Patents

Literature

90results about How to "Consistent particle size" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

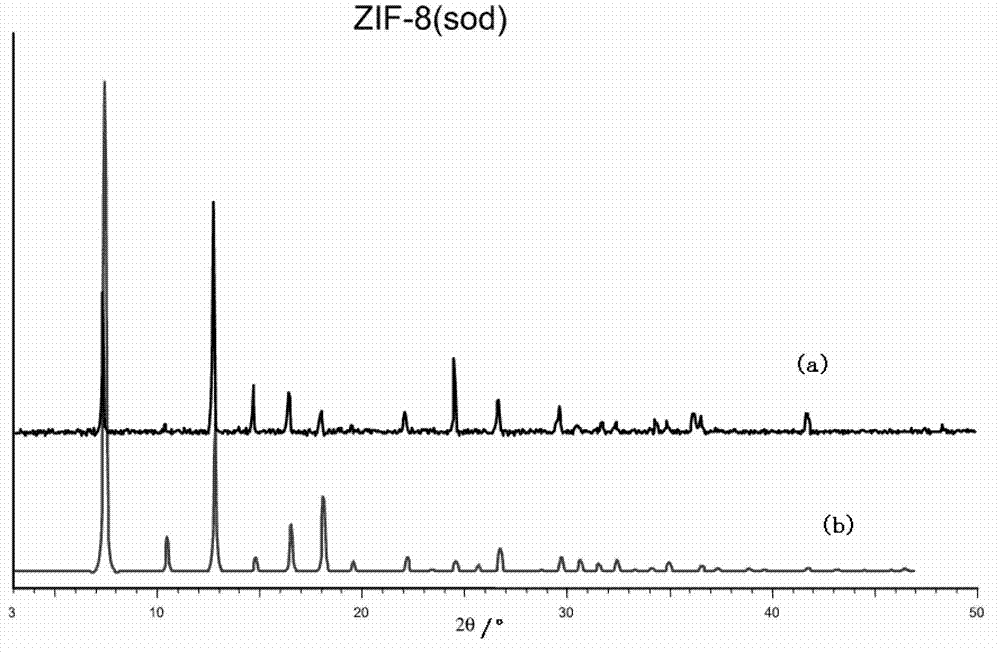

Large-scale adsorbing material ZIF-8 preparation method and forming method

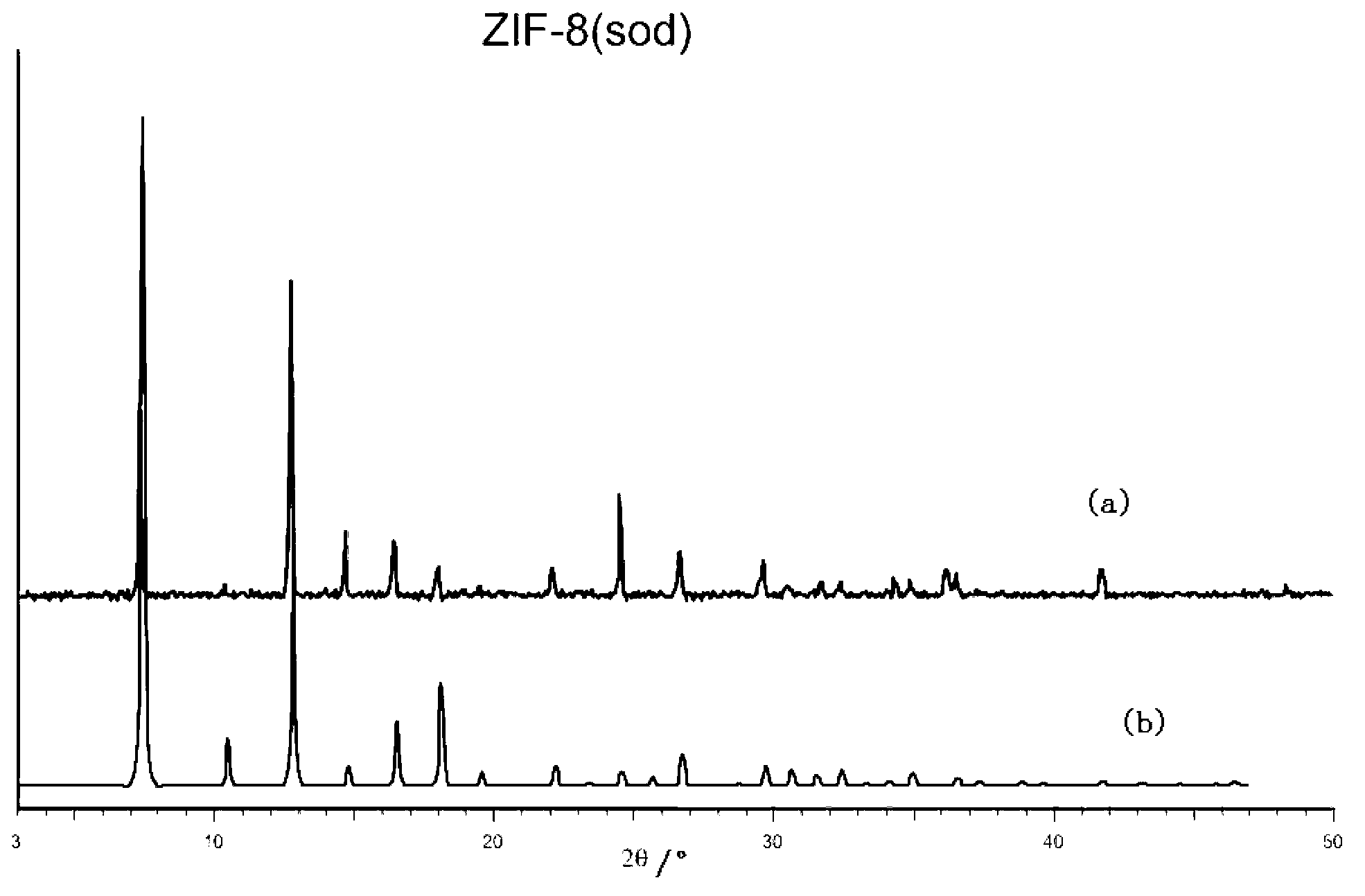

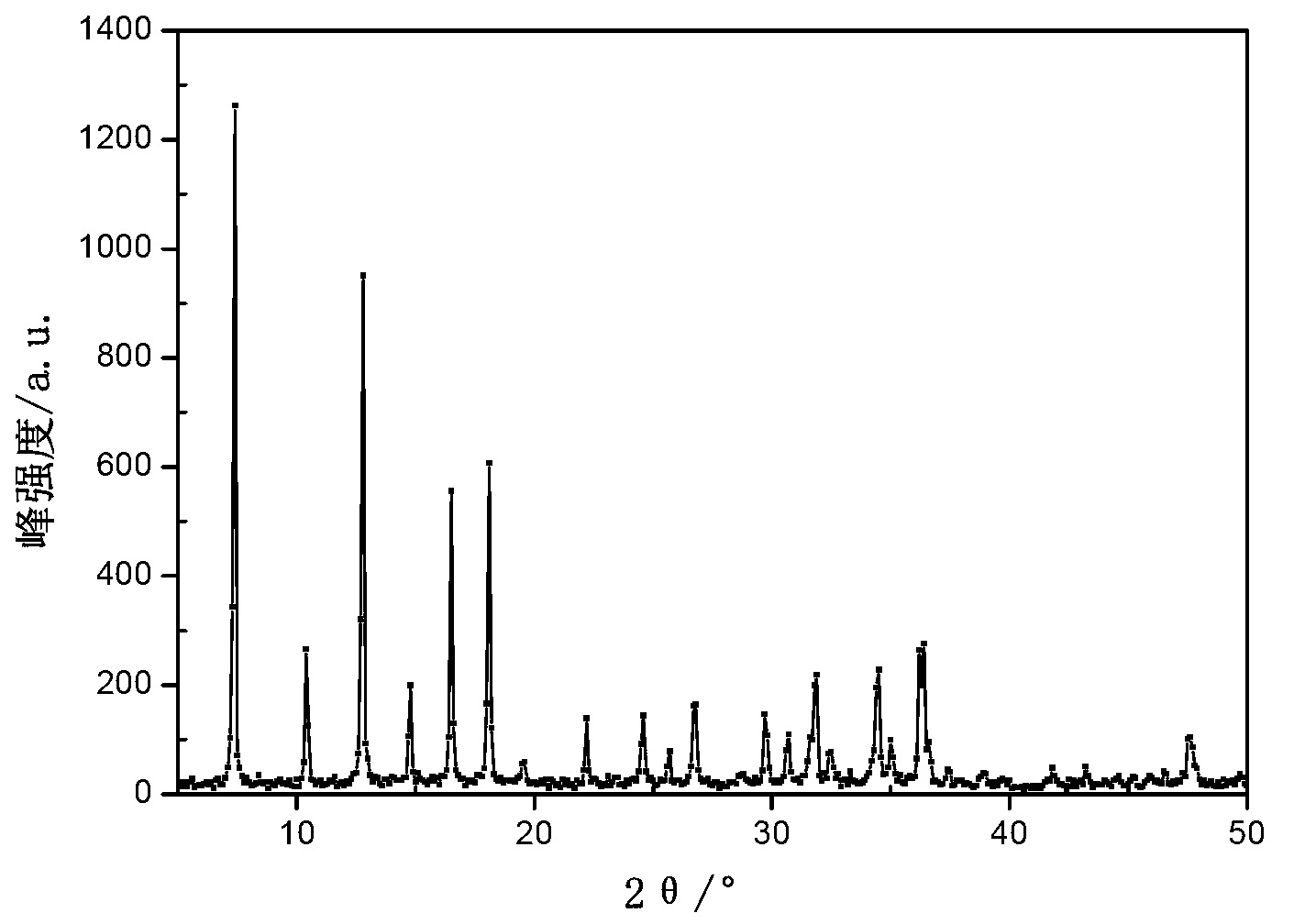

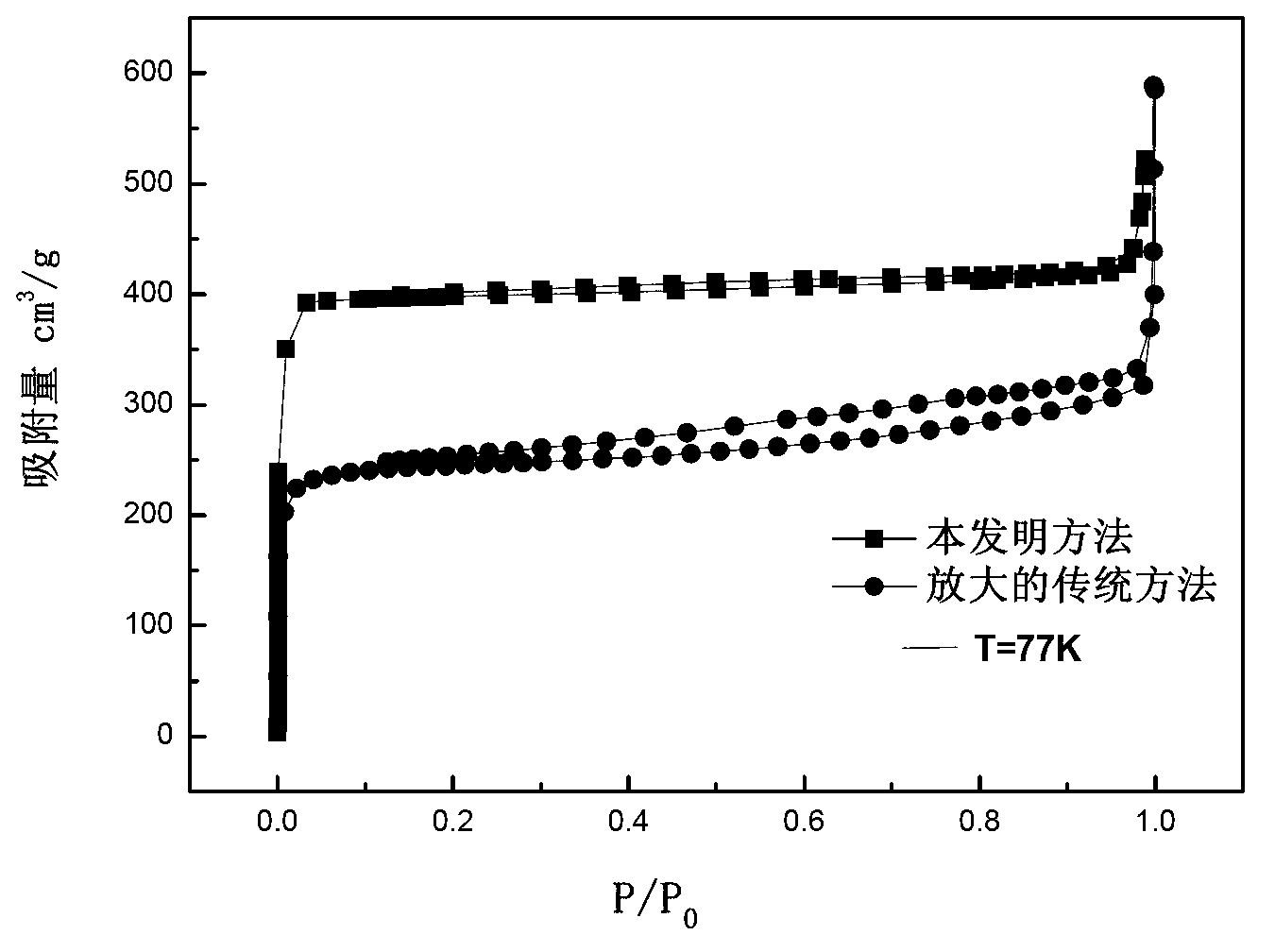

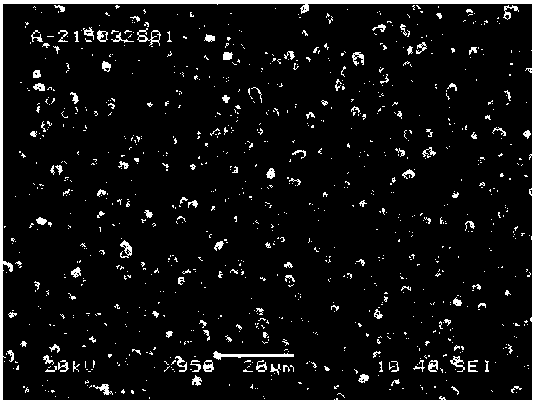

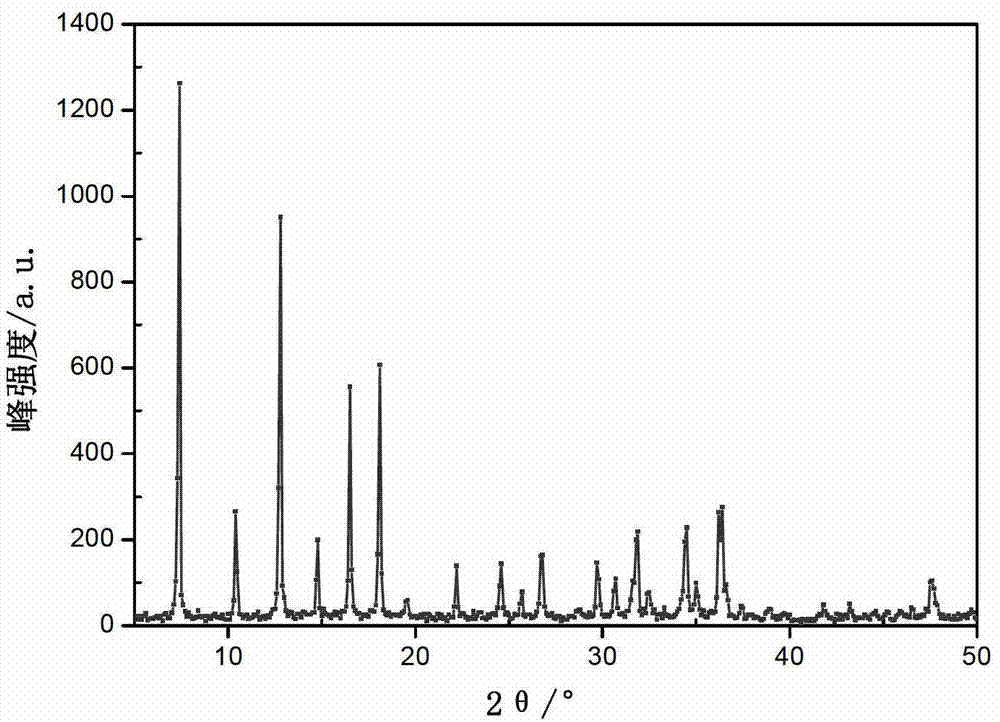

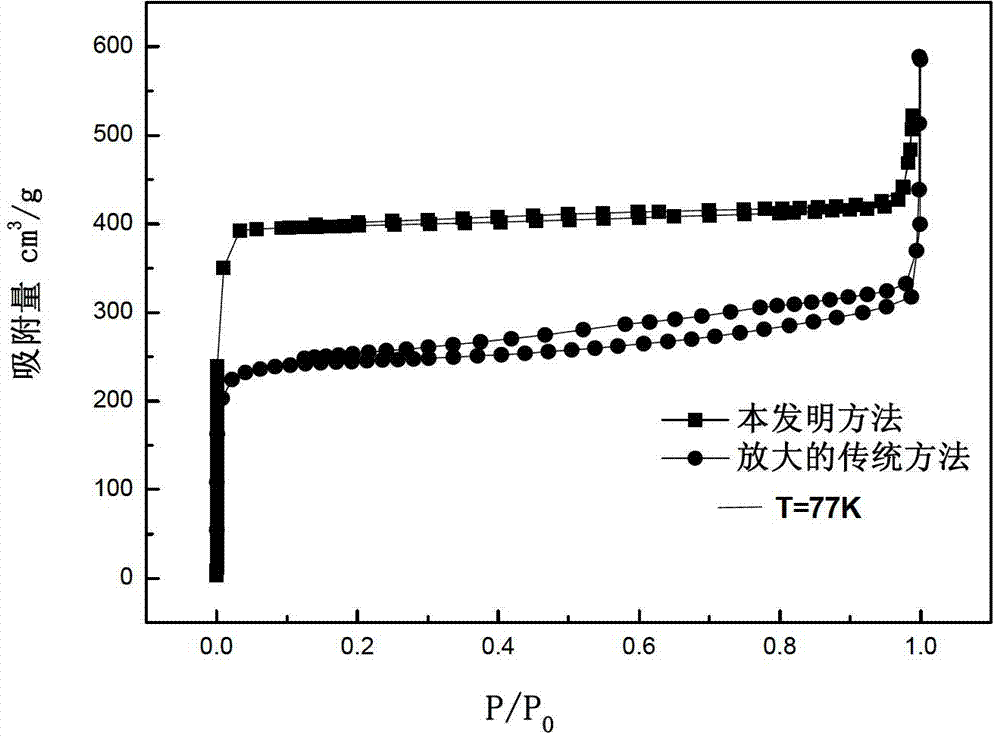

ActiveCN103230777AHigh crystallinityLarge specific surface areaOther chemical processesRoom temperatureCrystallization temperature

The invention discloses a large-scale adsorbing material ZIF-8 synthesizing and forming methods, and belongs to the technical field of adsorbing materials. The method comprises the steps of: pouring 70-75ml of dimethyl formamide (DMF) into a polytetrafluoroethylene liner with the volume of 100ml, and adding Zn(NO3)2.6H2O and 2-methylimidazole according to a molar ratio of 1:(2-4) to be fully dissolved; crystallizing under self-generated pressure; heating from a room temperature to a preset crystallization temperature through programs, and then preserving a constant temperature for a plurality of hours; cooling, filtering in vacuum and washing; weighing and putting ZIF-8 powder into a mortar, and adding an adhesion agent to be completely ground together; then adding a peptizing agent, and completely grinding the peptizing agent in the mortar until wet fine powder is formed; and tabletting the obtained wet fine powder through a tabletting machine so as to obtain a platy ZIF-8 mateiral. The ZIF-8 synthesized by the method has high crystallinity and good adsorption property.

