Patents

Literature

51results about How to "Synthetic even" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

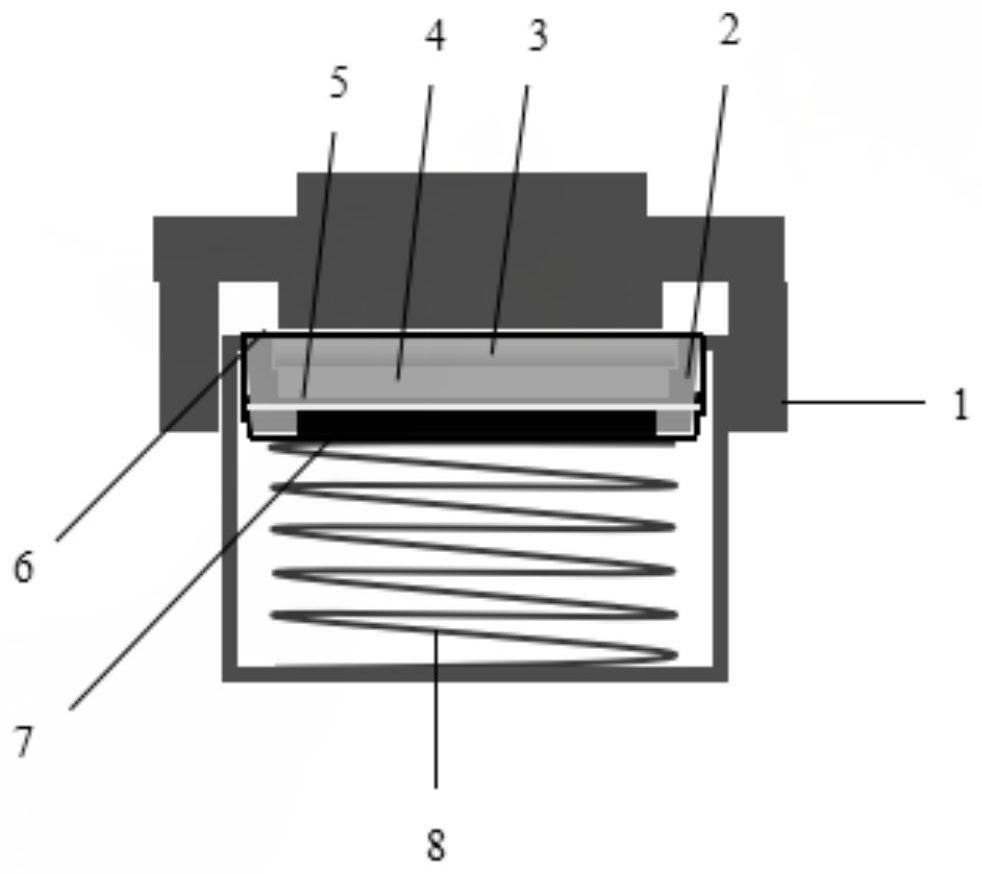

High-performance lithium iron phosphate cathode material and preparation method of lithium iron phosphate cathode material

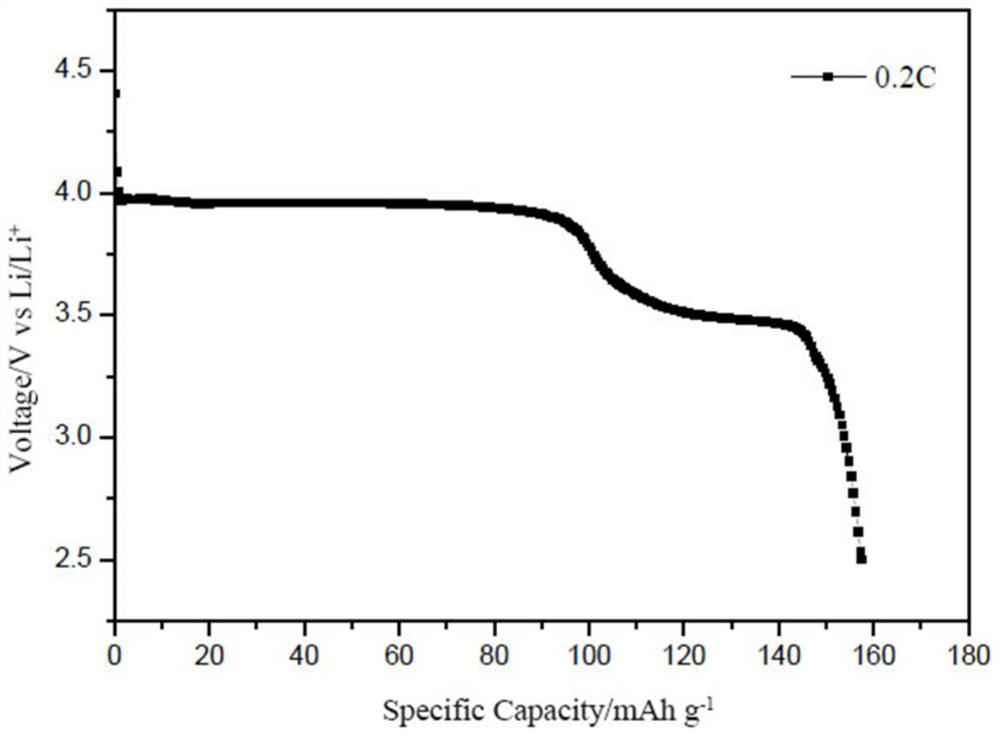

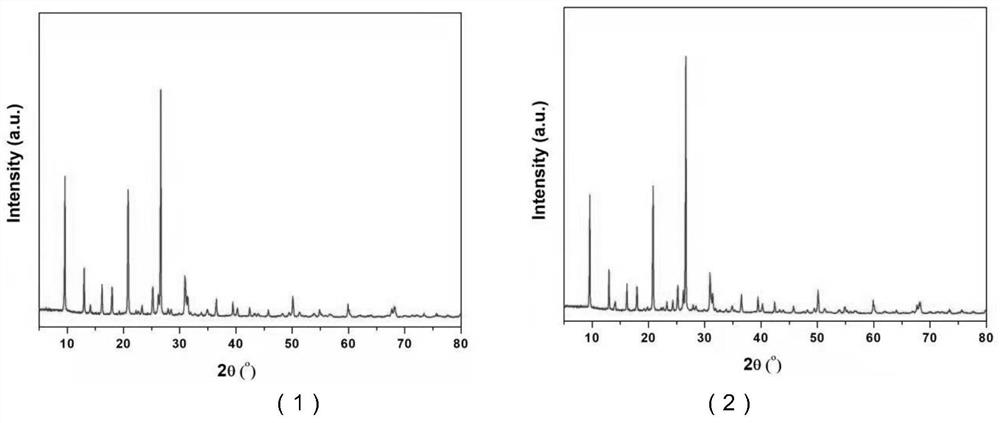

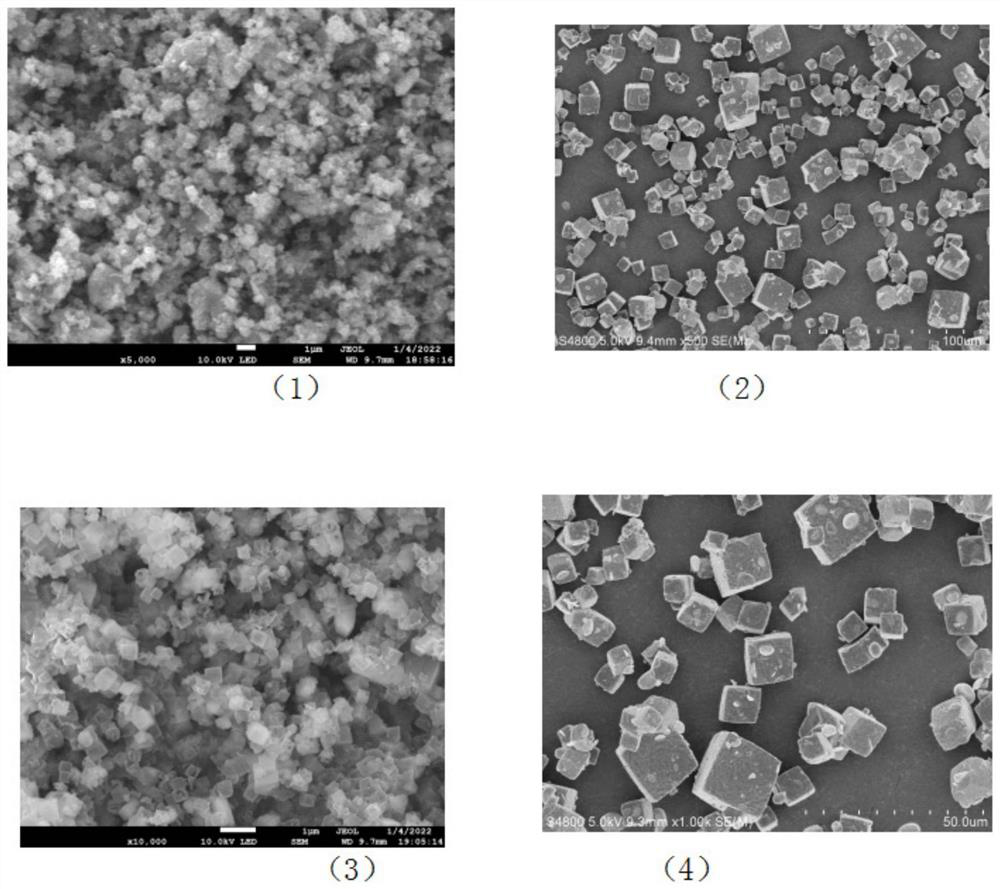

The invention relates to a cathode material lithium iron phosphate for a lithium ion cell and a preparation method of lithium iron phosphate. The preparation method comprises the following steps: synthesizing a lithium iron phosphate cathode material through a hydrothermal method by taking a ferric iron salt as an iron source and a nanocrystalline metal oxide as a doped source, subsequently mixing lithium iron phosphate with organic acid or sugars, and sintering at high temperature to obtain the high-performance lithium iron phosphate cathode material coated by carbon. According to the preparation method disclosed by the invention, the ferric iron salt with low price is used as the raw material, so that the cost is saved; and the nanoscale metal oxide is used as the doping element, so that a crystal nucleus is provided for hydrothermal crystallization and the implementation of the reaction is accelerated.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

