Patents

Literature

92 results about "Aragonite" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Aragonite is a carbonate mineral, one of the three most common naturally occurring crystal forms of calcium carbonate, CaCO₃ (the other forms being the minerals calcite and vaterite). It is formed by biological and physical processes, including precipitation from marine and freshwater environments.

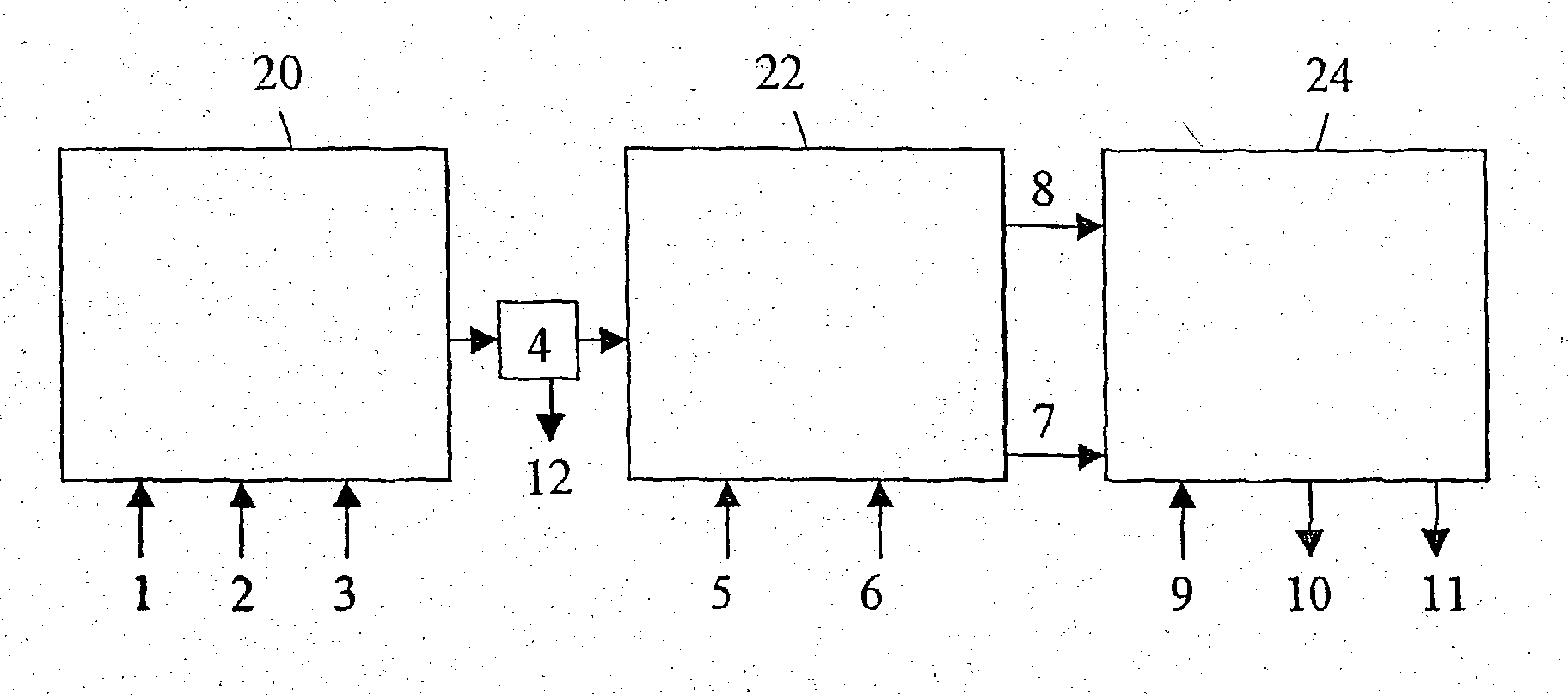

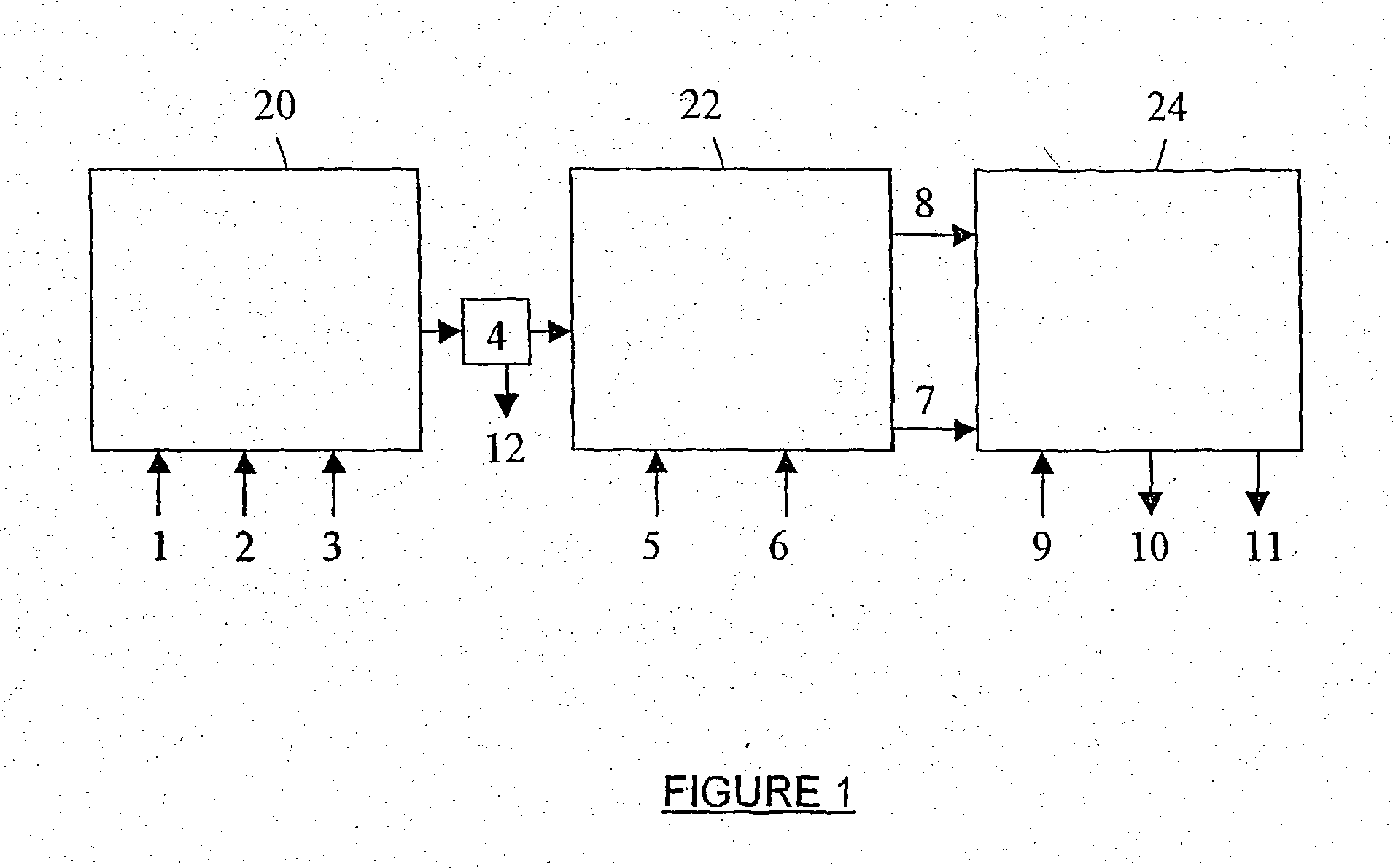

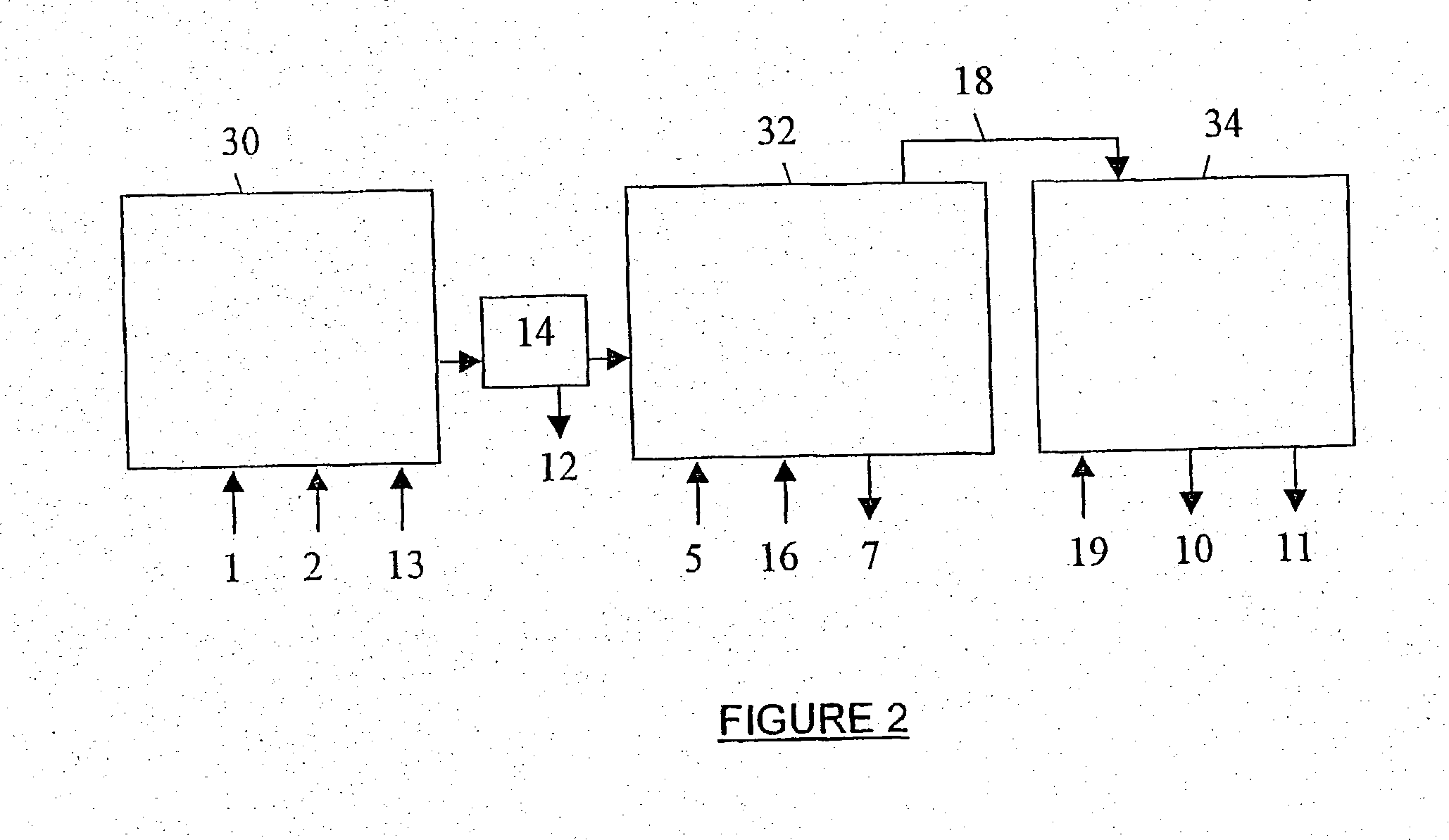

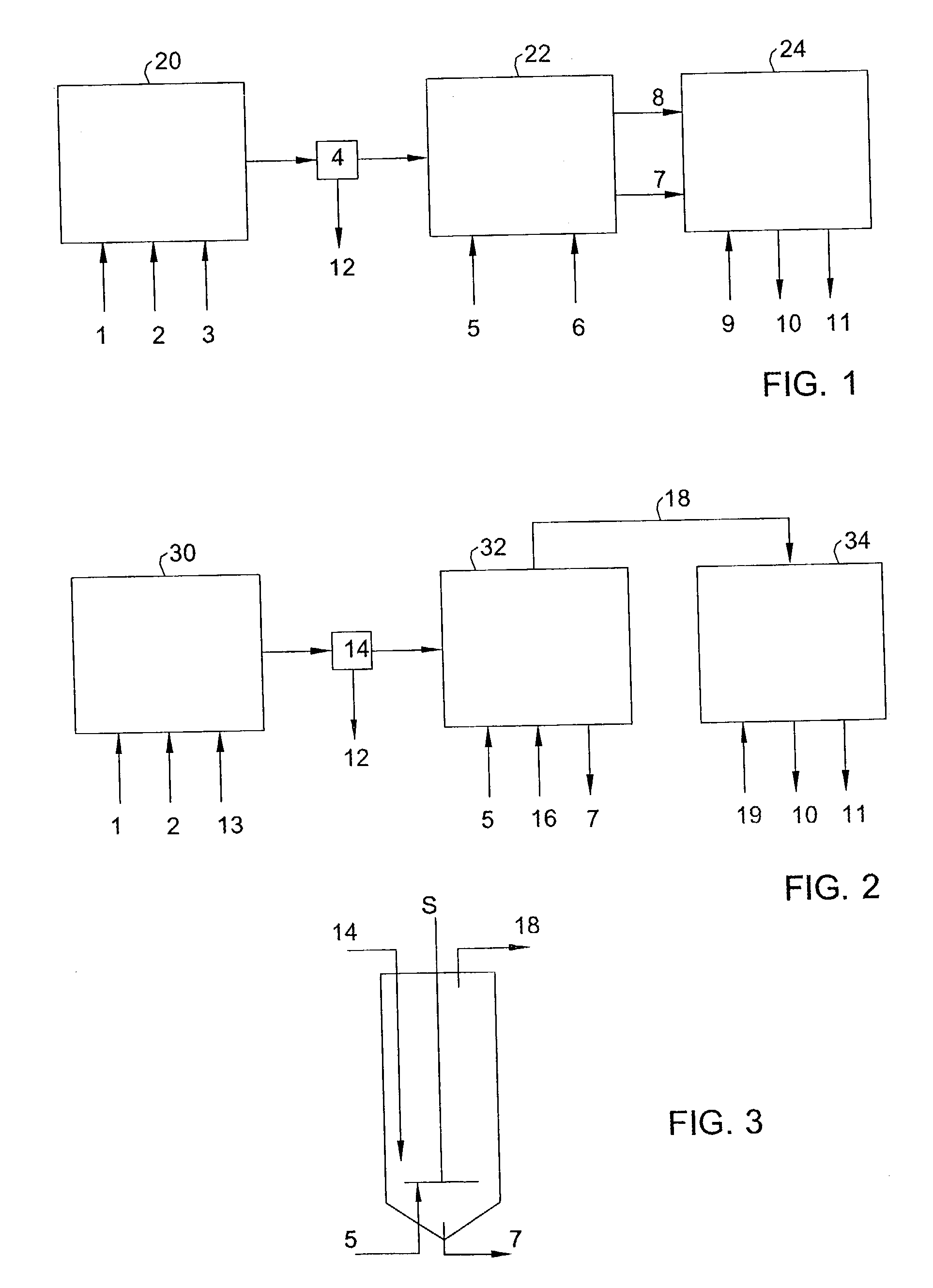

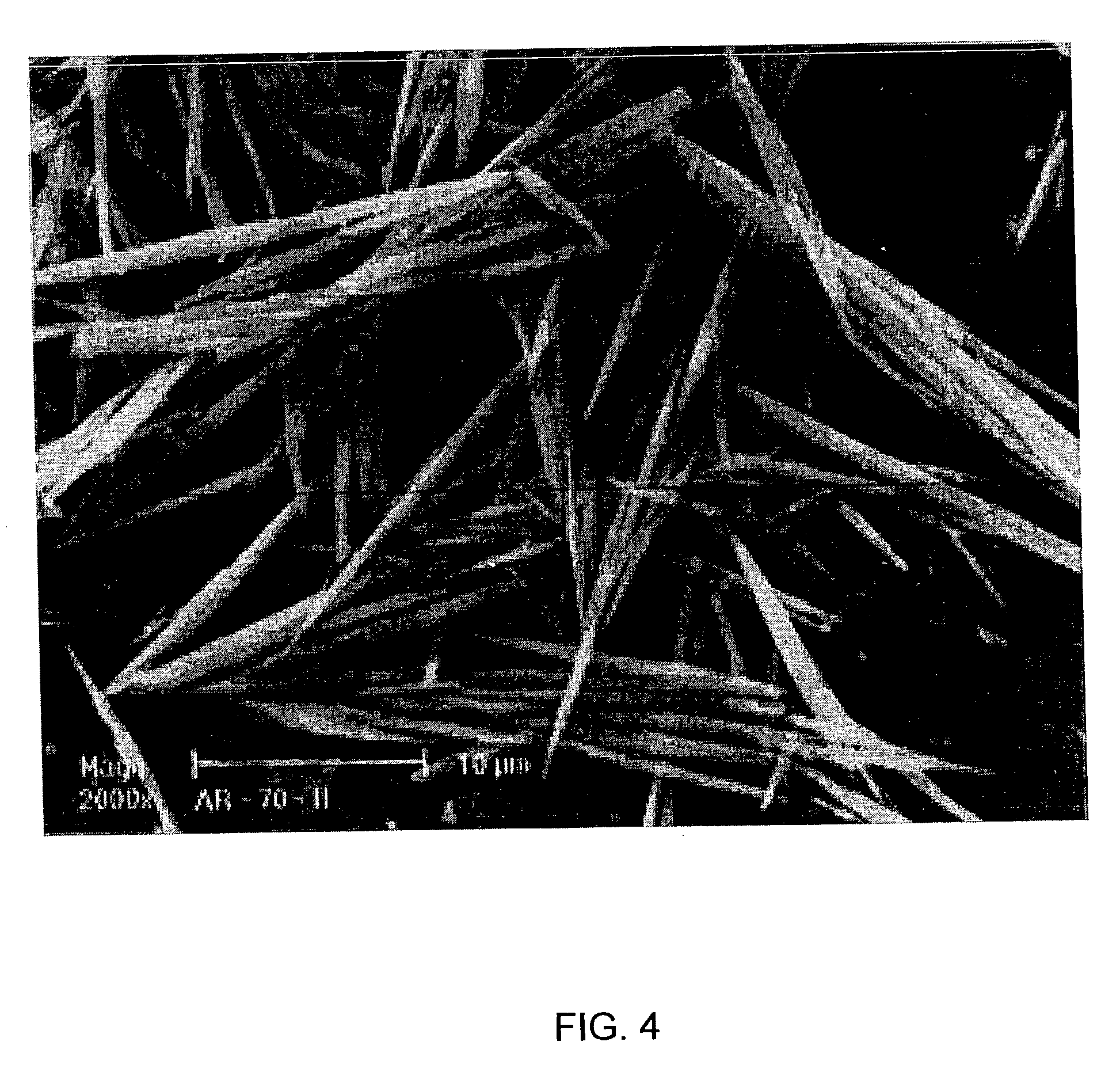

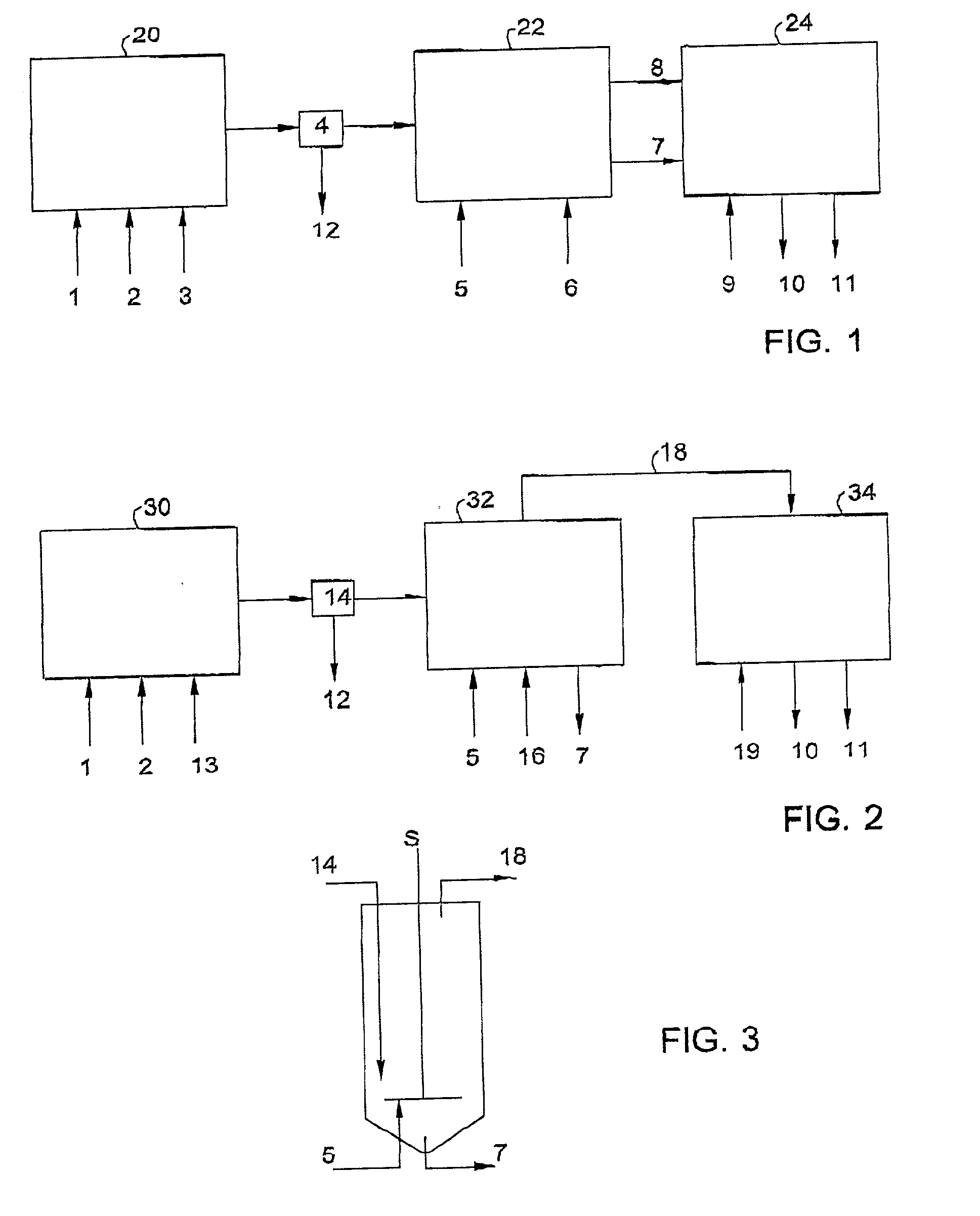

Precipitated aragonite and a process for producing it

InactiveUS20030213937A1Less expensiveEfficient and less-expensiveCalcium/strontium/barium carbonatesInorganic/elemental detergent compounding agentsParticulatesAragonite

