Patents

Literature

121 results about "Maximum power density" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

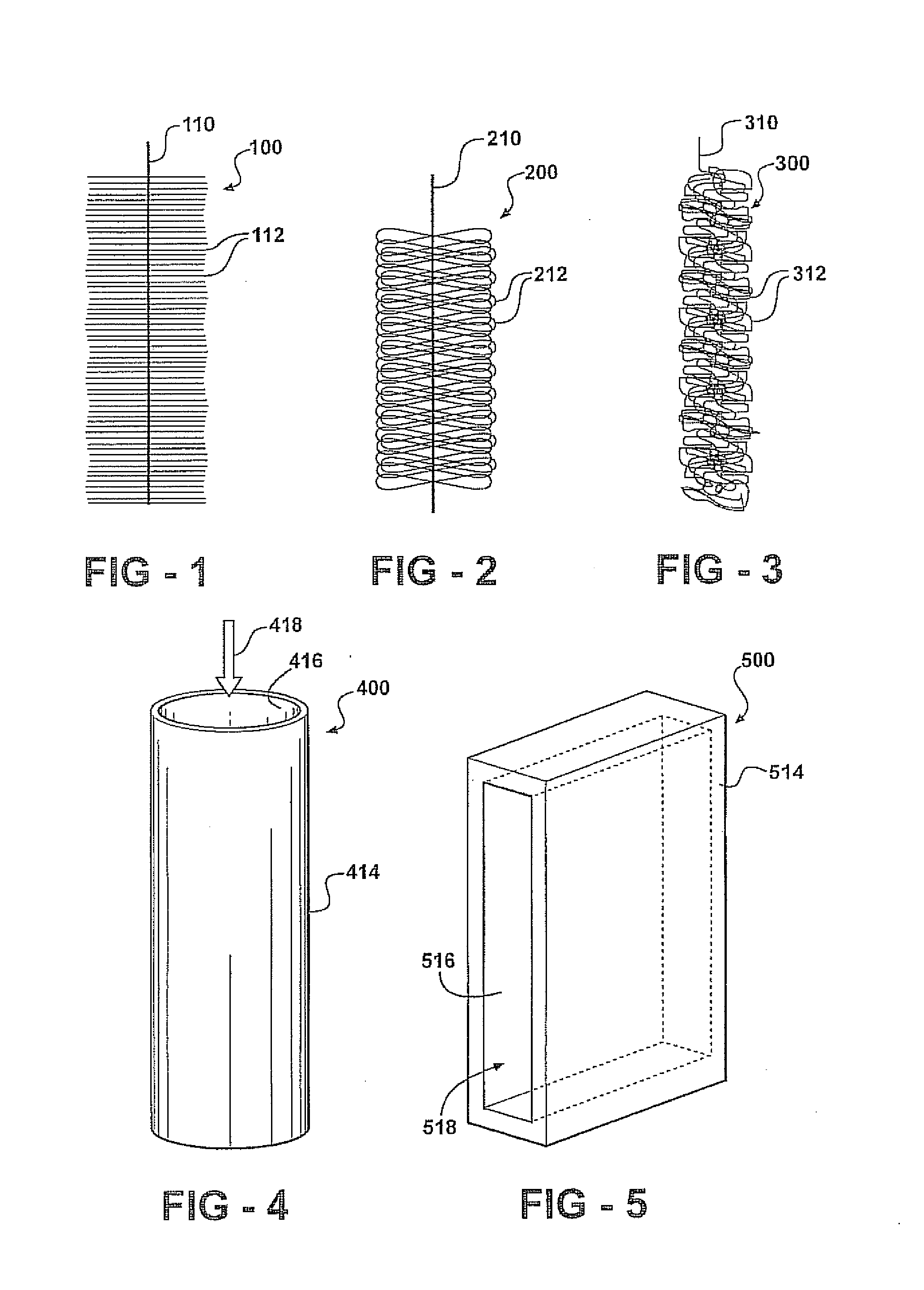

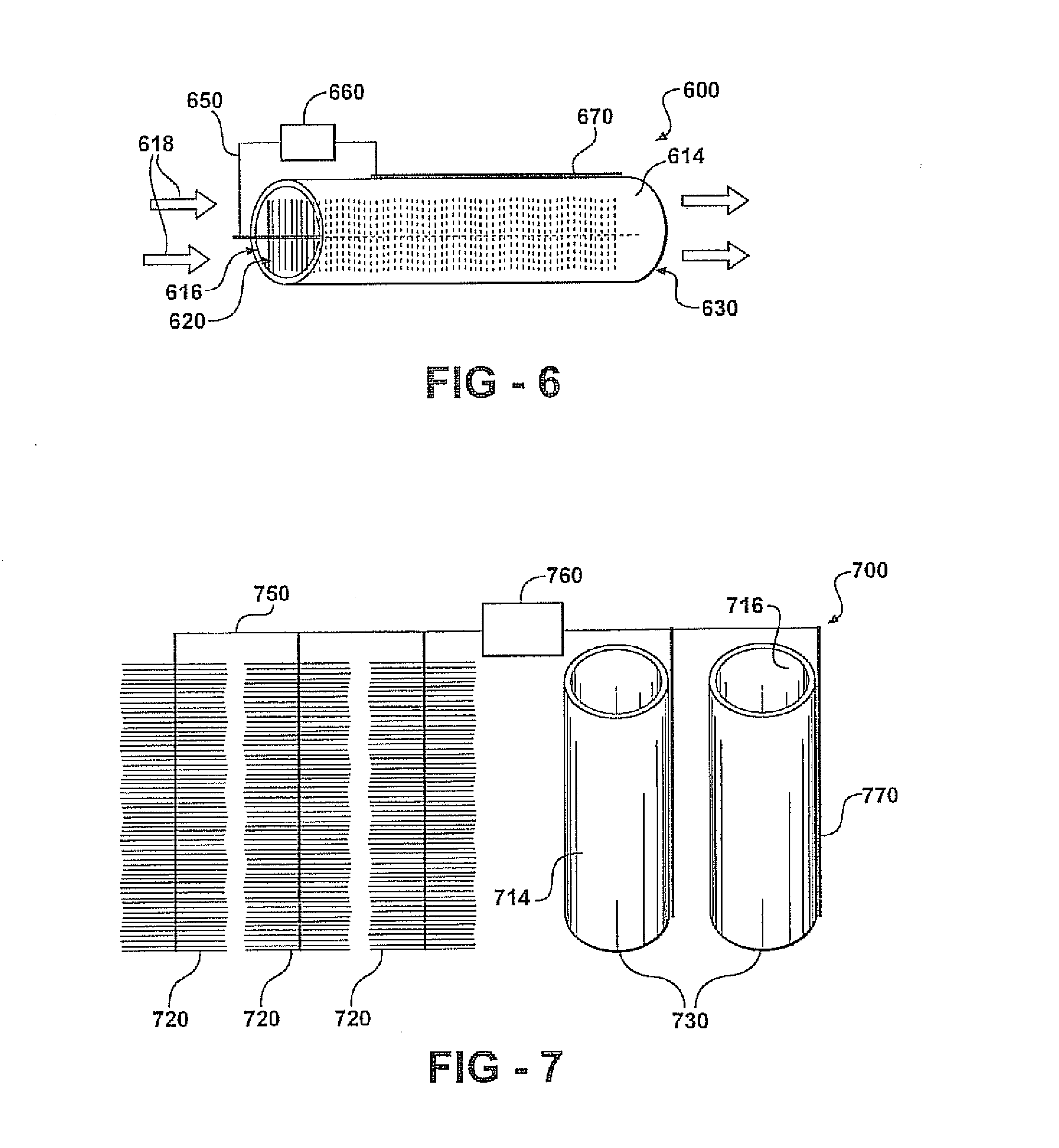

Electrodes and methods for microbial fuel cells

InactiveUS20080292912A1Raise the potentialImprove performanceTreatment by combined electrochemical biological processesCell electrodesMicrobial fuel cellFuel cells

Methods of improving a performance parameter of a microbial fuel cell are provided according to embodiments of the present invention which include heating an electrode and exposing the heated electrode to ammonia gas to produce a treated electrode characterized by an increased positive surface charge on the electrode surface. Improved performance parameters include increased maximum power density, increased coulombic efficiency, increased volumetric power density and decreased microbial fuel cell operation time to achieve maximum power density

Owner:PENN STATE RES FOUND

Electrodes and methods for microbial fuel cells

InactiveUS20100151279A1Raise the potentialImprove performanceTreatment by combined electrochemical biological processesCell electrodesMicrobial fuel cellFuel cells

Methods of improving a performance parameter of a microbial fuel cell are provided according to embodiments of the present invention which include heating an electrode and exposing the heated electrode to ammonia gas to produce a treated electrode characterized by an increased positive surface charge on the electrode surface. Improved performance parameters include increased maximum power density, increased coulombic efficiency, increased volumetric power density and decreased microbial fuel cell operation time to achieve maximum power density

Owner:PENN STATE RES FOUND

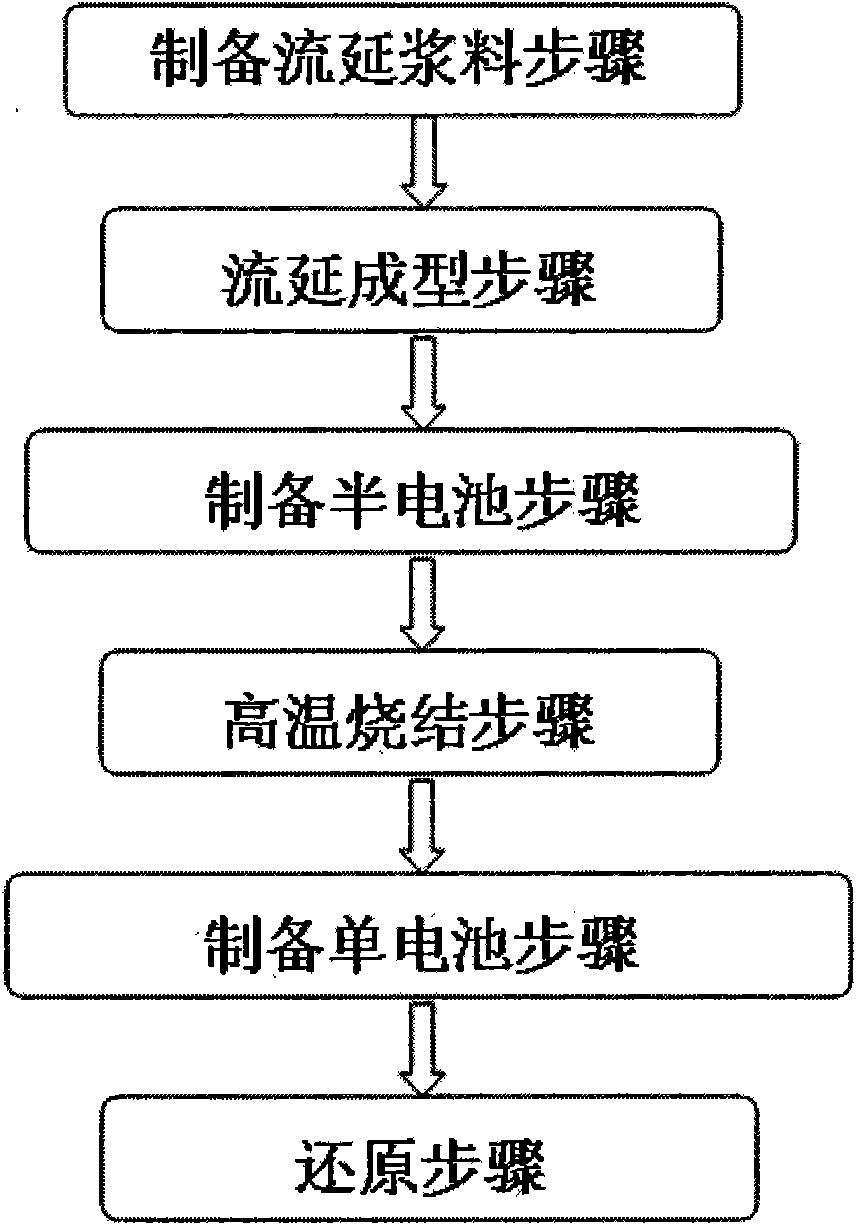

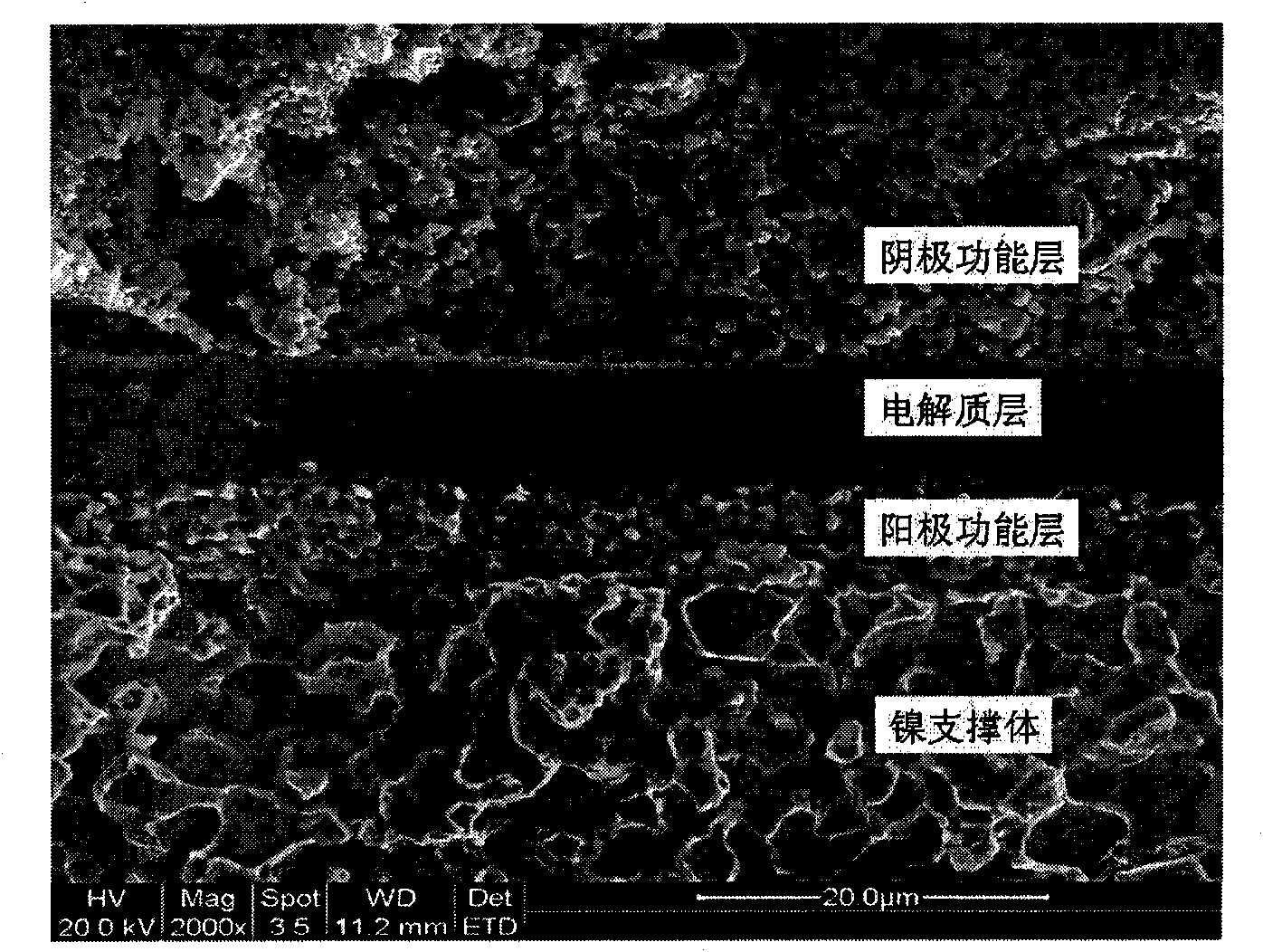

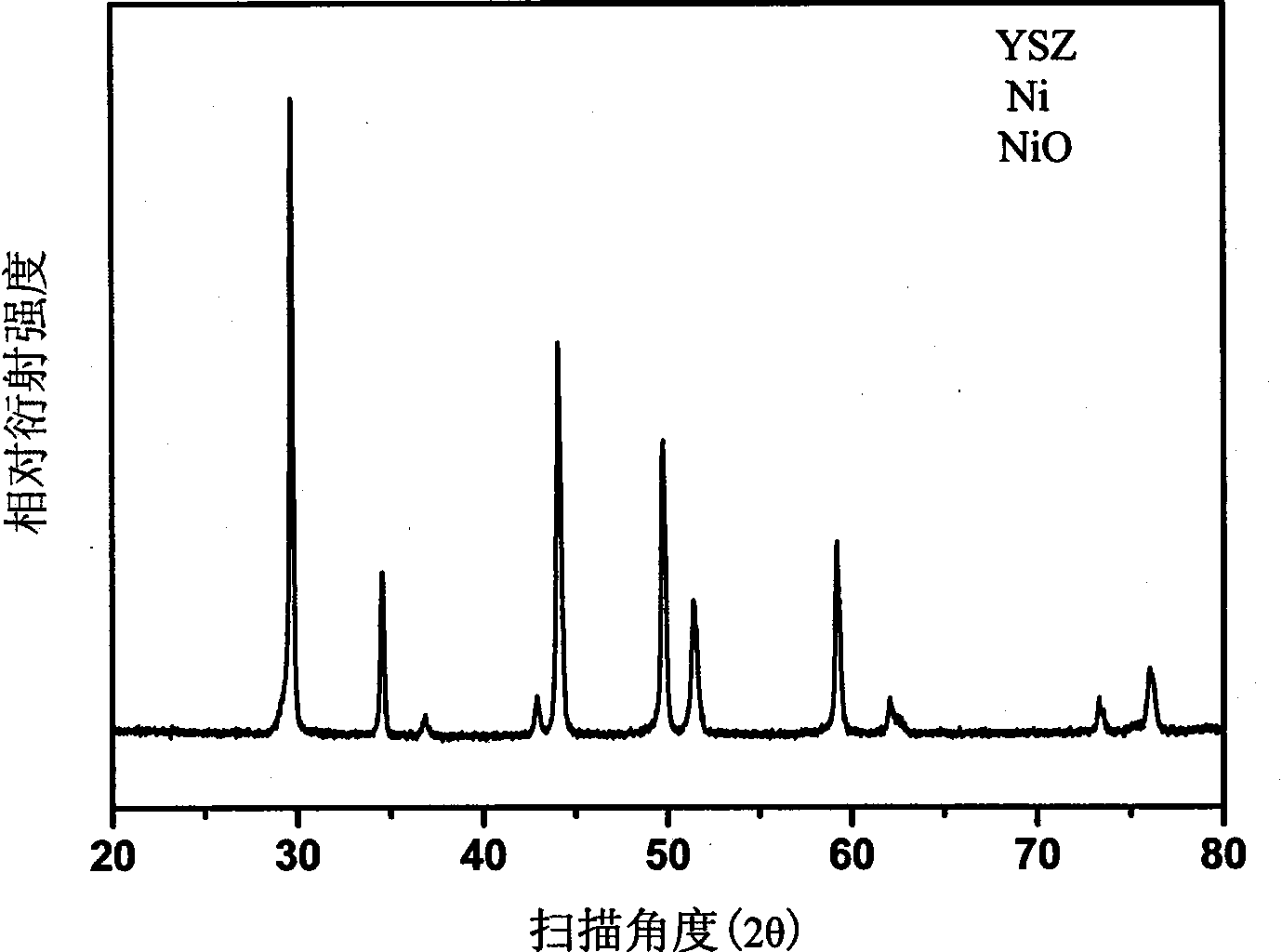

Method for preparing metallic support type solid oxide fuel cell

InactiveCN101562255AAvoid defects such as crackingAvoid cathodic activity reductionFinal product manufactureSolid electrolyte fuel cellsFuel cellsSlurry

The invention provides a method for preparing a metallic support type solid oxide fuel cell, and belongs to a method for preparing a solid oxide fuel cell (SOFC). The invention aims to simplify process, lower cost and prepare the fuel cell with excellent electric property. The method comprises the following steps: (1) a tape casting slurry preparation step; (2) a tape casting formation step; (3) a half cell preparation step; (4) a high-temperature sintering step; (5) a monocell preparation step; and (6) a reducing step. The method has the advantages of wide raw material source, simple preparation process and low cost; and the open-circuit voltage of the prepared SOFC, which is measured at a temperature of 750 DEG C, is 1.01V, the maximum power density is 0.64w / cm, so that the SOFC can be applied to the preparation of the large-area metallic support type solid oxide fuel cell.

