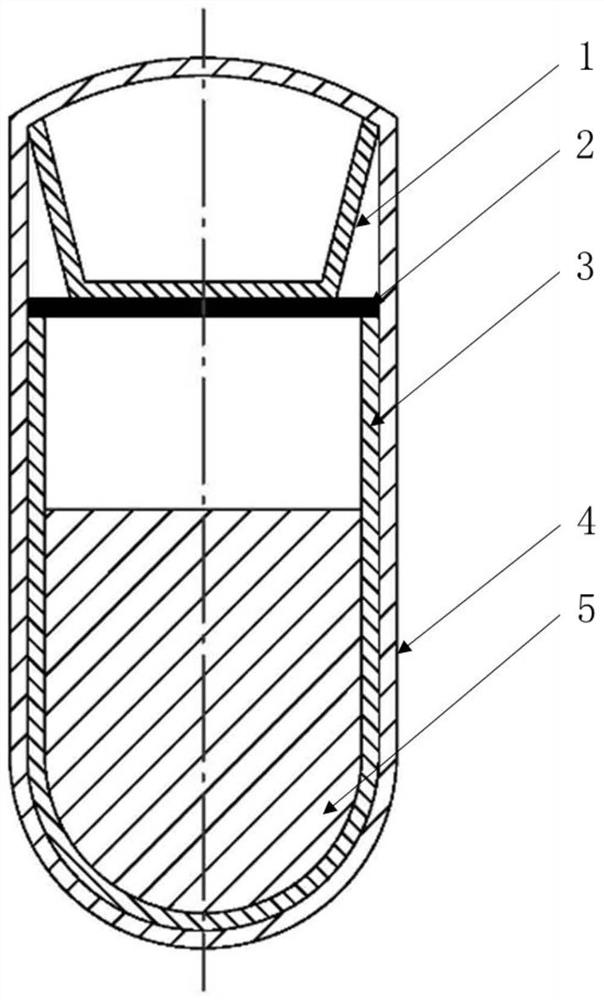

Aluminum antimonide polycrystalline material synthesizing process device and synthesis method

A technology for synthesizing aluminum antimonide and polycrystalline materials, which is applied in the growth of polycrystalline materials, chemical instruments and methods, single crystal growth, etc., can solve the problems of complex structure, difficult control, high cost, etc., and achieve a positively small cavity , the effect of suppressing the loss of elements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035]Embodiment 1: Step 1, silicon nitride ceramic crucible and graphite gasket treatment. Soak a silicon nitride ceramic crucible with a wall thickness of 5 mm in aqua regia for 24 hours, take it out, rinse it with deionized water, then soak it with 10% hydrofluoric acid solution for 30 minutes, rinse it with deionized water, and then ultrasonicate it in deionized water Take it out for 2 hours, rinse it with deionized water, put it into a vacuum drying oven at 120 degrees Celsius and dry it for 2 hours for later use. Soak a graphite gasket with a thickness of 2 mm in aqua regia for 24 hours, take it out and rinse it, and then ultrasonicate it in deionized water for 2 hours.

[0036] Step two, weighing and loading. In a 100-class clean room, use an electronic level to weigh a certain mass of high-purity aluminum with a purity of 99.999% and high-purity antimony with a purity of 99.9999% at a molar ratio of 1:1, and the precision of the electronic balance is not less than 10 ...

Embodiment 2

[0040] Embodiment 2: Step 1, silicon nitride ceramic crucible and graphite gasket treatment. Soak a silicon nitride ceramic crucible with a wall thickness of 5 mm in aqua regia for 24 hours, take it out, rinse it with deionized water, then soak it with 10% hydrofluoric acid solution for 45 minutes, rinse it with deionized water, and then ultrasonicate it in deionized water After 3 hours, take it out, rinse it with deionized water, put it into a vacuum drying oven at 120 degrees Celsius and dry it for 4 hours for later use. Soak a graphite gasket with a thickness of 2 mm in aqua regia for 24 hours, take it out and rinse it, and then ultrasonicate it in deionized water for 3 hours.

[0041] Step two, weighing and loading. In a 100-class clean room, use an electronic level to weigh a certain mass of high-purity aluminum with a purity of 99.999% and high-purity antimony with a purity of 99.9999% at a molar ratio of 1:1, and the precision of the electronic balance is not less than...

Embodiment 3

[0044] Embodiment 3: Step 1, silicon nitride ceramic crucible and graphite gasket treatment. Soak a silicon nitride ceramic crucible with a wall thickness of 5 mm in aqua regia for 24 hours, take it out, rinse it with deionized water, then soak it with 15% hydrofluoric acid solution for 45 minutes, rinse it with deionized water, and then ultrasonicate it in deionized water After 3 hours, take it out, rinse it with deionized water, put it into a vacuum drying oven at 120 degrees Celsius and dry it for 4 hours for later use. Soak a graphite gasket with a thickness of 2 mm in aqua regia for 24 hours, take it out and rinse it, and then ultrasonicate it in deionized water for 3 hours.

[0045] Step two, weighing and loading. In a 100-class clean room, use an electronic level to weigh a certain mass of high-purity aluminum with a purity of 99.999% and high-purity antimony with a purity of 99.9999% at a molar ratio of 1:1, and the precision of the electronic balance is not less than...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com