Guiding agent for preparing 4A zeolite

A technology of a directing agent and zeolite, which is applied in the field of preparing a directing agent for 4A zeolite, can solve the problems of unsatisfactory crystallized product quality, low crystallinity of 4A zeolite, and reduced material circulation, and achieves low cost, low production cost and good product quality. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] The directing agent is formulated with Al 2 o 3 Industrial sodium aluminate solution with a concentration of 55g / L, SiO 2 Water glass and sodium hydroxide with a concentration of 10% by weight are used for batching, the silicon-aluminum ratio is controlled to be 9, the sodium-aluminum ratio is 12, the mixture is evenly mixed, and the preparation is ready for use.

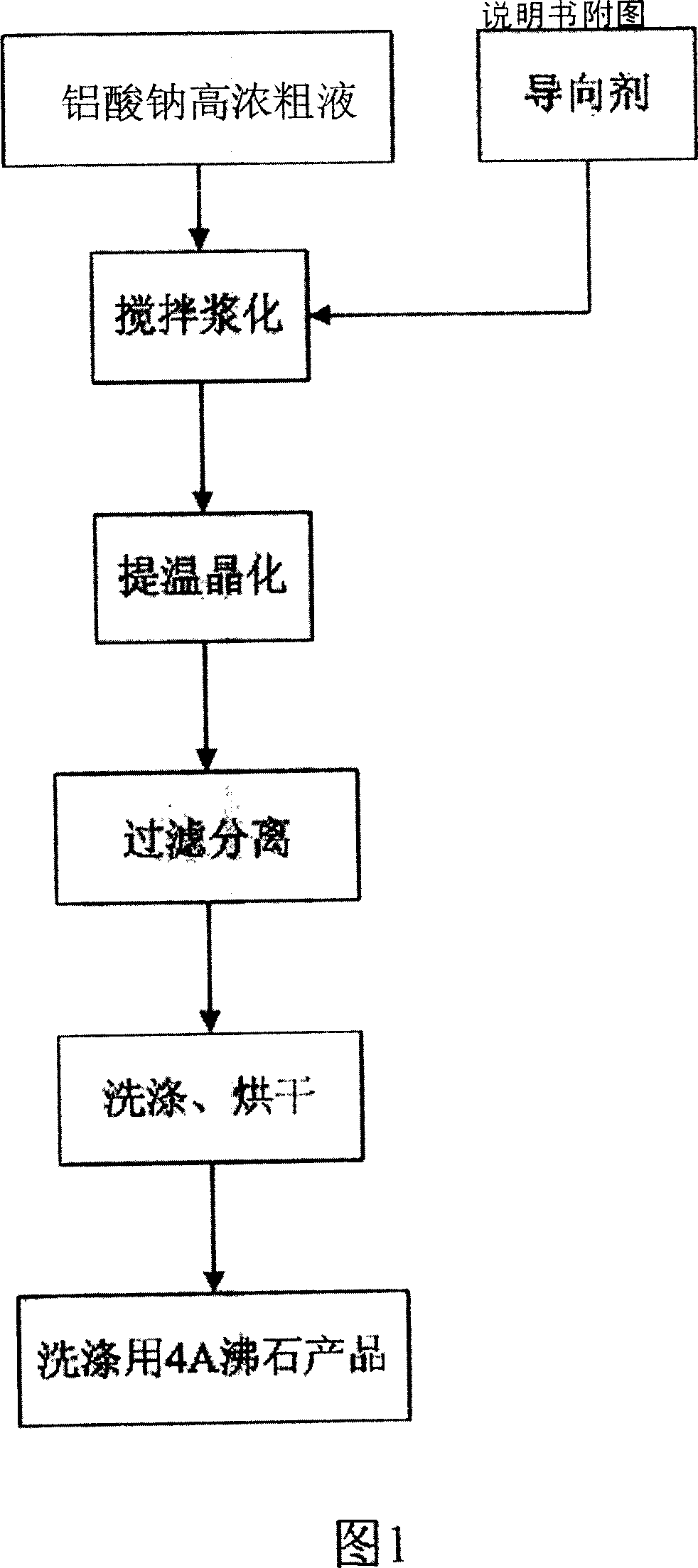

[0016] A method for producing 4A zeolite for washing using sodium aluminate solution in the sintering alumina production process, in Al 2 o 3 Add SiO 2 Water glass with a concentration of 27% by weight, heat the two solutions to 51±1°C respectively, and then press the two solutions to [SiO 2 ] / [Al 2 o 3 ]=1 were respectively added to the slurrying tank, the stirring speed of the slurrying tank was 40 rpm, and after stirring for 5 minutes, the directing agent was added in an amount of 1‰ of the total solution volume, and then the temperature was raised to 93±1°C, crystallized 1 hour, after filtration, w...

