Preparation method for rapidly synthesizing DD3R molecular sieve

A molecular sieve and mother liquor synthesis technology, applied in the chemical industry, can solve the problems of difficulty in DD3R synthesis, long synthesis time, low product yield, etc., and achieve the effects of controllable morphology, short synthesis time and uniform particle size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1220

[0071] Example 1 Preparation of all-silicon DD3R molecular sieve by reacting at 220°C for 6 hours

[0072] Mix 5.24 grams of ethylenediamine, 1.65 grams of amantadine and 39.24 grams of water and stir for 0.5 hours, add 3.88 grams of ammonium fluorosilicate, stir for 1 hour, and put it in an oven at 220 ° C for 6 hours to react, SiO 2 :H 2 O: amantadine (Adam): ethylenediamine (EDA) = 1:100:0.5:4, after filtering and washing, DD3R molecular sieves were obtained.

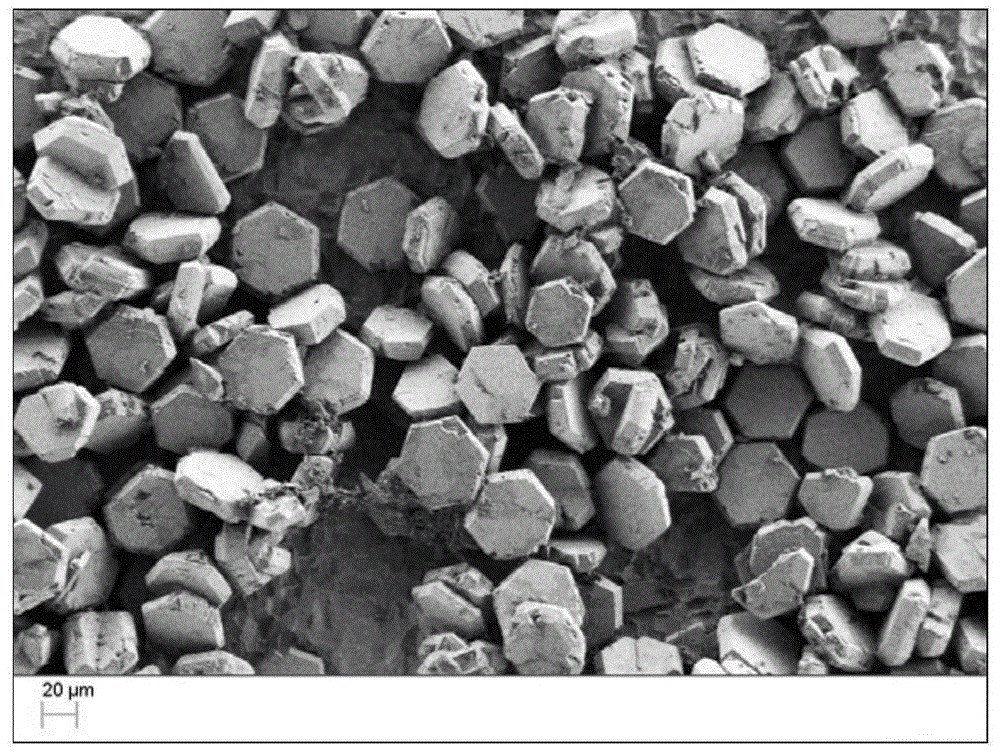

[0073] figure 1 Scanning electron micrographs of DD3R molecular sieves prepared for this method. It can be seen from the figure that the DD3R molecular sieve grains are hexagonal, uniform in size, and the diagonal particle size is about 50 microns. The crystallinity is good, and the yield is calculated based on the equivalent molar number of silicon dioxide converted from the ammonium fluorosilicate added to the molecular sieve synthesis mother liquor, which can reach 50%.

