Preparation method for aluminum-doped zinc oxide (AZO) nano array

A technology of aluminum-doped zinc oxide and nano-array, which is applied in the manufacture of hybrid/electric double-layer capacitors and electrodes of hybrid capacitors, can solve the problem of effectively ensuring the doping uniformity of reactant morphology and the difficulty of electron transmission in polycrystalline films. , complex process and other issues, to achieve the effect of good crystallinity and chemical orientation, low cost and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

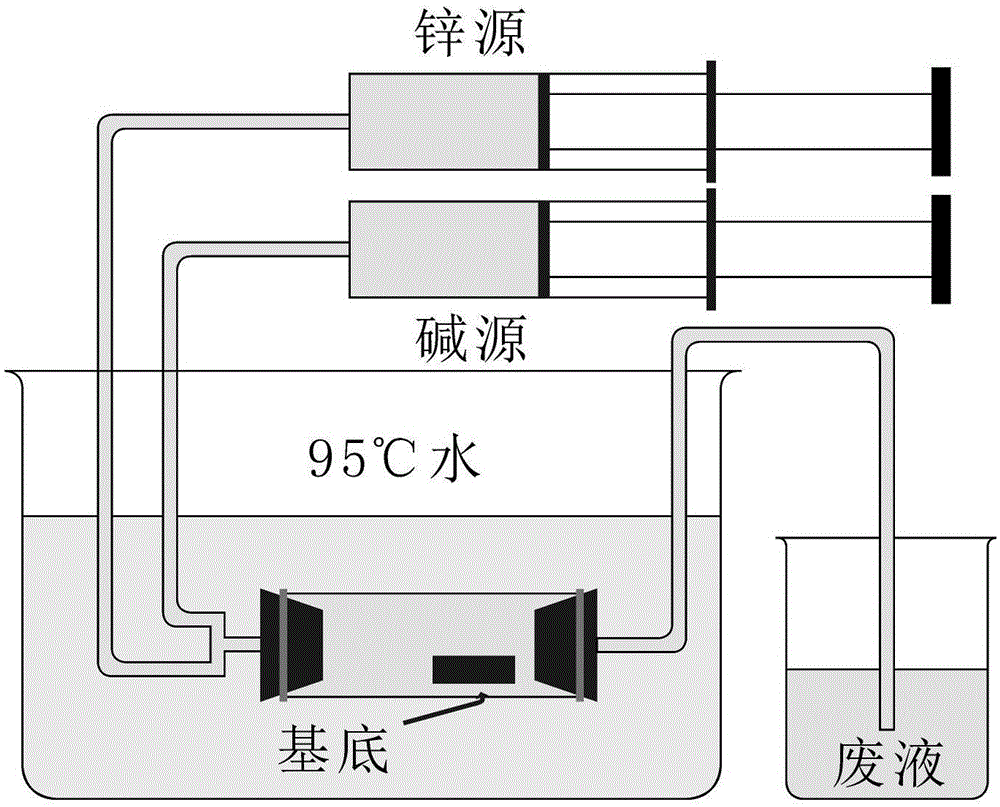

[0036] A method for preparing aluminum-doped zinc oxide nano-arrays. The preparation method is to inject growth sources and doping sources at a continuous constant rate, and precisely control the concentration of chemical reaction liquid, so that the aluminum-doped nano-array with high carrier concentration can be controlled and prepared. Zinc oxide array, and composite with nickel oxide material to obtain high-capacity capacitor electrode material, the specific steps of the preparation method are as follows:

[0037] (1) Clean the glass and deposit an Al-doped zinc oxide film as a seed layer by magnetron sputtering, and place the substrate seed layer upwards in the liquid-phase chemical reaction chamber of the continuous growth device;

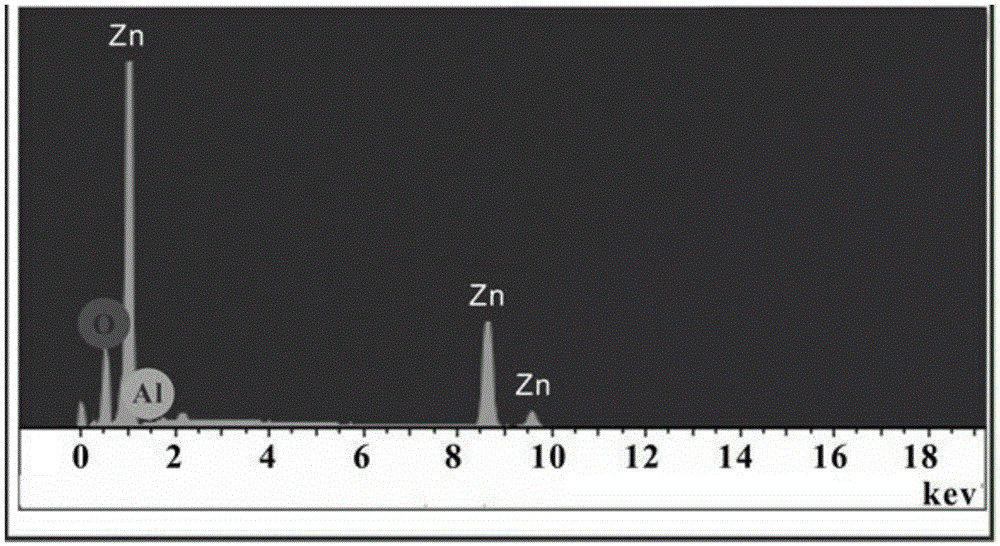

[0038] (2) Prepare a mixed aqueous solution of 50mM zinc nitrate and 5mM aluminum nitrate and inject it into one of the syringes of the continuous growth device used;

