Preparation method of aragonite type white mud calcium carbonate

A calcium carbonate and aragonite-type technology, applied in calcium carbonate/strontium/barium, chemical instruments and methods, calcium/strontium/barium compounds, etc., can solve problems such as high control requirements and affecting alkali recovery efficiency, and achieve adaptability Strong, improve the quality and application performance, the effect of high crystal phase purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

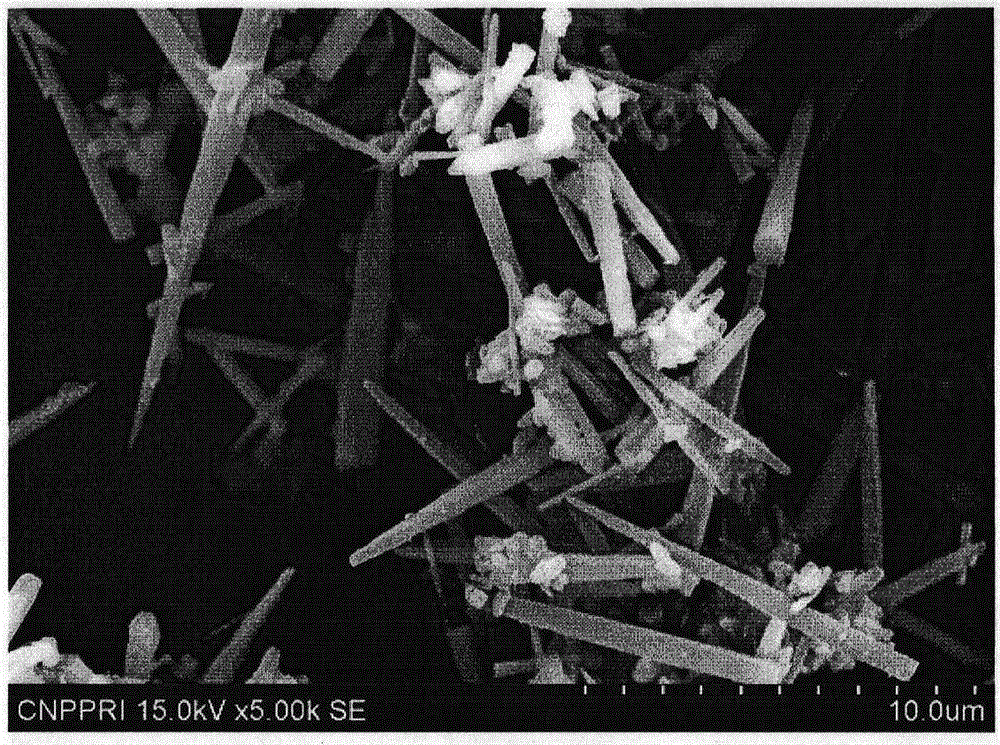

Image

Examples

Embodiment 1

[0021] 1) In a 2.0L reaction vessel, add 400mL of purified green liquid with a concentration of 70g / L, calculated as NaOH, then add 1.65g of disodium hydrogen phosphate, and add 135.9g of slaked lime at a time under the condition of stirring, the purity of slaked lime It is 89.8%, that is, the effective calcium hydroxide content is 89.8%. The reaction temperature was controlled at 80° C., and a crystal nucleus solution was formed after 30 minutes of reaction.

[0022] 2) In the crystal nucleus solution, continuously add 1100mL of purified green liquor with a concentration of 124.5g / L. Calculated by NaOH, the green liquor addition rate is 0.15mL / min / g calcium hydroxide, the reaction temperature is 80°C, and the green liquor is added After the heat preservation is finished, it is kept warm for 30 minutes. After the heat preservation is finished, the aragonite type white mud calcium carbonate is obtained through filtration and washing treatment, and water is added to make aragoni...

