Patents

Literature

540results about How to "Guaranteed grinding effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

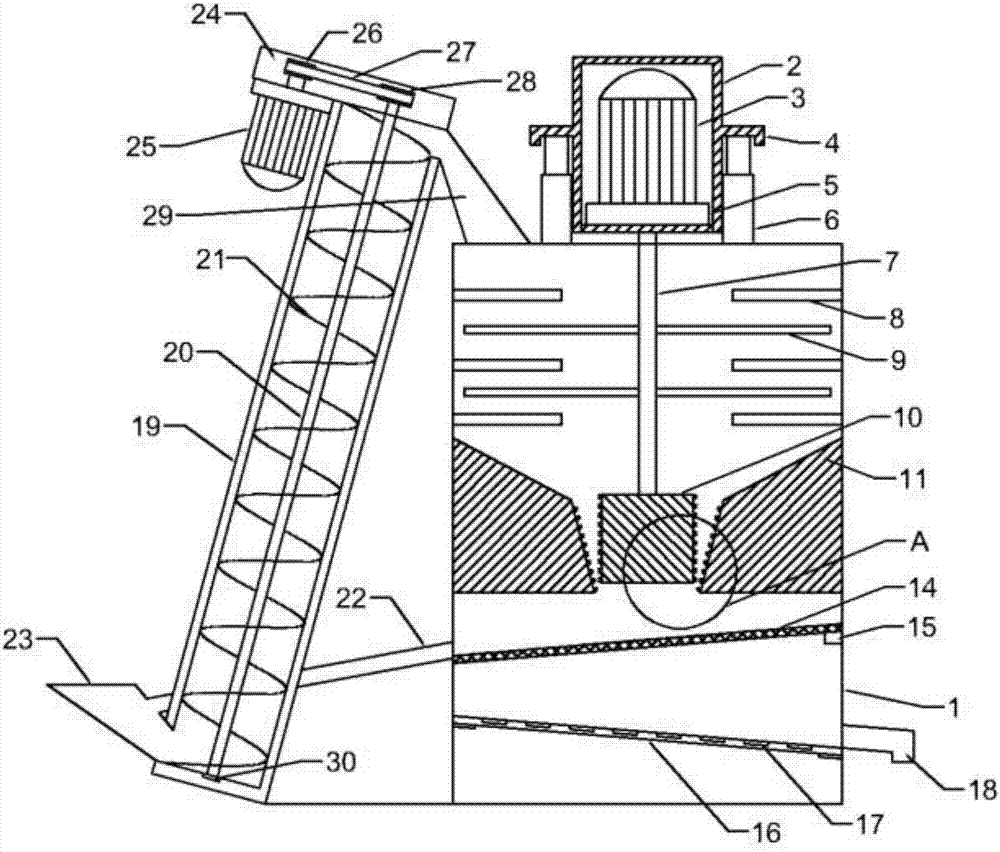

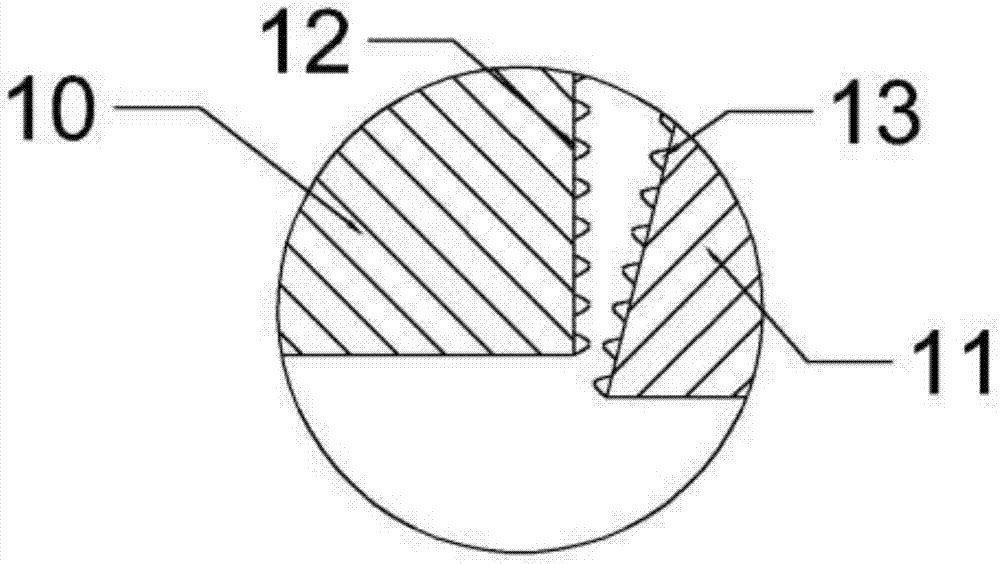

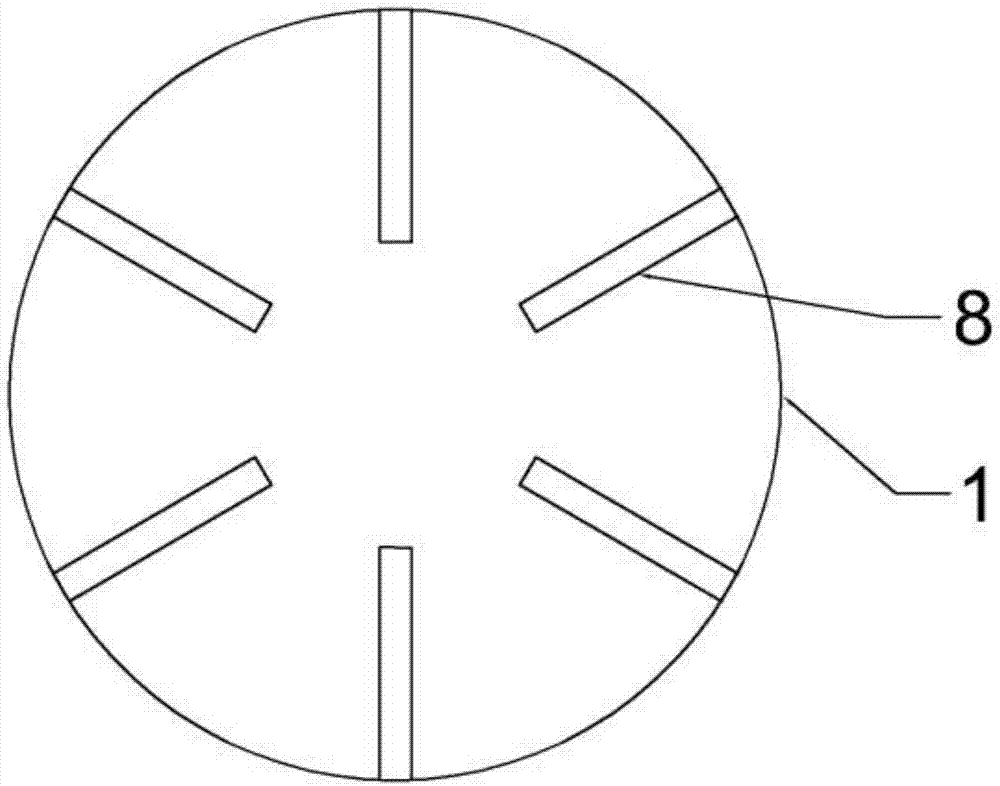

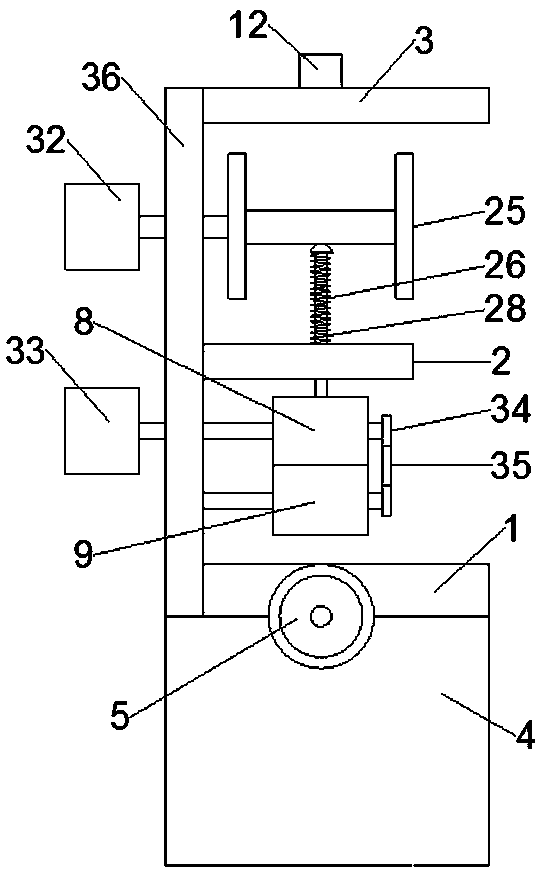

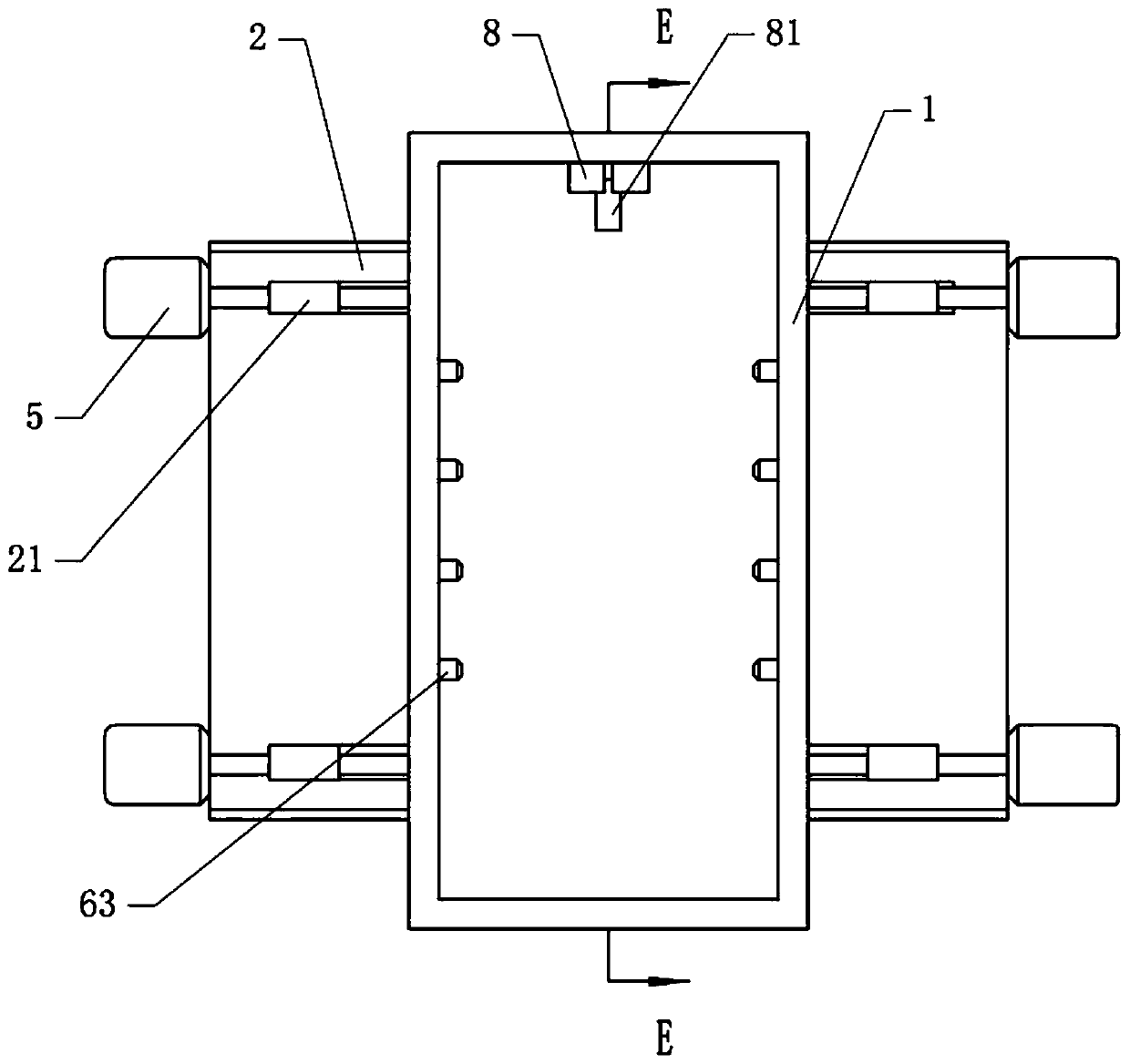

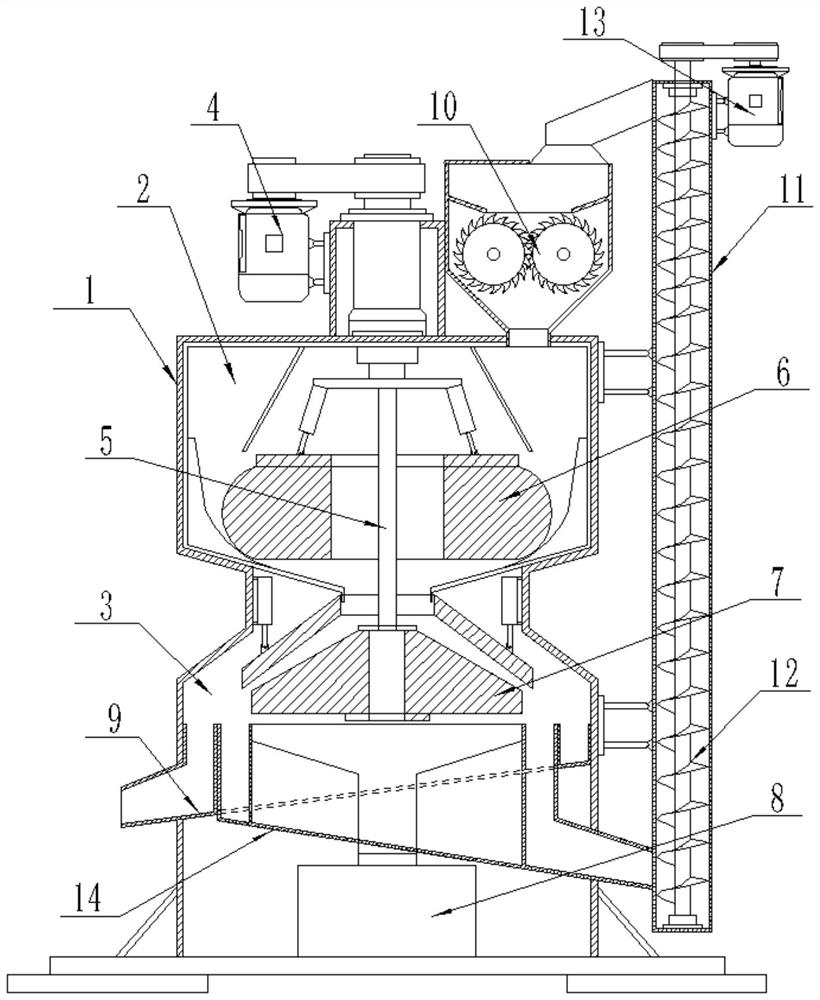

Traditional Chinese medicine pulverizing and grinding integrated machine

InactiveCN107350061ARealize crushing and grindingQuality assuranceGrain treatmentsReducerEngineering

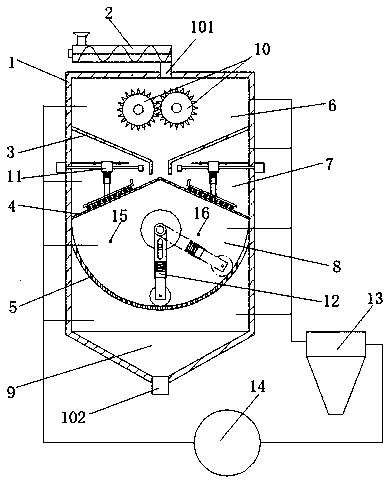

The invention discloses a traditional Chinese medicine crushing and grinding machine, which comprises a crushing cylinder and a screw feeder. The top of the crushing cylinder is provided with a sealed installation box. The bottom of the cylinder is connected to the output end of the cylinder, the bottom of the cylinder is fixed on the top of the crushing cylinder, a rotating motor is installed inside the sealed installation box, the output end of the rotating motor is connected to the reducer, and the output end of the reducer is connected to the output The shaft is connected, and the output shaft passes through the sealed installation box downwards and extends into the inside of the crushing cylinder. The present invention can chop the Chinese herbal medicine through the cooperation between the fixed blade and the rotating blade, and then realize the grinding of the Chinese herbal medicine through the extrusion between the rotating grinding head and the fixed grinding seat, thereby realizing the crushing and grinding of the Chinese herbal medicine and A good grinding effect can be obtained.