Embodiment 2

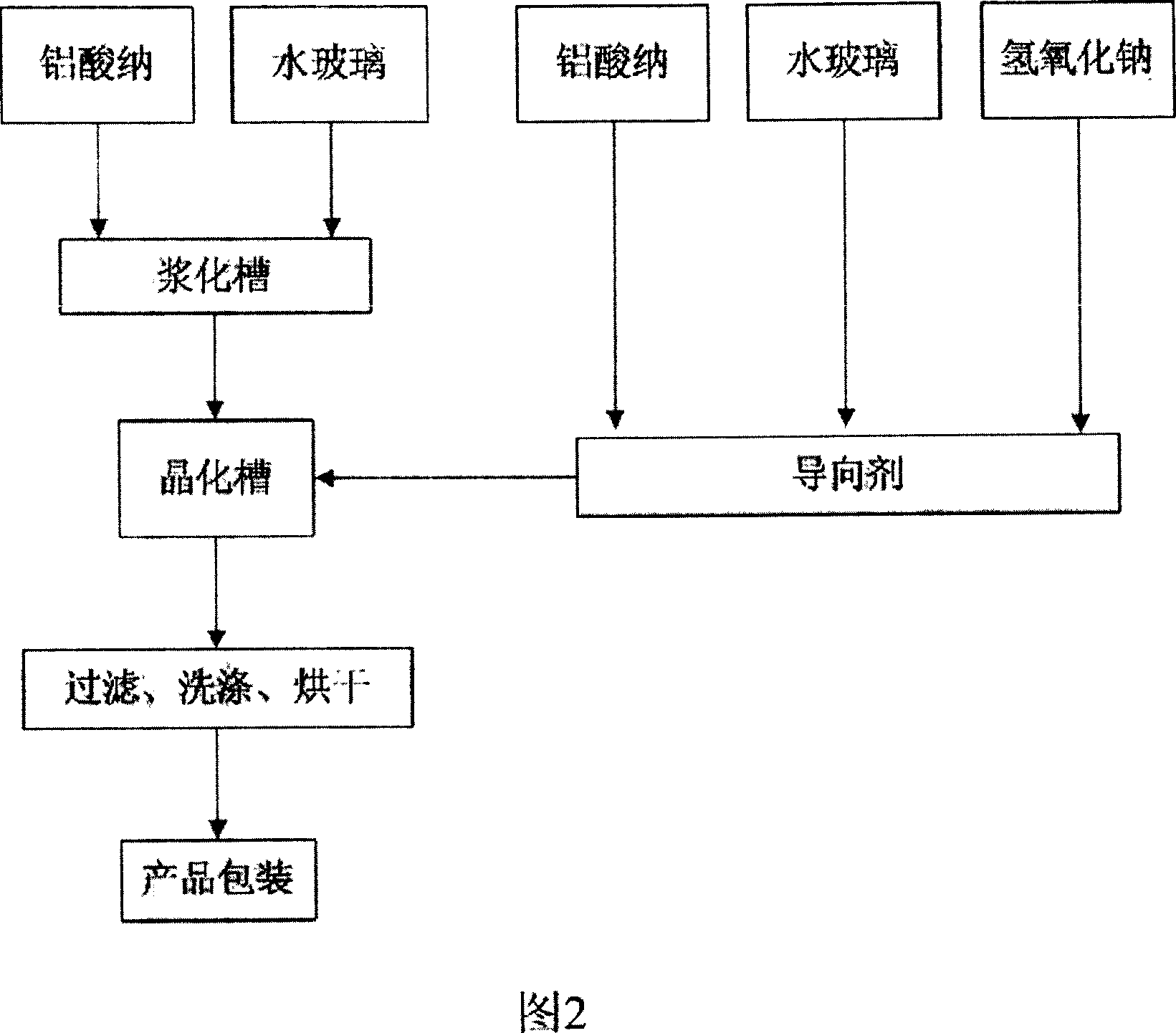

[0020] The directing agent is formulated with Al 2 o 3 Industrial sodium aluminate solution with a concentration of 40g / L, SiO 2 Water glass and sodium hydroxide with a concentration of 12% by weight are used for batching, and the silicon-aluminum ratio is controlled to be 10, and the sodium-aluminum ratio is 13, and the mixture is evenly mixed and ready for use.

[0021] A method for producing 4A zeolite for washing using sodium aluminate solution in the sintering alumina production process, in Al 2 o 3 Add SiO 2 Water glass with a concentration of 25% by weight, heat the two solutions to 53±1°C respectively, and then press the two solutions to [SiO 2 ] / [Al 2 o 3 ]=1.9 Under synchronous and continuous slurrying, the glue enters the slurrying tank, and then the pulped slurry is pumped into the empty crystallization tank while slurrying, and the stirring speed of the crystallization tank is 40 rpm. Stir for 10 minutes and add the directing agent in an amount of 1‰ of the...

Embodiment 3

[0025] The directing agent is formulated with Al 2 o 3 Industrial sodium aluminate solution with a concentration of 50g / L, SiO 2 Water glass and sodium hydroxide with a concentration of 20% by weight are used for batching, and the silicon-aluminum ratio is controlled to be 9, and the sodium-aluminum ratio is 12, and the mixture is evenly mixed and ready for use.

[0026] A method for producing 4A zeolite for washing using sodium aluminate solution in the sintering alumina production process, in Al 2 o 3 Add SiO 2 Water glass with a concentration of 20% by weight, heat the two solutions to 55±1°C respectively, and then press the two solutions to [SiO 2 ] / [Al 2 o 3 ]=1 Under synchronous continuous slurrying, the gel is formed and enters the slurrying tank, and then the pulped slurry is pumped into the empty crystallization tank while slurrying, and the stirring speed of the crystallization tank is 40 rpm. Stir for 30 minutes and add the directing agent, the amount added i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| crystallinity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com