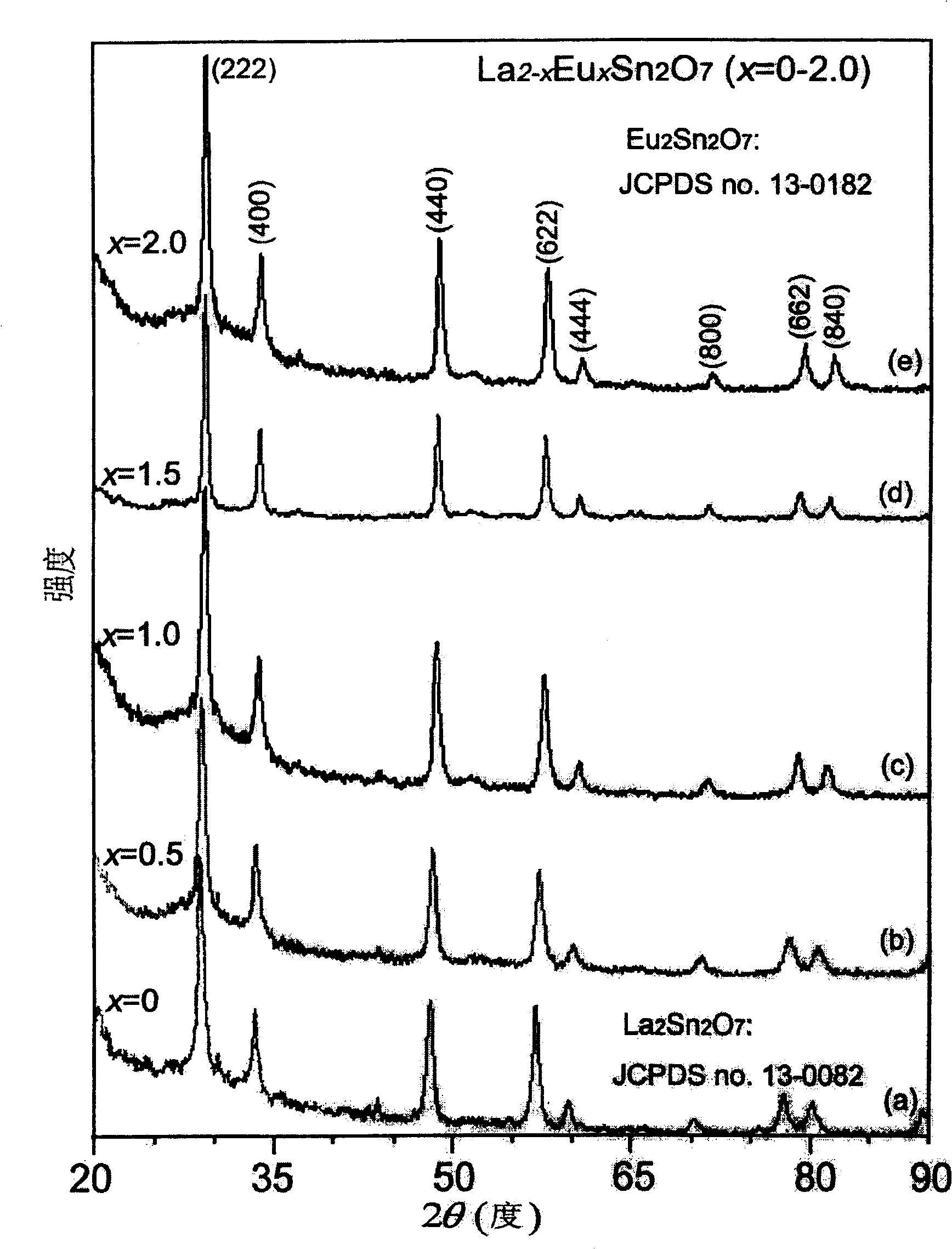

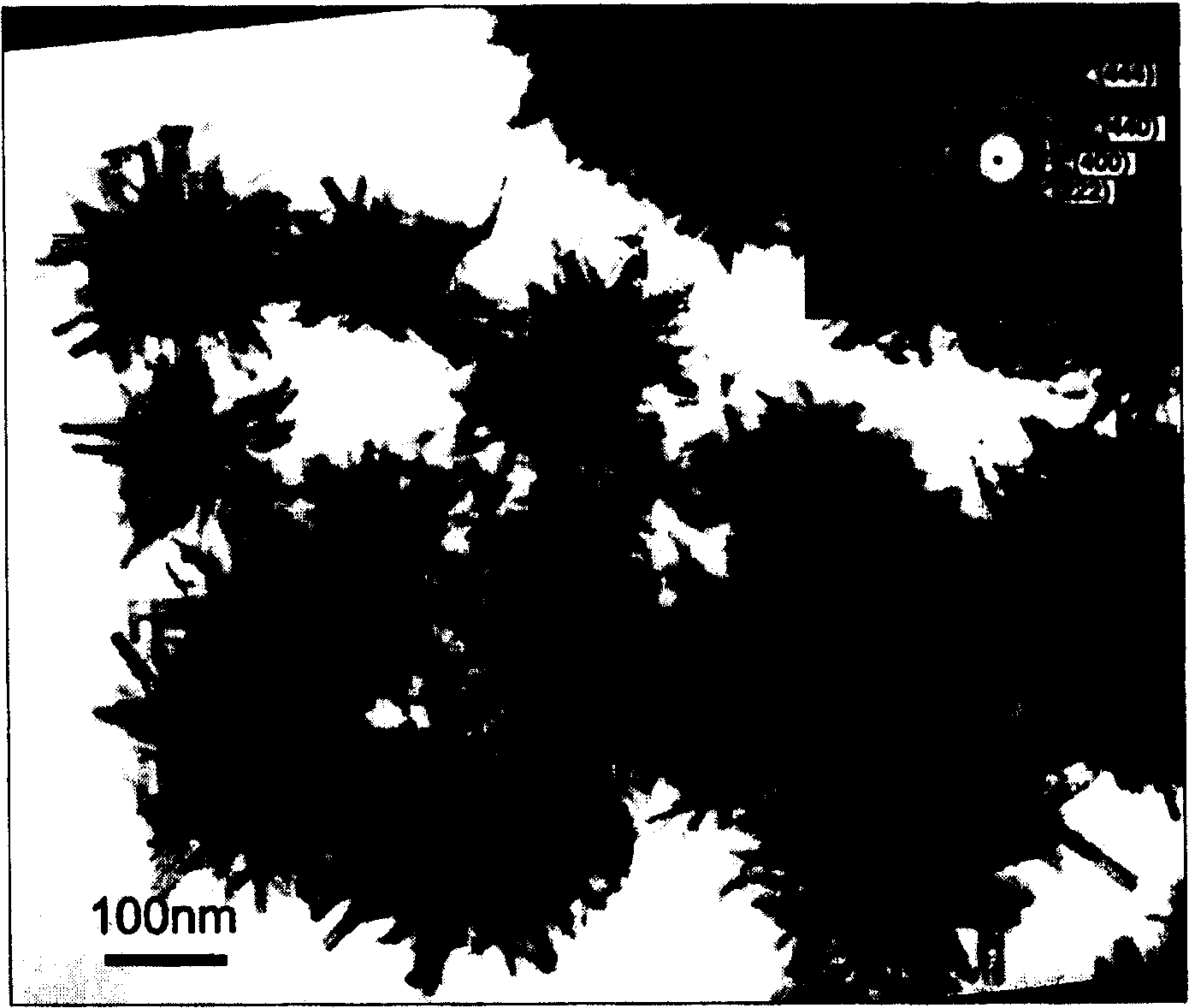

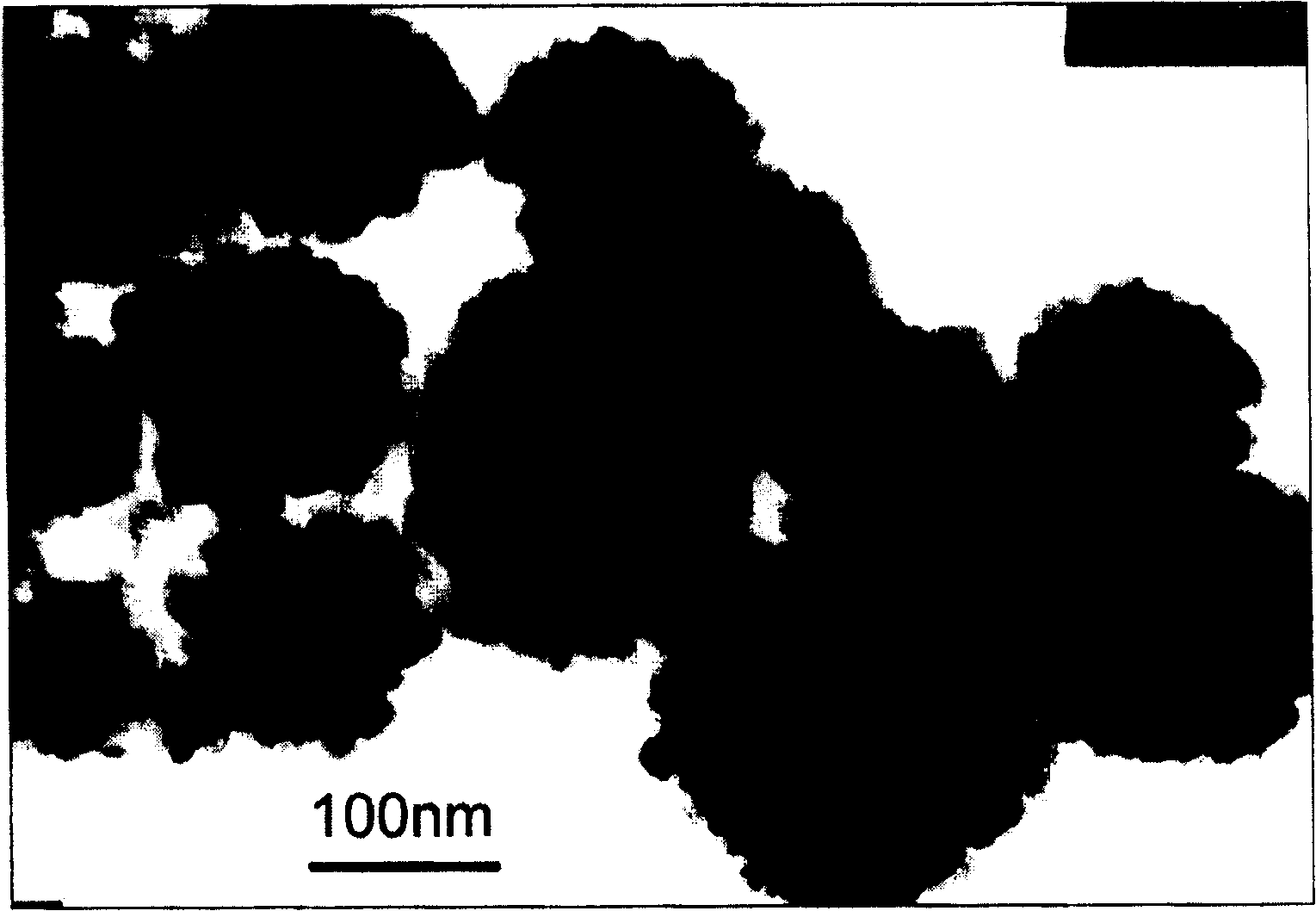

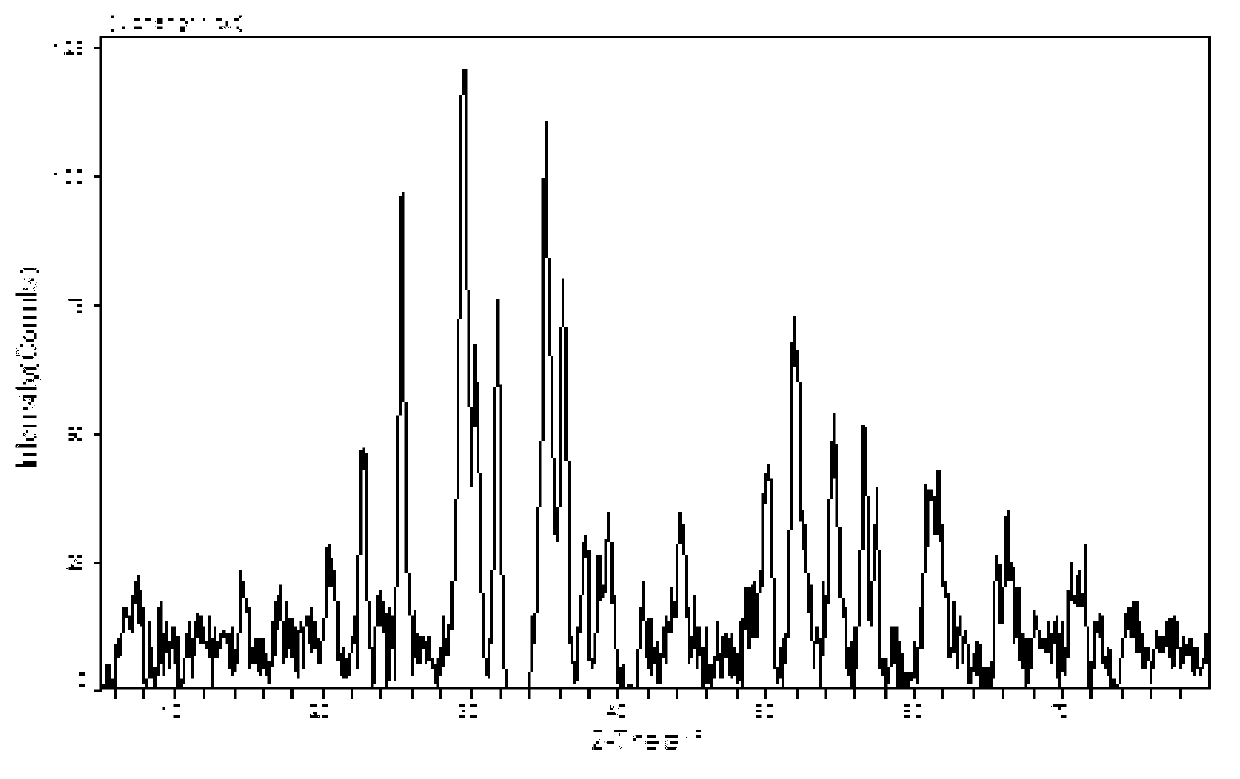

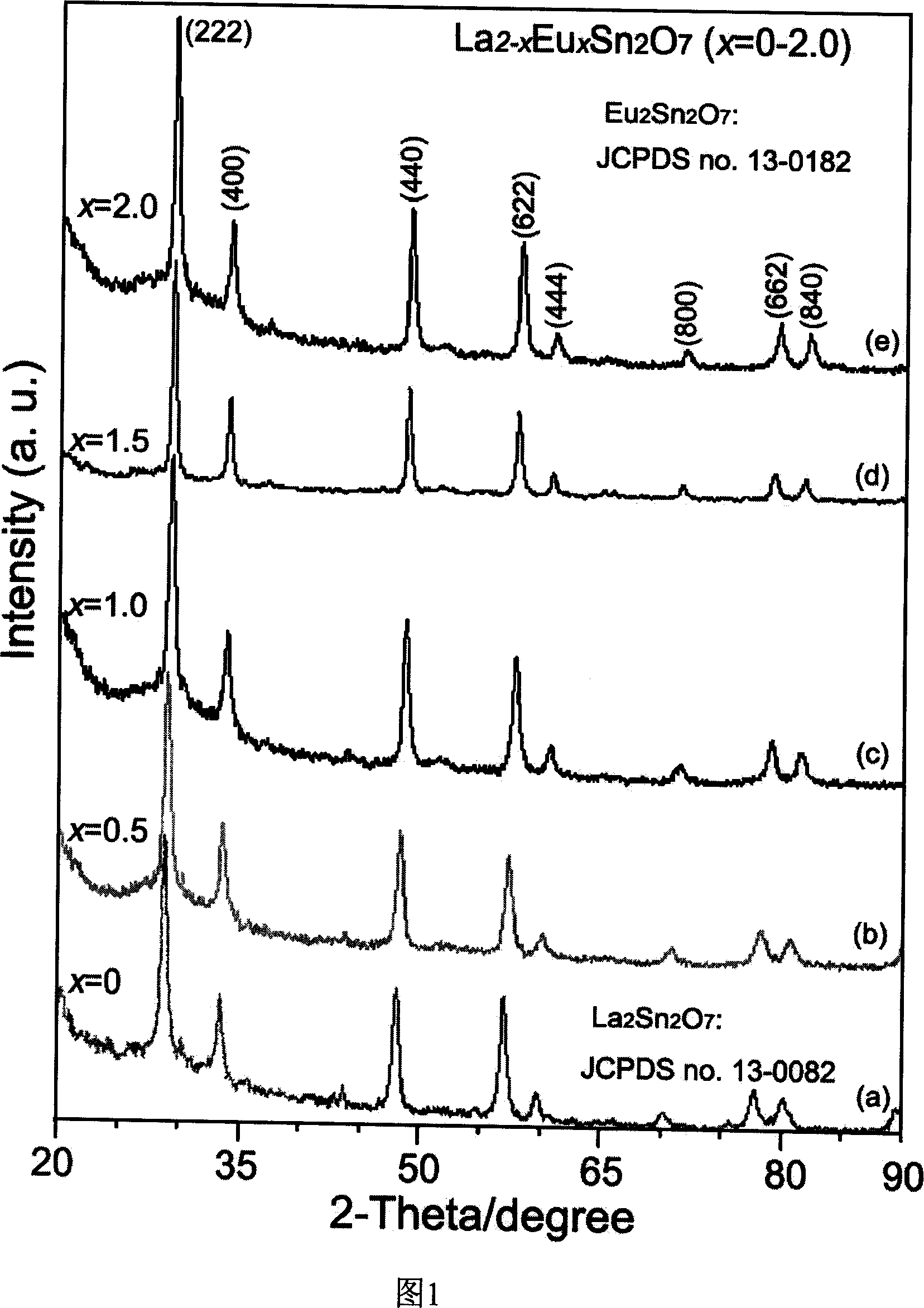

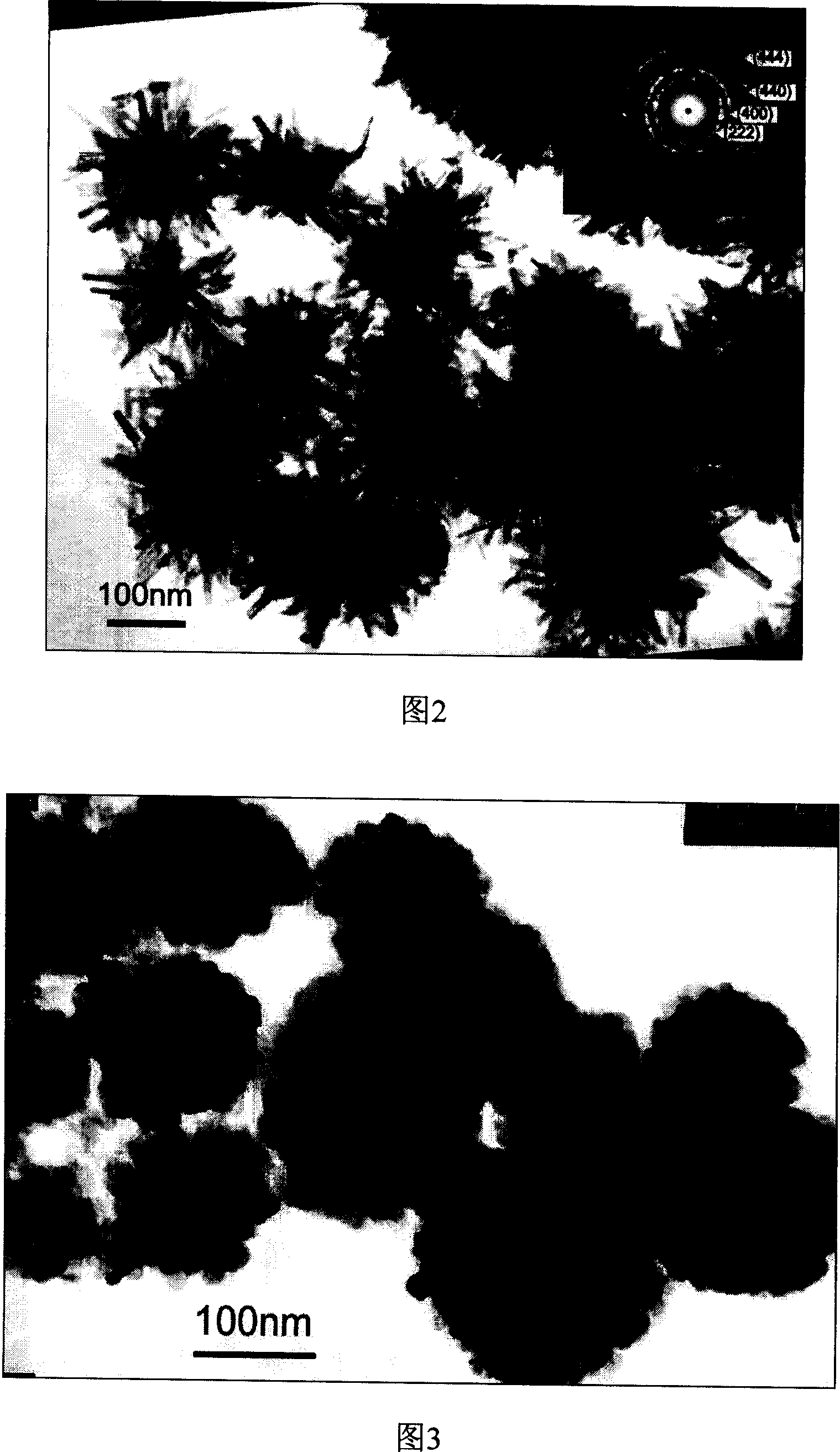

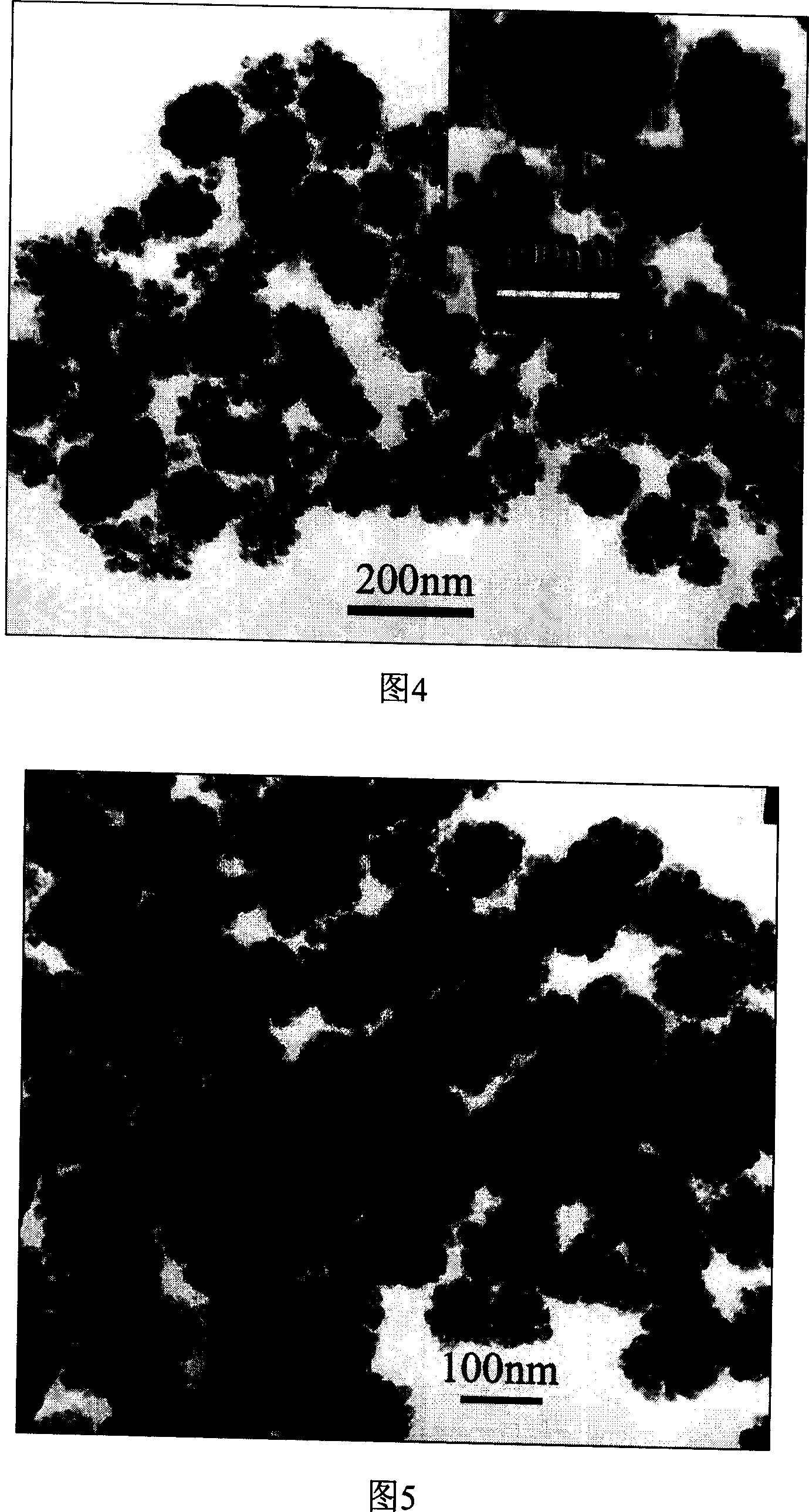

Lanthanum stannate, europium stannate and its composite stannate nanopowder synthesis method

InactiveCN1951822AAchieve synthesisThe ratio can be adjusted arbitrarilyTin compoundsRare earth metal compoundsRare earthPotassium

The invention discloses a synthesizing method of lanthanum stannate, europium stannate and composite stannate nanometer powder, which comprises the following steps: dissolving lanthanum stannate and europium stannate with different molar rates or lanthanum stannate or europium stannate in the deionized water; stirring; adding sodium stannate or potassium stannate with the molar weight as the sum of lanthanum stannate and europium stannate in the solution; stirring; putting terminal solution into high-pressure autoclave; setting the filling density at 80-90%; disposing for 4-30h within 180-250 deg.c through hot water; centrifuging the disposed solution; cleaning; drying the product; obtaining the product with diameter at 15-35nm. The molecular formula of the product is La2-xEuxSn2O7 (x=02), which produces single and one-phase product.

Owner:ZHEJIANG SCI-TECH UNIV

Process for producing lithium ion battery anode material ferrtilithium phosphate

InactiveCN1741301AHigh yieldLow costElectrode manufacturing processesLithium compoundsMicrowave ovenBall mill

A method for preparing lithium iron orthophosphate being used as material of lithium cell positive electrode includes mixing iron orthophosphate with lithium phosphate and cane sugar according to designed ratio , grinding mixture by dry method in grinder for 12 ¿C 36 hours , putting ground power into heat ¿C treatment oven for carbonization , forming plate by pressing , placing plate in container and placing container into microwave oven for synthesizing reaction , grinding reacted matter to be powder being able to pass through 400 micron screen for being used as final product .

Owner:GUIZHOU NEW MATERIAL MINING DEV

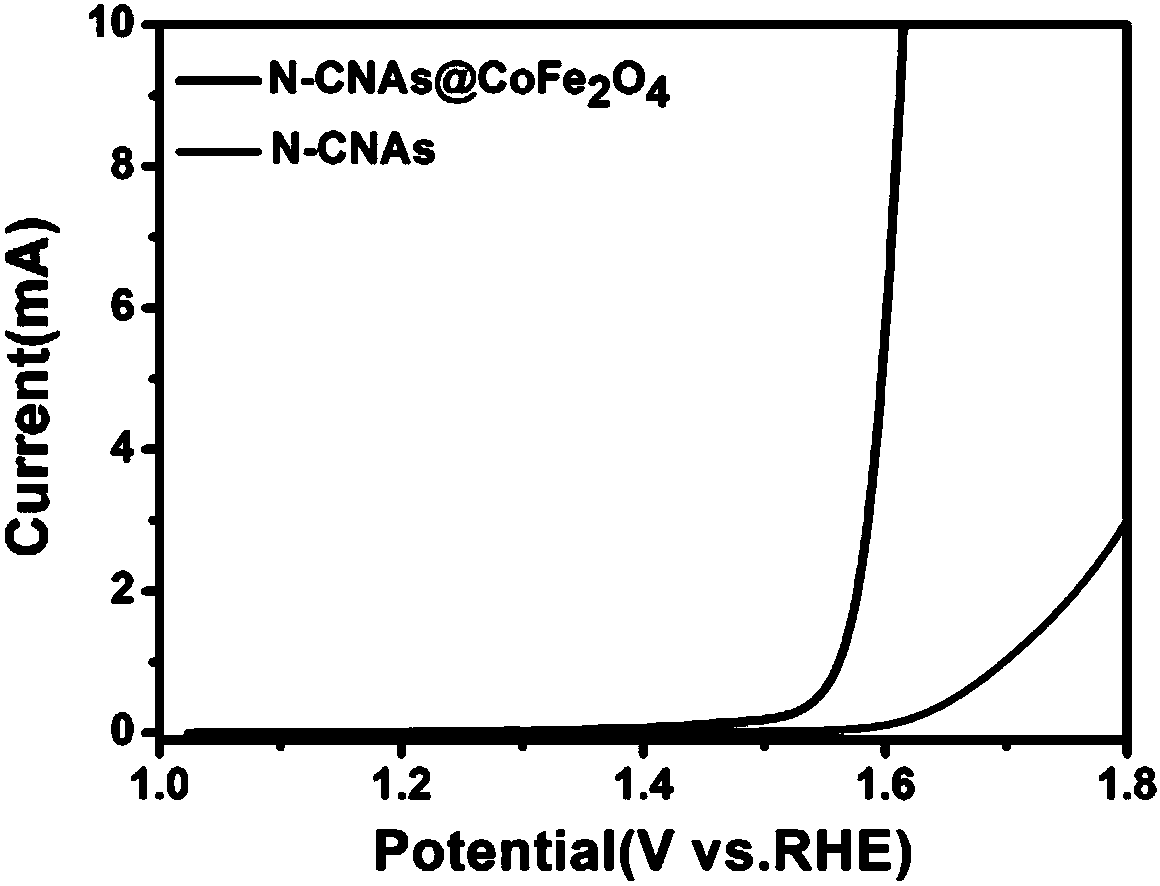

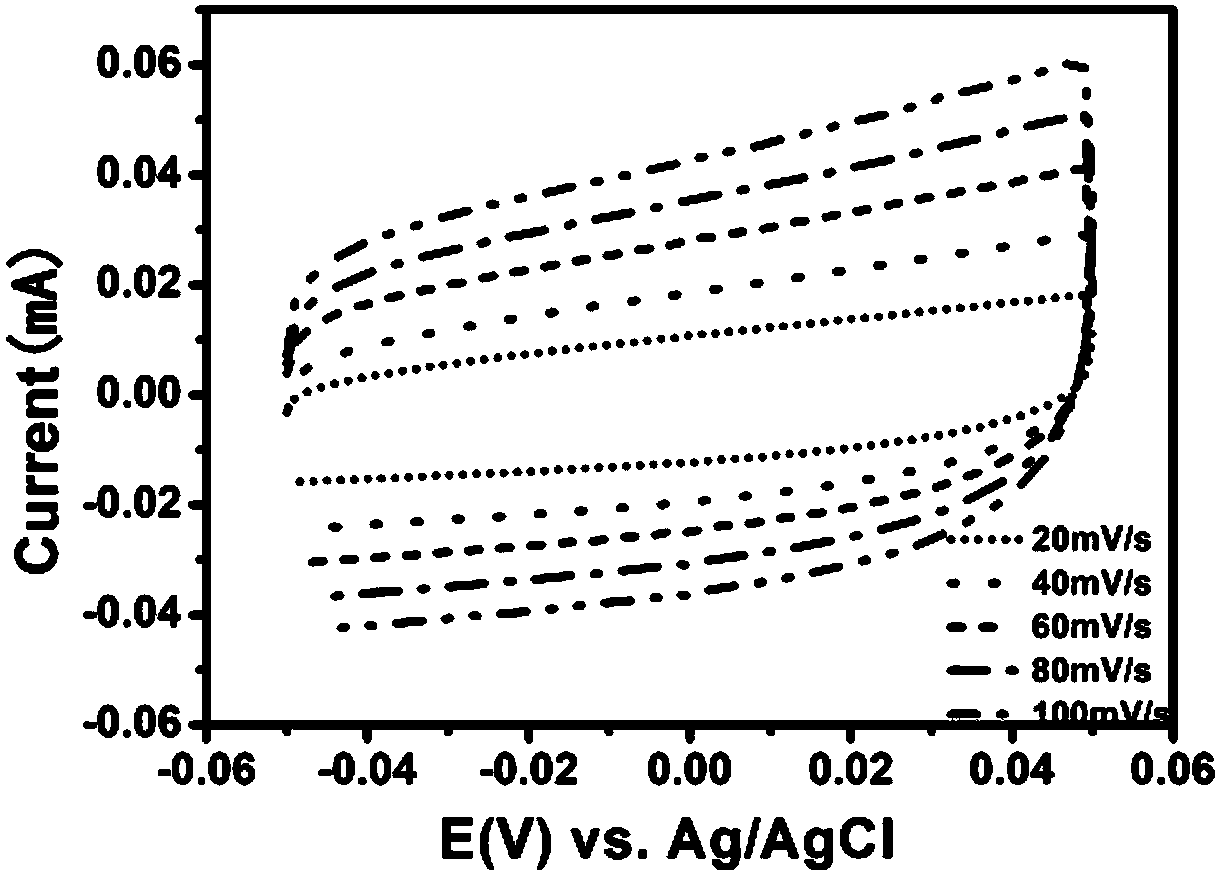

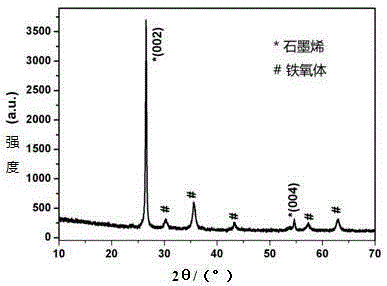

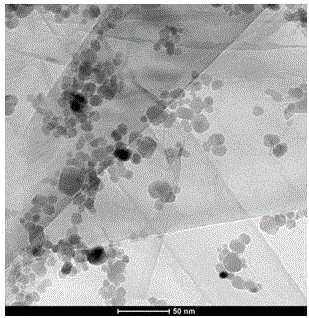

Nitrogen-doped carbon nano-array/ cobalt ferrite material

InactiveCN108183228ALarge specific surface areaMany catalytic sitesCell electrodesConductive polymerMetal-organic framework

The invention provides a nitrogen-doped carbon nano-array / cobalt ferrite material obtained by calcining a polyaniline-iron-cobalt metal organic framework, the nano material is a double-metal oxide, and has a large specific surface area, a plurality of catalytic sites, and higher catalytic efficiency. The polyaniline-iron-cobalt metal organic framework has good compatibility with various metal ions, a uniform multi-metal spinel can be easily synthesized from the polyaniline-iron-cobalt metal organic framework, the double-metal oxide and a conductive polymer are combined, so that advantages of different types of electrode materials can be combined with each other, and at the same time, nitrogen-doped carbon can be formed by polyaniline calcination, conductivity is further improved, and the defects of poor conductivity and poor stability of iron-cobalt oxides can be solved.

Owner:UNIV OF JINAN

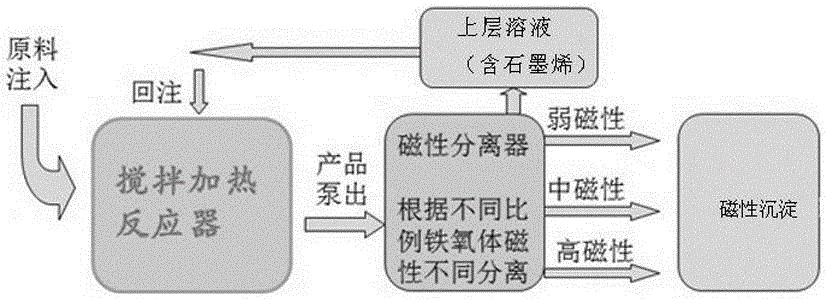

Continuous synthesis method of graphene/ferrite nanocomposite

InactiveCN105199667AImprove absorbing performanceGood dispersionOther chemical processesNickel saltHigh volume manufacturing

The invention discloses a continuous synthesis method of a graphene / ferrite nanocomposite. According to the synthesis method, the graphene / ferrite nanocomposite is prepared by taking graphene, sodium hydroxide aqueous solution and ferric salt solution or ferric salt solution doped with nickel salt and zinc salt and adopting a reverse co-precipitation method. By adopting the synthesis method, continuous synthesis of the nanocomposite is realized by continuous material injection and continuous magnetic separation and output of products, obtained ferrite and graphene are mixed evenly and are combined firmly, and an excellent absorbing property is achieved. Therefore the synthesis method has the advantages of continuous synthesis capability, low synthesis temperature, low energy consumption, low cost and quantity production capability, and has better application prospect.