Owner:BEIJING UNIV OF CHEM TECH

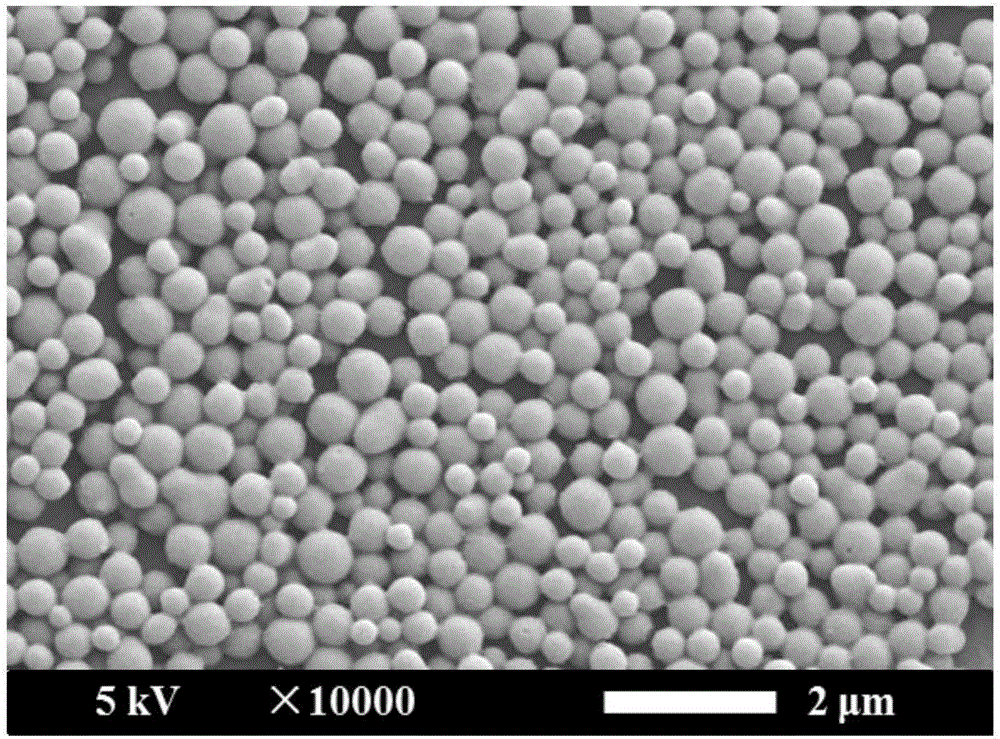

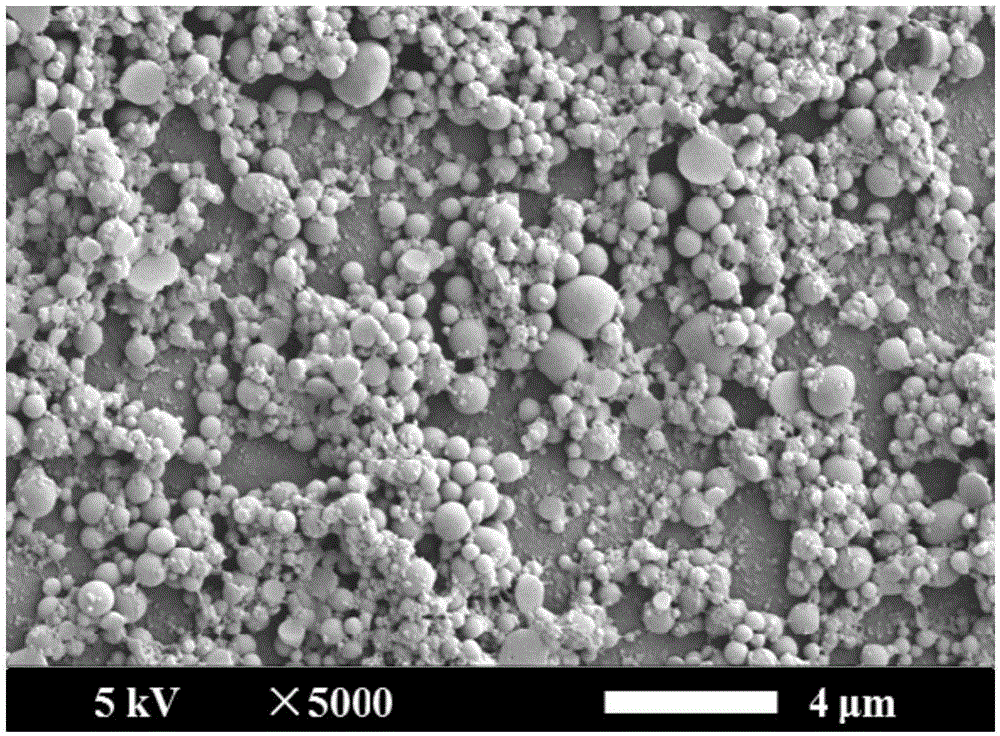

High-density and small-particle size nickel-cobalt-manganese hydroxide and preparation method thereof

InactiveCN107640792AHigh density and small tap densityLow tap densityCell electrodesSecondary cellsHigh densityManganese

The invention discloses a high-density and small-particle size nickel-cobalt-manganese hydroxide and a preparation method thereof. For the high-density and small-particle size nickel-cobalt-manganesehydroxide provided by the invention, a general chemical formula is NixCoyMnz(OH)2, wherein x+y+z=1, x is larger than or equal to 0.3 and smaller than or equal to 0.8, y is larger than or equal to 0.1and smaller than or equal to 0.4, and z is larger than or equal to 0.1 and smaller than or equal to 0.4; the particle sizes are d10 larger than or equal to 2 microns, d50 equal to 2.5-4 microns and d90 smaller than or equal to 6 microns, the tap density is larger than or equal to 1.4g / cm<3>, the specific surface area is 5-20m<2> / g, and the shape is spherical or spheroidal. The invention also discloses the preparation method of the high-density and small-particle size nickel-cobalt-manganese hydroxide. The preparation method is strong in controllability, can stably control the particle sizes ineach production batch without using a surfactant and is low in production cost, high in efficiency and good in physicochemical index of a final product.

Owner:ZHUJI PAWA NEW ENERGY

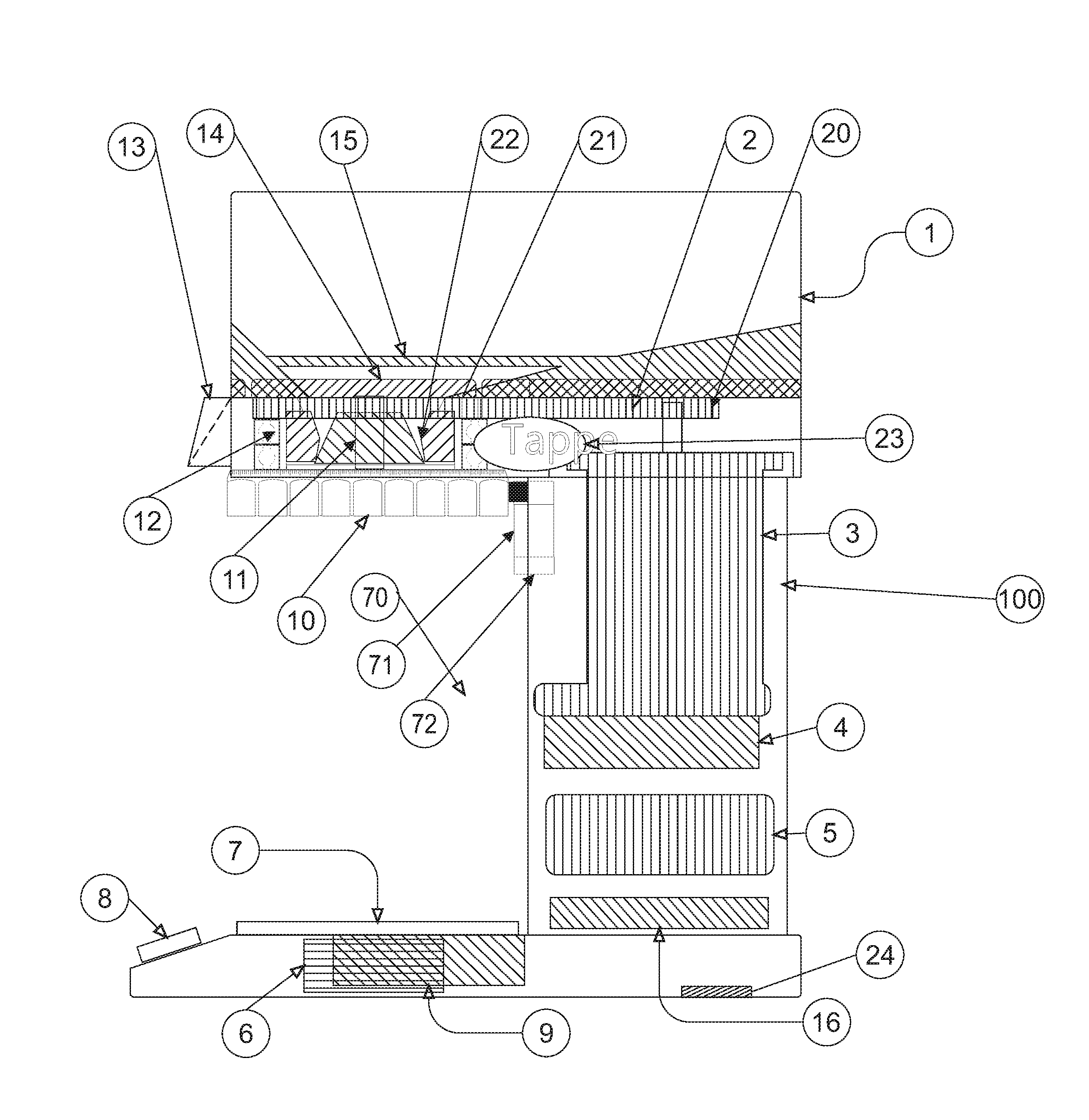

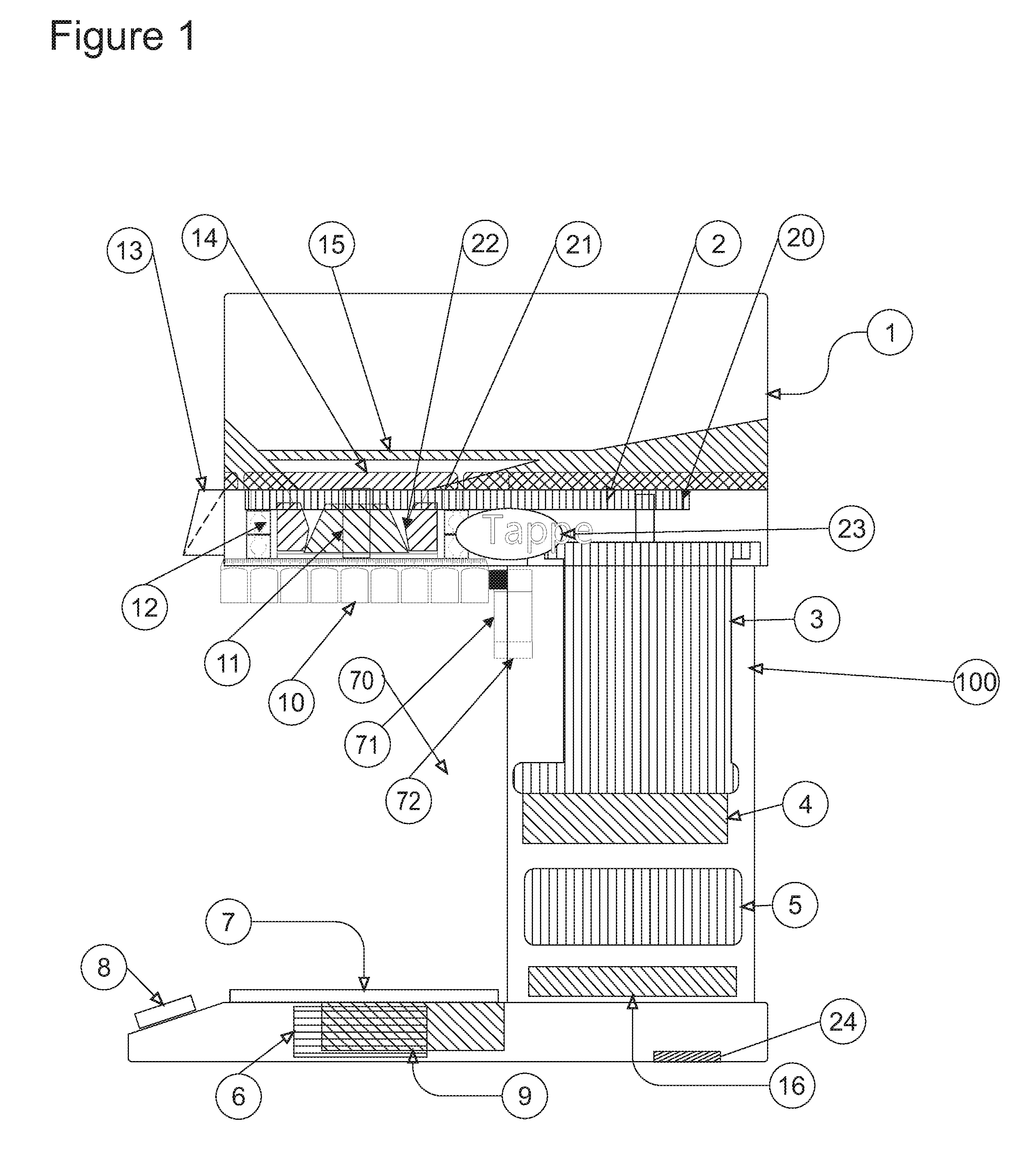

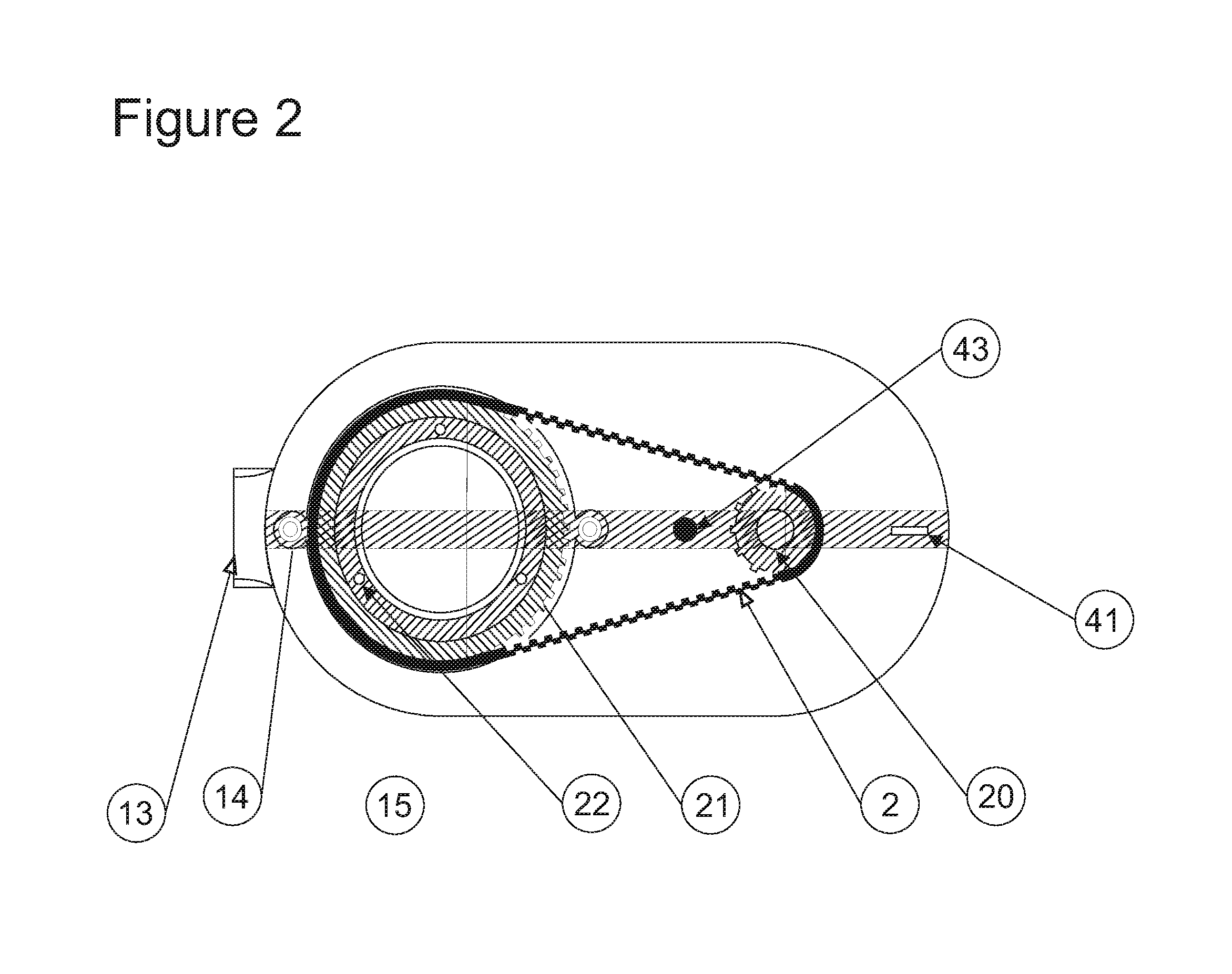

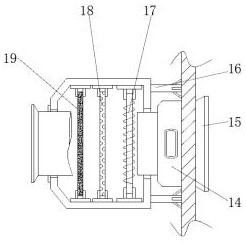

Variable Speed Coffee Grinder

InactiveUS20160220067A1Increase speedConsistent particle sizeCoffee millsSpice millsProduction rateUser input

The present invention is an improved method to grind coffee where grinding speed can be adjusted either on demand or according to a programmed profile. By lowering the rotational speed of the grinding burrs, the user can insure more consistent particle size for types of coffee or methods of brewing where it is desirable, or dramatically increase speed for greater productivity. By incorporating a load cell, the grinder is able to identify coffee brewing device and deliver portioned ground coffee according to program settings or user input. The device also features an improved hopper design to reduce waste and ease whole bean removal. More importantly is a new method to calibrate the distance between the grinder mills and to automatically adjust grinder particle size so that a given numerical value is consistent for each grinder and every user.