Owner:中博源仪征新能源科技有限公司

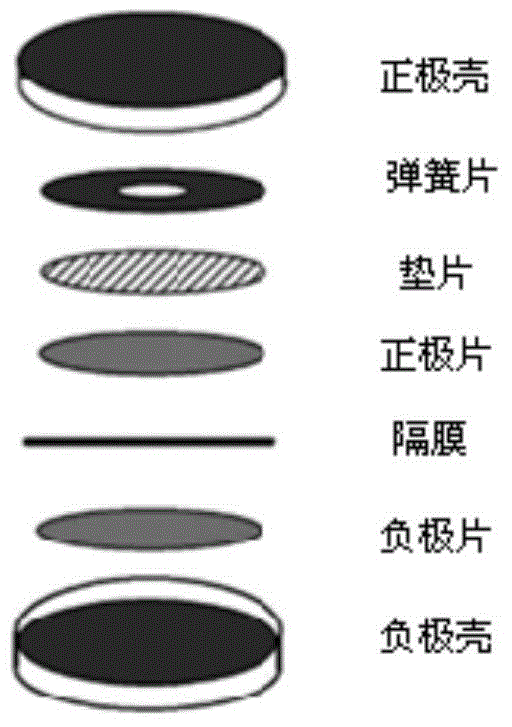

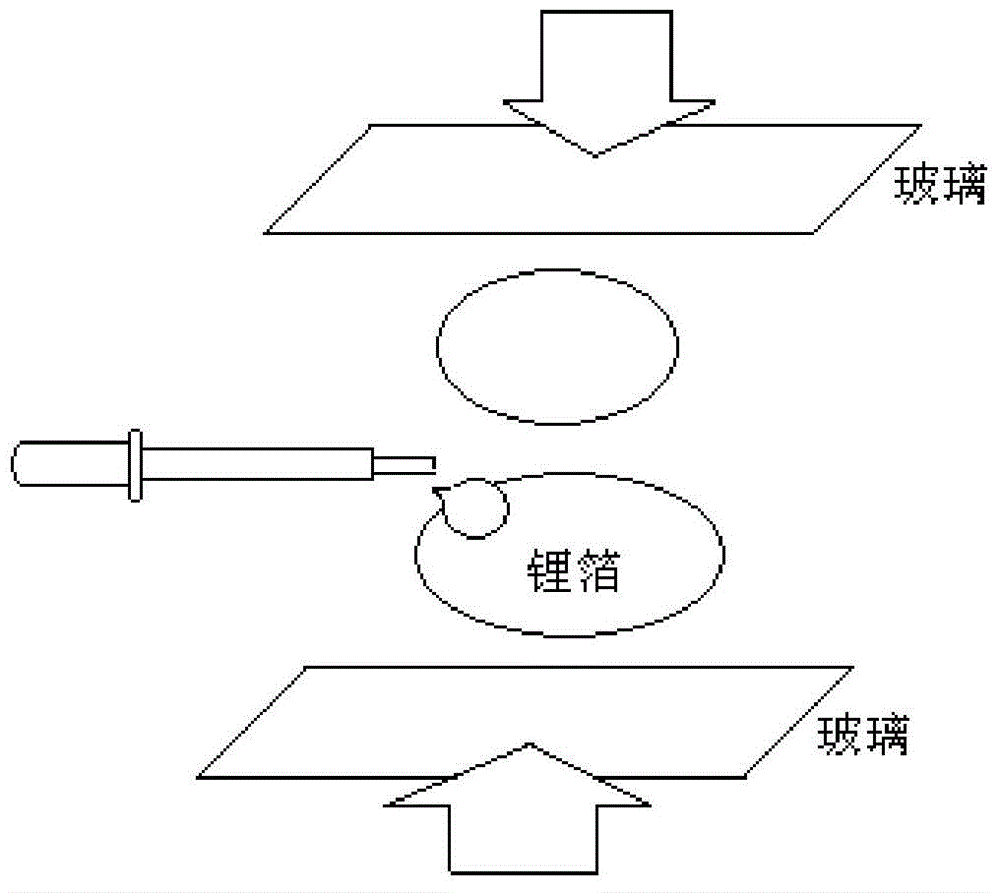

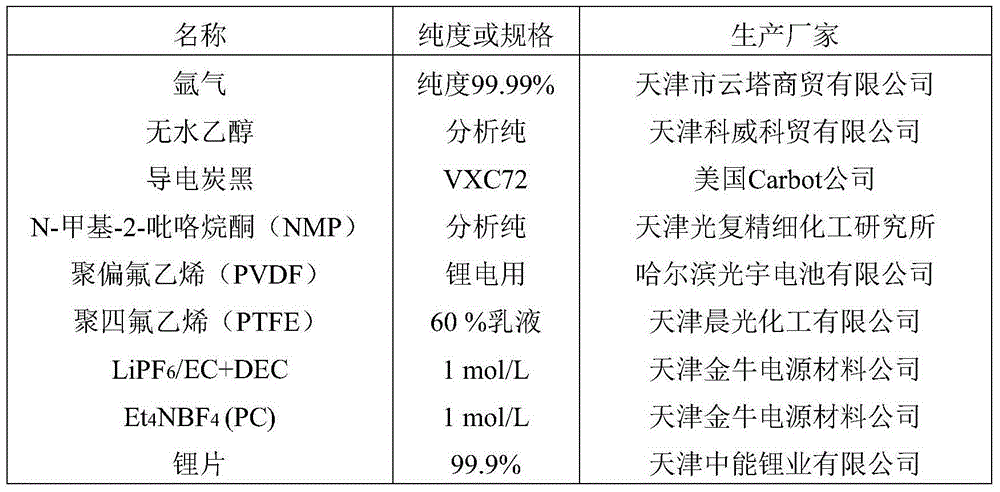

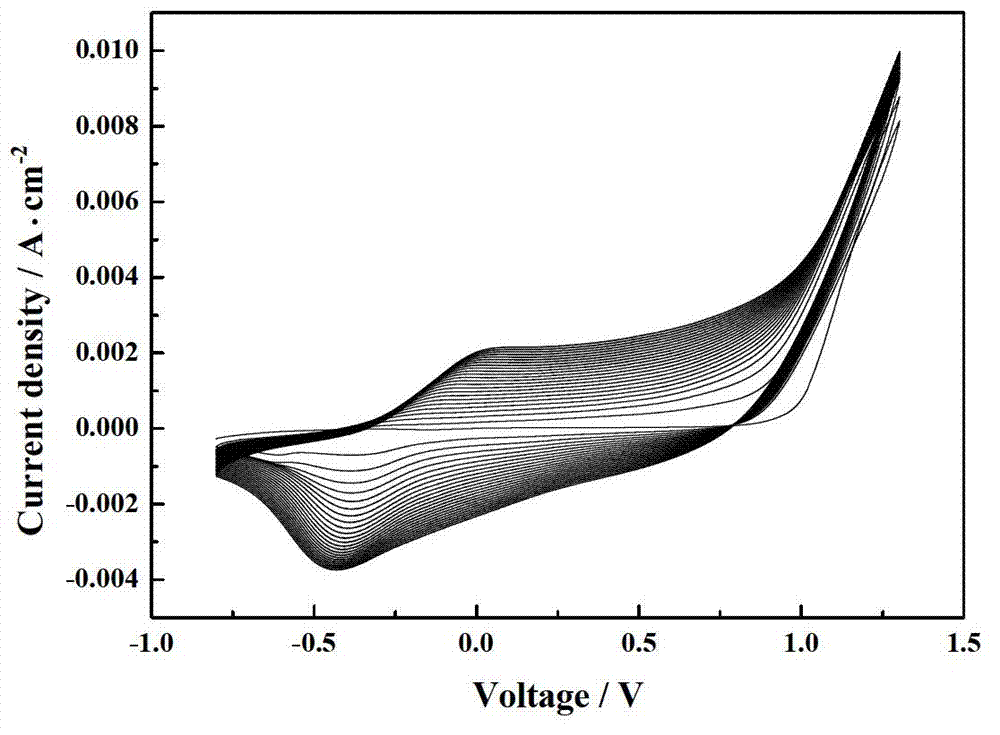

Preparation method of lithium ion capacitor (LIC) adopting pre-lithiation hard carbon negative electrode

InactiveCN104538194ALower impedanceImprove performanceDouble layer capacitorsHybrid/EDL manufactureActivated carbonHigh energy

The invention discloses a preparation method of a lithium ion capacitor (LIC) adopting a pre-lithiation hard carbon negative electrode. Commercial activated carbon serves as a positive electrode, hard carbon serves as the negative electrode and 1M LiPF6 / EC+DEC serves as an electrolyte to assemble the LIC. The embedded lithium volume of the LIC is 400 mAh / g, the highest energy density and power density are 76.5 Wh / kg and 5.1 kW / kg respectively, and the energy keeping rate can still be as high as 92.0 percent after 1000 times of circulation. The energy density of the LIC after 15 hours of pre-lithiation can reach 97.2 Wh / kg, and small impedance and good circulation performance are achieved (after 1000 times of circulation at the current density of 1A / g, the energy keeping rate is 91.2 percent). When the mass proportion of the positive electrode and the negative electrode is 2.2, the energy keeping rate is 57.0 percent. Meanwhile, the LIC has quite small charge transfer internal resistance (10.4), and the maximum energy density and the maximum power density are 88.7 Wh / kg and 12 kW / kg.

Owner:TIANJIN UNIV

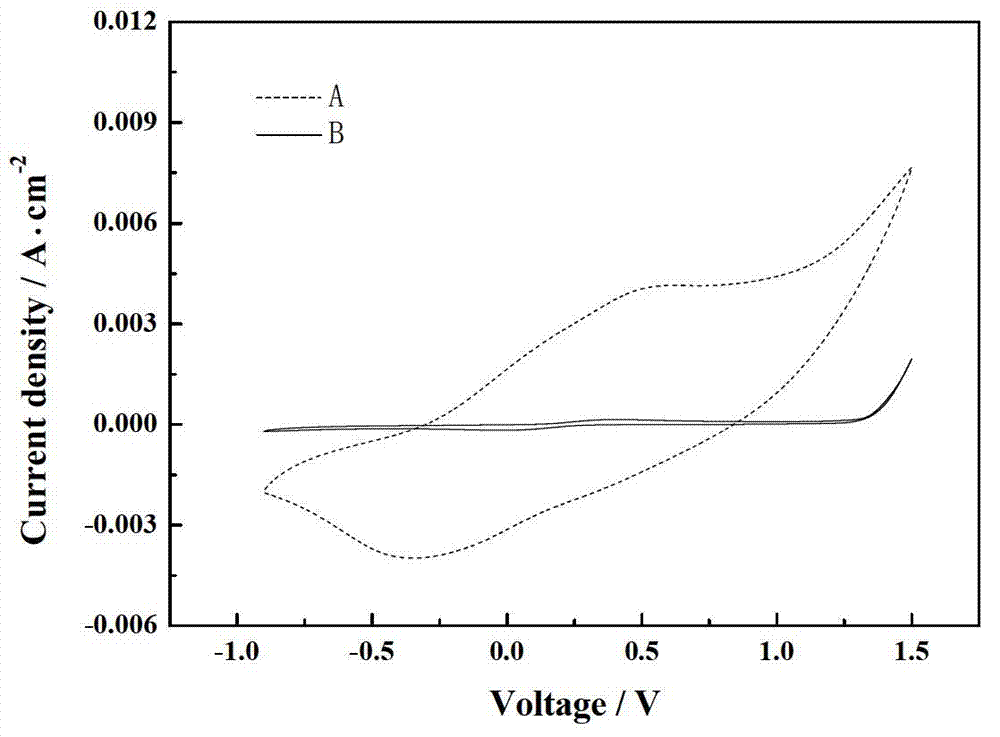

Preparation method of composite anode of microbial fuel cell with carbon-base material modified by conductive complex

InactiveCN102780010AReduce usageReduce production processCell electrodesSupporting electrolyteInternal resistance

The invention relates to a preparation method of a composite anode of a microbial fuel cell with a carbon-base material modified by a conductive complex. The preparation method comprises purifying a multi-wall carbon nanotube; placing the purified multi-wall carbon nanotube into a 0.1 to 0.5mol / L supporting electrolyte solution, and dispersing the carbon nanotube in the solution, with 5% to 20% of carbon nanotube; adding 3,4-ethylenedioxythiophene monometers into the solution to obtain a well-dispersed 3,4-ethylenedioxythiophene / multi-wall carbon nanotube suspending solution; electrically depositing a complex on the anode surface by cyclic voltammetry; and carrying out vacuum drying, washing with deionized water, and room-temperature airing in sequence to obtain the modified anode. The method provided by the invention can reduce use amount of toxic reactants and shorten the preparation process so as to save the preparation cost. The modified anode has the advantages of peculiar surface effect, good conductivity and electrochemical activity, is remarkably improved in the maximum power density and open-circuit voltage in comparison with the unmodified anode when used in a battery, and can greatly reduce the battery internal resistance.

Owner:QINGDAO UNIV OF SCI & TECH

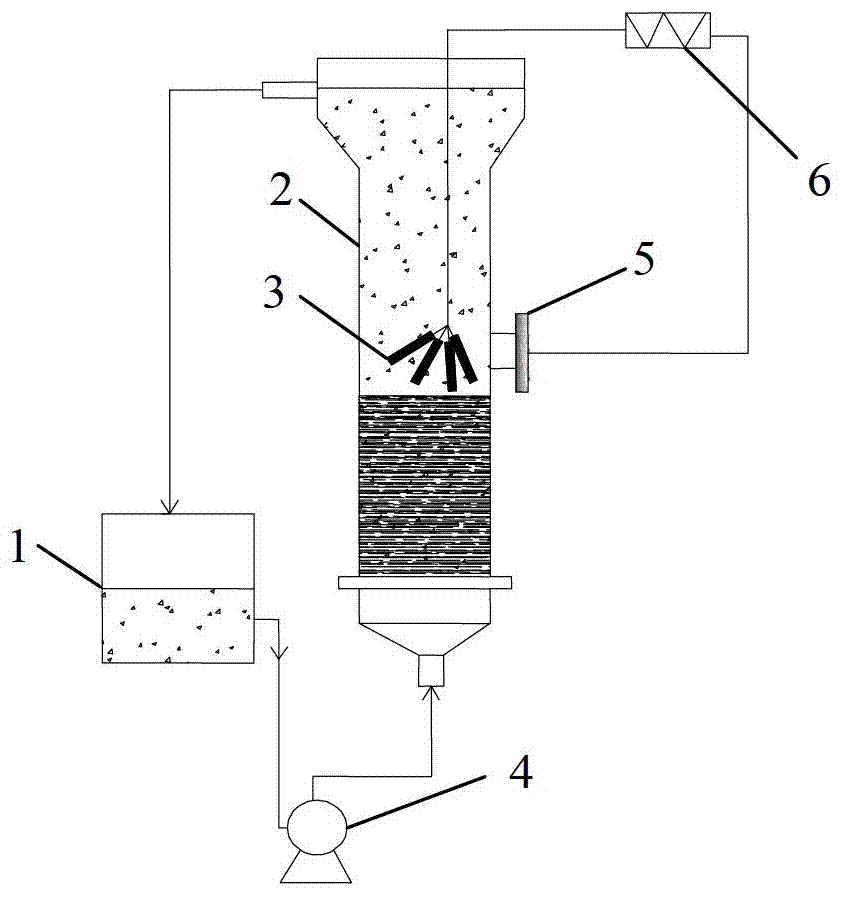

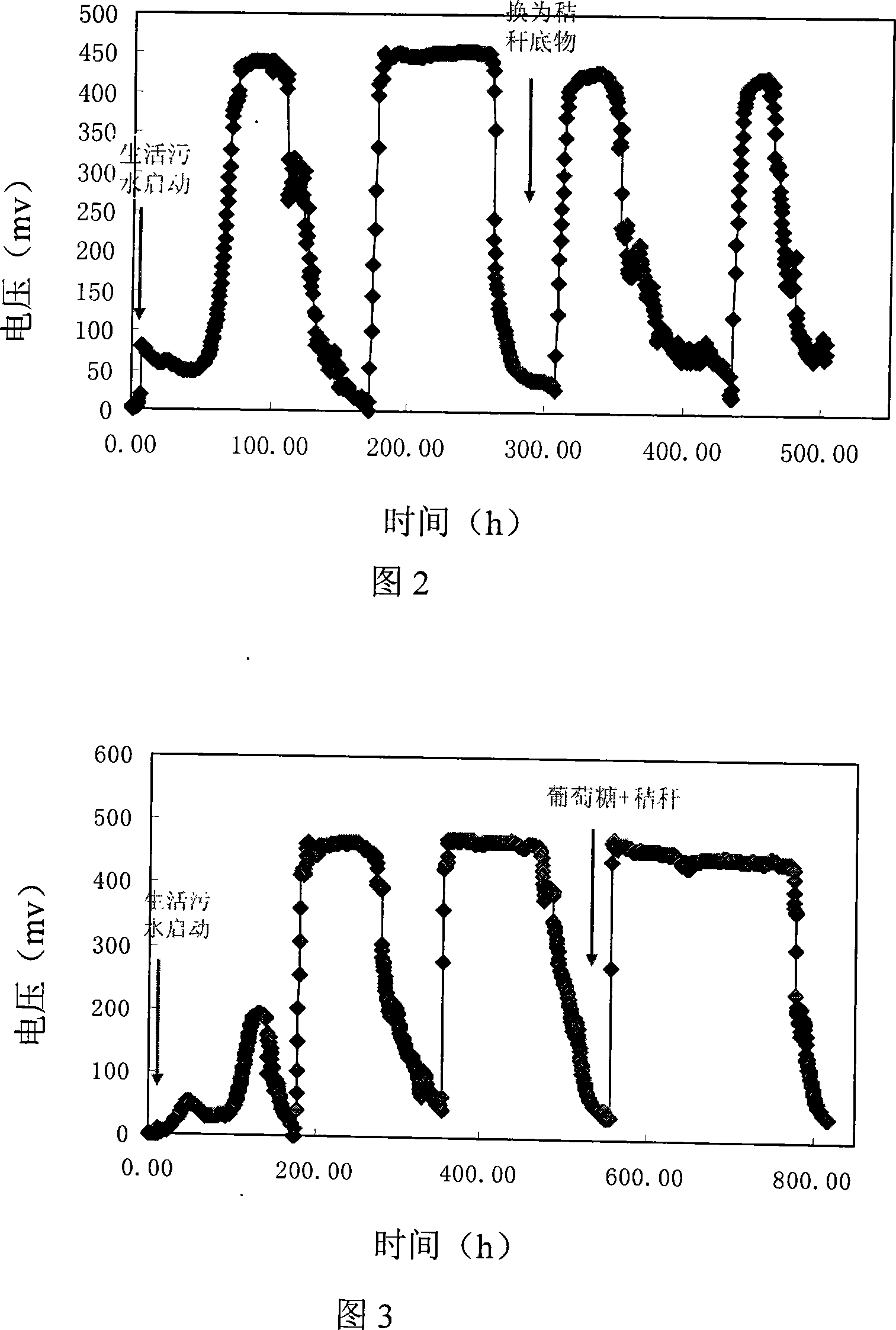

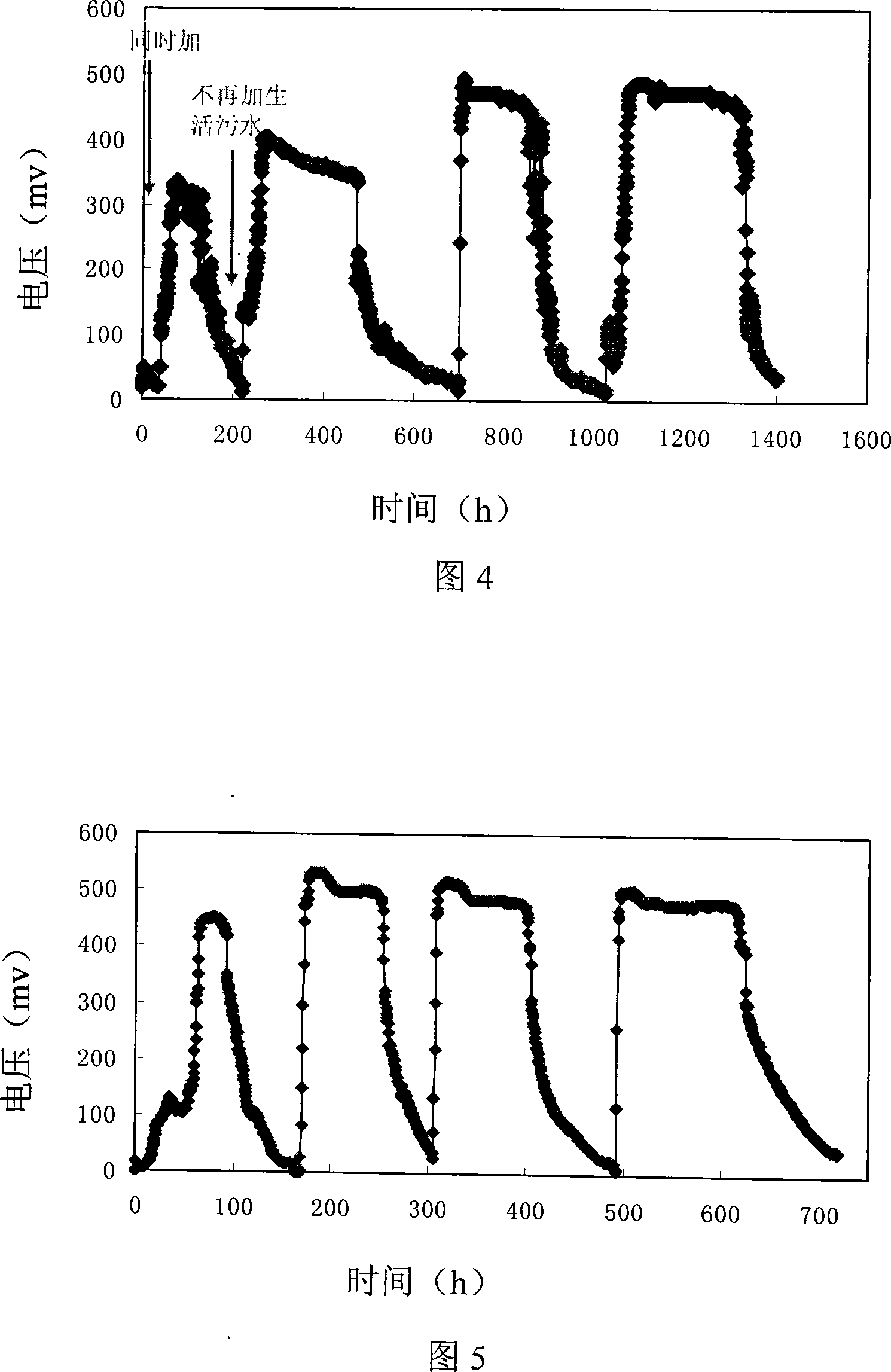

Method for microbe fuel battery and power generation by using straw stalk

InactiveCN101188306ADoes not affect mass transferImprove efficiencyBiochemical fuel cellsElectricityFuel cells

