Patents

Literature

36results about How to "High crystal phase purity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

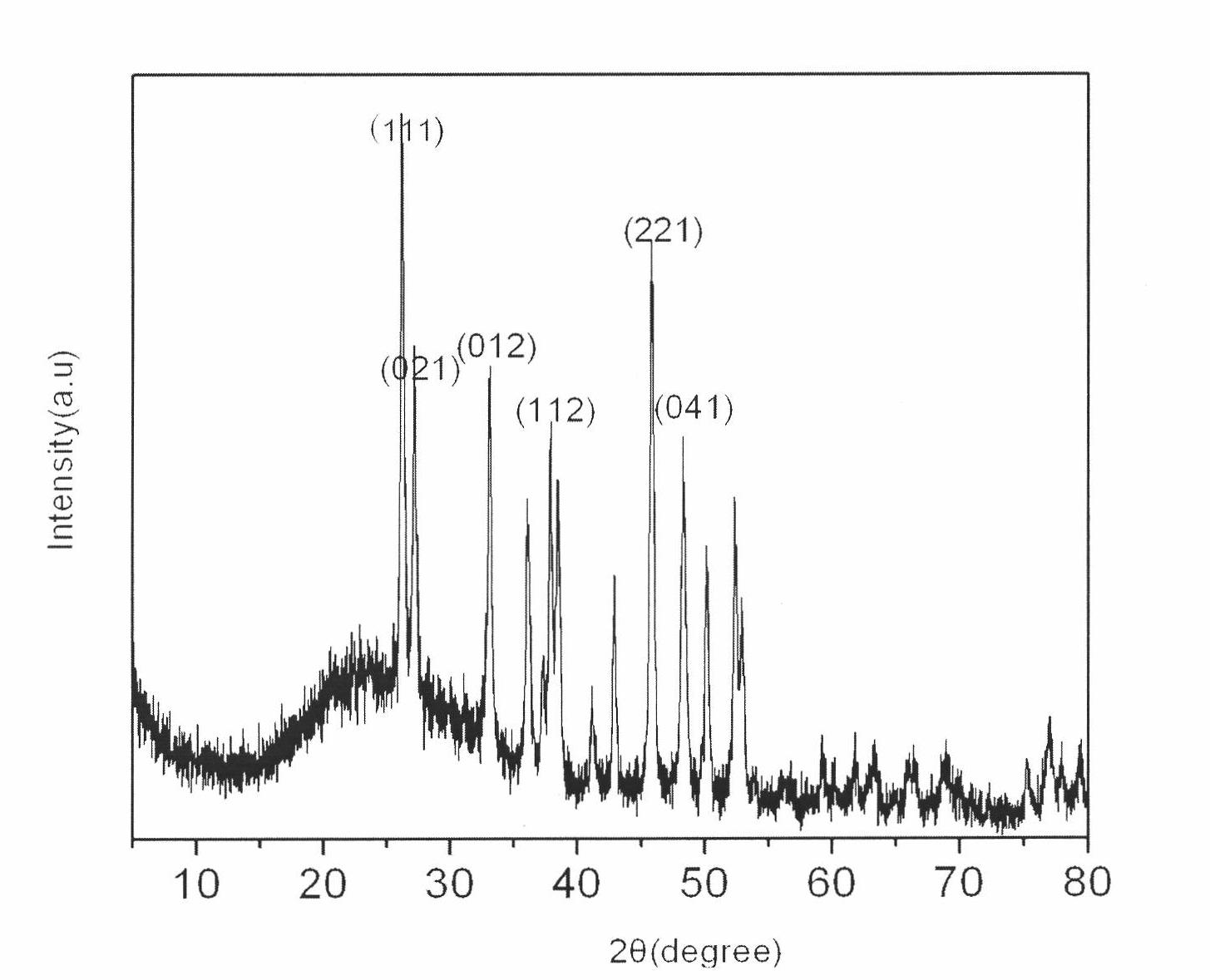

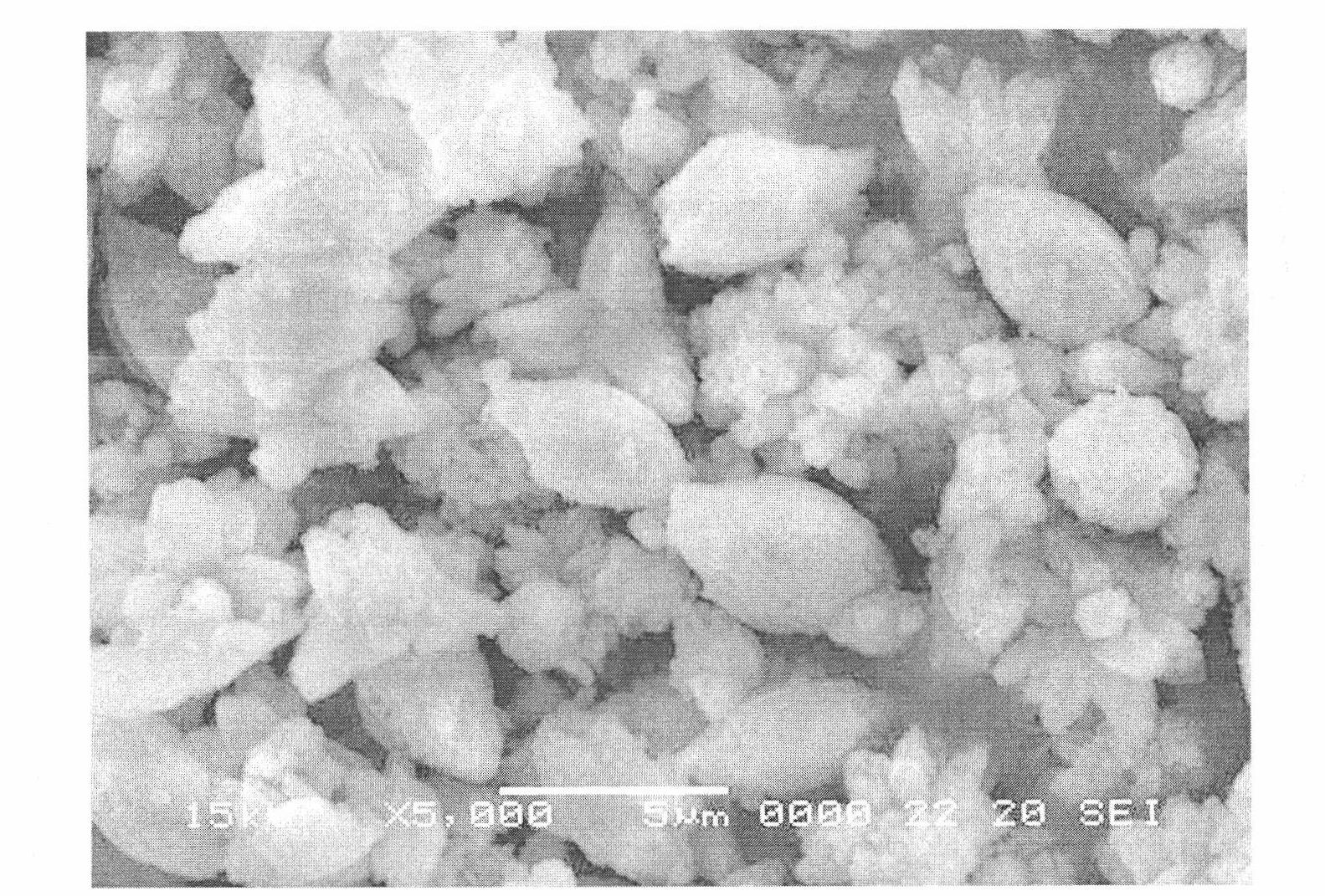

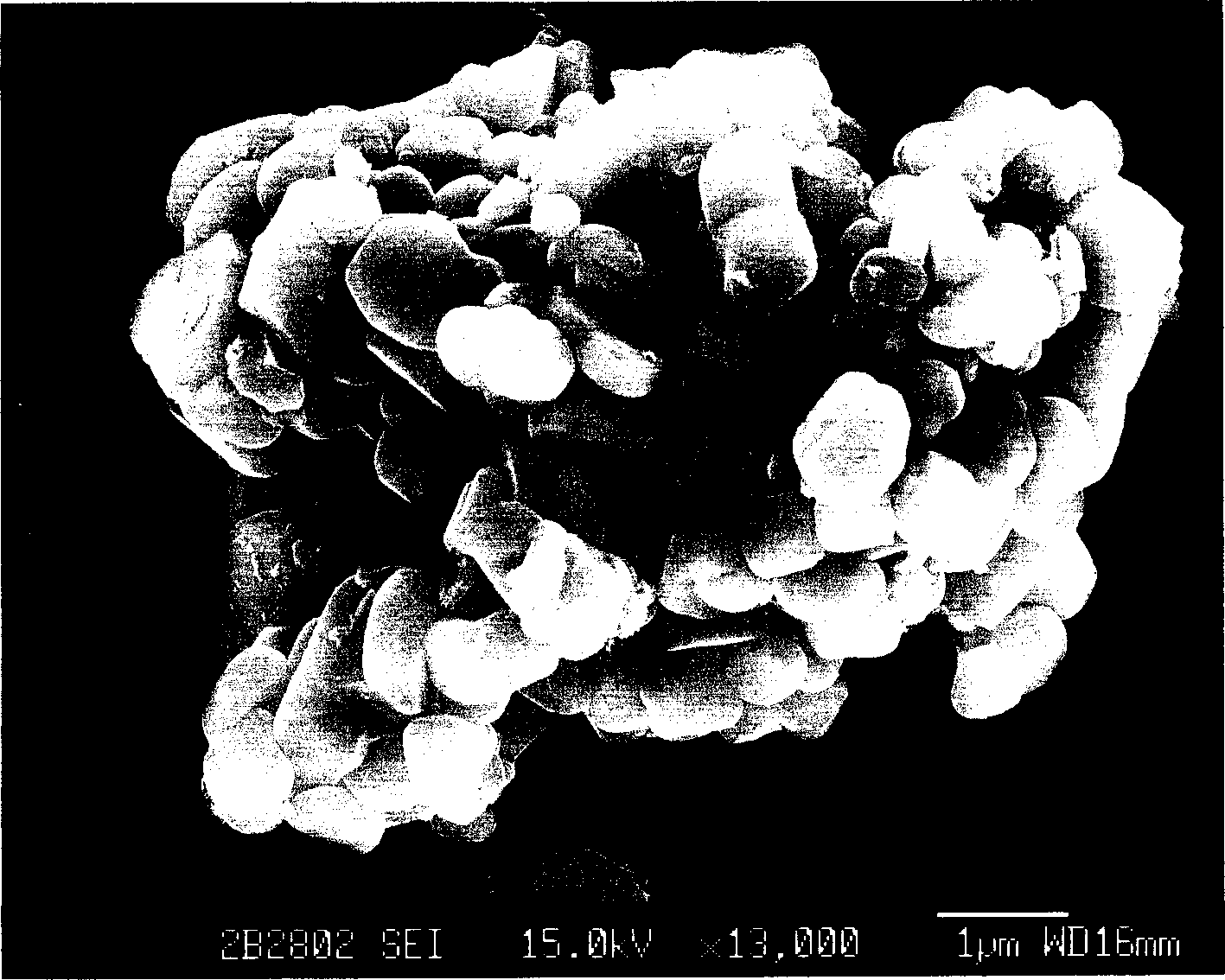

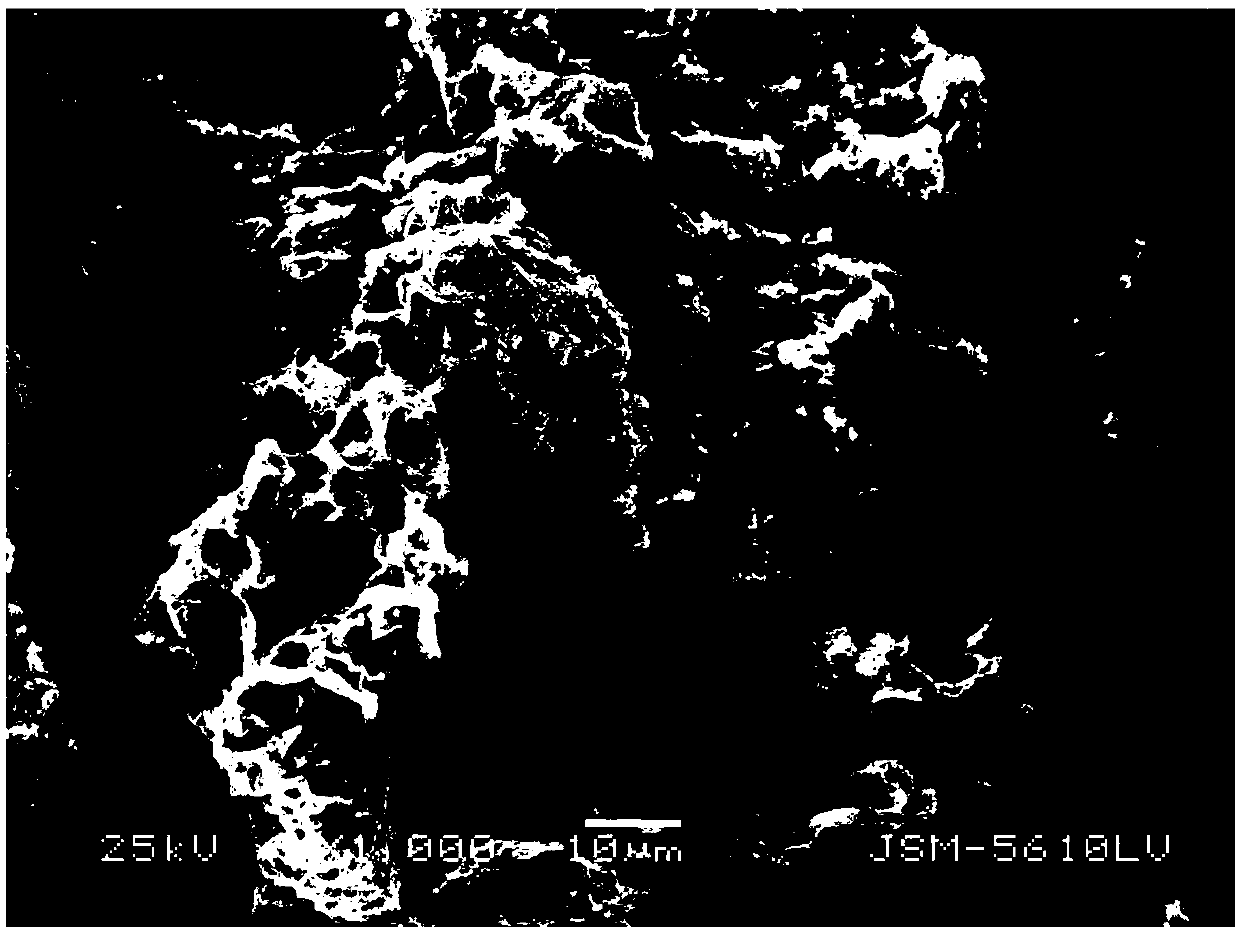

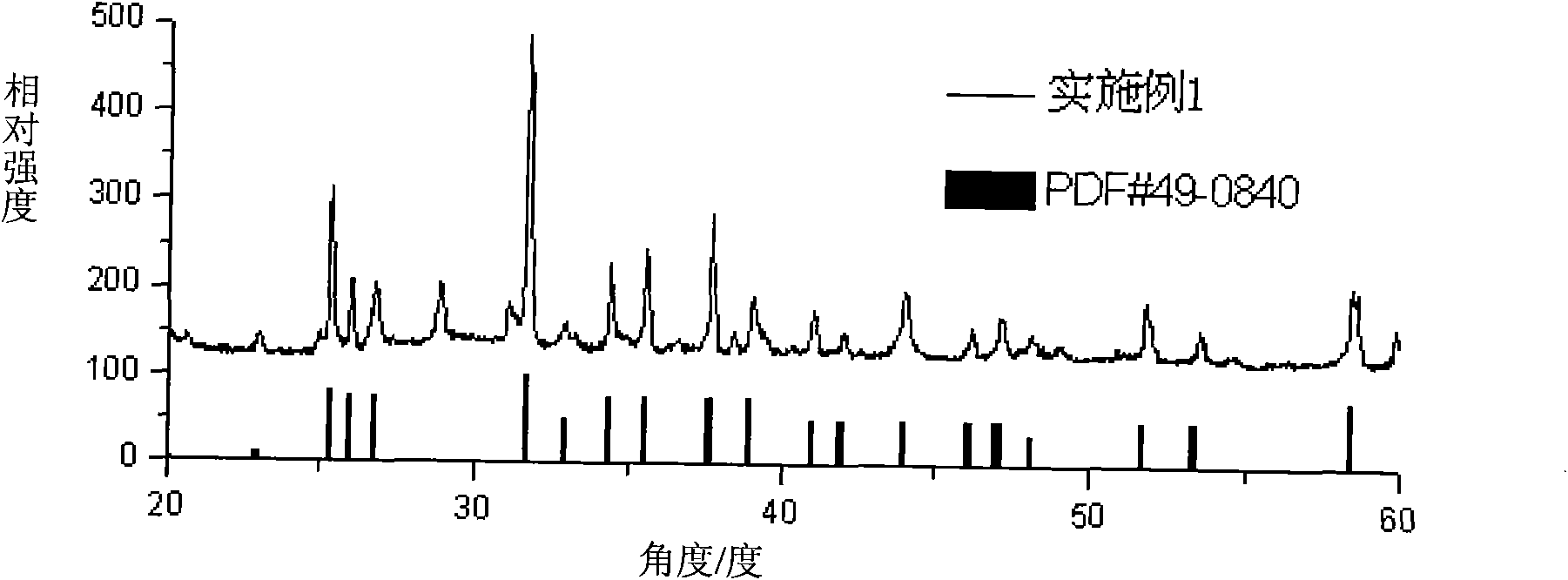

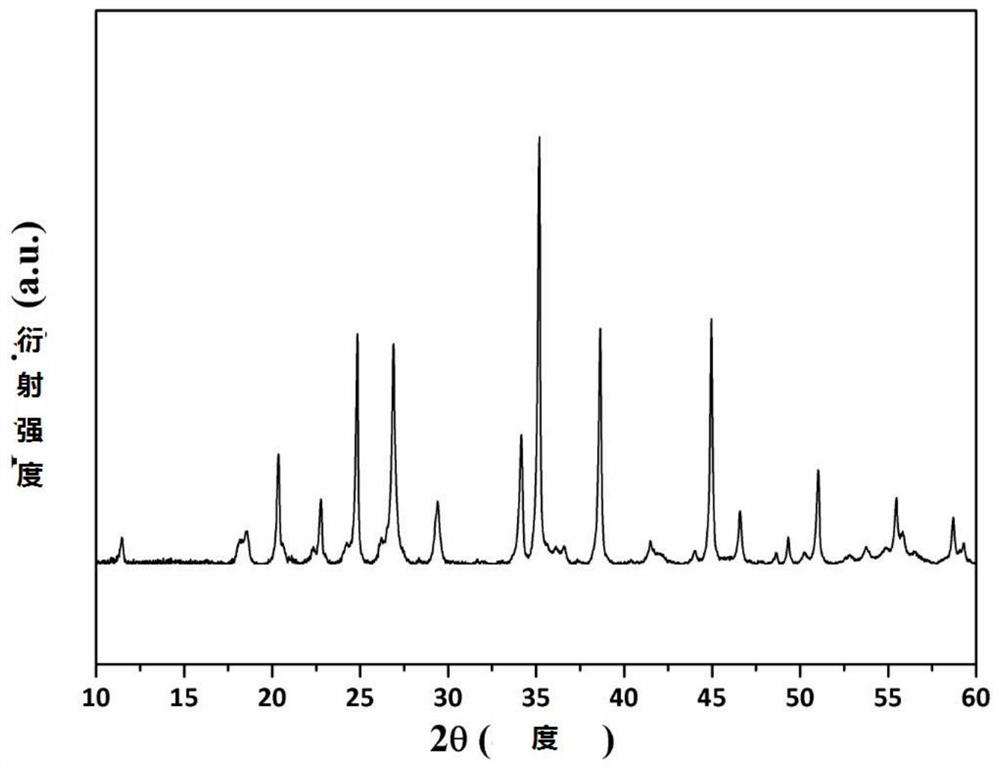

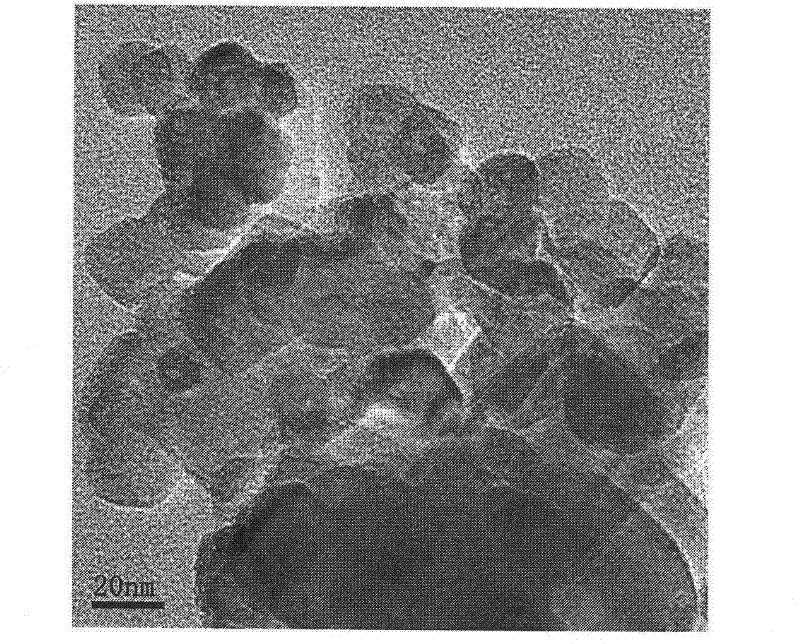

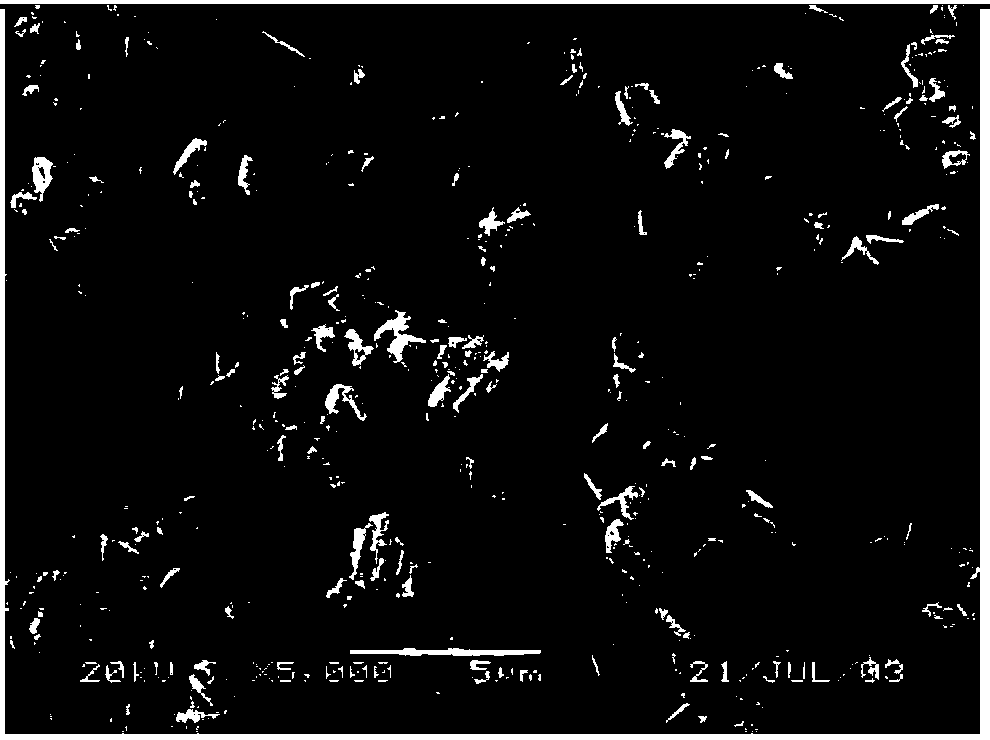

Preparation method of multiaperture ferrite

InactiveCN103101980AEasy to prepareThe reaction raw materials are simple and cheapIron compoundsCobalt compoundsFluid phaseFerrite powder

