Application of super-microporous MOF adsorbent material in hydrocarbon gas separation

A technology for the separation of hydrocarbon gases and gases, applied in separation methods, dispersed particle separation, alkali metal oxides/hydroxides, etc., can solve the problems of MOF adsorbent particles, mechanical properties and adsorption properties that have not been obtained. Performance cannot meet the needs of practical applications, the adsorption performance of shaped particles cannot be satisfied, etc., to achieve the effect of process optimization, consistent particle size, and small pore size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

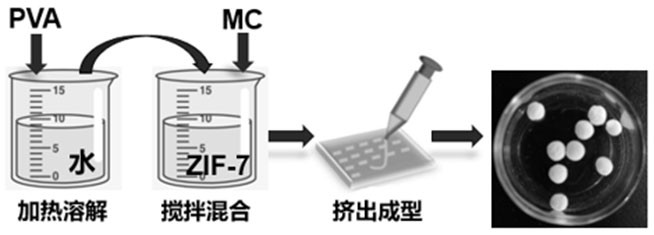

[0031]This method uses a PVA + MC composite method,

[0032]First, the preparation of the aqueous solution of PVA is carried out, and the preparation method is:

[0033]It is weighing 1 g of PVA particles in a beaker equipped with 10 ml of deionized water, heating is stirred for 1 hour, the heating temperature is 90 ° C, so that the PVA is completely dissolved in water, and the concentration is 0.1 g / ml gel liquid;

[0034]The ziF-7 is formed, the steps are as follows:

[0035]1 Weigh 0.92 g of ZIF-7 powder in a beaker, stir well;

[0036]2 Add a pre-referred amount of 0.03 g of MC powder, stir well, mix well;

[0037]3 Add 0.5 ml of the above-mentioned prepared PVA aqueous solution to the mixed powder in step 2, stir well, mix well;

[0038]4 The paste formed, extruded by the syringe, molded granulation, room temperature, gave spherical particles having a particle diameter of 3 mm;

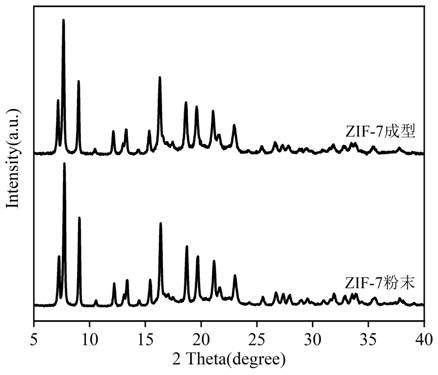

[0039]figure 1 The protected ziF-7 crystal structure is maintained compared to the original powder, and the XRD peak rema...

Embodiment 2

[0041]Improve the embodiments, increase the content of the MC, steps below:

[0042]1 Weigh 0.9 g of ZIF-7 powder in a beaker, stir well;

[0043]2 Add a pre-referred amount of 0.05 g of MC powder, stir well, mix well;

[0044]3 Add 0.5 ml of the above-mentioned prepared PVA aqueous solution to the mixed powder in step 2, stir well, mix well;

[0045]4 The paste formed, extruded by the syringe, molded granulation, room temperature, gave spherical particles having a particle diameter of 3 mm;

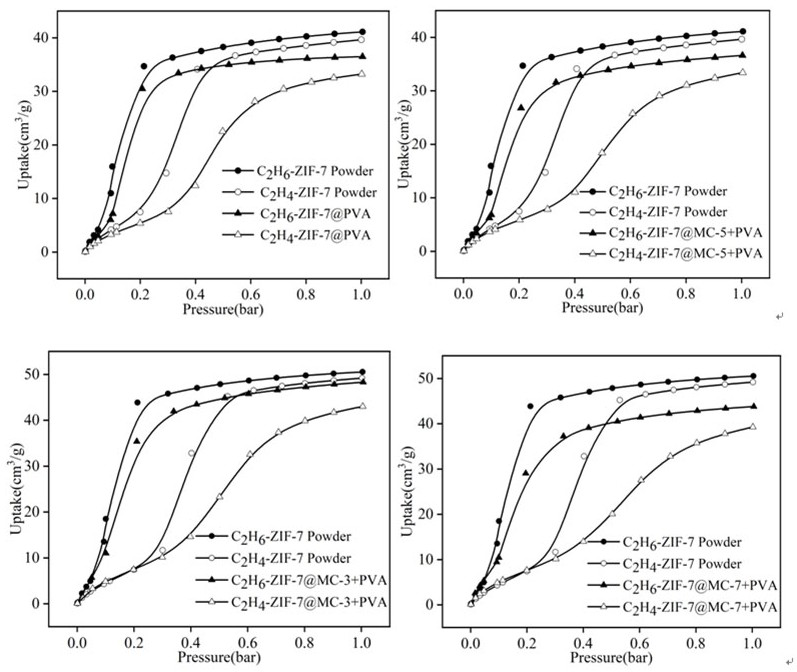

[0046]The spherical particle mechanical strength obtained by the above method reaches 68 N / , and the adsorption properties of 298K and 1BAR are compared to the primary powder, the adsorption performance can maintain the original adsorption performance, the same as the PVA forming method, and the separation performance is close to The structural stability is 550 ° C, which can fully meet the actual needs of the industrial.

Embodiment 3

[0048]Improvement in Example 2 increased by an MC content to 7%, steps as follows:

[0049]1 Weigh 0.88g ZIF-7 powder in a beaker, stir well;

[0050]2 Add a pre-referred to 0.07 g of MC powder, stir well, mix well;

[0051]3 Add 0.5 ml of the above-mentioned prepared PVA aqueous solution to the mixed powder in step 2, stir well, mix well;

[0052]4 The paste formed, extruded by the syringe, molded granulation, room temperature, gave spherical particles having a particle diameter of 3 mm;

[0053]The spherical particle mechanical strength obtained by the above method reaches 57 N / , the adsorption performance is poor, and the decrease is about 15%, and the thermal stability remains around 550 ° C.

[0054]byfigure 2 It can be seen that as the MC binder increases, the adsorption performance is gradually decreased, and the molded particle adsorption amount is only 10%, which can be realized than about 10% compared to ZIF-7 powder.2Hide6 / C2Hide4High efficiency separation.

[0055]FromFigure 4 It is seen t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com