Owner:TEAHAN MICHAEL

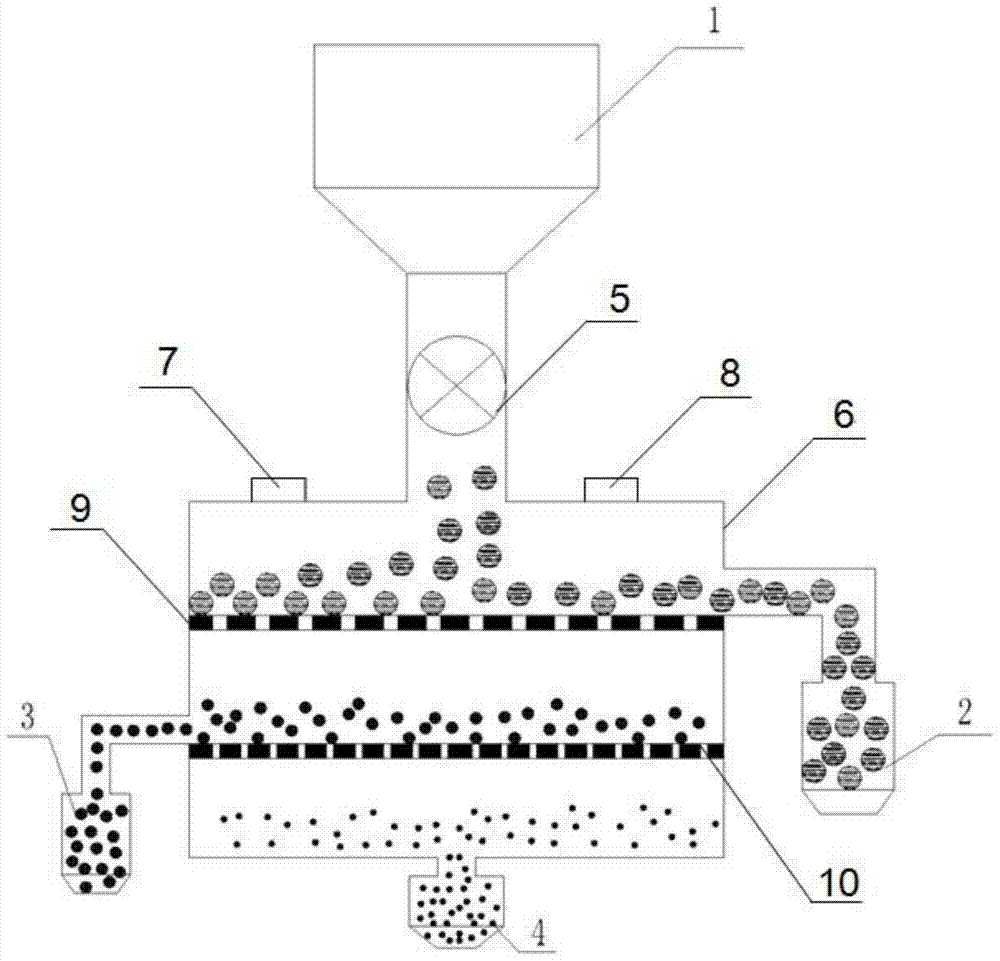

Method for preparing titanium alloy spherical powder at all levels

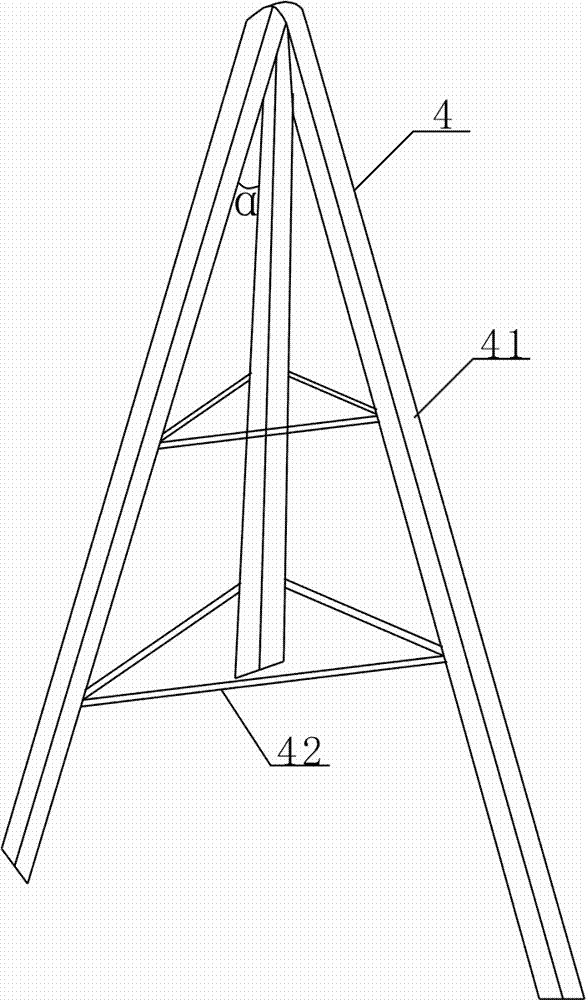

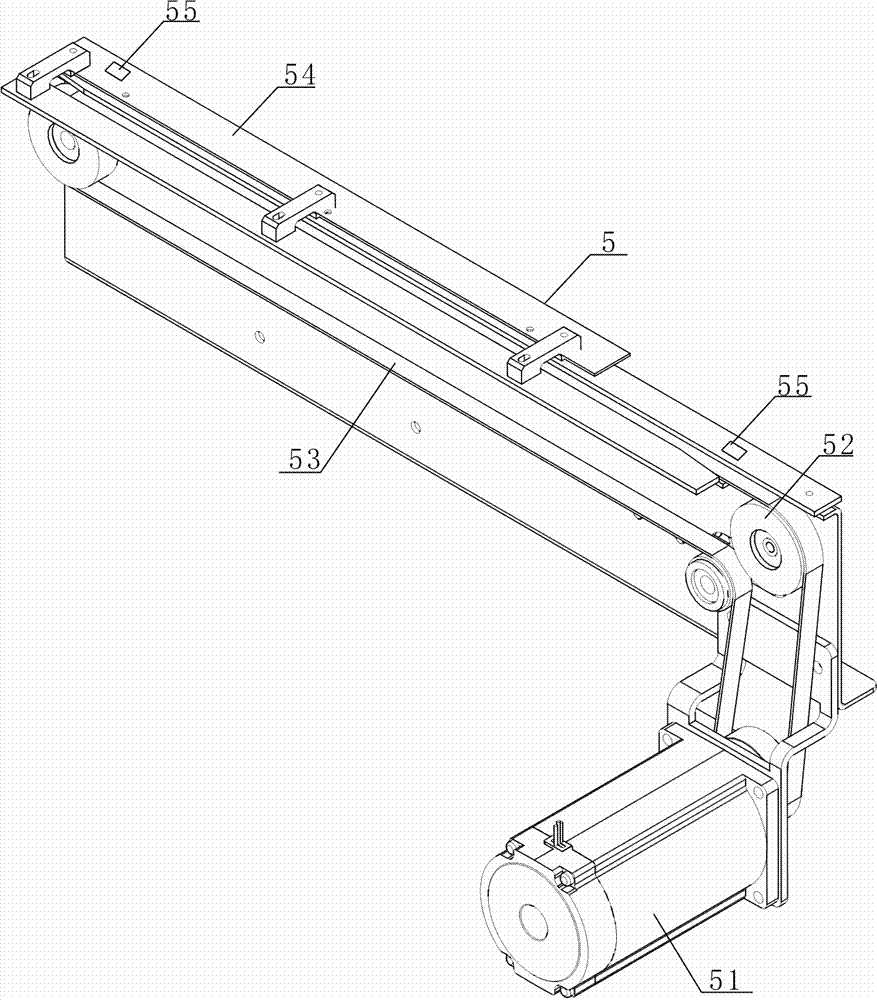

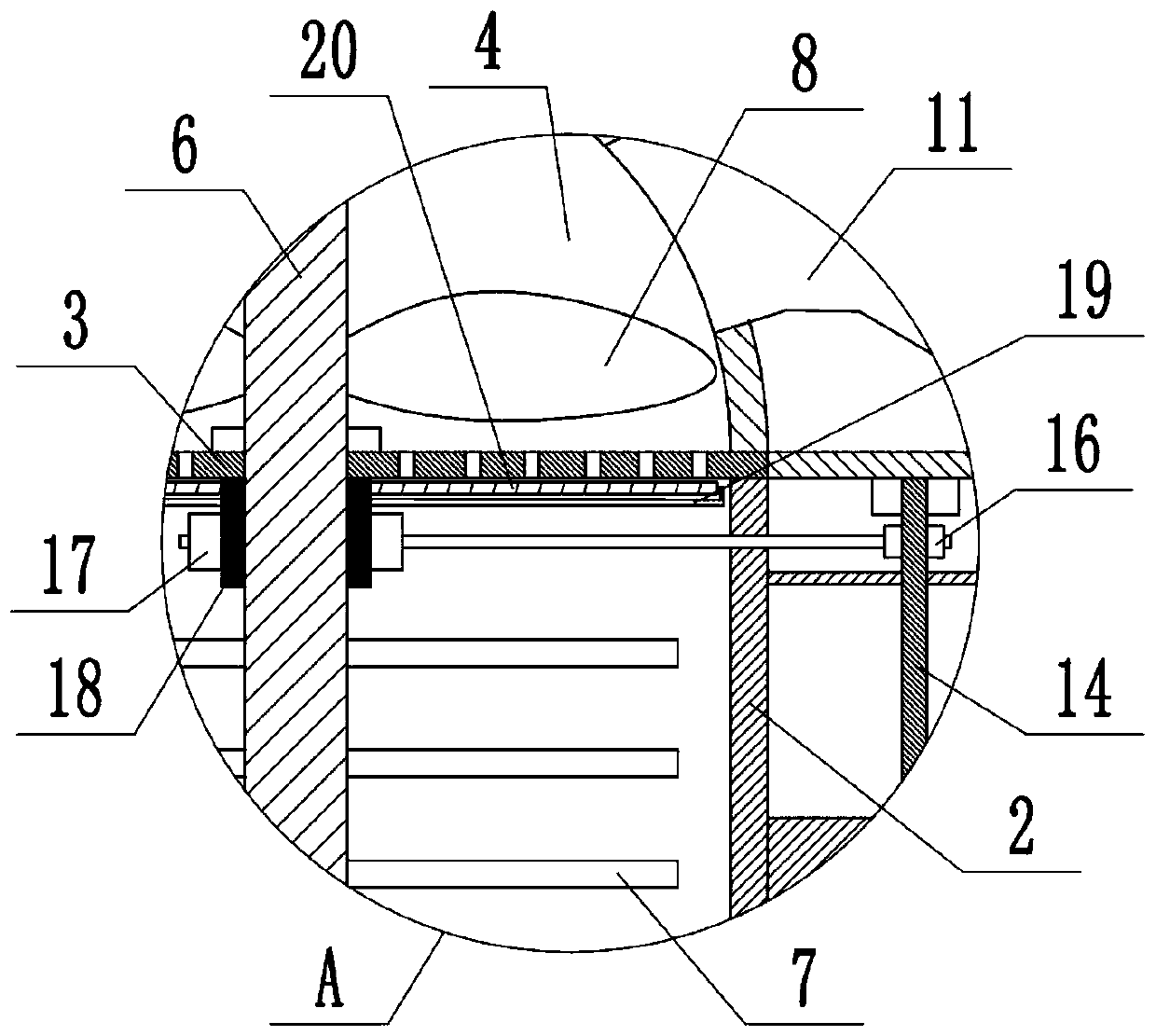

The invention provides a method for preparing titanium alloy spherical powder at all levels. The method comprises the steps that cylinder electrode bars are made of titanium alloy; the cylinder electrode bars are made into powder through a plasma rotating electrode powder manufacturing device, low-temperature argon is blown into a vacuum furnace in the process of condensation and flying of the powder, the powder is cooled rapidly and solidified so that the temperature of the powder can be lowered to the room temperature rapidly, and therefore titanium alloy powder is obtained; the titanium alloy powder is screened through a powder screening device, and then the all levels of titanium alloy spherical powder with the granularity ranging from 40 micrometers to 200 micrometers can be obtained. According to the method for preparing the titanium alloy spherical powder at all levels, the powder is prepared through the plasma rotating electrode powder manufacturing device, and the low-temperature argon is blown into the powder in the process of condensation and flying of the powder so that the powder can be cooled rapidly and solidified and the temperature of the powder can be lowered to the room temperature; as a result, the titanium alloy spherical powder which is identical in particular size, good in sphericity degree, smooth in surface, free of cracks and good in mobility is obtained; in the process of screening, inert gas shielding is adopted, the content of impurity elements including O, H and N in the titanium alloy spherical powder is smaller than 1000 ppm, as a result, the ductility of a powder sintered metal product is effectively improved, and the compression performance and the sintering character of the powder are improved.

Owner:SINO EURO MATERIALS TECH OF XIAN CO LTD

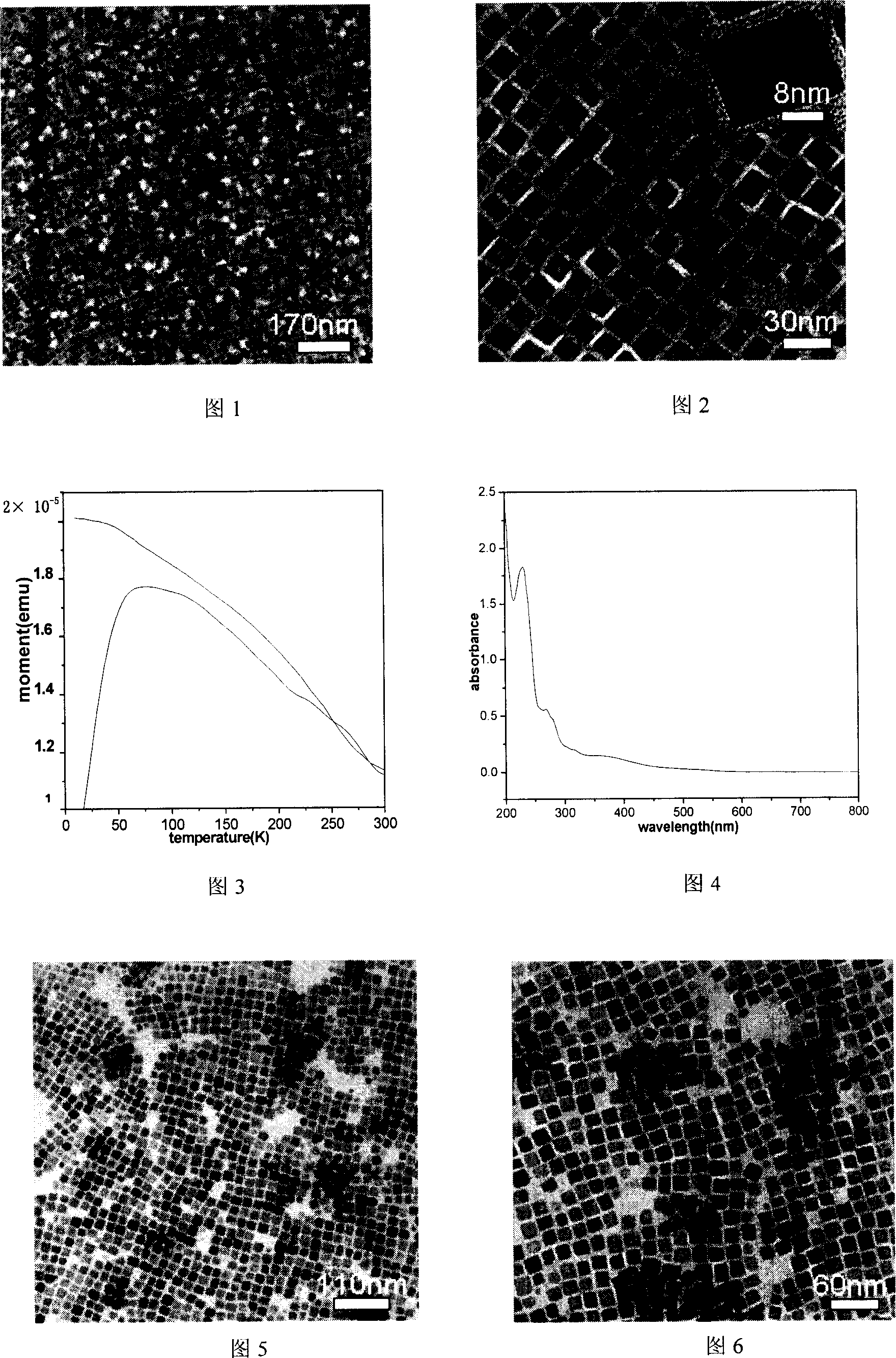

Method for preparing Nano cube of hematite

InactiveCN101003388AUniform particle sizeUniform shapeFerric oxidesMagnetic storageSuperparamagnetism

This invention discloses a method for preparing hematite nanocubes. The method comprises: (1) adding soluble inorganic ferric salt 0.8-2.4 mmol, potassium oleate or sodium oleate 2-4 mol times of ferric ions, ethanol 4-10 mL and oleic acid 1-5 mL into water 16 mL, stirring to uniformly demix, and placing in a sealed container; (2) standing at 160-220 deg.C for more than 8 h; (3) centrifuging to separate the solid precipitate, washing with ethanol, drying, and dispersing in alkane solvent; (4) centrifuging to separate the solid precipitate, adding ethanol into the obtained red alkane colloidal solution to precipitate aggregates of hematite nanocubes with average side length of 14-17 nm. The method has such advantages as easy operation, easy control, mild conditions and no pollution. The obtained hematite nanocubes have good monodispersity, uniform particle sizes, and regular and uniform morphology. The hematite nanocubes exhibit superparamagnetism at normal temperature, and can be used in magnetic storage and medical fields.

Owner:UNIV OF SCI & TECH OF CHINA

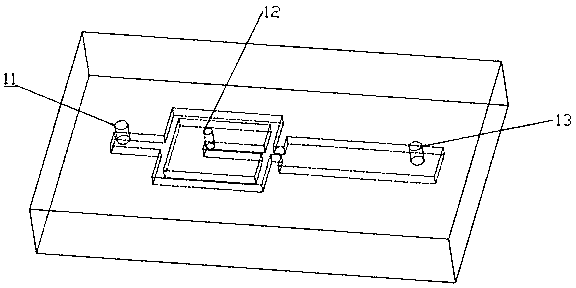

Method for generating micro-droplet by vibrating pipeline to control micro-fluidic chip

InactiveCN110052298AControl build sizeSmall sizeLaboratory glasswaresFluid controllersWave shapeGas phase

The invention discloses a method for generating a micro-droplet by vibrating a pipeline to control a micro-fluidic chip. The method comprises the following steps: selecting a certain type of the micro-fluidic chip, under a certain continuous phase flow point, adjusting flow of dispersion phase fluid, and enabling the flow thereof to be exactly weaker than critical flow in which droplets are continuously generated; applying one time of impact vibration with precision-adjustable amplitude and pulse number to a non-gas-phase fluid pipeline in upstream dispersion phase or continuous phase of a two-phase fluid inlet of the micro-fluidic chip through an electromagnetic vibrator; controlling a size of the micro-droplet generated in the micro-fluidic chip through the amplitude of the above impactvibration; and controlling the micro-fluidic chip to generate the single micro-droplet through a single impact wave-shaped pulse in the impact vibration; thereby generating the single or arbitrary number of the micro-droplets. The method is capable of actively controlling a generating size and frequency of the micro-droplet, and greatly improving production efficiency of the droplet.

Owner:CHINA JILIANG UNIV

Preparation method of spherical nickel hydroxid

InactiveCN101062792AConsistent particle sizeOvercoming the "Consistency Deficiency" ProblemNickel oxides/hydroxidesCollection periodNickel oxide hydroxide

The invention discloses a preparing method of sphere nickel hydroxide, which comprises the following steps: adding nickel ion with density at 1. 7 -2. 2mol / L, ammonial solution with density at 7-10mol / L, alkali metal hydroxide solution with density at 6-8mol / L into reactor; making the reaction pass two steps of nucleation period and growing period through controlling flow-ratio and time; controlling the feed, reaction and collection period for 22-24 h; aging the half-finished product; washing; drying; getting the product. This invention possesses simple craft and even grain size distribution, which resolves the problem of 'consistency defect'.

