Method for preparing titanium alloy spherical powder at all levels

A spherical powder and titanium alloy technology, which is applied in the field of powder metallurgy industry, can solve the problems of poor sphericity of titanium alloy powder, decline in the quality of spherical powder, and easy introduction of impurity elements, etc., to achieve good sphericity, improve elongation, and fluidity Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

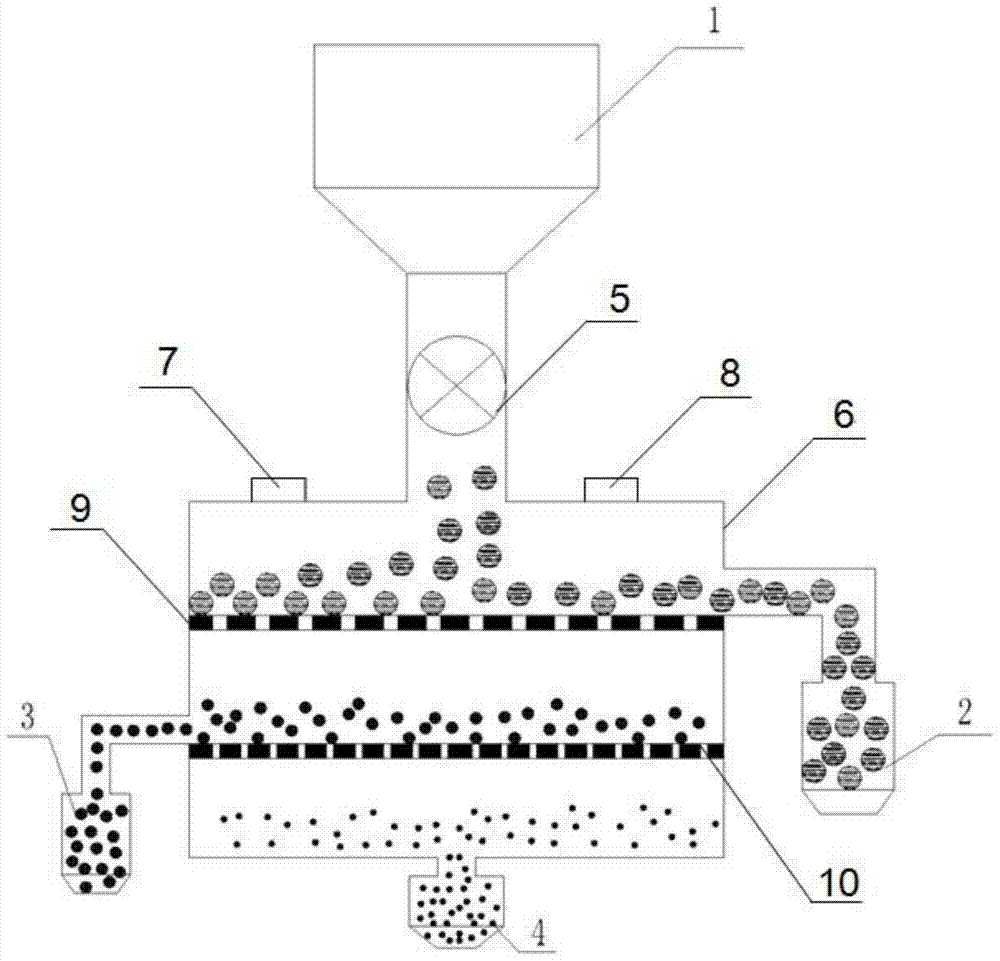

Image

Examples

preparation example Construction

[0020] The preparation method of titanium alloy spherical powder at various levels of the present invention is specifically implemented according to the following steps:

[0021] Step 1, use titanium alloy as raw material to make a cylindrical electrode rod, the diameter of the cylindrical electrode rod is Ф = 75mm ~ 80mm, and the length L = 700mm, and then install the cylindrical electrode rod horizontally in the vacuum furnace of the plasma rotary electrode powder making equipment side;

[0022] Step 2, install the plasma gun horizontally on the other side of the vacuum furnace through the plasma gun feeding mechanism, and make the plasma gun coaxial with the cylindrical electrode rod;

[0023] Step 3, vacuumize the vacuum furnace and fill it with mixed gas (the mixed gas is a mixture of helium and argon with a mass ratio of 3:1), then start the plasma gun to generate an arc, and at the same time start the electrode rotation mechanism to make the metal electrode Rotating at...

Embodiment 1

[0032] Step 1. Use titanium alloy as raw material to make a cylindrical electrode rod. The diameter of the cylindrical electrode rod is Ф=75mm and the length L=700mm. Then install the cylindrical electrode rod horizontally on one side of the vacuum furnace of the plasma rotary electrode powder making equipment. ;

[0033] Step 2, install the plasma gun horizontally on the other side of the vacuum furnace through the plasma gun feeding mechanism, and make the plasma gun coaxial with the cylindrical electrode rod;

[0034] Step 3, vacuumize the vacuum furnace and fill it with mixed gas (the mixed gas is a mixture of helium and argon with a mass ratio of 3:1), then start the plasma gun to generate an arc, and at the same time start the electrode rotation mechanism to make the metal electrode Rotating at a high speed with a speed of 25,000 rpm, the high temperature generated by the arc gradually melts the end of the cylindrical electrode rod, and the molten metal droplets are thro...

Embodiment 2

[0038] Step 1. Use titanium alloy as raw material to make a cylindrical electrode rod. The diameter of the cylindrical electrode rod is Ф=78mm and the length L=700mm. Then install the cylindrical electrode rod horizontally on one side of the vacuum furnace of the plasma rotary electrode powder making equipment ;

[0039] Step 2, install the plasma gun horizontally on the other side of the vacuum furnace through the plasma gun feeding mechanism, and make the plasma gun coaxial with the cylindrical electrode rod;

[0040] Step 3, vacuumize the vacuum furnace and fill it with mixed gas (the mixed gas is a mixture of helium and argon with a mass ratio of 3:1), then start the plasma gun to generate an arc, and at the same time start the electrode rotation mechanism to make the metal electrode Rotating at a high speed with a speed of 28,000 rpm, the high temperature generated by the arc gradually melts the end of the cylindrical electrode rod, and the molten metal droplets are throw...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com