Device and method for preparing nanometer calcium carbonate through micropore pipe

A technology of nano-calcium carbonate and microporous tubes, applied in the direction of calcium carbonate/strontium/barium, nanotechnology for materials and surface science, nanotechnology, etc., can solve the problem of no distribution, high power consumption, complicated cleaning process, etc. problem, to achieve the effect of uniform gas-liquid mixing, enhanced penetration ability, and enhanced dispersion degree

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

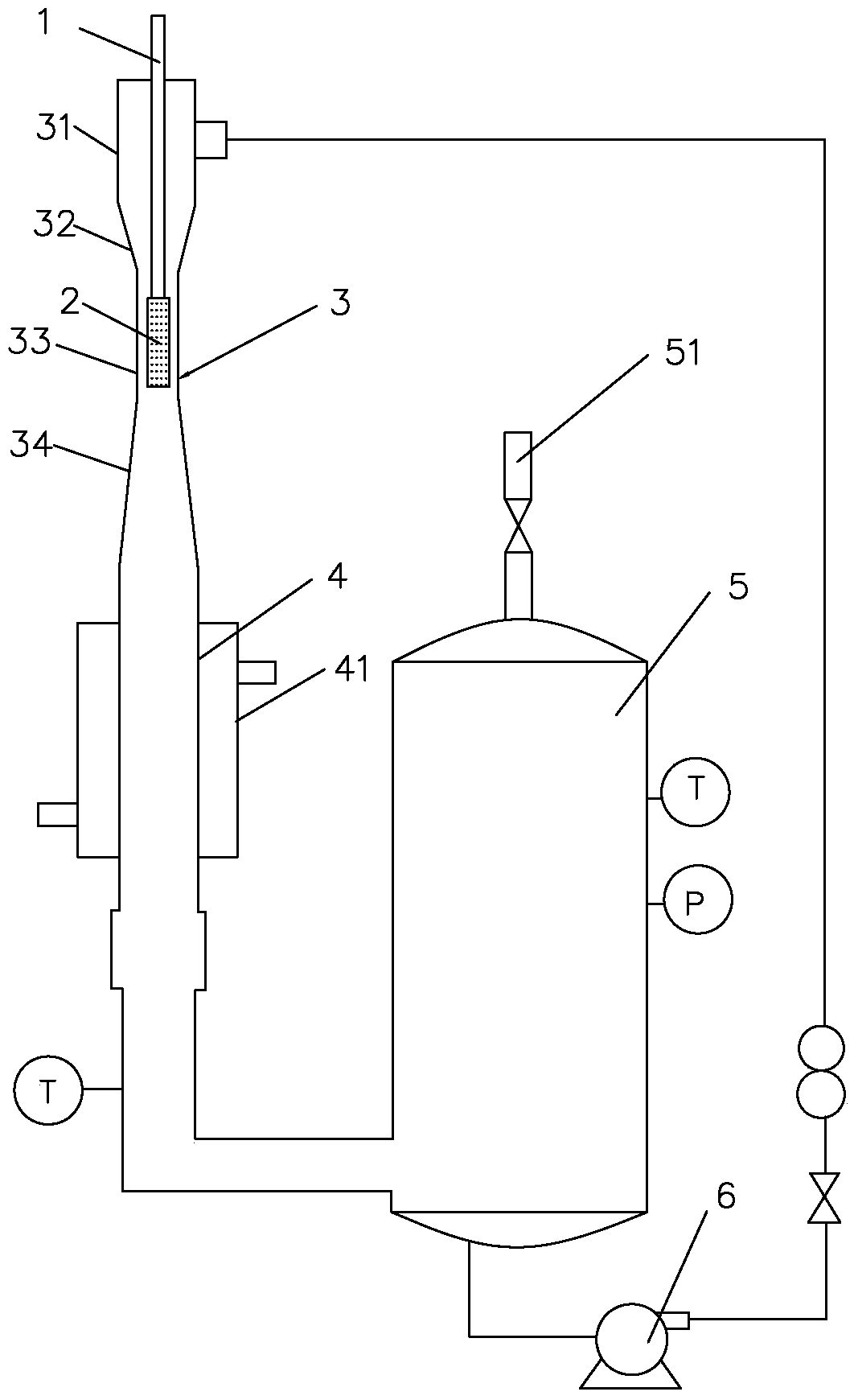

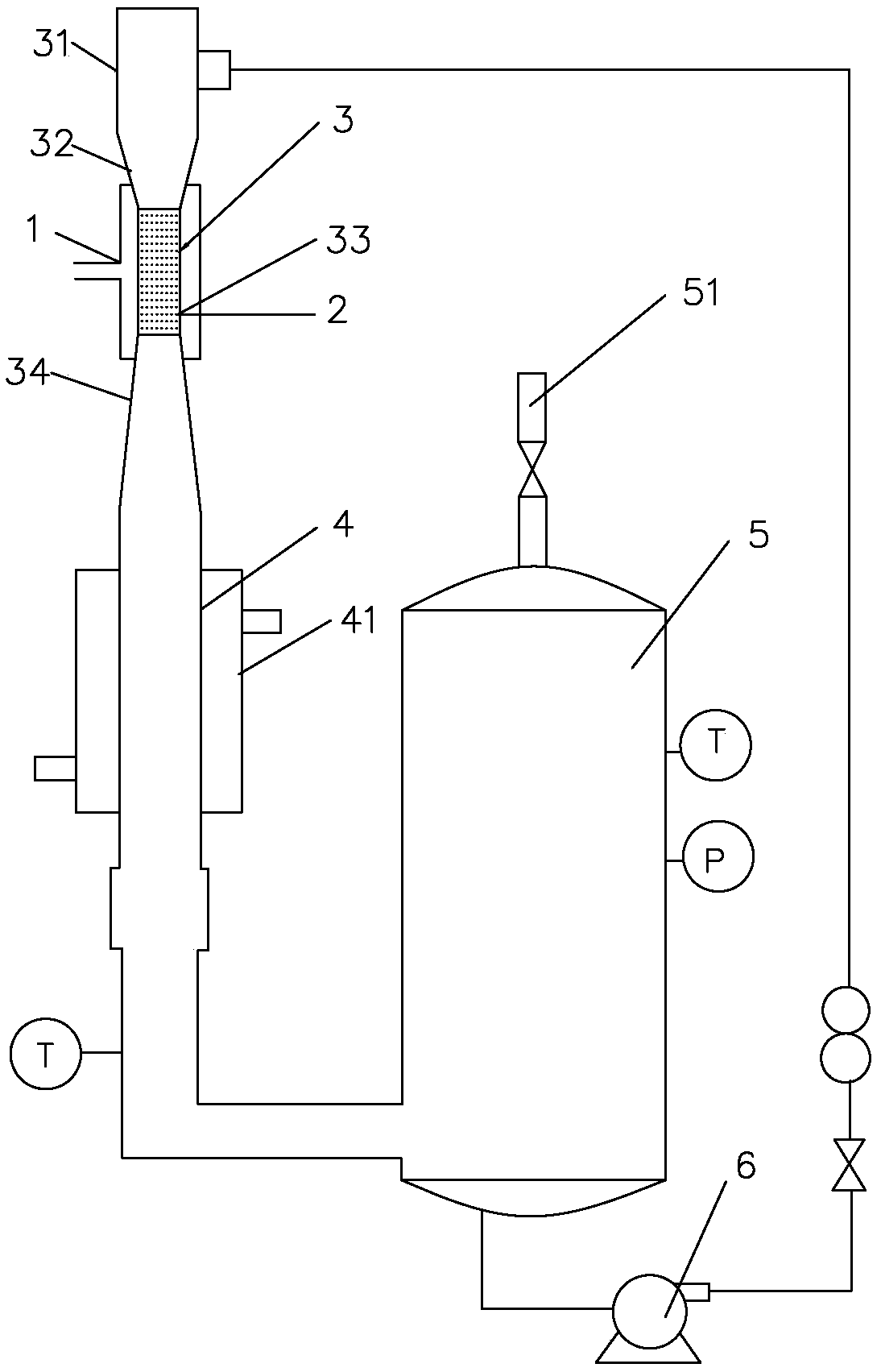

[0056] Such as figure 1 Shown, a kind of device that utilizes microporous tube to prepare nano-calcium carbonate of the present embodiment comprises microporous tube 2, air inlet pipe 1 and liquid storage tank 5, strong pump 6, powerful pump 6, Venturi tube 3, reaction tube 4, described Venturi tube 3 is made up of inlet section 31, constriction section 32, throat 33, diffusion section 34 connected in sequence, the liquid outlet of described liquid storage tank 5 is connected with powerful pump 6 connected to the liquid inlet, the liquid outlet of the powerful pump 6 is connected to the inlet section 31 of the Venturi tube 3, the diffusion section 34 of the Venturi tube 3 is connected to the liquid inlet of the reaction tube 4, and the reaction tube The liquid outlet of 4 links to each other with the liquid inlet of liquid storage tank 5, and described microporous pipe 2 is provided with air vent, air inlet wall and air outlet wall, and described air vent connects air inlet wa...

Embodiment 2

[0063] Such as figure 1 As shown, the difference between the device for preparing nano-calcium carbonate using microporous tubes in this embodiment and Example 1 is that the pore diameter of the microporous tubes 2 is 20 μm.