Owner:李同乐 +2

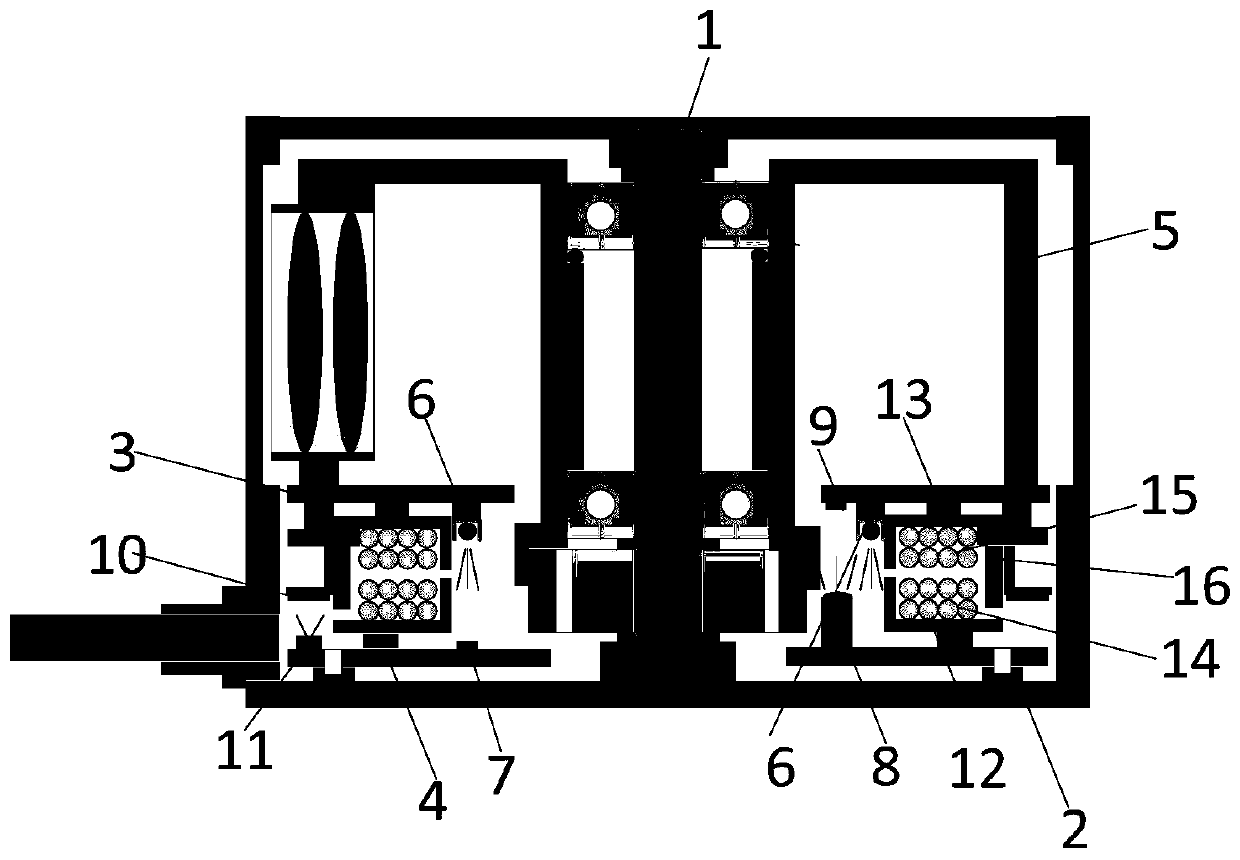

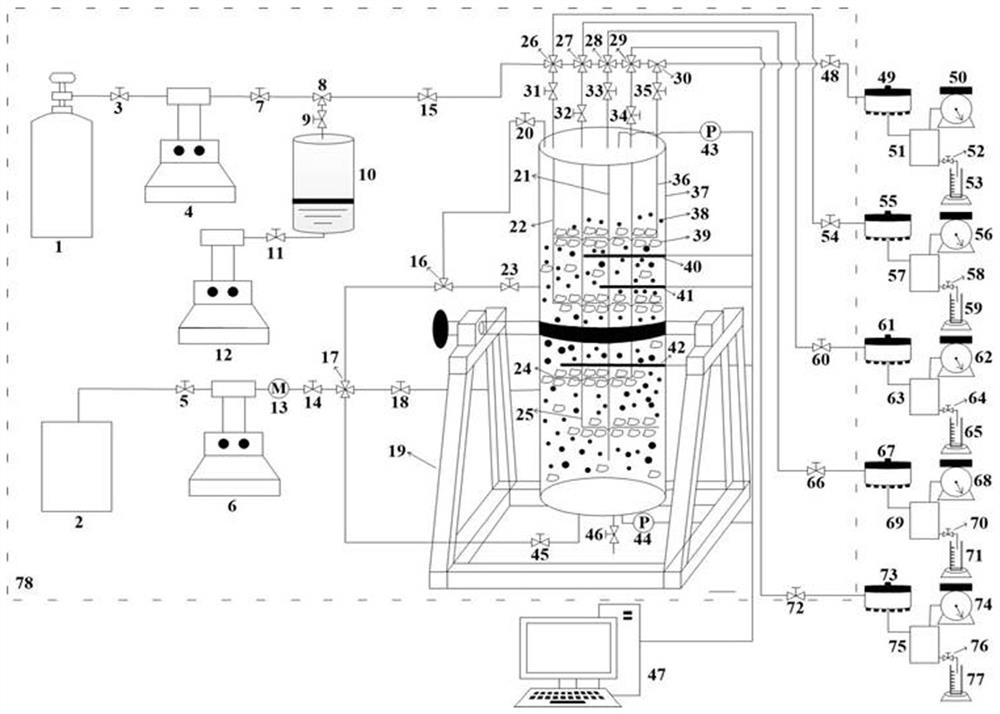

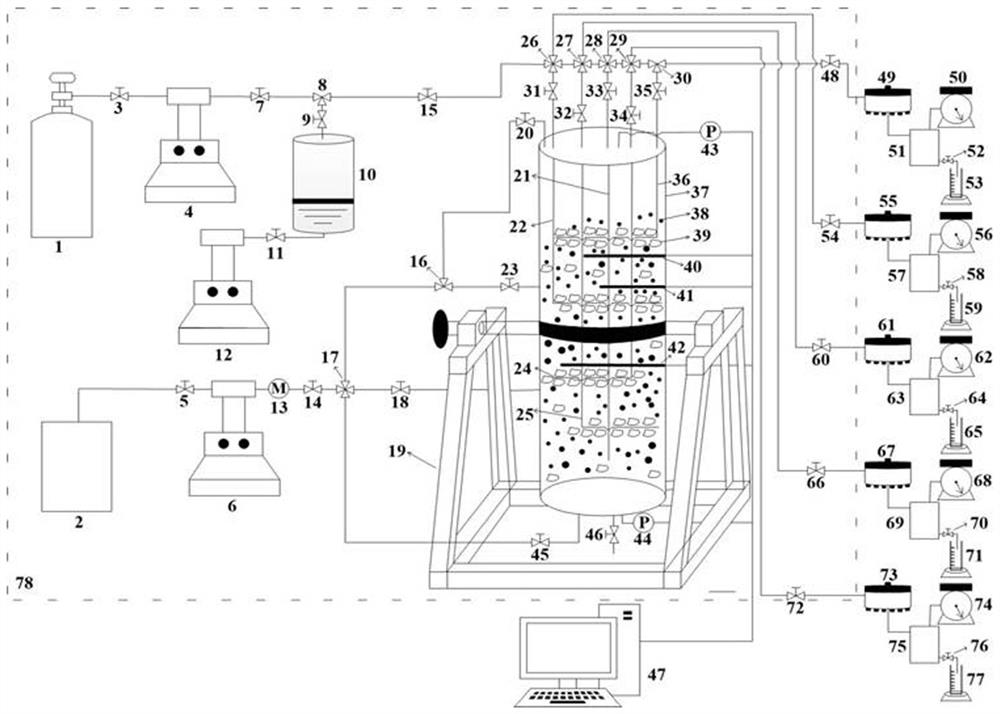

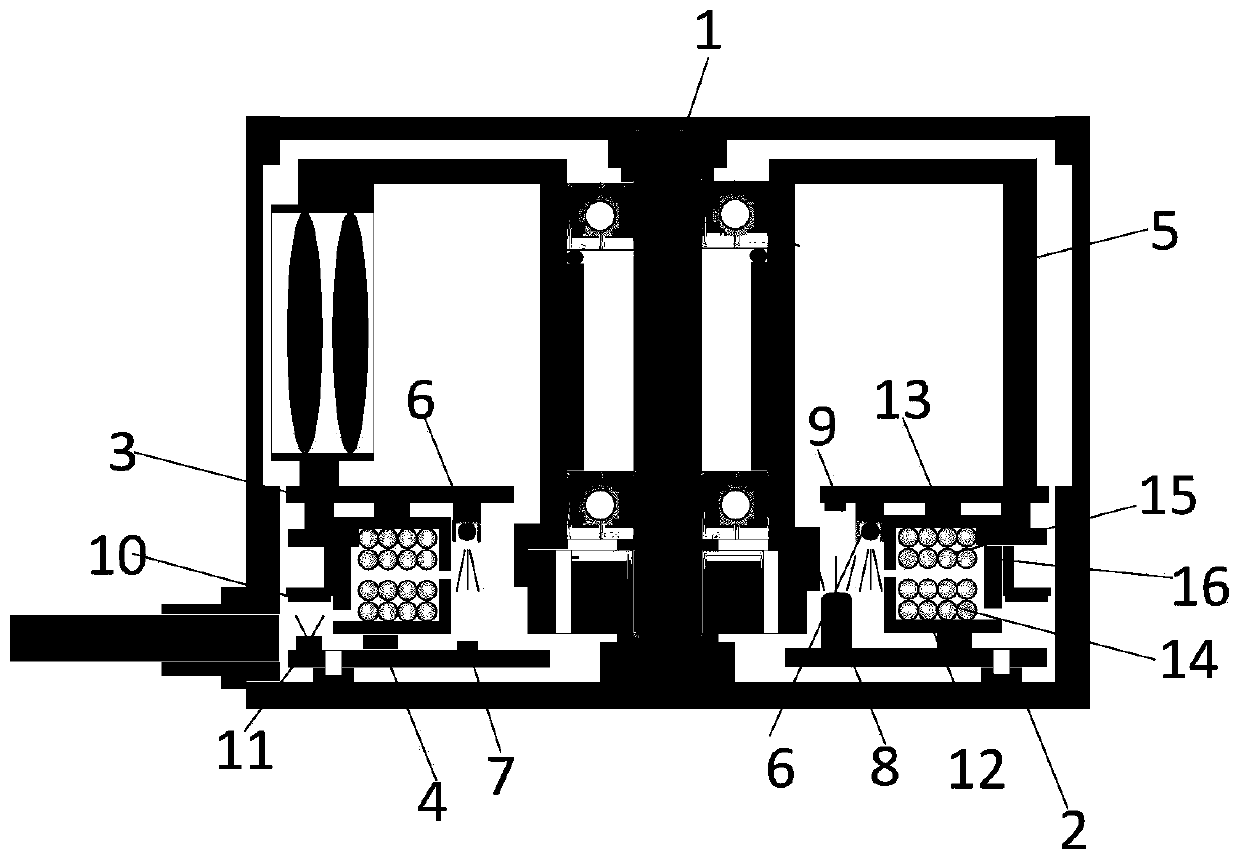

Reservoir forming and developing simulated experiment system and method for submarine natural gas hydrate

ActiveCN111794722ASynthesis fastSynthetic evenFluid removalEducational modelsGraduated cylinderHorizontal wells

The invention relates to a reservoir forming and developing simulated experiment system and method for submarine natural gas hydrate. The reservoir forming and developing simulated experiment system and method for submarine natural gas hydrate consists of a fluid injection part, a hydrate synthesis / decomposition part and a withdrawal fluid metering part, wherein the fluid injection part comprisesa high-pressure displacement pump, a natural gas cylinder, a middle container and a seawater storage tank; the hydrate synthesis / decomposition part comprises a high-low-temperature test box, a high-pressure reaction kettle, a simulating straight well pipeline, a simulating horizontal well pipeline, a temperature sensor, a pressure sensor and a computer, wherein the high-pressure reaction kettle ispositioned in the high-low-temperature test box; fluid injection and withdrawal interfaces are uniformly distributed in the end cover and the wall surfaces of a kettle body; the pressure sensor and the temperature sensor are connected to the computer through guide-out wires; and the withdrawal fluid metering part comprises a back-pressure valve, a gas-liquid separator, a measuring barrel and a gas meter. The system can be utilized to perform experiments such as submarine natural gas hydrate synthesis simulation or submarine natural gas hydrate exploitation, is simple and convenient in operation, and can provide important support for submarine natural gas hydrate reservoir development technical evaluation and establishment.

Owner:SOUTHWEST PETROLEUM UNIV

Method of preparing zirconium diboride/aluminum-ferric trioxide composite powder

InactiveCN101033143ASynthetic evenReduce production efficiencySelf-propagating high-temperature synthesisAl powder

This invention relates to a method for composing high performance and easy sintered ZrB2 / Al2O3-Fe compound powder by self-spread high temperature recovery and ball-mill technology including: mixing ZrO2, B2O3 and Al powder uniformly and pressing to molding, then putting it in a self-spread high temperature composition device protected by Ar to ignite and fire it, which is crushed to get pure ZrB2-Al2O3 ceramic complex phase powder to be ball-milled with simple substance Fe powder to get a ZrB2 / Al2O3-Fe compound powder.

Owner:FUDAN UNIV

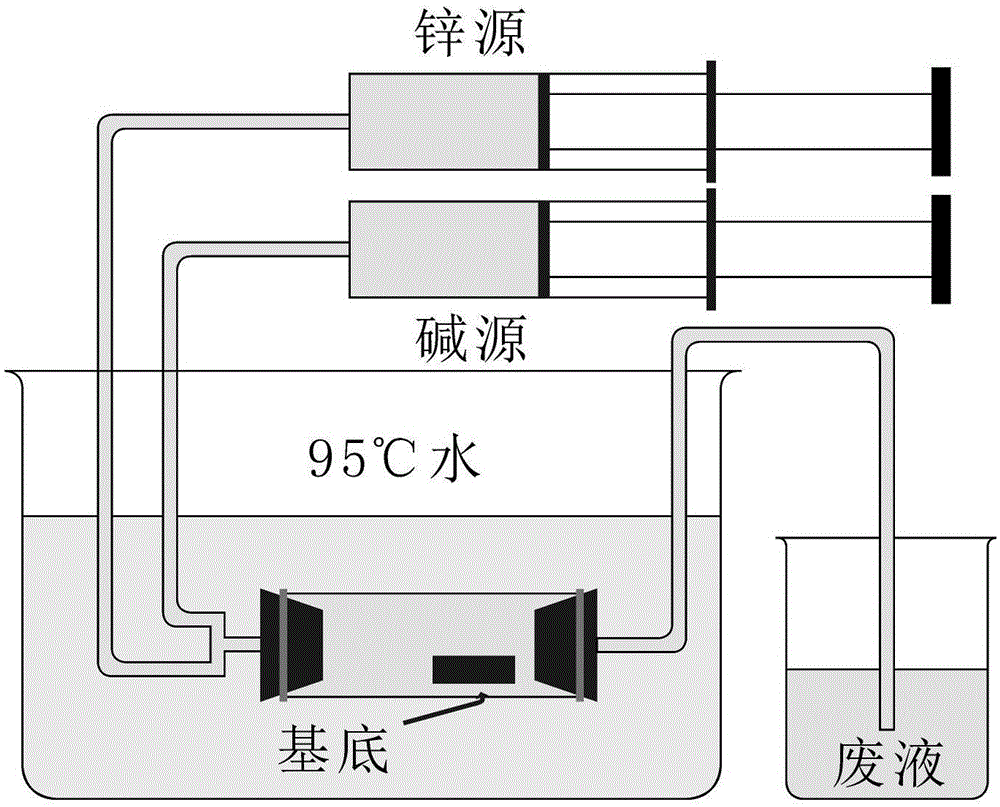

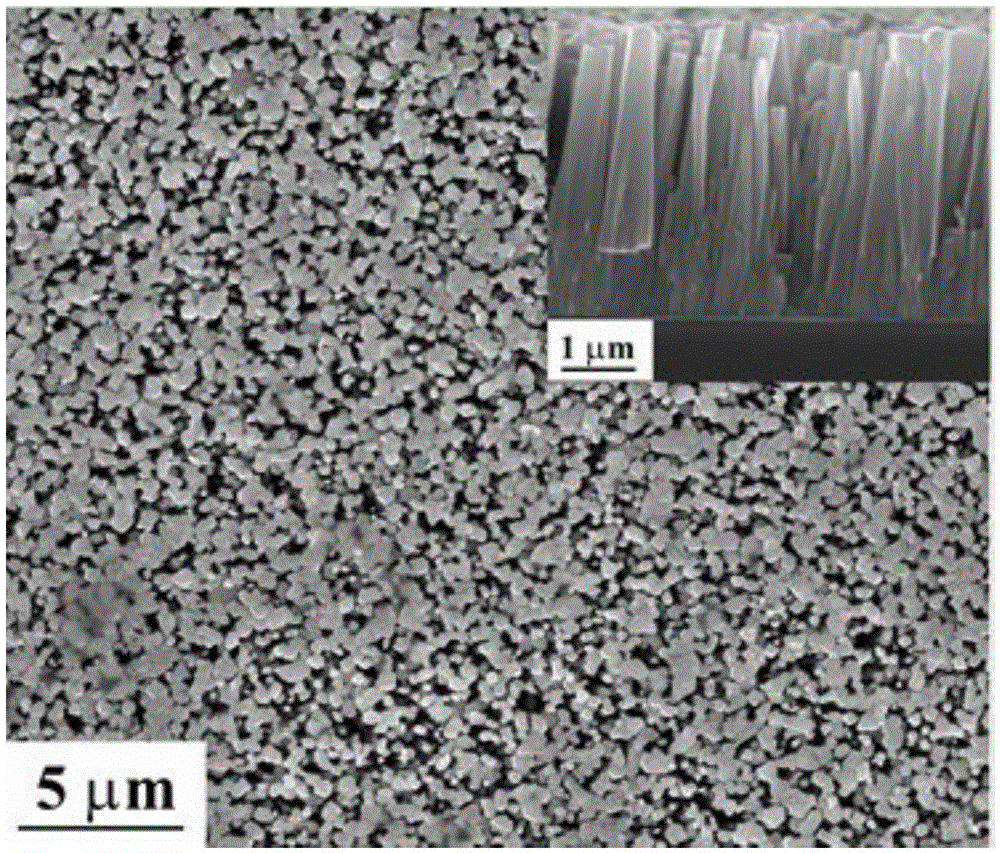

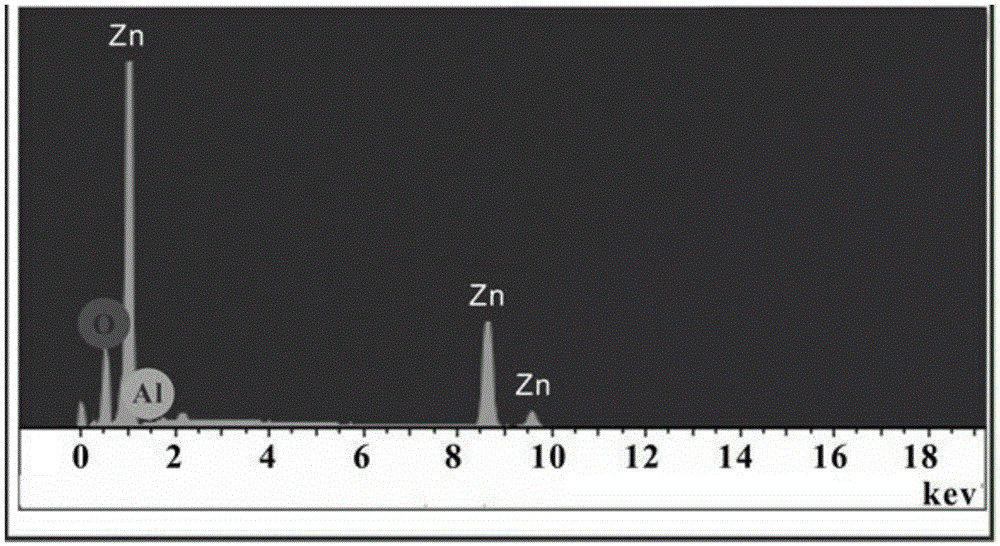

Preparation method for aluminum-doped zinc oxide (AZO) nano array

ActiveCN105118694AConstant concentrationHigh crystallinityHybrid capacitor electrodesHybrid/EDL manufactureChemical reactionAluminum doped zinc oxide

The invention provides a preparation method for an aluminum-doped zinc oxide (AZO) nano array. The method is performed as follows: precisely controlling the concentration of chemical reaction solution by continuously injecting growing sources and doping sources at a constant speed to controllably prepare an aluminum-doped zinc oxide (AZO) array with high carrier concentration; compounding the aluminum-doped zinc oxide (AZO) array and a nickel oxide material to obtain a capacitor electrode material with high electricity capacity. The capacitor electrode material with high electricity capacity is attained in such a way that an aluminum-doped zinc oxide (AZO) array with high conductivity prepared by a continuous flow injecting method and a nickelnanosheet material with poor conductivity but high electricity capacity are combined. In comparison to a conventional hydrothermal method, the carrier concentration obtained from the preparation method provided in the invention increases three orders of magnitude. In the method, an aluminum-doped zinc oxide (AZO) material with high carrier concentration and a nickel oxide with poor conductivity are combined such that the advantages of the two materials are brought into full play and the electricity capacity of a capacitor is substantially increased. Beyond that, the continuous flow injecting and doping method provides a new idea for controllable precise doping. The method is simple in operation, cost-effective and enjoys great application prospects.

Owner:UNIV OF SCI & TECH BEIJING

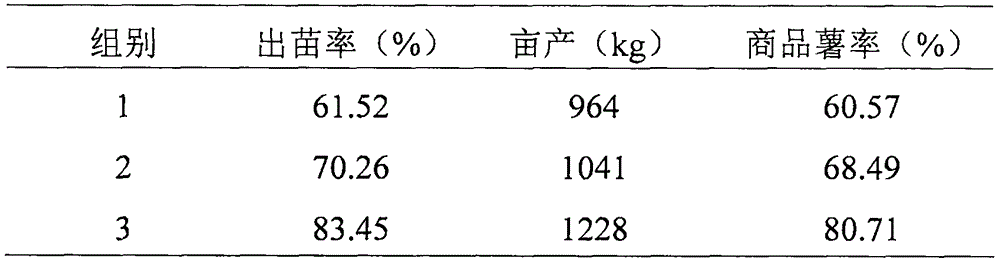

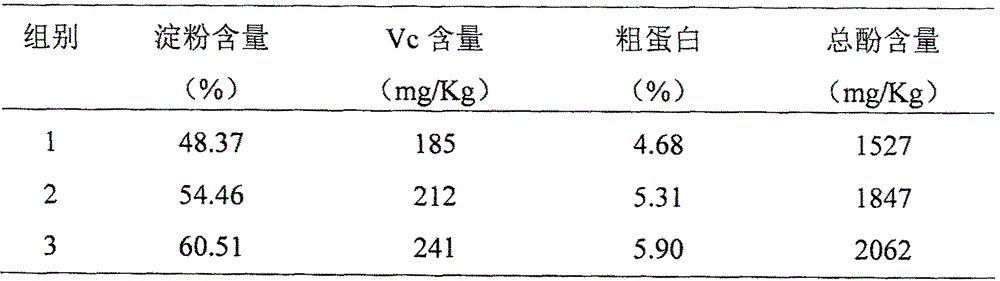

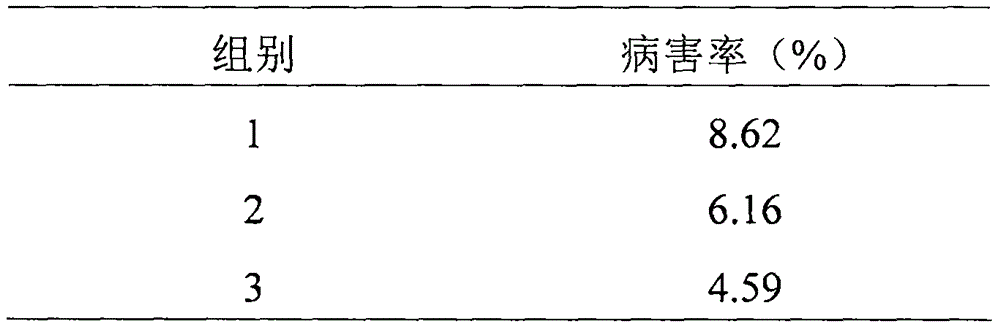

Sweet potato seed processing method

ActiveCN106612739AReduce the possibilityAvoid spreadingCalcareous fertilisersNitrogenous fertilisersAgricultural sciencePlant disease resistance

The invention belongs to the field of agricultural cultivation and particularly relates to a sweet potato seed processing method. The sweet potato seed processing method can significantly improve the emergence rate, the disease resistance and the yield of sweet potatoes, enhance quality of sweet potatoes and promote development of sweet potato cultivation industry.

