Patents

Literature

42results about How to "To achieve the purpose of crushing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

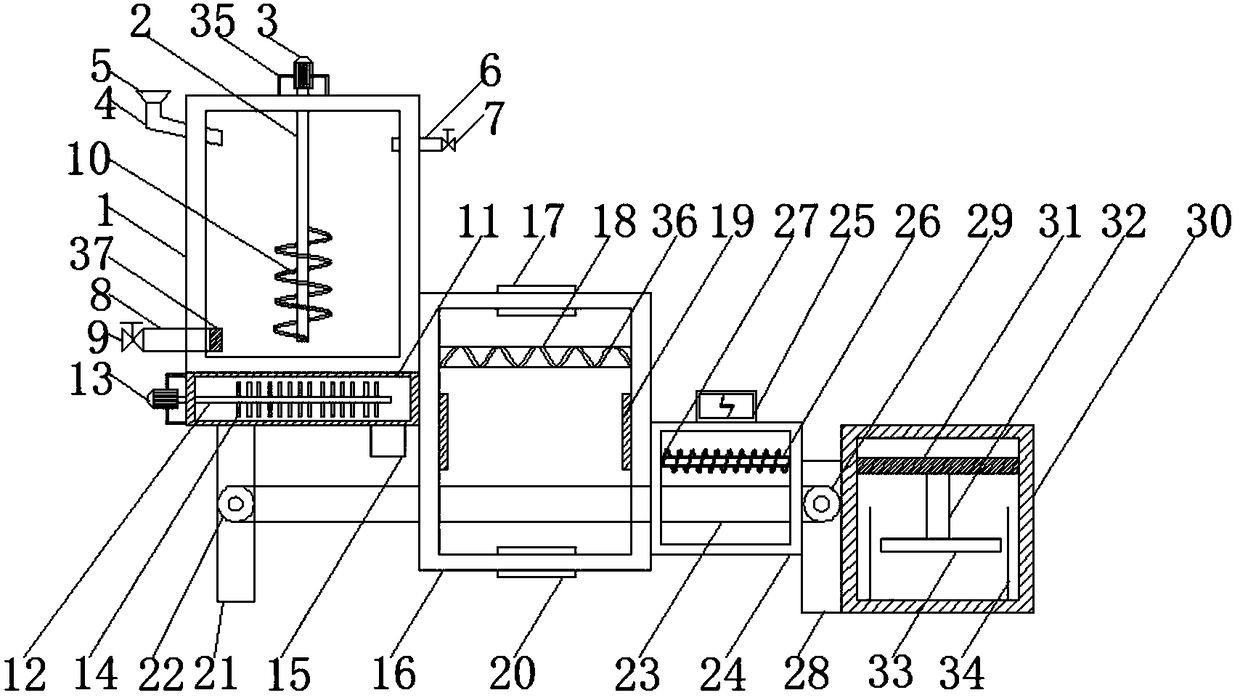

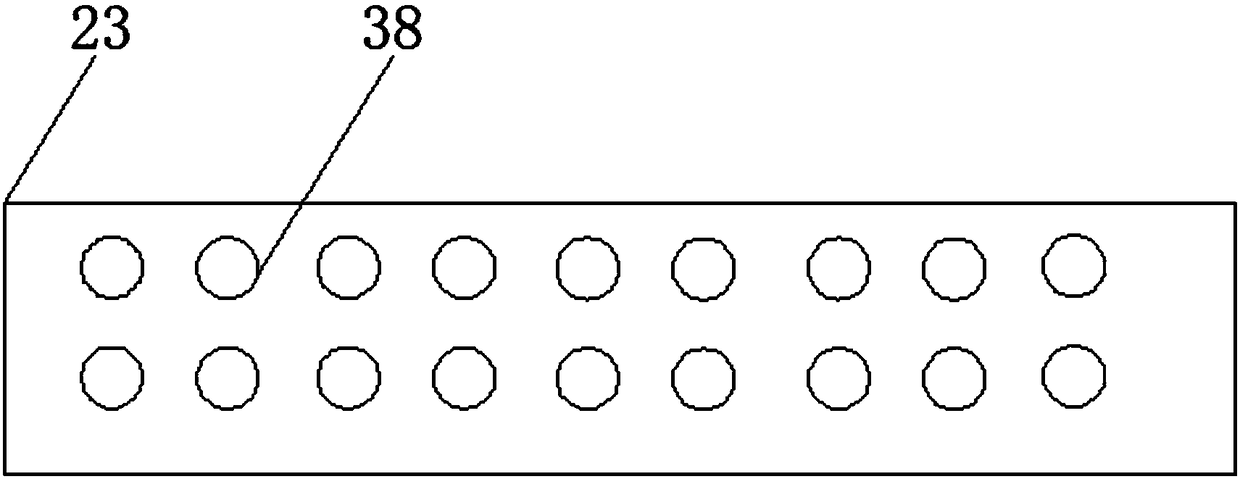

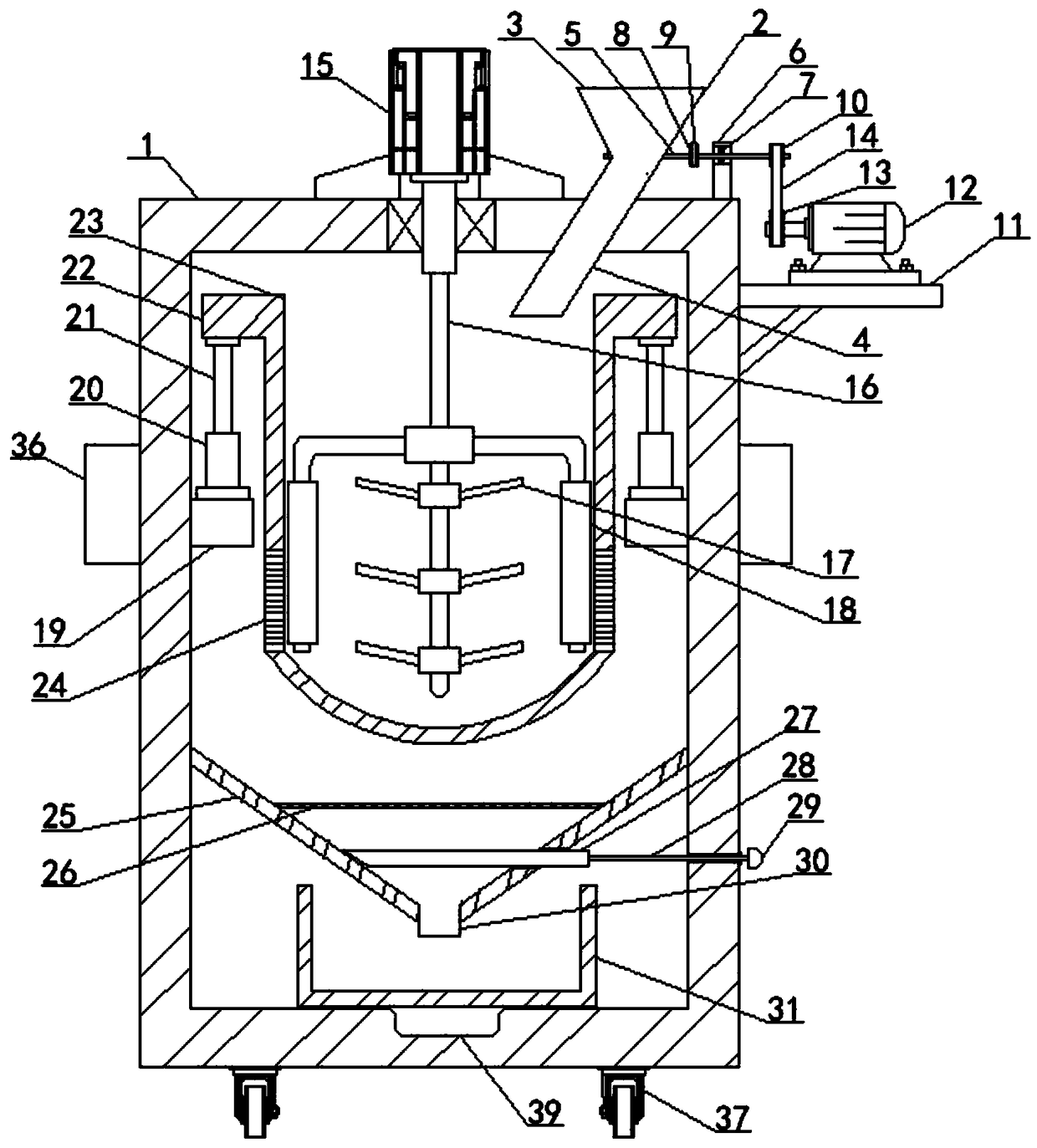

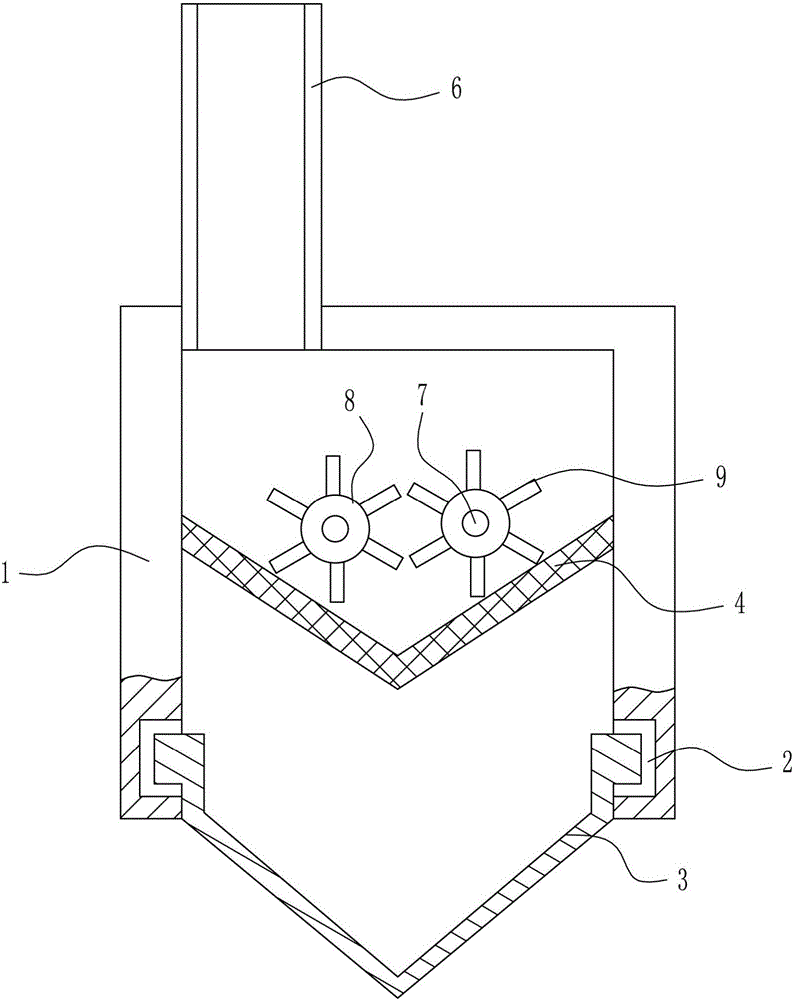

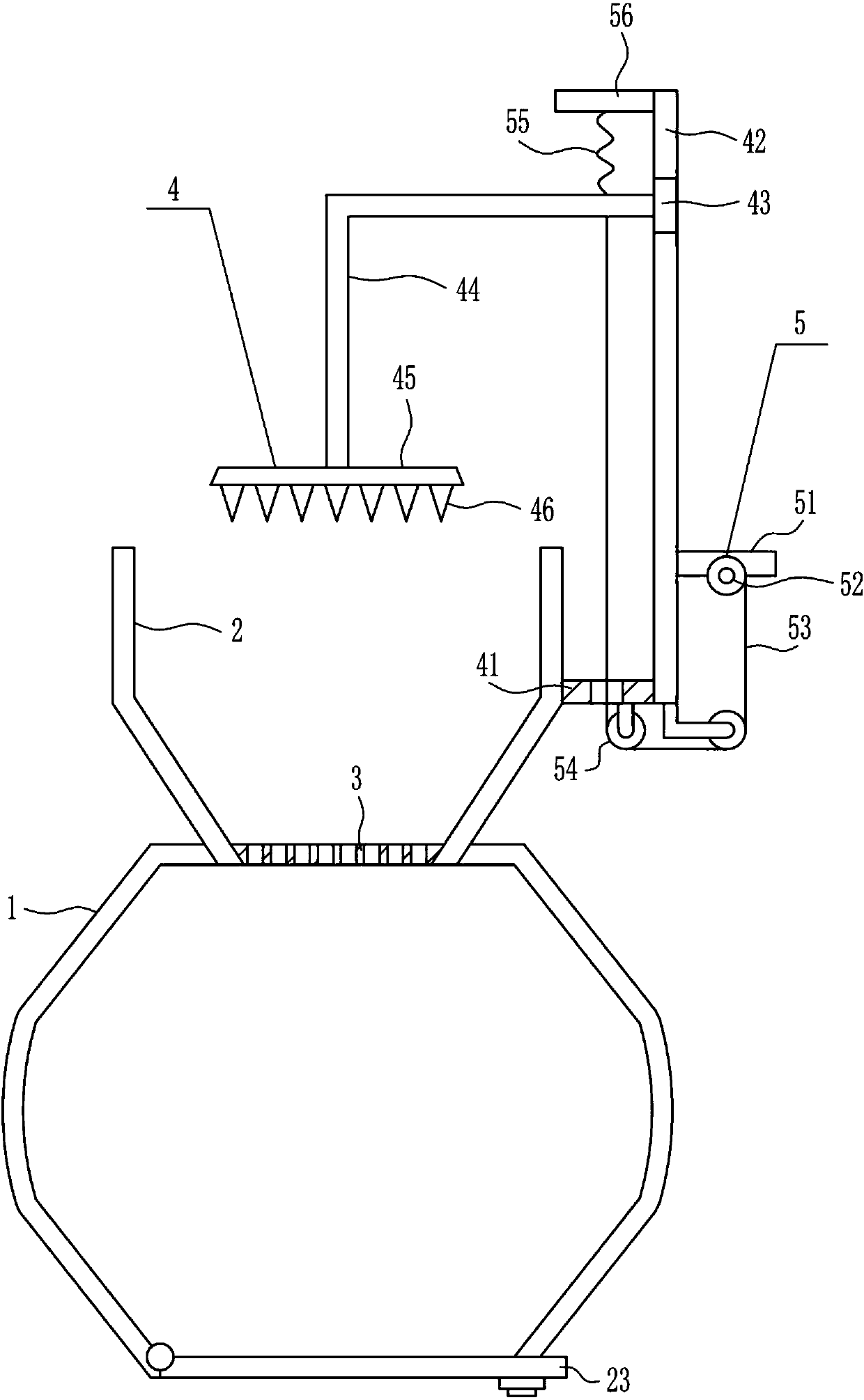

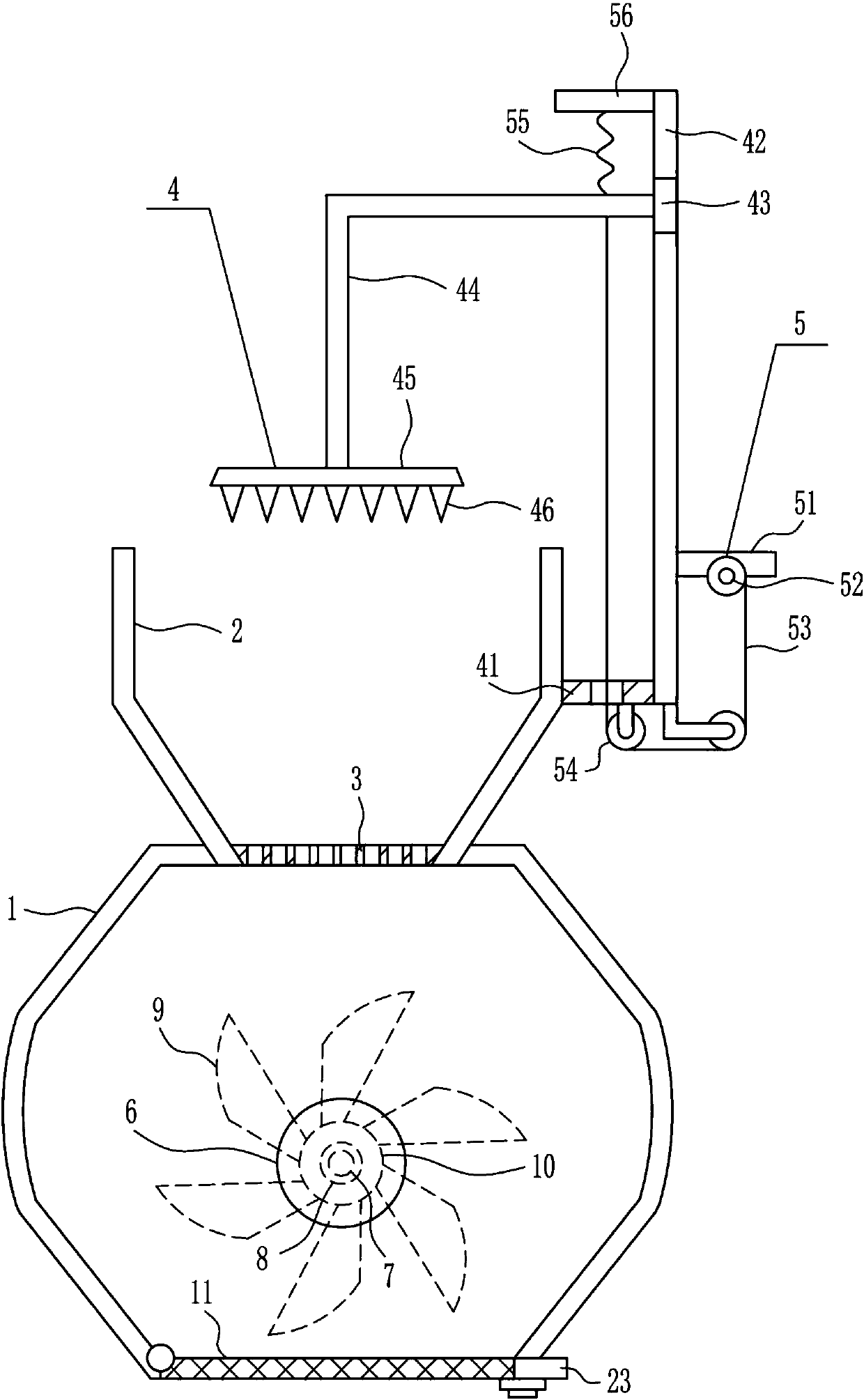

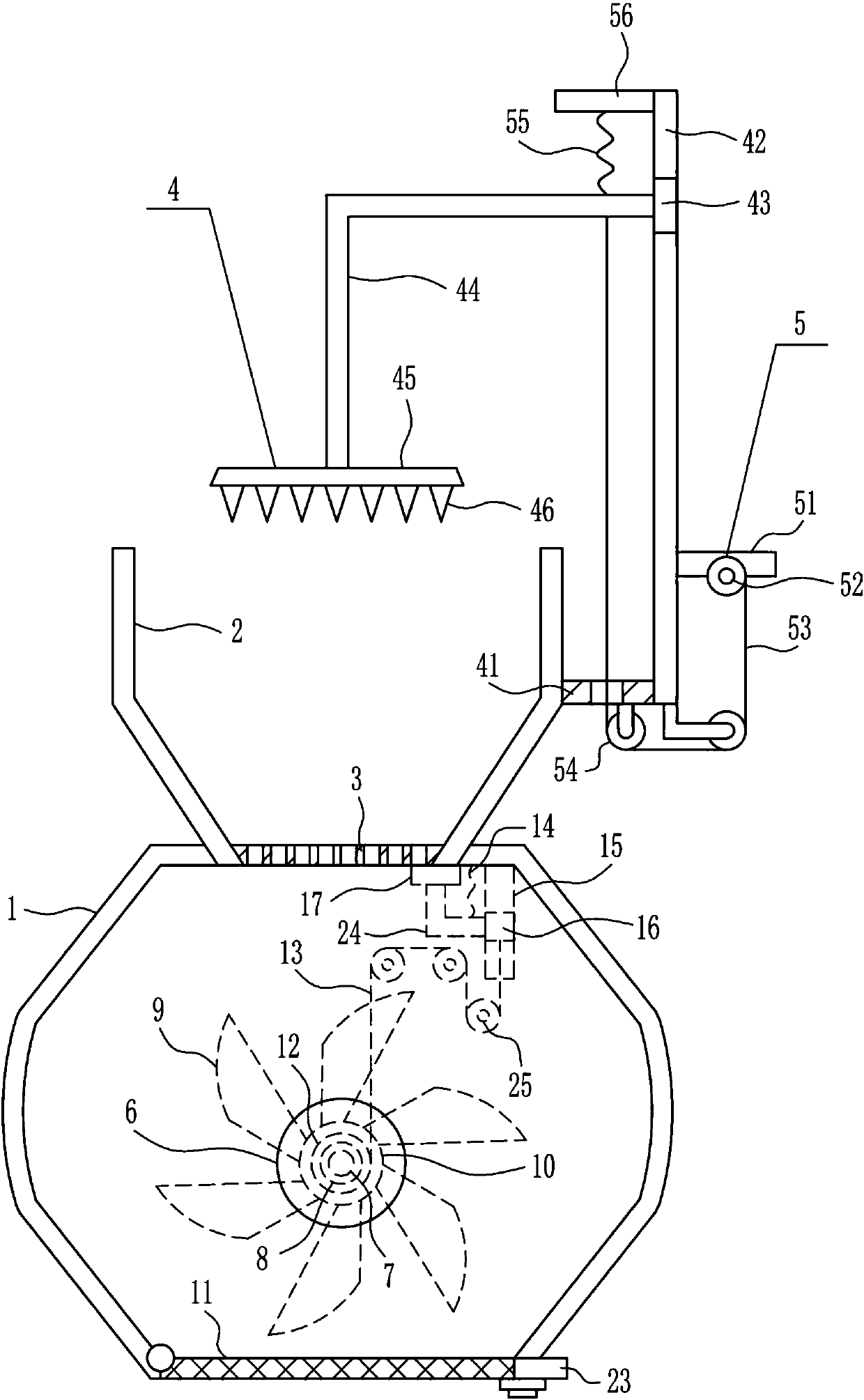

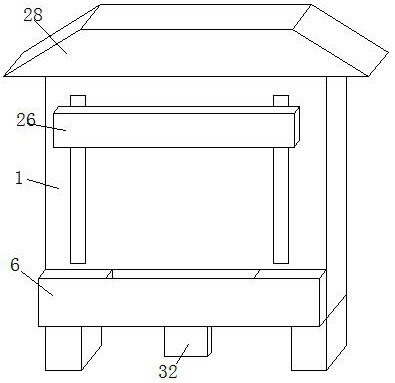

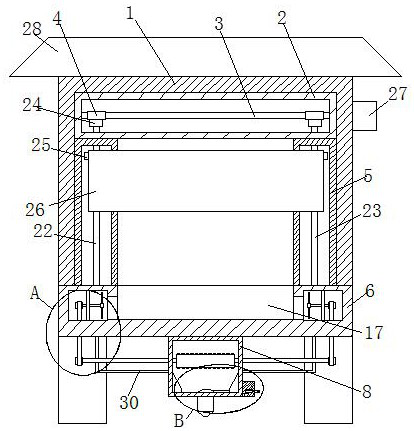

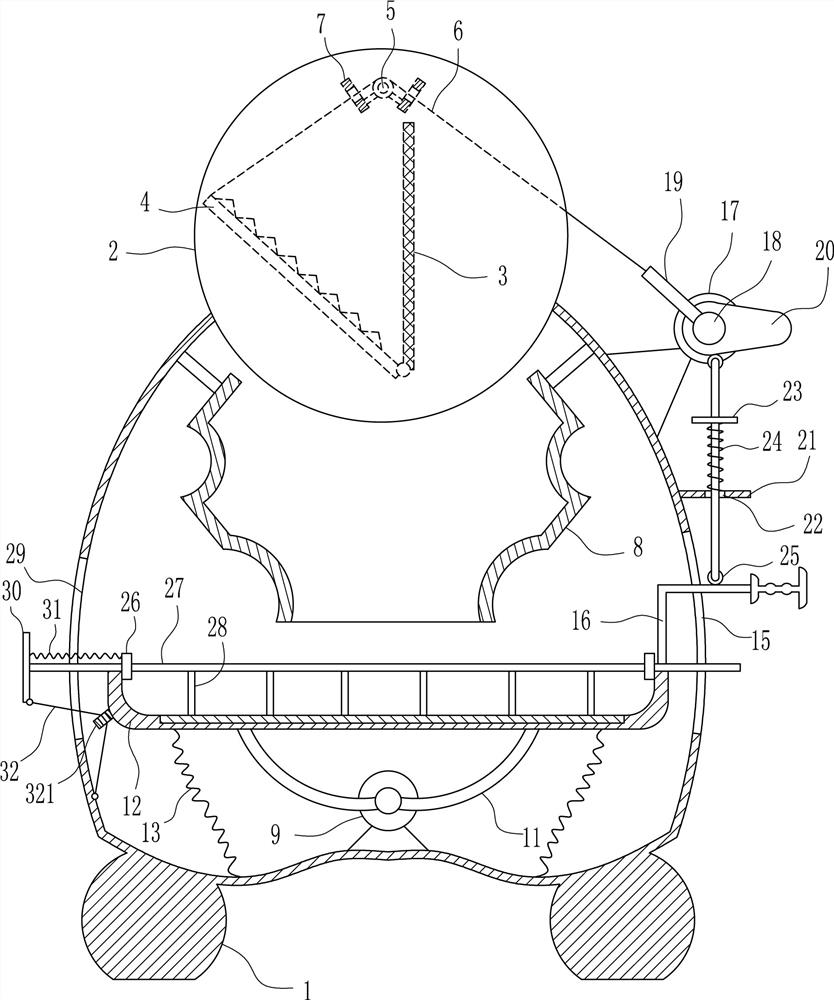

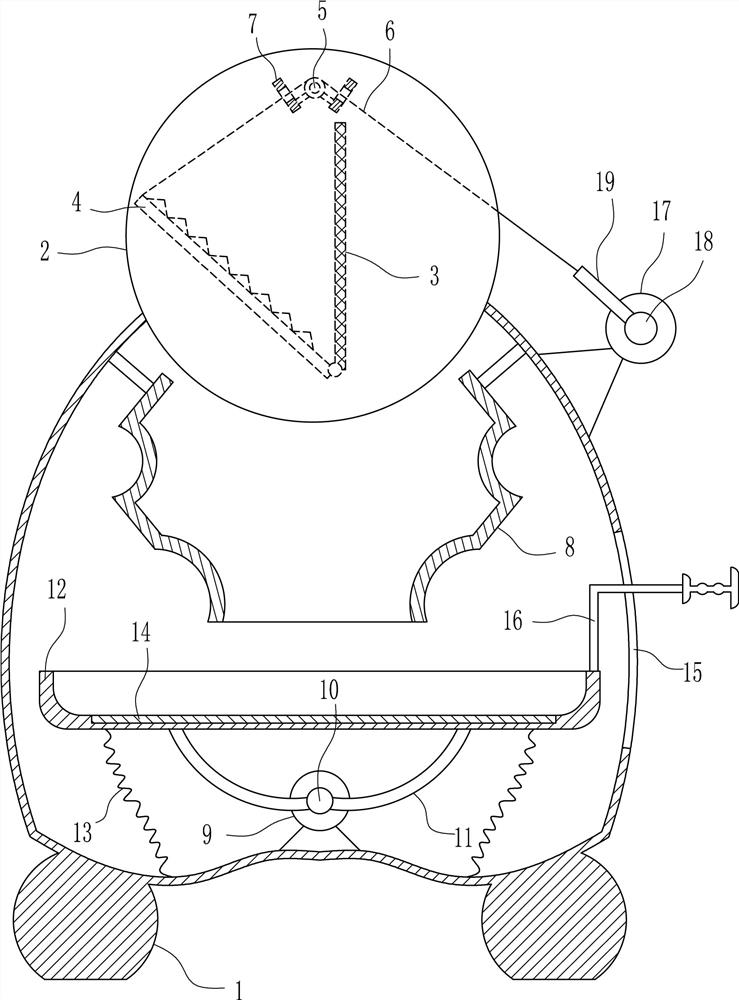

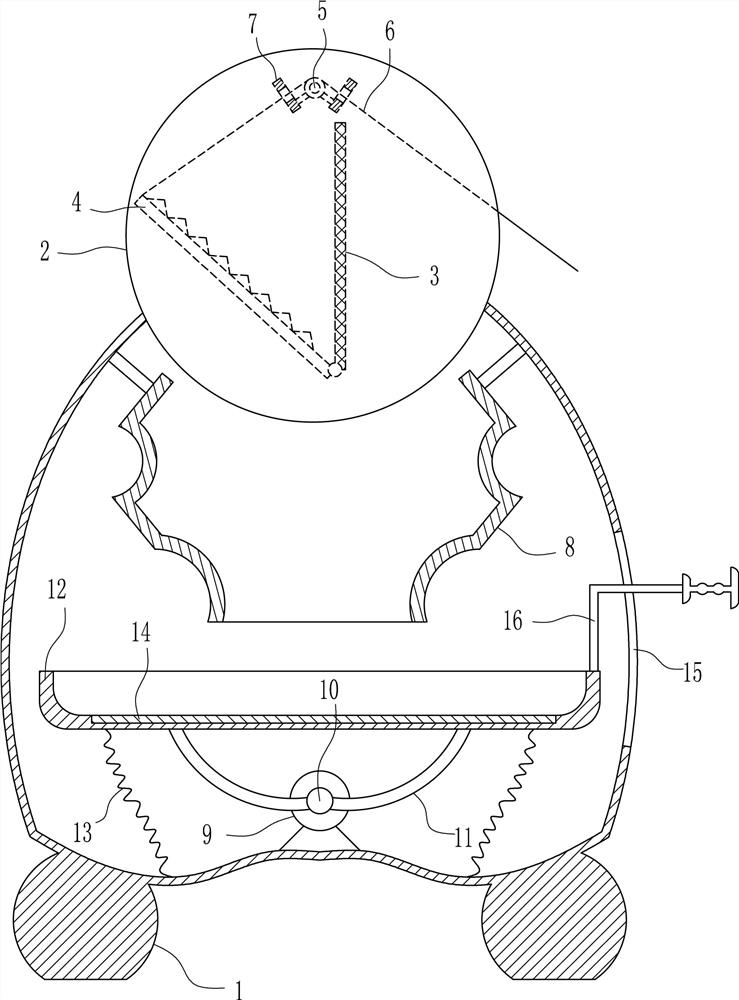

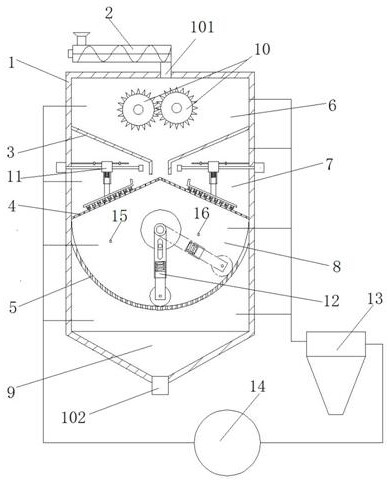

Urban waste recycling and treatment integrated device

InactiveCN109420657AEasy to rinseSolve the inconvenienceSolid waste disposalDrying gas arrangementsFiltrationEngineering

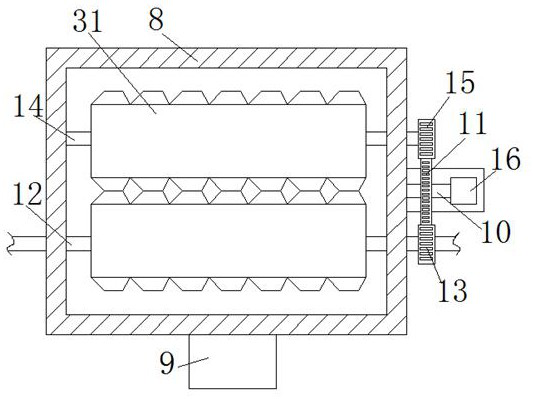

An urban waste recycling and treatment integrated device is disclosed, including a cleaning chamber. A stirring shaft penetrates and is connected to the top of the cleaning chamber. The top of the stirring shaft is connected to a first motor. A discharge pipe penetrates and is connected to the left bottom of the cleaning chamber. The bottom of the outer side of the stirring shaft is sleeved with astirring blade. The bottom of the cleaning chamber is connected with a crushing chamber. The outer side of a cutter shaft is connected to cutters in an equally spaced manner. The right side of the cleaning chamber is connected to a disinfection chamber, and the right side of the disinfection chamber is connected to a filtration chamber. Through combination of the disinfection chamber, an air blower, a heating tube, a heating wire and an exhaust fan, a problem that a high amount of bacteria and viruses are liable to breed when urban waste is mixed together is solved. Through the cleaning chamber, the stirring shaft, the first motor, a feeding pipe, a feeding hopper, the stirring blade, a water feeding pipe and a throttle valve, the problem of inconvenient handling of impurities such as medium and small-size sand and soil in urban waste is solved.