Owner:HUNAN CORUN NEW ENERGY CO LTD

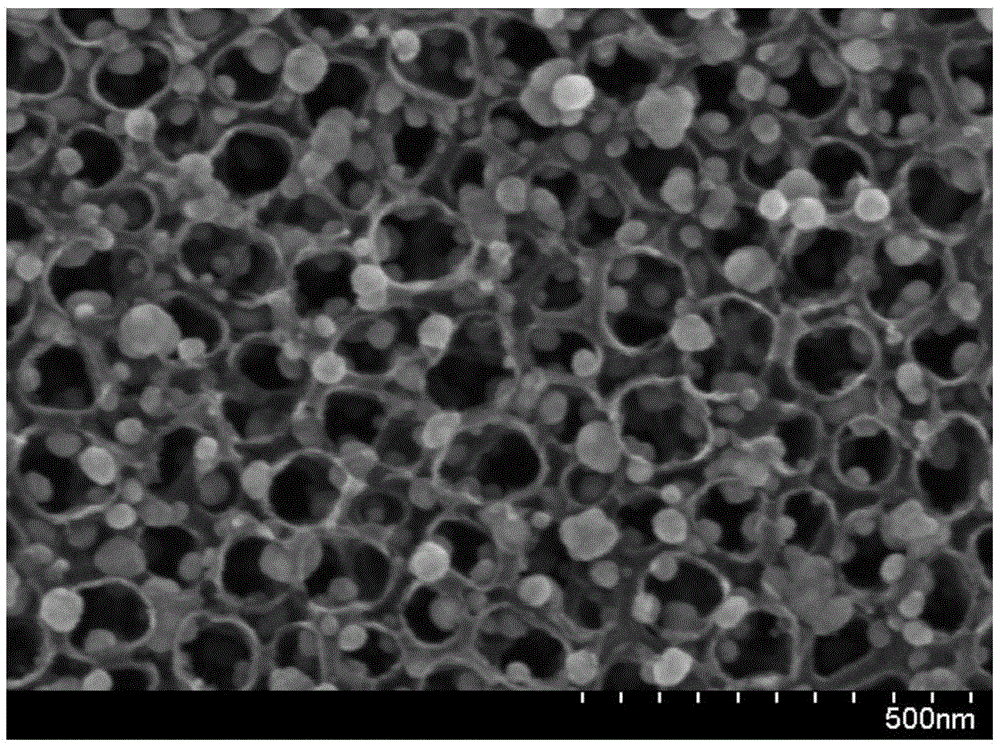

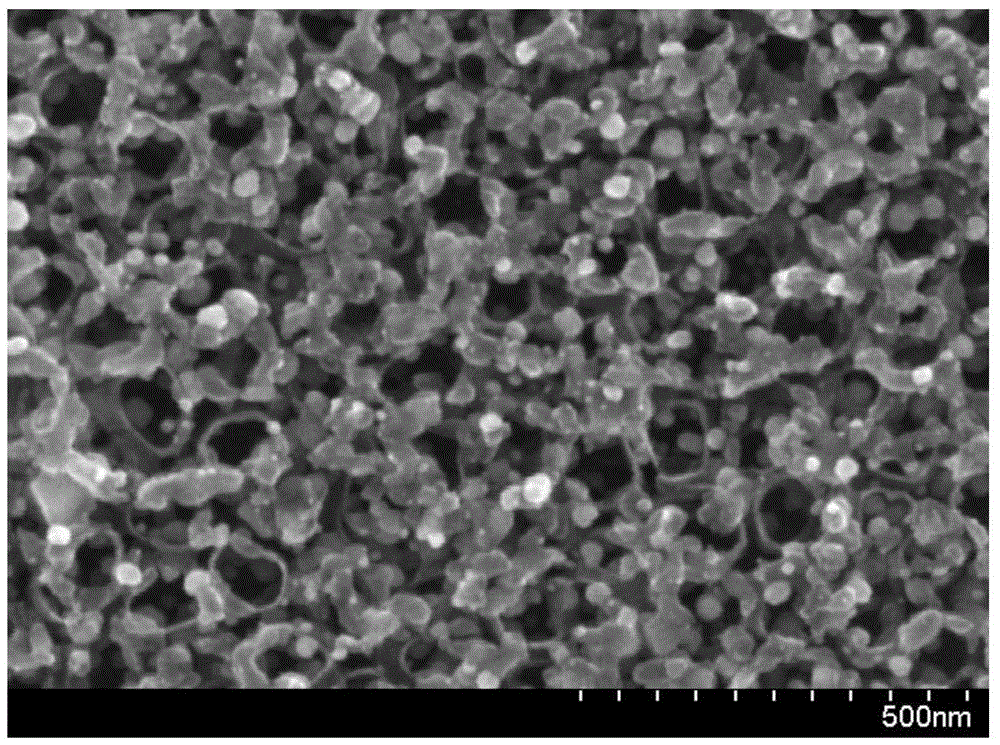

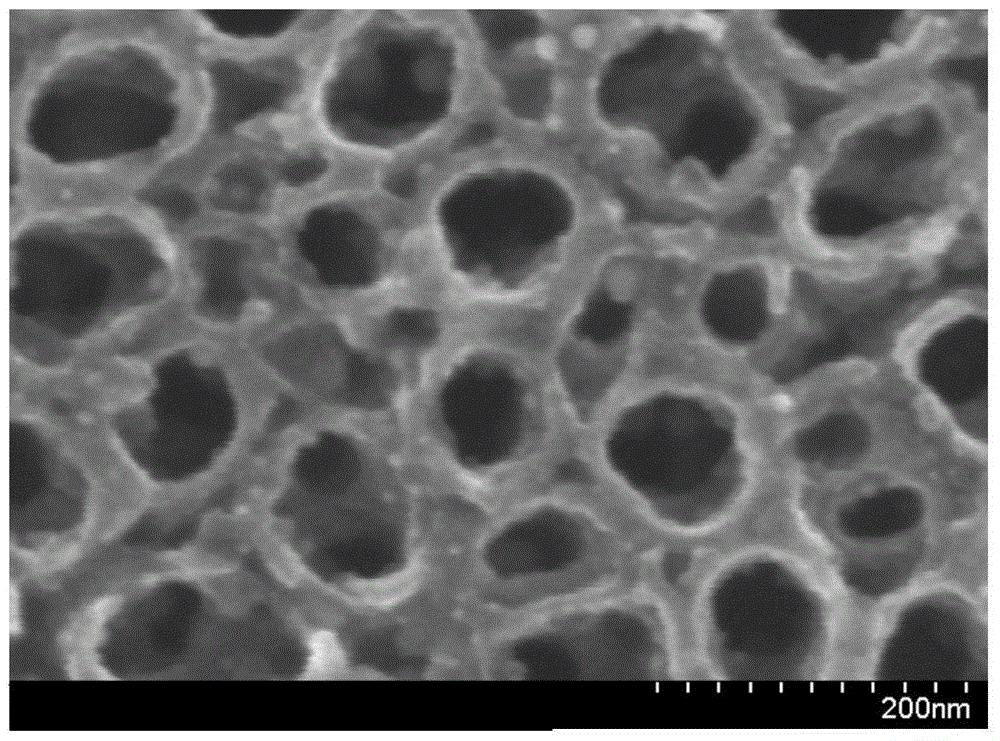

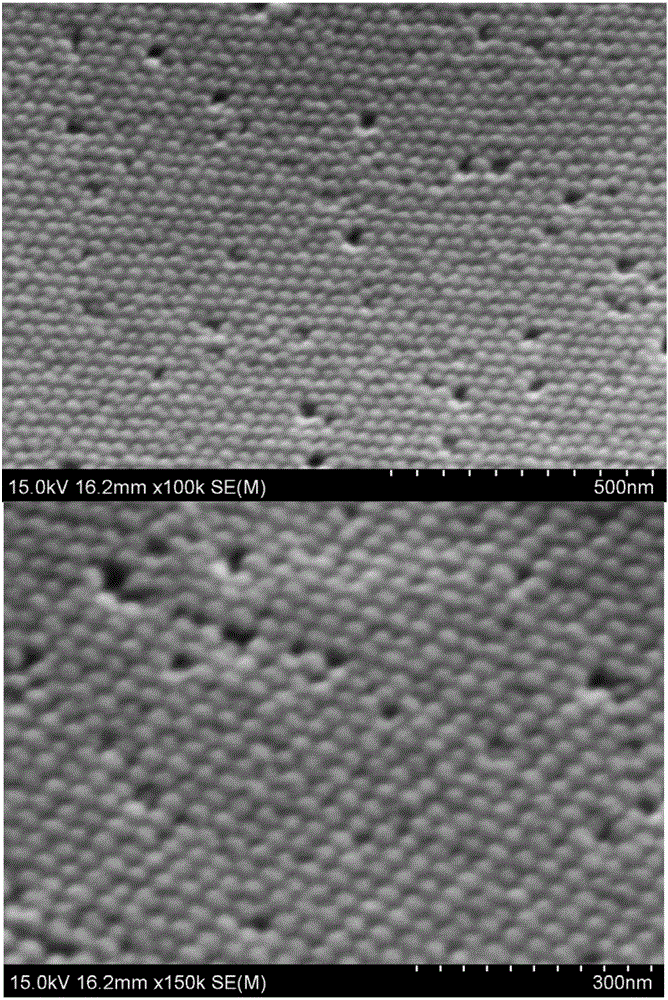

Method for preparing nontoxic antibacterial coating on surface of medical implant material

ActiveCN105617460ADoes not affect antibacterial propertiesImprove surface structurePharmaceutical delivery mechanismCoatingsAntibacterial propertyRegenerative medicine

The invention discloses a method for preparing a nontoxic antibacterial coating on the surface of a medical implant material and relates to a medical implant material. The invention provides the method for preparing the nontoxic antibacterial coating on the surface of the medical implant material, wherein the cytotoxicity of a silver composite membrane layer on the surface of an implant material can be remarkably reduced while excellent antibacterial property is maintained, and the method is mainly applied to the antibacterial modification of the implant surface in bone and tooth replacement and tissue regenerative medicine. The method comprises the following steps: pretreating the to-be-treated medical implant material; preparing a solution containing AgNO3, short peptide and electrolyte or reductive substance; and building a nano silver / short peptide composite membrane layer on the surface of the medical implant material. The cytotoxicity of the nano silver membrane layer on the surface of the implant material can be remarkably reduced while excellent antibacterial property is maintained. The method can be applied to the nontoxic antibacterial modification of the surfaces of multiple implants. The method is simple in technology, requires small investment and can be widely applied to the surface modification of medical implants while large-scale production can be realized.

Owner:XIAMEN UNIV

Preparation method of gamma-Fe2O3/ZnFe2O4 magnetic composite nano particle

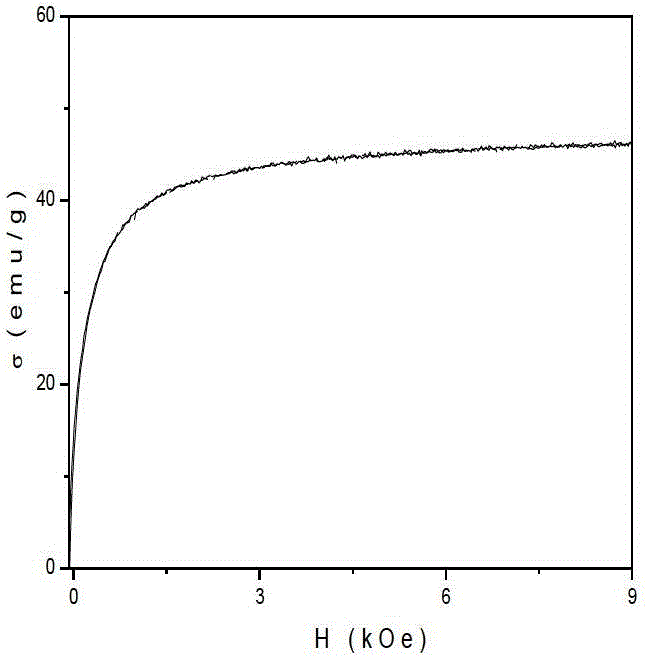

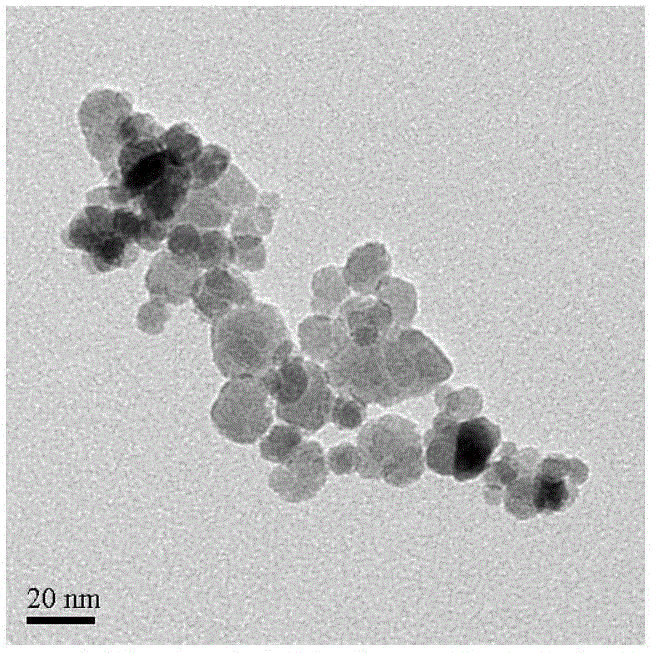

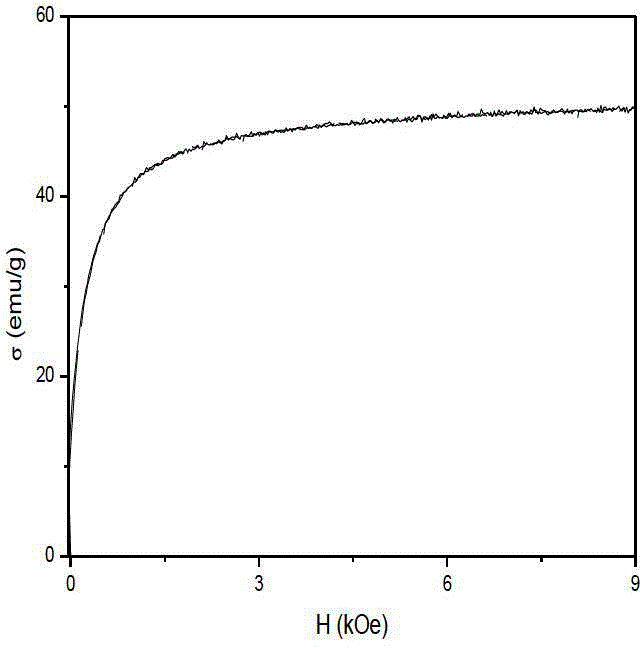

InactiveCN102910682ALow costUnique formation mechanismMaterial nanotechnologyNanomagnetismSurface layerMicroparticle

The invention provides a preparation method of gamma-Fe2O3 / ZnFe2O4 magnetic composite nano particle with a core-shell structure. The method comprises the steps that firstly hydroxide precursor is prepared, and the hydroxide precursor is treated through FeCl2 solution to form gamma-Fe2O3 matrix particle; then ZnCl2 is added to perform surface modulation, and a ZnFe2O4 surface layer is formed on gamma-Fe2O3 matrix; and finally gamma-Fe2O3 / ZnFe2O4 magnetic composite nano particle powder is obtained after acetone dehydration and vacuum drying. The method has the advantages that the formation mechanism is unique, the cost of raw material is low, the condition is mild, the energy consumption is low, and the preparation process is easy to operate.

Owner:SOUTHWEST UNIV

Large-scale adsorbing material ZIF-8 preparation method and forming method

ActiveCN103230777BHigh crystallinityLarge specific surface areaOther chemical processesPhysical chemistryCrystallization temperature

The invention discloses a large-scale adsorbing material ZIF-8 synthesizing and forming methods, and belongs to the technical field of adsorbing materials. The method comprises the steps of: pouring 70-75ml of dimethyl formamide (DMF) into a polytetrafluoroethylene liner with the volume of 100ml, and adding Zn(NO3)2.6H2O and 2-methylimidazole according to a molar ratio of 1:(2-4) to be fully dissolved; crystallizing under self-generated pressure; heating from a room temperature to a preset crystallization temperature through programs, and then preserving a constant temperature for a plurality of hours; cooling, filtering in vacuum and washing; weighing and putting ZIF-8 powder into a mortar, and adding an adhesion agent to be completely ground together; then adding a peptizing agent, and completely grinding the peptizing agent in the mortar until wet fine powder is formed; and tabletting the obtained wet fine powder through a tabletting machine so as to obtain a platy ZIF-8 mateiral. The ZIF-8 synthesized by the method has high crystallinity and good adsorption property.

Owner:山西润金茂环保科技有限公司

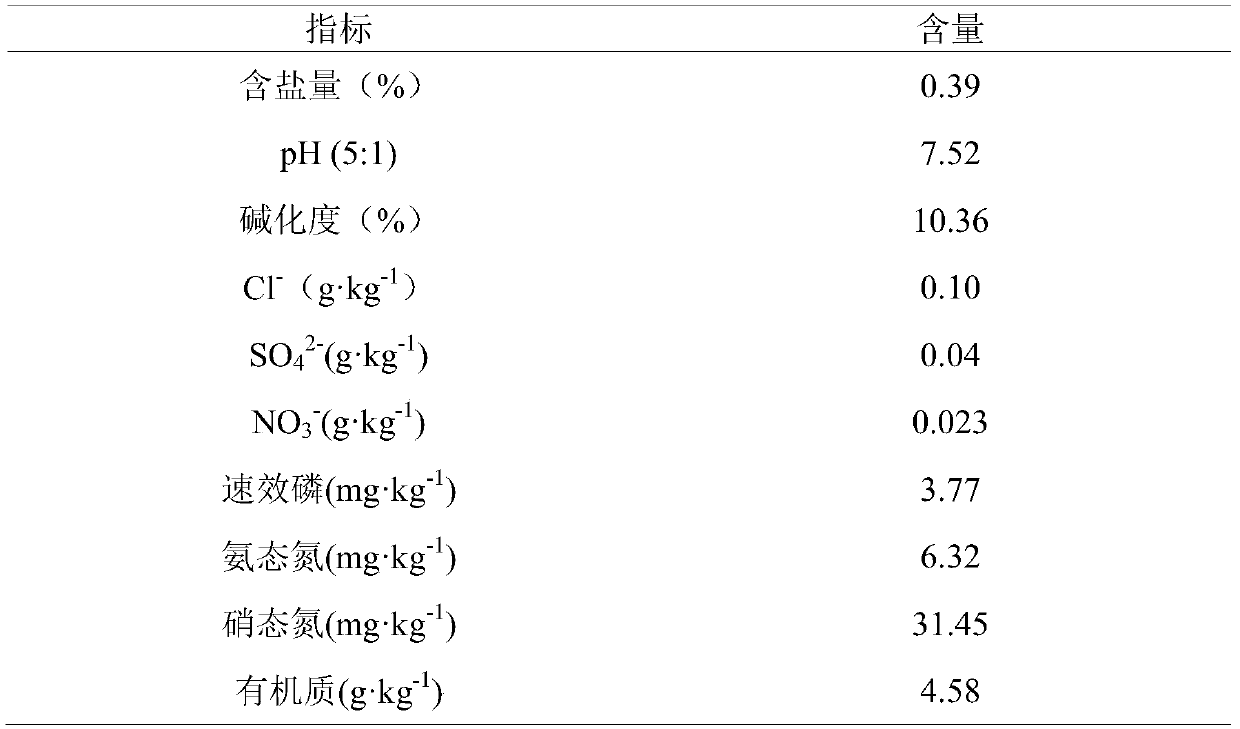

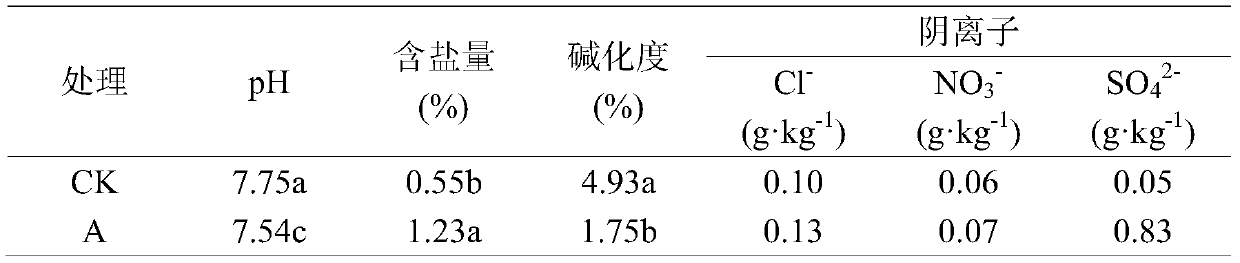

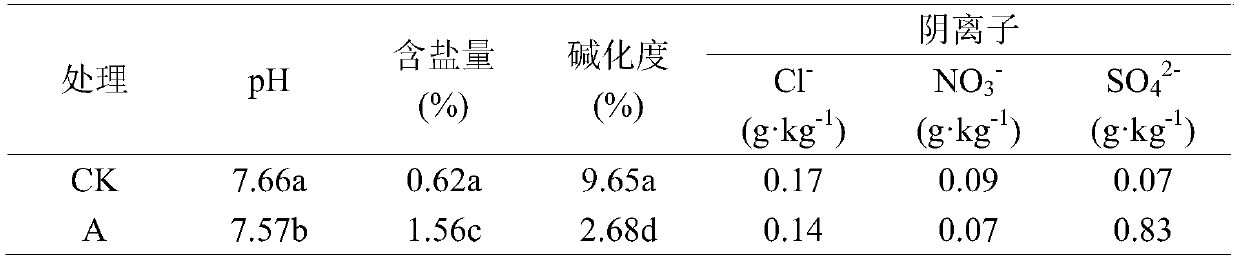

Preparation method and application method of saline-alkali soil improver

InactiveCN110437844AHarm reductionRegulate pHOther chemical processesOrganic fertilisersSoil aggregateAlkali soil

The invention relates to a preparation method and an application method of a saline-alkali soil improver, and belongs to the field of soil conditioners, wherein the saline-alkali soil improver comprises, by mass, 84-88% of modified desulfurization gypsum, 10.8-15% of ammoniated humic acid, and 0.8-1.2% of anion linear polyacrylamide with a molecular weight of 1000000-2000000. According to the present invention, by combining modified desulfurization gypsum, ammoniated humic acid and anion linear polyacrylamide, the product has characteristics of complementary function, economy and applicability, can improve the soil aggregate structure, increase the organic matters in soil, enhance the stress tolerance, the salt return and the external stress buffer ability of soil, increase the fertility of soil and promote the growth of crops, has low cost, is an environmentally friendly material, can ensure the quality of improved saline-alkali soil and promote the growth of crops, cannot cause secondary pollution to soil, and has low price.