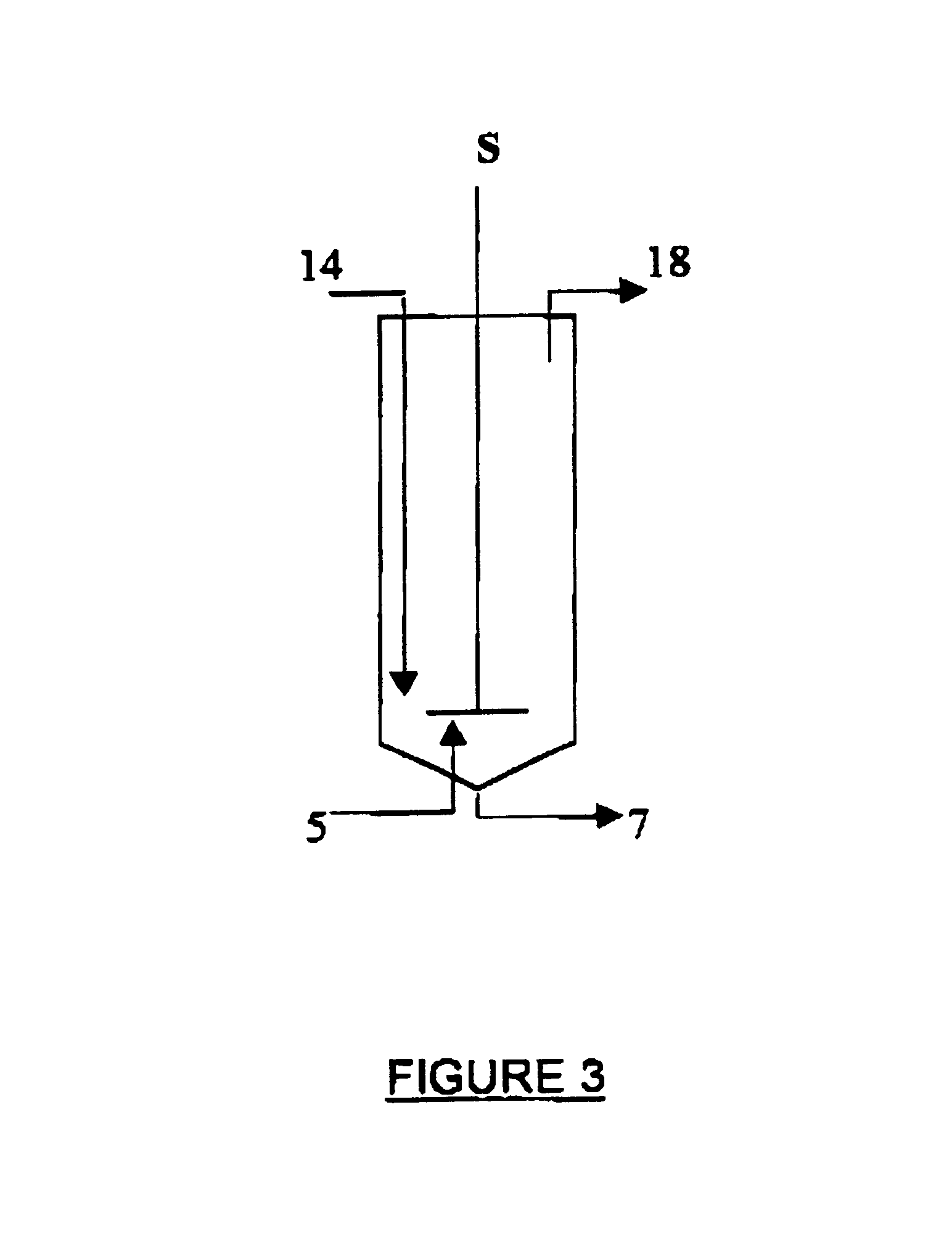

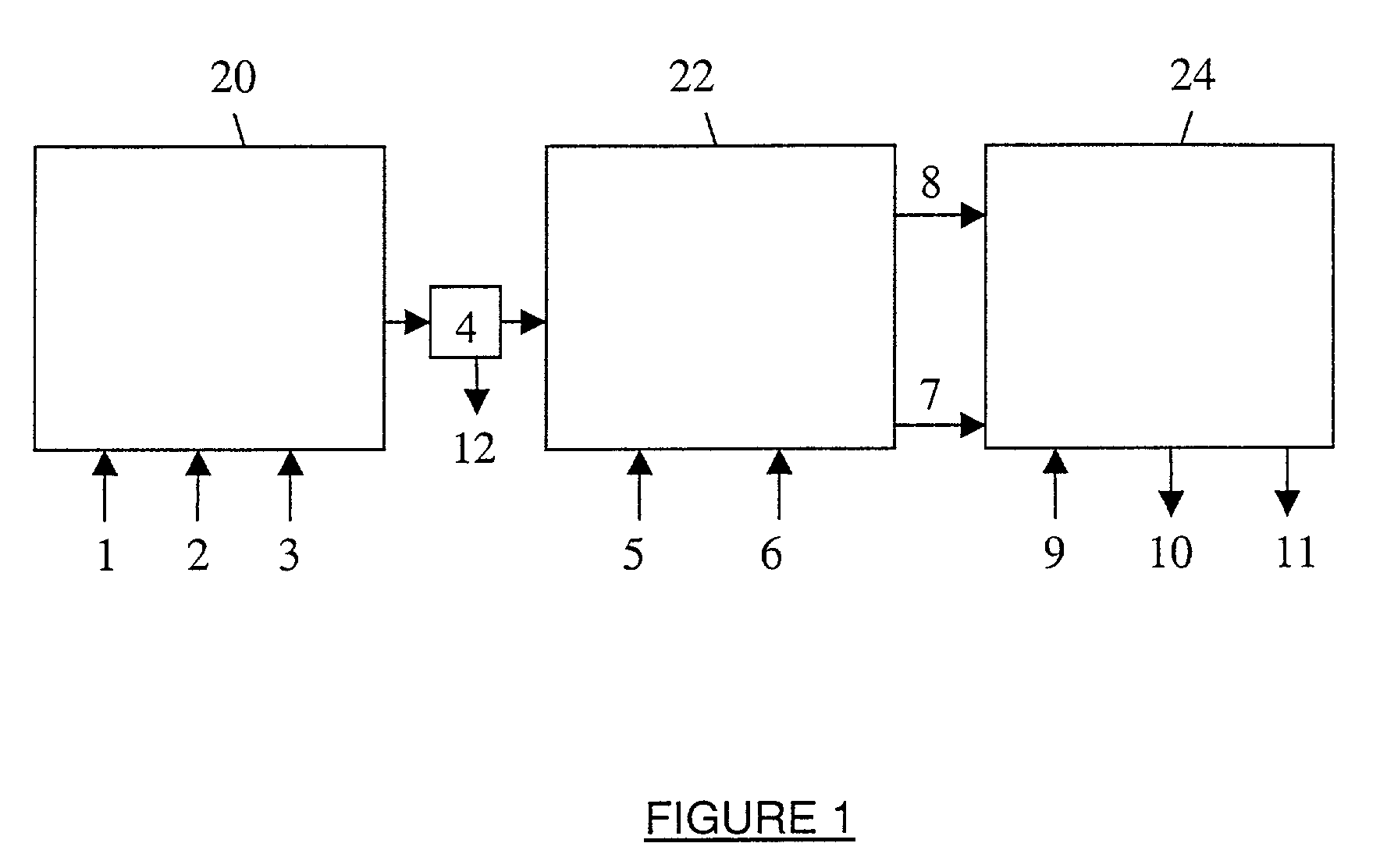

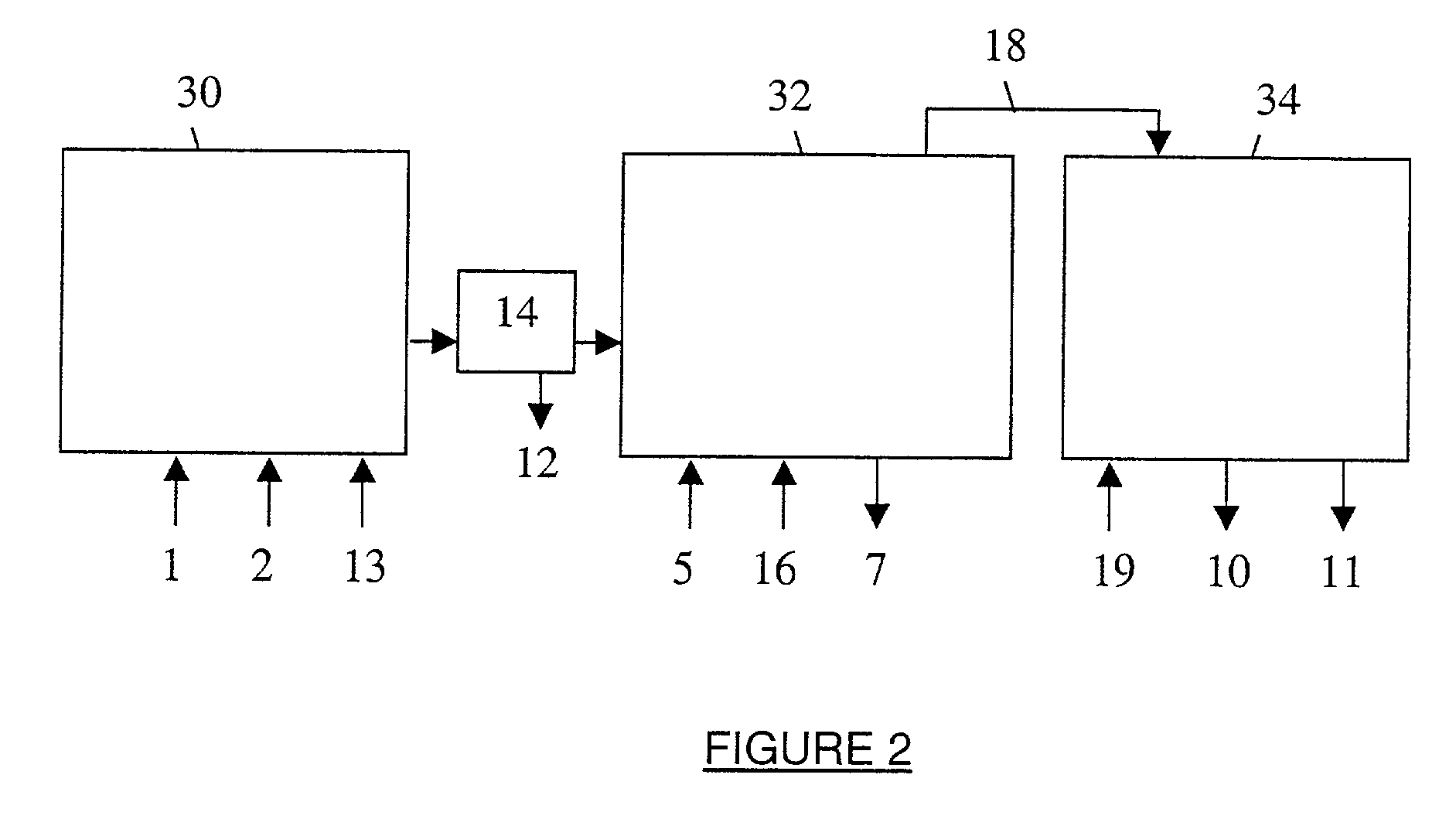

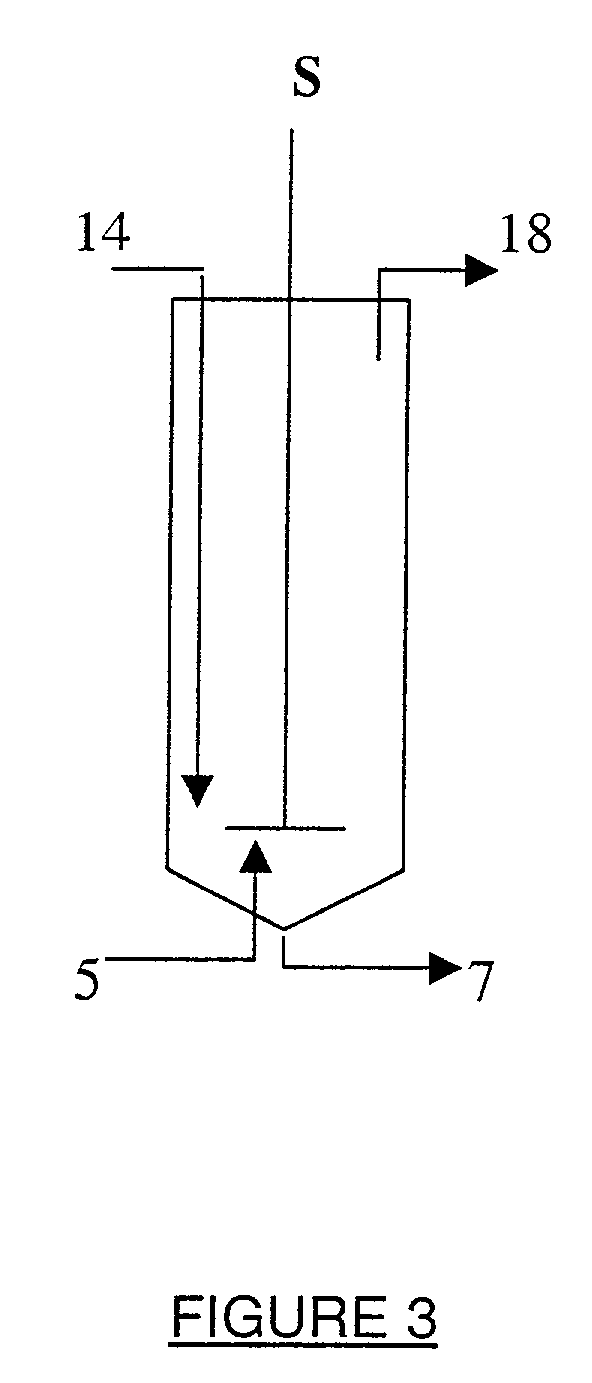

Disclosed is a novel form of particulate precipitated aragonite, and a novel process for producing it.

Owner:3P TECH

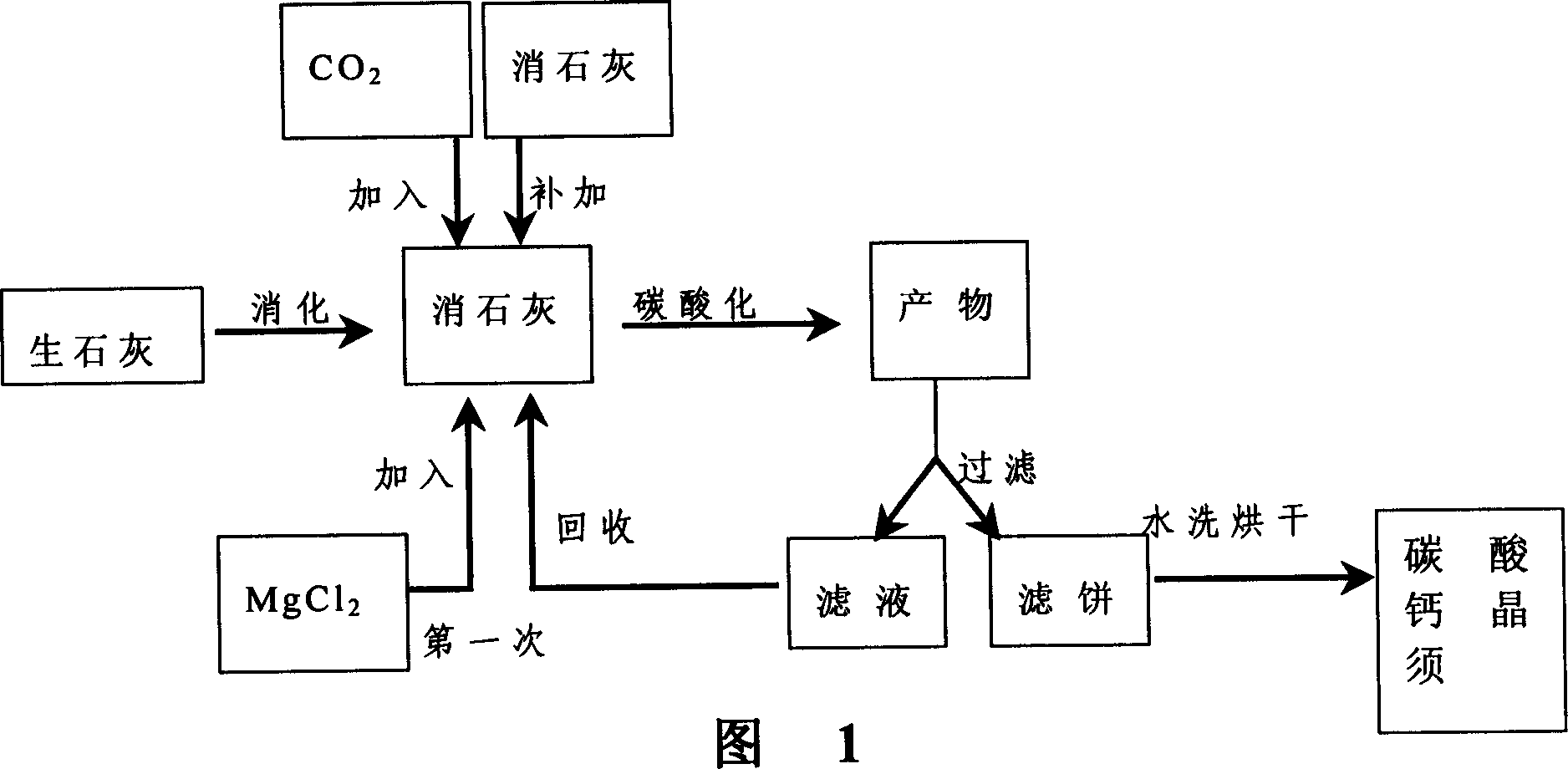

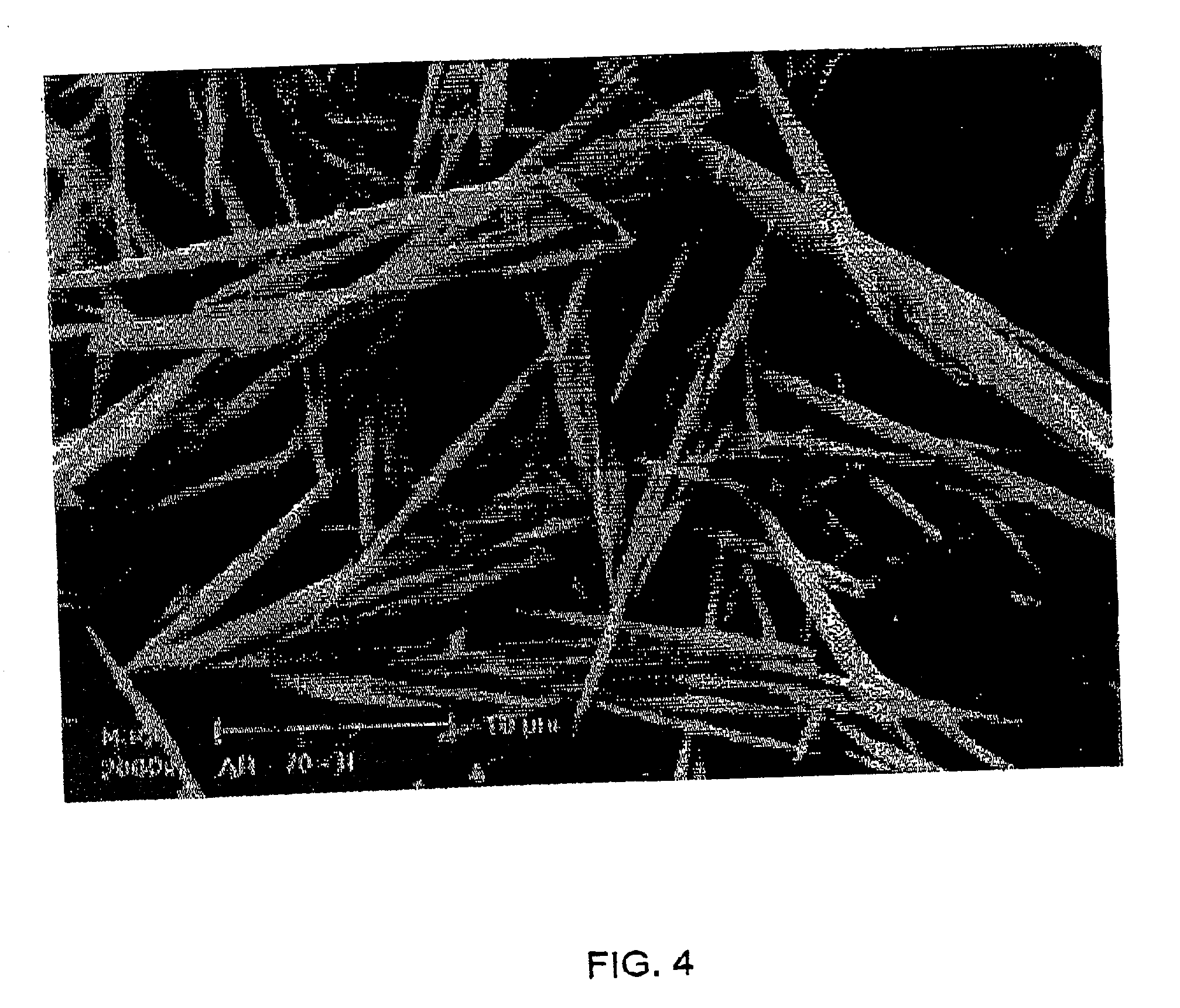

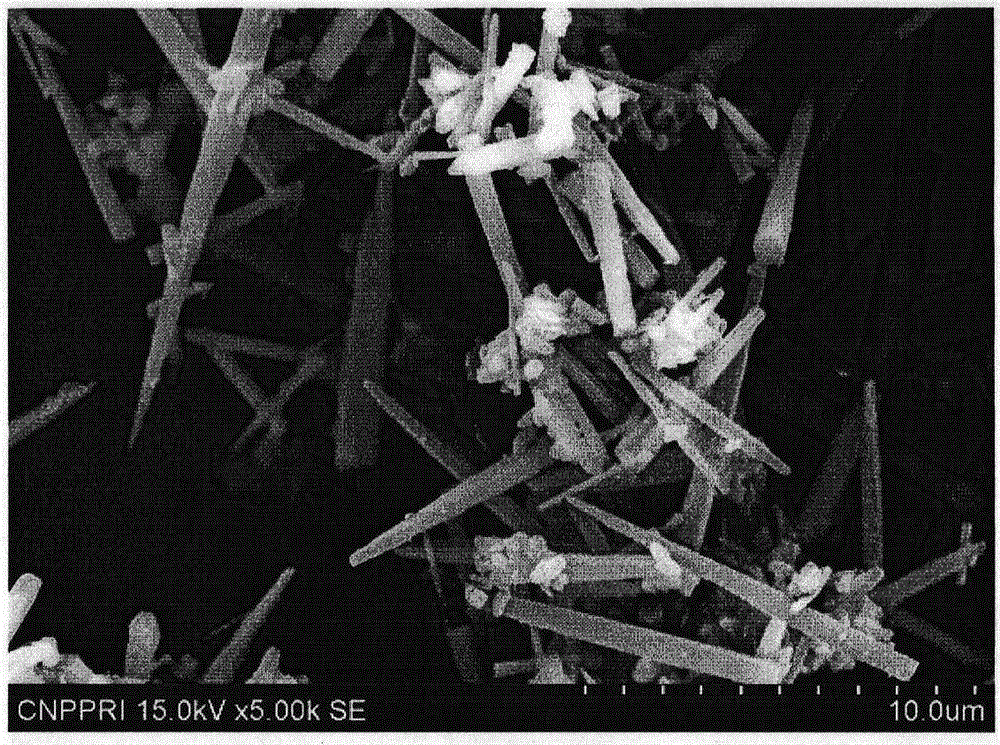

Method for preparing aragonite type calcium carbonate whisker

InactiveCN1641077AReduce manufacturing costReduce qualityCalcium/strontium/barium carbonatesPolycrystalline material growthMagnesium saltDiameter ratio

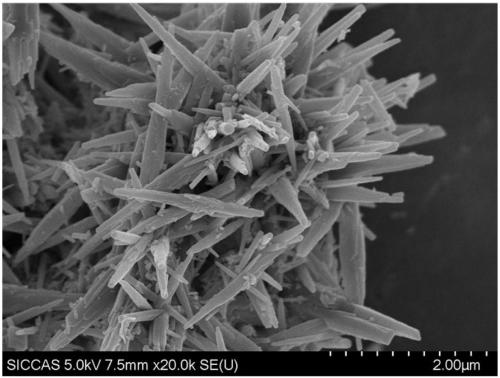

The present invention relates to the preparation process of high purity aragonite type calcium carbonate whisker. The present invention prepares aragonite type calcium carbonate whisker with lime or slaked lime as main material and magnesium salt as crystal salt controlling agent and through a CO2 carbonating process. The process features the repeated use of the magnesium salt solution and the homogeneous replenishment of lime slurry during carbonating reaction. The process has low production cost, less environmental pollution and high calcium carbonate whisker yield, and the prepared calcium carbonate whisker has high purity and high length / diameter ratio. The process is suitable for industrial production of calcium carbonate whisker.