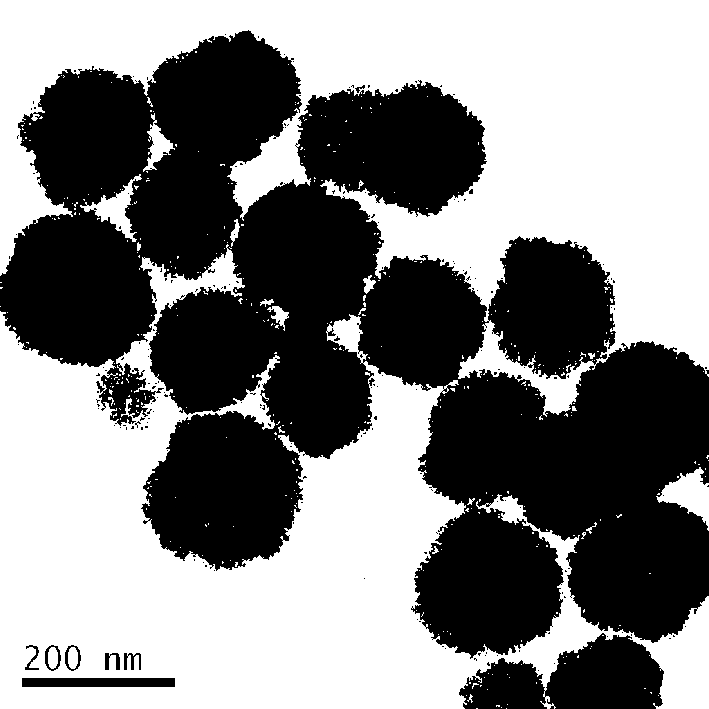

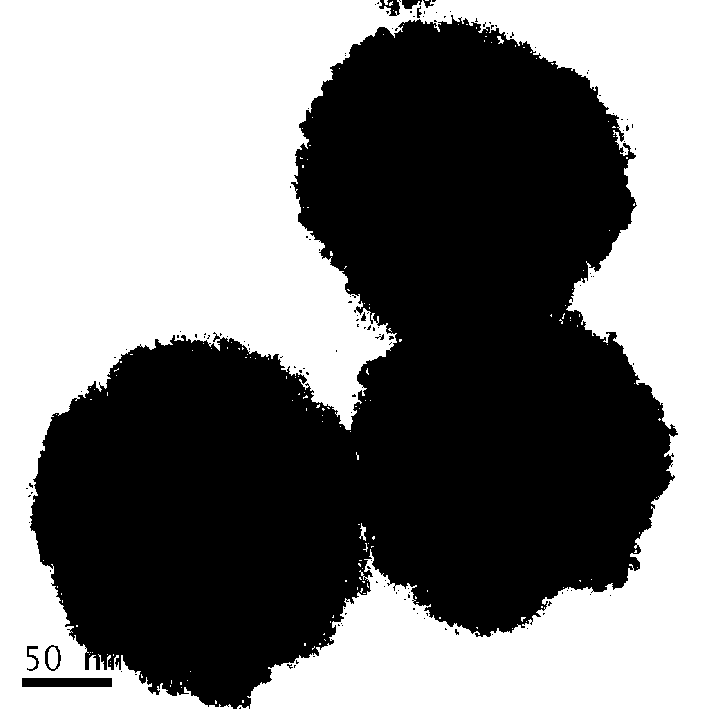

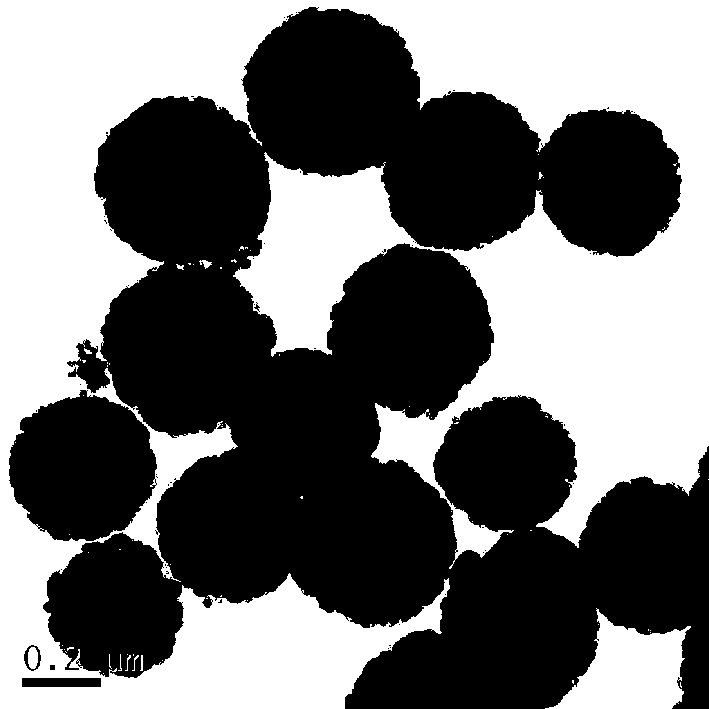

The invention provides a method for preparing multiaperture spherical magnetic ferrite (zinc ferrite, nickel ferrite, cobalt ferrite and manganese ferrite) by taking dodecylamine as a precipitator by a solvothermal method. The preparation method is characterized in that an ethylene glycol solution of ferric trichloride and chloride is used as a reaction solution; dodecylamine is used as the precipitator; and the ethylene glycol solution and the dodecylamine are stirred and mixed uniformly at the room temperature to form a liquid phase reaction solution; and the liquid phase reaction solution is transferred to a reaction kettle for hydrothermal reaction at 180-250 DEG C. Products are separated, washed and dried to obtain corresponding multiaperture ferrite powder after reaction. The preparation method has the characteristics of being low in raw materials, simple in process, convenient in operation, controllable in shape, and the like.

Owner:LUDONG UNIVERSITY

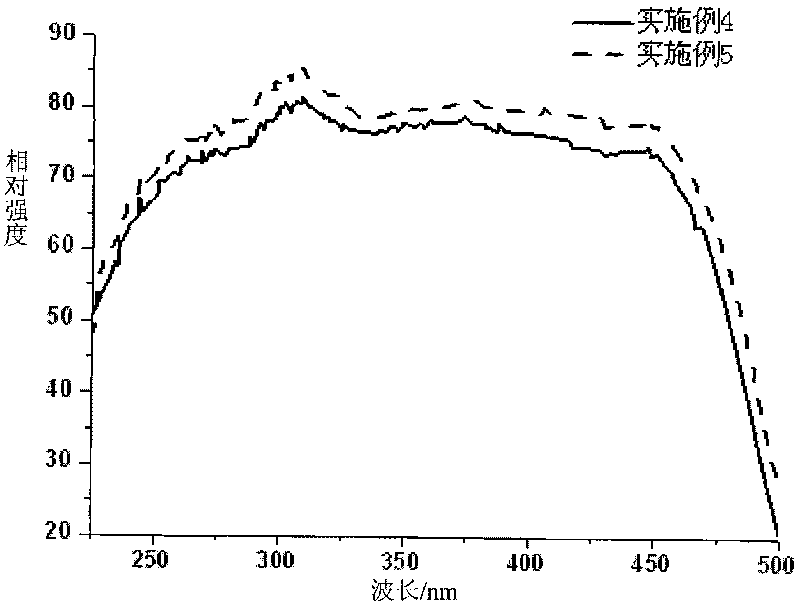

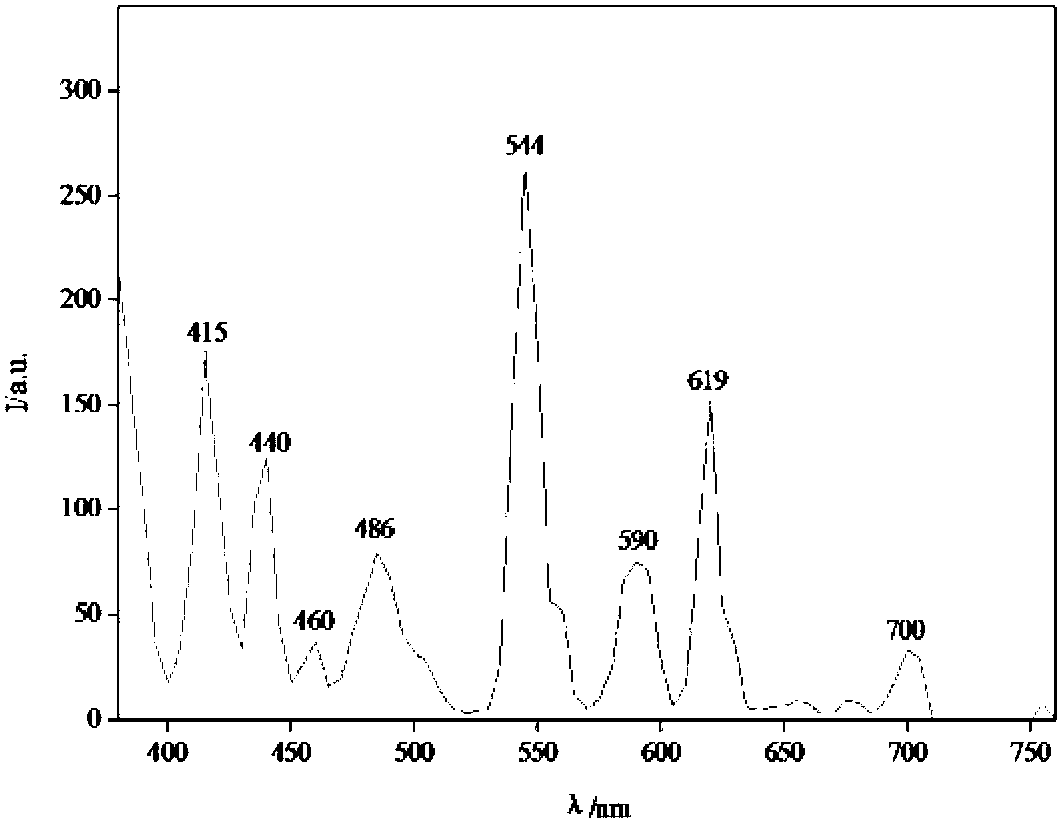

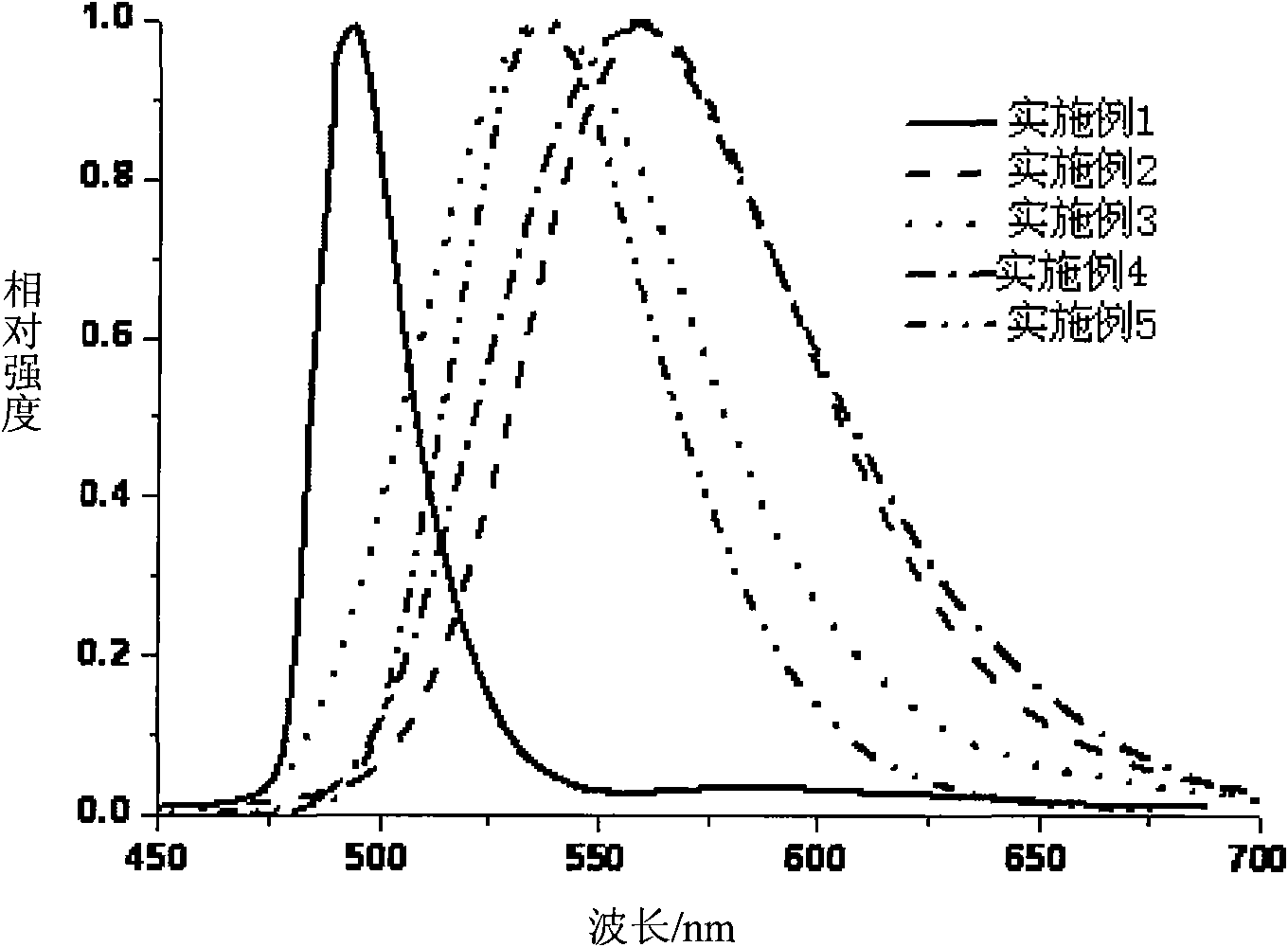

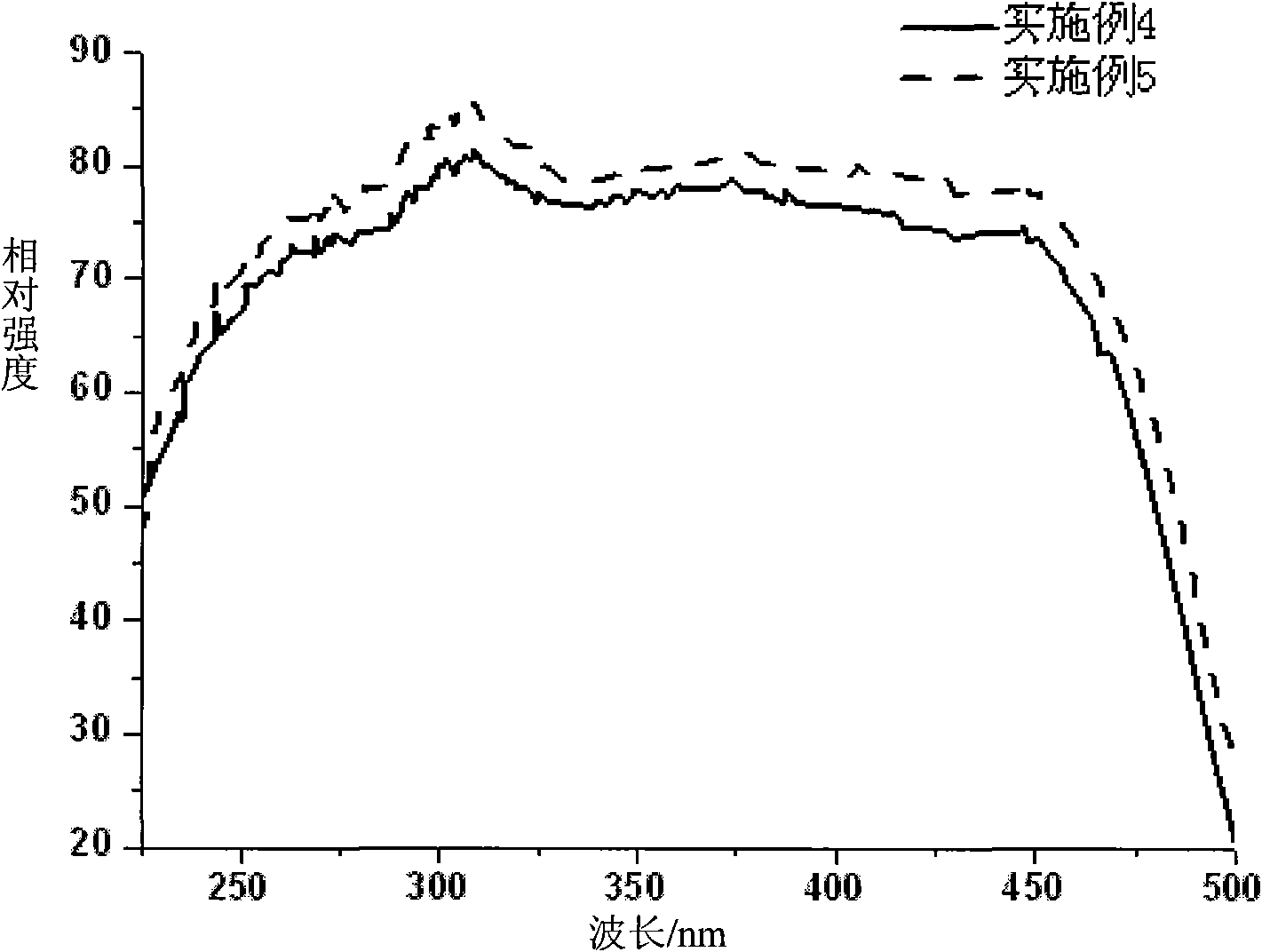

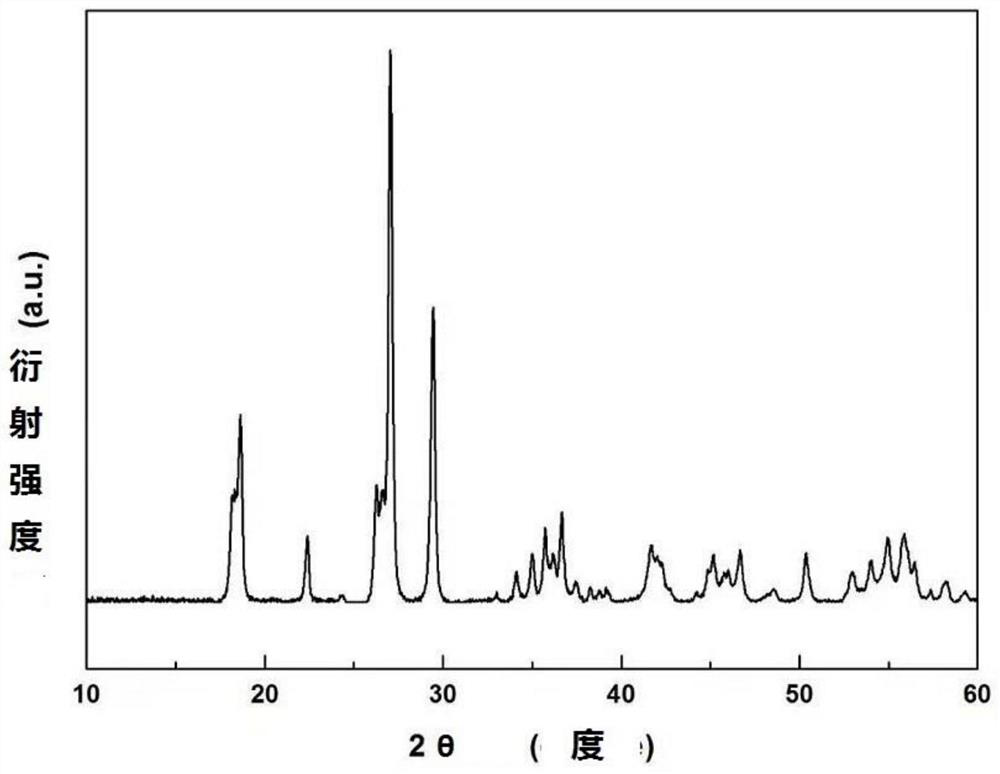

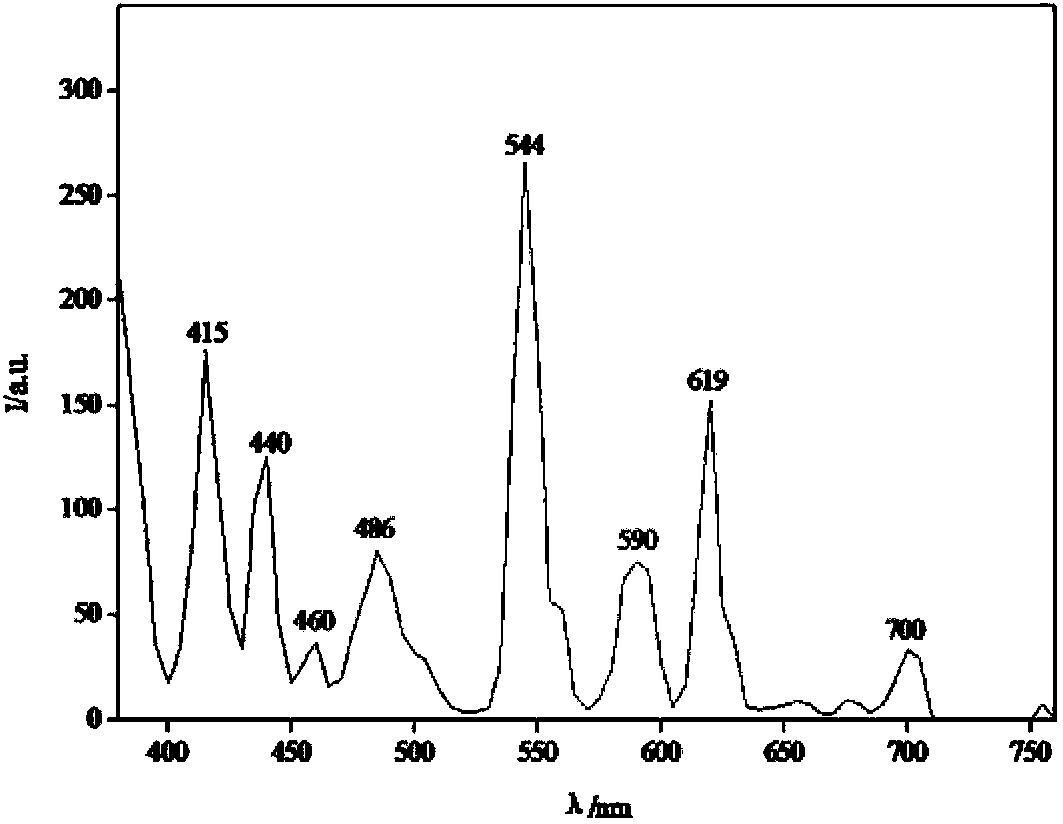

Synthetic rare earth doped nitric oxide fluorescent powder and preparation method thereof

InactiveCN101760190AEasy to operateProcess window widthLuminescent compositionsThermal decayDisplay device

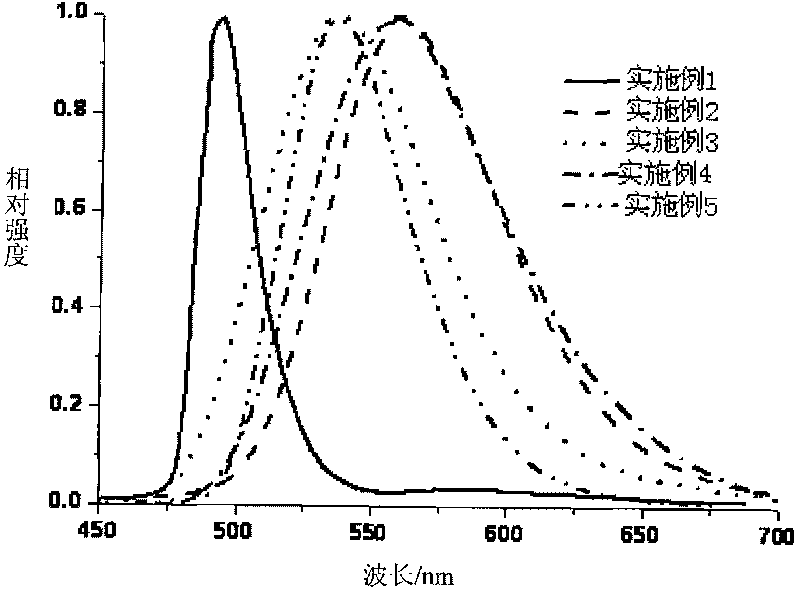

The invention relates to synthetic rare earth doped nitric oxide fluorescent powder and a preparation method thereof, which is characterized in that the general chemical formula of the rare earth doped nitric oxide fluorescent powder is A1-xByOzN2 / 3+4 / 3y-2 / 3z : xRe, wherein A is one or the combination of two or more of Ca ion, Sr ion and Ba ion and comes from the oxide, carbonate or nitrate whichcontains A element; B is one or the combination of Si ion and A1 ion, at least contains Si ion and comes from the nitride which contains B element; Re is one or the combination of two or more of Eu ion, Ce ion, Dy ion and Mn ion and comes from the oxide, nitrate or acetate which contains Re element; and the relations of X is more than or equal to 0 and less than 1.0, Y is more than or equal to 1.0 and less than or equal to 2.0 and Z is more than 0 and less than or equal to 2.0 are satisfied. The luminescent material is of stable physical and chemical properties, strong thermal decay resistance and high quantum efficiency, is suitable for excitation of wavelength at 300nm-600nm and is widely applicable in LED lighting and display devices. The fluorescent powder is synthesized through two-step synthesis by taking cheap compounds as the materials and the fluorescent powder synthesized through the method under normal pressure is of pure phase.