Owner:SHENZHEN TECHAND ECOLOGY & ENVIRONMENT CO LTD +2

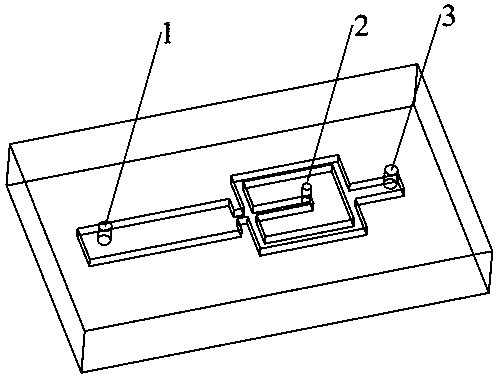

Method for generating micro-droplets by controlling flow focusing type microfluidic chip through vibration pipeline

InactiveCN108499500ASmall sizeControl frequencyBurettes/pipettesChemical/physical/physico-chemical processesControl flowMechanical vibration

The invention discloses a method for generating micro-droplets by controlling a flow focusing type microfluidic chip through a vibration pipeline. According to the method disclosed by the invention, in a system for generating the micro-droplets through the flow focusing type microfluidic chip, mechanical vibration with controllable amplitude and frequency is applied to a dispersion-phase fluid pipeline of the outer part of the chip through a mechanical vibrator, and the generation of the micro-droplets in the flow focusing type microfluidic chip is controlled. According to the method disclosedby the invention, the amplitude and frequency of the mechanical vibrator of the outer part are controlled to realize the aims of generating the micro-droplets with different sizes, controlling the generation frequency of the droplets and also improving the generation frequency of the micro-droplets.

Owner:CHINA JILIANG UNIV

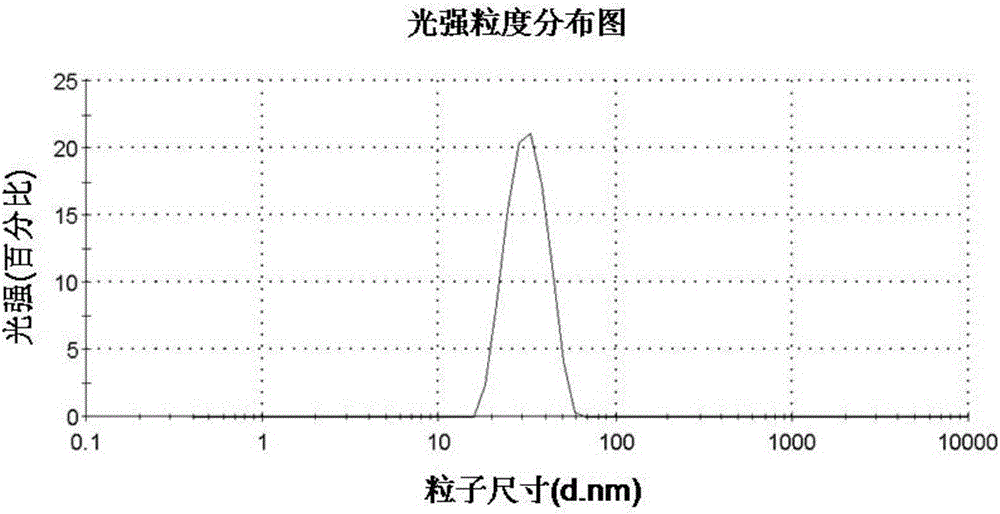

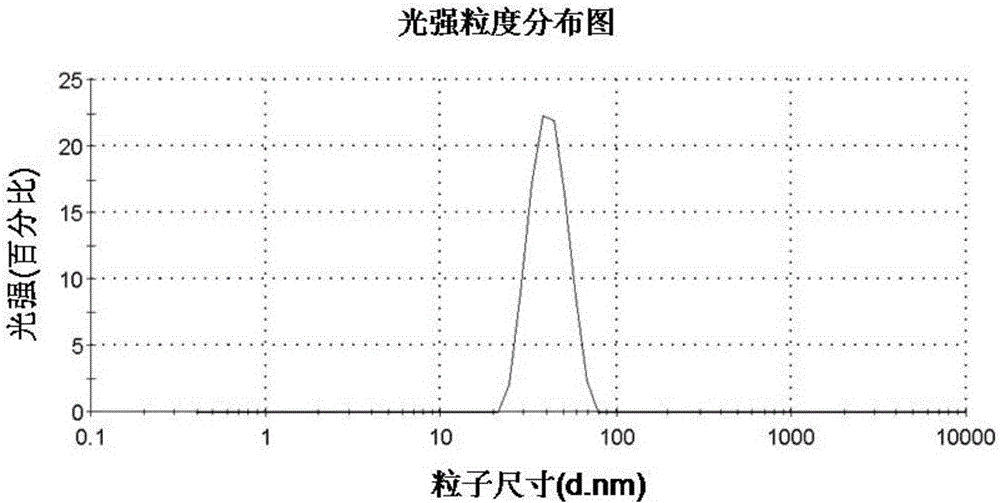

Method for preparing monodisperse large-particle-diameter silica sol through organic-inorganic complex catalysis

The invention relates to a method for preparing monodisperse large-particle-diameter silica sol through organic-inorganic complex catalysis. The method includes the following steps that 1, silica powder is added into an inorganic alkali solution, the mass ratio of the silica powder to water is controlled to be 1:8-15, and a reaction is conducted to obtain a silica sol mother solution with the pH of 9.5-10.5; 2, an organic alkali solution is added into the silica sol mother solution, a reaction is conducted at 70-90 DEG C to increase the particle diameter, and the system pH value in the reaction process is controlled to be 9.5-10.5; 3, after the reaction is finished, unreacted solid impurities in reaction liquid are removed, the product is concentrated to needed concentration, and then the monodisperse large-particle-diameter silica sol is obtained. According to the difference of the relative use quantities and proportions of two kinds of catalysts added in two steps and the difference of the particle diameters, activities and use quantities of the selected silica powder, the monodisperse large-particle-diameter silica sol with the mean particle diameter ranging from 20 nm to 100 nm or so is prepared.