Owner:NAT UNIV OF DEFENSE TECH

Precipitated aragonite and a process for producing it

InactiveUS6685908B1Less expensiveEfficient and less-expensiveInorganic/elemental detergent compounding agentsCalcium/strontium/barium carbonatesParticulatesAragonite

Owner:3P TECH

Preparation method of aragonite crystal form calcium carbonate

InactiveCN101570344ASuitable for industrial productionLow priceCalcium/strontium/barium carbonatesLiquid productDigestion Treatment

The invention relates to a preparation method of aragonite crystal form calcium carbonate, comprising the following steps: lime is sent into a digestion equipment and added with water for digestion treatment, water and quick lime are added slowly according to the ratio of 3:1 to 5:1, calcium hydroxide emulsion is obtained by filtrating, the calcium hydroxide emulsion is sent into a carbonization equipment, magnesium hydroxide needle crystal is added as a seed crystal, CO2 is injected in the materials which are mixed at the same time, aragonite crystal form light calcium carbonate is obtained by carbonization reaction; the light calcium carbonate screened pulp is sent into a filtration device for dehydrating and calcium carbonate filter cake is obtained; the sodium polyacrylate is added as a dispersant and light calcium carbonate with particle size distribution of 1-2 mum is obtained after grinding, thus obtaining a dispersion liquid product which reachs 70% of solid content or the liquid product is sent into a drying device for drying to obtain light calcium carbonate dry powder. The preparation method enjoys cheap price, simple preparation process and perfect performance, thus being applicable to the industrialized production. The obtained aragonite crystal form calcium carbonate is suitable to be a papermaking coating.

Owner:董承智

Precipitated aragonite and a process for producing it

InactiveUS20010033820A1Less expensiveEfficient and less-expensiveCalcium/strontium/barium carbonatesInorganic/elemental detergent compounding agentsParticulatesAragonite

Disclosed is a novel form of particulate precipitated aragonite, a novel process for producing it and compositions containing it.