[0039] (3) Prepare 50mM hexamethylenetetramine as a base salt and inject ...

Embodiment 1

[0046] (1) Clean the glass and deposit an Al-doped zinc oxide film as a seed layer by magnetron sputtering, and place the substrate seed layer upwards in the liquid-phase chemical reaction chamber of the continuous growth device;

[0047] (2) Prepare a mixed aqueous solution of 50mM zinc nitrate and 5mM aluminum nitrate and inject it into one of the syringes of the continuous growth device used;

[0048] (3) Prepare 50mM hexamethylenetetramine as a base salt and inject it into another syringe of the device;

[0049] (4) Keep the temperature of the liquid-phase chemical reaction chamber at 95°C by heating in a water bath, set the constant injection rate (6ml / h) and constant injection time (16h) of the reaction source, and start the continuous flow injection method to prepare aluminum-doped ZnO arrays;

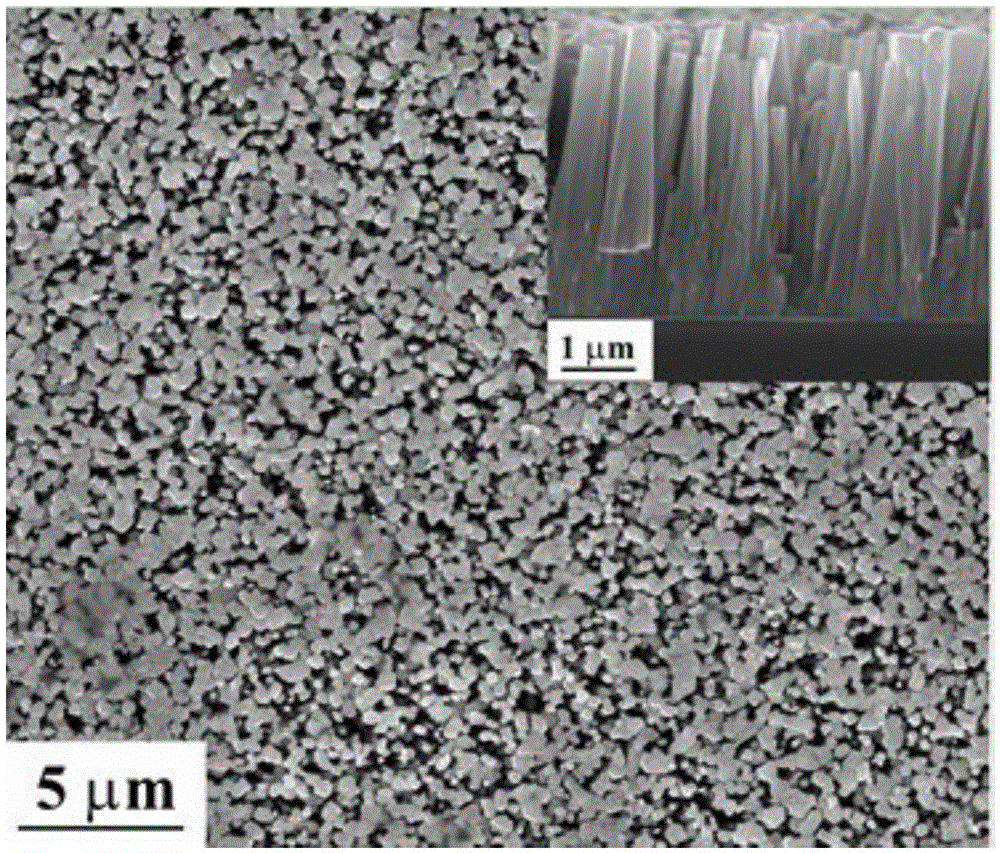

[0050] (5) After the hydrothermal reaction is over, stop heating the reaction chamber, wait for it to cool to room temperature, take out the sample, rinse it with deionized wate...

Embodiment 2

[0053] The other steps are unchanged as in Example 1, and will not be repeated here, but step (3) is changed to: prepare 50mM hexamethylenetetramine and 5M sodium hydroxide solution respectively as lye, and keep the concentration of hexamethylenetetramine Adding amount is constant, injects in another syringe of device after the lye pH is adjusted to 5.00 by changing the adding amount of sodium hydroxide.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com