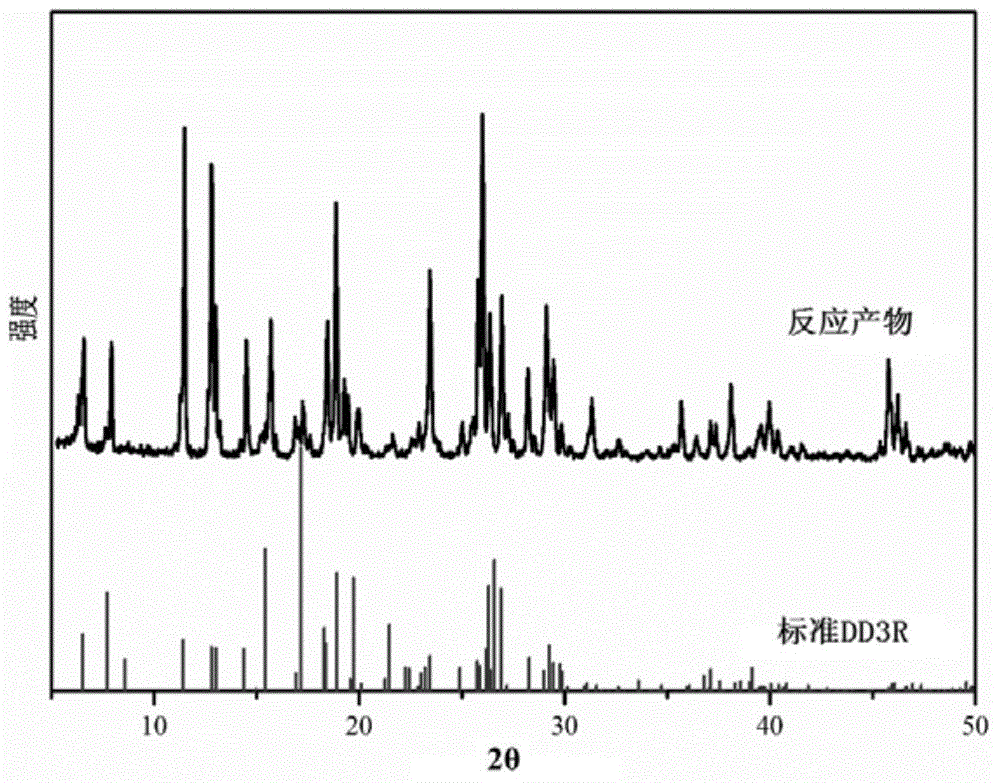

[0074] figure 2 The XRD spectrum of ...

Embodiment 2220

[0075] Example 2 Preparation of all-silicon DD3R molecular sieve by reacting at 220°C for 12 hours

[0076] The difference from Example 1 is that it was placed in an oven at 220° C. for 12 hours to react. All the other steps are the same as in Example 1.

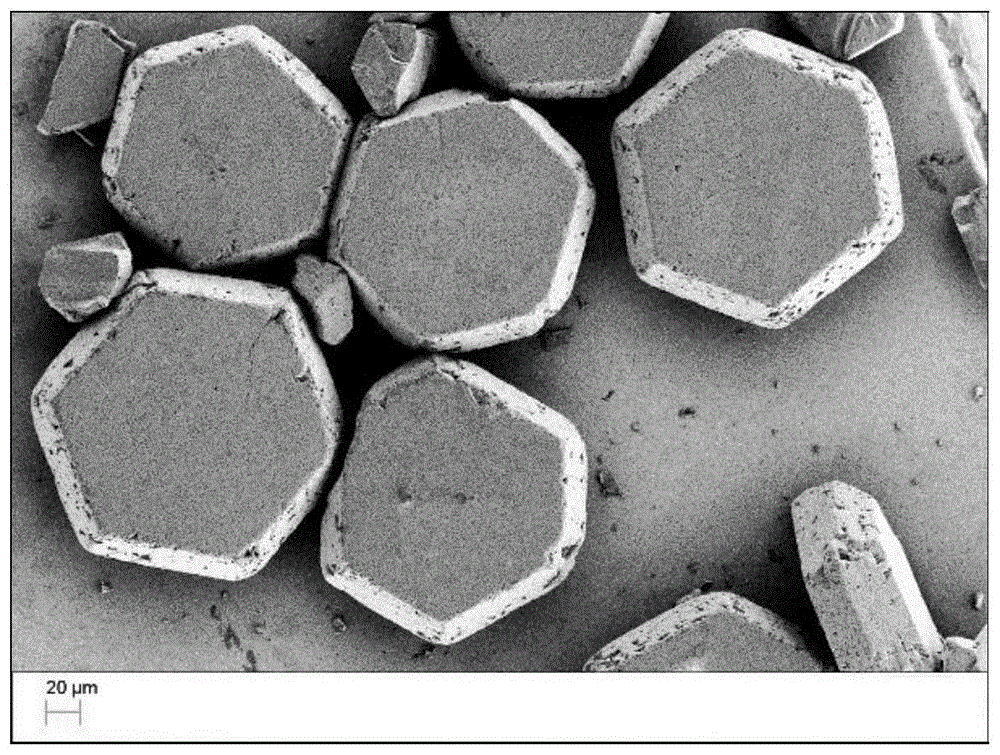

[0077] image 3 Scanning electron micrographs of DD3R molecular sieves prepared for this method. It can be seen from the figure that the particle size of DD3R molecular sieve is uniform, and the diagonal particle size of the hexagon is about 150 μm. At the same time, the crystallinity is good. Compared with the 6-hour reaction, the crystallinity is greatly improved, and the particle size increases from 50 microns to 150 microns. The yield is calculated on the basis of the equivalent moles of silicon dioxide added to the ammonium fluorosilicate synthesis mother liquor, which is close to 100%.

[0078] Figure 4 The XRD spectrum of the DD3R molecular sieve prepared by this method is consistent with the standard spectrum. ...

Embodiment 3

[0079] Example 3 Adding 0.1wt% seed crystals and reacting at 220°C for 12 hours to prepare all-silicon DD3R molecular sieves

[0080] The difference from Example 1 is that after adding 3.88 g of ammonium fluorosilicate and stirring for 1 hour, 50 mg of DD3R molecular sieve seed crystals were added, stirred for 5 minutes, and then placed in an oven at 220° C. for 12 hours. All the other steps are the same as in Example 1.

[0081] Figure 5 Scanning electron micrographs of DD3R molecular sieves prepared for this method. It can be seen from the figure that the DD3R molecular sieve crystal has a hexagonal shape, and the hexagonal diagonal particle size is about 6-15 microns. Compared with Example 2, the crystallinity is equivalent, and the crystal grain size is greatly reduced. The yield is calculated on the basis of the equivalent moles of silicon dioxide added to the ammonium fluorosilicate synthesis mother liquor, which is close to 100%.

[0082] Image 6 The XRD spectrum...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com