Owner:IRICO

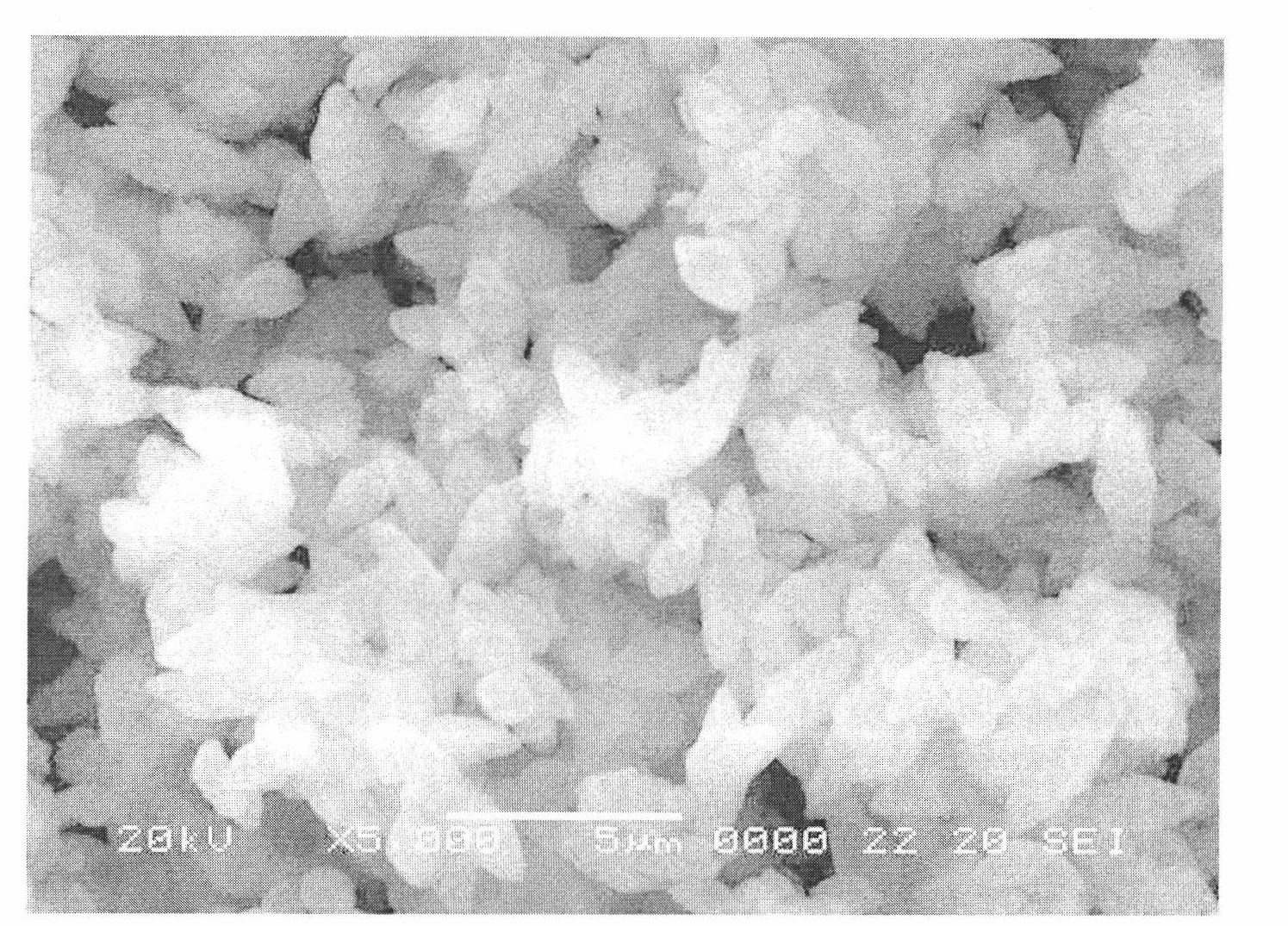

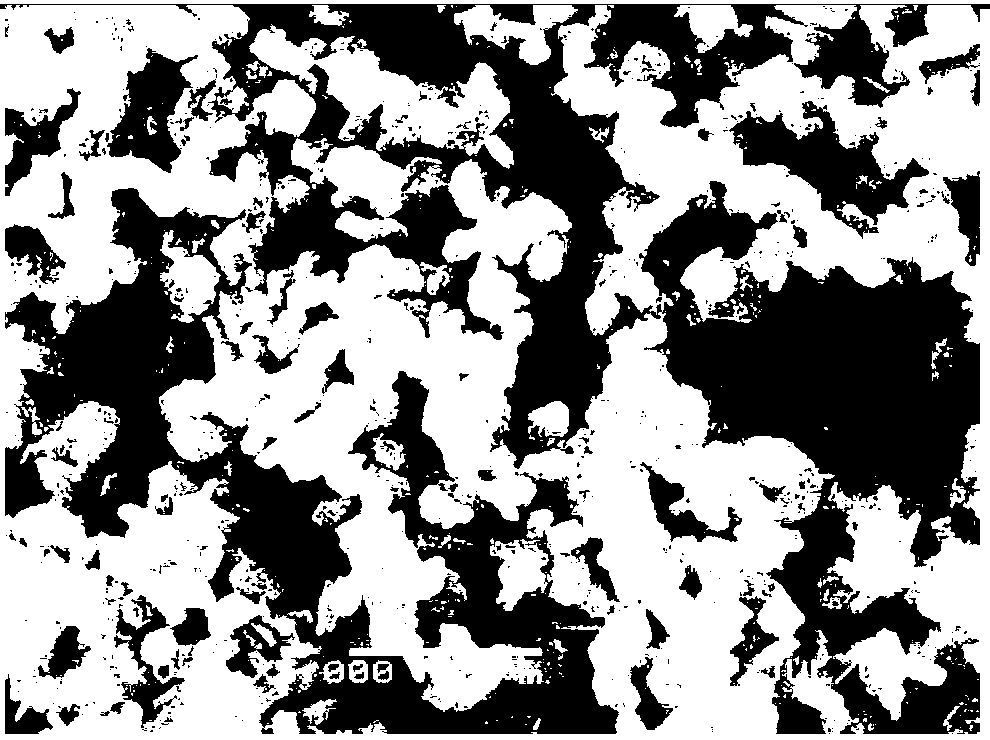

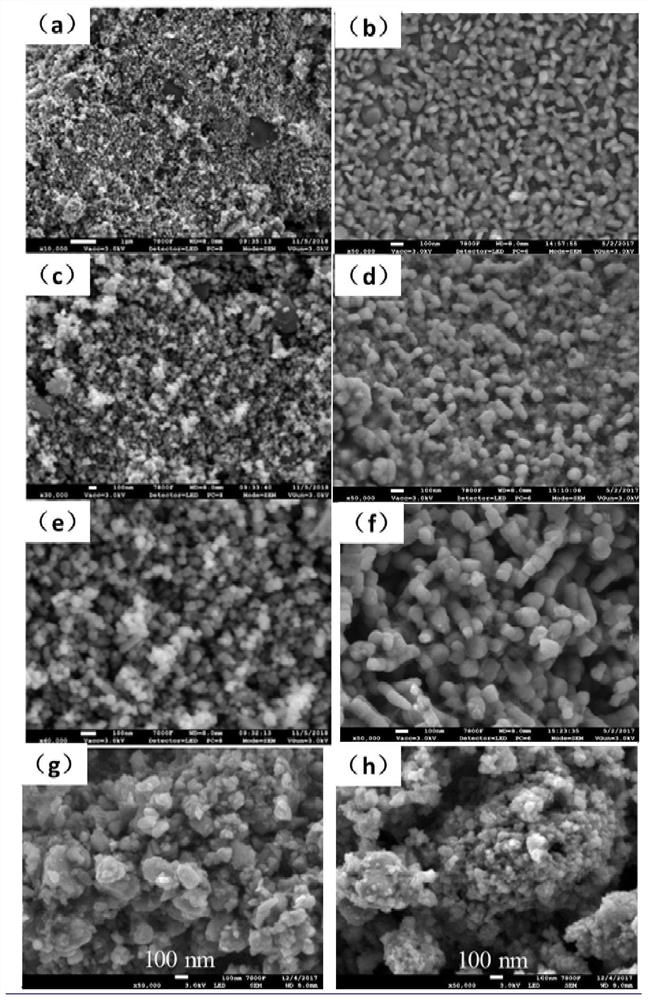

Method for preparing calcium carbonate with controllable topography by using calcium sulfate

InactiveCN101983924AHigh crystal phase purityUniform shape controlCalcium/strontium/barium carbonatesReaction temperatureTopography

The invention provides a method for preparing calcium carbonate with controllable topography by taking calcium sulphate as calcium resource, and the topography of calcium carbonate comprises fusiformis, sphere, rod shape and the like. The invention is characterized in that calcium sulphate which is slightly soluble to water is dispersed in N, N-dimethyl formamide or absolute ethyl alcohol to form suspension solution; carbonate solution is added to react for certain time to decentralize and separate products; after the product is dispersed to deionized water to be stirred for certain time, the product is decentralized, washed and dried to obtain single-phase calcium carbonate powder. The topography of the product can be controlled by changing preparation conditions, such as reaction temperature, reaction time, reactant density and dissolved solvent and the like. The method has the characteristics of cheap raw material, simple technology, simple operation, controllable topography and the like.

Owner:LUDONG UNIVERSITY

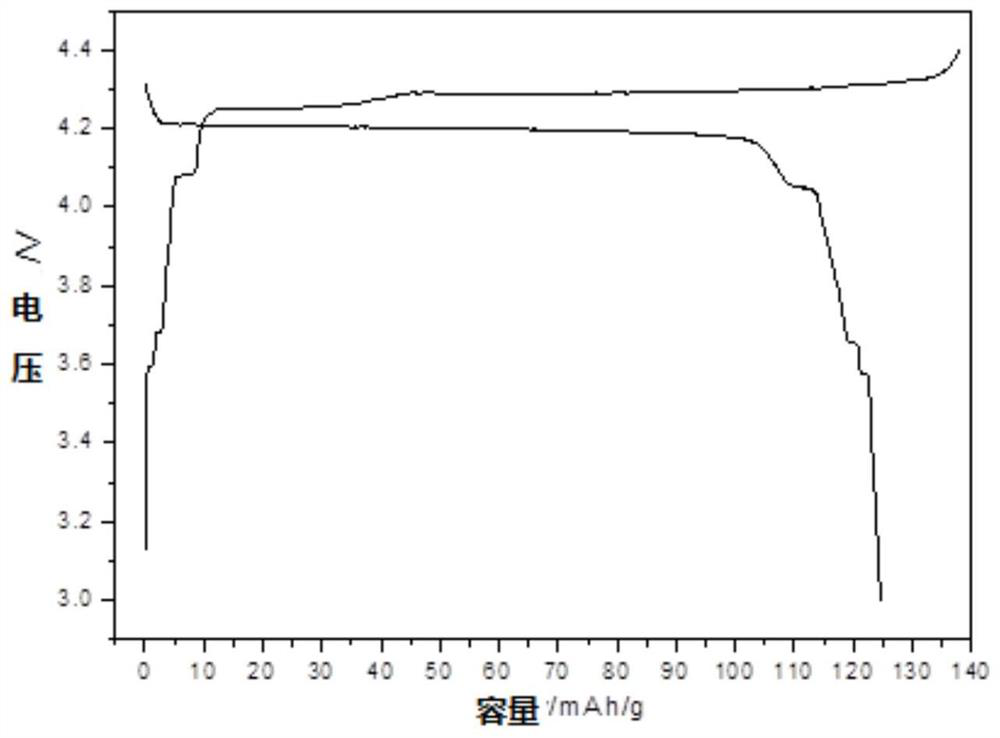

Lithium ion positive electrode material and preparation method thereof

InactiveCN1450676AHigh initial capacityEasy to operateElectrode manufacturing processesLithium compoundsSolventOxygen

This invention discloses a Li ion positive material and its preparation method solving the problem of reducing the circulation attenuation of the positive ionic material with the oxide general formula: xA2O.yM2Om.zN2On, the material is composed of 2-D hexagonal laminated crystal, compound oxide crystal of 3-D spinel structure or lithium vanadium oxide in the following processing steps: to electrolyse metal directly to form metal alkoxide in alcohol soluble absolute electrolyte containing organic additives then to mix with solution with assistant alkali salt or base to form positive sol precursor to dry to remove the solvent and form positive powder precursor under 120 to 550 deg.C. to process in solid phase reaction for 0.5-48h in 450-960 deg.c.

Owner:GUIZHOU ZHENHUA E CHEM INC

Artificial diopside material and its preparation method

The present invention is artificial pure diopside crystal material and its preparation process. The artificial diopside crystal material is prepared with silica sand, tail pyrite, kaolin, albite, limestone and other mineral materials, and through the technological steps of compounding material, smelting, forming, annealing, coring, crystallization, etc. Chemically, the materials consist of SiO2 47-61 wt%, Al2O3 4-9 wt%, CaO 12-20 wt%, MgO 4-7 wt%, TiO2 2-15 wt%, NaO2+KO2 3-7 wt%, ZrO2 1-4 wt%, ZnO 0-4 wt%, P2O5 1-4 wt%, F 1-3 wt% and C 1-3 wt%. The artificial pure diopside crystal material consists of micron level crystal grains, and has high compactness, high mechanical performance, high wear resistance, high corrosion resistance, excellent impact performance, no radioactivity and other features.

Owner:CHENGDU UNIVERSITY OF TECHNOLOGY

Preparation method for improving thermal stability of magnesium-aluminum hydrotalcite

ActiveCN111825111AGood dispersionHigh crystal phase purityHydrotalciteMagnesium saltAluminium hydroxide

The invention discloses a preparation method for improving the thermal stability of magnesium-aluminum hydrotalcite. The preparation method comprises the following steps: using magnesium hydroxide andalpha-phase aluminum hydroxide products as raw materials, carrying out acid dissolution-ball milling-alkali precipitation-crystallization process flow to prepare the magnesium-aluminum hydrotalcite product with high thermal stability. Aiming at the problem that a large amount of salt-containing wastewater is generated in the production process due to the fact that soluble magnesium salt / aluminumsalt is used as a raw material in a traditional process, a magnesium source / aluminum source is innovatively improved, a production technology combining a physical method and a chemical method is designed, and the prepared magnesium-aluminum hydrotalcite product has the advantages of being high in thermal stability, good in dispersity and the like.