A microbiological fuel cell and a method for generating electricity by use of straws relate to a fuel cell and a method for generating electricity. The invention solves the problem that crop straws are not used efficiently, and particularly straw solids are not directly used in MFC. The microbiological fuel cell of the invention is composed of a container, catalytic anodes, anode wires, air cathodes, cathode wires, a cathode cover and a sealing cover. The method of the invention includes the steps of the pretreatment of the straws, the detoxifying treatment of the straws to obtain a straw solid substrate and a straw liquid substrate, the start-up of the cell, the treatment of the straw solid substrate or the straw liquid substrate. When the electricity is generated by the invention by using the straw solid substrate, the maximum power of the cell reaches 502mW / m<2>, and the degradation rate is about 45percent. When the electricity is generated by using the straw liquid substrate, the maximum power reaches 1288m W / m<2>, and the degradation rate of COD is 60 percent. The invention has the advantages of simple technology, convenient operation, high efficiency, no pollution, reduction of cost and relief of the energy crisis, and the straws in rural areas can be used efficiently.

Owner:HARBIN INST OF TECH

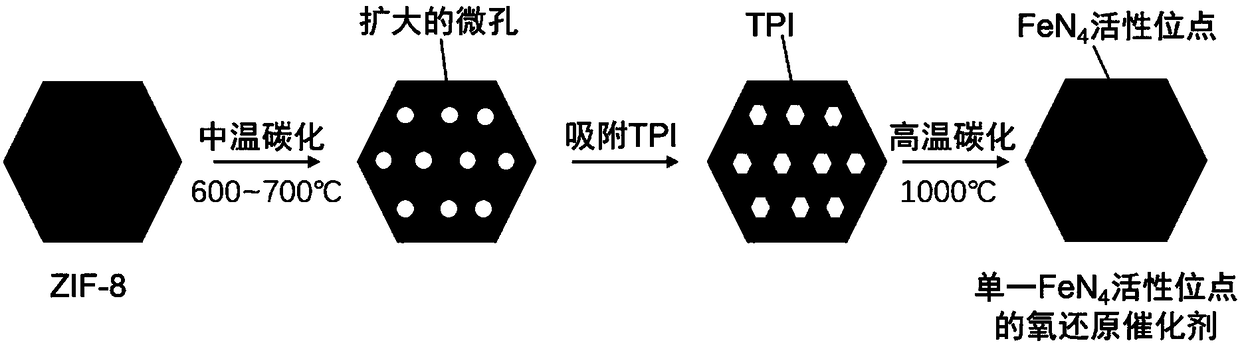

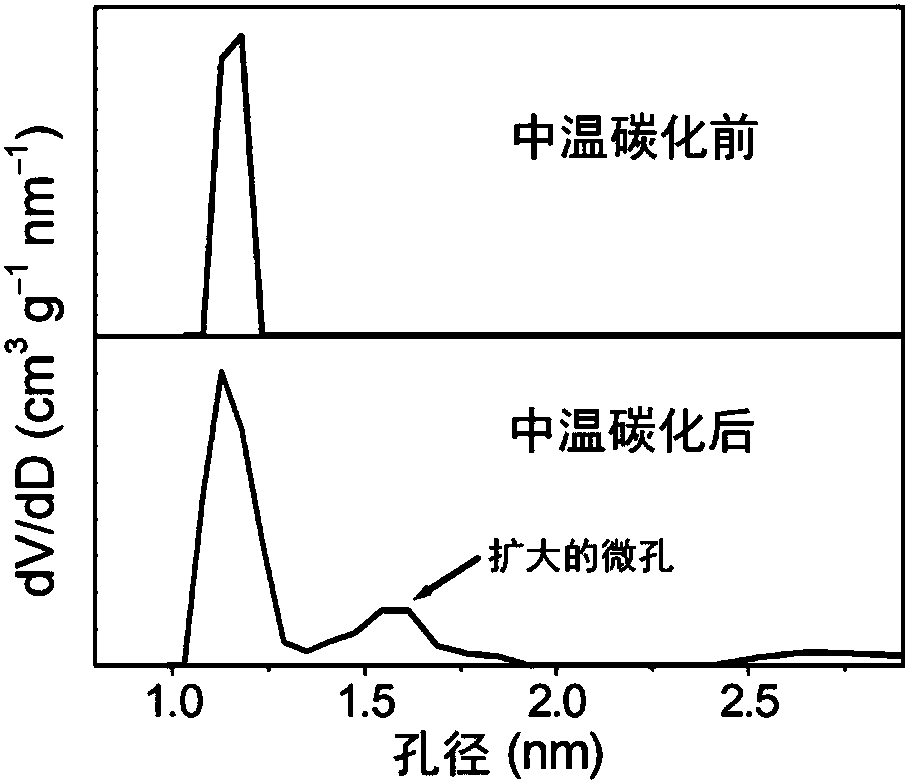

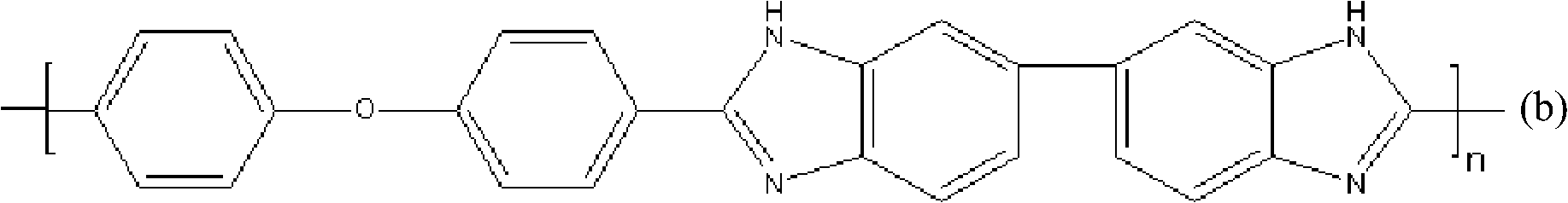

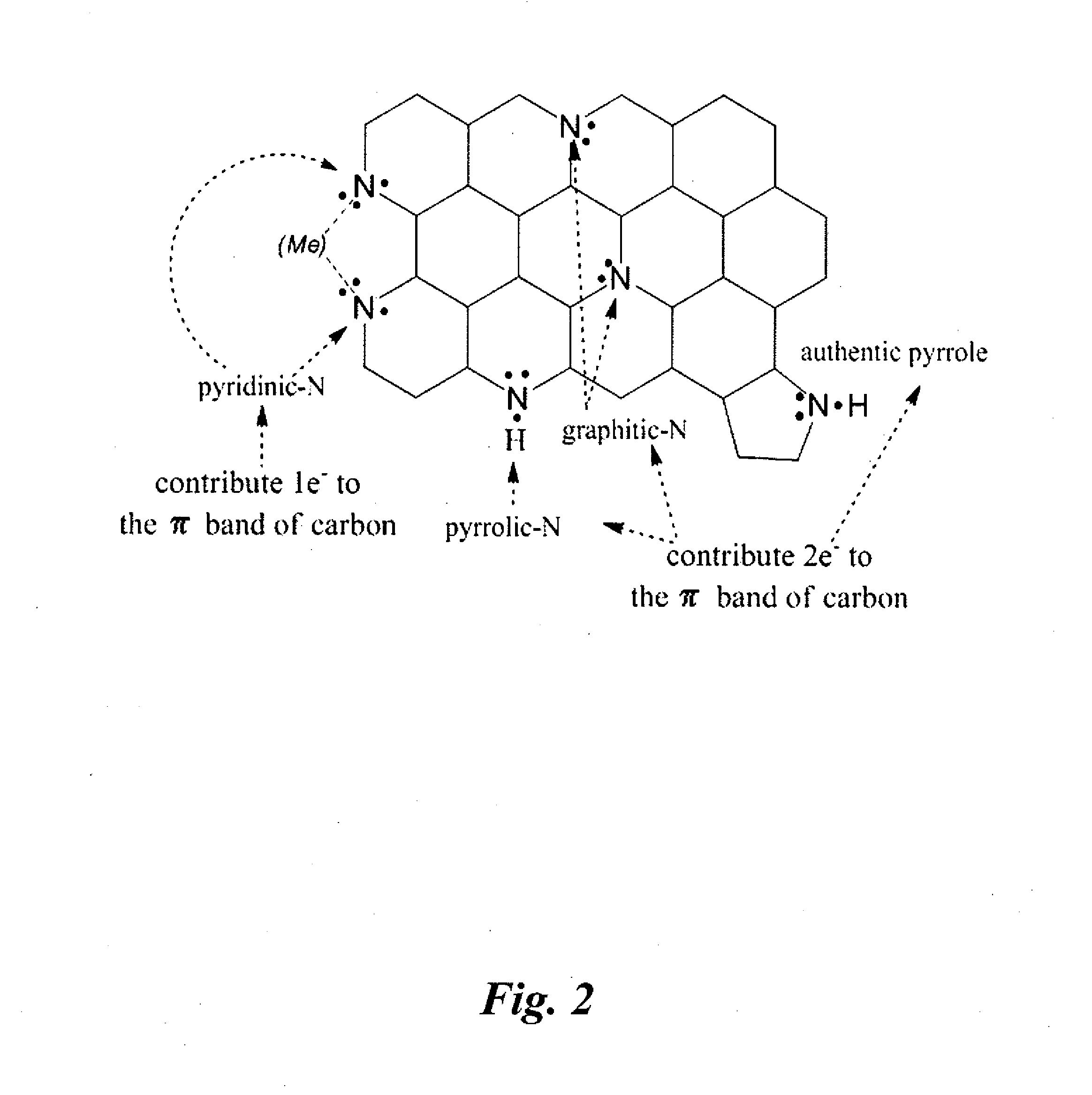

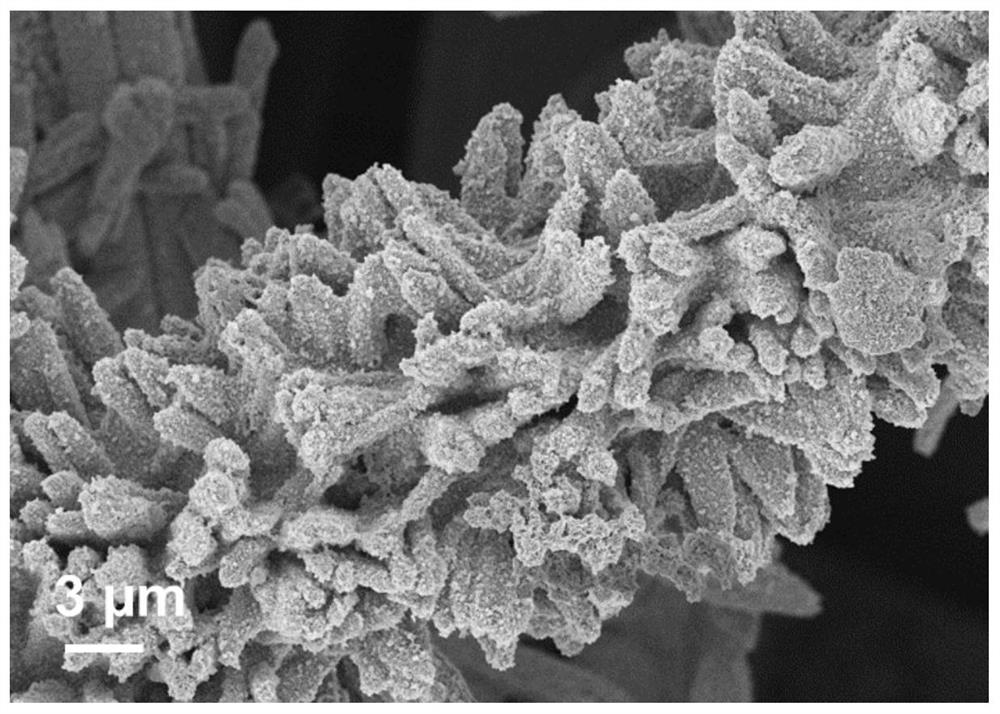

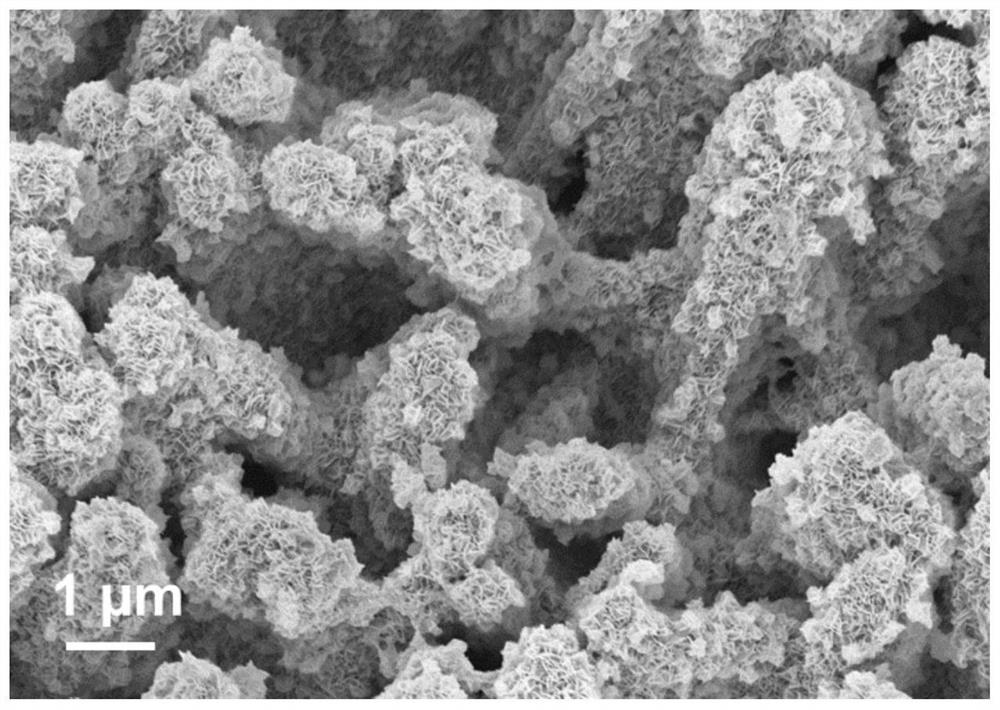

Preparation for high-activity iron nitrogen carbon catalyst by adopting middle-temperature carbonized metal framework compound pore expanding technology

InactiveCN108232209AUniform adsorptionSimple processMaterial nanotechnologyCell electrodesMetal frameworkCarbonization

The invention discloses preparation for a high-activity iron nitrogen carbon catalyst by adopting a middle-temperature carbonized metal framework compound pore expanding technology and belongs to thetechnical field of electrocatalysis. The preparation comprises the following steps: firstly, dispersing middle-temperature carbonized ZIF-8 nanoparticles into de-ionized water; adding a TPI water solution; carrying out ultrasonic treatment to uniformly adsorb, so as to adsorb [Fe(Phen)3]<2+> with positive charges into an expanded micro-pore to form a range-limited [Fe(Phen)3]<2+>@ZIF precursor; finally, carrying out high-temperature carbonization to obtain the high-activity iron nitrogen carbon catalyst provided by the invention. The high-activity iron nitrogen carbon catalyst is composed of three elements including Fe, N and C; the Fe and the N form a Fe-N4 ligand and the Fe-N4 ligand is embedded into a N-doped C matrix. The preparation disclosed by the invention has the advantages of simple technology, abundant raw materials and convenience for large-scale production. By adopting the preparation disclosed by the invention, an oxygen reduction catalyst with a single FeN4 active site is prepared and has excellent oxygen reduction activity under an acidic condition; the half-wave potential can reach 0.82V; compared with performance of a commercial Pt / C catalyst, the maximum power density of the high-activity iron nitrogen carbon catalyst in a proton exchange membrane fuel cell can reach 800mW cm<-2>.

