Patents

Literature

354results about How to "Solve the small density" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

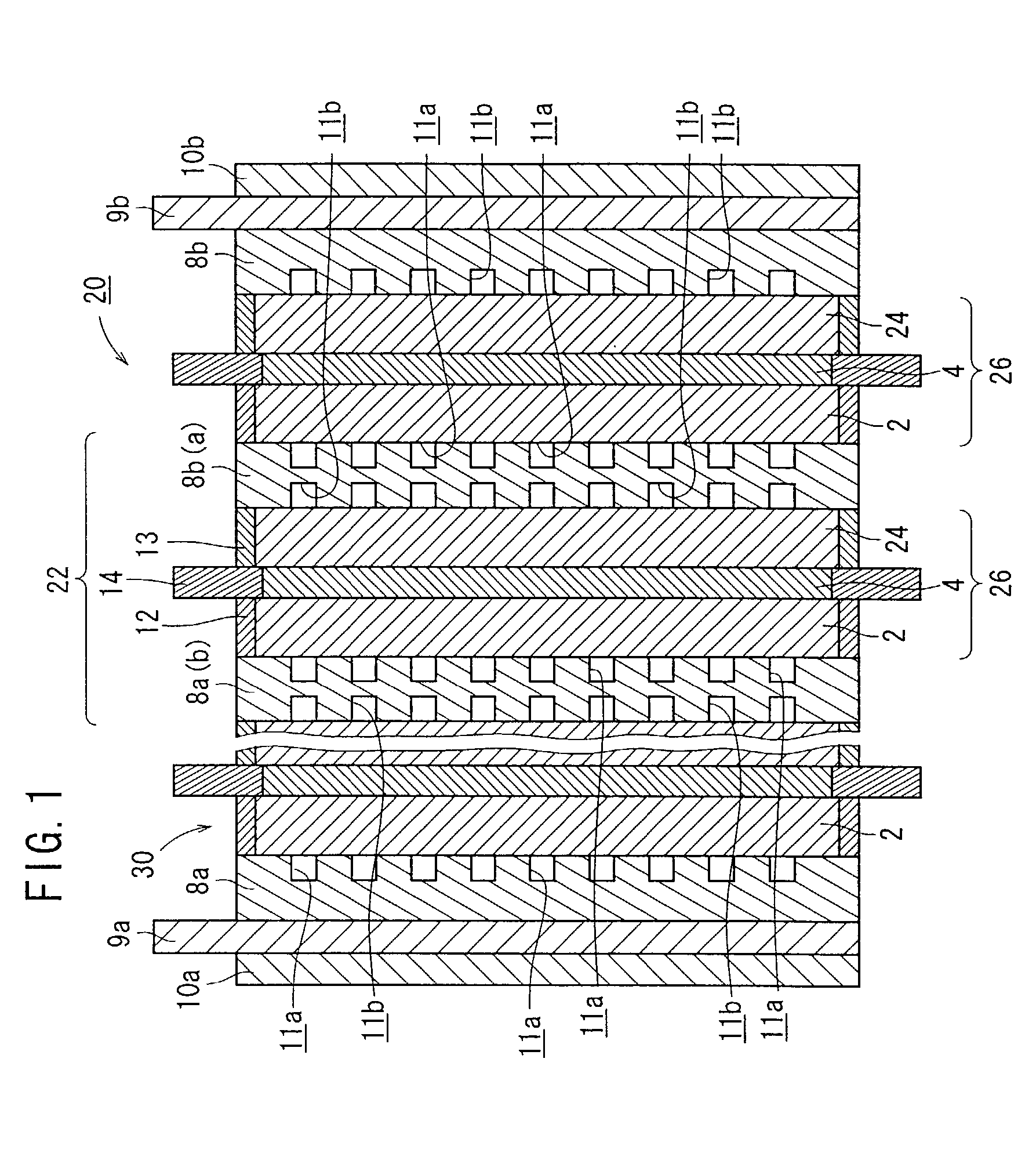

Ultrascalable petaflop parallel supercomputer

InactiveUS20090006808A1Massive level of scalabilityUnprecedented level of scalabilityProgram control using stored programsArchitecture with multiple processing unitsMessage passingPacket communication

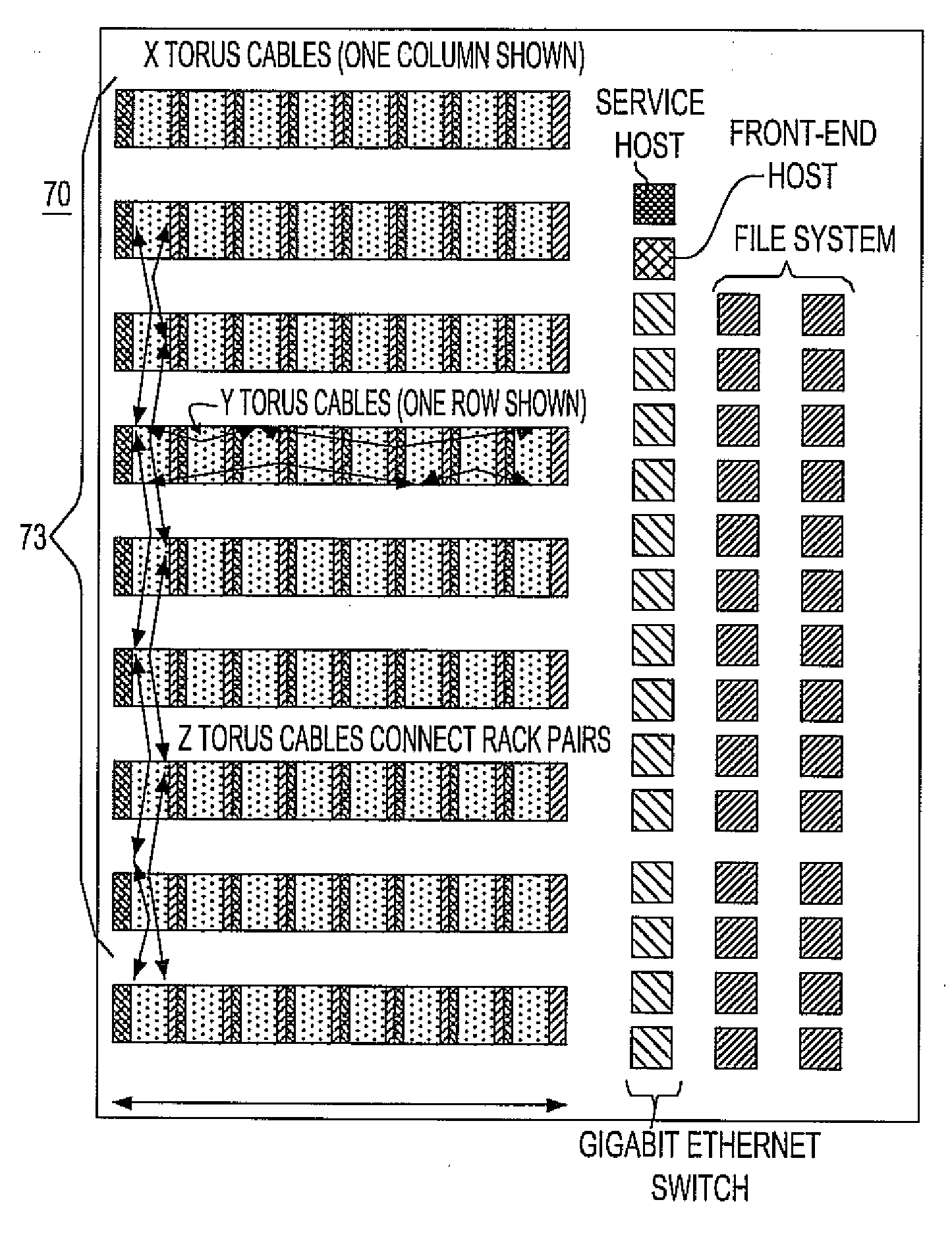

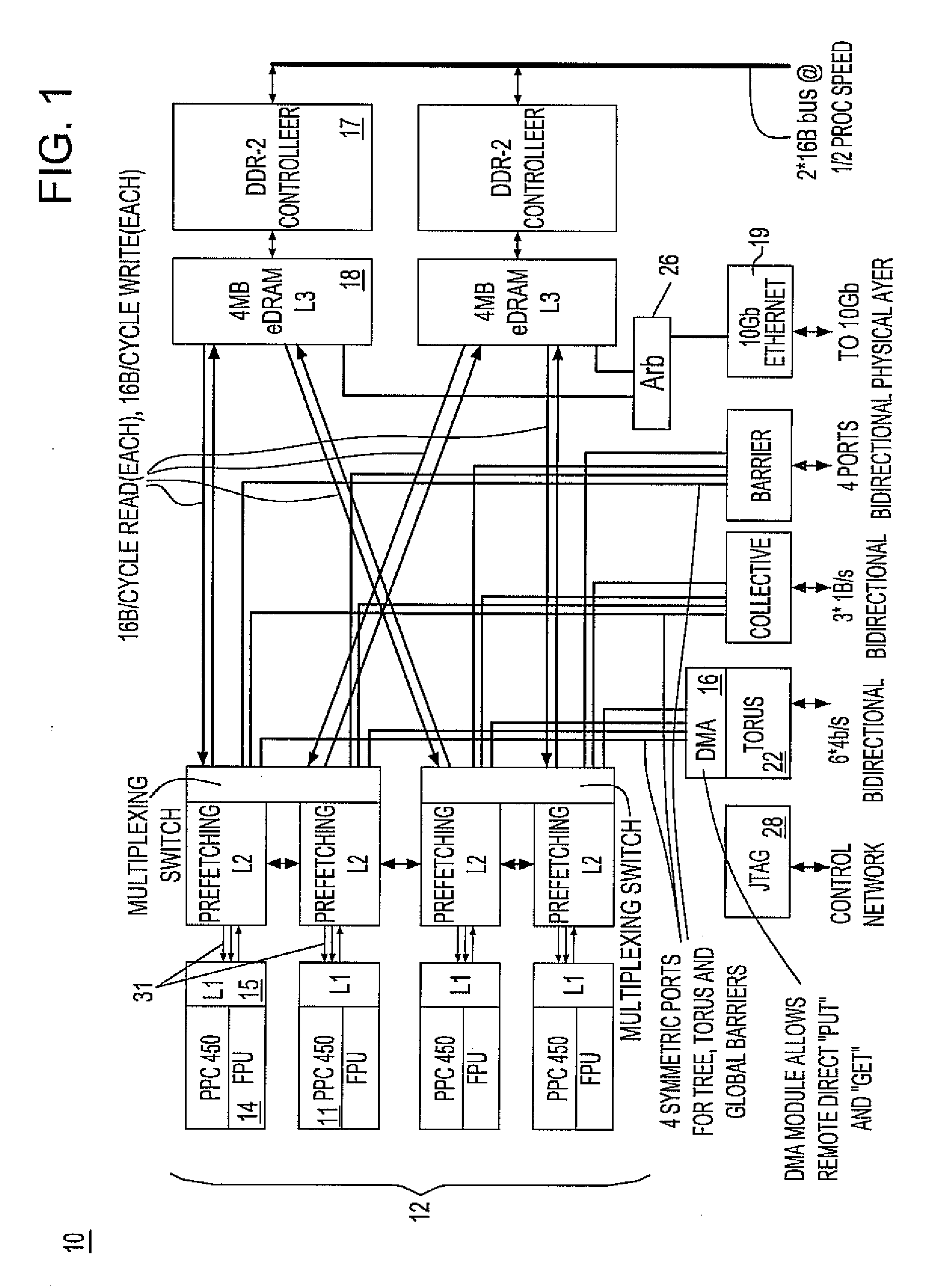

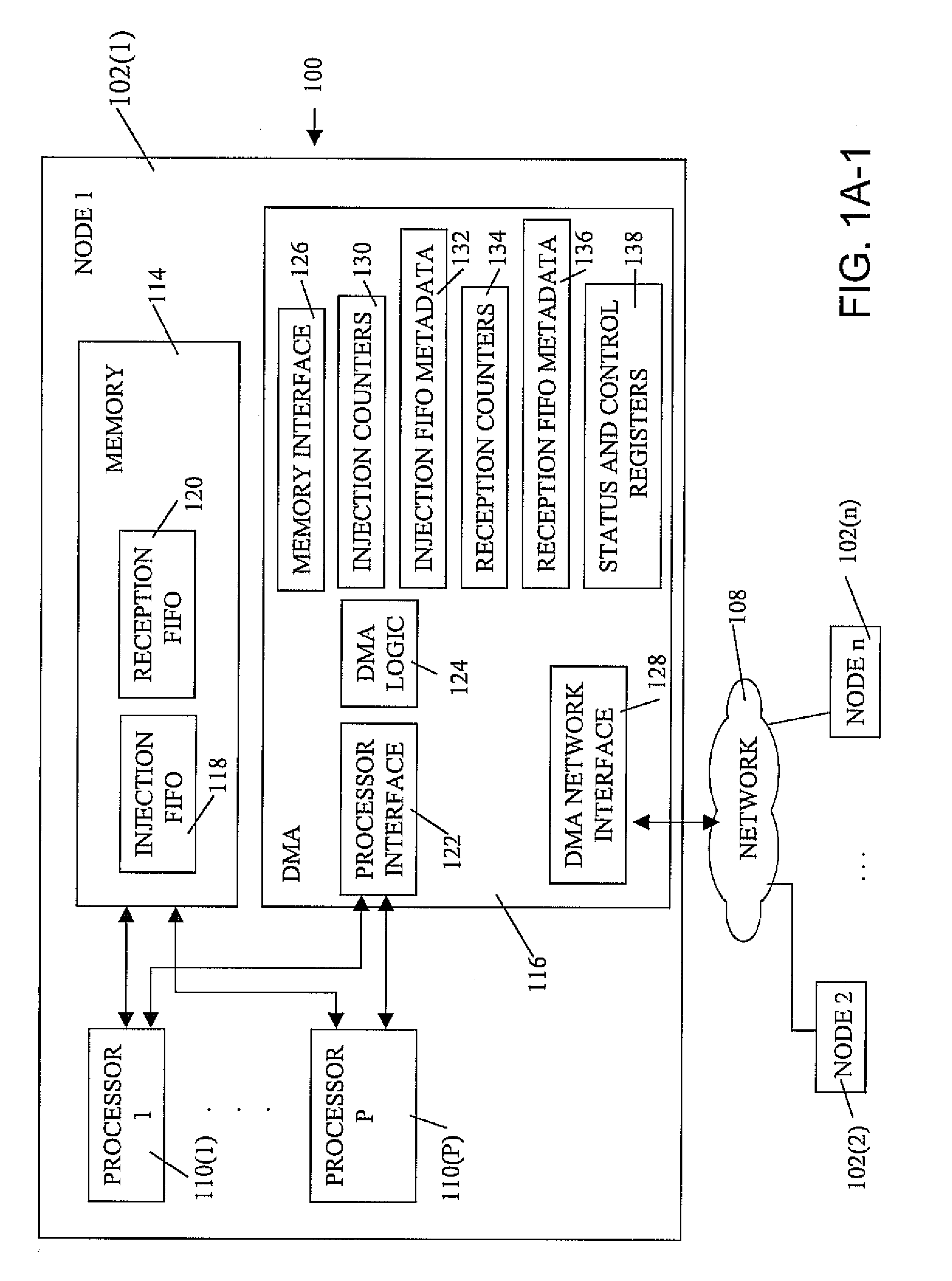

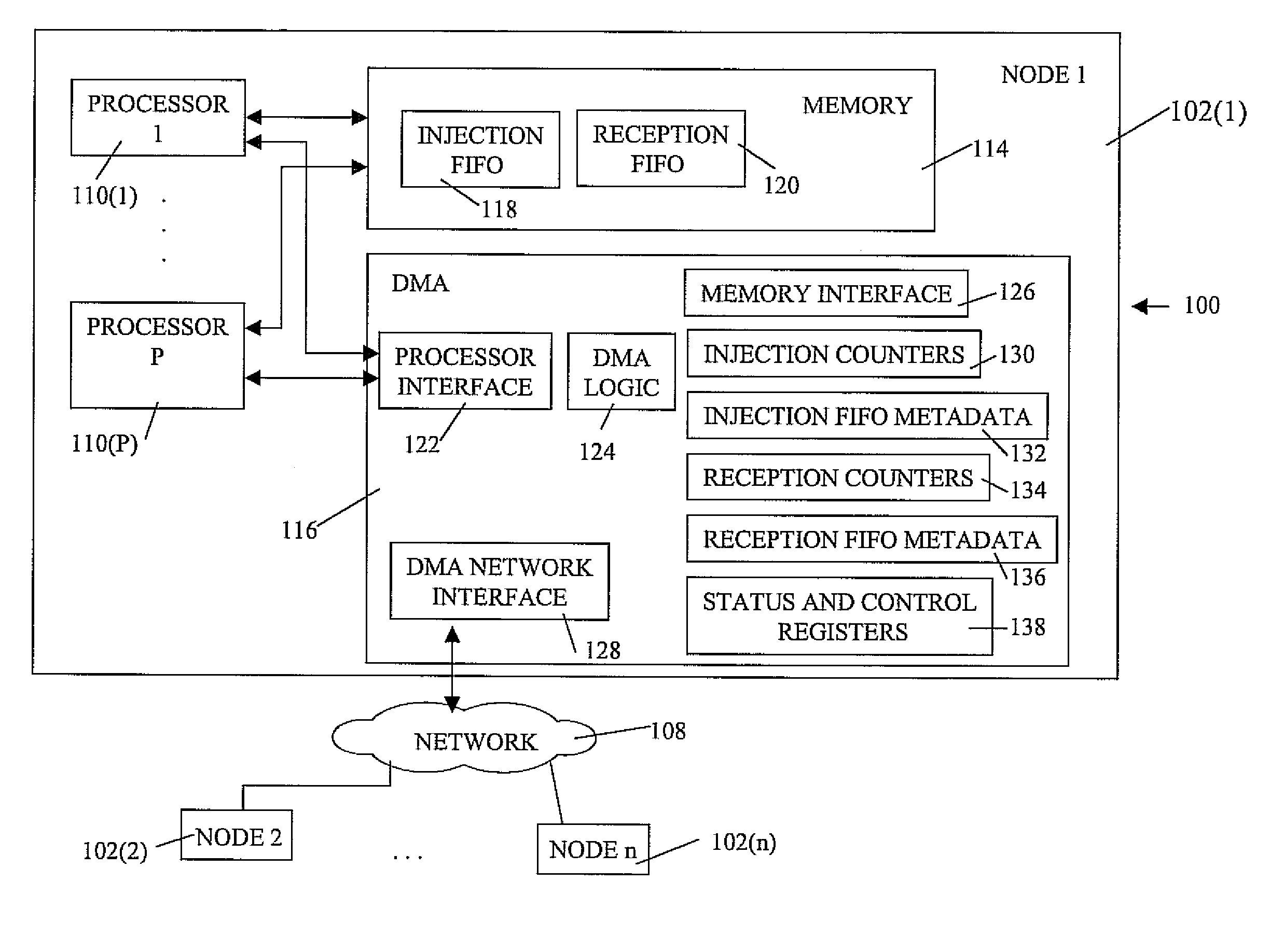

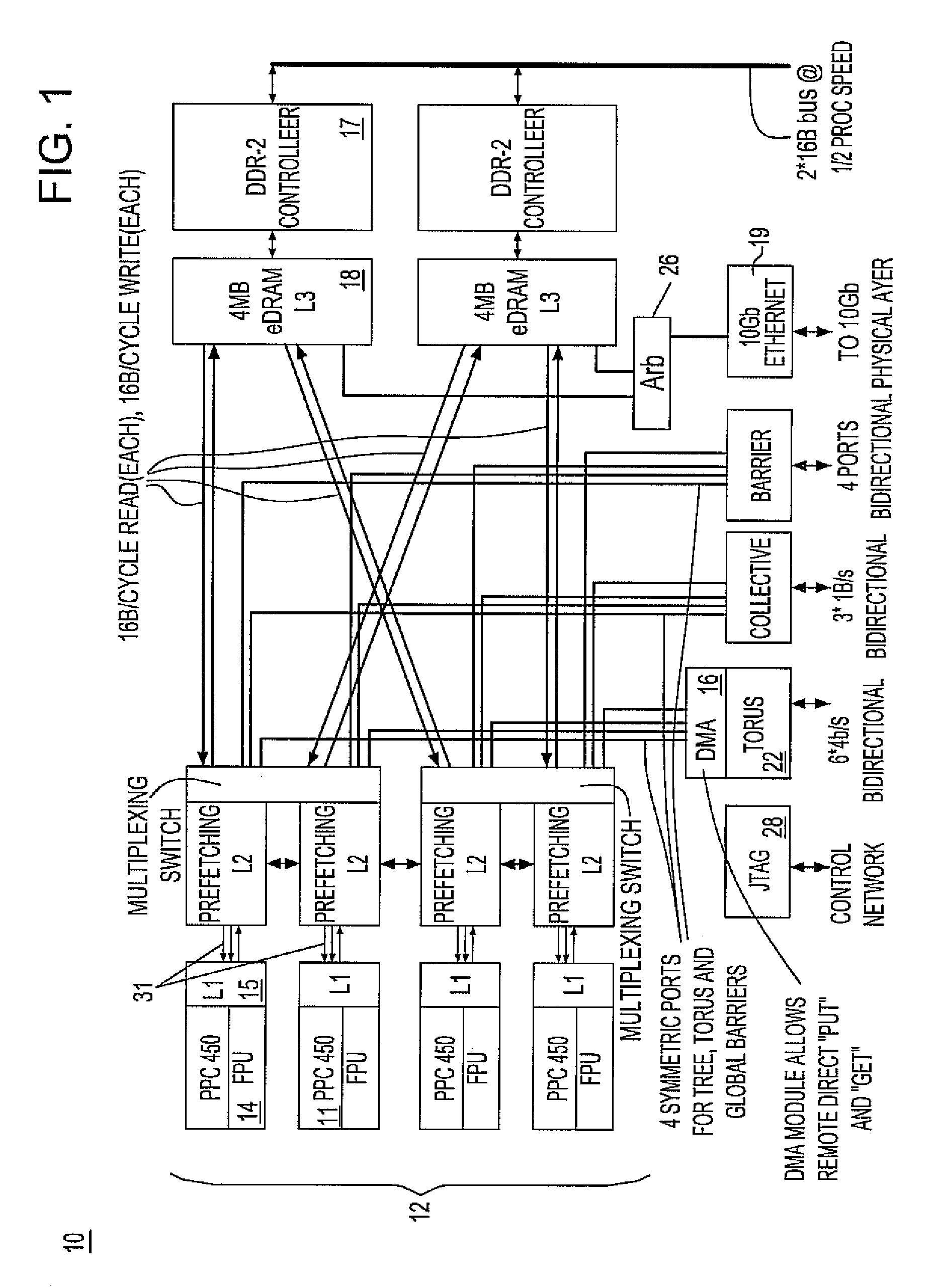

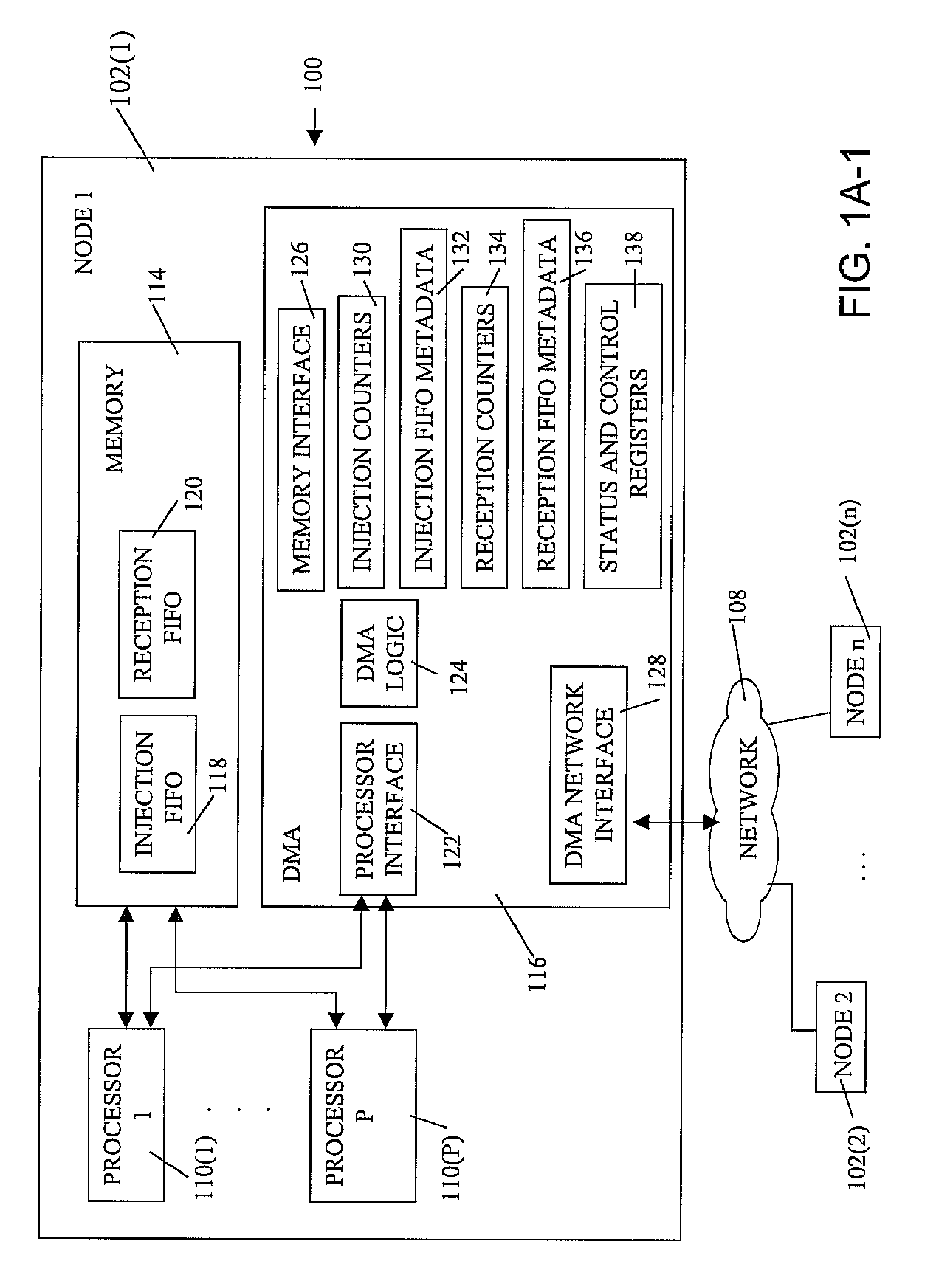

A novel massively parallel supercomputer of petaOPS-scale includes node architectures based upon System-On-a-Chip technology, where each processing node comprises a single Application Specific Integrated Circuit (ASIC) having up to four processing elements. The ASIC nodes are interconnected by multiple independent networks that optimally maximize the throughput of packet communications between nodes with minimal latency. The multiple networks may include three high-speed networks for parallel algorithm message passing including a Torus, collective network, and a Global Asynchronous network that provides global barrier and notification functions. These multiple independent networks may be collaboratively or independently utilized according to the needs or phases of an algorithm for optimizing algorithm processing performance. Novel use of a DMA engine is provided to facilitate message passing among the nodes without the expenditure of processing resources at the node.

Owner:IBM CORP

Ultrascalable petaflop parallel supercomputer

InactiveUS7761687B2Maximize throughputDelay minimizationGeneral purpose stored program computerElectric digital data processingSupercomputerPacket communication

A massively parallel supercomputer of petaOPS-scale includes node architectures based upon System-On-a-Chip technology, where each processing node comprises a single Application Specific Integrated Circuit (ASIC) having up to four processing elements. The ASIC nodes are interconnected by multiple independent networks that optimally maximize the throughput of packet communications between nodes with minimal latency. The multiple networks may include three high-speed networks for parallel algorithm message passing including a Torus, collective network, and a Global Asynchronous network that provides global barrier and notification functions. These multiple independent networks may be collaboratively or independently utilized according to the needs or phases of an algorithm for optimizing algorithm processing performance. The use of a DMA engine is provided to facilitate message passing among the nodes without the expenditure of processing resources at the node.