Owner:QINGDAO UNIV OF SCI & TECH

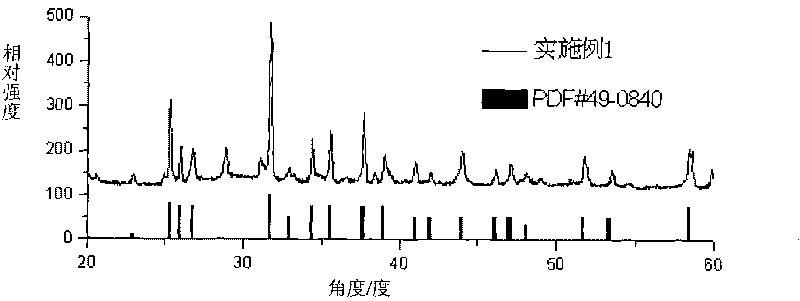

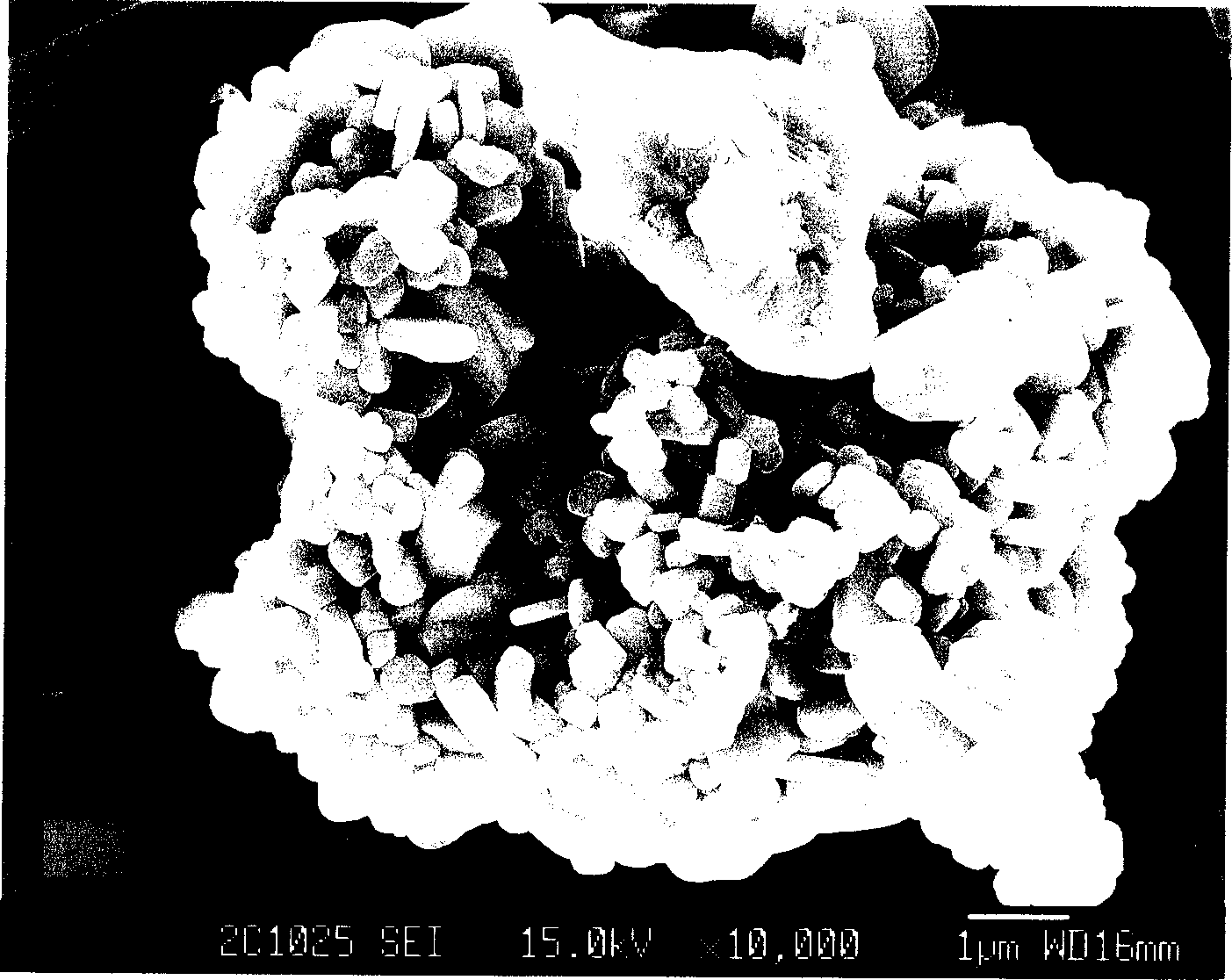

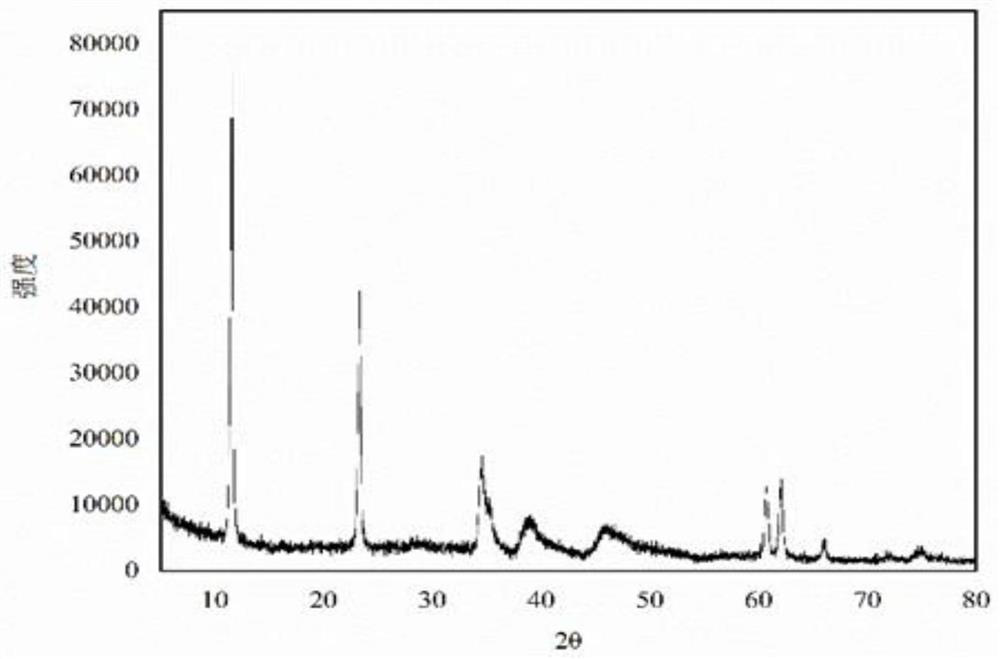

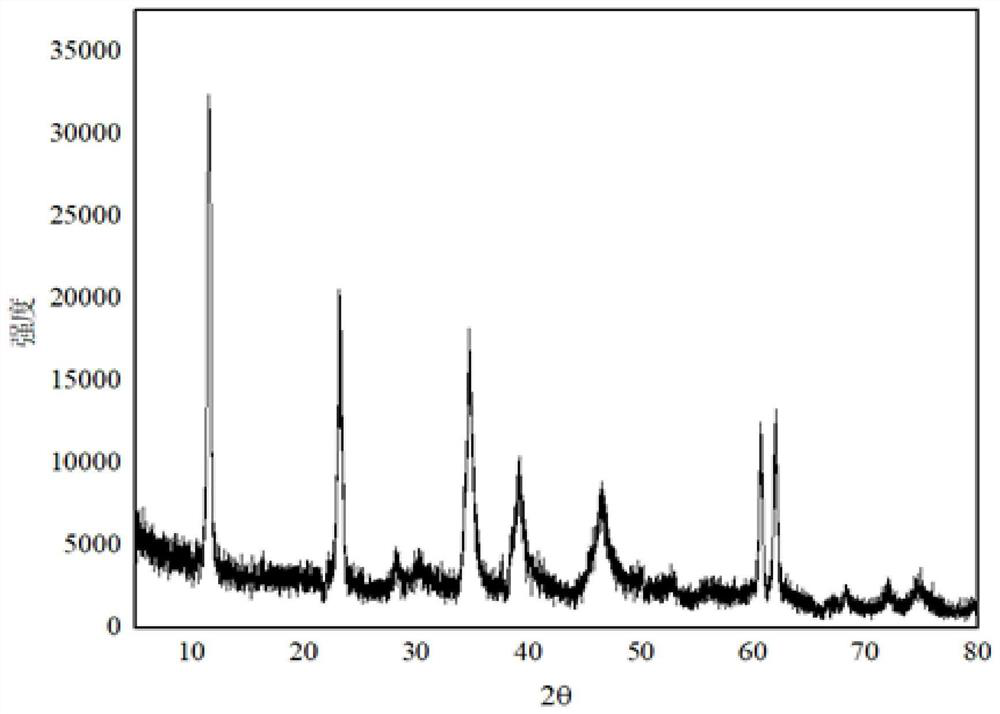

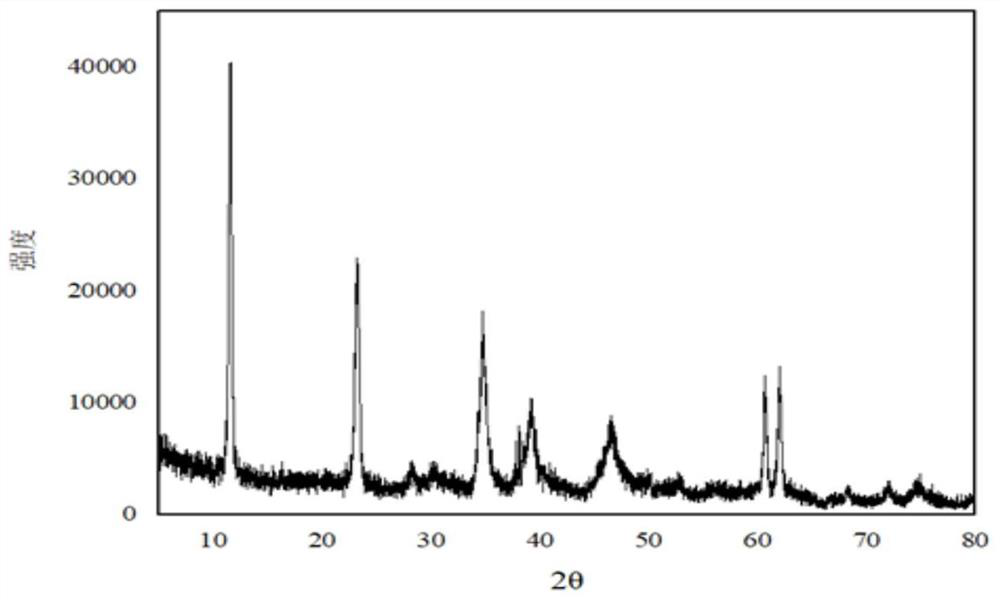

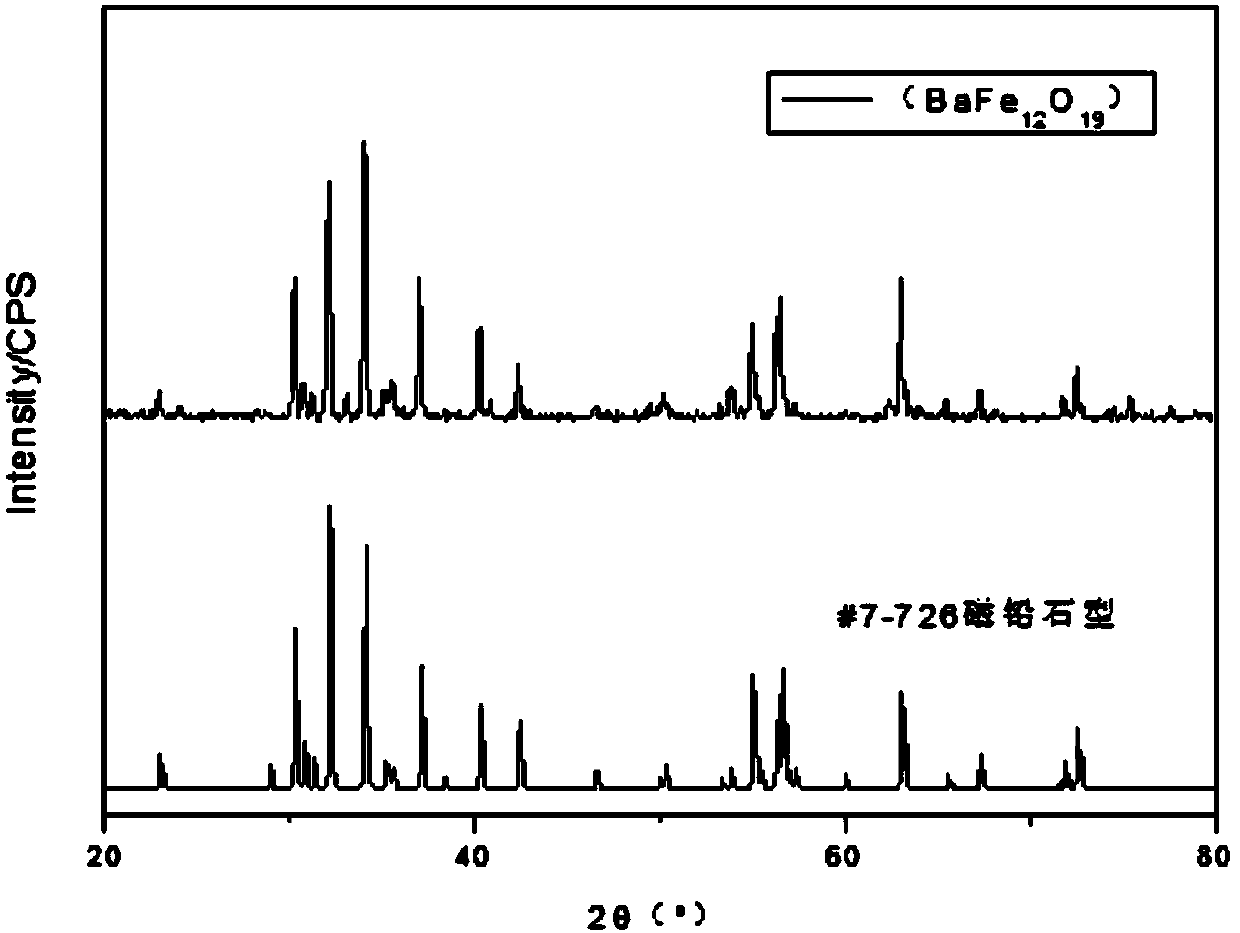

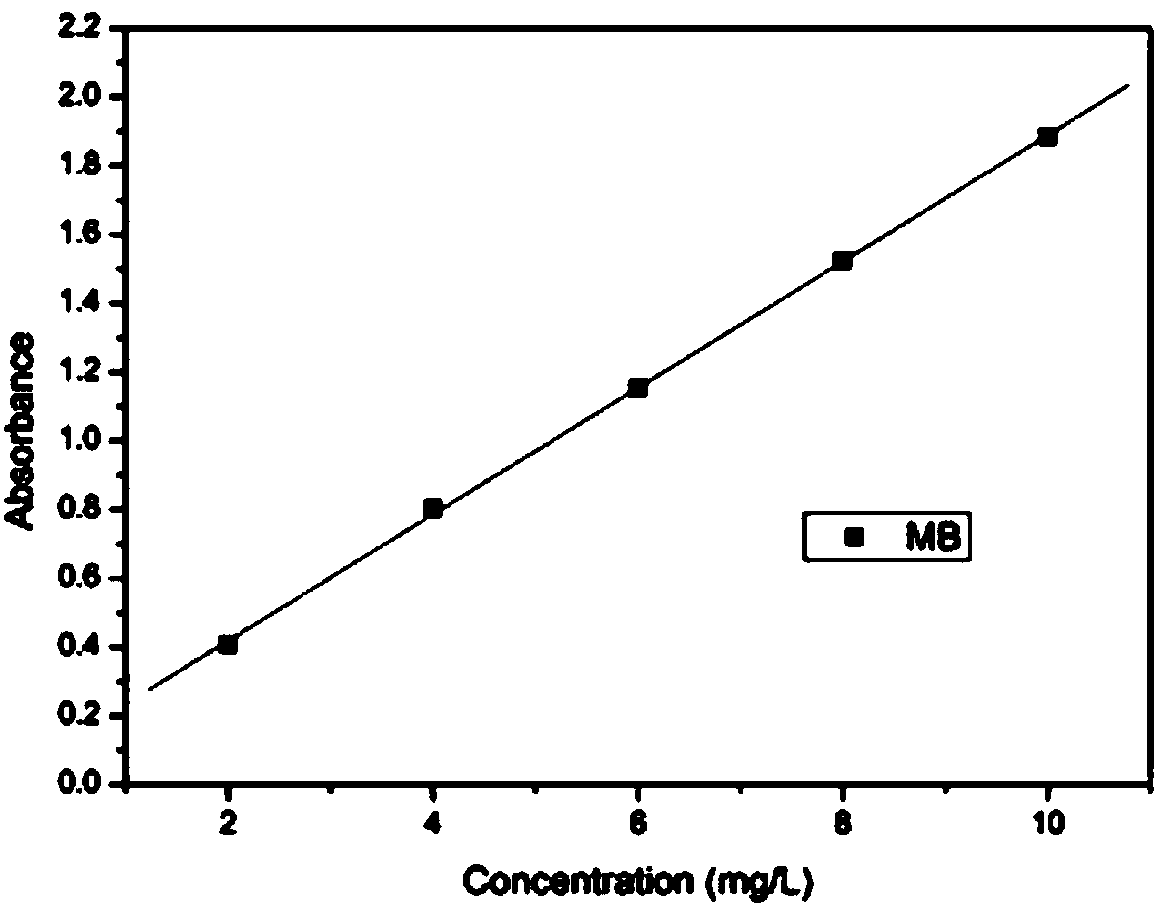

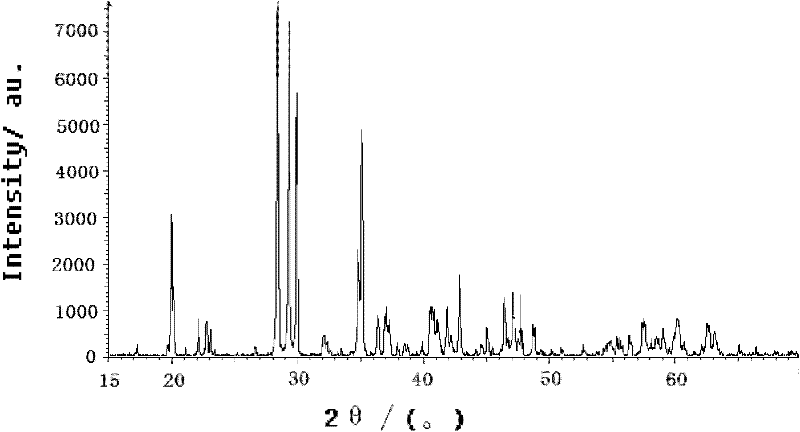

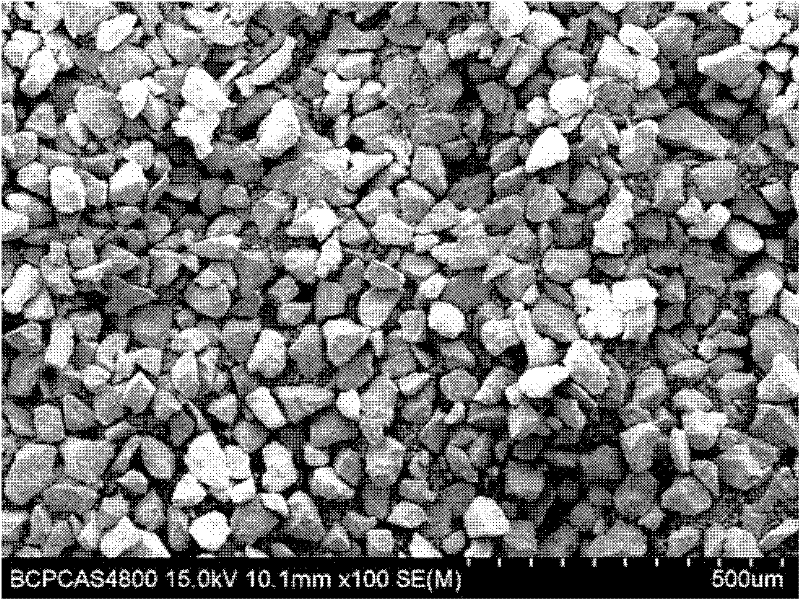

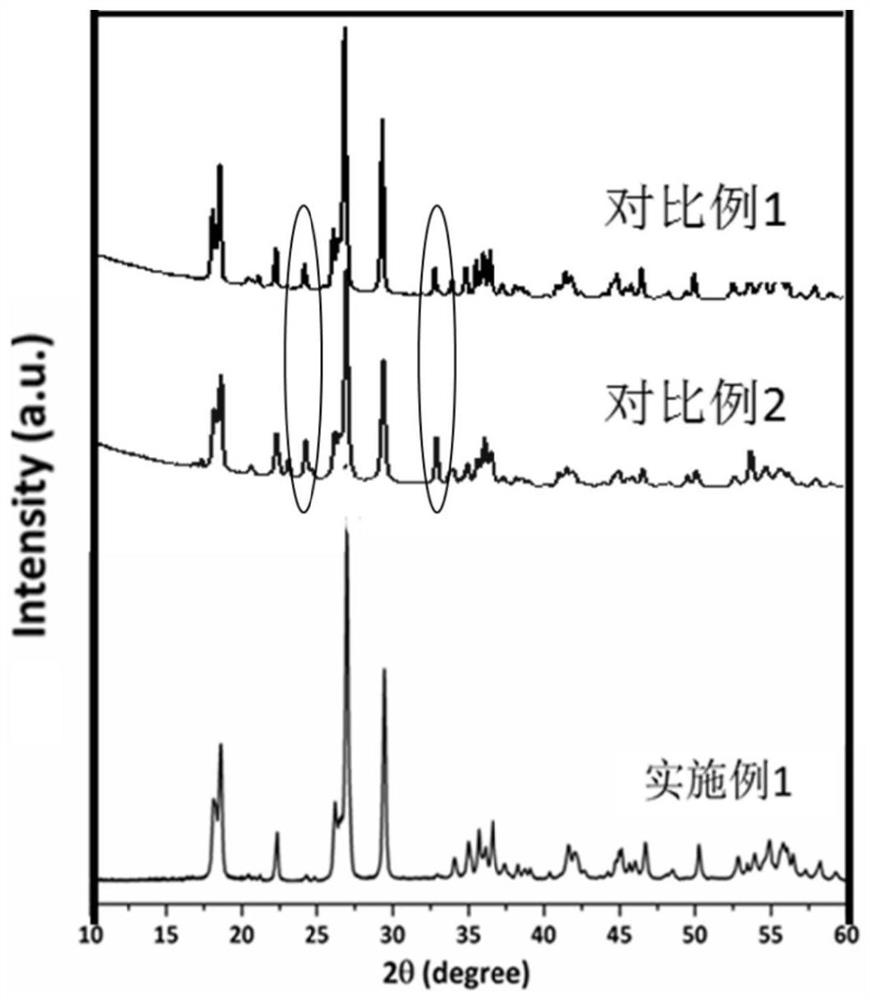

Preparation method and application of porous magnetoplumbite barium ferrite

InactiveCN107684893AHigh crystal phase purityGood crystal phase purityOther chemical processesWater contaminantsCombustionBarium nitrate

The invention relates to a preparation method and application of porous magnetoplumbite barium ferrite. The method takes citric acid as a complexing agent, ammonium hydroxide as a precipitator, and iron nitrate nonahydrate and barium nitrate as the raw materials, and a sol-gel method and a self-propagating combustion method are combined to prepare the porous magnetoplumbite barium ferrite. The method has the advantages that the raw materials are cheap and easy to get, the process is simple, the operation is convenient, the method is energy-saving and efficient, the homogeneity of the product is good, and the morphology is controllable; a prepared magnetoplumbite barium ferrite powder has a porous structure, is high in specific surface area and relatively good in adsorptive property, can beapplied to the absorption of pollutants in the environment field, and is easy to separate and recycle.

Owner:WUHAN INSTITUTE OF TECHNOLOGY

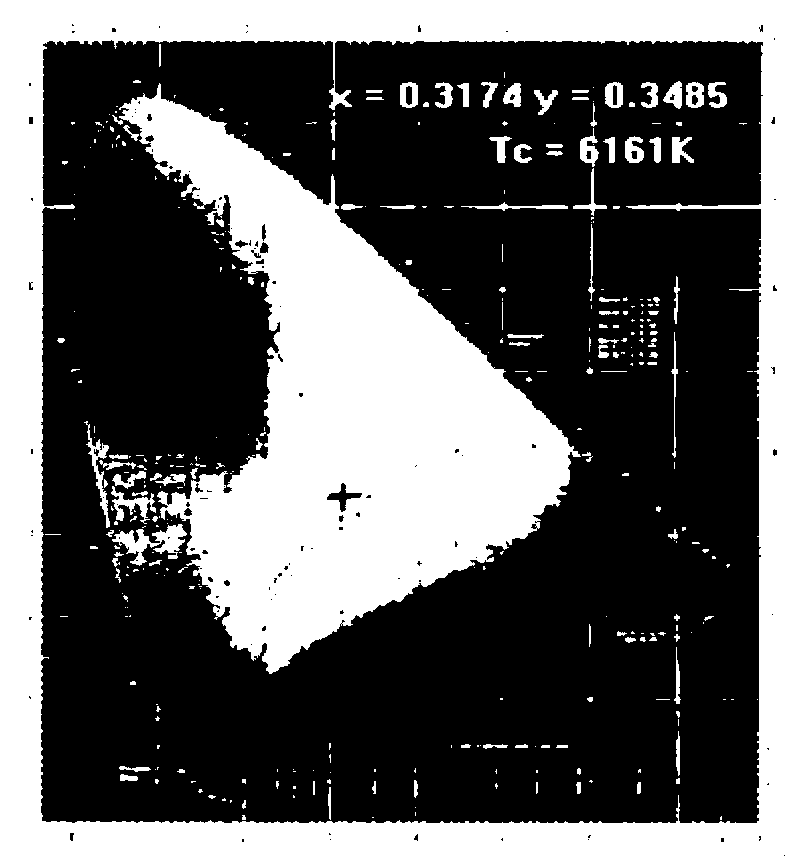

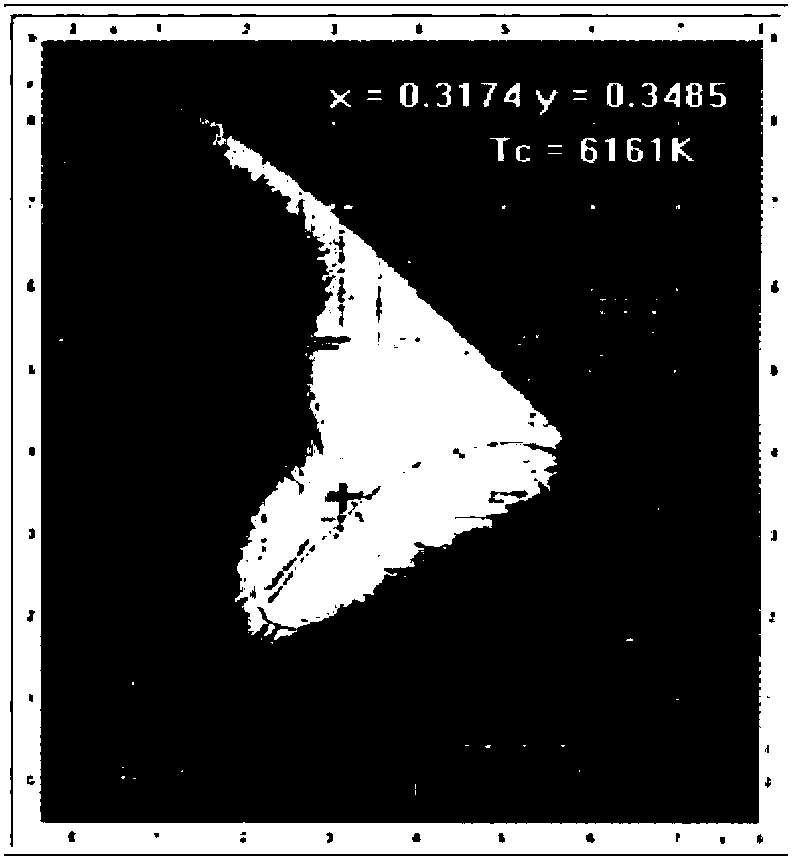

Preparation method of single-substrate fluorescent powder for white-light LEDs (light-emitting diodes)

InactiveCN103013505AHigh crystal phase purityUniform particle sizeGas discharge lamp usageLuminescent compositionsAnhydrous ethanolReducing atmosphere

The invention provides a preparation method of single-substrate fluorescent powder for white-light LEDs (light-emitting diodes), which comprises the following steps: after completely dissolving Tb4O7 in a concentrated nitric acid solution, regulating the pH value to 4-7 with ammonia water, sequentially adding anhydrous CaCl2, Ca(NO3)2.4H2O and anhydrous ethanol, uniformly stirring, adding a slow release agent citric acid solution, continuously stirring until the slow release agent is uniformly dispersed in the solution, adding ethyl silicate, and stirring to form a uniform and transparent solution; and regulating the pH value of the uniform and transparent solution to 6-8 with ammonia water to form a gel, drying the gel, grinding to form powder, putting the dry gel powder in a resistance furnace, and sintering in a weak reducing atmosphere. The preparation method provided by the invention implements activation of the Ca2SiO3Cl2 substrate to emit white light by using the single Tb<3+>.

Owner:SHAANXI UNIV OF SCI & TECH

Synthetic rare earth doped nitric oxide fluorescent powder and preparation method thereof

InactiveCN101760190BEasy to operateProcess window widthLuminescent compositionsThermal decayDisplay device

Owner:IRICO

Haze-reduction paint for building wall surfaces and preparation method

ActiveCN109897575ALarger than surfaceLarge hole volumeCovering/liningsNon-macromolecular adhesive additivesAcrylic resinSorbent

The invention provides haze-reduction paint for building wall surfaces and a preparation method. The method includes the steps: firstly, preparing pseudo-boehmite sol coated tourmaline loaded zinc oxide nano-crystalline composite spherical fine particles to serve as photocatalysts; secondly, preparing slurry from the particles, nano-silicon dioxide, nano-wollastonite, super-fine talcum powder, defoaming agents, dispersing agents, coalescing agents, preservatives and water; finally, matching the slurry, organosilicone acrylic resin and thickening agents to form the haze-reduction paint for thebuilding wall surfaces. By the aid of a pseudo-boehmite sol coated tourmaline loaded zinc oxide nano-crystalline composite material with the advantages of large specific surface, high pore volume andthe like, outward flow of catalytic active matters is avoided, the haze-reduction paint is provided with a adsorbent with excellent performance, the paint and the zinc oxide nano-crystalline are compound, high adsorption capacity of the adsorbent and visible light drive photocatalysis to degrade cationic organic pollutants, air quality is improved, the paint has remarkable effects on control of large-area haze, and further, and the paint is simple in preparation process, low in raw material cost and suitable for large-scale popularization.

Owner:中烯新材料(福建)股份有限公司

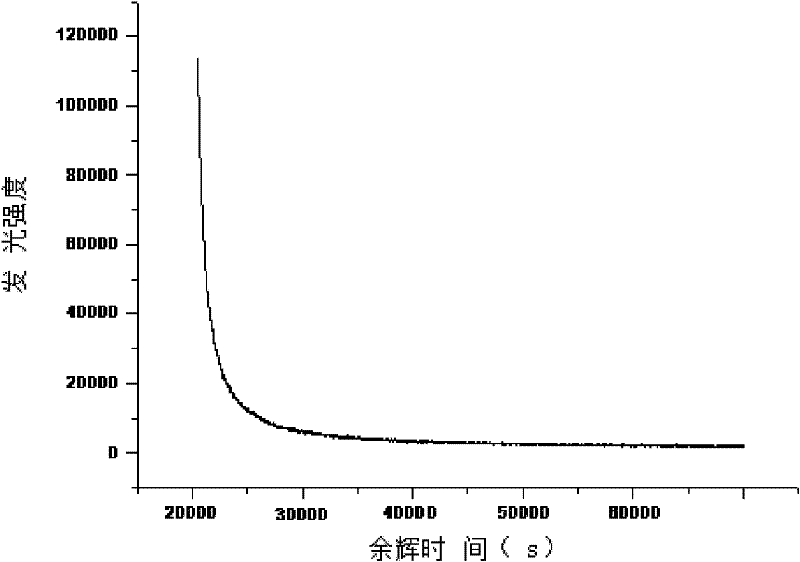

Rapidly synthesized aluminate long-afterglow luminescent material and preparation method thereof

InactiveCN102337133AConsistent particle sizePrecipitation is fine and uniformLuminescent compositionsAluminateHydrogen

The invention provides a rapidly synthesized aluminate long-afterglow luminescent material and a preparation method thereof. The preparation method comprises the following steps: dissolving weighed soluble raw materials Sr, Al, Eu and Dy according to a general formula Sr(1-x-y) Al2O4:Eux, Dyy into deionized water for preparing a mixed solution; then, adding a urea solution in the mixed solution, heating and mixing so as to form a precipitate, separating the precipitate from the liquid, and then drying the washed precipitate through microwave drying for 30 minutes at the power of 600W so as to obtain a composite precursor powder with fine and uniform particle diameter; subsequently, carrying out microwave sintering on the powder for 15-25 minutes under the mixed protective atmosphere formed by hydrogen and nitrogen at the power of 2000-3000W; and finally, grinding and screening.