Owner:江苏佳鑫环保工程有限公司

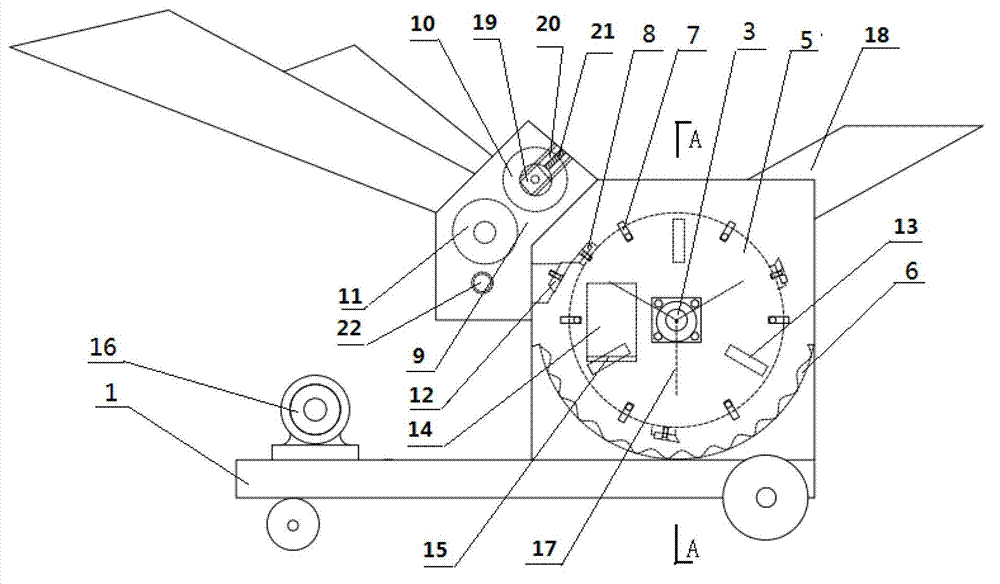

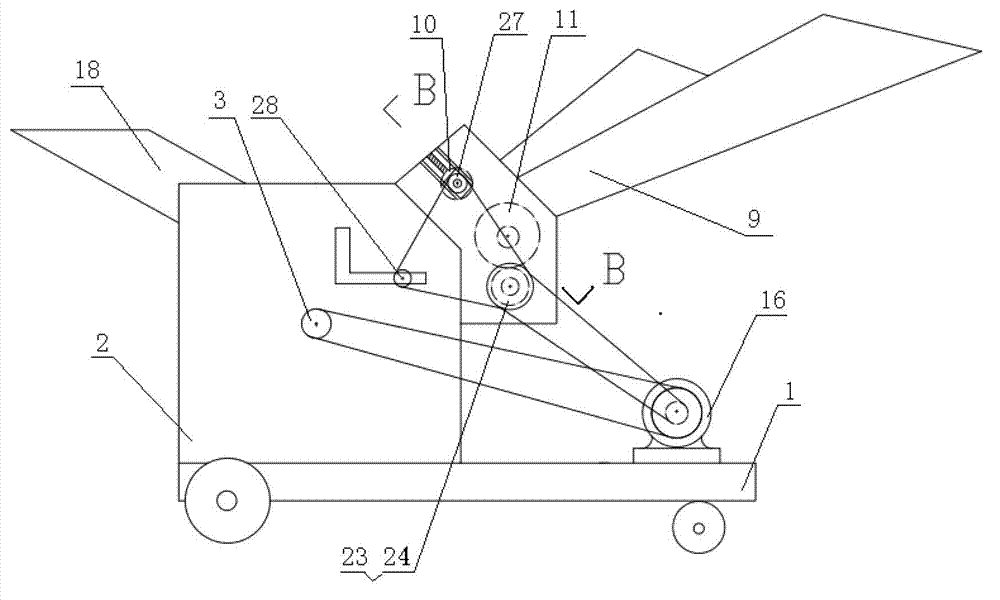

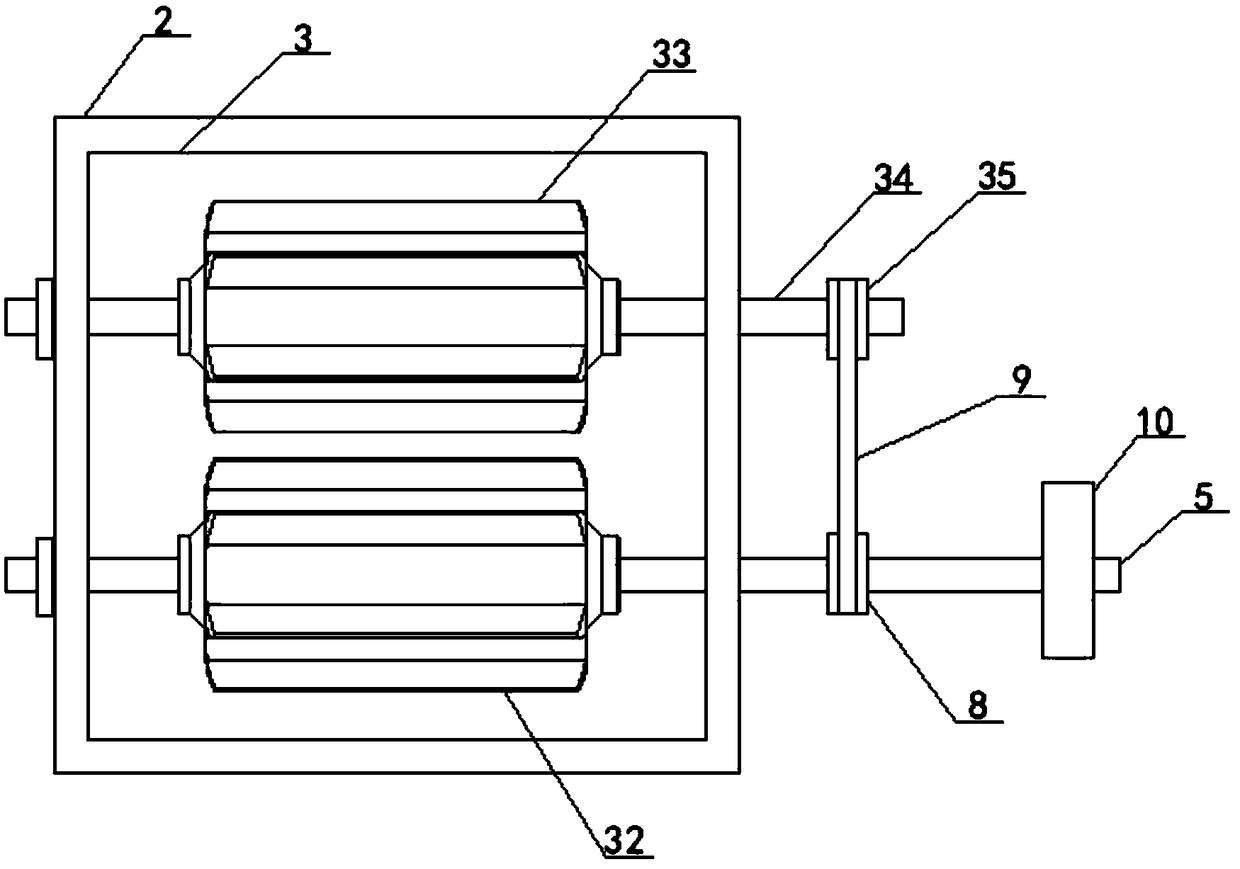

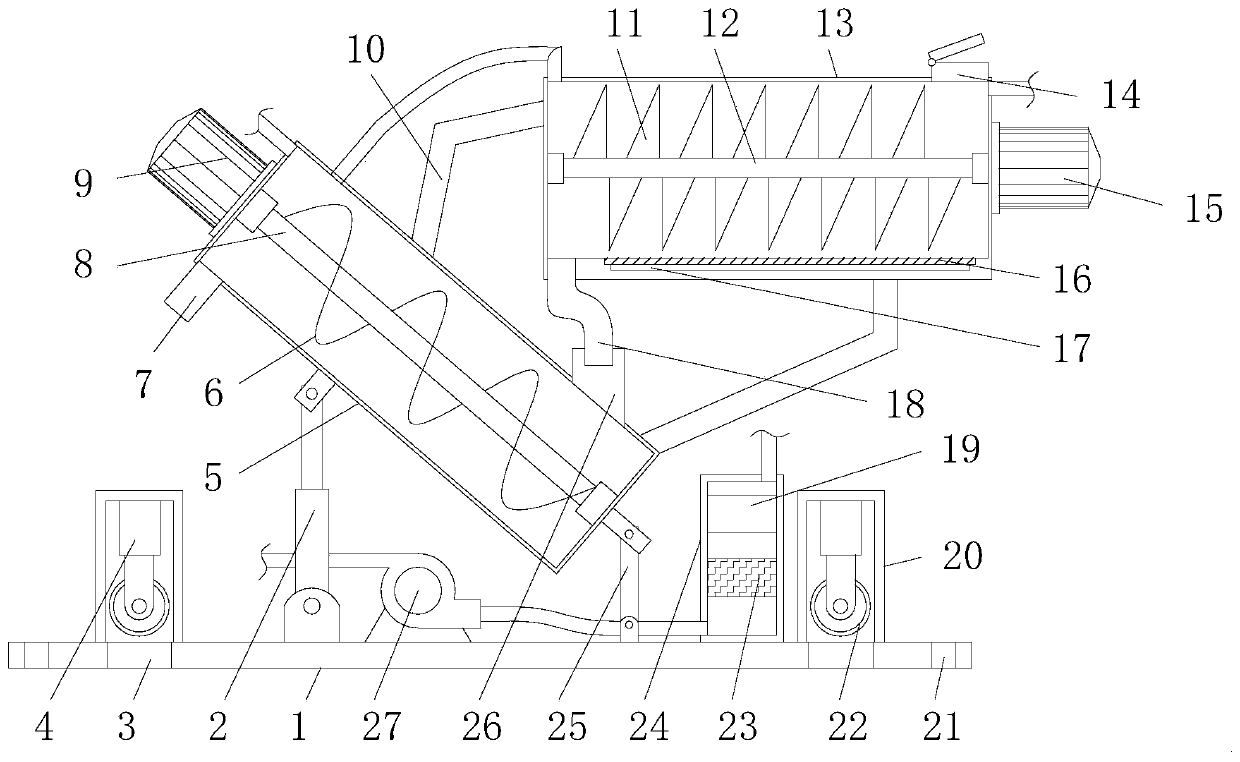

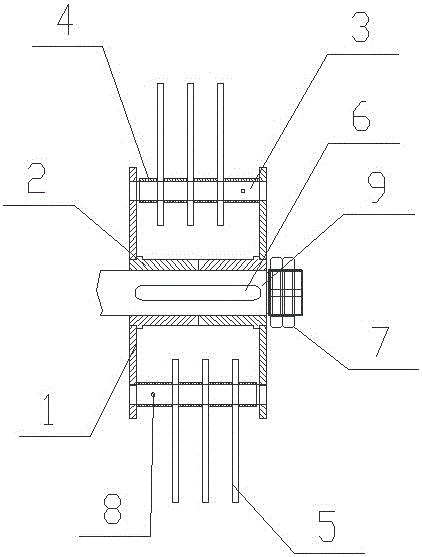

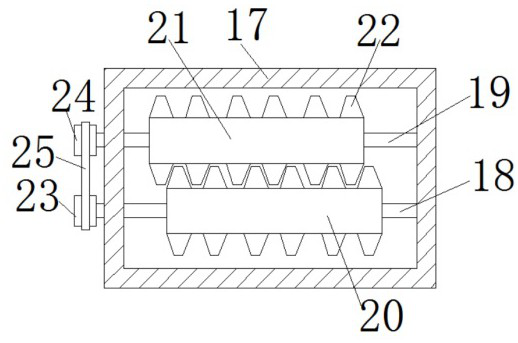

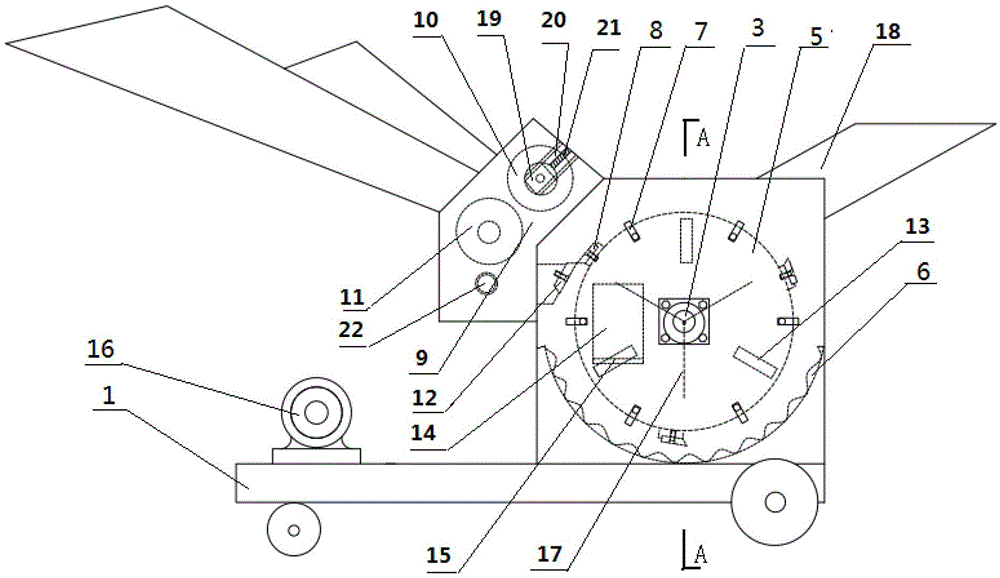

Branch slicing shredder

The invention relates to a branch slicing shredder. A shell and a motor are fixed on a base of the shredder, a round cutter I and a round cutter II are installed in the shell through a spindle, a jaw plate is fixed below the shell, hammer components uniformly distributed between the round cutter I and the round cutter II and a driving cutter are arranged in a stagger manner, an upper feed roller and a lower feed roller are installed on the main feed port of the shell, a main stationary knife is fixed below the main feed port, auxiliary moving cutters are uniformly distributed on the outer side surfaces of the round cutter II, a support plate is fixed below the side feed port of the shell, the motor is used for driving the spindle and the upper feed roller as well as the lower feed roller, and fan blades are installed in the shell through the spindle. According to the branch slicing shredder, the side plane of the round cutter II is used for locating so as to control the feeding length of a hard branch with large diameter, the moving cutters installed on the side plane of the round cutter II is used for planing and slicing, and both thick branches and thin branches can be fed smoothly through automatic regulation of the gap size of two feed rollers.