Owner:BEIHANG UNIV

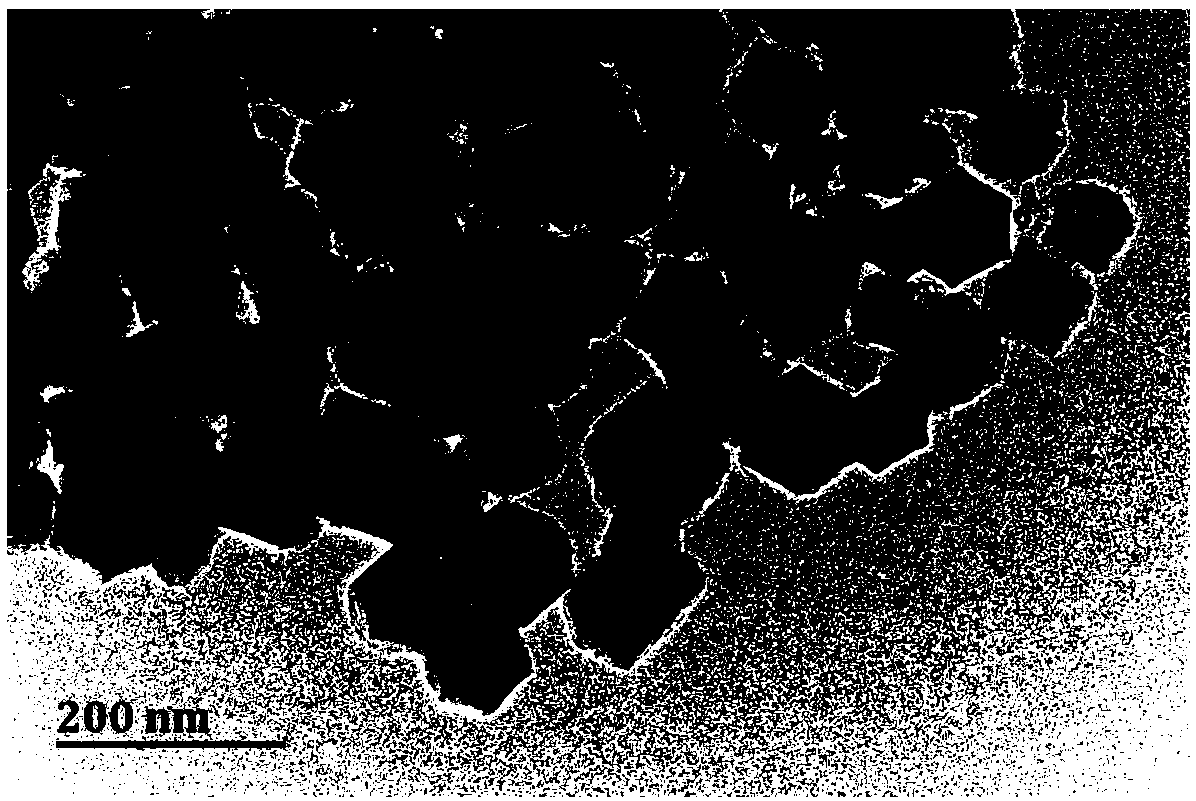

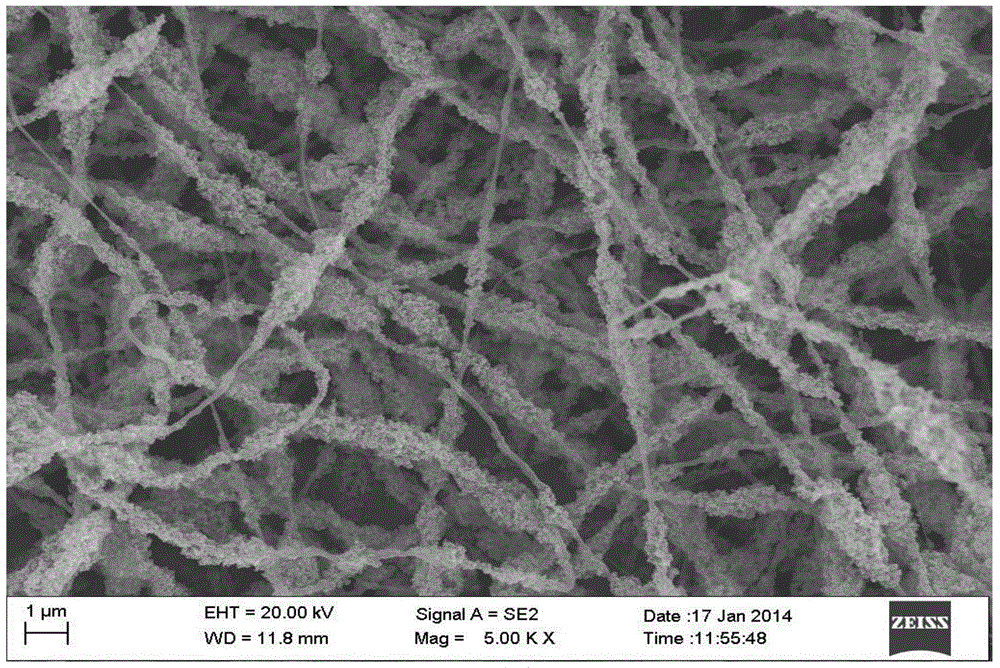

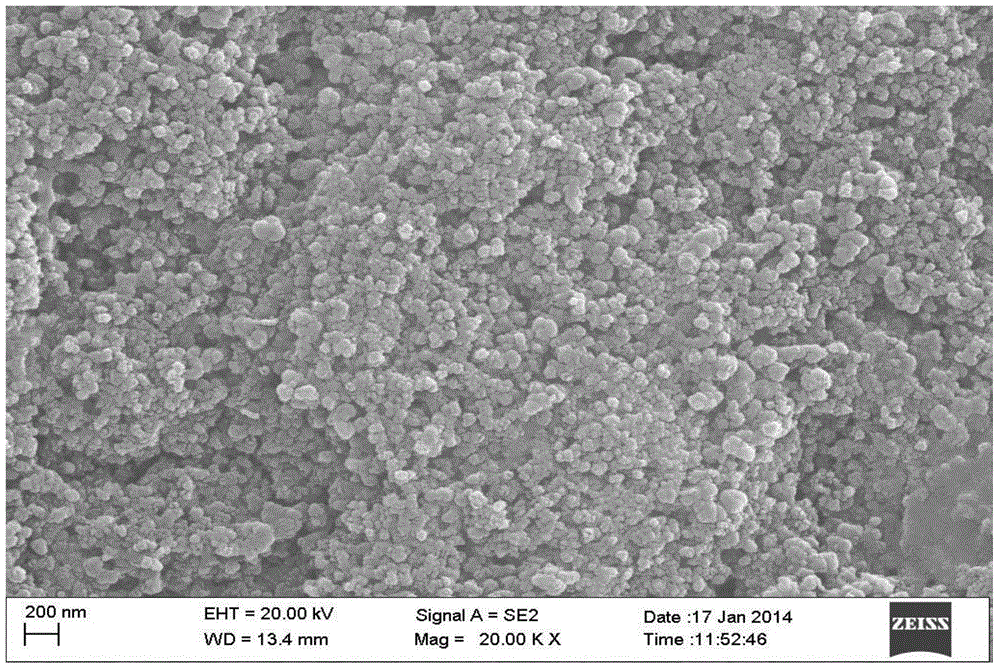

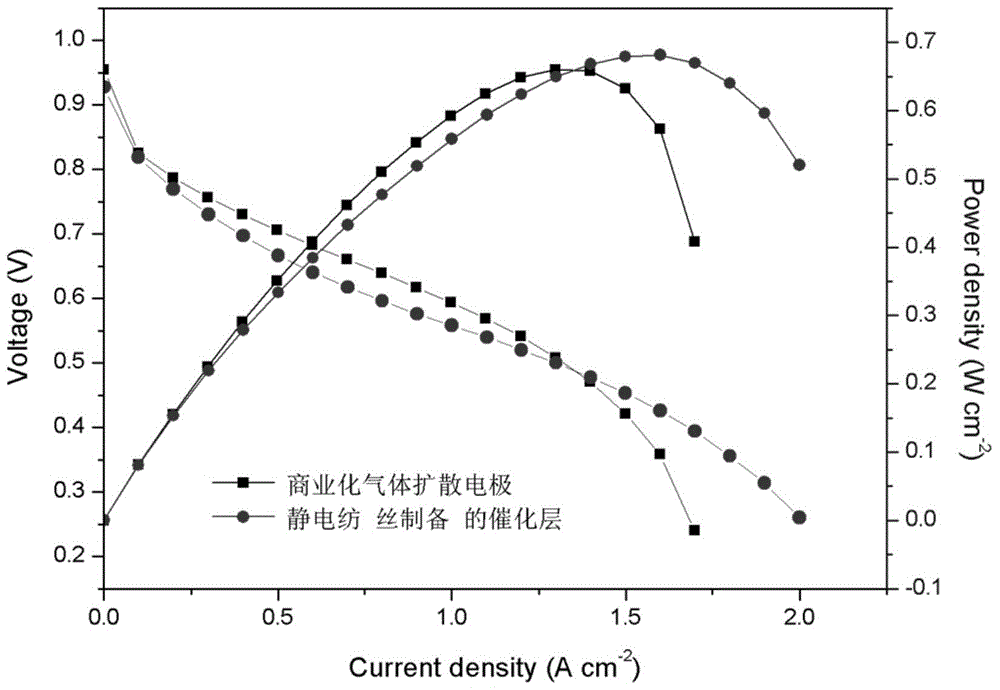

Preparation method of low-platinum catalytic layer for proton exchange membrane fuel cell

InactiveCN105633421AOptimizing the Three-Phase InterfaceImprove pore structureCell electrodesPlatinumElectrospinning

The invention discloses a preparation method for a low-platinum catalytic layer for a proton exchange membrane fuel cell. In the catalytic layer, a low-loading Pt / C-Nafion catalytic layer is directly prepared by an electrospinning technology, a binding agent can be selected from a macromolecule polymer such as poly acrylic acid (PAA) and poly vinyl alcohol (PVA), the thickness of the binding agent is 1-4 micrometers. The maximum power density of a single battery with the negative electrode loading being 0.2mg cm<-2> of the catalytic layer prepared by electrospinning, and is superior to that of a commercial gas diffusion electrode with the negative electrode loading being 0.5mg cm<-2>; and moreover, when the negative electrode loading is reduced to 0.056mg cm<-2>, the maximum power density of the single battery is still 561mw cm<-2>.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

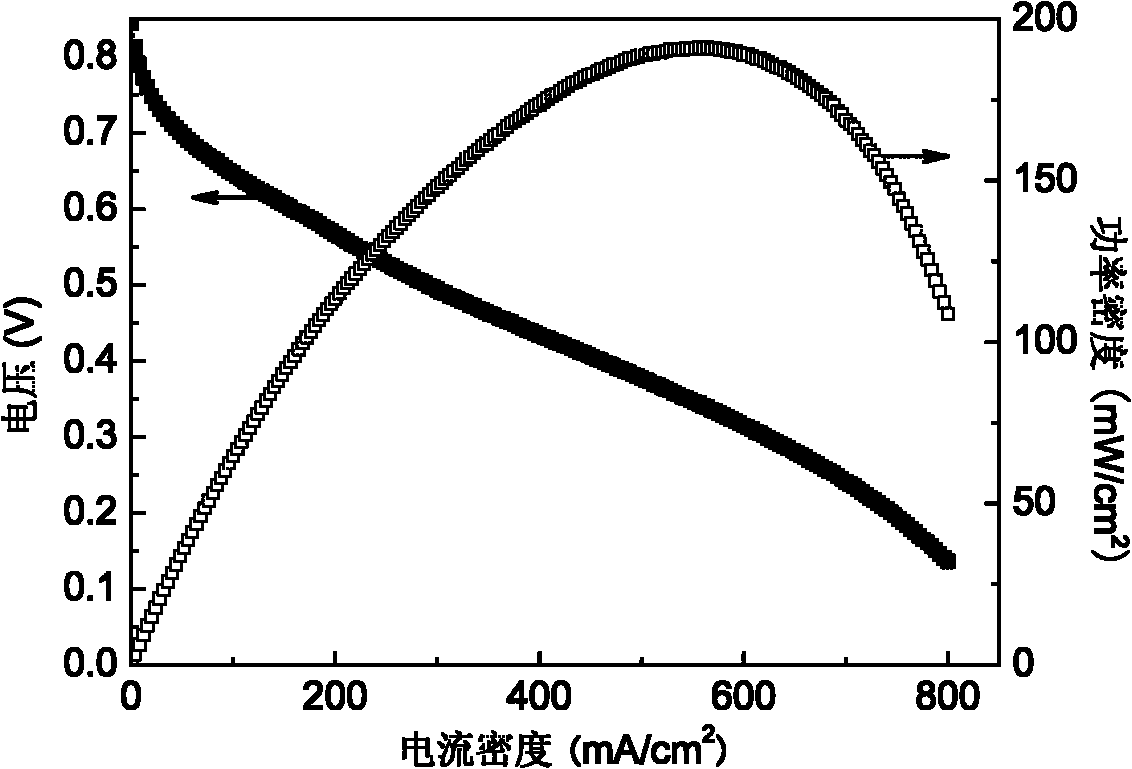

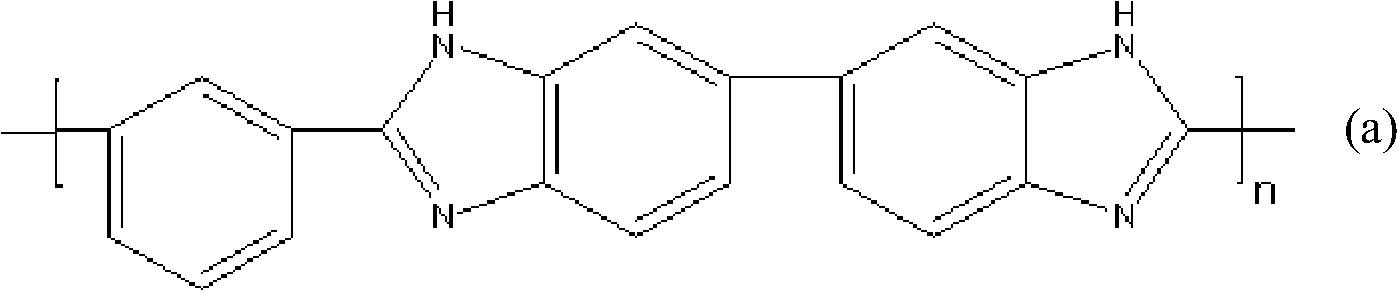

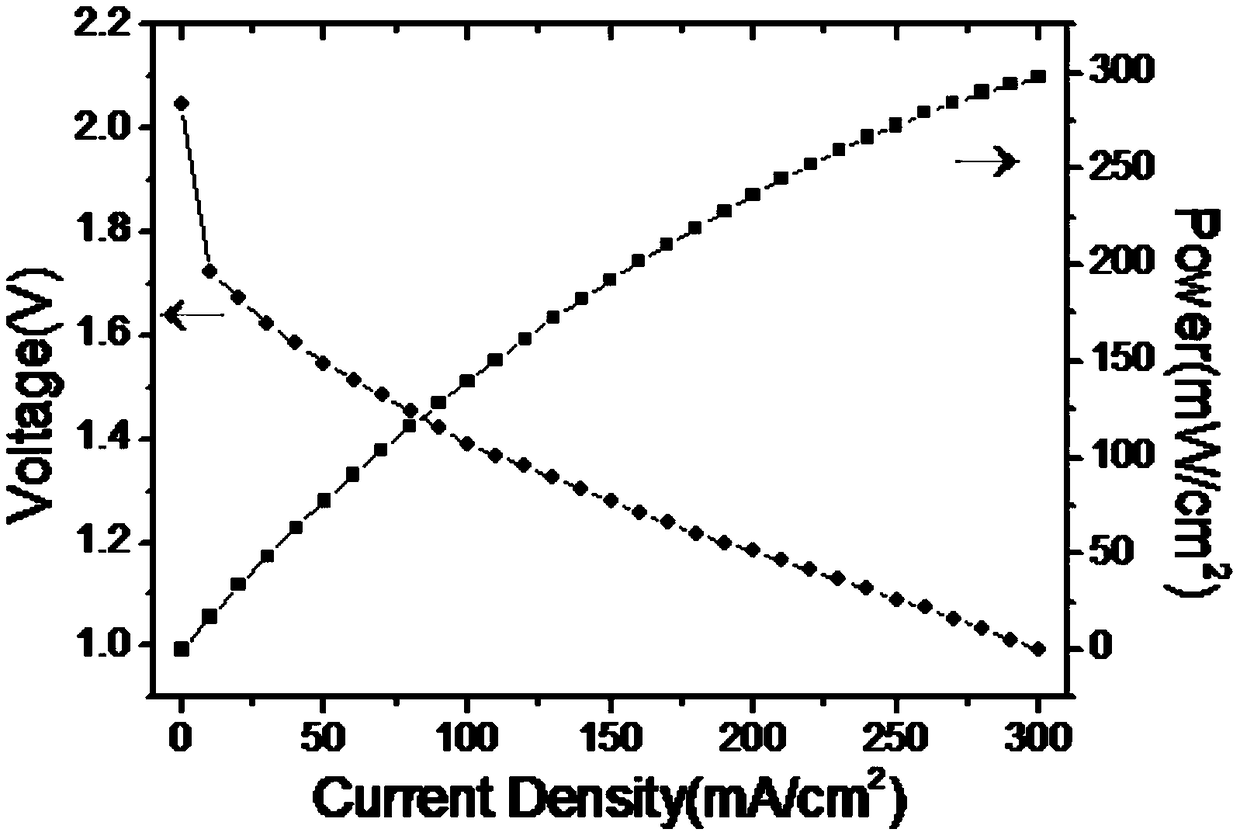

Method for preparing phosphate-doped polybenzimidazole membrane electrode for fuel cell

The invention discloses a method for preparing a phosphate-doped polybenzimidazole membrane electrode for a fuel cell. On the one hand, 4,4'-oxybis(benzoic acid) and 3,3',4,4'-biphenyltetramine serve as monomers to prepare poly[2,2'-(p-oxy- diphenylene)-5-5'-bisbenzimidazole], the poly[2,2'-(p-oxy-diphenylene)-5-5'-bisbenzimidazole] is cast to form a membrane, and the membrane is doped with phosphate to prepare an electrolyte membrane with good mechanical strength; on the other hand, in the process of preparing a phosphate-doped gas diffusion electrode, poly-[2,2'-(m-phenylene)-5,5'-bisbenzimidazole] is prepared into the gas diffusion electrode in the presence of a platinum / carbon catalyst, the gas diffusion electrode is doped with phosphate, the components are uniformly distributed, strong-volatility acid is not used in the process, and a process of mixing solid materials does not exist. The membrane electrode prepared by the method can be used for hydrogen-oxygen fuel cell power generation under the conditions that the temperature is higher than 100 DEG C and the humidification is not carried out. The open-circuit voltage is 0.845V, and the maximum power density is 191mW / cm<2> (560mA / cm<2>, 0.34V) under the conditions that the temperature of the fuel cell is 150DEG C and the humidification is not carried out. The preparation method has the advantages of controllable conditions in the technological process and good repeatability of the process.

Owner:SHANGHAI JIAO TONG UNIV

Enzyme biological fuel cell and preparing method thereof

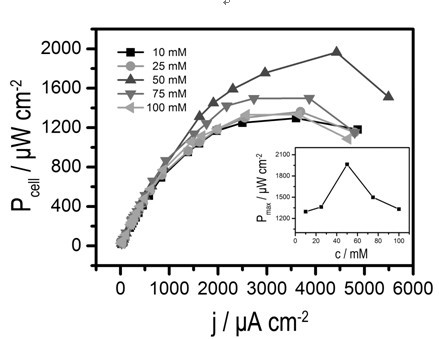

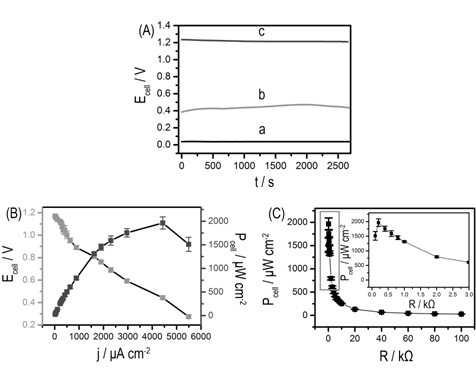

InactiveCN102569861AHigh outputLight up successfullyBiochemical fuel cellsInternal resistanceConcentrations glucose

An enzyme biological fuel cell is prepared by the steps of separating a negative pole and a positive pole by phenol proton exchange membrane (DuPontTMPFSA NRE-211), preparing substrate materials of the negative pole and the positive pole to be grapheme-nanu-au composition, respectively loading laccase and glucose oxidase on substrate materials, using the loaded laccase and glucose oxidase to catalyze respectively oxygen and glucose substrate in a cathode chamber and an anode chamber to receive and lose electrons, and forming a loop by the fact that electrons start from the anode, pass through an external circuit and reach the cathode. When glucose concentration of the enzyme biological fuel cell in the anode chamber is 50 mM, open-circuit voltage of the cell is 1.2V, maximum power density of the cell is 1.96+-0.13mW cm-2, and internal resistance of the cell is only 200 omega. Two enzymebiological fuel cells connected in series can light a red or a yellow luminous diode successively. After the enzyme biologica fuel cell is assembled for 70 days, open circuit potential of the cell remains 80% of the best value. The preparing method is also disclosed.