Owner:IRICO

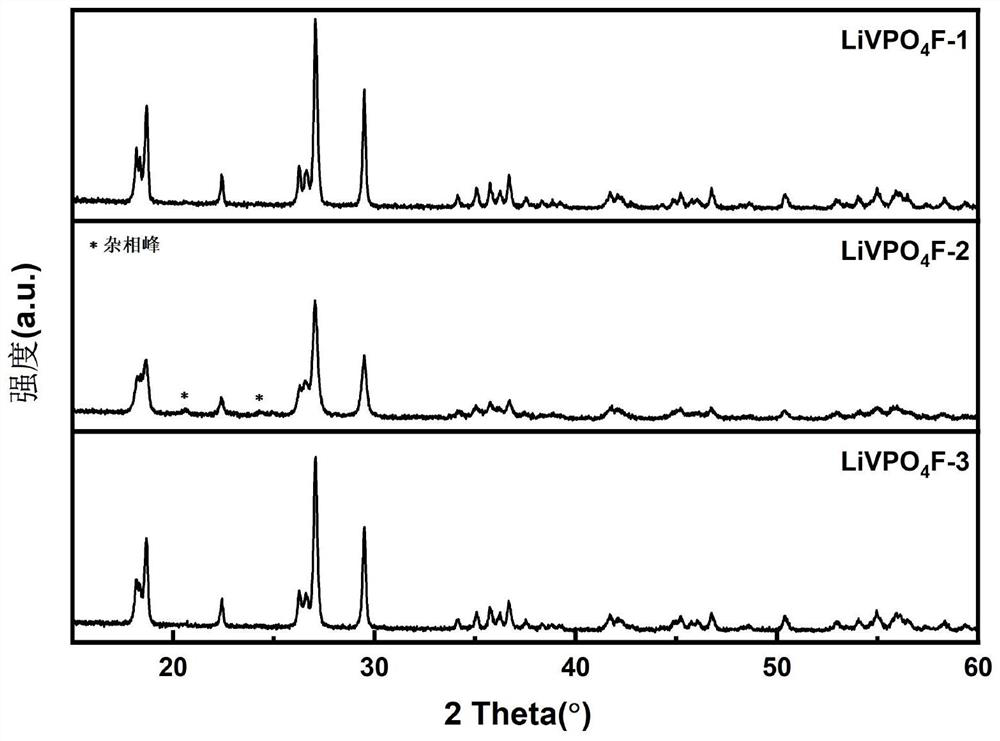

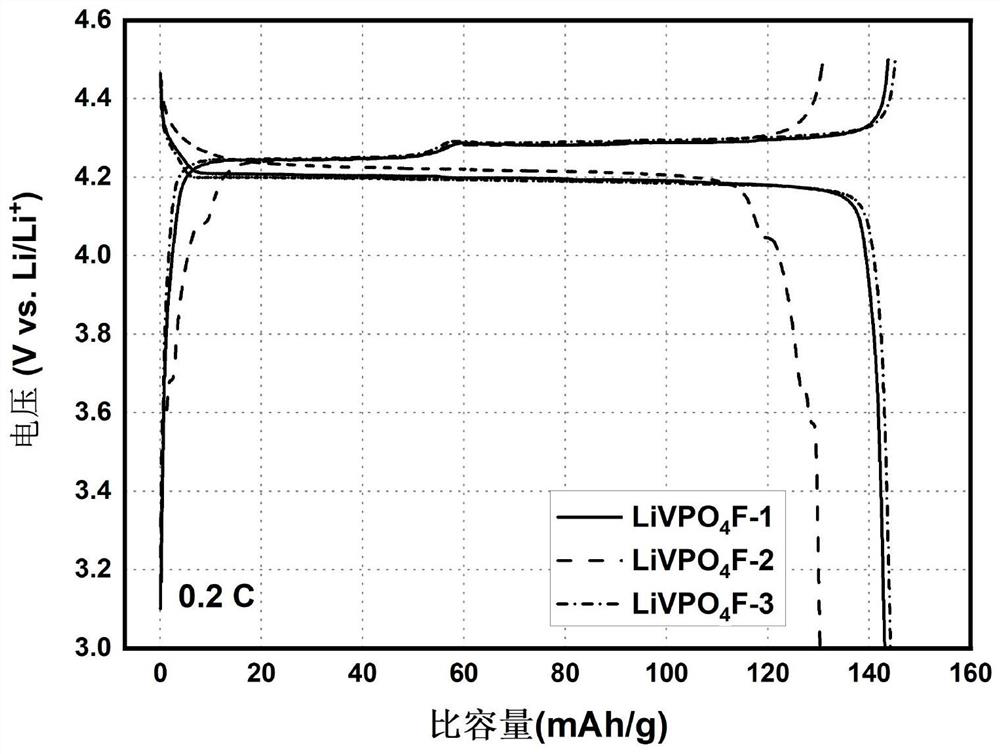

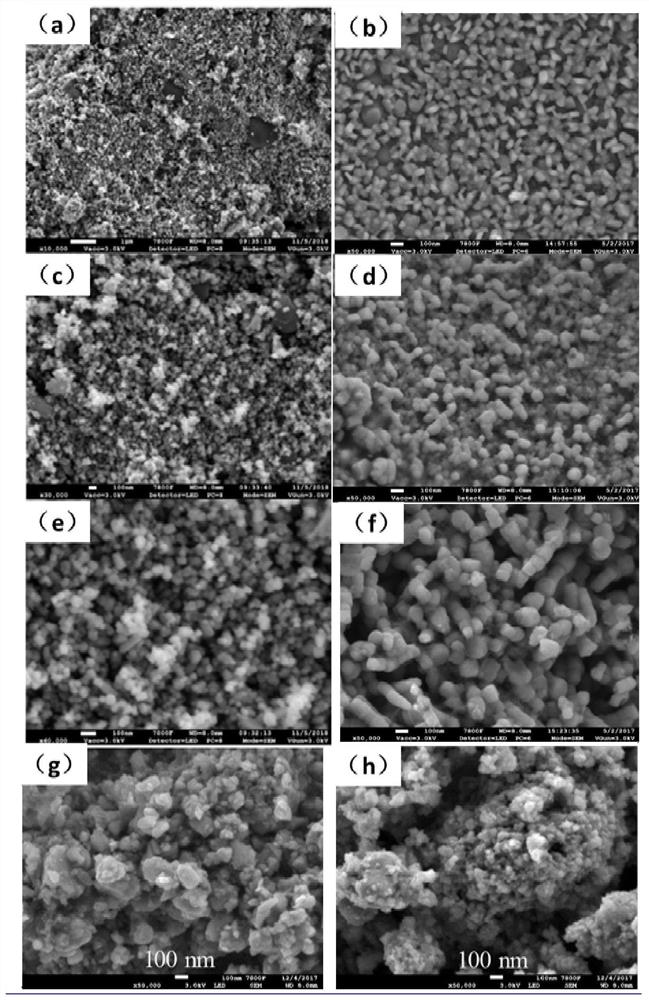

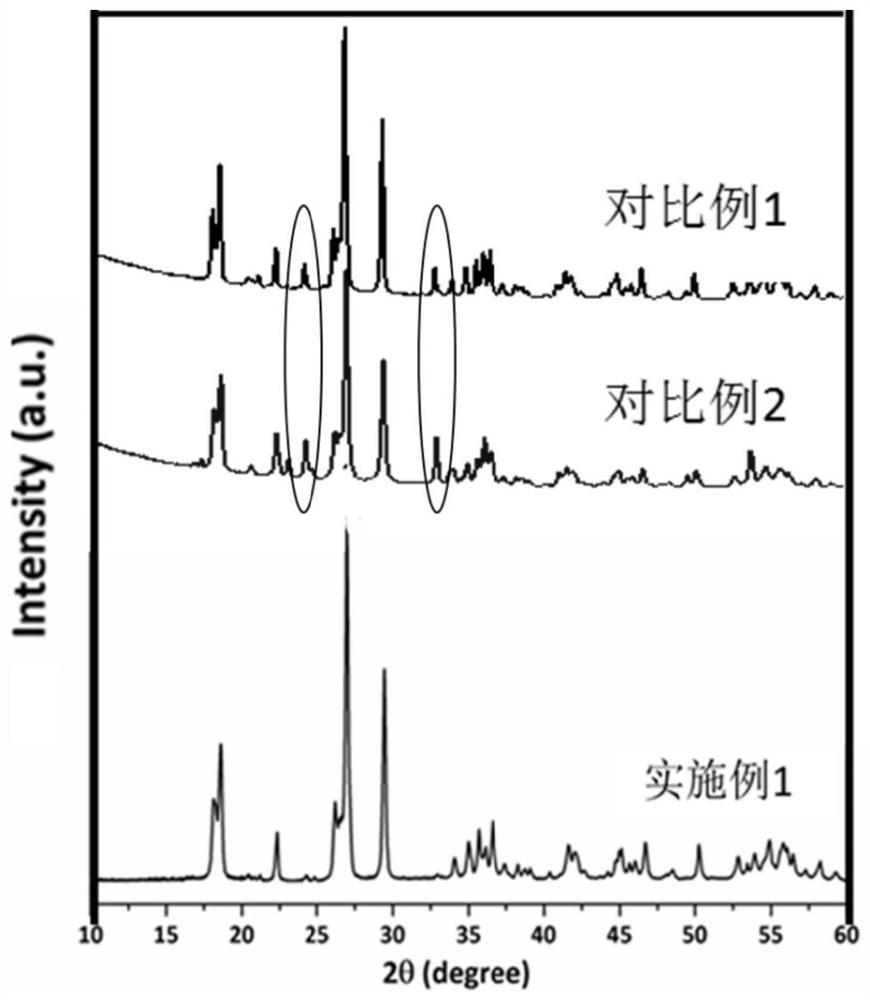

Carbon-coated LiVPO4F positive electrode material as well as preparation and application thereof

ActiveCN112573501AHigh crystal phase purityImprove electronic conductivityCell electrodesSecondary cellsOXALIC ACID DIHYDRATEPhysical chemistry

The invention discloses a preparation method of a carbon-coated LiVPO4F positive electrode material. The preparation method comprises the following steps: adding oxalic acid, citric acid or ascorbic acid into deionized water to form a transparent solution, sequentially adding a vanadium source, a lithium source, a phosphorus source and a fluorine source according to the molar ratio of 1:1:1:1 at the temperature of 20-90 DEG C, conducting uniform mixing in the solution, conducting reacting for 1-12h to form a colloidal solution, and conducting drying at the temperature of 70-140 DEG C for 6-48hto obtain a solid product; carrying out heat treatment on the dried solid product in an inert atmosphere at the temperature of 300-500 DEG C for 1-12h to obtain an intermediate product; and mixing the intermediate product with a fluorine-containing polymer (PTFE, PVDF or PCTFE) accounting for 5%-100% of the mass of the intermediate product, carrying out ball milling for 1-24 hours, and conductingsintering in an inert atmosphere at the temperature of 500-800 DEG C for 1-12 hours to obtain the pure-phase LiVPO4F / C positive electrode material. The carbon-coated LiVPO4F material prepared by theinvention has high crystalline phase purity, and the introduction of the fluorine-containing polymer not only can be used as an additional fluorine source to effectively improve the crystalline phasepurity of the material, but also can be used as a carbon source to coat the surface of LiVPO4F to improve the electron conductivity of the material, thereby obtaining excellent electrochemical properties.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

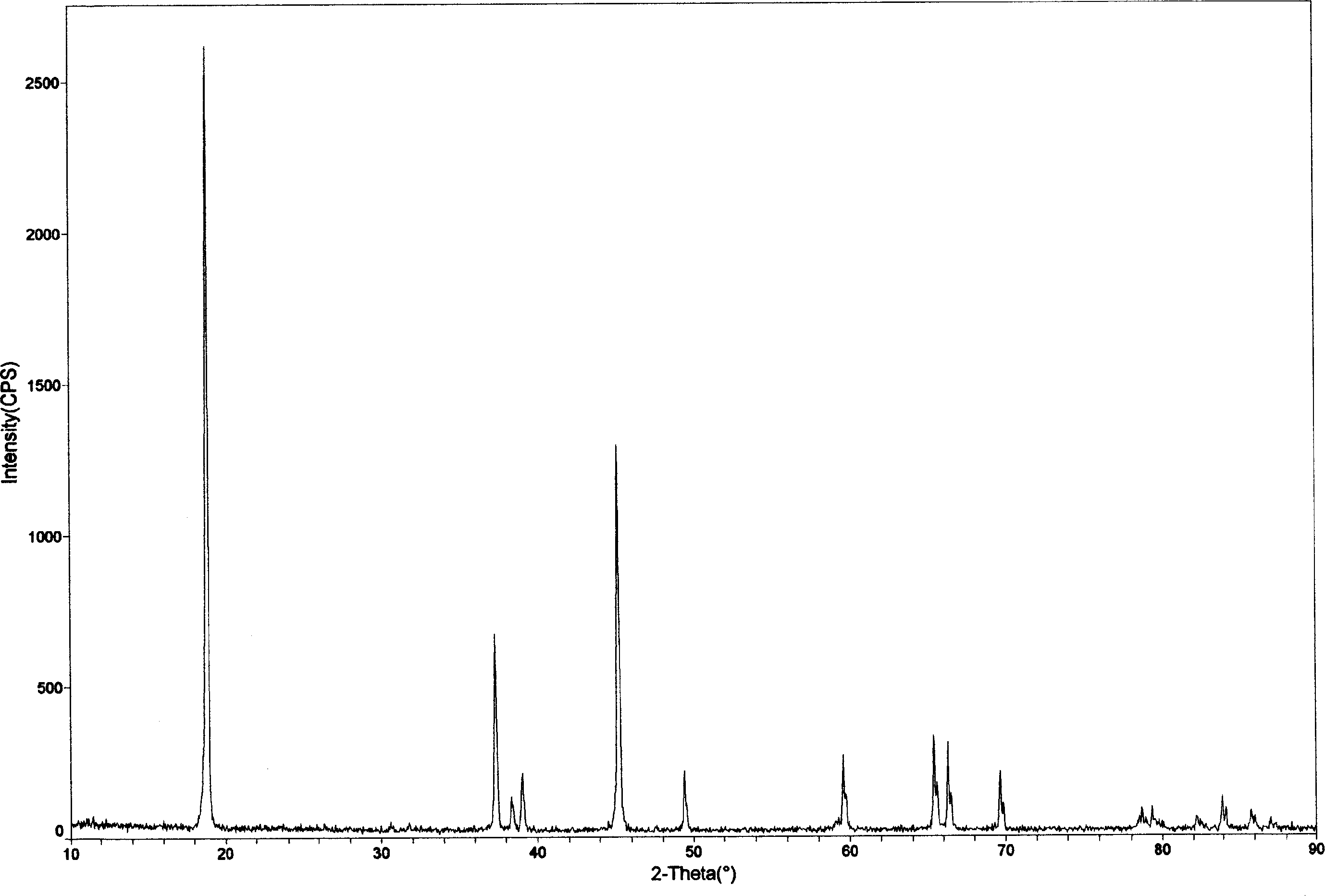

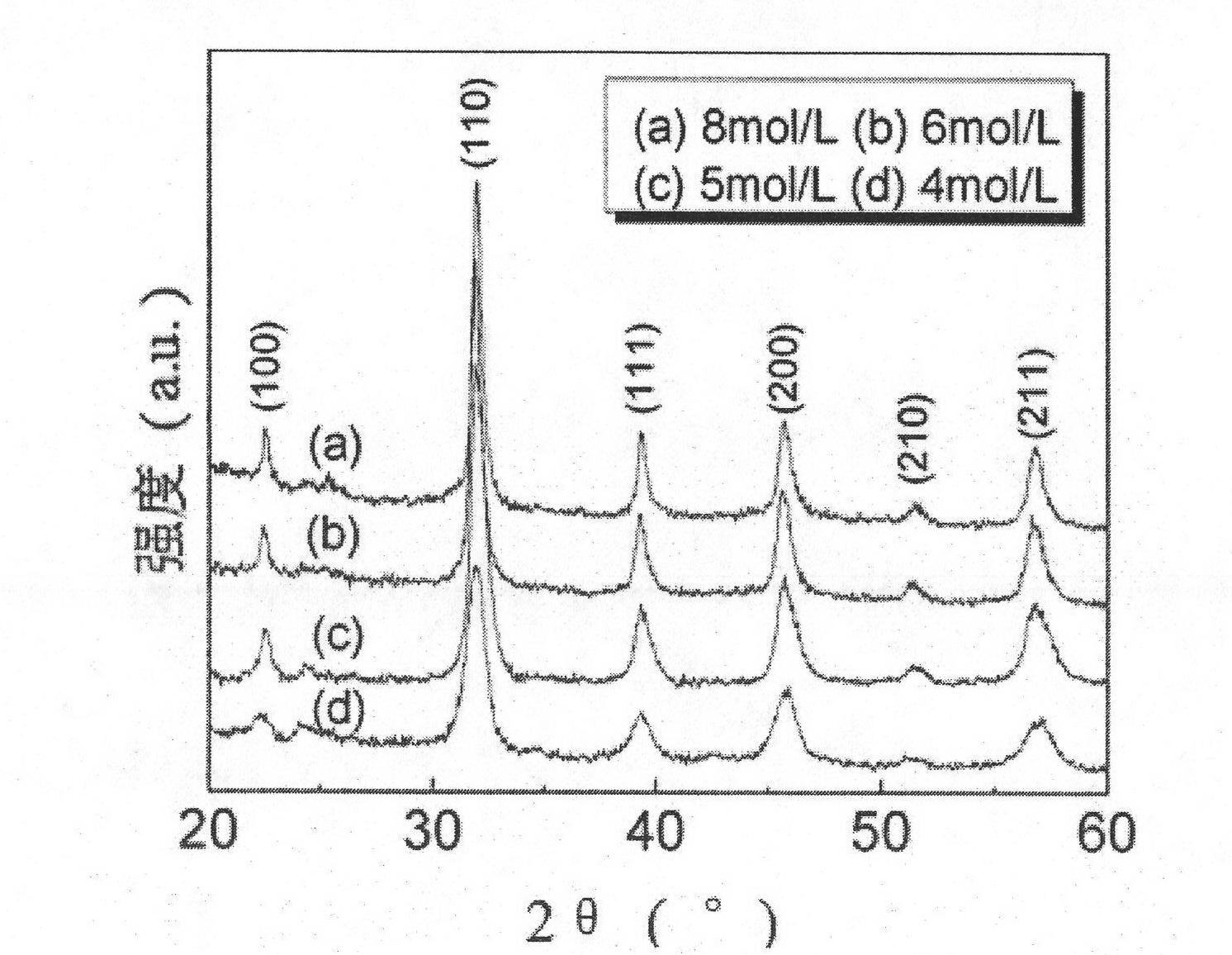

Method for preparing nanometer barium-strontium titanate powder

InactiveCN101786654ASmall granularityUniform particle sizeNanostructure manufactureTitanium compoundsStrontium titanateBarium strontium titanate

The invention discloses a method for preparing nanometer barium-strontium titanate powder, and aims to solve the technical problem that the barium-strontium titanate powder prepared by the conventional preparation method is big in grain size, uneven in grain size distribution and impure in crystal phase. The technical scheme comprises the following steps of: adding barium acetate, strontium acetate, tetrebutyl titanate, sodium oleate, oleic acid, normal butyl alcohol and sodium hydroxide in a hydrothermal kettle, heating the materials to react the materials, using ethanol to wash the mixture to obtain a precipitate, dissolving the precipitate in cyclohexane, adding ethanol into the mixed solution for reaction at room temperature to obtain a nanocrystalline BST precipitate, performing centrifugal separation of the nanocrystalline BST precipitate, using the ethanol to wash the residual oleic acid, and air-drying the precipitate at room temperature. In the invention, the barium-strontium titanate powder is prepared by a liquid-solid solution method, the grain size of the barium-strontium titanate powder by the method is reduced from 50 nanometers in the prior art to 10 to 25 nanometers, the grain size distribution is uniform, and the crystal phase purity is also improved.

