below by means of specific embodiments:

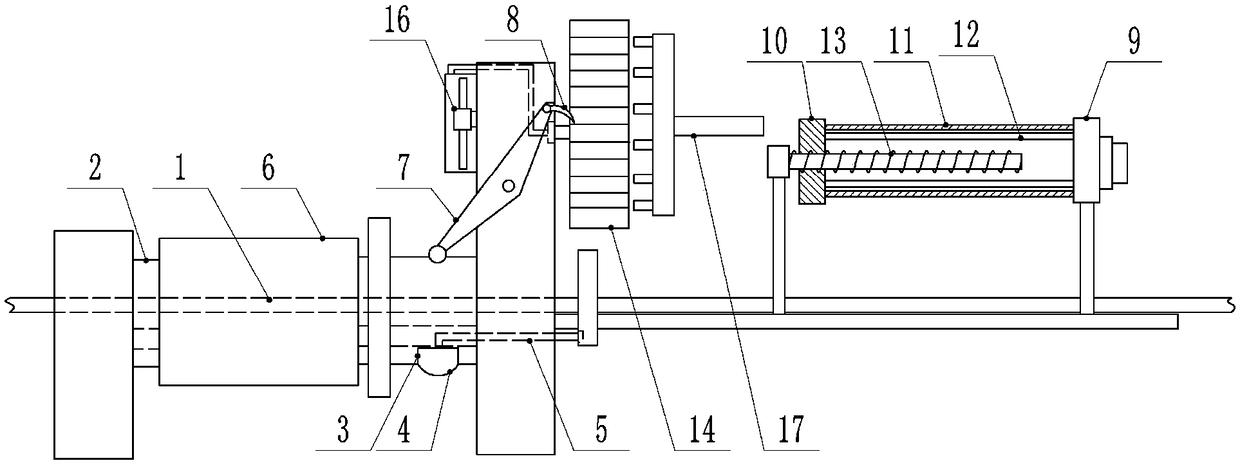

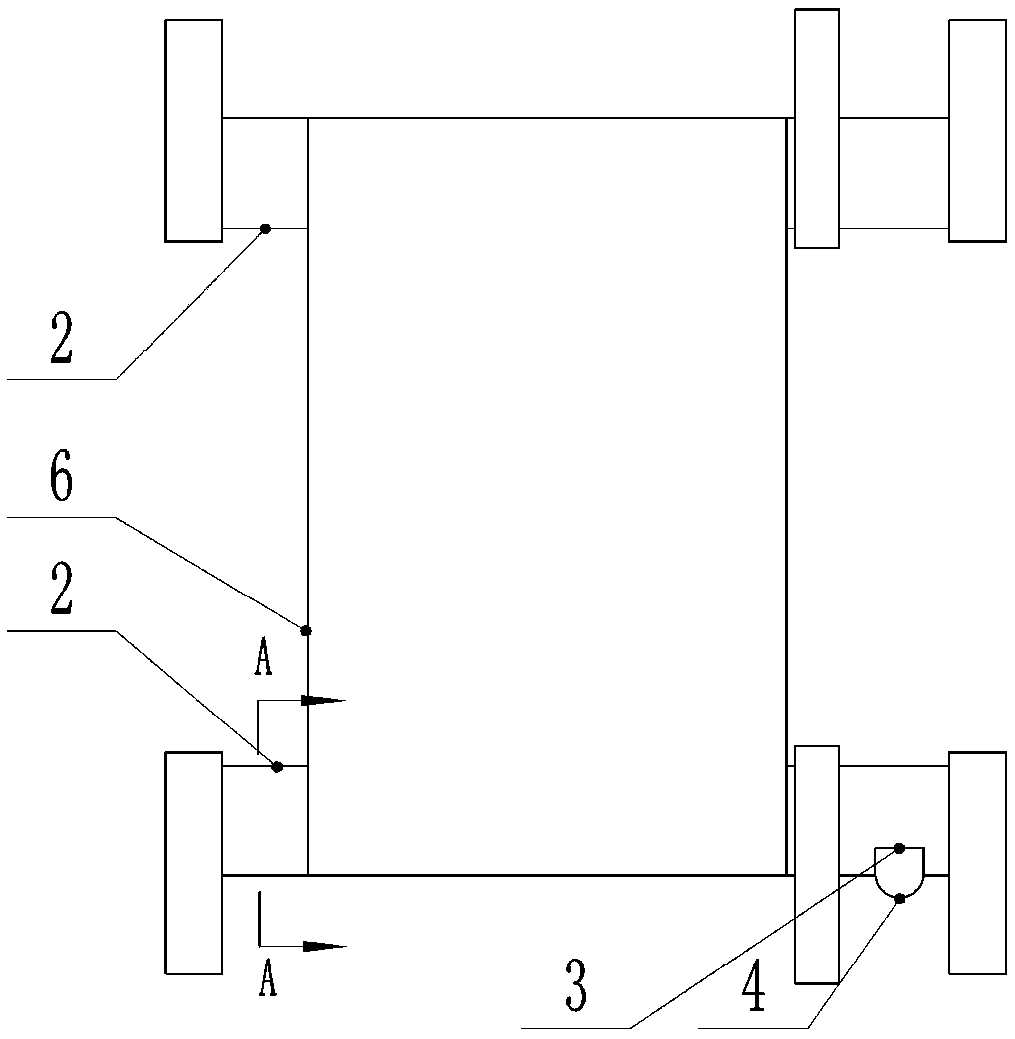

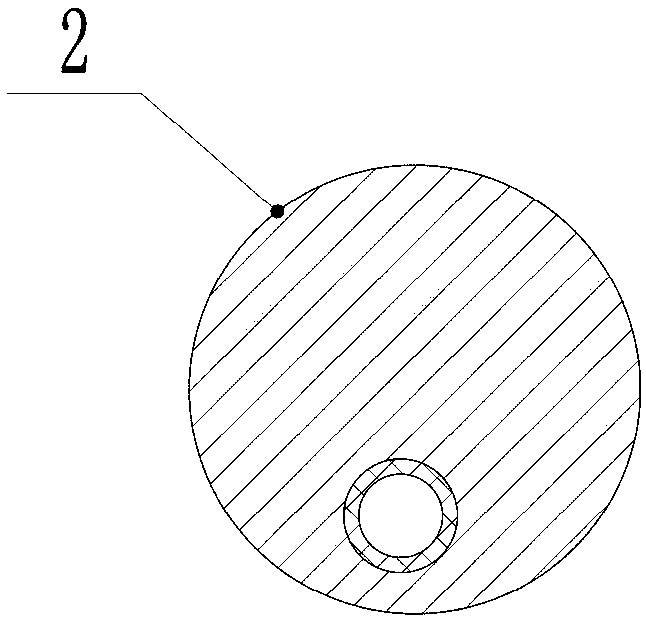

[0020] The reference signs in the drawings of the description include: conveyor belt 1, sleeve rod 2, groove 3, air bag 4, air pipe 5, polishing belt 6, ornament 7, pawl 8, fixed plate 9, moving plate 10, elastic cylinder 11, Elastic bar 12, lead screw 13, gear 14, through hole 15, blower 16, branch pipe 17.

[0021] Example figure 1 Shown: Processing equipment for furniture panels, including a conveying mechanism, a grinding mechanism, a cleaning mechanism, a dust collection mechanism, a driving mechanism and a painting mechanism.

[0022] The transmission mechanism is used for automatic transmission of the wood boards to be processed to improve the processing efficiency of the wood boards. The transmission mechanism includes a driving wheel, a driven wheel and a conveyor belt 1 sleeved between the driving wheel and the driving wheel. The driving wheel is connected wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com