Owner:INT BUSINESS MASCH CORP

Electrodes and methods for microbial fuel cells

InactiveUS20080292912A1Raise the potentialImprove performanceTreatment by combined electrochemical biological processesCell electrodesMicrobial fuel cellFuel cells

Methods of improving a performance parameter of a microbial fuel cell are provided according to embodiments of the present invention which include heating an electrode and exposing the heated electrode to ammonia gas to produce a treated electrode characterized by an increased positive surface charge on the electrode surface. Improved performance parameters include increased maximum power density, increased coulombic efficiency, increased volumetric power density and decreased microbial fuel cell operation time to achieve maximum power density

Owner:PENN STATE RES FOUND

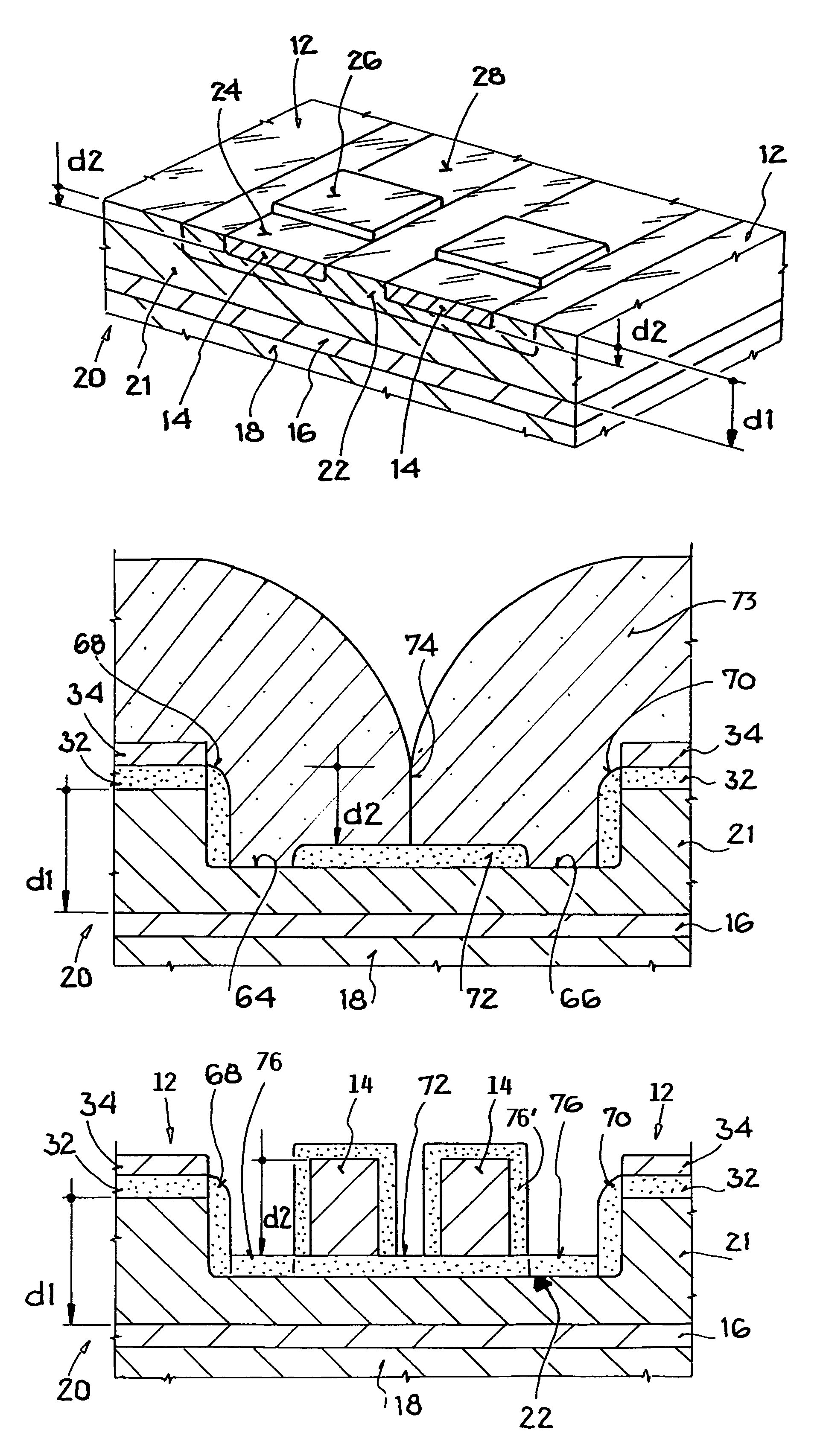

Method of producing active semiconductor layers of different thicknesses in an SOI wafer

ActiveUS7001804B2Reduce the overall heightSolve the small densitySolid-state devicesSemiconductor/solid-state device manufacturingSemiconductor materialsEngineering

An SOI wafer including an active semiconductor material layer on an insulating layer is processed to form thereon first and second active semiconductor regions that respectively have different thicknesses and that are vertically and laterally insulated. In the process, a trench is etched into the SOI wafer, seed openings are formed in the bottom of the trench to reach the underlying active material layer, the trench is filled with epitaxially grown semiconductor material progressing from the seed openings, some of the epitaxially grown material is removed to form the second active regions, and oxide layers are provided so that the second active regions are laterally and vertically insulated from the first active regions formed by remaining portions of the active semiconductor material layer.

Owner:ATMEL GERMANY

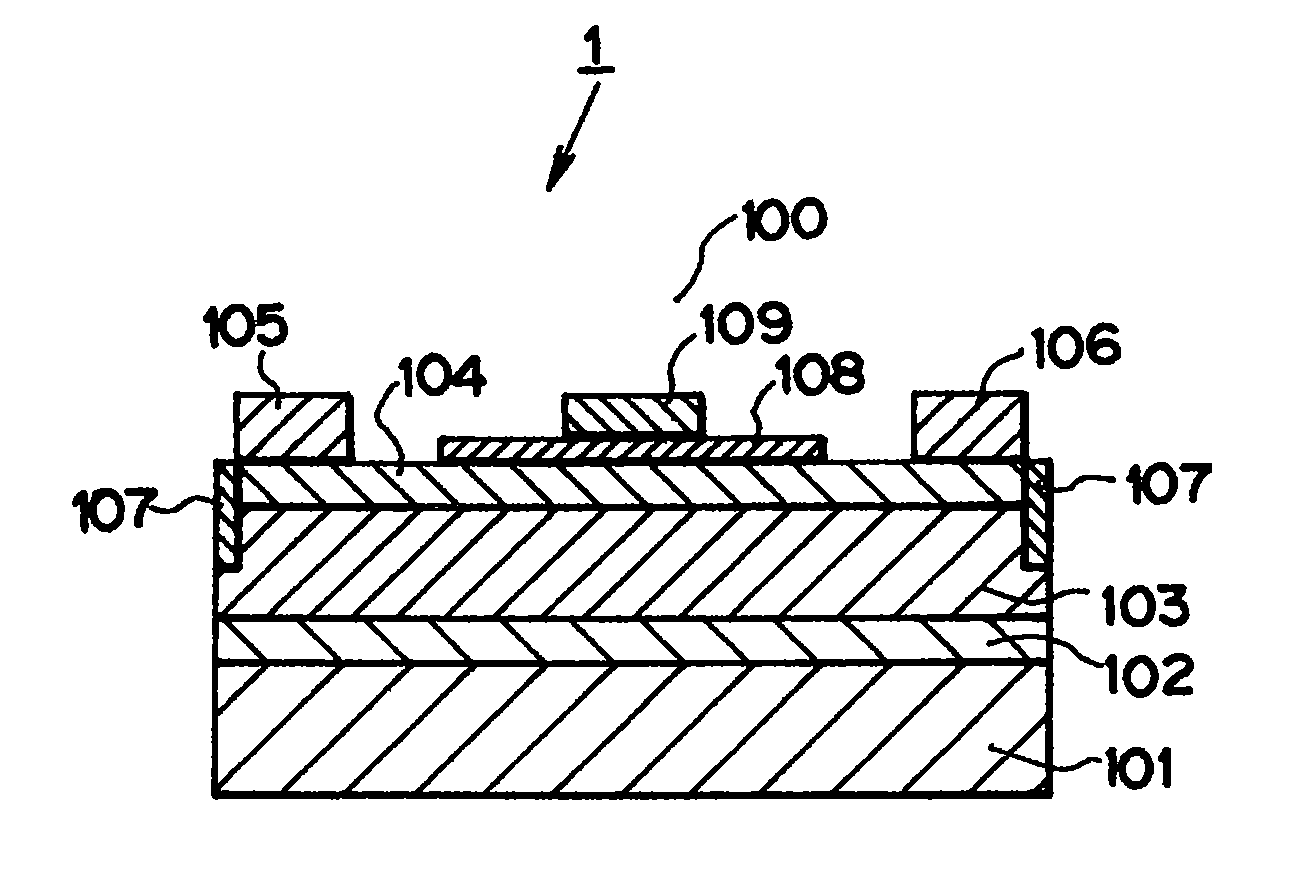

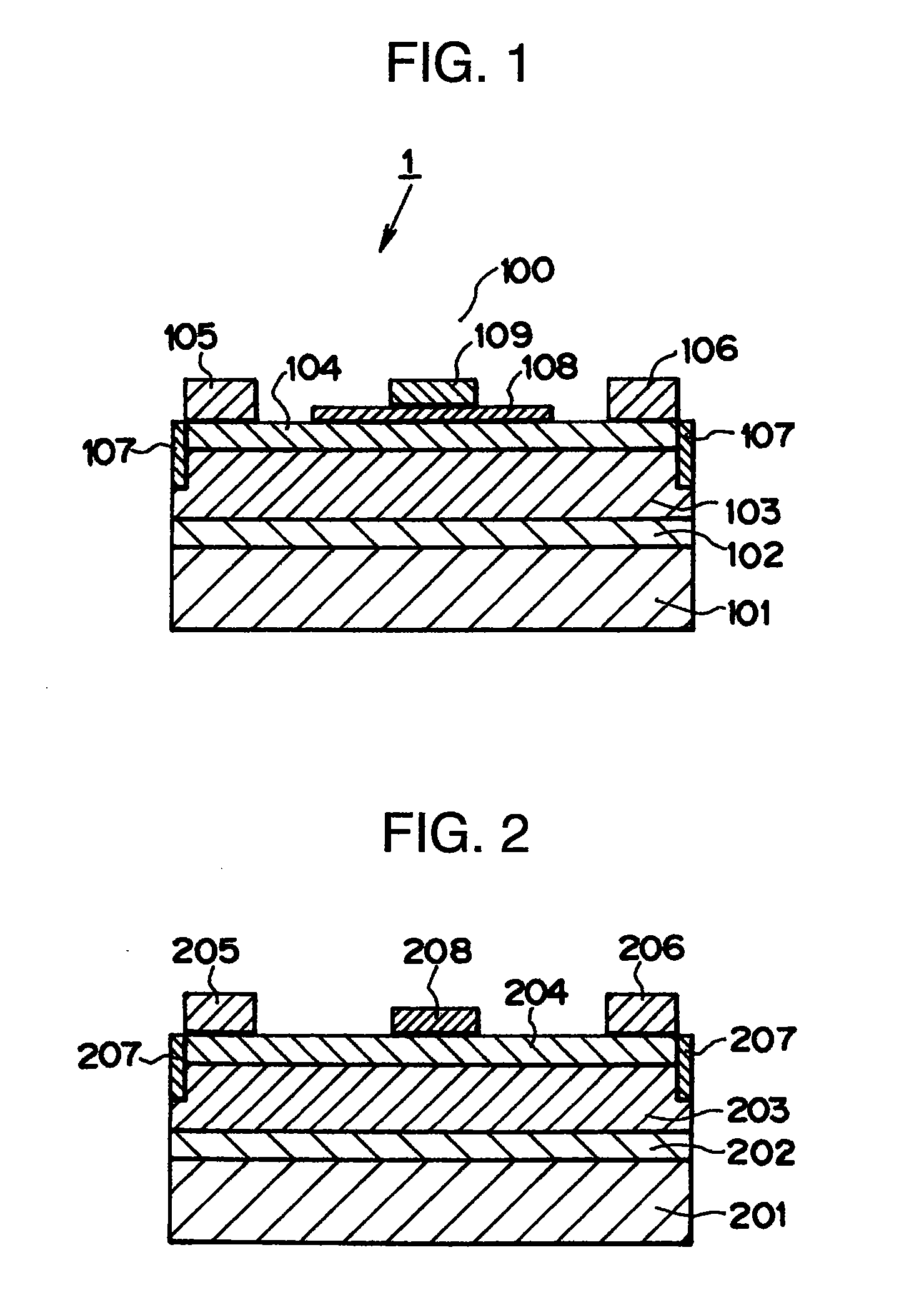

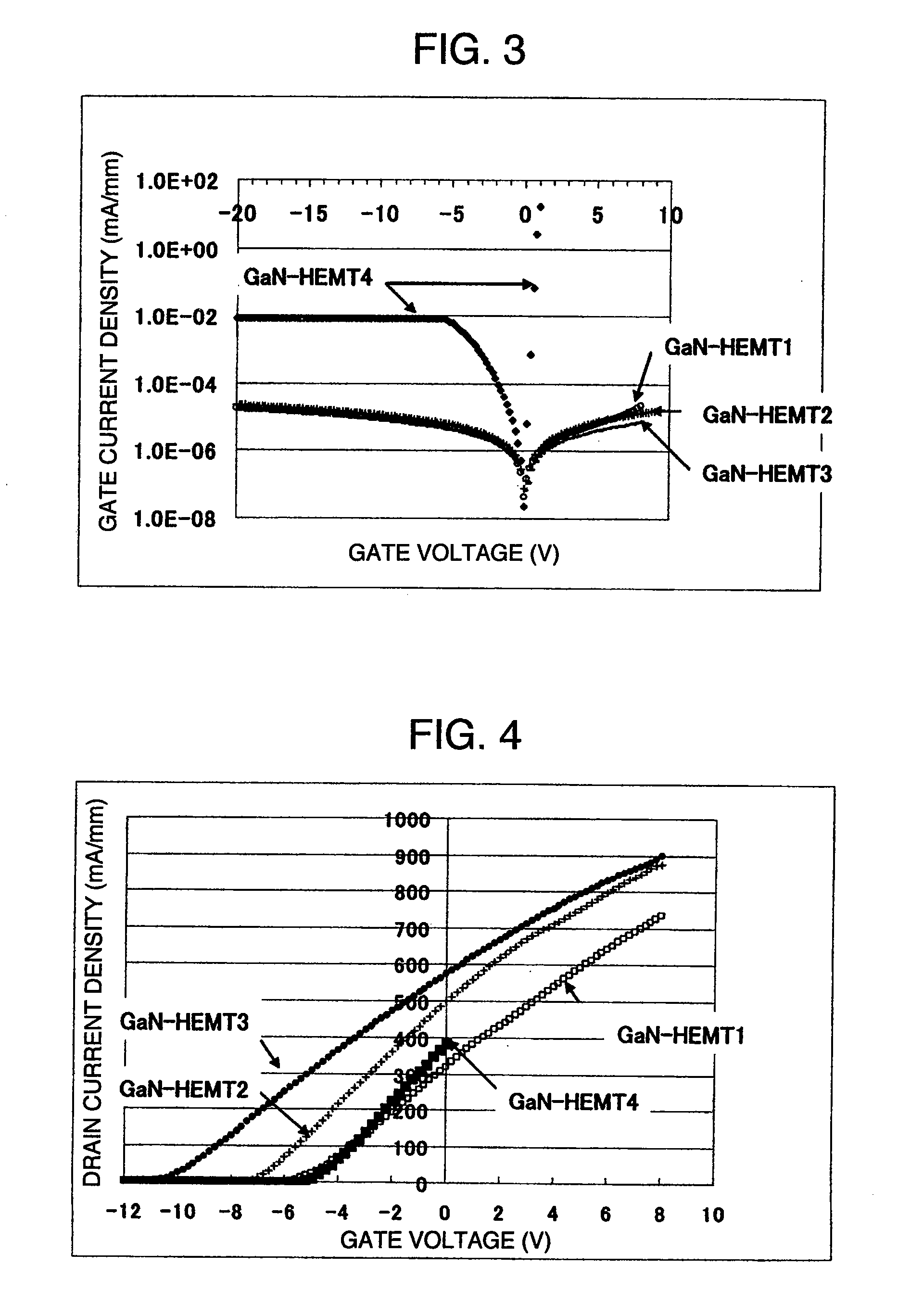

Semiconductor field effect transistor and method for fabricating the same

InactiveUS20110012110A1Improve mobilityImprove performanceSemiconductor/solid-state device manufacturingSemiconductor devicesHysteresisGallium nitride

A gallium nitride based field effect transistor having good current hysteresis characteristics in which forward gate leakage can be reduced. In a gallium nitride-based field effect transistor (100) having a gate insulation film (108), part or all of a material constituting the gate insulation film (108) is a dielectric material having a relative dielectric constant of 9-22, and a semiconductor crystal layer A (104) in contact with the gate insulation film (108) and a semiconductor crystal layer B (103) in the vicinity of the semiconductor crystal layer A (104) and having a larger electron affinity than the semiconductor crystal layer A (104) constitute a hetero junction. A hafnium oxide such as HfO2, HfAlO, HfAlON or HfSiO is preferably contained, at least partially, in the material constituting the gate insulation film (108).

Owner:SUMITOMO CHEM CO LTD +1

Activated carbon for use in electric double layer capacitors

InactiveUS20060240979A1Solve the small densityIncreased durabilityCarbon compoundsHybrid capacitor electrodesActivated carbonEngineering

Activated carbon adapted for electric double layer capacitors is provided, which capacitors can give a large power density per unit volume and which capacitors, even when charge-and-discharge cycle is repeated under a large current or a constant voltage is continuously applied for a long time, undergo less decrease in output density. That is, the present invention relates to the activated carbon manufactured by carbonization of coconut shell, which has a BET specific surface area of 2000 m2 / g to 2500 m2 / g, an average pore diameter of 1.95 nm (19.5 Å) to 2.20 nm (22 Å) and a pore volume of pores having a pore diameter calculated according to a Cranston-Inkley method of 5.0 nm (50 Å) to 30.0 nm (300 Å), of 0.05 cm3 / g to 0.15 cm3 / g.

Owner:MITSUBISHI CHEM CORP

Cathode active material powder for lithium secondary battery

ActiveUS20070099087A1Large volume capacity densityHigh safetyPositive electrodesCobalt compoundsComposite oxideCharge and discharge

It is to provide a cathode active material powder for a positive electrode for a lithium secondary battery, which has a large volume capacity density, high safety and excellent durability for charge and discharge cycles. A cathode active material powder for a lithium secondary battery characterized by comprising a first composite oxide powder represented by the formula (1) LipQxMyOzFa (wherein Q is Co or Mn, M is aluminum or an alkaline earth metal element or a transition metal element other than Q, provided that when Q is Co, 0.9≦p≦1.1, 0.980≦x≦1.000, 0≦y≦0.02, 1.9≦z≦2.1, x+y=1, and 0≦a≦0.02, and when Q is Mn, 1≦p≦1.3, x=2−y, 0≦y≦0.05, z=4, and a=0), having an average particle size D50 of from 5 to 30 μm, and having a compression breaking strength of at least 40 MPa; and a second composite oxide powder represented by the formula (2) LipNixCoyMnzNqOrFa (wherein N is aluminum or an alkaline earth metal element or a transition metal element other than Ni, Co and Mn, 0.9≦p≦1.1, 0.2≦x≦0.8, 0≦y≦0.4, 0≦z≦0.5, 0≦q≦0.05, 1.9≦r≦2.1, x+y+z+q=1, and 0≦a≦0.02), having an average particle size D50 of from 2 to 30 μm, and having a compression breaking strength less than 40 MPa; in a ratio (weight ratio) of the first composite oxide powder / the second composite oxide powder being from 95 / 5 to 30 / 70.

Owner:SUMITOMO CHEM CO LTD

Positive electrode active material for lithium secondary battery and process for producing the same

InactiveUS20060263690A1Large volume capacity densityHigh safetyElectrode manufacturing processesCobalt compoundsChemistryComposite oxide

A positive electrode active material for a lithium secondary battery containing a lithium-cobalt composite oxide, which has a large volume capacity density, has a high safety and is excellent in charge and discharge cyclic durability, and its production process, are provided. A lithium-cobalt composite oxide represented by the formula LipCoxMyOzFa (wherein M is a transition metal element other than Co or an alkaline earth metal element, 0.9≦p≦1.1, 0.980≦x≦1.000, 0≦y≦0.02, 1.9≦z≦2.1, x+y=1 and 0≦a≦0.02) and comprising a mixture containing substantially spherical hard first particles of lithium-cobalt composite oxide having such a sharp particle size distribution that the volume basis cumulative size D10 is at least 50% of the average particle size D50, and the volume basis cumulative size D90 is at most 150% of the average particle size D50, and second particles of lithium-cobalt composite oxide filling the space among the first particles, in a mass ratio of first particles / second particles of from 1 / 2 to 9 / 1, and process for producing the same.

Owner:SEIMI CHEM CO LTD

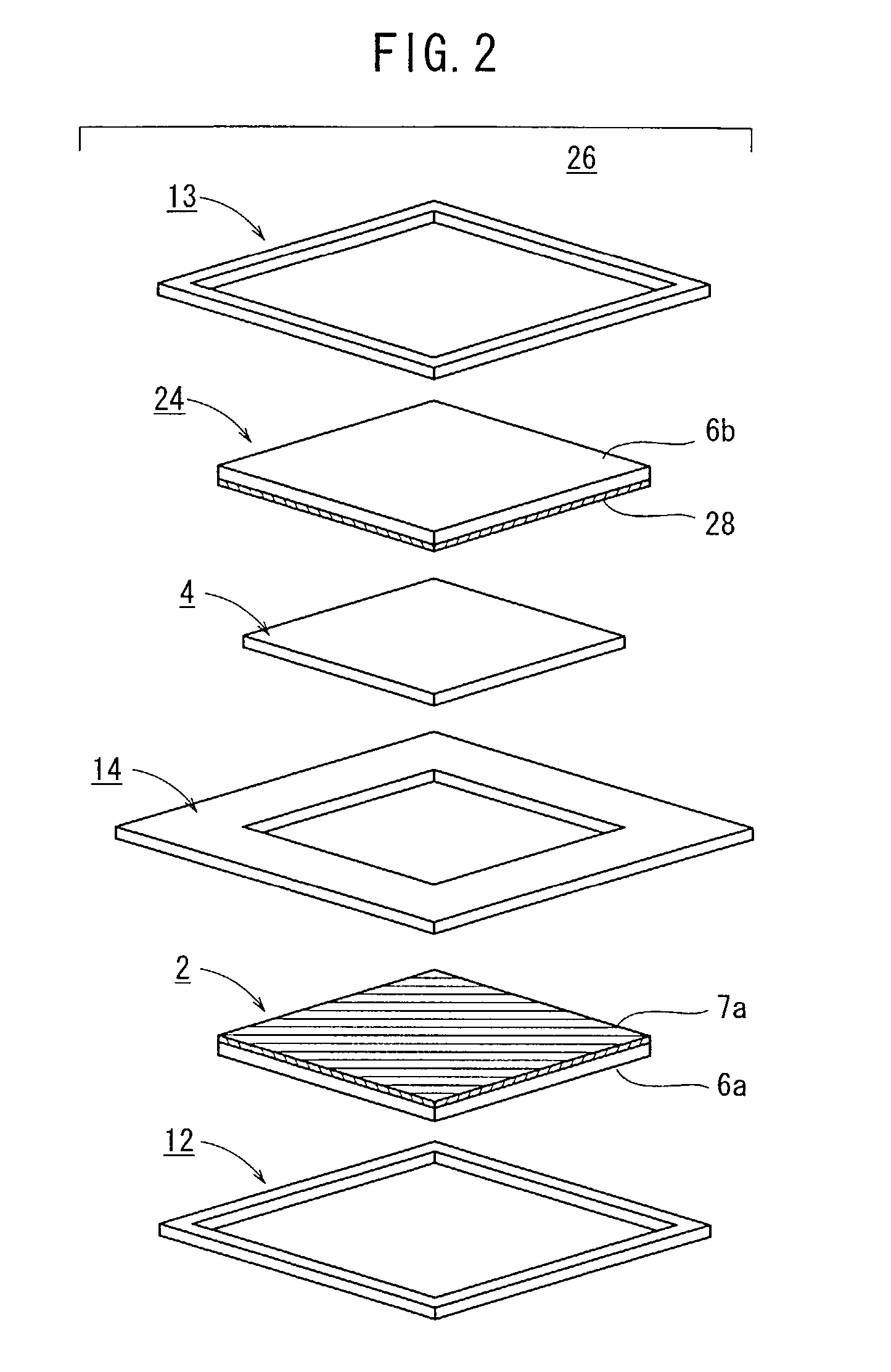

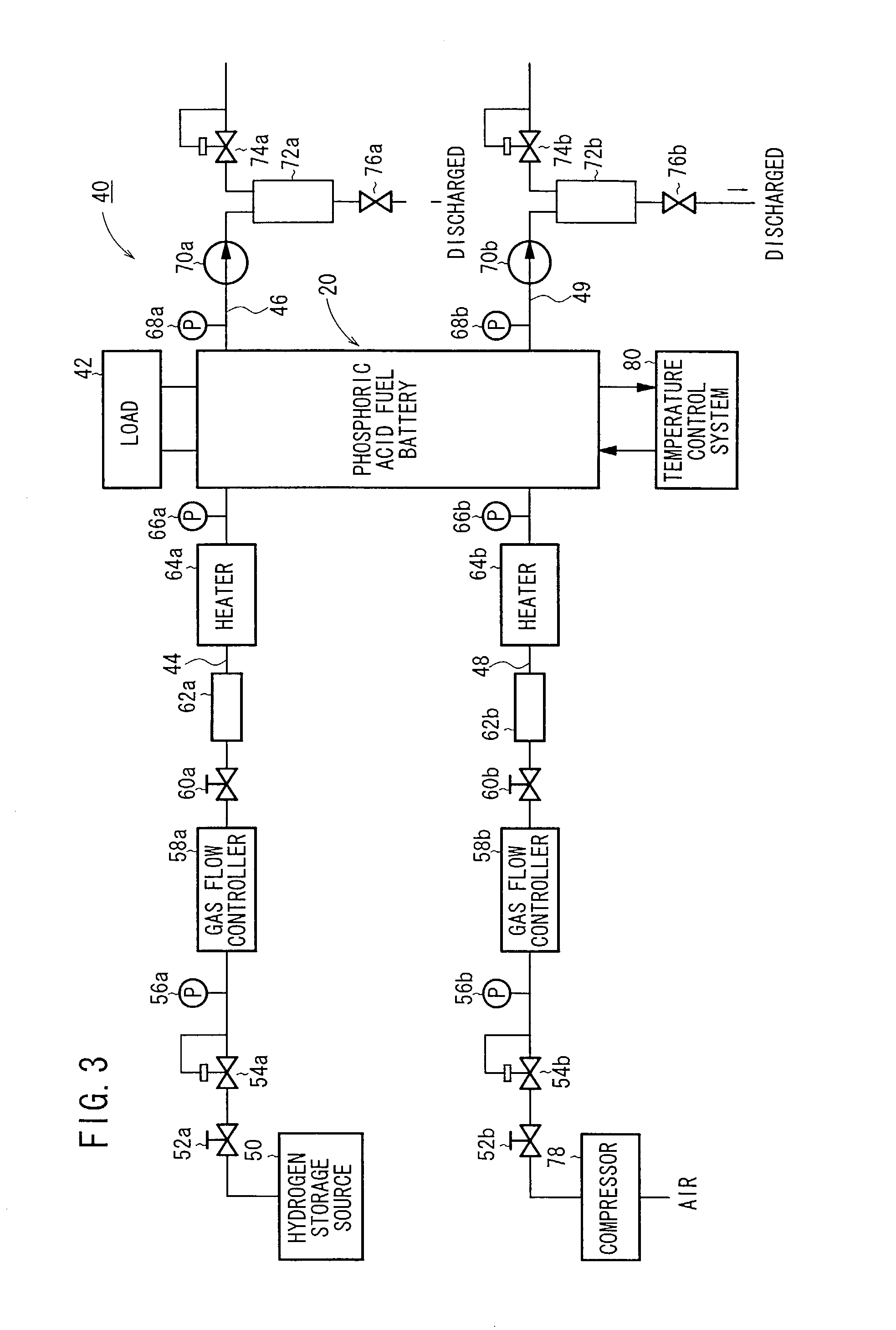

Basic polymer electrolyte fuel cell

InactiveUS6986962B2Cost reductionHigh outputSolid electrolytesFuel cells groupingCarbon blackMn alloy

A fuel cell has a unit cell whose output is increased. A unit cell of a fuel cell includes a cathode electrode having a gas diffusion layer and an electrode catalyst layer. The electrode catalyst layer is made of carbon black carrying a Pt—Mn-based alloy such as a Pt—Mn alloy on its particle surface. For operating the fuel cell which includes the cathode electrode, it is preferable to make the pressure of an oxygen-containing gas supplied to the cathode electrode higher than the pressure of an hydrogen-containing gas supplied to an anode electrode to make the pressure at the cathode electrode higher than the pressure at the anode electrode.