Owner:NANJING UNIV

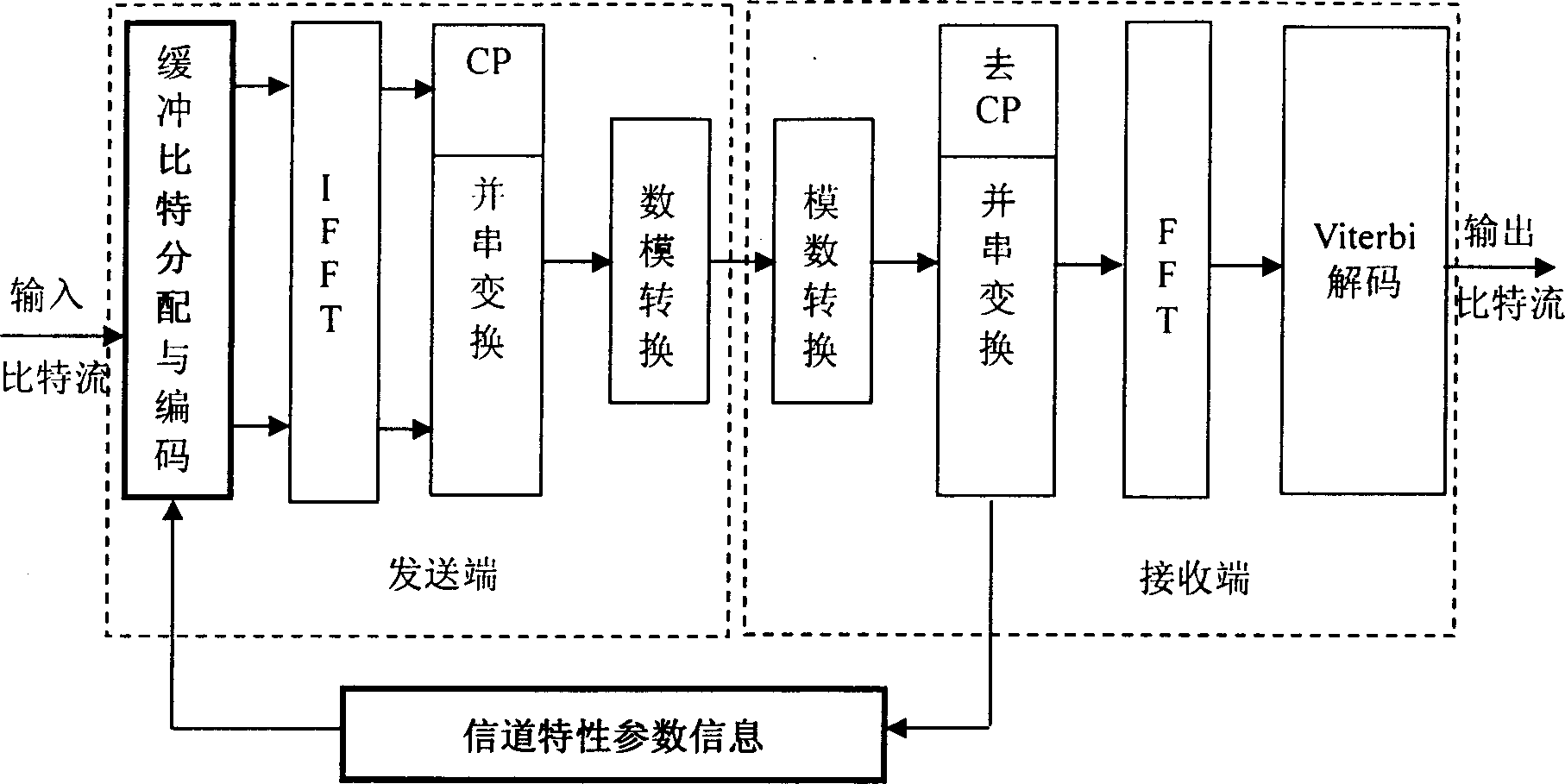

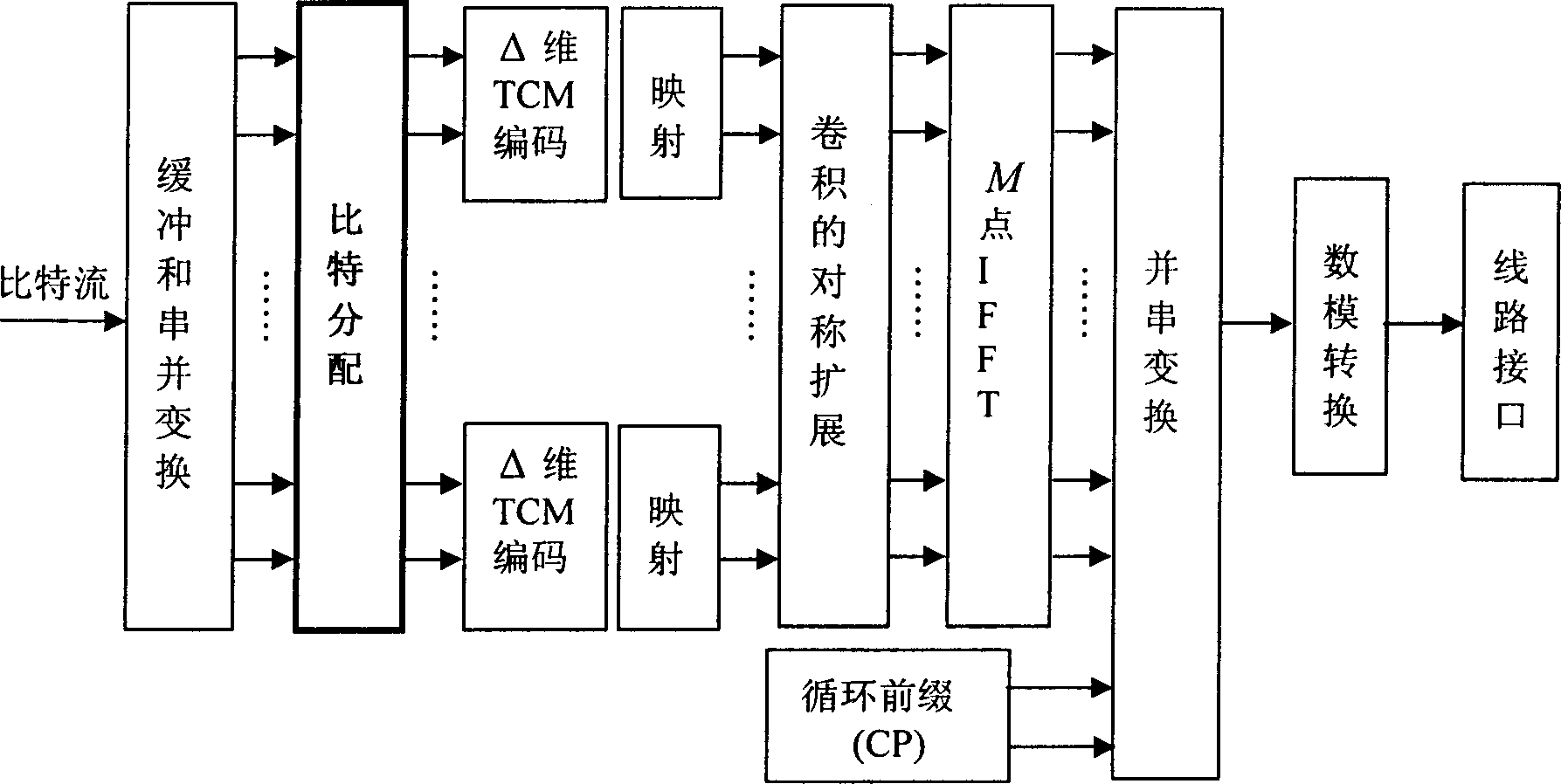

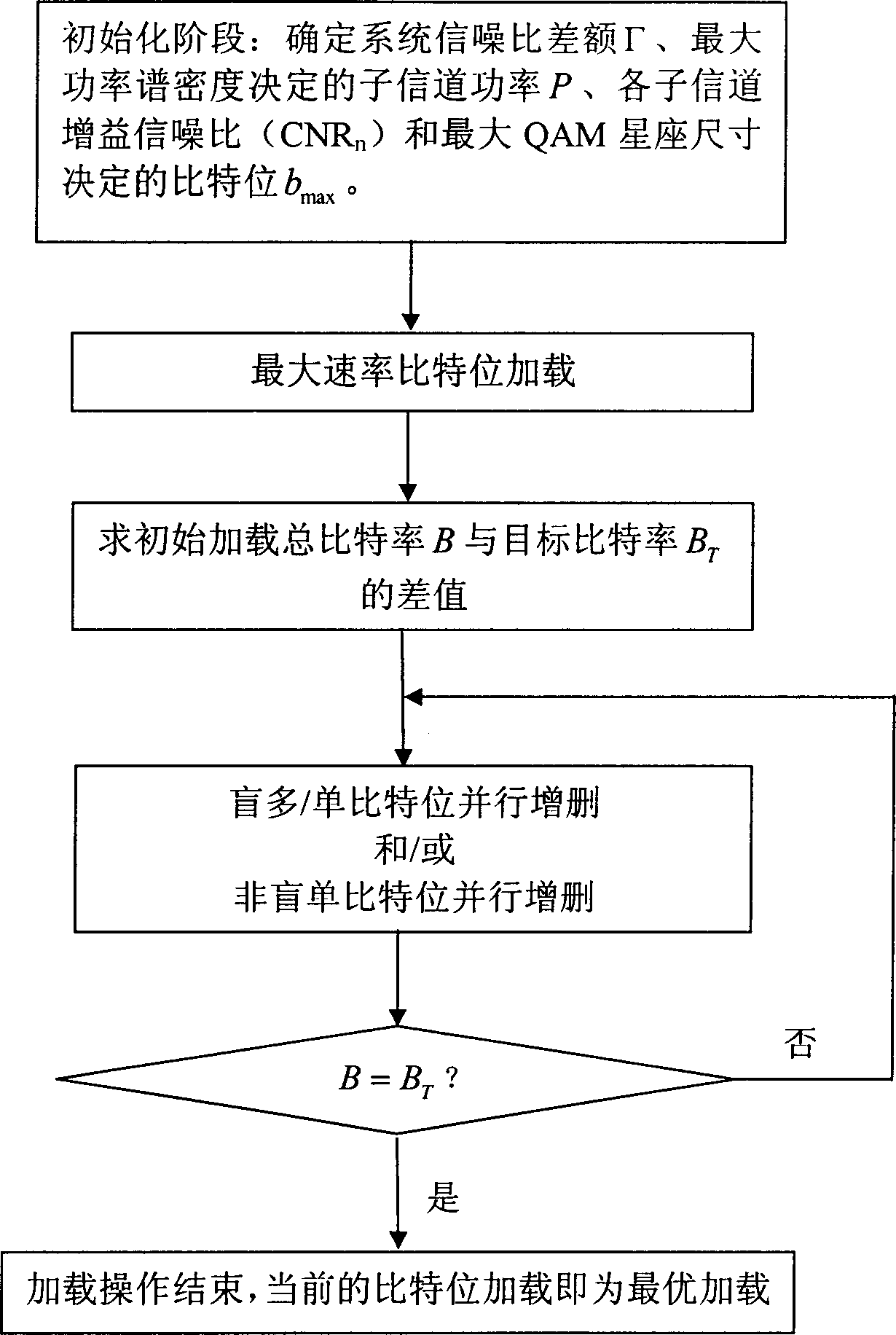

Multi sub-channel parallel bit loading method for optimal power distribution in DMT system

InactiveCN1805421AReduced sort complexityImprove computing efficiencyMulti-frequency code systemsUltrasound attenuationByte

The invention belongs to a dispersed multi-audio frequency modulation system resource distribution technique, which is characterized in that: in initialization step, loading maximum speed byte on the system, according to target error code demand, sub-channel attenuation and noise interference, and limited by system maximum power density spectrum and maximum QAM constellation size; in the target speed byte distribution step, processing multiple sub-channel parallel loading on one effective byte distribution relative to initialization loading process, utilizing blind-multiple / single-byte and / or non-blind single byte parallel increase and delete to quickly retract to target byte rate according to the difference between the initialization byte rate and the target byte rate. The invention can avoid general greed loading method, while it can keep the validity of byte loading in the parallel loading process that tending to the target byte rate, and realize the byte loading in optimized power distribution, with minimum calculation and less complex.

Owner:TSINGHUA UNIV +1

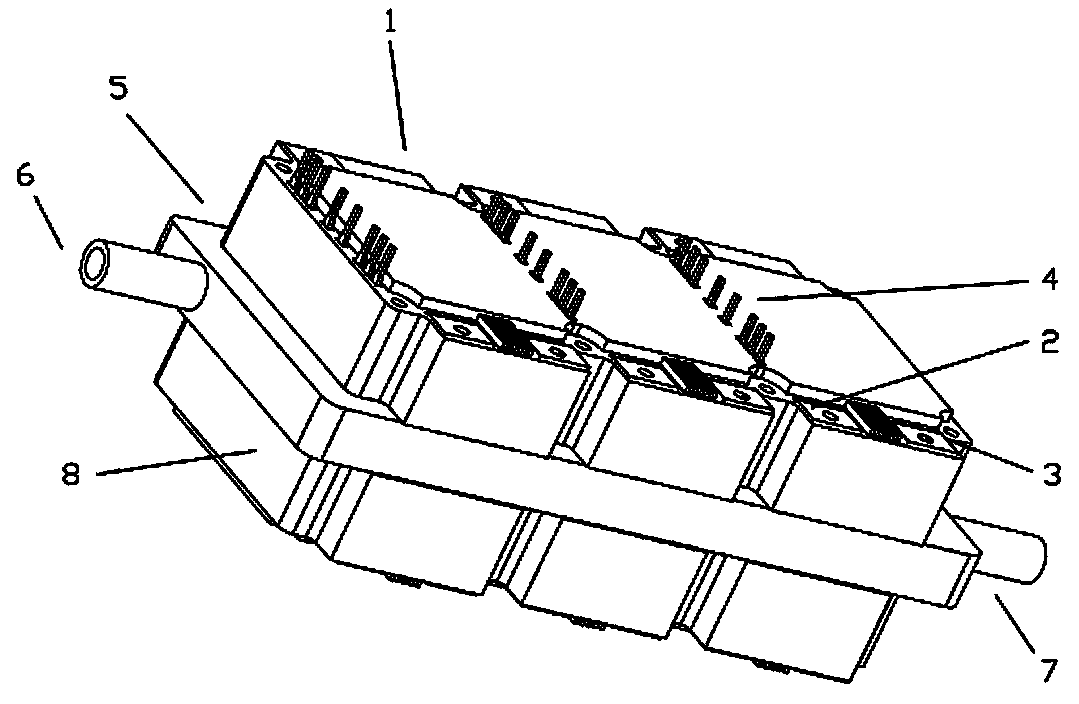

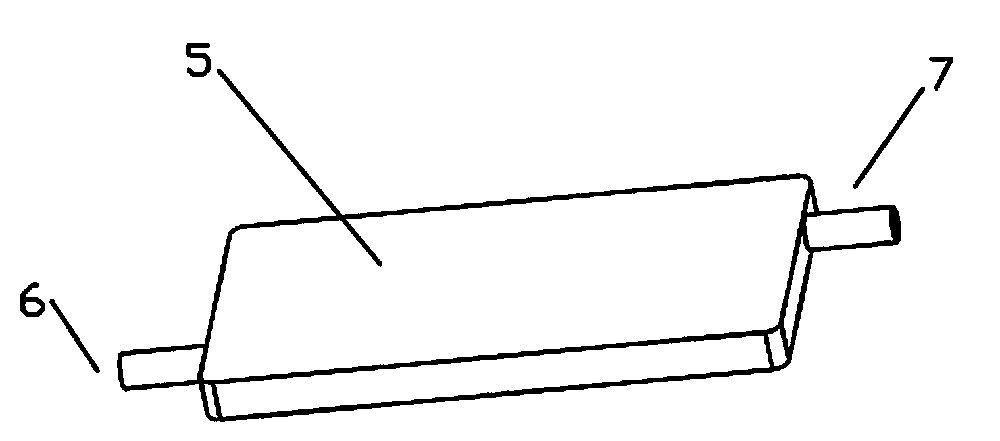

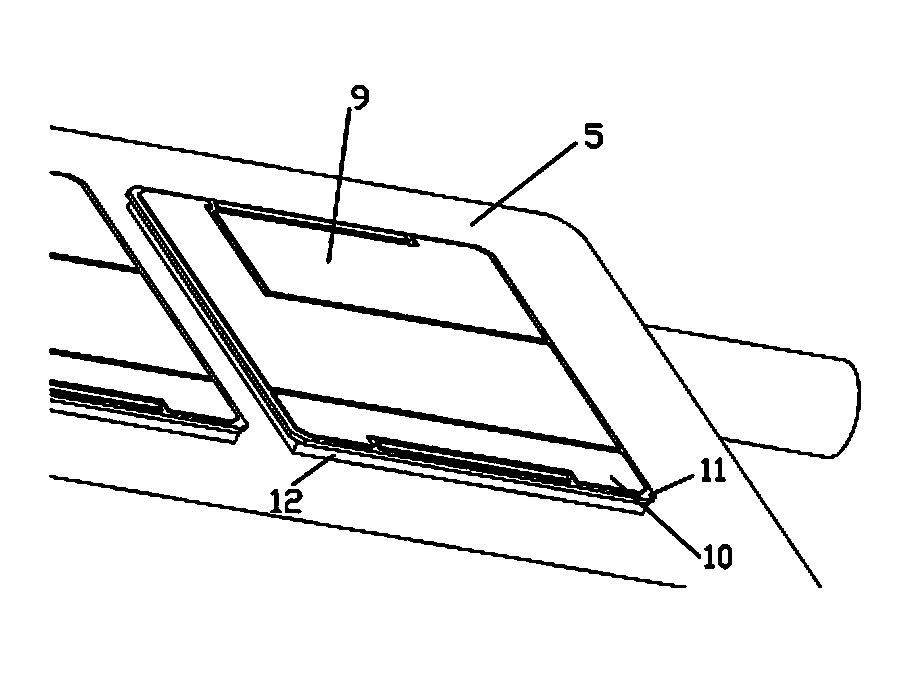

Power module packaging structure with water-cooled heat sink used for two-sided cooling

InactiveCN103779294AMaximize Power DensityMake full use of cooling capacitySemiconductor/solid-state device detailsSolid-state devicesCushioningUltrasonic welding

Provided is a power module packaging structure with a water-cooled heat sink used for two-sided cooling. The power module packaging structure comprises the tabular water-cooled heat sink with a water inlet and a water outlet. Power device units are packaged on the upper surface of the water-cooled heat sink and the lower surface of the water-cooled heat sink, a power terminal located on the surface of a shell is made into a shape by which a nut can be fixed conveniently, and a signal terminal located on the surface of the shell is specially made into a shape which has good welding performance and facilitates fixing and clamping of a PCB. The water-cooled heat sink is fixedly connected with insulating substrates of the power device units directly or through a cushioning material layer, and the power terminal and the signal terminal are directly welded to surface metal layers of the insulating substrates in an ultrasonic welding mode. The shell is fixedly connected with the heat sink, and the signal terminal and the power terminal are directly fixed onto the shell in an injection molding mode. The power module packaging structure has the advantages of being reasonable in structure and convenient to use and install, making full use of the cooling capacity of the water-cooled heat sink, obtaining maximum power density and the like.