Owner:SHANDONG YINFENG NANOMETER NEW MATERIAL CO LTD

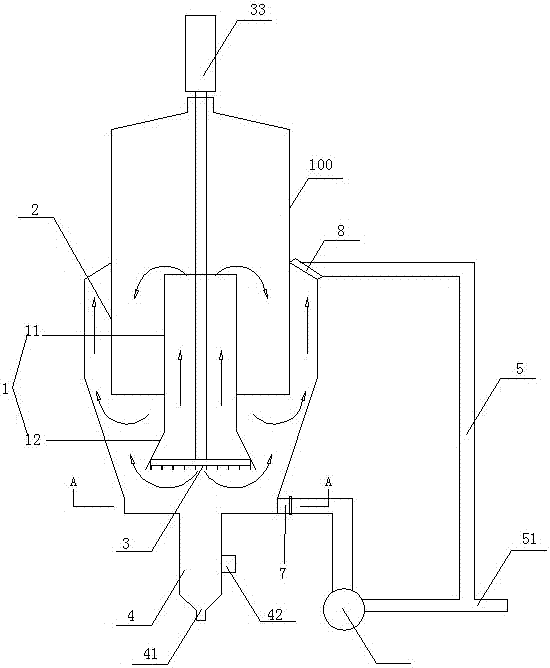

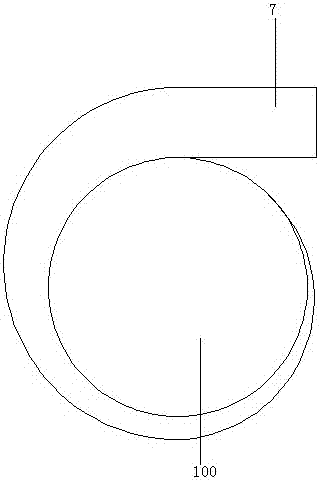

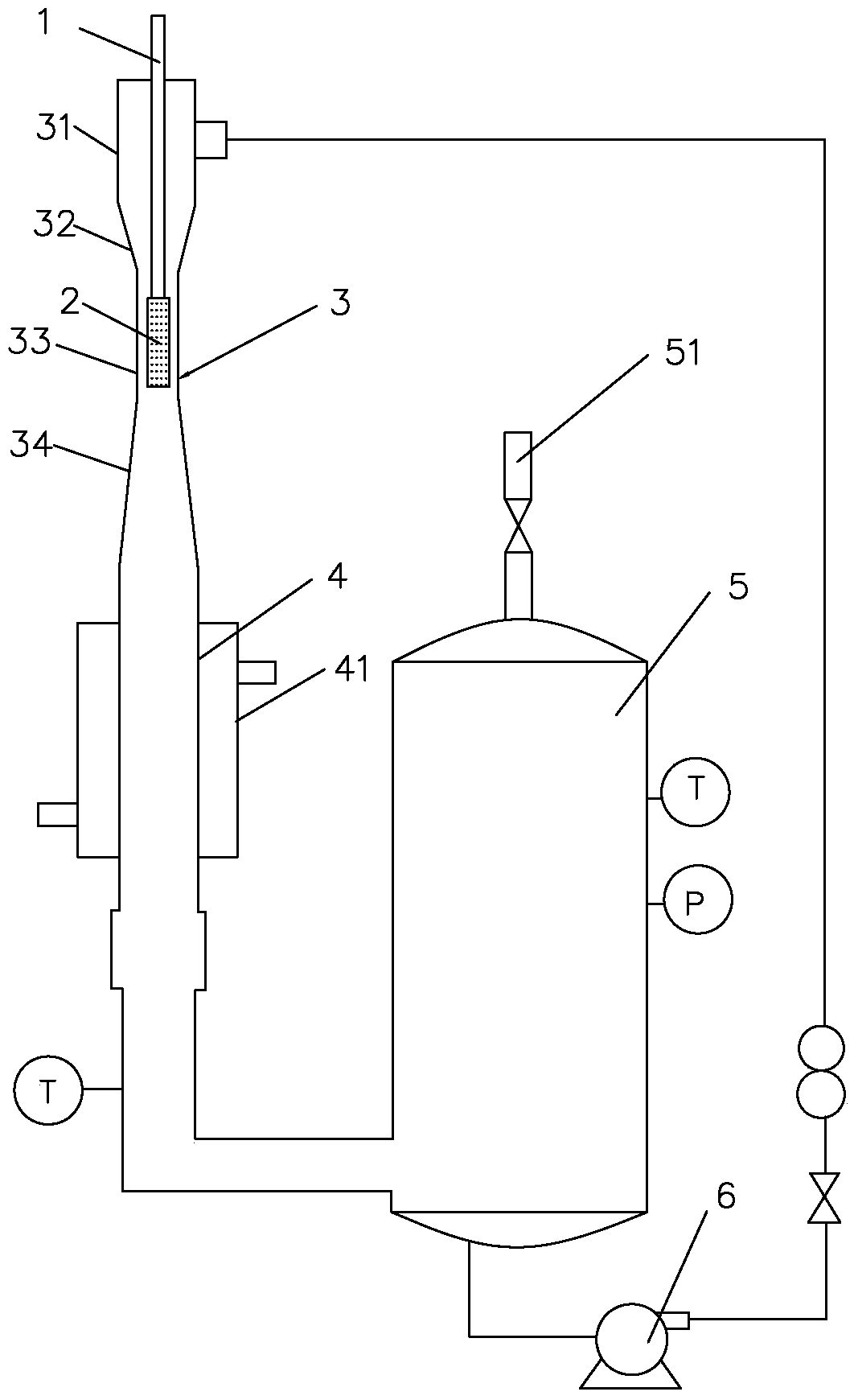

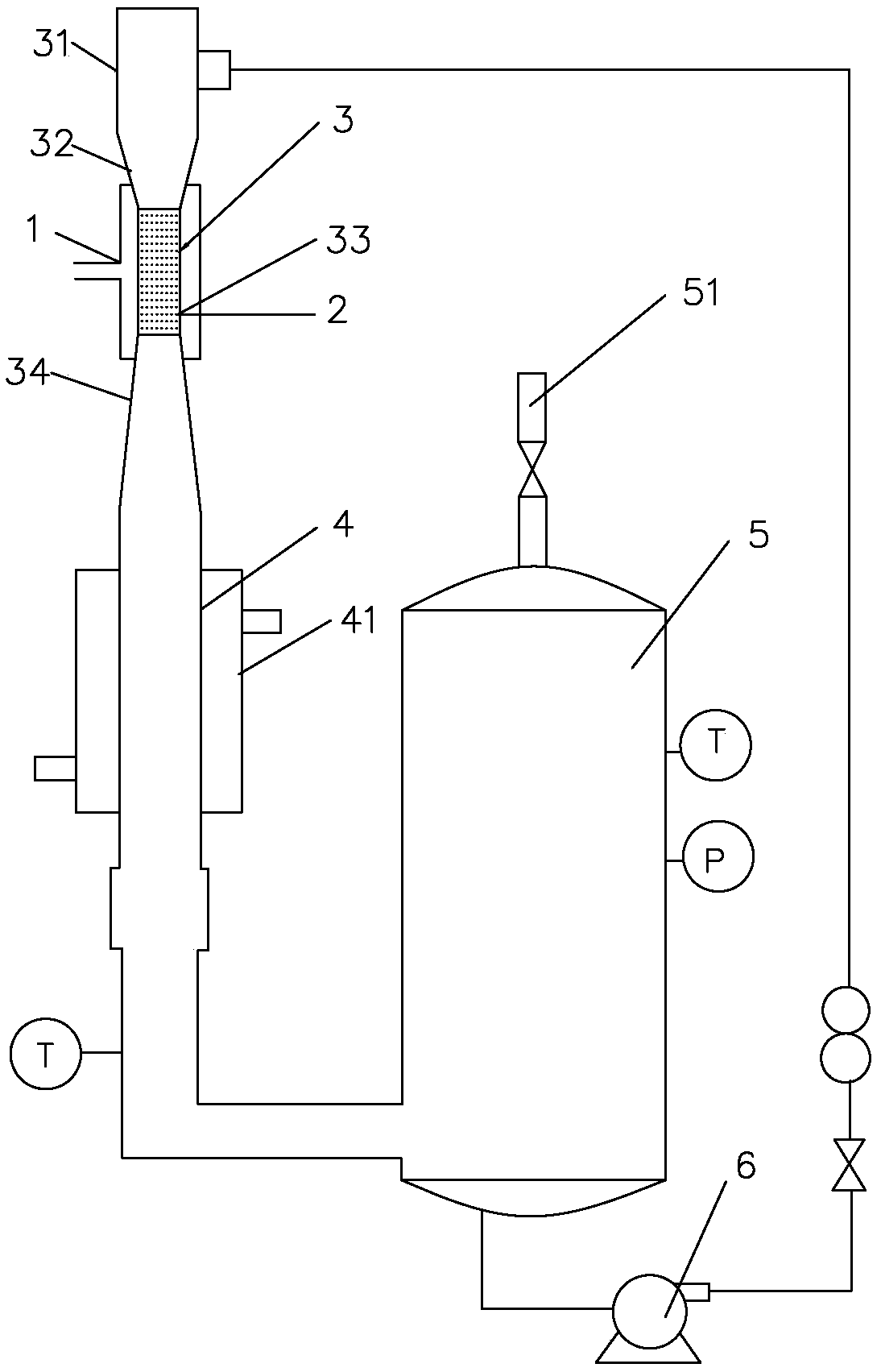

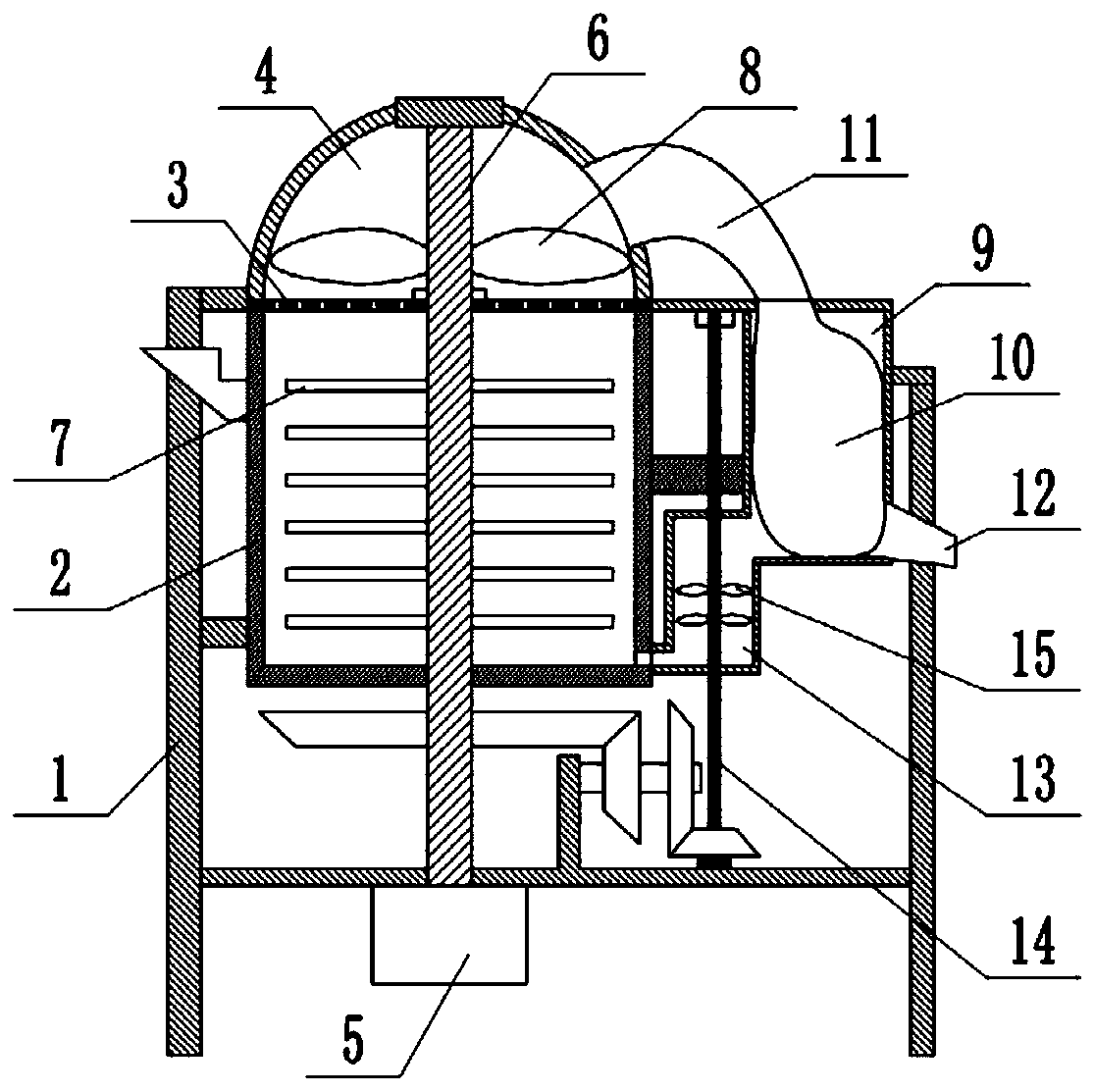

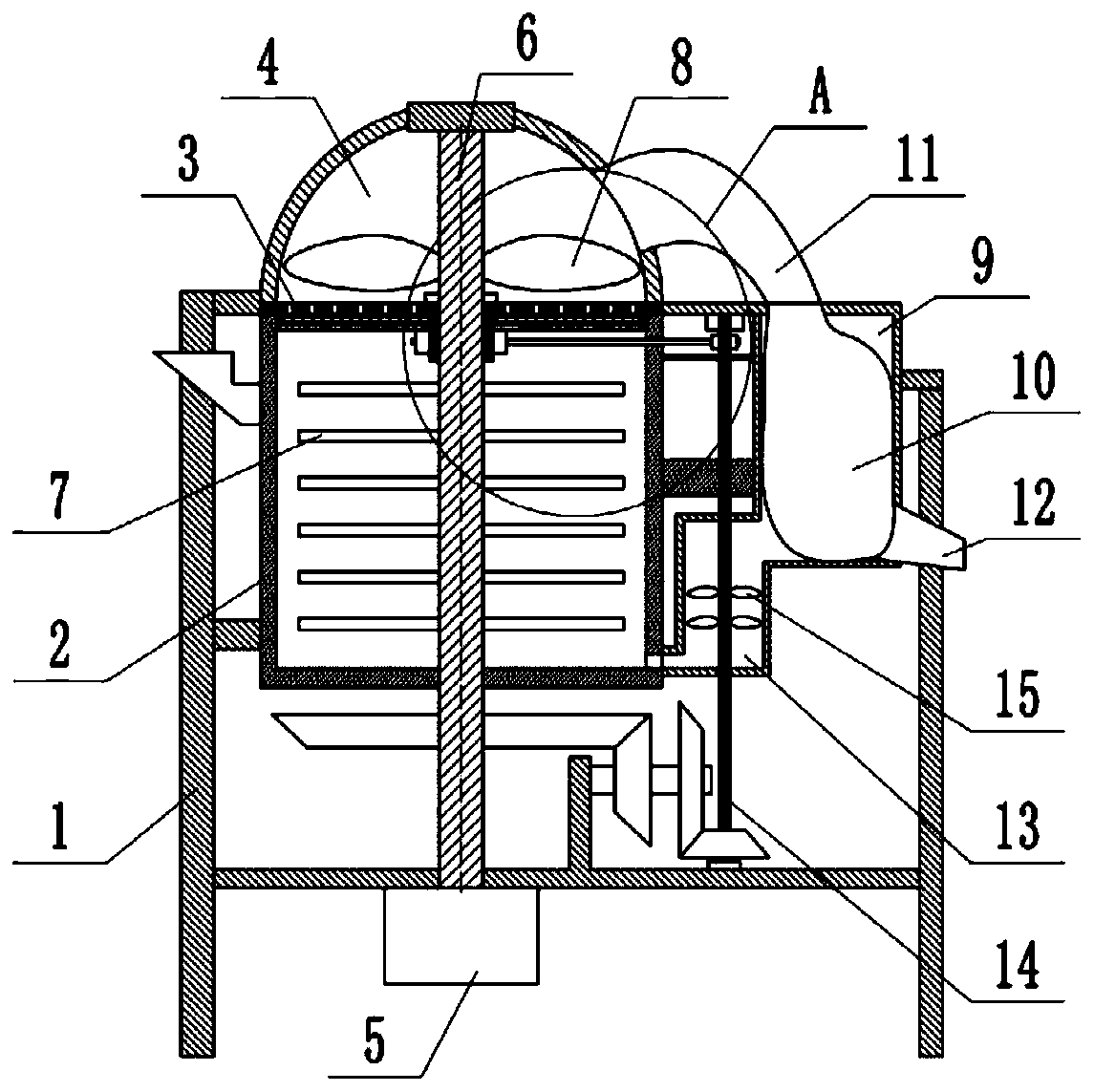

Vacuum crystallization device for titanium dioxide

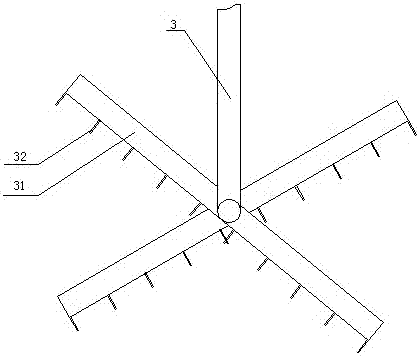

PendingCN107349618AImprove crystallization speedHigh crystallinityRotary stirring mixersTransportation and packagingCyclonePropeller

The invention discloses a vacuum crystallization device for titanium dioxide. A crystallization tank comprises a flow guide barrel, a baffle, a propeller, an elutriation pipe and a circulation pipe, wherein the flow guide barrel comprises an upper cylindrical flow guide barrel body and a lower conical flow guide barrel body; stirring paddles are arranged in the lower conical flow guide barrel body and comprise main paddles and auxiliary paddles arranged on the lower sides of the main paddles; a mother liquor outlet and a crystal outlet are arranged in the bottom of the elutriation pipe; the upper part of the circulation pipe is connected with a circulating fluid outlet, the lower part of the circulation pipe is connected with a crystalline liquid inlet pipe, a material inlet is arranged on the circulating pipe, and the crystalline liquid inlet pipe is a spiral cyclone pipe. The vacuum crystallization device has the benefits of use convenience, simplicity in operation, good crystallization effect, uniform crystal size, no blind angles during stirring, consistent crystal size and good crystallization effect.

Owner:南京圆点环境清洁技术有限公司

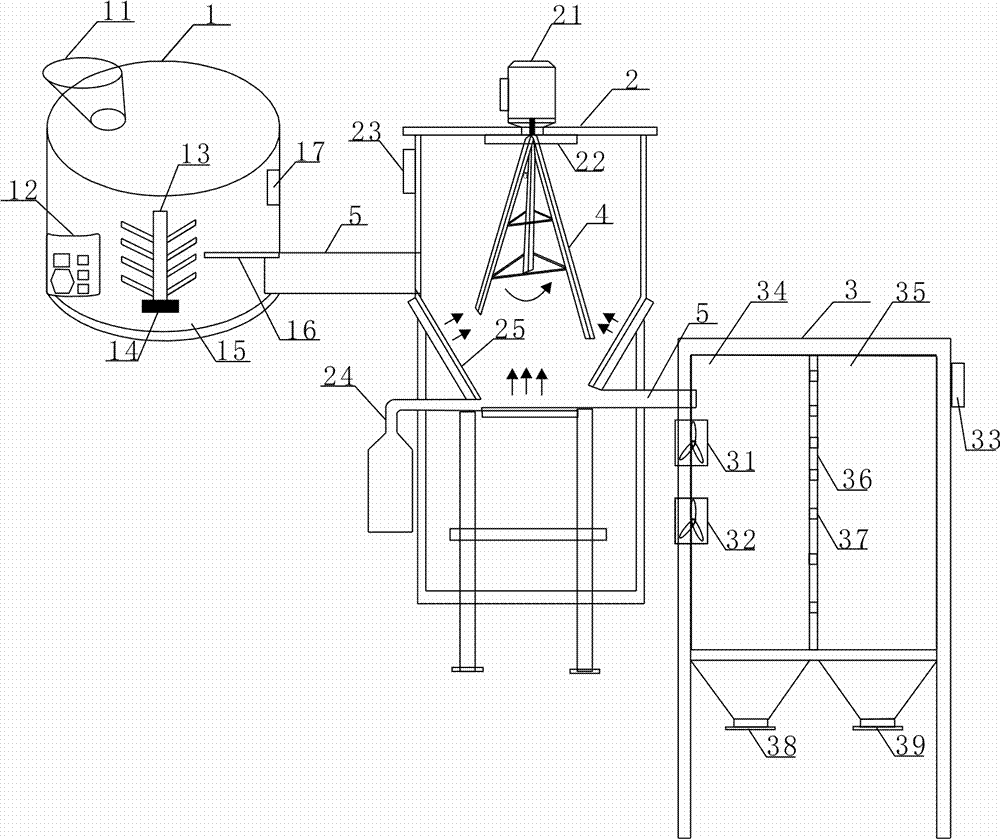

Device and method for preparing nanometer calcium carbonate through micropore pipe

ActiveCN105502462ASmall particle sizeConsistent particle sizeCalcium/strontium/barium carbonatesMaterial nanotechnologyReaction rateLiquid storage tank

The invention relates to the technical field of nanometer material preparation, and discloses a method and device for generating nanometer calcium carbonate particles by generating nano-scale carbon dioxide bubbles through a micropore pipe, making the carbon dioxide bubbles rapidly mixed and react with calcium hydroxide suspension under pressure through a Venturi jet pipeline reactor. In the flowing direction of the calcium hydroxide suspension, the device is sequentially provided with a liquid storage tank, a powerful pump, a Venturi tube, the micropore pipe, a reaction pipe and the like. In the throat part of the Venturi tube, compressed carbon dioxide gas penetrates through the pipe wall of the micropore pipe to be mixed with the calcium hydroxide suspension passing at a high speed to form foam high in gas content, a series of carbon dioxide adsorption and dissolution and acid-base neutralization reactions (commonly known as carburizing reactions) are continuously conducted in the reaction pipe and the liquid storage tank, and then nanometer calcium carbonate particles are generated. The carburizing reaction rate and the carbon dioxide utilization rate are high, and generated nanometer calcium carbonate is excellent in quality.

Owner:广东星燃石化设计院有限公司

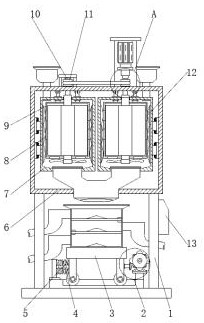

Powder stirring device and stirring method thereof

ActiveCN107159049ANovel structureImprove automation and intelligenceShaking/oscillating/vibrating mixersTransportation and packagingElectricityEngineering

The invention discloses a powder stirring device and a stirring method thereof. The powder stirring device comprises a pre-stirring bin, a main stirring bin and a distributing bin which communicate with one another successively through a conveying assembly; a first motor is arranged at the bottom of the pre-stirring bin and is connected with a chassis through a bearing of the first motor; a first stirring paddle is arranged in the center of the chassis; an image acquirer is arranged at a position, which corresponds to a powder feeding part, of the pre-stirring bin; a PLC is arranged on the outside of the pre-stirring bin; the PLC is electrically connected with the image acquirer and the first motor respectively; the inside of the main stirring bin is funnel-shaped; a second stirring paddle is arranged on the top in the main stirring bin and is connected with a bearing of a second motor through a rotating plate; vibrating components are respectively adhered to the funnel-shaped bottom of the main stirring bin; and a first controller is arranged on the outside of the main stirring bin and is electrically connected with the second motor and the vibrating components.

Owner:雅安晶玉新材料有限公司

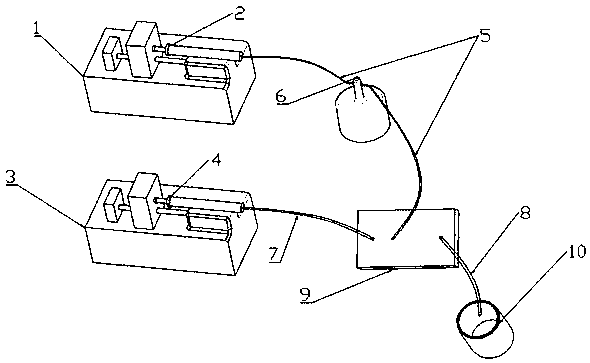

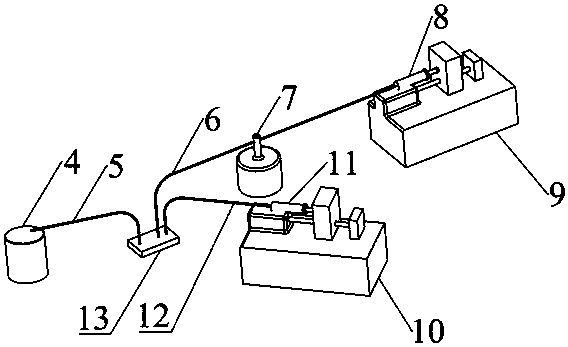

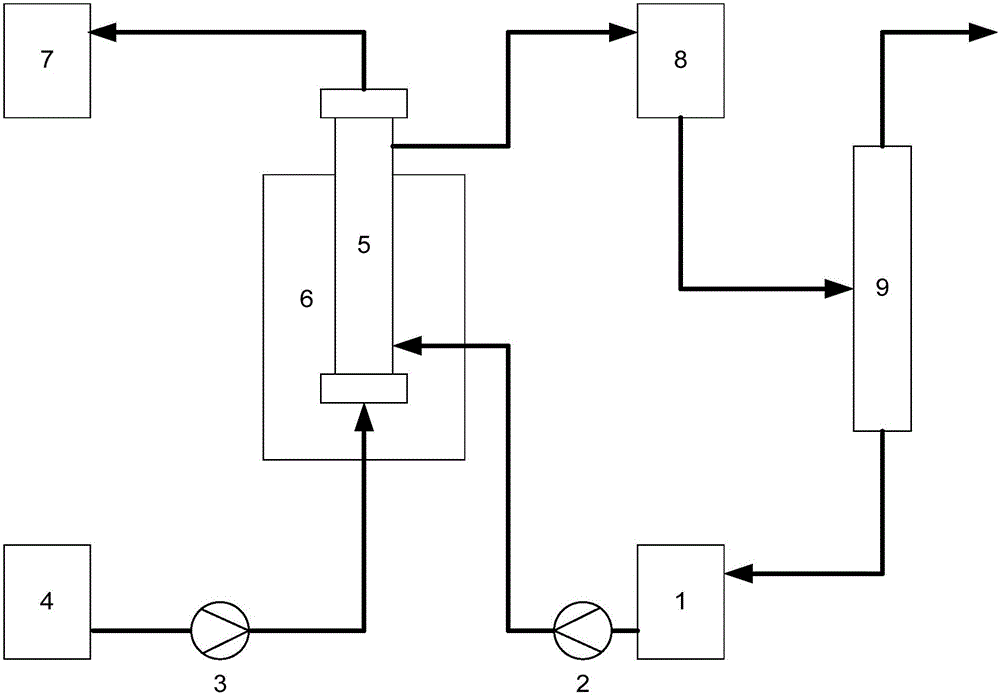

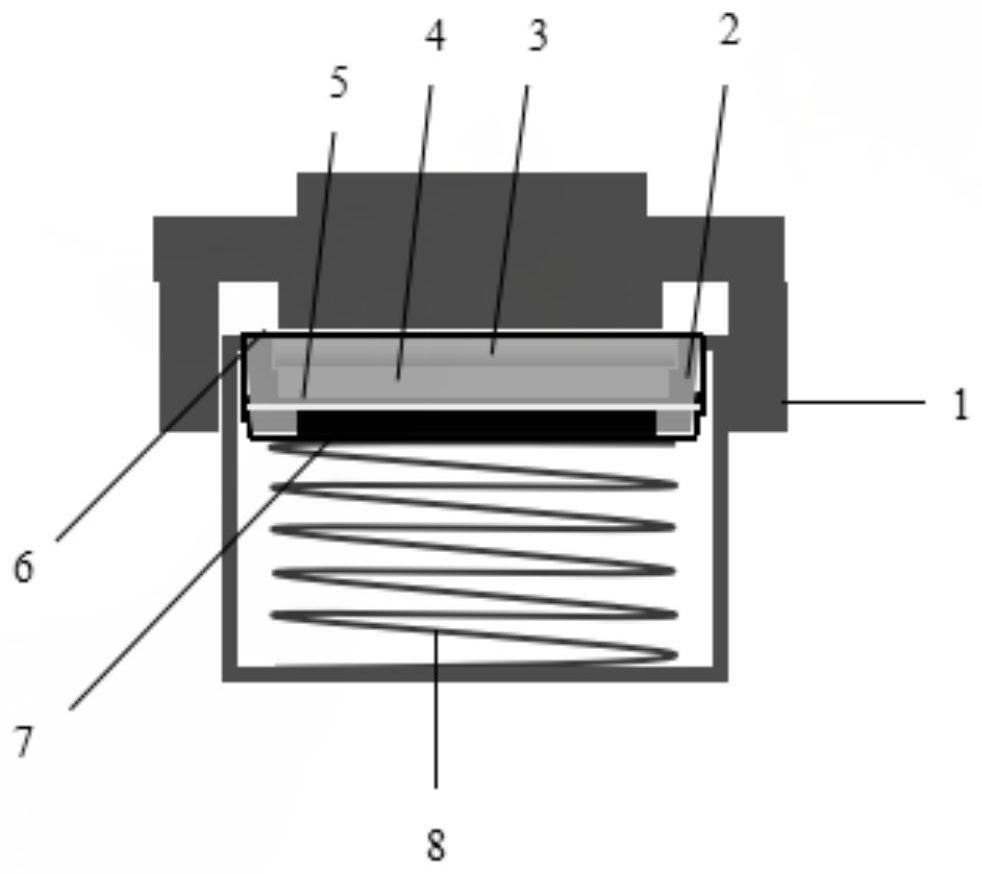

Particle controllable preparation method and device based on ultrasonic auxiliary continuous anti-solvent film dialysis process

ActiveCN106512737AReduce concentration polarizationPromote decentralized controlDialysisMaterial granulationPeristaltic pumpDispersity

The invention discloses a particle controllable preparation method and device based on an ultrasonic auxiliary continuous anti-solvent film dialysis process. A first sealed container of the device is connected with a first peristaltic pump. The first peristaltic pump is connected with a lower end connector of a film module shell pass. A fourth sealed container is connected with an upper end connector of the film module shell pass. A second sealed container is connected with a second peristaltic pump. The second peristaltic pump is connected with a lower end connector of a film module tube pass. Hollow fiber film bundles in a film module form a tubular structure, the tube pass of the film module is formed, and the space between the hollow fiber bundles and a film module shell forms the shell pass of the film module. By the adoption of the ultrasonic auxiliary continuous operation film module, the anti-solvent and solvent on the two sides of a film are controlled to penetrate towards the opposite sides correspondingly, raw materials are promoted to be separated out of a solution, and particle growth and dispersion are adjusted and controlled through dynamic dialysis and ultrasound enhancing, so that particles which are controllable in particle size, narrow in particle size distribution and good in dispersity are prepared efficiently, and the preparation method and device can be used for preparing various oral preparations or can be used for further processing of injections.

Owner:SOUTH CHINA UNIV OF TECH

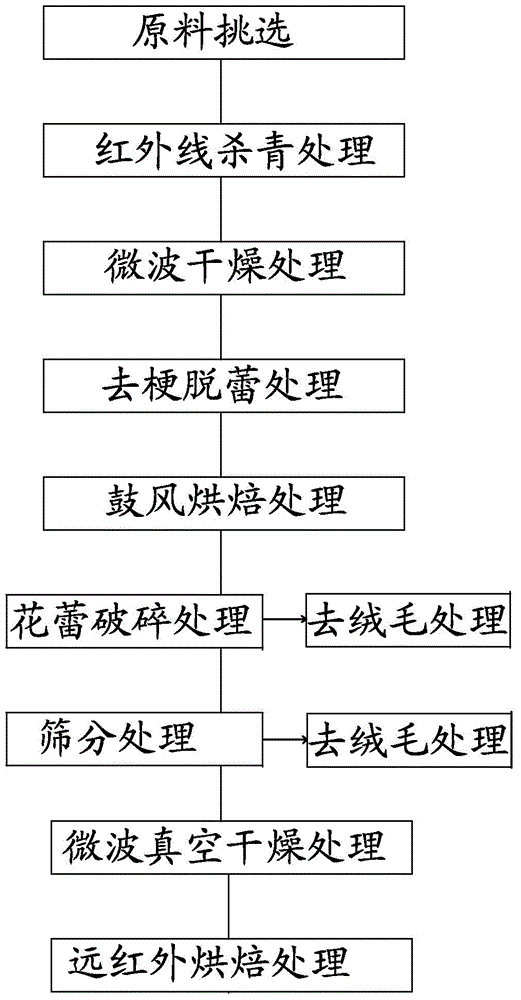

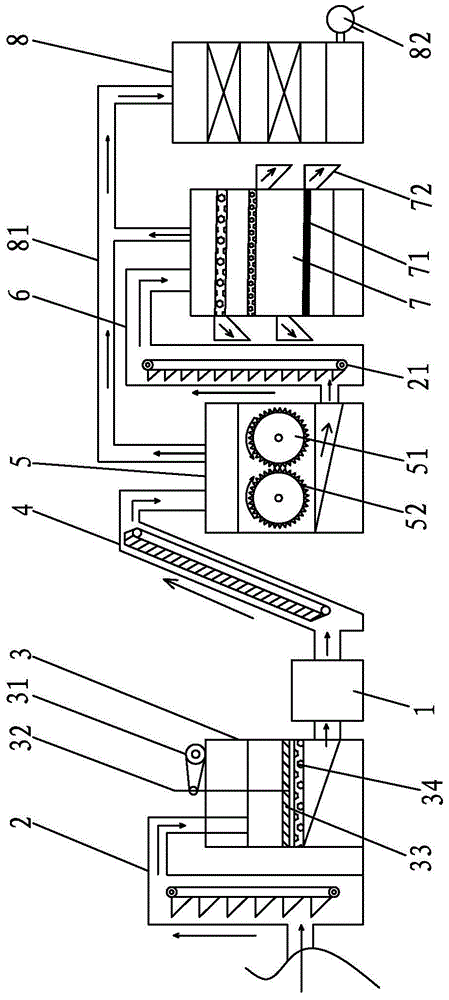

Preparation method for loquat flower bud tea

The invention relates to the processing field of health care tea, in particular to a preparation method for a loquat flower bud tea. The method is realized by the steps of: a. raw material selection; b. infrared enzyme deactivation treatment; c. microwave drying treatment; d. stalk removing and bud stripping treatment; e. blast baking treatment; f. flower bud crushing treatment; g. sieving treatment; h. fluff removal treatment at the same time of step f; h. microwave vacuum drying treatment; and i. far infrared baking process. Compared with the prior art, the invention has the advantage that the method gives consideration to the characteristic that loquat flower buds are rich in ursolic acid, oleanolic acid and other triterpene acid, 18 amino acids, and flavone active substances, during processing multiple low-temperature drying is carried out by stages, thus maximumly keeping the physiologically active ingredients of loquat flower buds. Also, the method provided by the invention has properly arranged processes, thus being convenient for large-scale industrial production.