Owner:江苏晨朗电子集团有限公司 +1

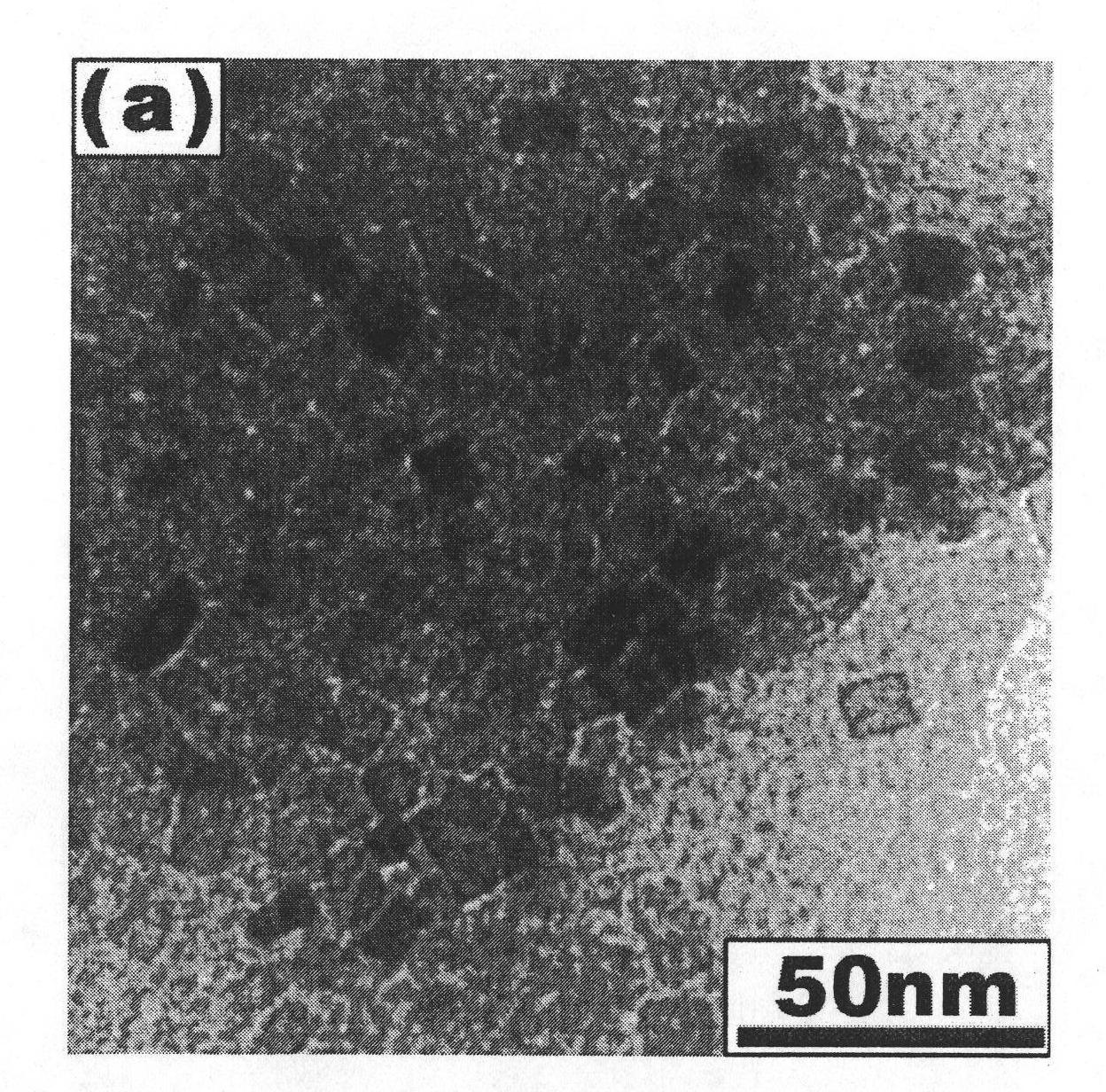

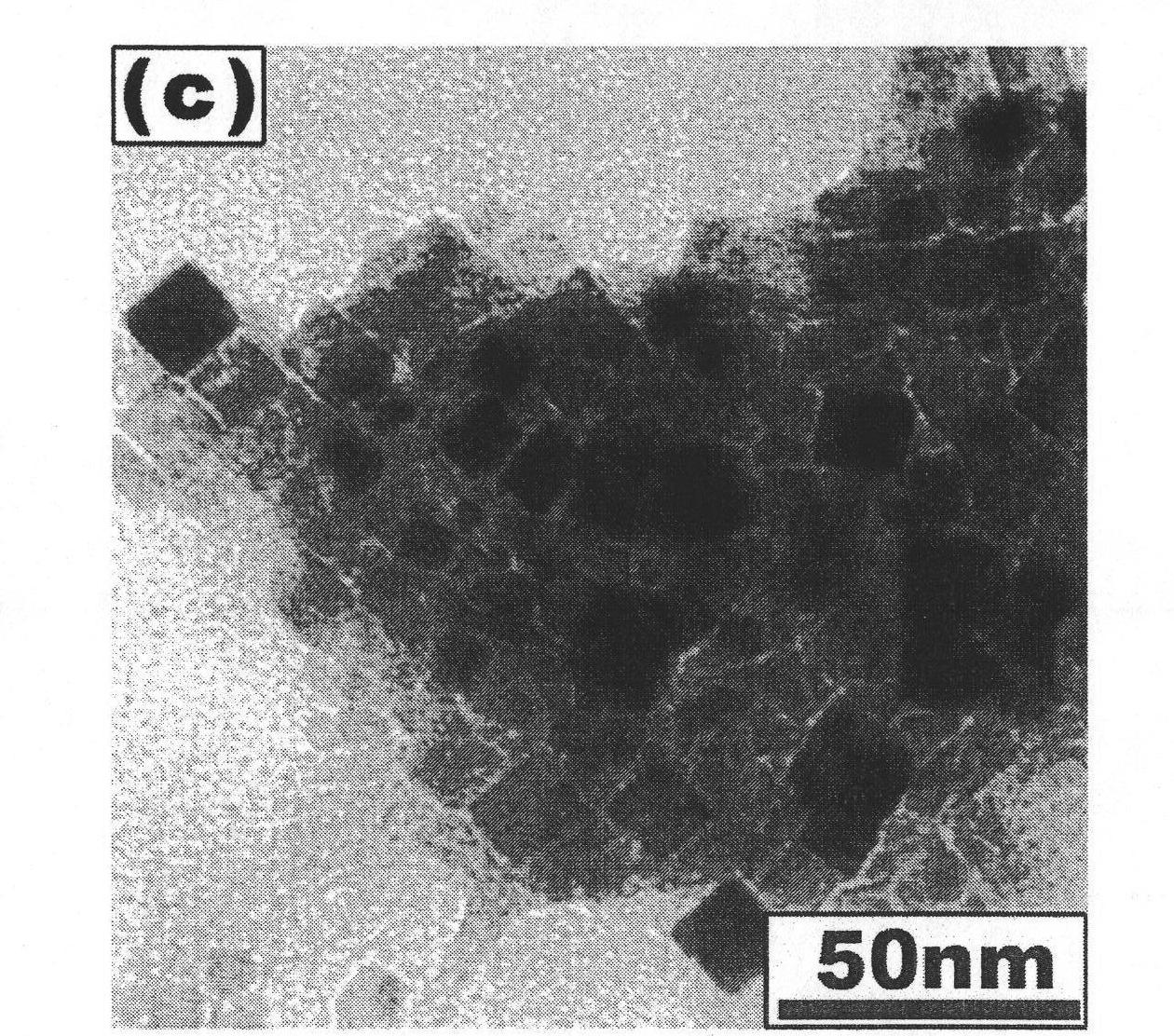

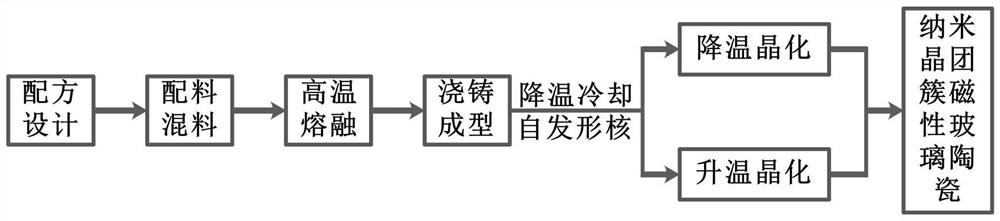

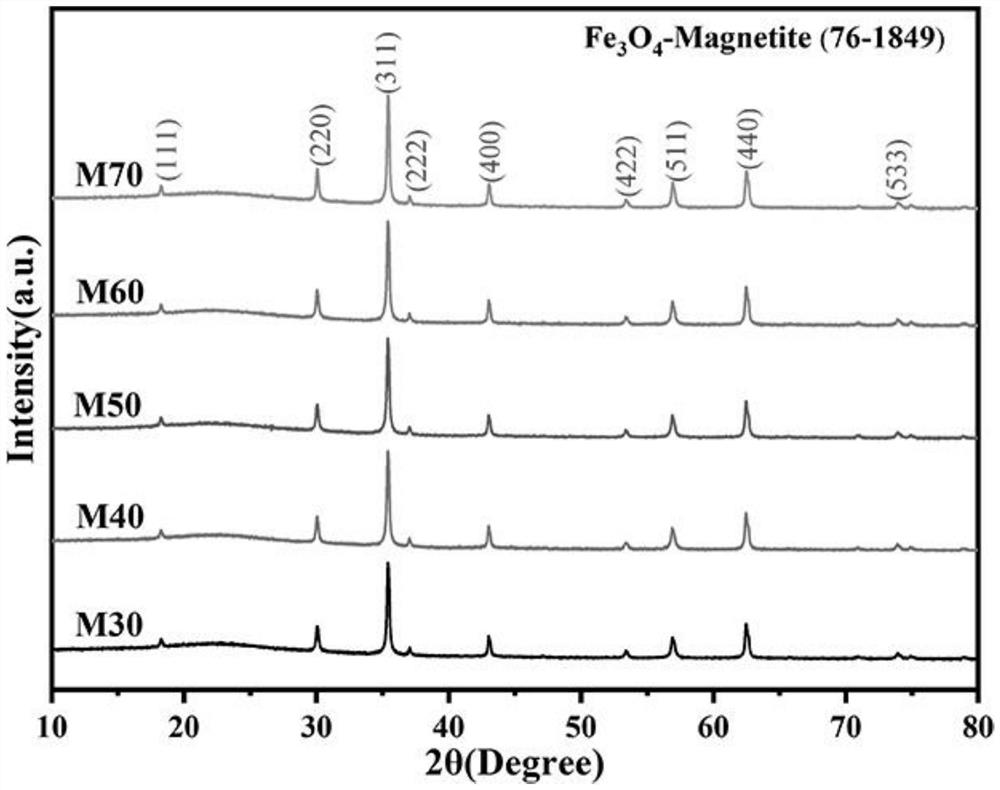

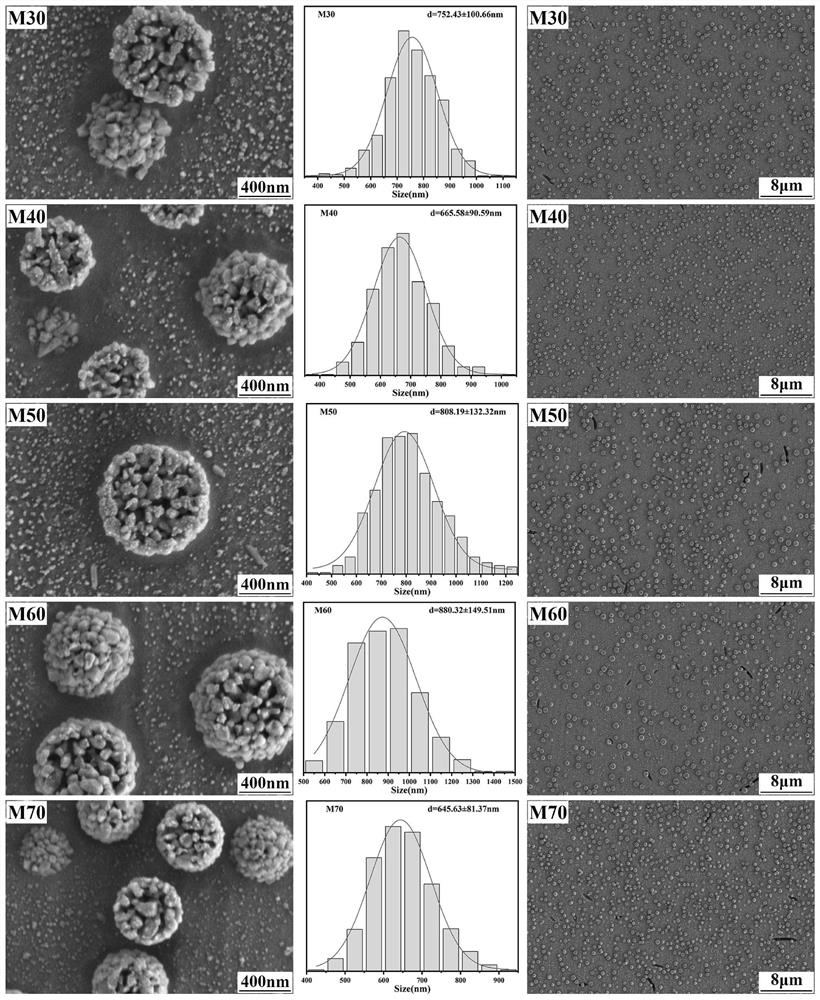

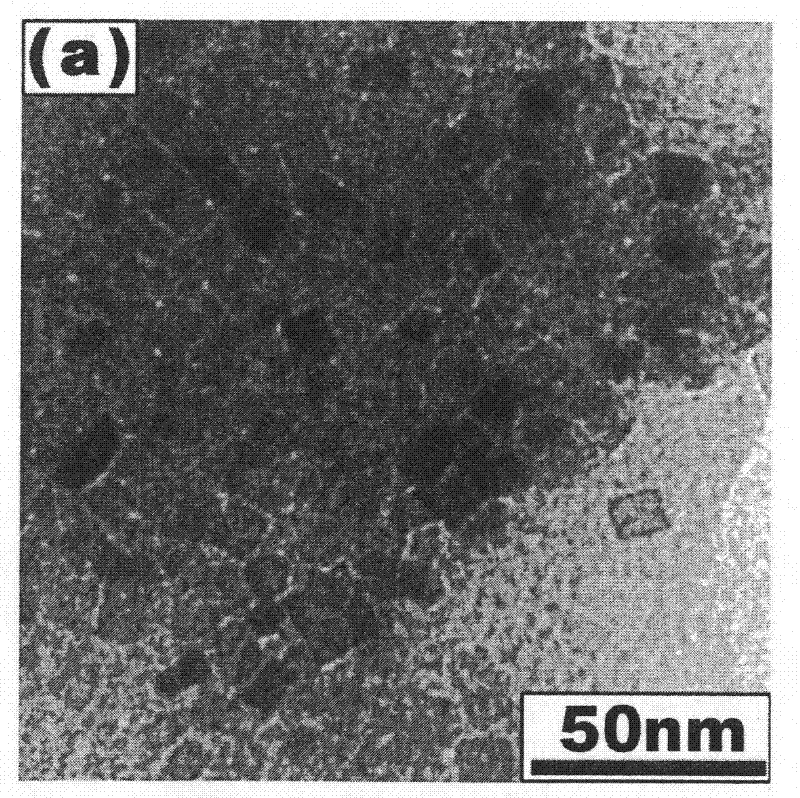

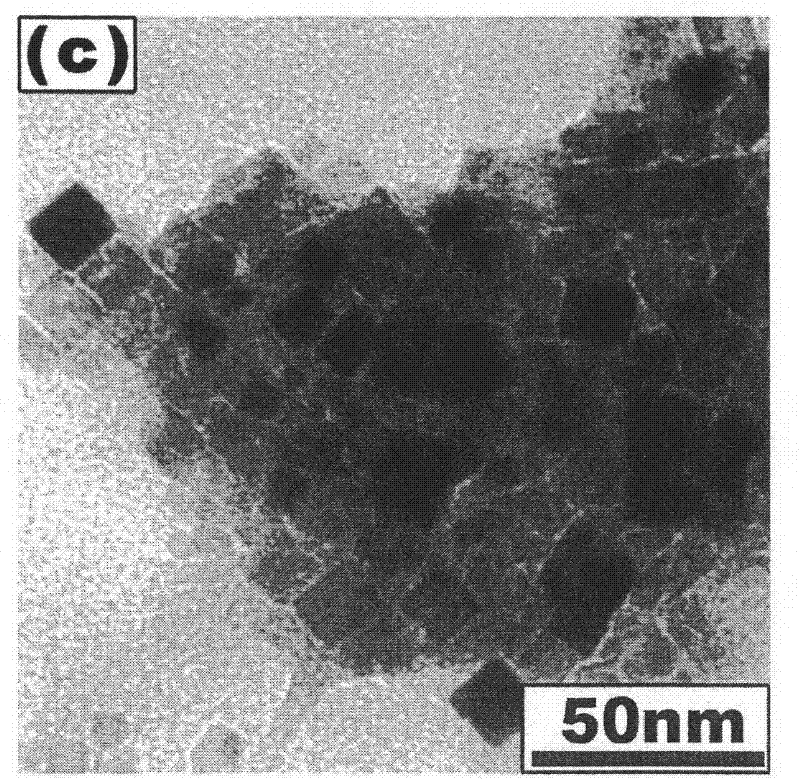

Solid-waste-based nanocrystalline cluster magnetic glass ceramic and preparation method thereof

PendingCN113264682ASimple preparation processLow costGlass furnace apparatusGlass shaping apparatusMagnetic phaseWater processing

The invention provides a solid-waste-based nanocrystalline cluster magnetic glass ceramic and a preparation method thereof; the magnetic glass ceramic belongs to a B2O3-Fe2O3-SiO2 system, and is prepared by taking high-silicon, iron-rich or boron-containing industrial solid waste as a main raw material through a high-temperature melting-self-nucleation crystallization method; and the preparation process is simple, and the cost is low. The base glass formula comprises 45-60% of SiO2, 2-30% of B2O3, 15-30% of Fe2O3, 3-15% of Al2O3, less than or equal to 9% of CaO + MgO and less than or equal to 6% of Na2O + K2O. The solid-waste-based nanocrystalline cluster magnetic glass ceramic belongs to ferromagnetic glass ceramic, the magnetic phase magnetite is nanocrystalline and is mainly uniformly dispersed in the glass phase in a cluster structure form, has the structural characteristics of the glass ceramic and a magnetic function, the crystalline phase purity is high, the saturation magnetization Ms reaches 20 emu / g, the coercive force Hc reaches 57Oe, and the magnetic glass ceramic can be made into magnetic glass fiber, the electromagnetic shielding / wave-absorbing material and the magnetic glass ceramic powder, and is applied to the fields of electrical insulation, information technology, wastewater treatment and the like.

Owner:INNER MONGOLIA UNIV OF SCI & TECH

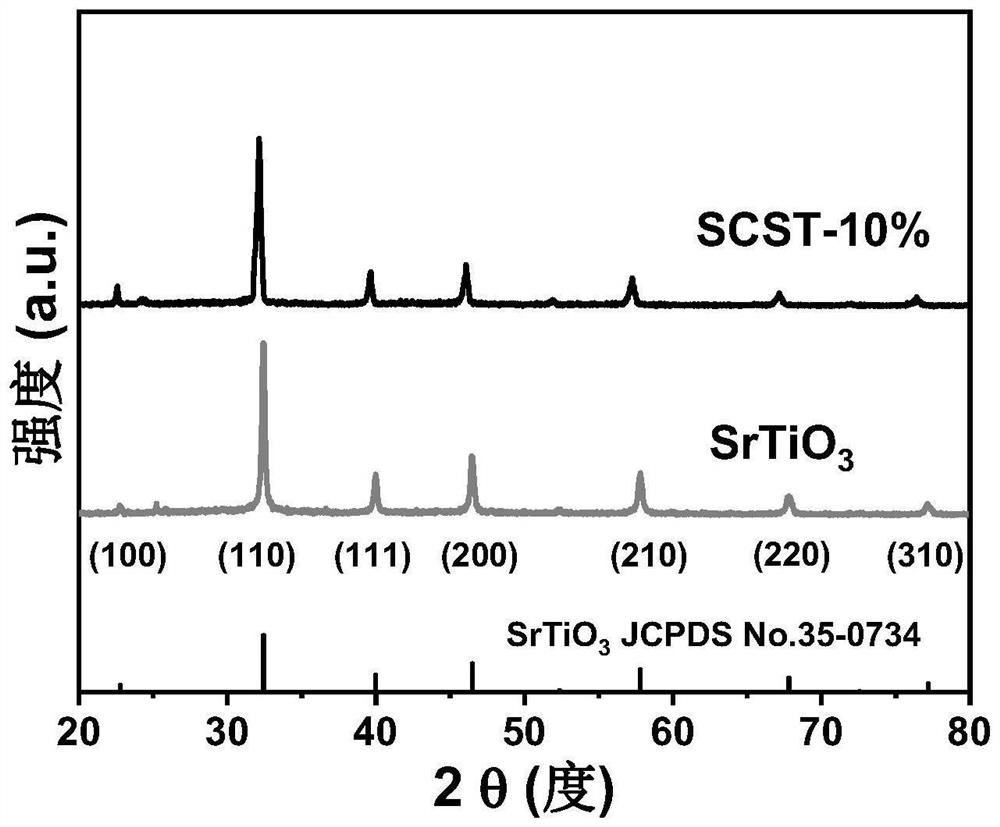

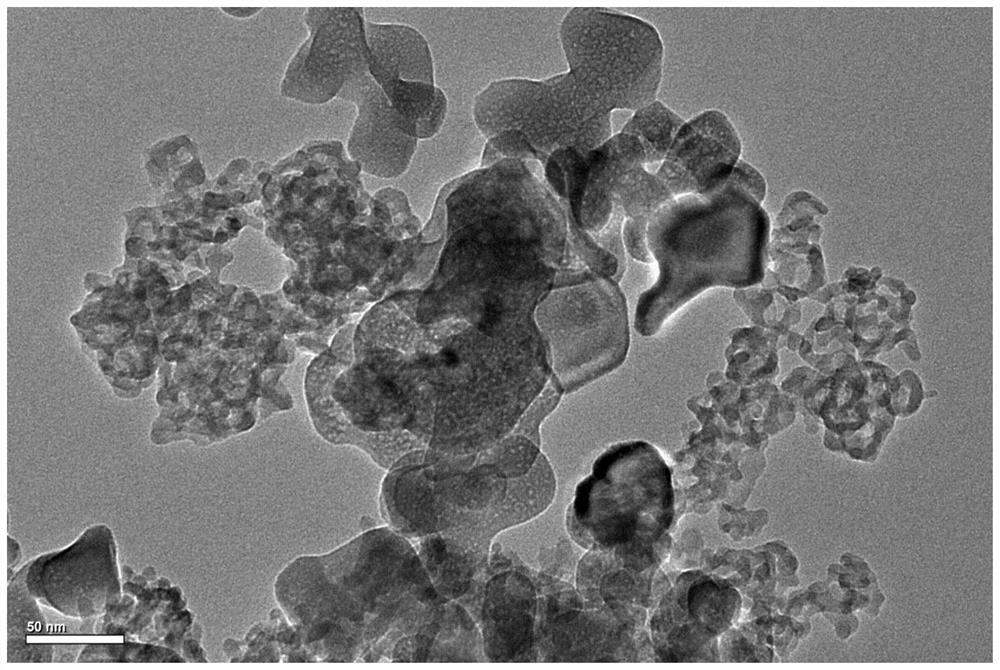

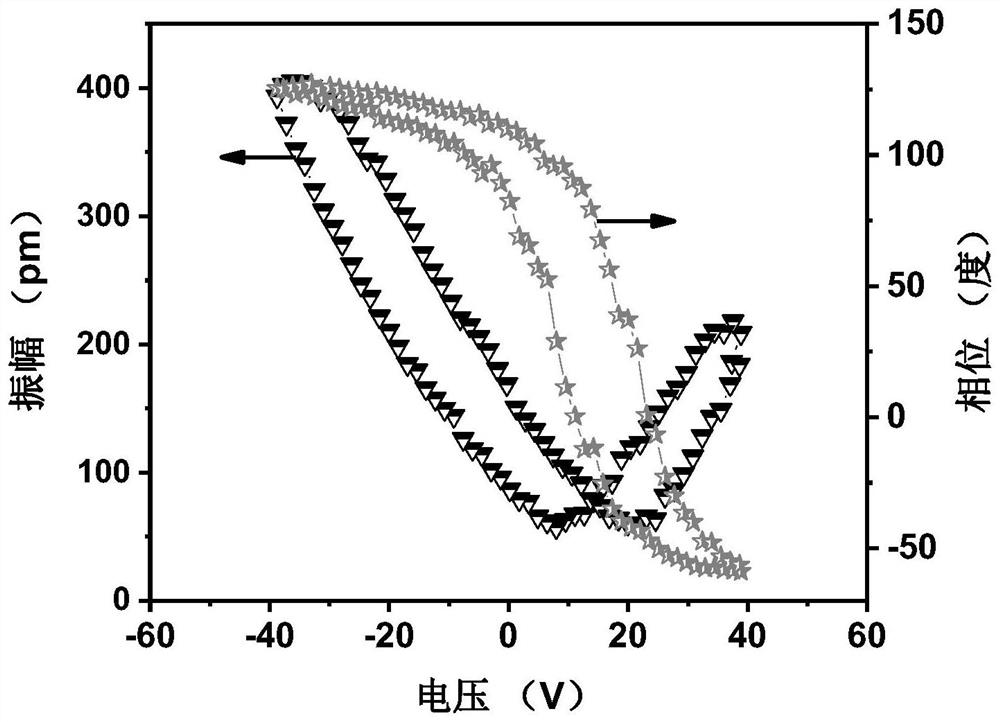

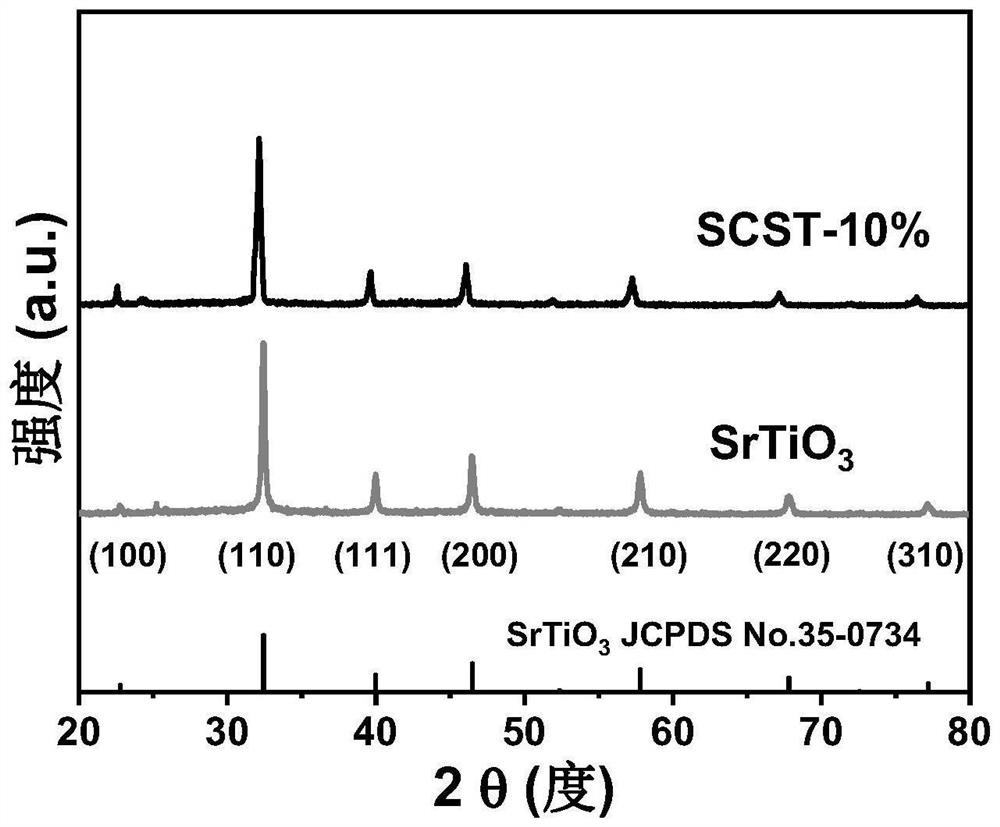

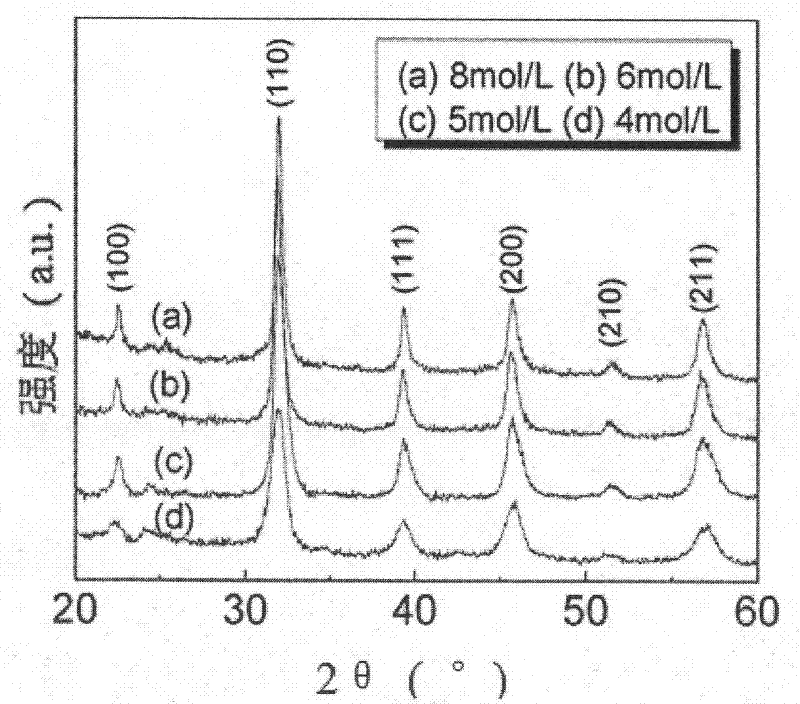

Tin and cerium-strontium titanate solid solution piezoelectric hydrogen production catalyst as well as preparation method and application thereof

ActiveCN113893846AImproved piezoelectric responseHigh crystal phase purityWater contaminantsWater/sewage treatment with mechanical oscillationsPtru catalystPhysical chemistry

The invention relates to the technical field of piezoelectric catalytic hydrogen production materials, and provides a tin and cerium-strontium titanate solid solution piezoelectric hydrogen production catalyst as well as a preparation method and application thereof. The chemical general formula of the material prepared according to the invention is SnxCeySr(1-x-y)TiO3 (x is more than 0 and less than or equal to 0.15, and y is more than 0 and less than or equal to 0.15). A Sr source, a Ce source, a Sn source and a Ti source are mixed with water and ethylene glycol, a coprecipitation method is adopted, a precursor of the tin and cerium-strontium titanate solid solution piezoelectric hydrogen production catalyst is prepared, and finally the solid solution piezoelectric hydrogen production catalyst is formed through high-temperature calcination. The result of the embodiment shows that the piezoelectric hydrogen production performance of SrTiO3 is greatly improved due to the introduction of Sn and Ce. Moreover, when x is equal to 0.1 and y is equal to 0.1, the hydrogen production efficiency is the best, reaches 411 [mu]mol / g and is far higher than 53.45 [mu]mol / g of SrTiO3.