Owner:3P TECH

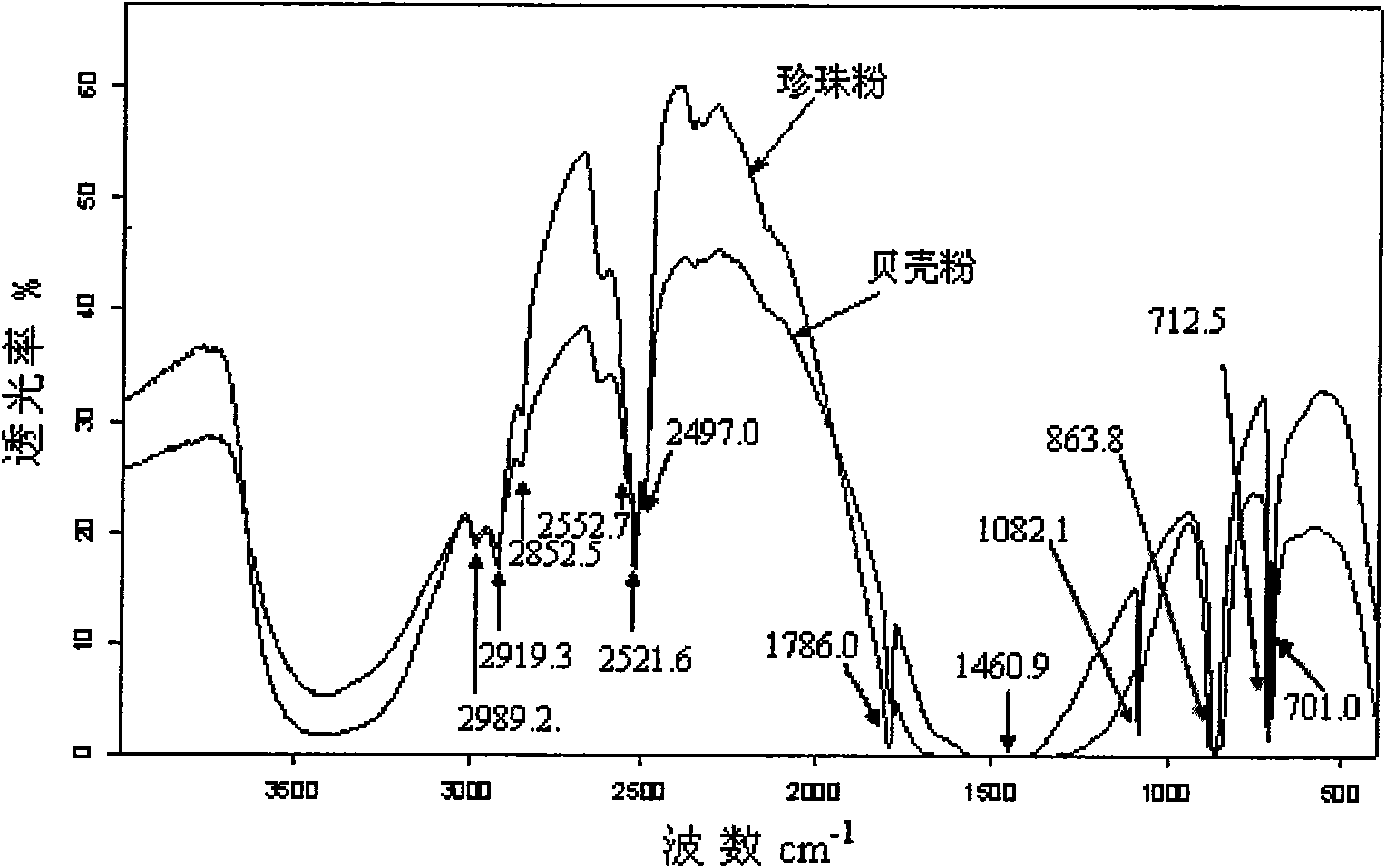

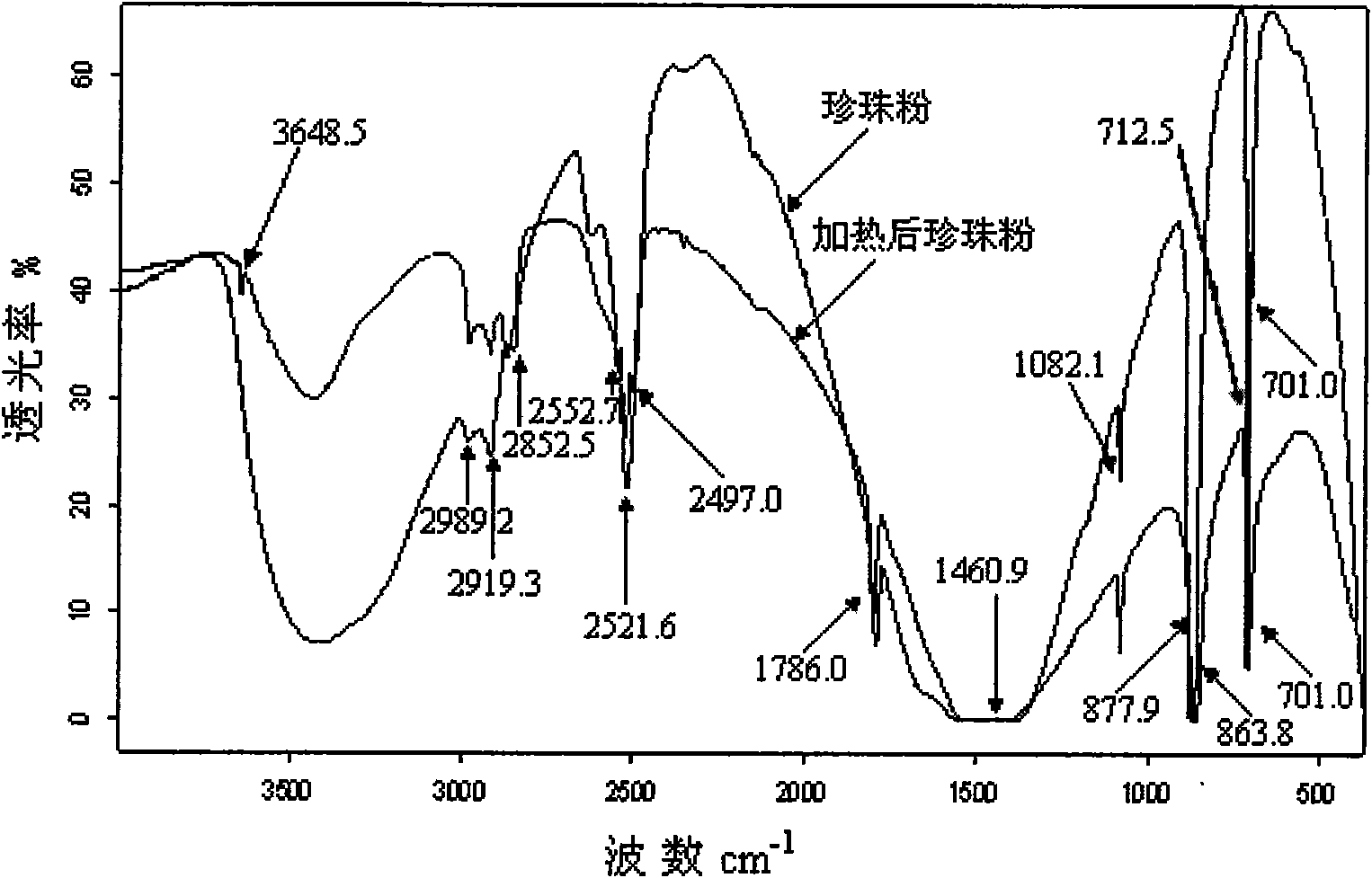

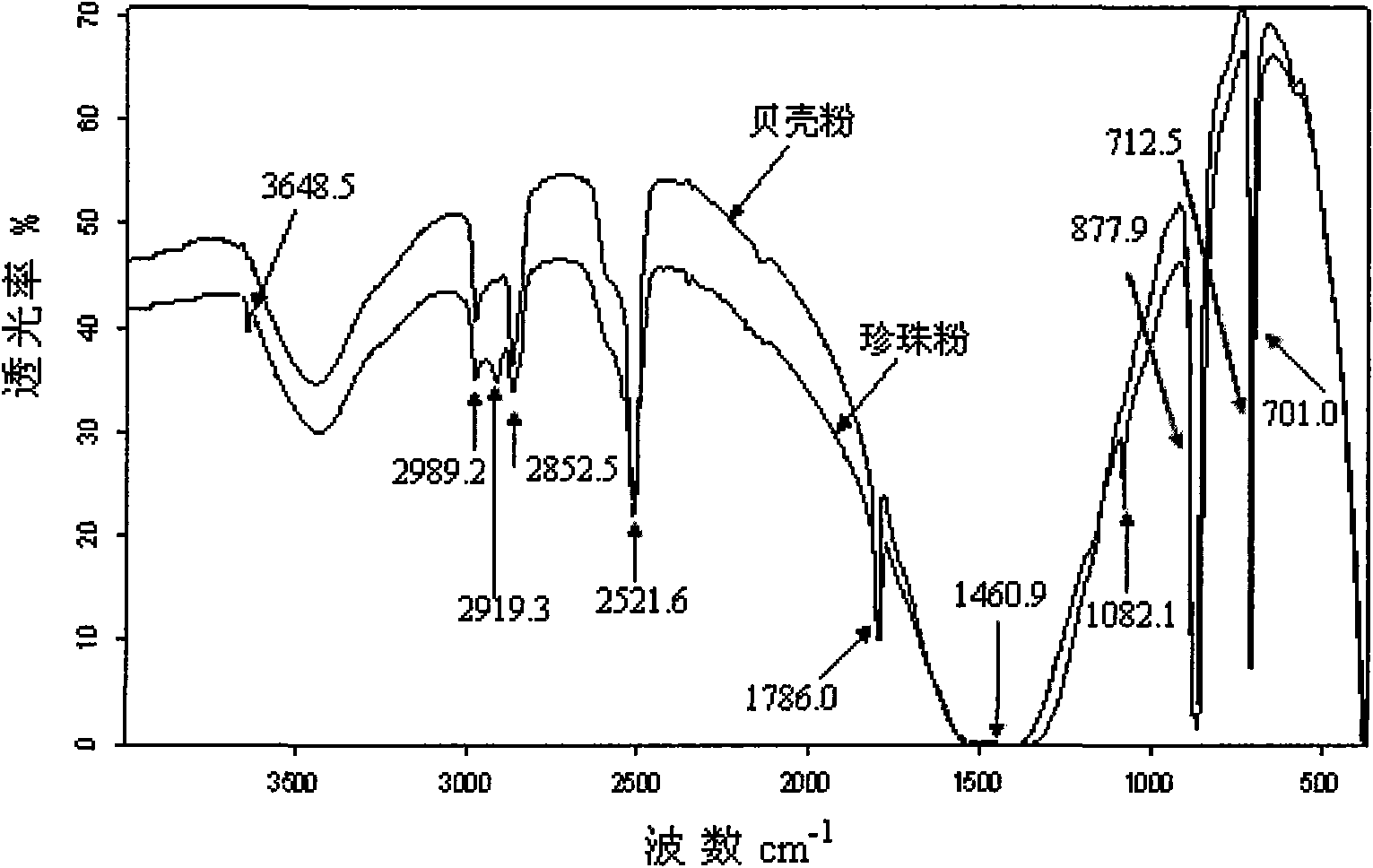

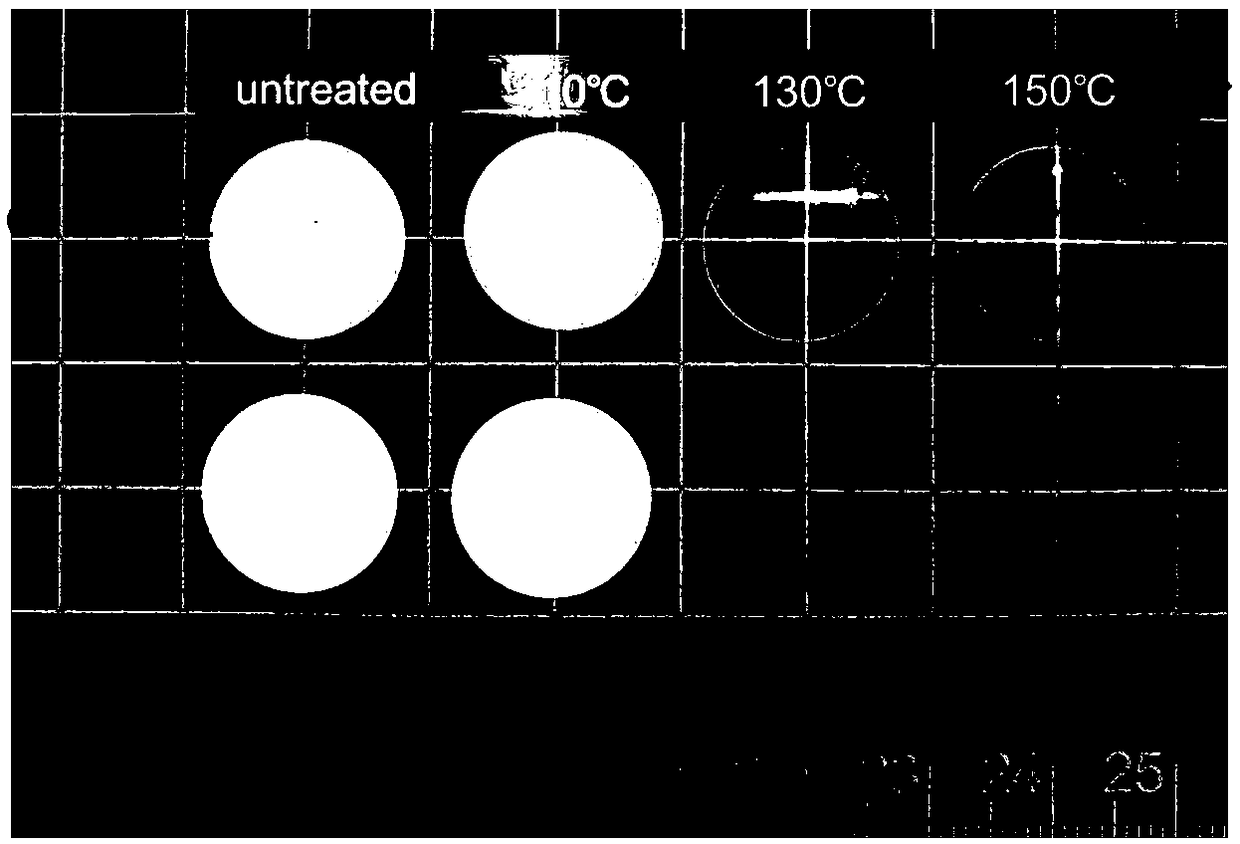

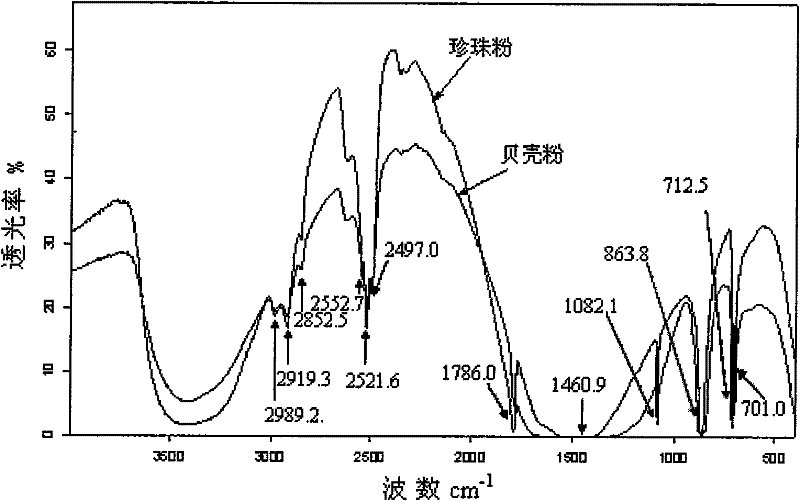

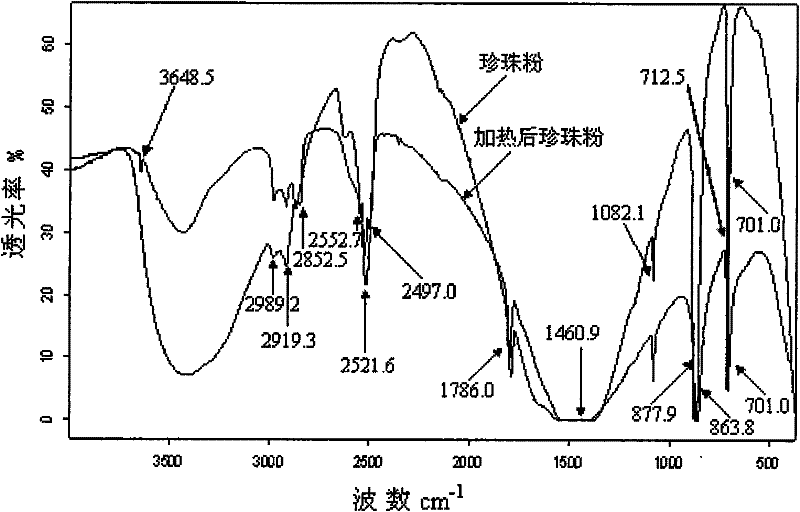

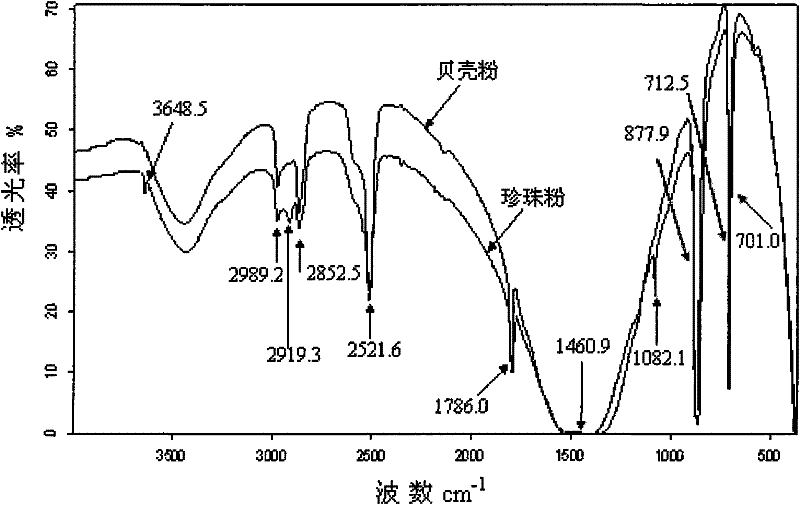

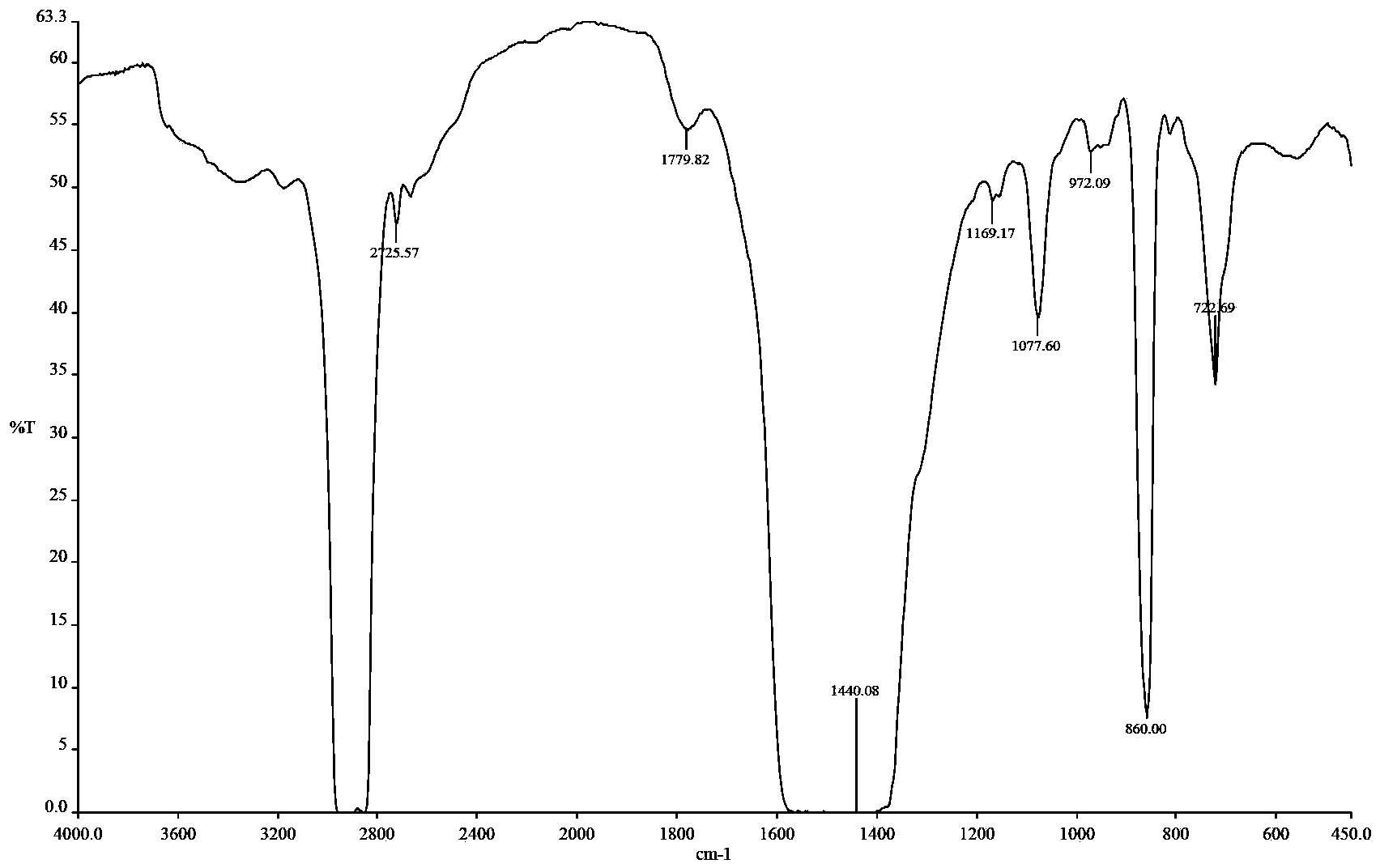

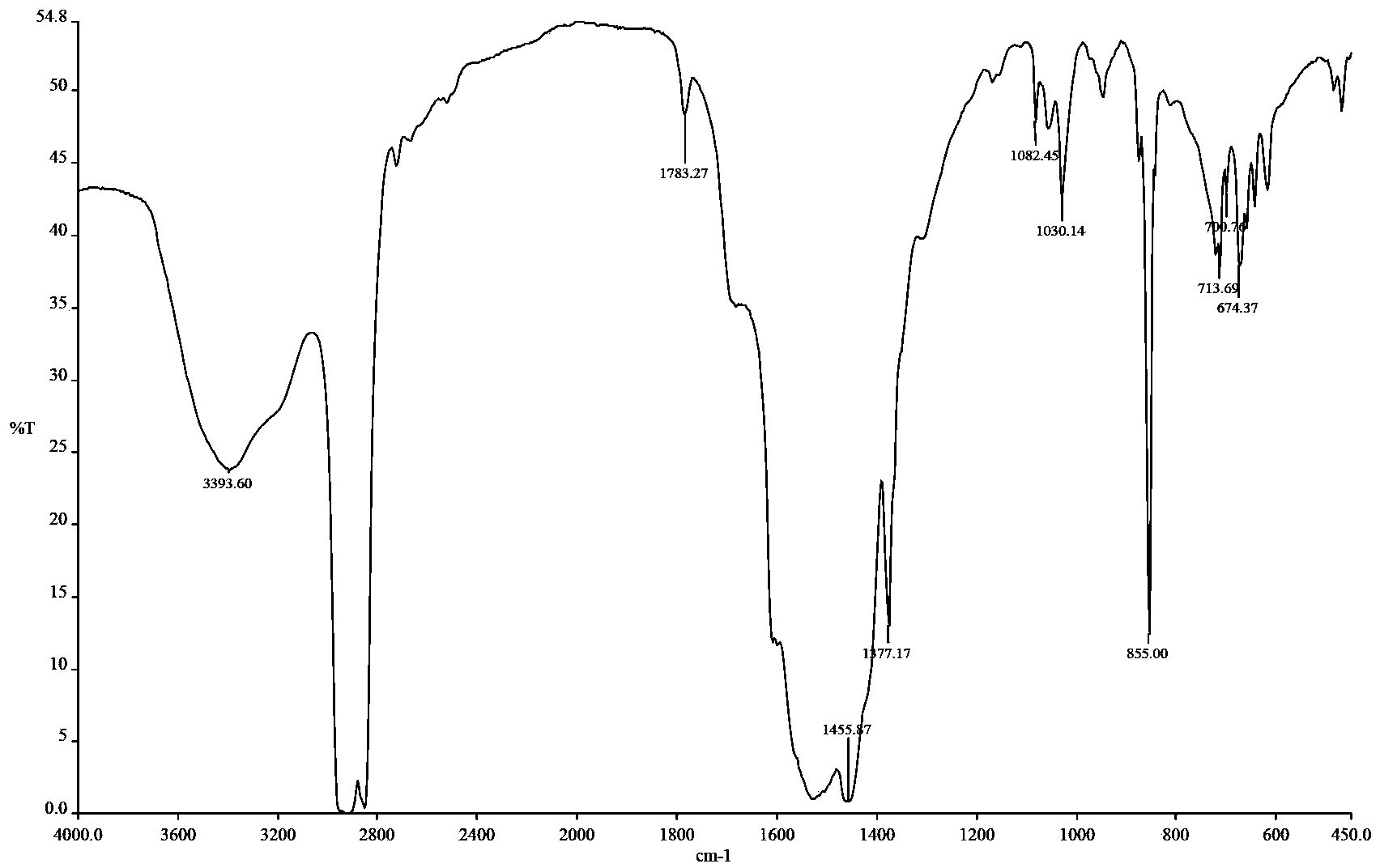

Method for distinguishing pearl powders from shell powders

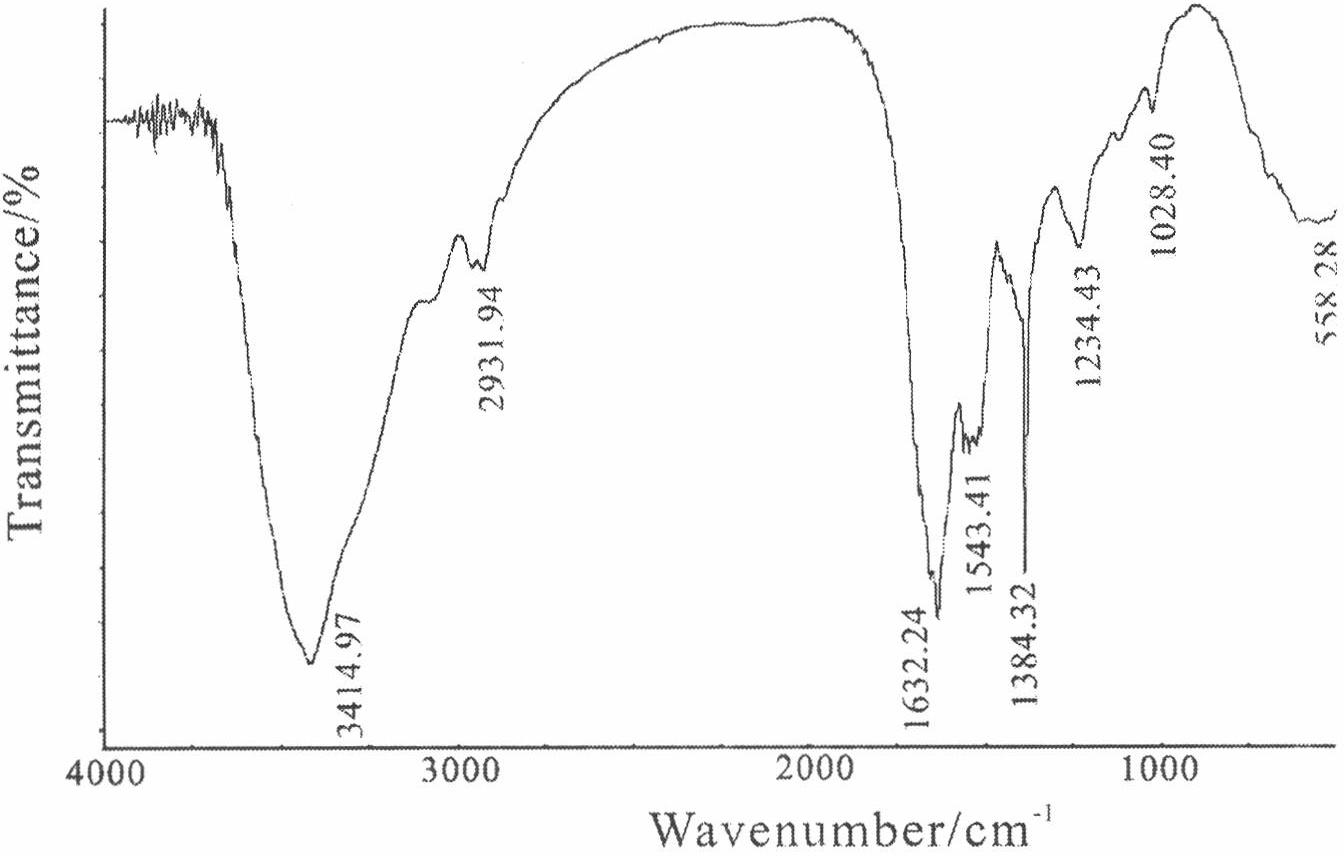

InactiveCN101620176AEasy to distinguishSimple methodPreparing sample for investigationColor/spectral properties measurementsAragonitePotassium bromide

The invention relates to a method for distinguishing pearl powders from shell powders, comprising the following steps: the pearl powders and the shell powders are calcined and then respectively mixed with potassium bromide to be made into transparent flakes, then the infrared spectrum of the transparent flakes is measured under the conditions of resolution of 4 cm<-1> and scanning for 16 times with the scanning range of 400-4000 cm <-1>, the pearl powders and the shell powders are distinguished according to the characteristic peak of 701.0 cm <-1>, 1082.1 cm <-1>, 2919.3 cm<-1> and 3468.5 cm <-1>; as organic substances in the calcined pearl powders are partially decomposed, the crystal type of calcium carbonate changes from the aragonite type to the calcite type, and the calcium carbonate starts to decompose; the organic substances in the shell powders are almost totally decomposed, the aragonite type calcium carbonate is totally converted into the calcite type calcium carbonate, and the calcium carbonate does not start to decompose into calcium oxide yet, therefore, the method can be used for distinguishing the pearl powders from the shell powders. Compared with the prior distinguishing method, the method can simply, rapidly and effectively distinguish the pearl powders from the shell powders with obvious phenomenon.

Owner:钱国英 +2

Processing technique for natural biological calcium carbonate powder filler

InactiveCN101230207APure hueMaintain uniformityInorganic pigment treatmentBiological materialsMechanical property

The invention discloses a processing technology for natural biological calcium carbonate miropowder filling material. The processing technology comprises the steps that pretreatments of water washing, drying and coarse grinding are performed to the natural biological material, then the pretreated material is crushed and graded, to obtain natural biological calcium carbonate filling material which is smaller than 38 micrometers, the crushed and graded natural biological calcium carbonate filling material is baked for 0.01 to 24 hours at 100 to 900 DEG C in a high-temperature furnace, and the natural biological calcium carbonate miropowder filling material is obtained through air oxidation. The invention has the characteristics that the processing technology can maintain an aragonite crystal form in natural shells to the largest extent, and can main the heterogeneity and the strong polarity of the microcrystalline surface of the natural shells to the largest extent, so that the shell miropowder has a superior micropore structure; the filling material can obviously improve the mechanical property and the hot property of high molecular material, and simultaneously the pollution problem caused by shells and egg shells to the environment is also solved.

Owner:SHAOXING UNIVERSITY

Precipitated aragonite and a process for producing it

InactiveUS20030180208A1Inorganic/elemental detergent compounding agentsCalcium/strontium/barium carbonatesParticulatesAragonite

Owner:3P TECH

Precipitated aragonite and a process for producing it

InactiveUS20030161894A1Calcium/strontium/barium carbonatesInorganic/elemental detergent compounding agentsParticulatesAragonite

Disclosed is a novel form of particulate precipitated aragonite, and a novel process for producing it.

