Method for preparing ferrum-fluorine-codoped nano-titanium dioxide visible light photocatalyst

A nano-titanium dioxide, photocatalyst technology, applied in physical/chemical process catalysts, chemical instruments and methods, chemical/physical processes, etc., can solve problems such as large band gap energy, low solar energy utilization, and low photogenerated carrier efficiency. , to achieve the effect of small particle size, good photocatalytic performance and simple equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

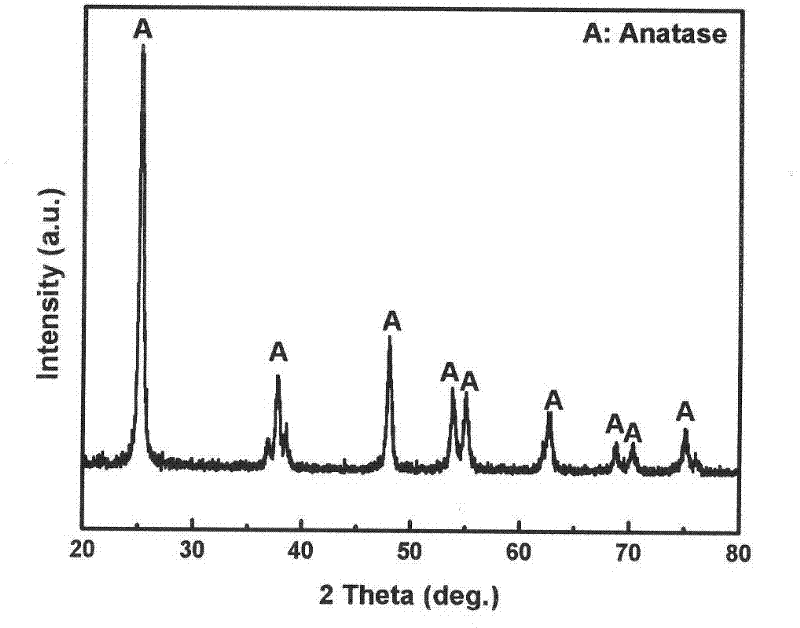

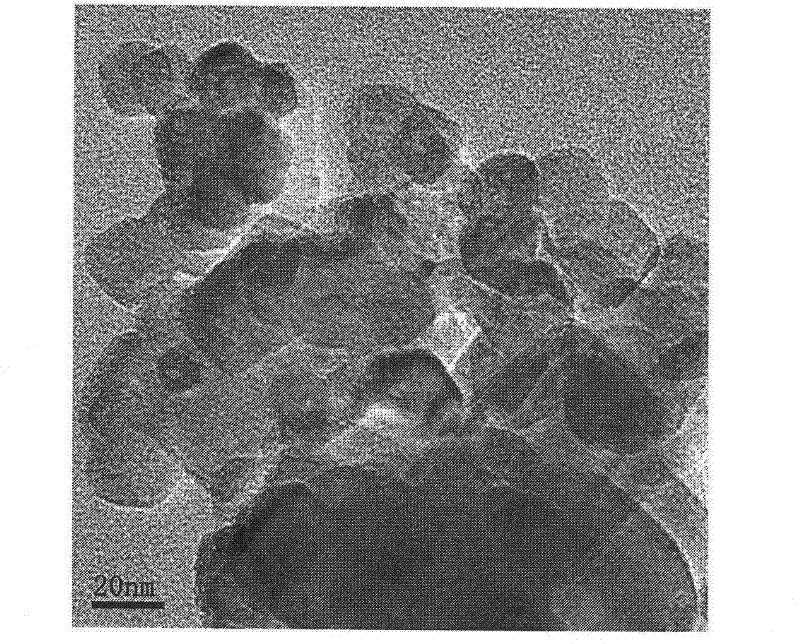

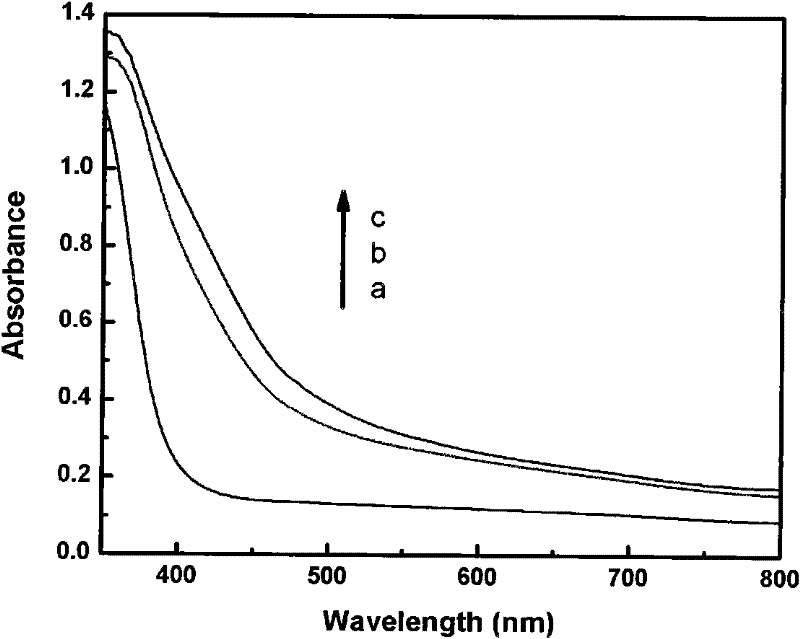

Embodiment 1

[0033] At room temperature, measure 45.8ml of 0.8M tetrabutyl titanate ethanol solution into the reactor and stir evenly. Slowly add 1.00ml of nitric acid (analytical grade, 65-68wt%) dropwise, and continue stirring for 30 minutes. Measure 18ml of 0.0014M ferric chloride and 0.10M ammonium fluoride ethanol solution, add dropwise into the reactor, and stir at room temperature for 30min, hydrolysis reaction occurs, and light yellow titanium dioxide sol is obtained. Then the obtained titanium dioxide sol was aged at room temperature for 60 h to obtain a titanium dioxide gel. Then dry the titanium dioxide gel at 70° C. for 15 hours to obtain a titanium dioxide xerogel. Finally, the obtained xerogel was ground and refined, and sieved with 200 meshes; calcined at 400° C. for 3 hours to obtain iron and fluorine co-doped nano-titanium dioxide visible light photocatalyst. In this embodiment, the molar ratio of the raw materials used is: tetrabutyl titanate: absolute ethanol: water: n...

Embodiment 2