Owner:周耀鑫

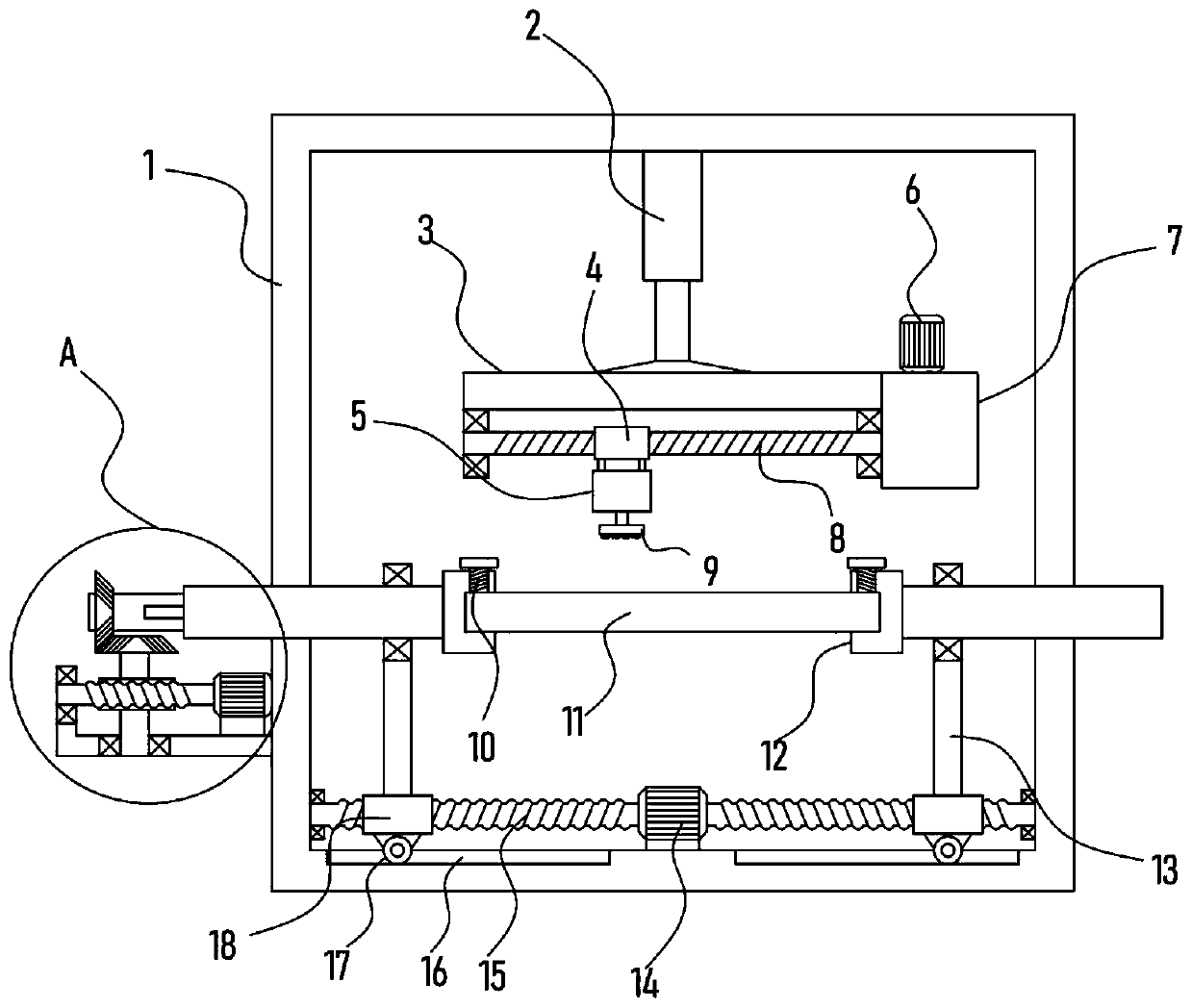

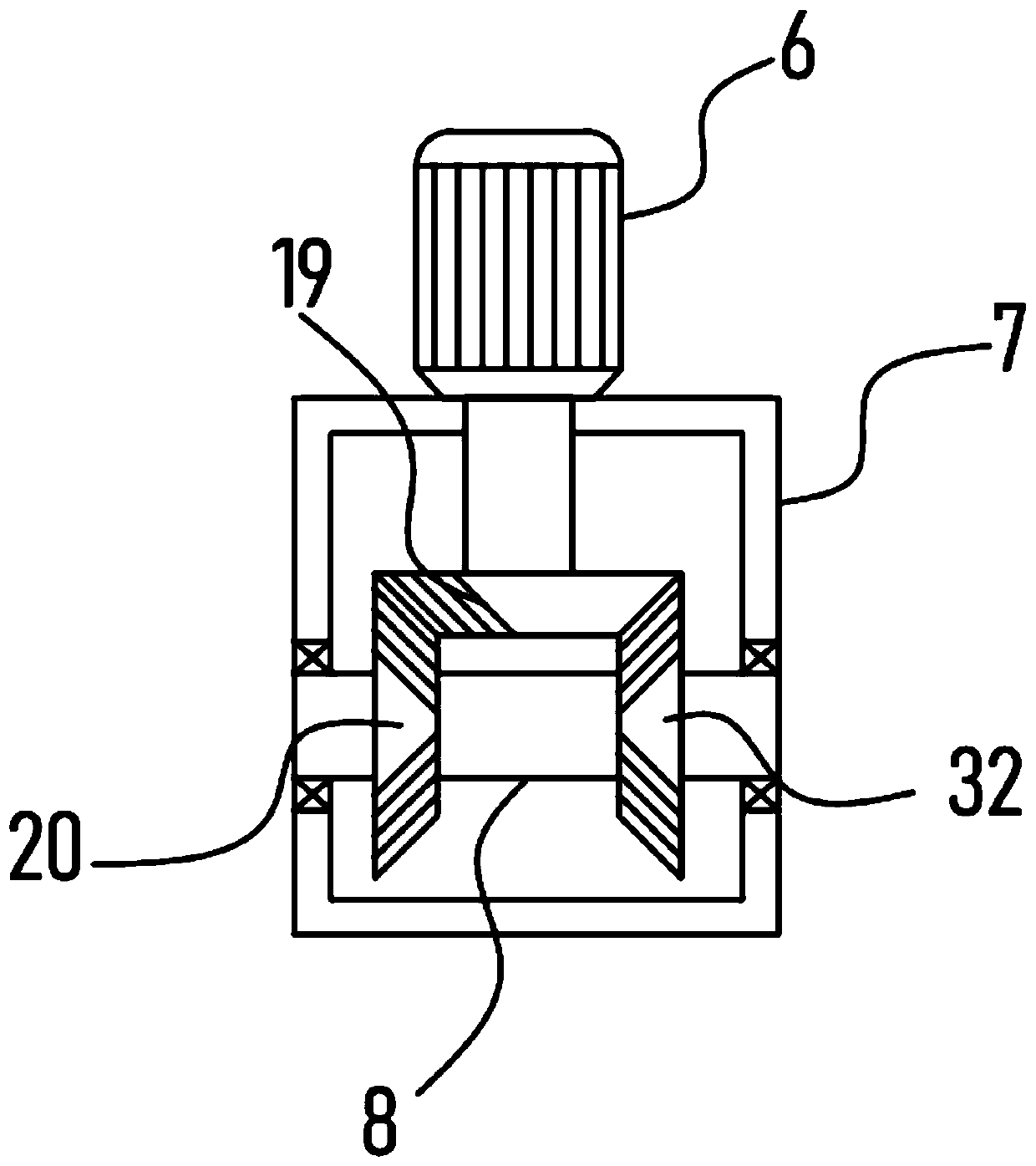

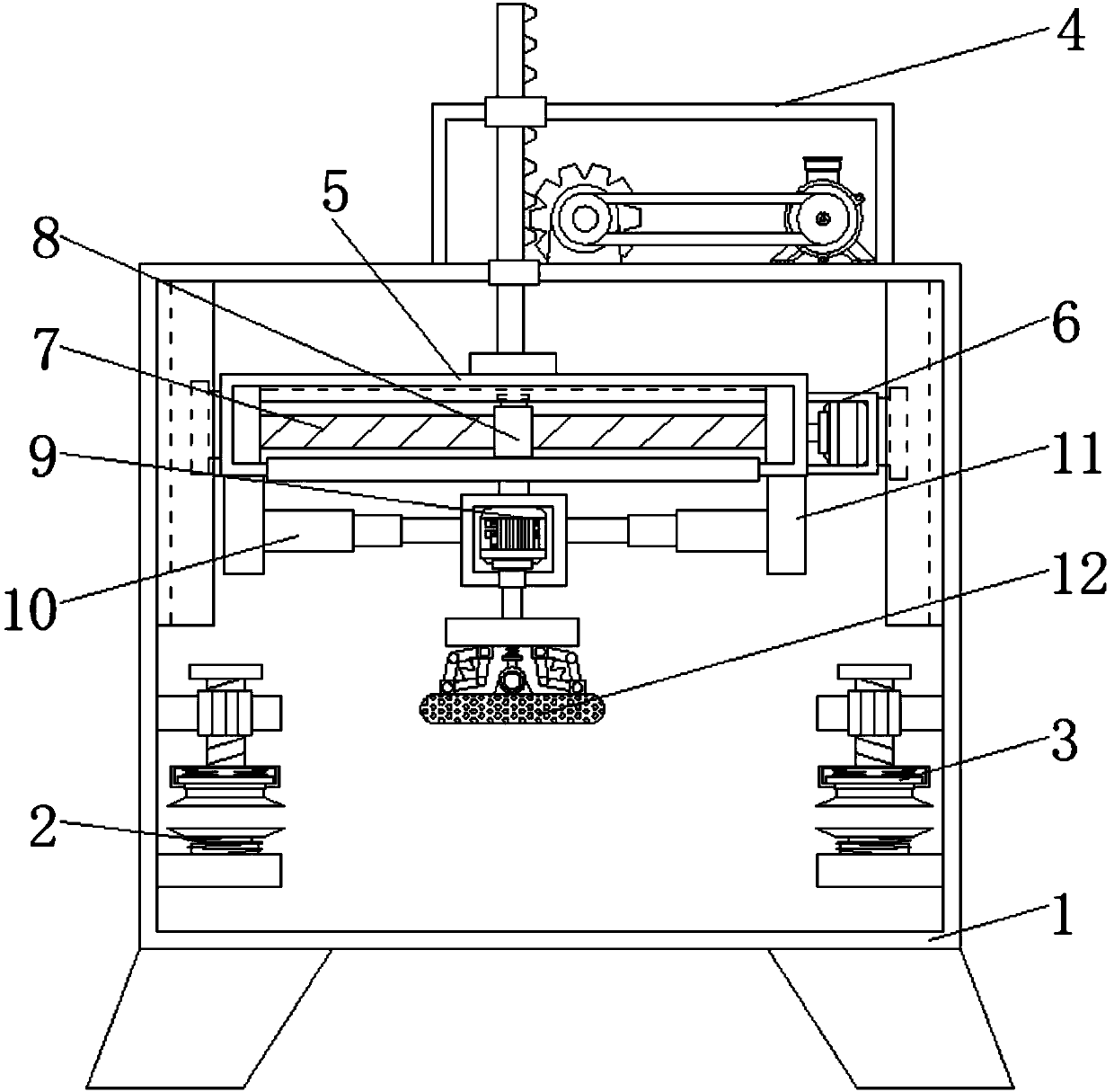

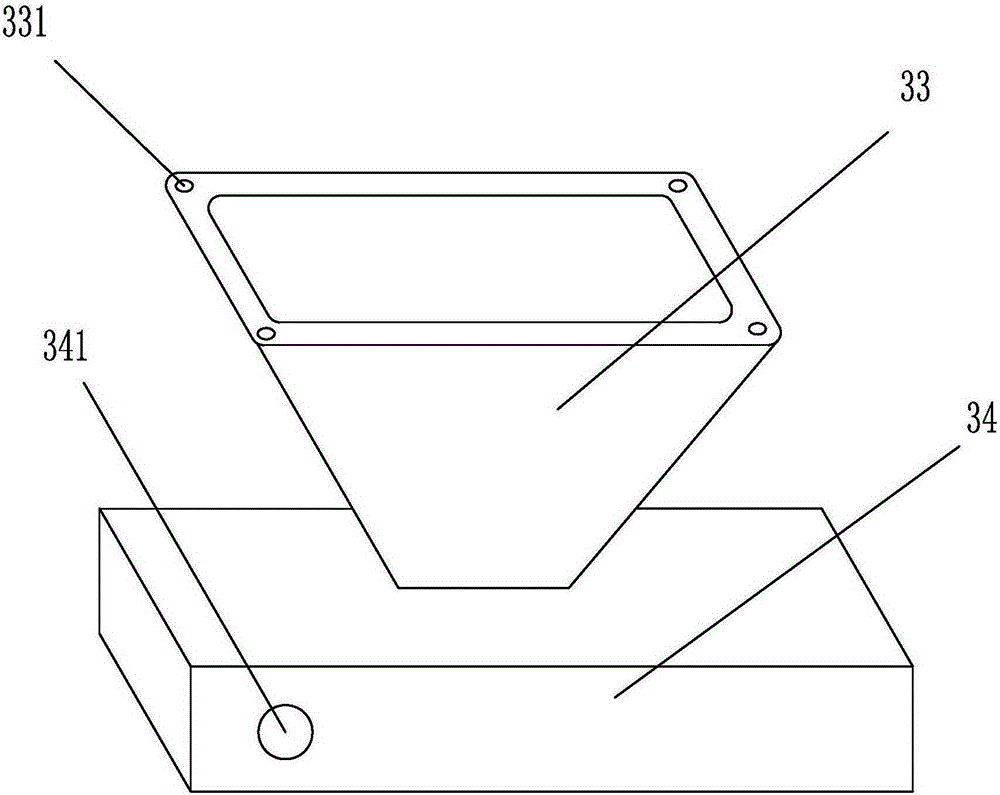

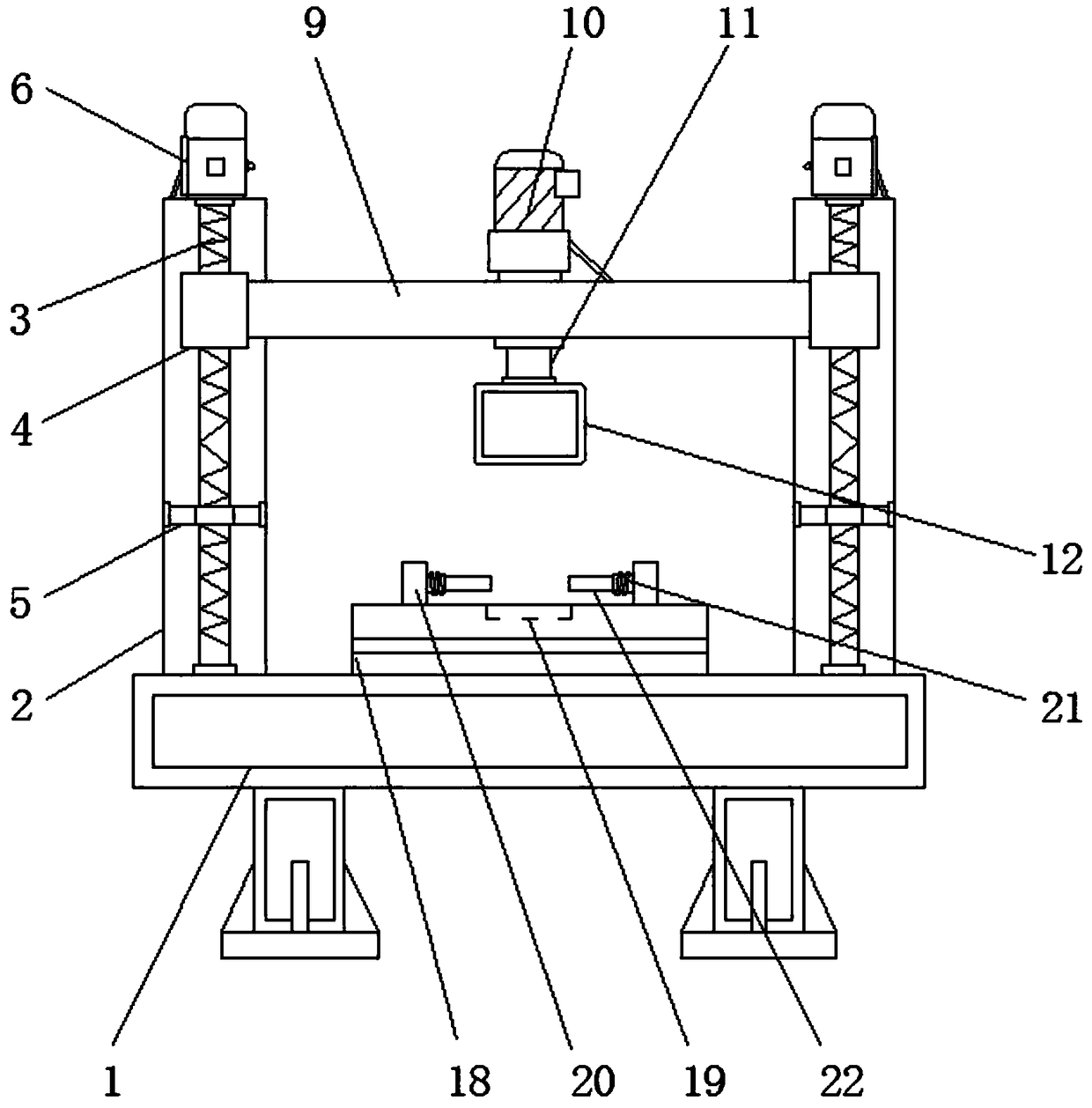

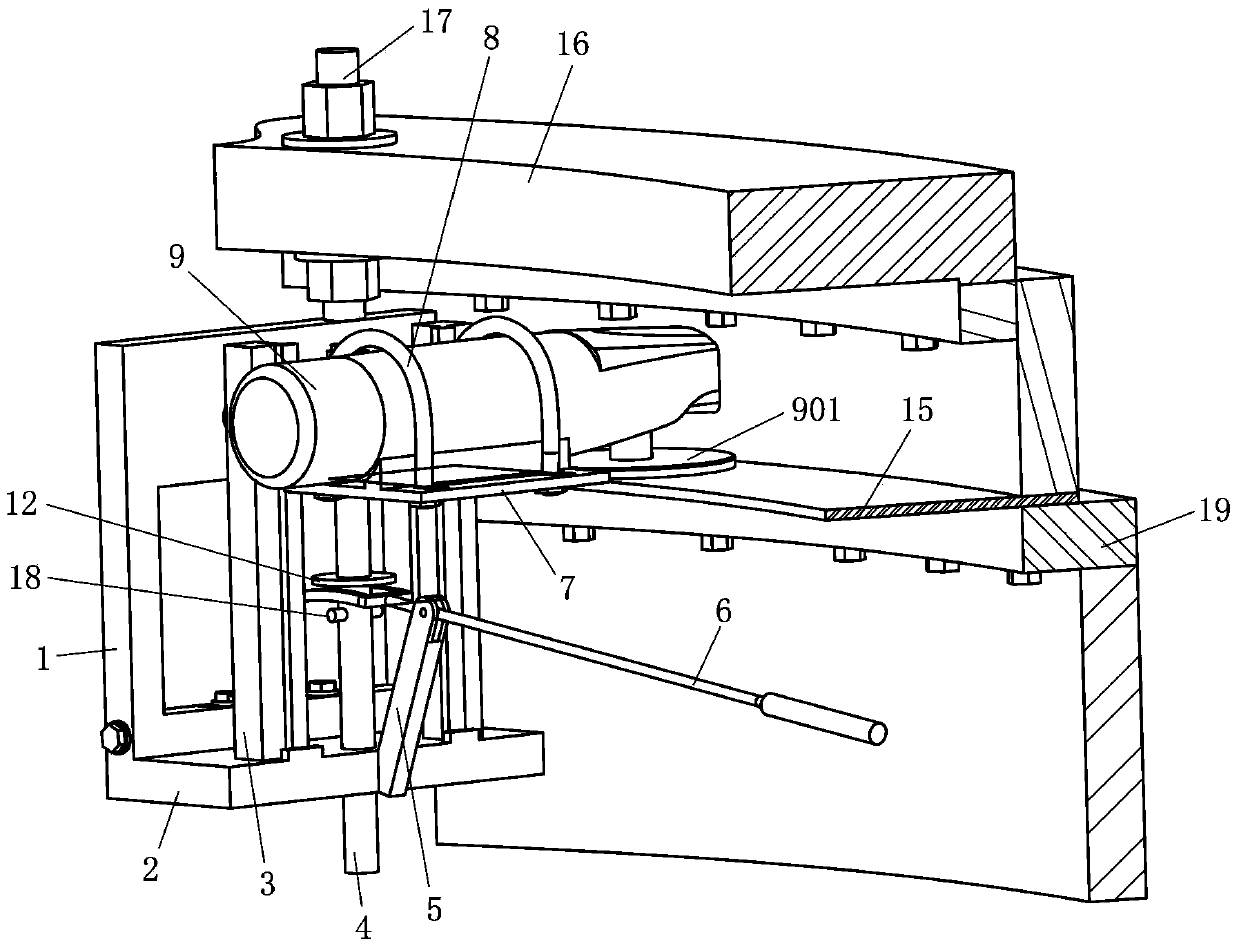

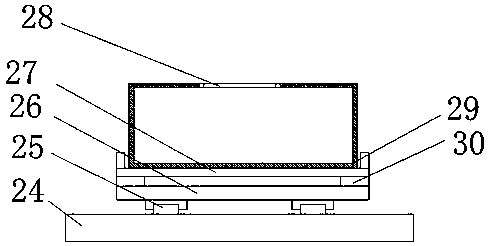

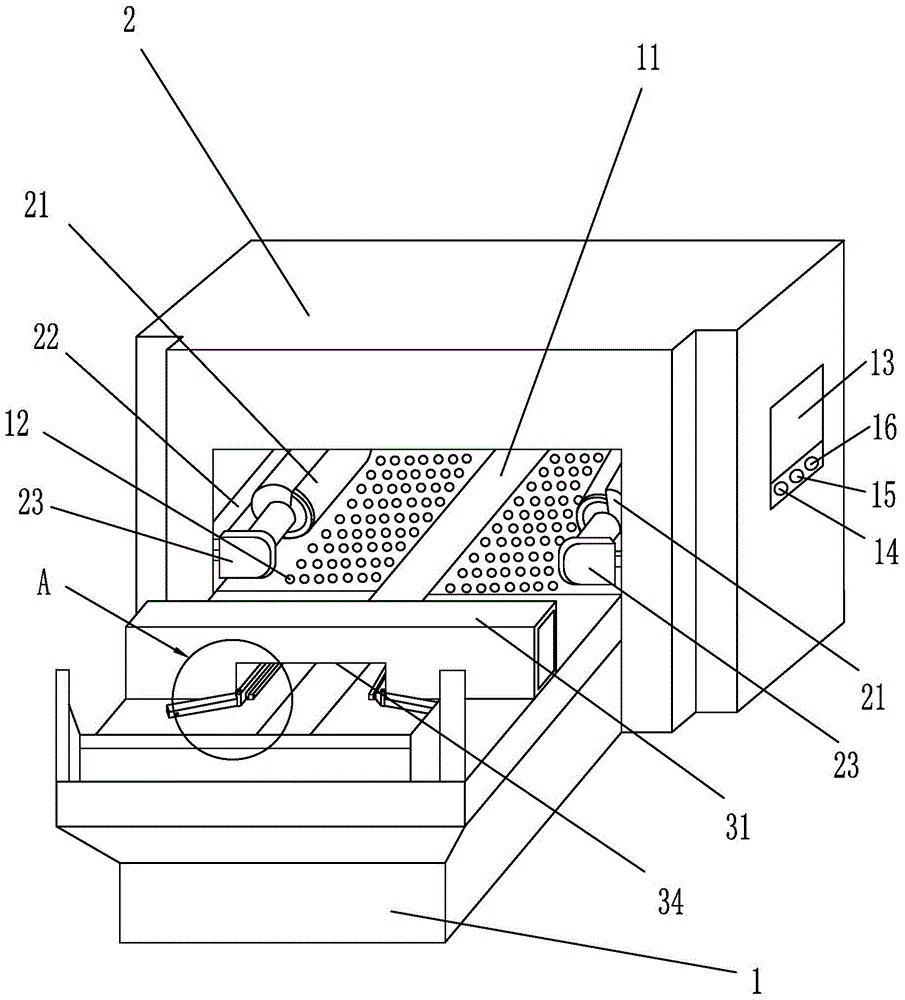

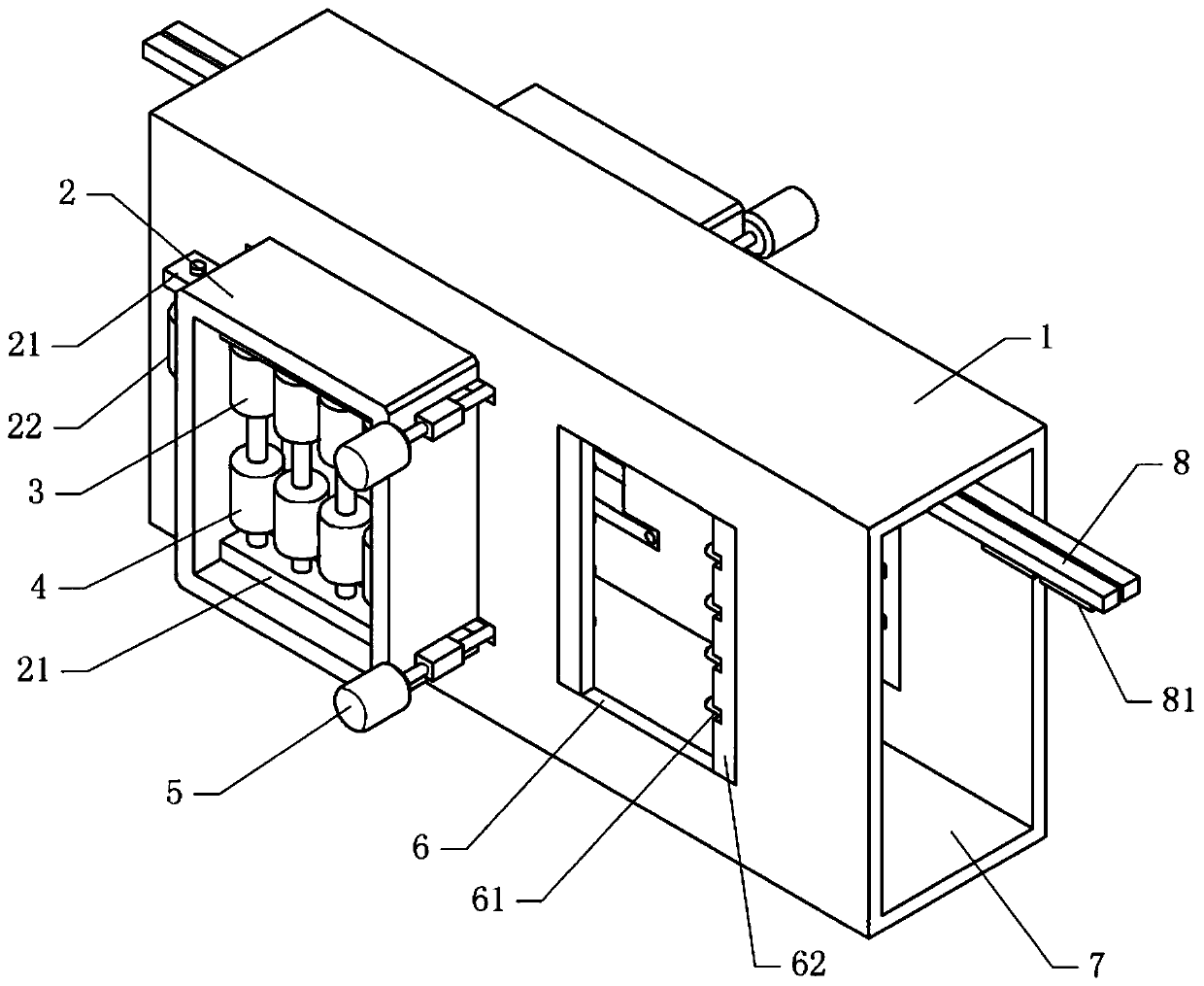

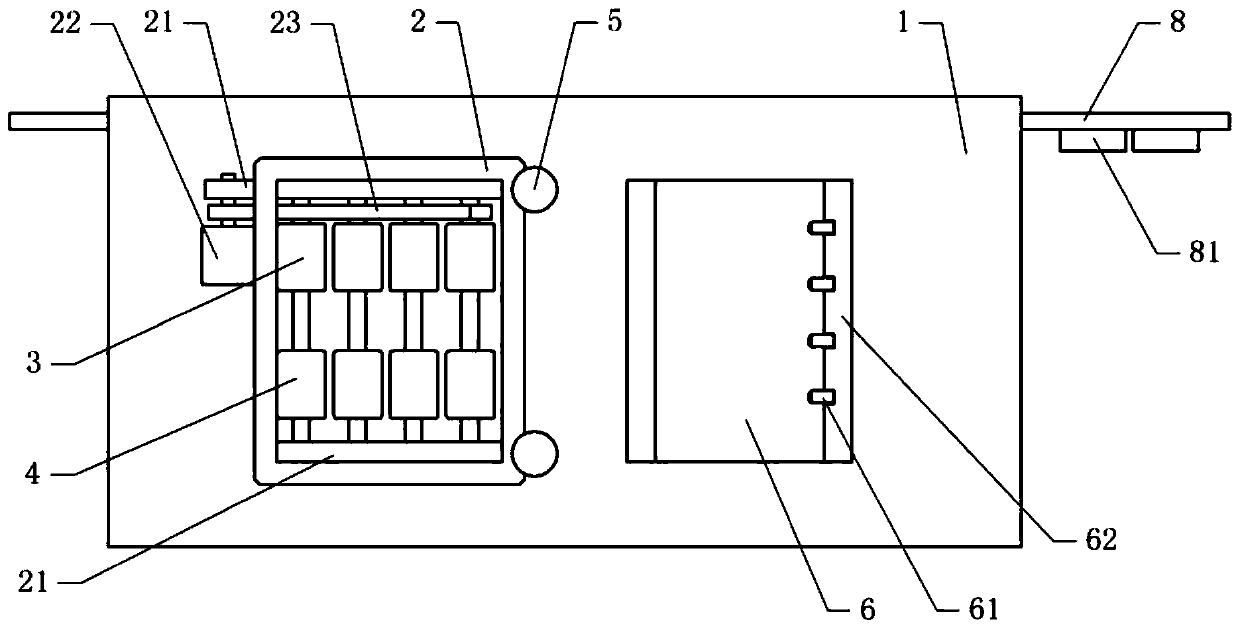

Mechanical plate grinding device with overturning function

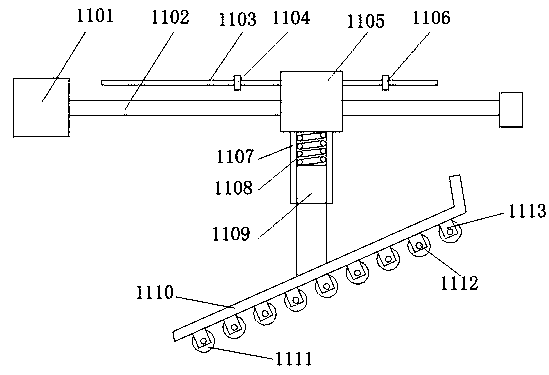

InactiveCN111300185ARealize clamping and fixingRealize the grinding effectGrinding drivesGrinding feedersEngineeringMachining

The invention discloses a mechanical plate grinding device with an overturning function, and relates to the technical field of machining. The mechanical plate grinding device comprises a supporting frame, wherein an electric push rod is vertically fixed at the inner top of the supporting frame; a translation mechanism for driving a grinding mechanism to move transversely is arranged in a steeringbox; an adjusting mechanism for driving two clamping plates to move oppositely is arranged on the supporting frame; and the supporting frame is provided with an overturning mechanism used for drivingthe clamping plates to rotate. According to the mechanical plate grinding device with the overturning function, the two clamping plates are driven by the arranged adjusting mechanism to move oppositely to clamp and fix a plate, so that stability of the plate in the grinding process is guaranteed, and a grinding effect is guaranteed; a grinding plate in the arranged grinding mechanism rotates to achieve grinding effects on the surface of the plate, and the translation mechanism can drive the grinding plate to transversely move relative to the plate, so that the grinding range of the plate is greatly widened, and the working efficiency is improved; and the arranged overturning mechanism can overturn the plate, so that sufficient double-face grinding effects of the grinding plate are achievedon the surface of the plate.

Owner:武文家

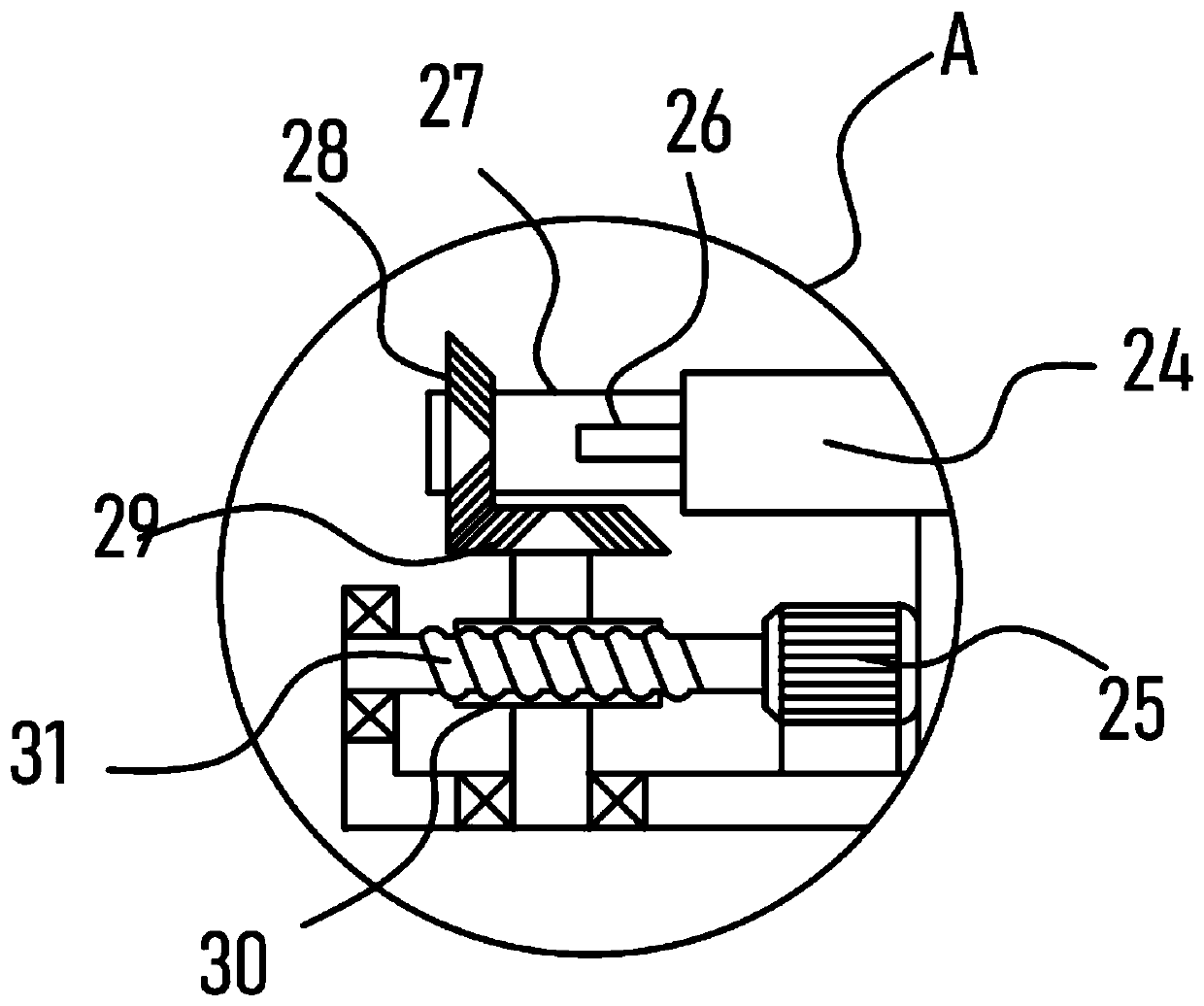

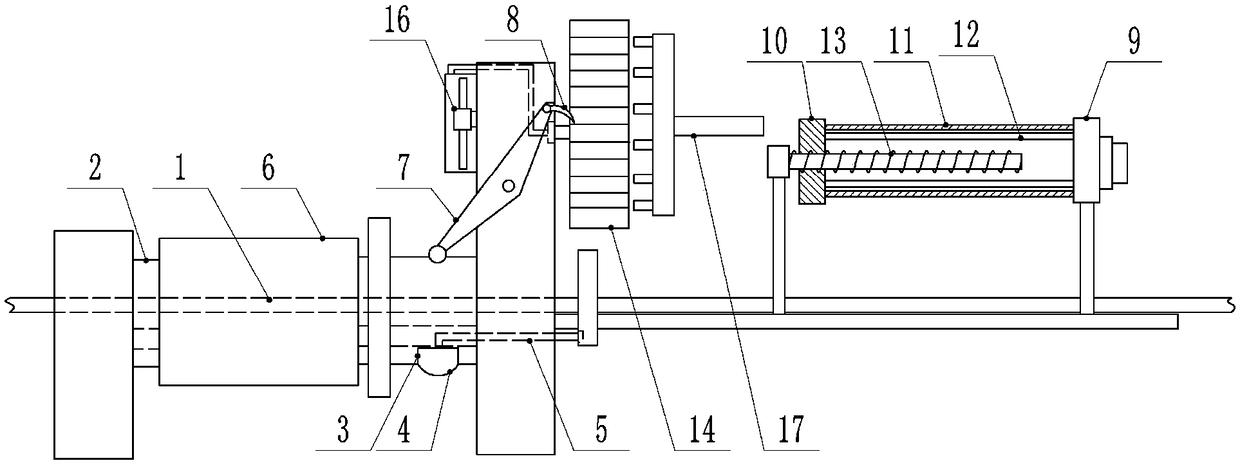

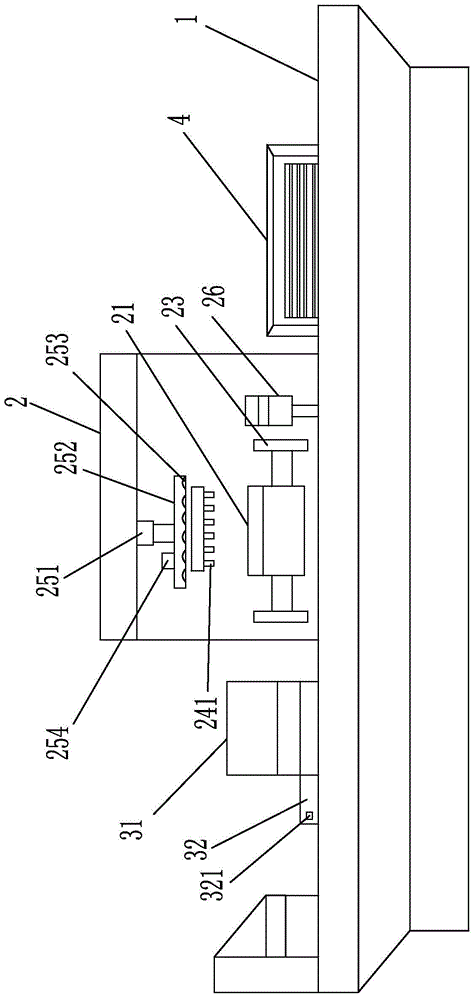

Tabletop processing and polishing device for long metal tables

InactiveCN107443235AAvoid grinding cornersReduce investmentPolishing machinesGrinding drivesDrive shaftFixed frame

The invention discloses a desktop processing and polishing device for a metal long table, which comprises a frame, a drive motor is installed in the middle of the upper plane of the frame, a rotating shaft is installed at the right end of the driving motor, and the rotating shaft A transmission helical gear is installed on the top, and the middle position of the bottom end of the fixed frame is pierced with a transmission shaft. The top end of the transmission shaft is equipped with a driven helical gear. Engagement, the bottom end of the transmission shaft is equipped with a turntable, the bottom end of the turntable is installed with a first transmission rod, the middle position of the frame is horizontally equipped with a slide bar, and the slide bar is installed with a A slider, the top of the slider is equipped with a connecting block, the top of the connecting block is connected with a second transmission rod, the first transmission rod is connected with the second transmission rod, the present invention makes the feeding cylinder The frequency of liquid discharge is consistent with the frequency of the movement of the grinding disc along the horizontal left and right directions, and the coolant is sprayed out synchronously during grinding.