Owner:嘉兴斯达微电子有限公司

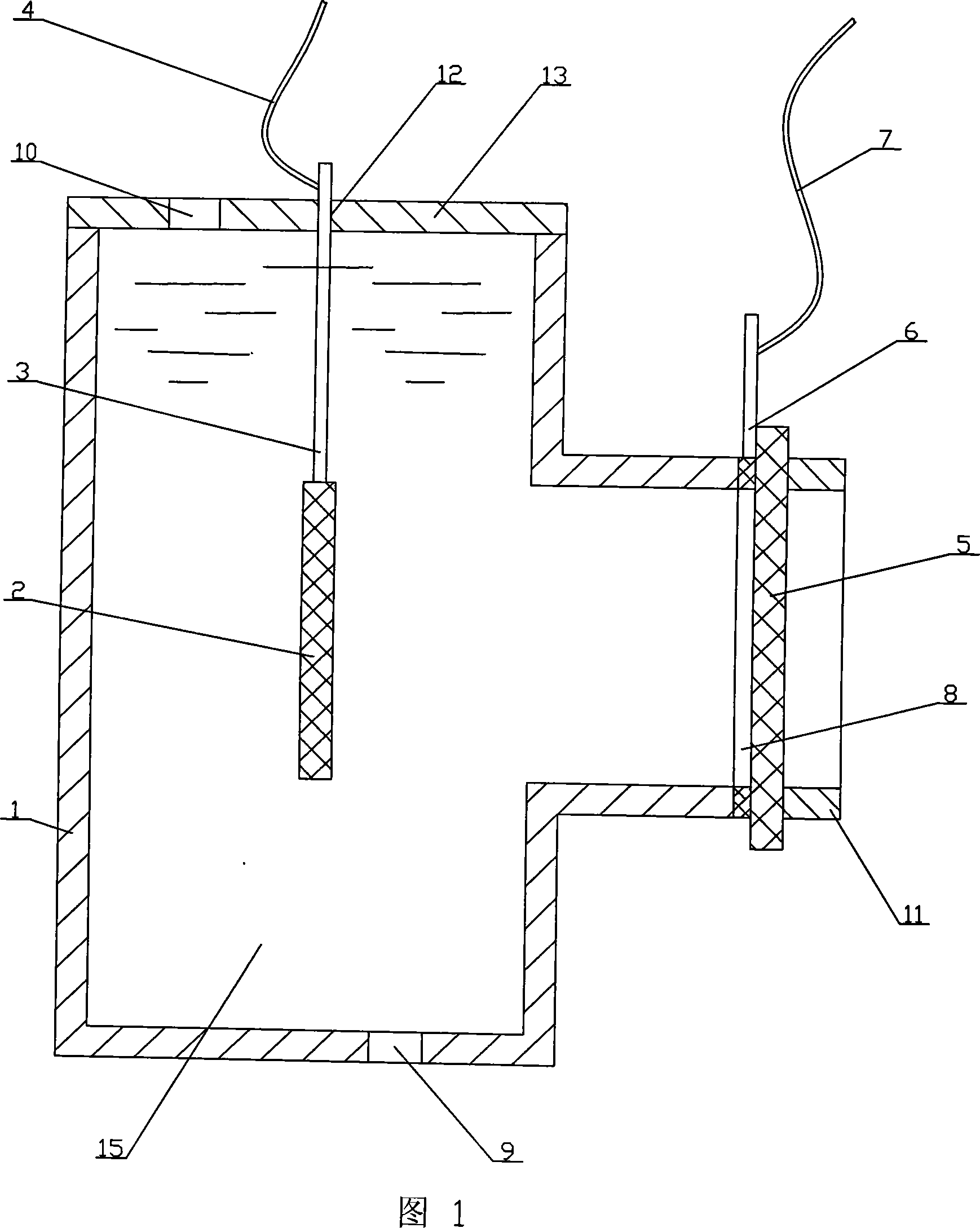

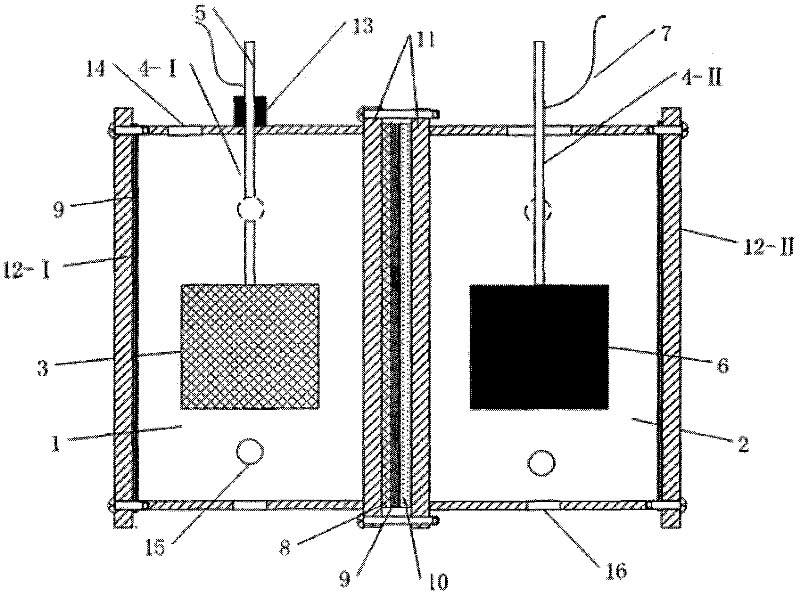

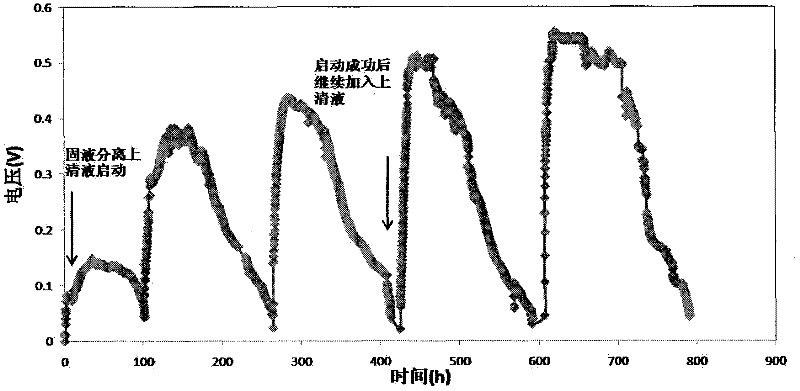

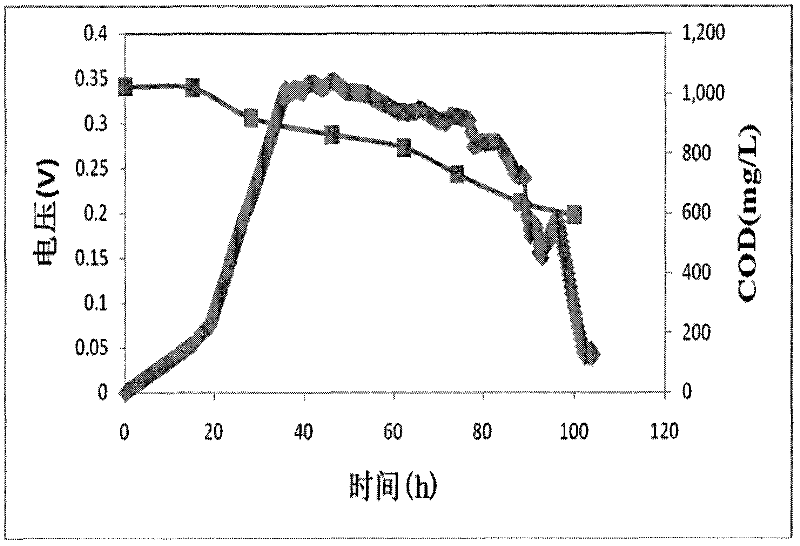

Microbiological fuel cell and recycling method for cassava waste mash

InactiveCN102347504APromote degradationImprove power generation performanceFinal product manufactureBiochemical fuel cellsSolubilityChemical oxygen demand

The invention relates to a microbiological fuel cell and a method for generating electricity by cassava waste mash, which belong to the field of environment protection and the comprehensive utilization of resources and aim to solve the problem that the cassava waste mash has big processing difficulty and is difficult to recycle. The double-chamber microbiological fuel cell is adopted. The invention specifically discloses a processing method for generating electricity by the cassava waste mash, which comprises the following steps: 1. carrying out solid-liquid separation; 2. carrying out ultrasound-high-temperature anaerobic short-range fermentation combined treatment; 3. starting the microbiological fuel cell; and 4. processing solid substance and supernate in each step. In the method, when cassava waste mash stoste is adopted for generating electricity, the maximum power density of the cell reaches 285mW / m2, and the total chemical oxygen demand (COD) degradation efficiency is 42%. When the fermented supernate is used for generating electricity, the maximum power density is 670mW / m2, and the solubility COD degradation efficiency is 91%. As a new path for disposing the cassava waste mash, the method makes up the deficiency existing in the traditional waste mash processing technology, the electricity generation performance of the processed waste mash can be obviously improved, and the mode of generating electricity by biomass resources, such as the waste mash and the like, becomes feasible.

Owner:BEIJING NORMAL UNIVERSITY

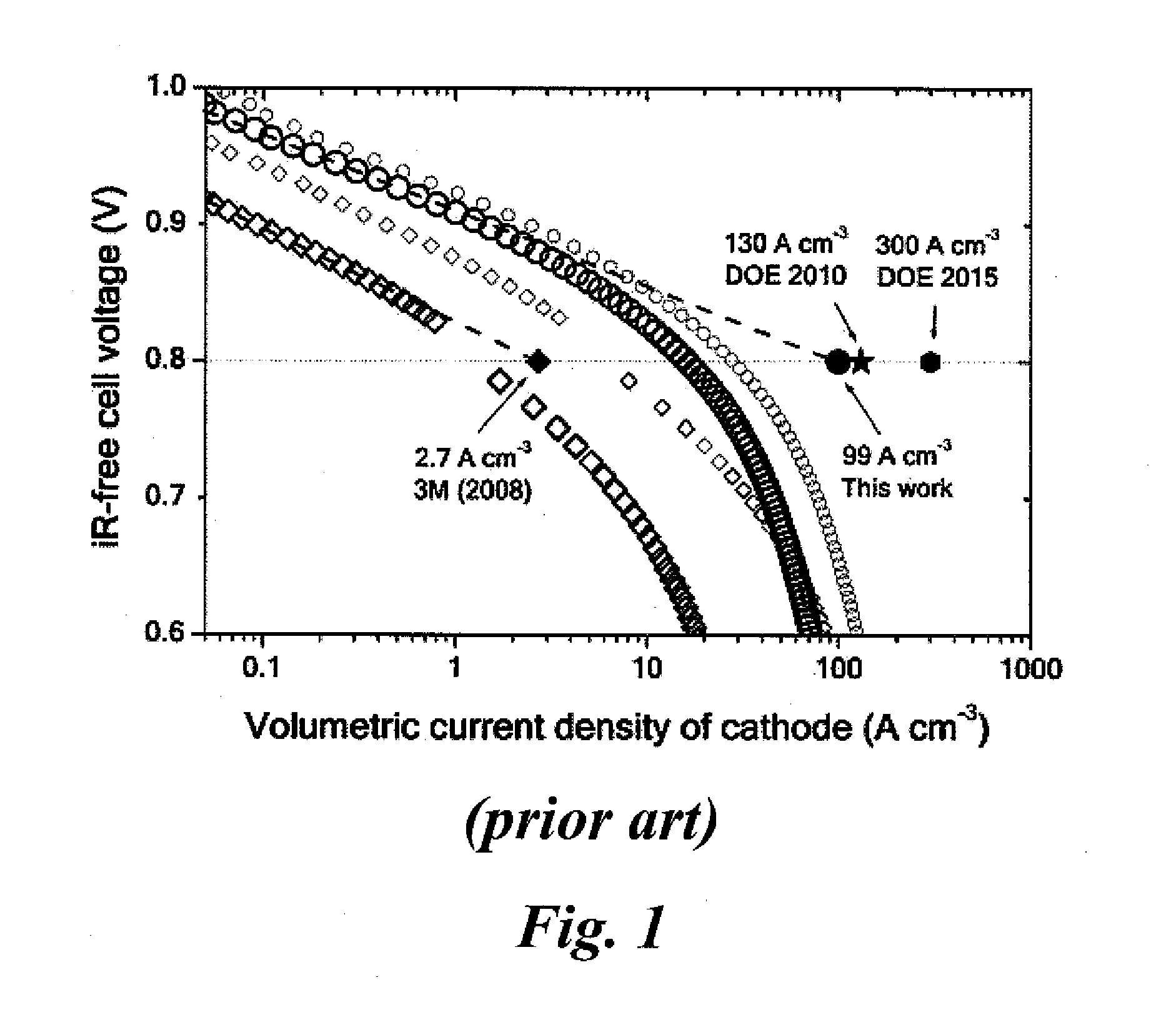

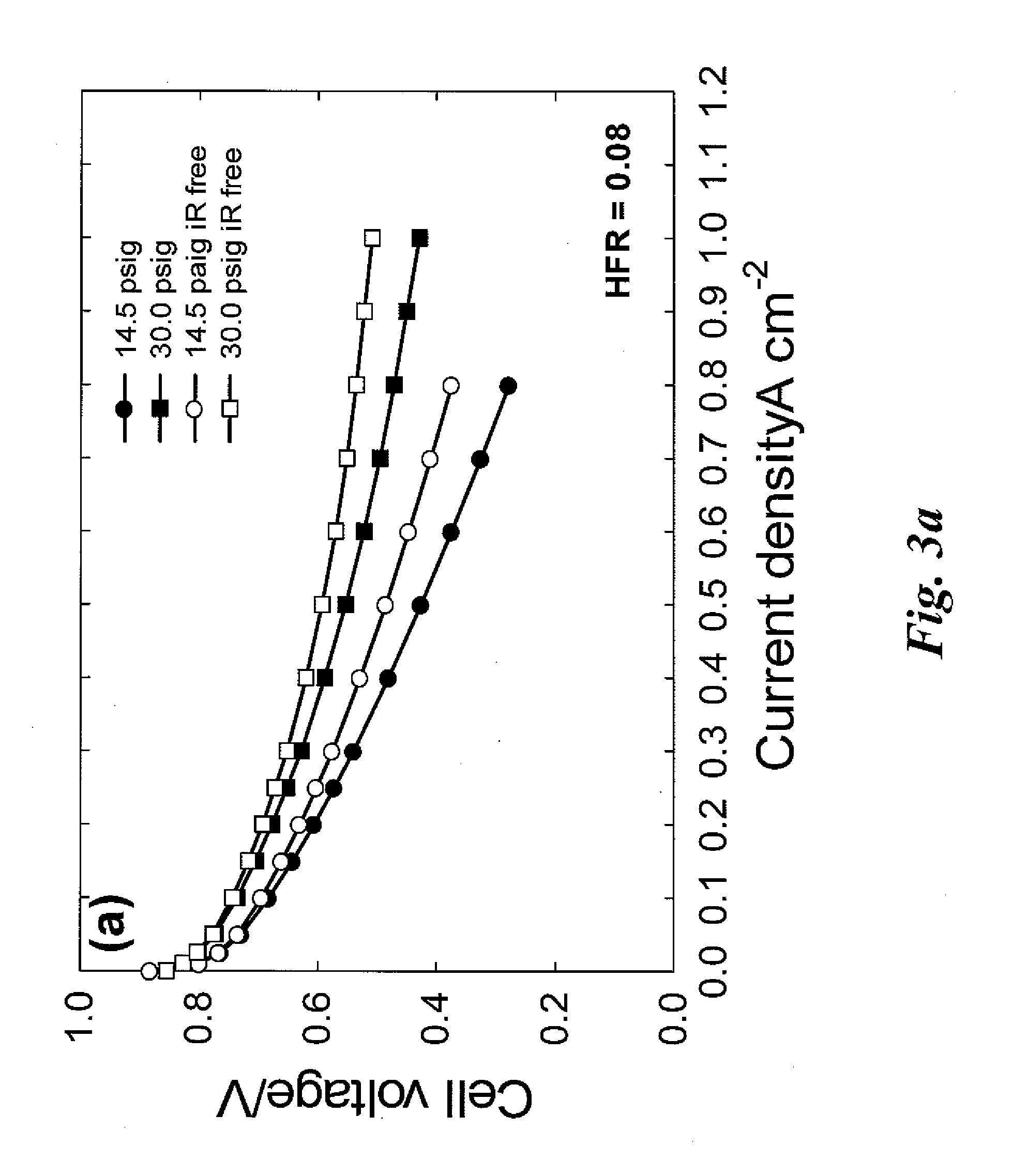

Non-precious metal catalysts

ActiveUS20140045098A1Raise the overpotentialHigh cost of precious metalOrganic-compounds/hydrides/coordination-complexes catalystsActive material electrodesFuel cellsChloride

A catalyst for oxygen reduction reaction (ORR) for a fuel cell was prepared by pyrolyzing a mixture of polyaniline, cyanamide, carbon black, and a non-precious metal salt under an inert atmosphere. The pyrolyzed product was treated to remove acid soluble components and then pyrolyzed again. The resulting powder was used to prepare a cathode for a membrane electrode assembly that was used in a fuel cell. When iron(III) chloride was used as the salt, the resulting catalyst was porous with a web-shaped structure. It displayed a maximum power density of 0.79 W / cm at 0.4 V in H2 / O2 at 1.0 bar back pressure.

Owner:TRIAD NAT SECURITY LLC

Method for clearing away aged RTV coating of insulator in dry manner

ActiveCN105251737ABroaden applicationClear effective implementationCleaning processes and apparatusSurface coverLaser

A method for clearing away an aged RTV coating of an insulator in a dry manner comprises the following steps of (1), determining the size and the shape of the insulator and the thickness, the use time and the RTV material composition of the RTV coating; (2), according to parameters determined in the step (1), determining a clearing-away power density threshold value and a damage power density threshold value output by lasers, wherein the clearing-away power density threshold value is the minimum clearing-away power density of the RTV coating to be cleared away, the damage power density threshold value is the maximum power density capable of being borne when the insulator surface covered with the RTV coating to be cleared away is radiated by the lasers, and when the damage power density threshold value exceeds the maximum power density, the insulator surface will be damaged; and thirdly, according to the clearing-away power density threshold value and the damage power density threshold value determined in the step (2), the power setting of a laser device is adjusted, and the output laser scans the surface of the insulator. According to the method, on the premise that the insulator surface is not damaged, the aged RTV coating of the insulator surface can be efficiently, conveniently and rapidly cleared away.

Owner:SHENZHEN GRADUATE SCHOOL TSINGHUA UNIV

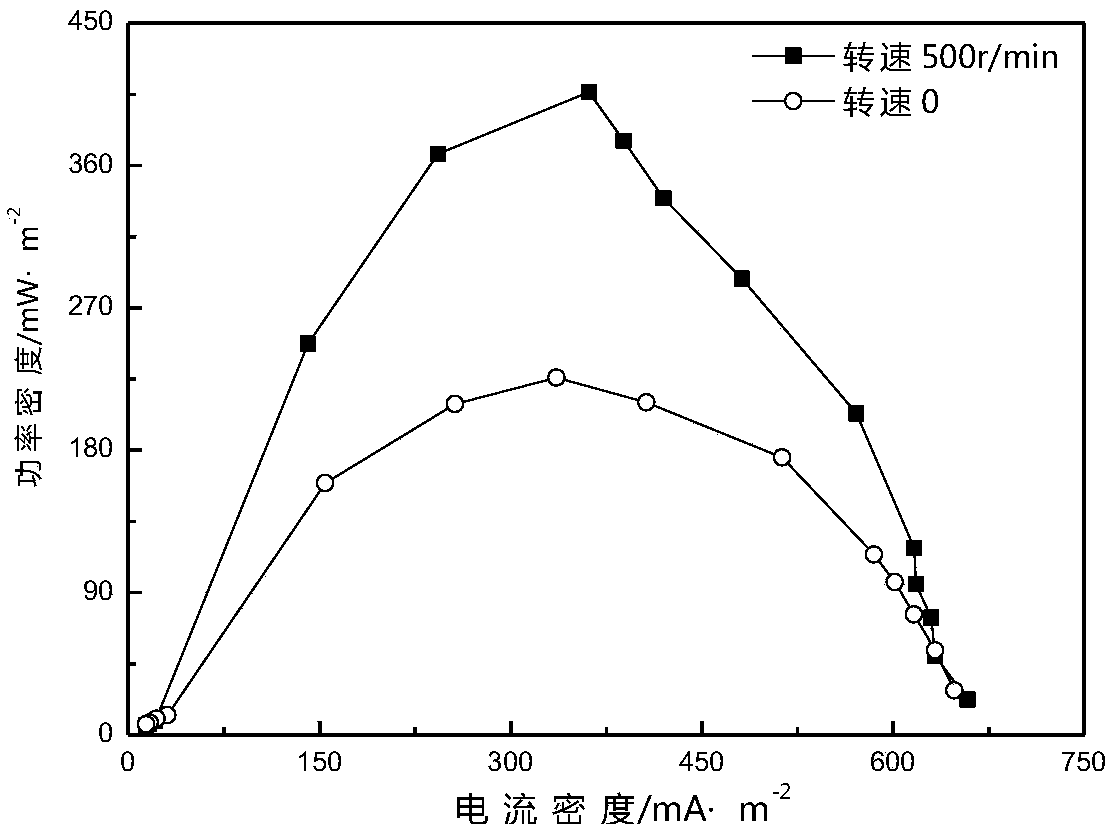

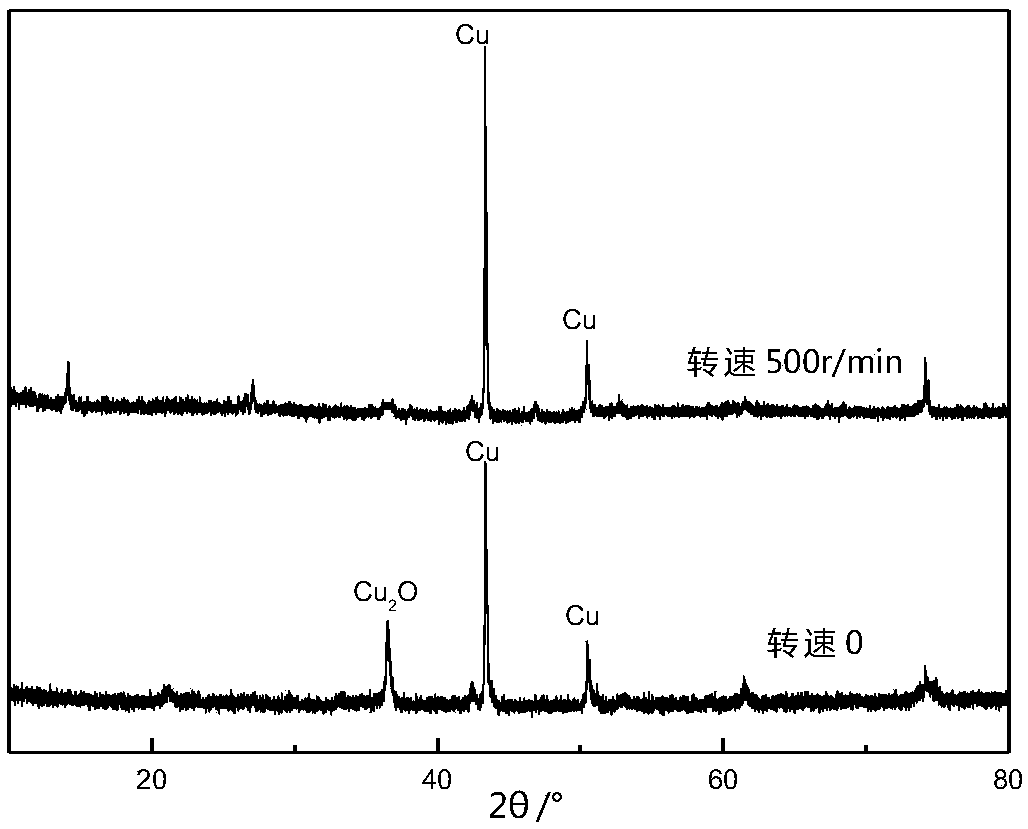

Microbial fuel cell for processing acid copper-containing waste water of mine, and copper recycling method

InactiveCN107946623AImprove microenvironmentHigh removal rateWaste water treatment from quariesTreatment by combined electrochemical biological processesSucroseEffective volume

The invention discloses a microbial fuel cell for processing acid copper-containing waste water of mine, and a copper recycling method. Processing of the acid copper-containing waste water of mine bythe microbial fuel cell comprises the following three steps (1) enrichment of a positive electrode electrochemical active microorganism: dewatered sludge is a positive electrode inoculum, and a culture domestication liquid taking sucrose as the main part is added for performing domestication for seven days to obtain a positive electrode culture; the main components of a positive electrode substrate comprise residual sludge, glucose and the like; and the volume ratio of the positive electrode culture to the substrate is 1:1 to 1:4; (2) establishment of an MFC system: the effective volume of theMFC is 100-250mL; the spacing between a positive electrode carbon brush and a negative electrode carbon brush is 4-6cm; and after the output voltage of the MFC reaches 400-600mV, a positive electrodestirring apparatus is started at the rotary speed of 450-550r / min and at the maximum power density of 580.8mW / m<2>; and (3) processing of the acid copper-containing waste water of mine and copper recycling in a negative electrode room: a negative electrode is taken out after operation for 25-30 days; a negative electrode reduction product is collected, and detection proves that the product is elementary copper; after the reaction, the negative electrode liquid is 6.5-6.9 in pH value; and negative electrode Cu<2+> removal ratio is 92.2%.