Owner:JIANGSU COASTAL AREA AGRI SCI RES INST

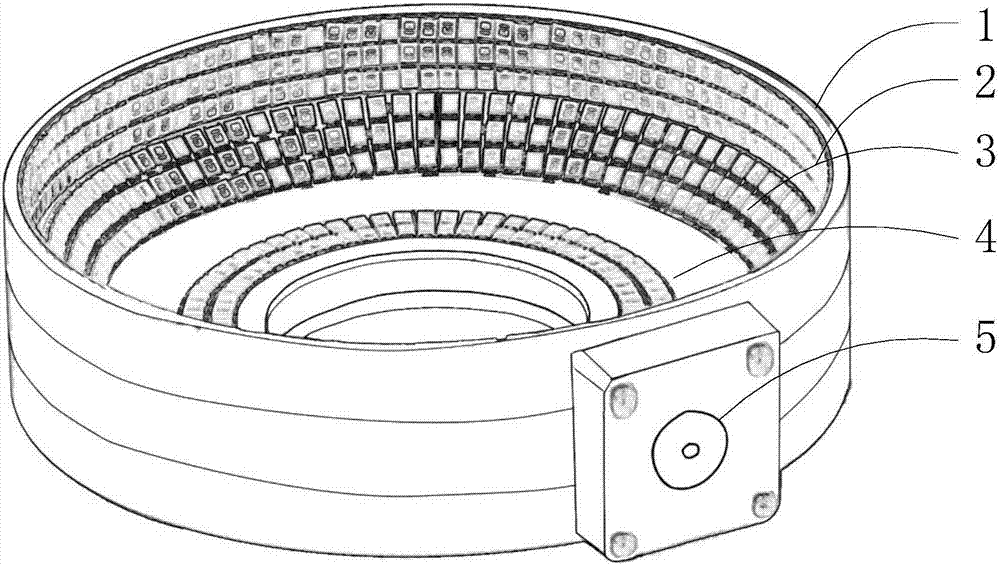

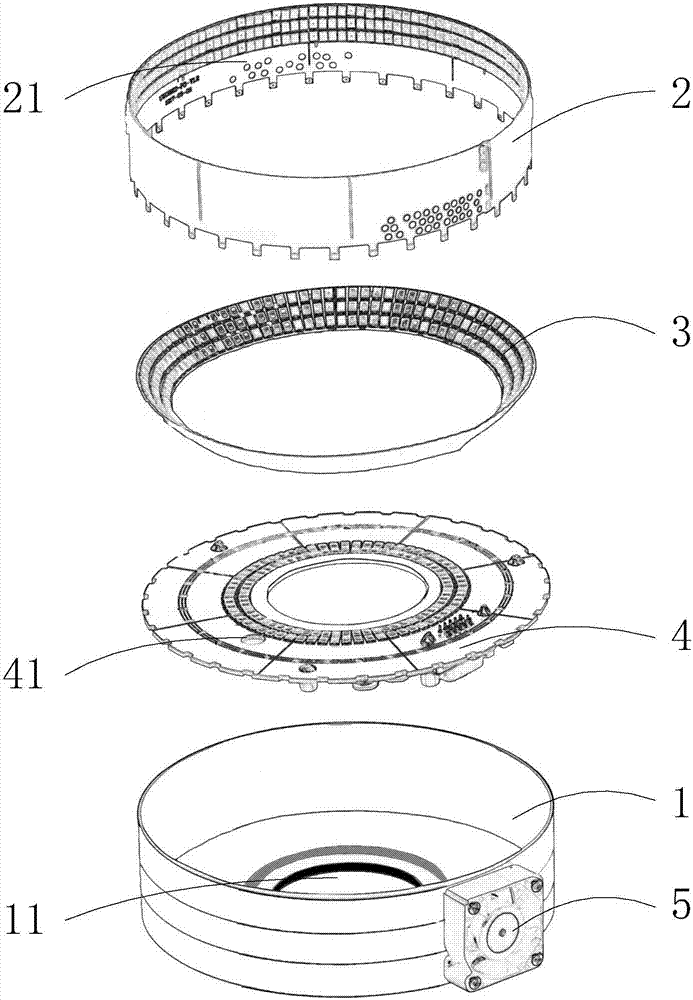

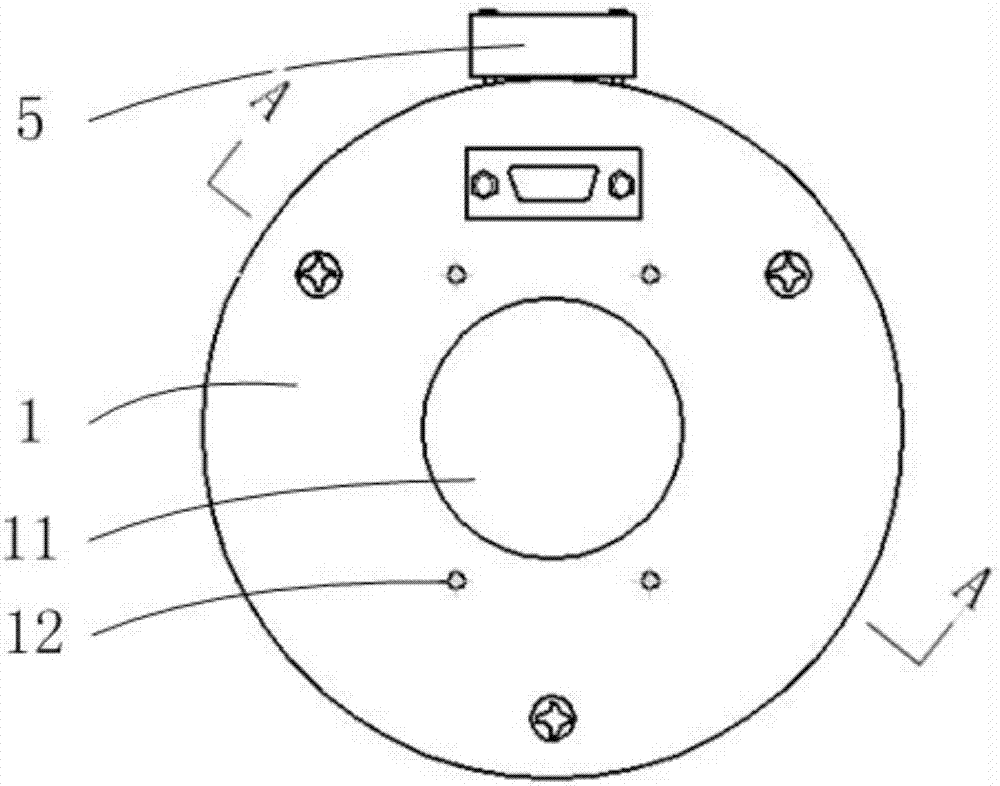

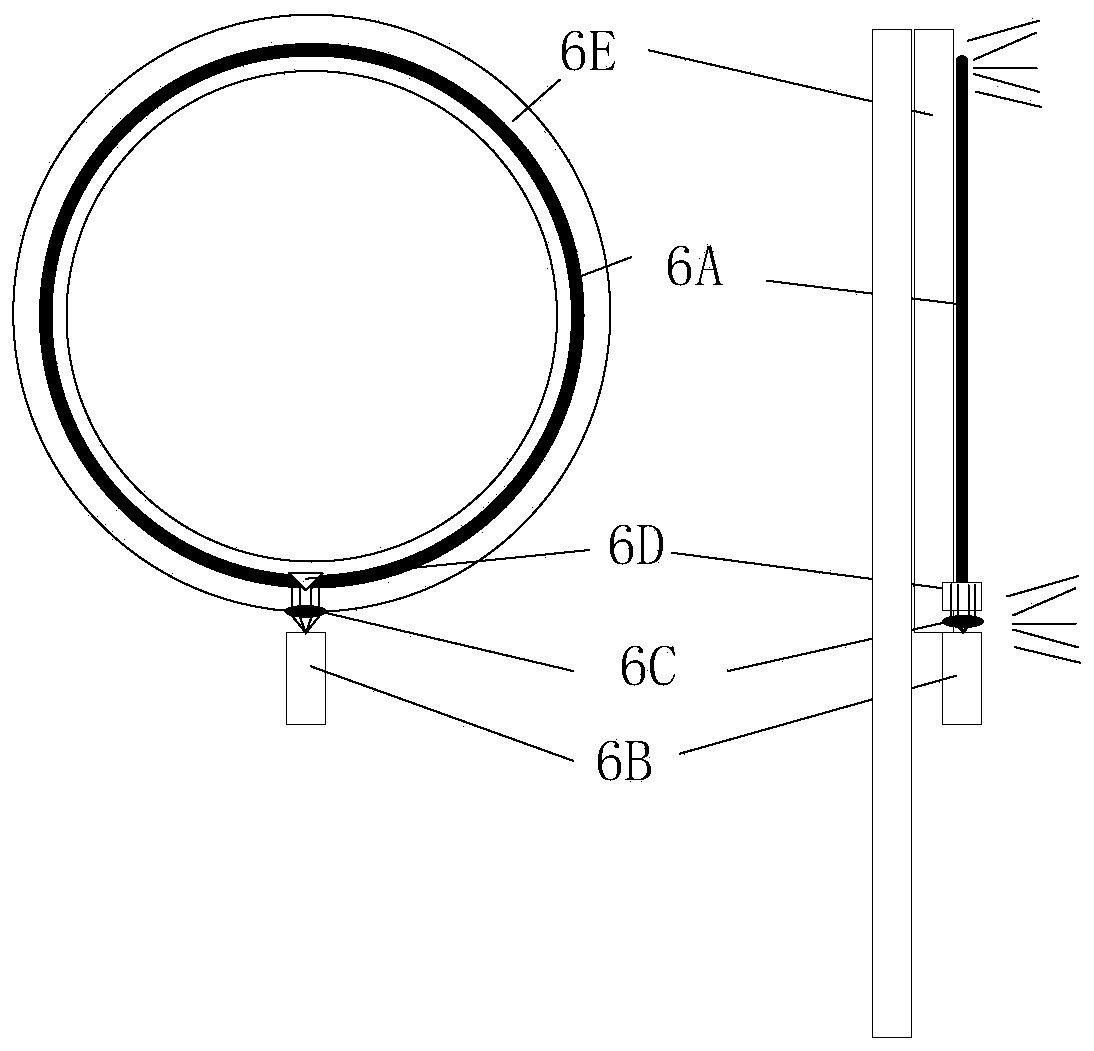

LED ring light source used for visual inspection lighting

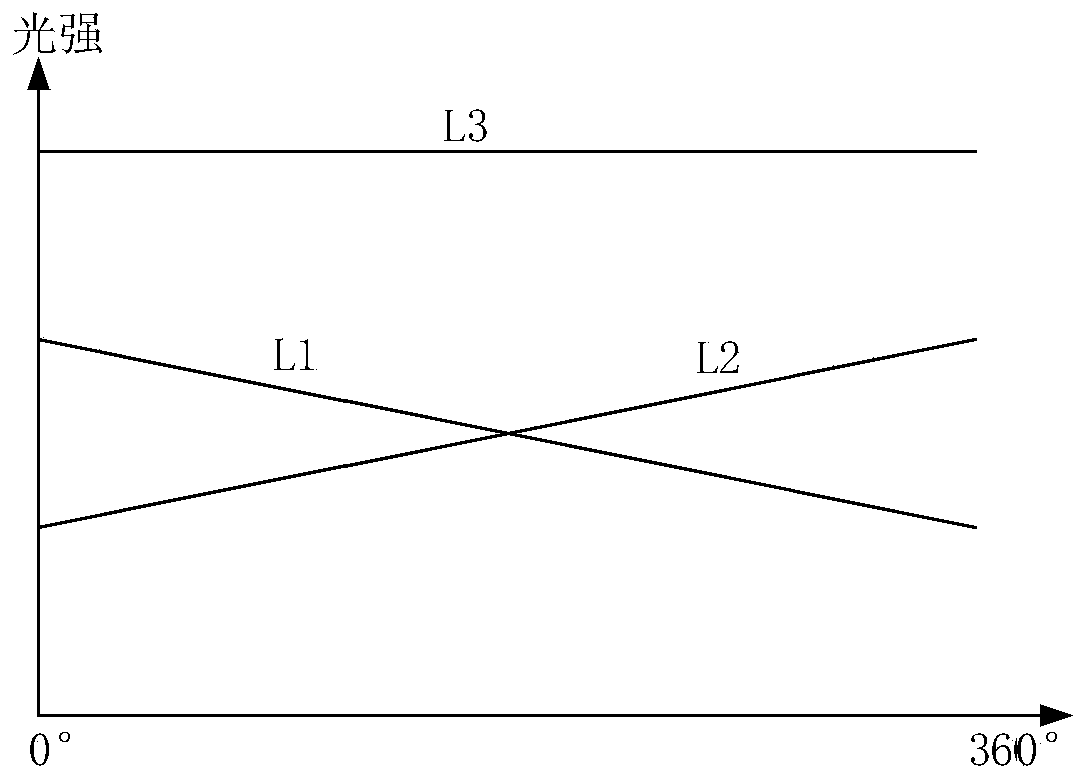

PendingCN107514576AIncrease contrastFeature highlightsLight source combinationsElongate light sourcesMachine visionVisual inspection

The invention discloses an LED ring light source used for visual inspection lighting, and belongs to the field of machine visual inspection. The LED ring light source comprises a shell, an outer ring light-emitting disc, a middle ring light-emitting disc and an inner ring light-emitting disc; the shell is a cylinder with an opening in the top face, and a through hole is formed in the bottom face of the shell; the inner ring light-emitting disc is installed on the bottom face of the shell; the lower edge of the outer ring light-emitting disc is connected with the edge of the outer side of the inner ring light-emitting disc; and the edge of the outer side of the middle ring light-emitting disc is connected with the outer ring light-emitting disc, the edge of the inner side of the middle ring light-emitting disc is connected with the inner ring light-emitting disc, and an included angle alpha is formed between the middle ring light-emitting disc and the inner ring light-emitting disc. The LED ring light source is matched with a lifting mechanism to be freely lifted, and the flexible low-angle lighting effect can be provided; red, green, blue and white LEDs are arranged according to a certain manner, three-ring eight-zone control is formed, color mixing is carried out more flexibly by adjusting the different-color LEDs in different zones, and meanwhile, the using scope of the light source is enlarged.

