A kind of calcium carbonate powder grinding device

A technology of calcium carbonate powder and grinding device, which is used in drying gas arrangement, lighting and heating equipment, grain processing, etc. the effect of leaking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

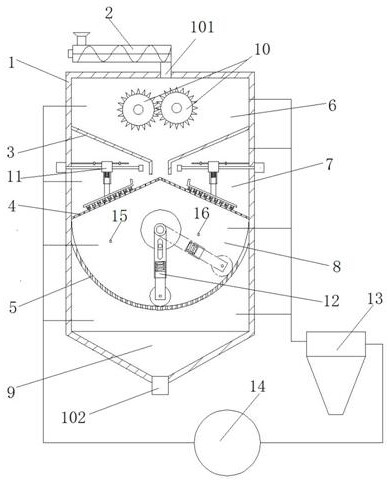

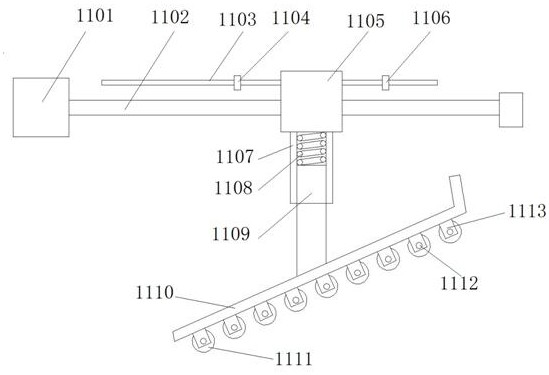

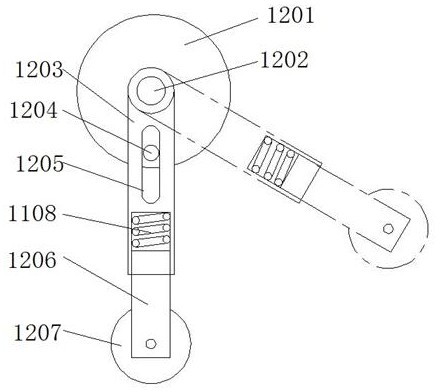

[0023] This implementation includes a housing 1, the housing 1 is provided with a feed port 101, and the bottom of the housing 1 is provided with a discharge port 102, and the feed port 101 is connected with a screw feeder 2. This embodiment also includes a cyclone separator 13 and a heater 14, the housing 1 is sequentially provided with a material guide plate 3, a first grinding sieve plate 4 and a second grinding sieve plate 5, which divide the inside of the housing 1 into four areas from top to bottom. The above four areas are sequentially from top to bottom the crushing area 6, the first grinding area 7, the second grinding area 8 and the storage area 9, the crushing area 6 is provided with a crushing device, and the first grinding area 7 is provided with The first grinding device, the second grinding area 8 is provided with a second grinding device 12, and the four areas are all communicated with the cyclone separator 13, and the cyclone separator 13 is connected with a he...

Embodiment 2

[0030] This embodiment is further optimized on the basis of Embodiment 1. In this embodiment, the connection position between the first grinding sieve plate 4 and the housing 1 is provided with a material return port, and the material guide plate 3 and the housing 1 The connection position is provided with a material return inlet, and the material return port and the material return inlet are connected through the first screw feeder.

[0031] Principle of the present invention is as follows:

[0032] First, feed through the screw feeder 2, and the calcium carbonate enters the crushing area 6 and is pulverized through the crushing device; then enters the first grinding area 7 and undergoes primary grinding through the first grinding device; then enters the second grinding area 8 undergoes secondary grinding through the second grinding device 12, and finally enters the material storage area 9 for storage; during the process from the material storage area 6 to the material storag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com