Owner:扶风永恒农牧机械制造有限责任公司

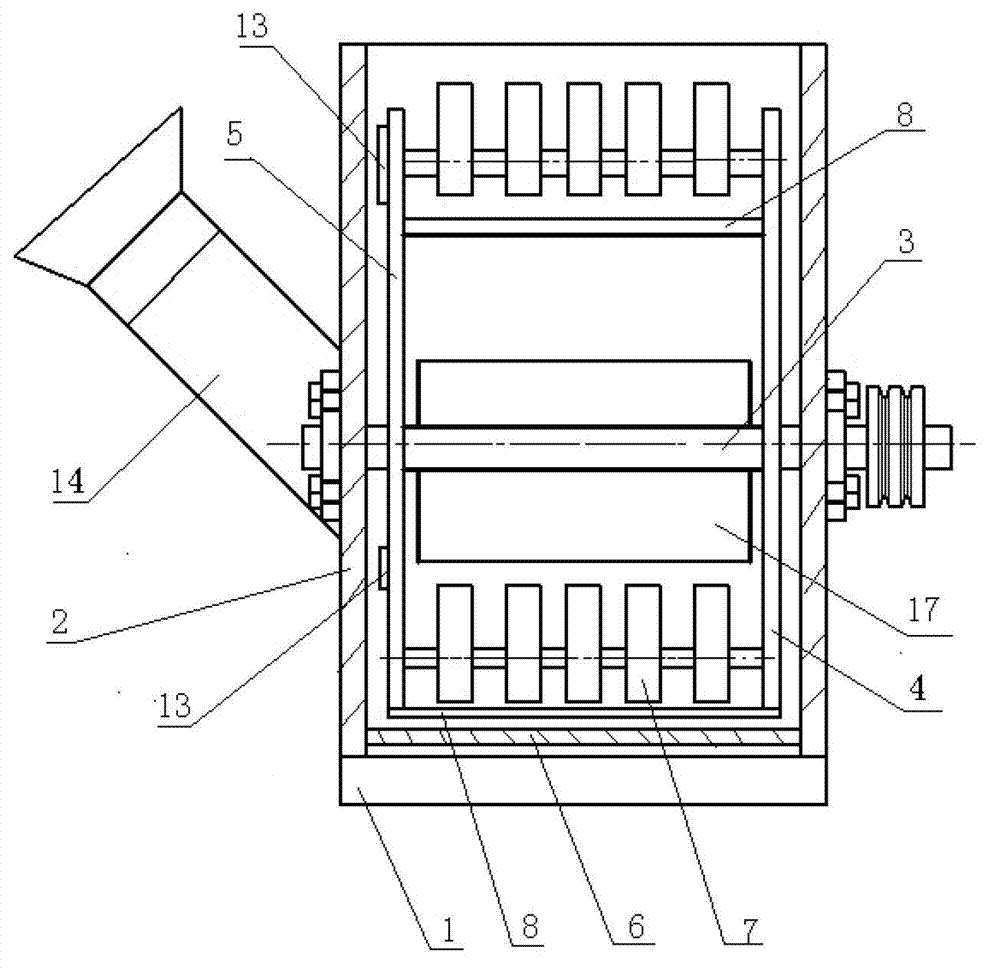

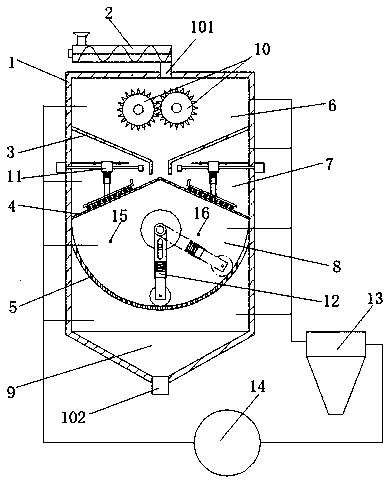

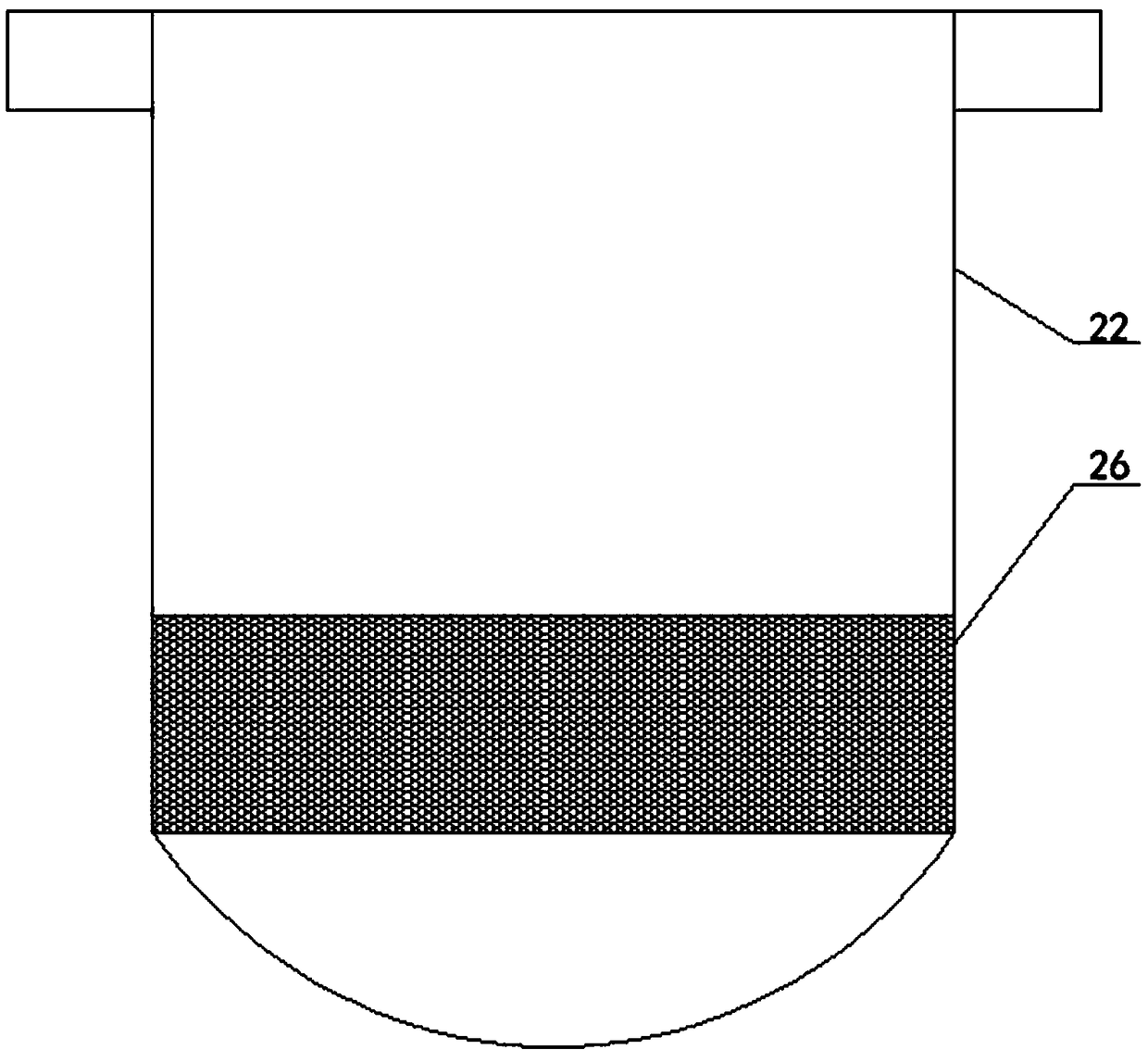

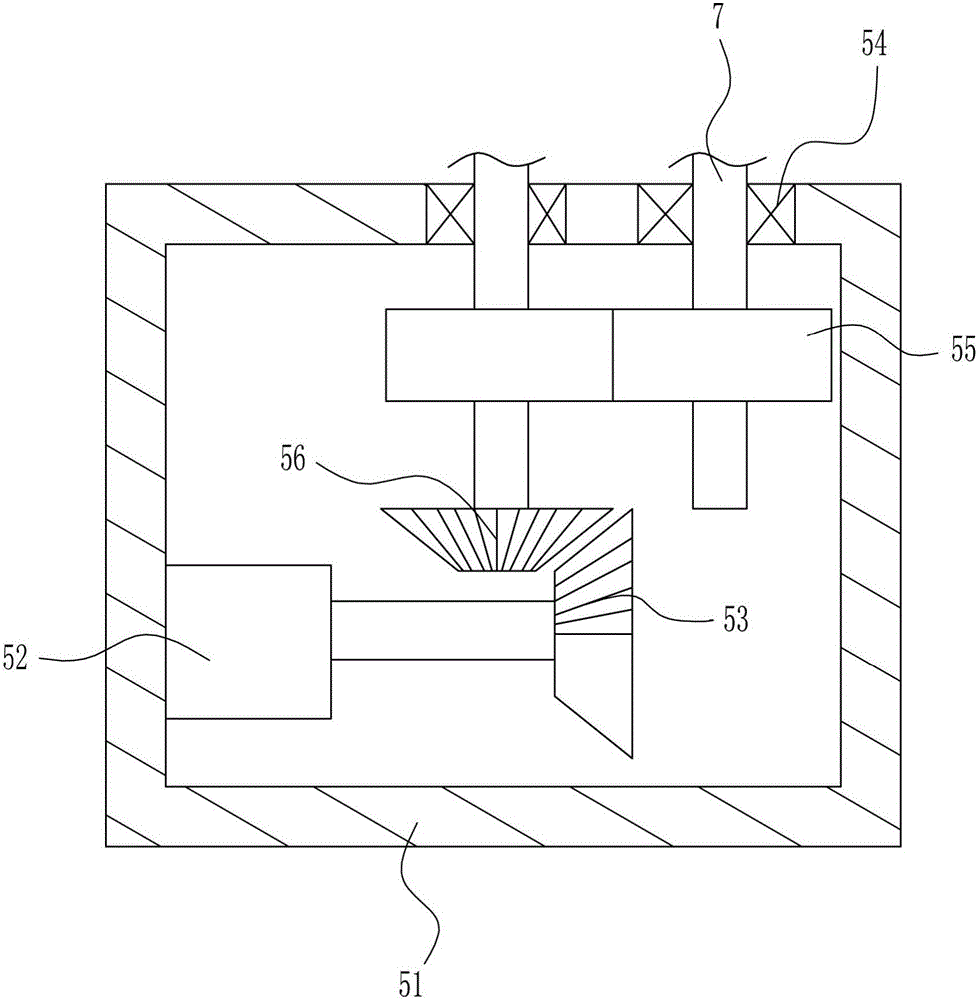

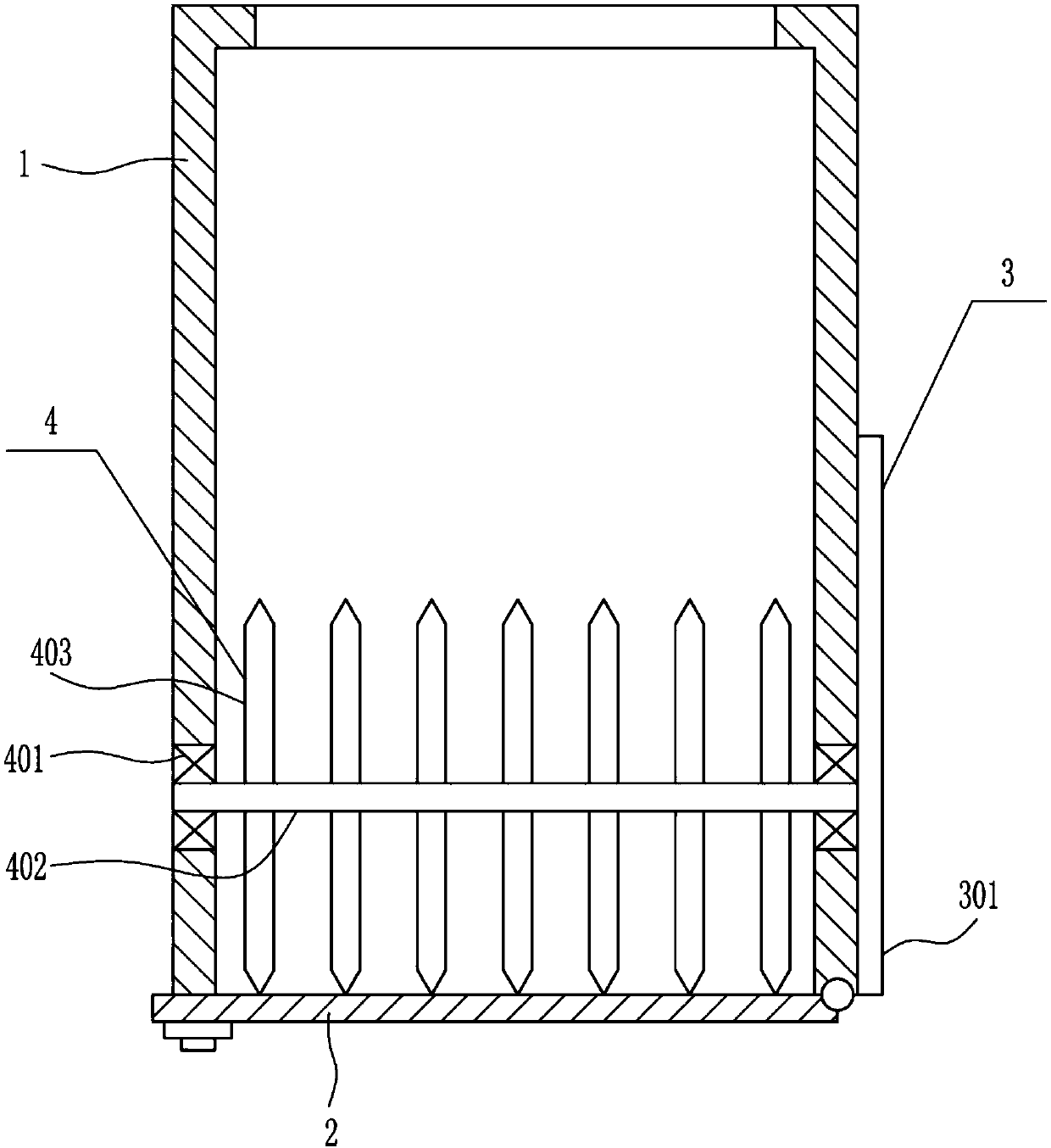

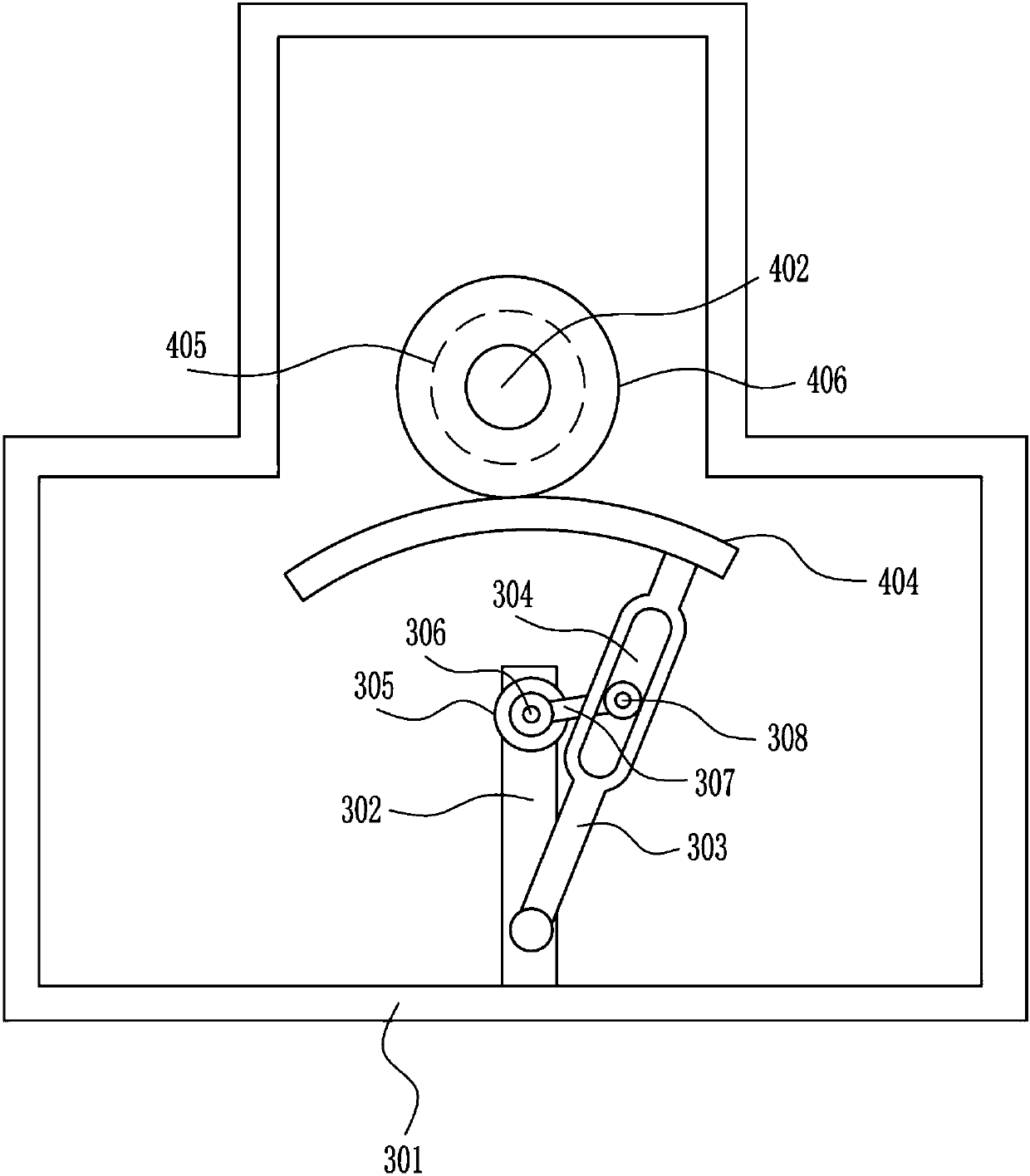

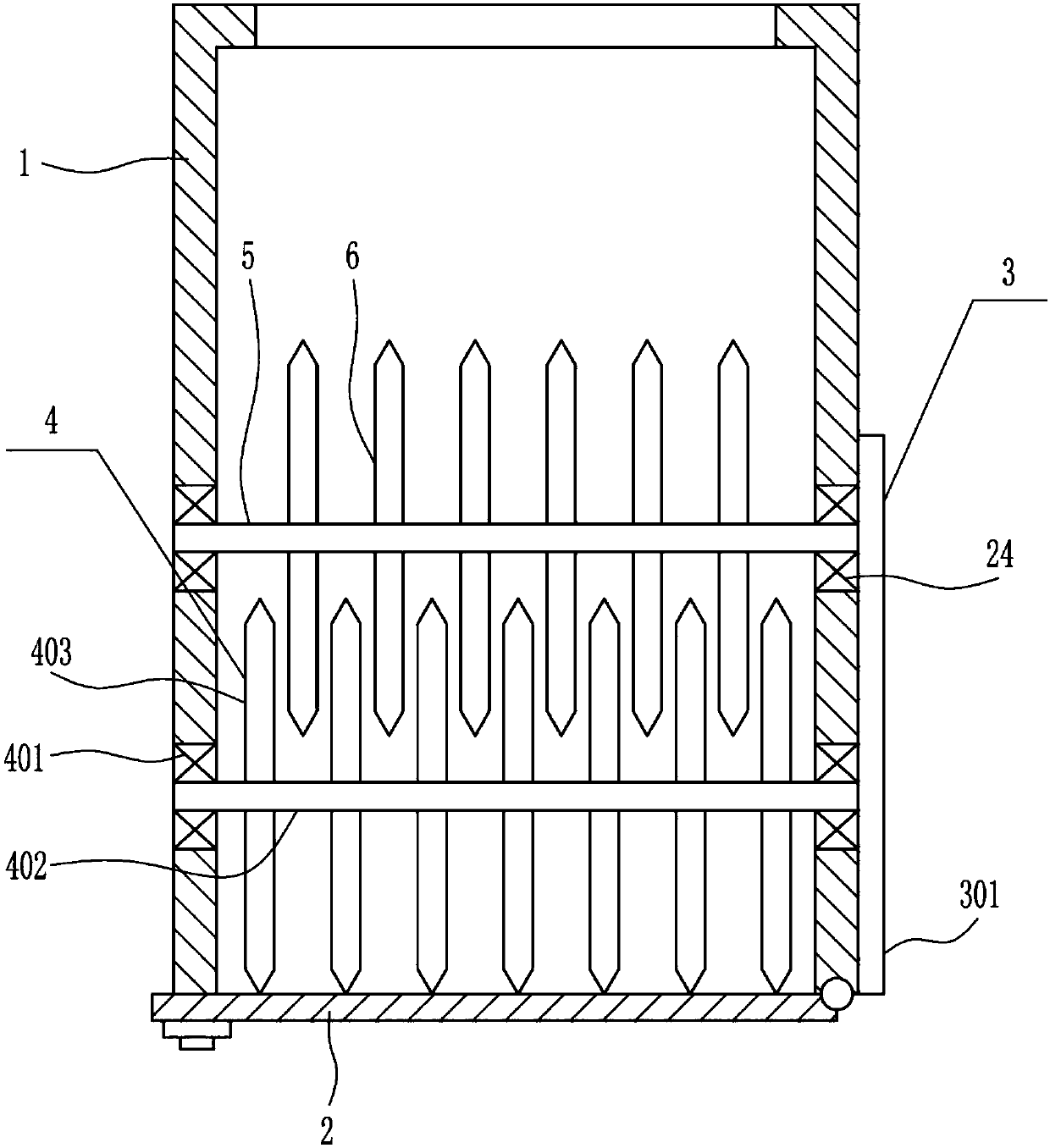

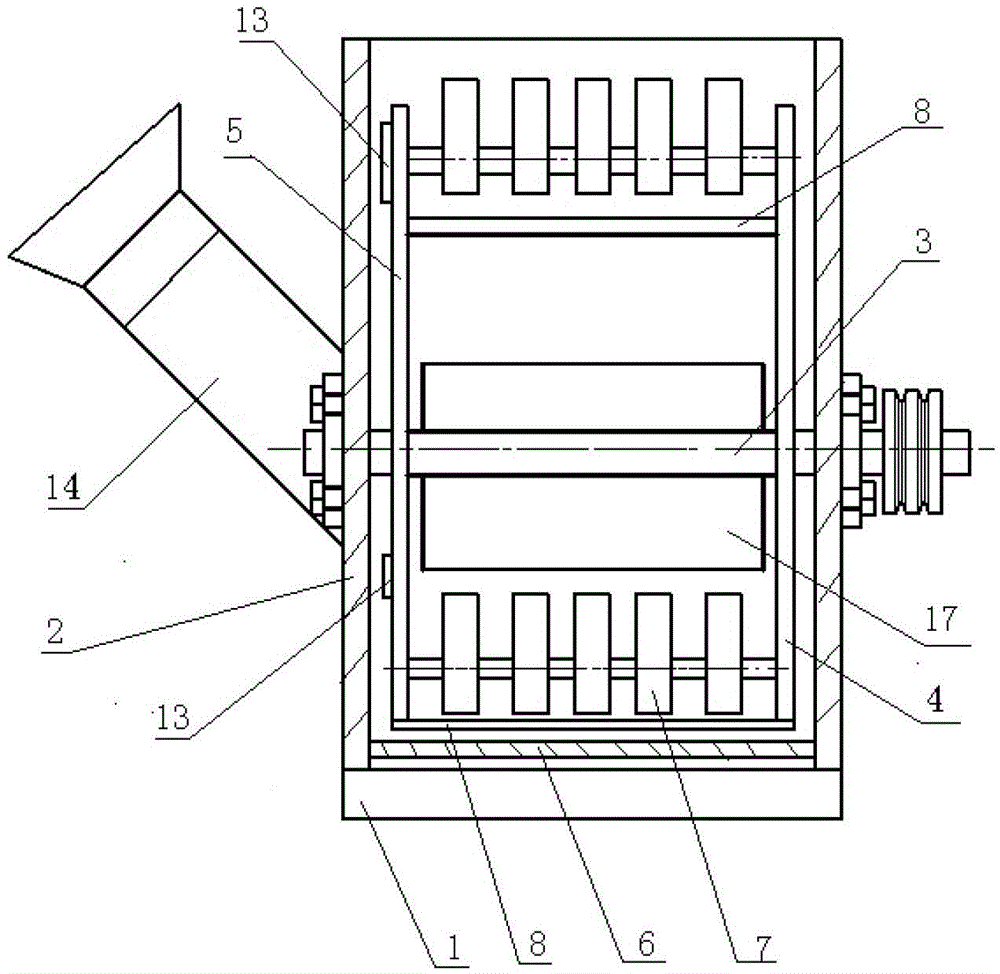

Grinding device for calcium carbonate powder

ActiveCN109174415AAchieve smashAchieve dryingDrying gas arrangementsDrying solid materialsEngineeringSieve

The invention discloses a grinding device for calcium carbonate powder. The grinding device comprises a casing, wherein a feeding inlet is arranged on the casing; and the feeding inlet is connected with a screw feeder. The grinding device is characterized by further comprising a cyclone separator and a heater. The casing is internally and sequentially provided with a guiding plate, a first grinding sieve plate and a second grinding sieve plate from top to bottom, and the guiding plate, the first guiding sieve plate and the second grinding sieve plate divide the interior of the casing into fourareas; the four areas sequentially include the smashing area, the first grinding area, the second grinding area and the storage area from up to down; the smashing area is internally provided with a smashing device; the first grinding area is provided with a first grinding device; the second grinding area is provided with a second grinding device; the four areas communicate with the cyclone separator; the cyclone separator is connected with the heater; and an outlet of the heater communicates with the four areas. The grinding device can smash and then grind calcium carbonate, dry the powder during grinding, and effectively prevent the dust in the grinding device from leaking.

Owner:石棉县亿欣钙业有限责任公司

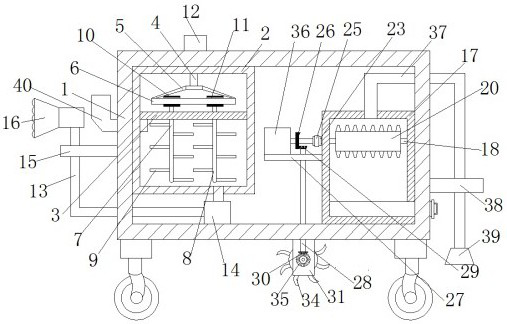

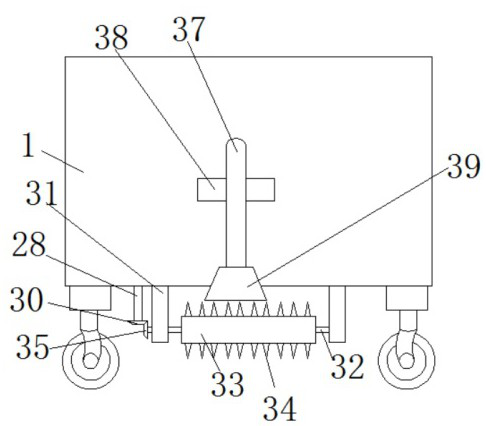

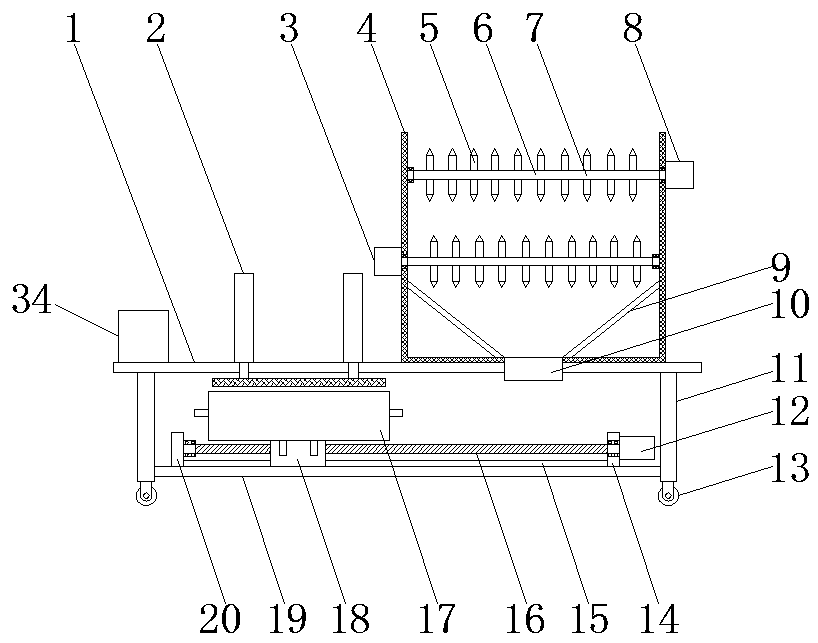

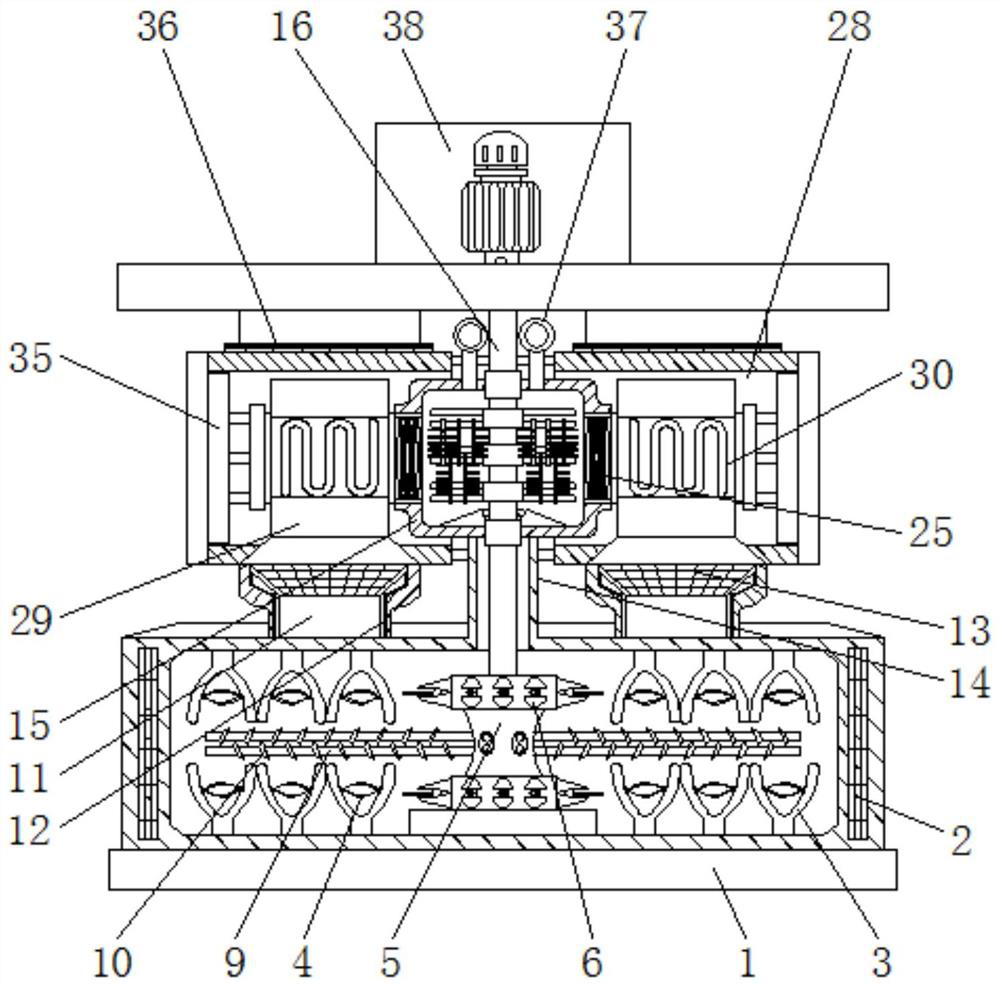

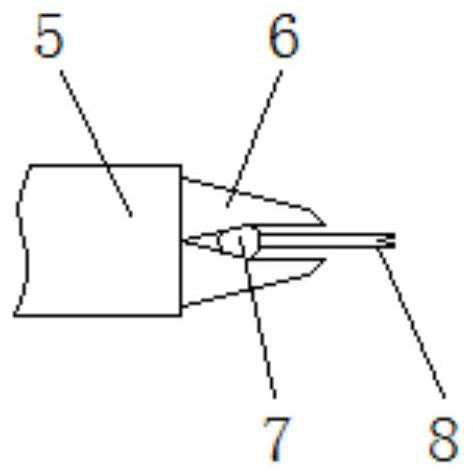

Efficient smashing device for food on naval vessels

InactiveCN109225501ATo achieve the purpose of crushingImprove crushing effectGrain treatmentsEngineeringStore food

The invention relates to the technical field of food and discloses an efficient smashing device for food on naval vessels. The efficient smashing device comprises a box; a feeding part is arranged onthe top of the right end of the box; a feeding port is formed on the top of the feeding part; a discharge hole is formed on the bottom of the feeding part; a spindle rod is arranged on the lower end of an inner chamber of the feeding part; a support base is fixedly connected with the top of the right end of the box. The efficient smashing device for food on naval vessels is capable of achieving the purposes of conveniently collecting and timely fetching, under the action of a baffle, a filter screen, a closing plate and a storage box; the baffle is designed in conical shape, so that food can quickly fall off; the storage box is arranged as a transparent PE box and is marked with scale lines, so that a user can directly know the storage state and can conveniently take food; the closing plate is designed for plugging the discharge hole in the manner of pulling and drawing and is used for buffering the discharge of food; when the storage box is full, food accumulation caused by excessivefood stored in advance and waste caused by incapability of collecting and storing food immediately can be effectively avoided.