Owner:李劲松

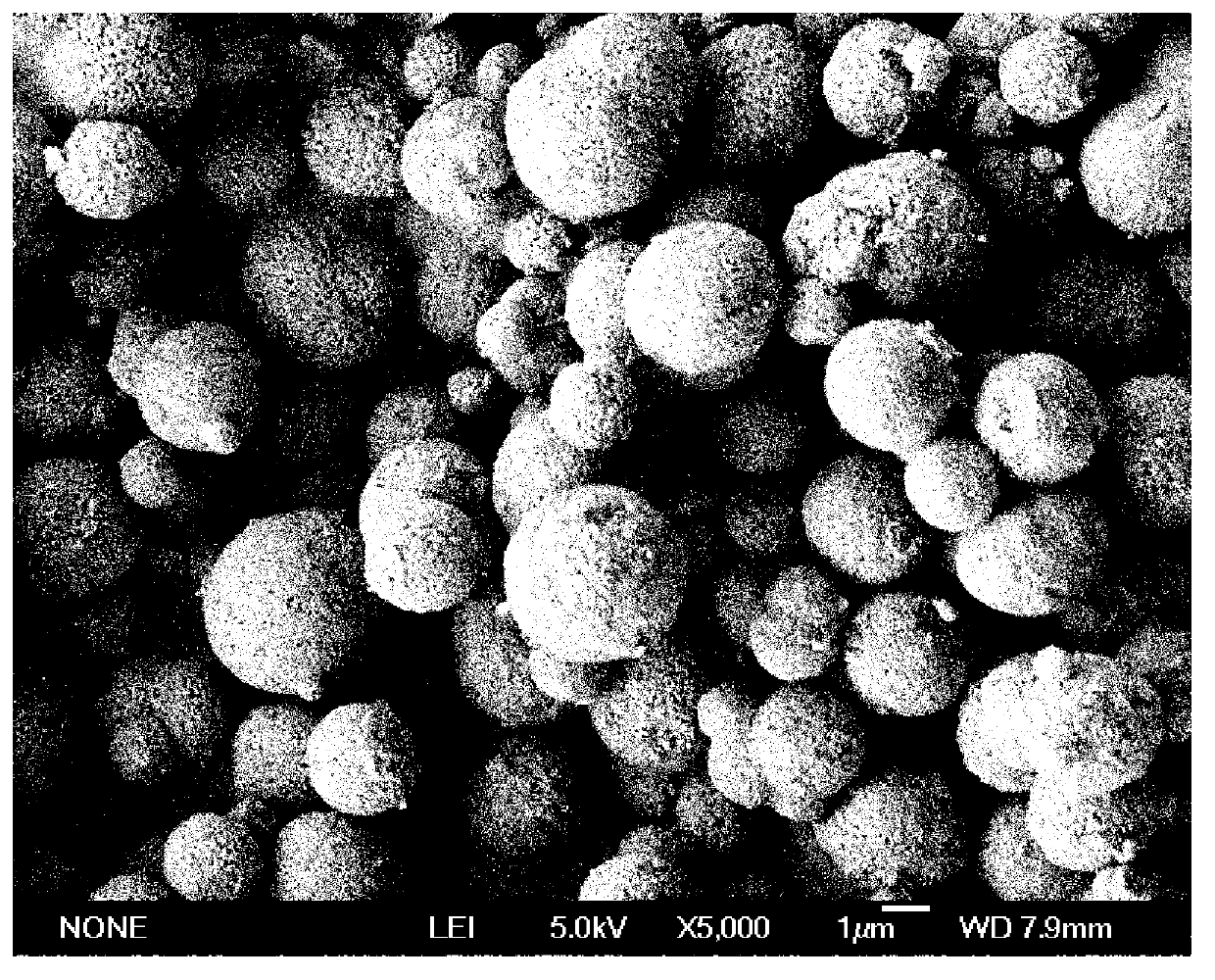

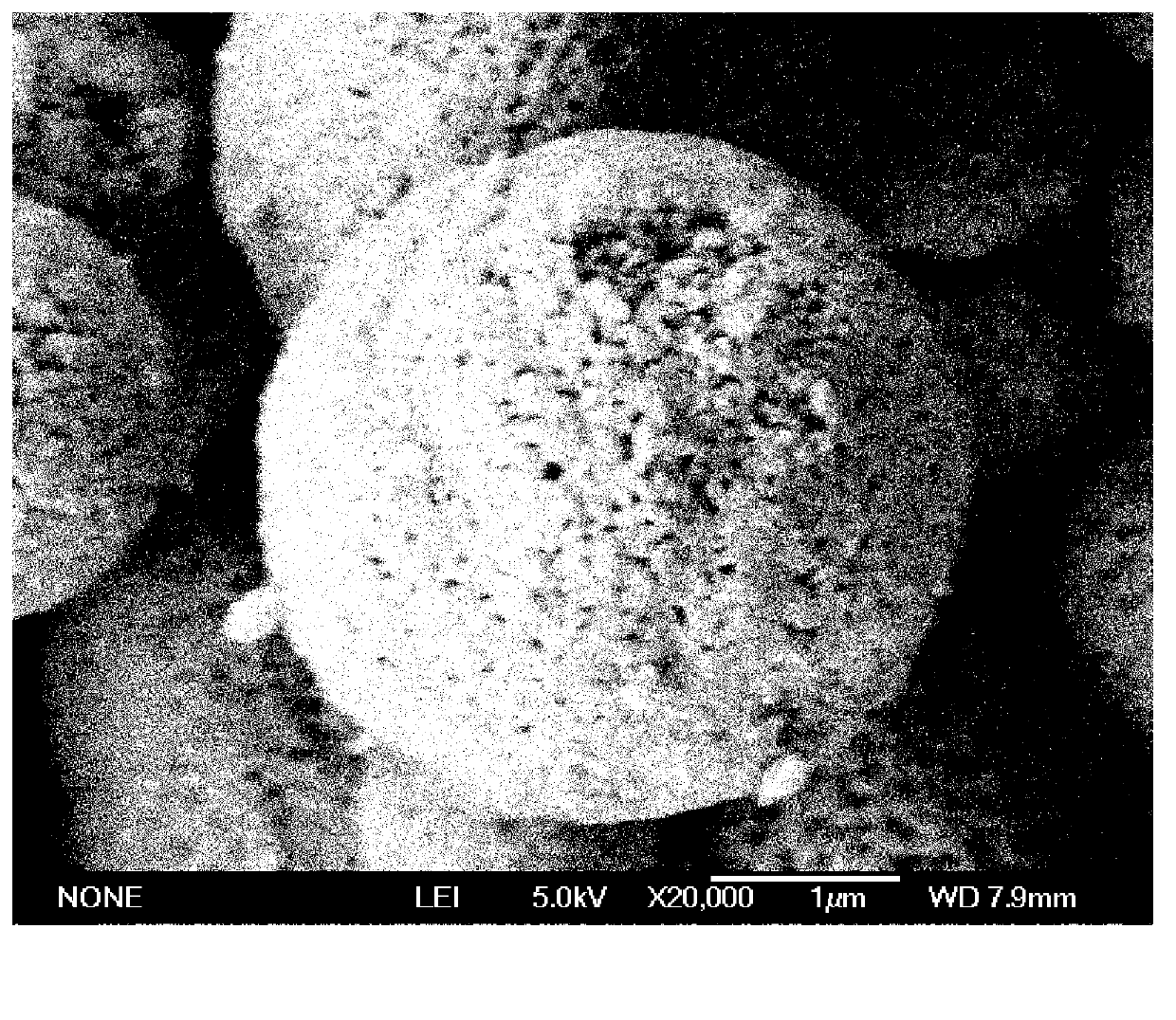

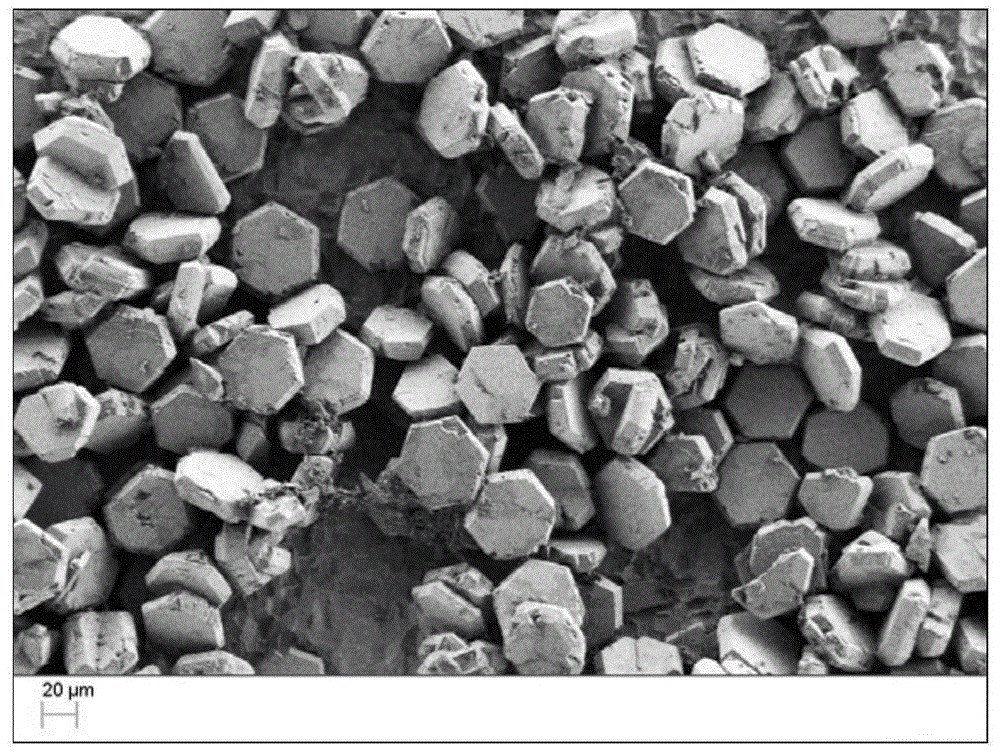

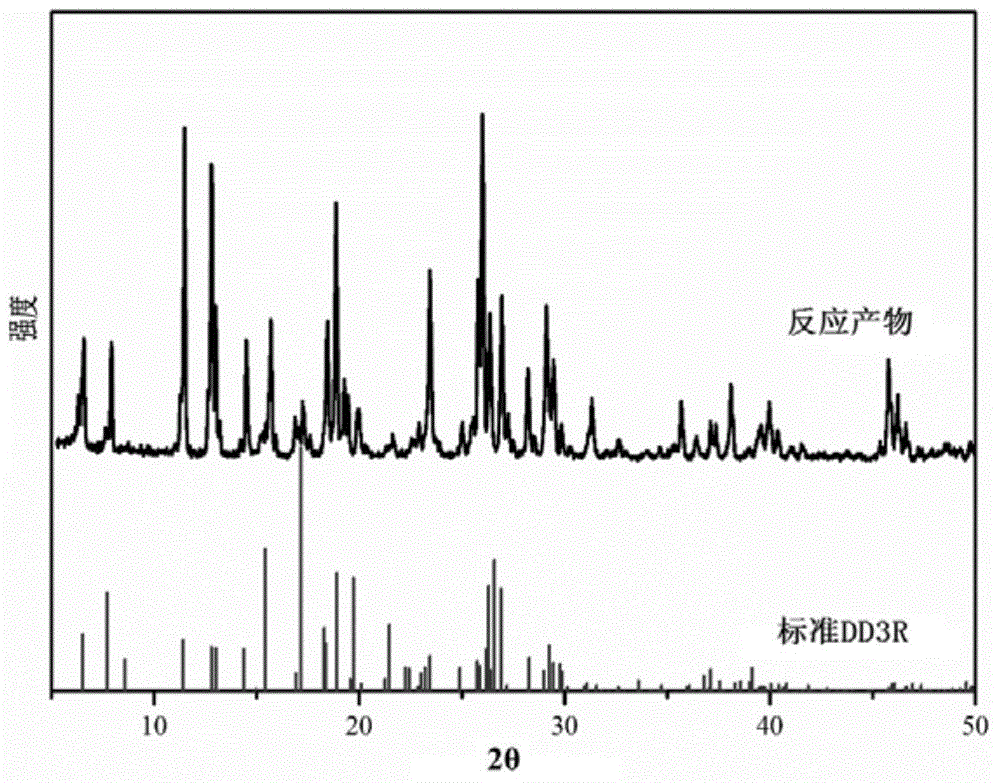

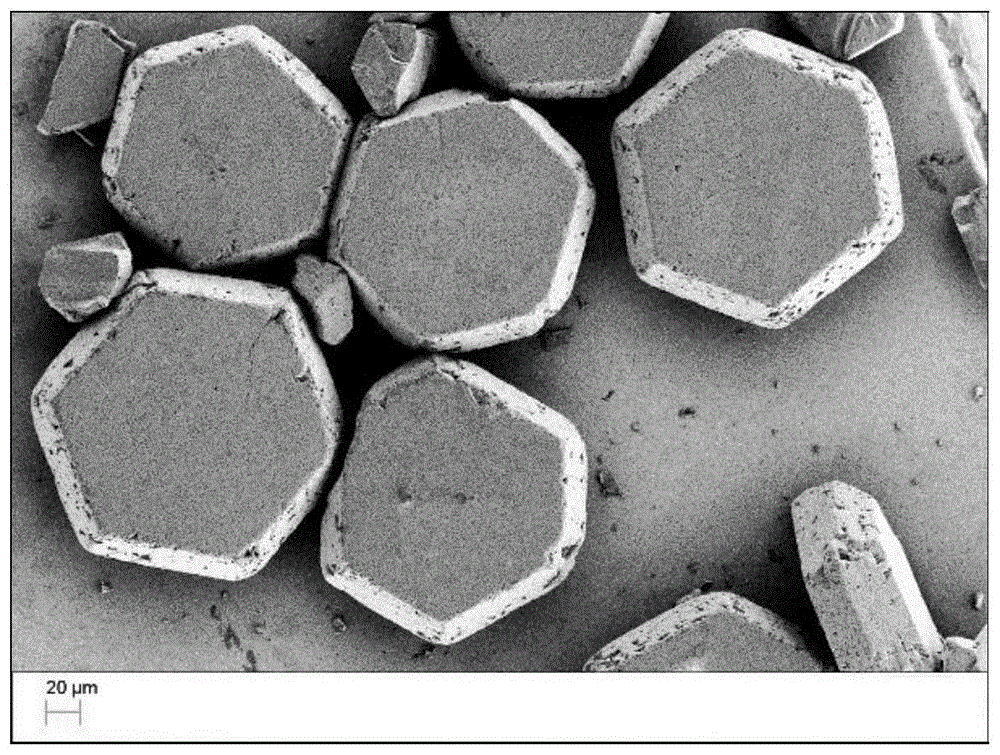

Preparation method for rapidly synthesizing DD3R molecular sieve

ActiveCN105129812ASynthesis fastFast granularitySilicaMolecular-sieve silica-polymorphsMolecular sieveEthylene diamine

The invention provides a preparation method for rapidly synthesizing DD3R molecular sieve. The method comprises the following steps: 1, mixing a silicon source, adamantanamine, water and ethylene diamine to obtain a molecular sieve synthesis mother liquor, or mixing the silicon source, adamantanamine, an aluminum source, water and ethylene diamine to obtain the molecular sieve synthesis mother liquor, wherein the silicon source contains ammonium fluorosilicate; and 2, heating and reacting the molecular sieve synthesis mother liquor, filtering, and washing to obtain the DD3R molecular sieve. The preparation method adopts the silicon source containing ammonium fluorosilicate to synthesize the DD3R molecular sieve, so the preparation method has the advantages of simple and convenient operation, short synthesis time, uniform DD3R particles, controllable particle size of 4-150[mu]m, and controllable morphology. The preparation method allows the DD3R molecular sieve with good crystallization property and uniform granularity to be rapidly synthesized without adding crystal seeds.

Owner:SHANGHAI ADVANCED RES INST CHINESE ACADEMY OF SCI

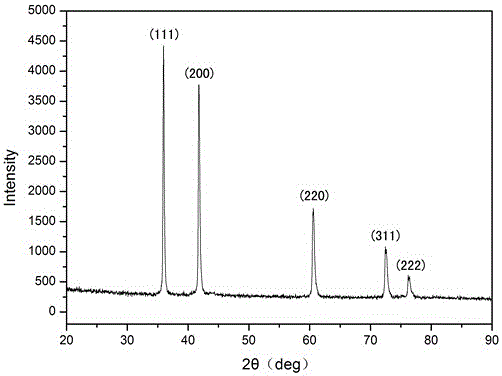

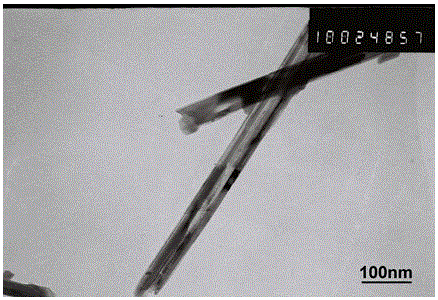

Nano (Ti, M) C solid solution crystal whisker and preparation method thereof

ActiveCN106087060AWell mixedLower reaction synthesis temperaturePolycrystalline material growthFrom solid stateDistilled waterWhiskers

The invention discloses a nano (Ti, M) C solid solution crystal whisker and a preparation method thereof. The nano (Ti, M) C solid solution crystal whisker is prepared from the following components: 40-79.9% of Ti, 0.1-40% of M and the balance of C, wherein M is at least one of W, Mo, V, Cr, Ta and Nb. Preparation raw materials comprise a component precursor of (Ti, M) C, a halogenating agent and a catalyst. The preparation method comprises the following steps: preparing a precursor mixed solution from all raw materials with distilled water, and drying so as to obtain precursor mixed powder; putting the precursor mixed powder into a reaction furnace, performing carbon-thermal reaction at 1100-1300 DEG C, firing the obtained nano (Ti, M) C solid solution crystal whisker for 4-6 hours at 350-400 DEG C in the presence of air for decarbonization, washing, performing eccentric separation, and finally drying, thereby obtaining the nano (Ti, M) C solid solution crystal whisker. The nano (Ti, M) C solid solution crystal whisker can be used as a nano ceramic phase crystal whisker toughening reinforcing metal based and ceramic based composite material, and is in good interface combination with a substrate.

Owner:SICHUAN UNIVERSITY OF SCIENCE AND ENGINEERING

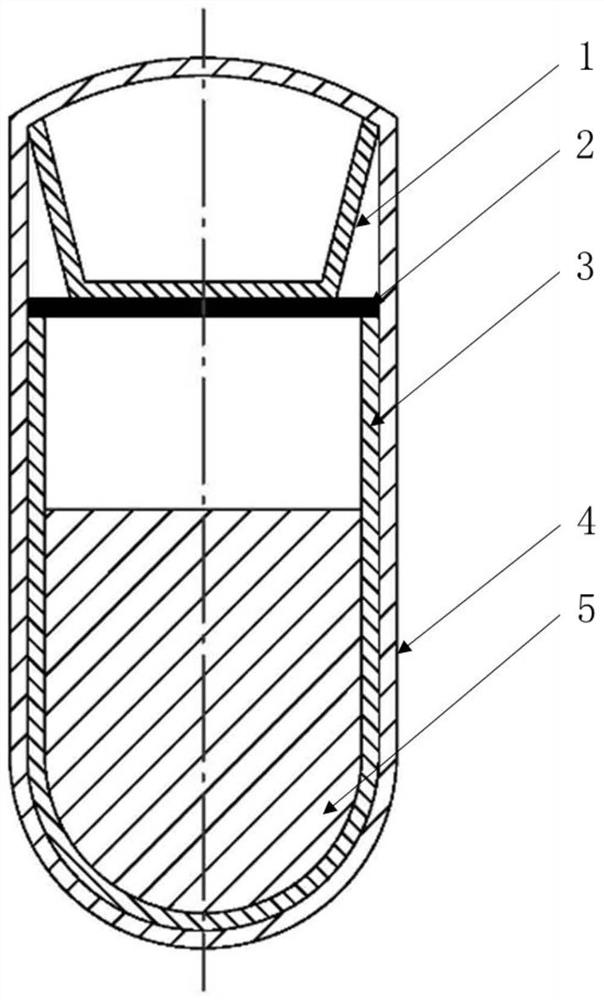

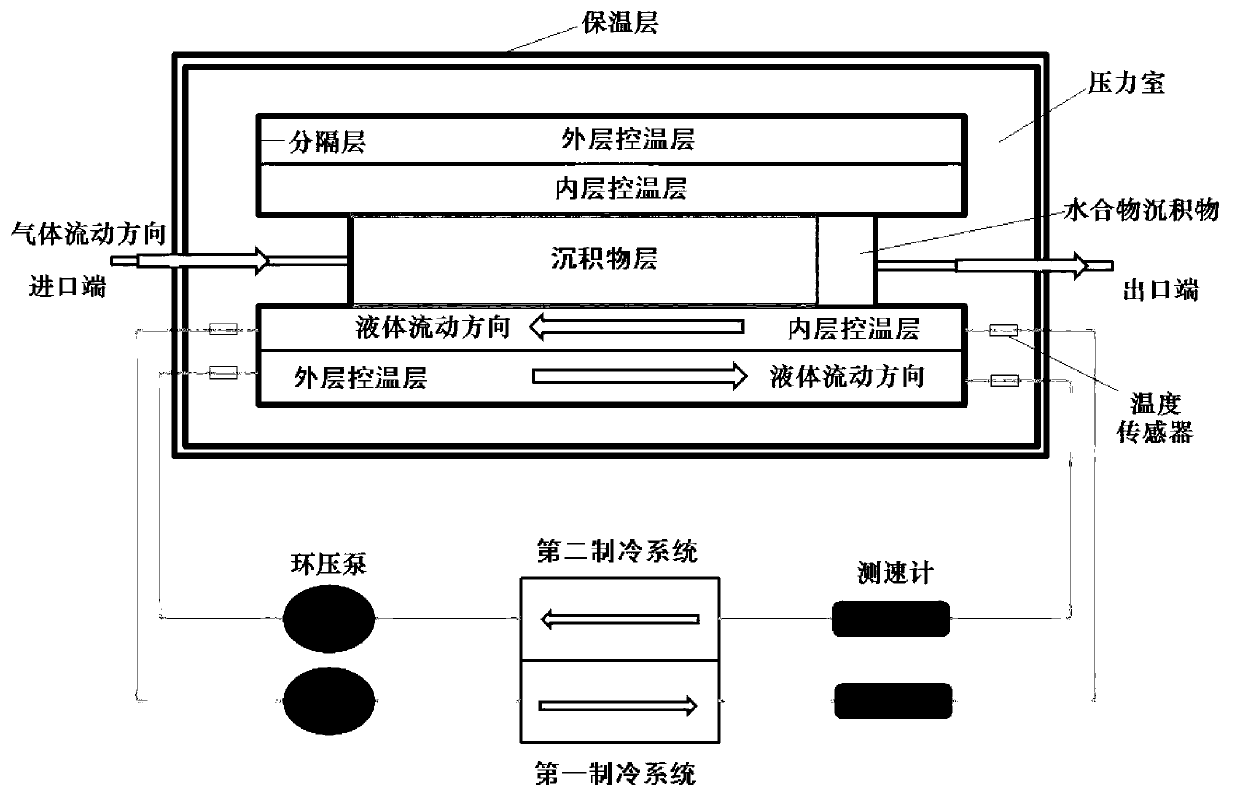

Double-layer temperature control system for hydrate sediment long core composition and decomposition

ActiveCN103105876ASynthetic evenSolve the difficulty of synthesisTemperatue controlTemperature controlDecomposition

The invention discloses a double-layer temperature control system for hydrate sediment long core composition and decomposition. The double-layer temperature control system for hydrate sediment long core composition and decomposition comprises a pressure chamber and a cooling system, a spacer layer is arranged inside the pressure chamber, a sediment layer and a composition temperature control layer are arranged inside the pressure chamber, an inlet end and an outlet end are respectively arranged on two sides of the sediment layer, the composition temperature control layer is placed outside the sediment layer and is tightly contacted with the sediment layer, and the composition temperature control layer comprises an inner temperature control layer and an outer temperature control layer. The cooling system comprises a first cooling system and a second cooling system, wherein the first cooling system is connected with the inner temperature control layer, the second cooling system is connected with the outer temperature control, the flow direction of cooling liquid in the inner temperature control layer is opposite to the flow direction of air in the sediment layer, and the flow direction of cooling liquid in the outer temperature control layer is the same with the flow direction of air in the sediment layer. According to the double-layer temperature control system for hydrate sediment long core composition and decomposition, the hydrate sediment long core can be fast and evenly composited in composition process, and constant environment temperature is provided for decomposition.

Owner:北京中科力森科技有限公司

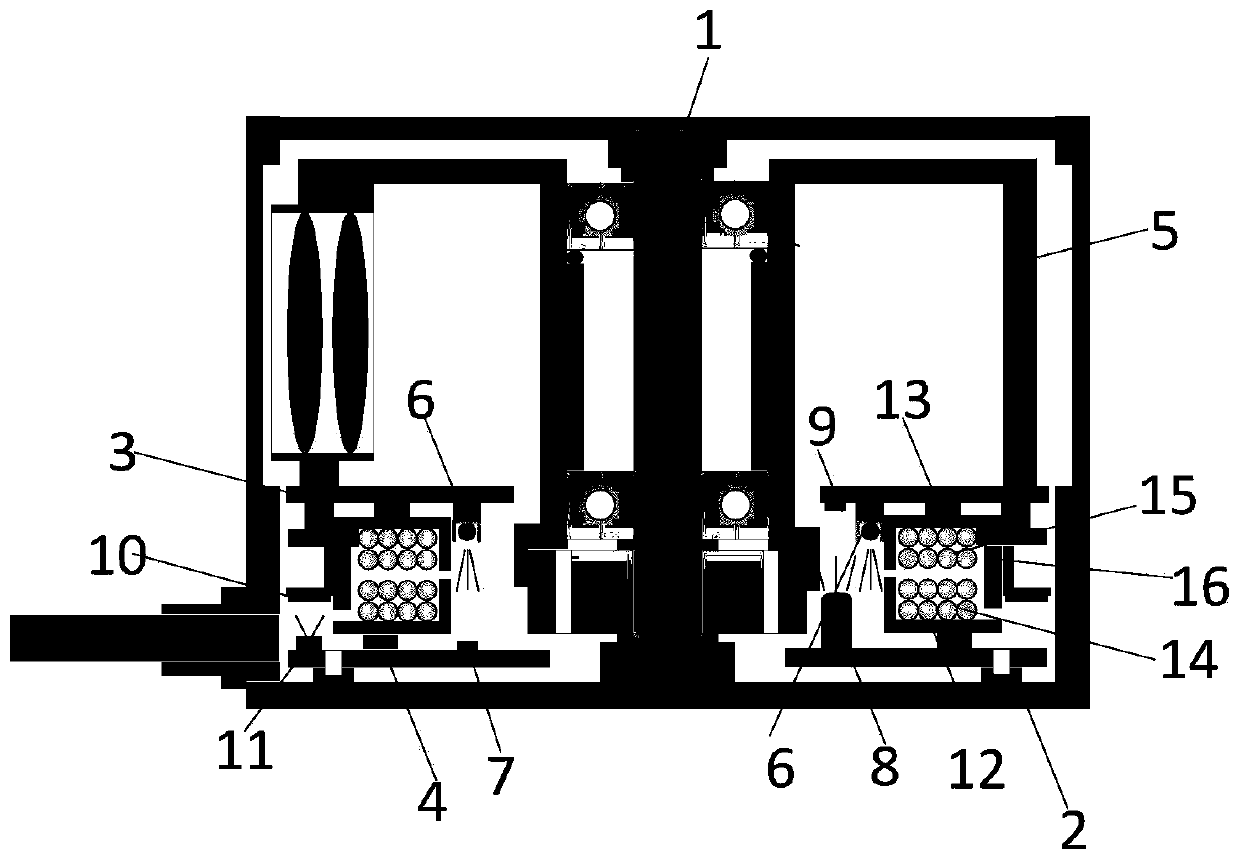

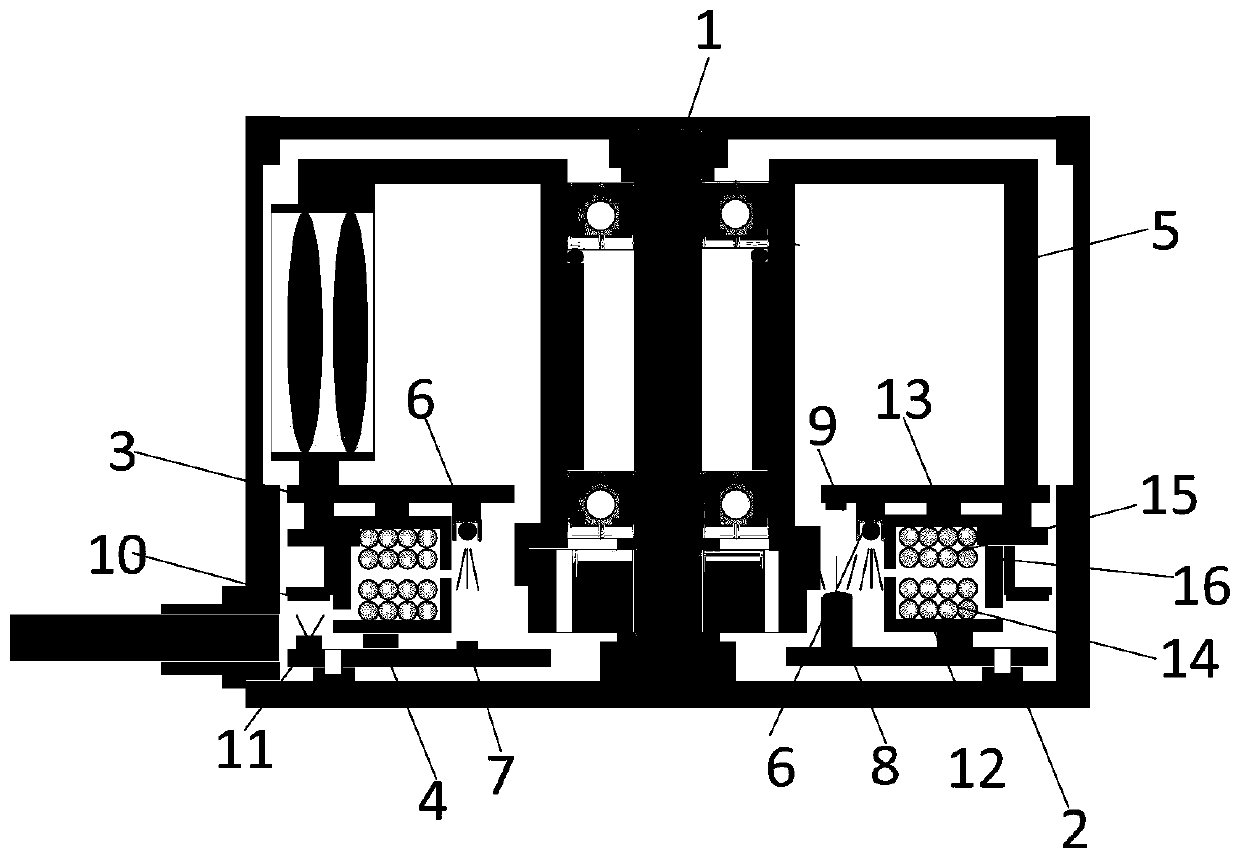

Laser radar

ActiveCN110018462AShort traceEasy to install and maintainWave based measurement systemsRadarMechanical reliability

The application discloses a laser radar. The laser radar in the present application comprises a main shaft, a radar rotor, a base, a first mainboard, a second mainboard, an angle measuring assembly, apower supply assembly and a communication assembly. The first mainboard is fixedly arranged relative to the radar rotor and is arranged around a main shaft, and the second mainboard is fixedly arranged relative to the base and is closer to the base than the first mainboard; the angle measuring assembly, the power supply assembly and the communication assembly are disposed between the first mainboard and the second mainboard, and at least a portion of the angle measuring assembly, at least a portion of the power supply assembly, and at least a portion of the communication assembly are disposedaround the main shaft; a first measuring module, a first power supply module and a first communication module are fixedly arranged relative to the radar rotor, and a second measuring module, a secondpower supply module and a second communication module are fixedly arranged relative to the radar stator. The laser radar can shorten the traces of each module, facilitate installation and maintenance, and improve the mechanical reliability of the laser radar.