Owner:JIANGSU UNIV OF TECH

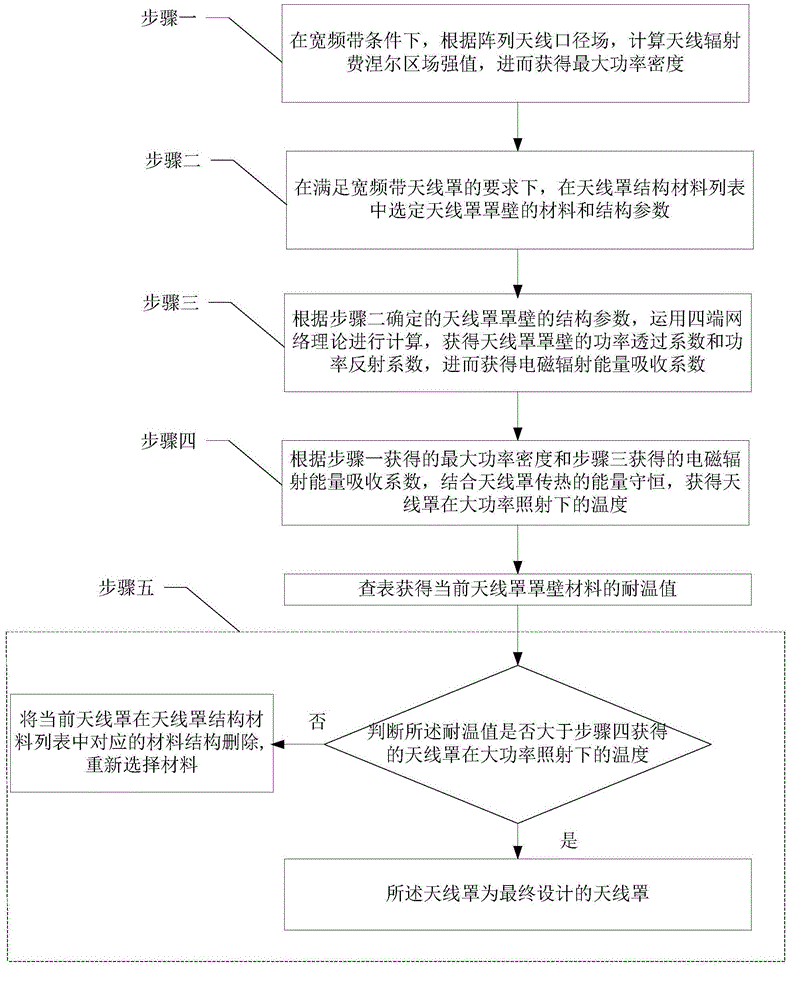

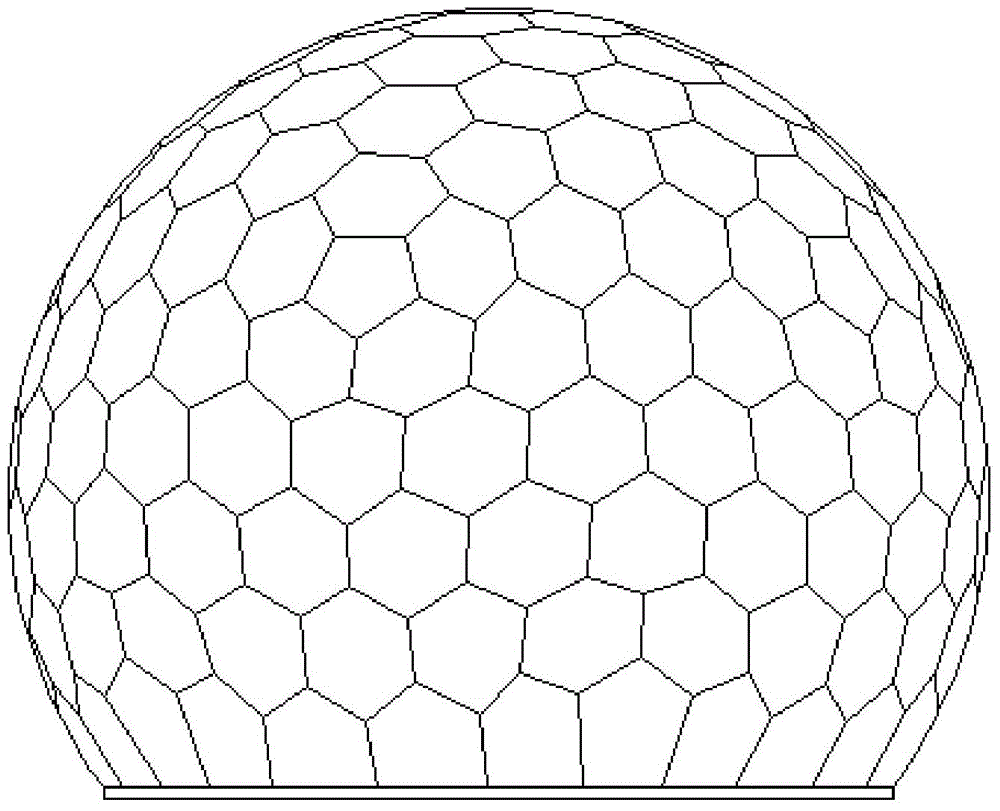

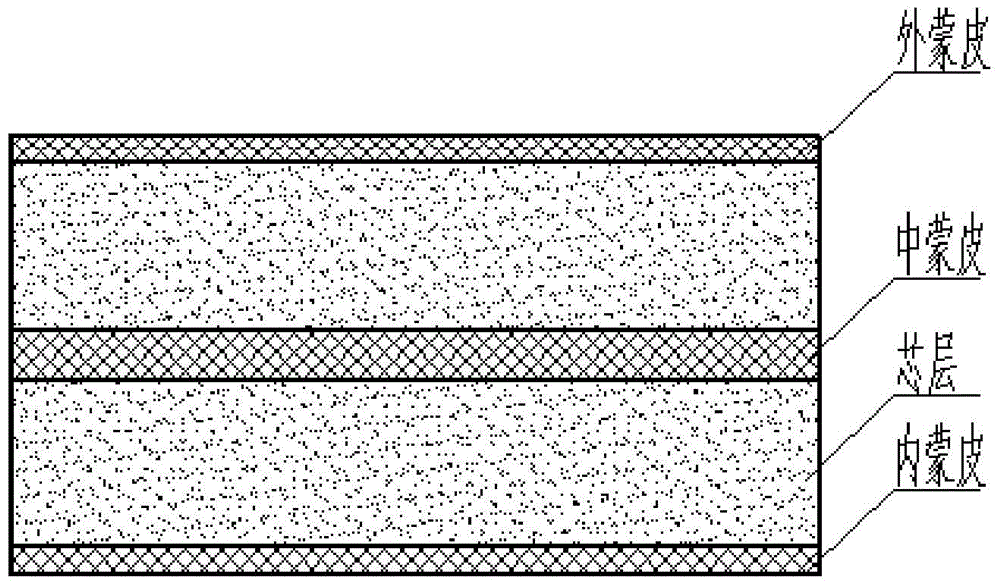

Method for designing large-power-resisting broadband radar antenna cover

ActiveCN104577324AAddresses issues with designs not suitable for high-power broadband radomeRadiating element housingsRadarEnergy absorption

The invention discloses a method for designing a large-power-resisting broadband radar antenna cover, which belongs to the technical field of large-size ground radar antenna covers, and aims to solve the problems that a method for designing an antenna cover starting with material study is not applicable to large-size ground antenna covers. The method comprises the following steps: under the condition of broadband, acquiring maximum power density of radiation of an antenna according to an array antenna aperture field; selecting the material and structural parameters of the wall of the antenna cover; furthermore acquiring electromagnetic radiation energy absorption coefficients; furthermore, with the combination of energy conservation of heat conduction of the antenna cover, acquiring the temperature of the antenna cover under large-power radiation; judging whether the temperature resisting value of the material of the wall of the antenna cover at present is greater than the acquired temperature or not, if the temperature resisting value of the material of the wall of the antenna cover at present is greater than the acquired temperature, taking the antenna cover as a finally designed antenna cover, otherwise, reselecting an antenna cover structure material and redesigning the antenna cover. The method can be used for designing large-size ground radar antenna covers.

Owner:HARBIN TOPFRP COMPOSITE

Method of Production of Grain-Oriented Electrical Steel Sheet

ActiveUS20090114316A1Reduce magnetostrictionReduce the Watt lossInorganic material magnetismFurnace typesSheet steelElectrical steel

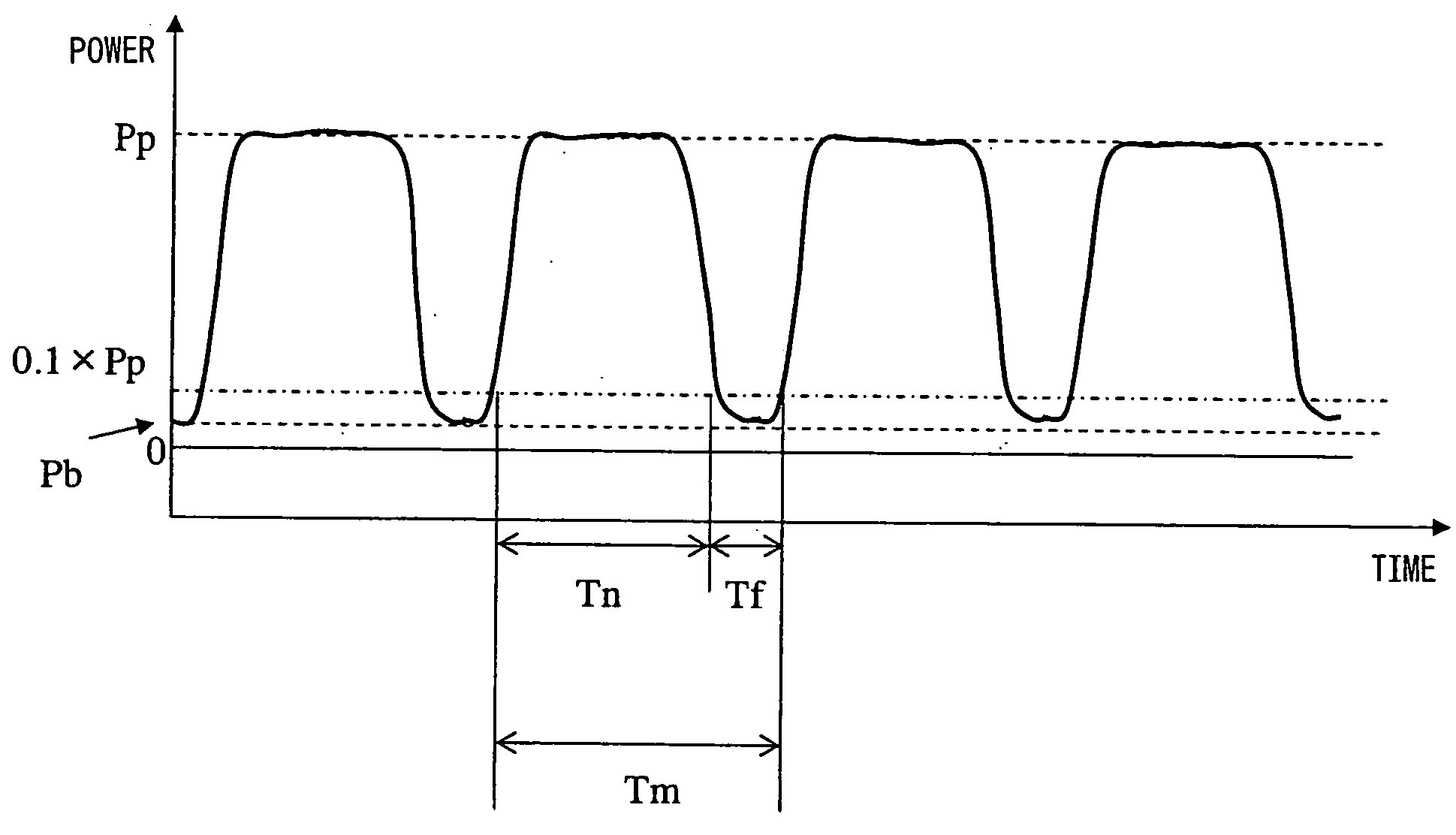

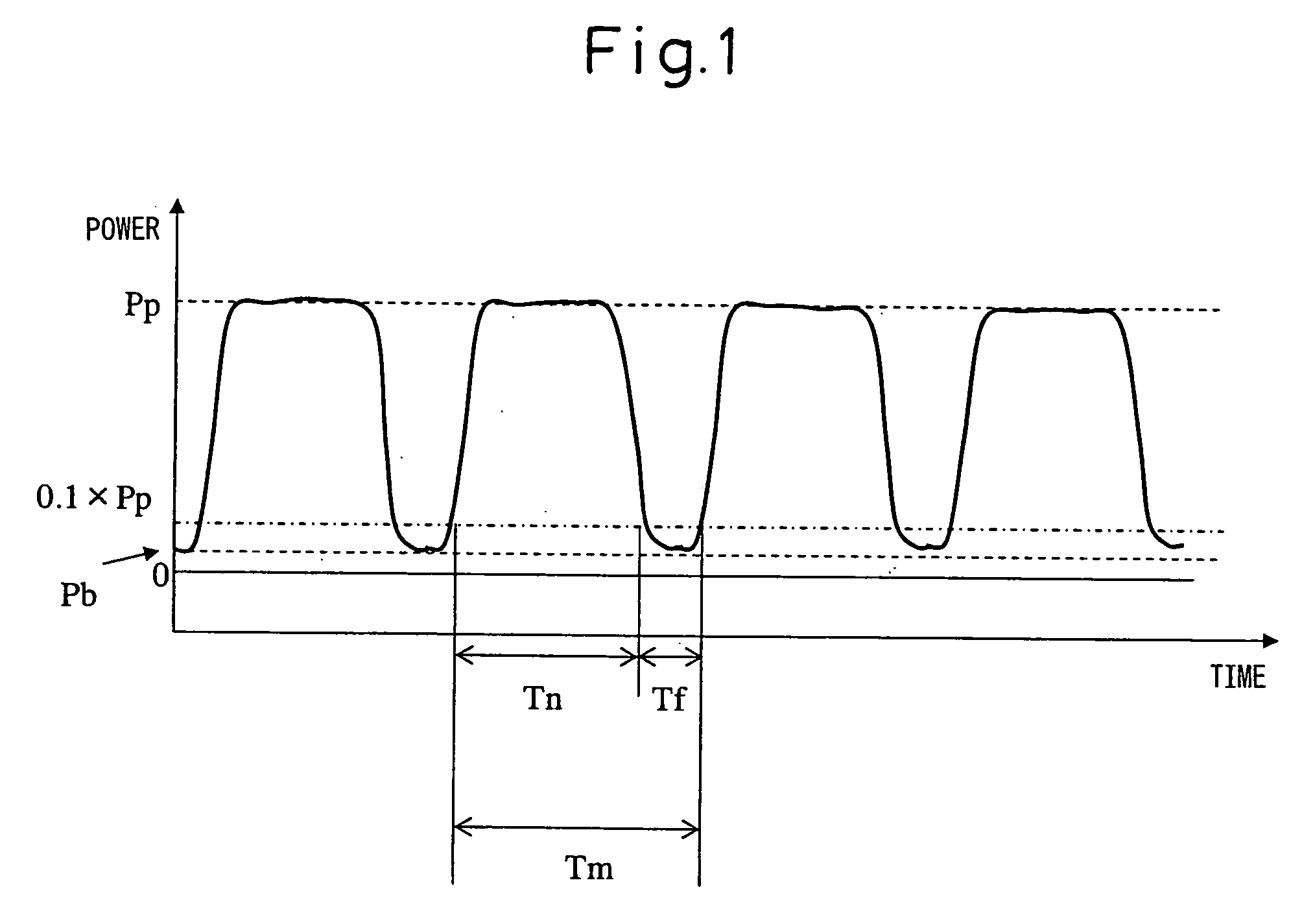

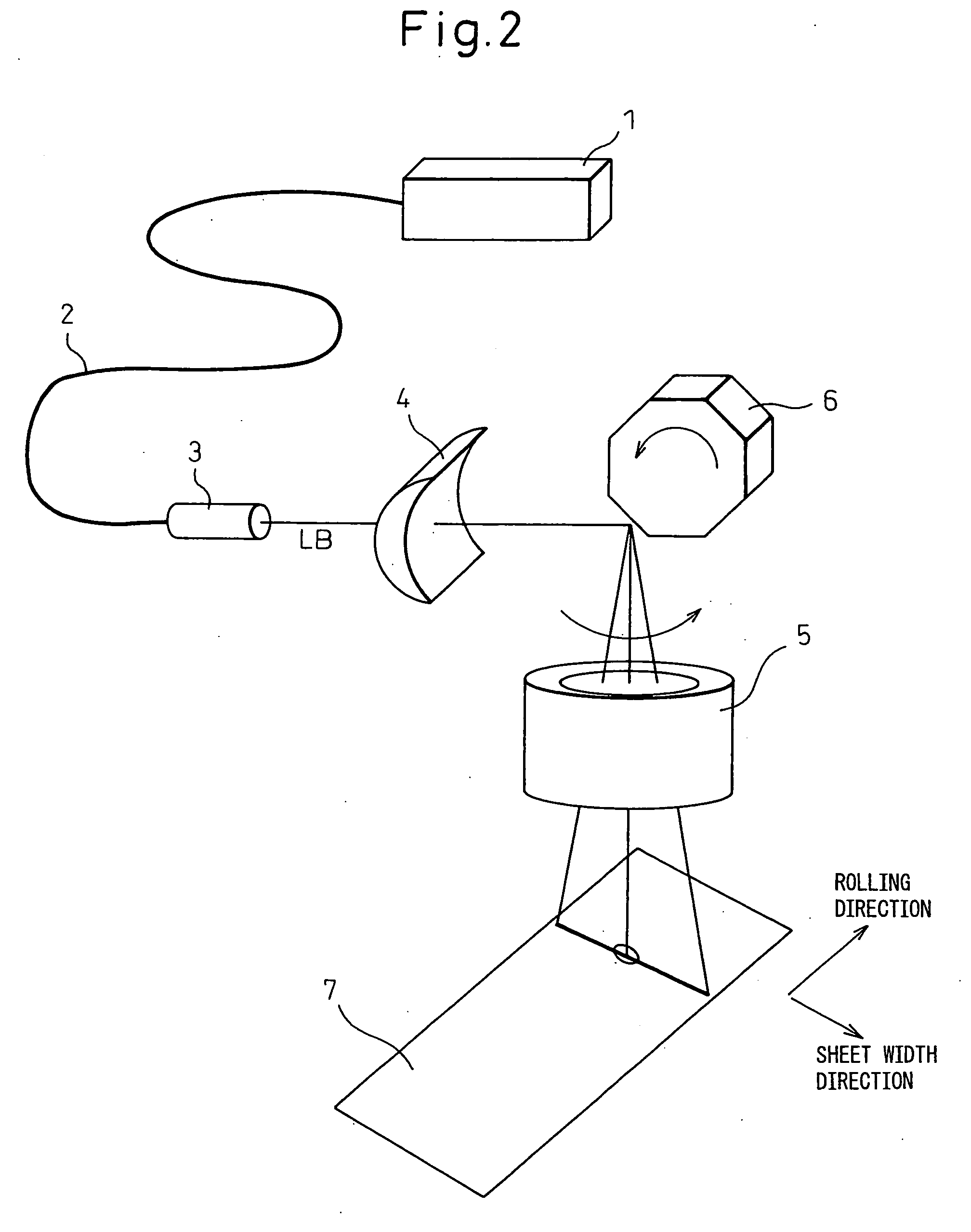

The present invention provides a method of production of grain-oriented electrical steel sheet greatly reducing the Watt loss of the grain-oriented electrical steel sheet and making the magnetostriction as small as possible, that is, a method of production of grain-oriented electrical steel sheet with small magnetostriction by improving the magnetic properties by irradiation by a finely focused laser beam comprising using a power modulated laser controlled in maximum power density to 1×102 to 1×104 W / mm2 to optimize the amount of strain given by laser irradiation in both the sheet width direction and rolling direction and, in particular, to make the modulation duty 70% to less than 100%.