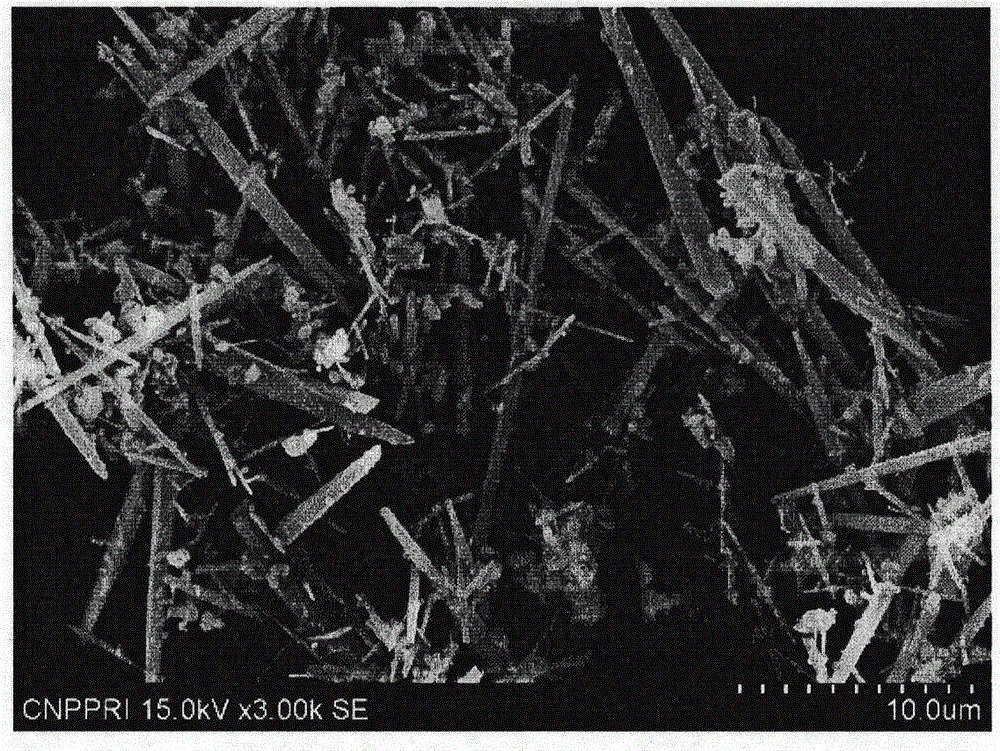

Embodiment 2

[0025] 1) In a 2.0L reaction vessel, add 400mL of purified green liquor with a concentration of 70g / L, calculated as NaOH, then add 1.65g of disodium hydrogen phosphate, and add 146.06g of slaked lime at a time under the condition of stirring, the purity of slaked lime It is 83.55%, that is, the effective calcium hydroxide content is 83.55%. The reaction temperature was controlled at 80° C., and a crystal nucleus solution was formed after 30 minutes of reaction.

[0026] 2) In the crystal nucleus solution, continuously add 1100mL of purified green liquor with a concentration of 124.5g / L, calculated as NaOH, the green liquor addition rate is 0.16mL / min / g calcium hydroxide, the reaction temperature is 80°C, and the green liquor is added After the heat preservation is finished, it is kept warm for 30 minutes. After the heat preservation is finished, the aragonite type white mud calcium carbonate is obtained through filtration and washing treatment, and water is added to make arag...

Embodiment 3

[0029] 1) In a 2.0L reaction vessel, add 400mL of purified green liquid with a concentration of 100g / L, calculated as NaOH, then add 1.65g of disodium hydrogen phosphate, and add 135.9g of slaked lime at a time under the condition of stirring, the purity of slaked lime It is 89.8%, that is, the effective calcium hydroxide content is 89.8%. The reaction temperature was controlled at 80° C., and a crystal nucleus solution was formed after 30 minutes of reaction.

[0030] 2) In the crystal nucleus solution, continuously add 1100mL of purified green liquor with a concentration of 113.6g / L. Calculated by NaOH, the green liquor addition rate is 0.15mL / min / g calcium hydroxide, the reaction temperature is 80°C, and the green liquor is added After the heat preservation is finished, it is kept warm for 30 minutes. After the heat preservation is finished, the aragonite type white mud calcium carbonate is obtained through filtration and washing treatment, and water is added to make aragon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com