Owner:朱友富

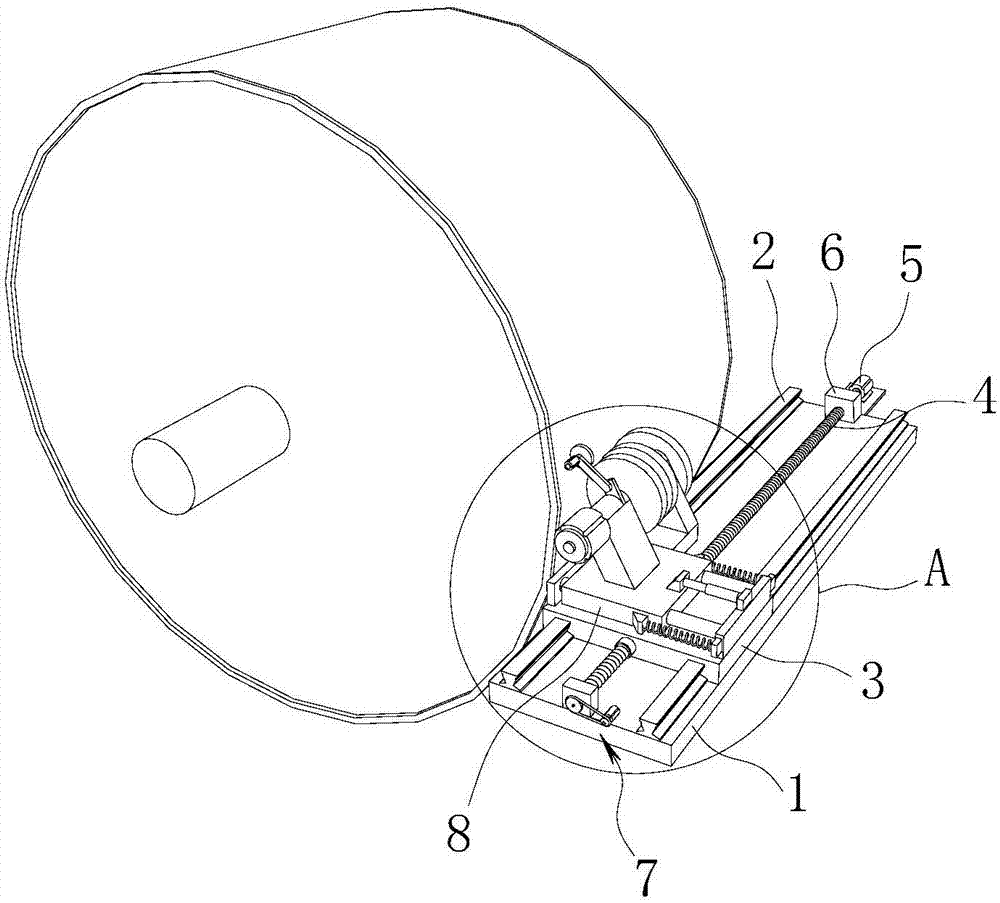

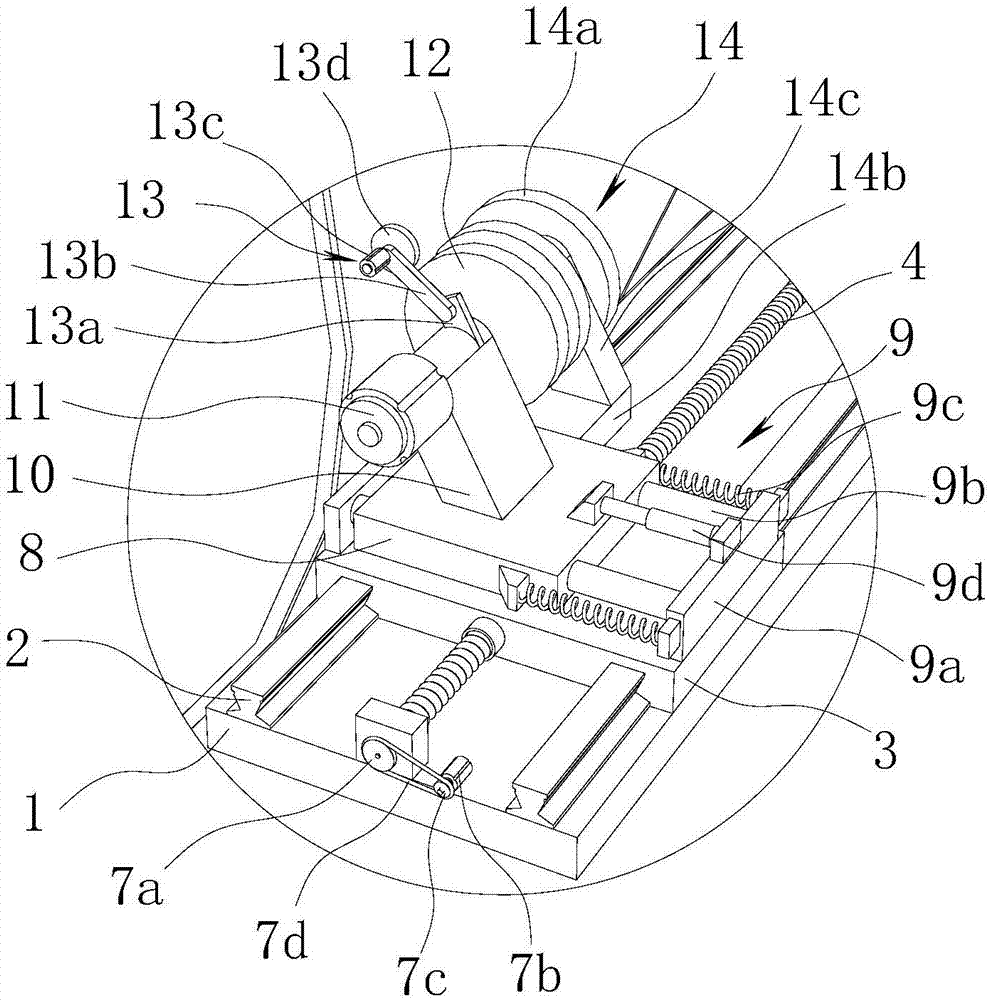

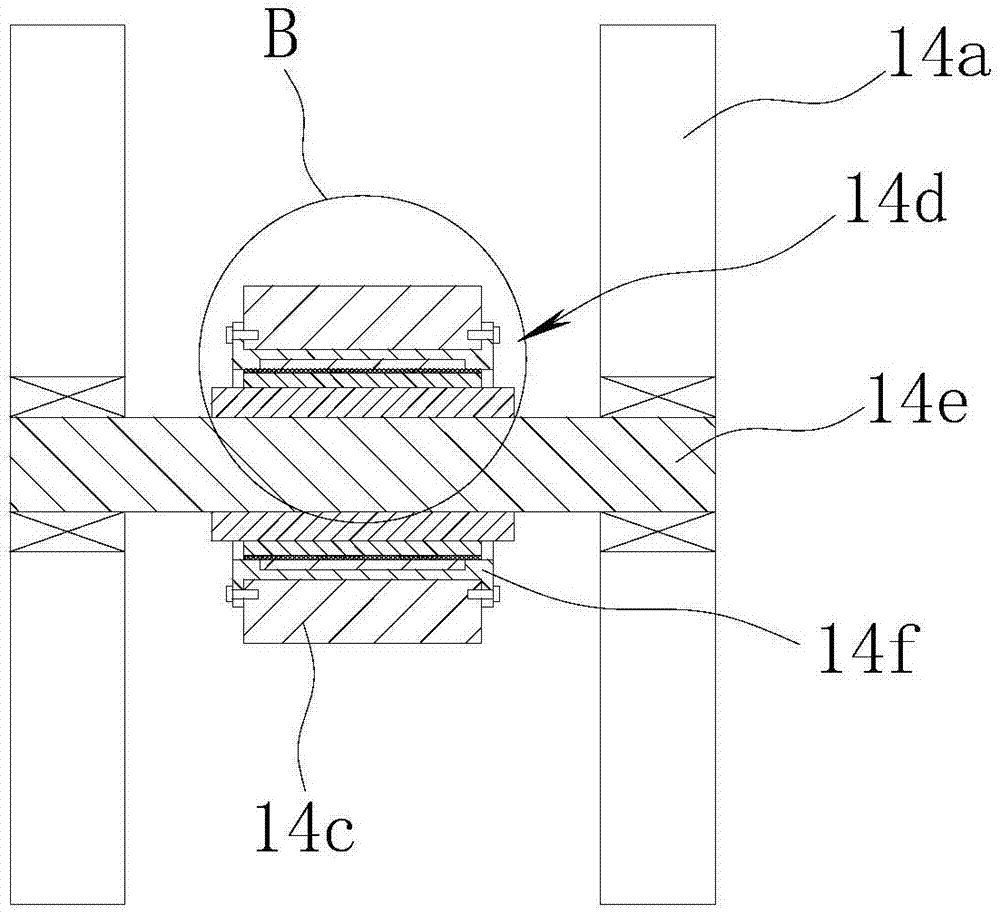

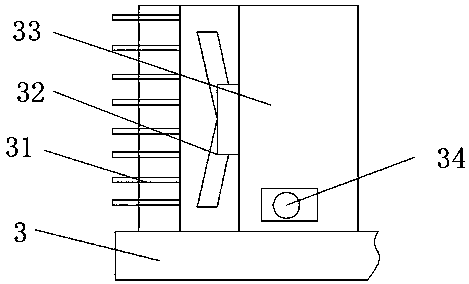

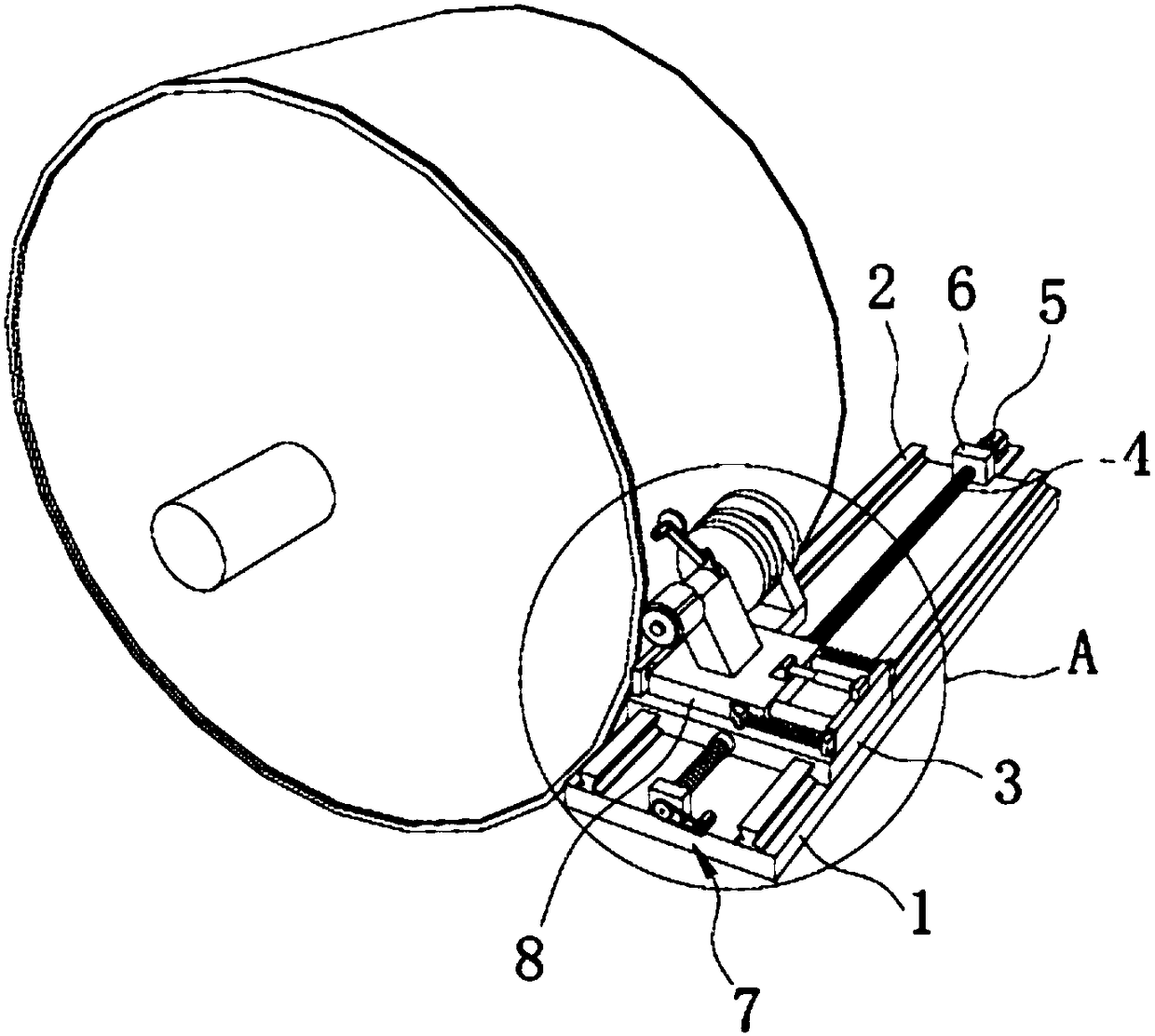

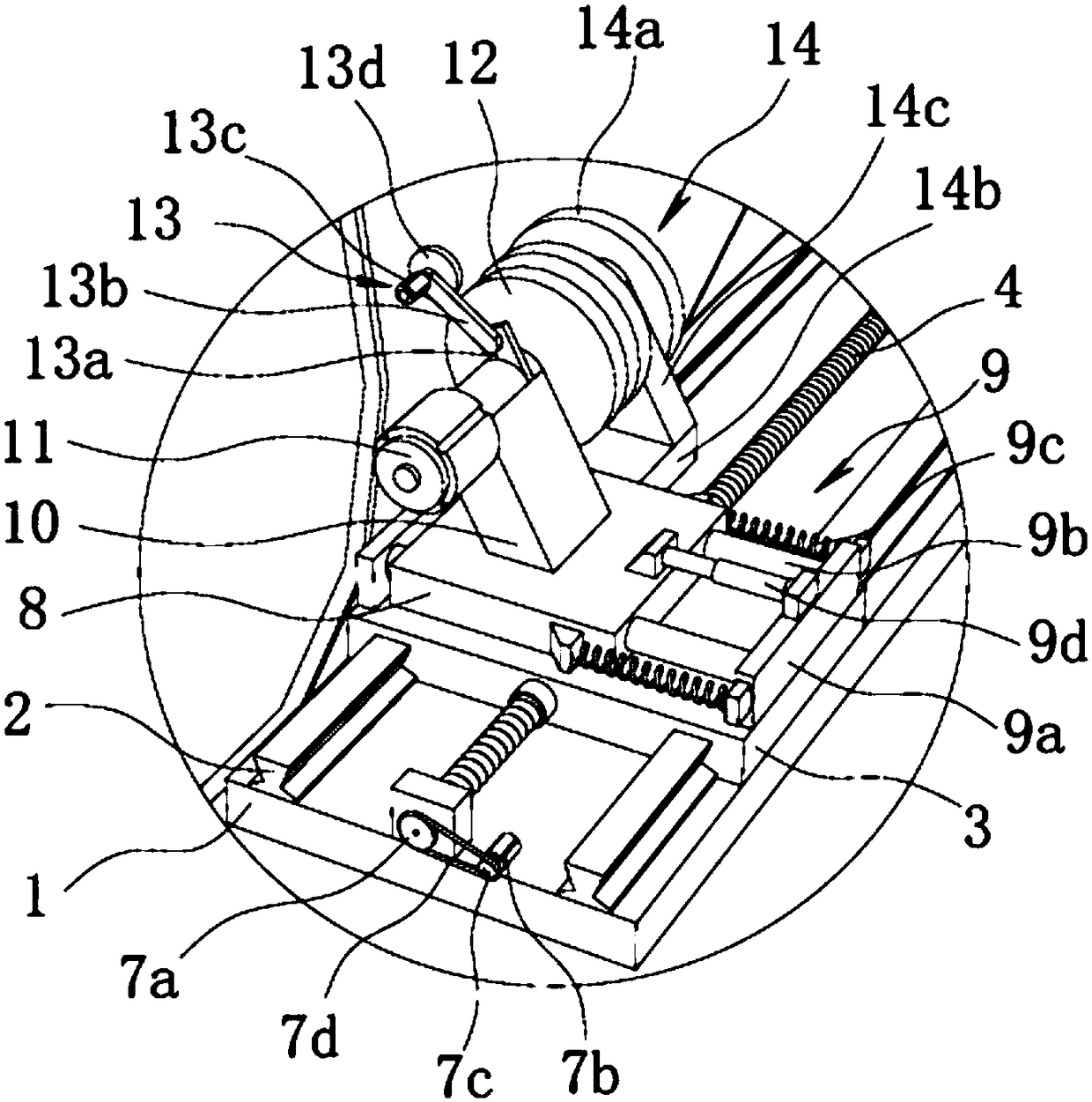

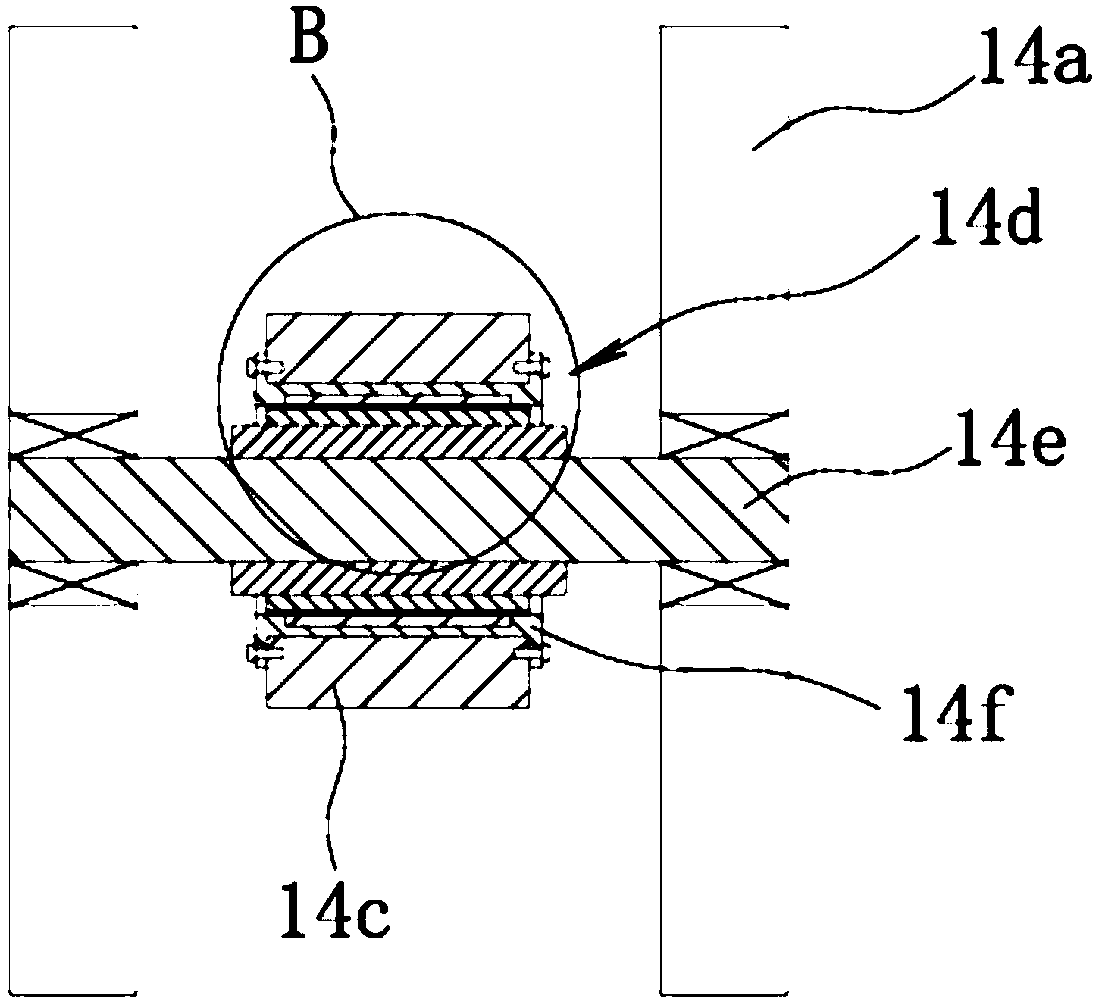

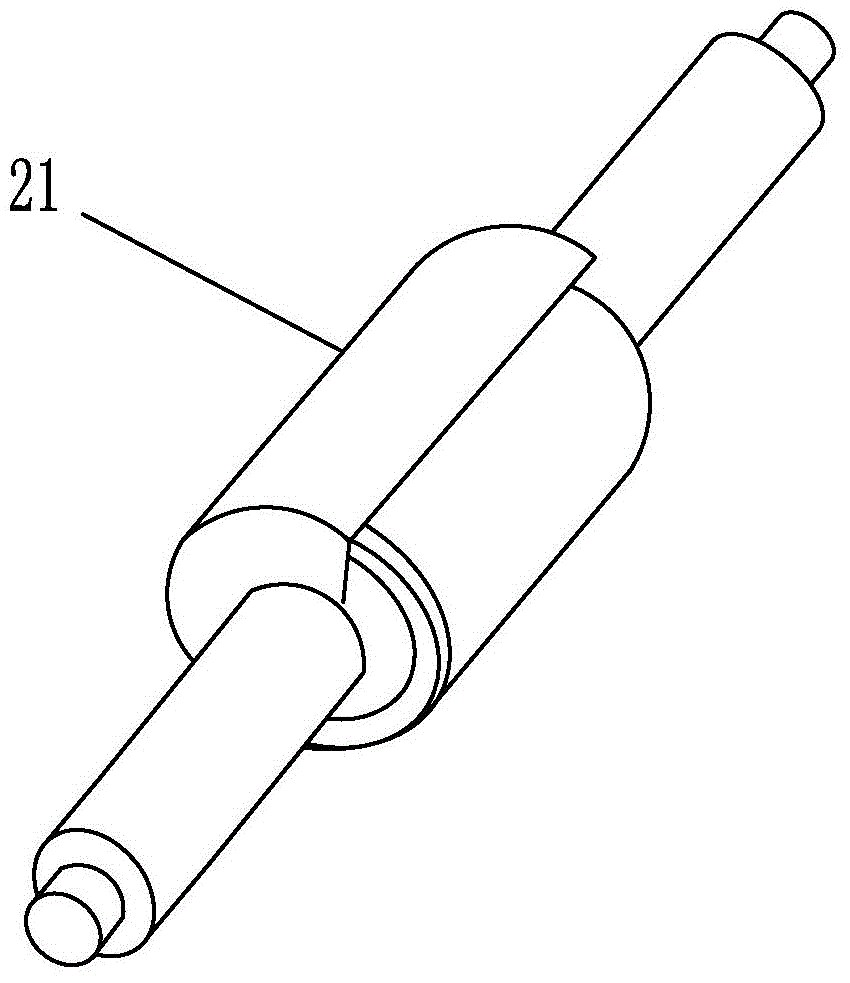

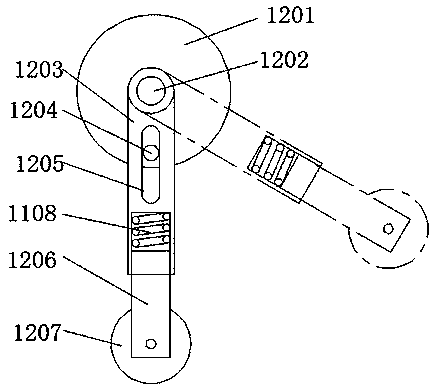

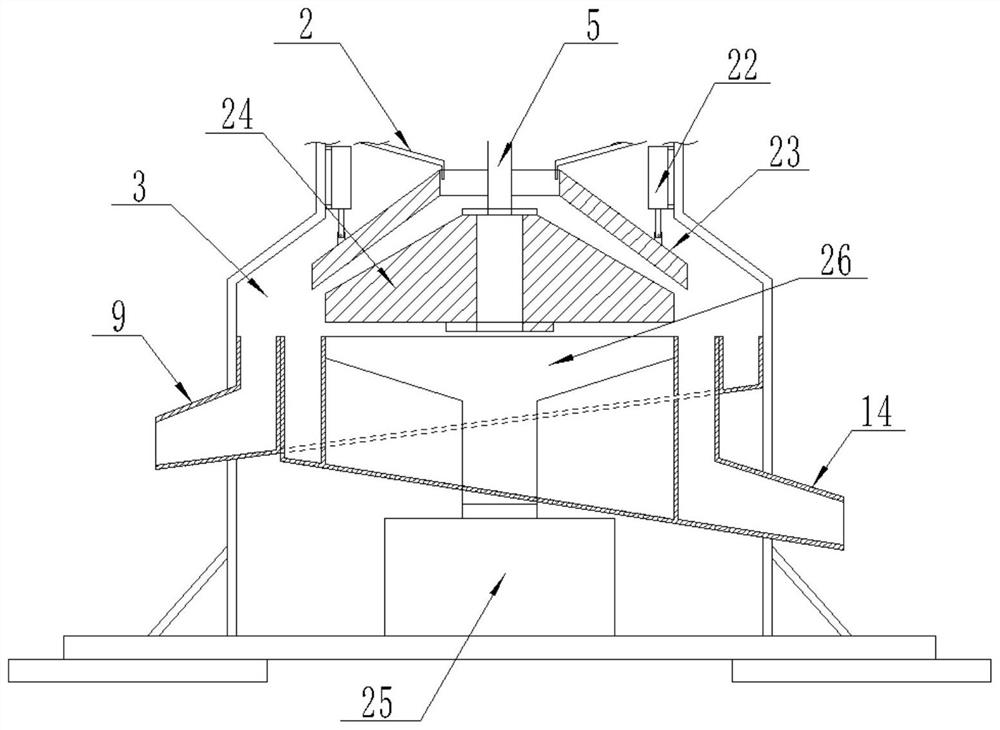

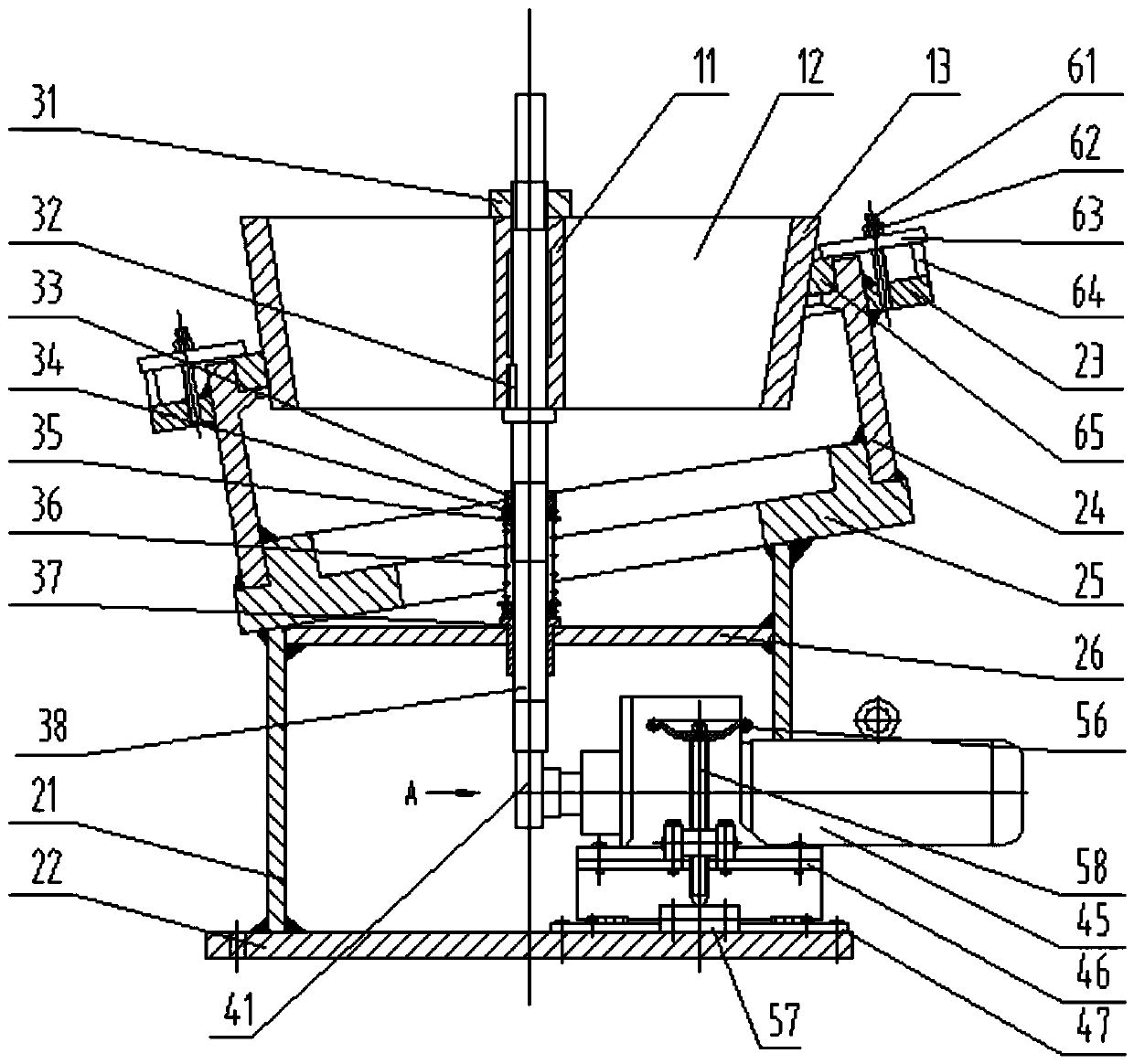

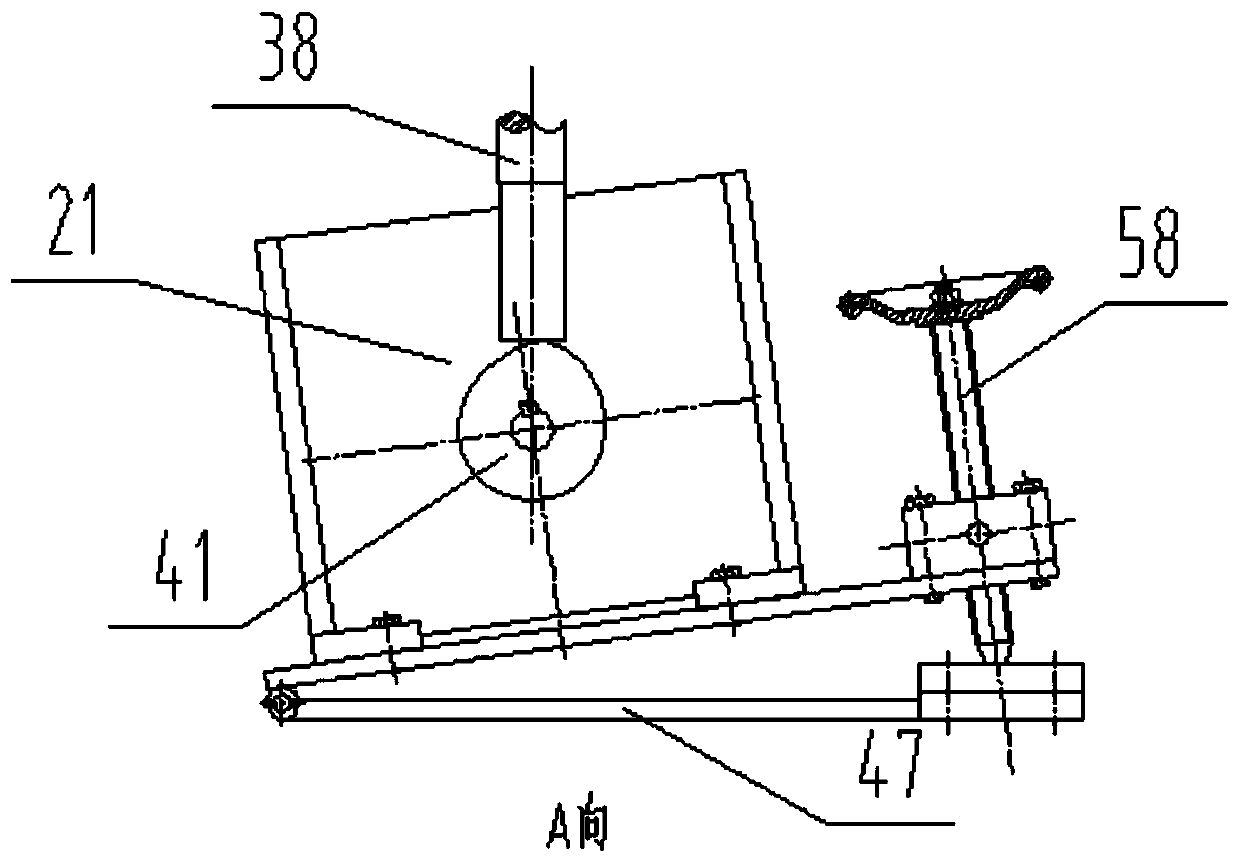

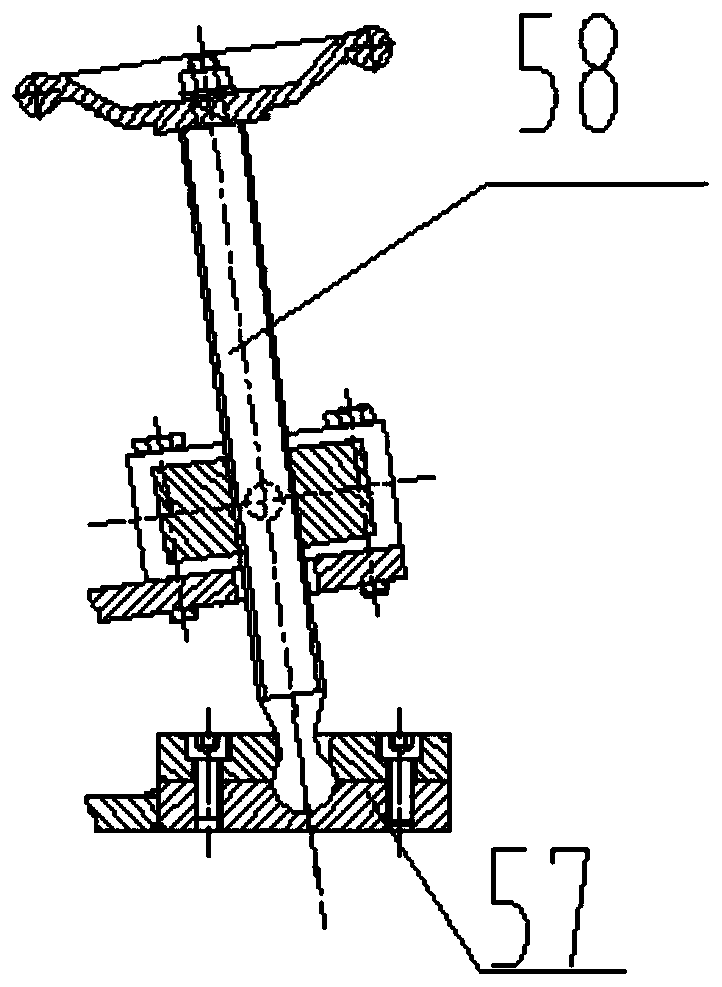

Grinding equipment for cathode roller

ActiveCN107009207AAvoid excessive wearGuaranteed grinding effectGrinding carriagesRevolution surface grinding machinesEngineeringCathode

The invention discloses grinding equipment for a cathode roller and belongs to the technical field of grinding equipment. According to the technical key point, the grinding equipment comprises a support arranged on the side edge of the roller surface of the cathode roller; guide rails are arranged on the support; an axial sliding seat is arranged on the guide rails and connected with a driving screw rod in a threaded mode; the driving screw rod is connected with a first driving motor, and the driving screw rod and the guide rails are arranged parallelly; supporting seats matched with the driving screw rod are arranged at the two ends in the length direction of the support correspondingly; the driving screw rod is connected with a displacement detecting mechanism; a radial sliding seat is movably arranged on the axial sliding seat and connected with a radial driving mechanism; an installing table is arranged on the radial sliding seat; a second driving motor is installed on the installing table in the axial direction of the cathode roller; and a power output shaft of the second driving motor is connected with a grinding wheel. The grinding equipment for the cathode roller is reasonable in structure, high in using safety, convenient to use and used for grinding the cathode roller.