Owner:CHINA MARITIME POLICE ACADEMY

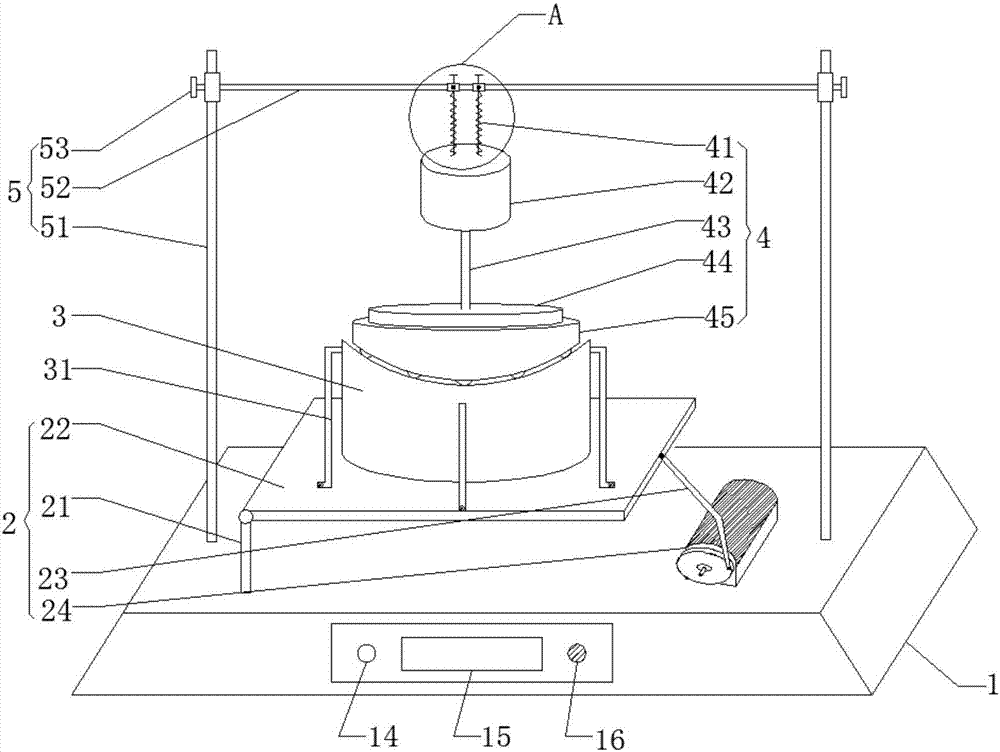

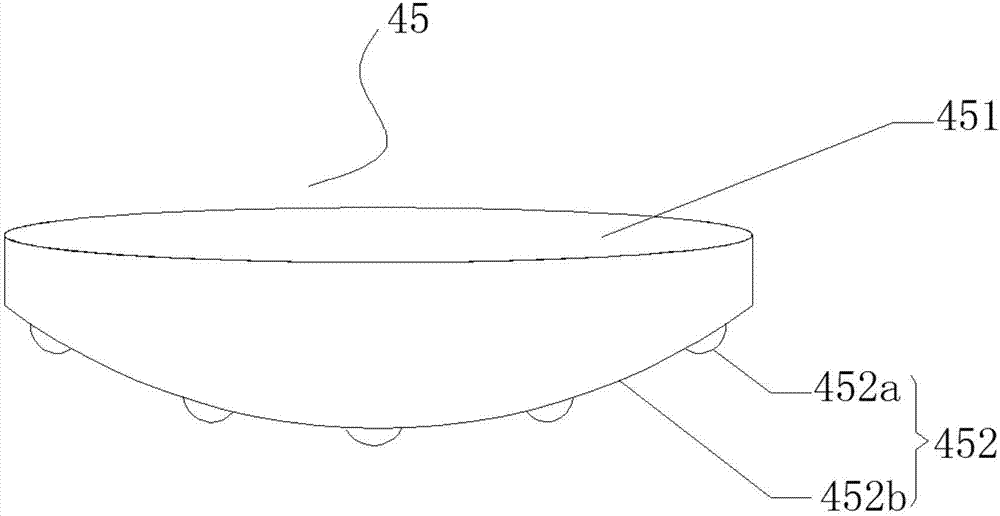

Small-quality powder electric grinding machine

A small-quality powder electric grinding machine comprises a base, a material carrying platform, a mortar body, a lifting grinding mechanism and a supporting frame which are connected in sequence from bottom to top, wherein the supporting frame is used for supporting the lifting grinding mechanism. The lifting grinding mechanism comprises a telescopic unit, a grinding motor, a coupler, a counterweight disc and a grinding piece which are connected sequentially from top to bottom. The telescopic unit is vertically fixed to the supporting frame. The lower end face of the grinding piece is opposite to the upper end face of the mortar body, and the lower end face of the grinding piece and the upper end face of the mortar body are both in an arc shape. The small-quality powder electric grinding machine has the advantages that through the combined design of the lifting grinding mechanism with the mortar body and a worktable structure, materials can be ground automatically, efficiency is high, the grinding quality and the grinding particle size further can be selected according to the requirements, the structure is simple, operation is convenient, and practicability is high; and through the structural design of an S-shaped boss and the concave face on the grinding piece, the purpose of smashing is achieved, the grinding efficiency is improved, and labor intensity is reduced.

Owner:YANGTZE UNIVERSITY

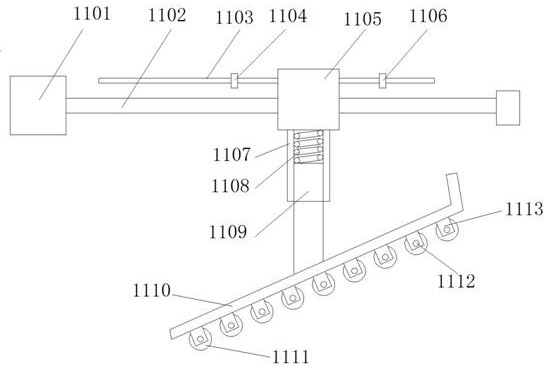

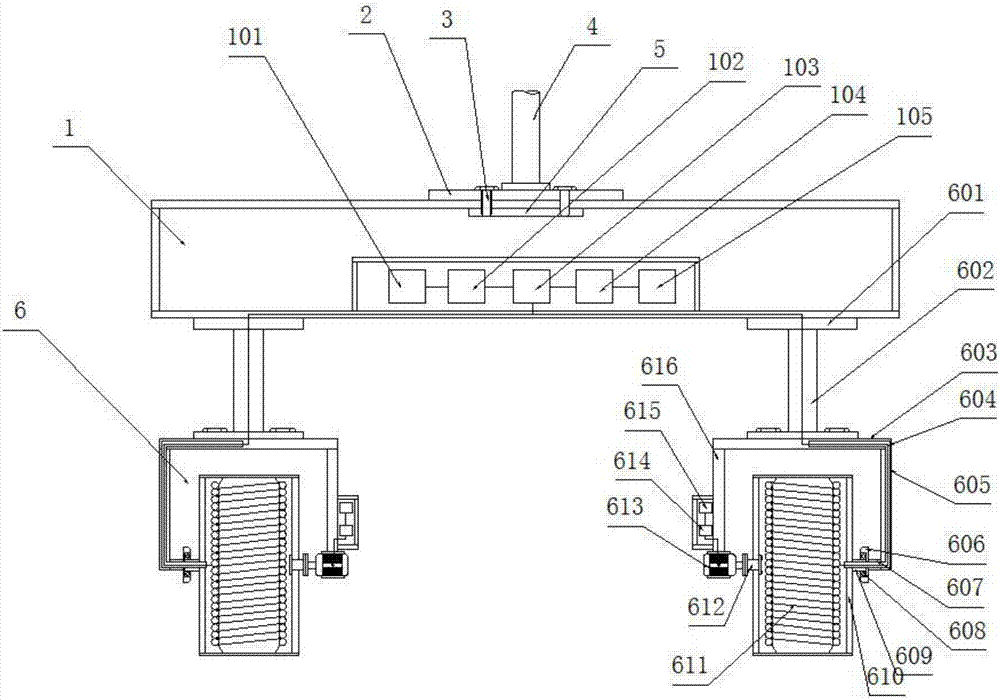

Automatic feeding device for rubber machinery

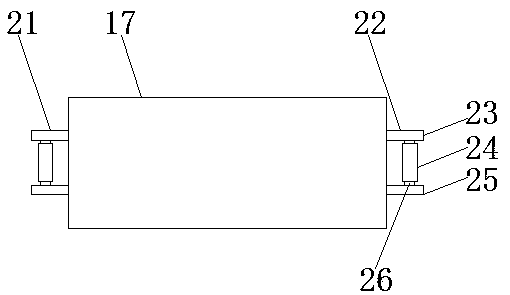

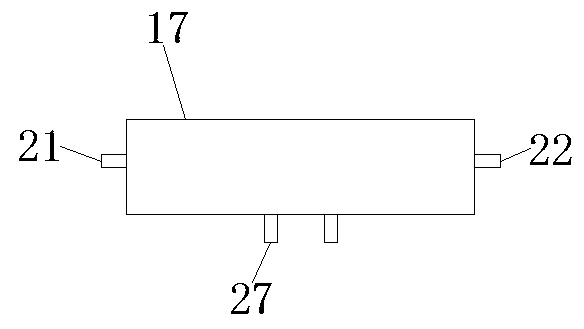

InactiveCN110774471ATo achieve the purpose of crushingTo achieve the purpose of heatingDispersed particle filtrationGrain treatmentsGlass fiberElectric machinery

The invention discloses an automatic feeding device for rubber machinery. The automatic feeding device comprises a supporting plate, wherein the right end of the top of the supporting plate is fixedlyconnected with a filter box, and an inner cavity of the filter box is fixedly connected with a quartz sand filter screen and a glass fiber filter screen layer in sequence from top to bottom. The automatic feeding device is provided with a first motor, a first transmission shaft and crushing teeth, so that the purpose of crushing materials can be achieved; a heating plate is arranged, so that thepurpose of heating the materials in a crushing box can be achieved; a pipeline and a fan are arranged, so that the materials in a conveying box can be dried; the filter box, the quartz sand filter screen and the glass fiber filter screen layer are arranged, so that hot air can be filtered; and two second electric telescopic rods and supporting rods which are symmetrical front and back are arranged, so that people can pour the materials in the crushing box completely, material residues are avoided, meanwhile, the conveying work of the conveying box is facilitated, and the conveying box can uniformly and orderly deliver the materials into a material mixing machine.

Owner:化明松 +1

Corrugated board smashing recycling machine

The invention relates to a smashing recycling machine, in particular to a corrugated board smashing recycling machine. The corrugated board smashing recycling machine aims at achieving the technical effects of being capable of carrying out multi-stage smashing treatment, preventing fragments from being splashed out and saving labor. In order to achieve the technical effect, the corrugated board smashing recycling machine comprises a collection box and the like, a crushing mechanism is connected to the middle of the top wall of the collection box, a smashing mechanism is arranged on the inner rear wall of the collection box, and the smashing mechanism is connected with the crushing mechanism. The effects that multi-stage smashing treatment can be achieved, fragments can be prevented from being splashed out, and labor can be saved are achieved, the purpose of carrying out multi-stage smashing treatment on corrugated boards for recycling is achieved by arranging the crushing mechanism andthe smashing mechanism, and a baffle, a fixing rod and a hook are arranged in order to achieve the purpose that after all the corrugated boards are smashed, the smashed corrugated boards can be collected.

Owner:HANGZHOU ZHENMING IND

Grinding method for calcium carbonate powder

ActiveCN109174414ANo leakageAchieve smashDrying gas arrangementsDrying solid materialsMetallurgyCalcium carbonate

The invention discloses a grinding method for calcium carbonate powder. The grinding method includes the steps that through a spiral feeding machine, calcium carbonate is sent into a smashing area ofgrinding devices and smashed in the smashing area through a smashing device; after smashing, the calcium carbonate enters into a first grinding area, is subjected to primary grinding through the firstgrinding device, then enters into a second grinding area, is subjected to secondary grinding through the second grinding device, and finally enters into a storage area to be stored; and in the process, the air heated by a heater enters into the smashing area, the first grinding area, the second grinding area and the storage area to heat and dry the calcium carbonate. By drying the calcium carbonate during the process of smashing and grinding, it is ensured that the calcium carbonate powder does not leak and the calcium carbonate is collected according to different grades.

Owner:石棉县亿欣钙业有限责任公司

Completely smashing device for character design drawing for cartoon game development

ActiveCN106669922ATo achieve the purpose of crushingTo achieve dredging effectSievingScreeningCharacter designElectric machinery

Owner:NINGBO KAKU CARTOON MAKING

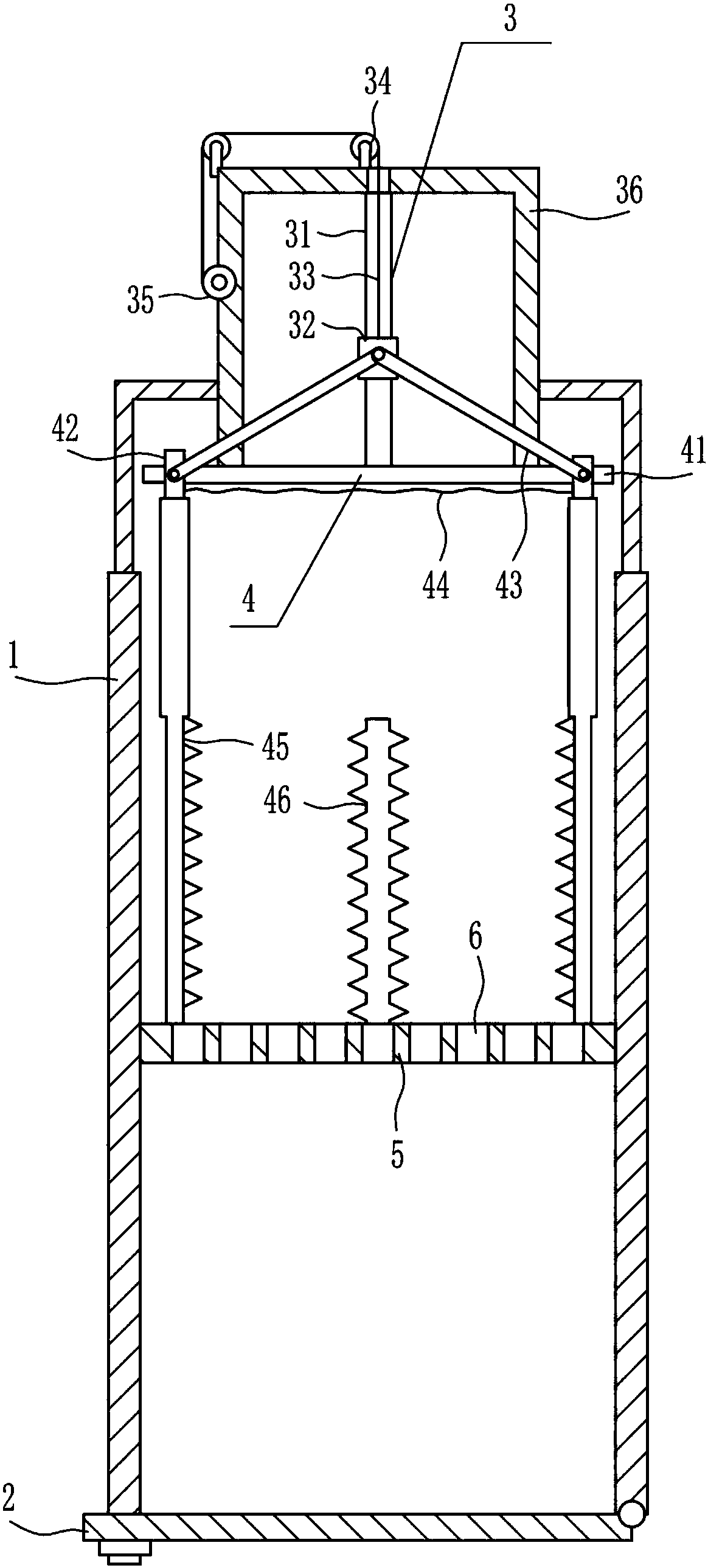

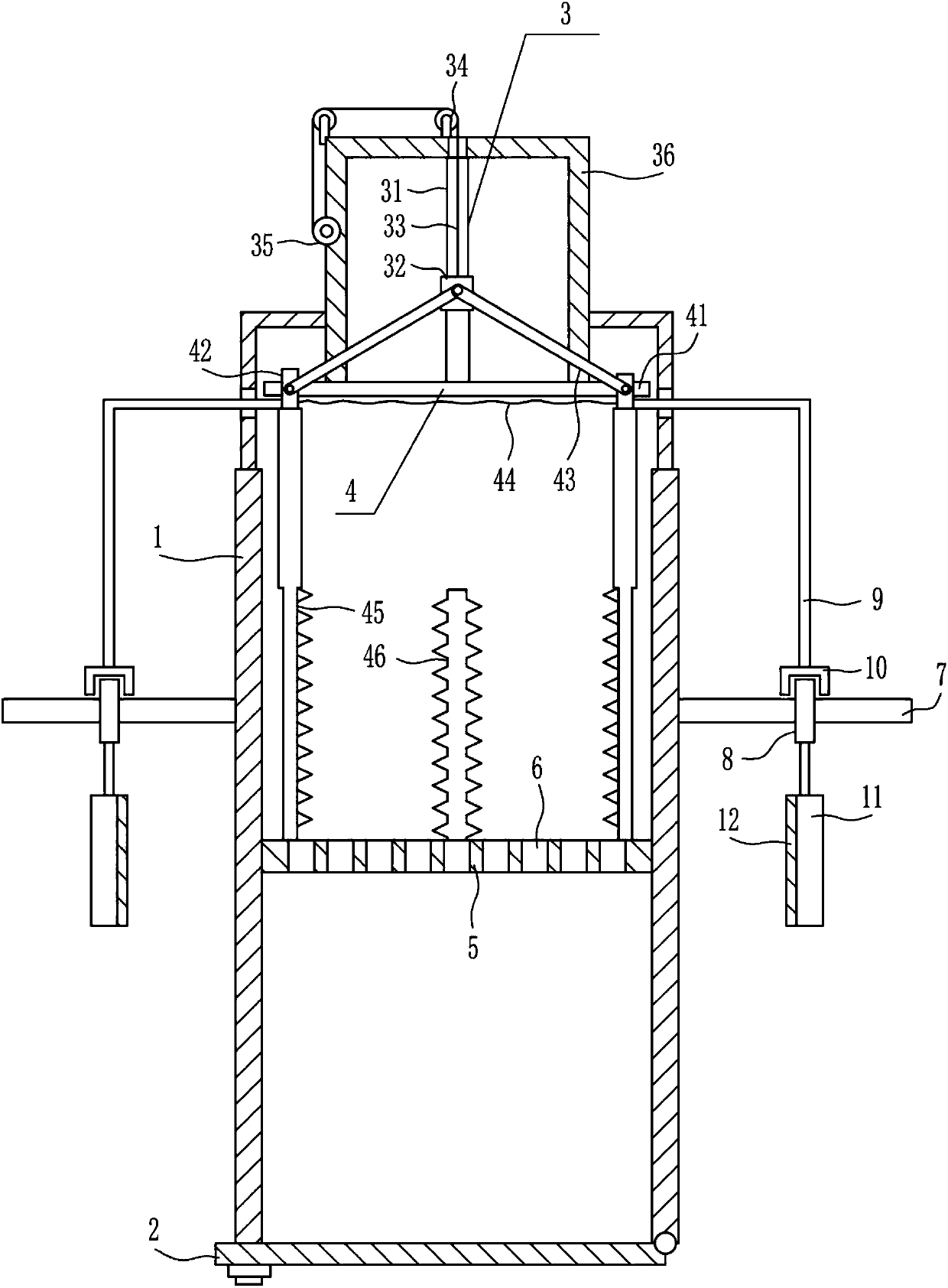

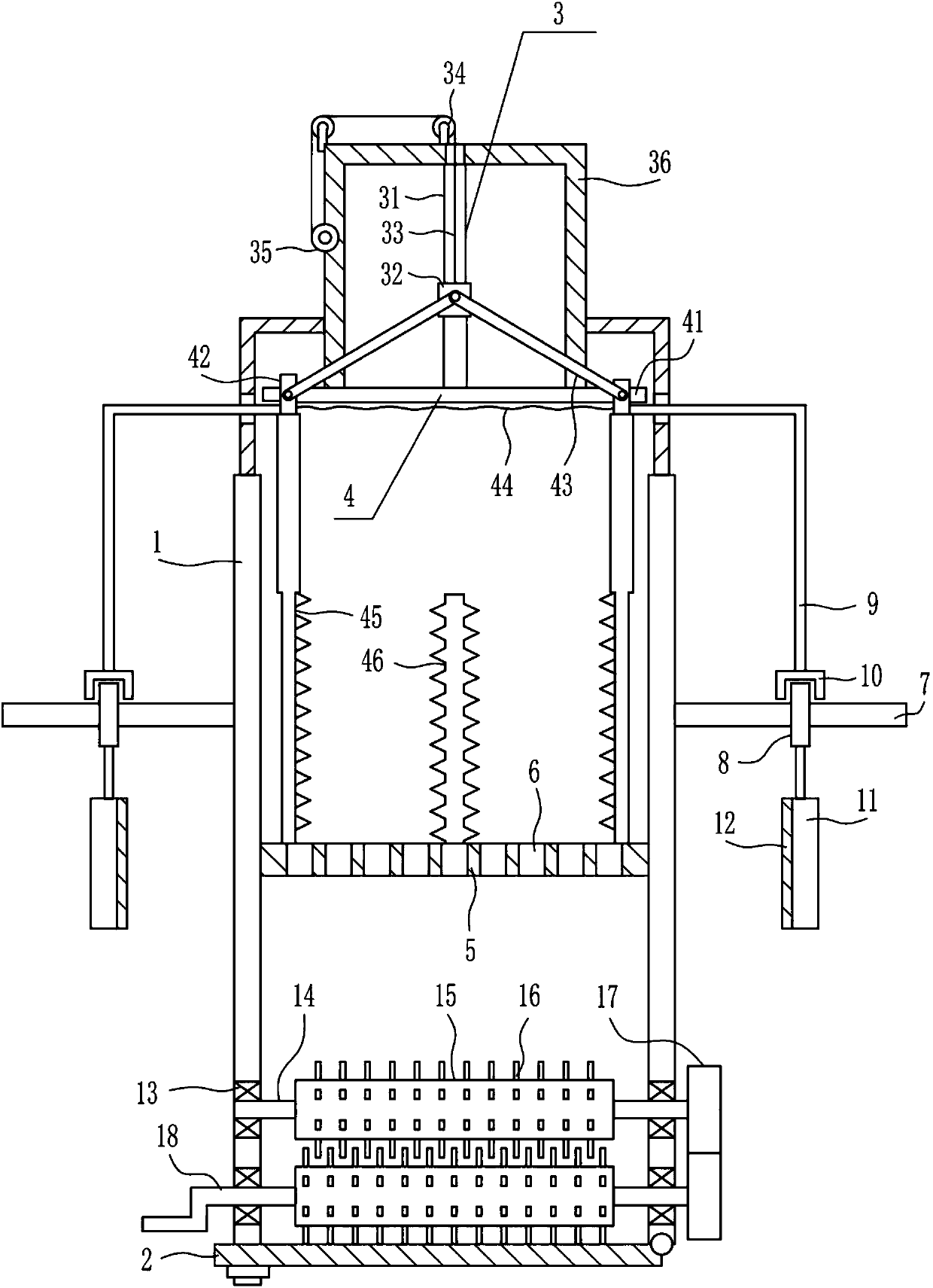

Processing machine for waste molded case of circuit breaker

ActiveCN107626377ATo achieve the purpose of crushingAvoid stickingGrain treatmentsEmbedded systemLeft wall

The invention relates to a processing machine, in particular to a processing machine for a waste molded case of a circuit breaker. The processing machine for the waste molded case of the circuit breaker has the advantages that multi-stage crushing treatment can be carried out, blockage can be prevented, and the occurrence of the wall adhesion phenomenon can be prevented.The processing machine forthe waste molded case of the circuit breaker comprises a processing box and the like; a baffle is connected to the bottom end of the right wall of the processing box in a rotating mode; the left partof the bottom of the baffle is fixed to the bottom end of the left wall of the processing box in a bolt connection mode; a fixing plate is connected to the middle part of the interior of the processing box; through holes are uniformly formed in the fixing plate; a driving mechanism is connected to the top of the processing box; and a processing mechanism is connected to the driving mechanism. According to the processing machine, the driving mechanism and the processing mechanism are arranged so that the purpose of carrying out crushing treatment on the waste molded case of the circuit breakerpoured into the processing box can be achieved, and a rod is continuously loosened so that the purpose of knocking on the left side of the processing box can be achieved.

