Grinding device for calcium carbonate powder

A technology of calcium carbonate powder and grinding device, which is applied in the direction of drying gas arrangement, drying solid material, drying machine, etc., which can solve the problems of air leakage, air pollution, inability to crush, grind and dry calcium carbonate, and prevent leakage Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

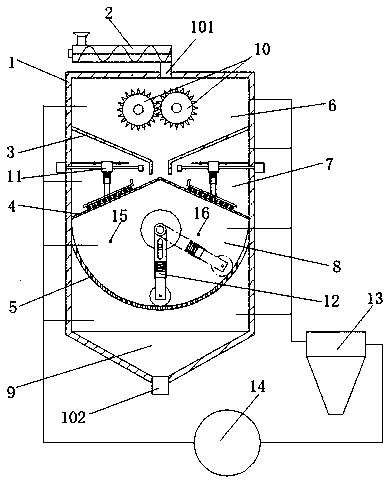

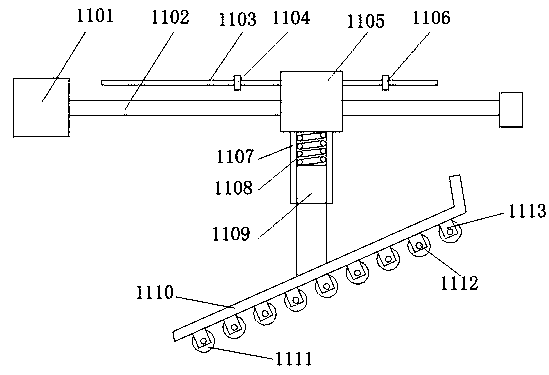

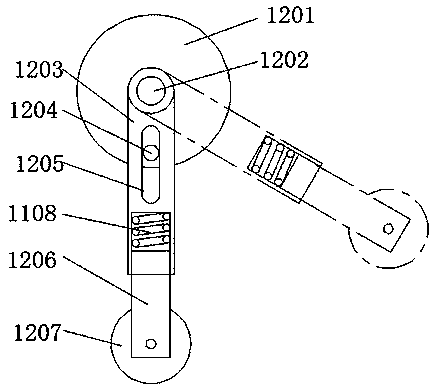

[0023] This embodiment includes a casing 1, a feed port 101 is provided on the casing 1, a discharge port 102 is provided at the bottom of the casing 1, and a screw feeder 2 is connected to the feed port 101. This embodiment also includes a cyclone separator 13 and heater 14, the housing 1 is provided with a guide plate 3, a first grinding sieve plate 4, and a second grinding sieve plate 5, which divide the interior of the housing 1 into four areas from top to bottom, so From top to bottom, the four areas are the scrap area 6, the first grinding area 7, the second grinding area 8 and the storage area 9. The scrap area 6 is equipped with a shredding device, and the first grinding area 7 is provided with The first grinding device, the second grinding area 8 is provided with a second grinding device 12, the four areas are all connected to the cyclone separator 13, the cyclone separator 13 is connected with a heater 14, and the outlet of the heater 14 is connected to the The four a...

Embodiment 2

[0030] This embodiment is further optimized on the basis of embodiment 1. In this embodiment, the connection position of the first grinding sieve plate 4 and the housing 1 is provided with a return port, and the guide plate 3 and the housing 1 The connection position is provided with a return material inlet, and the return material inlet is connected with the return material inlet through the first screw feeder.

[0031] The principle of the present invention is as follows:

[0032] First, the material is fed by the screw feeder 2, the calcium carbonate enters the crushing area 6 and is crushed by the crushing device; then it enters the first grinding area 7 and is ground by the first grinding device for one level; then it enters the second grinding area 8 through the second grinding device 12 for secondary grinding, and finally into the storage area 9 for storage; from the scrap area 6 to the storage area 9, the heater 14 heats the air and enters the scrap area 6, The first grind...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com