Owner:3P TECH

Solid Forms for Tissue Repair

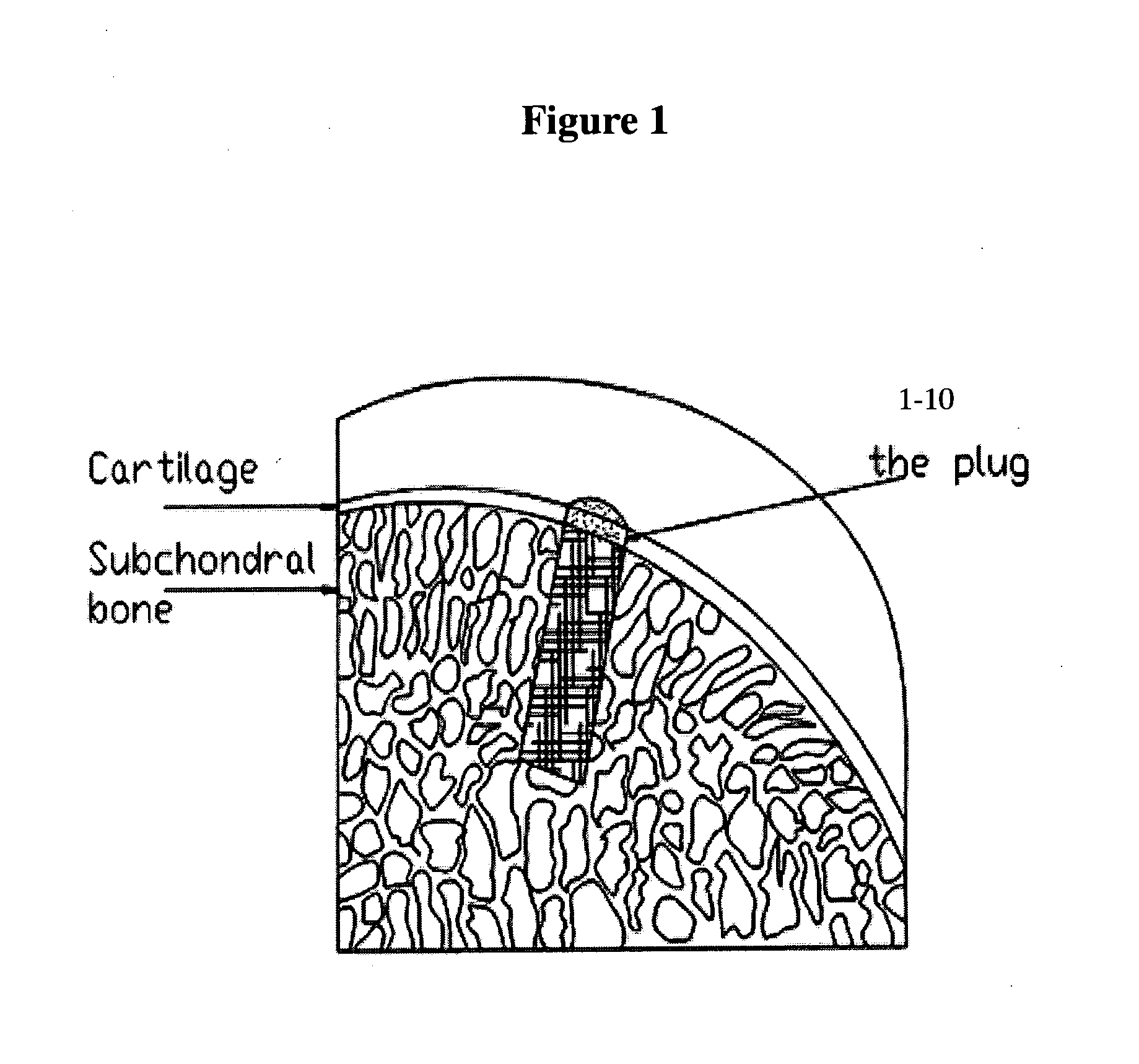

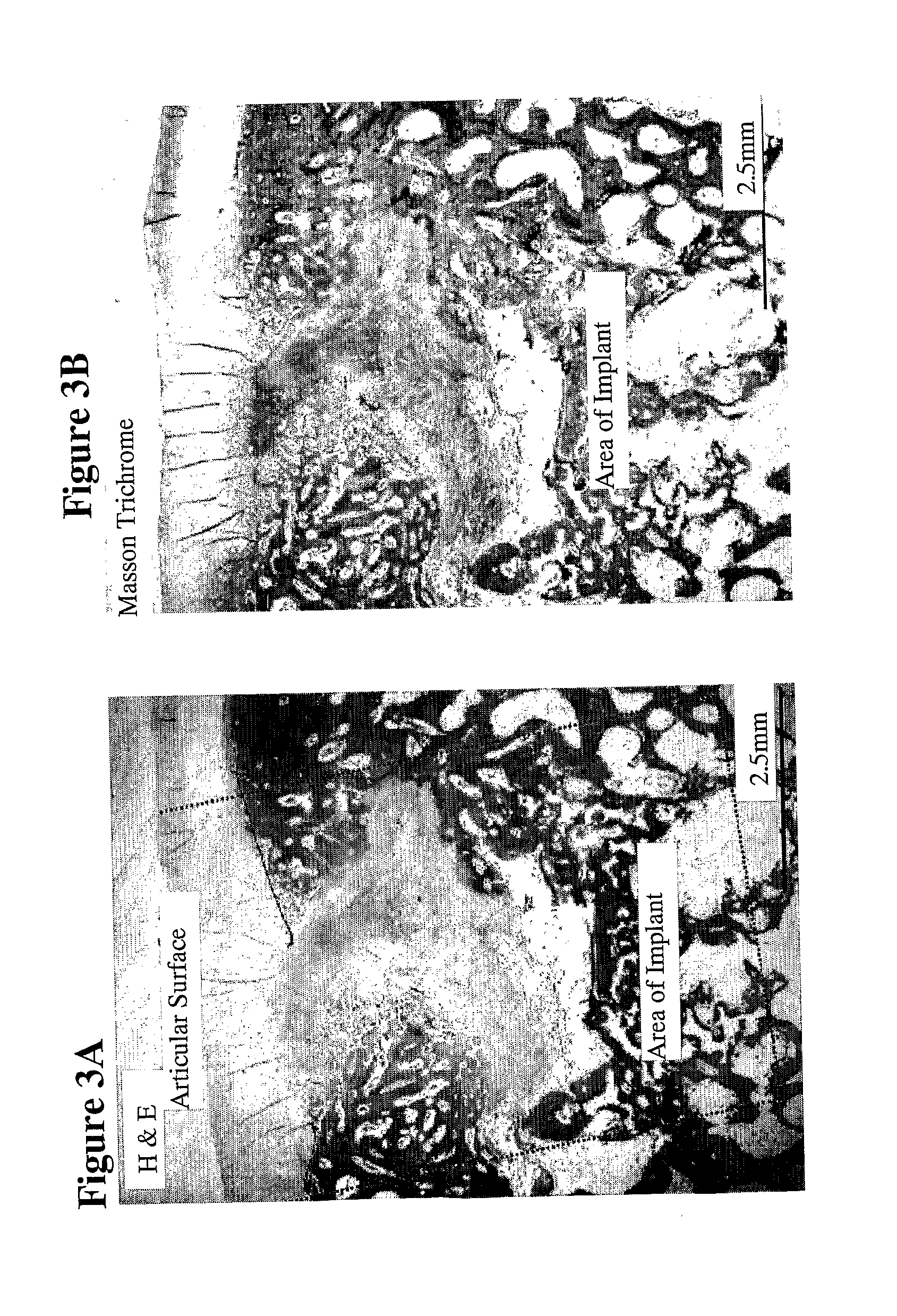

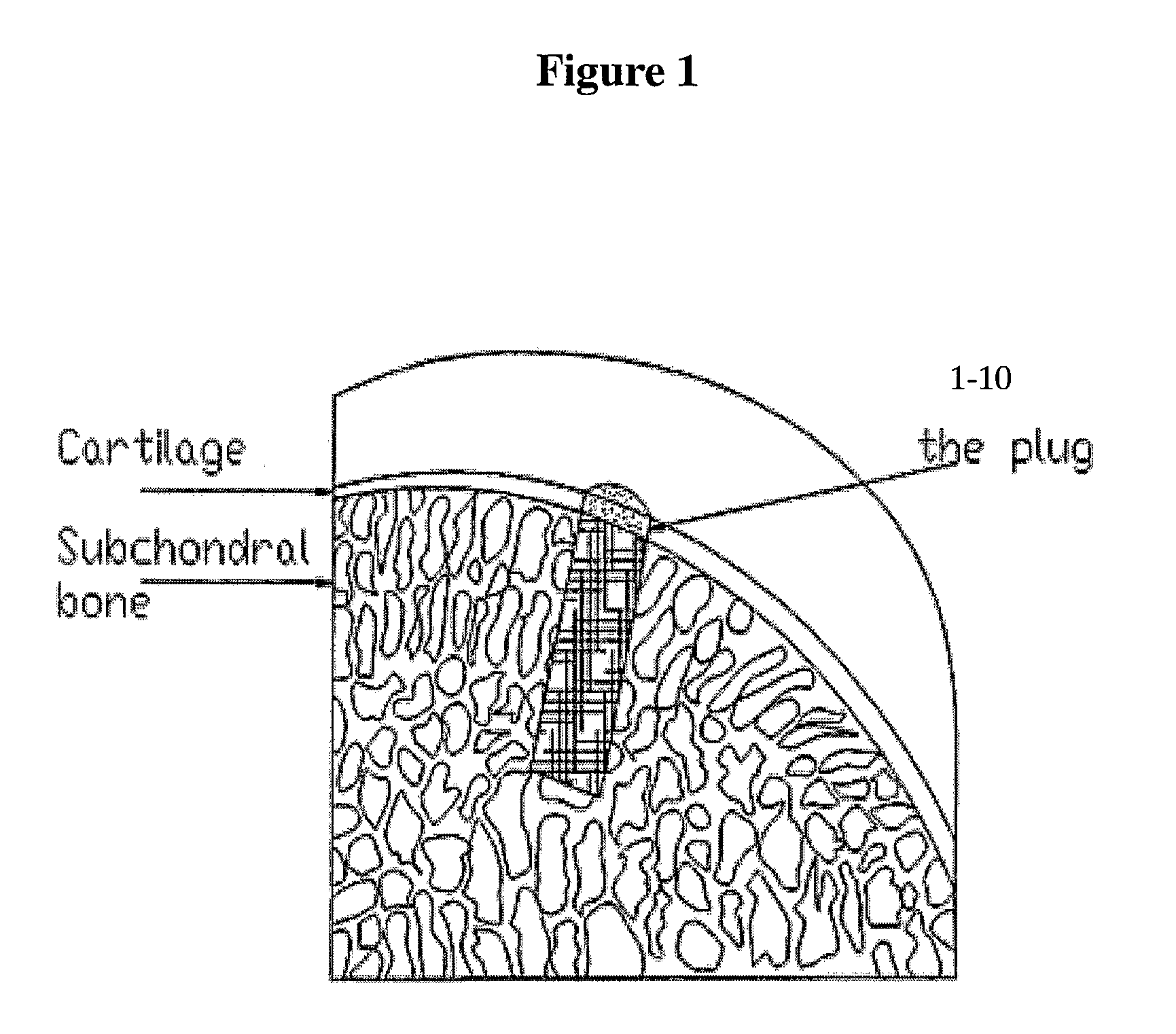

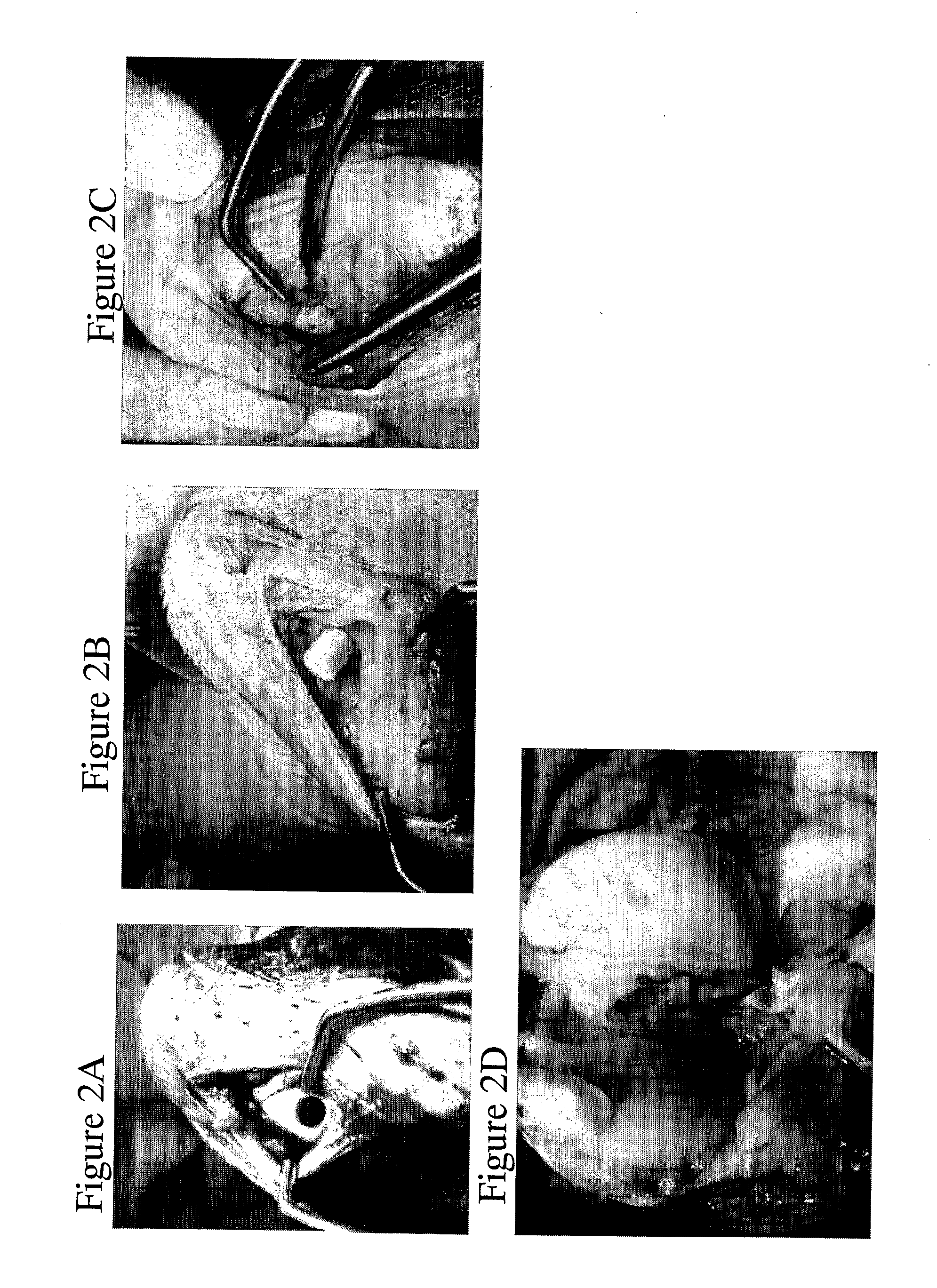

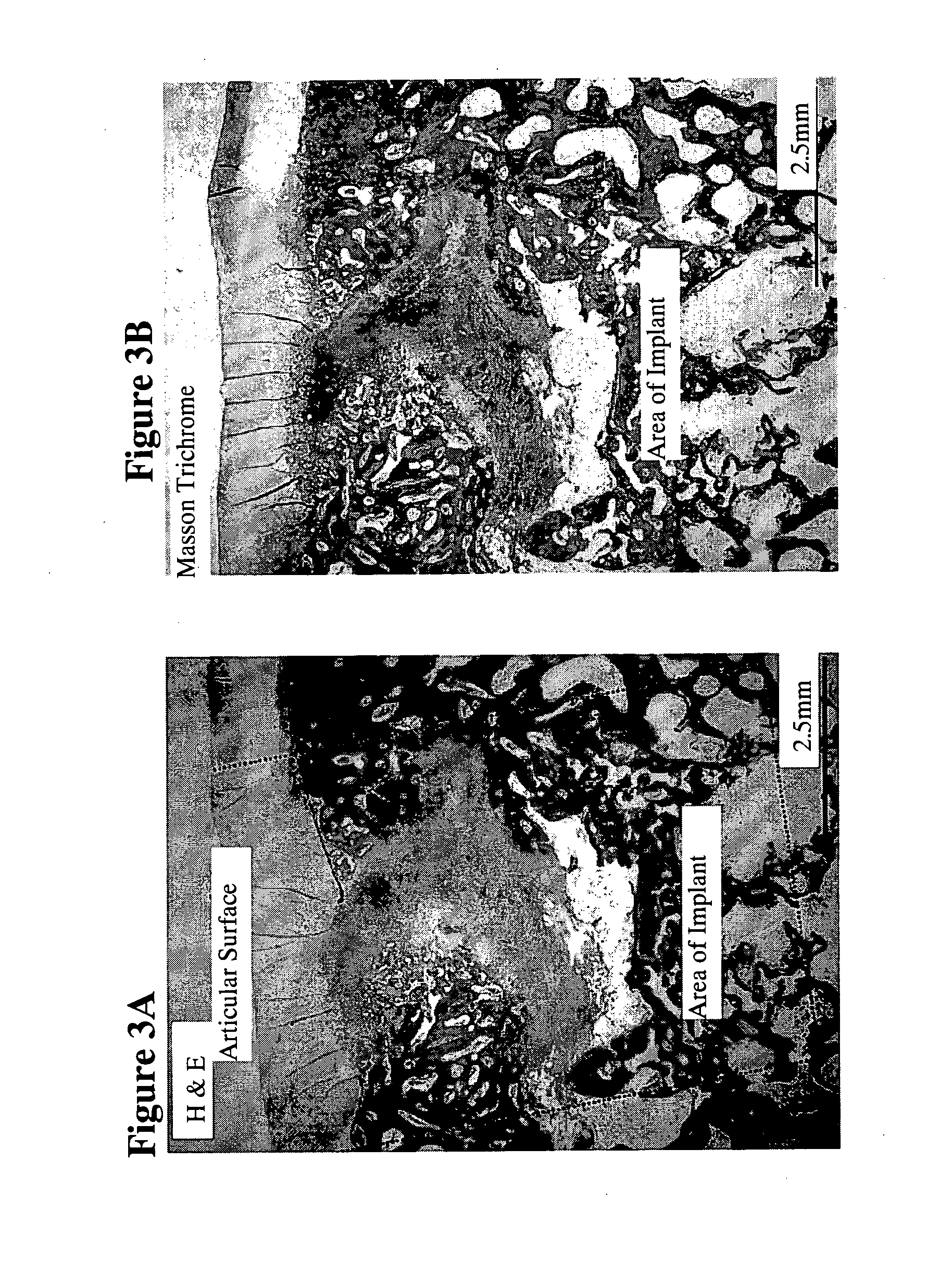

ActiveUS20120189669A1Easy adhesionPromote blood vessel formationPeptide/protein ingredientsAntipyreticTissue repairAragonite

This invention provides aragonite- and calcite-based scaffolds for the repair, regeneration, enhancement of formation or a combination thereof of cartilage and / or bone, which scaffolds comprise at least two phases, wherein each phase differs in terms of its chemical content, or structure, kits comprising the same, processes for producing solid aragonite or calcite scaffolds and methods of use thereof.

Owner:CARTIHEAL 2009

Solid Forms for Tissue Repair

ActiveUS20120177702A1Promote regenerationPromote repairCalcium/strontium/barium carbonatesPeptide/protein ingredientsTissue repairAragonite

This invention provides aragonite- and calcite-based scaffolds for the repair, regeneration, enhancement of formation or a combination thereof of cartilage and / or bone, which scaffolds comprise at least two phases, wherein each phase differs in terms of its chemical content, or structure, kits comprising the same, processes for producing solid aragonite or calcite scaffolds and methods of use thereof.