Owner:GUANGDONG FINE YUAN SCI TECH CO LTD

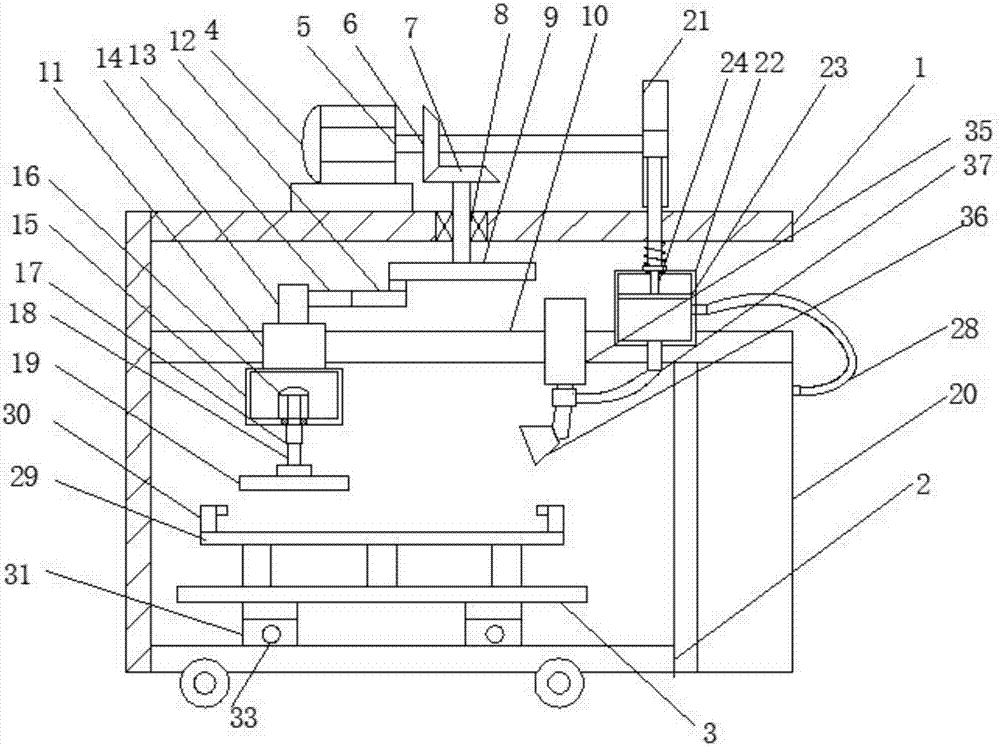

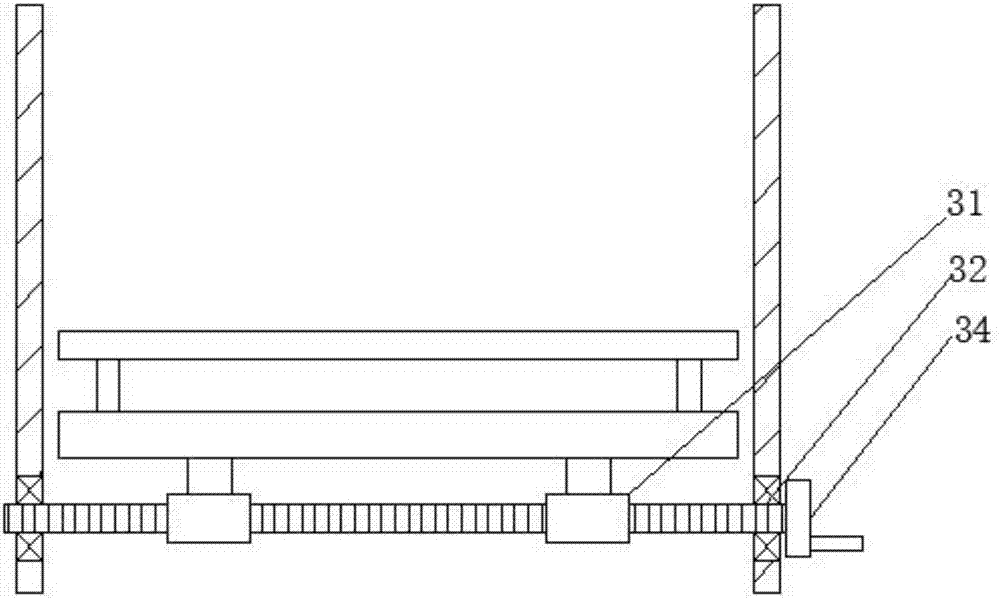

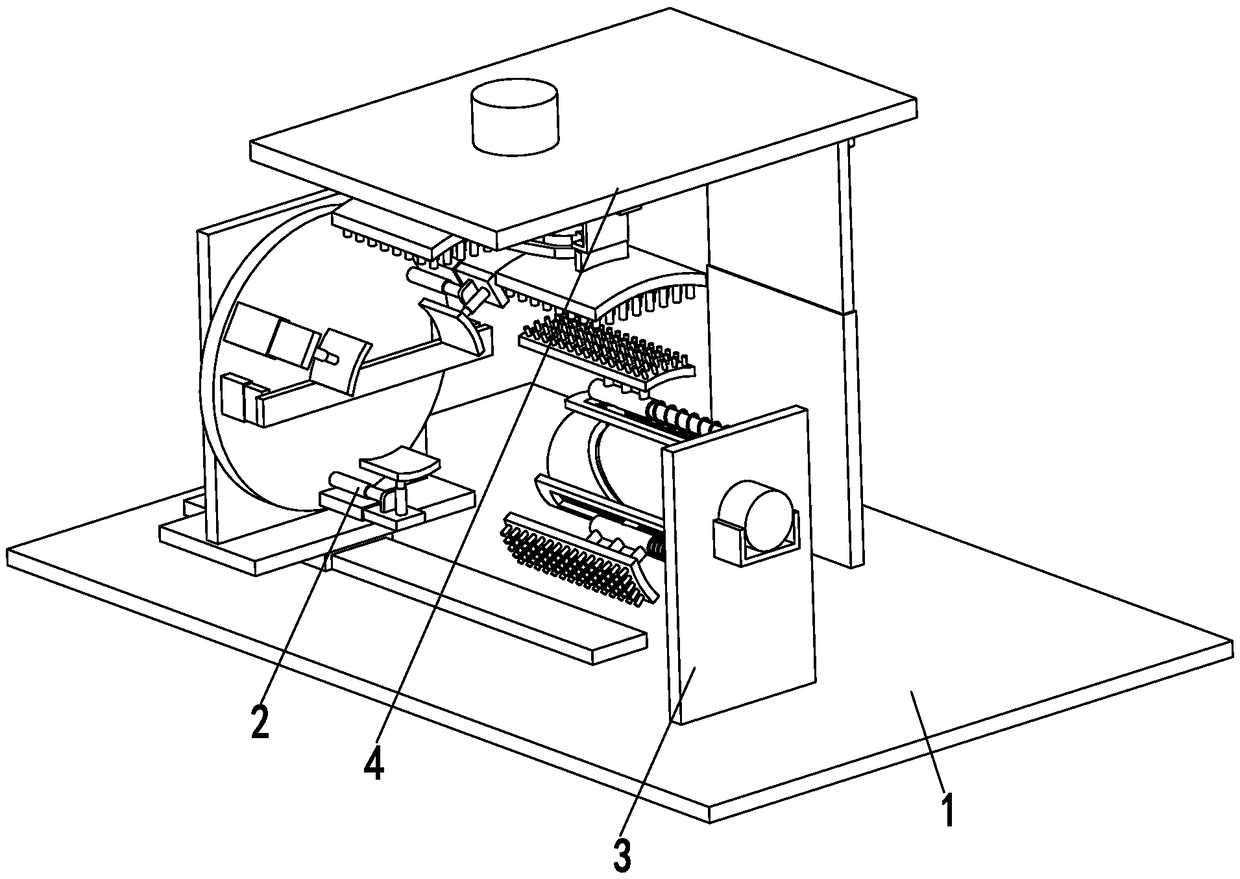

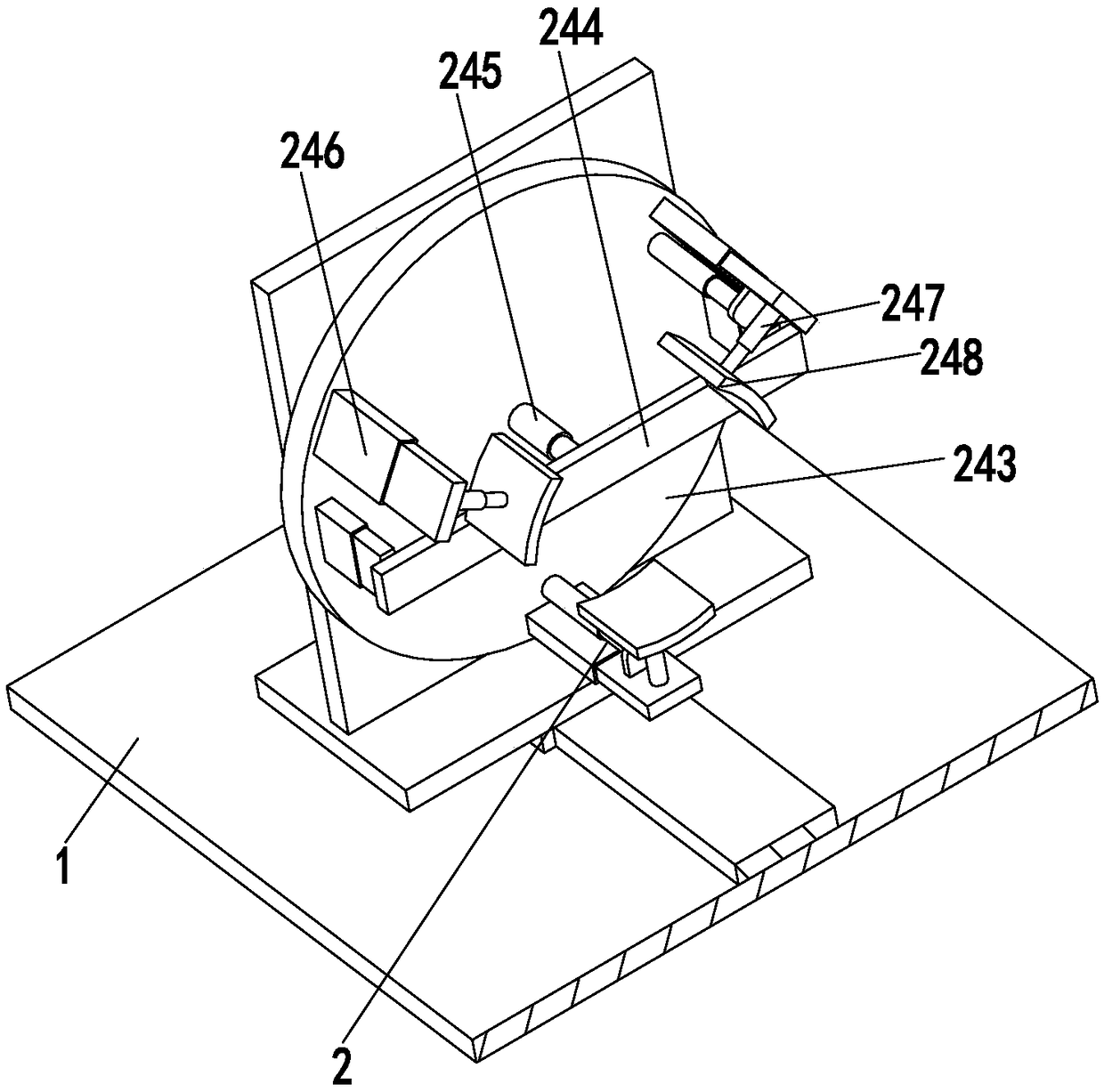

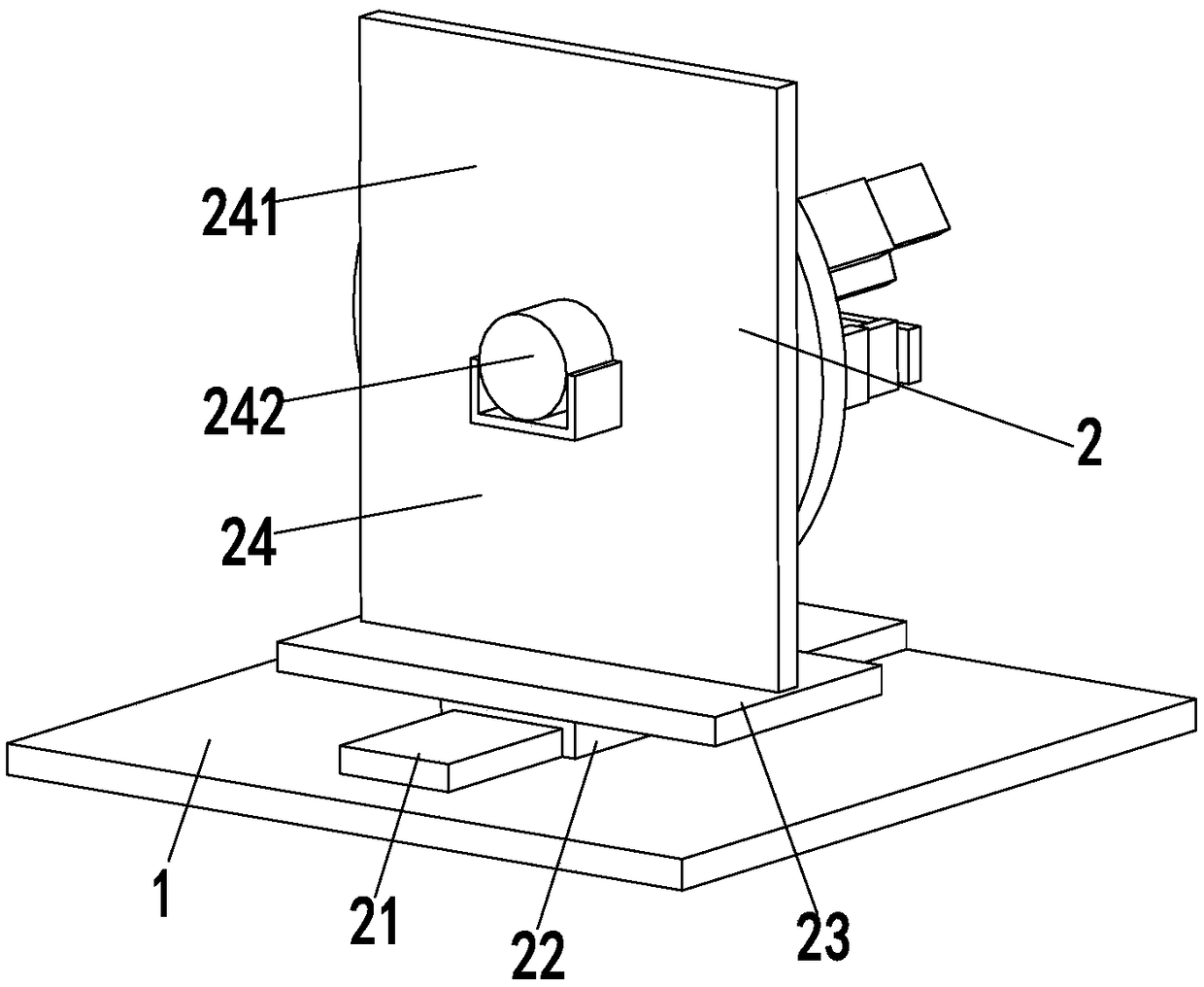

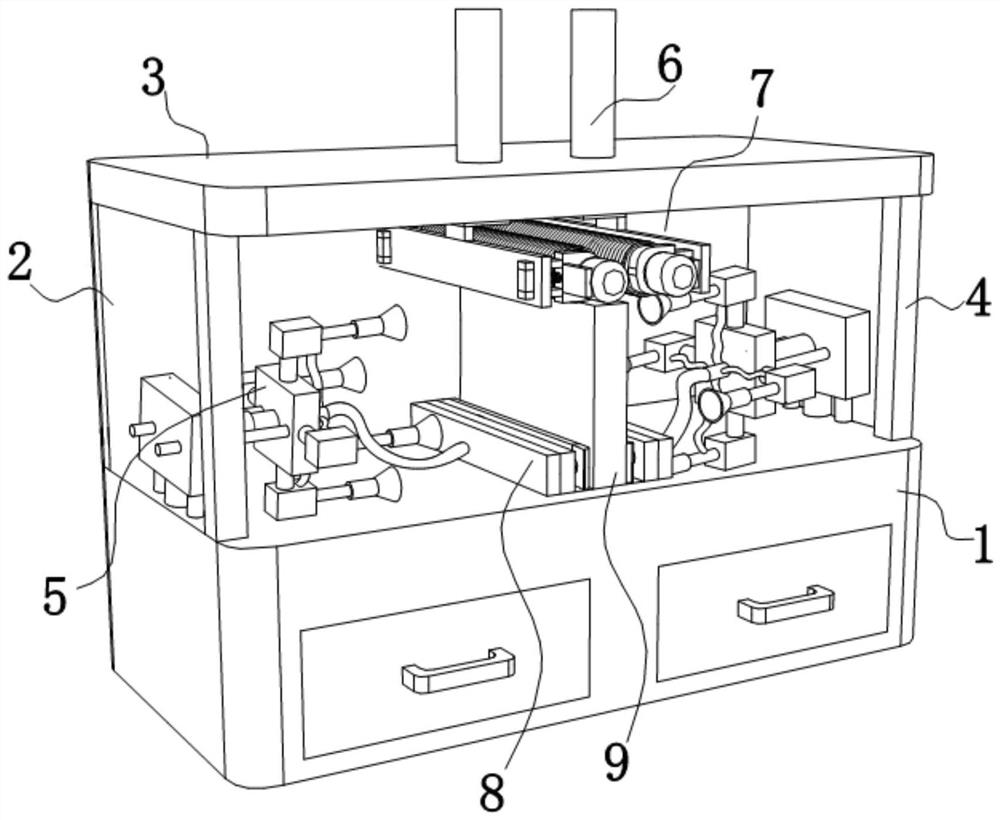

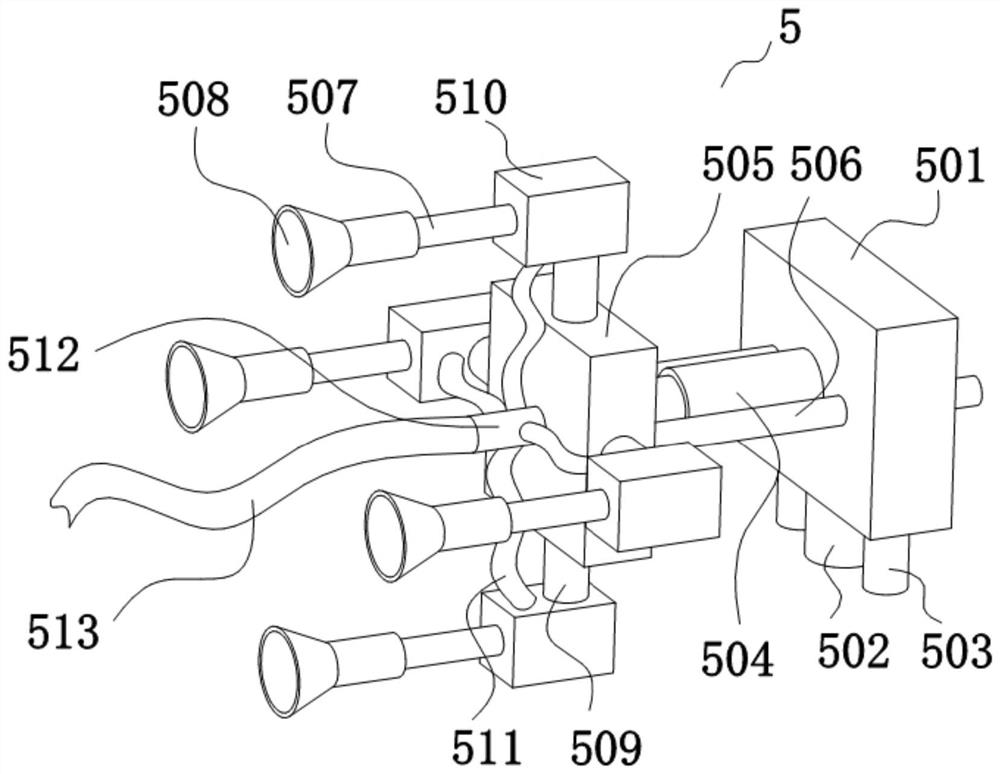

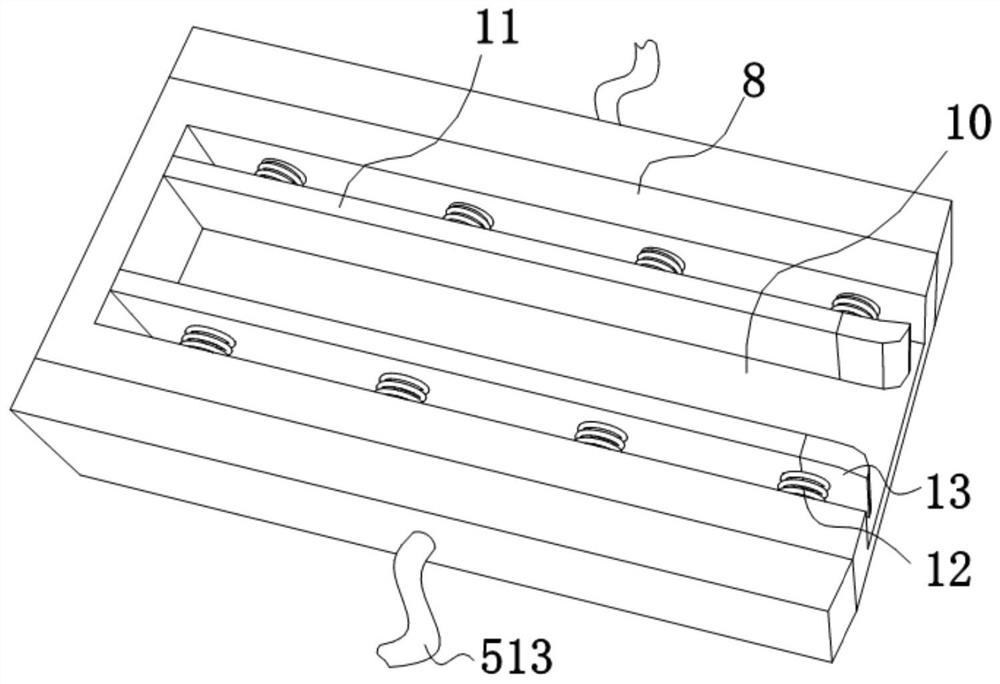

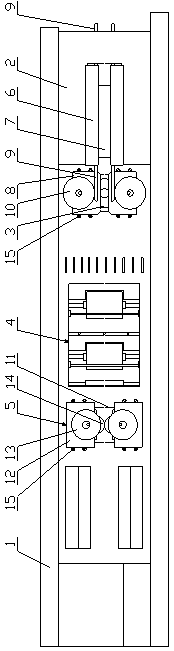

Workpiece grinding machine of numerical-control electric spark machine tool

InactiveCN108789046ASolve the costSolve labor intensityGrinding carriagesGrinding drivesNumerical controlEngineering

The invention relates to a workpiece grinding machine of a numerical-control electric spark machine tool. The workpiece grinding machine of the numerical-control electric spark machine tool comprisesa base plate, a fixing device, an inner wall grinding device and an outer wall grinding device. The fixing device and the inner wall grinding device are sequentially installed on the base plate from left to right. The outer wall grinding device is installed on the back side of the base plate. The inner wall grinding device comprises a fixing plate, a rotating motor, a rotating column, sliding blocks, limiting frames, telescopic rods, springs, adjusting air cylinders and first steel wire brushes. The outer wall polishing device comprises a lifting frame, a rotating motor, a rotating column, a cam, connection sliding blocks, connection frames, guide rails and second steel wire brushes. The workpiece grinding machine of the numerical-control electric spark machine tool can solve the problemsthat in an existing annular workpiece grinding process, the labor cost is high, the labor intensity is high, the work efficiency is low, the grinding difficulty is large, and the adjustability is poor; the automatic grinding function on the annular workpiece can be achieved; and the workpiece grinding machine of the numerical-control electric spark machine tool has the advantages of being low in labor cost, low in labor intensity, high in work efficiency, small in polishing difficulty, good in adjustability and the like.

Owner:浙江芊荷科技有限公司 +1

Furniture board machining equipment

PendingCN108636644AEfficient removalQuality assuranceBelt grinding machinesLiquid spraying apparatusSlagEngineering

The invention relates to the field of board painting devices, and discloses furniture board machining equipment. The furniture board machining equipment comprises a conveying mechanism and a paintingmechanism; and the conveying mechanism comprises a conveying belt. The furniture board machining equipment further comprises a polishing mechanism; the polishing mechanism comprises a first rotating roller and a second rotating roller arranged in parallel; a sleeve rod sleeves the first rotating roller; the sleeve rod is provided with a long hole for enabling the first rotating roller to penetratethrough; the long hole is positioned in the eccentric position of the sleeve rod, and is parallel to the axial direction of the sleeve rod; the second rotating roller is the same in structure with the first rotating roller; a polishing belt is sleeved between the first rotating roller and the second rotating roller; the polishing belt comprises an upper-layer belt and a lower-layer belt; and a conveying belt penetrates between the upper-layer belt and the lower-layer belt. The furniture board machining equipment can solve the problem of influence on the board surface painting quality by burrsor slag on the surfaces of boards.

Owner:四川三虎家居有限公司重庆分公司

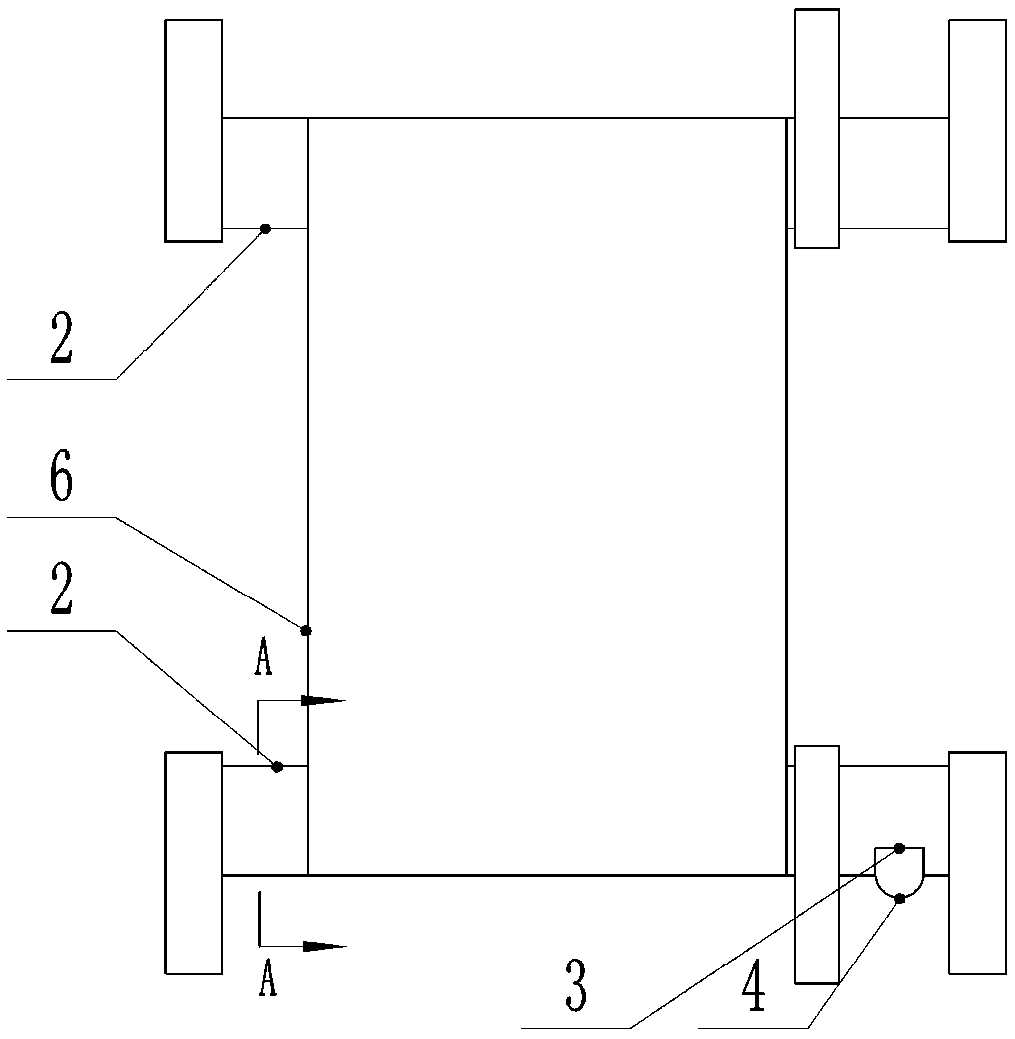

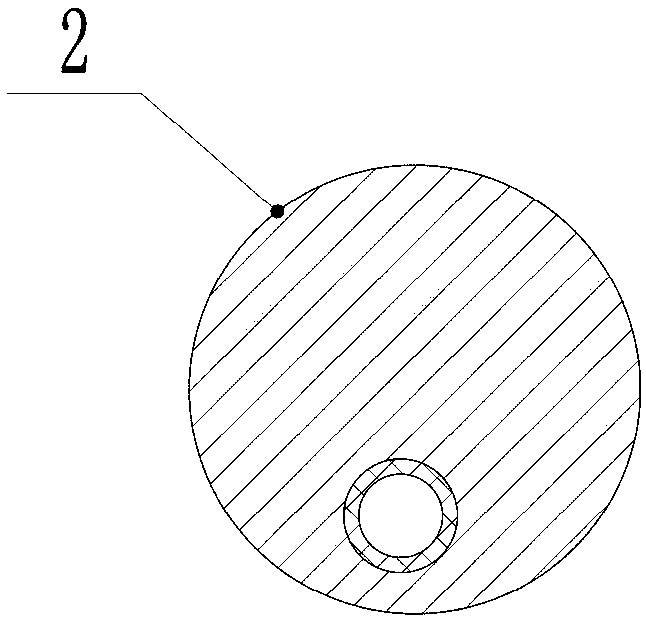

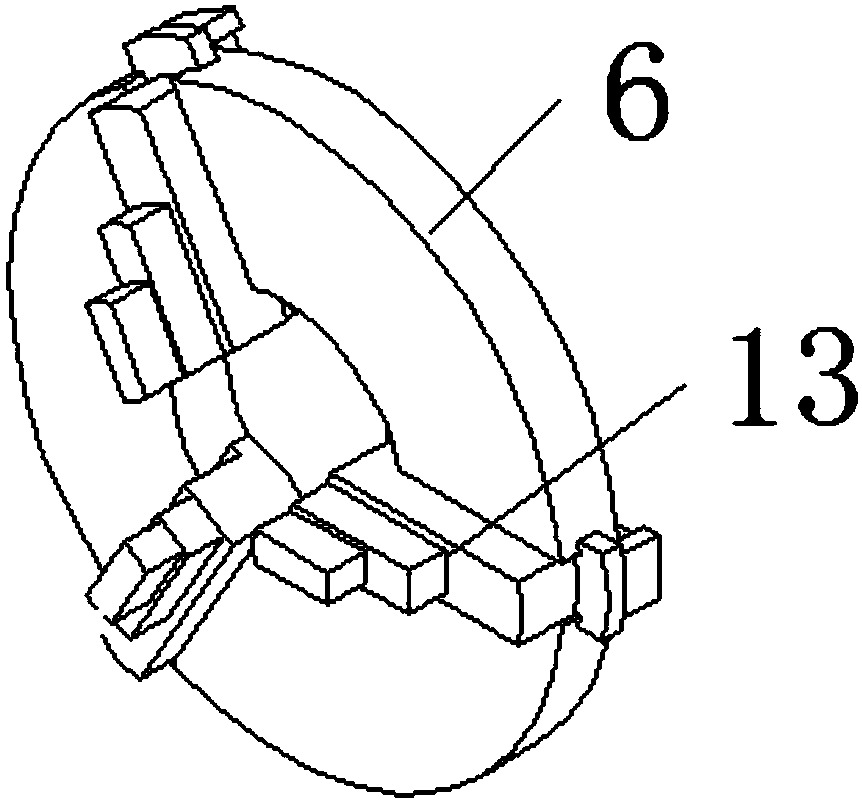

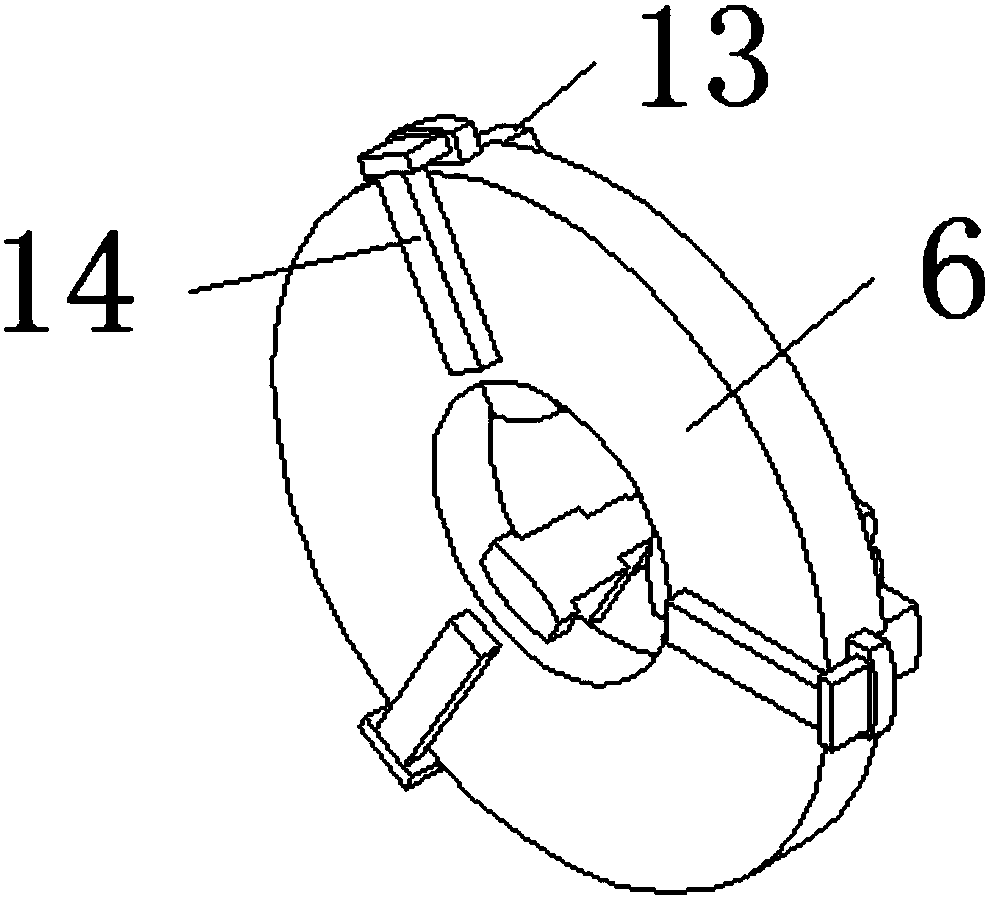

Polishing device suitable for double-side submerged arc longitudinally welded pipe weld

InactiveCN108372464ARealize processingGuaranteed grinding effectGrinding carriagesBelt grinding machinesEngineeringMechanical engineering

