High-speed vortex pulverizer

A pulverizer and eddy current technology, which is applied in the field of material crushing equipment, can solve the problems of uneven crushing particles, low efficiency, and easy heating of equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

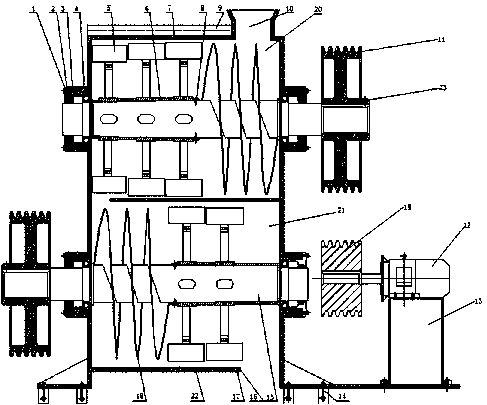

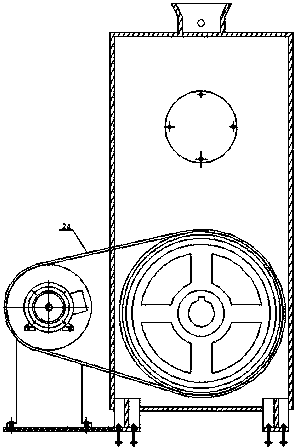

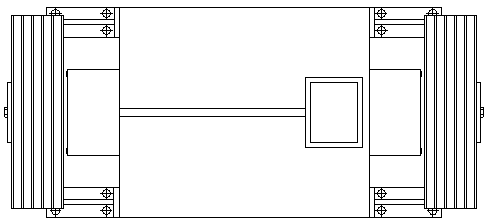

[0026] Such as Figure 1~14 As shown, a high-speed eddy current pulverizer includes screws (1), felt ring oil seal (2), bearing end cover (3), deep groove ball bearing (4), blade (5), shaft sleeve (6), box body (7), set screw (8), water-cooled water pipe (9), feed hopper (10), large pulley (11), motor (12), motor support frame (13), anchor bolt (14), spindle (15), clapboard (16), hard rubber (17), screw conveying blade (18), pin hole (19), primary crushing chamber (20), secondary crushing chamber (21), dovetail groove (22 ), small pulley (23), conveyor belt (24), key (25), cross card slot (26), knife rest (27). The screw (1) fastens the bearing cover (3) and the box body (7), the anchor bolt (14) fixes the box body (7) tightly on the ground, the blade (5) and the knife holder ( 27) Connected together through the cross card slot (26), the M8 positioning screw (8) determines the position of the first group, the knife rest (27) is fixed on the main shaft (15) through the key (2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com