Crushing method, swirling collision crushing mechanism and multipolar crushing device

A technology of crushing mechanism and crushing device, applied in grain processing and other directions, can solve problems such as wear and tear of crushing equipment, and achieve the effect of avoiding wear and tear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

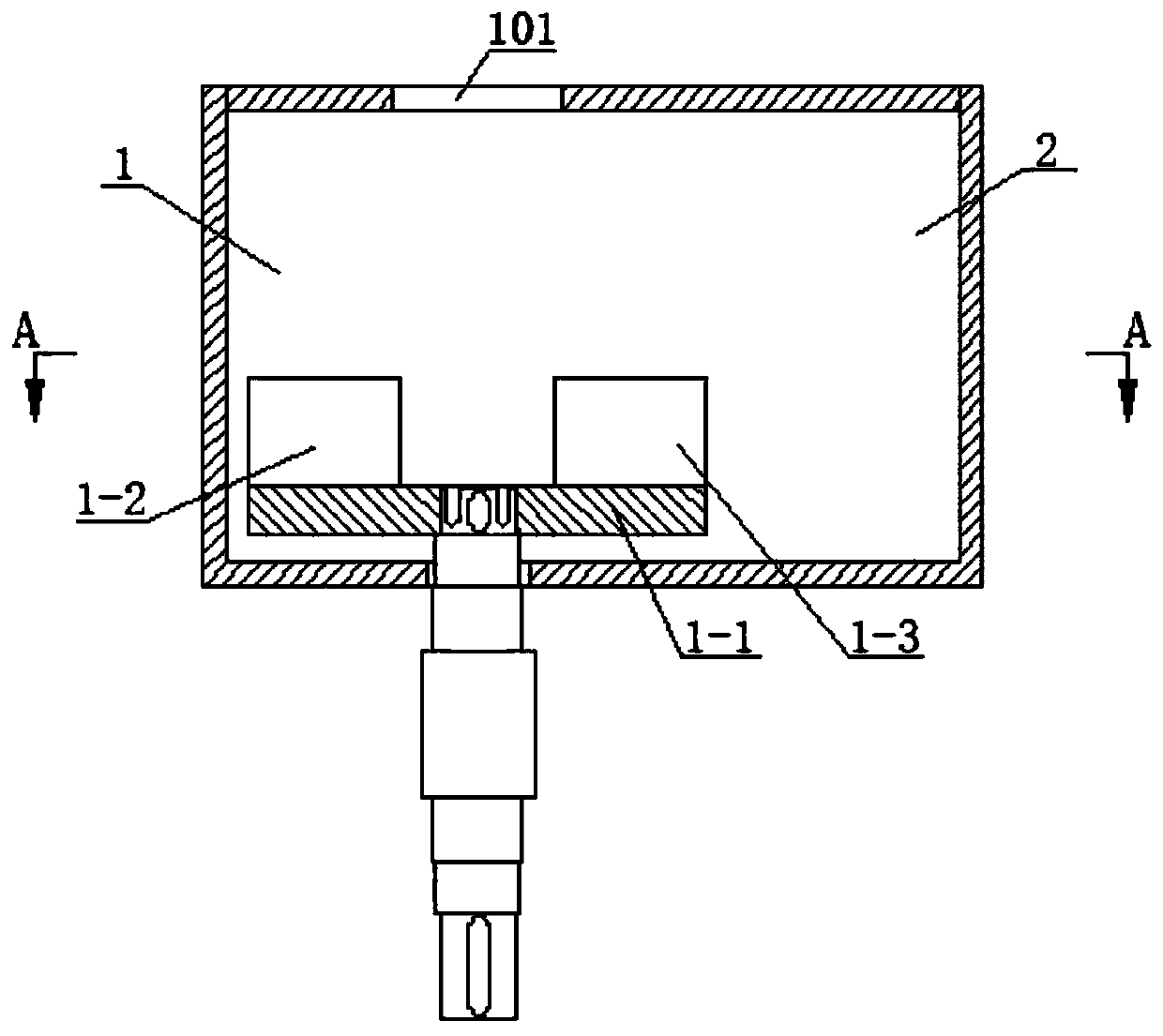

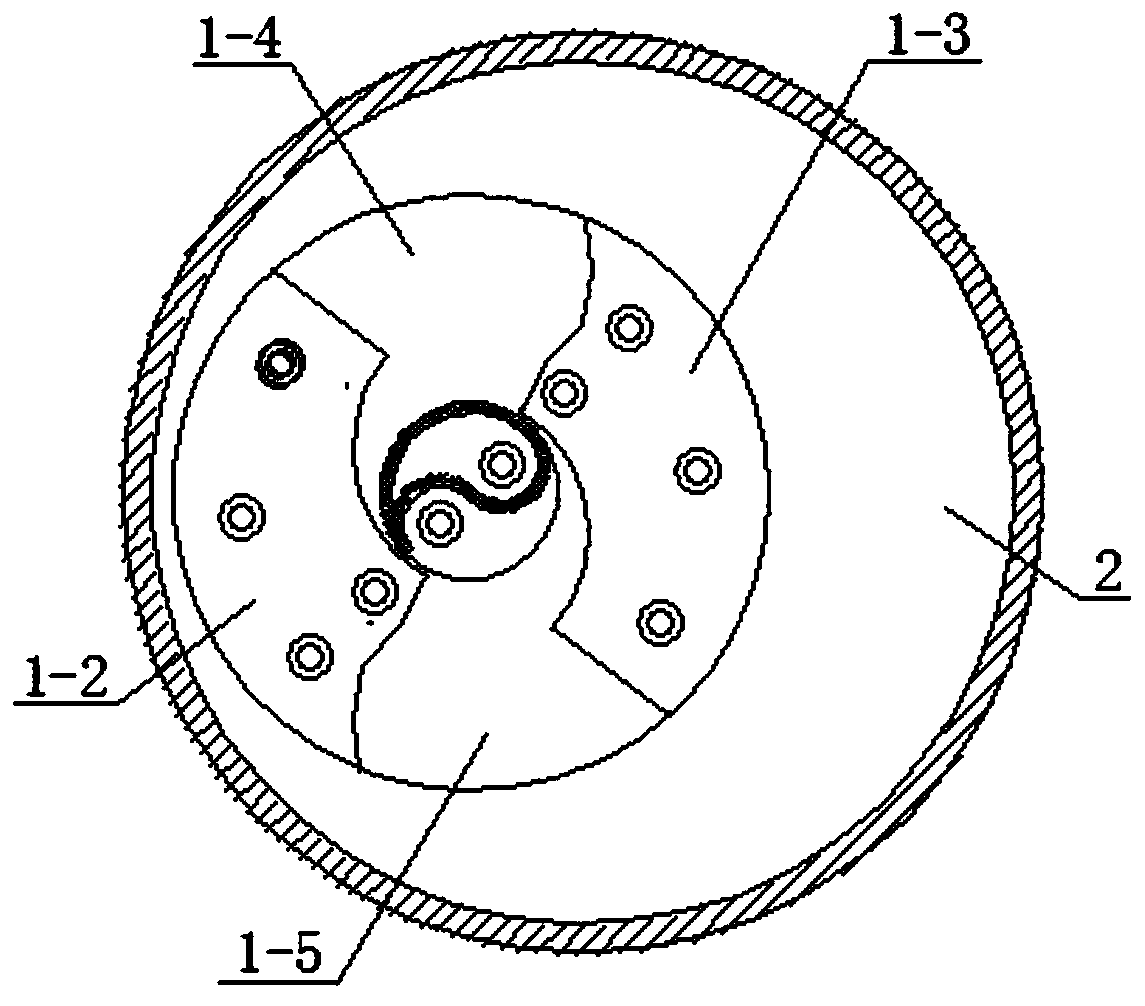

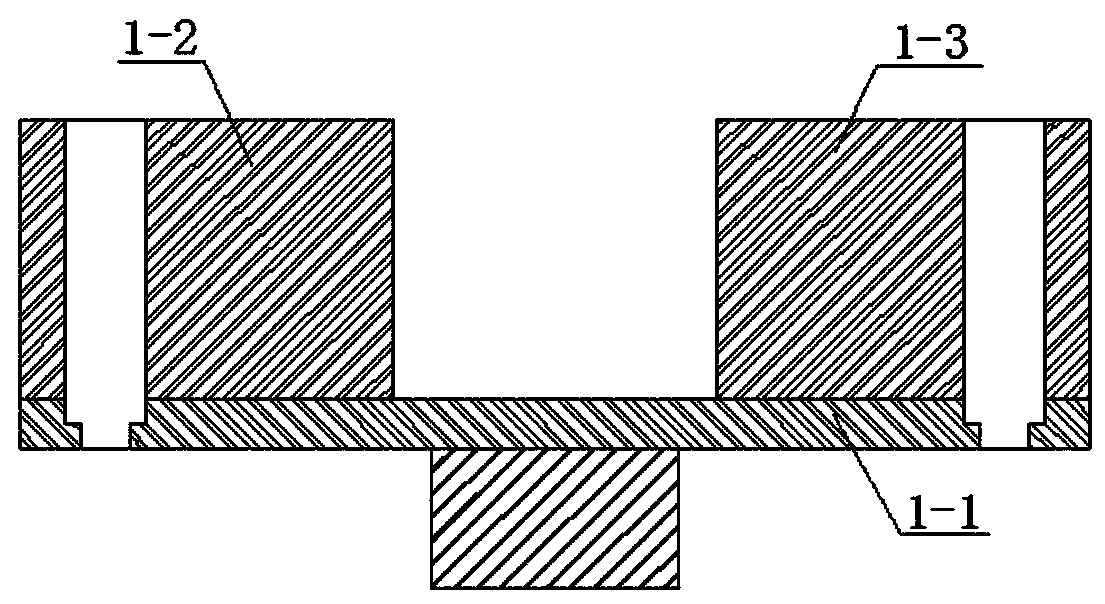

[0029] In order to solve the problems existing in the prior art, this embodiment provides a swirl type colliding crushing mechanism, such as Figure 1-3 As shown, it includes: a rotor assembly, which is accommodated in the material rejection chamber 1 provided with a feed inlet 101, and the rotation axis of the rotor assembly is arranged in a vertical