[0064] The present embodiment utilizes microporous tube to prepare the method for nano-calcium carbonate, comprises the steps: (1) enter liquid: the calcium hydroxide suspension liquid of liquid storage tank 5 is delivered to the entrance of Venturi tube 3 under the effect of powerful pump 6 Section 31, wherein the Baume concentration of calcium hydroxide slurry is 10 ° Be ', and flow velocity is 88L / min; (2) mixing: carbon dioxide gas is passed in the inlet pipe 1, and carbon dioxide gas passes through the pipe wall of microporous pipe 2 Carbon dioxide microbubbles are formed, mixed with the calcium hydroxide suspension liquid flowing through the throat 33 of the Venturi tube 3 at high speed to form a gas-liquid mixed foam, wherein the gas pressure volu...

Embodiment 3

[0067] Such as figure 1 As shown, the difference between the device for preparing nano-calcium carbonate using microporous tubes in this embodiment and Example 1 is that the pore diameter of the microporous tubes 2 is 60 μm.

[0068]The present embodiment utilizes microporous tube to prepare the method for nano-calcium carbonate, comprises the steps: (1) enter liquid: the calcium hydroxide suspension liquid of liquid storage tank 5 is delivered to the entrance of Venturi tube 3 under the effect of powerful pump 6 Section 31, wherein the Baume concentration of the calcium hydroxide slurry is 6 ° Be ', and the flow rate is 30L / min; (2) mixing: carbon dioxide gas is passed into the intake pipe 1, and the carbon dioxide gas passes through the pipe wall of the microporous pipe 2 Carbon dioxide microbubbles are formed, mixed with the calcium hydroxide suspension liquid flowing through the throat 33 of the Venturi tube 3 at high speed to form a gas-liquid mixed foam, wherein the volu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com