Owner:HESAI TECH CO LTD

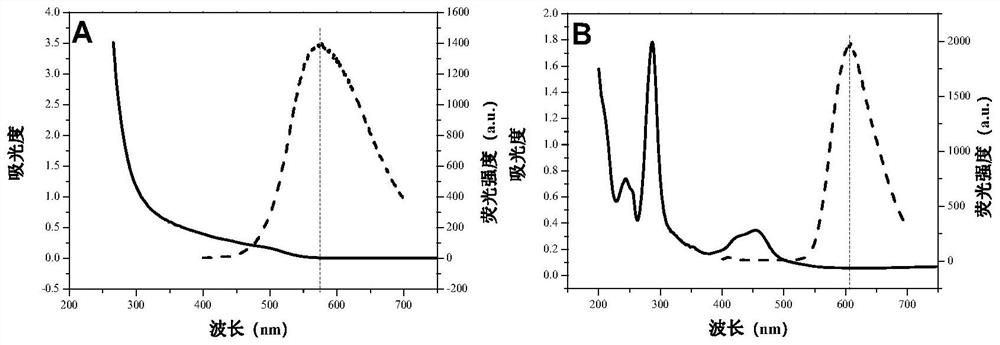

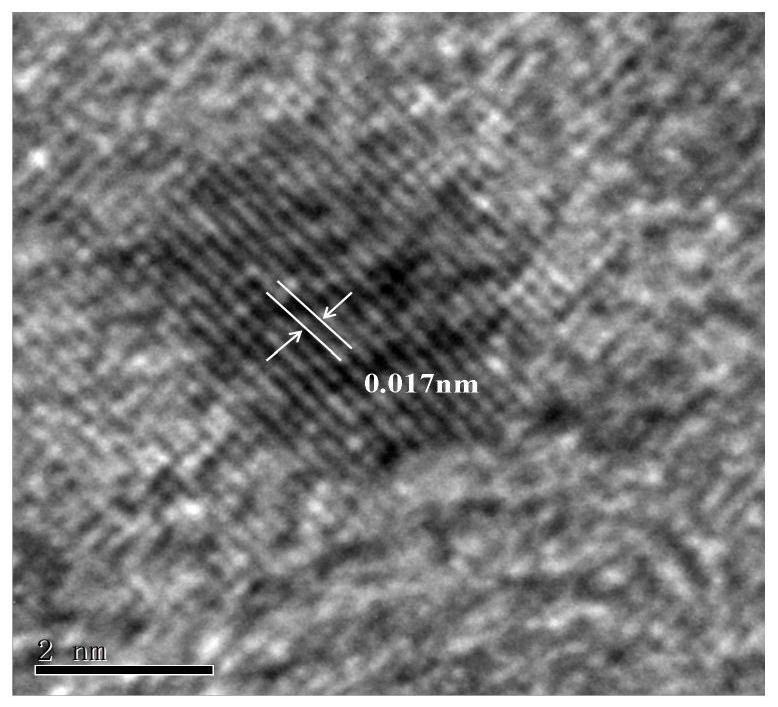

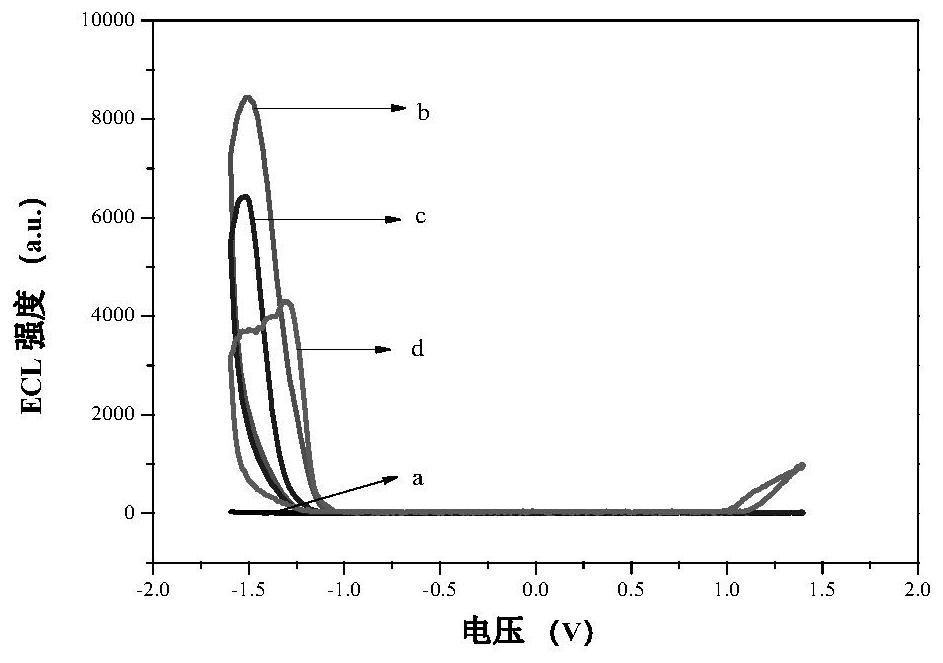

Ratio type quantum dot ECL aptamer sensor and manufacturing method thereof

PendingCN112326638AHigh selectivityRealize mutual influenceChemiluminescene/bioluminescenceMaterial electrochemical variablesPotassium persulfateAptamer

The invention belongs to the technical field of new materials and analysis sensing, and particularly relates to a ratio type quantum dot ECL aptamer sensor and a manufacturing method thereof, the ratio type quantum dot ECL aptamer sensor comprises a cathode electrode and an anode electrode, the ratio type quantum dot ECL aptamer sensor is characterized in that: the cathode electrode is cadmium selenide quantum dots, and the anode electrode is modified ruthenium silicon particles (RuSi@Ru(bpy)32+); the constructed ratio type electrochemiluminescence aptamer sensor is applied to the detection ofthe antibiotic kanamycin, and has certain practical significance; ECL signals are generated by ruthenium-silicon particles and a co-reactant n-propylamine at an anode, and ECL signals are generated by cadmium selenide quantum dots and a co-reactant potassium persulfate at a cathode, so that a ratio type ECL sensor is designed, false negative existing in an experiment is eliminated, experimental data is more reliable, the selectivity of the sensor can be greatly improved by introducing an aptamer, and the sensitivity of the sensor is improved. The sensor can be applied to biological analysis or ion detection, and the designed sensor is applied to antibiotic detection of environmental analysis pollutants.

Owner:安徽理工大学环境友好材料与职业健康研究院(芜湖) +1

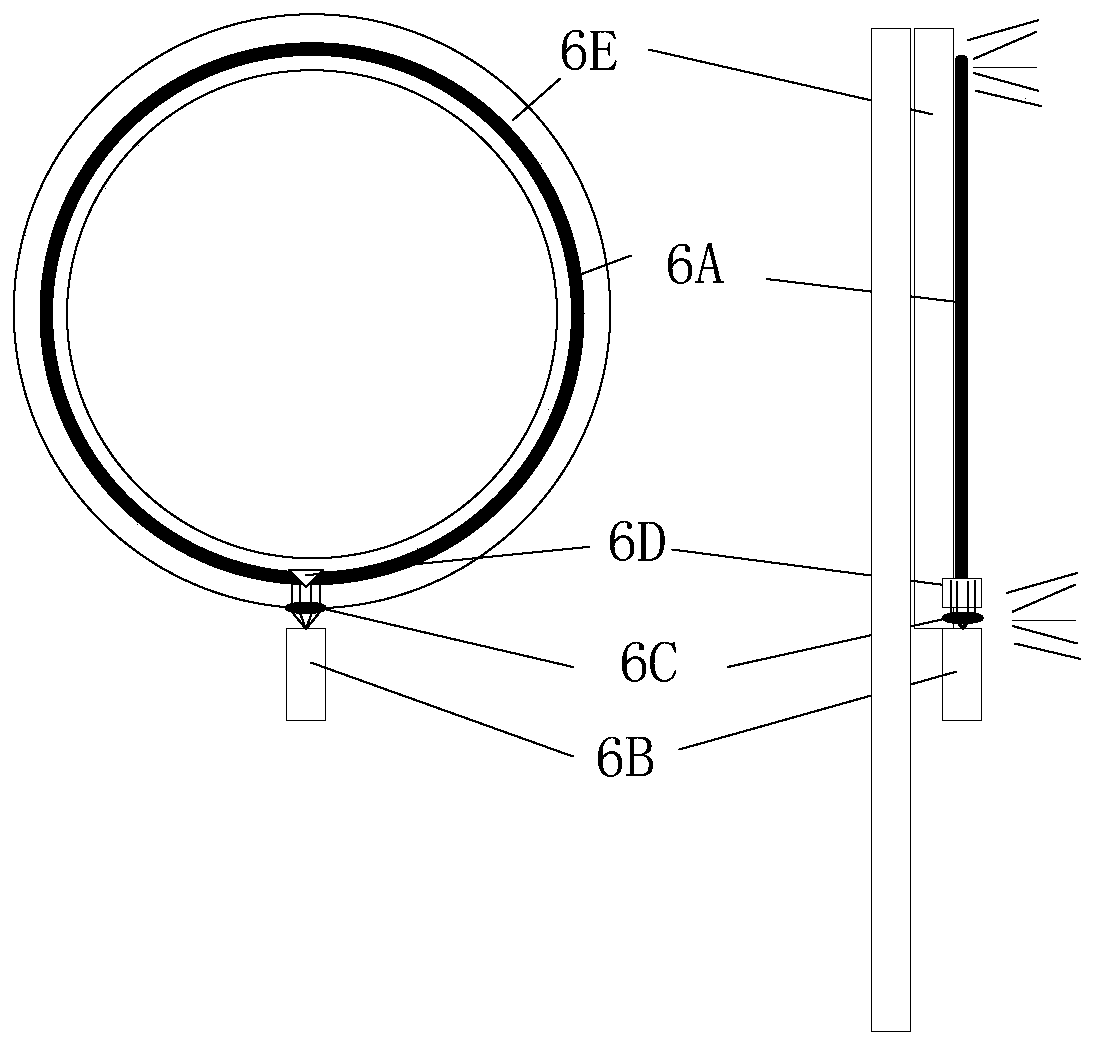

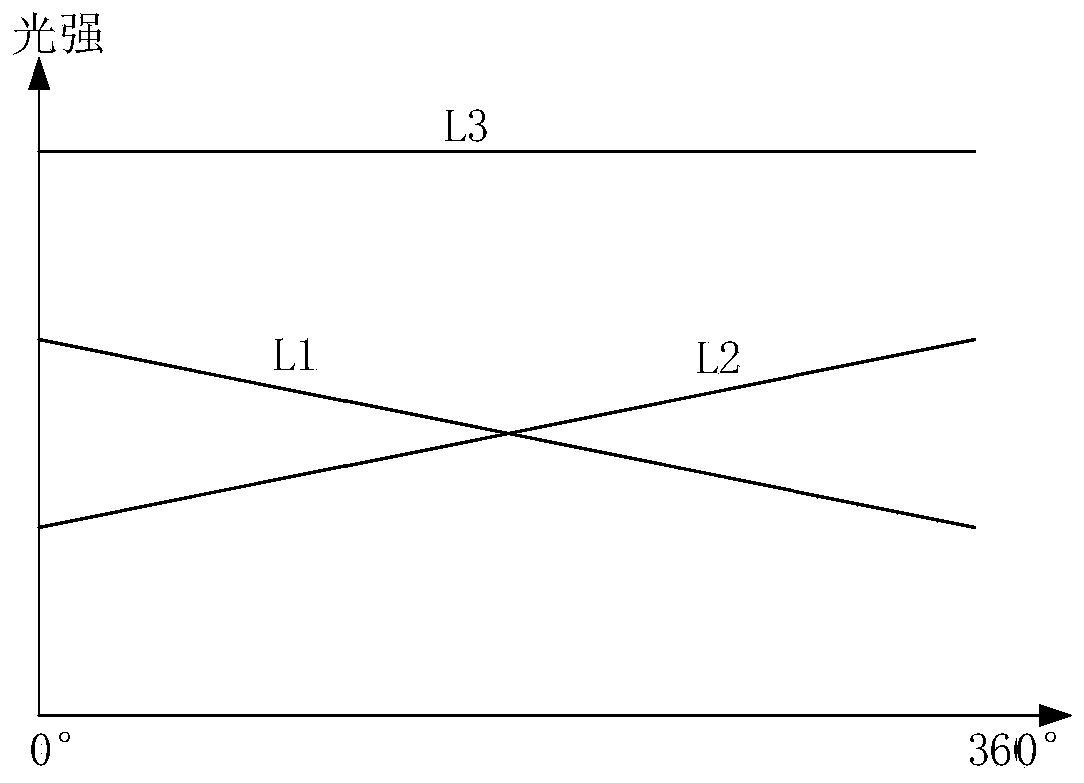

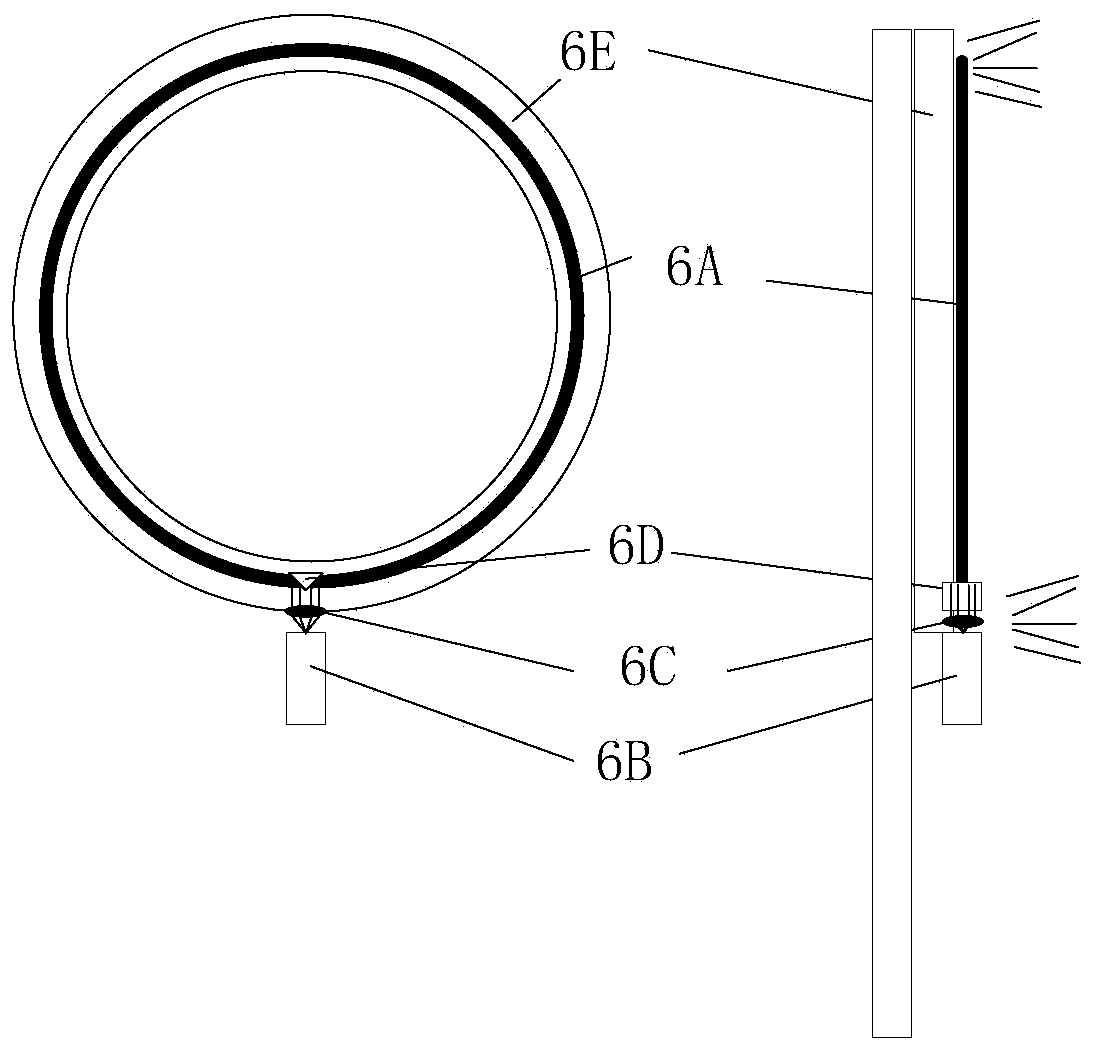

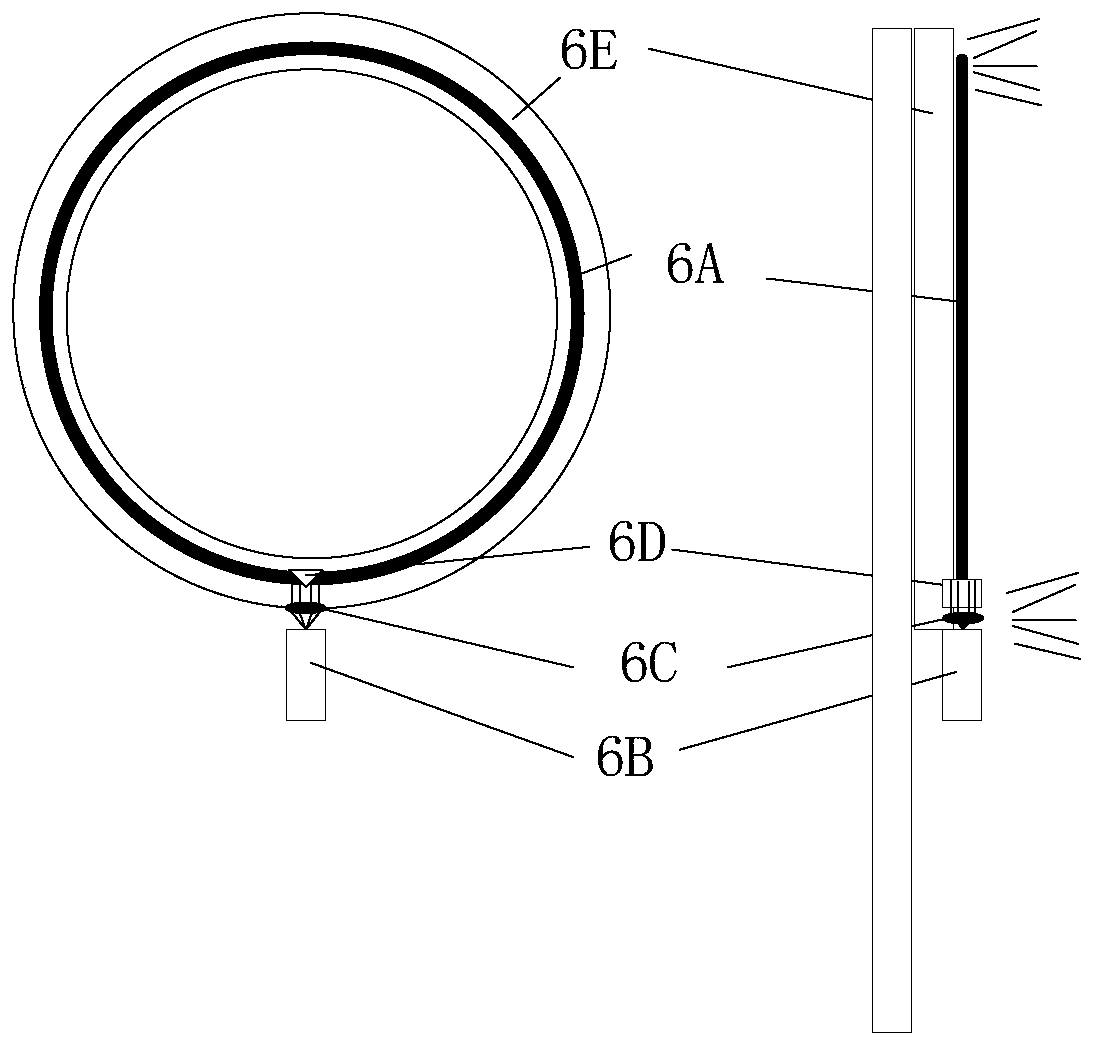

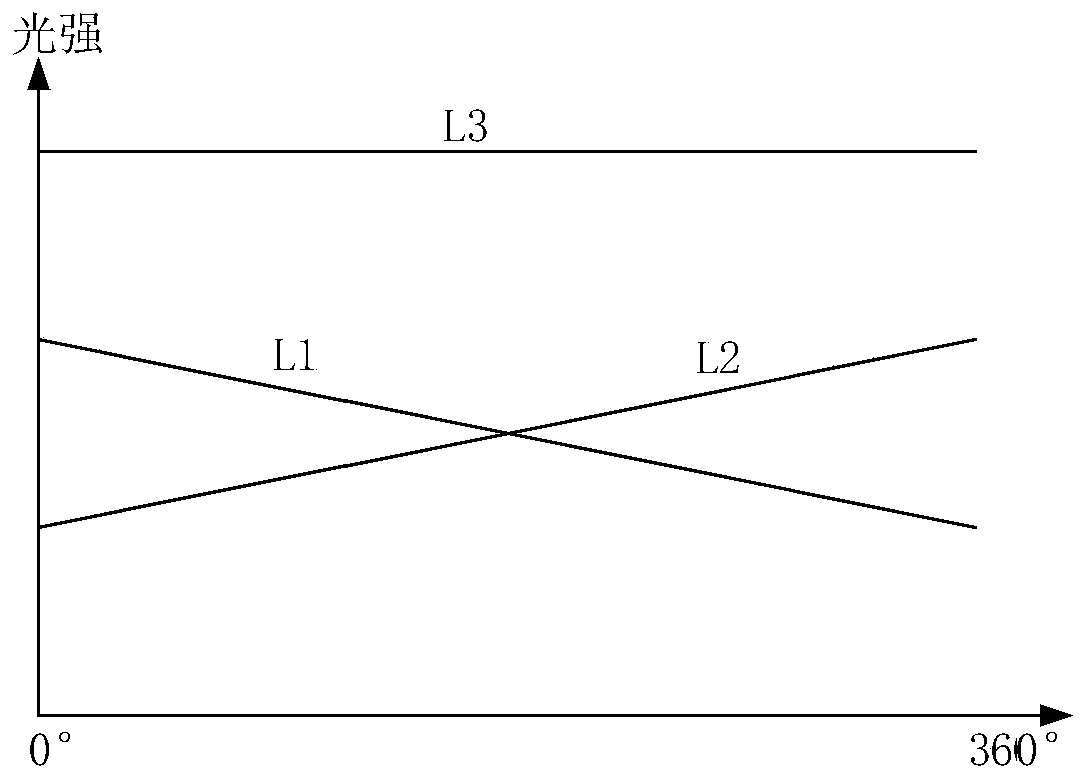

Laser radar

The application discloses a laser radar. The laser radar in the application comprises a main shaft and a communication module; the communication module comprises at least one light-emitting element and at least one light receiving element; the light-emitting element and the light-receiving element can move relatively, and the light receiving element is located at a light path of at least one of beam emitted by the light-emitting element; and the light-emitting element takes the main shaft as the center and is arranged surrounding the main shaft, thereby constructing an annular light-emitting element. The scheme disclosed by the application can realize the stable transmission f the light signal with low cost.

Owner:HESAI TECH CO LTD

Novel lithium ferric manganese phosphate positive electrode material synthesis method

ActiveCN113060715AImprove electrochemical performanceSynthetic evenCell electrodesSecondary cellsPhosphoric acidManganese

The invention relates to the technical field of lithium ion batteries, and provides a novel lithium ferric manganese phosphate positive electrode material synthesis method, which comprises: S1, placing manganese dioxide, phosphoric acid and water in a container, stirring, adding aniline, and continuously stirring to obtain polyaniline; s2, weighing an iron source, a lithium source, a carbon source and an organic auxiliary agent, adding into polyaniline, and grinding and stirring; s3, drying and calcining in an air atmosphere to obtain a precursor; s4, adding the carbon source into the precursor again, adding the grinding medium, and grinding to obtain grinding slurry; s5, performing vacuum drying on the grinding slurry to obtain reaction powder; and S6, sintering the reaction powder in a protective atmosphere, cooling to room temperature, crushing, and sieving to obtain the polyaniline / carbon coated iron manganese phosphate lithium ion battery positive electrode material. Through the technical scheme, the problems of low discharge capacity ratio and poor cycling stability in the prior art are solved.

Owner:河北九丛科技有限公司

Preparation method of SSZ-13 molecular sieve composite material

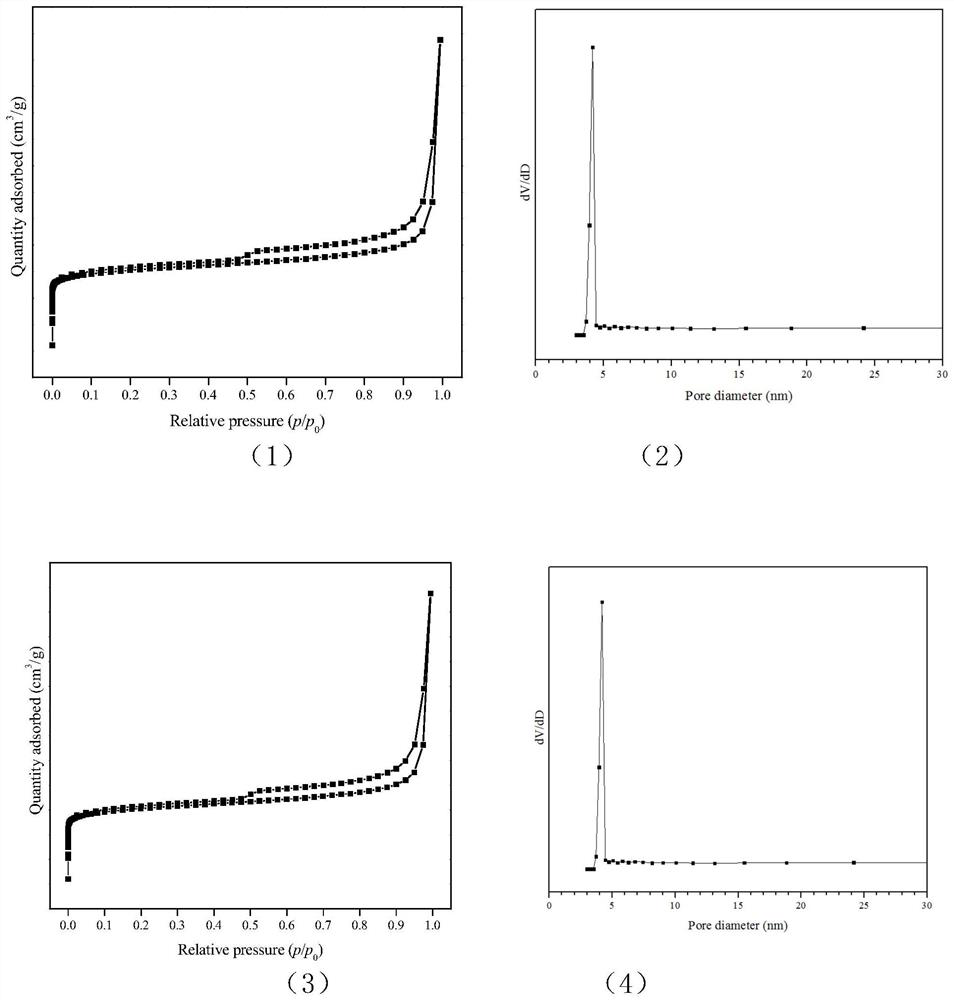

ActiveCN114655963AHigh yieldReduce manufacturing costMolecular sieve catalystsCrystalline aluminosilicate zeolitesMolecular sieveHalloysite

The invention belongs to the field of molecular sieve synthesis, and particularly relates to a preparation method of an SSZ-13 molecular sieve composite material. The preparation method of the SSZ-13 molecular sieve composite material comprises the following steps: synthesizing an SSZ-13 molecular sieve seed crystal; pretreating halloysite; and synthesizing the SSZ-13 molecular sieve composite material. According to the method, the pretreated halloysite is added into the SSZ-13 growth solution for crystallization reaction, so that the yield is increased, and the production cost is greatly reduced; the SSZ-13 molecular sieve composite material obtained by the invention has the property of a hierarchical porous structure, the porosity of a molecular sieve and a catalyst can be improved, and the yield and the catalytic performance are improved.