The invention discloses a polishing device suitable for double-side submerged arc longitudinally welded pipe weld. The polishing device comprises a base, a sliding groove is formed in the surface of the base, a slider is mounted inside the sliding groove in the surface of the base in a matched manner, a chuck mounting seat is fixedly mounted at the upper end of the slider and is of an annular structure, a chuck is mounted on the inner surface of the chuck mounting seat in a matched manner, sliding grooves are uniformly formed in the surface of the chuck, and clamping claws are mounted in the sliding grooves in the surface of the chuck in a matched manner and connected with the chuck through a third electric extensible rod. The chuck is adopted as a clamp, so that the polishing device is suitable for processing pipelines different in diameter; distance among the chucks is adjustable, so that the polishing device is suitable for processing pipelines different in length; a polishing beltis adopted for polishing, so that polishing effect is ensured.

Owner:姜慧 +1

Multifunctional robot polishing equipment

ActiveCN108655911ATimely collectionAdd collection functionGrinding carriagesGrinding machinesCouplingEngineering

The invention provides multifunctional robot polishing equipment. The multifunctional robot polishing equipment comprises a polishing motor, a fixed plate, a fixed sleeve, a connecting plate, a robotpower arm, a robot extension arm, an ER50-3200 six-axle robot, a fixed clamping base, a base, a support plate, an I-shaped frame, a waste chip and dust collecting environmental-protection barrel structure, an adjustable dust and waste chip blowing machine structure, a quick polishing replacement rod structure, a height-adjustable clamping plate structure and a sleeve coupling. Through arrangementof a collecting barrel, a metal hose, a dust guide pipe, a joint base, a support lining base and a dust guide hopper, dust and waste chips generated by polishing are timely collected, the collecting function is added, the pollution is prevented, and the environment is protected; through arrangement of a transparent piece, the collecting condition of the dust and the waste chips in the collecting barrel can be timely determined to achieve replacement or cleaning; and through arrangement of fan blades and a blowing motor, the waste chips and the dust generated by polishing are timely blown out to guarantee the polishing efficiency.

Owner:柳州中科机器人自动化股份有限公司

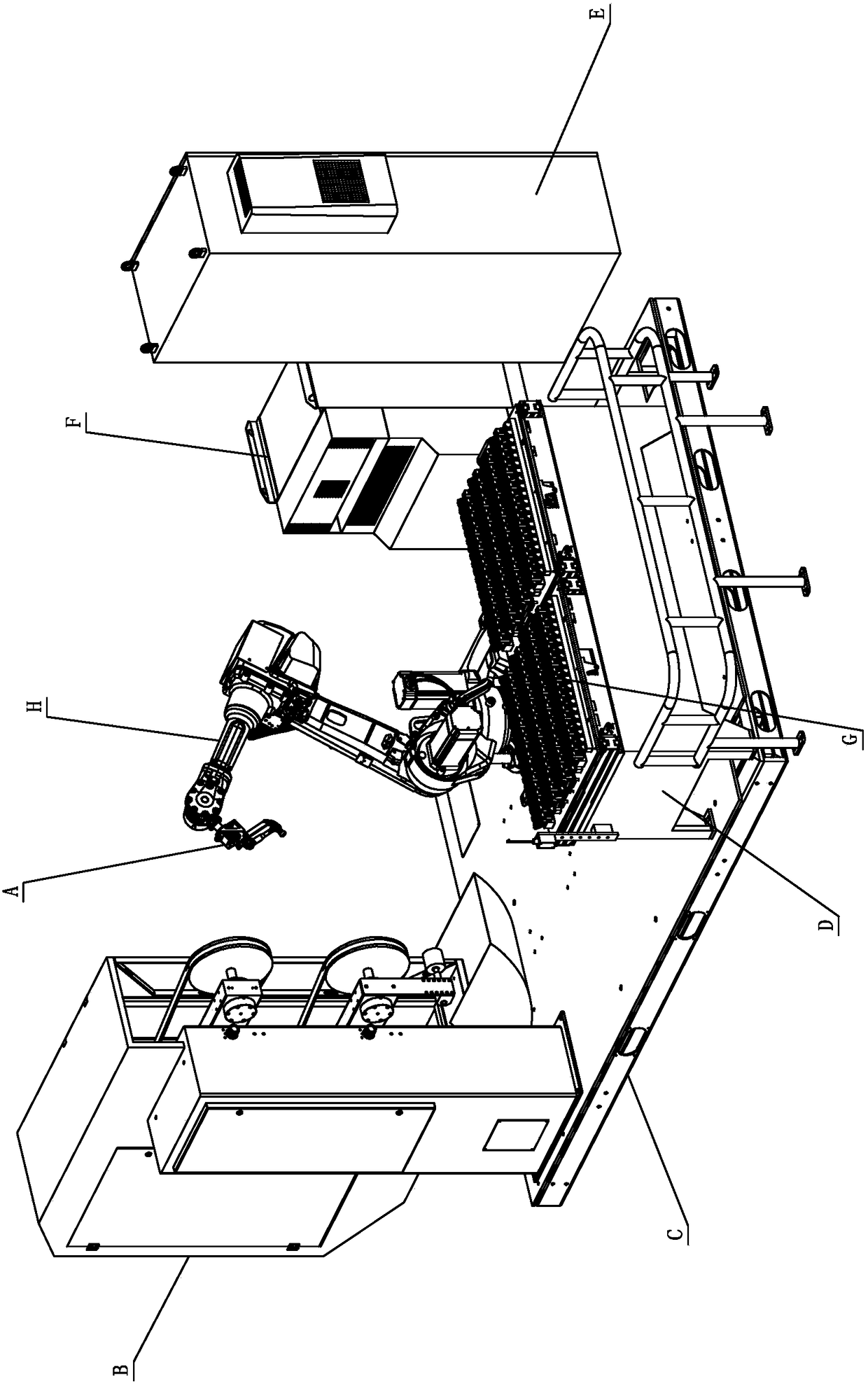

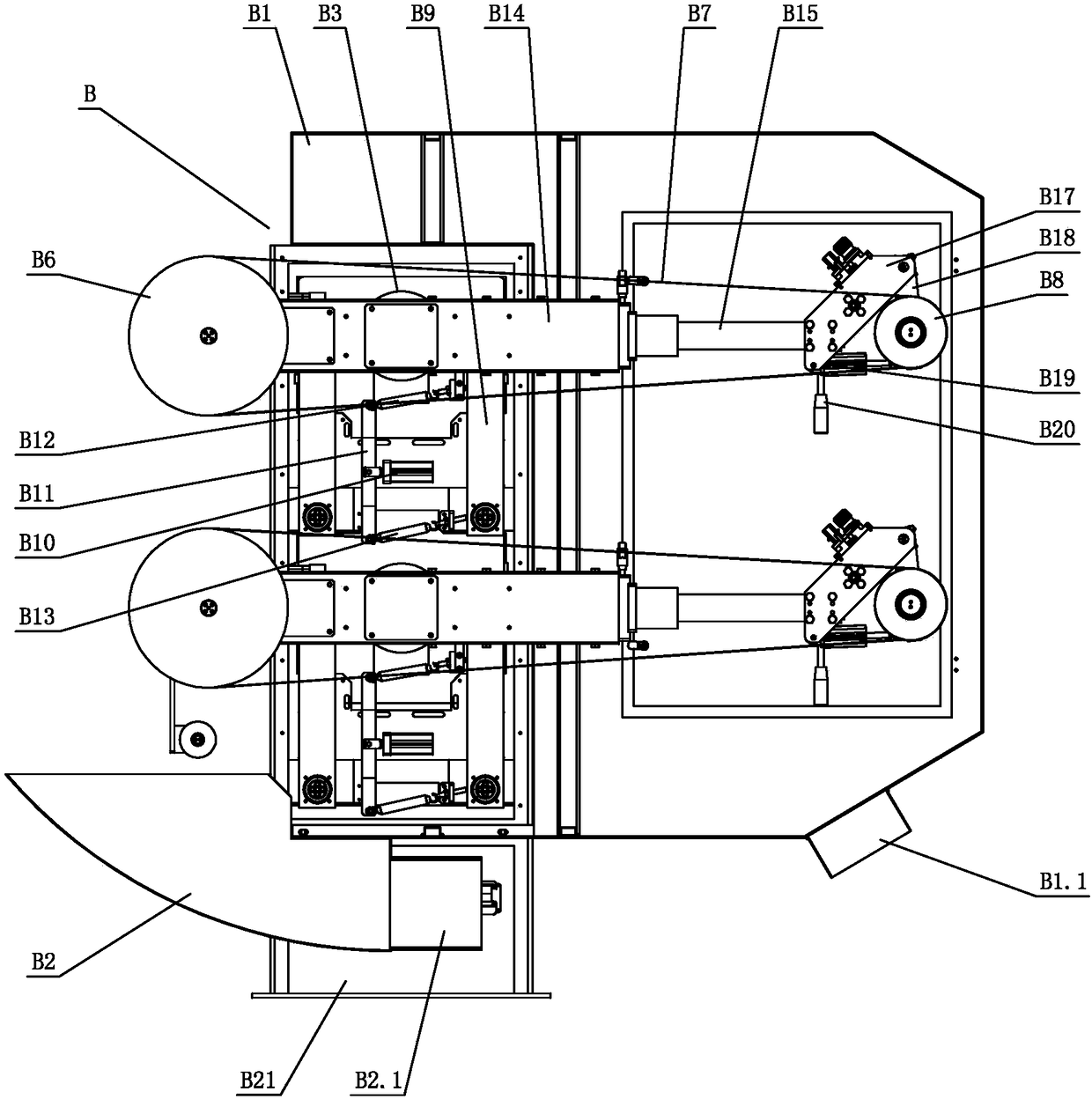

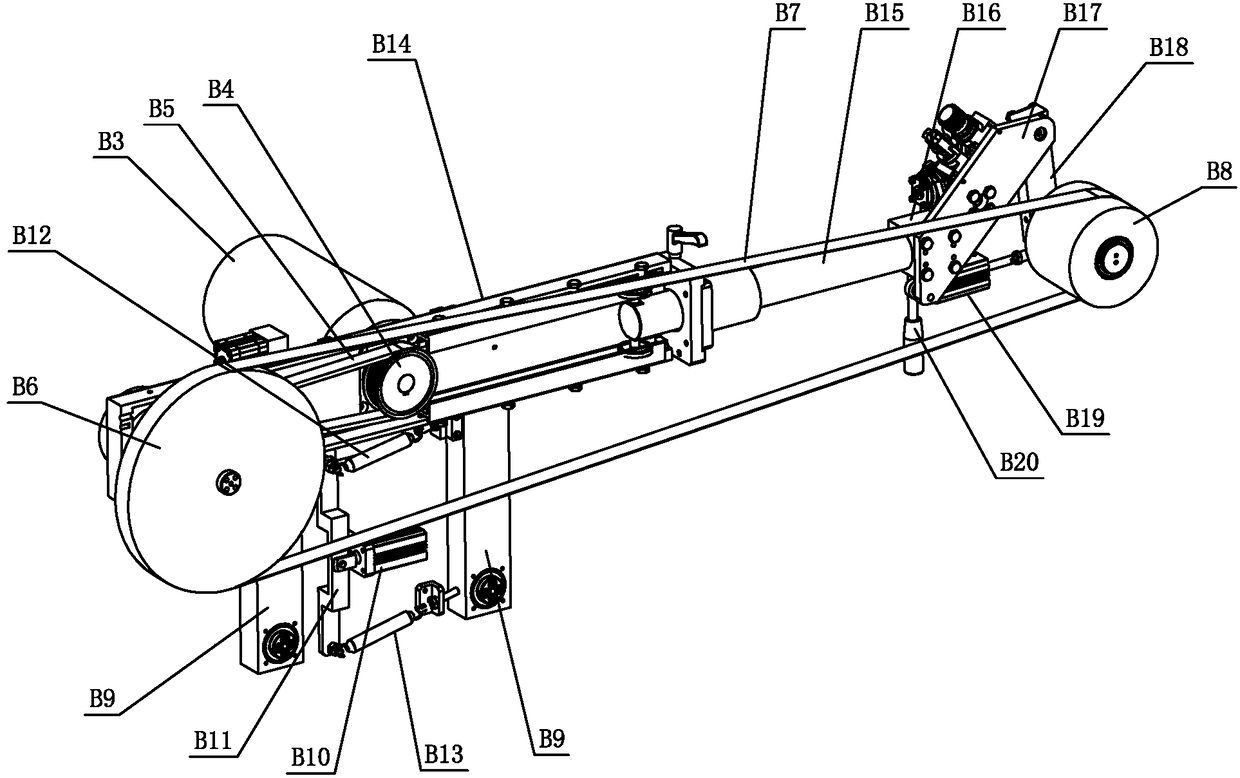

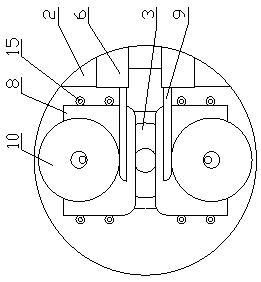

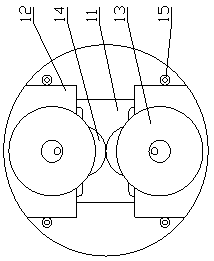

Double-station belt sanding system for sanding hammer heads

PendingCN108340249AShorten the timeEasy to operateBelt grinding machinesGrinding feedersEngineeringAutomation

A double-station belt sanding system for sanding hammer heads comprises a belt sanding mechanism, a feeding and discharging mechanism, a conveying robot and a control mechanism. The belt sanding mechanism, the feeding and discharging mechanism and the conveying robot are electrically connected with the control mechanism. The belt sanding mechanism comprises two or more belt sanding assemblies which are movably arranged overall relative to a sanding support. A force control device is arranged between the belt sanding assemblies and the sanding support. The feeding and discharging mechanism comprises a feeding and discharging worktable. Two or more feeding and discharging pushing devices are arranged on the feeding and discharging worktable. Each feeding and discharging pushing device is provided with a detachable storage plate in a matched mode and drives the storage plate to reciprocate. A plurality of hammer head workpieces are arranged on the storage plates. The double-station belt sanding system for sanding hammer heads has the characteristics of being high in automation degree, high in sanding efficiency, good in sanding quality, convenient to operate, low in labor intensity, low in labor cost, reliable in performance, good in sanding consistency, high in work stability and high in safety coefficient, and effectively improving production efficiency.