Owner:CARTIHEAL 2009

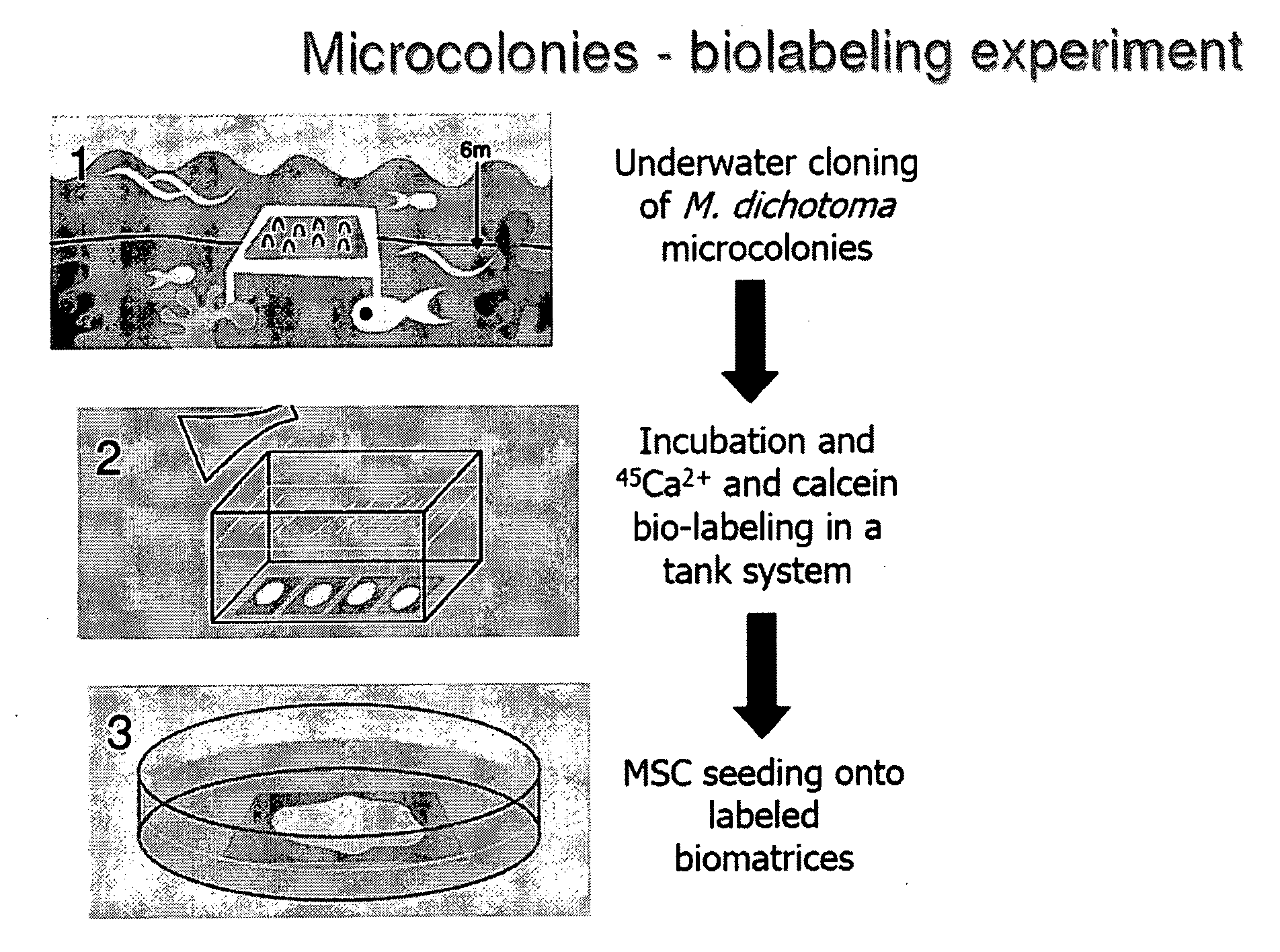

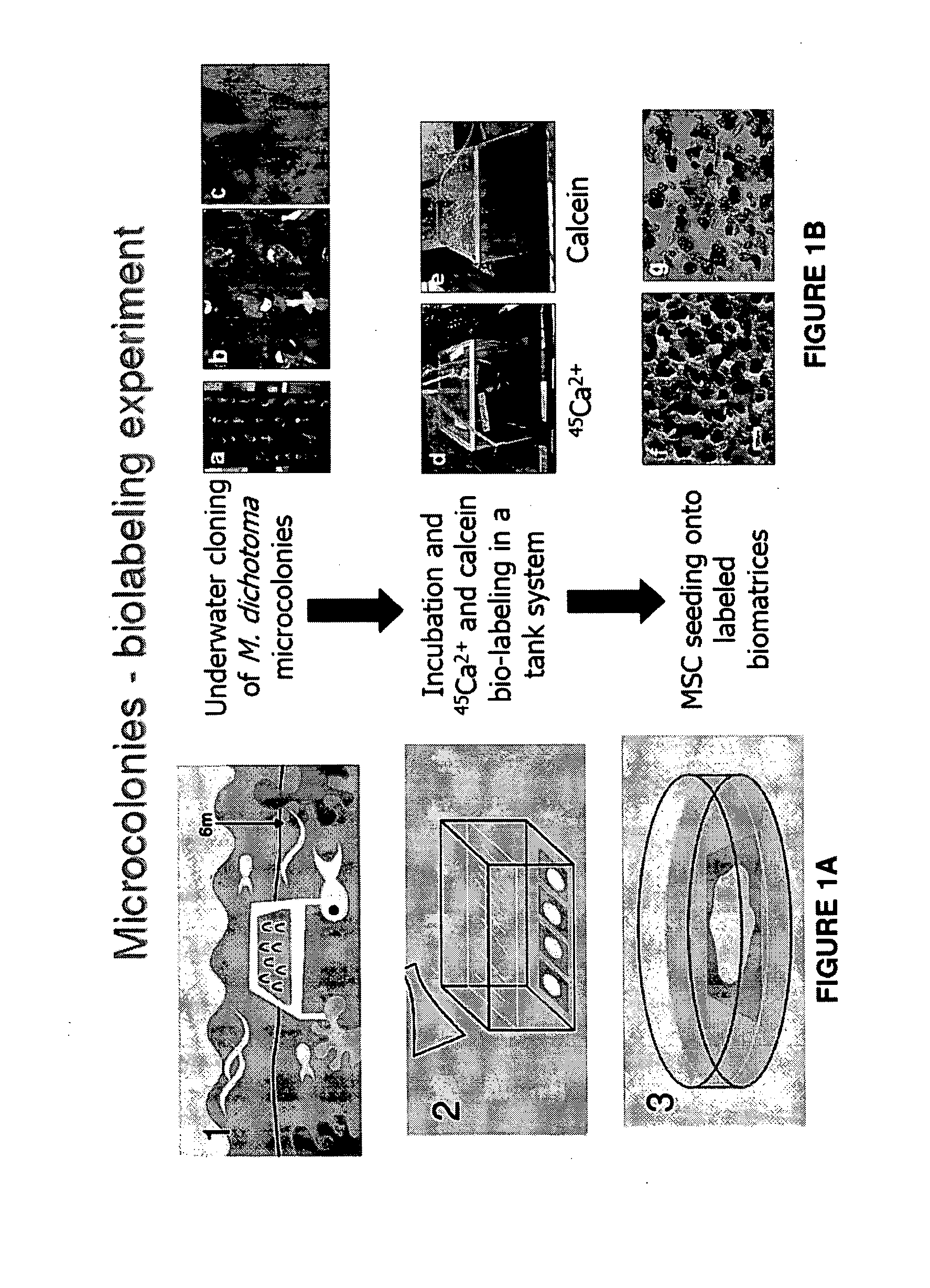

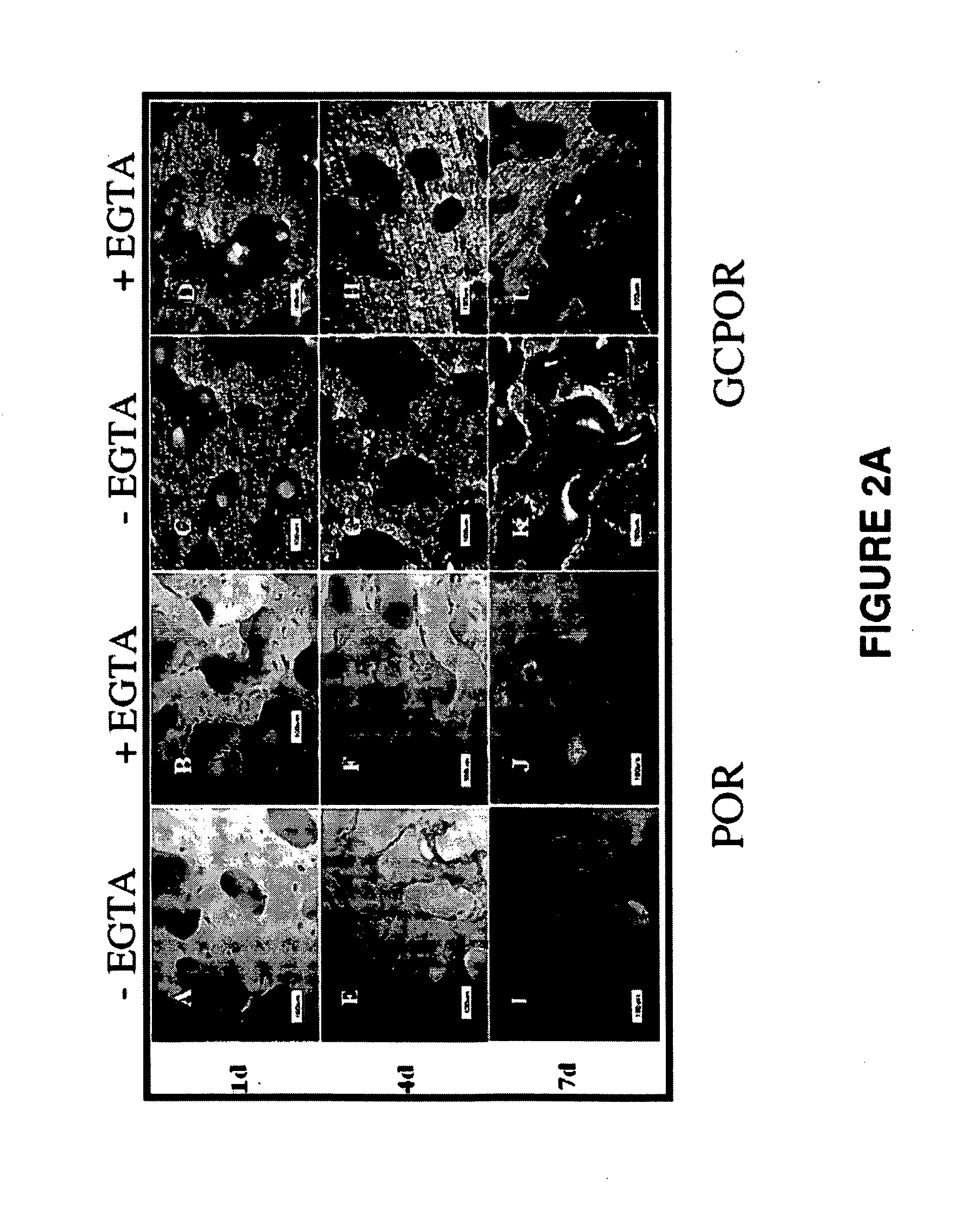

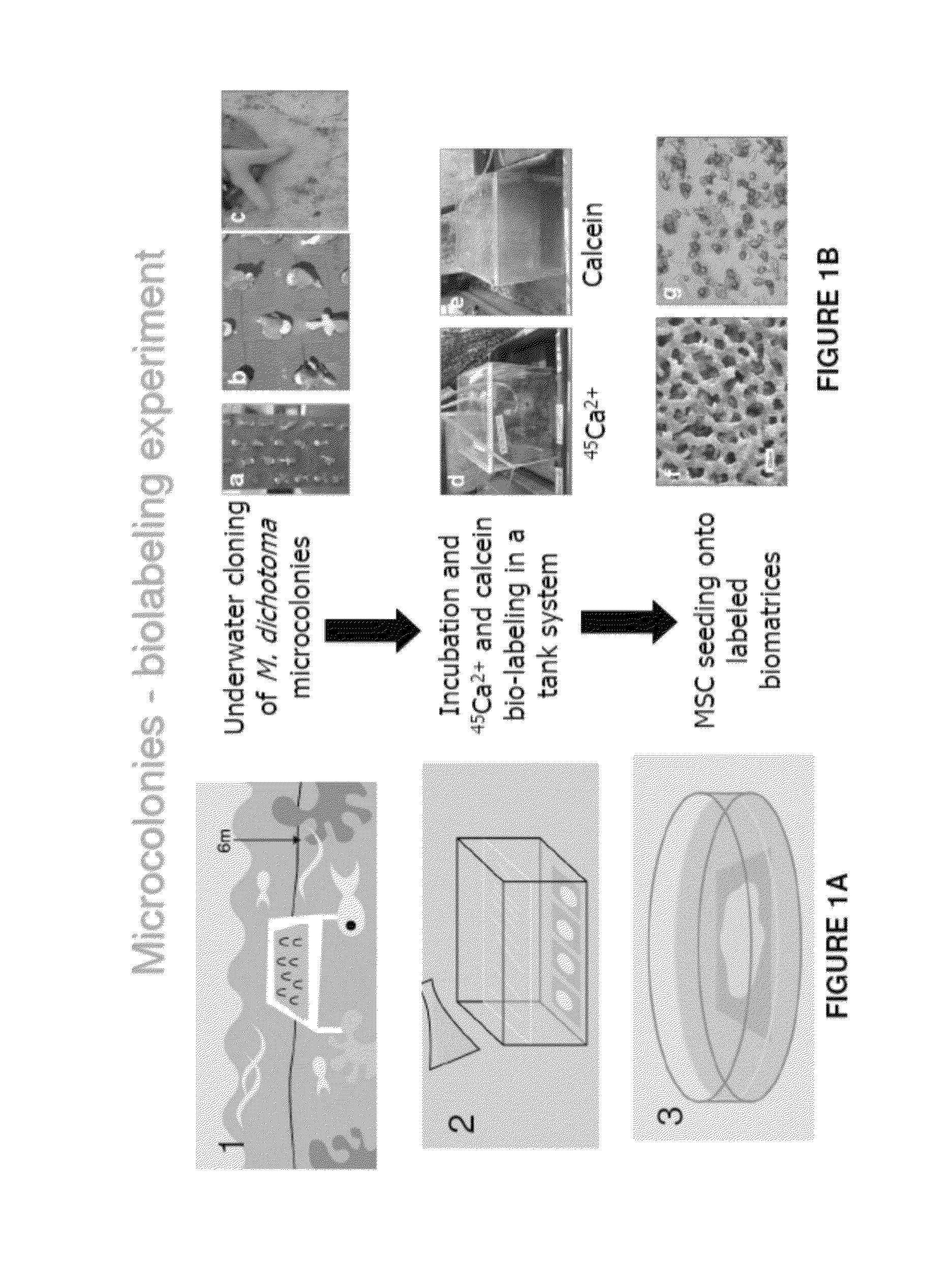

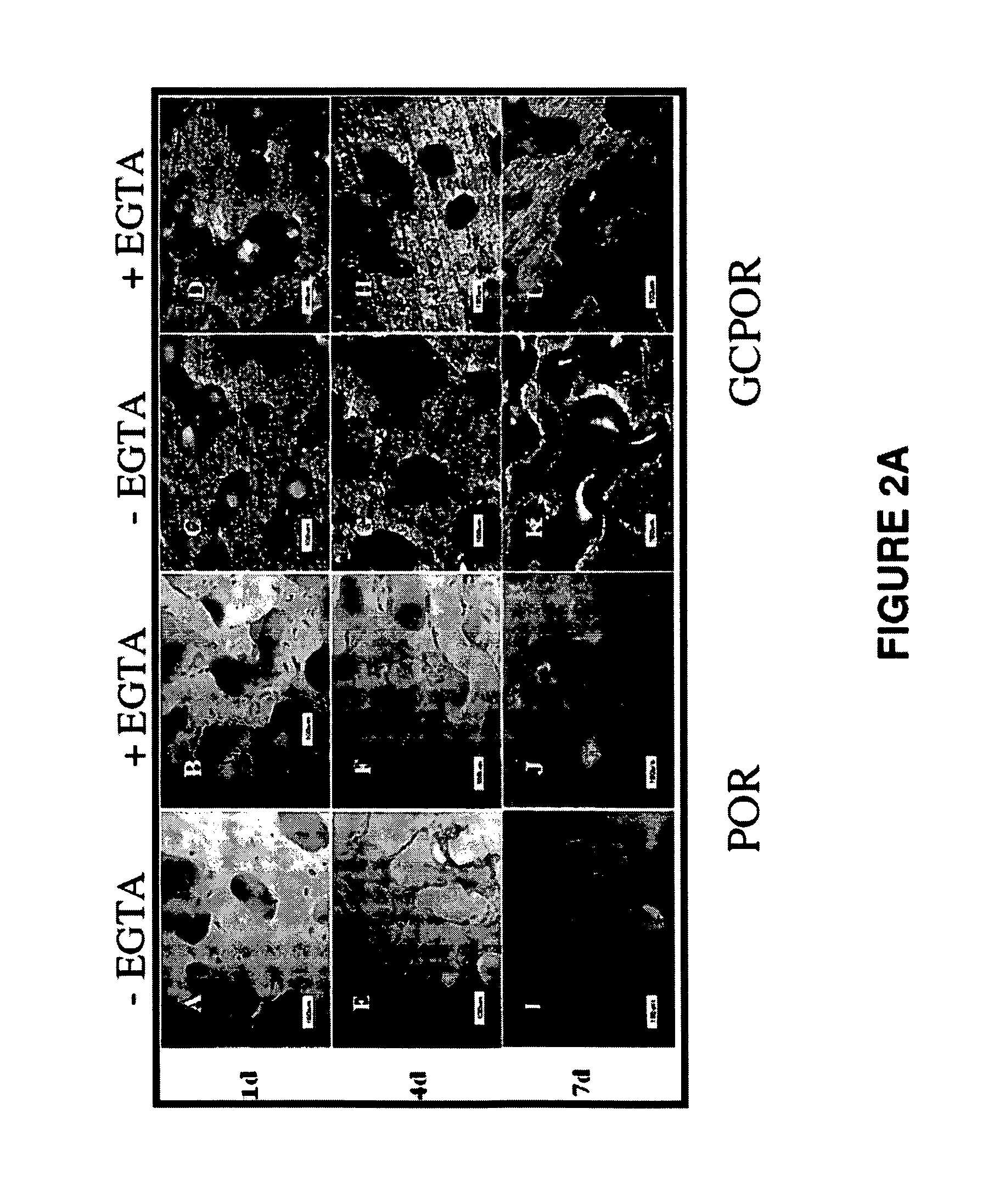

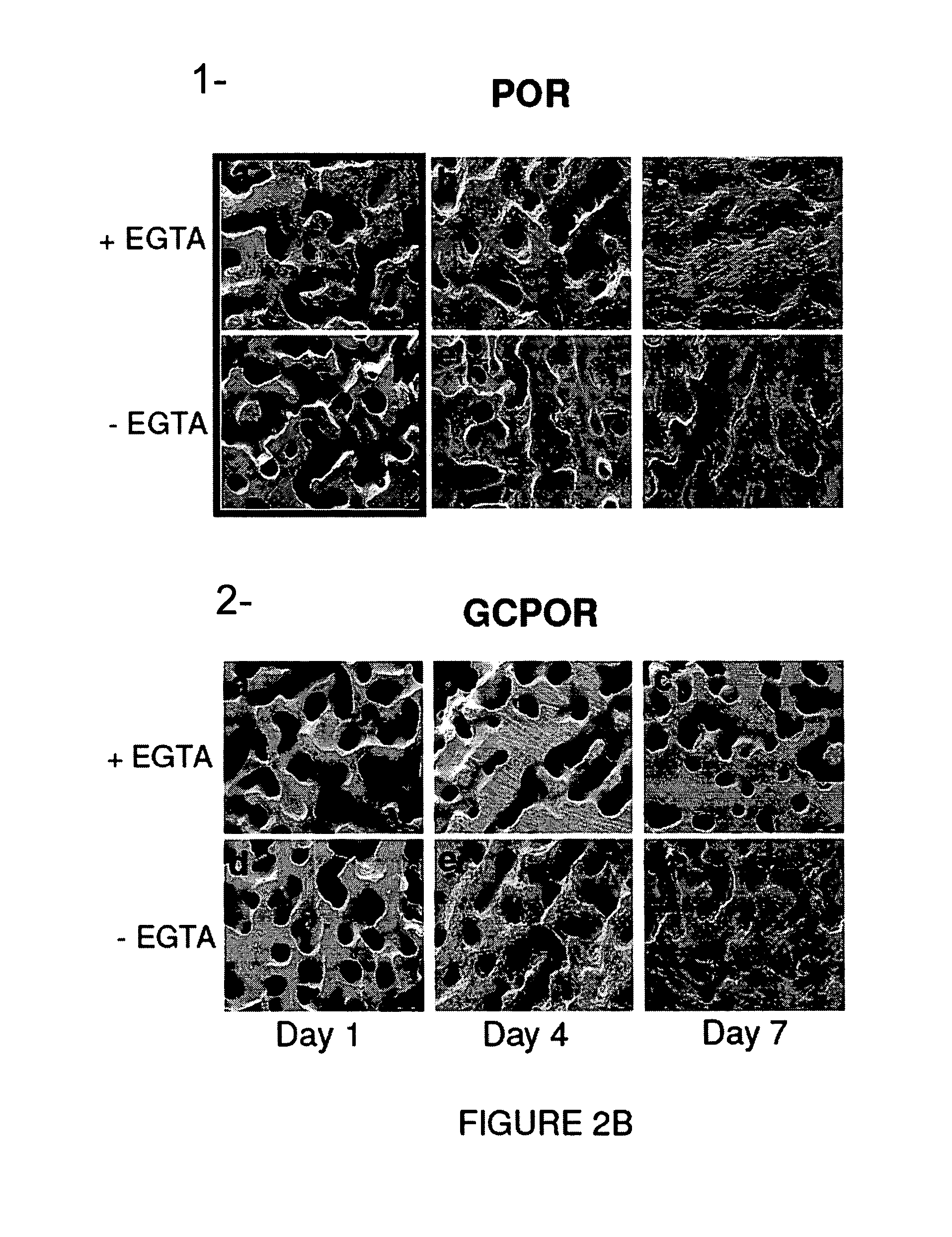

Calcium-mediated effects of coral and methods of use thereof

This invention is directed to coral scaffolds seeded with precursor cells in culture in the presence of a chelator and uses thereof in inducing or enhancing bone and / or cartilage formation in a subject, and kits related thereto. This invention is also directed to use of cadherin-upregulating coral for treating cancer or inhibiting cancer progression. This invention is also directed to use of aragonite or calcite-producing species for in vivo calcium release, and its application to the treatment of skin diseases, disorders or conditions.

Owner:BEN GURION UNIVERSITY OF THE NEGEV

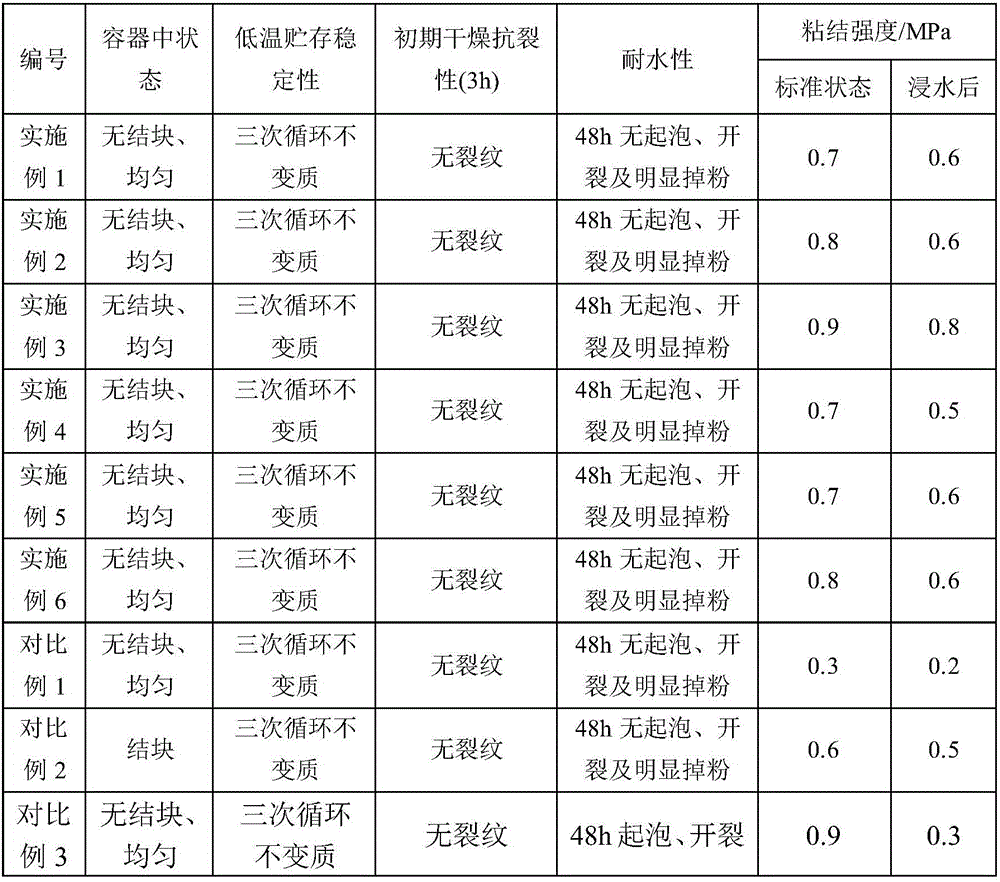

Environmental interior wall putty powder

The invention belongs to the technical field of energy conservation and environment protection and particularly relates to an environmental interior wall putty powder. The environmental interior wall putty powder is composed of, by weight percentage, 25%-30% of white cement, 10%-15% of mineral powder, 10%-15% of aragonite powder, 5%-8% of porous absorbent materials, 1.5%-2.2% of dispersible emulsion powder, 1%-5% of bonder, 1%-3% of magnesium lithium silicate, 0.2%-1% of water-retaining agent, 2%-5% of negative ion powder, 0.05%-0.25% of antiseptic and mildewproof agent, 0.2%-0.8% of surfactant, 1%-3% of degerming agent, 0.02%-0.1% of deforming agent and quartz sand powder as balance. The environmental interior wall putty powder is green and environmentally friendly and achieves the functions of heat preservation and insulation, bacteria and mildew prevent, moisture absorption and desorption, air cleaning and the like, and meanwhile, achieves good decorative effects, high waterproofness and scrubbing resistance, thereby being capable of directly serving as decorative materials.

Owner:HEBEI CHENYANG INDAL & TRADE GROUP CO LTD

Secondary convex-surface porcelain plate picture and firing technology thereof

InactiveCN108299014AHigh glossIncrease the precipitation rateSpecial ornamental structuresPotassiumSlurry

The invention relates to a secondary convex-surface porcelain plate picture. The secondary convex-surface porcelain plate picture comprises a porcelain plate base plate and a bottom glaze layer arranged on the surface of the porcelain plate base plate, wherein a convex point formed by sintering convex-surface glaze is dispensed on the surface of the bottom glaze layer; bottom glaze selects matte glaze, and is prepared from the following components in parts by weight: 30 to 40 parts of micalex, 10 to 20 parts of potassium feldspar, 25 to 35 parts of kaolin, 0.5 to 2 parts of bone meal, 4 to 10parts of sodium feldspar, 6 to 18 parts of barium carbonate, 3 to 18 parts of aragonite, 2 to 8 parts of limestone, 6 to 15 parts of borax, 10 to 20 parts of epsomite and 10 to 15 parts of aluminum oxide; when the secondary convex-surface porcelain plate picture is fired, firstly, each glaze slurry raw material is wetly milled to generate material slurry; then the matte glaze is sprayed on the surface of the porcelain plate base plate, and is dried and fired; then convex surface glaze is dispensed on a matte base plate, and secondary firing is carried out to prepare the secondary convex-surface porcelain plate picture. According to the secondary convex-surface porcelain plate picture and a firing technology thereof, the convex surface glaze is dispensed on the matte glaze, and secondary firing is carried out; a production technology is simple and convenient, so that the porcelain plate picture has a bulge and a good transparent feeling; the porcelain plate picture is stereoscopic and vivid and has a good expressive force.

Owner:李佳融

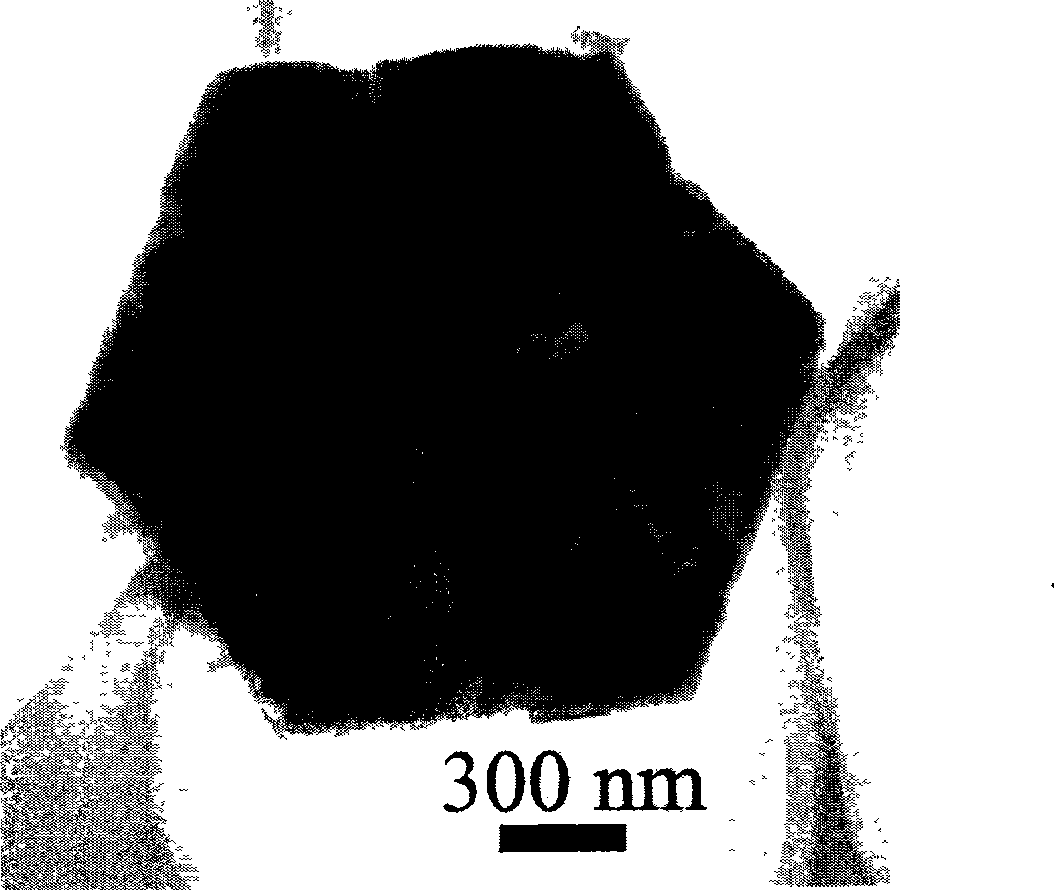

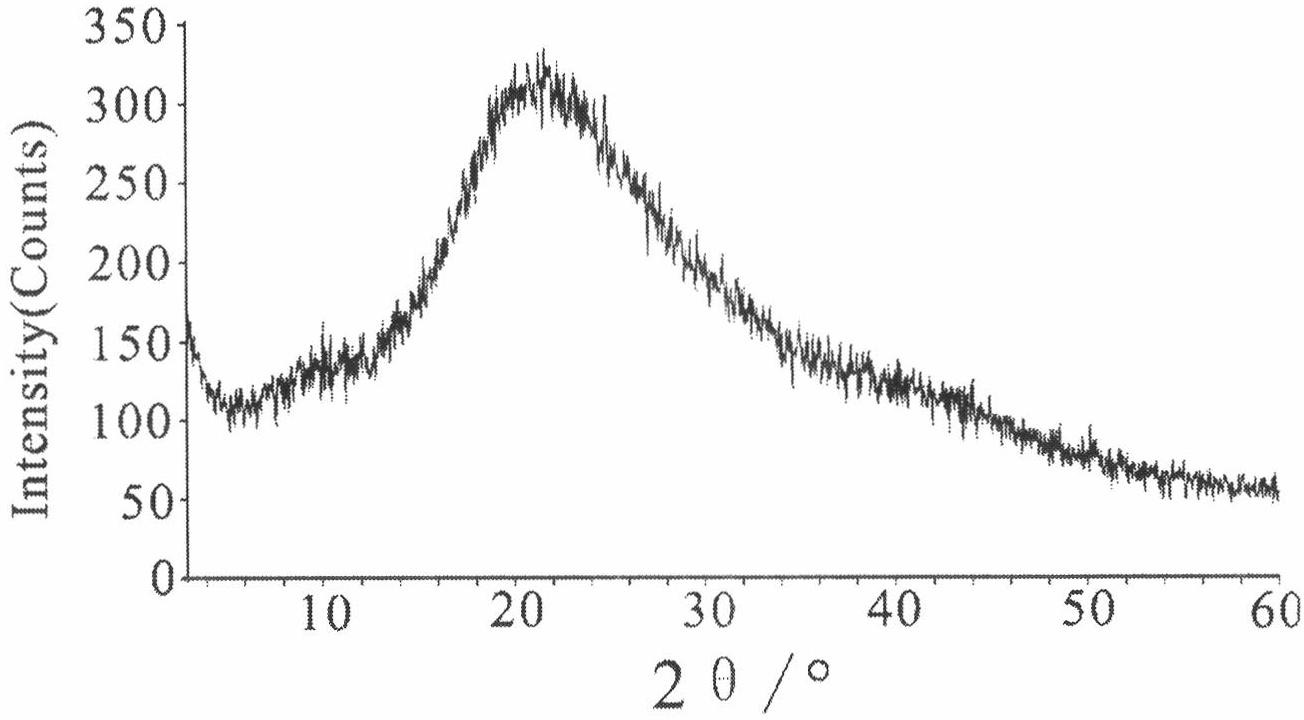

Quasi-hexagonal sheet calcium carbonate metastable-state crystal particle and method of preparing the same

InactiveCN101508454ANarrow particle size distributionGood coating effectCalcium/strontium/barium carbonatesInorganic compound additionAragoniteDodecyl sulfate

The invention discloses a quasi-hexagonal flaky calcium carbonate metastable crystal form (aragonite) grain and a preparation method thereof. The grain is mainly quasi-hexagonal flake, and has narrow grain size distribution with average grain diameter of between 1 and 2 mu m. The method is to use a calcium salt system consisting of organic calcium salt (calcium dodecyl sulfate and the like), an organic additive (n-amyl alcohol and the like) and ammonia to react with carbon dioxide to generate the quasi-hexagonal flaky calcium carbonate metastable crystal form (aragonite) grain. The grain has strong capability of product surface coating and covering, is easy to disperse, and has excellent optical performance and printing performance, so that a paper product prepared by the grain has higher whiteness, brightness and shading performance, can save dosage of paper pulp, and can reduce cost of paper making.

Owner:SHANDONG UNIV

Calcium-mediated effects of coral and methods of use thereof

This invention is directed to coral scaffolds seeded with precursor cells in culture in the presence of a chelator and uses thereof in inducing or enhancing bone and / or cartilage formation in a subject, and kits related thereto. This invention is also directed to use of cadherin-upregulating coral for treating cancer or inhibiting cancer progression. This invention is also directed to use of aragonite or calcite-producing species for in vivo calcium release, and its application to the treatment of skin diseases, disorders or conditions.

Owner:BEN GURION UNIVERSITY OF THE NEGEV

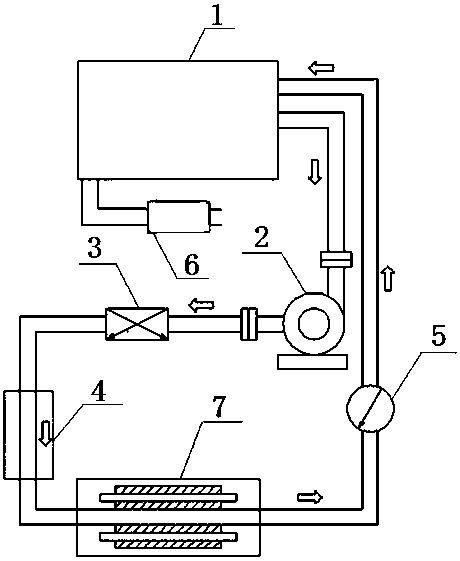

Descaling device and method of circulation cooling water system

InactiveCN108017166AImprove descaling efficiencyIncrease the number of hydrogen bondsScale removal and water softeningWater/sewage treatment by magnetic/electric fieldsClosed loopEngineering

The invention relates to a descaling device and method, in particular to a descaling device and method of a circulation cooling water system. According to the descaling device of the circulation cooling water system, a water tank, a pump, a valve, a cooling part and a flow meter are connected into a closed loop through a pipe, a scale inhibitor storage tank is connected onto the water tank, and anadjustable permanent magnet is arranged on the pipe. According to the descaling method, in order to improve the descaling efficiency, a scale inhibitor is added after the magnetic field runs for a certain period, remaining scaling ions are removed by the scale inhibitor, the number of hydrogen bonds and activation energy of a water system can be increased through positive ions in the scale inhibitor, and accordingly the descaling rate is greatly increased; the proportion of aragonite to vaterite can be conveniently increased, the proportion of calcite is reduced, the descaling efficiency of the scale inhibitor can also be improved through the magnetic field, the use quantity of the composite non-phosphorus corrosion and scale inhibitor is greatly lowered at the same time, the production cost is lowered, and secondary pollution is reduced.

Owner:NORTHWEST RES INST OF MINING & METALLURGY INST

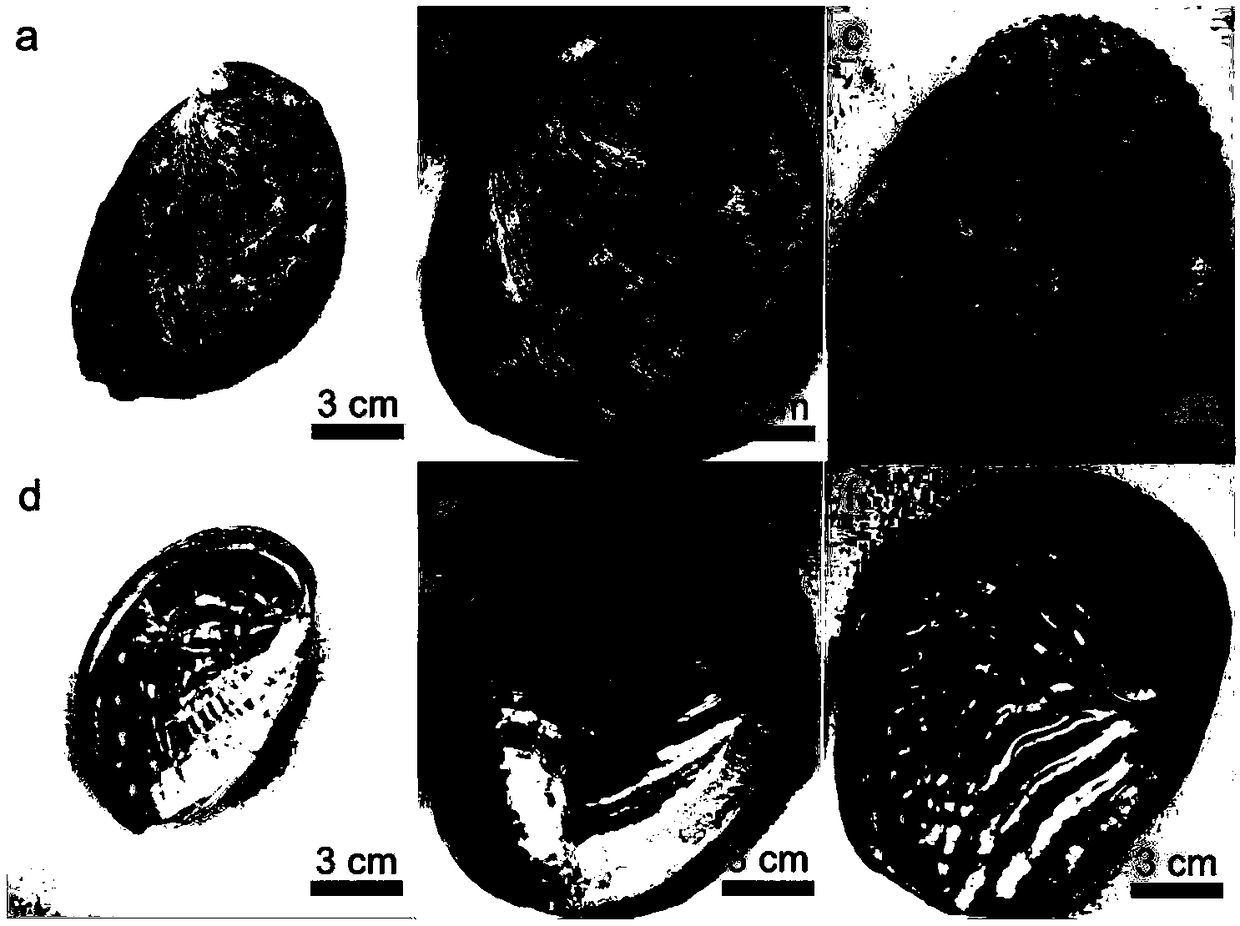

Abalone shell pearl layer powder and processing method thereof

ActiveCN103623005AResolve the contradiction between supply and demandGuarantee safe and effectiveNervous disorderMetabolism disorderBiotechnologyAlgal pigment

The invention discloses abalone shell pearl layer powder and a processing method of the abalone pearl layer powder. Abalone shell is used as a raw material, abalone shell pearl layer with an aragonite structure is prepared through a crushing process, the prepared pearl layer powder has the characteristics of solubility in acid, insolubility in acid and insolubility in water, and the content of aragonite calcium carbonate is equal or greater than 94 percent; the prepared pearl layer powder has the original nacreous luster of the inner layer of the abalone shell, and the removal rate of impurities such as calcium carbonate with a non-aragonite structure, cuticle, prismatic-calaite layers, algal pigment and the like is not lower than 91 percent. According to the invention, under a lower temperature condition, an acid solution with lower concentration is adopted, the impurities can be removed within short time through acid pickling, a medicinal composition pearl layer is retained to a great extent, superfine grade and nanoscale pearl layer powder can be further obtained through smashing, the conception is novel, the raw materials are rich, the production efficiency is high, the production cost is low, the processing technology is simple, green environmental protection is achieved, the implementation is convenient, the abalone shell pearl layer powder conforms to industrial development trend of traditional Chinese medicine modernization and internationalization, and a greater generalization performance is achieved.