Owner:山东泓泰恒瑞新材料有限公司

Hexaaza [3.3.3] propellane compounds as key intermediates for new molecular explosives and a method for preparing the same

ActiveUS8609861B1Synthetic evenGood energyOrganic chemistryNitrated aromatic explosive compositionsArylHalogen

Provided are hexaaza[3.3.3]propellane compounds represented by the following formula (I), which can be used as a main skeleton structure for novel molecular explosives and method for preparing the same:wherein, R is H, C1-C20 alkyl, cycloalkyl, arylalkyl or aryl, which may contain heteroatoms such as oxygen, nitrogen, sulfur, halogen, etc. or unsaturations; and X is H2, O or S.

Owner:AGENCY FOR DEFENSE DEV

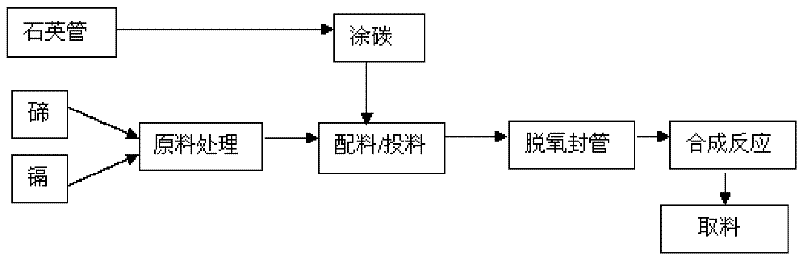

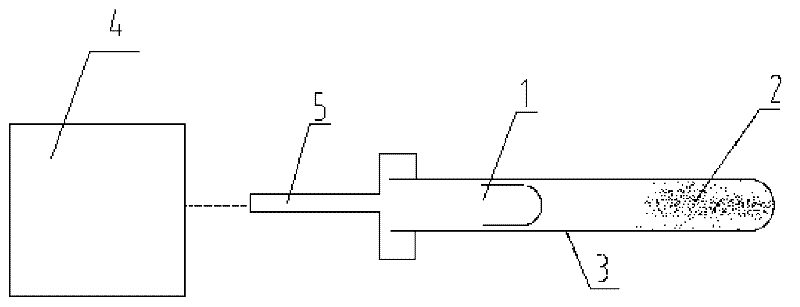

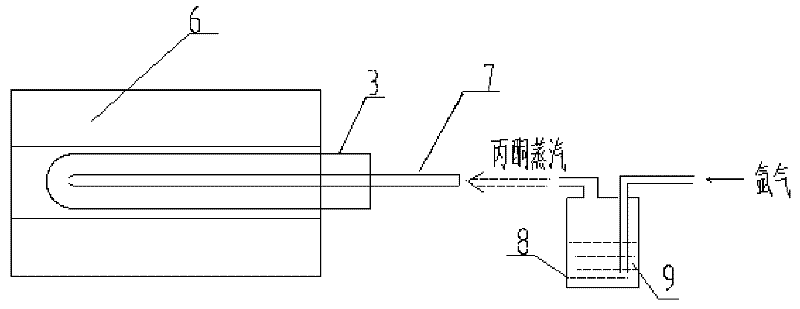

Method for preparing high-purity cadmium telluride

ActiveCN101734630BAvoid direct contactEvenly meltedBinary selenium/tellurium compoundsMolten stateCarbon coating

The invention discloses a method for preparing high-purity cadmium telluride. The reaction process is carried out in a closed quartz tube with melting point above cadmium and tellurium and after carbon coating treatment, wherein the mass ratio of a 5N cadmium material to a 5N tellurium material is 1: 1.1-1.15. The method comprises the following steps: dividing the weighed tellurium material into N parts according to the charging times N, dividing the weighed cadmium material into N-1 parts, alternately adding each part of tellurium material and each part of cadmium material into the quartz tube and adding the tellurium material into the quartz tube firstly and lastly, removing oxygen after charging, sintering and sealing the tube by using a sealed bulb, and slowly performing high-temperature and high-pressure synthetic reaction. The method has the advantages that the contact area of the raw materials is larger in a molten state, the reaction speed is more sufficient compared with the solid raw material, the micro-sized crushing treatment for the raw materials is avoided, the shape requirement of the raw materials is relaxed, the preparation cost is greatly reduced, the purity of the raw material is ensured, the method is suitable for large-scale production, the synthetic conversion rate of the cadmium telluride can reach 98 to 99.5 percent, and the single-tube yield of 800 to 1,000 grams can be ensured by using the quartz tube with the inside diameter of 32 millimeters under the premise of safety.

Owner:中国东方电气集团有限公司

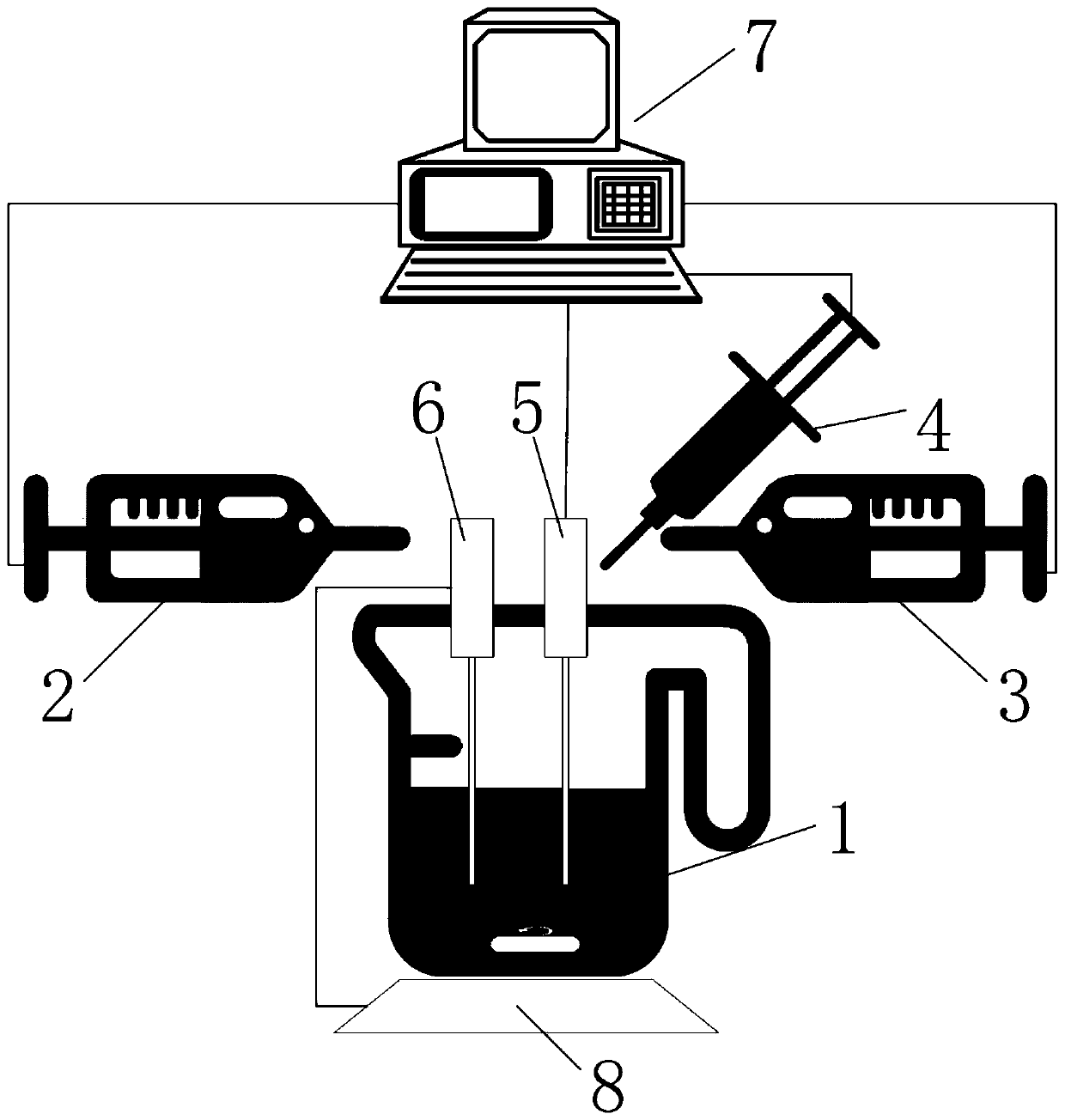

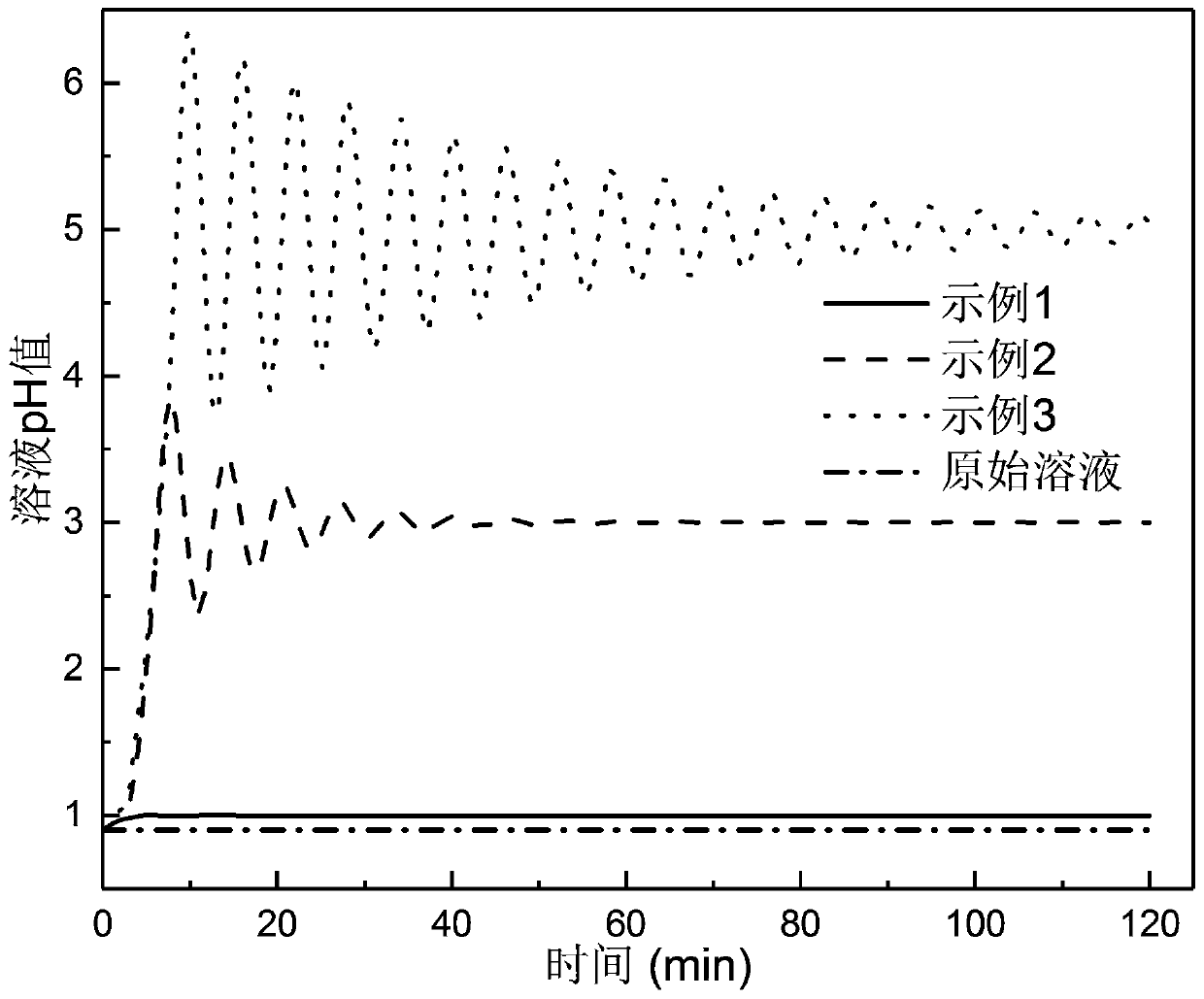

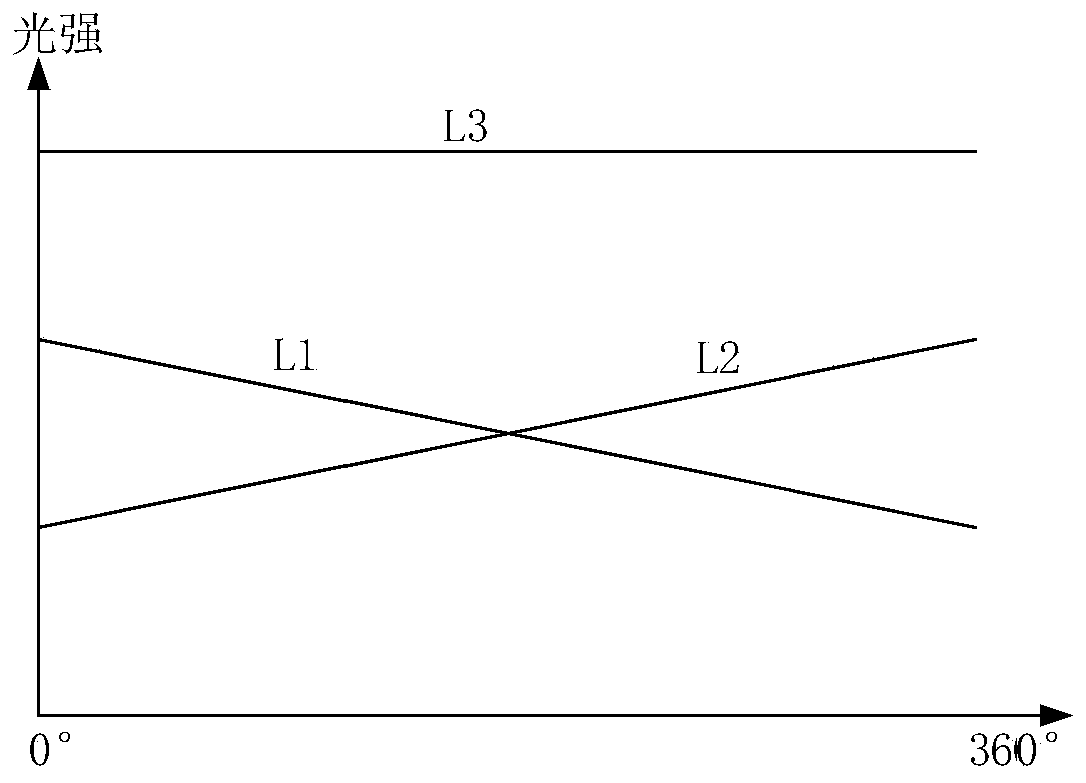

Device and method for synthesizing catalyst by using novel redox coprecipitation method

InactiveCN110756123AReduce reunionEvenly distributedProcess control/regulationChemical/physical/physico-chemical stationary reactorsPtru catalystRedox

The invention discloses a device for synthesizing a catalyst by using a novel redox coprecipitation method. The device is characterized by comprising a reaction tank (1), an oxidant solution injectionpump (2), a reducing agent solution injection pump (3), an alkaline solution injection pump (4), a pH probe (5), a temperature probe (6), an upper computer (7) and a magnetic stirrer (8) with a heating function, wherein the upper computer (7) is used for controlling the ion concentration and the redox reaction speed in the reaction tank (1) through control on the propelling speed of the oxidant solution injection pump (2) and the propelling speed of the reducing agent solution injection pump (3), is used for measuring the pH value of a solution accurately through the pH probe (5) in the reaction tank (1), and is used for controlling the propelling speed of the alkaline solution injection pump (4) so that the pH value of the prepared solution is stabilized within a preset range of the setpH value. Through the device, the pH value in the reaction tank can be controlled with high precision, so that the synthesis reaction speed is controlled, the degree of automation is high, and manualerrors are reduced.

Owner:HUAZHONG UNIV OF SCI & TECH

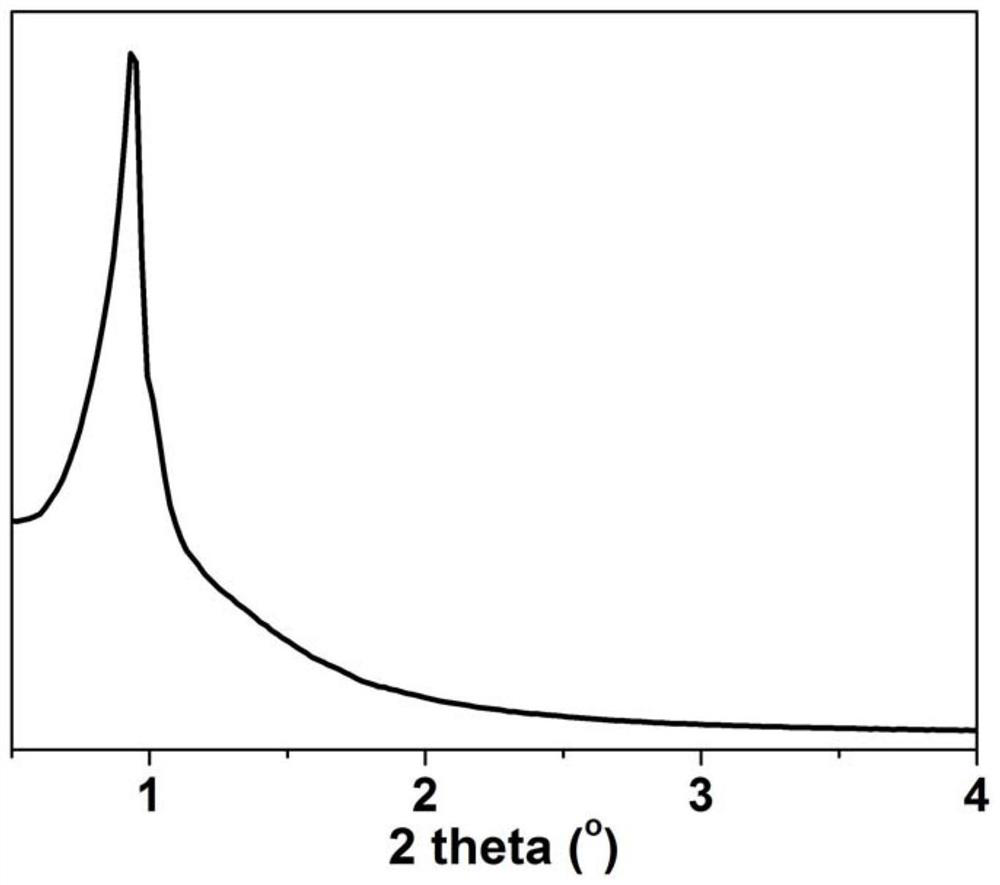

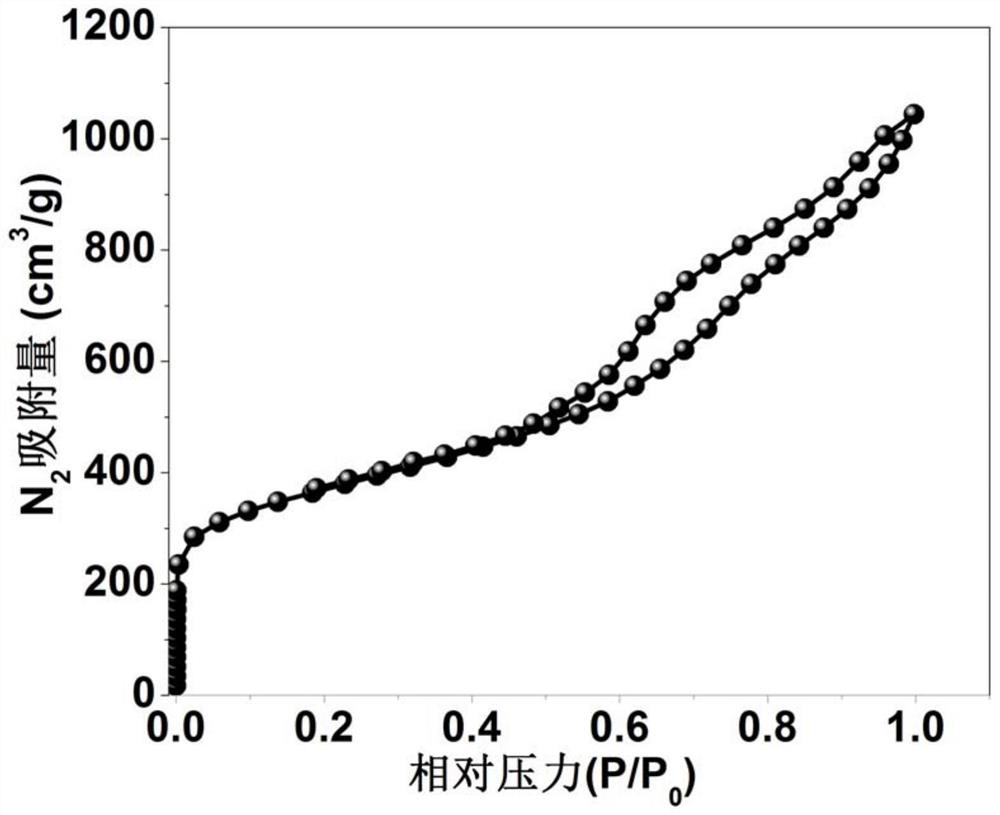

Method for preparing mesoporous silica material

The invention provides a method for preparing a mesoporous silica material, which comprises: grinding raw materials, which comprises one or more of rice hull ash from biomass power plants, silicon dioxide(SiO2)-containing smoke dust from metallurgical enterprises, micro silicon powder from metallurgical silicon plants and natural kieselguhr minerals, into fine powder, stirring and mixing the finepowder with 0.5 to 4 mol / L solution of hydrochloric acid, processing for 2 to 4 hours at 40 to 60 DEG C and separating out an intermediate raw material; mixing the intermediate raw material, NaOH, structure director and H2O in a molar ratio of 1:0.2-0.5:0.05-0.2:150-200 and stirring for 8 to 24 hours; performing hydrothermal synthesis or microwave synthesis and regulating the pH value of the synthesis solution to 10 to 12; and drying the synthesis solution, roasting for 2 to 5 hours at 400 to 800 DEG C, and cooling to obtain the mesoporous silica material. In the invention, the provided process flow is short; the operation is simple; the application range is wide; the product performance is high; the environmental load is small; the energy consumption is low; the cost is low; the added value of the product is high; and the problem of the shortage of a mesoporous silica raw material is solved.