Owner:HONDA MOTOR CO LTD

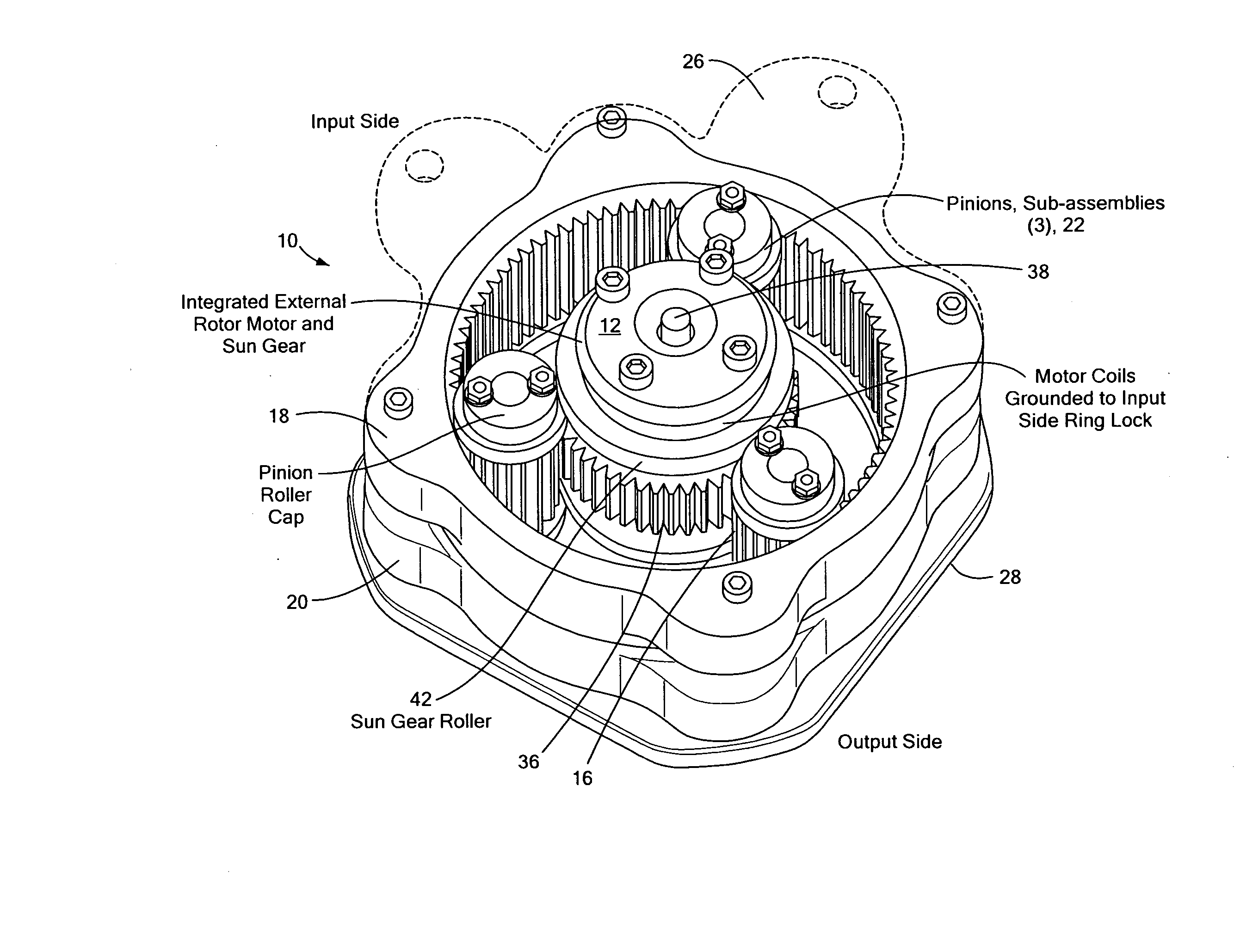

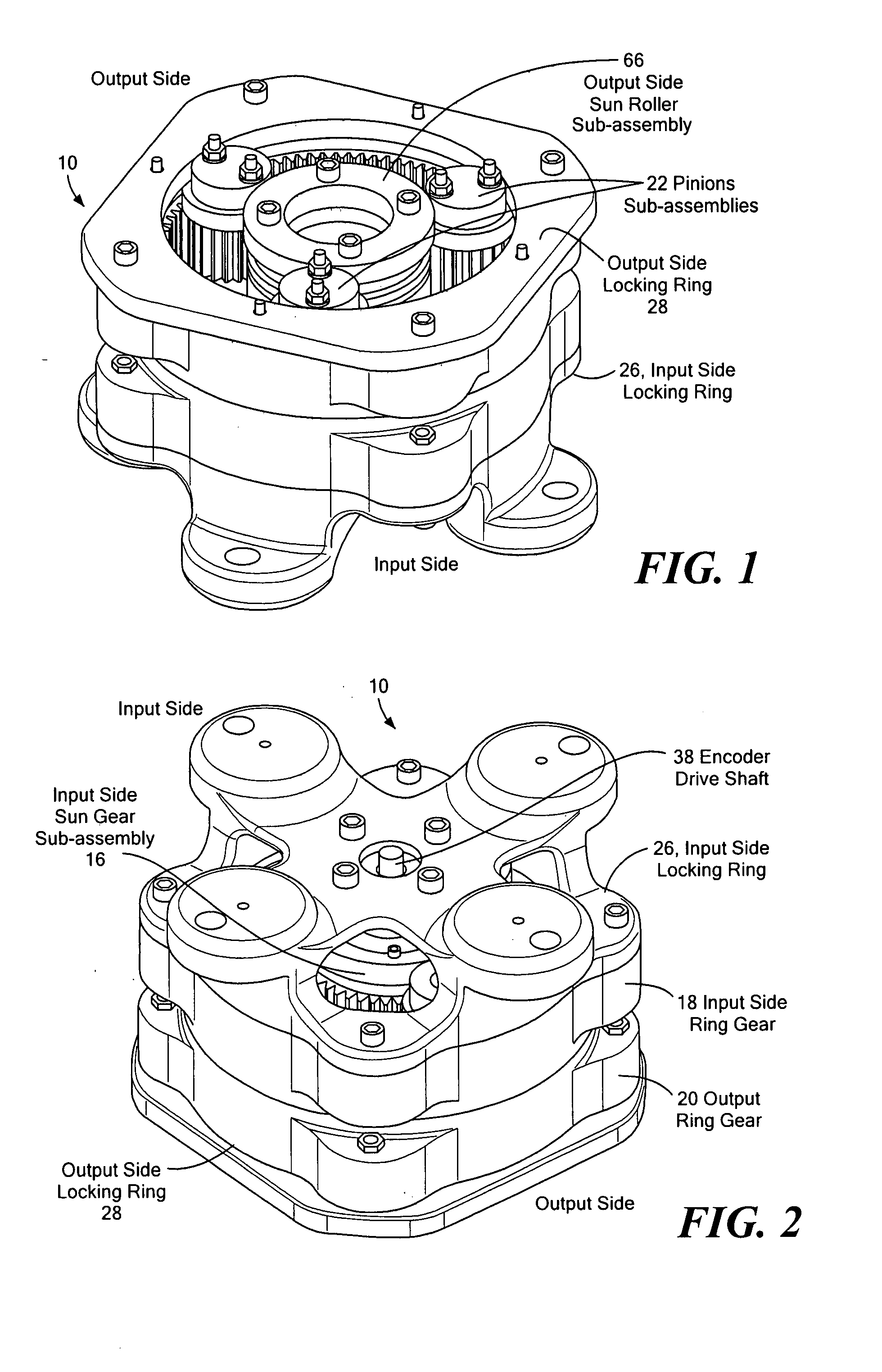

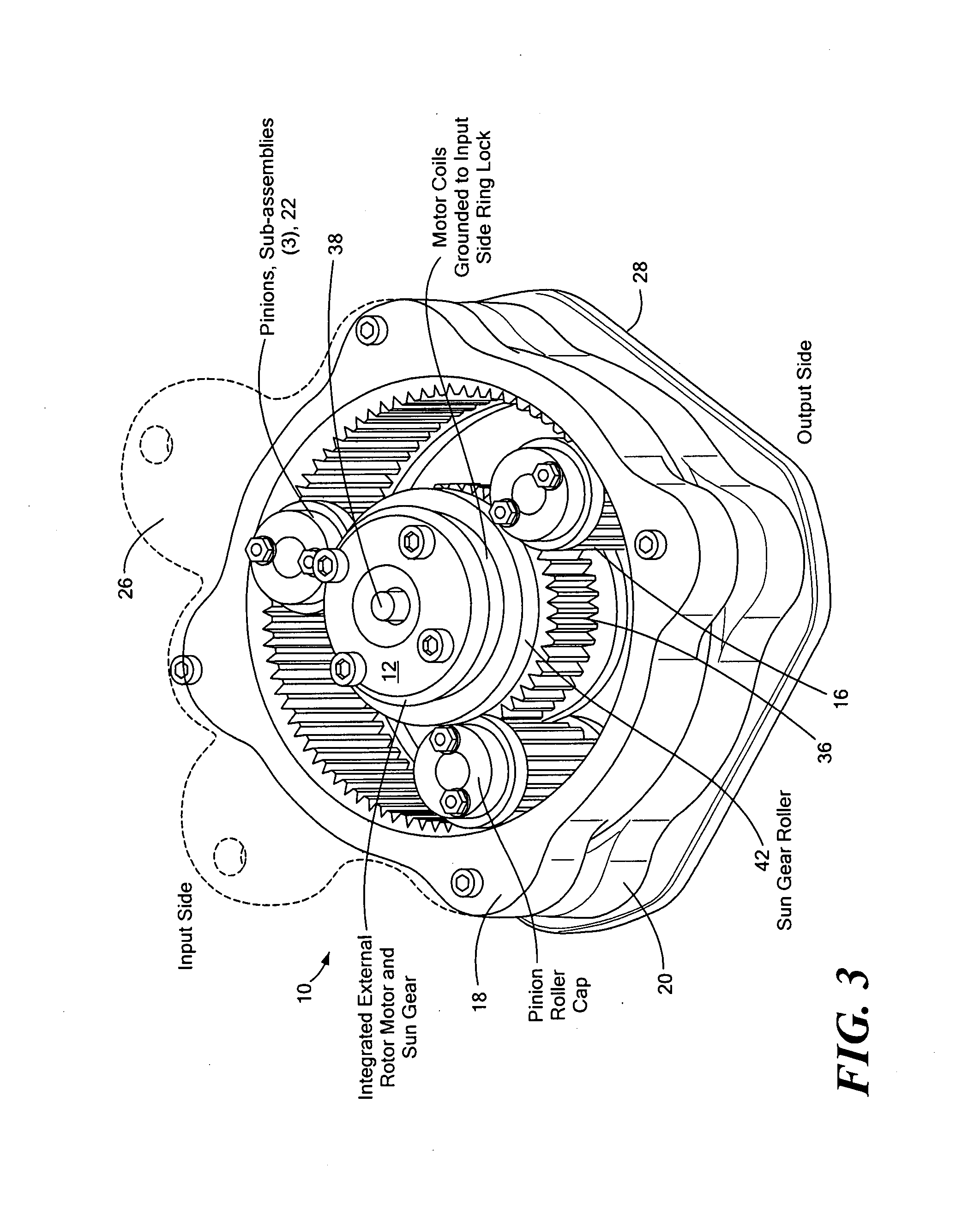

Gear bearing drive

InactiveUS20080045374A1Saving weightSave spaceProgramme-controlled manipulatorMagnetic circuitGear wheelRobotic arm

A gear bearing drive provides a compact mechanism that operates as an actuator providing torque and as a joint providing support. The drive includes a gear arrangement integrating an external rotor DC motor within a sun gear. Locking surfaces maintain the components of the drive in alignment and provide support for axial loads and moments. The gear bearing drive has a variety of applications, including as a joint in robotic arms and prosthetic limbs.

Owner:NORTHEASTERN UNIV +1

Positive electrode active material powder for lithium secondary battery

InactiveUS20050220700A1Increase volume capacity densityHigh densityAlkali metal oxidesPositive electrodesAlkaline earth metalManganese

A lithium-nickel-cobalt-manganese composite oxide powder for a positive electrode of a lithium secondary battery, which has a large volume capacity density and high safety and is excellent in the charge and discharge cyclic durability, is presented. It is a lithium-nickel-cobalt-manganese composite oxide powder for a lithium secondary battery, represented by the formula LipNixCoyMnzMqO2-aFa (wherein M is a transition metal element other than Ni, Co or Mn, or an alkaline earth metal element, 0.9≦p≦1.1, 0.2≦x≦0.5, 0.1≦y≦0.4, 0.2≦z≦0.5, 0≦q≦0.05, 1.9≦2-a≦2.1, x+y+z+q=1, and 0≦a≦0.02). The lithium-nickel-cobalt-manganese composite oxide is an agglomerated granular composite oxide powder having an average particle size D50 of from 3 to 15 μm, formed by agglomeration of many fine particles, and the compression breaking strength of the powder is at least 50 MPa.

Owner:AGC SEIMI CHEM CO LTD

Lithium-containing composite oxide and its production method

ActiveUS20090148772A1Large volume capacity densityImprove securityCell electrodesLithium compoundsAlkaline earth metalDischarge rate

The present invention provides a lithium-containing composite oxide for a positive electrode for a lithium secondary battery, which has a large volume capacity density and high safety, and excellent durability for charge and discharge cycles and charge and discharge rate property, and its production method.The lithium-containing composite oxide is represented by the general formula LipNxMyOzFa (where N is at least one element selected from the group consisting of Co, Mn and Ni, M is at least one element selected from the group consisting of Al, Sn, alkaline earth metal elements and transition metal elements other than Co, Mn and Ni, 0.9≦p≦1.2, 0.965≦x<2.00, 0<y≦0.035, 1.9≦z≦4.2, and 0≦a≦0.05), wherein when a powder of the lithium-containing composite oxide is classified into small particles with an average particle size of 2 μm≦Ds50≦8 μm and large particles with an average particle size of 10 μm≦Dl50≦25 μm, a content of the small particles is from 15 to 40% by weight and a content of the large particles is from 60 to 85% by weight, and 0.01≦ys≦0.06, 0≦yl≦0.02 and 0≦yl / ys<1, where (ys) is a ratio of the M element in the above general formula in the small particles and (yl) is a ratio of the M element in the general formula in the Large particles.

Owner:SUMITOMO CHEM CO LTD

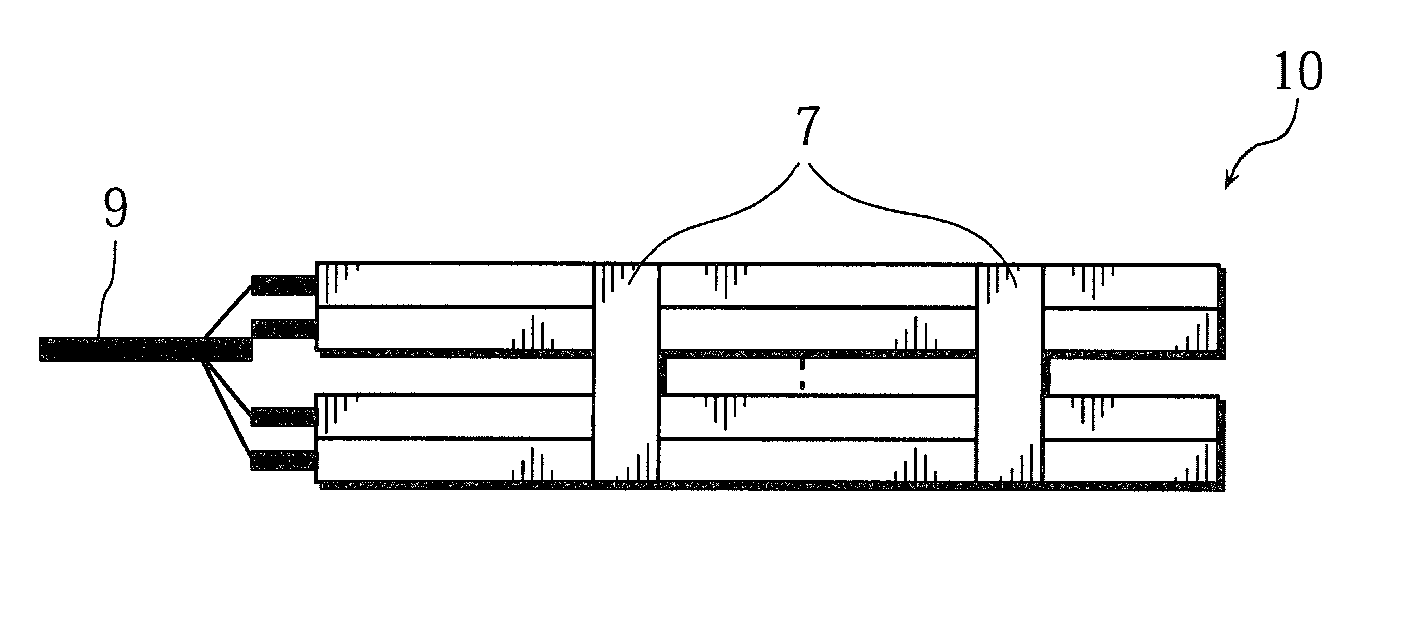

Battery module

InactiveUS20080292950A1Suppresses battery temperature riseAvoid spreadingPrimary cell to battery groupingSmall-sized cells cases/jacketsEngineeringMechanical engineering

A spacer (52) interposed between a plurality of batteries in a battery module has an inner cavity. A filling agent having fire-extinguishing capability is filled in the inner cavity. An opening can be formed at a portion (low-melting point portion (14)) of the spacer (52) by heat so that the filling agent can flow out of the spacer.

Owner:SANYO ELECTRIC CO LTD

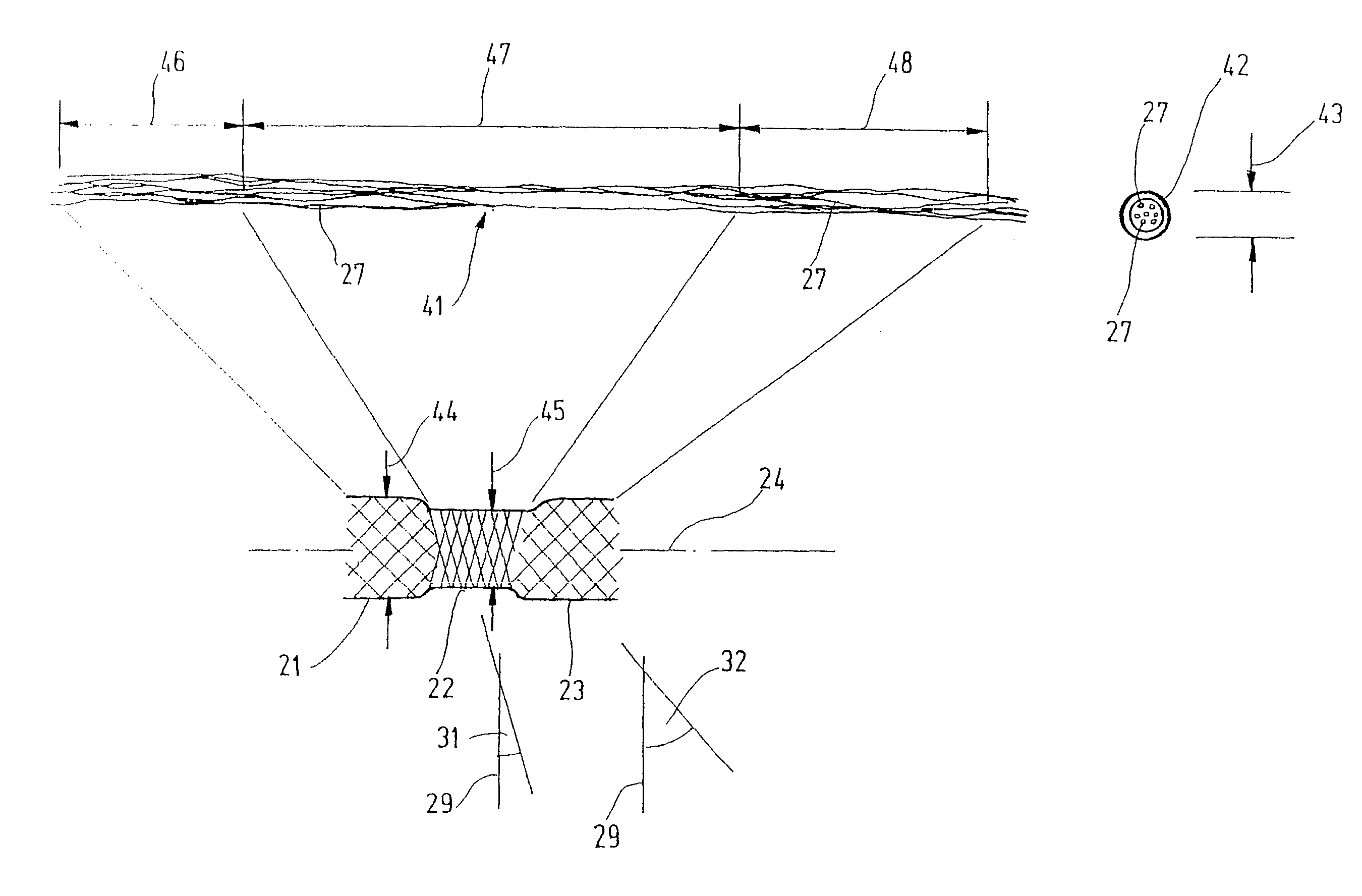

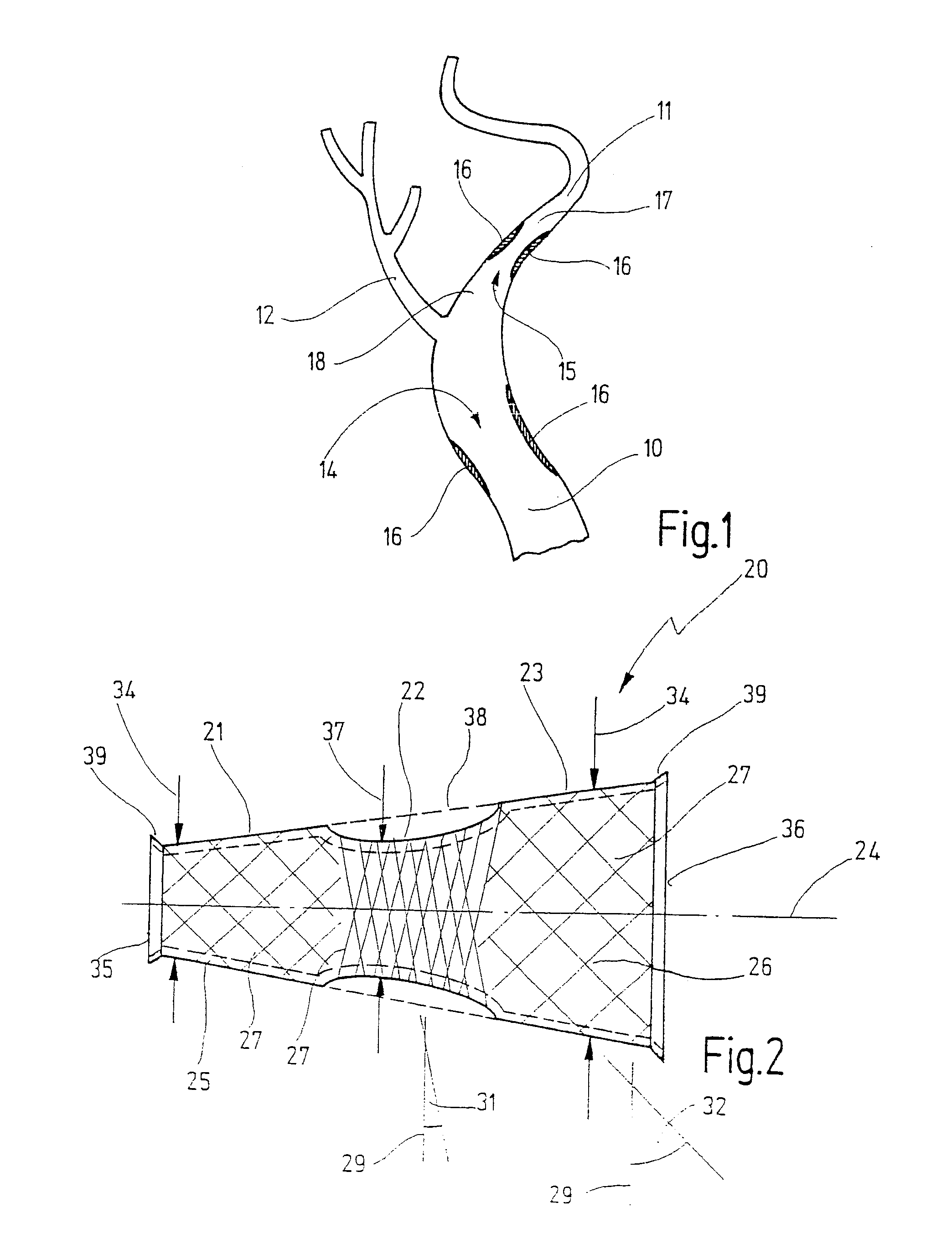

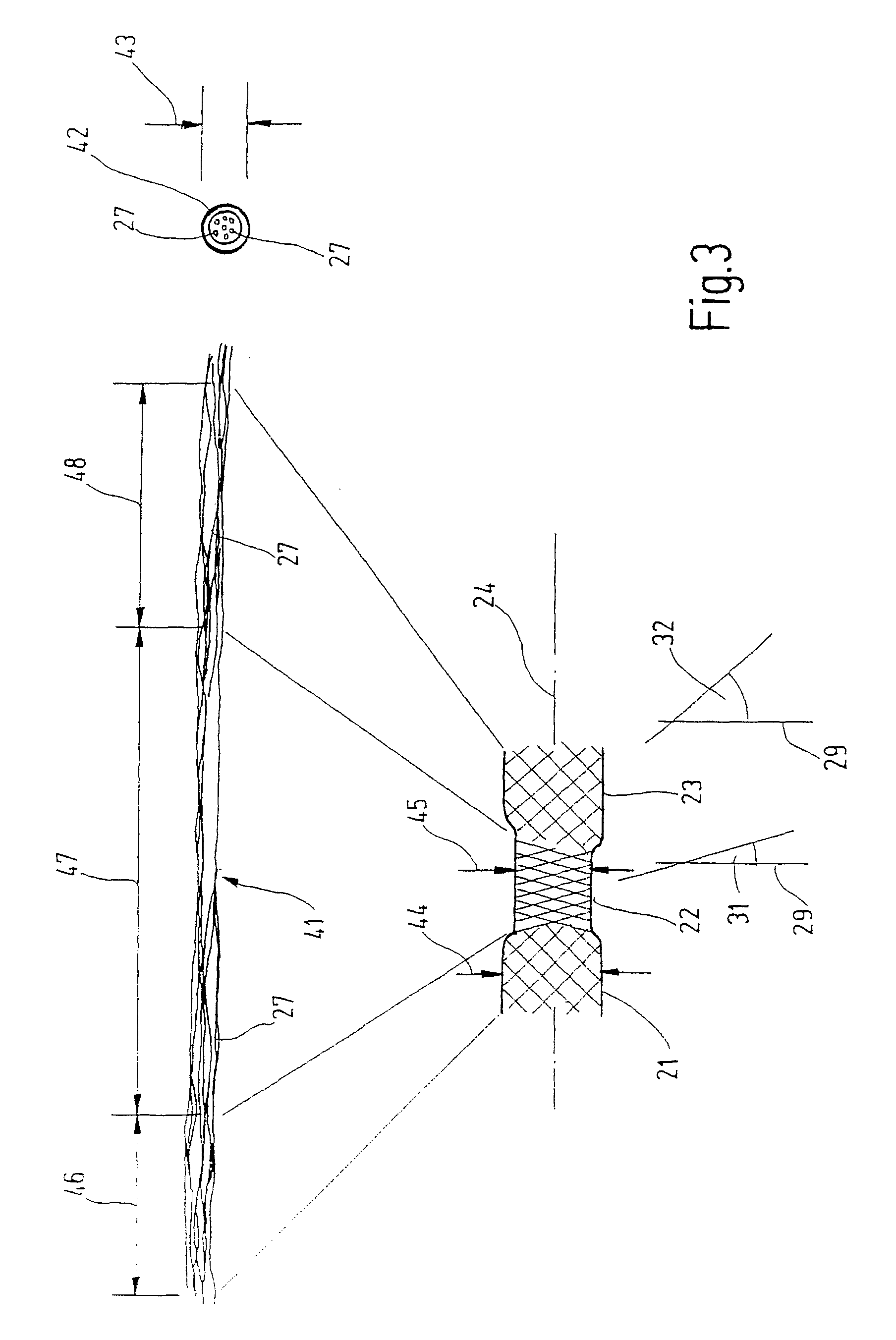

Braided stent to be implanted in a blood vessel

ActiveUS20090216307A1Improve protectionSolve the small densityStentsOrnamental textile articlesBraided stentBlood vessel

A braided stent to be implanted in a blood vessel comprises a hollow body which is stretchable in its longitudinal direction and whose circumferential surface is formed by a braid of a multiplicity of filamentary elements which, in the expanded state of the braided stent, intersect a plane, perpendicular to the longitudinal direction, at a braiding angle. The braided stent has a smaller braiding angle in a central portion than in its distal and proximal portions which adjoin the central portion in the longitudinal direction.