Owner:山东润耀环保科技有限公司

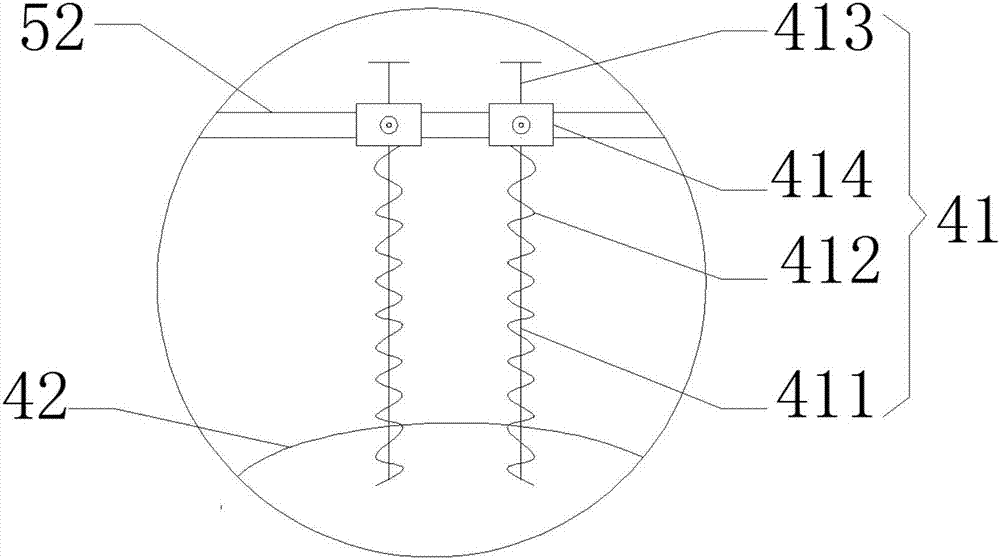

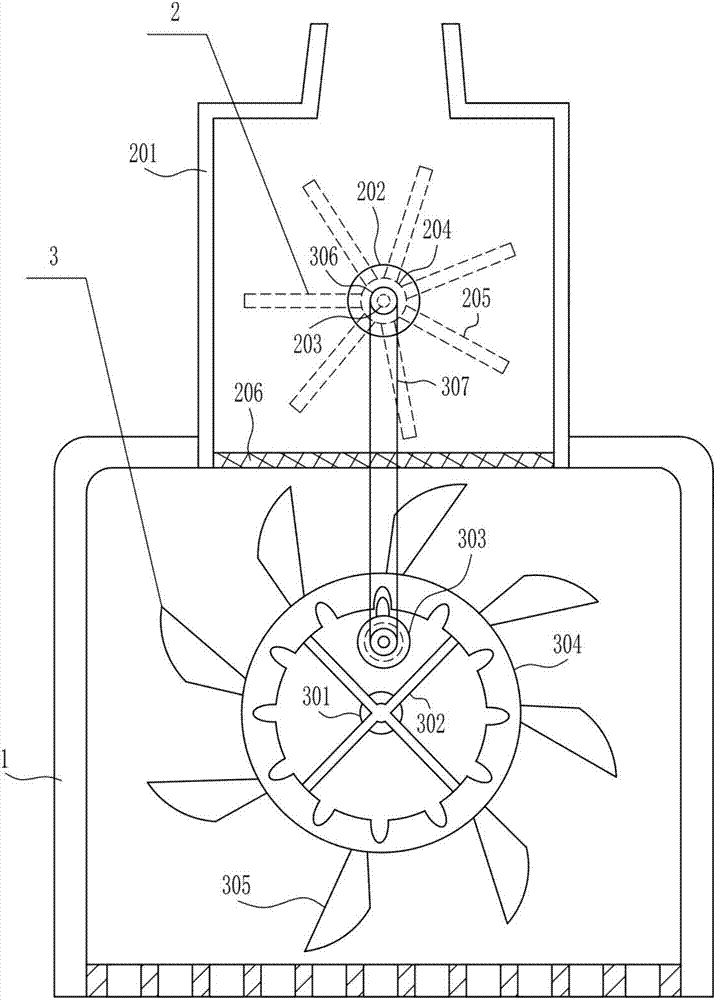

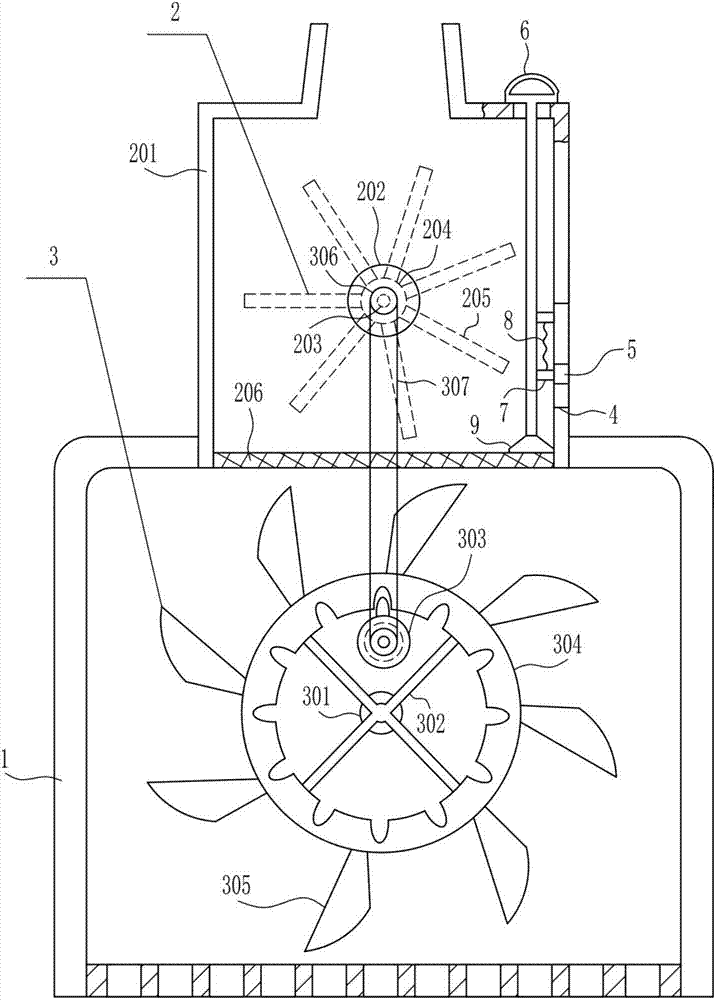

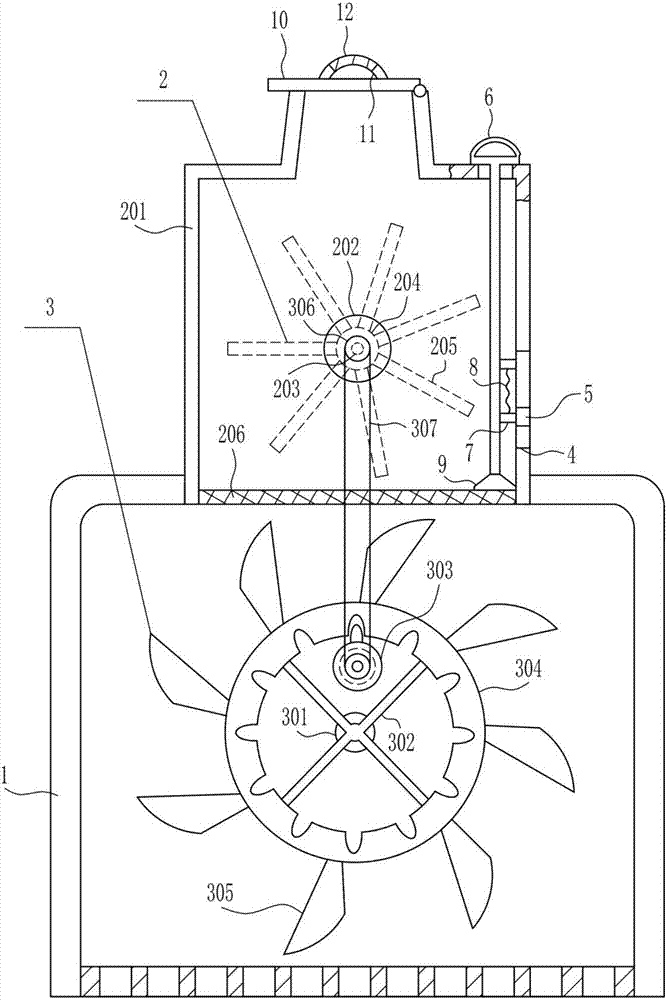

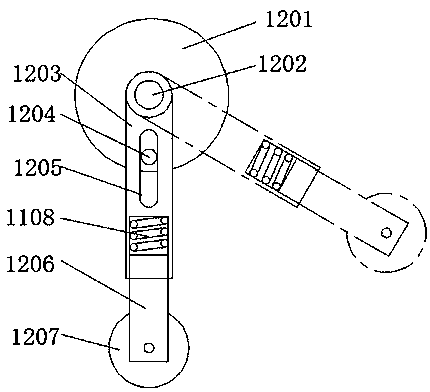

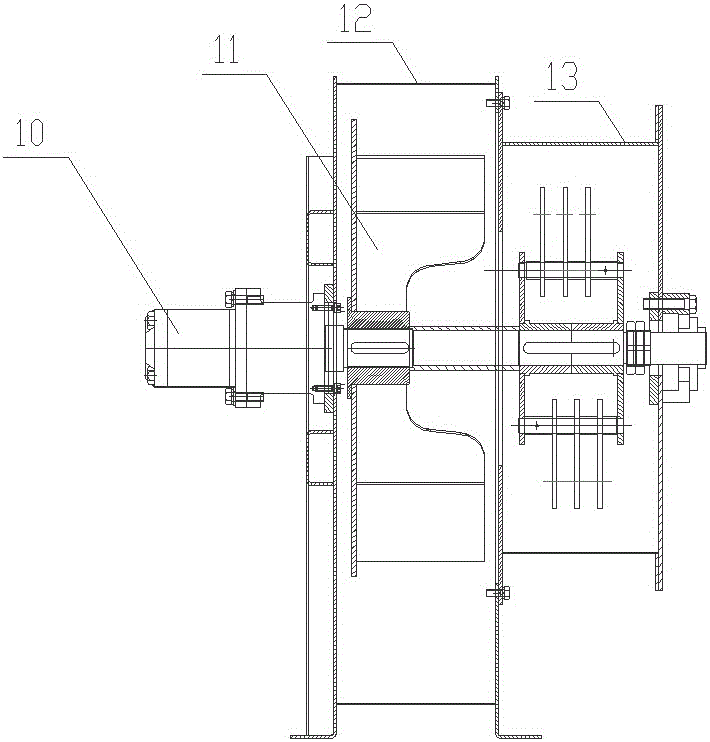

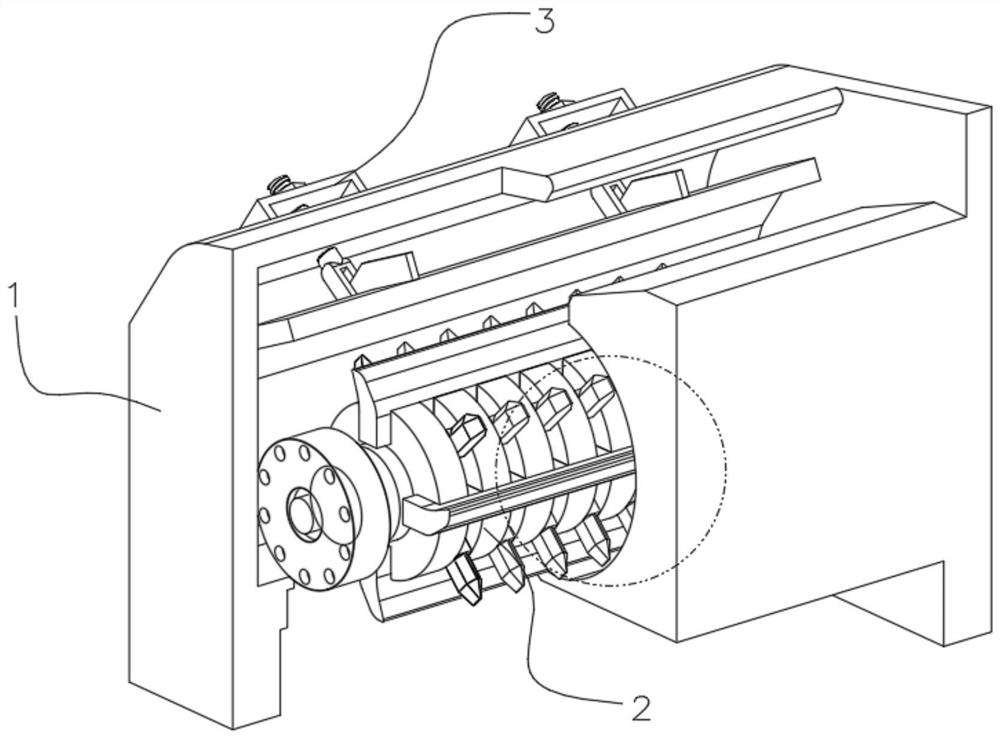

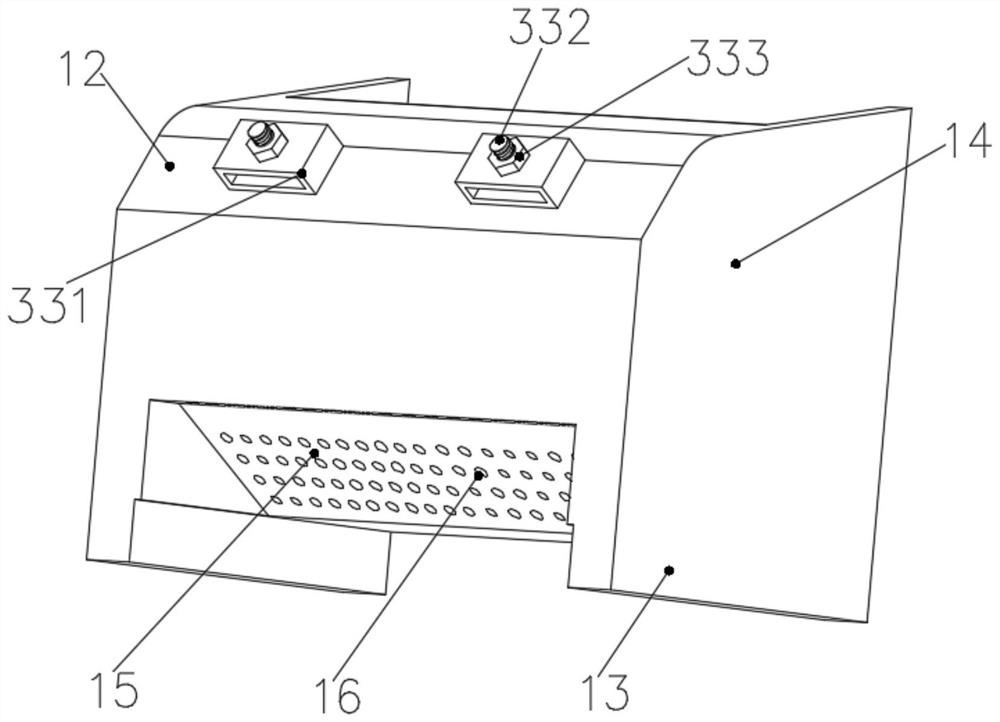

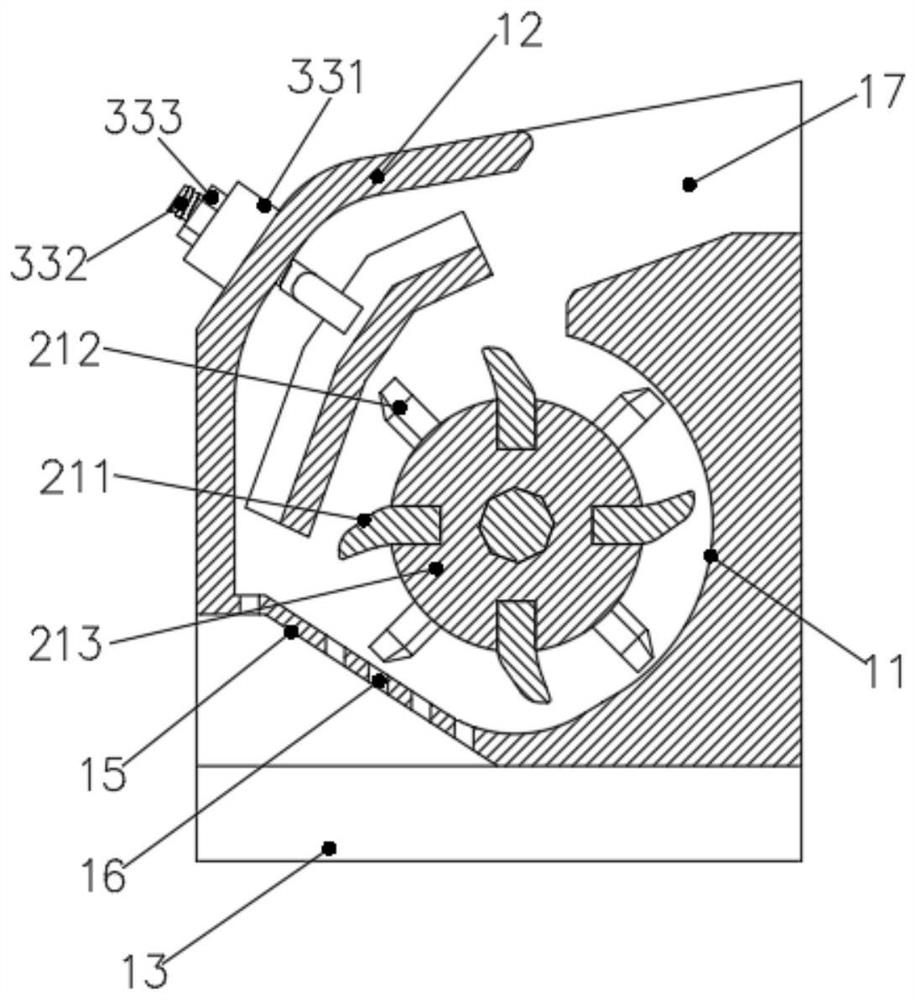

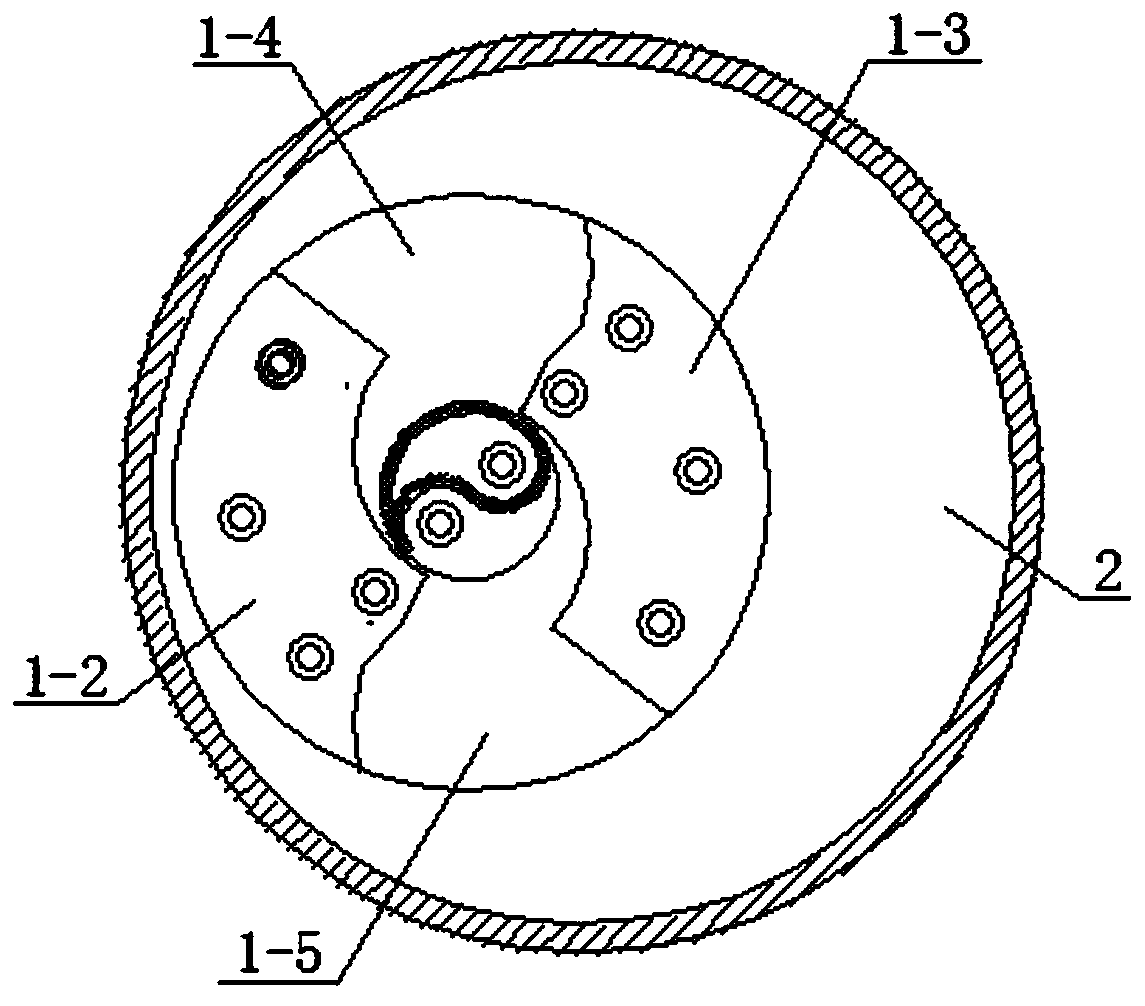

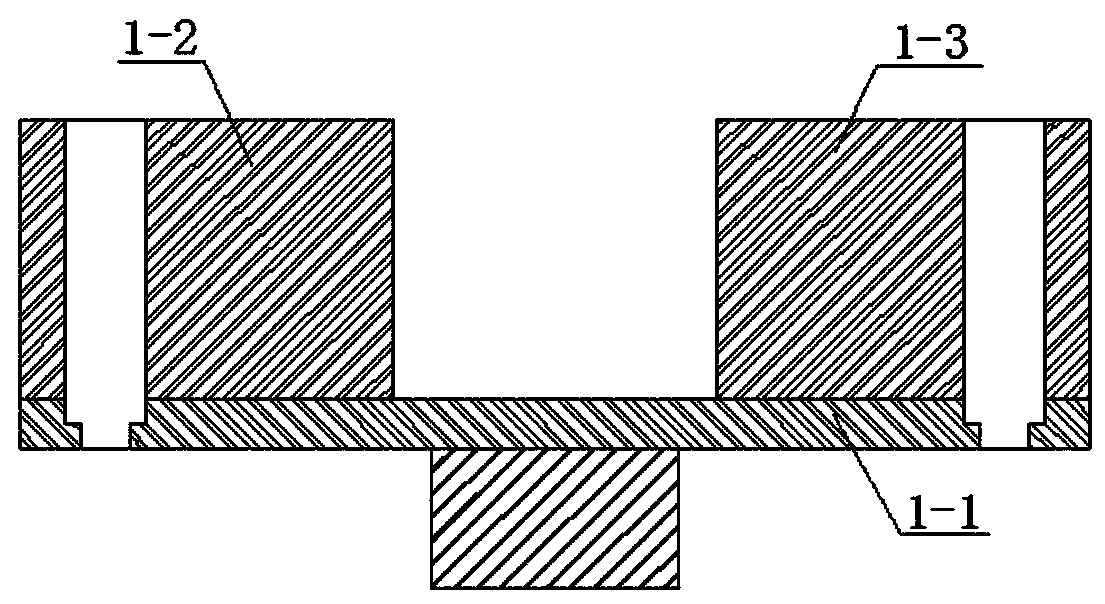

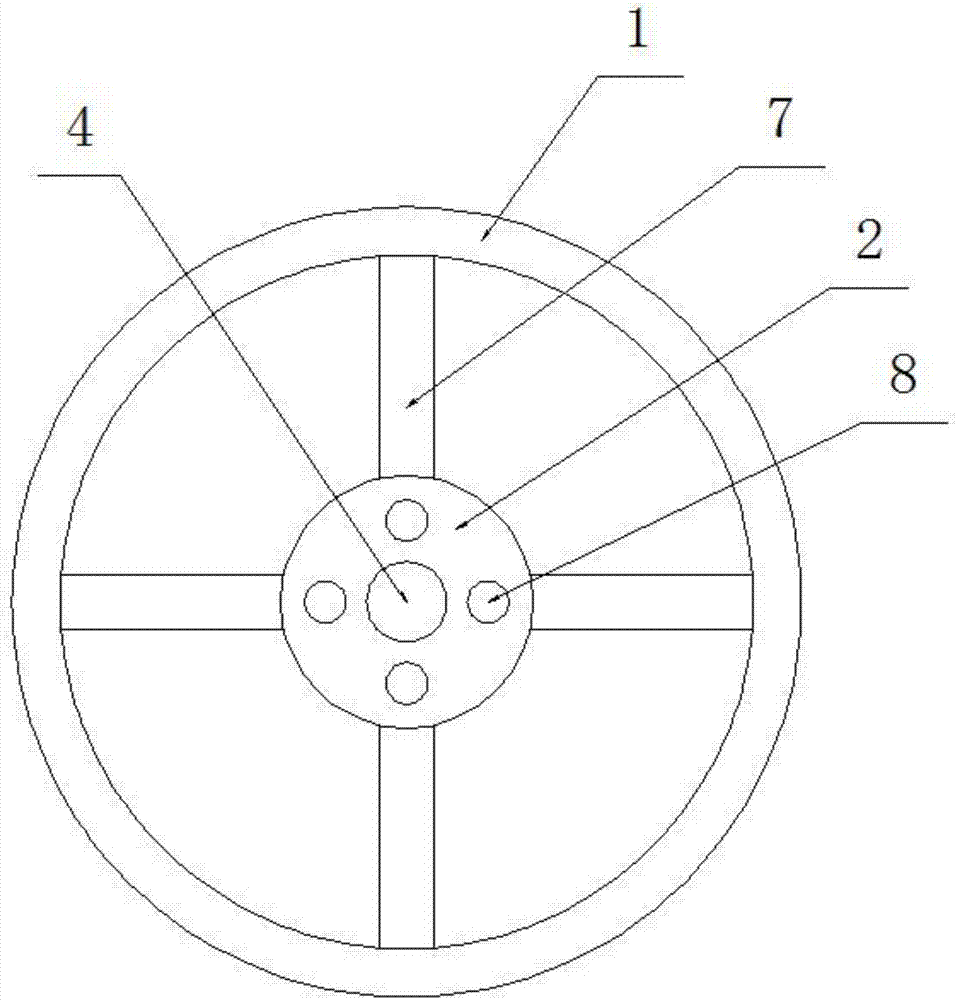

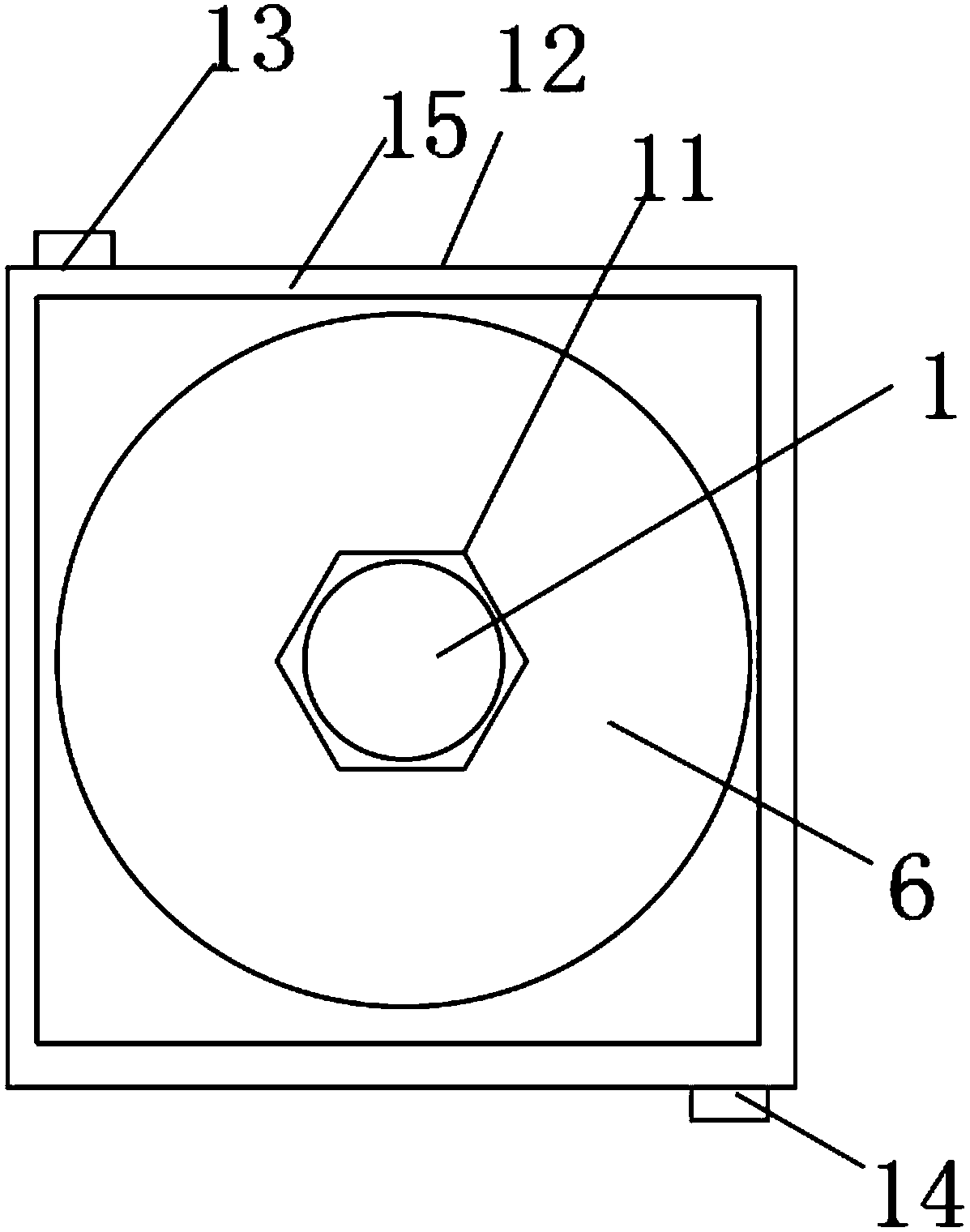

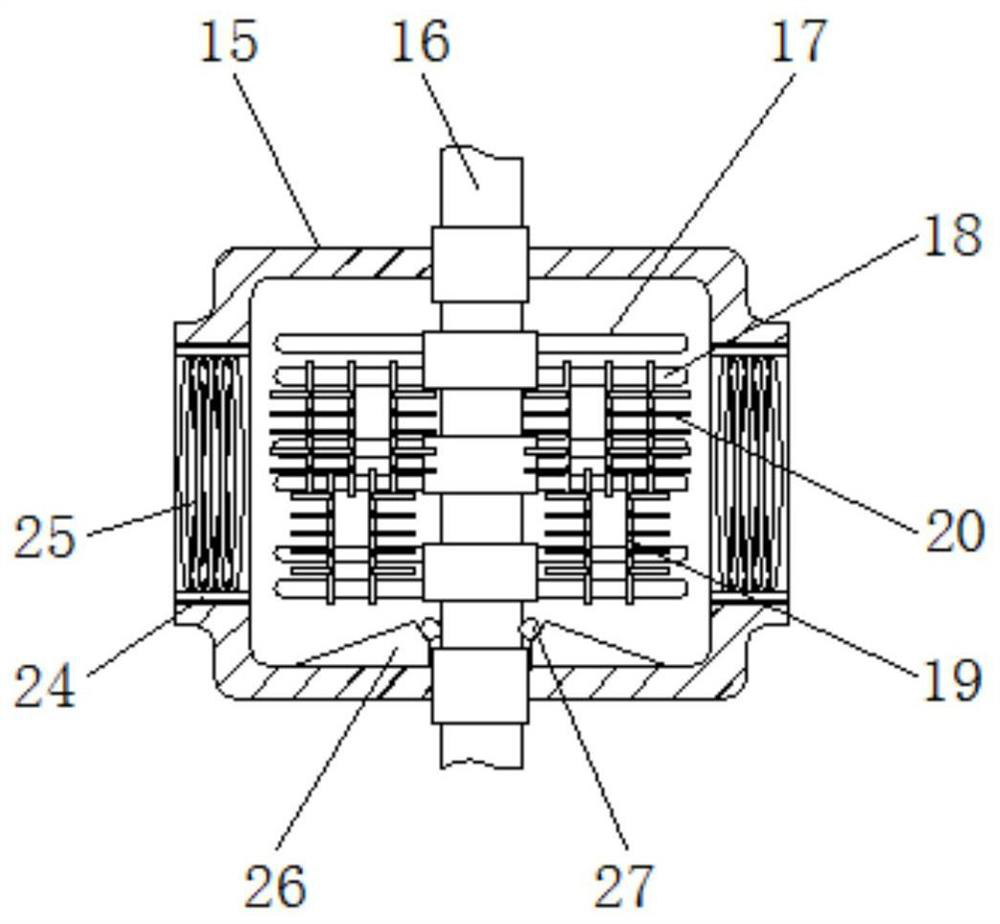

Pulverizing device for fan and fan comprising pulverizing device

The invention relates to a pulverizing device for a fan and the fan comprising the pulverizing device, and solves problems that the conventional fan is incomplete in function, complicated in equipment, easy to block a volute casing, and easy to damage. The pulverizing device comprises rotating disks, connecting shafts, spacer bushes and pulverizing blades, wherein the rotating disks are disk-like bodies having annular sleeves at centers; the rotating disks are arranged in pairs by using one end surface of the sleeve as a symmetrical plane; a plurality of connecting shafts are arranged between opposite sides of the rotating risks; the connecting shafts are fixed on the two rotating disks; a plurality of pulverizing blades sleeve the connecting shafts; the spacer bushes are arranged between each pulverizing blade and each rotating disk and between the pulverizing blades; the spacer bushes are fixedly connected with the connecting shafts. The pulverizing device has advantages of simple structure, assembly / disassembly and maintenance convenience, is used in coordination with the fan, can pulverize while suction so as to avoid fan blocking phenomenon and influence on suction wind, has good pulverization and suction effects and high efficiency, is not easy to damage, and has long duration of work and small interference.

Owner:青岛中汽特种汽车有限公司

Recovery equipment for waste discharging plastic pipes used for wastewater treatment

InactiveCN107553781ATo achieve the purpose of crushingAvoid cloggingSievingScreeningWastewaterSewage treatment

The invention relates to recovery equipment, in particular to recovery equipment for waste discharging plastic pipes used for wastewater treatment. According to the technical purpose, the recovery equipment for the waste discharging plastic pipes used for wastewater treatment is provided, multi-stage treatment can be performed, clogging and wall adhering can be prevented, and recovery is convenient. For achieving the technical purpose, the recovery equipment for the waste discharging plastic pipes used for wastewater treatment is provided and comprises a collecting tank and the like; and the left side of the bottom of the collecting tank is rotationally connected with a baffle, the right side of the bottom of the baffle is fixed to the right side of the bottom of the collecting tank in a bolt connection mode, the middle of the top of the collecting tank is connected with a treatment box, the bottom wall of the treatment box is connected with a screening plate, and the right side of thetreatment box is connected with a crushing mechanism. According to the recovery equipment provided by the invention, by arranging the crushing mechanism and a drive mechanism, the purpose that the waste discharge plastic pipes are crushed and treated is achieved.

Owner:许锦翔

Device for recycling waste tools of power grid structure

InactiveCN107755037ATo achieve the purpose of crushingAvoid lossGrain treatmentsPower gridBolt connection

The invention relates to a recycling device, in particular to device for recycling waste tools of a power grid structure, and aims to solve the technical problem of providing a device which is capableof implementing multi-stage crushing treatment and crushing treatment under a sealed condition for the waste tools of the power grid structure. To solve the technical problem, the invention providesthe device for recycling the waste tools of the power grid structure. The device comprises a tank body and the like, wherein a driving mechanism is connected with the lower part of the right side of the mounting tank; a crushing mechanism is connected with the lower part inside the mounting tank; the crushing mechanism is connected with the driving mechanism; a first baffle plate is rotationally connected with the bottom end of the right wall of the mounting tank; the left part of the first baffle plate is fixed at the bottom end of the left wall of the mounting tank in a bolt connection mode.Due to adoption of the driving mechanism and the crushing mechanism, the purpose of crushing waste tools poured into the device is achieved, and by controlling an electronic push rod to stretch and withdraw, the tank body is opened and closed through a second baffle plate.

Owner:刘松

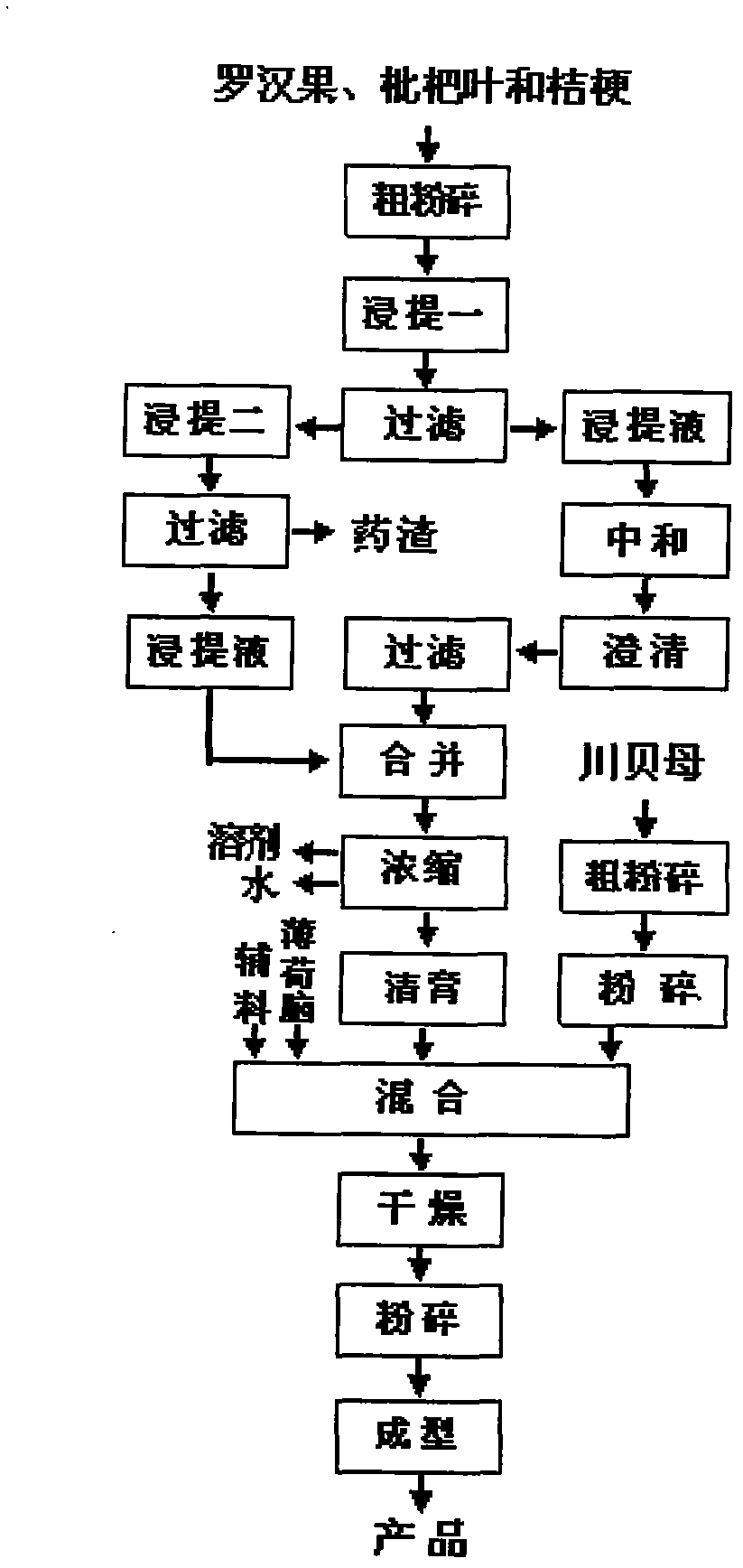

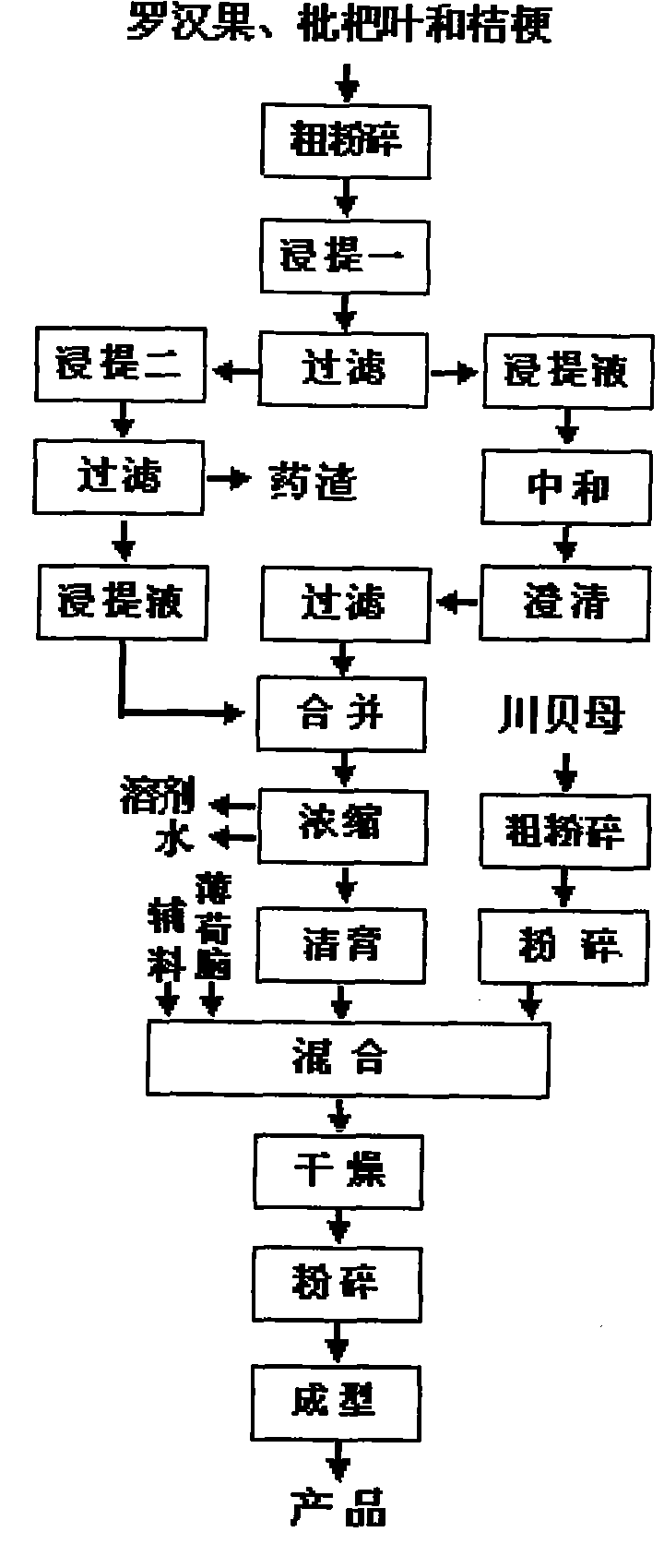