direction, and is parallel to the material feeding direction so that the material is in the Under the action of the rotor assembly, it is thrown tangentially; it also includes a crushing chamber 2, which is horizontally connected with the material throwing chamber 1, so that the materials thrown out tangentially along the rotor assembly are collided and crushed in the crushing chamber 2. In this way, after the material is fed, it can be thrown out along the tangential direction under the high-speed rotation of the rotor assembly, and high-speed friction and collision will occur between the material particles thrown out along the t...

Embodiment 2

[0035] The present invention also provides a multi-pole crushing device, such as Figure 4 As shown, it includes a hopper 3 and a discharge chamber 4, and the swirl type colliding crushing mechanism of the embodiment 1 is communicated between the hopper 3 and the discharge chamber 4. Specifically, the hopper 3, the collision swirling crushing mechanism, and the discharge chamber 4 are distributed up and down in sequence.

[0036] In this embodiment, the discharge end of the hopper 3 is evenly provided with a plurality of material distribution ports 301 in a ring shape, and the material distribution ports 301 are connected with the material rejection chamber 1 in Embodiment 1, and each of the material removal ports Cavities 1 are provided with the collision swirl crushing mechanism. Specifically, such as Figure 5As shown, there are four throwing chambers 1, and the bottom end of the corresponding hopper 3 is provided with four distribution ports 301, that is, the distributio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com