Owner:JOTEC

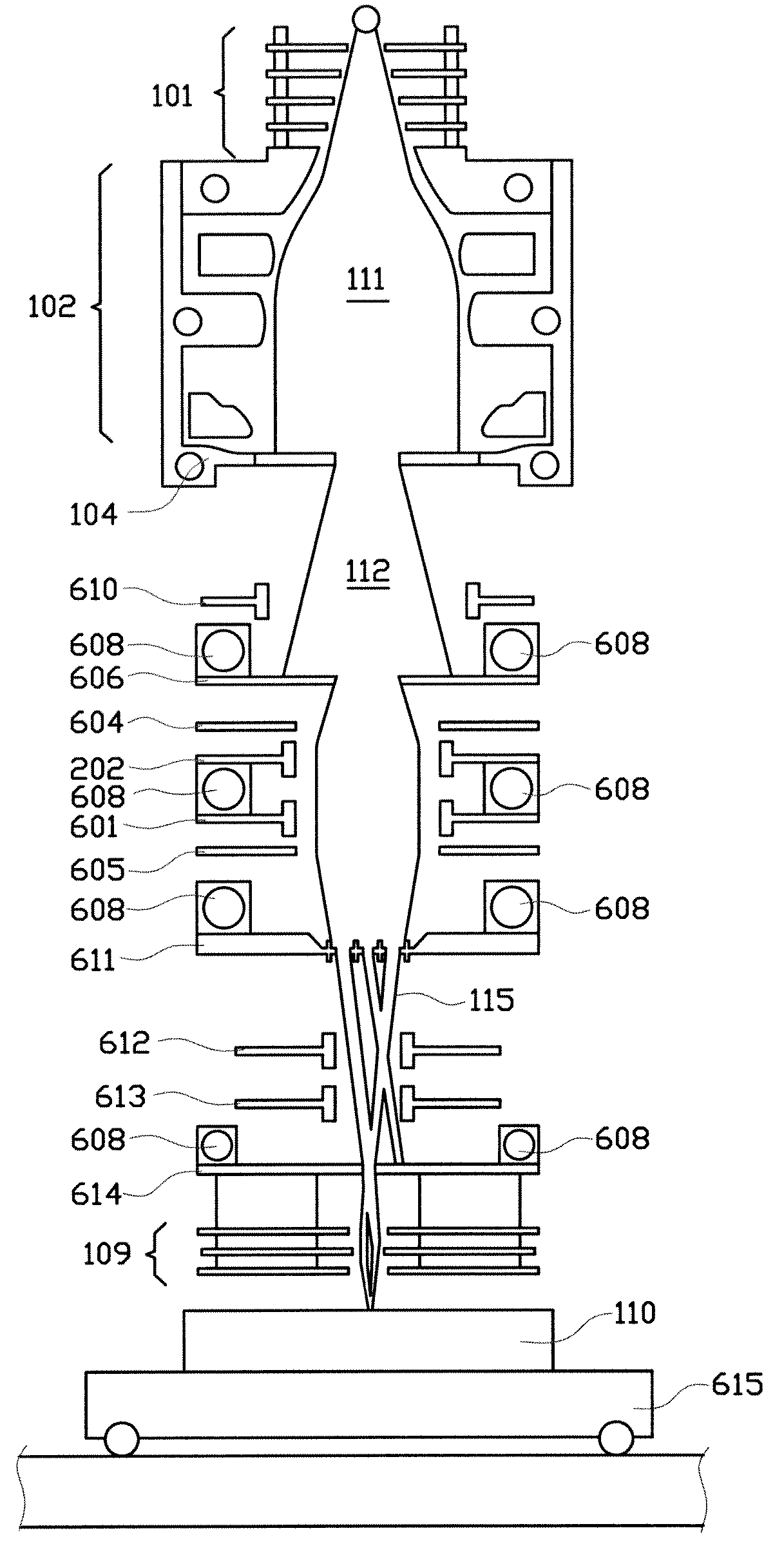

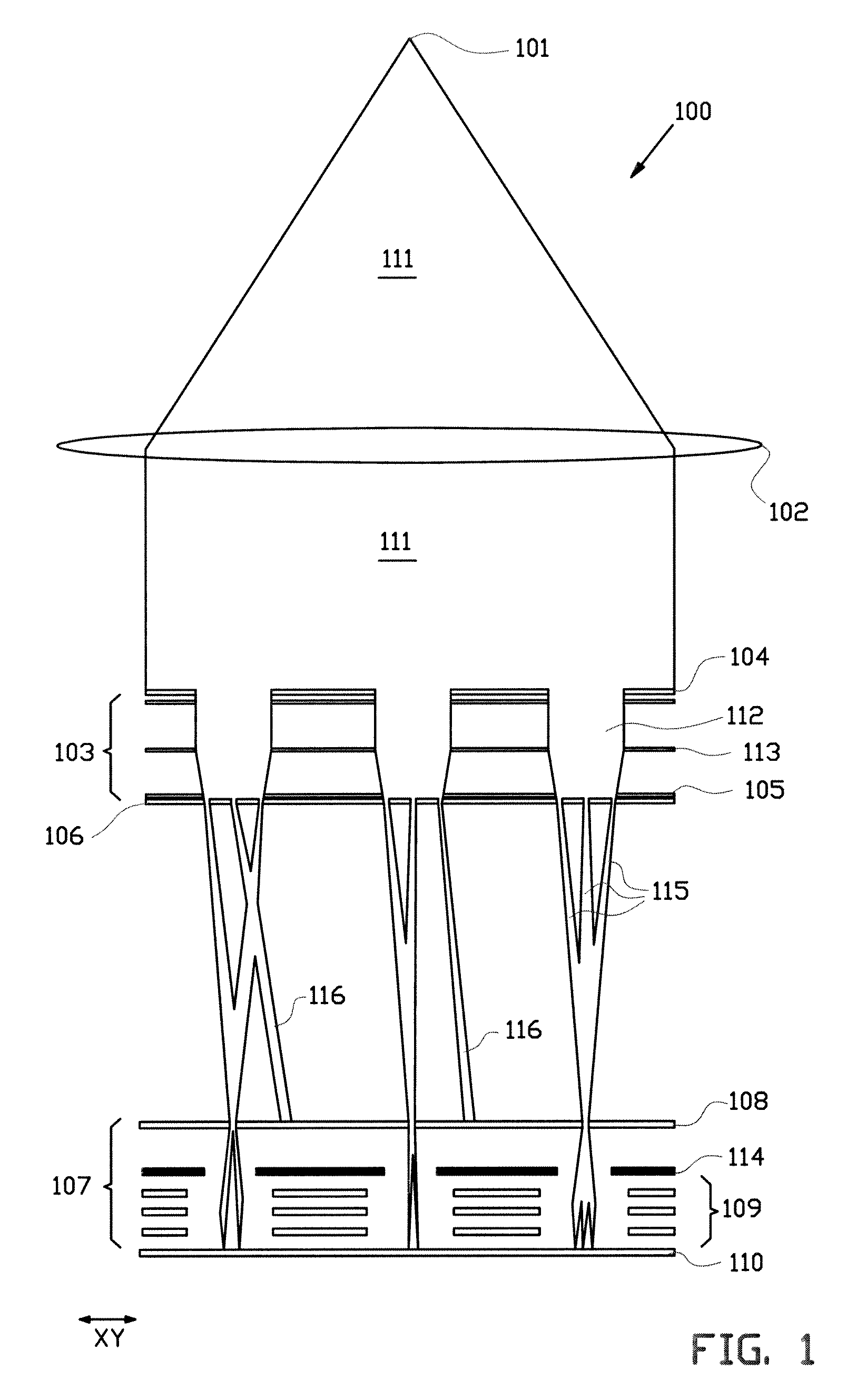

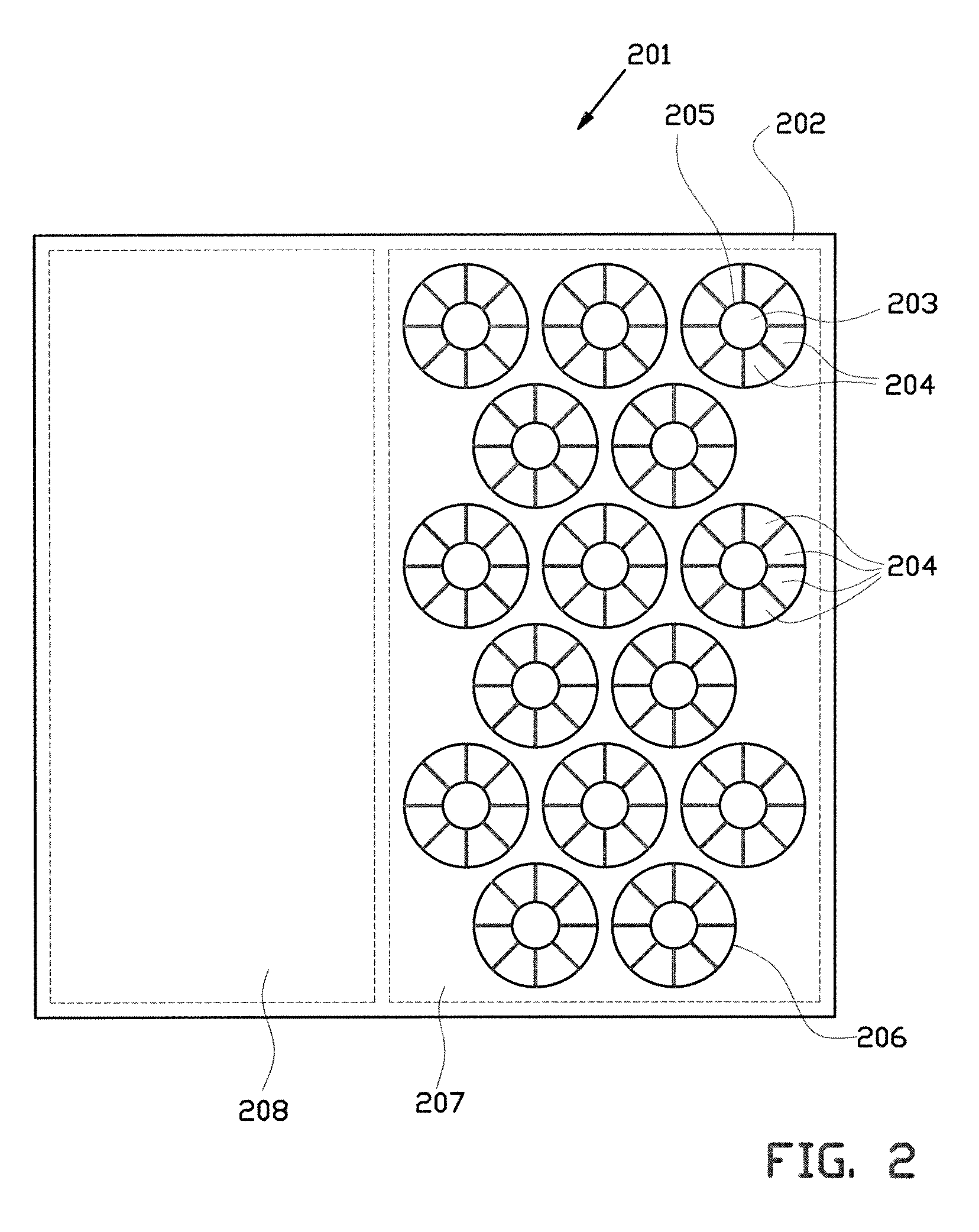

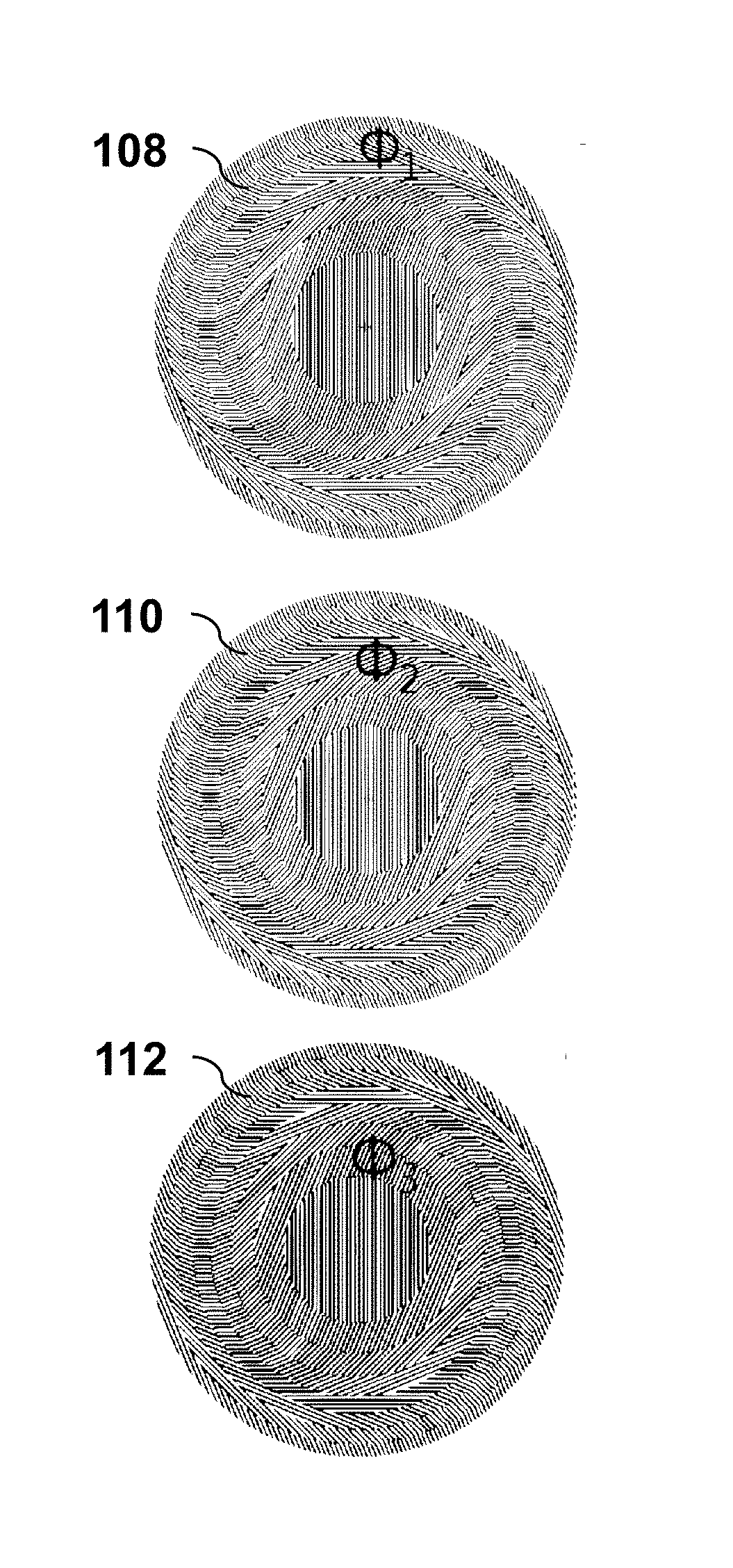

Charged particle system comprising a manipulator device for manipulation of one or more charged particle beams

ActiveUS20120273690A1Not easy to produceImprove balanceOptical radiation measurementParticle separator tubesLithographic artistPlanar substrate

The invention relates to a charged particle system such as a multi beam lithography system, comprising a manipulator device for manipulation of one or more charged particle beams, wherein the manipulator device comprises at least one through opening in the plane of the planar substrate for passing at least one charged particle beam there through. Each through opening is provided with electrodes arranged in a first set of multiple first electrodes along a first part of a perimeter of said through opening and in a second set of multiple second electrodes along a second part of said perimeter. An electronic control circuit is arranged for providing voltage differences the electrodes in dependence of a position of the first and second electrode along the perimeter of the through opening.

Owner:ASML NETHERLANDS BV

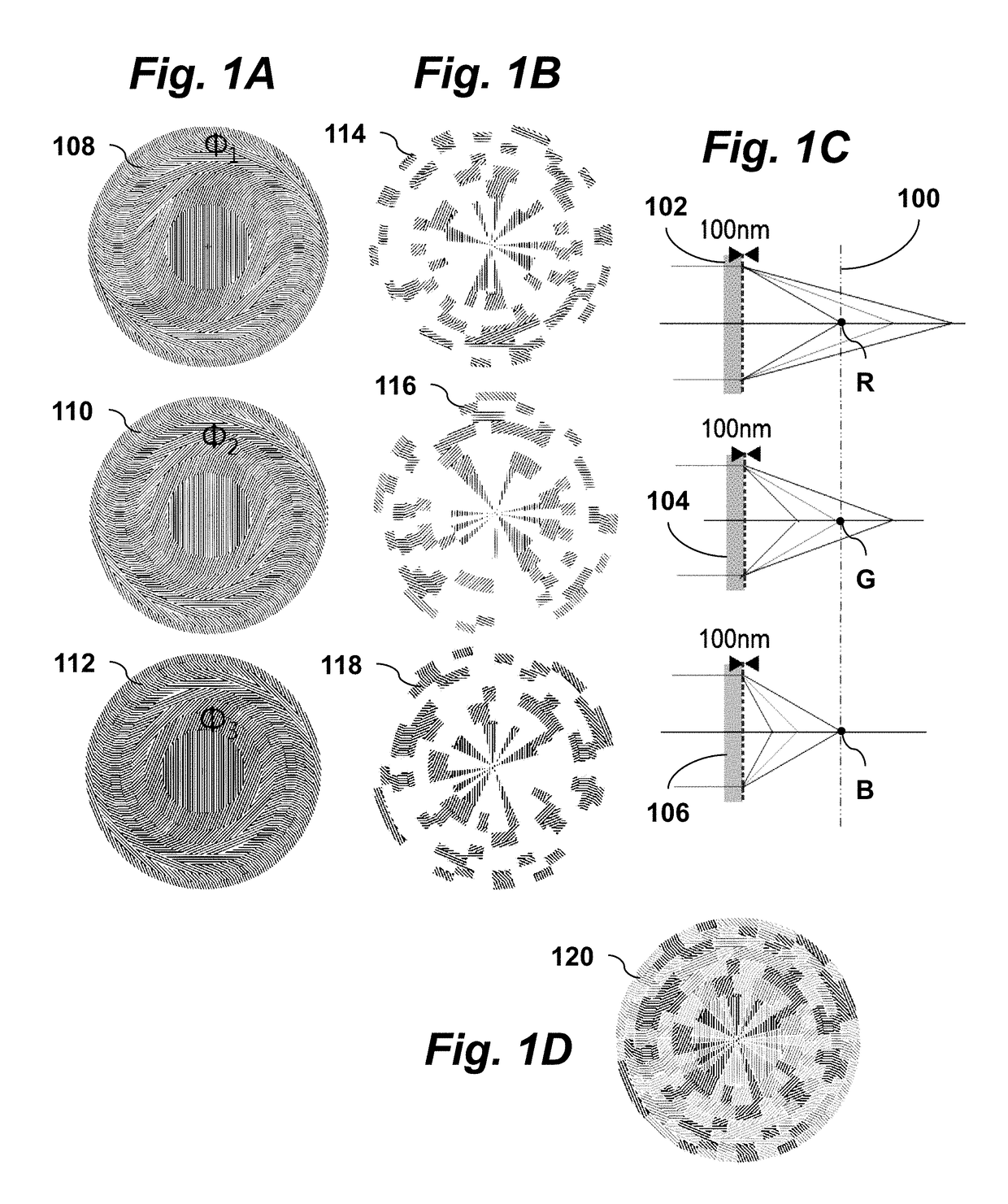

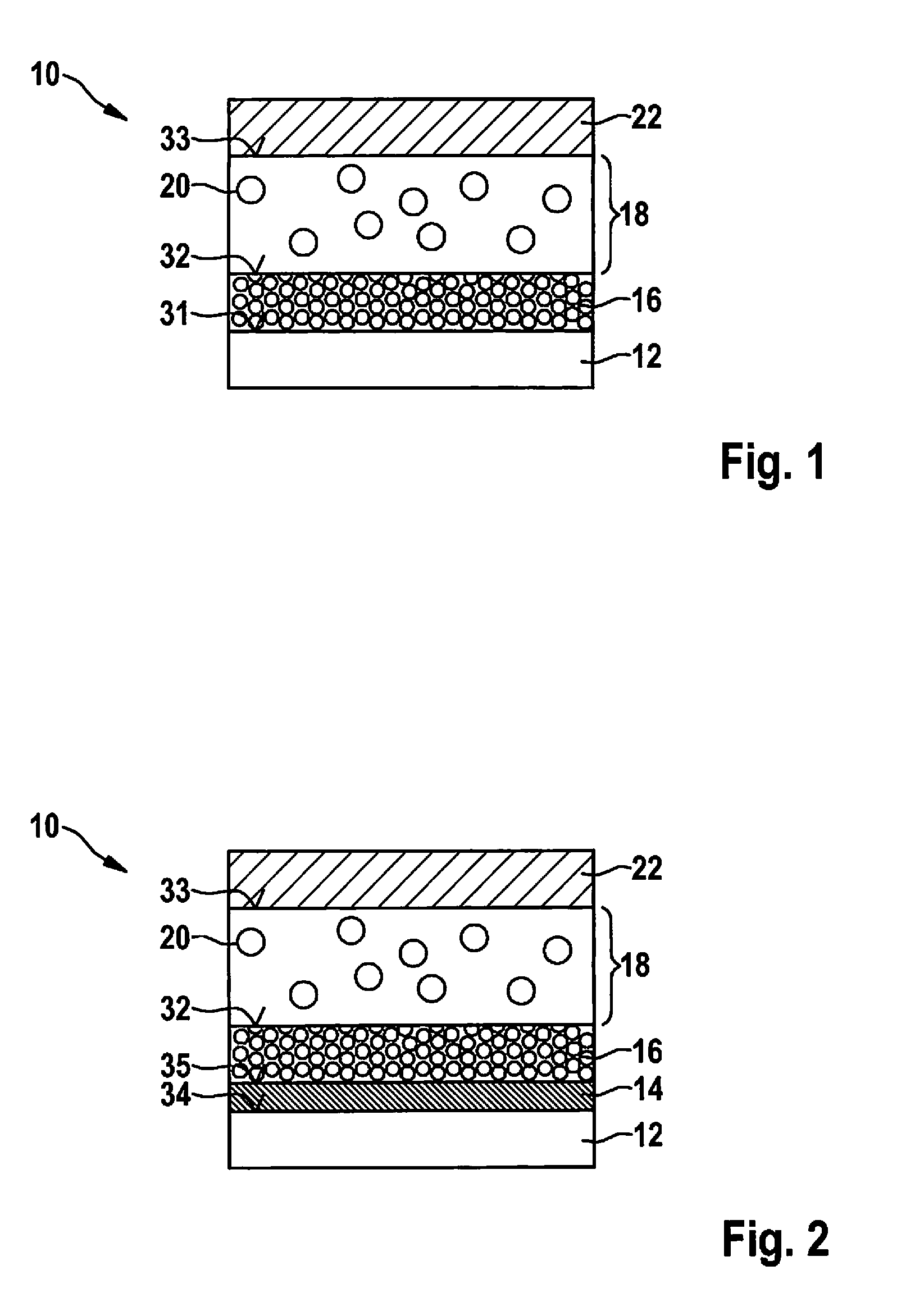

Spatially Multiplexed Dielectric Metasurface Optical Elements

ActiveUS20170219739A1Improve performanceEasy to createNon-linear opticsOptical elementsDielectricPhase response

A multifunctional dielectric gradient metasurface optical device has a layer of nanoscale dielectric gradient metasurface optical antenna elements deposited on a substrate layer, arranged with spatially varying orientations, shapes, or sizes in the plane of the device such that the optical device has a spatially varying optical phase response capable of optical wavefront shaping. The spatially varying optical phase response is a spatial interleaving of multiple distinct phase profiles corresponding to multiple optical sub-elements, thereby providing multifunctional wavefront shaping in the single optical element.