[0036] At room temperature, measure 35.8ml of 1.0M tetrabutyl titanate ethanol solution into the reactor and stir evenly. 0.50 ml of nitric acid (analytical pure, 65-68 wt%) was slowly added dropwise, and the stirring was continued for 30 min. Measure 18ml of 0.0014M ferric chloride and 0.10M ammonium fluoride ethanol solution, add dropwise into the reactor, and stir at room temperature for 30min, hydrolysis reaction occurs, and light yellow titanium dioxide sol is obtained. Then the obtained titanium dioxide sol was aged at room temperature for 60 h to obtain a titanium dioxide gel. Then dry the titanium dioxide gel at 80° C. for 12 hours to obtain a titanium dioxide xerogel. Finally, the obtained xerogel was ground and refined, and sieved with 200 meshes; calcined at 500° C. for 2 hours to obtain iron-fluorine co-doped nano-titanium dioxide visible light photocatalyst. In this embodiment, the molar ratio of the raw materials used is: tetrabutyl titanate: absolute ethanol: ...

Embodiment 3

[0039] At room temperature, measure 45.8ml of 0.8M tetrabutyl titanate ethanol solution into the reactor and stir evenly. 0.25ml of nitric acid (analytical pure, 65-68wt%) was slowly added dropwise, and the stirring was continued for 30 minutes. Measure 18ml of 0.0014M ferric chloride and 0.10M ammonium fluoride ethanol solution, add dropwise into the reactor, and stir at room temperature for 30min, hydrolysis reaction occurs, and light yellow titanium dioxide sol is obtained. Then the obtained titanium dioxide sol was aged at room temperature for 48 hours to obtain a titanium dioxide gel. Then dry the titanium dioxide gel at 70° C. for 15 hours to obtain a titanium dioxide xerogel. Finally, the obtained xerogel was ground and refined, and sieved through a 200-mesh sieve; calcined at 600° C. for 2 hours to obtain a visible-light photocatalyst of nano-titanium dioxide co-doped with iron and fluorine. In this embodiment, the molar ratio of the raw materials used is: tetrabutyl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com