Preparation method of pseudo-boehmite with high purity and high crystallization degree

A pseudo-boehmite, high crystallinity technology, applied in the preparation of alkali metal aluminate/alumina/aluminum hydroxide, alumina/aluminum hydroxide, etc., can solve the problem of amorphous pseudo-boehmite, sol Aggregation into gel, uneven particle size distribution, etc., to achieve the effect of complete crystal grains, improved purity, and high purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

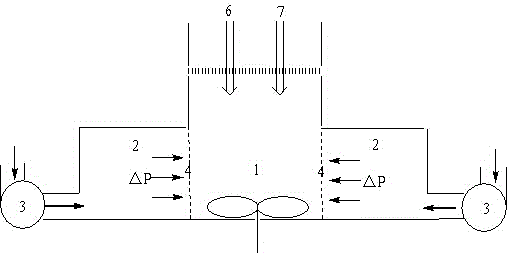

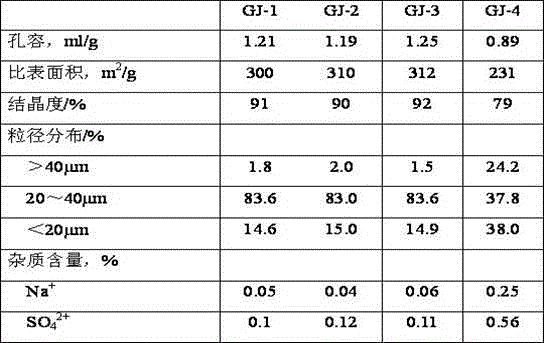

[0040] 1 L of bottom water and 8.7 g of ethylene glycol were added to the bottom of Reactor 1, and the reaction temperature was adjusted to 30°C. Adjust the feeding speed of the two feeding pipes on the reactor, and the NaAlO with a concentration of 10g / 100ml 2 The solution has a flow rate of 20ml / min and a concentration of 30g / 100ml of Al 2 (SO 4 ) 3 The solution flows into the reactor in parallel at a flow rate of 15ml / min. After forming a gel for 20 minutes, after the aluminum hydroxide sol reaches 7.6g / 100ml, apply a specific pressure in the pressure zones on both sides to keep the pressure difference △P at 0.5-2.0 Between MPa, keep the sol concentration between 5 and 15g / 100ml, and continue to react for 1.0h. After the reaction is over, start the stirring paddle, adjust the rotation speed to 1200r / min, adjust the pH value of the reactor to 9.5 and set the temperature at 15°C / min. The reaction temperature was raised to 80°C in the high-temperature section, aged for 1.0 ...

Embodiment 2

[0042] Add 2L of bottom water and 10g of glycerol to the bottom of reactor 1, and adjust the reaction temperature to 40°C. Regulate the feeding speed of two feeding pipes on the reactor, the NaAlO that concentration is 15g / 100ml 2 The solution has a flow rate of 25ml / min and a concentration of 35g / 100ml of Al 2 (SO 4 ) 3 The solution flows into the reactor in parallel at a flow rate of 20ml / min, and after forming a gel for 30 minutes, after the aluminum hydroxide sol reaches 10g / 100ml, apply a specific pressure in the pressure zones on both sides to keep the pressure difference △P at 0.5-4.0MPa In between, keep the sol concentration between 5 and 15g / 100ml, and continue the reaction for 0.5h. After the reaction is over, start the stirring paddle, adjust the rotation speed to 1000r / min, adjust the pH value of the reactor to 9.0 and react at a rate of 10°C / min. The temperature was raised to 90°C in the high temperature section, aged for 1.5 hours, filtered, washed and dried t...

Embodiment 3

[0044] 1.5L of bottom water and 8.7g of ethylene glycol were added to the bottom of reactor 1, and the reaction temperature was adjusted to 25°C. Adjust the feed rate of the two feeding pipes on the reactor, and the NH concentration of 10g / 100ml 4 OH solution ml / min flow rate and Al concentration of 35g / 100ml 2 (SO 4 ) 3 The solution flows into the reactor in parallel at a flow rate of 20ml / min. After forming a gel for 20 minutes, after the aluminum hydroxide sol reaches 7.4g / 100ml, apply a specific pressure in the pressure zones on both sides to keep the pressure difference △P at 0.7~ Between 2.0MPa, maintain the sol concentration between 5 ~ 15g / 100ml, continue to react for 1.0h, after the end of the reaction, start the stirring paddle, adjust the rotation speed to 1500r / min, adjust the pH value of the reactor to 9.5 and the rate of 15℃ / min Raise the reaction temperature to 75°C in the high temperature section, perform aging for 2.0 hours, filter, wash and dry to obtain p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| crystallinity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com