Owner:THE BOARD OF TRUSTEES OF THE LELAND STANFORD JUNIOR UNIV +2

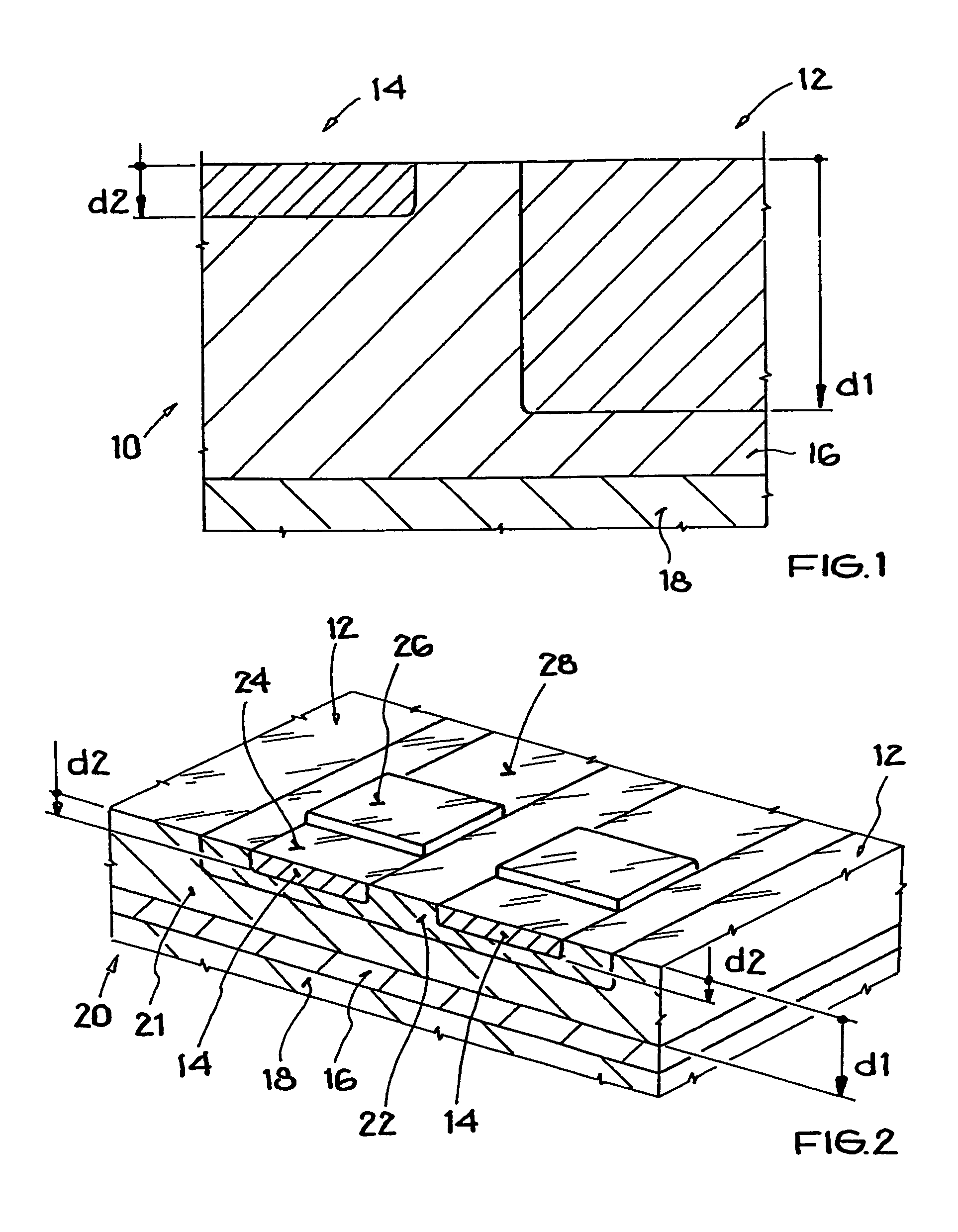

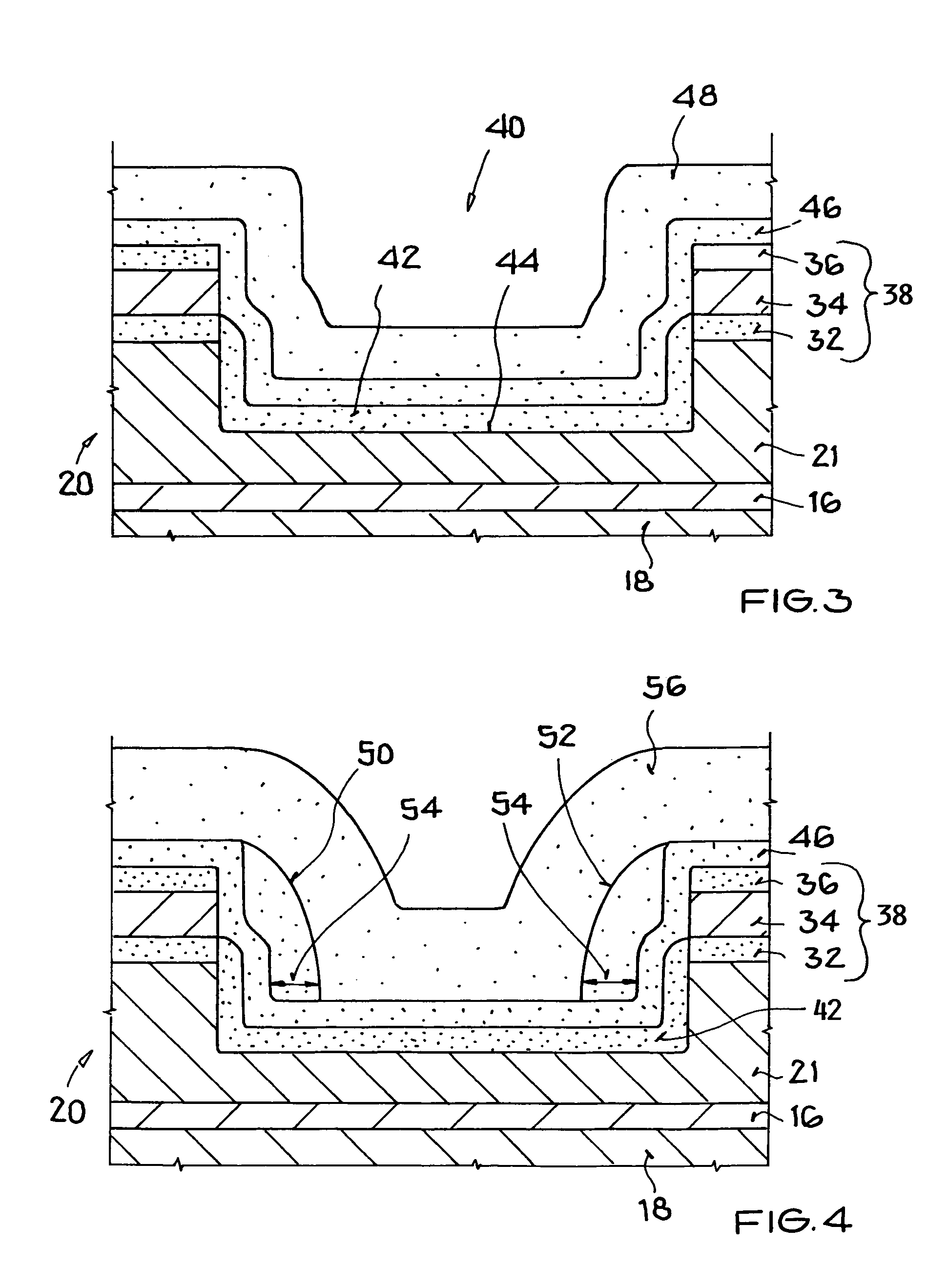

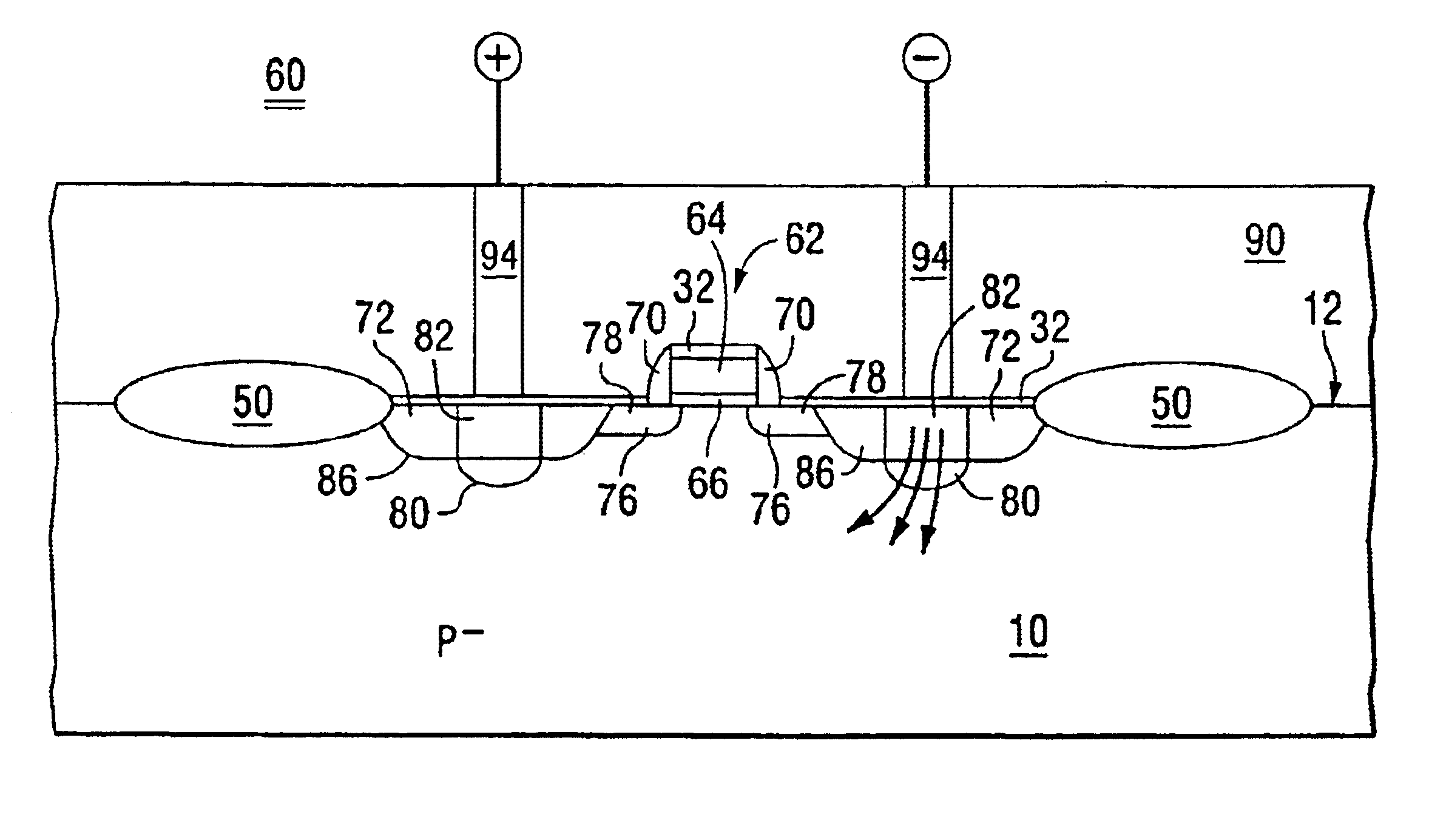

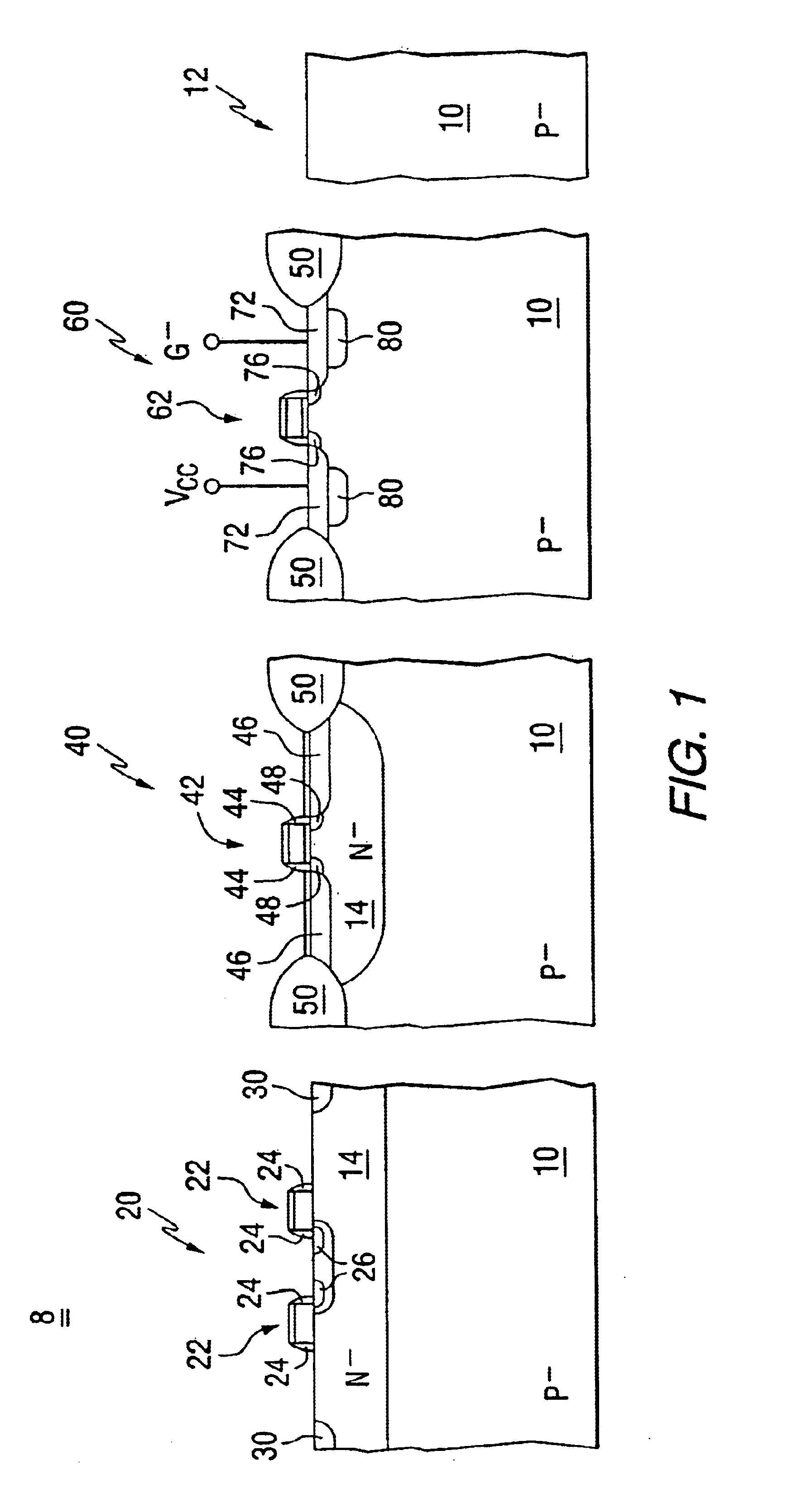

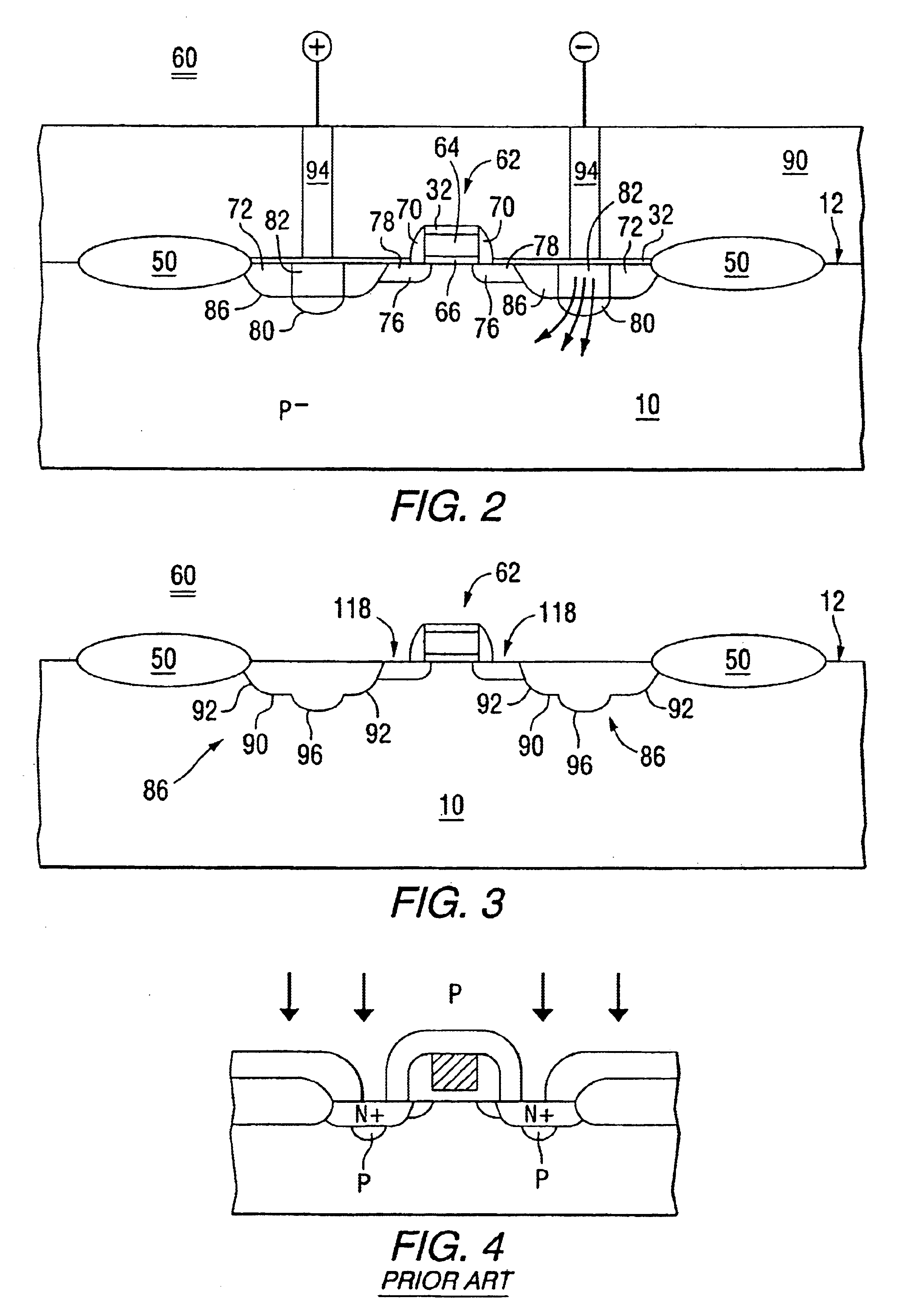

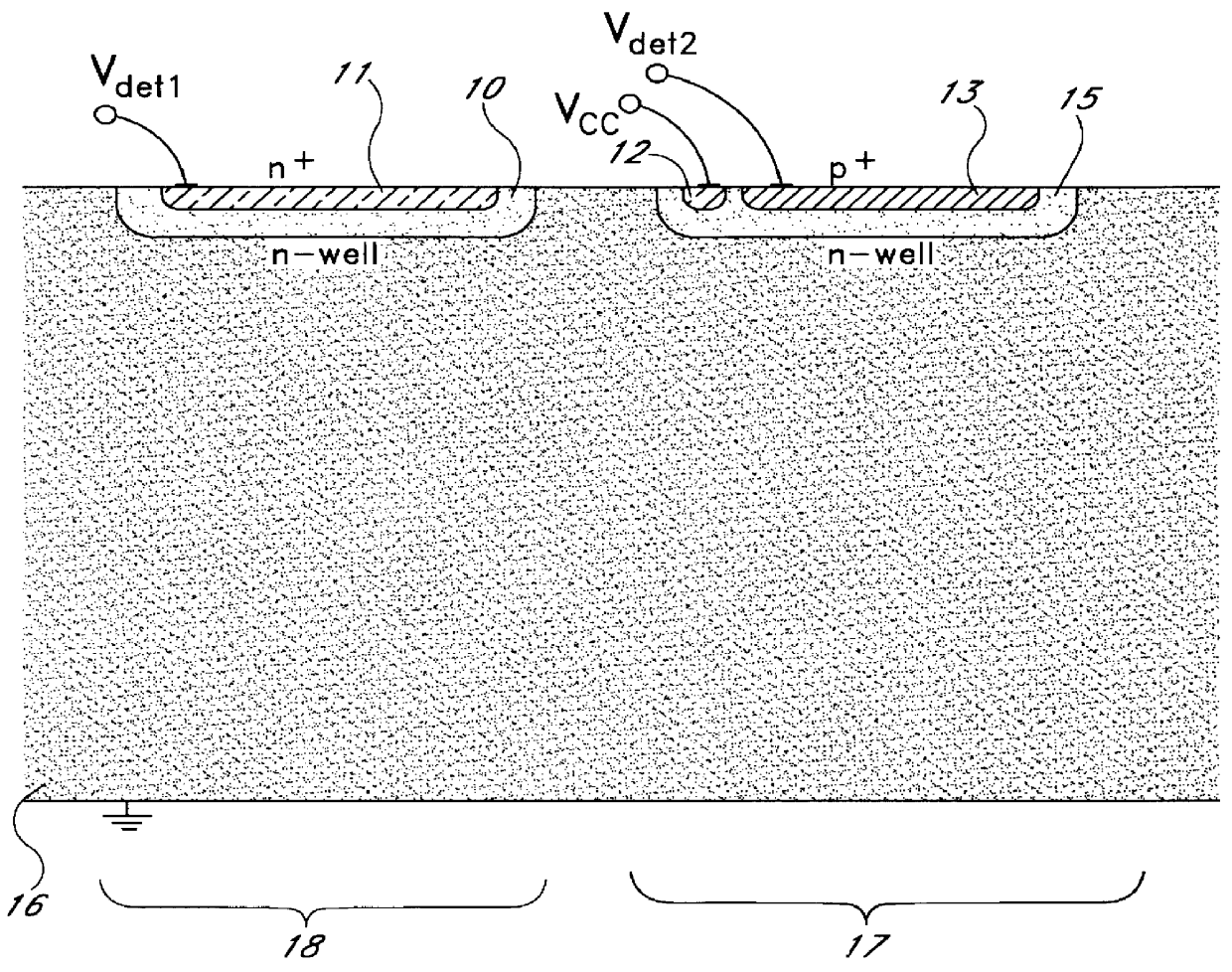

ESD protection for semiconductor products

InactiveUS6873017B2Reduces lateral currentCurrent densityTransistorSemiconductor/solid-state device detailsEngineeringMechanical engineering

Device 60 in FIG. 3 has junctions 86 each with a lateral portion 90 and a second portion 92 extending upward toward the surface 12 from the lateral portion 90. The lateral portions 90, as illustrated in FIG. 3, are more or less formed along a plane parallel with the surface 12. The upwardly extending portions 92 include characteristic curved edges of the diffusion fronts which are associated with the planar process. With the regions 80 and 82 each having relatively high net dopant concentrations of different conductivity types, each lateral junction portion 90 includes a relatively large sub region 96 which extends more deeply into the layer 10. When compared to other portions of the junctions 86, the subregions 96 are characterized by a relatively low breakdown voltage so that ESD current is initially directed vertically rather than laterally.

Owner:SEMICON COMPONENTS IND LLC

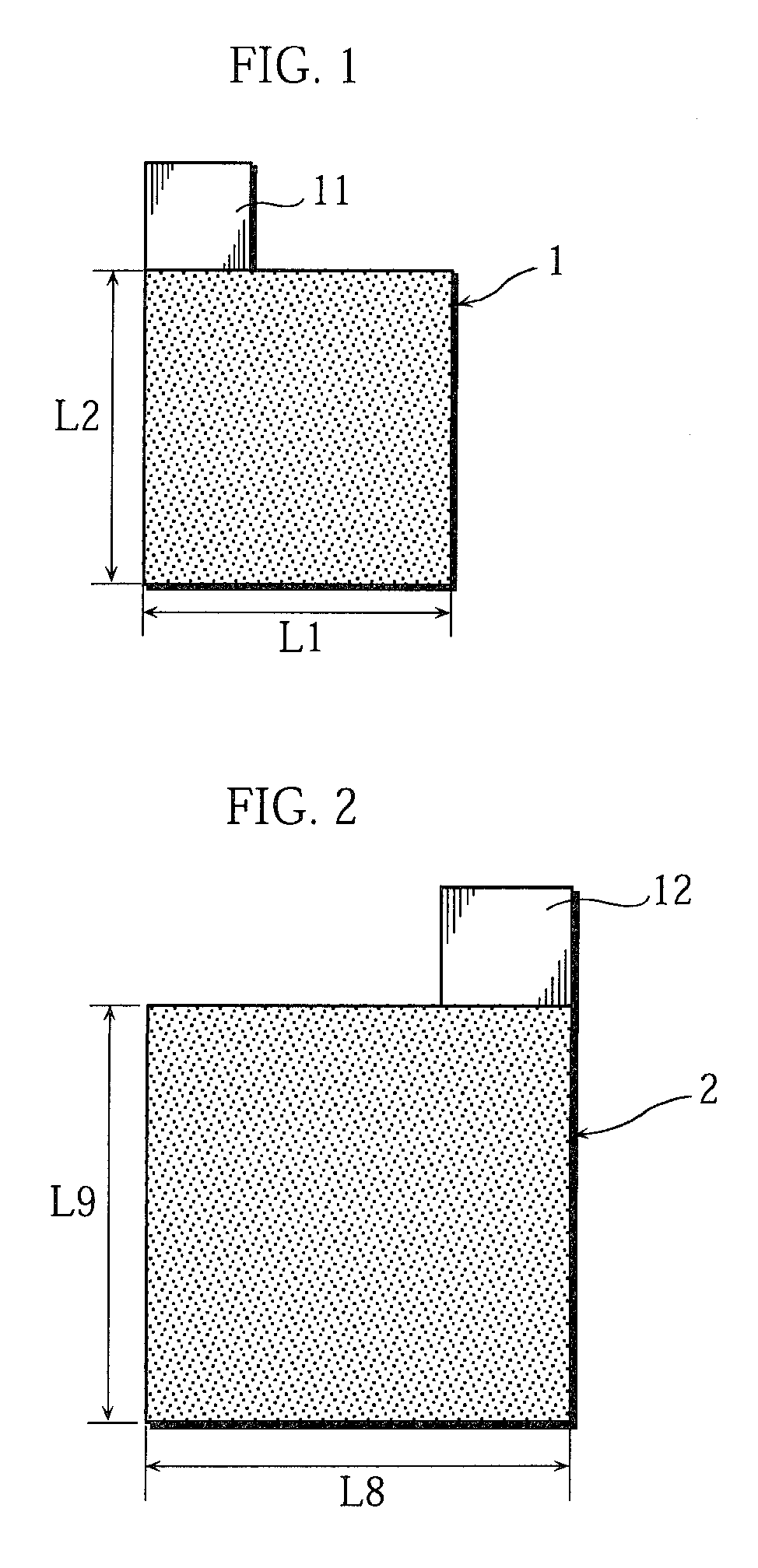

Positive electrode active material powder for lithium secondary battery

ActiveUS20050271944A1Large volume capacity densityLow compression breaking strengthAlkali metal oxidesLi-accumulatorsBreaking strengthAlkaline earth metal

To provide a lithium-nickel-cobalt-manganese composite oxide powder for a positive electrode of a lithium secondary battery, which has a large volume capacity density and high safety and is excellent in the charge and discharge cyclic durability. A positive electrode active material powder for a lithium secondary battery characterized by comprising a first granular powder having a compression breaking strength of at least 50 MPa and a second granular powder having a compression breaking strength of less than 40 MPa, formed by agglomeration of many fine particles of a lithium composite oxide represented by the formula LipNixCoyMnzMqO2-aFa (wherein M is a transition metal element other than Ni, Co and Mn, Al or an alkaline earth metal element, 0.9≦p≦1.1, 0.2≦x≦0.8, 0≦x≦0.4, 0≦z≦0.5, y+z>0, 0≦q≦0.05, 1.9≦2−a≦2.1, x+y+z+q=1, and 0≦a≦0.02) to have an average particle size D50 of from 3 to 15 μm, in a weight ratio of the first granular powder / the second granular powder being from 50 / 50 to 90 / 10.