Owner:GUANGDONG LXD ROBOTICS CO LTD

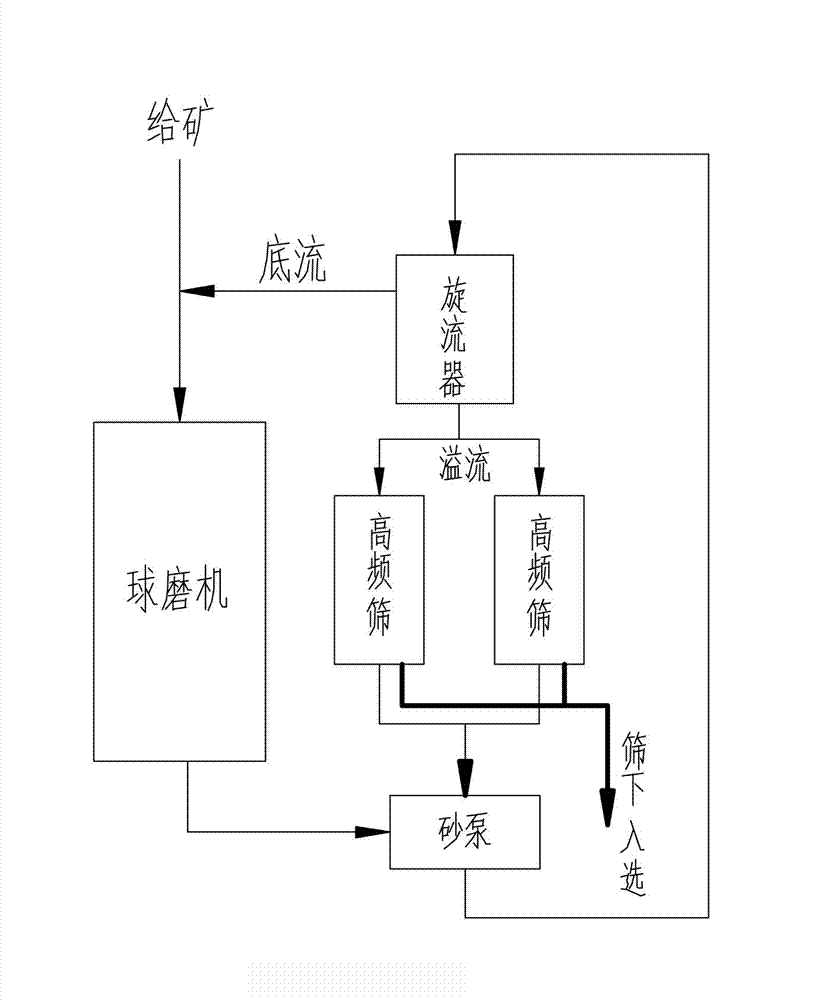

Ore grinding grading method for improving ore grinding processing capacity

The invention relates to mineral processing process improvement in the metallurgical industry, belongs to a process for improving grading efficiency and reducing qualified grade return quantity to increase processing capacity of a ball mill, and particularly relates to an ore grinding grading method for improving ore grinding processing capacity. The ore grinding grading method comprises firstly enabling products after ore crushing to enter the ball mill for ore grinding, sending discharged ore from the ball mill to a hydrocyclone for separation through a slurry pump, returning setting sand in the hydrocyclone to the ball mill, sending fine fraction products which are overflow of the hydrocyclone to a high-frequency vibration sieve for secondary separation through an ore division device, returning products on the sieve to enter the slurry pump, recycling to enter the hydrocyclone for separation, and conducting follow-up grading procedures on products below the sieve. The ore grinding grading method solves a problem that the existing ore grinding grading process is low in grading efficiency, low in platform efficiency of grinding machines, unstable in work and the like. The ore grinding grading method is mainly suitable to mineral separation processing of copper mine and lead and zinc metal ore.

Owner:HUBEI XINYING ENVIRONMENTAL TECH +1

Ceramic bond and preparation method thereof

ActiveCN105150122ALower firing temperatureImprove gripAbrasion apparatusGrinding devicesChromium sesquioxideLithium carbonate

The invention relates to a ceramic bond and a preparation method thereof, and belongs to the technical field of grinding wheel bonds. The ceramic bond is prepared from, by weight, 20%-40% of borosilicate glass, 22%-43% of feldspar, 10%-35% of nepheline syenite, 5%-13% of clay, 2%-5% of lithium carbonate and 3%-13% of chromium sesquioxide. According to the ceramic bond, all the components are subjected to a synergistic effect within a limited dosage range, the firing temperature of the ceramic bond is lowered to be 1000 DEG C, high-temperature burning loss of ceramic microcrystal grinding materials is avoided, the revolving strength of a grinding wheel manufactured through the bond is improved, and the grinding linear velocity reaches 80 m / s maximally. The preparation method is easy and convenient to operate, easy to control and suitable for industrial application and popularization.

Owner:白鸽磨料磨具有限公司

Grinding device for finish machining of ores

InactiveCN108993682AImprove work efficiencyIncrease grinding rateCocoaGrain treatmentsEngineeringMachining

The invention discloses a grinding device for finish machining of ores. The grinding device for finish machining of the ores comprises a grinding box body; a bearing is clamped in the middle part of the upper surface of the grinding box body; a rotating shaft is sleeved with the bearing; the top of the rotating shaft is fixedly connected with an output shaft of a driving device; the lower surfaceof the driving device is fixedly connected to the upper surface of the grinding box body; a plurality of crushing blades are fixedly connected to the left and right side surfaces of the rotating shaft; and the crushing blades are positioned in the grinding box body. The grinding device for finish machining of the ores, disclosed by the invention, has the advantages that ore raw materials penetratethrough small holes in a screening plate to fall into a grinding groove by arranging the driving device when the ore raw materials are small to a certain degree; a grinding disc can also be driven torotate at a high speed in the rotating process of the rotating shaft so that the ore raw materials in the grinding groove can be ground and machined; the ore raw materials entering the grinding box body are crushed and ground in sequence so that the grinding effect and the grinding efficiency of the grinding disc can be both guaranteed.

Owner:周佩龙

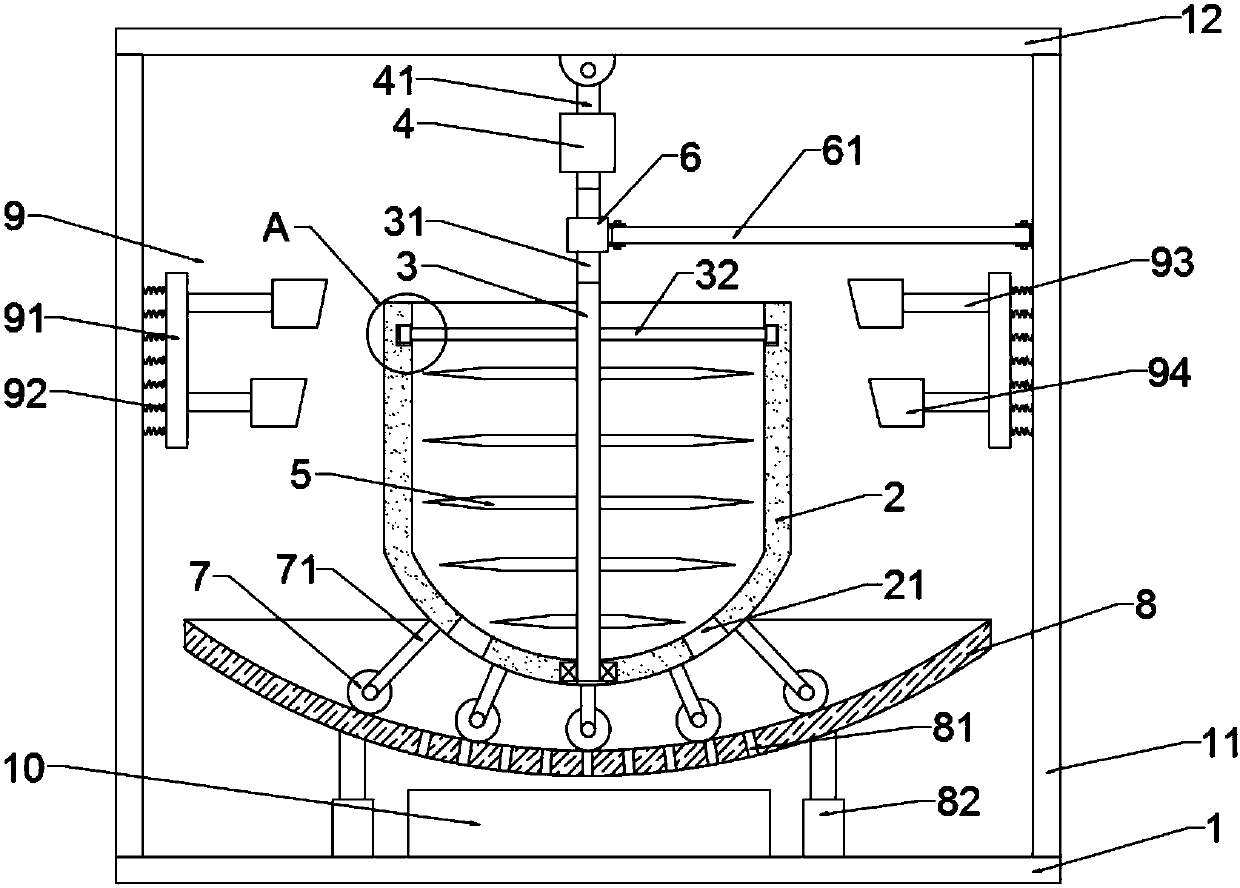

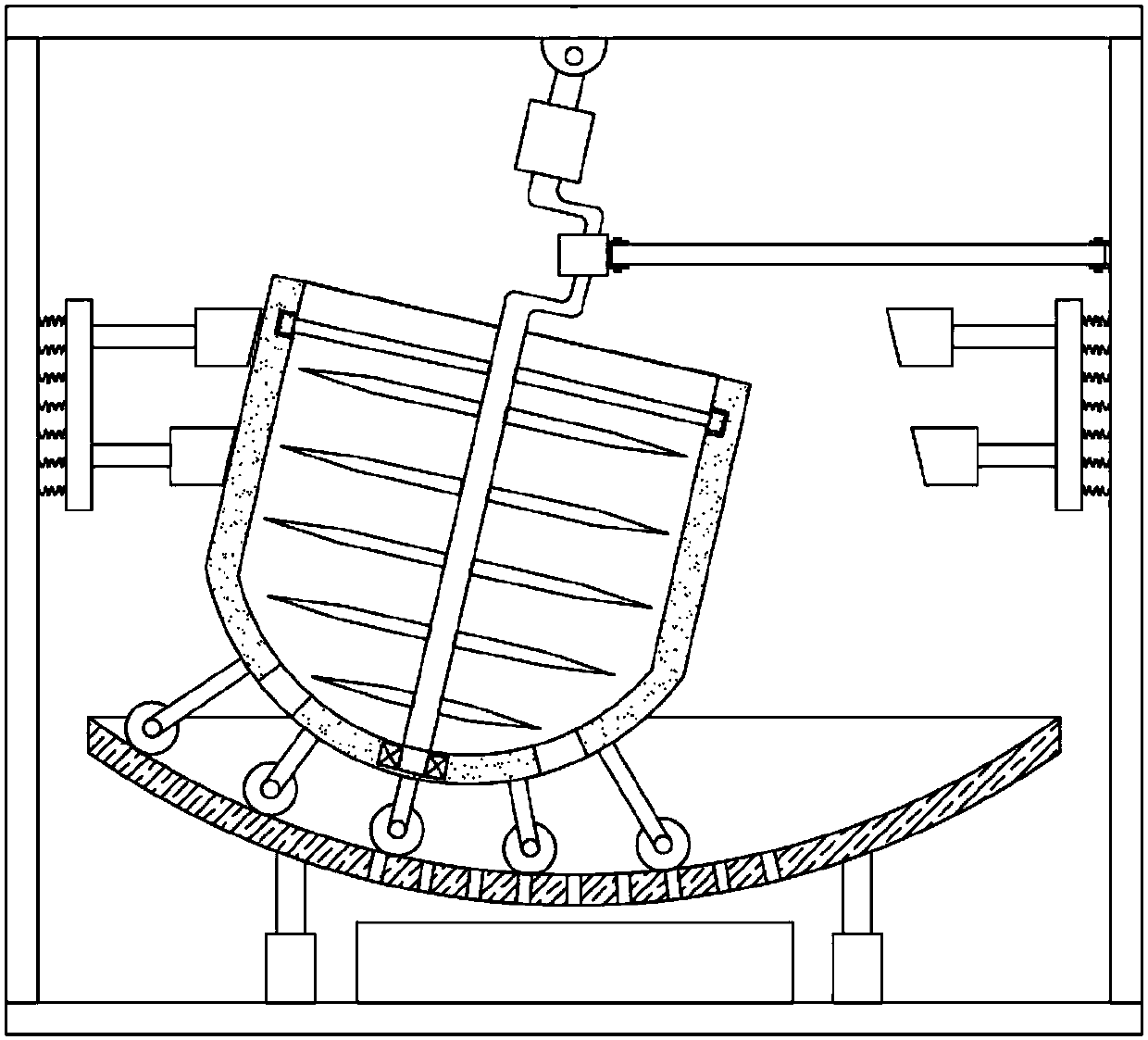

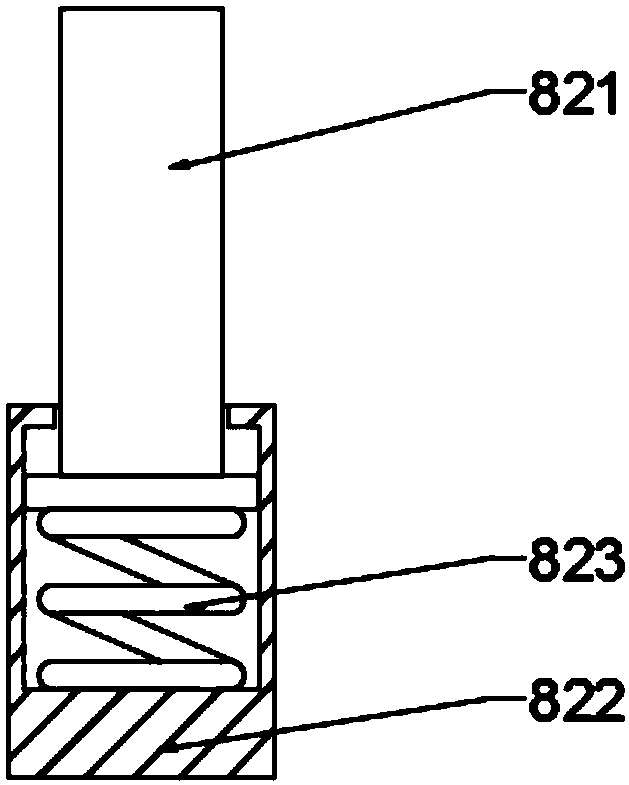

Stable polishing device for bamboo products

PendingCN107553239ATo achieve the purpose of clamping and fixingGuaranteed grinding effectGrinding drivesGrinding work supportsEngineeringMobile device

The invention discloses a stabilizing grinding device for bamboo products, which comprises an outer frame, fixing devices are fixedly connected to both sides of the inner wall of the outer frame, and a moving device is fixedly connected to the top of the outer frame, and the bottom of the moving device penetrates the outer frame. frame and extend to the inside of the outer frame, one end of the mobile device inside the mobile device is fixedly connected to the mobile frame, the right side of the mobile frame is fixedly connected to the first motor, and one end of the output shaft of the first motor passes through the mobile frame and extends to The inside of the moving frame, the invention relates to the technical field of bamboo products related equipment. The stable grinding device for bamboo products achieves the purpose of clamping and fixing bamboo products without manual fixing, reduces the burden on workers, ensures the effect of grinding bamboo products, is convenient to adapt to bamboo products of different sizes, improves the practicability of the device, and is convenient The grinding process ensures the quality of the grinding, improves the stability of the device, and is convenient for taking out and placing bamboo products.

Owner:安吉县安信信息有限公司

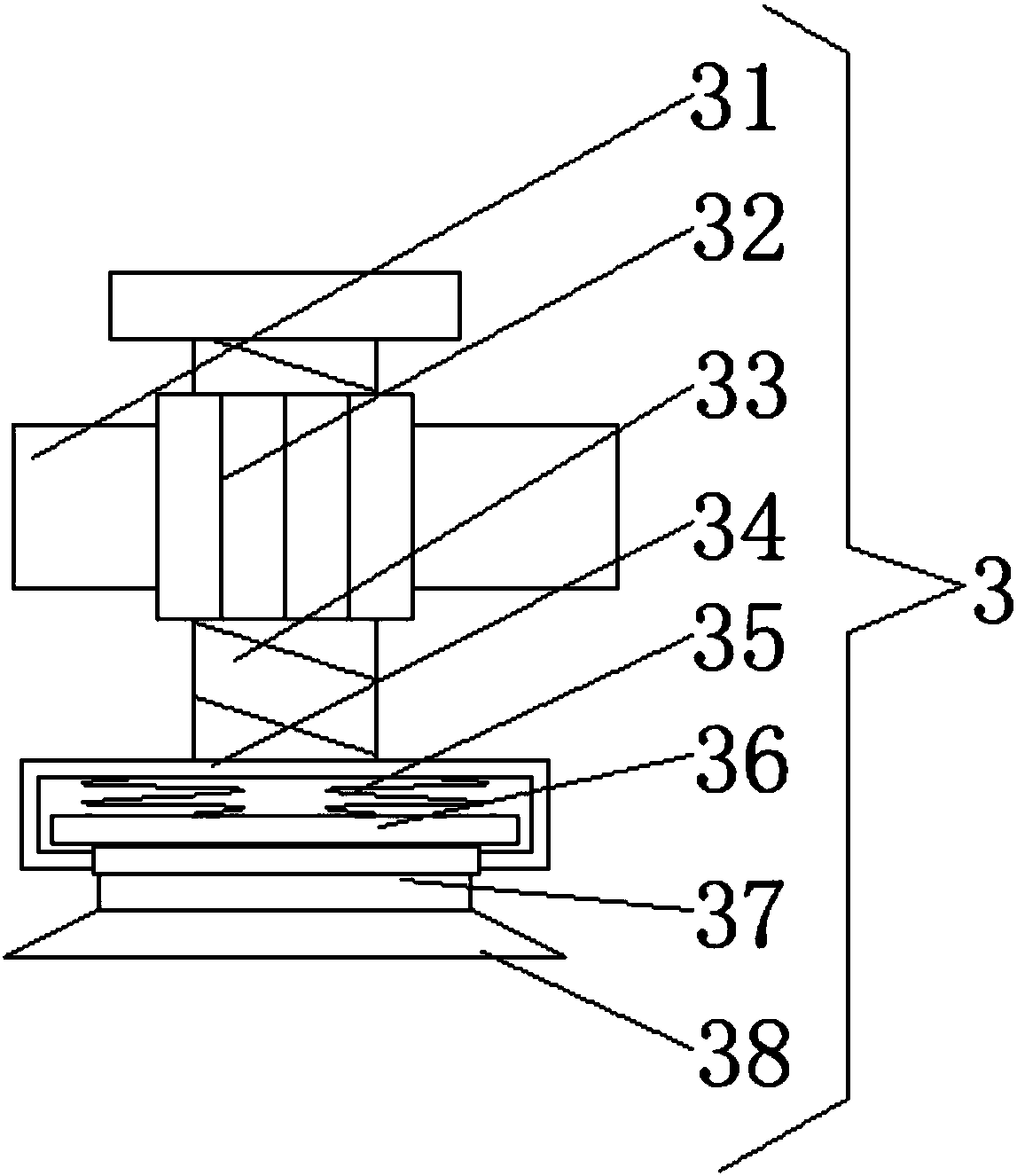

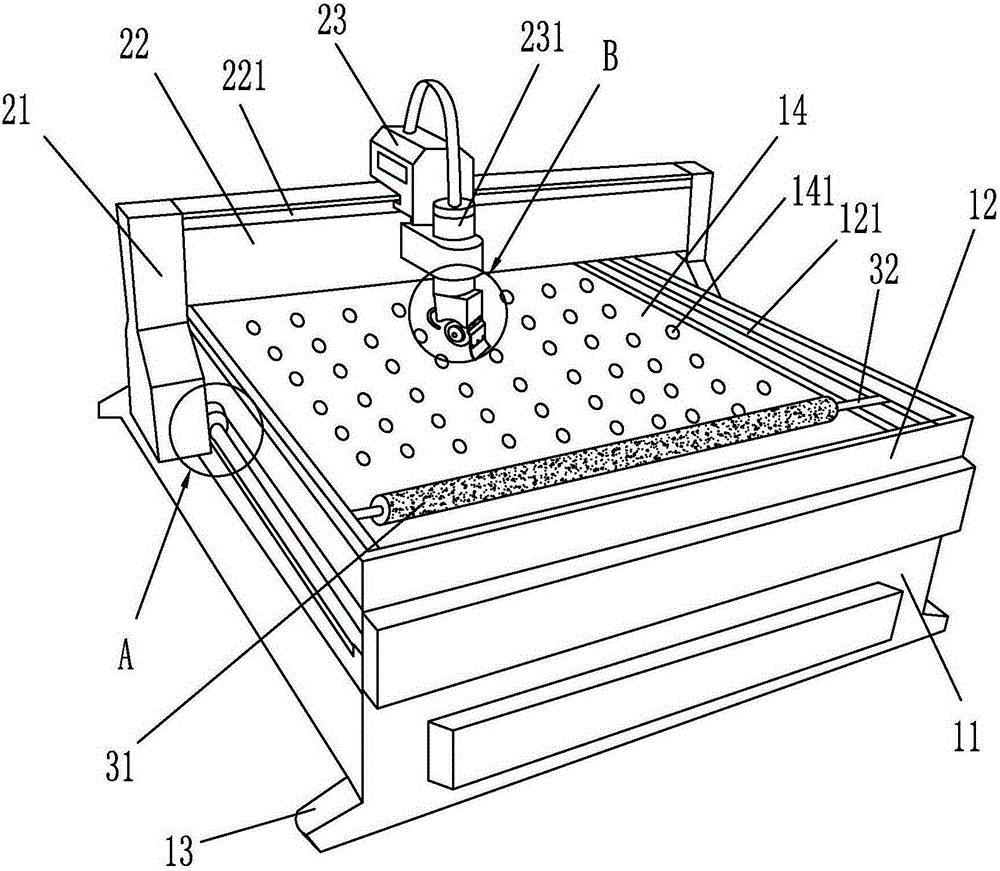

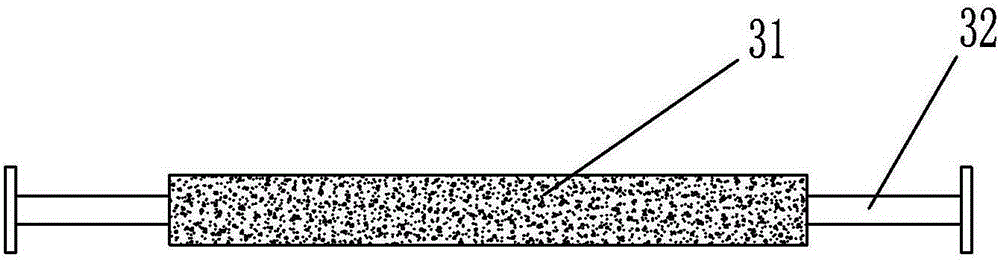

Engraver applied to plane glass

The invention discloses an engraver applied to plane glass. The engraver comprises an engraver body, a moving mechanism and a cleaning device. The moving mechanism is arranged on the engraver body. The cleaning device is arranged in the engraver body. A protection frame is arranged above the engraver body which is internally provided with a water leakage worktable. A sewage collecting room is arranged at the lower end of the engraver body. A sewage collecting device is arranged in the sewage collecting room. The sewage collecting device comprises a sewage collecting barrel and a sewage storing box. The sewage storing box is connected below the sewage collecting barrel. The moving mechanism comprises a front-back moving mechanism and a left-right moving mechanism. The left-right moving mechanism is arranged on the front-back moving mechanism. The cleaning device comprises a cleaning roller and a rotating shaft. The engraver is high in practicability, the stability of the engraver is improved, the grinding effect of the engraver is ensured, operation is convenient in the whole process, effects are obvious, and the drying effect is improved.