Preparation method of sugarless fritillaria cirrhosa-fructus momordicae granules for relieving cough

InactiveCN102119996AKeep active ingredientsTo achieve the purpose of crushingInorganic non-active ingredientsGranular deliverySolventChemistry

The invention provides a preparation method of sugarless fritillaria cirrhosa-fructus momordicae granules for relieving cough, which comprises the following steps of: firstly, drying and coarsely crushing traditional Chinese medicines, crushing fritillaria cirrhosa through gas flow, and extracting fructus momordicae, loquat leaves and balloon flower by a semi-bionic extraction method and an ethanol extraction method or a semi-bionic extraction method or an ethanol extraction method and a water extraction method to prepare clear cream; and then, adding fritillaria cirrhosa powder, menthol and auxiliary materials to prepare granules for relieving cough by a conventional method. The granules prepared by the invention solve the problem that the granular traditional Chinese medicine preparation takes sucrose as a flavoring agent which can decompose some medical effective components and can influence absorption, and the granules can meet the requirements of all people for taking the traditional Chinese medicine preparation. The granules are especially suitable for being taken by patients with diabetes, hyperglycemia, hypertension, obesity and the like. By using the method, after the traditional Chinese medicines are coarsely crushed, the contact area between the traditional Chinese medicine powder and a solvent is increased in the extraction process, the extraction time is shortened, the transfer rate is high, the time is saved, the production cycle is shortened, the utilization ratio of the raw materials is improved, and the effective components of the raw medicines are kept.

Owner:GUANGXI JIANFENG PHARMA

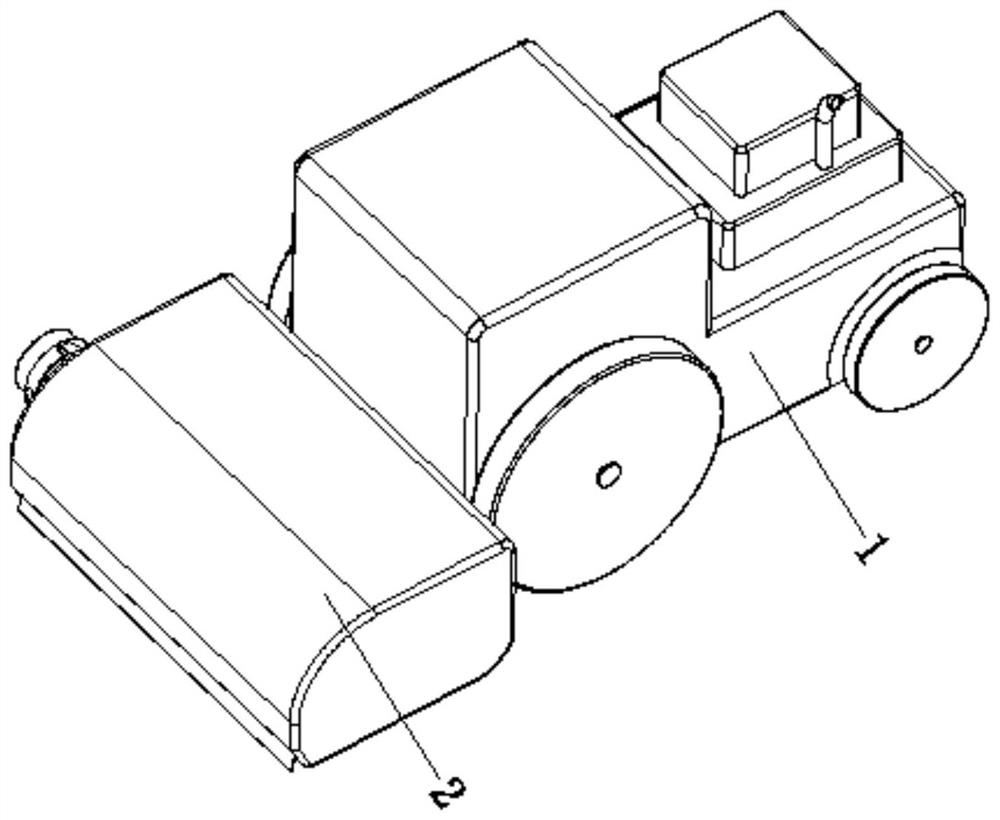

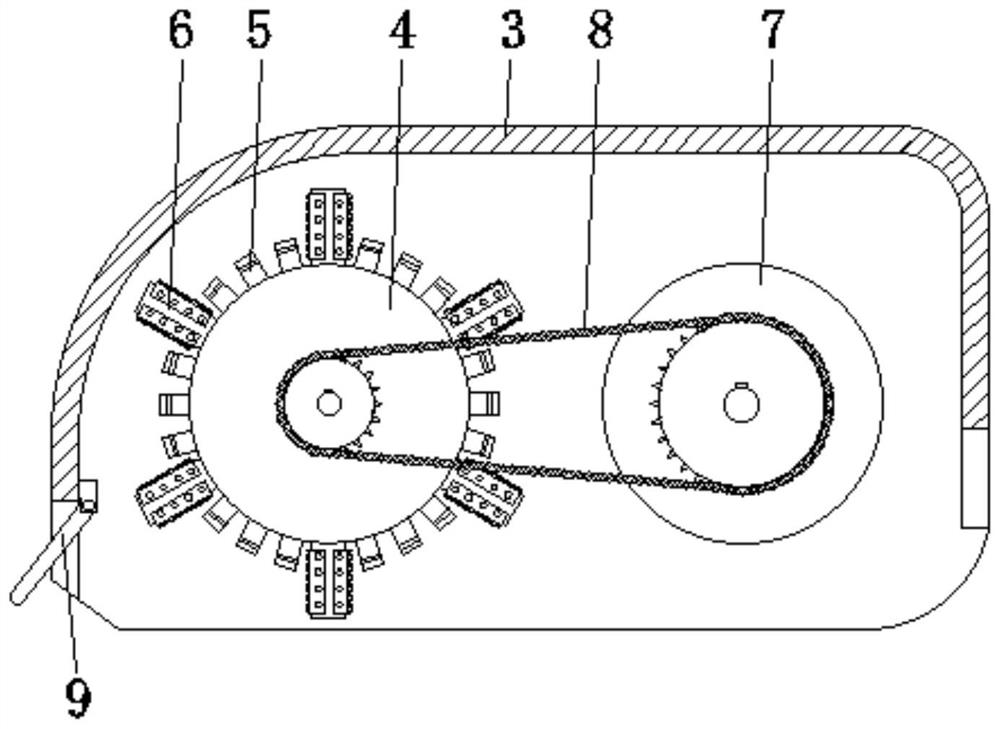

Straw smashing equipment

InactiveCN112544259APrevent death by pharynxExtended service lifeCuttersAgricultural engineeringAgricultural machinery

The invention discloses straw smashing equipment. The equipment comprises a power machine and a smashing device, the smashing device is fixed to the tail of the power machine through a rack, and a smashing roller device is rotatably connected between the two corresponding sides in a shell. A material stirring device is rotationally connected to the position, close to the smashing roller device, between the two corresponding sides in the shell, the position, located at the end, between the smashing roller device and the material stirring device is in transmission connection through a chain transmission assembly, and a baffle is rotationally connected to the position, close to the bottom, of the inner wall of the shell. The invention relates to the technical field of agricultural machinery.The straw smashing equipment achieves the effects of winding prevention and high adaptability, straw can be prevented from being wound on a roller, the situation that the straw is stuck can be avoided, smashing is facilitated, meanwhile, the service life of the equipment is prolonged, the straw smashing equipment can adapt to accumulated damp straw, limitation is reduced, smashing is more thorough, and the using performance is improved.

Owner:李宣红

Security-enhanced ventilative pressure discharge and temperature control plastic recycling smelting furnace

InactiveCN108724528AEasy to storeInfluence transfer processCharge composition/statePlastic recyclingTemperature controlIntermittent heating

The invention discloses a security-enhanced ventilative pressure discharge and temperature control plastic recycling smelting furnace and relates to the field of plastic recycling equipment. The smelting furnace comprises a preparation chamber, a partition board and a material melting chamber. The left and right sidewalls of the preparation chamber are both internally provided with electric heating layers. An external heat insulation electric heating guard barrel is arranged on the outer side of the material melting chamber. A cavity is formed in the position, close to the left side, of the interior of the partition board. The left side of the cavity is connected with an electromagnetic control mechanism. The right side of the cavity is connected with a starting mechanism. The electromagnetic control mechanism is in threaded connection with the starting mechanism. The smelting furnace conducts continuous intermittent heating on plastics in the preparation chamber so that the plastics in the preparation chamber can be kept in a fluidic state all the time, and the plastics is stored well. When the plastics gets into the preparation chamber to make contact with the transition thermalization temperature of a transition thermalization tube, the fluidic state of the plastics is ensured. In the starting process, an operator can be protect against direct contact with a high-voltage switch for turning on a machine starting device, and the operation environment is safer.