Owner:SUMITOMO CHEM CO LTD

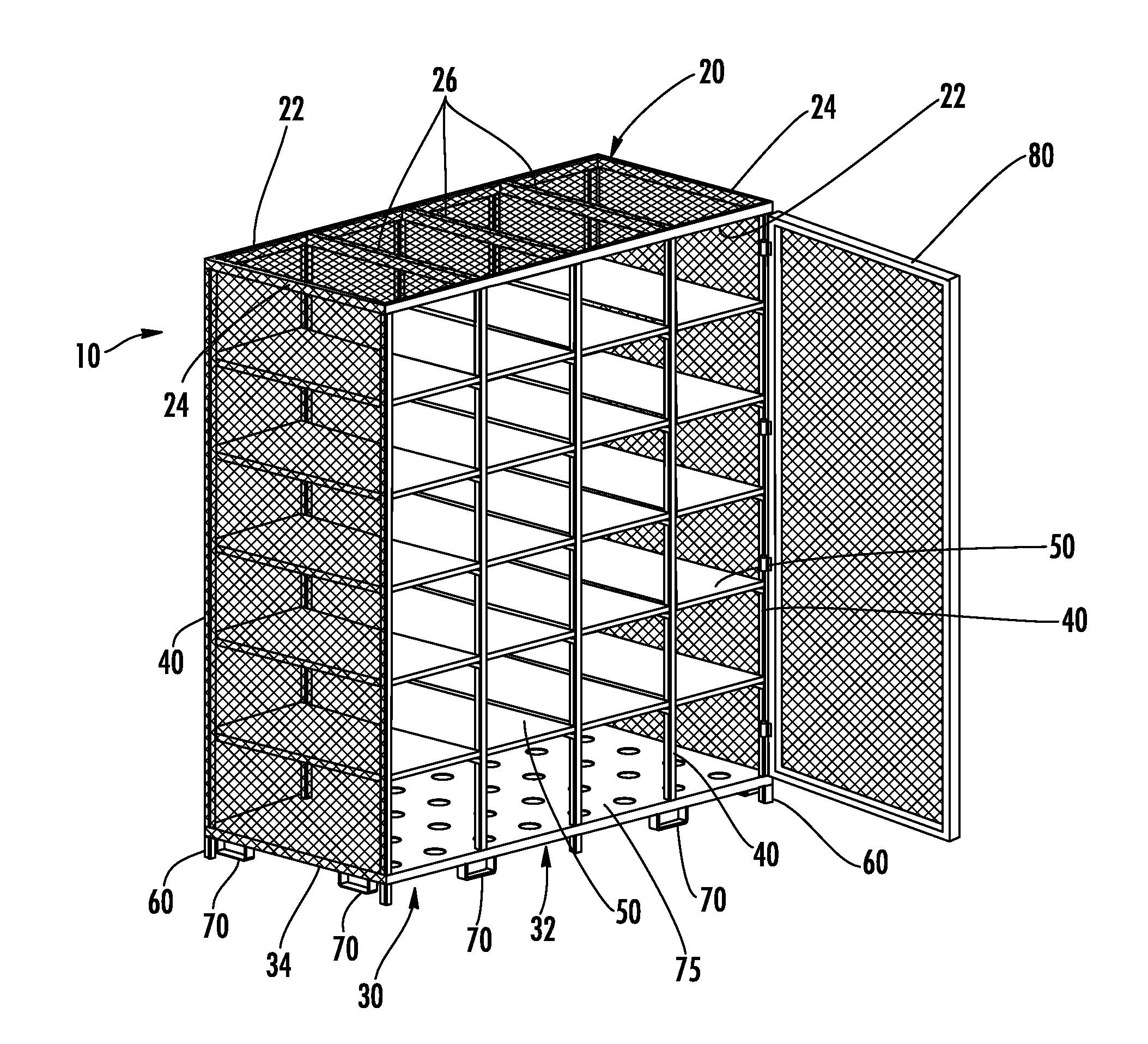

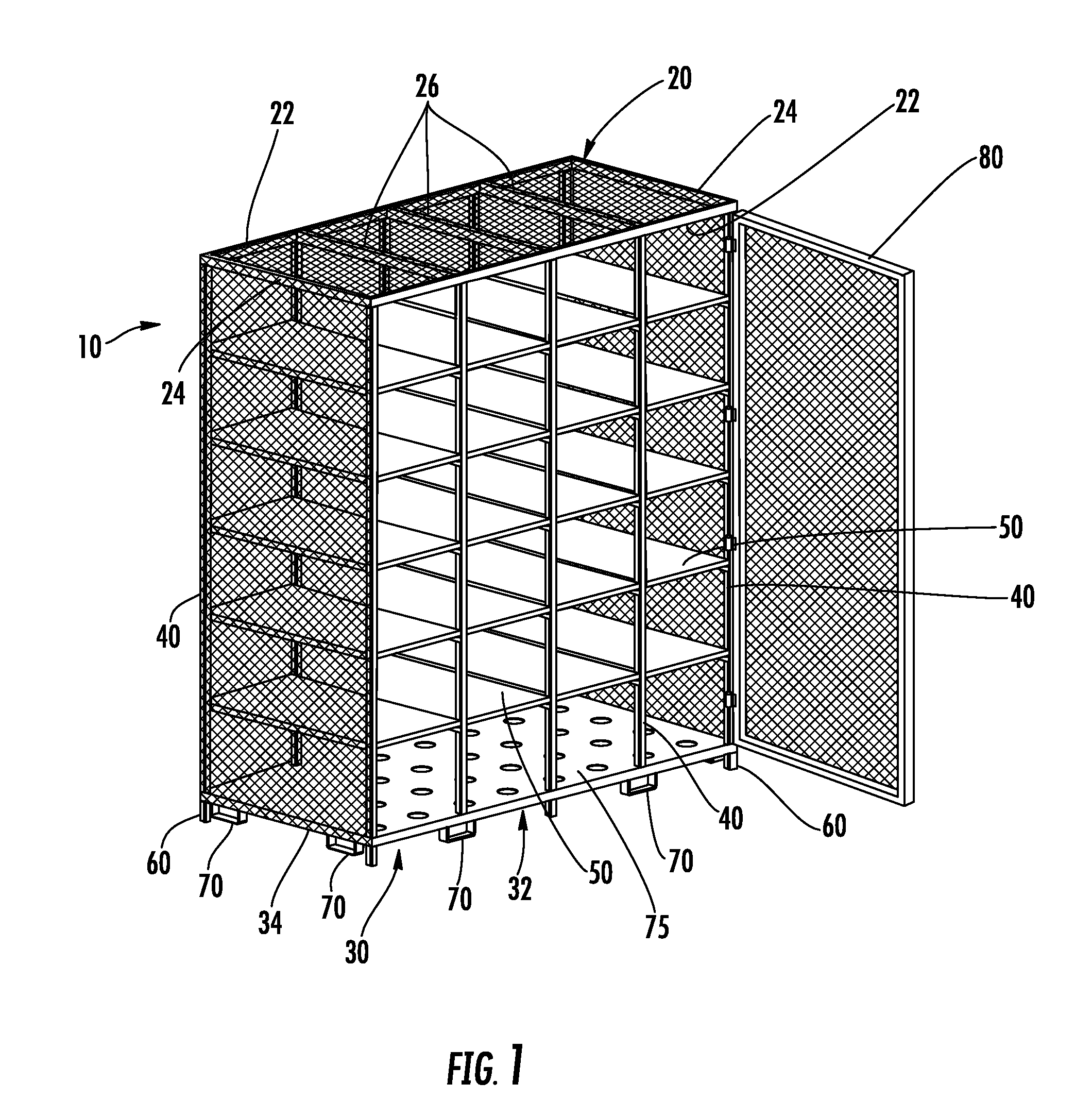

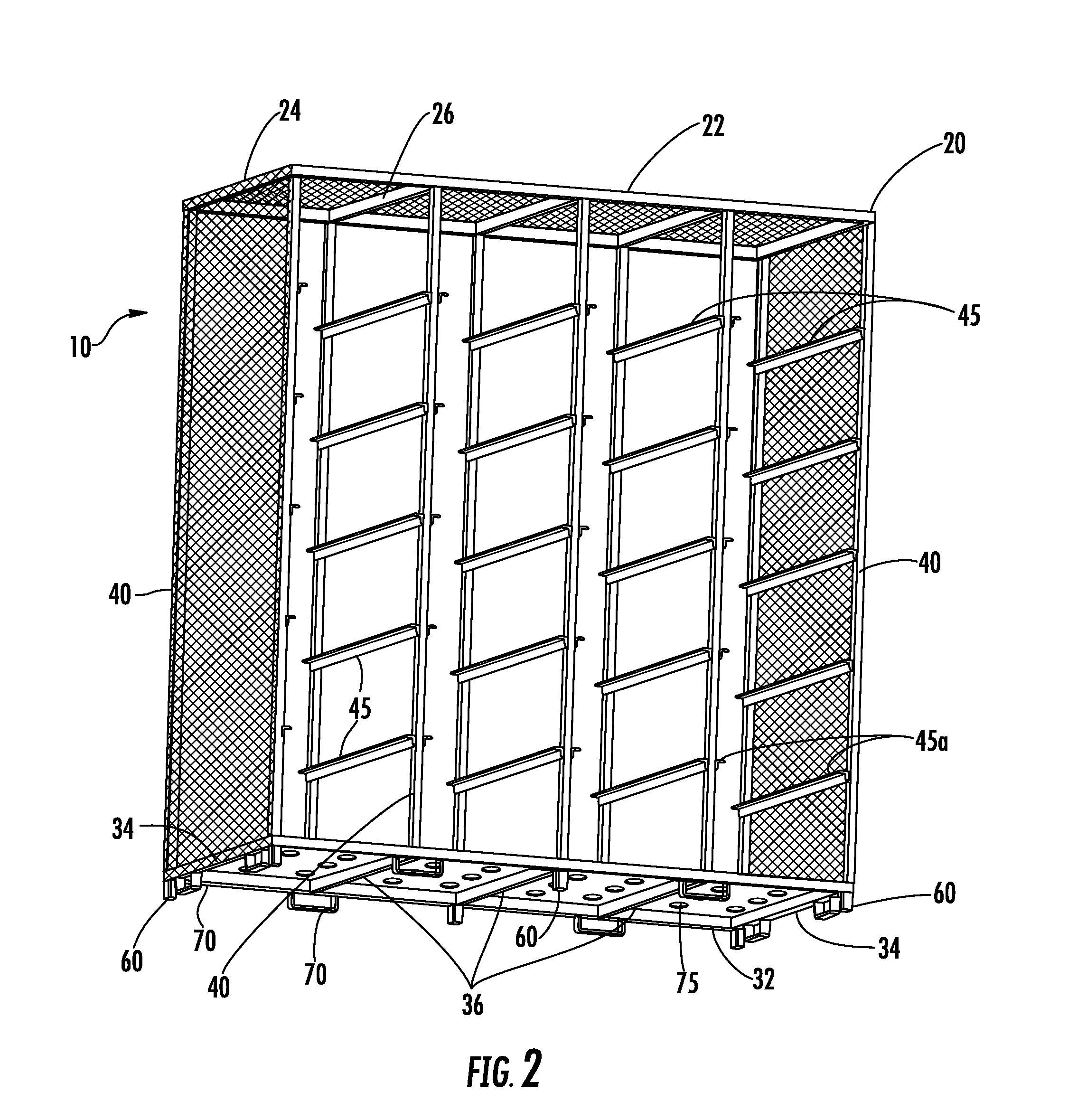

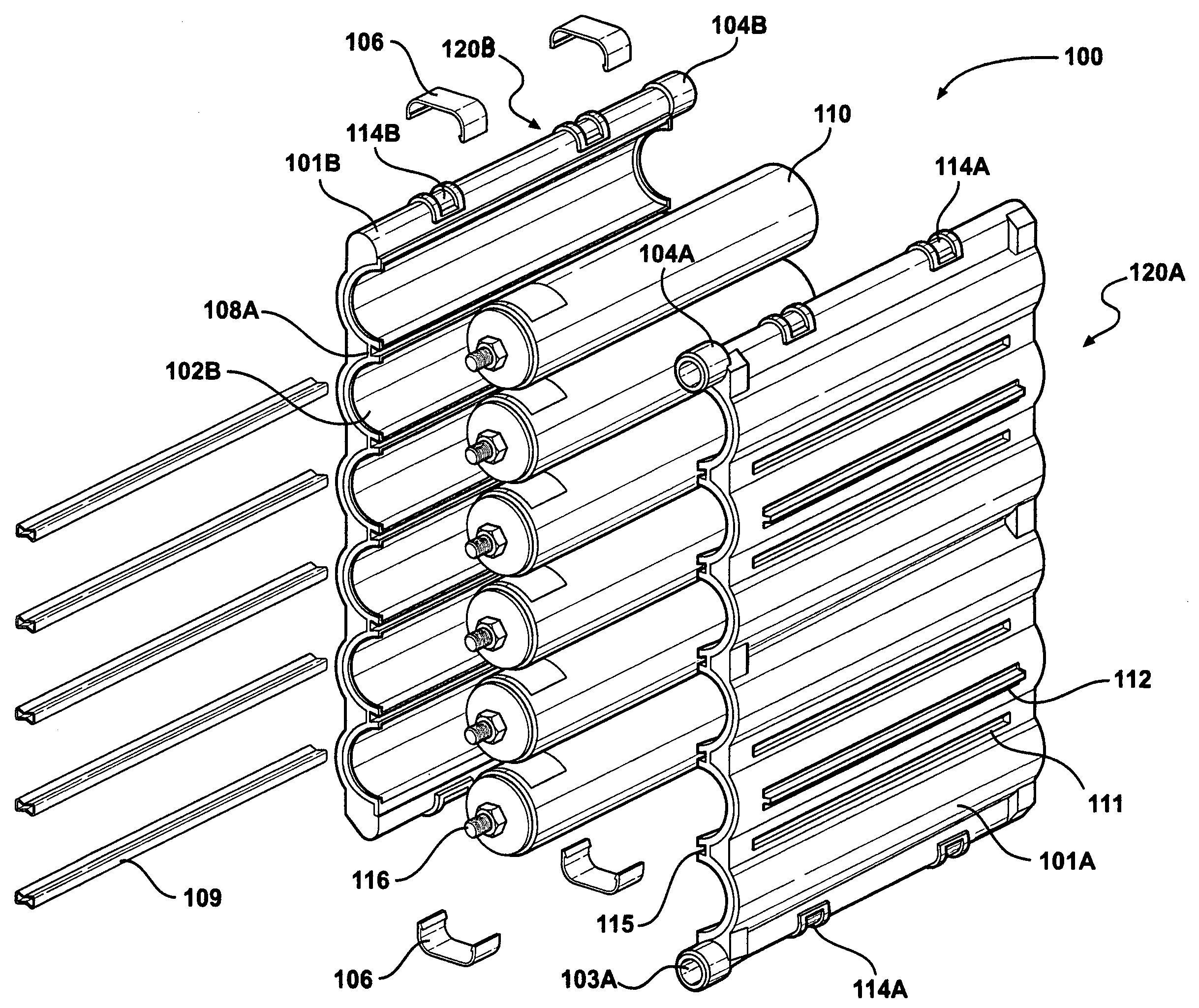

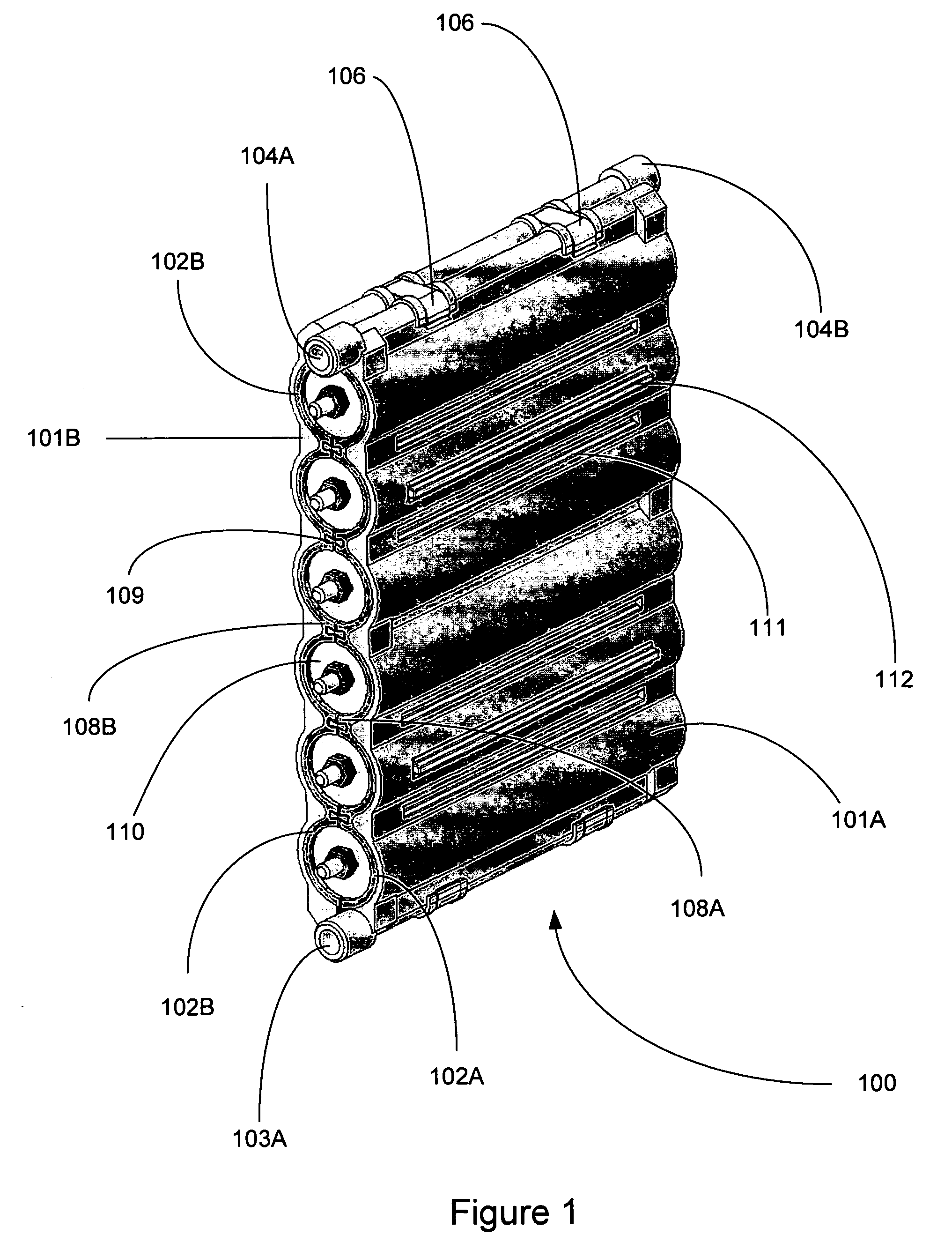

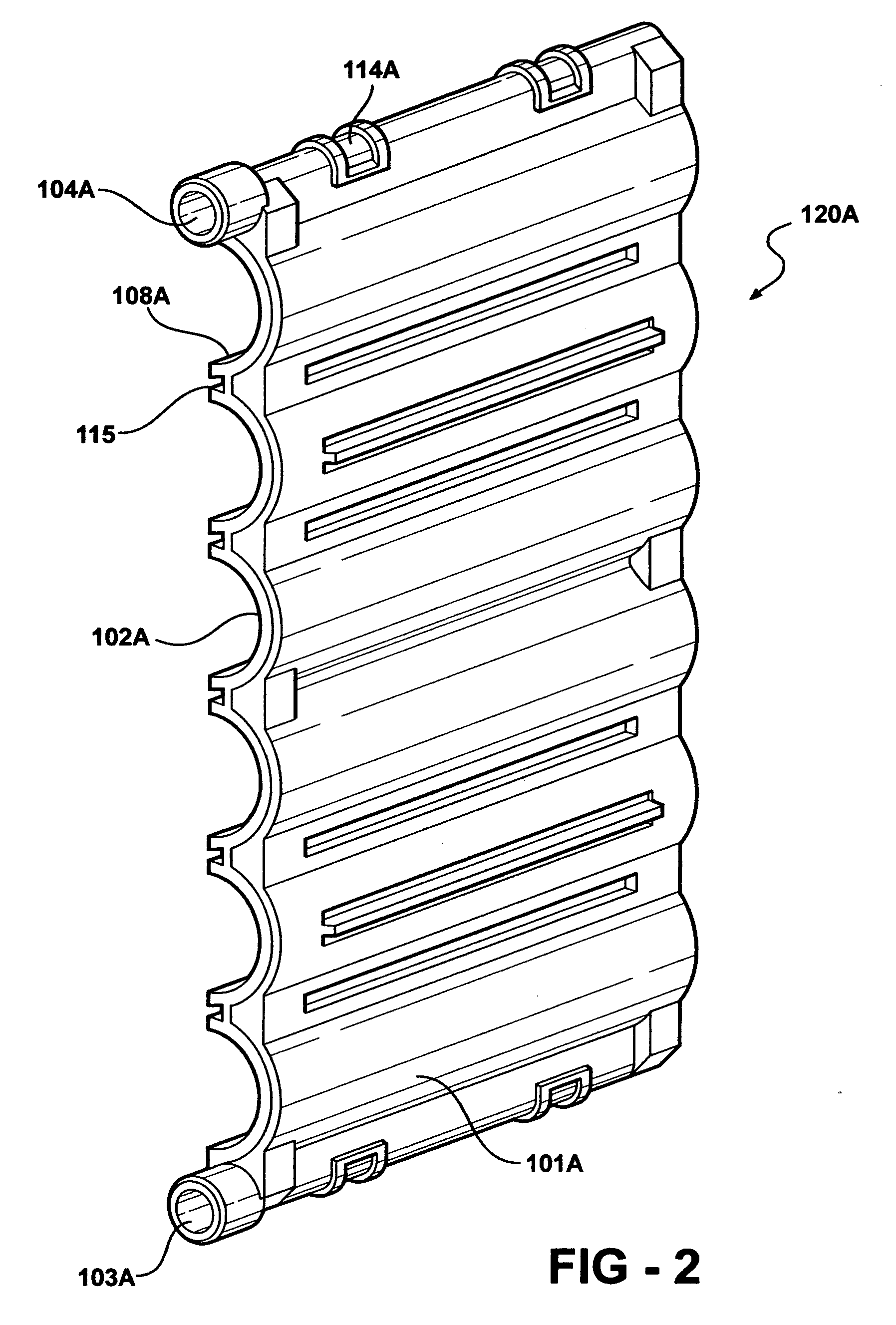

Movable storage racks for transportation of goods

InactiveUS20080193247A1Maximize the use of spaceIncreasing weight loadVehicle with removable loadingStorage devicesTransport engineeringRefrigeration

The invention provides a racking system for the storage and transportation of goods. The racking system allows for storage and transportation of an increased amount of goods over a given area of floor space on transportation vehicles, facilitates air flow around goods being shipped to improve refrigeration, increases ease of loading and off-loading goods in relation to a transportation vehicle, and decreases time spent loading and off-loading goods. The racking system can particularly be combined with a railway car for improved long-haul transportation of goods, particularly perishable goods, such as boxed butchered meat products.

Owner:MARTIN MARIETTA MATERIALS

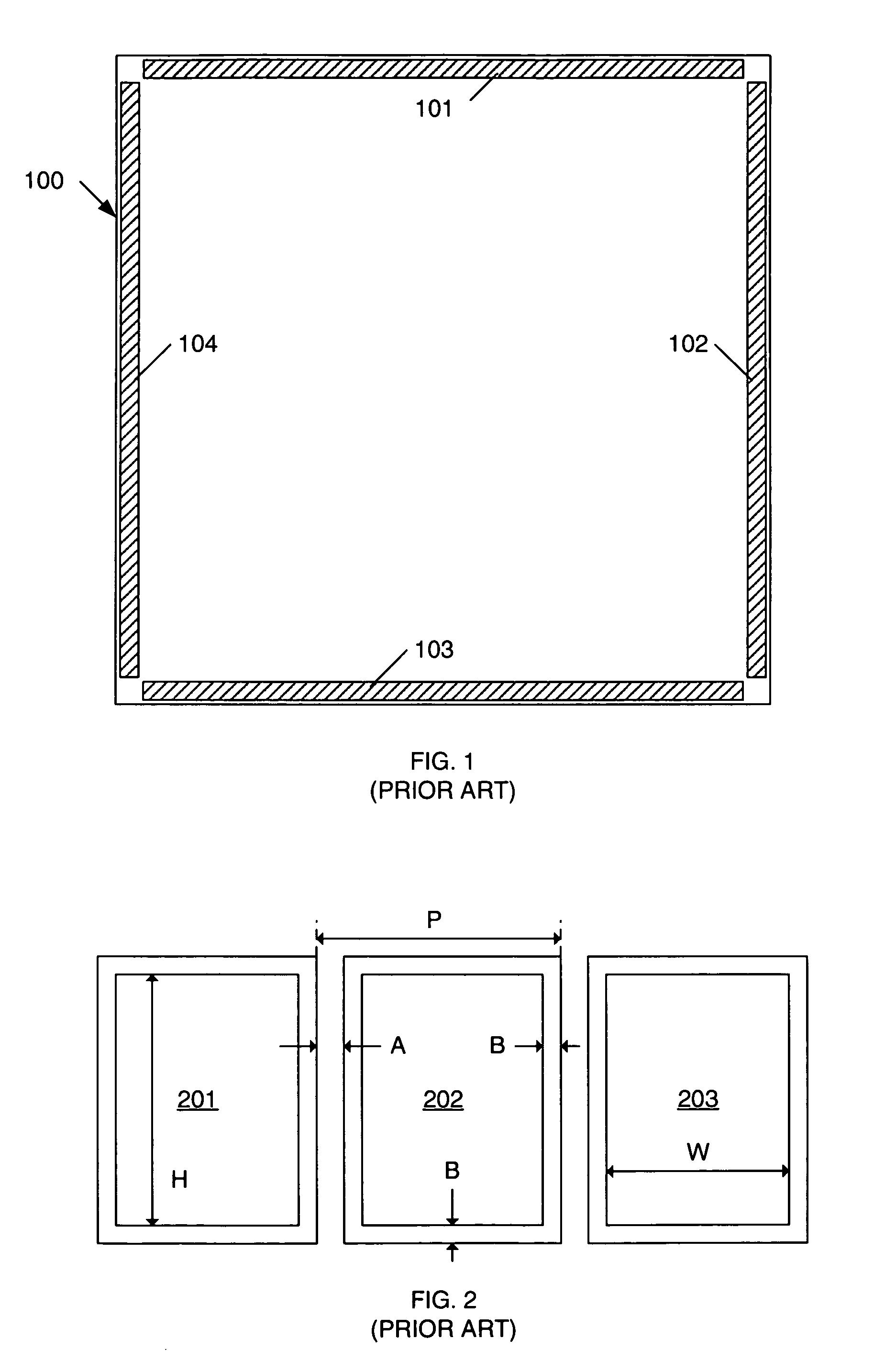

Semiconductor die with high density offset-inline bond arrangement

ActiveUS7064450B1High pad densityLarge “packing densitySemiconductor/solid-state device testing/measurementSemiconductor/solid-state device detailsHigh densitySemiconductor chip

Owner:XILINX INC

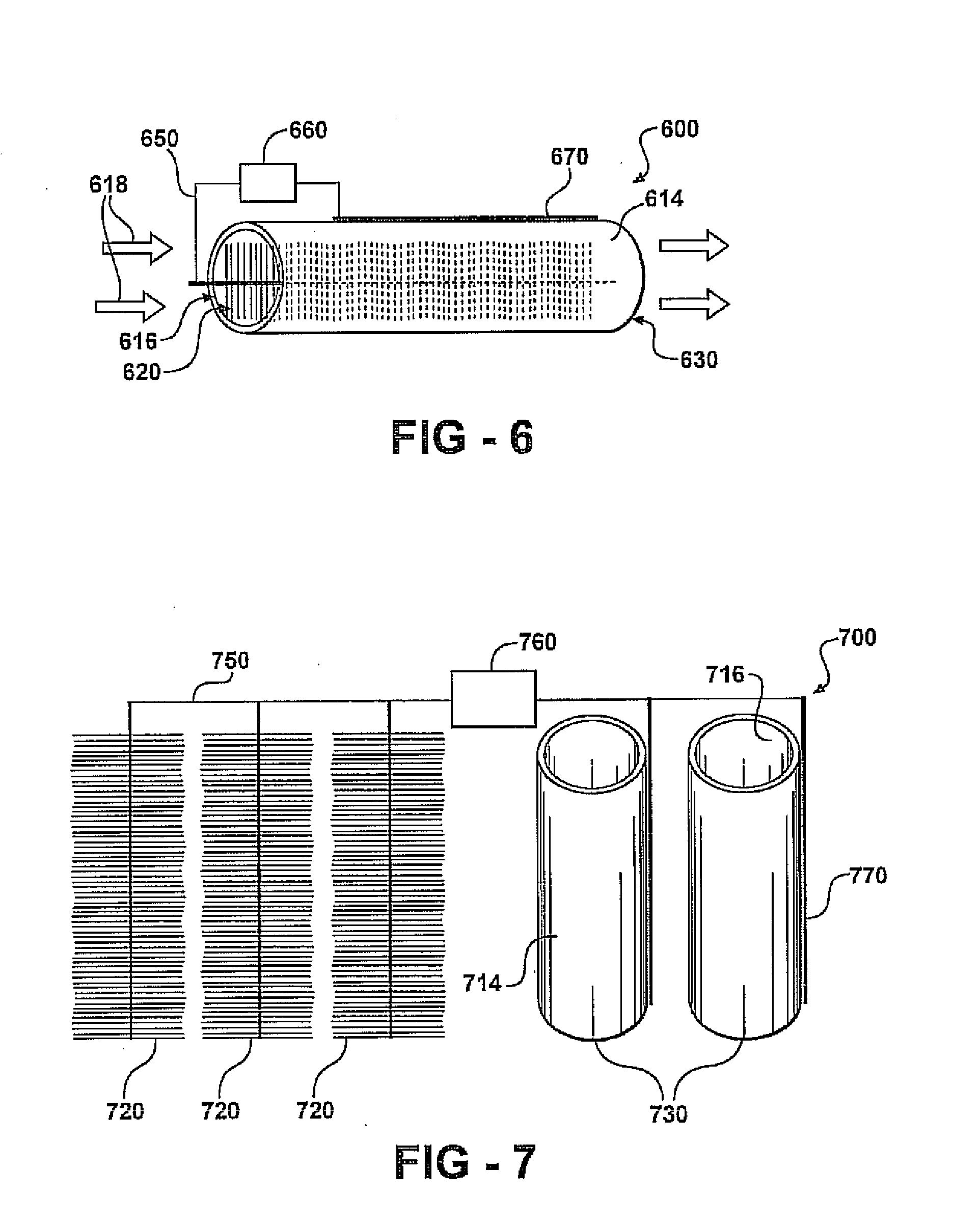

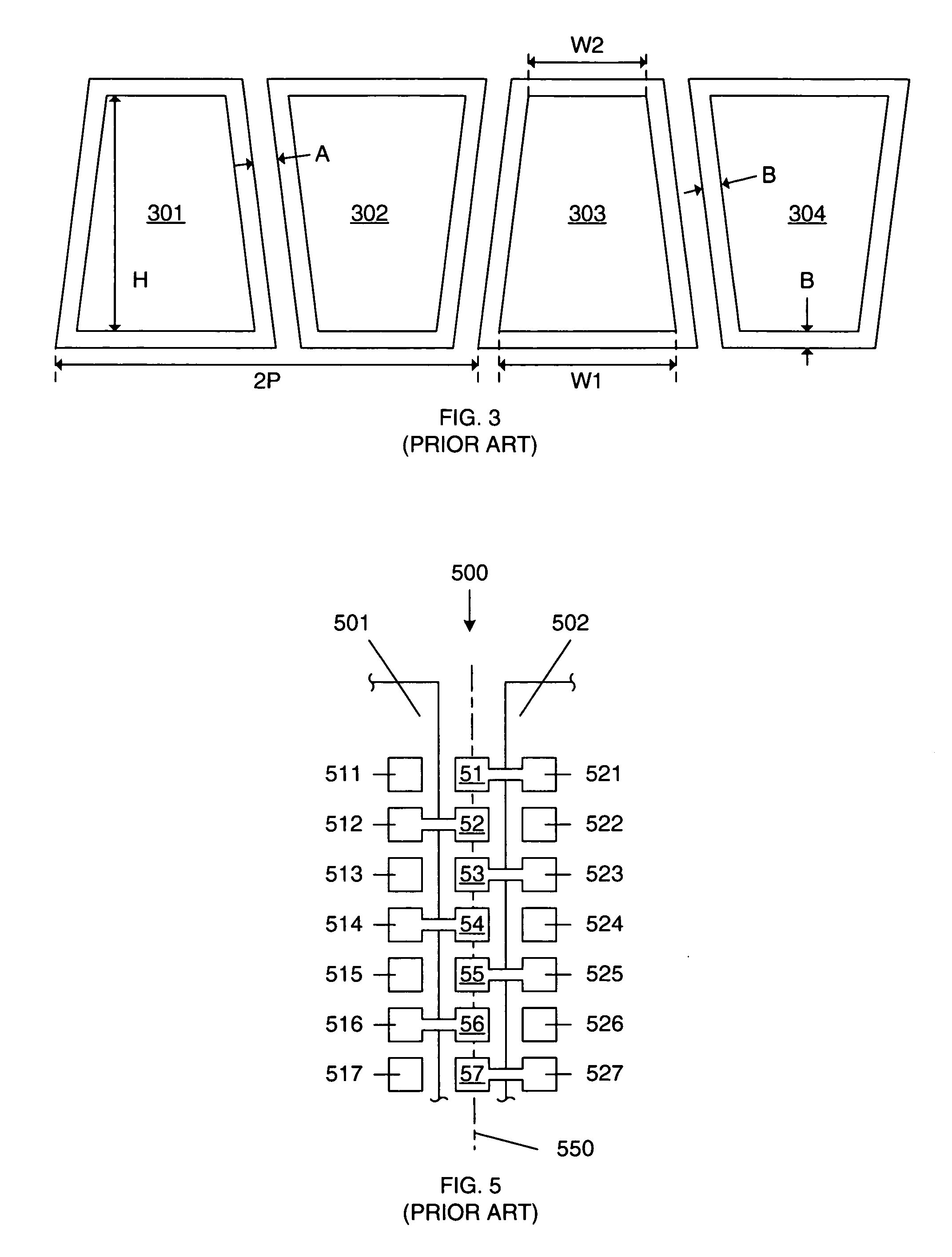

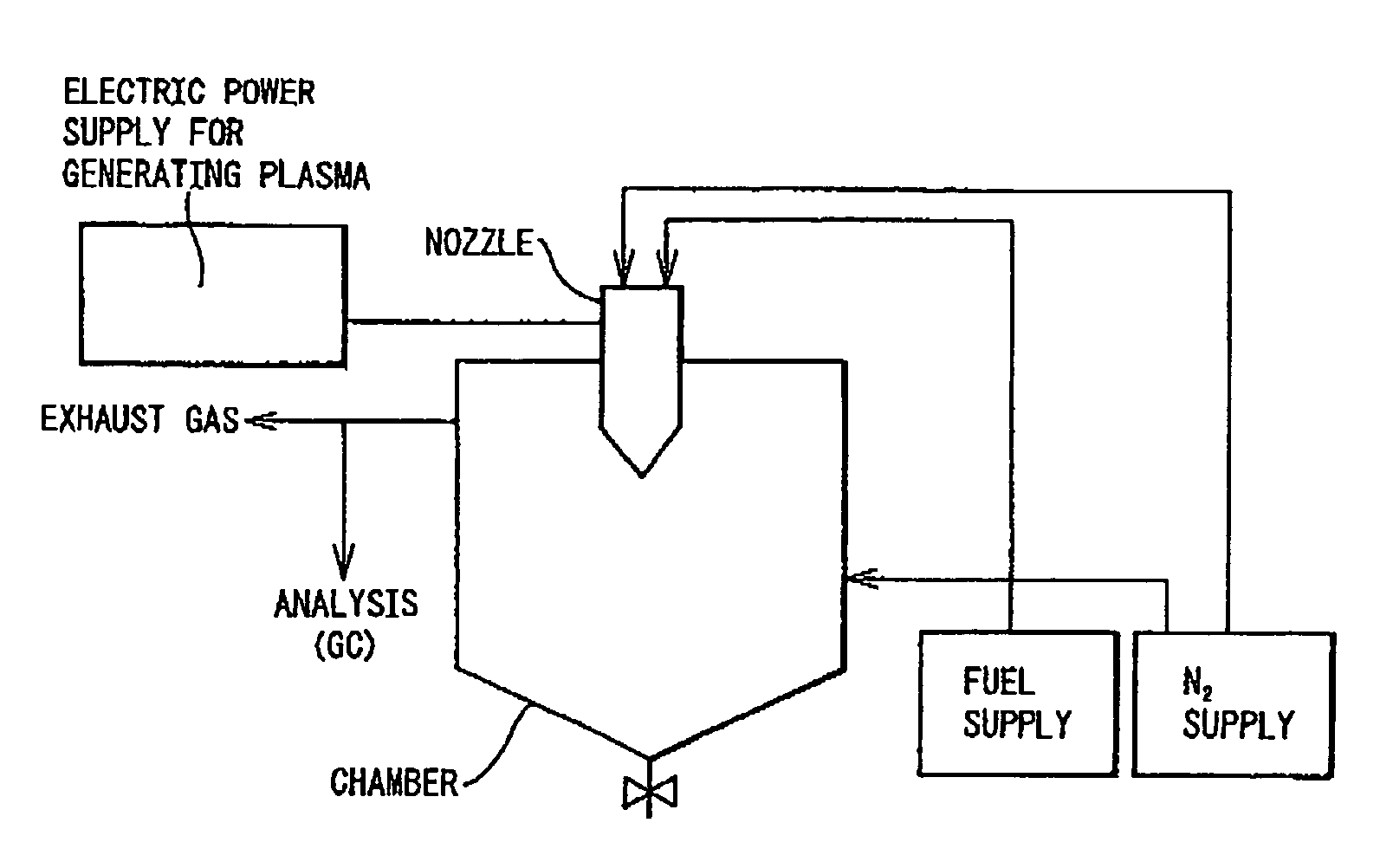

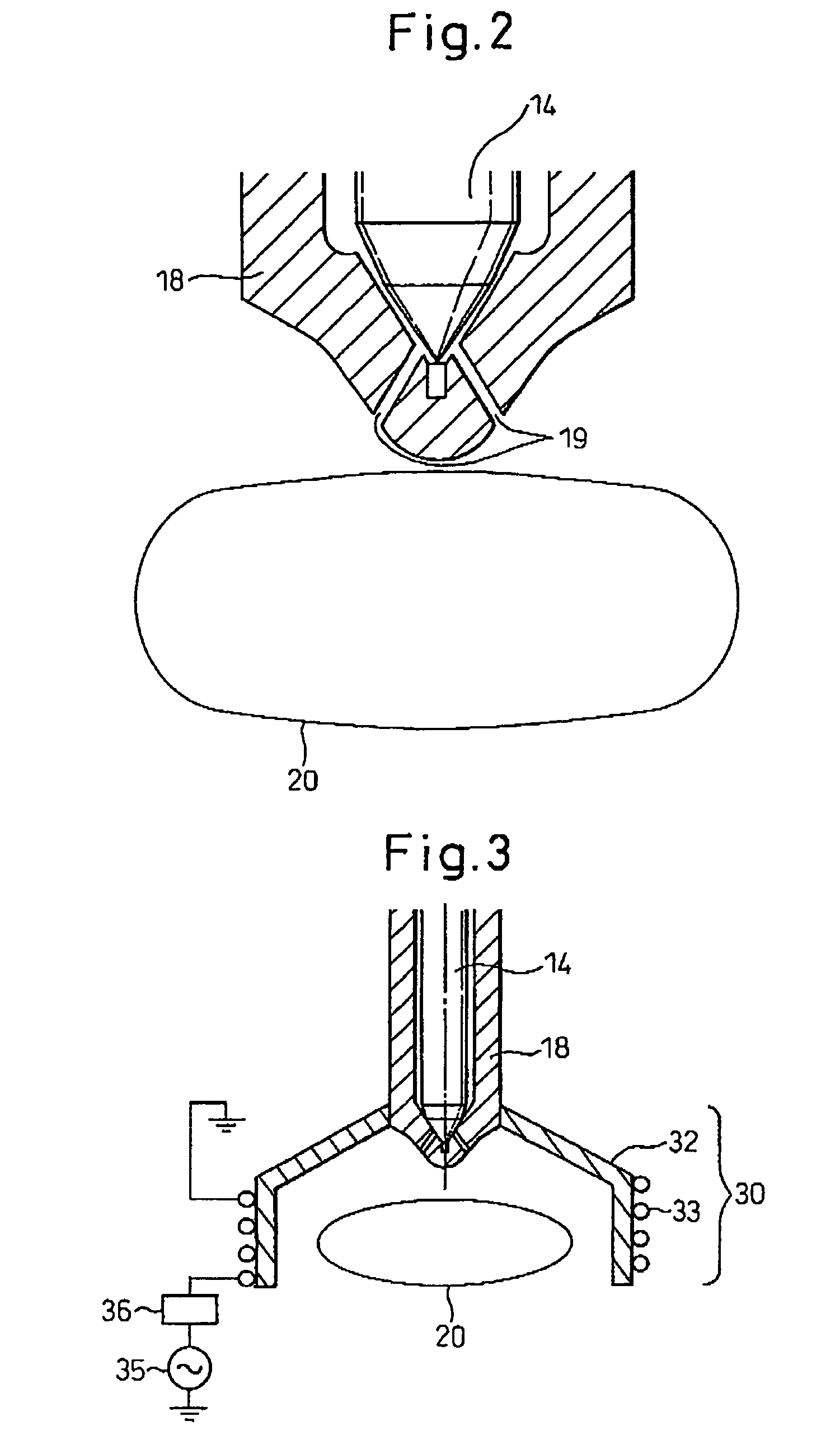

Plasma injector, exhaust gas purifying system and method for injecting reducing agent

InactiveUS7481043B2Solve the small densitySolve the large consumptionLiquid surface applicatorsInternal combustion piston enginesInjection portExhaust fumes

The present invention provides a plasma injector wherein a reducing agent injected from an injection port (19) at the distal end portion of an injection nozzle (18) is at least partially converted into a plasma; an exhaust gas purifying system; and a method for injecting a reducing agent. Using the plasma injector, the exhaust gas purifying system, and the method for injecting a reducing gas of the present invention, it is possible to vaporize a reducing agent supplied in an injection manner and / or to provide a highly reactive reducing agent from the reducing agent.