Owner:SHENGZHOU HUANDING GLASS TECH CO LTD

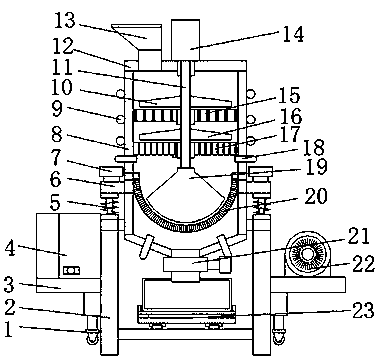

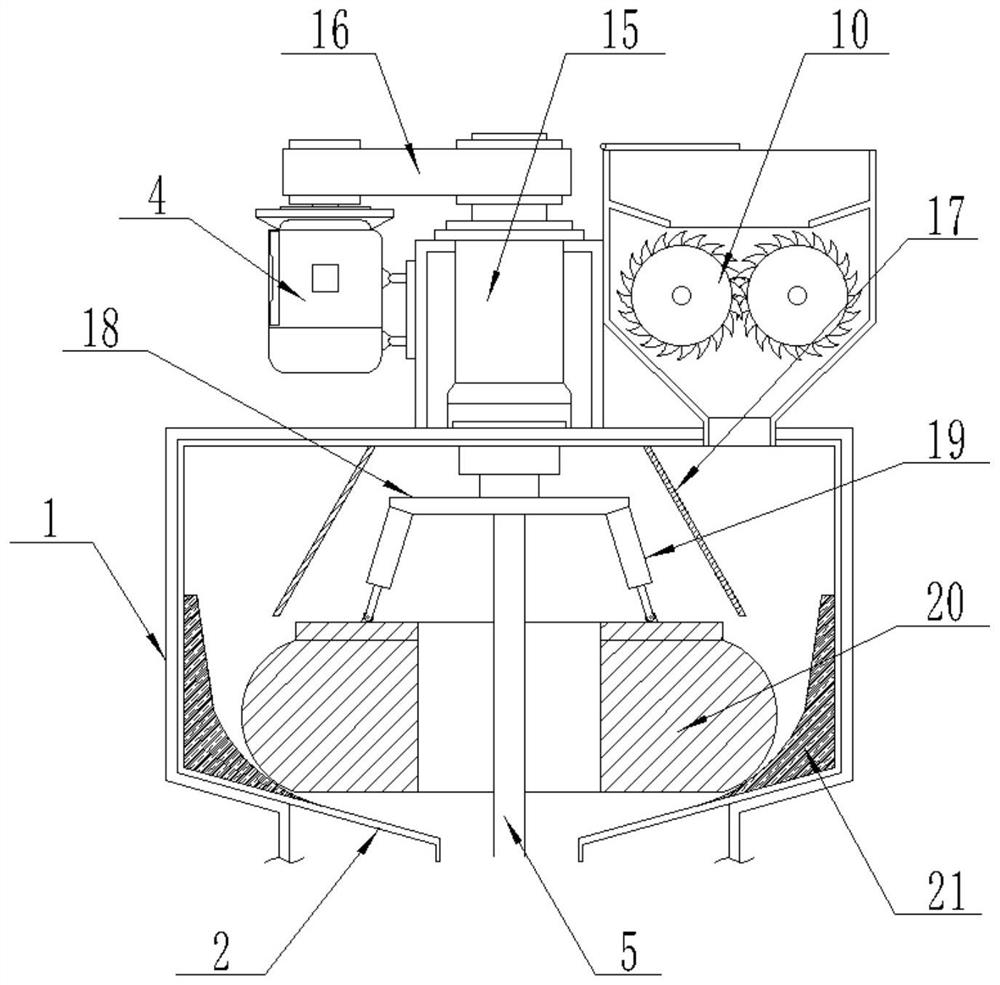

Traditional Chinese medicinal material treatment device for improving refining degree

ActiveCN107812576AIncrease granularityAvoid stickingGrain treatmentsEngineeringTraditional Chinese medicine

The invention discloses a traditional Chinese medicinal material treatment device for improving the refining degree. The traditional Chinese medicinal material treatment device comprises a bottom plate, a smashing cylinder, a rotary shaft and a grinding bowl. Vertical frames are symmetrically fixed to the left side and the right side of the top of the bottom plate, and a top plate is connected tothe position between the tops of the vertical frames on the two sides. The top of the rotary shaft is connected with the output end of a motor, the motor is fixed to a mounting frame, the top of the mounting frame is hinged to the lower surface of the top plate, and the bottom of the rotary shaft is rotatably fixed to the bottom face of an inner cavity of the smashing cylinder. A section of bent axle is arranged on the rotary shaft, a sleeve is movably arranged on the bent axle in a sleeving mode, a gap exists between the sleeve and the bent axle, a connection rod is hinged to one side of thesleeve, and the other end of the connection rod is hinged to the left side face of the vertical frame on the right side. A grinding roller is arranged at the bottom of the smashing cylinder, and the grinding roller abuts against the inner cavity face of the grinding bowl. The traditional Chinese medicinal material treatment device can effectively improve the refining degree of the traditional Chinese medicinal materials so that the traditional Chinese medicinal materials can be better absorbed by a human body when the traditional Chinese medicinal materials are treated.

Owner:江西半边天药业有限公司

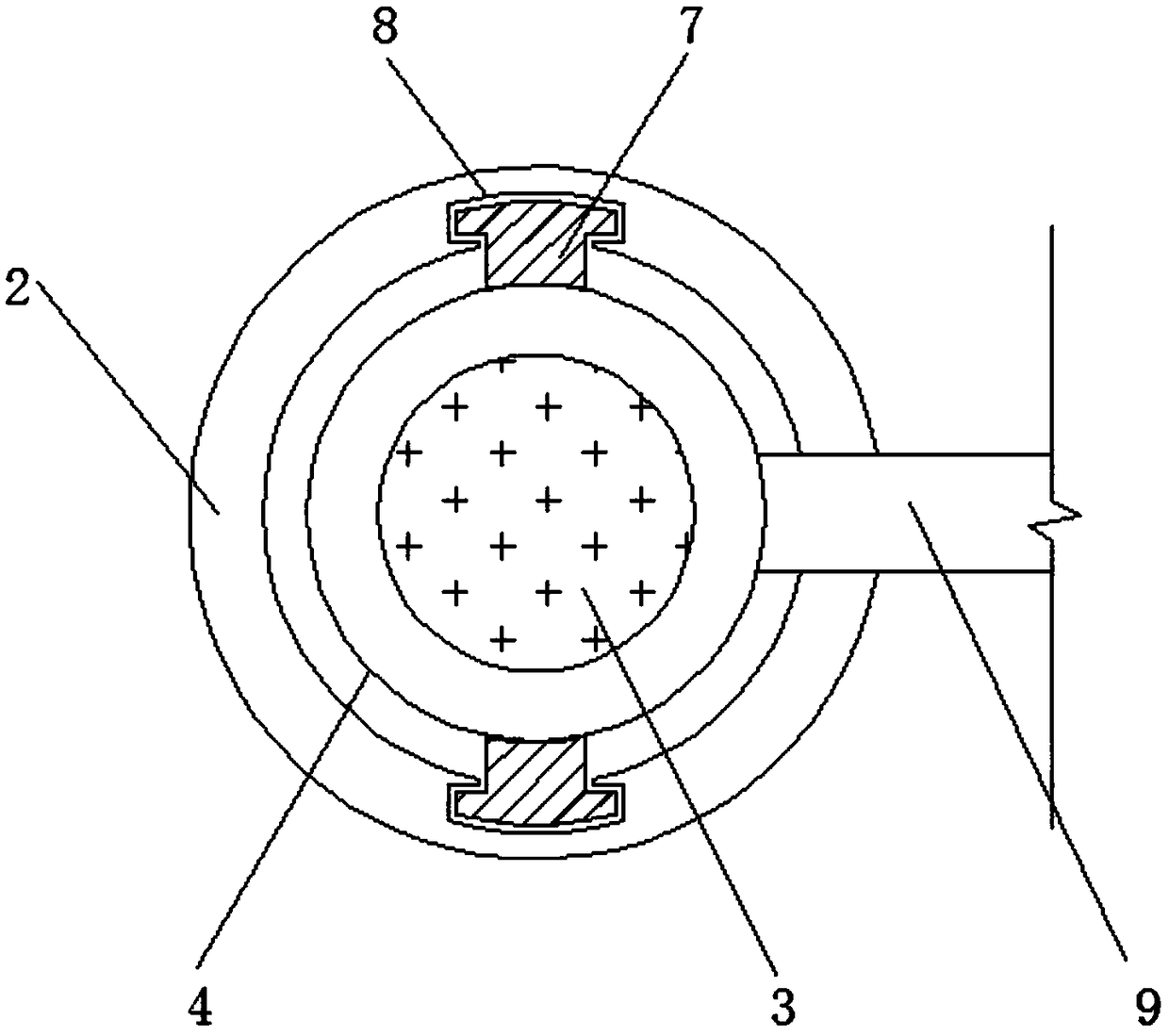

Grinding device for tubular accessory convenient to fix and capable of improving grinding efficiency

InactiveCN108481137AEasy to fixImprove grinding efficiencyGrinding machinesGrinding/polishing safety devicesArchitectural engineeringGasket

The invention discloses a grinding device for a tubular accessory convenient to fix and capable of improving grinding efficiency. The grinding device comprises a base, a cross beam, a rotating shaft,a second connecting spring and an operation table, wherein vertical columns are fixed on the two sides of the left side and the right side of the base, connecting rods are arranged inside the verticalcolumns, and sleeve rods are arranged on the two sides of the left side and the right side of a cross beam, and a second motor is arranged at the top of the cross beam; a rotating shaft penetrates through the cross beam and is connected with the second motor, a grinding disc is fixed at the bottom of the rotating shaft, the top of the second connecting spring is connected with the inner wall of the grinding disc, and the bottom of the second connecting spring is installed with an outer grinding piece; and a gasket is installed on the left side of a third connecting spring, and a protective plate is connected with the upper portion of a sundry collecting box. The grinding device for the tubular accessory convenient to fix and capable of improving grinding efficiency has the beneficial effects that an inner grinding piece and the outer grinding piece are arranged, and the radian direction of the inner grinding piece and the radian direction of the outer grinding piece are consistent, and can be tightly attached and laminated to the inner wall and the outer wall of the tubular accessory; and meanwhile, the tubular accessory can be subjected to grinding treatment at the same time, sothat the grinding efficiency of the device is improved.

Owner:芜湖市奥尔特光电科技有限公司

Grinding device

The invention discloses a grinding device, which comprises a slide seat, a sliding device and a grinder, wherein the sliding device can slide along the slide seat, and the grinder is detachably arranged on the sliding device and comprises a grinding sheet used for grinding the surface to be ground. The grinding device provided by the invention has the advantages that the complete contact between the grinding sheet of the grinder and the surface of a brake disc can be conveniently ensured through regulating the vertical height of the sliding device, the grinding effect can be conveniently and reliably ensured, the smoothness of the surface of the ground brake disc is ensured, and the technical requirements are met. In addition, the grinding device provided by the invention has the advantages that the structure is simple, the weight is light, the size is smaller, and the installation, the operation and the control are convenient.

Owner:XINJIANG GOLDWIND SCI & TECH

Aqueous expansion-preventing transparent primer of medium-density fiber board as well as preparation method and application thereof

ActiveCN102516847AReduce swellingImprove permeabilityPolyurea/polyurethane coatingsSpecial surfacesFiberMedium density

The invention discloses an aqueous expansion-preventing transparent primer of a medium-density fiber board as well as a preparation method and application thereof. The aqueous expansion-preventing transparent primer of the medium-density fiber board is prepared from 65-70 parts of aqueous acrylic resin, 15-16 parts of aqueous expansion-preventing resin, 0.5-1.5 parts of grinding auxiliary agent, 2-2.5 parts of film-forming auxiliary agent, 0.1-0.5 part of flatting agent, 0.3-0.8 part of defoaming agent, 0.5-0.8 part of thickening agent and 10.4-11.6 parts of water. By using the aqueous expansion-preventing transparent primer of the medium-density fiber board, the drying and grinding performances are guaranteed, and the expansion phenomenon is not generated after the aqueous expansion-preventing transparent primer is coated on the medium-density fiber board; the aqueous primer is safe and environmentally-friendly, and has efficient sealing performance; and the expansion effect of the wood fiber is eliminated by just requiring one working procedure of spray-coating the aqueous expansion-preventing transparent primer of the medium-density fiber board during the primer treatment of the medium-density fiber board, thus the working procedure is simplified, and the efficiency of grinding personnel is improved.

Owner:深圳市雷巴环保材料有限公司

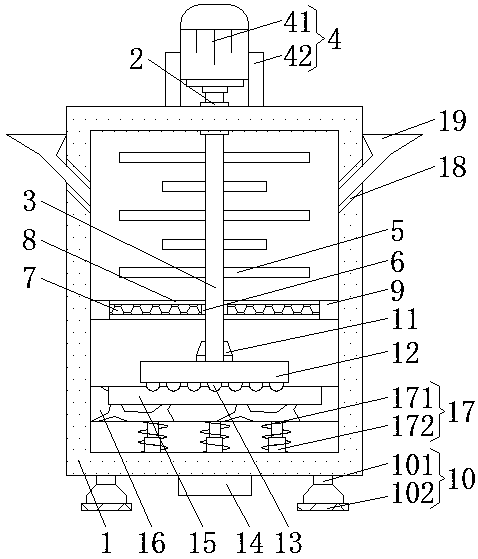

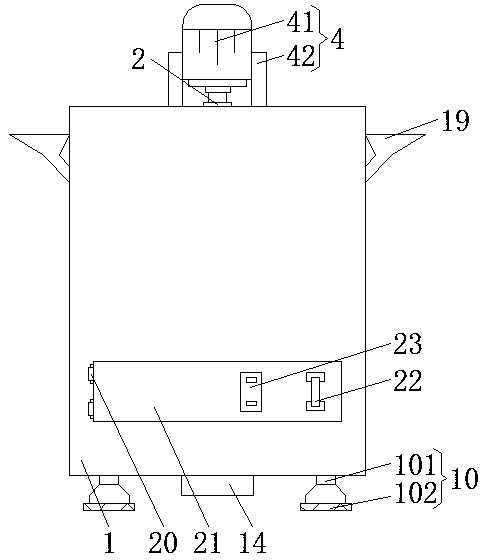

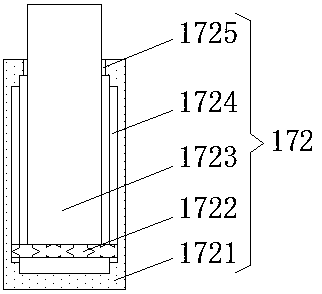

Multistage milling device for polymer chemical material particles

PendingCN108405063AGuaranteed grinding effectAvoid quality degradationHollow article cleaningCocoaCompound (substance)Engineering

The invention belongs to the technical field of medical equipment and particularly relates to a multistage milling device for polymer chemical material particles. The multistage milling device aimingat solving the problems that an existing milling device is difficult to clean, meanwhile the heat generated during milling is not completely dissipated, and damage to the milling device is caused easily. According to the multistage milling device, the following scheme is provided, the multistage milling device comprises a support frame, vertically-arranged shock absorbers are connected to the fourcorners of the top of the support frame through bolts, and the tops of the four shock absorbers are all connected with mounting blocks through bolts, and the same milling box is welded to the ends, close to each other, of the four mounting blocks. According to the multistage milling device, the polymer chemical material particles are milled by a first milling disc and a second milling disc and then ball-milled by a ball milling head and a third milling disc, so that the milling effect of the polymer chemical material particles can be ensured, the milling device is easy and convenient to clean, and the corrosion of the residual polymer chemical material to the milling device can be effectively avoided.

Owner:LINYI UNIVERSITY

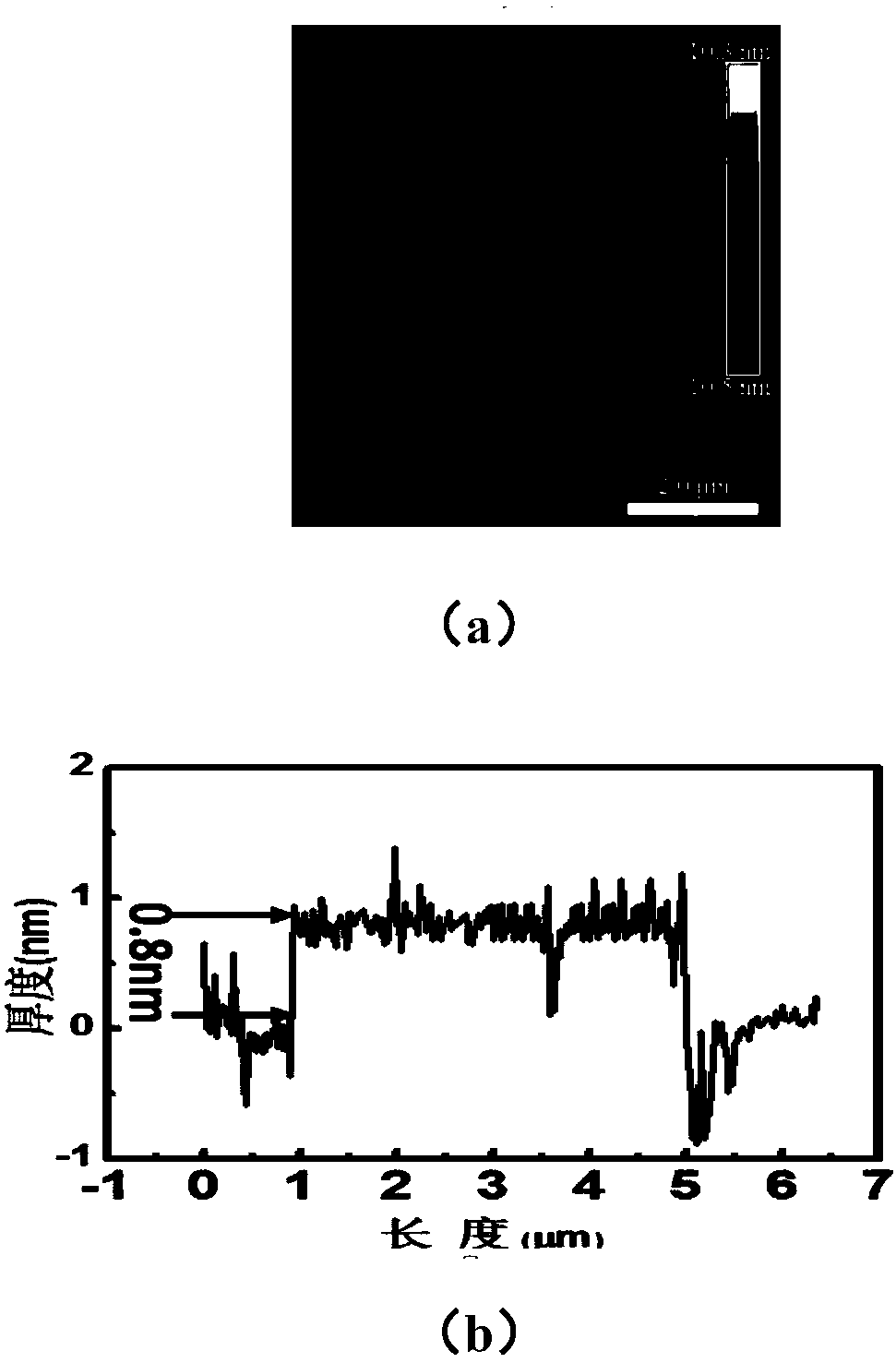

Graphene composite material and preparation method and application thereof

The invention relates to a graphene composite material and a preparation method and application thereof. The average number of layers of the graphene composite material is 1, 2 or 3 layers, the thickness is 0.34-1.25nm, and the order of magnitude of conductivity is 104-105s / m. The preparation method of the graphene composite material includes the following steps of: taking water as a solvent, adding multi-layer graphite and a macromolecular polymer to the water, uniformly mixing, grinding and / or performing ultrasonic treatment to obtain graphene composite material dispersion liquid, and then freezing and drying to prepare the graphene composite material. According to the scheme of the invention, the macromolecular polymer is added to the multi-layer graphite aqueous solution, the viscosityof the system is increased, the peeling and dispersion of graphite can also be realized by using the shearing force, and thus the single-layer or few-layer graphene composite material with less defects, relatively high quality and good conductivity can be prepared.

Owner:INST OF CHEM CHINESE ACAD OF SCI +1

Aluminum alloy metal part grinding and polishing device

ActiveCN112775777AEffectively fixedEasy to polishGrinding carriagesGrinding drivesStructural engineeringMechanical engineering

The invention belongs to the technical field of aluminum alloy machining equipment, and discloses an aluminum alloy metal part grinding and polishing device which comprises a grinding table and an aluminum alloy plate. Two symmetrically-distributed fixing assemblies are arranged at the top of the grinding table. Each fixing assembly comprises a first hydraulic rod, wherein the mounting end of the first hydraulic rod is arranged at the top of the grinding table, a fixing plate is arranged at the output end of the first hydraulic rod, a first electric telescopic rod is arranged on one side of the fixing plate, a first moving plate is arranged at the output end of the first electric telescopic rod, second electric telescopic rods are arranged on the end face of the periphery of the first moving plate, second moving plates are arranged at the other ends of the second electric telescopic rods, first air guide pipes are arranged at one ends of the second moving plates, and suckers are arranged at the other ends of the first air guide pipes. According to the aluminum alloy plate polishing device, through the arrangement of a polishing assembly, the fixing assemblies and a containing plate, the two side faces of an aluminum alloy plate can be ground at a time, the aluminum alloy plate can be ground and pre-cleaned, and the grinding precision is controlled.