Owner:安徽圣贝诺建筑装饰工程有限公司

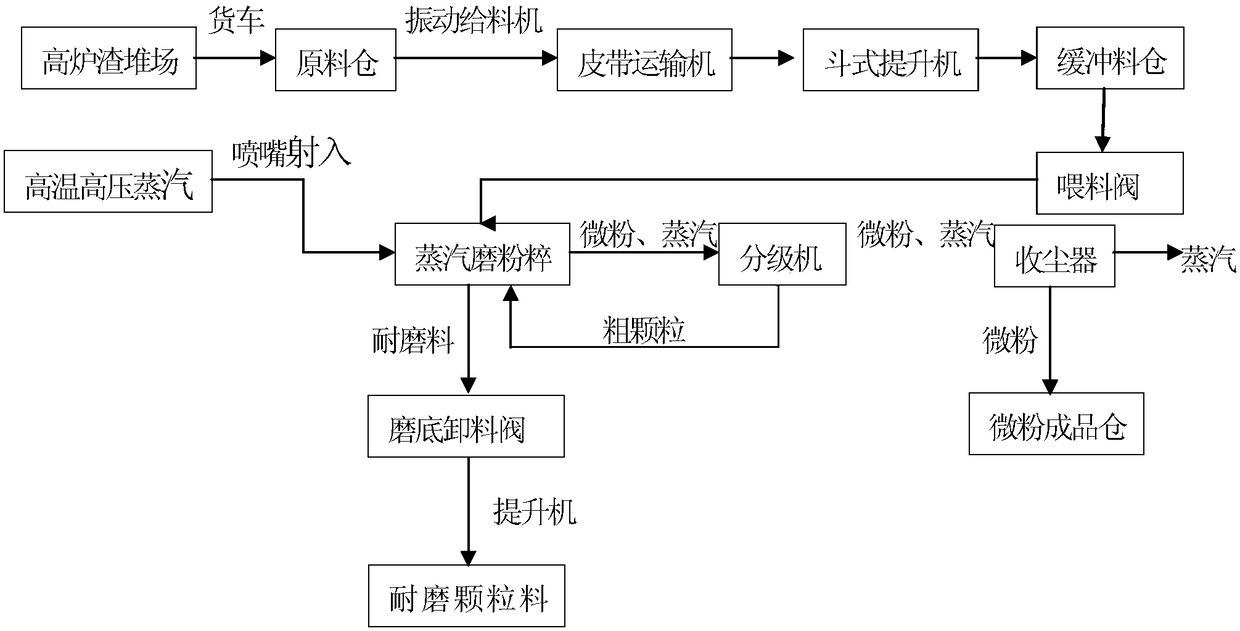

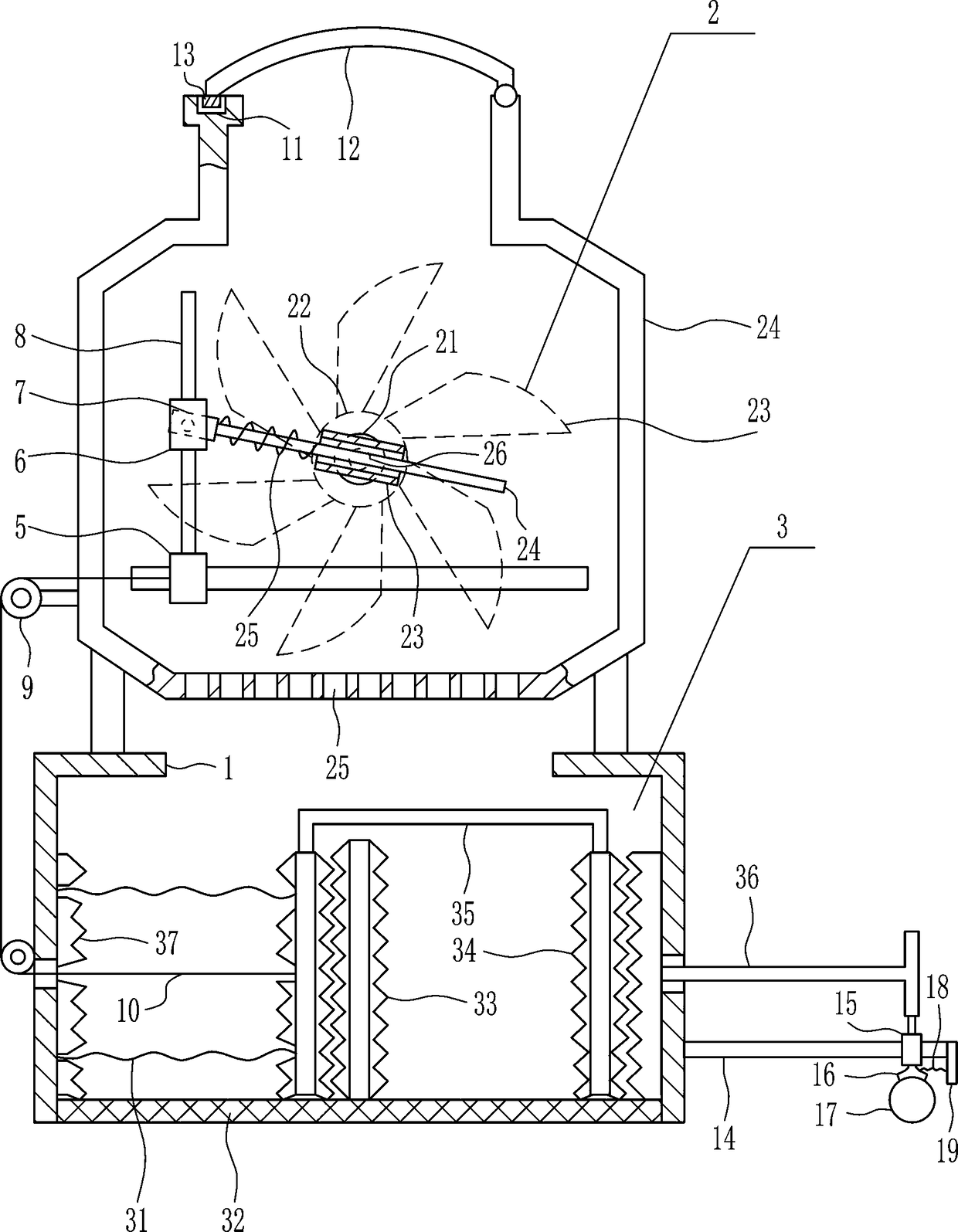

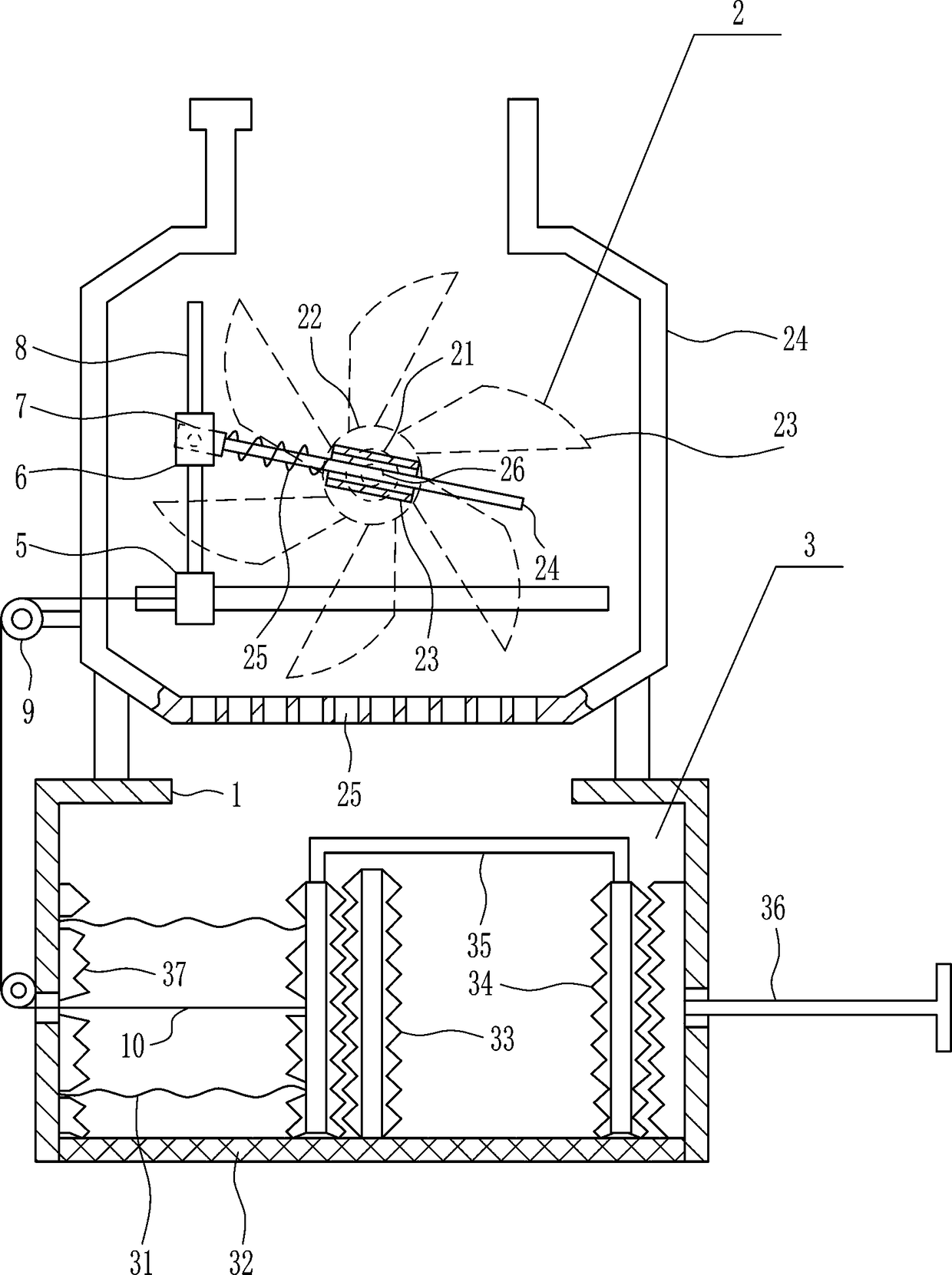

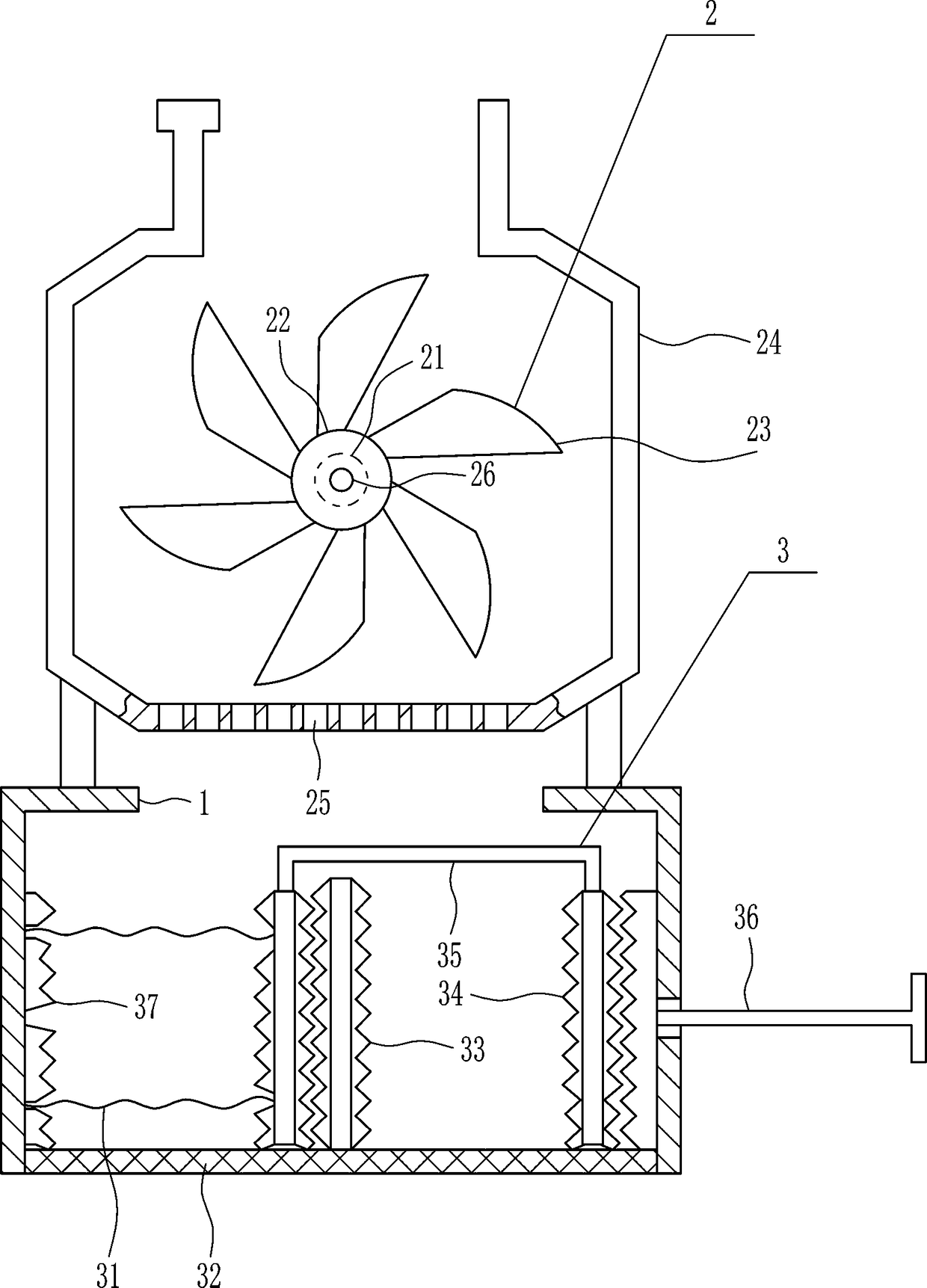

Method for producing ore slag micro powder by blast furnace water slag

InactiveCN108298835ARealize comprehensive utilizationRealize green productionCement productionSlagHigh pressure

The invention discloses a method for producing ore slag micro powder by blast furnace water slag. The method comprises the following steps of (1) conveying the blast furnace water slag to a buffer material cabin; then, feeding the materials into a steam mill through a feeding valve; (2) crushing the blast furnace water slag under the impact of high-temperature and high-pressure steam in the steammill; feeding the crushed micro particle mixture into a grading machine to be graded into micro powder and coarse particles; (3) feeding the micro powder into a dust collector; returning the coarse particles back into the steam mill to be crushed again; (4) separating the micro powder and the steam to obtain a finished product of the ore slag micro powder. The method solves the problem of easy generation of dust and noise pollution of a conventional ore slag micro powder production process by a ball mill and a vertical mill. The green production of the ore slag micro powder is realized; meanwhile, the self produced high-temperature and high-pressure steam in a steel plant is used as power in the production process, so that the cost is obviously reduced through being compared with that of the conventional process using the ball mill or vertical mill.

Owner:SICHUAN DAZHOU IRON & STEEL GROUP

Disposable oxygen catheter nose sucker processor for otolaryngology department

InactiveCN108144713ARealize the purpose of crushing againTo achieve the purpose of crushingGrain treatmentsUrologyNose

The invention relates to a processor, in particular to a disposable oxygen catheter nose sucker processor for the otolaryngology department. The invention aims to solve the technical problem so as toprovide the disposable oxygen catheter nose sucker processor for the otolaryngology department, which can be used for multi-stage processing and accomplishing under a sealed condition, and is beneficial to saving manpower and avoiding blockage. In order to solve the technical problem, the invention provides the disposable oxygen catheter nose sucker processor for the otolaryngology department. Thedisposable oxygen catheter nose sucker processor for the otolaryngology department comprises a collecting frame and the like, wherein a crushing mechanism is connected to the top part of the collecting frame; and a processing mechanism is connected into the collecting frame. In order to achieve the effects on multi-stage processing, accomplishing under the sealed condition, and saving manpower and avoiding blockage, the disposable oxygen catheter nose sucker processor for the otolaryngology department is provided with the crushing mechanism and the processing mechanism, so that a nose suckercan be multi-stage crushed, and the aim of improving the processing speed is achieved; and through arranging a cover plate, the nose sucker can be crushed under the sealed condition, and the aim of preventing chippings from being spilled is achieved.

Owner:黄东平

Crushing device for limestone machining

PendingCN113000139ATo achieve the purpose of crushingUniform particlesGrain treatmentsStructural engineeringPellets

The invention discloses a crushing device for limestone machining, and relates to the field of limestone crushing machines. The crushing device comprises a bottom supporting frame, wherein a rotary bin is arranged at the front end of the bottom supporting frame, the rotary bin is of a semi-arc shape, a crushing device body is located in the bottom supporting frame, the crushing device body and the rotary bin are matched with each other to circularly crush limestone, a mounting transverse plate is arranged on the back of the bottom supporting frame, an impact crushing device is arranged on the mounting transverse plate, and the impact crushing device conducts impact crushing on the limestone conveyed by the crushing device body. According to the device, the limestone is thrown onto a crushing plate to be crushed through a roller rotating at a high speed and a crushing claw, then the limestone is extruded and ground through the crushing claw and an extrusion plate, the limestone which falls on a screening plate and is not crushed completely is crushed again through a crushing cutter, and the crushing claw and the rotary bin carry large limestone which is still likely to remain again and throw the large limestone to the crushing plate again to be crushed again, and it is guaranteed that the crushed limestone particles are uniform.

Owner:安徽省恒金矿业有限公司

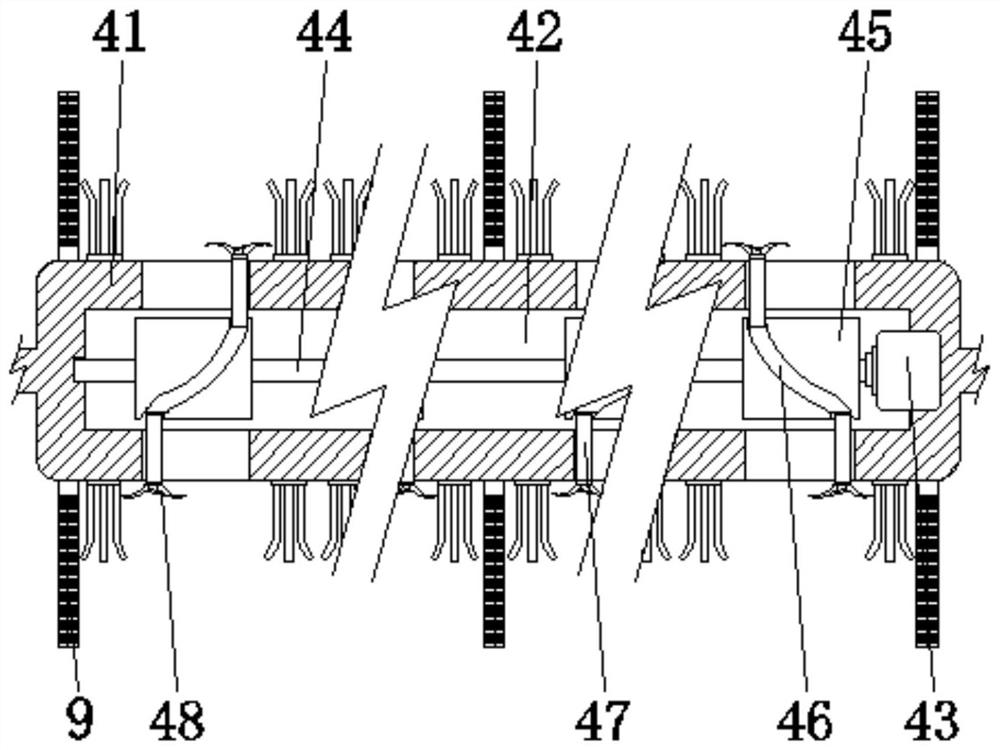

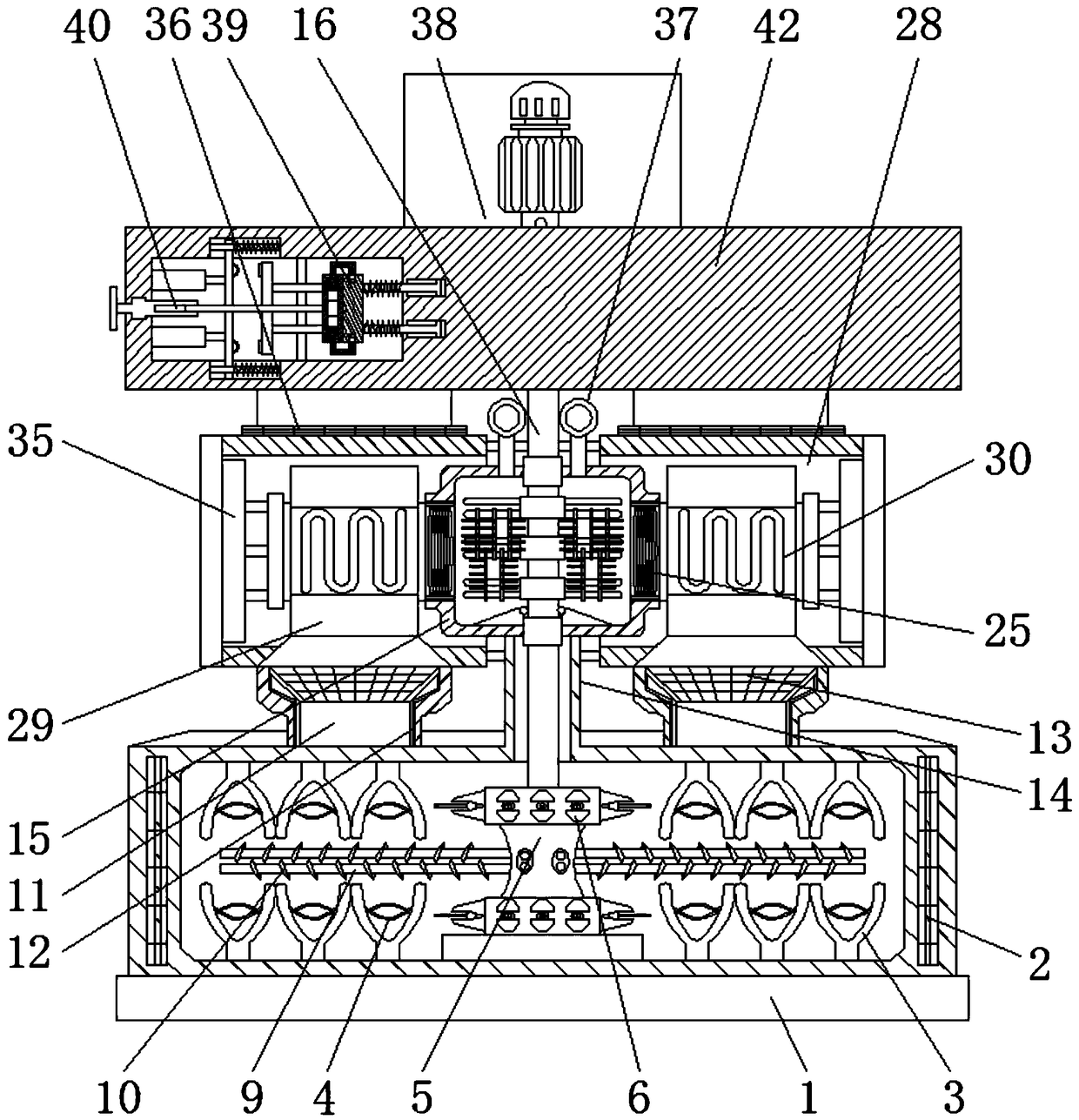

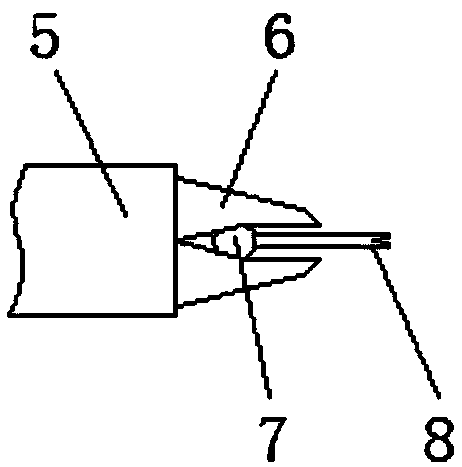

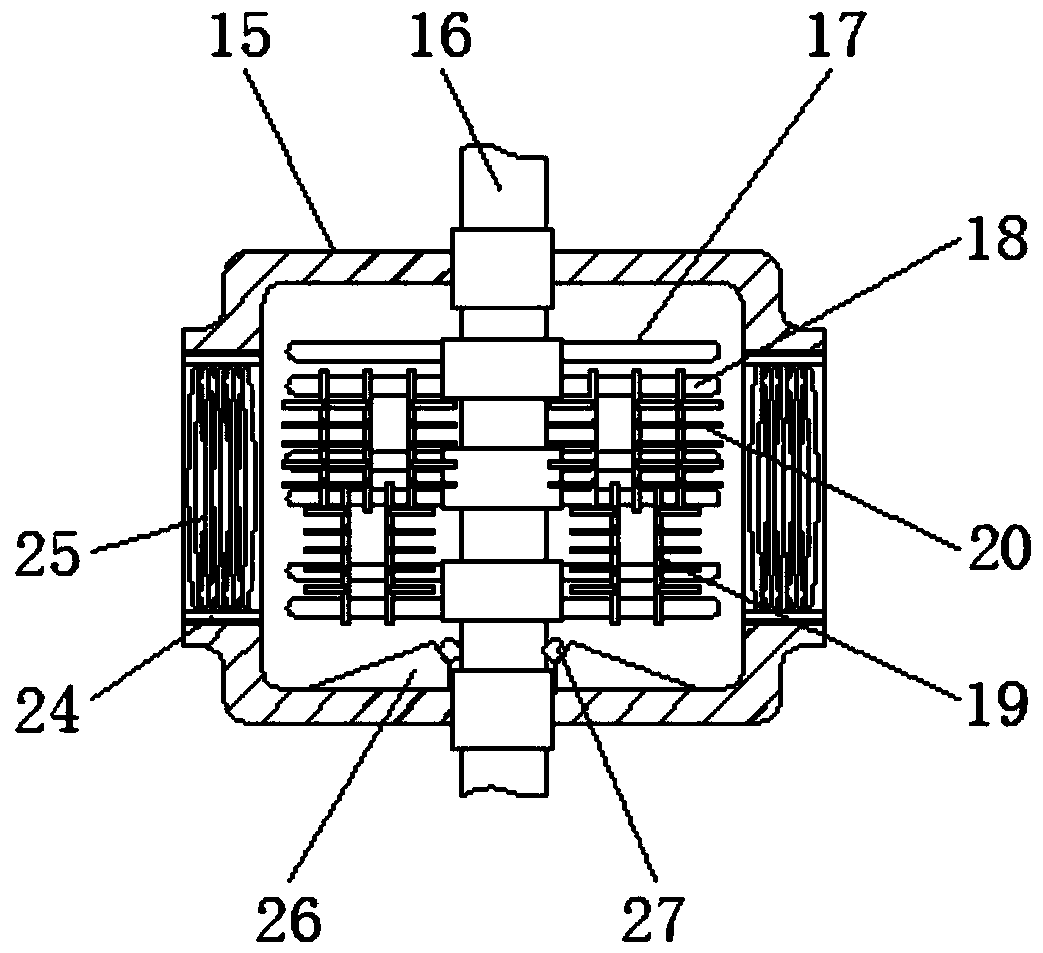

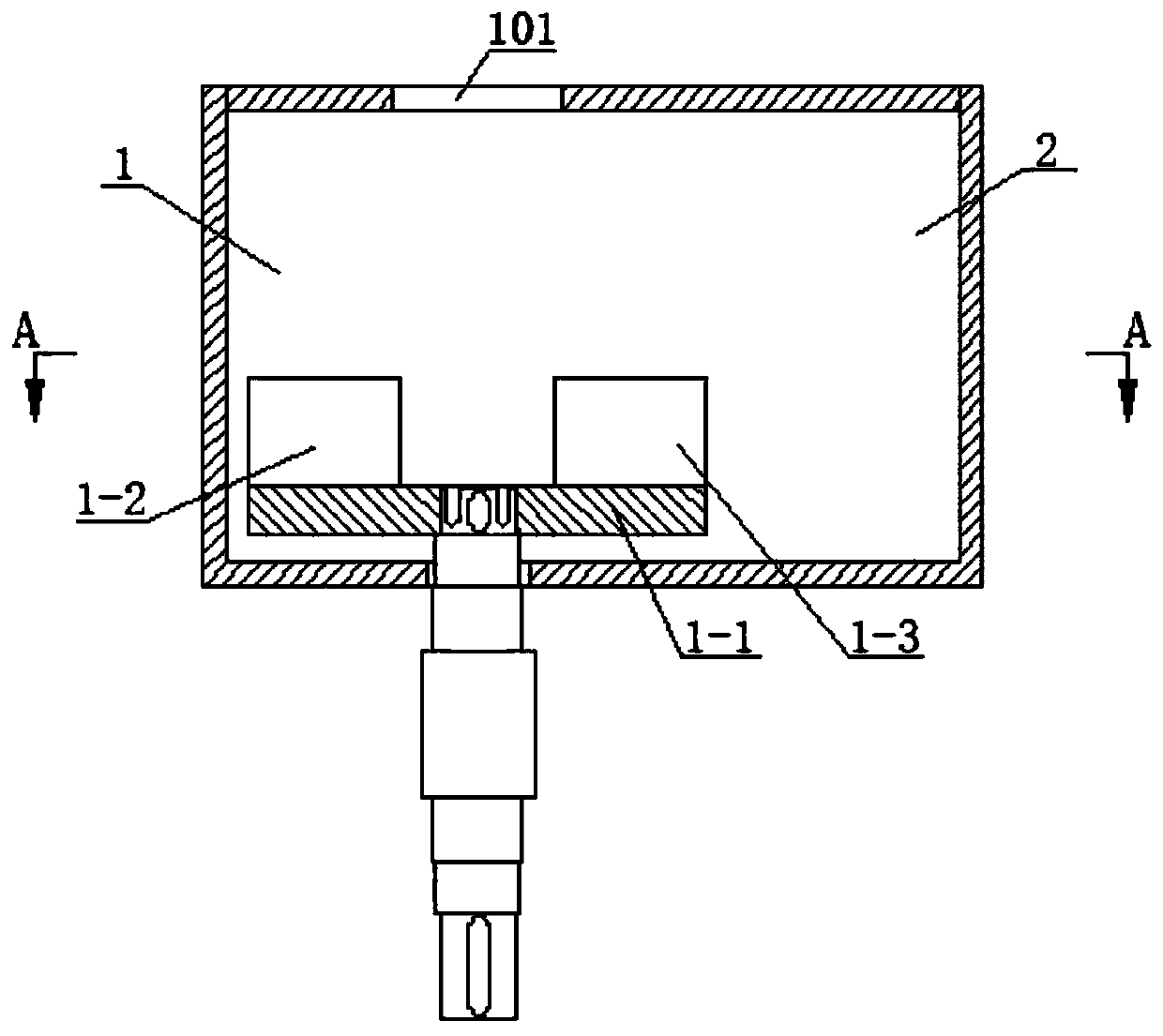

Crushing method, swirling collision crushing mechanism and multipolar crushing device

PendingCN110508375ATo achieve the purpose of crushingSolve wear and tearGrain treatmentsMechanical engineeringClassical mechanics

The invention provides a crushing method, a swirling collision crushing mechanism and a multipolar crushing device, and belongs to the technical field of hard material crushing. According to the crushing method, materials are thrown out along a tangential direction under the action of high-speed rotation, and high-speed friction and collision is generated among the thrown materials, so that the purpose of material beating is realized. The swirling collision crushing mechanism adopting the crushing method comprises a rotor assembly arranged in a material throwing cavity with a material inlet; arotating axis line of the rotor assembly is perpendicular to the ground and is parallel to a material feeding direction, so that the materials are thrown out along the tangential direction under theaction of the rotor assembly; and the crushing mechanism further comprises a crushing cavity horizontally communicating with the material throwing cavity, so that the materials thrown out along the tangential direction of the rotor assembly are collided and crushed in the crushing cavity, and abrasion to crushing equipment is avoided. The invention further provides the multipolar crushing device comprising the swirling collision crushing mechanism.