Owner:TOYOTA JIDOSHA KK

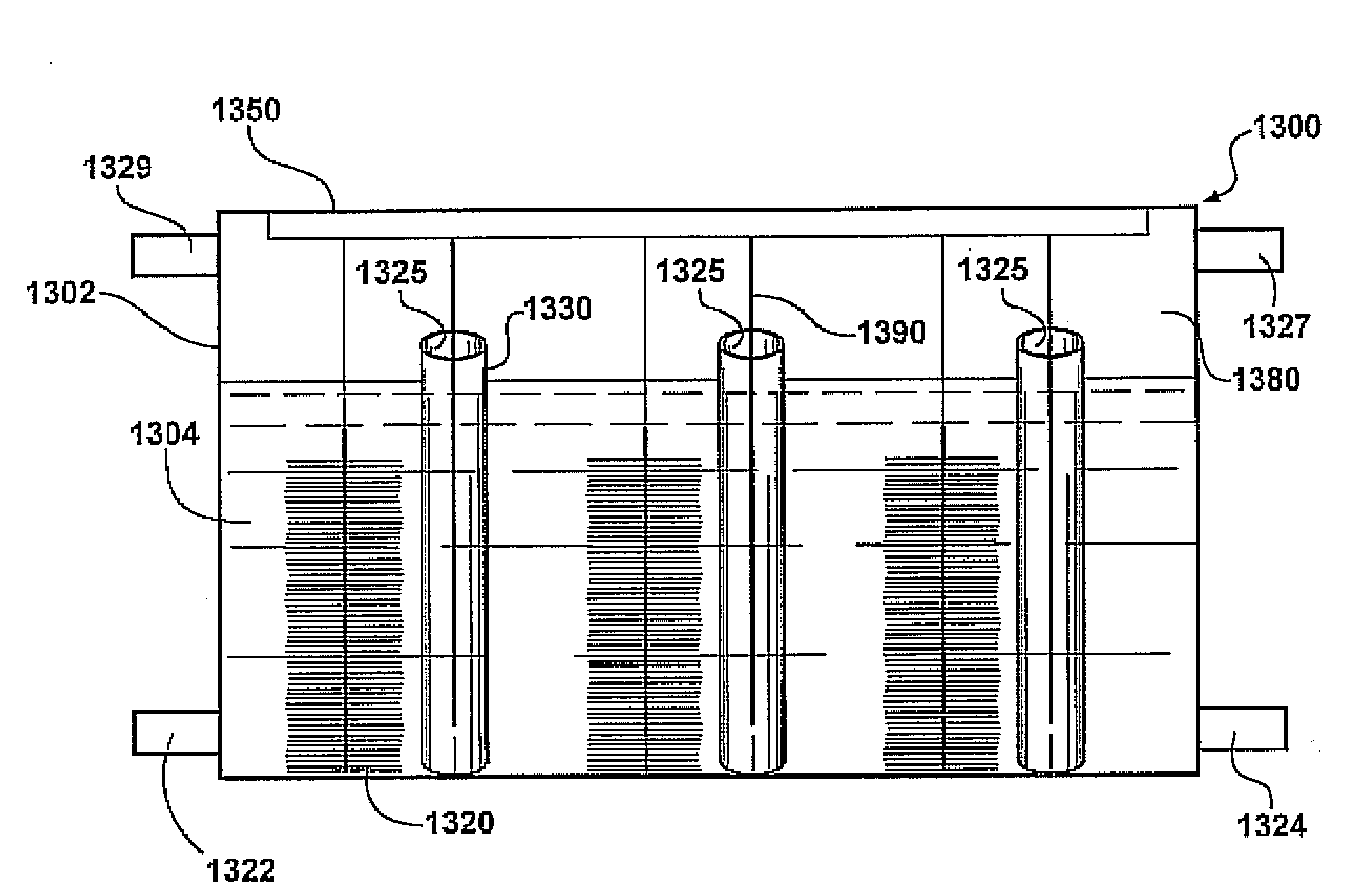

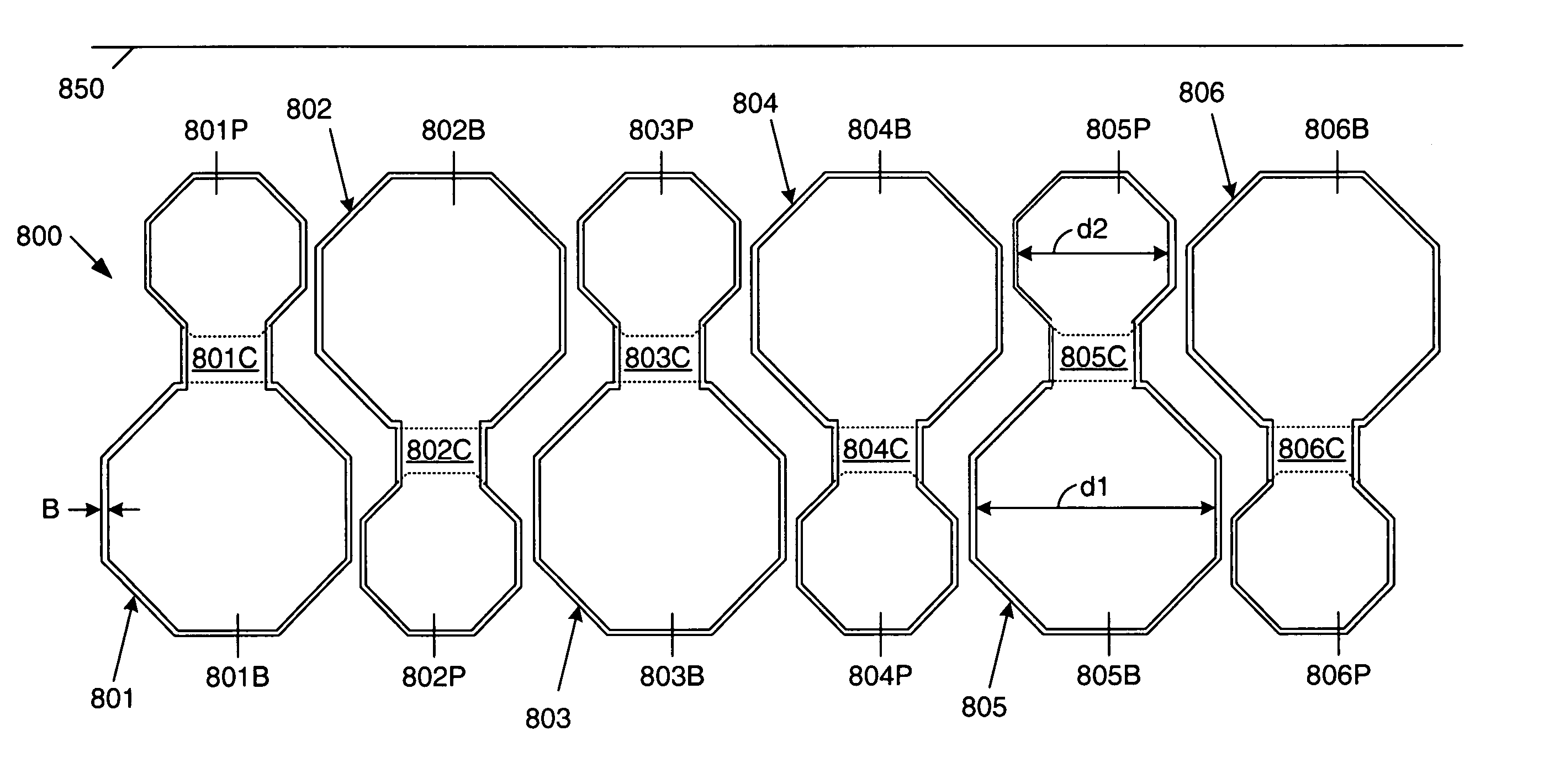

Device for housing electrochemical cells

ActiveUS20090148754A1Equally distributedUniform cell coolingSecondary cellsCell component detailsTemperature controlElectrochemical cell

Disclosed herein is a device for housing a plurality of electrochemical cells, wherein the housing provides stability, temperature control and maximum packing density. The battery module housing comprises a first semi-enclosure and a second semi-enclosure, wherein the first and second semi-enclosure are aligned to form compartments there between. Each compartment is designed to accommodate at least one electrochemical cell, such as a cylindrical battery or a prismatic battery. Each semi-enclosure comprises an interior wall and an exterior wall. The interior and exterior wall align together to form a flow path between the walls through which coolant or any other thermal management medium may flow. The coolant enters the semi-enclosure through a coolant inlet, flows between the interior and exterior walls; then flows out of the semi-enclosure through a coolant outlet.

Owner:BATTERY PATENT TRUST

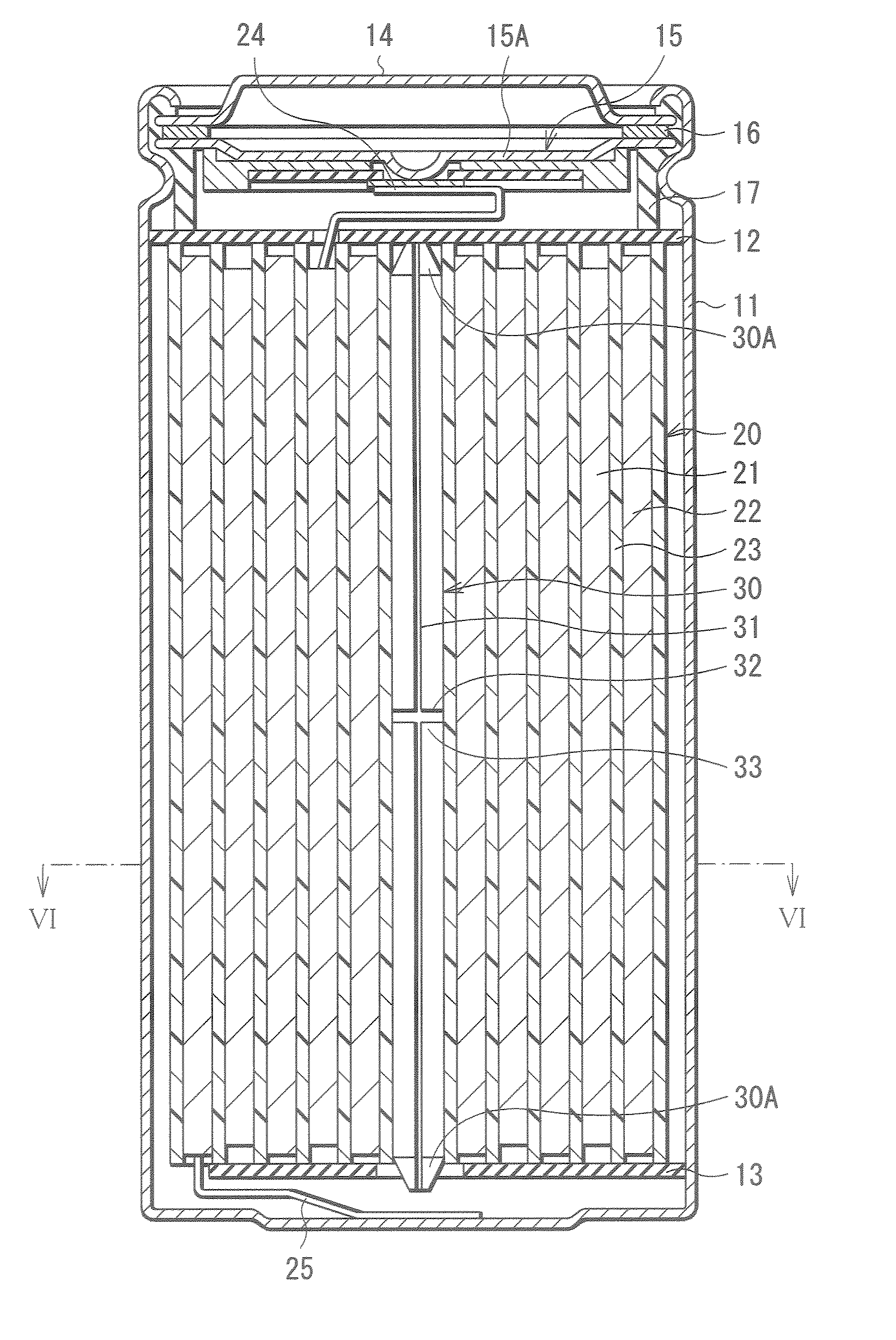

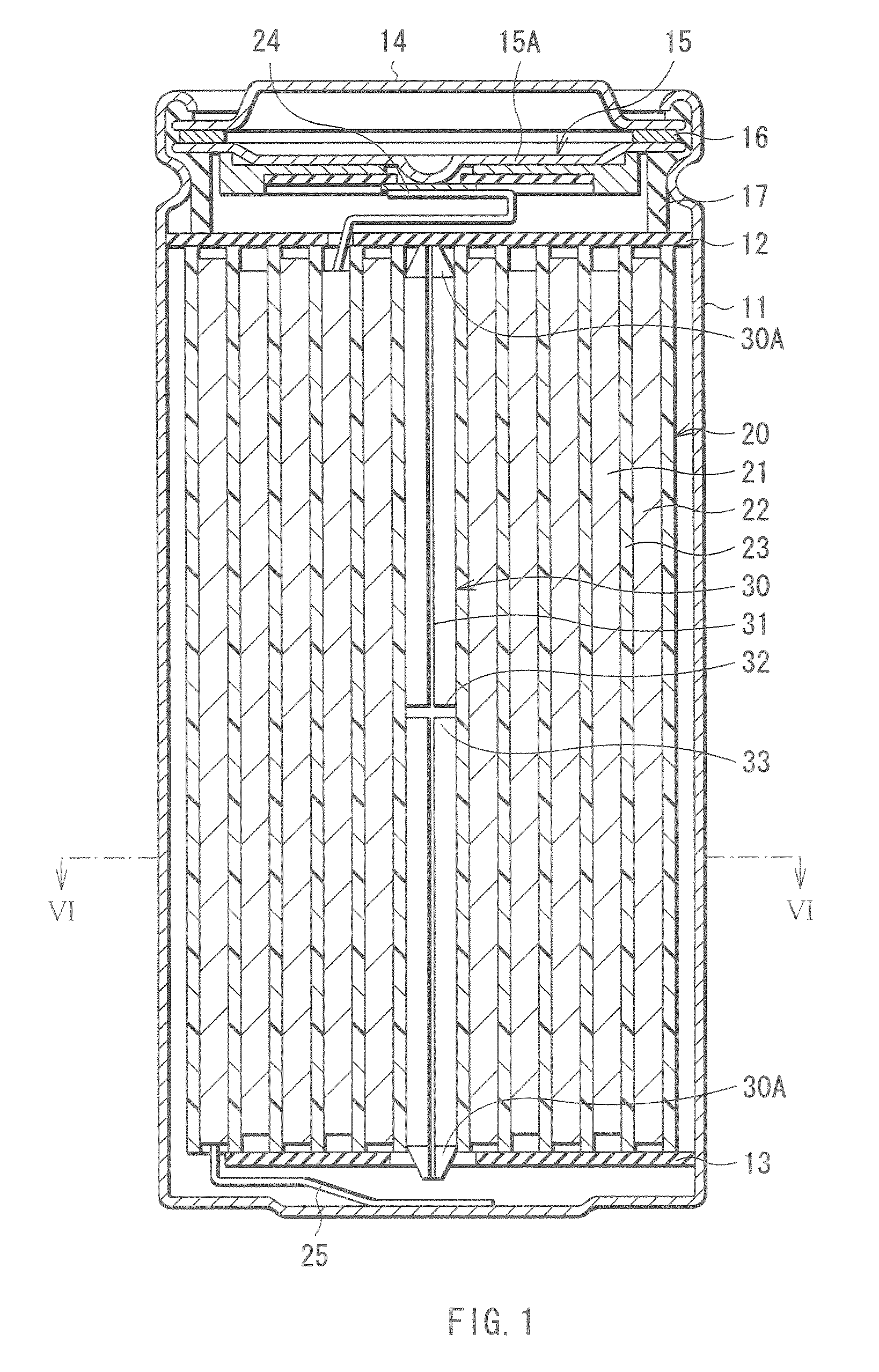

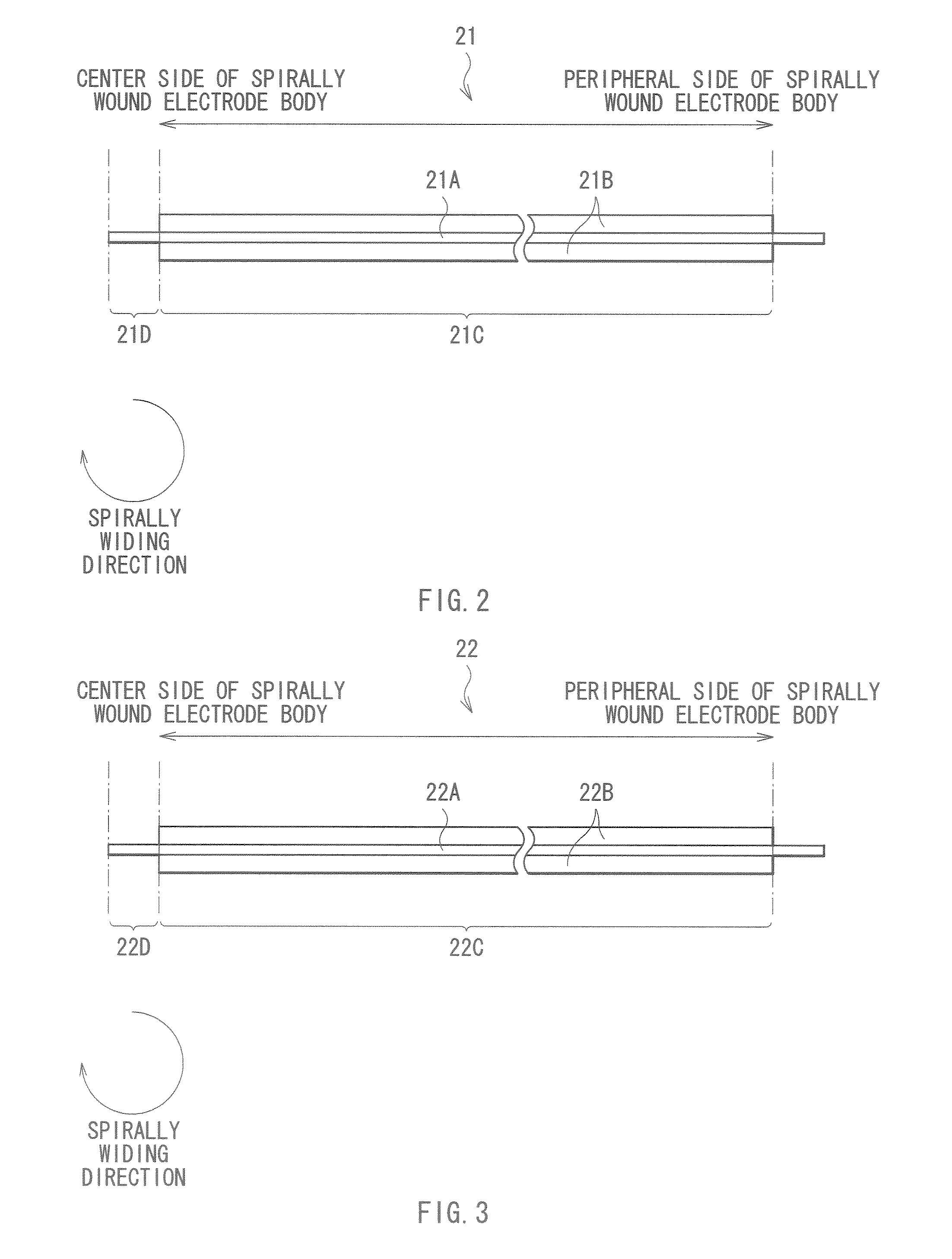

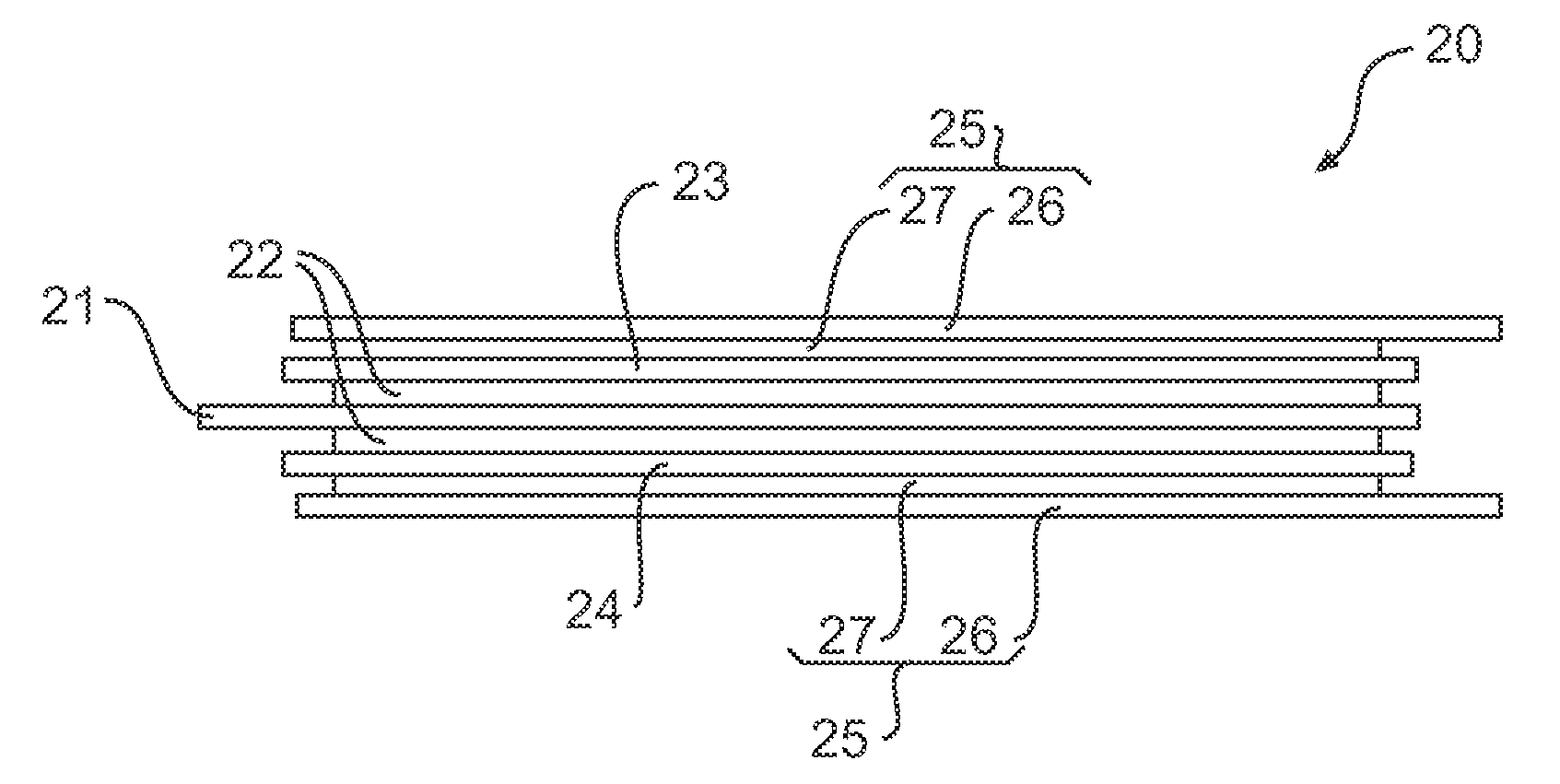

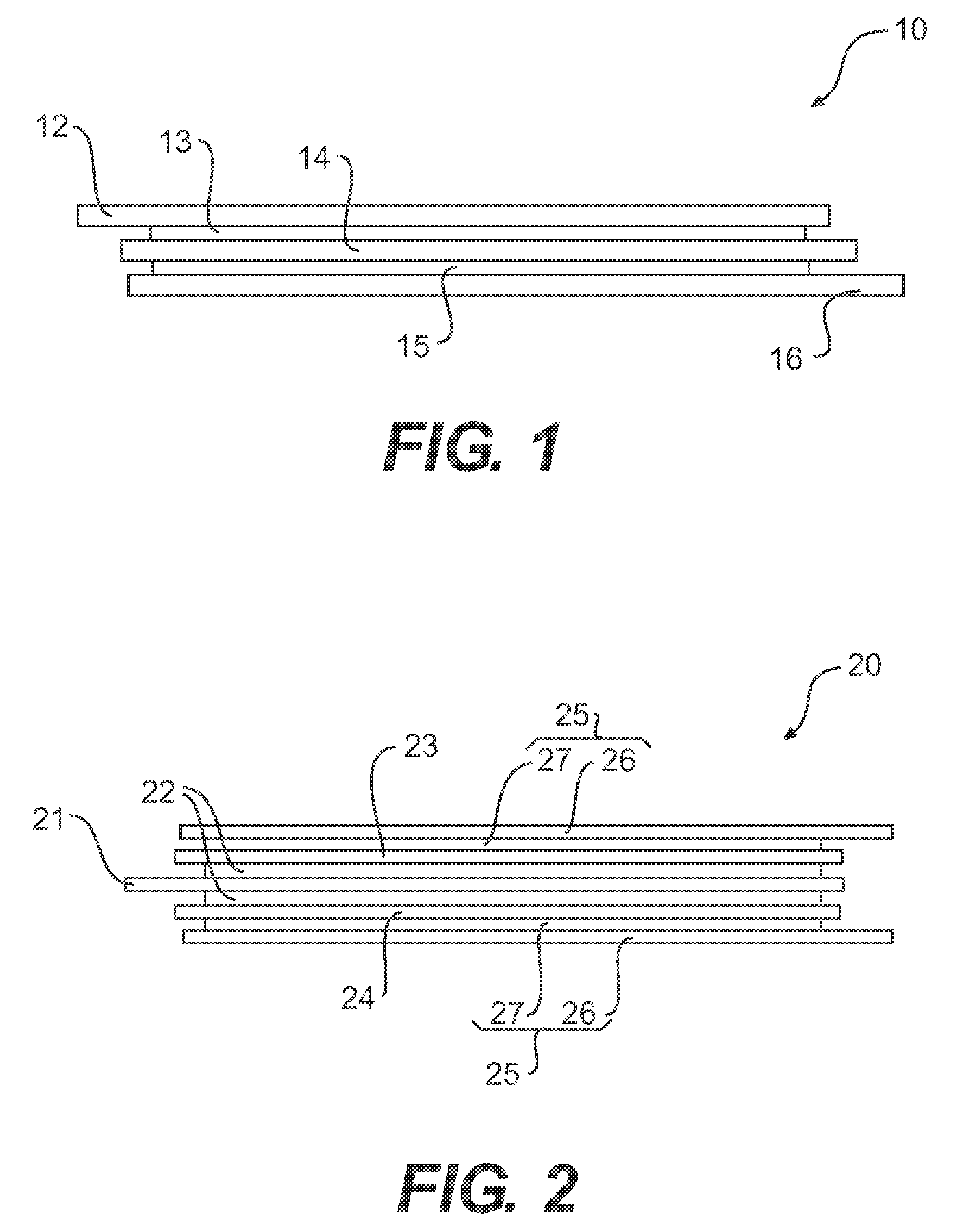

Battery and Center Pin

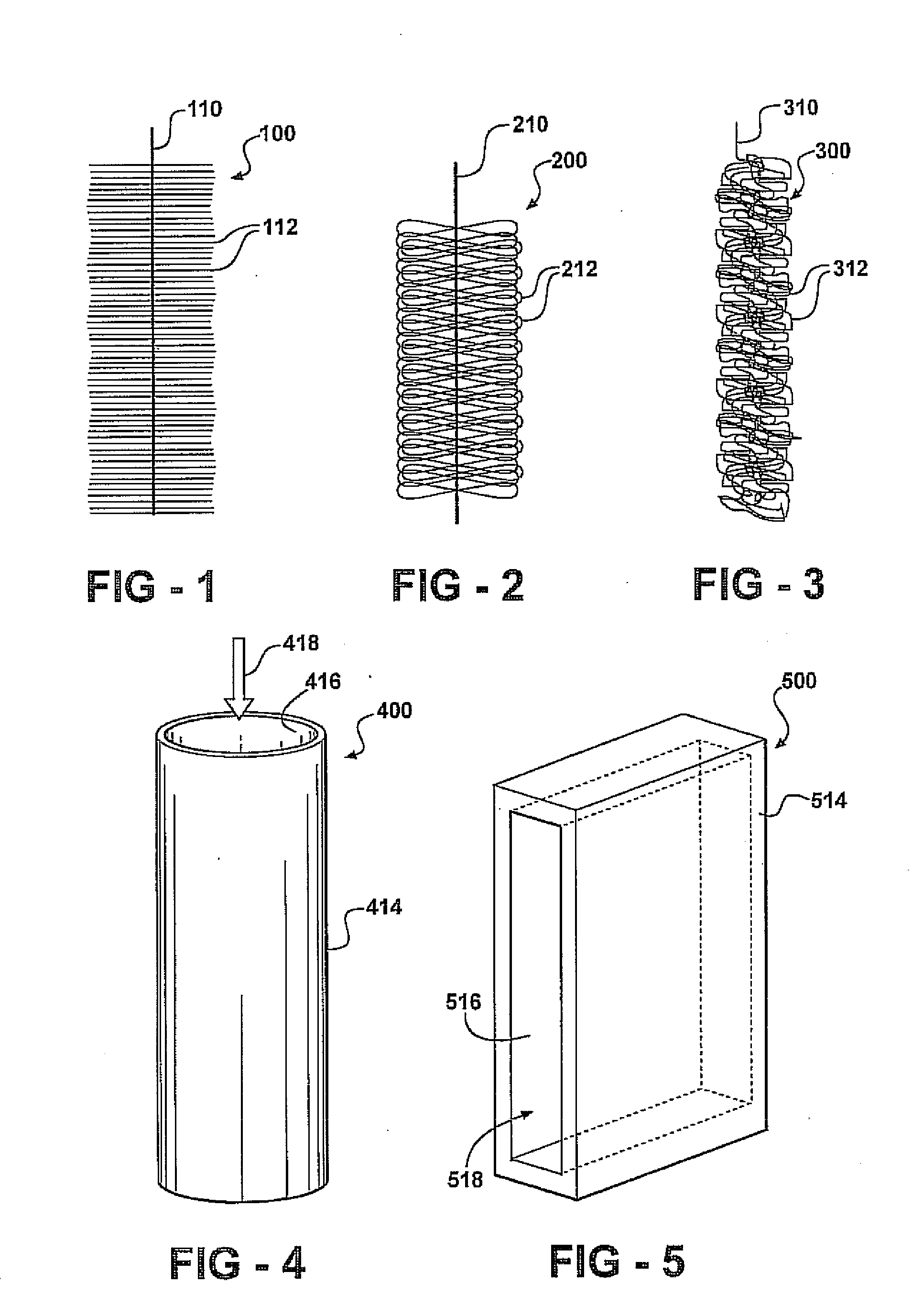

ActiveUS20070269711A1Improve securityLarge energy densityAssembling battery machinesCell electrodesEllipseEngineering

A battery with improved safety that can more surely short-circuit electrodes when flattened out by the external force is provided. A center pin (30) is inserted in the center of a spirally wound electrode body formed by layering and spirally winding a cathode and an anode with a separator in between. The center pin (30) has a cut line (31) provided in the longitudinal direction and a first cutout (32) vertically crossing the cut line (31). When flattened out by the external force, a corner (33) at an intersection of the cut line (31) and the first cutout (32) is projected, and short-circuit is surely generated. Further, it is preferable that the center pin (30) has a second cutout (34) in the direction perpendicular to the cut line (31) in a position facing the cut line (31) in the circumferential direction. It is also preferable that the center pin (30) has a cross sectional shape of an oval or an ellipse, and the cut line (31) is provided in a position where the diameter of the oval or the ellipse is the largest.