Owner:FUZHOU FUDA MARINE SCI & TECH CO LTD

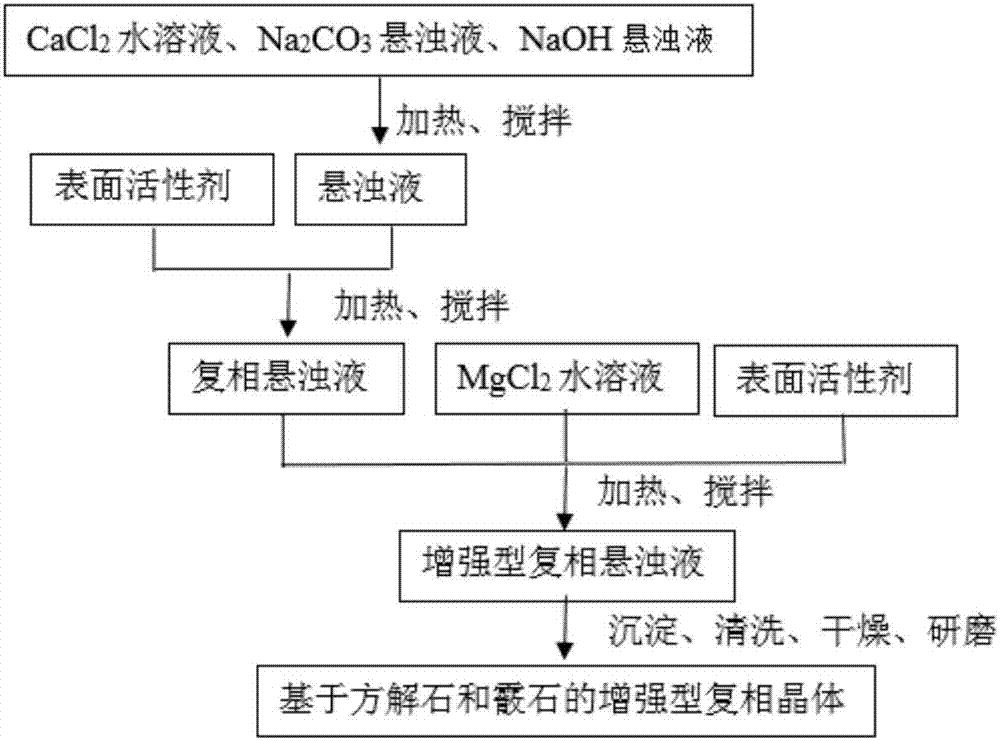

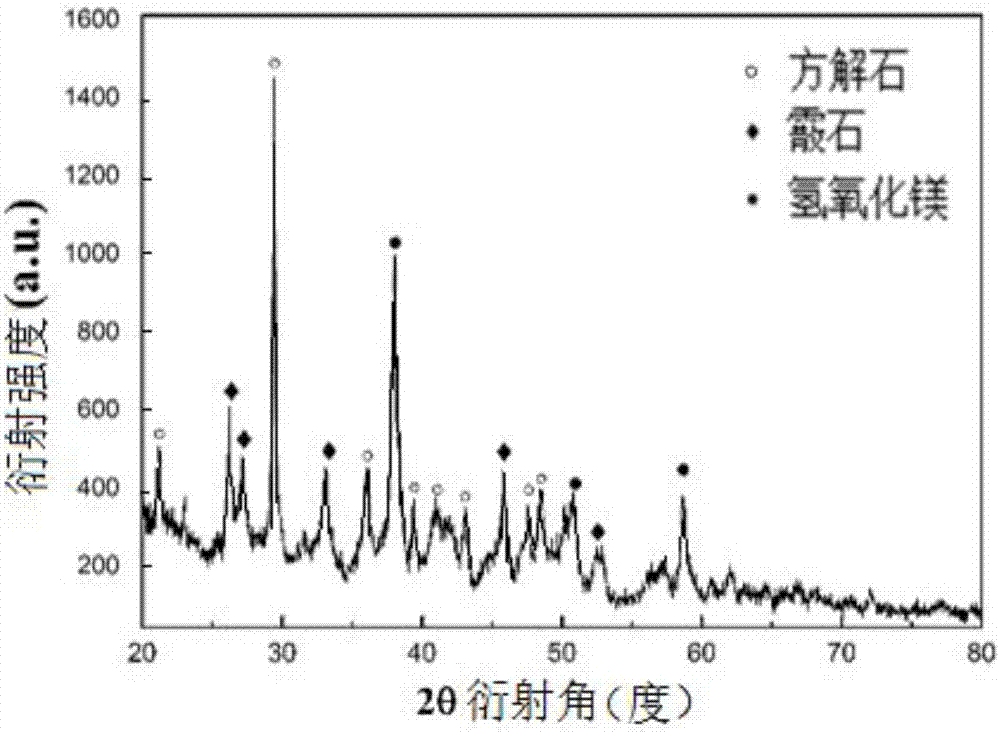

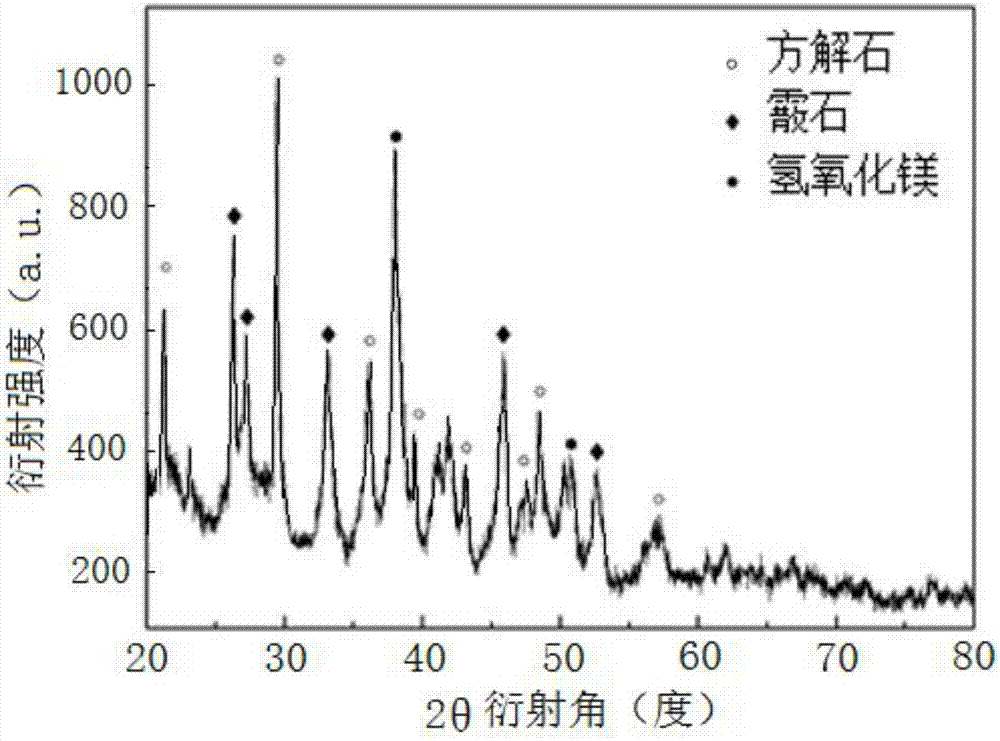

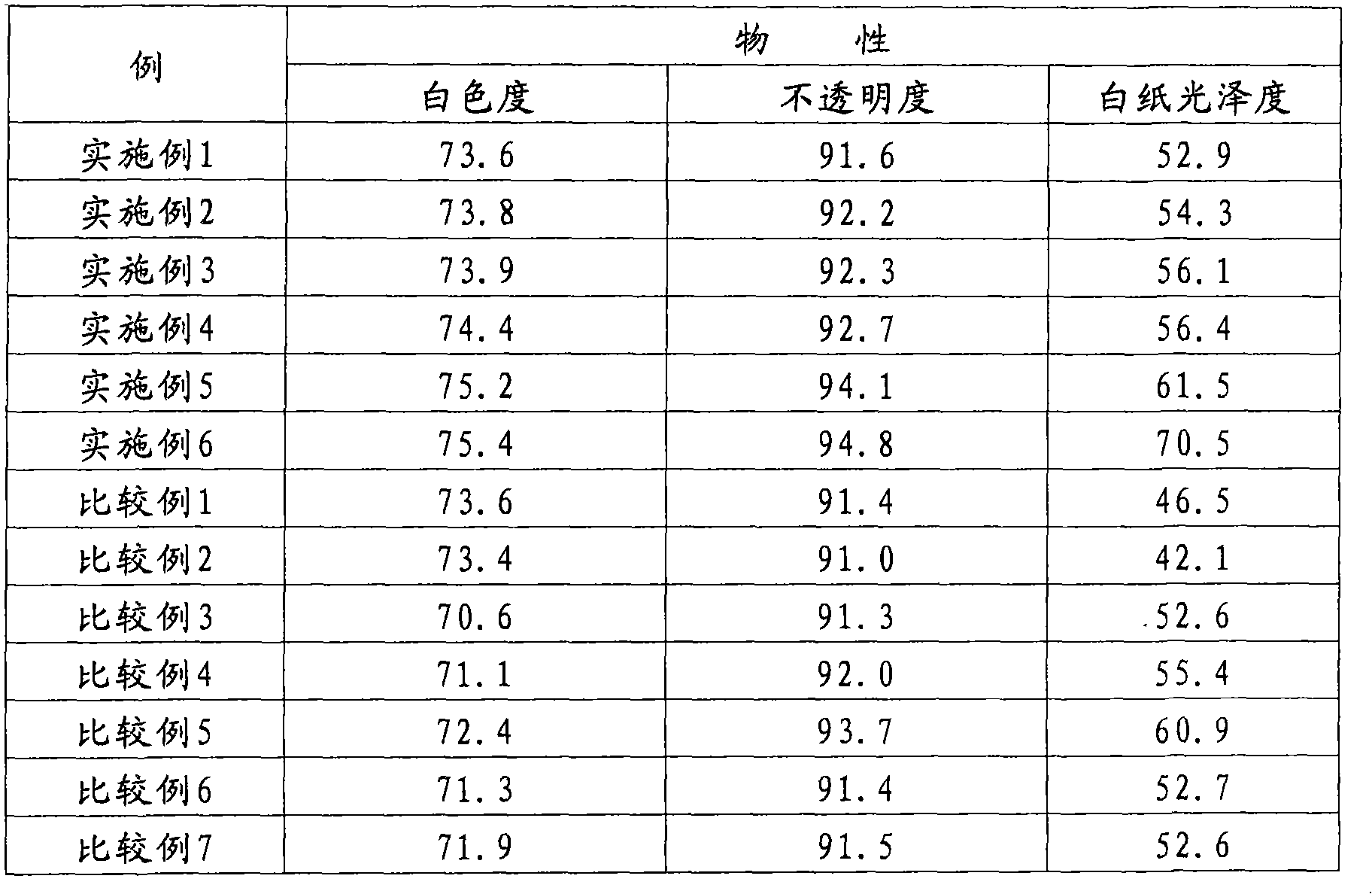

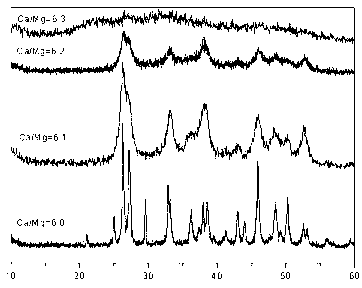

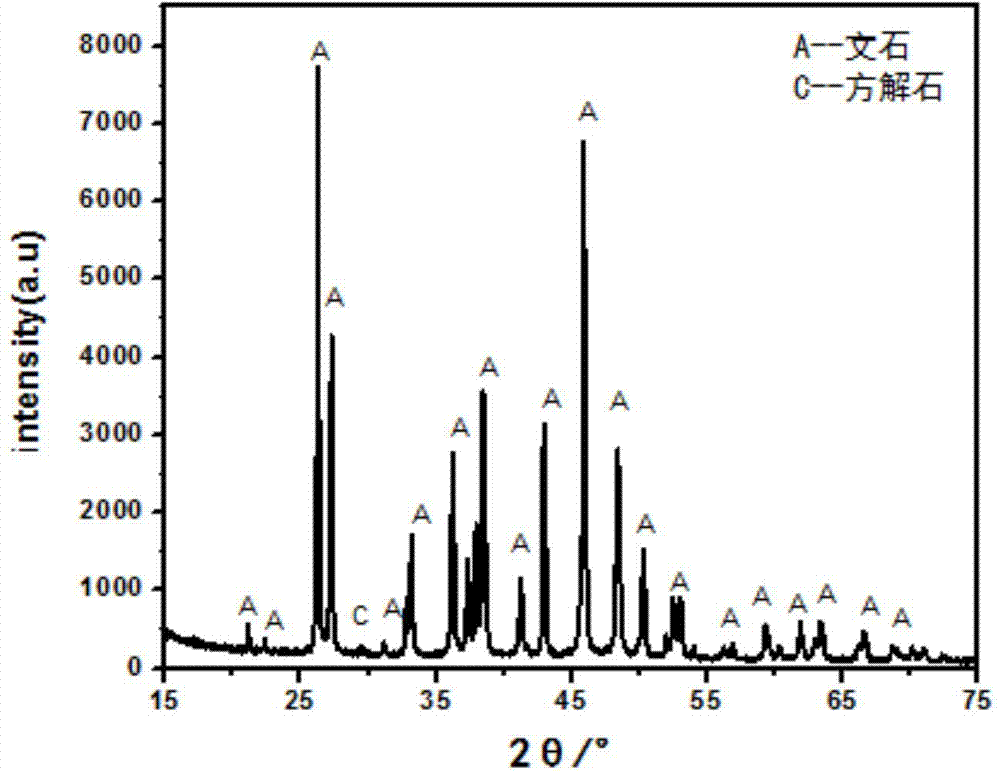

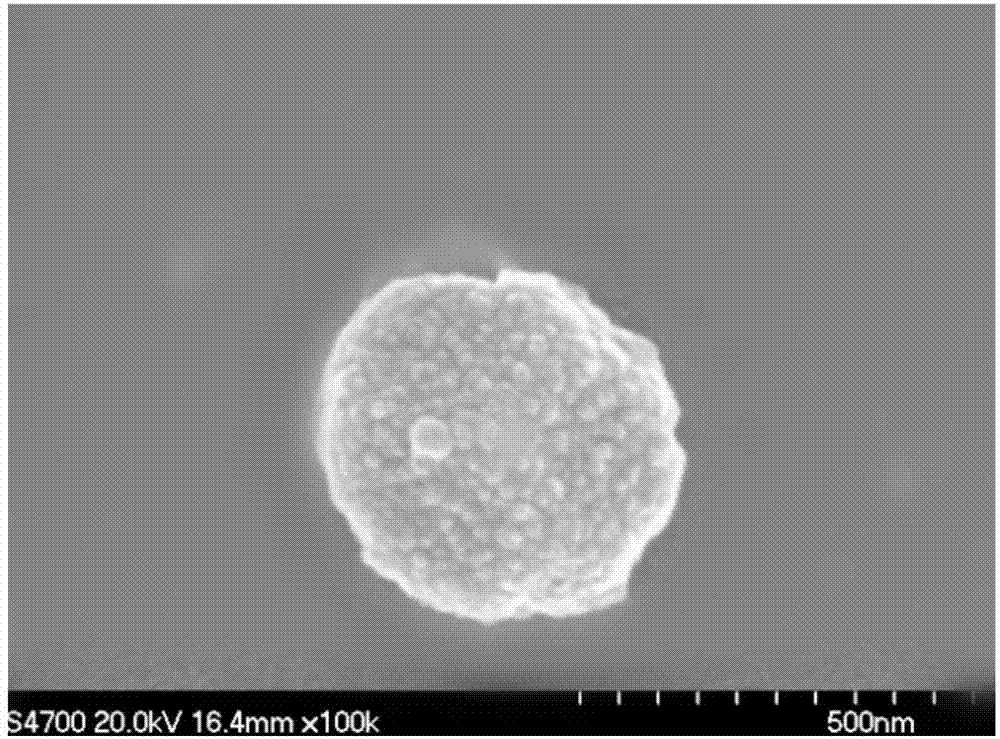

Preparation method of enhanced multiphase crystal based on calcite and aragonite

The invention discloses a preparation method of an enhanced multiphase crystal based on calcite and aragonite. The preparation method mainly solves the problems that in the prior art, a calcium carbonate preparation method is complicated, expensive and not easy to control whiteness. The preparation method comprises the steps of firstly mixing calcium chloride, magnesium chloride, sodium carbonate and sodium hydroxide with deionized water so as to prepare into solutions; then mixing the calcium chloride solution, the sodium carbonate suspension liquid and the sodium hydroxide suspension liquid, heating, and stirring to prepare into a calcite and aragonite multiphase suspension liquid; adding a magnesium chloride water solution into the calcite and aragonite multiphase suspension liquid, and preparing into the enhanced multiphase crystal based on calcite and aragonite; precipitating, cleaning, drying, and grinding to obtain lamellar crystals with the thickness being 0.05 to 0.1 micrometer, the diameter being 0.2 to 4 micrometers and uniform size distribution. According to the preparation method of the enhanced multiphase crystal based on calcite and aragonite provided by the invention, the whiteness of the crystal is improved, the used raw materials are cheap, the process is simple, and the enhanced multiphase crystal can be applied in manufacturing plastics, rubbers, catalysts, medicines, ceramics, papermaking, ink and coatings.

Owner:XIDIAN UNIV

Coating solution and coated paper coated with the same

InactiveCN101541901ACalcium/strontium/barium carbonatesNon-fibrous pulp additionCalcium hydroxideKaolin clay

A coating solution comprising: (A) an aragonite-type light calcium carbonate microparticle having an average major axis diameter of 1.0 to 2.8 [mu]m and an average minor axis diameter of 0.15 to 0.3 [mu]m, which is produced by diluting a calcium hydroxide slurry that has been treated by high-speed shearing until the slurry has a viscosity of 1000 cP or more at a concentration of 400 g / l to a concentration more than 50 g / l and then blowing carbon dioxide into the diluted slurry at a reaction starting temperature of 20 to 60 DEG C and at a rate of 1 to 3 I / min per kg of calcium hydroxide; and (B) a pigment comprising a wet heavy calcium carbonate cake. The coating solution enables to provide a coated paper having an excellent degree of brilliance and an excellent degree of whiteness, despite containing no kaolin.

Owner:OKUTAMA IND

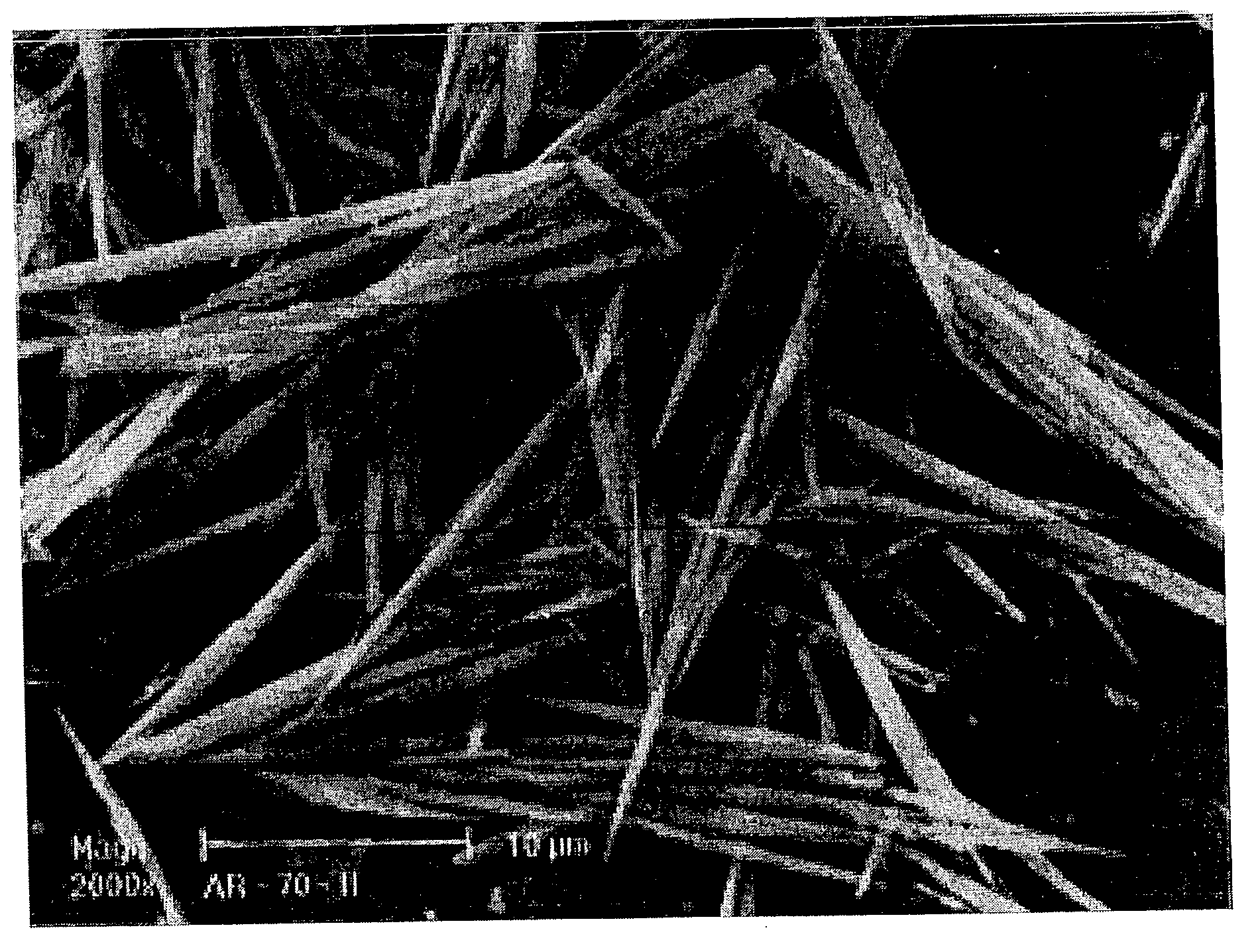

Preparation method of Porous aragonite structure micron sheet, ceramic diaphragm and preparation method thereof

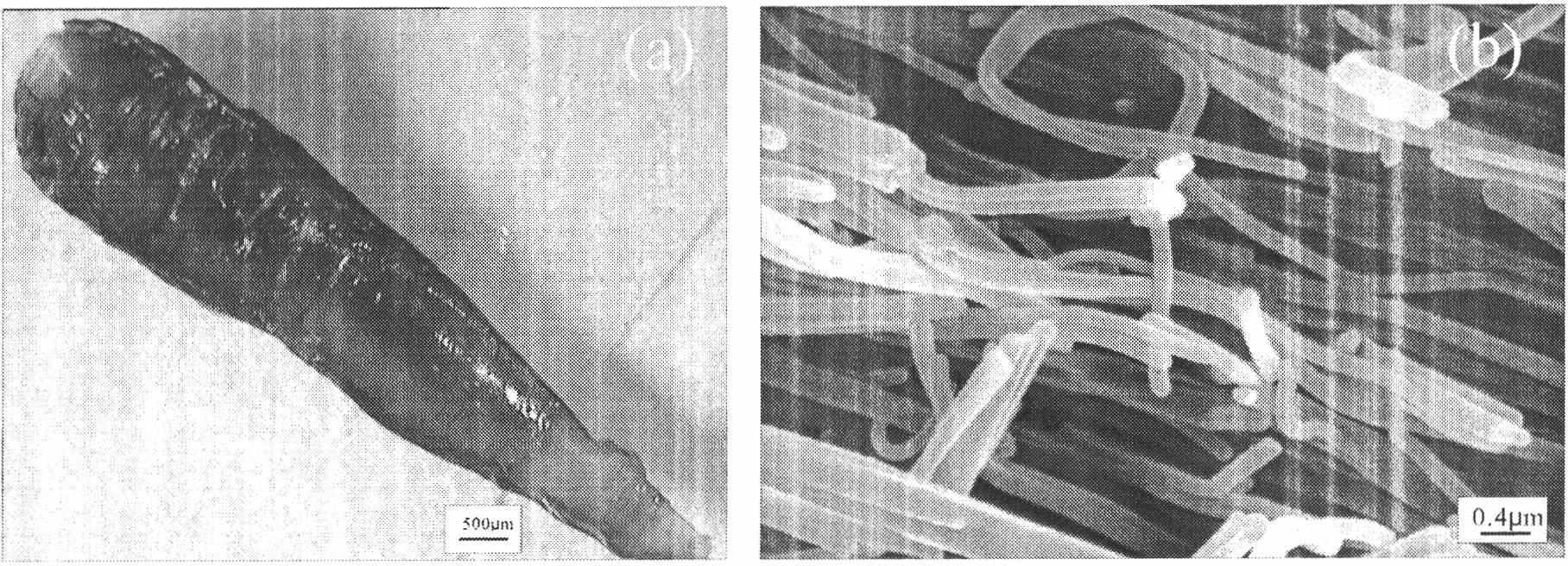

ActiveCN109244318AImprove mechanical propertiesImprove wettabilityFinal product manufactureCell component detailsAragoniteLithium-ion battery

The invention provides a preparation method of a porous aragonite structure micron sheet, comprising the following steps: A) processing the shell body is treated in an acid solution to obtain a shellbody nacre layer with the aragonite structure; B) processing that nacreous layer of the shell body to obtain nacreous layer fragments; C) treating that nacre fragments in an alkaline solution to obtain a porou aragonite structure micron sheet. The present application also provides a separator, the preparation method thereof, and a lithium ion battery. The invention adopts a simple preparation process to successfully separate a single-layer porous aragonite structure micron sheet from a natural shell body, and further applies the single-layer porous aragonite structure micron sheet to a diaphragm. Compared with the zero-dimensional nano-ceramic particle coating of commercial ceramic diaphragm, the porous aragonite structure microchip coating prepared in the present invention not only has good lithium ion conductivity, excellent electrolyte wettability and membrane breaking temperature of the diaphragm is improved, the mechanical strength is good, the scraping process is simple, and thediaphragm has great industrial application prospect.