Owner:HUAQIAO UNIVERSITY +1

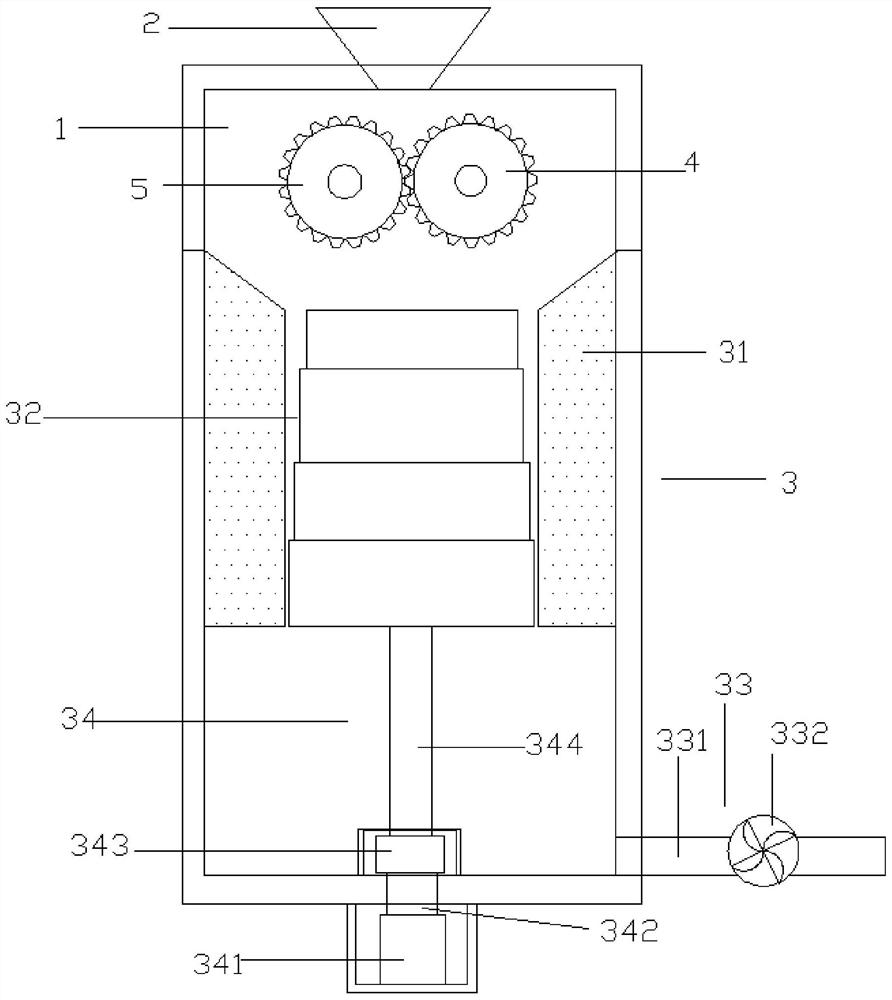

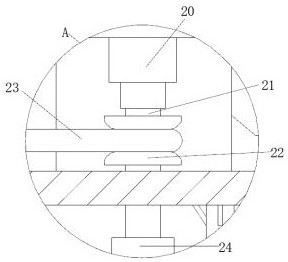

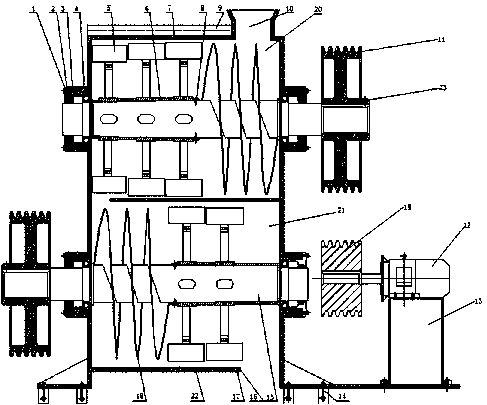

Milling device for bentonite crushing process

The invention discloses a milling device for bentonite crushing process. The milling device comprises a crushing chamber, a feeding opening formed in the top end opening in the crushing chamber and agrinding chamber arranged at the bottom of the crushing chamber and communicating with the crushing chamber, a driving crushing gear and a driven crushing gear matched with the driving crushing gear are arranged in the crushing chamber, a driving motor is arranged on the outer wall of the back surface of the crushing chamber, the output end of the driving motor is fixedly connected with the driving crushing gear, a driving body is arranged on the inner wall of the driving chamber, a driving mechanism in clearance fit with the grinding body is arranged in the grinding body, a discharging mechanism communicating with the grinding chamber is arranged at the bottom of one side of the grinding chamber, the middling device further comprises a driving structure, one end of the driving structure is arranged at the bottom of the outer side of the grinding chamber, and the other end of the driving structure penetrates through the bottom of the grinding chamber and is connected with the grindingstructure. According to the milling device, the milling effect for bentonite is high, the follow-up use and the performance of corresponding products are ensured, different needs are met, the costs are saved, and the use range of the device is increased.

Owner:常德宏利膨润土有限公司

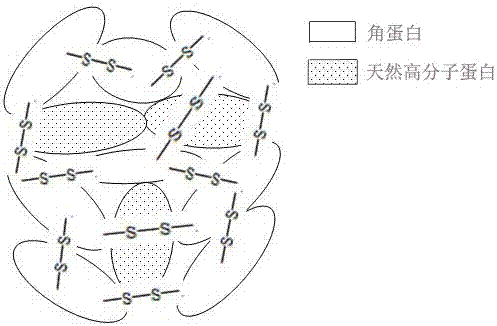

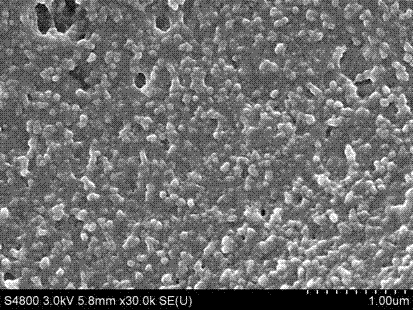

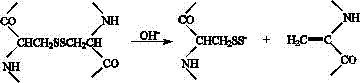

Method for preparing natural protein compound micelle with disulfide bond reconstruction method

ActiveCN107118358AConsistent particle sizeShape is easy to controlProtein solutionBiocompatibility Testing

The invention discloses a method for preparing a natural protein compound micelle with a disulfide bond reconstruction method, and aims to solve the technical problems that the amphiphilic block copolymer of an artificially synthesized polymeric micelle has a low metabolic rate in a living body and can accumulate and parts of amphiphilic block copolymer have certain toxicity for the living body. The method comprises the following steps: preparing a keratin solution; preparing a natural macromolecule protein solution; preparing the compound micelle with the disulfide bond reconstruction method: a: mixing the keratin solution prepared in 1) with the natural macromolecule protein solution prepared in 2) to obtain a protein mixed solution; b: carrying out the quantitative reconstruction of a disulfide bond: putting the mixed solution of two types of protein in a constant temperature of 15-25 DEG C, standing for 3-12h, and measuring the specific numerical value of a sulfhydryl content in the mixed solution; c: calculating a quantity of an oxidizing agent which needs to be added, and obtaining the protein compound micelle after the oxidizing agent is added. The method which adopts the technical scheme has the outstanding advantages of safety, no toxin, stable structure, good biocompatibility, metabolizable product, low price and the like.

Owner:ZHONGYUAN ENGINEERING COLLEGE

Method for preparing nano titanium dioxide at high temperatures

ActiveCN105417577AImprove protectionShort reaction timePhysical/chemical process catalystsNanotechnologyPhoto catalyticNanometre

The invention relates to the field of preparation of photo-catalytic materials, in particular to a method for preparing anatase nano titanium dioxide at high temperatures. According to the technical scheme, the method for preparing the anatase nano titanium dioxide comprises the following steps of (1) preparing titanium dioxide sol; (2) preparing titanium dioxide reaction liquid; (3) preparing high-temperature amorphous titanium dioxide; and (4) preparing the anatase nano titanium dioxide. Compared with the prior art, the method for preparing the anatase nano titanium dioxide at the high temperatures has the obvious advantages that nano titanium dioxide powder with high purity and even particle sizes can be prepared by the aid of the method; the titanium dioxide is white and neutral and is free of odor and good in stability; and the method is simple in process, low in cost and high in product purity.

Owner:珠海市雅科波罗家具有限公司

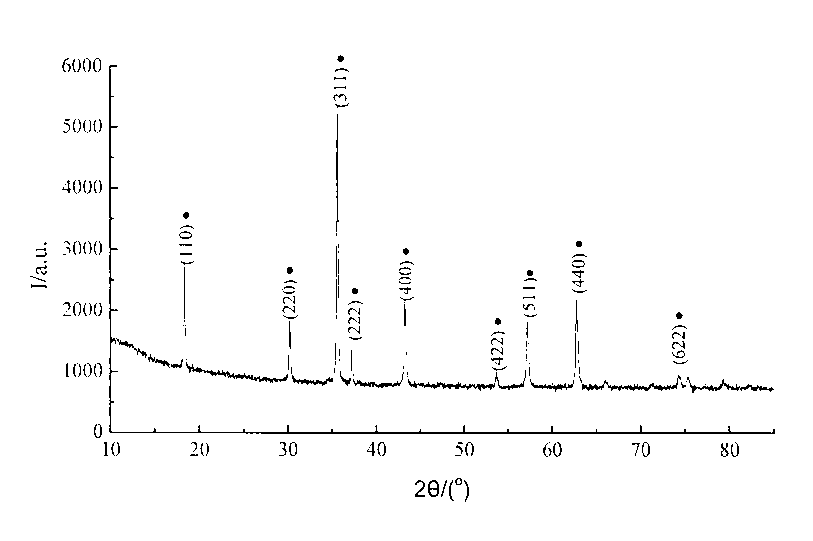

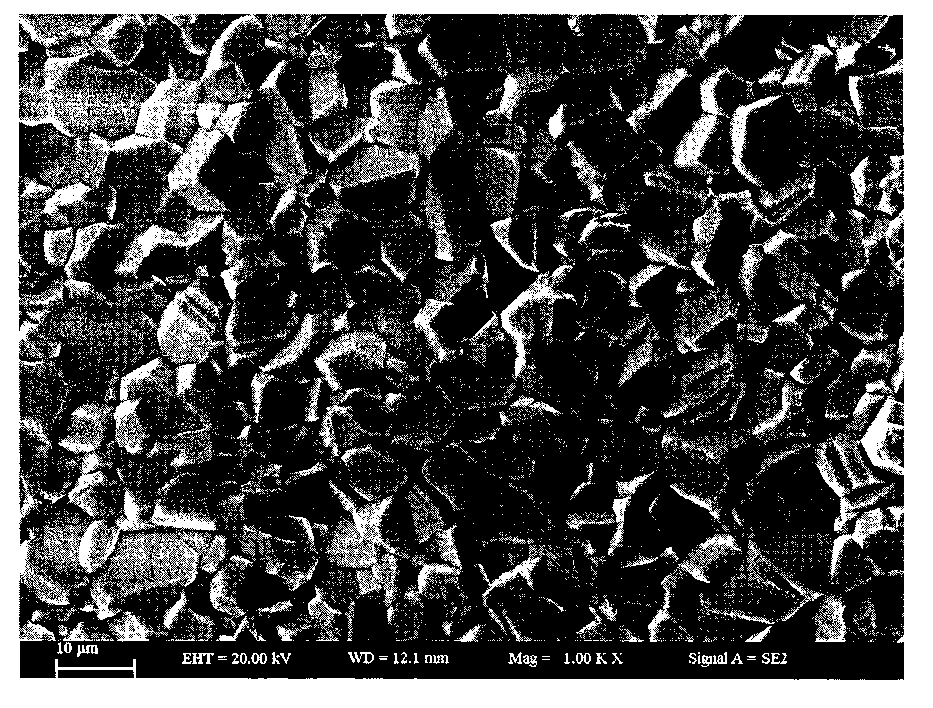

Negative temperature coefficient heat sensitive ceramic material preparation method

The present invention relates to a negative temperature coefficient heat sensitive ceramic material preparation method. According to the method, two or three analytical pure oxides selected from manganese, nickel, iron and magnesium are adopted as raw materials, a functional additive and a solvent are added to carry out a reaction, calcinations is performed to obtain powder with characteristics of uniform mixing, consistent particle size and good crystallinity, and the obtained powder is subjected to processing processes such as sheet pressing molding, sintering, slicing, coating of the electrode, and scribing to obtain the negative temperature coefficient heat sensitive ceramic material with a characteristic of good resistance value and B value consistency. Compared to the conventional solid phase reaction method and the liquid phase reaction method, the method of the present invention has the following advantages that: raw material cost is low, a preparation process is simple, process parameters are easily controlled, and the like, wherein the heat sensitive ceramic material prepared by the method has good consistency and good uniformity, and industrial scale production prospects are provided.

Owner:XINJIANG ZHONGKE SENSING CO LTD

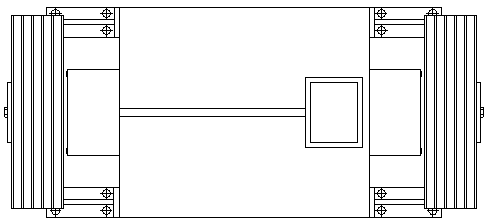

Superfine crushing and discharging device for fungus raw materials

ActiveCN111482248AConsistent particle sizeTake advantage ofGrain treatmentsProcess engineeringCrusher

The invention relates to the technical field of fungus raw material processing equipment, and particularly discloses a superfine crushing and discharging device for fungus raw materials. The superfinecrushing and discharging device includes a crushing drum and a crushing mechanism arranged in the crushing drum, a negative pressure chamber communicating to the crushing drum is arranged above the crushing drum, a screen is fixedly connected between the negative pressure chamber and the crushing drum, the negative pressure chamber is connected with a material collecting mechanism; and the crushing drum is provided with a driving mechanism for driving the crushing mechanism, the negative pressure chamber is internally provided with a negative pressure material suction mechanism connected to the driving mechanism, and the driving mechanism is connected with a negative pressure exhaust mechanism for sucking gas in the material collecting mechanism. The driving mechanism is used to drive thecrushing mechanism, the negative pressure material suction mechanism and the negative pressure exhaust mechanism to operate simultaneously, and the problem that in the prior art, fungus materials cannot be fully pulverized to a substantially uniform particle size is solved.

Owner:CHONGQING DEZHUANG AGRI PROD DEV CO LTD

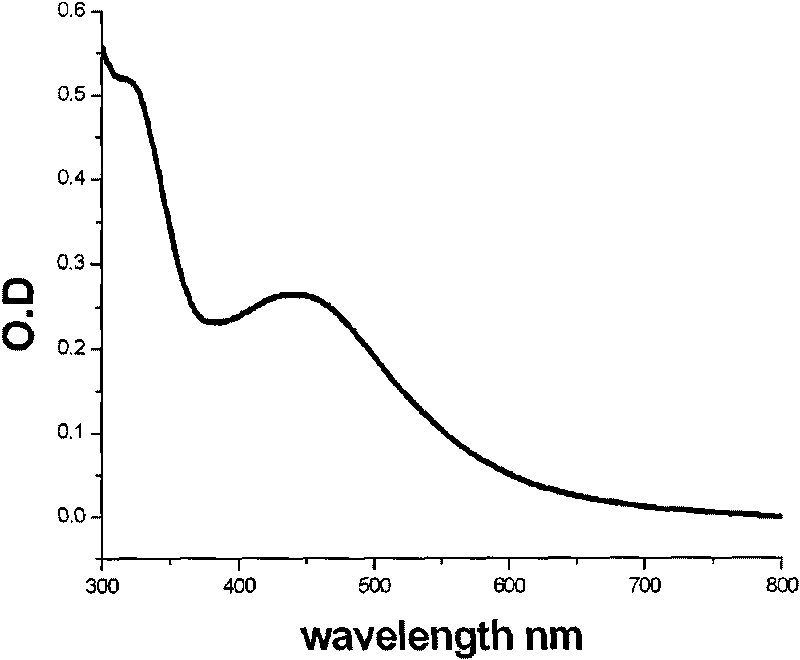

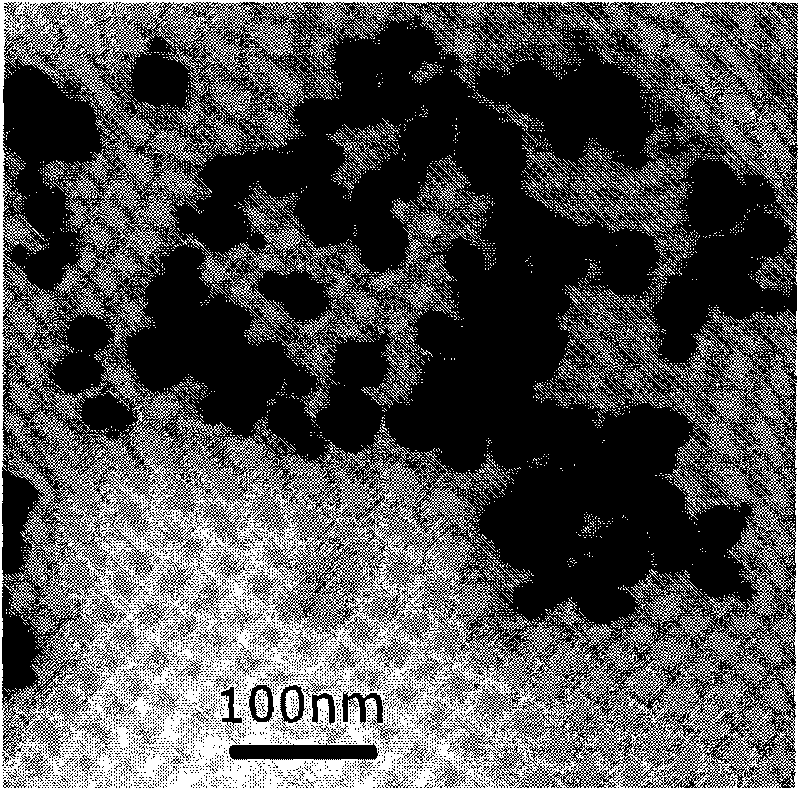

Preparation method of vernonia anthelmintica compound silver nanometer colloid

InactiveCN101721445AAvoid pollutionConsistent particle sizeInorganic active ingredientsPharmaceutical delivery mechanismWater bathsRoom temperature

The invention relates to a preparation method of a vernonia anthelmintica compound silver nanometer colloid, comprising the following steps of: firstly preparing an extracting solution of vernonia anthelmintica; then uniformly mixing the extracting solution of the vernonia anthelmintica with a silver nitrate solution; and reacting at room temperature or by heating in water bath or adding into a sodium hydroxide solution for oscillating reaction at the room temperature so as to obtain the vernonia anthelmintica compound silver nanometer colloid. The vernonia anthelmintica compound silver nanometer colloid obtained by using the preparation method is directly used in the fields of medicine and health, compounds the functions of the heat clearing, the deswelling, the disinfestation and the tinea treatment of the vernonia anthelmintica and the characteristics of the diminish inflammation and the disinfection of silver nanometer particles and is expected to bring the enhanced drug effect for the treatment of skin diseases such as leucoderma and the like.