Owner:广东粤绿环境工程有限公司

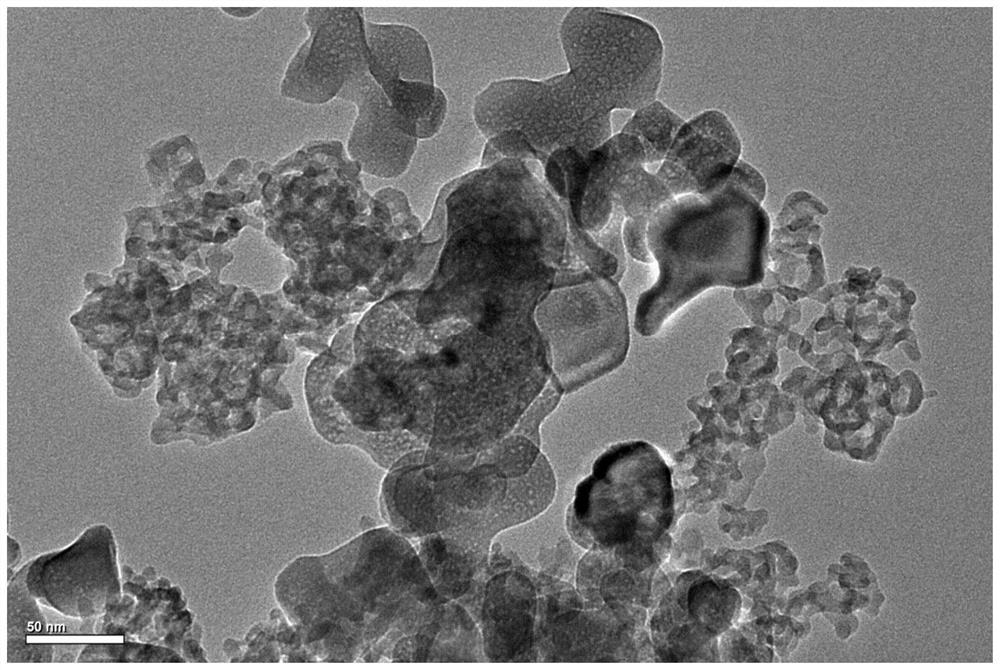

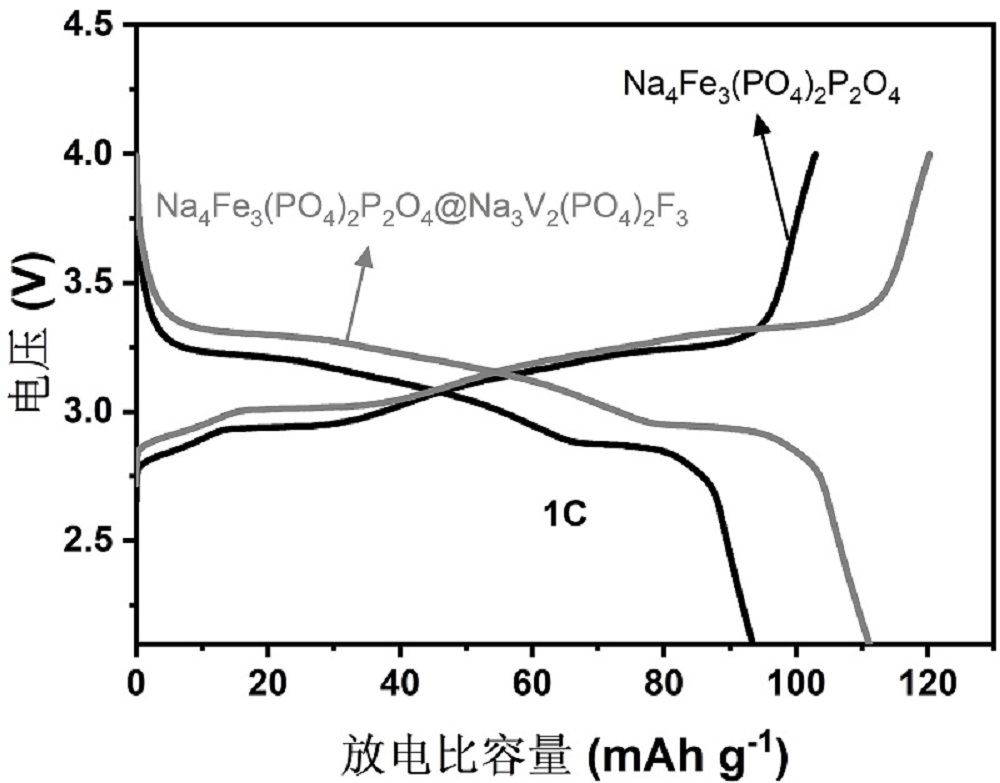

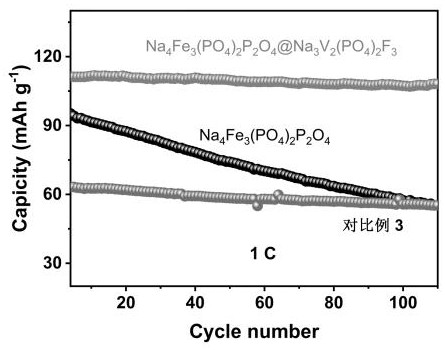

A fluorine-doped carbon-coated sodium ferric phosphate pyrophosphate@mesoporous carbon composite material and its preparation and application in sodium-ion batteries

ActiveCN110061233BImprove stabilityImprove cycle performanceSecondary cellsPositive electrodesPhysical chemistrySodium-ion battery

The invention belongs to the technical field of sodium ion batteries, and specifically discloses a fluorine-doped carbon-coated phosphate ferric sodium pyrophosphate @ mesoporous carbon composite material. The material comprises mesoporous carbon and fluorine-doped carbon-coated phosphate ferric sodium pyrophosphate dispersed in the mesoporous carbon in situ. The invention also discloses a preparation of the material and an application of the material as an active material for a sodium ion battery. The composite material of the invention has the characteristics of high specific capacity, highsafety and high rate as a positive electrode material of a sodium ion battery, and has rich system resources, low cost, a simple preparation method and a good application prospect.

Owner:湖南钠邦新能源有限公司

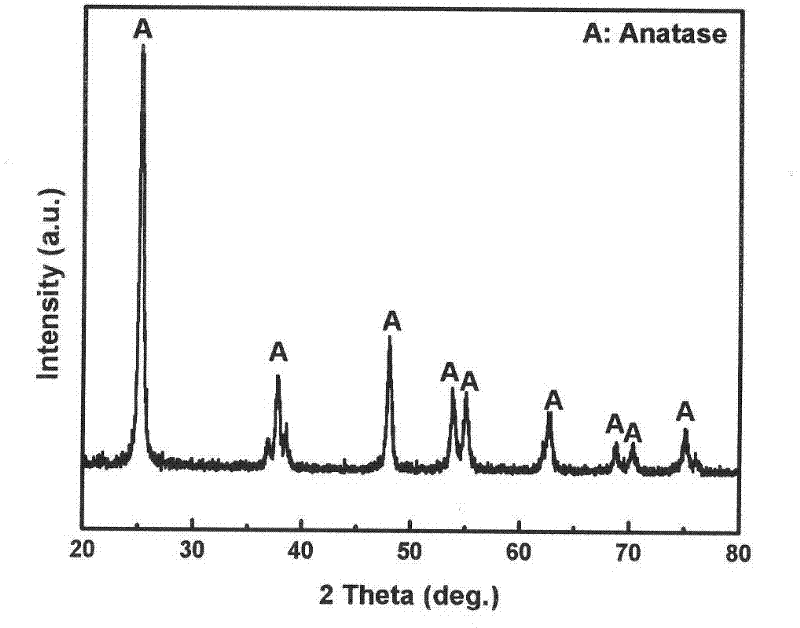

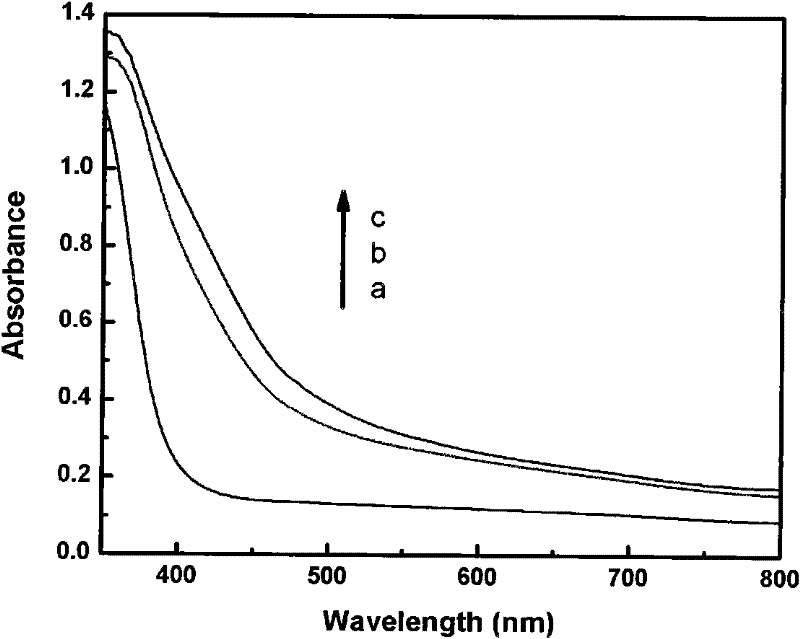

Method for preparing ferrum-fluorine-codoped nano-titanium dioxide visible light photocatalyst

InactiveCN101791562BImprove photocatalytic activityRich sourcesPhysical/chemical process catalystsRoom temperatureHydrolysis

The invention relates to a method for preparing a ferrum-fluorine-codoped nano-titanium dioxide visible light photocatalyst. The method comprises the following steps: (1) at the room temperature, adding nitric acid into the ethanol solution of tetrabutyl titanate dropwise, adding ferrum-fluorine-containing ethanol solution into the mixed solution with stirring, and stirring the mixed solution at the room temperature for 0.5 to 2 hours to perform a hydrolysis reaction to obtain light yellow titanium dioxide sol; (2) ageing the obtained titanium dioxide sol at the room temperature to obtain titanium dioxide gel, and drying the titanium dioxide gel to obtain dried titanium dioxide gel; and (3) grinding, screening and sintering the dried titanium dioxide gel to obtain the ferrum-fluorine-codoped nano-titanium dioxide visible light photocatalyst. The method has the characteristics of mild reaction conditions, easy control, simple equipment and rich raw material resources, simple synthetic process and high yield, and can be used for large-scale production; and the prepared ferrum-fluorine-codoped nano-titanium dioxide visible light photocatalyst has high performance.

Owner:DONGHUA UNIV

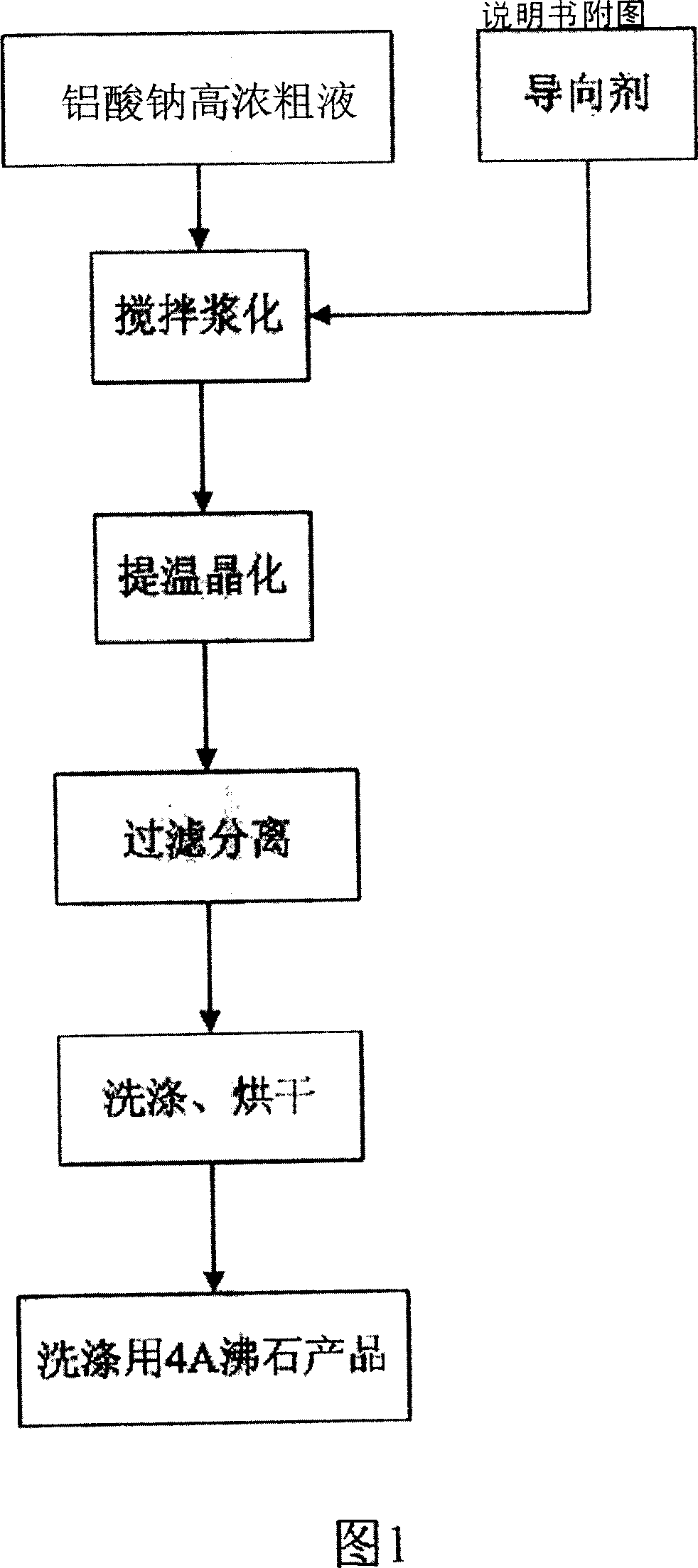

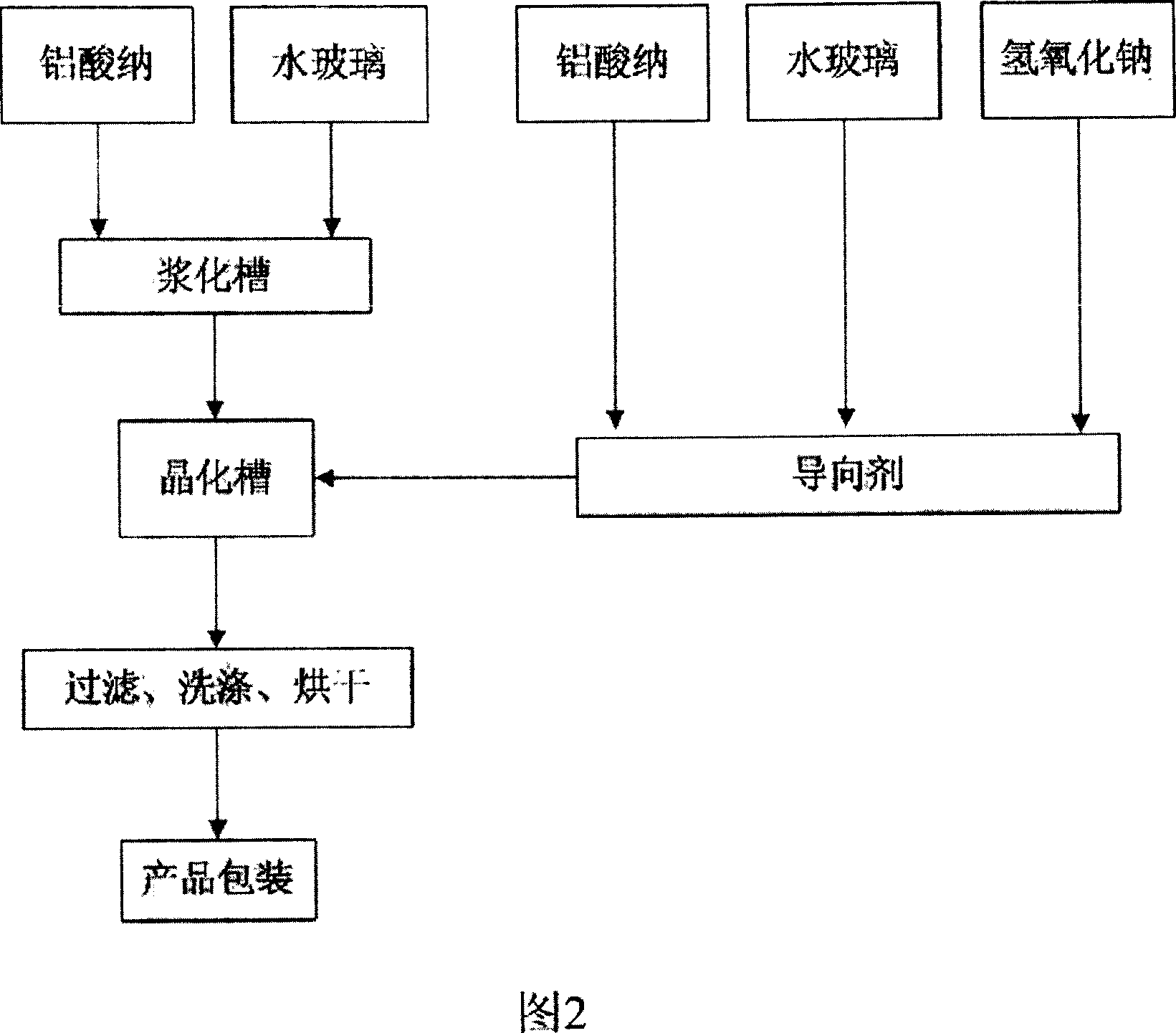

Guiding agent for preparing 4A zeolite

ActiveCN100348487CSimple compositionEasy to manufactureAluminosilicate zeolite type-ASodium aluminateSodium hydroxide

A guiding agent for preparing 4A zeolite from the solution of sodium aluminate generated in the production of alumina features that the solution of sodium aluminate, water glass and sodium hydroxide are proportionally mixed while the Si / Al ratio and Na / Al ratio are controlled to be 5-20 and 10-25. Its advantages are high productivity and high quality of 4A zeolite.

Owner:GUIZHOU BRANCH CHINA ALUMINUM IND

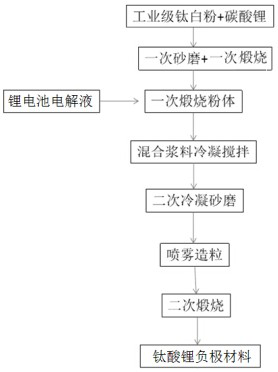

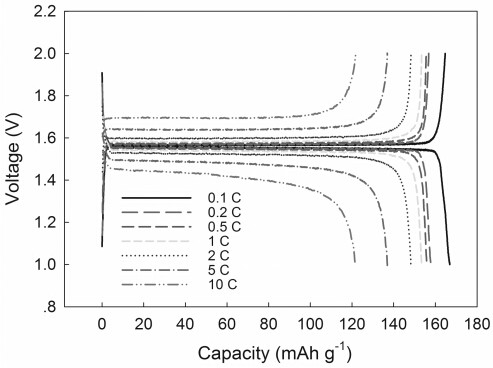

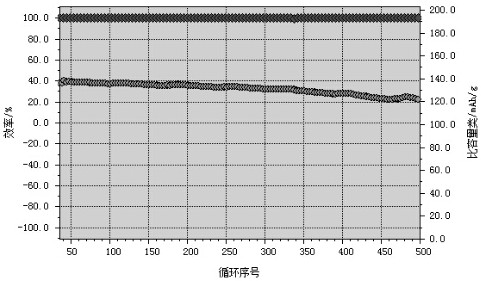

Solid electrolyte modified lithium titanate negative electrode material and preparation method thereof

ActiveCN110880593BImproved magnification performanceReduce surface alkalinitySecondary cellsNegative electrodesSolid state electrolyteElectrolytic agent

The invention relates to the field of electrode materials, and discloses a solid electrolyte modified lithium titanate negative electrode material and a preparation method thereof. The microscopic appearance of the lithium titanate negative electrode material is as follows: the secondary particles are spherical, and the particle size is 5-20 μm. The secondary particles are composed of primary particles with a grain size of 20-200 nm; the lithium titanate particles in the lithium titanate negative electrode material are attached to the lithium ion solid electrolyte composed of fluoride oxide and fluoride, and the lithium ion solid electrolyte The mass fraction is 0.1-3%; its preparation method is: one or more fluorine-containing lithium battery electrolytes, titanium dioxide and lithium salts are subjected to two times of sand milling, two times of spray granulation and two times of solid-phase calcination have to. The tap density of the prepared lithium titanate negative electrode material reaches 1.3 g / cm 3 Above, the pH value is 8‑10, and has a good rate performance, the 5C discharge capacity reaches 135 mAh g ‑1 above.

Owner:JIANGSU UNIV +1

A tin, cerium-strontium titanate solid solution piezoelectric hydrogen production catalyst and its preparation method and application

ActiveCN113893846BImproved piezoelectric responseHigh crystal phase purityWater/sewage treatment with mechanical oscillationsWater contaminantsStrontium titanatePtru catalyst

The invention relates to the technical field of piezoelectric catalytic hydrogen production materials, and provides a tin, cerium-strontium titanate solid solution piezoelectric hydrogen production catalyst and a preparation method and application thereof. According to the material prepared by the present invention, its general chemical formula is Sn x Ce y Sr (1‑x‑y) TiO 3 (0<x≤0.15, 0<y≤0.15). In the present invention, Sr source, Ce source, Sn source and Ti source are mixed with water and ethylene glycol, and a co-precipitation method is used to prepare a precursor of a tin, cerium-strontium titanate solid solution piezoelectric hydrogen production catalyst, and finally calcined at high temperature A solid solution piezoelectric hydrogen production catalyst is formed. The results of the examples show that the introduction of Sn and Ce makes SrTiO 3 The piezoelectric hydrogen production performance has been greatly improved. And, when x=0.1, y=0.1, it has the best hydrogen production efficiency, reaching 411 μmol / g, much higher than SrTiO 3 of 53.45 μmol / g.