Owner:KUNMING UNIV OF SCI & TECH

Aluminum antimonide polycrystalline material synthesizing process device and synthesis method

ActiveCN112458535AAvoid lostAvoid formingPolycrystalline material growthSingle crystal growth detailsGraphitePolycrystalline material

The invention relates to an aluminum antimonide polycrystalline material synthesizing process device and a synthesis method. High-purity antimony and high-purity aluminum are put into a silicon nitride ceramic crucible, a graphite gasket is covered and nested in a quartz crucible, an air gap exists between the graphite gasket and the upper surface of the silicon nitride ceramic crucible, and highvacuum in the silicon nitride ceramic crucible is not influenced during vacuumizing; after vacuumizing, a quartz plug and the quartz crucible are welded, and finally the quartz plug and the quartz crucible are synthesized in an inclinable rotating tubular furnace in a rotating mode, so that synthesis of single-phase aluminum antimonide in a small-cavity crucible without additional compensation isachieved, and elements are not lost in the synthesis process. According to the process device, the silicon nitride ceramic crucible does not react with an aluminum antimonide melt at high temperature,antimony evaporation is inhibited, the effect of cracking of the reaction that the outer quartz crucible adsorbs the aluminum element is prevented, it is guaranteed that melt components are not lostin the synthesis process, and the graphite gasket has the effect of adsorbing residual oxygen at high temperature. The synthesized aluminum antimonide polycrystalline material has the characteristic of uniform single-phase components.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

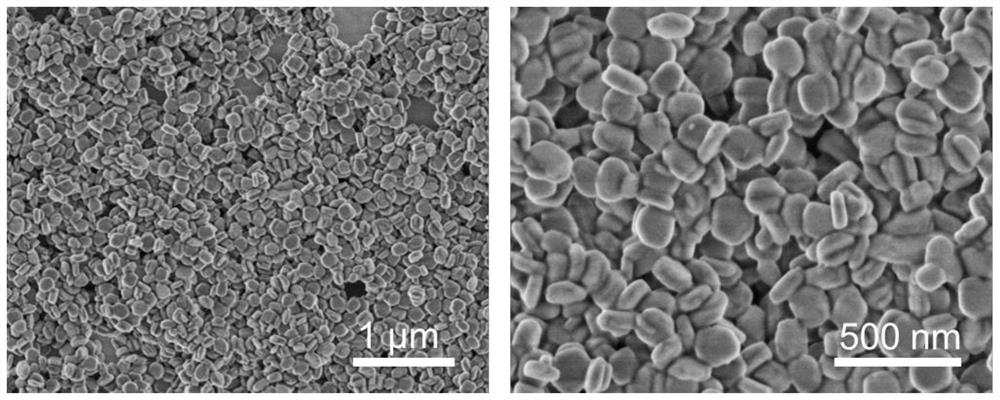

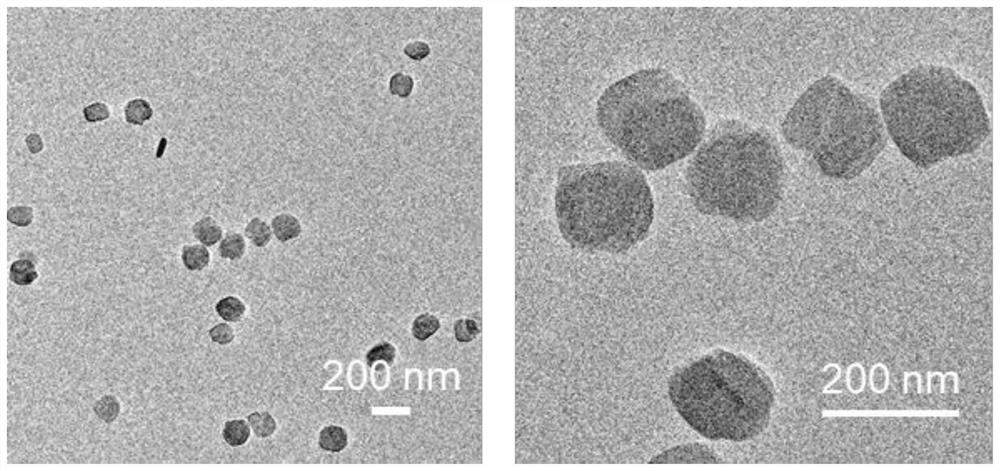

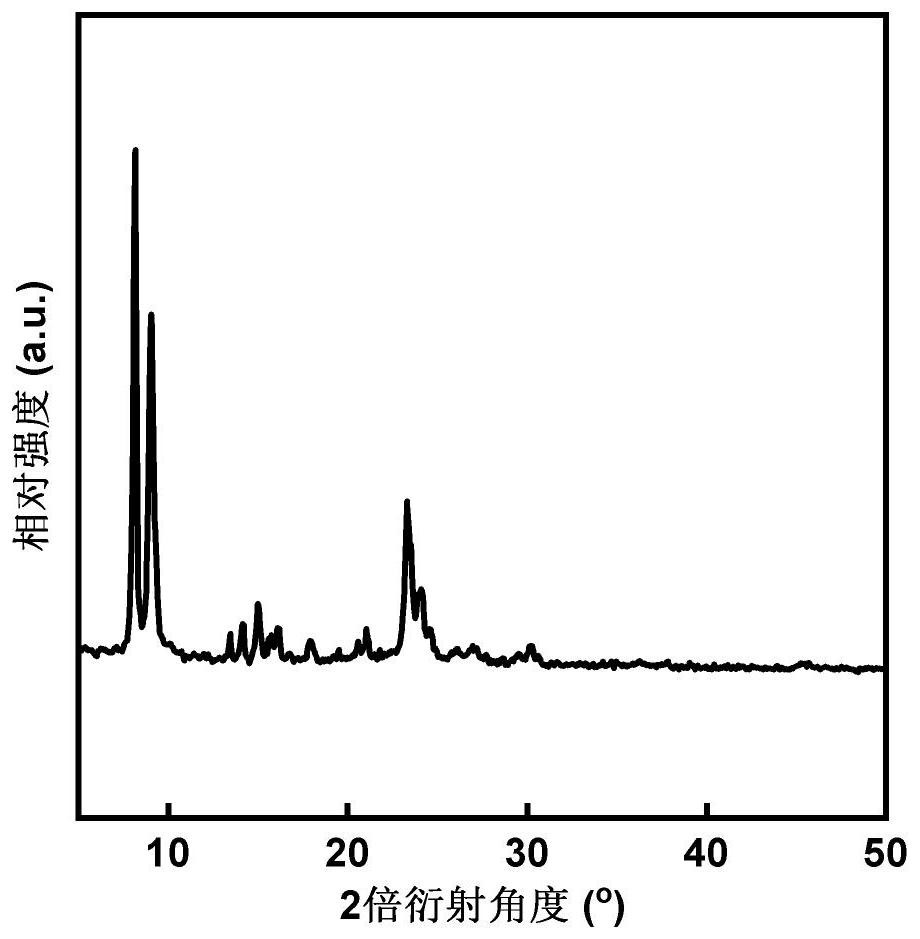

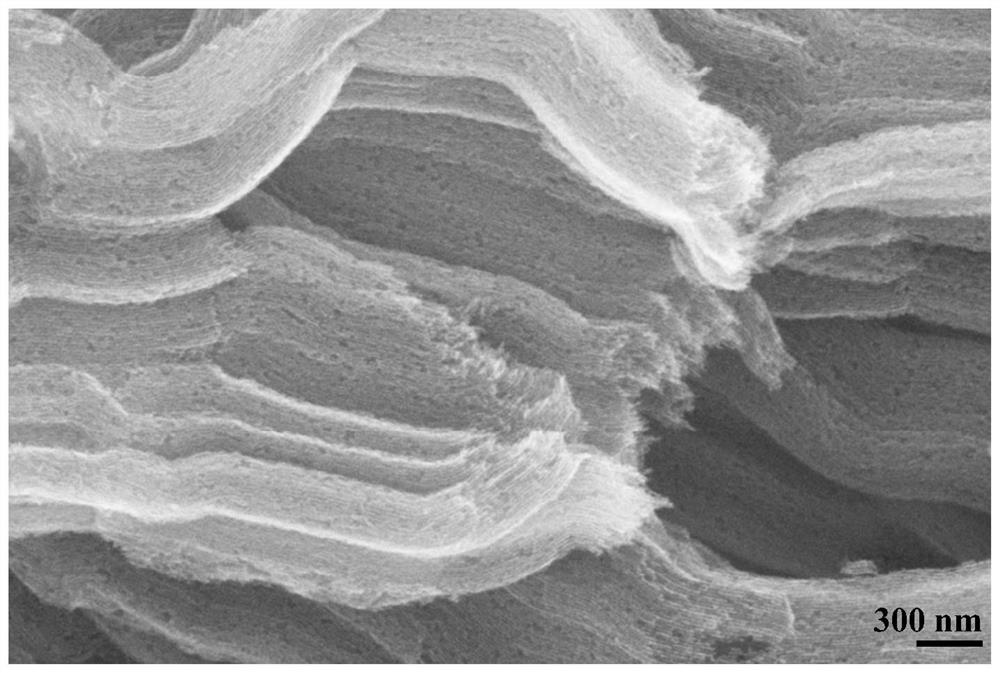

Nanometer flaky MFI molecular sieve and preparation method thereof

ActiveCN114380301ARapid responseHeating evenlyMaterial nanotechnologyCrystalline aluminosilicate zeolitesMolecular sieveCrystallite

The invention provides a nanosheet-shaped MFI molecular sieve and a preparation method thereof, and relates to the technical field of molecular sieves. The preparation method comprises the following steps: mixing a silicon source, tetrapropylammonium hydroxide and water, carrying out microwave heat treatment, and dialyzing and purifying to obtain an MFI crystallite solution; and carrying out hydrothermal treatment on the MFI crystallite solution to obtain the nanosheet-shaped MFI molecular sieve. The microwave heating assisted synthesis method has the advantages of fast reaction and uniform heating, and can efficiently synthesize the MFI zeolite crystallite with a uniform structure; the MFI crystallite molecular sieve with high purity and uniform structure is obtained through dialysis and purification, the MFI crystallite molecular sieve is used as a raw material to facilitate the generation of the nanosheet-shaped MFI molecular sieve with stable morphology, and the nanosheet-shaped MFI molecular sieve with uniform particle size, high purity and uniform structure is obtained. Moreover, the preparation method provided by the invention is simple to operate and simple in process, and the nanosheet zeolite material with the size required by practical application can be efficiently customized.

Owner:FUDAN UNIV

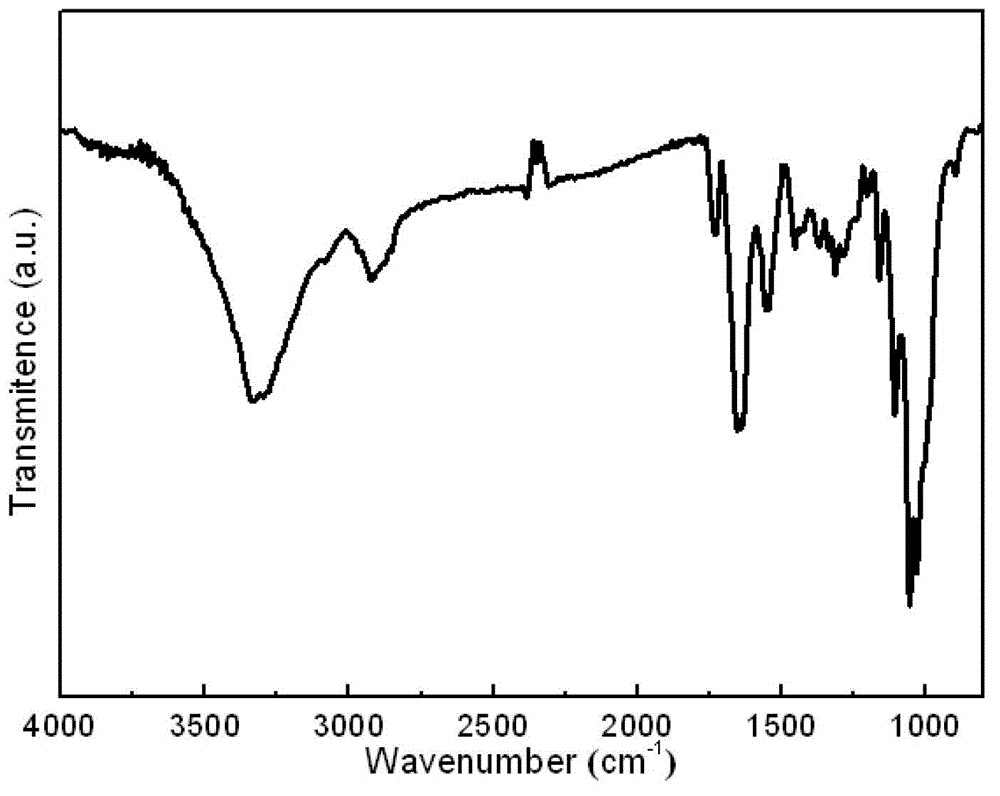

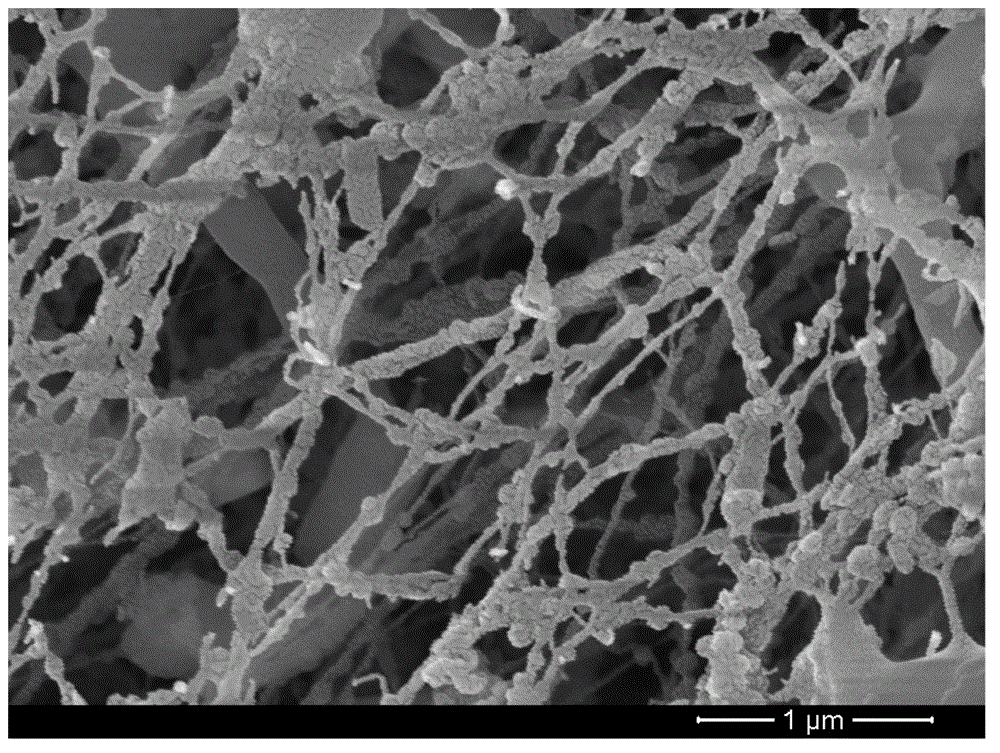

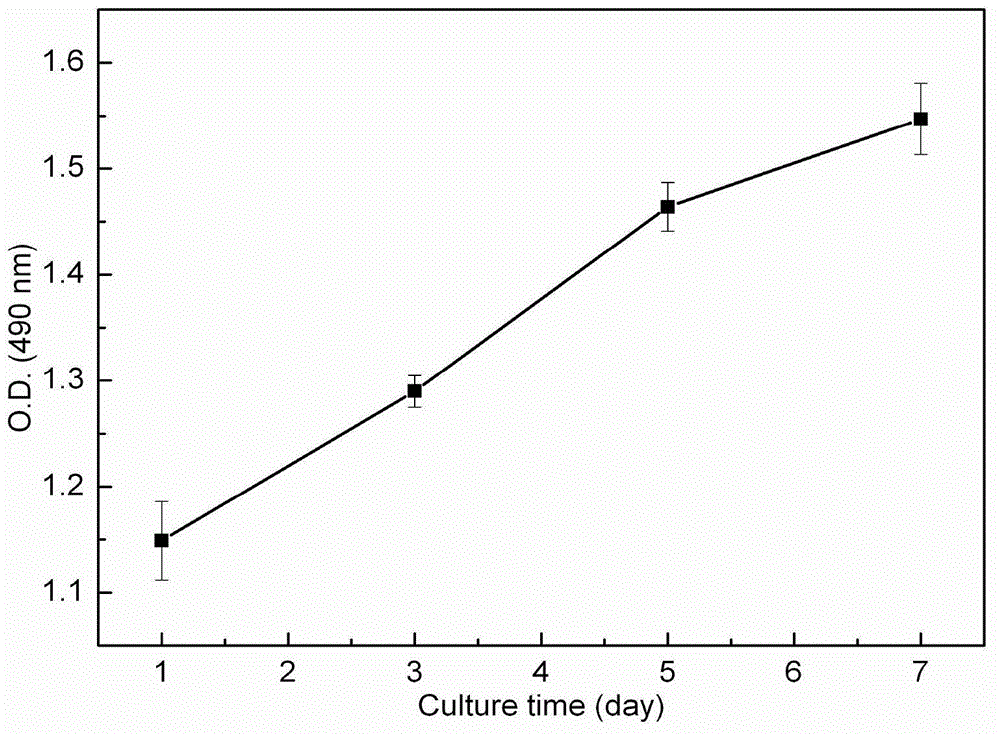

Bacterial cellulose/collagen composite material having biocompatibility and preparation method thereof

ActiveCN103041446BAddress the defect of lower biological activityPromote growthProsthesisFiberGenipin

The invention provides a bacterial cellulose / collagen composite material having biocompatibility and a preparation method thereof. The invention is characterized in that the composite material is prepared by taking bacterial cellulose, collagen and genipin as raw materials, wherein the mass ratio of the bacterial cellulose, the collagen and the genipin is (5-200):(0.1-5):(0.1-5). The invention has the characteristics of high synthesis efficiency, favorable synthesis uniformity, maintained structure and performance advantages of original BC and the like. In addition, the in vitro culture with fibroblasts discovers that the composite material has better biocompatibility.

Owner:CHINA TIANCHEN ENG +1

Lanthanum stannate, europium stannate and its composite stannate nanopowder synthesis method

The invention discloses a synthesizing method of lanthanum stannate, europium stannate and composite stannate nanometer powder, which comprises the following steps: dissolving lanthanum stannate and europium stannate with different molar rates or lanthanum stannate or europium stannate in the deionized water; stirring; adding sodium stannate or potassium stannate with the molar weight as the sum of lanthanum stannate and europium stannate in the solution; stirring; putting terminal solution into high-pressure autoclave; setting the filling density at 80-90%; disposing for 4-30h within 180-250 deg.c through hot water; centrifuging the disposed solution; cleaning; drying the product; obtaining the product with diameter at 15-35nm. The molecular formula of the product is La2-xEuxSn2O7 (x=02), which produces single and one-phase product.

Owner:ZHEJIANG SCI-TECH UNIV

Laser radar

PendingCN111308445AShort traceEasy to install and maintainWave based measurement systemsRadarEngineering

The invention discloses a laser radar. The laser radar comprises a main shaft, a radar rotor, a base, a first main board, a second main board, an angle measurement assembly, a power supply assembly and a communication assembly. The first main board is fixedly arranged relative to the radar rotor and surrounds the main shaft, and the second main board is fixedly arranged relative to the base and iscloser to the base than the first main board; the angle measuring assembly, the power supply assembly and the communication assembly are located between the first main board and the second main board, and at least one part of the angle measuring assembly, at least one part of the power supply assembly and at least one part of the communication assembly are arranged around the main shaft; the first measurement module, the first power supply module and the first communication module are fixedly arranged relative to the radar rotor, and the second measurement module, the second power supply module and the second communication module are fixedly arranged relative to the radar stator. According to the invention, the wiring of each module can be shortened, the installation and maintenance are convenient, and the mechanical reliability of the laser radar is improved.

Owner:HESAI TECH CO LTD

lidar

ActiveCN110018463BStable receptionImprove throughputWave based measurement systemsLight beamEngineering

This application discloses a laser radar. The laser radar in this application includes a main shaft and a communication assembly; the communication assembly includes at least one light-emitting element and at least one light-receiving element; wherein, the light-emitting element and the light-receiving element move relatively, and the light-receiving element is located at least one beam emitted by the light-emitting element on the light path; the light emitting element is centered on the main axis and arranged around the main axis, forming a ring-shaped light emitting element. The solution in this application can realize stable transmission of optical signals at a relatively low cost.

Owner:HESAI TECH CO LTD

Marine Gas Hydrate Accumulation-Development Simulation Experiment System and Method

ActiveCN111794722BSynthesis fastSynthetic evenFluid removalEducational modelsGraduated cylinderVapor–liquid separator

The invention relates to a marine natural gas hydrate accumulation-development simulation experiment system, which consists of a fluid injection part, a hydrate synthesis / decomposition part and a produced fluid metering part, and the fluid injection part includes a high-pressure displacement pump, a natural gas bottle, an intermediate container and seawater Storage tank; Hydrate synthesis / decomposition part includes high and low temperature test chamber, high pressure reactor, simulated vertical well pipeline, simulated horizontal well pipeline, temperature sensor, pressure sensor, computer, high pressure reactor is located in the high and low temperature test chamber, at the end of the kettle body The lid and the wall are arranged with fluid injection and extraction interfaces, and the pressure sensor and temperature sensor are connected to the computer through lead wires; the produced fluid metering part includes a back pressure valve, a gas-liquid separator, a graduated cylinder, and a gas meter. The system can be used for experiments such as synthesis simulation of marine gas hydrate reservoirs or exploitation of marine gas hydrates. The invention is easy to operate, and can provide important support for the evaluation and establishment of marine natural gas hydrate reservoir development technology.

Owner:SOUTHWEST PETROLEUM UNIV

Nitrogen-sulfur-phosphorus doped ordered mesoporous carbon material, preparation method and application thereof

ActiveCN112624084AInhibit aggregationSynthetic evenHybrid capacitor electrodesCarbon preparation/purificationO-Phosphoric AcidPolypyrrole

The invention discloses a nitrogen-sulfur-phosphorus doped ordered mesoporous carbon material, a preparation method and application thereof, wherein the nitrogen-sulfur-phosphorus doped ordered mesoporous carbon material has an ordered mesoporous structure and is doped with three elements of nitrogen, sulfur and phosphorus, and a precursor is filled into the pore channels of ordered mesoporous silicon oxide SBA-15 through a two-step method, wherein the first step is that mixed acid of phosphoric acid and sulfuric acid is filled into the pore channels of SBA-15 through an impregnation method, and the second step is that gas-phase pyrrole and 2-aminopyrrole are introduced into the pore channels of SBAe15 in a hydrothermal kettle, and an inorganic acid and a pyrrole compound are subjected to a polymerization reaction to generate a polypyrrole compound. According to the invention, the nitrogen-sulfur-phosphorus doped ordered mesoporous carbon material is obtained through high-temperature carbonization and template removal, and has a large specific surface area, a large pore volume and excellent super-capacitor performance.

Owner:ZHEJIANG NORMAL UNIVERSITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com

![Hexaaza [3.3.3] propellane compounds as key intermediates for new molecular explosives and a method for preparing the same Hexaaza [3.3.3] propellane compounds as key intermediates for new molecular explosives and a method for preparing the same](https://images-eureka.patsnap.com/patent_img/951df232-cf1b-4625-934d-fba604da49a0/US08609861-20131217-D00001.png)

![Hexaaza [3.3.3] propellane compounds as key intermediates for new molecular explosives and a method for preparing the same Hexaaza [3.3.3] propellane compounds as key intermediates for new molecular explosives and a method for preparing the same](https://images-eureka.patsnap.com/patent_img/951df232-cf1b-4625-934d-fba604da49a0/US08609861-20131217-D00002.png)

![Hexaaza [3.3.3] propellane compounds as key intermediates for new molecular explosives and a method for preparing the same Hexaaza [3.3.3] propellane compounds as key intermediates for new molecular explosives and a method for preparing the same](https://images-eureka.patsnap.com/patent_img/951df232-cf1b-4625-934d-fba604da49a0/US08609861-20131217-D00003.png)