Owner:XINJIANG TECHN INST OF PHYSICS & CHEM CHINESE ACAD OF SCI

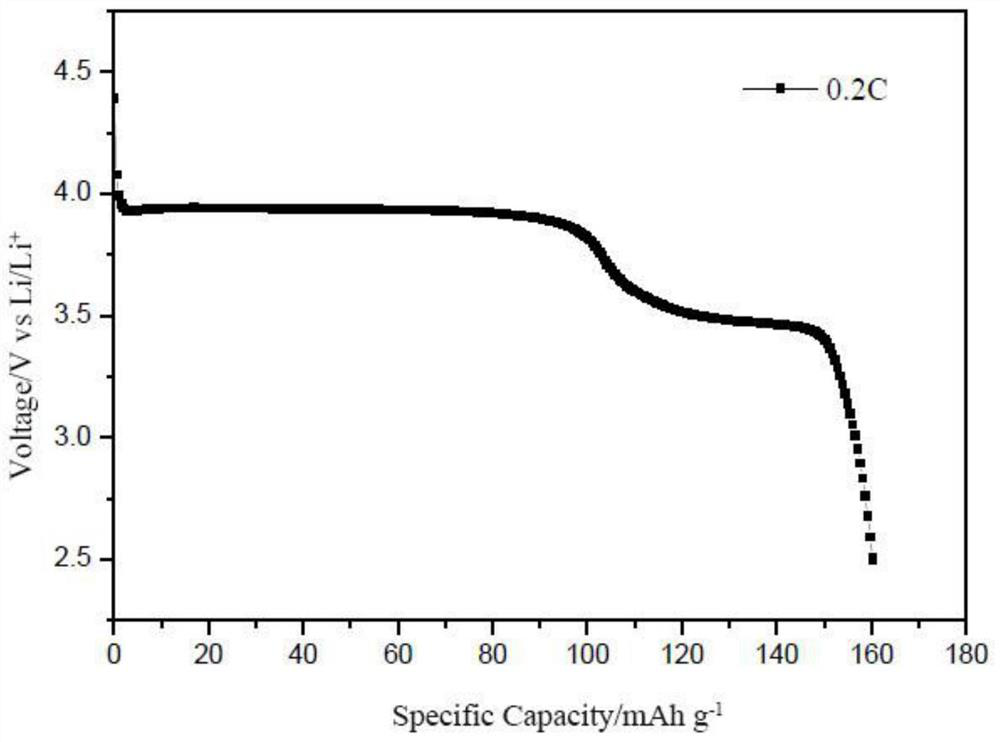

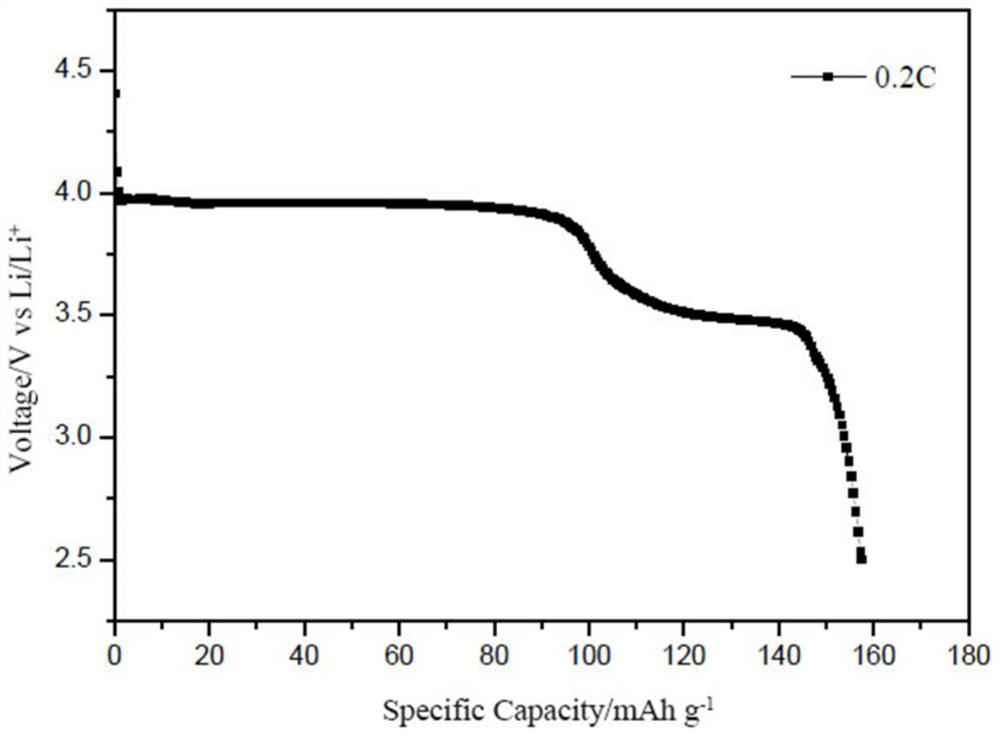

Novel lithium ferric manganese phosphate positive electrode material synthesis method

ActiveCN113060715AImprove electrochemical performanceSynthetic evenCell electrodesSecondary cellsPhosphoric acidManganese

The invention relates to the technical field of lithium ion batteries, and provides a novel lithium ferric manganese phosphate positive electrode material synthesis method, which comprises: S1, placing manganese dioxide, phosphoric acid and water in a container, stirring, adding aniline, and continuously stirring to obtain polyaniline; s2, weighing an iron source, a lithium source, a carbon source and an organic auxiliary agent, adding into polyaniline, and grinding and stirring; s3, drying and calcining in an air atmosphere to obtain a precursor; s4, adding the carbon source into the precursor again, adding the grinding medium, and grinding to obtain grinding slurry; s5, performing vacuum drying on the grinding slurry to obtain reaction powder; and S6, sintering the reaction powder in a protective atmosphere, cooling to room temperature, crushing, and sieving to obtain the polyaniline / carbon coated iron manganese phosphate lithium ion battery positive electrode material. Through the technical scheme, the problems of low discharge capacity ratio and poor cycling stability in the prior art are solved.

Owner:河北九丛科技有限公司

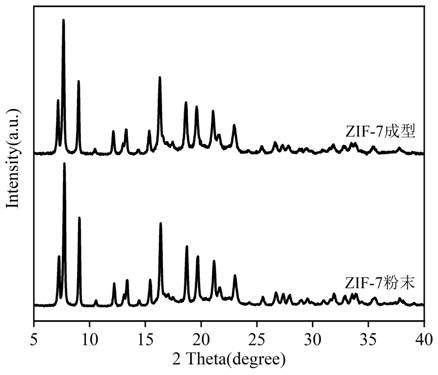

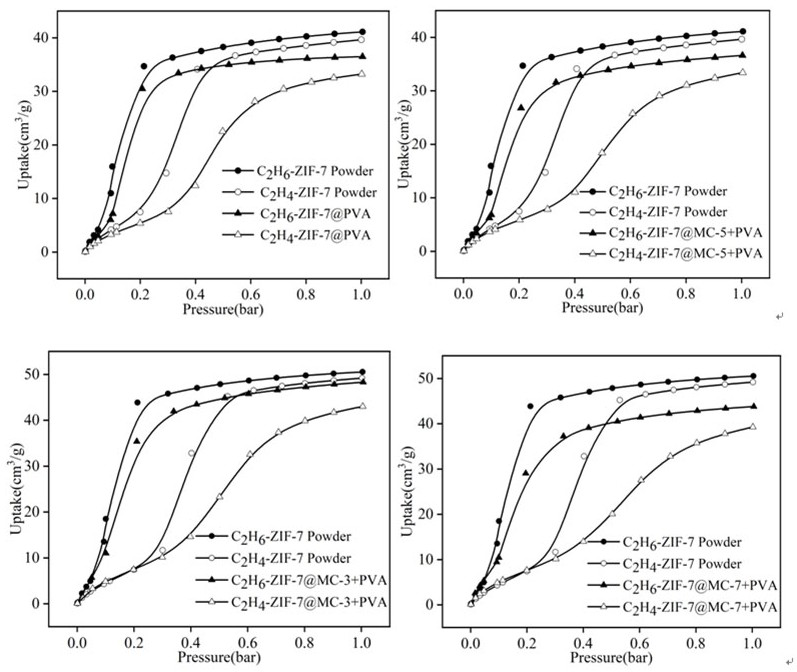

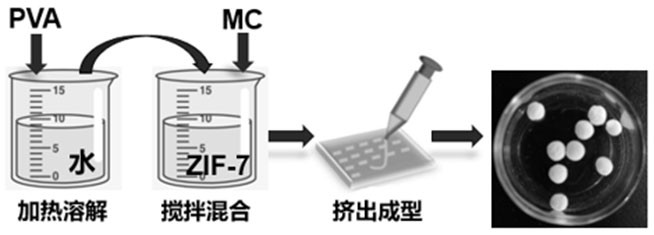

Application of super-microporous MOF adsorbent material in hydrocarbon gas separation

ActiveCN112717888AHigh puritySmall declineOther chemical processesChemical industryMeth-Polyvinyl alcohol

The invention relates to the field of application of a super-microporous MOF adsorbent material in hydrocarbon gas separation, in particular to application of super-microporous MOF adsorbent material forming particles in C2H6 / C2H4, the separation effect of the prepared and formed super-microporous MOF adsorbent material forming particles is tested in C2H4 / C2H6 mixed gas with the equal molar ratio, and the result shows that on the premise that high mechanical strength of the formed adsorbent particles is guaranteed, the adsorption capacity can also be maintained to be 89% of the original powder adsorption capacity, the separation effect is remarkable, the method is suitable for large-scale industrial application, polyvinyl alcohol and methyl cellulose are compounded to form MOF powder in the forming method, MOF spherical particles with high load rate are obtained, the powdery MOF adsorbent is effectively shaped via the method, and the obtained particles keep the crystalline structure of the original metal organic framework, so that the method is particularly suitable for the ultra-microporous MOF adsorbent; meanwhile, the technical effects of efficiently separating the ethane / ethylene mixture and obtaining high-purity ethylene in one step can be achieved.

Owner:TAIYUAN UNIV OF TECH

Rotary grain grinding device having grain size screening function and used for sugarcane water-retention controlled-release fertilizer processing

ActiveCN112705334AImprove product qualityReduce work intensityDrying gas arrangementsGrain treatmentsParticle chamberAgricultural science

The invention discloses a rotary grain grinding device having a grain size screening function and used for sugarcane water-retention controlled-release fertilizer processing. The rotary grain grinding device comprises a device base, a screening mechanism, a supporting frame, arc-shaped blocks and a second grain grinding spindle; the supporting frame is glidingly mounted on one side of the bottom of the device base; a damper is fixed to the outer wall of one side of the supporting frame; a return spring winds around one side of the surface of the damper; a device body is fixed to one side of the top end of the device base; an abrasive particle preparation box is fixed to one side of the interior of the device body; the arc-shaped blocks are fixed to the two inner side walls of the abrasive particle preparation box at equal intervals; and an abrasive particle chamber is fixed to one side of the top of the abrasive particle preparation box. According to the rotary grain grinding device, the product quality of the water-retention controlled-release fertilizer is improved, the difficulty of cleaning the device in the later period is reduced, the operation convenience of the device is enhanced, the work of manually screening the water-retention controlled-release fertilizer again in the later period is avoided, and the operation intensity of workers is reduced.

Owner:广东粤恬生物科技有限公司 +1

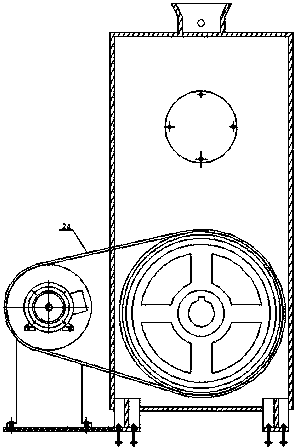

High-speed vortex pulverizer

InactiveCN108579954AReduce vibrationLow calorific valueGrain treatmentsMachining vibrationsBall bearing

The invention designs a high-speed vortex pulverizer. The high-speed vortex pulverizer comprises a screw, a felt ring oil seal, a bearing end cover, a deep groove ball bearing, a blade, a shaft sleeve, a box body, a positioning screw, a water cooling water pipe, a feeding hopper, a large belt wheel, a motor, a motor supporting frame, foundation bolts, a main shaft, a partition plate, hard rubber,a spiral conveying blade, a pin hole, a primary crushing chamber, a secondary crushing chamber, a dovetail groove, a small belt wheel, a conveying belt, a key, a cross clamping groove and a knife rest. A crushing chamber is divided into two parts, namely the primary crushing chamber and the secondary crushing chamber, the primary crushing chamber is used for completing the coarse crushing process,and the secondary crushing chamber is used for completing the fine crushing process so that materials can be uniformly crushed, particle sizes of discharged powder materials are consistent, the machine vibration, the heat productivity and the knife abrasion loss are reduced, and then the service life of the blade is prolonged.

Owner:宋欢

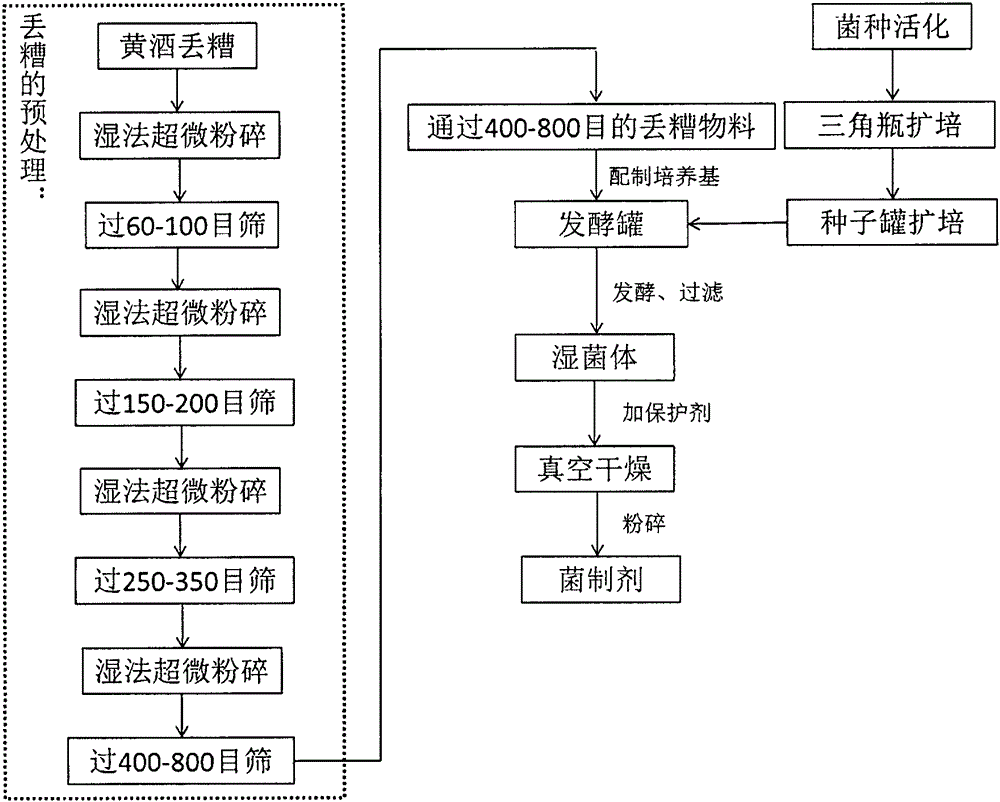

Method for promoting fermentation production of lactohacillin by preprocessing waste distiller's grains

InactiveCN105219820AConsistent particle sizeEvenly distributedMicroorganism based processesFermentationPre treatmentSuperfine grinding

The invention relates to a method for promoting fermentation production of lactohacillin by taking waste distiller's grains which is processed by a superfine grinding technology and a step-by-step screening technology in combination as a main matrix, and belongs to the field of processing and preparation of biological preparation. The method comprises the following steps: preprocessing the waste distiller's grains by virtue of the wet-process superfine grinding technology and the step-by-step screening technology; screening the ground waste distiller's grains, and grinding the screened waste distiller's grains again by virtue of a superfine grinding machine; such repeating, screening the waste distiller's grains by virtue of a sieve of 60-100 meshes, a sieve of 150-200 meshes, a sieve of 250-350 meshes and a sieve of 400-800 meshes step by step, and collecting materials finally passing through the sieve of 400-800 meshes so as to obtain a fermentation matrix; and propagating lactobacillus step by step, and fermenting so as to obtain a lactobacillus powder preparation. The yield and the titer of the lactobacillus powder preparation are respectively improved by 35.2% and 41.4%; and the method not only achieves recycling of the waste distiller's grains and protection of environment but also reduces the cost of producing the lactobacillus powder preparation.

Owner:SUZHOU SANJIEYANG WINE +1

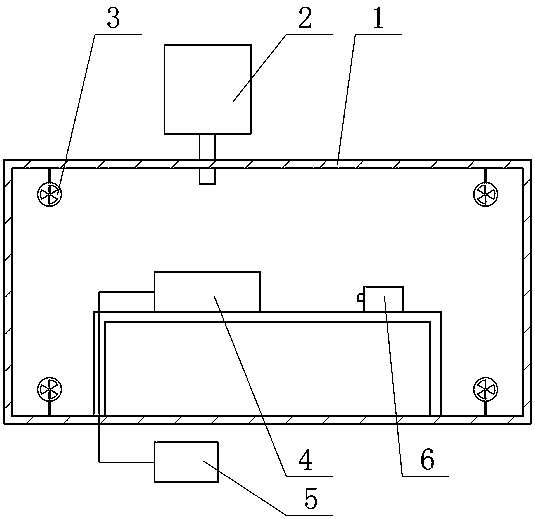

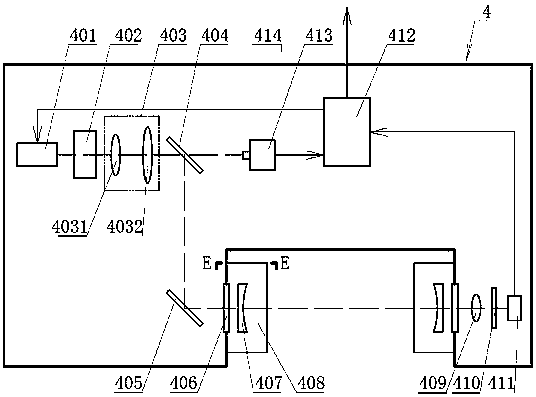

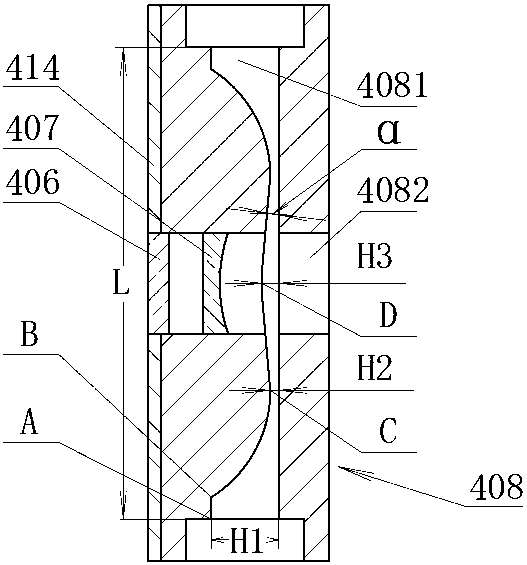

Small calibration system for forward scattering visiometer

ActiveCN108181267AConsistent particle sizeLarge particle sizeColor/spectral properties measurementsParticulatesVisibility

The invention provides a small calibration system for a forward scattering visiometer and relates to the technical field of detection. The system comprises a sealed simulation cabin, a particulate matter generator, stirring fans, a visibility measurement reference module and a computer, wherein the visibility measurement reference module enables a visibility measurement baseline in a sealed cavityof the sealed simulation cabin to be shortened to 0.5 m or shorter on the basis of the cavity enhancement principle. The technical problems that a baseline of a calibration simulation cabin for forward scattering visibility is too long and uniformity is difficult to guarantee in the prior art are solved. The system has the beneficial effects as follows: particulate matter has consistent grain size and is not prone to adsorption and agglomeration, and calibration and detection experiments achieve higher repeatability. The visibility measurement reference module based on the cavity enhancementprinciple can shorten the measurement baseline to be within 0.5 m, so that size of the calibration simulation cabin of the visiometer is greatly reduced, and cost is reduced; a mirror plane of each cavity mirror is protected by a special shielding gas hood, and gas is prevented from being mixed in a measurement area and influencing the visibility.

Owner:ZHEJIANG MEASUREMENT SCI RES INST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com