Owner:晏斯华

A kind of calcium carbonate powder grinding method

ActiveCN109174414BNo leakageAchieve smashDrying gas arrangementsDrying solid materialsPhysical chemistryMineralogy

The invention discloses a grinding method for calcium carbonate powder. The grinding method includes the steps that through a spiral feeding machine, calcium carbonate is sent into a smashing area ofgrinding devices and smashed in the smashing area through a smashing device; after smashing, the calcium carbonate enters into a first grinding area, is subjected to primary grinding through the firstgrinding device, then enters into a second grinding area, is subjected to secondary grinding through the second grinding device, and finally enters into a storage area to be stored; and in the process, the air heated by a heater enters into the smashing area, the first grinding area, the second grinding area and the storage area to heat and dry the calcium carbonate. By drying the calcium carbonate during the process of smashing and grinding, it is ensured that the calcium carbonate powder does not leak and the calcium carbonate is collected according to different grades.

Owner:石棉县亿欣钙业有限责任公司

Method for crushing electronic data

ActiveCN107358968ADegaussing completelyImprove the efficiency of degaussingErasing methodComputer equipmentData linking

The invention provides a method for crushing electronic data, and relates to computer equipment and facility. The method includes following steps: step 1, transmitting the electronic data according to the requirement of a user, and selecting a storage device as a carrier in a transmission process, wherein the storage device is preferred as a hard disc; step 2, detecting the electronic data in the hard disc, and disconnecting a data connection after determining the transmission of all the electronic data is completed; step 3, placing the hard disc with to-be-crushed data below a demagnetization apparatus, and demagnetizing the hard disc with the electronic data by employing the demagnetization apparatus; and step 4, detecting the hard disc after demagnetization processing in step 3, detecting whether the electronic data exists, repeating step 3 again if residual data appears, and finishing processing. According to the method, the to-be-crushed electronic data is exported and crushed, the electronic data can be crushed, the influence on equipment is prevented, the goal of crushing is achieved, and convenience can be brought to the users.

Owner:GUANGDONG XIANGKE SOFTWARE CO LTD

Weeding device for agricultural planting

PendingCN113068511AAchieve the purpose of mixingTo achieve the purpose of crushingMowersSpraying apparatusAgricultural scienceAgricultural engineering

The invention belongs to the technical field of weeding, crushing and stirring, and particularly relates to a weeding device for agricultural planting. Aiming at the problems that an existing weeding device for agricultural planting does not have a function of stirring herbicide and water during weeding and does not have a function of collecting and crushing removed grasses, the invention provides the following scheme that the weeding device for agricultural planting comprises a working box, wherein a stirring and herbicide spraying mechanism and a smashing mechanism are arranged in the working box; a weeding mechanism is arranged at the bottom of the working box; the stirring and herbicide spraying mechanism comprises a stirring box, a partition plate, a driving rotating rod, a rotating frame, a tooth steel ring, a first stirring rod, a second stirring rod, two stirring blades, a first gear, a second gear, a stirring motor, a herbicide spraying pipe, a herbicide spraying pump, a branch pipe plate and a spraying head; the stirring box is located in the working box; the stirring box is fixedly connected with the working box; and the partition plate is fixedly connected with the stirring box. The weeding device for agricultural planting provided by the invention is simple in structure, can stir the liquid herbicide and crush the removed grasses, and is convenient for people to use.

Owner:王秀军

Propaganda device capable of automatically adjusting layout

PendingCN114274700ATo achieve the purpose of crushingTo achieve the purpose of collectionBoard cleaning devicesDirt cleaningStructural engineeringMechanical engineering

Owner:STATE GRID SHANDONG ELECTRIC POWER CO LAIYANG POWER SUPPLY CO

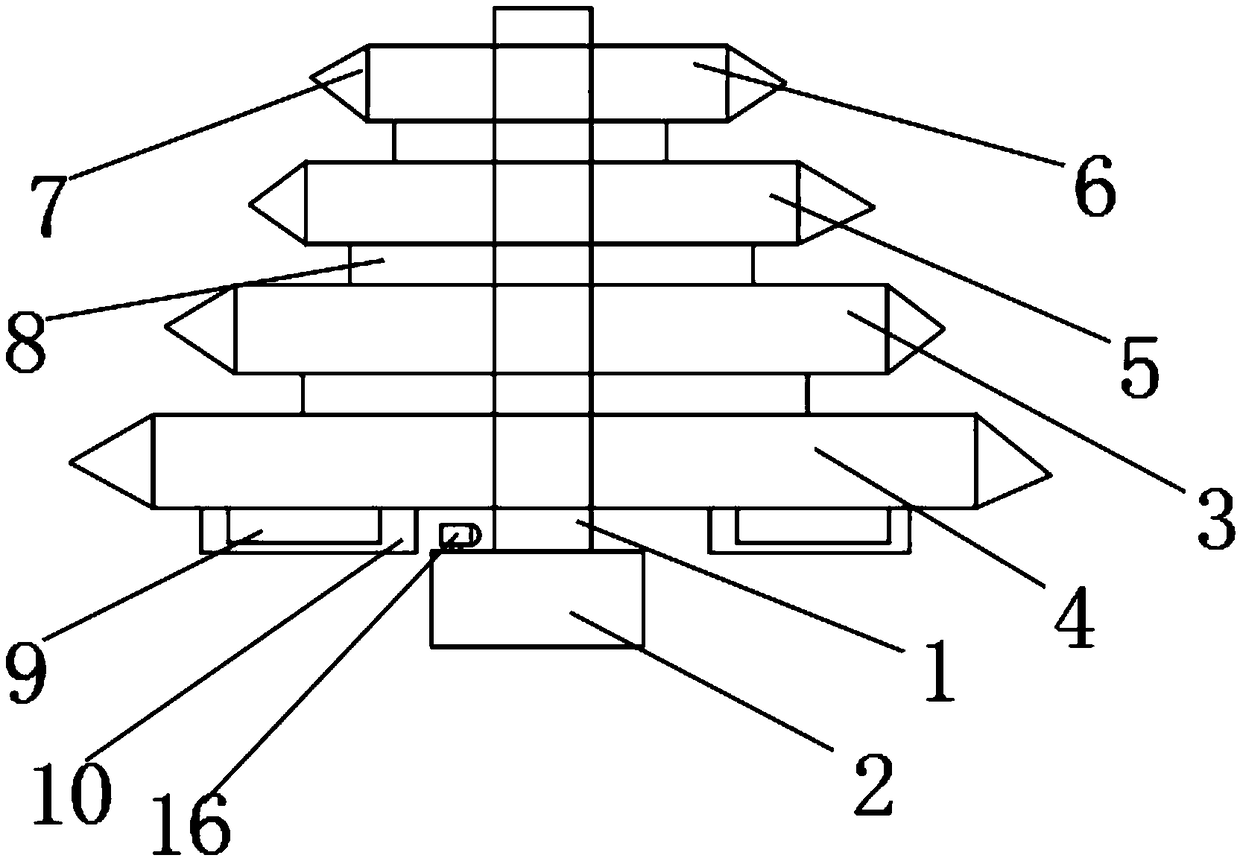

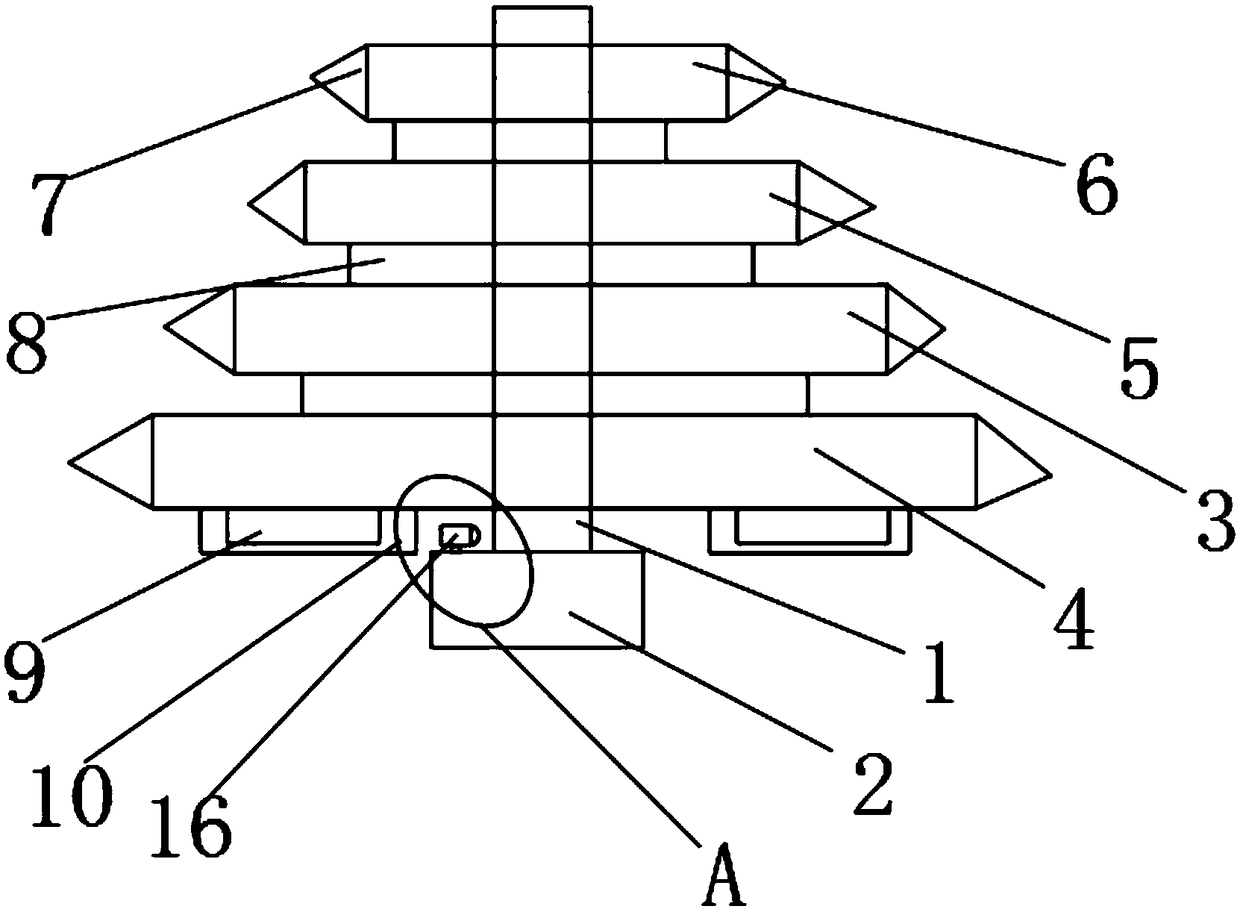

Multifunctional solid waste disposal cutter disk

InactiveCN109012964ATo achieve the purpose of crushingReduce processing efficiencySound producing devicesGrain treatmentsWater storage tankEngineering

The invention discloses a multifunctional solid waste disposal cutter disk. The multifunctional solid waste disposal cutter disk comprises a rotating shaft and a second cutter disk. The lower end of the rotating shaft is provided with a rotating wheel. A first cutter disk is arranged below the second cutter disk. A third cutter disk is arranged above the second cutter disk. A fourth cutter disk isarranged above the third cutter disk. The two ends of the fourth cutter disk are both provided with blades. One side of the fourth cutter disk is provided with a separation disk. One side of the first cutter disk is provided with a silencer. The outer surface of an outer shell is provided with a water inlet and a water outlet. The inner surface of the outer shell is provided with a water storagetank. The multifunctional solid waste disposal cutter disk is provided with a rotating speed sensing mechanism, the separation disk and the water storage tank, the working rotating speed of a machinecan be detected in real time, the situation that solid waste enters the parts between every two adjacent cutter disks and the friction force is increased can also be prevented, the temperature in thecutting process is reduced, accidents are prevented, the multifunctional solid waste disposal cutter disk is suitable for different working conditions, and better application prospects are achieved.

Owner:陈斌

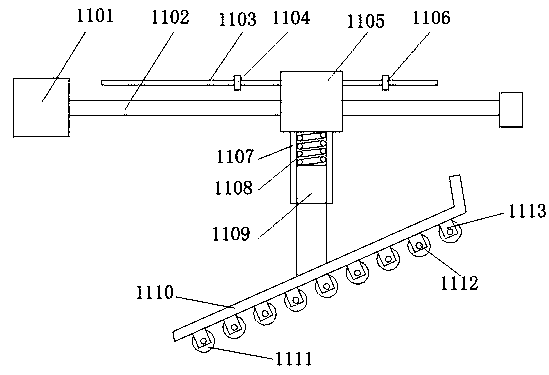

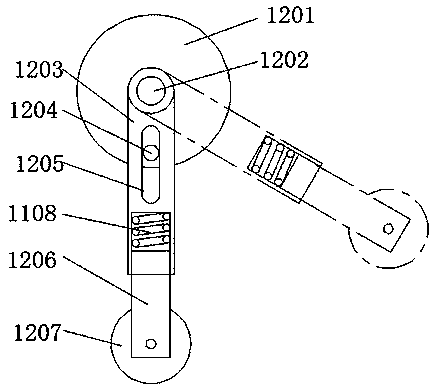

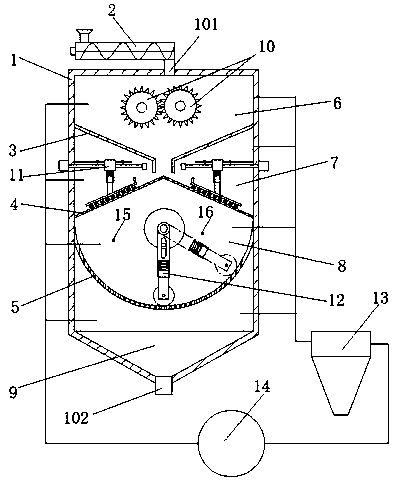

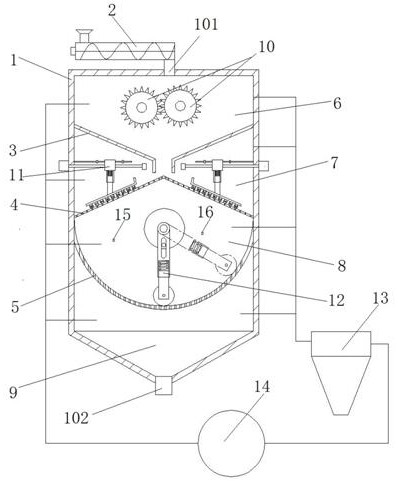

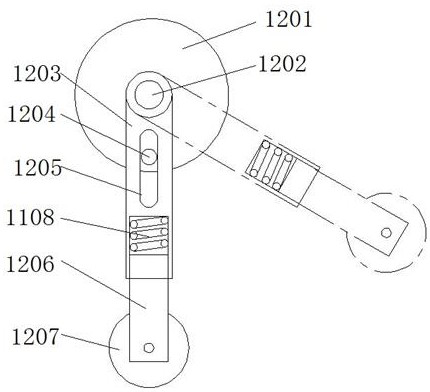

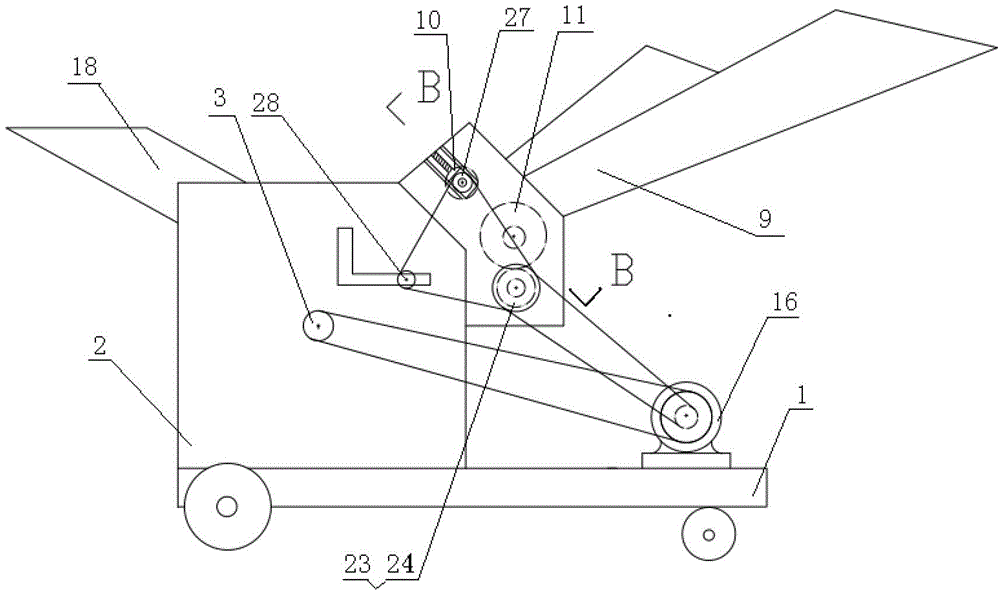

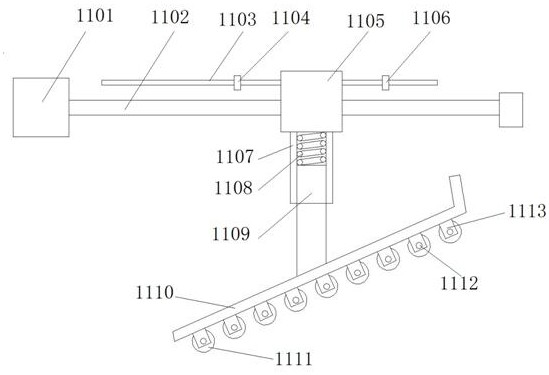

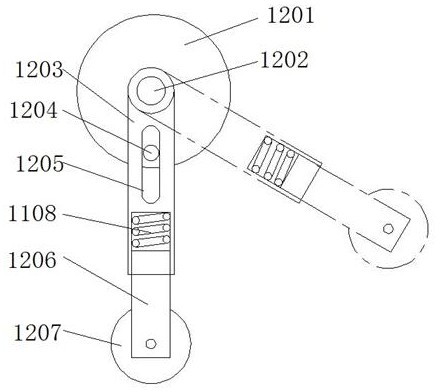

A damp caking feed crushing and drying equipment for animal husbandry

ActiveCN109351396BTo achieve the purpose of crushingDrying chambers/containersGrain treatmentsAnimal scienceAgricultural science

The invention relates to crushing and drying equipment, in particular to damp agglomerated feed crushing and drying equipment for the animal husbandry. The damp agglomerated feed crushing and drying equipment for the animal husbandry is short in crushing time of agglomerated cement, and can dry crushed feed in a swing mode. The damp agglomerated feed crushing and drying equipment for the animal husbandry comprises a mounting frame, mounting plates, a first net plate, a swing net plate, a guide wheel, a first steel wire rope, a first guide sleeve, a discharge frame, a bearing base, a first rotating rod, a connecting rod and the like; and the mounting plates are symmetrically connected between the top ends of the left and right walls of the mounting frame front and back. A speed reducing motor is started for forward and reverse alternate rotation to achieve the purpose of crushing the damp agglomerated feed without needing staff to pull the first steel wire rope; a second rotating rod isalternately rotated forwards or reversely; and a swing rod moves up and down through a cam, so that the purpose of swinging a swing frame without manually loosening the swing rod can be achieved.

Owner:黟县国有资产运营有限公司

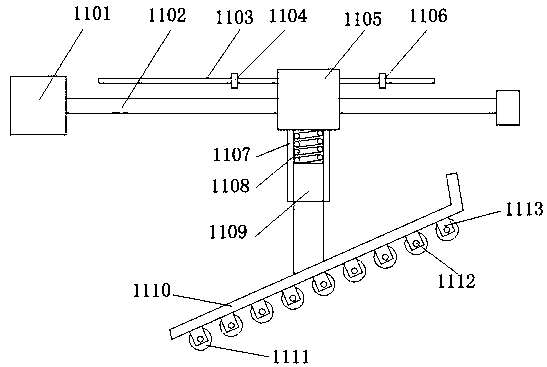

Crushing device for recycling farmland straw

The invention discloses a crushing device for recycling farmland straw. The device comprises an anti-skid sleeve, a first motor, a second motor, a first crushing device, a receiving tank, a bottom plate and a crushing box. The friction force between the hands of a user and the outer side of a handle is increased by arranging the anti-skid sleeve, so that the situation that the handle slides when the handle is held by the user is avoided. The first motor is used for rotating to drive a crushing blade on a crushing rotary shaft to rotate so as to crush the straw. The first crushing device is arranged, so that the aim of further crushing the straw is achieved, and the straw crushing effect is improved. The second motor rotates to drive a screw rod to rotate, so that a sliding block moves towards a first limiting plate on the screw rod, the receiving tank is further driven to move to the portion under a discharging pipe, the crushed straw falls into the receiving tank after passing throughthe discharging pipe, the crushed straw is collected, manual collection is not needed, and a large amount of manpower is saved.

Owner:荆门市手拉手农机股份有限公司

A multi-channel inlet, ventilating, exhausting, pressure-controlled and temperature-controlled smelting furnace for recycling plastics

InactiveCN108908789BEasy to storeInfluence transfer processPlastic recyclingCharge composition/stateTemperature controlThermal insulation

The invention discloses a multi-channel smelting furnace capable of ventilating, exhausting, pressure-relieving and temperature-controlled recycling of plastics, which includes a preparation chamber and a melting chamber. There is a fixed connection frame, and an external thermal insulation electric heating sleeve is arranged on the outside of the melting chamber, and the melting chamber is located above the fixed connection frame. The multi-channel inlet, ventilated, pressure-exhausted and temperature-controlled smelting furnace for recycled plastic achieves the purpose of continuous and intermittent heating of the plastic in the preparation room through uniformly arranged electric heating racks and electric heating nets installed on each electric heating rack, making the preparation room The plastic in the chamber can be kept in a fluid state at all times, so that the plastic can be better stored in the preparation chamber. When the plastic enters the preparation chamber, it first enters through the feed pipe and contacts the transition heat of the transition heating tube. After heating, ensure its own flow state, and avoid the plastic from condensing on the inner wall of the feed pipe, which will cause the blockage of the feed pipe.

Owner:安徽圣贝诺建筑装饰工程有限公司

Branch slicing shredder

The invention relates to a branch slicing shredder. A shell and a motor are fixed on a base of the shredder, a round cutter I and a round cutter II are installed in the shell through a spindle, a jaw plate is fixed below the shell, hammer components uniformly distributed between the round cutter I and the round cutter II and a driving cutter are arranged in a stagger manner, an upper feed roller and a lower feed roller are installed on the main feed port of the shell, a main stationary knife is fixed below the main feed port, auxiliary moving cutters are uniformly distributed on the outer side surfaces of the round cutter II, a support plate is fixed below the side feed port of the shell, the motor is used for driving the spindle and the upper feed roller as well as the lower feed roller, and fan blades are installed in the shell through the spindle. According to the branch slicing shredder, the side plane of the round cutter II is used for locating so as to control the feeding length of a hard branch with large diameter, the moving cutters installed on the side plane of the round cutter II is used for planing and slicing, and both thick branches and thin branches can be fed smoothly through automatic regulation of the gap size of two feed rollers.

Owner:扶风永恒农牧机械制造有限责任公司

A kind of calcium carbonate powder grinding device

ActiveCN109174415BAchieve smashAchieve dryingDrying gas arrangementsDrying solid materialsEngineeringMaterials science

The invention discloses a grinding device for calcium carbonate powder. The grinding device comprises a casing, wherein a feeding inlet is arranged on the casing; and the feeding inlet is connected with a screw feeder. The grinding device is characterized by further comprising a cyclone separator and a heater. The casing is internally and sequentially provided with a guiding plate, a first grinding sieve plate and a second grinding sieve plate from top to bottom, and the guiding plate, the first guiding sieve plate and the second grinding sieve plate divide the interior of the casing into fourareas; the four areas sequentially include the smashing area, the first grinding area, the second grinding area and the storage area from up to down; the smashing area is internally provided with a smashing device; the first grinding area is provided with a first grinding device; the second grinding area is provided with a second grinding device; the four areas communicate with the cyclone separator; the cyclone separator is connected with the heater; and an outlet of the heater communicates with the four areas. The grinding device can smash and then grind calcium carbonate, dry the powder during grinding, and effectively prevent the dust in the grinding device from leaking.

Owner:石棉县亿欣钙业有限责任公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com