Owner:MURATA MFG CO LTD

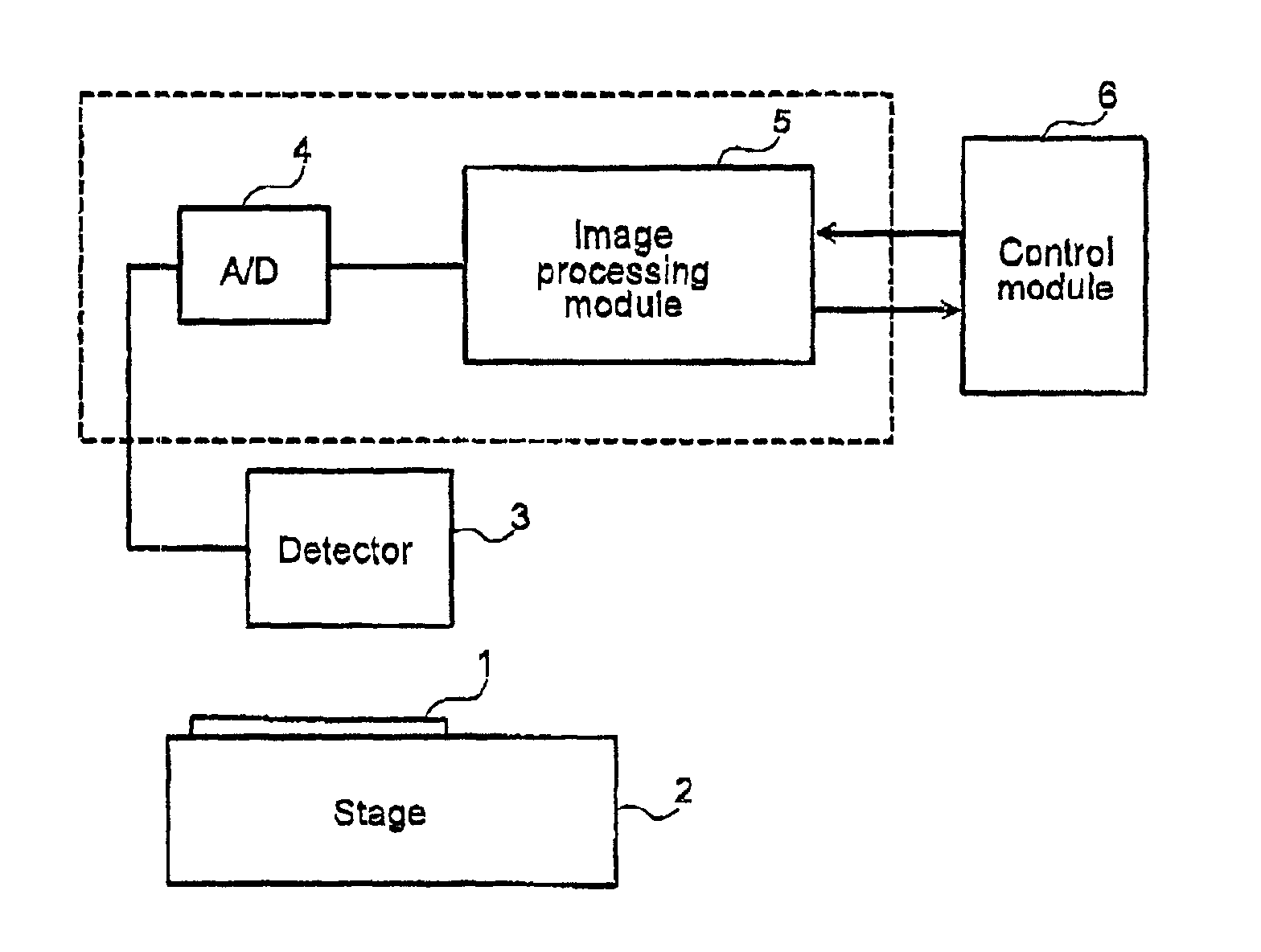

Image alignment method, comparative inspection method, and comparative inspection device for comparative inspections

InactiveUS7020350B2Solve the small densityLittle in luminance luminanceImage enhancementImage analysisReference imageImage alignment

The present invention provides a high-precision alignment method, device and code for inspections that compare an inspection image with a reference image and detect defects from their differences. In one embodiment an inspection image and a reference image are divided into multiple regions. An offset is calculated for each pair of regions. Out of these multiple offsets, only the offsets with high reliability are used to determine an offset for the entire image. This allows high-precision alignment with little or no dependency on pattern density or shape, differences in luminance between images, and uneven luminance within individual images. Also, detection sensitivity is adjusted as necessary by monitoring alignment precision.

Owner:HITACHI HIGH-TECH CORP

Process for producing lithium-containing composite oxide

ActiveUS20070264573A1Large volume capacity densityImprove securityNon-aqueous electrolyte accumulatorsElectrode thermal treatmentComposite oxideCharge and discharge

To provide a process for a lithium-containing composite oxide for a positive electrode for a lithium secondary battery, which has a large volume capacity density and high safety, and is excellent in the charge and discharge cyclic durability and low temperature characteristics. A process for producing a lithium-containing composite oxide represented by the formula LipNxMyOzFa (wherein N is at least one element selected from the group consisting of Co, Mn and Ni, M is at least one element selected from the group consisting of Al, alkaline earth metal elements and transition metal elements other than N, 0.9≦p≦1.2, 0.95≦x≦2.00, 0≦y≦0.05, 1.9≦z≦4.2 and 0≦a≦0.05), which comprises firing a mixture of a lithium source, an N element source, an M element source and if necessary, a fluorine source, characterized in that an aqueous solution having an M element source dissolved therein is mixed with an N element source powder or its pulverized product to form a slurry; if necessary after being pulverized, the slurry is dried for granulation to obtain a granulated product, which is mixed with a lithium source powder and if necessary, a fluorine source powder to obtain a mixture; and the mixture is fired at from 700 to 1,100° C. in an oxygen-containing atmosphere.

Owner:SUMITOMO CHEM CO LTD

Lithium Ion Rocking Chair Rechargeable Battery

InactiveUS20060234125A1Improve cycle lifeLower resistanceFinal product manufactureSecondary cellsLithiumElectrolysis

An electrochemical cell for a lithium ion rechargeable battery. The electrochemical cell comprises an anode including anode active material having a reduction potential of at least about 1.0 volt, a cathode including cathode active material having an oxidation potential of no more than about 3.7 volts, and an electrolyte separator separating the anode and the cathode.

Owner:BATHIUM CANADA

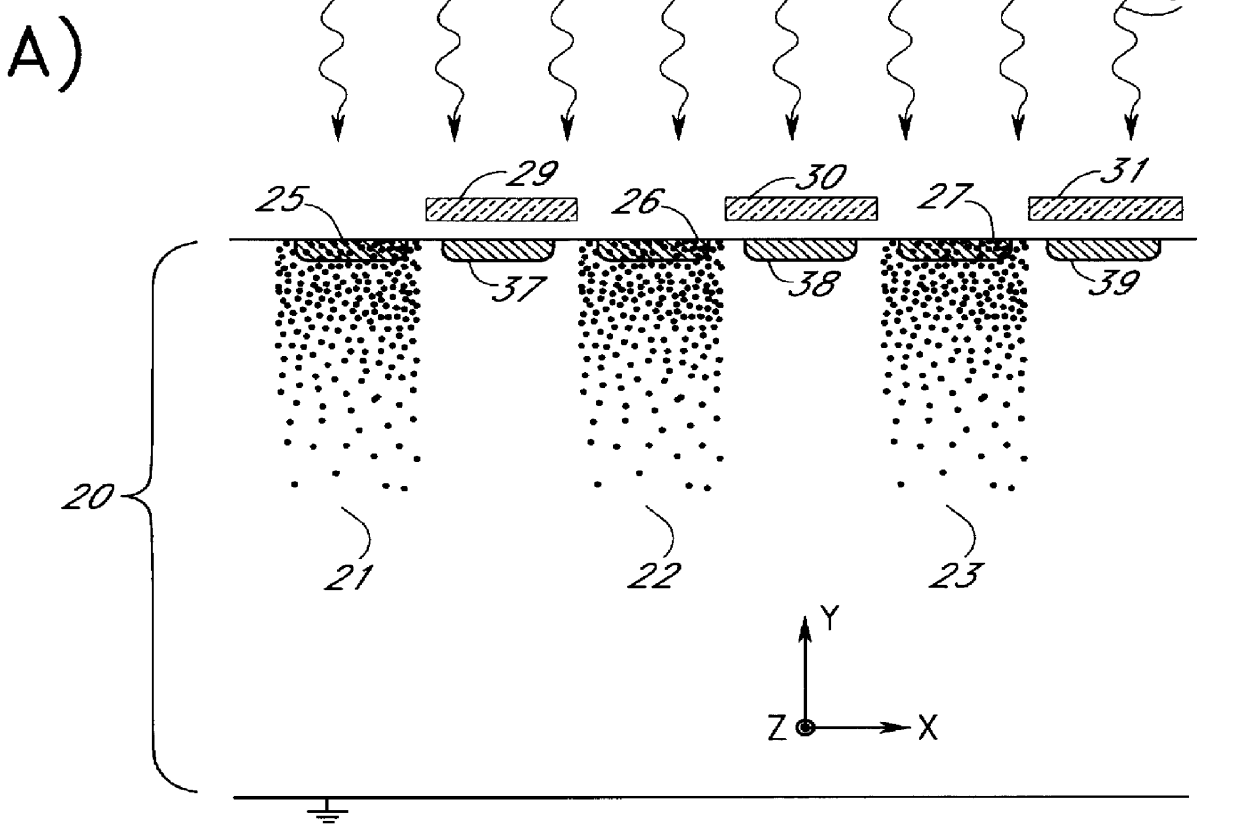

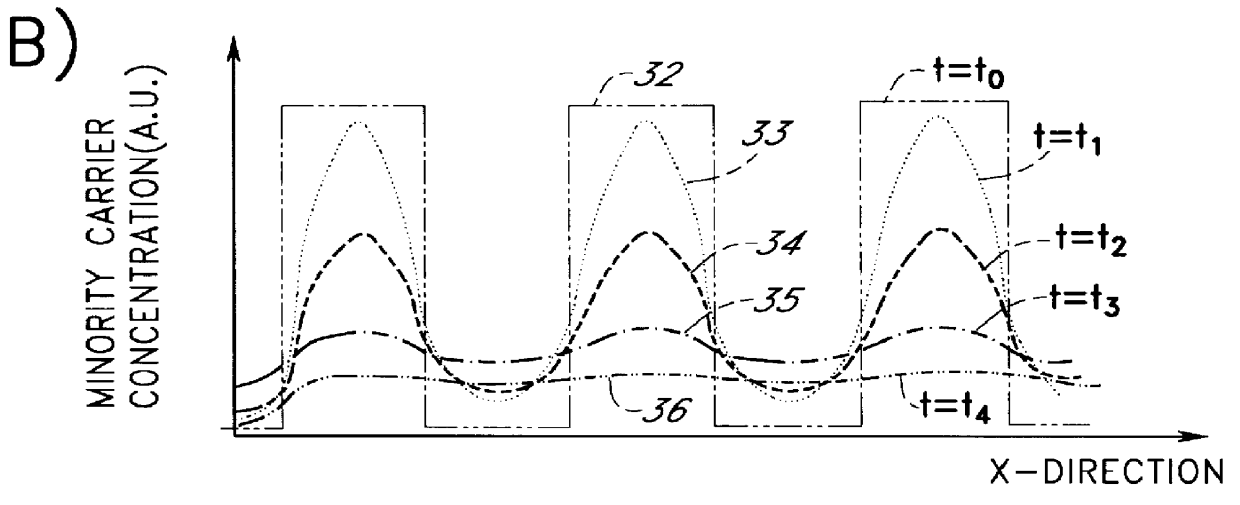

Spatially modulated detector for radiation

InactiveUS6157035AIncrease speedHigh speed detectionPhotometrySolid-state devicesFiberOptical detector

A novel radiation detector, a detection principle and an associated structure are provided for semiconductor substrate detectors in general and for CMOS based circuits in particular. For an optical detector, photons absorbed in the neutral zone of the substrate generate electron hole pairs that migrate by diffusion. A shadow mask gives a spatial modulation to the incident, and consequently, to the absorbed light in the semiconductor substrate. By measuring the magnitude of the spatial frequency component in the minority carrier distribution with a spatial frequency corresponding to that of the shadow mask, a fast detector is conceived. A shadow mask with higher spatial modulation frequency delivers a faster turn-off. The combination of a plurality of these detectors with an image fiber forms a basic system for constructing high-speed parallel optical interconnects between chips.

Owner:INTERUNIVERSITAIR MICRO ELECTRONICS CENT (IMEC VZW)

Galvanic element and method for the production thereof

InactiveUS20170054139A1Increase capacitanceLarge energy densitySolid electrolytesElectrode manufacturing processesMetallic lithiumElectrical conductor

A method for producing a galvanic element that includes the following steps: a) production of a layer sequence including, in this order, a current conductor assigned to an anode, an ion-conducting and electrically insulating separator, a cathode having lithium-containing cathode material, and a current conductor assigned to the cathode, and b) charging of the galvanic element, an anode including metallic lithium forming between the current conductor assigned to the anode and the separator during charging of the galvanic element. In addition, a battery cell including such a galvanic element, and a battery including a plurality of such battery cells, are also described.

Owner:ROBERT BOSCH GMBH

Process for producing lithium-containing composite oxide for positive electrode of lithium secondary battery

InactiveUS20080135802A1Large volume capacity densityImprove securityFuel cells groupingConductive materialComposite oxideSecondary stage

A process for producing a lithium-containing composite oxide having a large volume capacity density, high safety, excellent durability for charge / discharge cycles, and further, excellent low temperature characteristics, which is suitable for mass production, is provided.A process for producing a lithium-containing composite oxide represented by a general formula LipNxMyOzFa (wherein N is at least one type of element selected from the group consisting of Co, Mn and Ni, M is at least one type of element selected from the group consisting of Al, an alkali earth metal element and a transition metal element other than N, 0.9≦p≦1.2, 0.97≦x≦1.00, 0<y≦0.03, 1.9≦z≦2.2, x+y=1 and 0≦a≦0.02), the process comprising a step of firing a blended product containing a lithium source, an N element source, an M element source and, as the case requires, a fluorine source in an oxygen-containing atmosphere;wherein as the N element source and the M element source, a product produced by impregnating a solution containing the M element source into a powder containing the N element source and drying them, is employed, and as the above firing, a first-stage firing at from 250 to 700° C. is applied and a second-stage firing at from 850 to 1,100° C. is subsequently applied to the fired product of the first-stage firing.

Owner:AGC SEIMI CHEM CO LTD

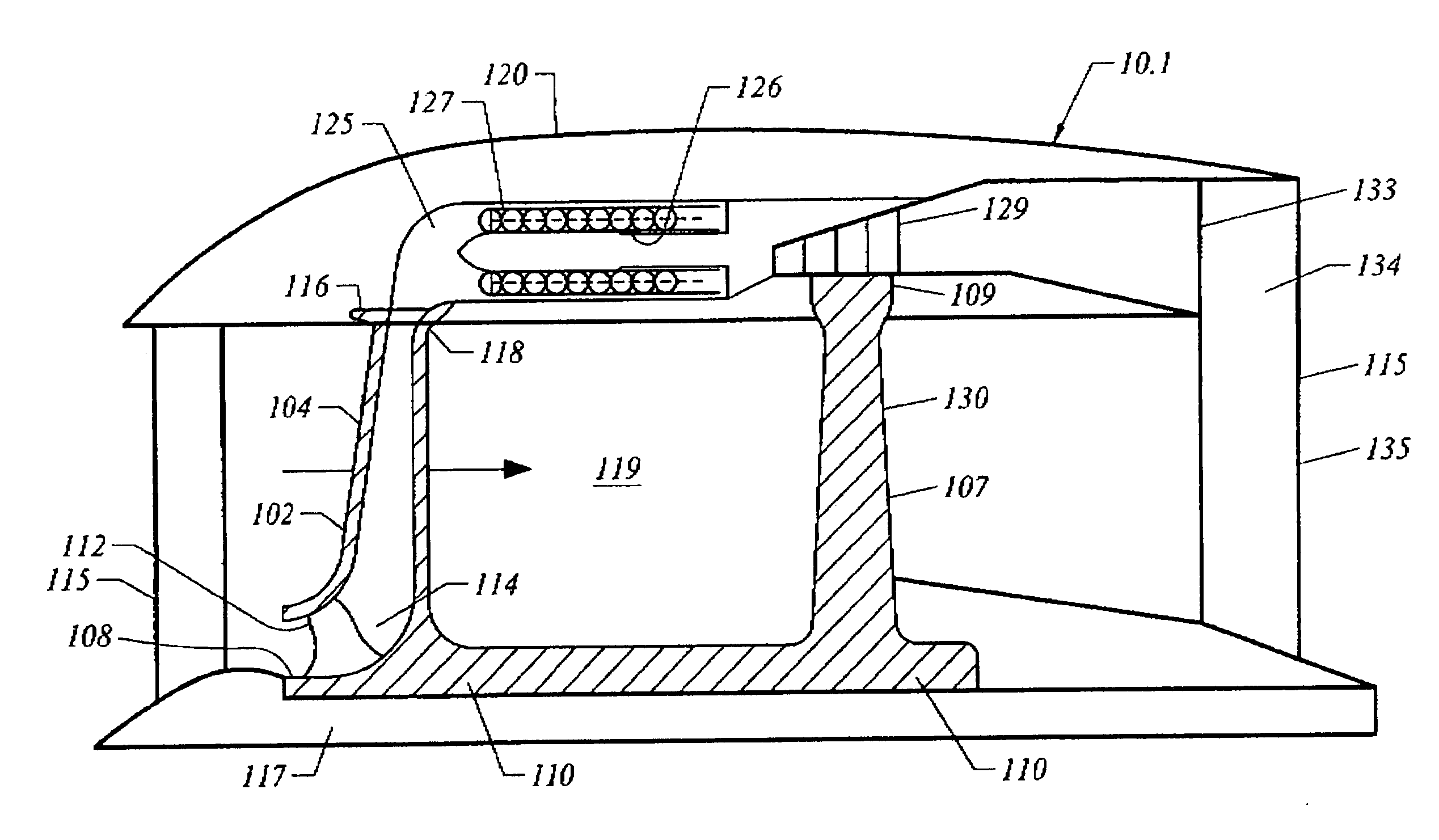

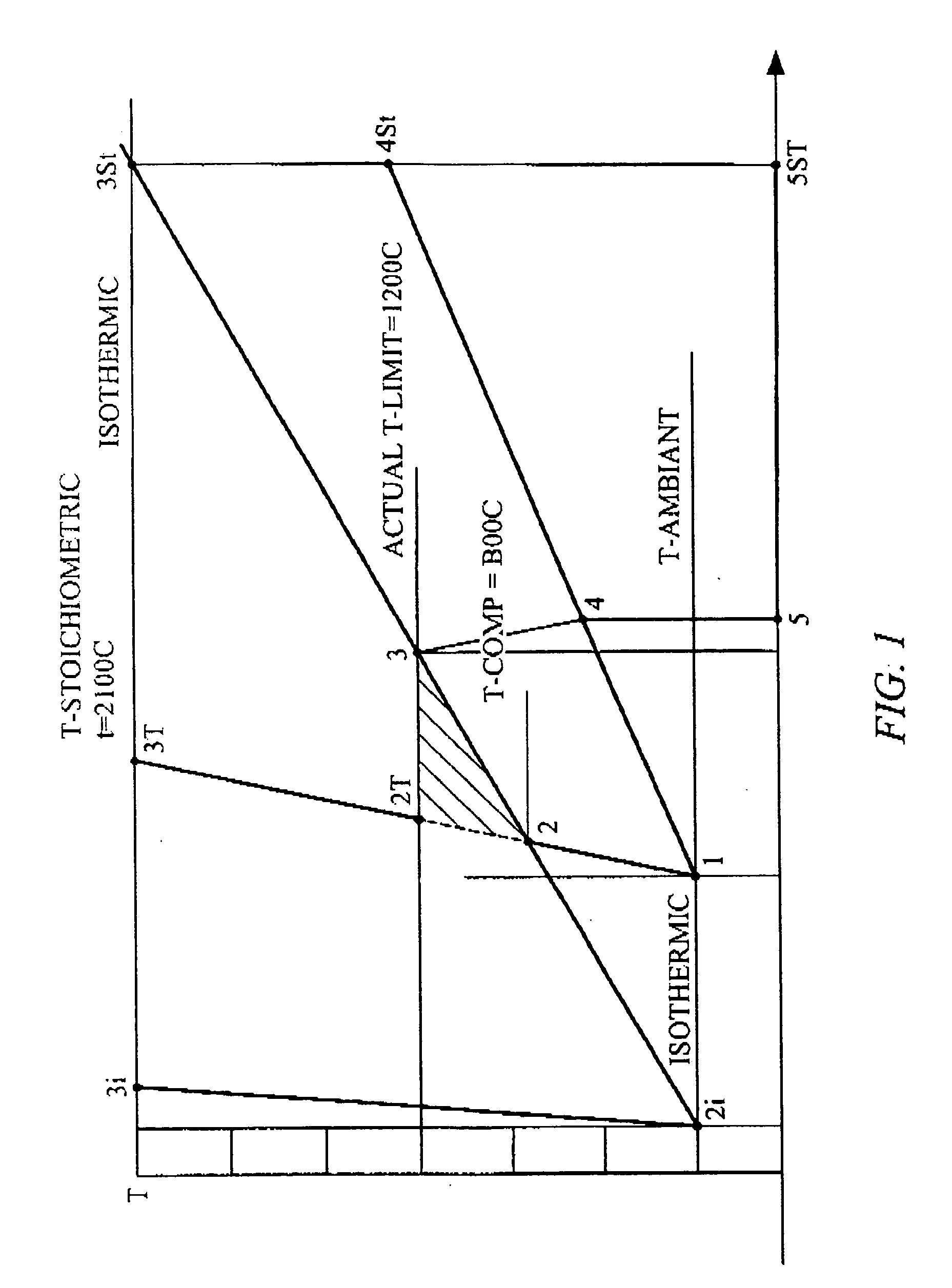

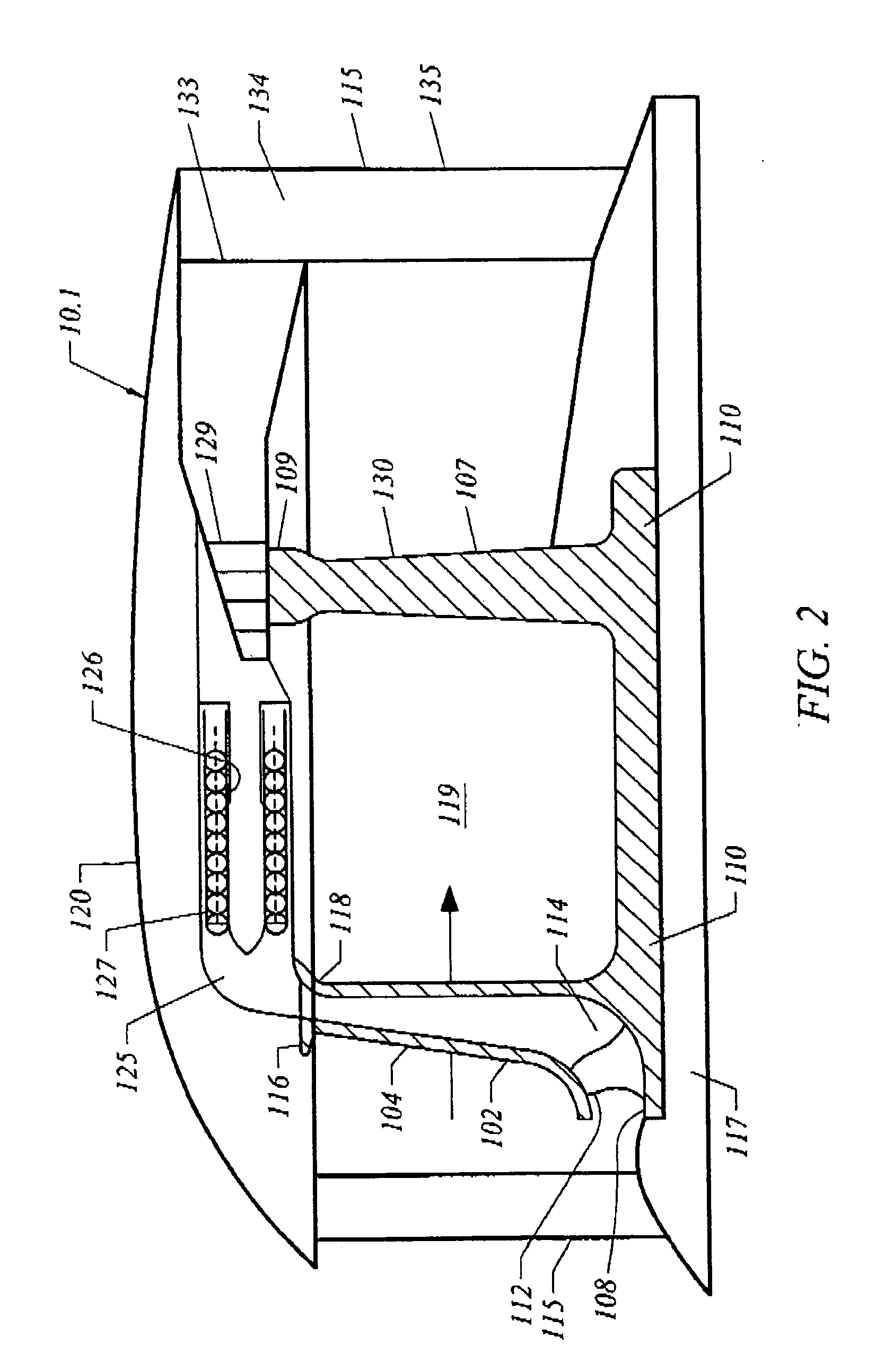

Universal Carnot propulsion systems for turbo rocketry

InactiveUS20060086078A1Maximum efficiencyLarge rangeWorking fluid for enginesGas turbine plantsJet engineCombustion

Turbofan jet engines utilizing the Carnot cycle for improved performance with isothermal compression of combustion air and, in part, isothermal expansion of thermally heated air, the engines having a turbofan compressor rotor with hollow fan blades in a core bypass passage through the engine and an annular, peripheral thermal chamber with staged turbine blades in an expansion chamber where heated gases are supplied to multiple stages to maintain peak temperatures.

Owner:PAUL MARIUS A

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com