Owner:JIANGXI DONGYANG ALUMINUM CO LTD

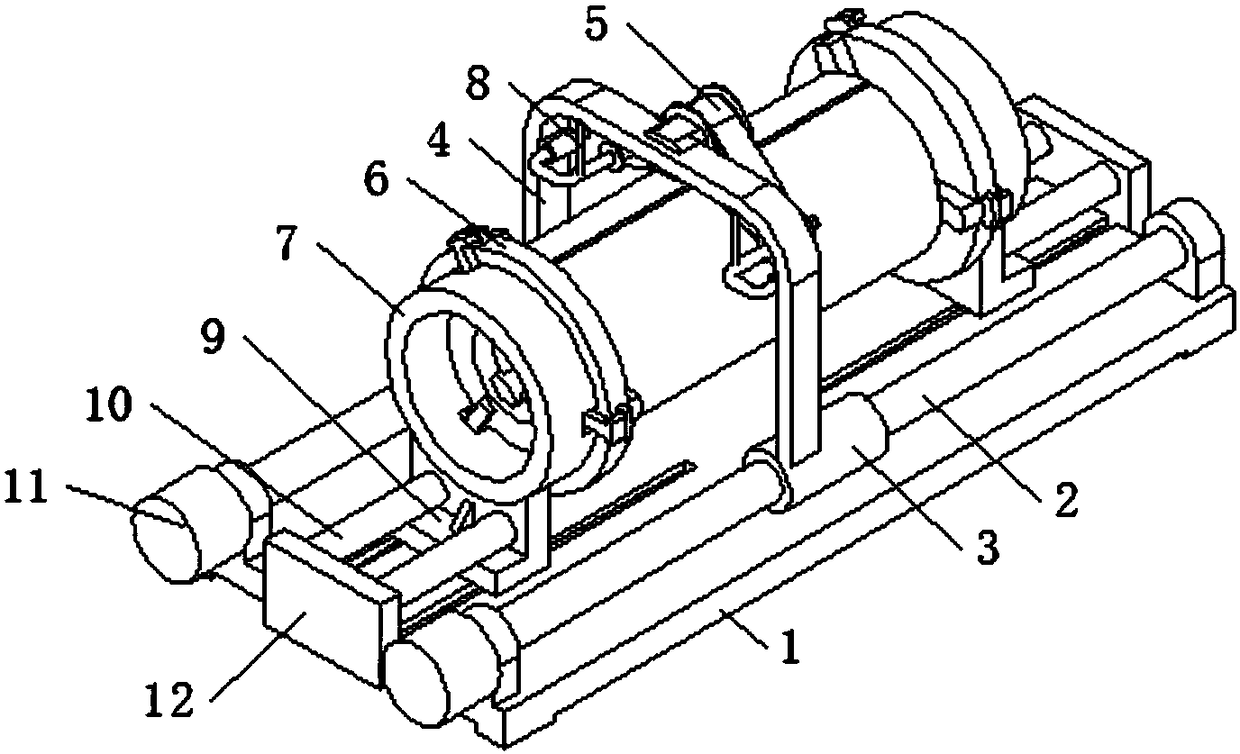

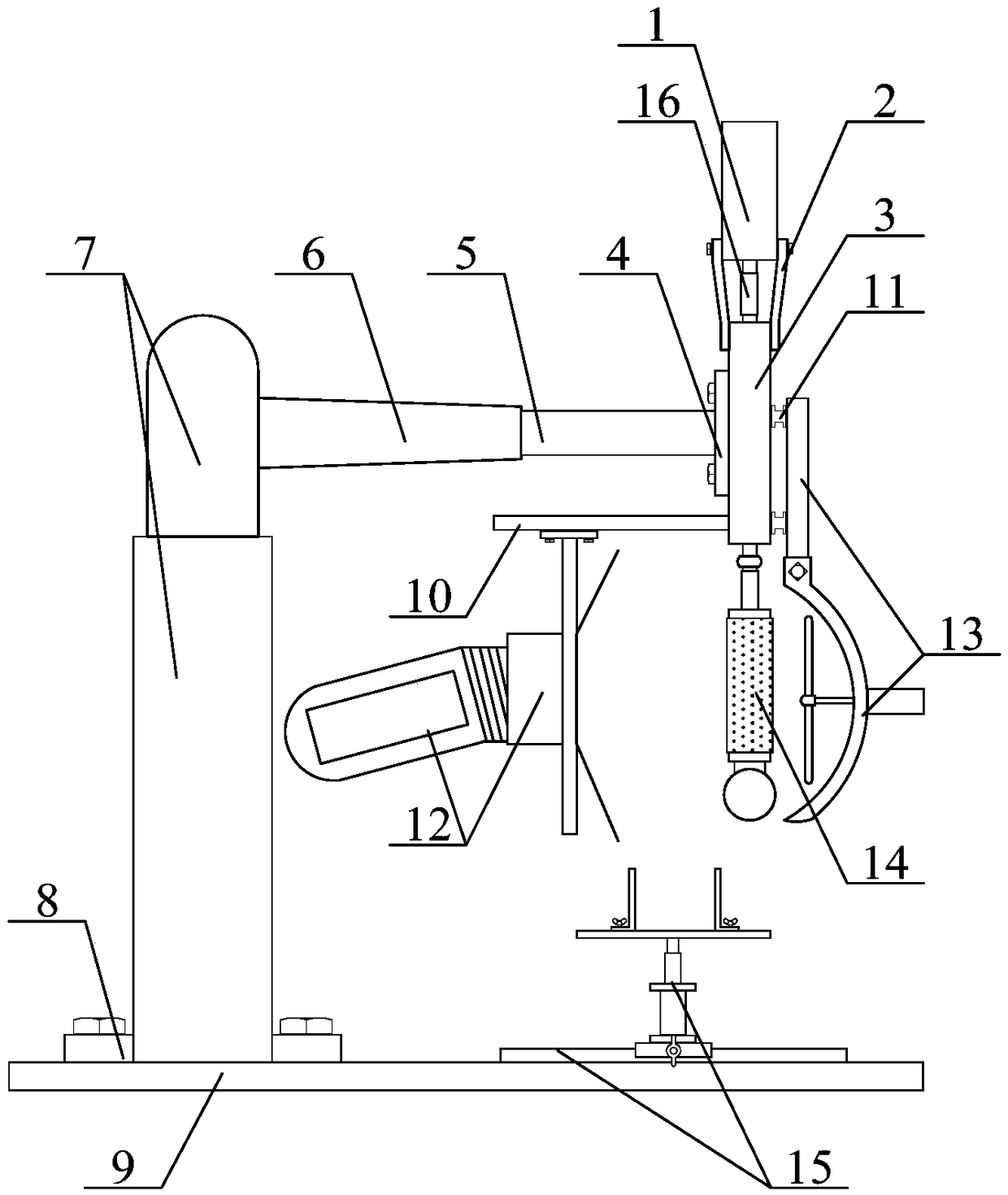

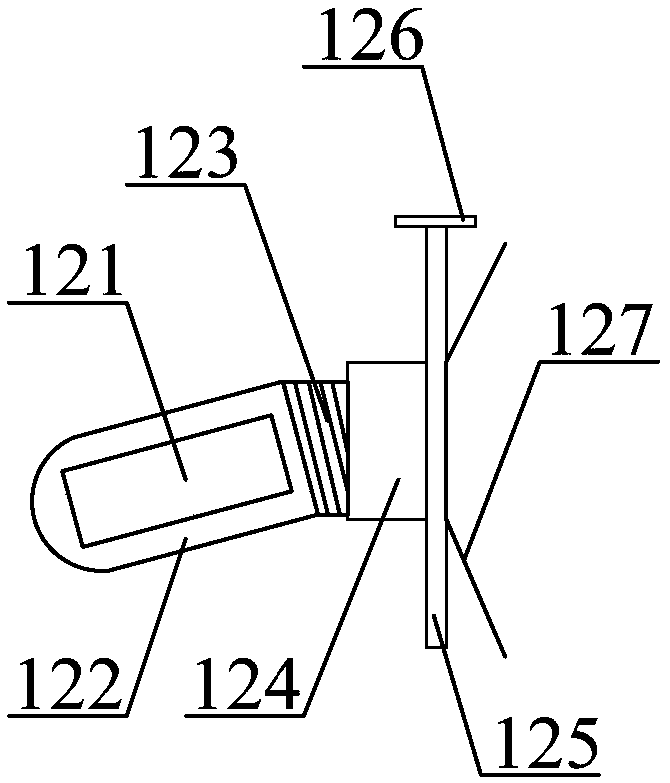

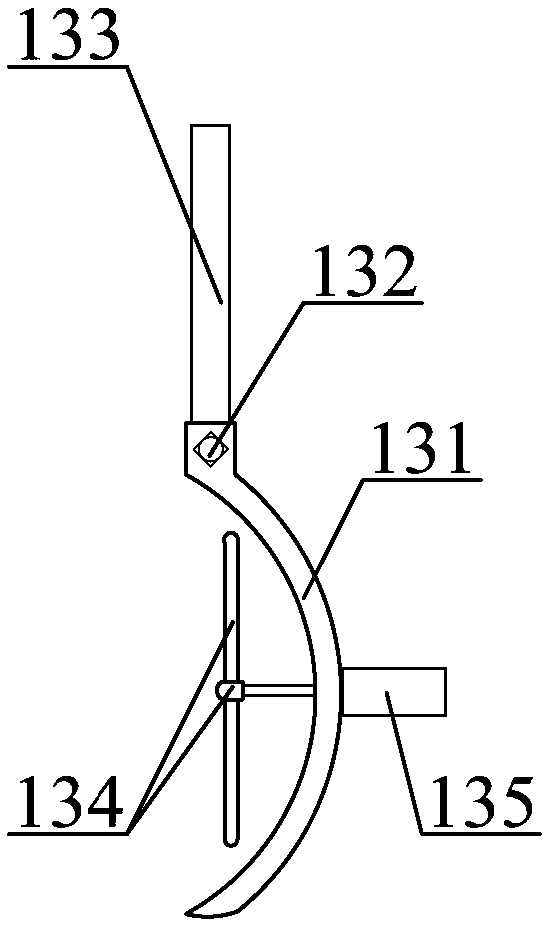

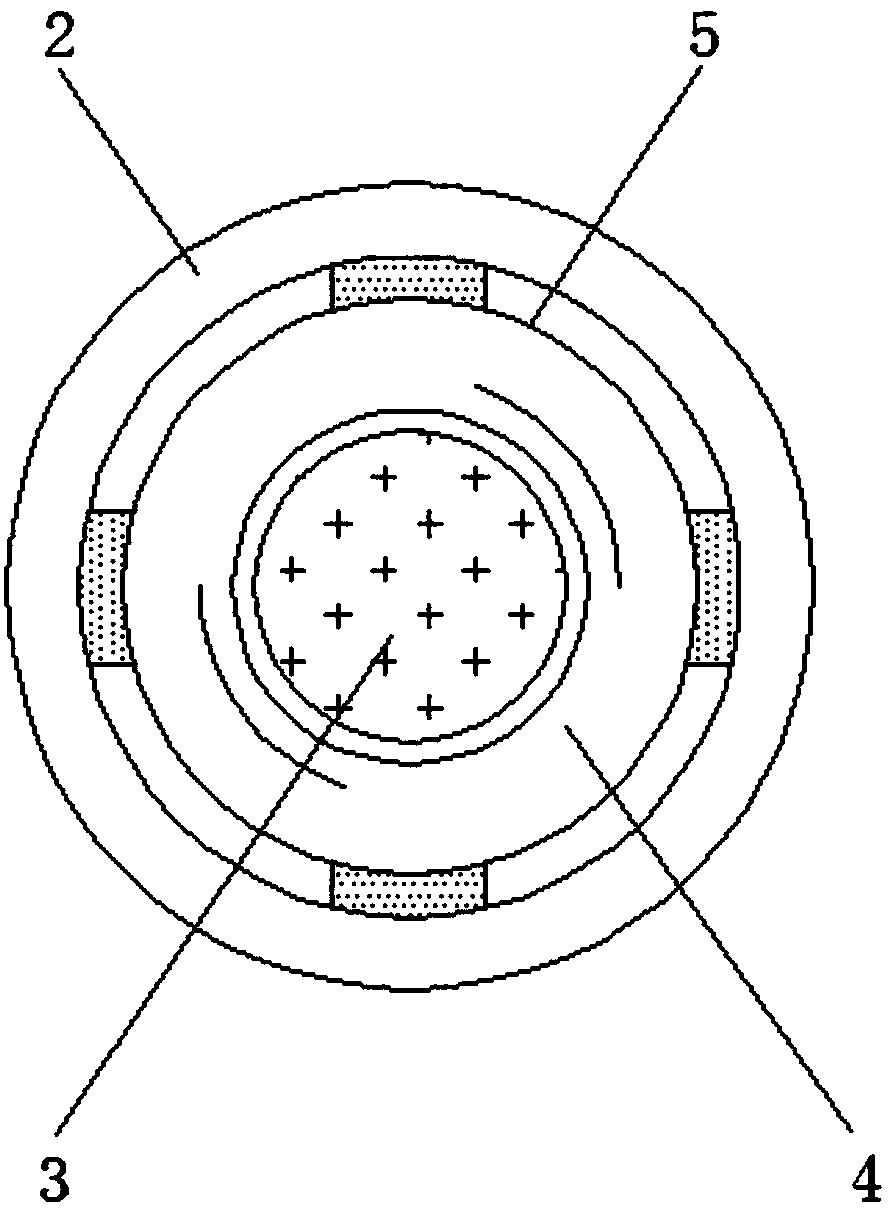

Grinding equipment for cathode roller and using method thereof

ActiveCN108466116AAvoid excessive wearGuaranteed grinding effectGrinding carriagesRevolution surface grinding machinesEngineeringGrinding wheel

The invention discloses grinding equipment for a cathode roller and a using method thereof, and belongs to the technical field of grinding equipment. The grinding equipment is characterized in that asupport seat is arranged on the side edge of the roller surface of the cathode roller, a guide rail is arranged on the support, an axial sliding seat is arranged on the guide rail, the axial sliding seat is in threaded connection with a driving screw rod, the driving screw rod is connected with a first driving motor, the driving screw rod and the guide rail are arranged in parallel, supporting seats matched with the driving screw rod are arranged at the two ends of the support in the length direction, the driving screw rod is connected with a displacement detection mechanism, a radial slidingseat is movably arranged on the axial sliding seat, the radial sliding seat is connected with a radial driving mechanism, a mounting table is arranged on the radial sliding seat, a second driving motor is arranged on the mounting table in the axial direction of the cathode roller, and a power output shaft of the second driving motor is connected with a grinding wheel. The grinding equipment for the cathode roller and the using method thereof are reasonable in structure, high in use safety, and convenient to use; and the grinding equipment is used for grinding the cathode roller.

Owner:GUANGDONG FINE YUAN SCI TECH CO LTD

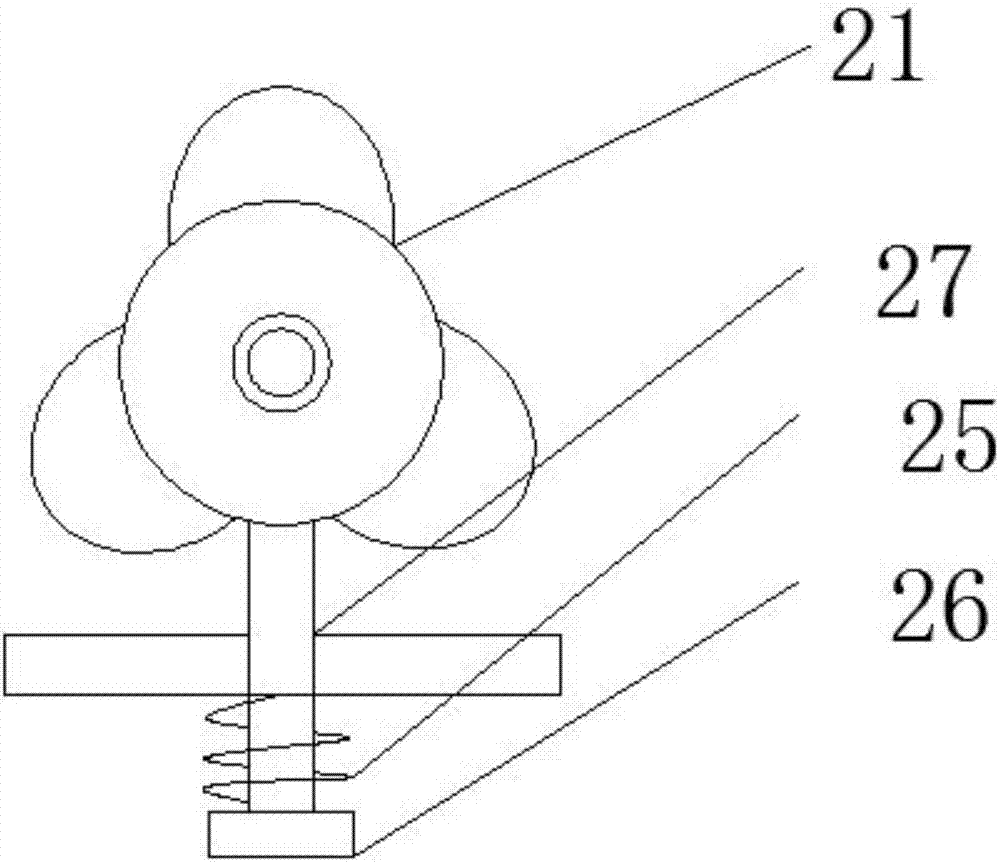

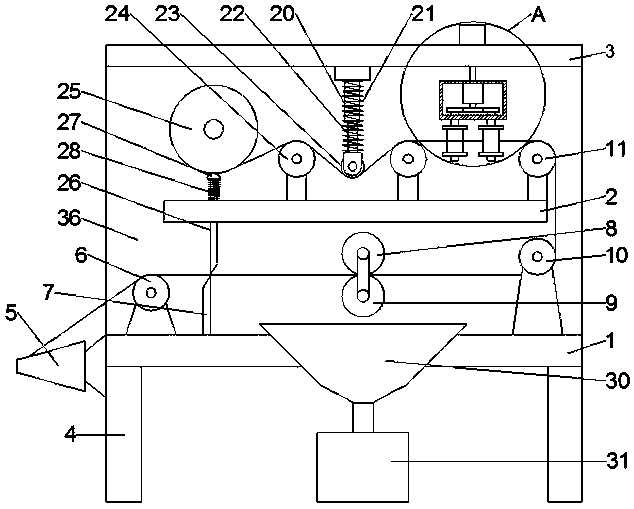

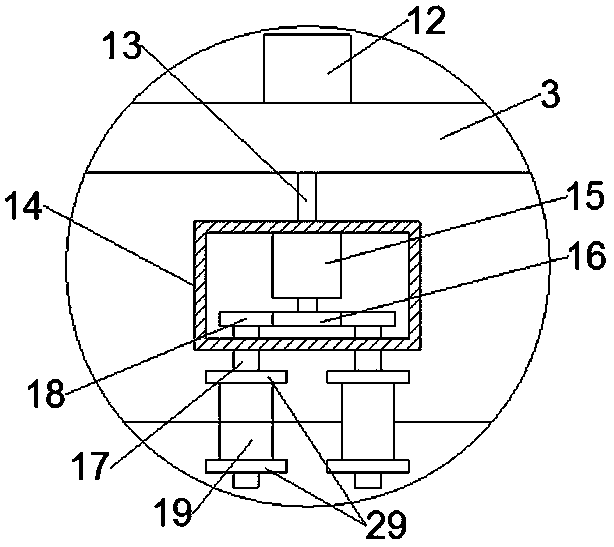

Convenient-to-use automated winding machine

PendingCN109305606AImprove qualityGuaranteed qualityFilament handlingSevering textilesYarnWinding machine

The invention discloses a convenient- to-use automated winding machine. The winding machine comprises a lower plate, a middle plate, an upper plate, a vertical plate, a yarn twisting cylinder, a fixedcutting blade, a grinding device, a waxing device, a yarn coiling reel and a movable cutting blade. Supporting plates are arranged on the left side and the right side of the bottom of the lower platerespectively. The vertical plate is fixed to the rear side above the lower plate. The middle plate parallel with the lower plate is arranged in a middle position of the vertical plate. The upper plate parallel with the middle plate is arranged on the top of the vertical plate. The yarn twisting cylinder is arranged on a side face of the supporting plate on the left side below the lower plate. A first guide pulley is arranged on the upper left side of the lower plate. The fixed cutting blade is arranged on the right side of the first guide pulley. A second guide pulley is arranged on the upperright side of the lower plate. The grinding device is arranged between the first guide pulley and the second guide pulley. According to the convenient- to-use automated winding machine, the structureis simple; flaws on the yarn can be eliminated in an automated manner; and yarn quality is improved.

Owner:湖州萌星服饰有限公司

Polishing mechanism for corners of glass

InactiveCN105171558APrevent splashPollution controlEdge grinding machinesGrinding feedersSewageMechanical engineering

The invention discloses a polishing mechanism for the corners of a piece of glass. The polishing mechanism comprises a working table, a polishing chamber, an adjusting device and a drying device, wherein the polishing chamber is arranged on the working table; the adjusting device is arranged on one side of the polishing chamber; the drying device is arranged on the other side of the polishing chamber; a polishing device is arranged in the polishing chamber, and comprises polishing wheels, an adjusting mechanism and supporting plates; the polishing wheel is fixed between the two supporting plates; the supporting plates are connected with the adjusting mechanism; a sucker gripper is fixed at the upper part in the polishing chamber, and comprises a telescoping mechanism, a sucker and suction holes; the adjusting device comprises a fixed case, an outside adjusting piece and an inside adjusting piece; and a control and adjustment system is arranged on the polishing chamber. The polishing mechanism has the advantages of being simple in structure, not only improving the stability and the continuity in operation of the polishing mechanism, but also ensuring the polishing effect of the polishing mechanism, being convenient and simple to use, reducing noise and pollutants generated in cutting, reducing pollutant discharge through a collecting effect of a sewage collection basin, being remarkable in effect and improving the operating efficiency.

Owner:SHENGZHOU HUANDING GLASS TECH CO LTD

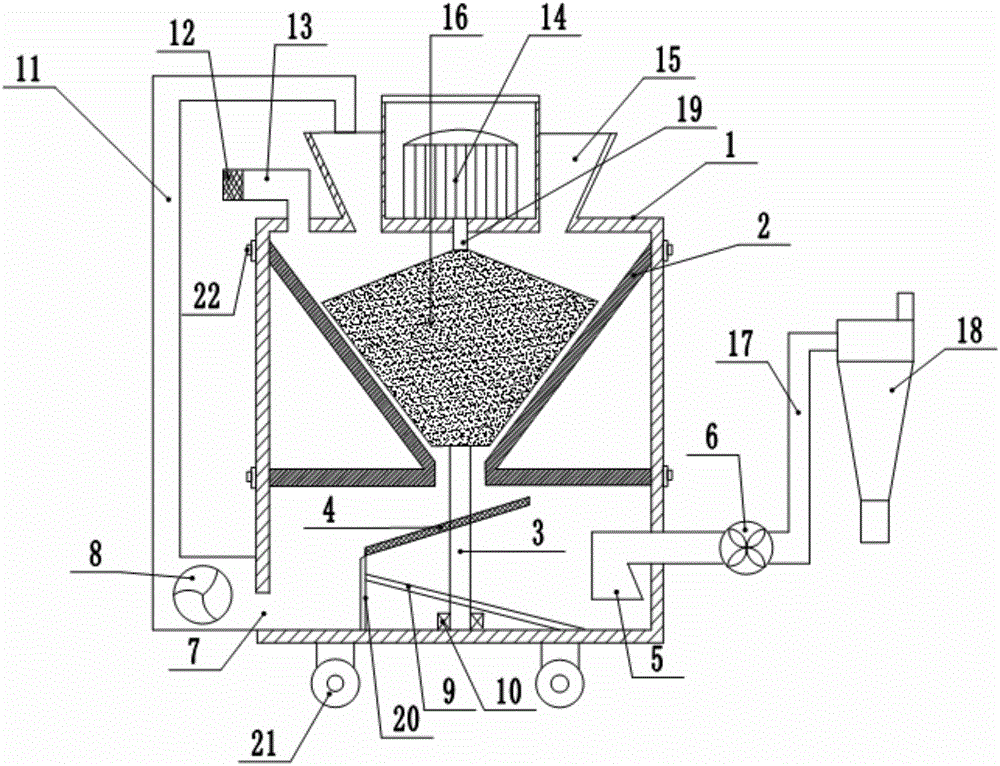

Grinding device for calcium carbonate powder

ActiveCN109174415AAchieve smashAchieve dryingDrying gas arrangementsDrying solid materialsEngineeringSieve

The invention discloses a grinding device for calcium carbonate powder. The grinding device comprises a casing, wherein a feeding inlet is arranged on the casing; and the feeding inlet is connected with a screw feeder. The grinding device is characterized by further comprising a cyclone separator and a heater. The casing is internally and sequentially provided with a guiding plate, a first grinding sieve plate and a second grinding sieve plate from top to bottom, and the guiding plate, the first guiding sieve plate and the second grinding sieve plate divide the interior of the casing into fourareas; the four areas sequentially include the smashing area, the first grinding area, the second grinding area and the storage area from up to down; the smashing area is internally provided with a smashing device; the first grinding area is provided with a first grinding device; the second grinding area is provided with a second grinding device; the four areas communicate with the cyclone separator; the cyclone separator is connected with the heater; and an outlet of the heater communicates with the four areas. The grinding device can smash and then grind calcium carbonate, dry the powder during grinding, and effectively prevent the dust in the grinding device from leaking.

Owner:石棉县亿欣钙业有限责任公司

Book perfect binding device with good gluing effect

PendingCN110154576AGuaranteed gluing effectGuaranteed grinding effectCasing-inBookbinding adhesiveMilling cutterEngineering

The invention discloses a book perfect binding device with a good gluing effect and belongs to the technical field of advertising and printing. The book perfect binding device comprises a worktable arranged along a front-back direction, and a book fixing structure, a facing cutter, a primer structure and a side glue structure on the worktable. A left clamping plate and a right clamping plate are arranged on the book fixing structure, two milling cutter baffle plates capable of sliding left and right are arranged above the facing cutter on the worktable, and guide bars are arranged on the frontand back sides of the bottoms of the left and right clamping plates along the front-back direction; horizontal front eccentric distracting wheels are arranged on the milling cutter baffle plates; theside glue structure comprises a side glue pot, two sliding plates slidably arranged left and right on the worktable above the side glue pot, back eccentric distracting wheels horizontally arranged onthe sliding plates and side gluing wheels, the lower parts of which are immersed into the side glue pot, on the sliding plates. According to the device, the side gluing wheels are arranged on the sliding plates capable of sliding left and right, and the eccentric distracting wheels matched with the guide bars on the front and back sides of the clamping plate are arranged on the sliding plates andthe milling cutter baffle plates for distracting the book fixing structure in advance before the book fixing structure passes through and / or distracting the book fixing structure when the book fixingstructures passes through.

Owner:麻城市阳光传媒印务有限公司

Cement grinding device capable of processing cement of different particle sizes

InactiveCN105750008AQuality assuranceLong milling timeGrain treatmentsCement grindingPolymer chemistry

The invention discloses a cement grinding device capable of processing cement of different particle sizes. The cement grinding device comprises a grinding box, wherein a discharge port is formed at the upper end of the grinding box; a rotation motor is arranged at the center of the discharge port; a grinding cone body is connected below the rotation motor through a first rotation shaft, wherein the diameter of the cross section of the grinding cone body is gradually reduced from top to bottom; grinding walls are arranged on the two sides of the grinding cone body; chutes and scale marks are arranged on the two side walls of the grinding box; the positions of the grinding walls on the two side walls of the grinding box can be changed by loosening / tightening screws on the chutes; the two side surfaces of the grinding cone body are grinding working surfaces; the two grinding working surfaces of the grinding cone body are parallel to the working surfaces of the grinding walls on the two sides respectively; the lower end of the grinding cone body is connected with a second rotation shaft; the bottom of the second rotation shaft is connected with a bearing in a rotating mode; and an oblique vibratory grid plate with right end higher than left end is arranged at the lower end of the grinding wall. The device has the advantages of high quality, high grinding efficiency and high automation degree in cement grinding production.

Owner:广西建筑材料科学研究设计院有限公司

Steel structure painting process

ActiveCN111097630AImprove work efficiencyEasy to transportGrinding drivesPretreated surfacesRoller millManufacturing engineering

The invention relates to the technical field of steel structure painting, and discloses a steel structure painting process. The process comprises the following steps that S1, a steel structure is clamped through a clamp, and then the steel structure is conveyed into a painting box through a sliding rail; S2, the positions of roller grinding mechanisms on the two sides of the painting box are adjusted till the distance between the roller grinding mechanisms is equal to the thickness of the steel structure; S3, the roller grinding mechanisms are started, then the steel structure is conveyed to the position between the roller grinding mechanisms, and the steel structure is ground through the roller grinding mechanisms; S4, the steel structure is conveyed to a painting assembly through the roller grinding mechanisms, and the two sides of the steel structure are painted through the painting assembly until the surfaces of the two sides of the steel structure are covered with paint; and S5, the steel structure is conveyed to an air injection assembly, the air injection assembly is rotated to face the steel structure, and paint on the steel structure is blown to be dry through the air injection assembly. The process is simple in method, the steel structure can be rapidly painted, and the painting efficiency of the steel structure is improved.

Owner:重庆实创钢结构有限公司

Grinding equipment for manufacturing superfine sand from waste bricks and tiles

The invention relates to grinding equipment for manufacturing superfine sand from waste bricks and tiles, and belongs to the technical field of grinding equipment. A crushing device for preliminarily crushing the waste bricks and tiles is mounted on a machine box, a first grinding device and a second grinding device for grinding the preliminarily crushed waste bricks and tiles are mounted in the machine box, a winnowing device is mounted in the machine box, and a material returning device in butt joint with the winnowing device and the crushing device is mounted on the machine box. According to the grinding equipment, after preliminarily crushed, the waste bricks and tiles are ground in the machine box through the first grinding device and the second grinding device which are different in structure, the superfine sand can be separated and discharged in the winnowing process under winnowing of the winnowing device, due to the fact that the weight of sand which is not fine enough is larger than that of the superfine sand, deviation is not enough after winnowing, the sand falls back into the material returning device to be ground again until the superfine sand is formed, in the whole process, it can be guaranteed that all the materials form the superfine sand, different driving directions are adopted for the first grinding device and the second grinding device during grinding, and the grinding effect is guaranteed.

Owner:中科世纪联绿生态环境(北京)有限公司

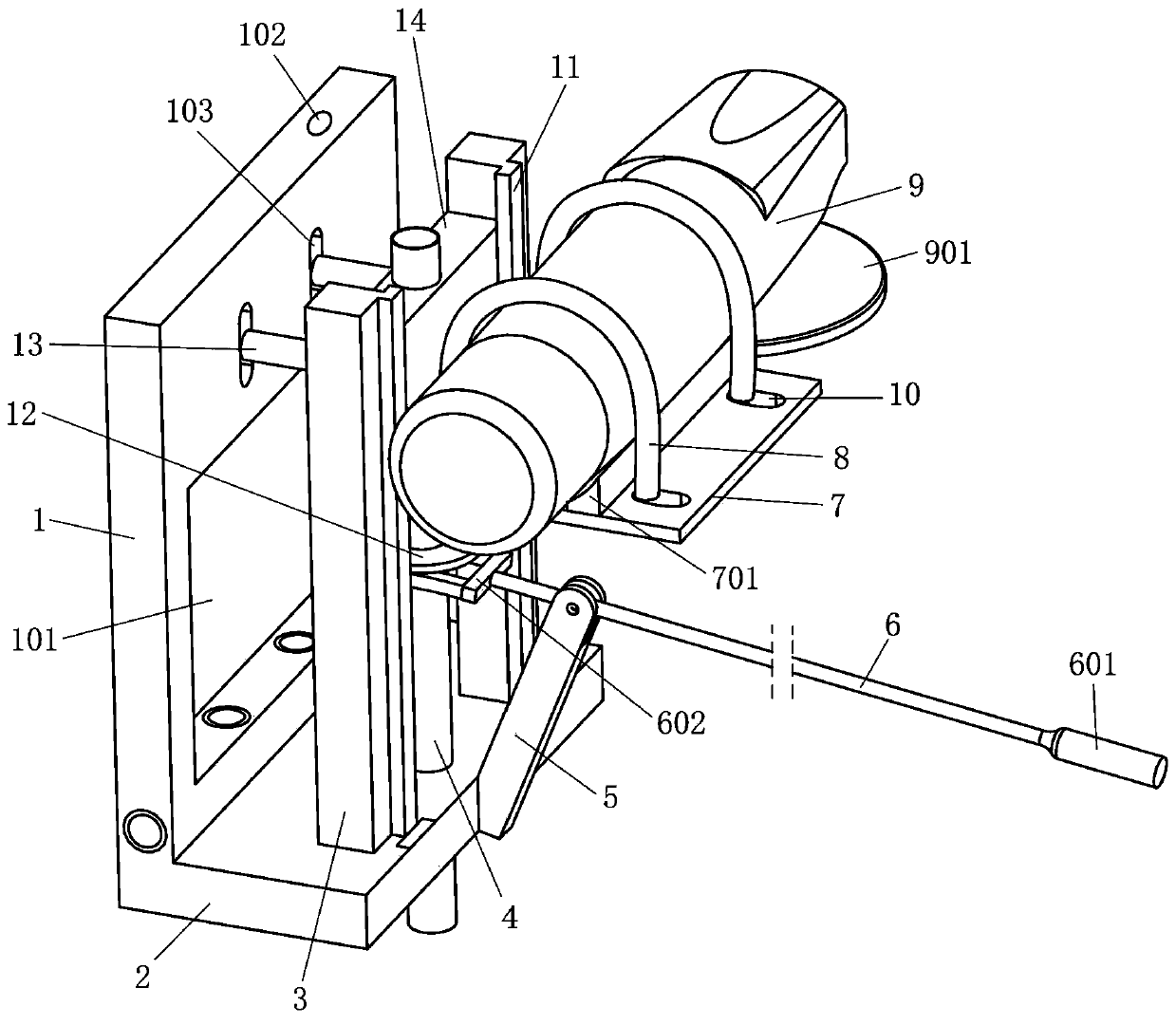

Grinding device of valve seat of butterfly valve

PendingCN110450015AGuaranteed grinding effectGrind evenlyGrinding drivesSeat surface grinding machinesEngineeringButterfly valve

The invention discloses a grinding device of a valve seat of a butterfly valve. The grinding device comprises a grinding barrel. The grinding barrel is in an inverted circular table shape, wherein theinterior of the inverted circular table shape is hollow, and an opening is formed in the upper end of the inverted circular table shape. A main shaft which is through up and down is arranged in the center of the grinding barrel. A drive head is connected to the upper end of the main shaft, and the main shaft is connected with the grinding barrel through a reinforcing plate. The circumferential lower side of the grinding barrel is in sleeved connection with a valve seat support inclined towards one side. A mounting groove for containing the valve seat is formed in the inner side of the circumferential upper end of the valve seat support, and a valve seat fixing mechanism for fixing the valve seat is arranged on the mounting groove. The main shaft can rotate around a spring, the lower end of the spring is mounted on an upper plate of the support, and a cam mechanism capable of promoting the main shaft to move up and down is mounted on a bottom plate of the support. A speed adjusting motor drives a cam to rotate, and therefore the main shaft is driven to move up and down, the main shaft and the grinding barrel are supported by the spring, and therefore the valve seat moves up and down while rotate circumferentially, the grinding effect is guaranteed, it is guaranteed that grinding of the inner wall of the valve seat is more uniform, and the sealing effect is better.

Owner:SHANGHAI KOKO VALVE GRP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com