Owner:UNIV OF SCI & TECH OF CHINA

Preparation method of aragonite type white mud calcium carbonate

InactiveCN104310451AAdaptableHigh crystal phase purityCalcium/strontium/barium carbonatesAragoniteGreen liquor

The invention belongs to the recovery utilization of solid waste-alkali recovery white mud in paper-making industry and in particular relates to a preparation method of aragonite type white mud calcium carbonate. The existing method for preparing white mud calcium carbonate with certain crystal form has the prominent problems that the preparation process control requirement is high and the alkali recovery efficiency is seriously influenced. Quicklime or hydrated lime and a part of purified green liquid are reacted at 60-100 DEG C to form a crystal nucleus solution, and then the crystal nucleus solution is reacted with the remained purified green liquid at 60-100 DEG C for 30-120min, the temperature is preserved for 30min, then filtering and washing are carried out to obtain the aragonite type white mud calcium carbonate. The filling performance of the prepared white mud calcium carbonate can be improved, and no obvious influence on the existing production process control and the alkali recovery efficiency is caused.

Owner:CHINA NAT PULP & PAPER RES INST CO LTD

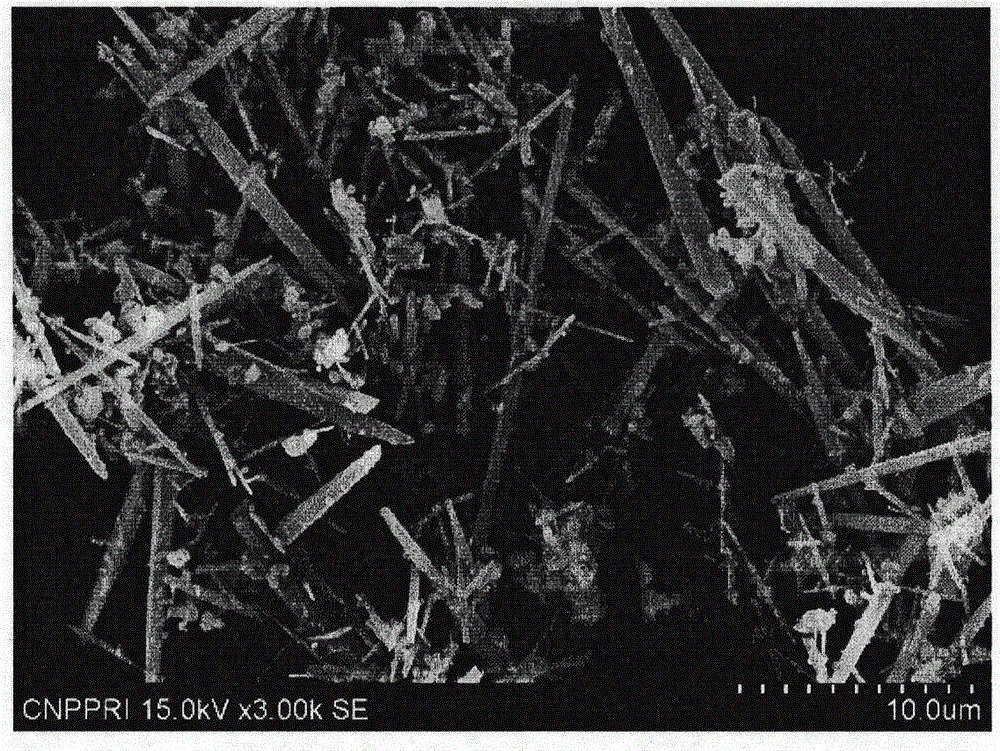

Aragonite type crystal seeds and aragonite type light calcium carbonate and preparation method thereof

ActiveCN109467112AControl impactRealize industrial productionCalcium/strontium/barium carbonatesCoatings with pigmentsSlurryAragonite

The invention discloses a preparation method of aragonite type crystal seeds and aragonite type light calcium carbonate. The preparation method comprises the following steps: calcining limestones anddigesting the limestones with hot water to prepare coarse slurry; after thickening the coarse slurry, removing impurities to prepare fine slurry; pumping the fine slurry into a carbonizing tower, adding a crystal form control agent to regulate, and uniformly stirring the mixture; introducing kiln gas to carbonize, detecting the pH value and the conductivity online, and judging the carbonizing endpoint; adding a crystal form modifier to regulate; screening the mixture to remove impurities, and carrying out filter press to obtain a filter cake; dispersing the filter cakes to prepare slurry andthen grinding the slurry to obtain aragonite crystal seeds for later use; then pumping the fine slurry into the carbonizing tower again, adding the aragonite type crystal seeds, and uniformly stirringthe mixture; and then introducing kiln gas again to carbonize to obtain the aragonite type crystal seeds. The aragonite type light calcium carbonate prepared by the method has a needle-like crystal shape, and not only can be used as papermaking filler, but also can be used as a paper coating material. The production process is simple, the production cost is relatively low, and industrial production is achieved.

Owner:DSSUN NEW MATERIAL SHANDONG

Method for synthesizing aragonite nanorod under conditions of normal pressure and temperature

InactiveCN102205984ASimple processRaw materials are easy to getCalcium/strontium/barium carbonatesNanotechnologyReaction temperaturePollution

The invention discloses a method for synthesizing an aragonite nanorod under conditions of normal pressure and temperature. In the method, a solen protein layer is taken as a substrate, and an aragonite nanorod product is obtained by reacting a calcium chloride solution with carbon dioxide for 3-12 hours under the conditions of normal pressure and temperature by using a carbon dioxide diffusion deposition method. By taking the solen protein layer as the substrate for reaction under the conditions of normal pressure and temperature, the method has the characteristics of low reaction temperature, less consumed energy, high purity (above 99 percent) of a product, simple synthesis process, readily available raw materials, no pollution and the like. The aragonite nanorod is an ideal organic-inorganic composite nanomaterial. The aragonite nanorod can be used as a reinforcing material for reinforcing the toughness of an organism and improving the plasticity of the organism, and also can be used as a biological active material which is specifically applied to the fields such as the medicine field and the like.

Owner:GUANGXI UNIV

Enzyme-aided pearl glossing process

The present invention relates to pearl post-treating process, and is especially one pearl treating process, in which bioactive enzyme is used in treating pearl to raise pearl brightness. The enzymatic pearl treating process includes the following steps: pre-treatment; compounding buffering liquid or saturated sodium carbonate solution; brightening pearl with enzyme preparation; brightening pearl with fluorescent brightener and others. Bioactive enzyme with biocatalytic effect in buffering liquid environment is utilized to eliminate attached matter in the surface of pearl for exposing bright pearl aragonite crystal, and the fluorescent brightener is used to shorten the brightening period.

Owner:ZHEJIANG RUANS PEARL LTD

Method for removing high concentration phosphor pollution in alkali wastewater

InactiveCN103130357AImprove thermal stabilityImprove adsorption efficiencyMultistage water/sewage treatmentWater/sewage treatment by sorptionHigh concentrationSorbent

The invention discloses a method for removing high concentration phosphor pollution in alkali wastewater, which comprises the following steps: Step1) synthesizing a magnesium doped aragonite (Mg / CaCO3) type calcium carbonate nano adsorbent; step2)adding the magnesium doped aragonite type calcium carbonate adsorbent in the water containing phosphor; step3) effecting the adsorbent in a solution for more than 4 hours; and step4) standing for a segment of time, and depositing the synthesized magnesium doped aragonite type calcium carbonate adsorbent particles to remove phosphor in the aqueous solution. The invention provides the method for removing the high concentration phosphor in alkali wastewater, the pollution clearance of high density phosphor (the concentration is 500mg / L) in the alkali wastewater can reach more than 80%, the foundation of the water environment purification and resource reutilization can be established, and the method for removing high concentration phosphor pollution in alkali wastewater has good economic and social benefit.

Owner:SUZHOU UNIV OF SCI & TECH

Method for distinguishing pearl powders from shell powders

InactiveCN101620176BEasy to distinguishSimple methodPreparing sample for investigationColor/spectral properties measurementsAragonitePotassium bromide

The invention relates to a method for distinguishing pearl powders from shell powders, comprising the following steps: the pearl powders and the shell powders are calcined and then respectively mixed with potassium bromide to be made into transparent flakes, then the infrared spectrum of the transparent flakes is measured under the conditions of resolution of 4 cm<-1> and scanning for 16 times with the scanning range of 400-4000 cm <-1>, the pearl powders and the shell powders are distinguished according to the characteristic peak of 701.0 cm <-1>, 1082.1 cm <-1>, 2919.3 cm<-1> and 3468.5 cm <-1>; as organic substances in the calcined pearl powders are partially decomposed, the crystal type of calcium carbonate changes from the aragonite type to the calcite type, and the calcium carbonatestarts to decompose; the organic substances in the shell powders are almost totally decomposed, the aragonite type calcium carbonate is totally converted into the calcite type calcium carbonate, and the calcium carbonate does not start to decompose into calcium oxide yet, therefore, the method can be used for distinguishing the pearl powders from the shell powders. Compared with the prior distinguishing method, the method can simply, rapidly and effectively distinguish the pearl powders from the shell powders with obvious phenomenon.

Owner:钱国英 +2

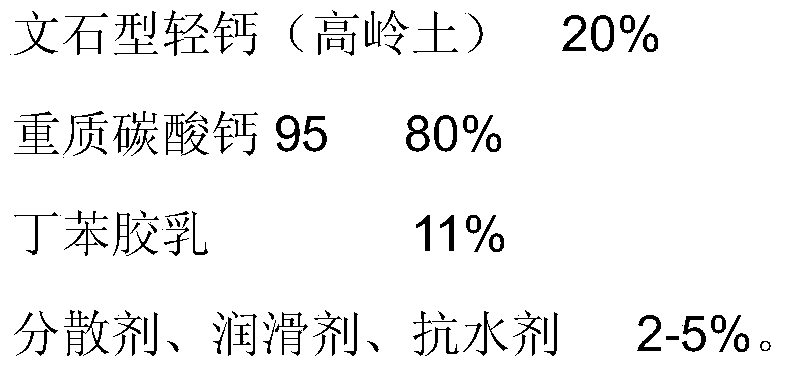

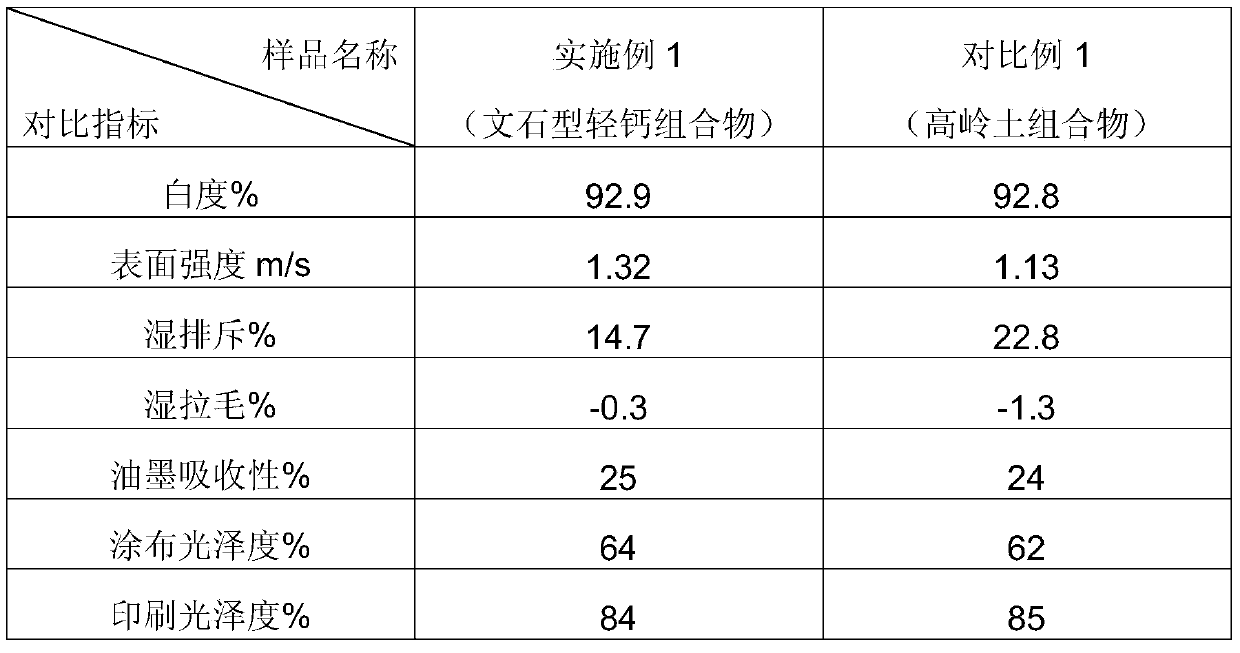

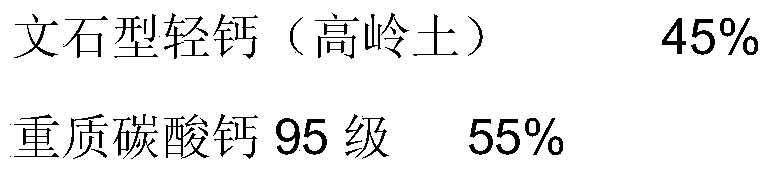

Aragonite-type light calcium composition used in paper coating, and application method thereof

InactiveCN105484099AReduce usageImprove qualityCoatings with pigmentsAragoniteButadiene-styrene rubber

Owner:DSSUN NEW MATERIAL SHANDONG

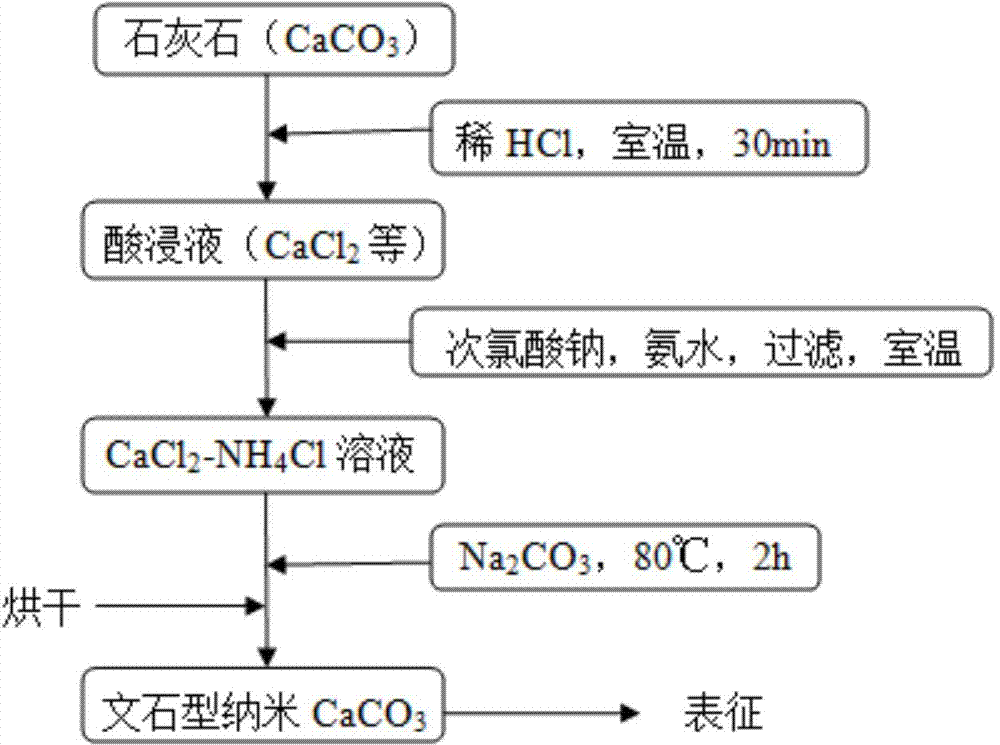

Method for preparing high purity aragonite type nano calcium carbonate by acidolysis of limestones

InactiveCN104118896ASolve low resource utilizationReduce pollutionCalcium/strontium/barium carbonatesMaterial nanotechnologyCombustionResource utilization

Owner:BEIJING UNIV OF CHEM TECH

Composite calcium naphthenate-based lubricating grease and preparation method thereof

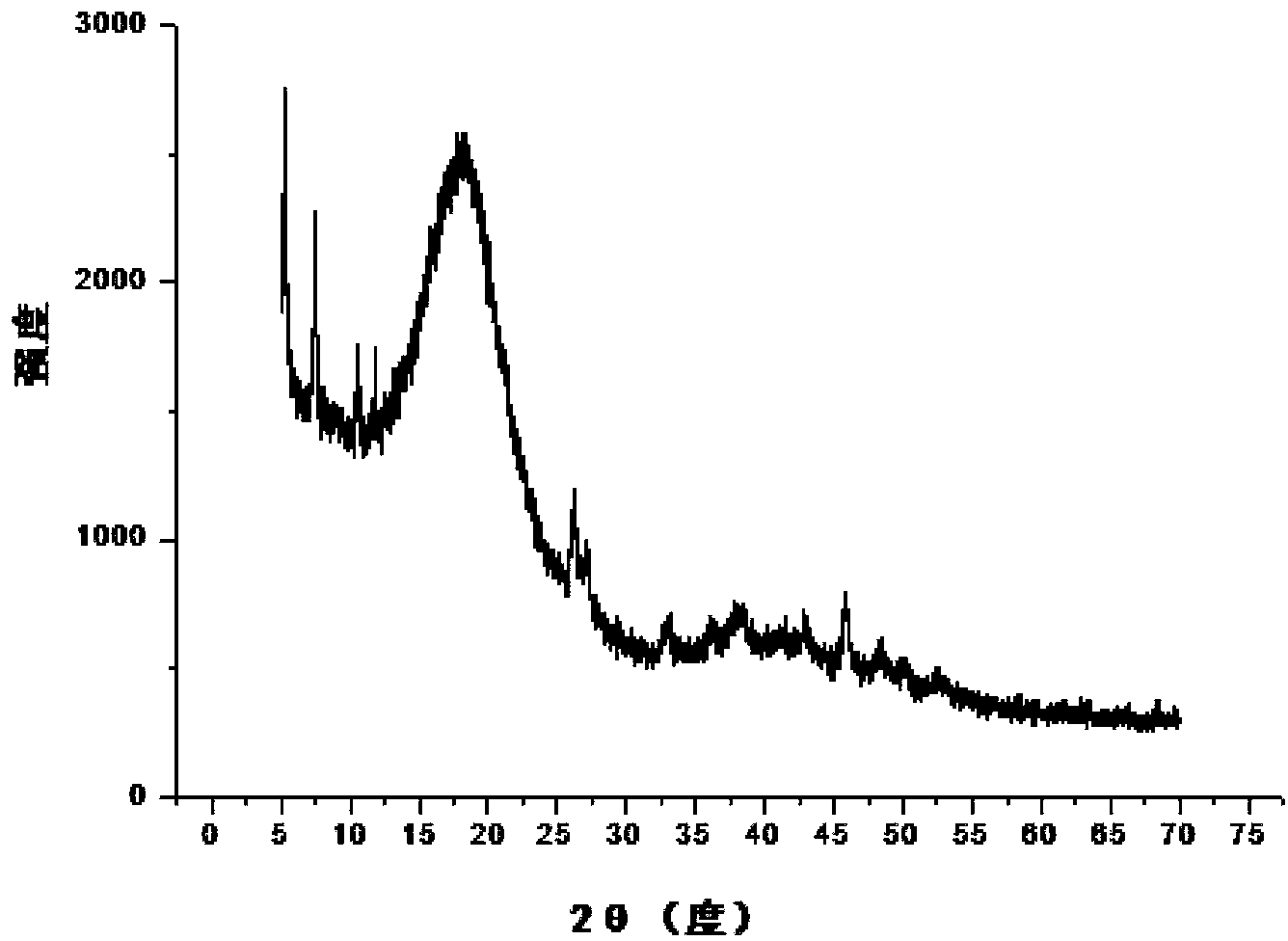

ActiveCN104293449AImprove corrosion resistanceStrong anti-salt spray performanceLubricant compositionSulfonateAragonite

The invention discloses composite calcium naphthenate-based lubricating grease which is characterized by including following components, on the basis of the weight of the lubricating grease, 20-70 wt% of non-Newtonian calcium naphthenate, 1-10 wt% of a calcium salt of a higher fatty acid and 25-70 wt% of a basic oil. An infrared spectrogram of the non-Newtonian calcium naphthenate has a characteristic absorption peak of aragonite-type calcium carbonate. The invention also discloses a preparation method of the composite calcium naphthenate-based lubricating grease and the composite calcium naphthenate-based lubricating grease prepared through the same. The composite calcium naphthenate-based lubricating grease has excellent anti-corrosion property and anti-salt fog property, and has performances comprising a high-temperature-resistant performance, a water-resistant performance, an adhesive performance, a colloid stability and the like, which are better than those of composite calcium sulfonate-based lubricating grease. The composite calcium naphthenate-based lubricating grease has a longer lubricating service life. The preparation method is simple, environmental-protective, low in cost and stable in product quality.

Owner:CHINA PETROLEUM & CHEM CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com