Owner:广东粤绿环境工程有限公司

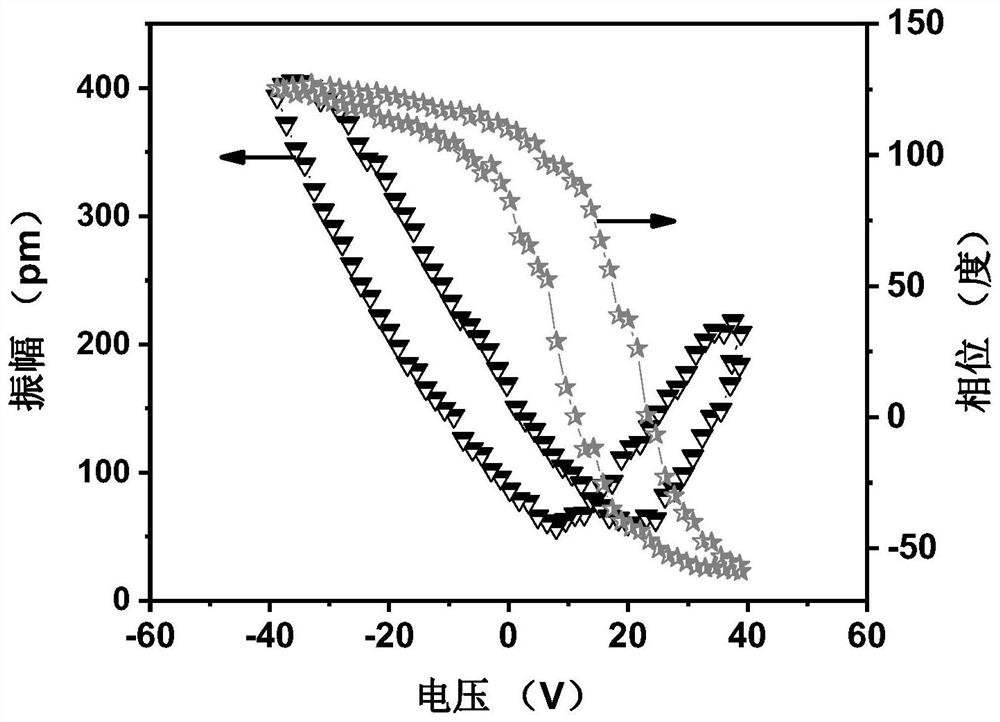

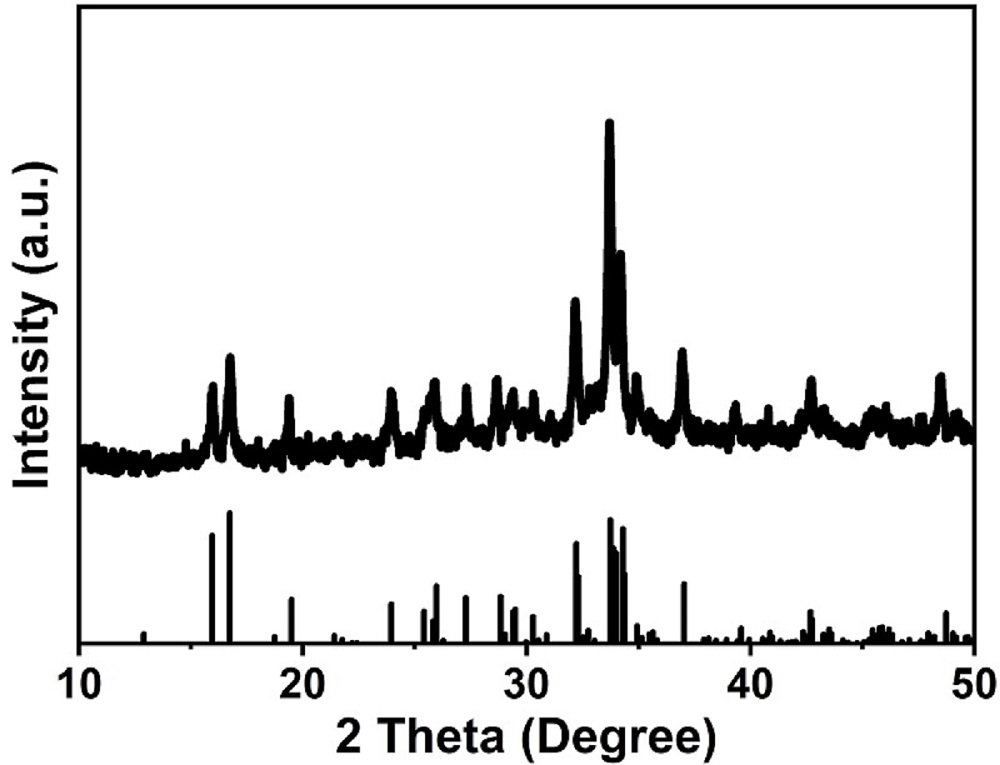

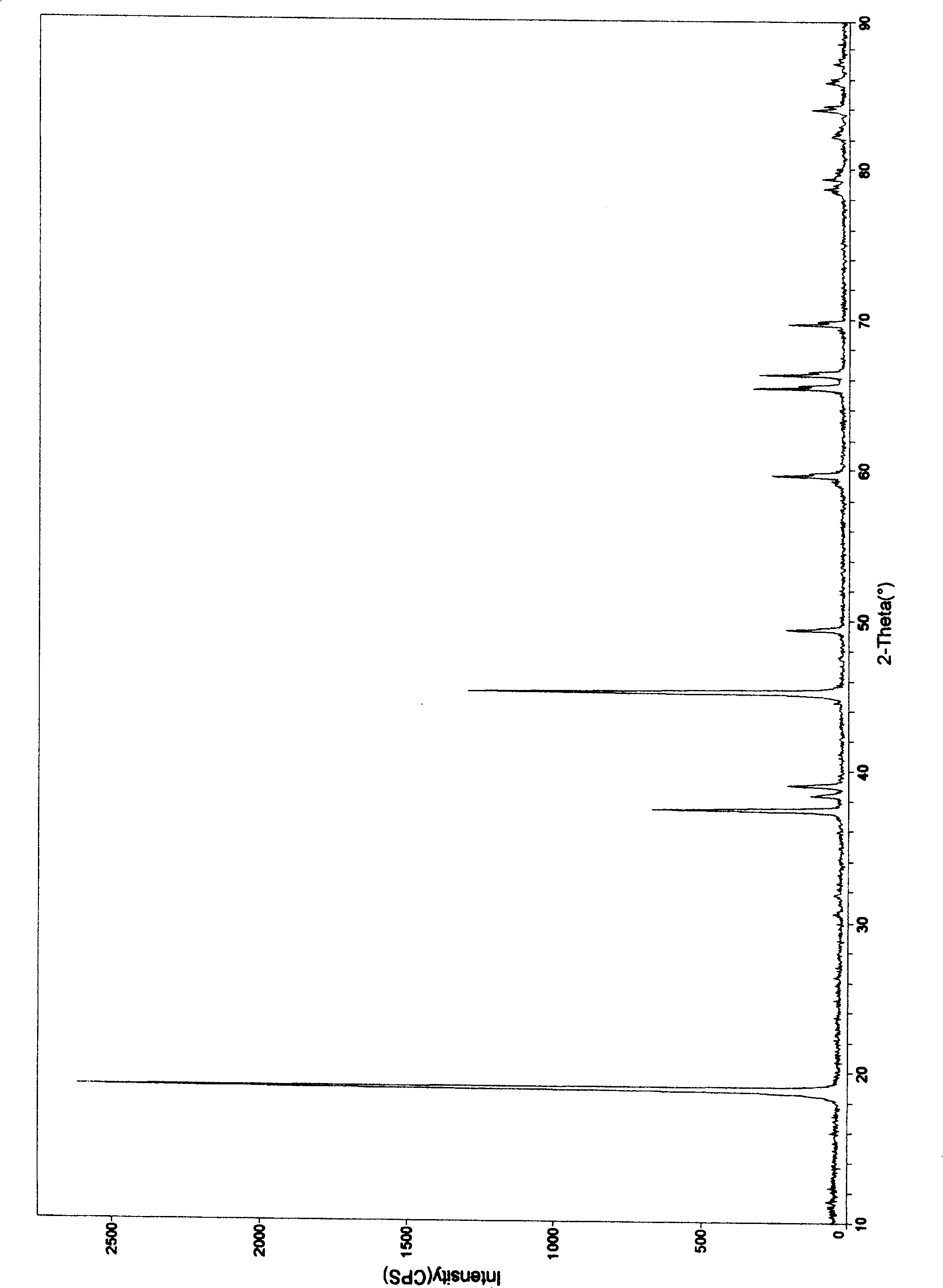

A kind of vanadium sodium fluorophosphate coated sodium ferric phosphate pyrophosphate composite material and its preparation method and application

ActiveCN114068938BImprove stabilityImprove cycle performanceMaterial nanotechnologySecondary cellsElectrical batteryPhysical chemistry

Owner:深圳市津工能源有限公司

Lithium ion positive electrode material and preparation method thereof

InactiveCN100429811CHigh initial capacityEasy to operateElectrode manufacturing processesLithium compoundsSolventOxygen

This invention discloses a Li ion positive material and its preparation method solving the problem of reducing the circulation attenuation of the positive ionic material with the oxide general formula: xA2O.yM2Om.zN2On, the material is composed of 2-D hexagonal laminated crystal, compound oxide crystal of 3-D spinel structure or lithium vanadium oxide in the following processing steps: to electrolyse metal directly to form metal alkoxide in alcohol soluble absolute electrolyte containing organic additives then to mix with solution with assistant alkali salt or base to form positive sol precursor to dry to remove the solvent and form positive powder precursor under 120 to 550 deg.C. to process in solid phase reaction for 0.5-48h in 450-960 deg.c.

Owner:GUIZHOU ZHENHUA E CHEM INC

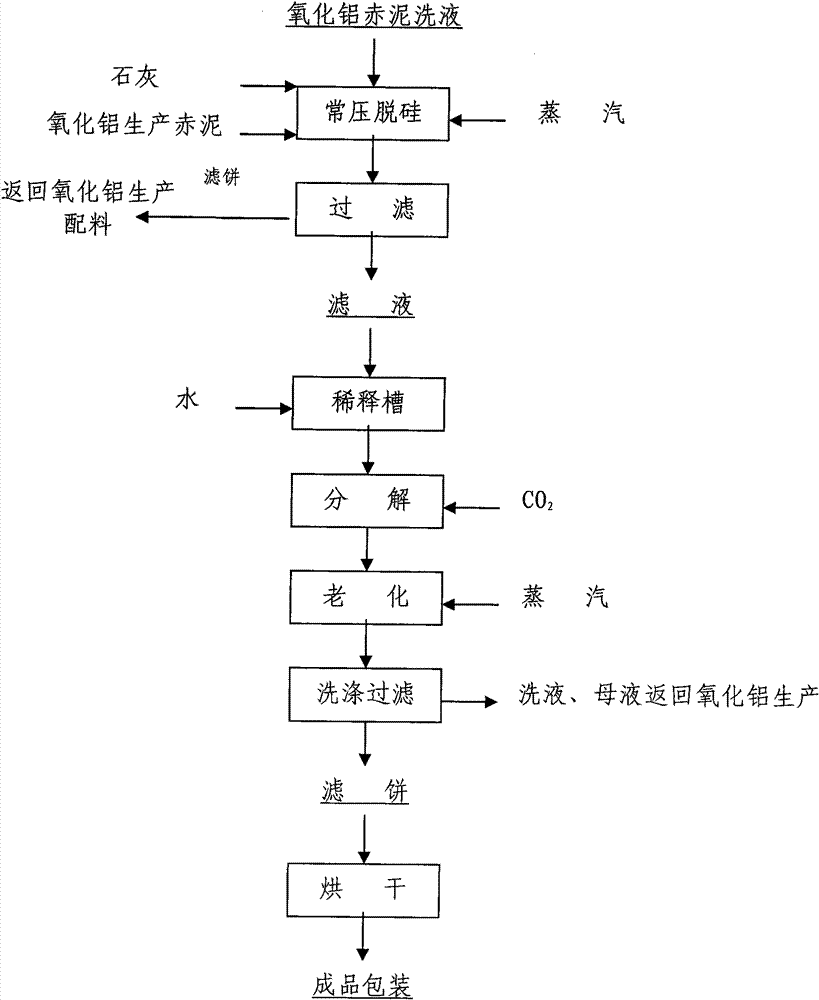

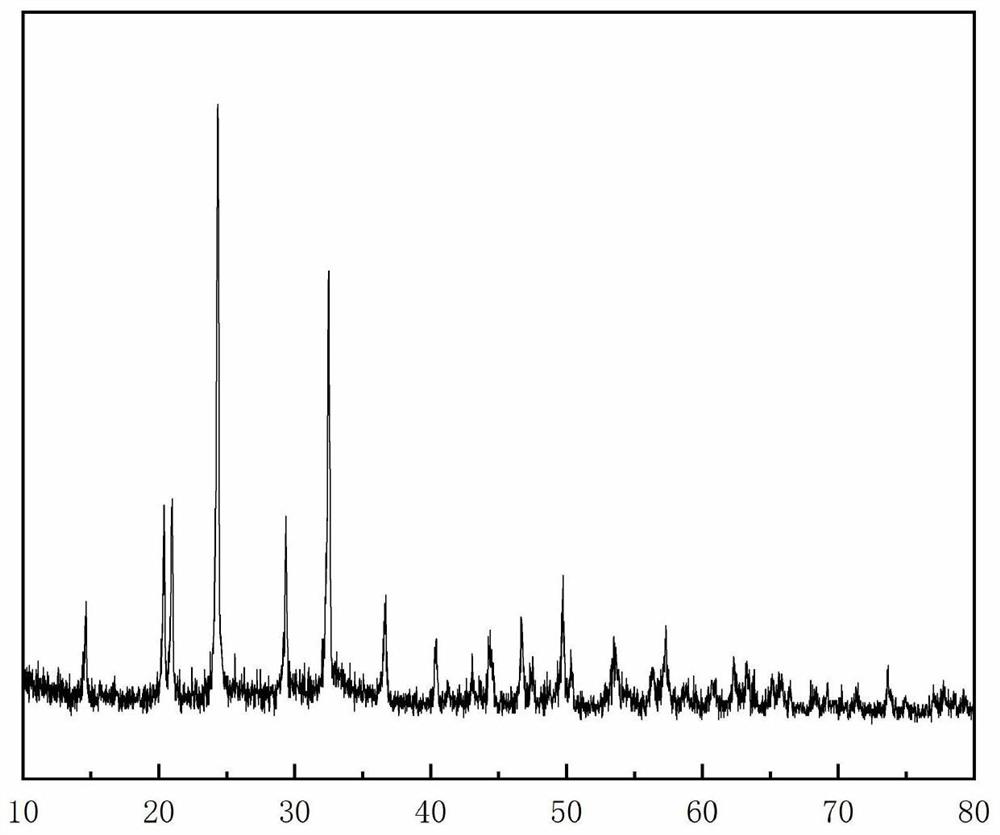

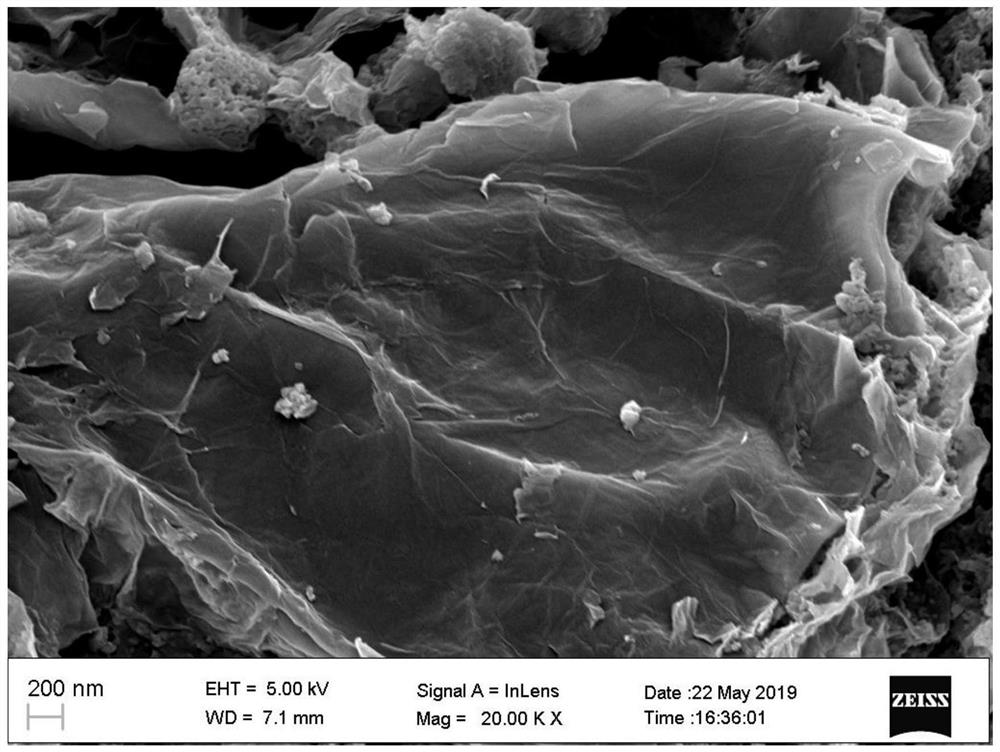

Method for producing boehmite by using washing liquor

The application relates to a method for producing boehmite by using washing liquor from the production of washing red mud by alumina, which comprises the following steps: delivering washing liquor from the production of the washing red mud by alumina to a desilicication tank, and adding red mud and lime to perform desilicication; when a desilicication index is more than or equal to 400 as required, filtering the product of the desilicication, transferring filtrate to a diluting tank for cooling, cooling to 20 to 60 DEG C, performing carbonation gelatinizing by using 20 to 60 volume percent CO2 gas obtained by concentrating and enriching CO2 waste gas generated in the production of alumina as a precipitator; heating the gelatinized slurry to 70 to 100 DEG C, keeping the temperature for 1 to 6 hour and aging; and washing the aged slurry with washing equipment, filtering the aged slurry to obtain filtrate and filter cake, and drying the filter cake by using drying equipment to obtain powdery boehmite. The method has the advantages of low production raw material cost and rich raw material source, is favorable for alumina production liquid balance, improvement on finished alumina yield, reduction of Al2O3 content of red mud discharged to the outside and recovery of alumina CO2 waste gas and is in accordance with the national circulating economy and waste recycling principle. The product produced has high crystalline phase purity and high peptizing performance and can be used as a binder, a drier, a purifier, a catalyst, a catalyst carrier and the like.

Owner:SHANXI ALUMINUM FACTORY TECH CHEM

Fluorinated phosphate sodium iron pyrophosphate@c@rgo composite material and its preparation and application in sodium-ion batteries

ActiveCN110299528BGood electrical propertiesGood crystal phaseSecondary cellsPositive electrodesPhosphateElectrical battery

The invention belongs to the field of electrode materials for sodium ion batteries, and specifically discloses a ferric sodium pyrophosphate phosphorus fluoride@C@RGO composite material. The compositematerial includes reduced graphene oxide and active particles compounded in situ on the surface of the reduced graphene oxide. The active particles are ferric sodium pyrophosphate phosphorus fluoride, and the chemical formula of the ferric sodium pyrophosphate phosphorus fluoride is Na4Fe3PO4P2O7F3. The invention also provides a preparation method and an application of the material. The materialhas the characteristics of high theoretical quantity, high voltage, stable cycling and low cost of raw materials, and has a good prospect of industrialization. It is discovered from the invention that, through the novel active ingredient and the innovative double-carbon in-situ composite morphology, the technical problems of phase transition, poor stability and poor electrical performance of the existing iron-based cathode material can be solved, and the voltage, capacity, rate and cycle stability of the material can be improved.

Owner:湖南钠邦新能源有限公司

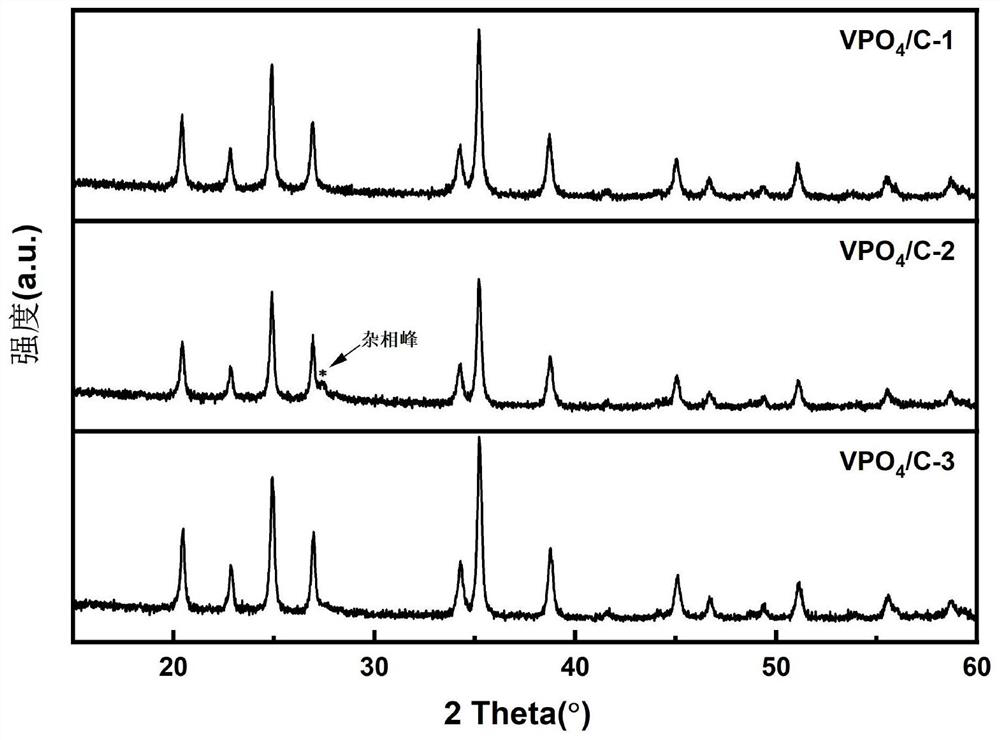

Preparation method and application of lithium vanadium fluorophosphate

ActiveCN112850684ASmall particle sizeEvenly distributedCell electrodesSecondary cellsCarbon compositesPhosphoric acid

The invention provides a preparation method and application of lithium vanadium fluorophosphate, and the method provided by the invention is summarized into two steps: 1, preparing carbon-coated vanadium phosphate (VPO4 (at) C) or carbon-coated vanadium trioxide (V2O3 (at) C) by a sol-gel method; and 2, preparing the carbon composite LiVPO4F through a low-temperature solvothermal method. In the first step, the sol-gel method is used for preparing carbon-coated VPO4 (at) C or V2O3 (at) C, and a carbon composite precursor with small particle size and uniform distribution can be obtained. In the second step, low-temperature hydrothermal synthesis of LiVPO4F is adopted, on one hand, volatilization of F is effectively avoided, and a high-purity LVPF material is prepared at low temperature; on the other hand, the crystallization phase formation of the LVPF is realized, and the volatilization of F at high temperature to generate impurities is avoided. The obtained LiVPO4F (at) C powder has nanoscale morphology, is very high in crystalline phase purity, and has excellent performance close to theoretical specific capacity at low magnification.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Artificial diopside material and its preparation method

The present invention is artificial pure diopside crystal material and its preparation process. The artificial diopside crystal material is prepared with silica sand, tail pyrite, kaolin, albite, limestone and other mineral materials, and through the technological steps of compounding material, smelting, forming, annealing, coring, crystallization, etc. Chemically, the materials consist of SiO2 47-61 wt%, Al2O3 4-9 wt%, CaO 12-20 wt%, MgO 4-7 wt%, TiO2 2-15 wt%, NaO2+KO2 3-7 wt%, ZrO2 1-4 wt%, ZnO 0-4 wt%, P2O5 1-4 wt%, F 1-3 wt% and C 1-3 wt%. The artificial pure diopside crystal material consists of micron level crystal grains, and has high compactness, high mechanical performance, high wear resistance, high corrosion resistance, excellent impact performance, no radioactivity and other features.

Owner:CHENGDU UNIVERSITY OF TECHNOLOGY

Preparation method of nano strontium barium titanate powder

InactiveCN101786654BSmall granularityUniform particle sizeNanostructure manufactureTitanium compoundsBarium strontium titanateBarium titanate

The invention discloses a preparation method of nano strontium barium titanate powder, which is used to solve the technical problems of large particle size, uneven distribution and impure crystal phase of the prepared strontium barium titanate powder prepared by the preparation method in the prior art. Its technical scheme puts barium acetate, strontium acetate, tetra-n-butyl titanate, sodium oleate, oleic acid, n-butanol and sodium hydroxide into a hydrothermal kettle to heat and react, washes out the precipitate with ethanol, and then washes out the precipitate with cyclohexane Then add ethanol to the mixed solution to produce nanocrystalline BST precipitate at room temperature, centrifuge the nanocrystalline BST precipitate, wash the residual oleic acid with ethanol, and dry it at room temperature. The present invention adopts the liquid-solid solution method to prepare barium strontium titanate powder, the particle size of the barium strontium titanate powder prepared is reduced from more than 50nm in the prior art to 10-25nm, and the particle size distribution is uniform, and the crystal phase purity is also obtained. improve.

Owner:江苏晨朗电子集团有限公司 +1

Preparation method of single-substrate fluorescent powder for white-light LEDs (light-emitting diodes)

InactiveCN103013505BHigh crystal phase purityUniform particle sizeGas discharge lamp usageLuminescent compositionsReducing atmosphereBiological activation

The invention provides a preparation method of single-substrate fluorescent powder for white-light LEDs (light-emitting diodes), which comprises the following steps: after completely dissolving Tb4O7 in a concentrated nitric acid solution, regulating the pH value to 4-7 with ammonia water, sequentially adding anhydrous CaCl2, Ca(NO3)2.4H2O and anhydrous ethanol, uniformly stirring, adding a slow release agent citric acid solution, continuously stirring until the slow release agent is uniformly dispersed in the solution, adding ethyl silicate, and stirring to form a uniform and transparent solution; and regulating the pH value of the uniform and transparent solution to 6-8 with ammonia water to form a gel, drying the gel, grinding to form powder, putting the dry gel powder in a resistance furnace, and sintering in a weak reducing atmosphere. The preparation method provided by the invention implements activation of the Ca2SiO3Cl2 substrate to emit white light by using the single Tb<3+>.

Owner:SHAANXI UNIV OF SCI & TECH

A repair method of carbon composite vanadium phosphate

ActiveCN112694076BHigh crystal phase purityLow soluble high valence vanadium contentCell electrodesSecondary cellsCarbon compositesPhosphoric acid

The invention provides a method for repairing carbon-composite vanadium phosphate, comprising the following steps: step 1, detecting the vanadium dissolution rate and element content of carbon-composite vanadium phosphate to be repaired, and judging whether the failure degree of carbon-composite vanadium phosphate and the ratio of element content are out of balance; step 2. Mix the coated reducing agent with the carbon composite vanadium phosphate to be repaired, the amount of the coated reducing agent is calculated according to the vanadium dissolution rate of the carbon composite vanadium phosphate to be repaired; step 3, the mixed material is treated at high temperature to obtain Repaired carbon composite vanadium phosphate. This repair method can effectively repair and regenerate materials that have been oxidized and deteriorated due to long-term placement in the air. The dissolution rate recovered to a level below 2000mg / kg.

Owner:DALIAN RONGKE ENERGY STORAGE GRP CO LTD

A kind of preparation method and application of lithium vanadium fluorophosphate

ActiveCN112850684BSmall particle sizeEvenly distributedCell electrodesSecondary cellsCarbon compositesPhosphoric acid

The present invention provides a preparation method of lithium vanadium fluorophosphate and application thereof. The method of the present invention is summarized into two steps. The first step is to prepare carbon-coated vanadium phosphate (VPO) by a sol-gel method. 4 @C) or carbon-coated vanadium trioxide (V 2 O 3 @C); the second step is low-temperature solvothermal preparation of carbon composite LiVPO 4 F. First step to prepare carbon-coated VPO using sol-gel method 4 @C or V 2 O 3 @C, carbon composite precursors with small particle size and uniform distribution can be obtained. The present invention adopts low-temperature hydrothermal synthesis of LiVPO through the second step 4 F, on the one hand, effectively avoids the volatilization of F, and prepares high-purity LVPF materials at low temperature; Obtained LiVPO 4 F@C powders have nanoscale morphologies, high crystal phase purity, and excellent performance close to the theoretical specific capacity at low magnifications.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com