Owner:NIPPON STEEL CORP

Method for directly preparing catalytic layer of platinum monoatomic layer used for proton exchange membrane fuel cell

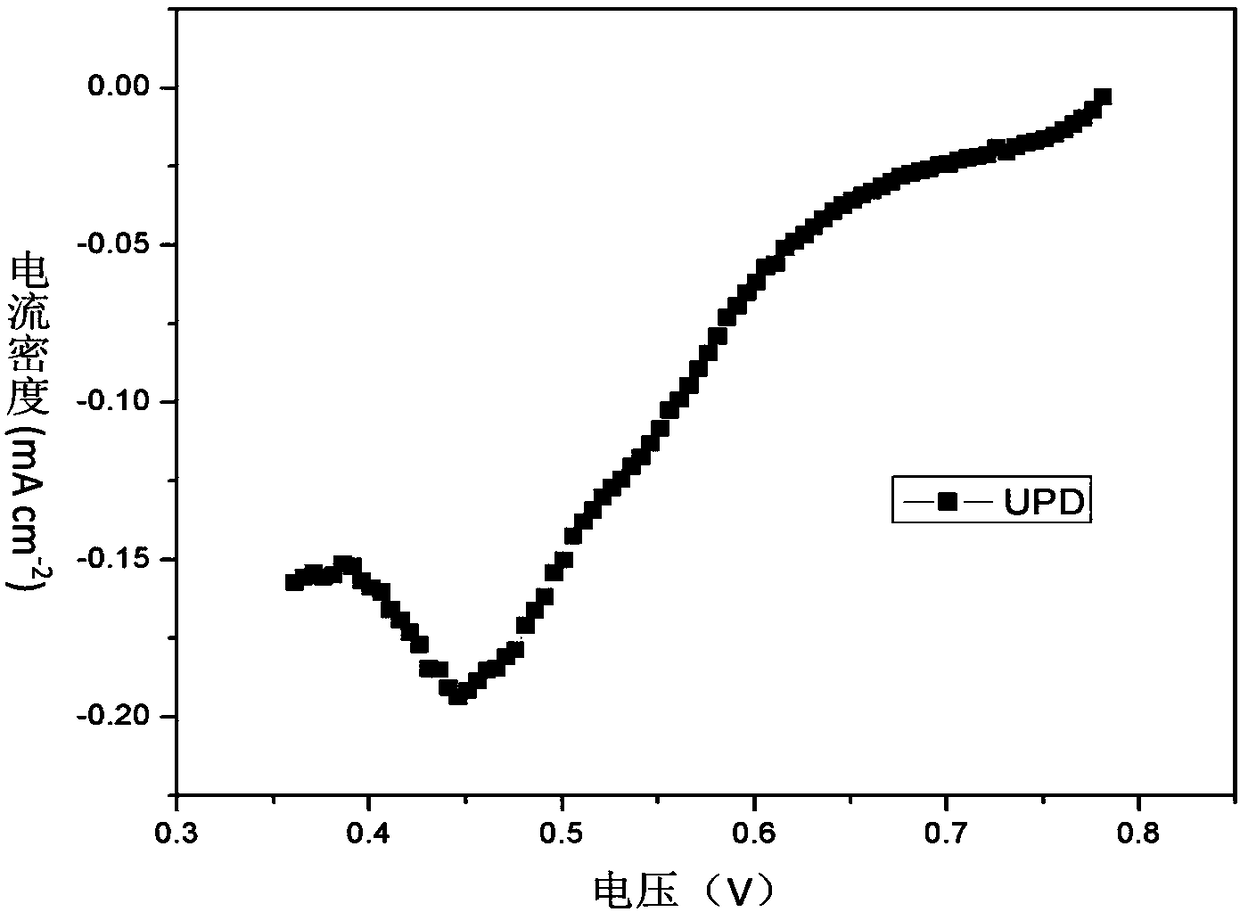

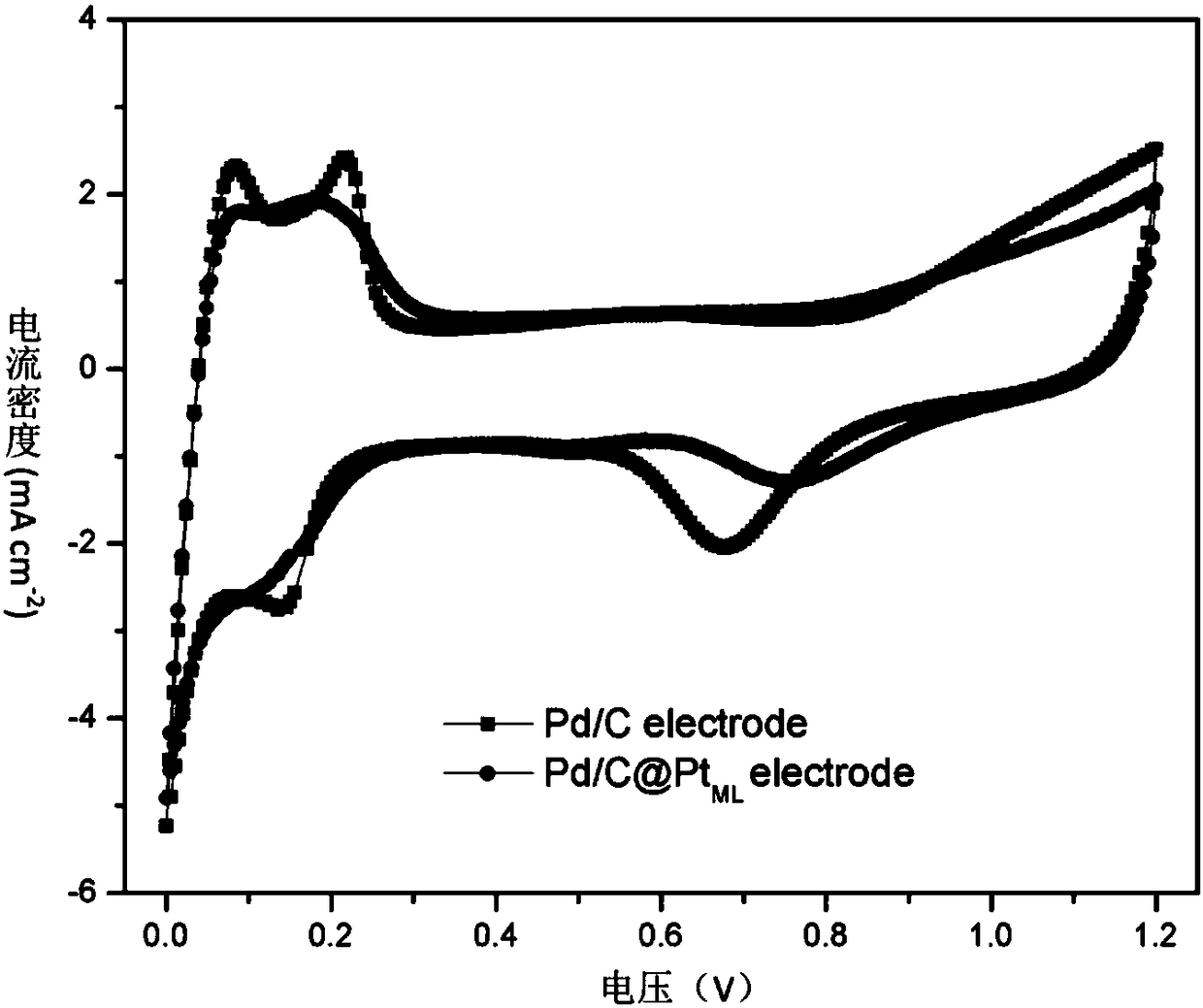

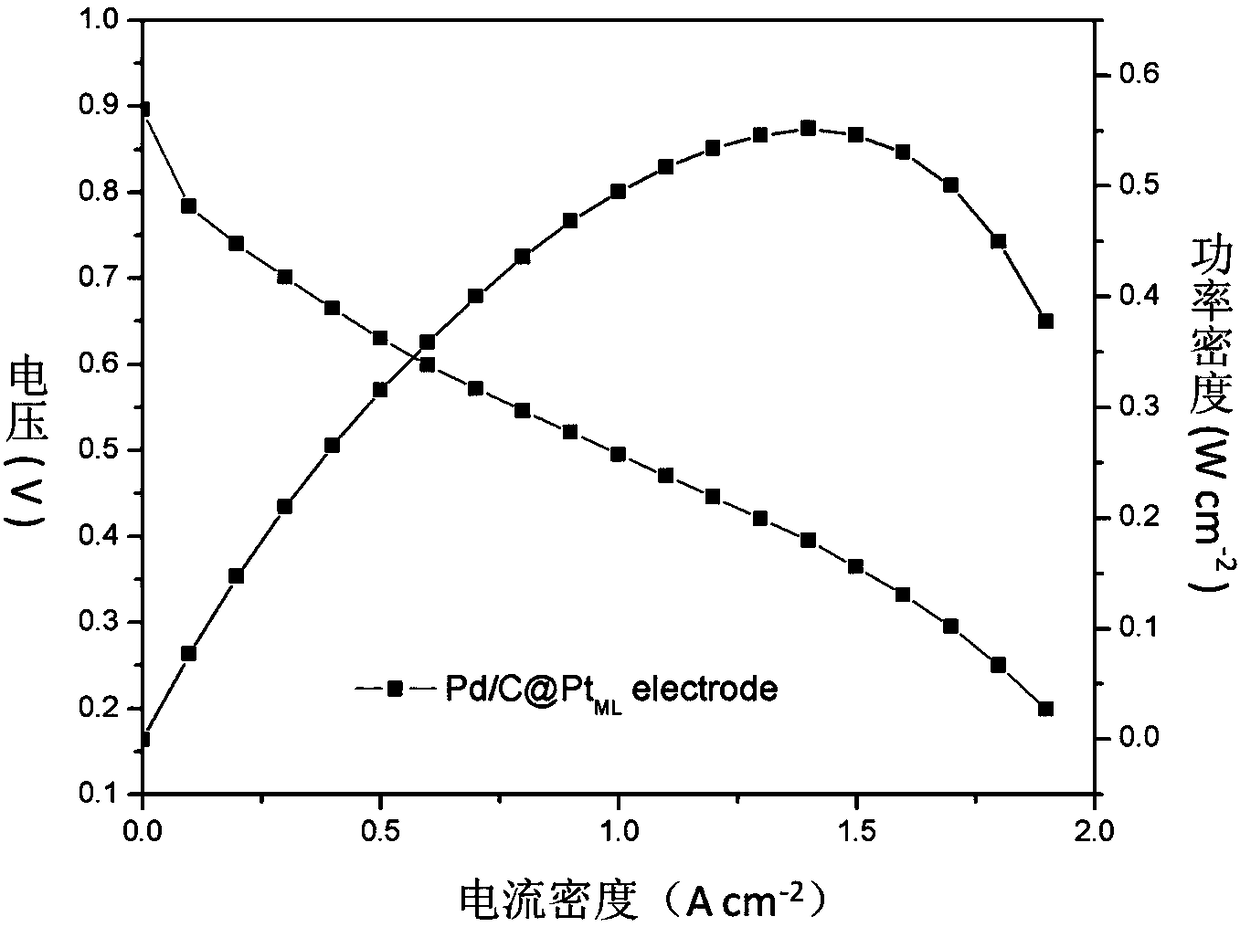

InactiveCN108075141AIncrease profitHighest Power Density ExcellentCell electrodesPlatinumElectrospinning

The invention discloses a method for directly preparing a catalytic layer of a platinum monoatomic layer used for a proton exchange membrane fuel cell. The method comprises the following steps of directly preparing a Pd / C catalytic layer in advance by using the catalytic layer through electrospinning technique, selecting polymer such as polyacrylic acid as a binder, afterwards, in a three-electrode system, adopting an underpotential deposition method to deposit Cu of a monoatomic layer on the Pd / C catalytic layer, then performing replacement to obtain the Pt of the monoatomic layer, and finally preparing a Pd / C@PtML catalytic layer. The Pd / C@PtML catalytic layer serves as a cathode, the Pd loading is 0.15mg / cm<-2>, the Pt loading is 0.02mg / cm<-2>, the maximum power density of a single cellis 560mW / cm<-2> (H2-Air), so that the Pd / C@PtML catalytic layer is superior to a catalytic layer of which the cathode Pt loading is 0.09mg / cm<-2>. By carrying out single cell acceleration attenuationtests on two catalytic layers, the Pd / C@PtML catalytic layer can be found to have better stability.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

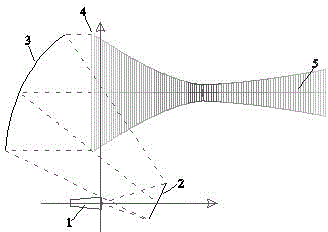

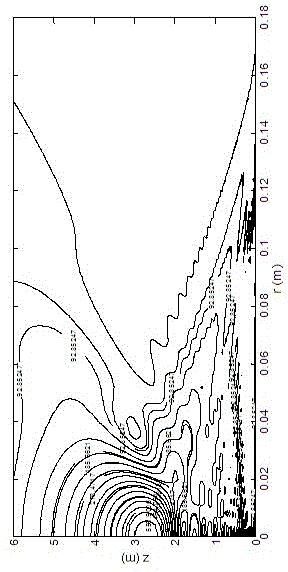

Millimeter-wave dual reflector antenna capable of focusing near-field wave beam

ActiveCN104103911AImprove power densityIncreased maximum power densityAntennasEffective powerParaboloid

The invention discloses a millimeter-wave dual reflector antenna capable of focusing a near-field wave beam. The antenna comprises a main reflector, an auxiliary reflector and a feed source, wherein a wave beam emitted by the feed source is reflected by the auxiliary reflector to the main reflector, and then emitted; a curved surface of the main reflector is a revolution paraboloid; and a central point of the main reflector is located at an intersection point of an emitting central axis of the auxiliary reflector and an axis of a radiation wave beam. The antenna is simple in structure and mature to process; the power density of a near-field region axis of the antenna is improved; the maximum power density of the axis is improved greatly under the same input power; a distance range of an effective power threshold is expanded; the efficiency of the antenna is improved; and a near-field gain of the antenna is increased.

Owner:中久安特装备有限公司

Method for manufacturing supercapacitor material by coating MOF (metal organic frame) with dopamine

InactiveCN109741958AIncrease energy densityImprove performanceHybrid capacitor electrodesVulcanizationMetal-organic framework

The invention relates to a method for manufacturing a supercapacitor material by coating a MOF (metal organic frame) with dopamine, comprising the following steps: taking a bi-metal MOF as a template,coating with dopamine, annealing and vulcanizing to obtain a supercapacitor material of a Zn<x>Co<1-x>S@C (x = 0.01-1.0) hollow structure, wherein the bi-metal MOF contains two metal nodes of Zn andCo. According to the method in the invention, the bi-metal MOF is used as a template and a raw material, coating vulcanization with dopamine is carried out to form a stable hollow structure Zn<x>Co<1-x>S@C (x = 0.01-1.0), which is used as a high-performance supercapacitor positive electrode material, excellent performance is shown, the energy density is up to 55. 47 Wh kg<-1>, and the maximum power density which can be achieved is 16.55 kW kg<-1>.

Owner:SHANDONG UNIV

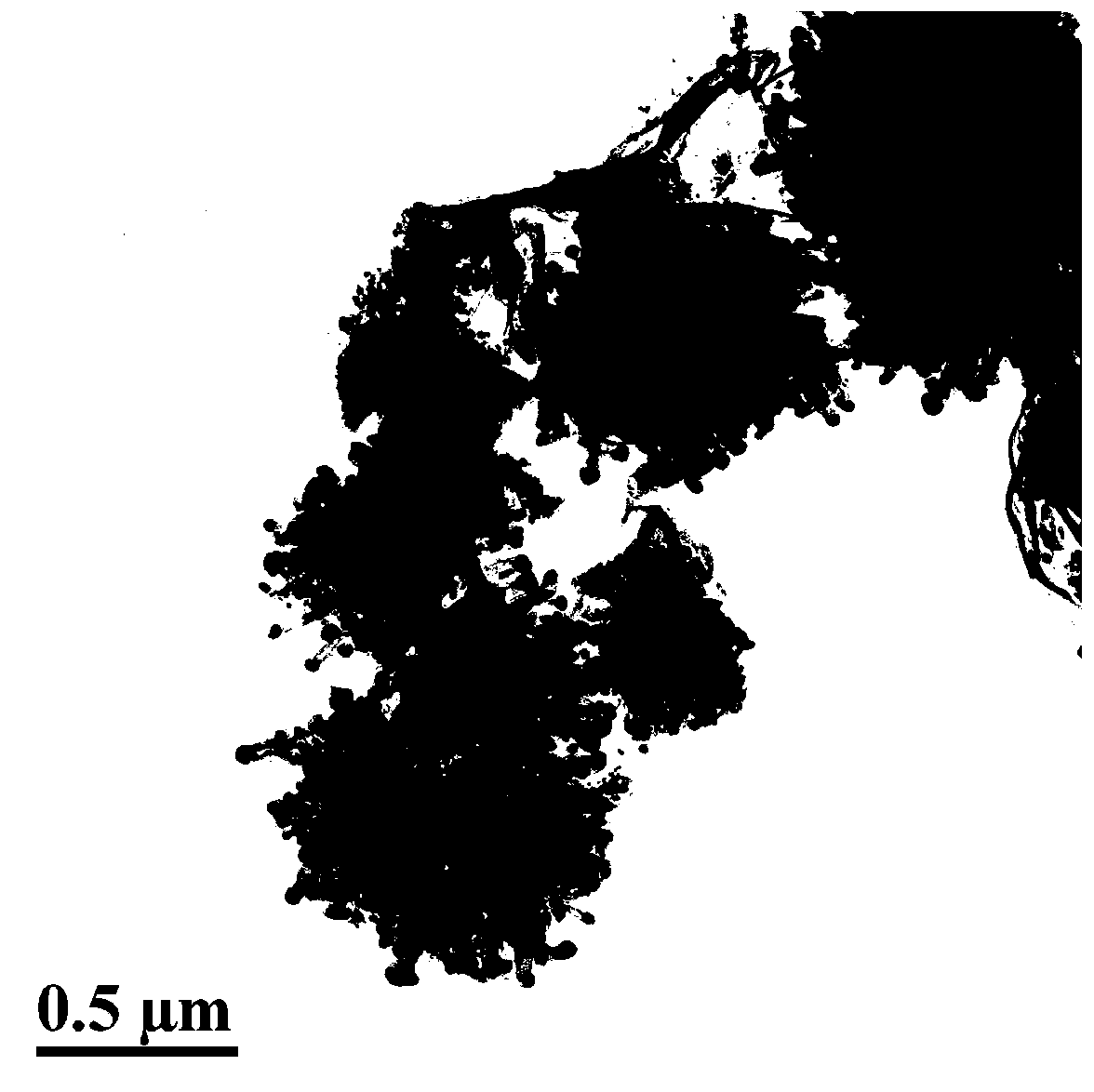

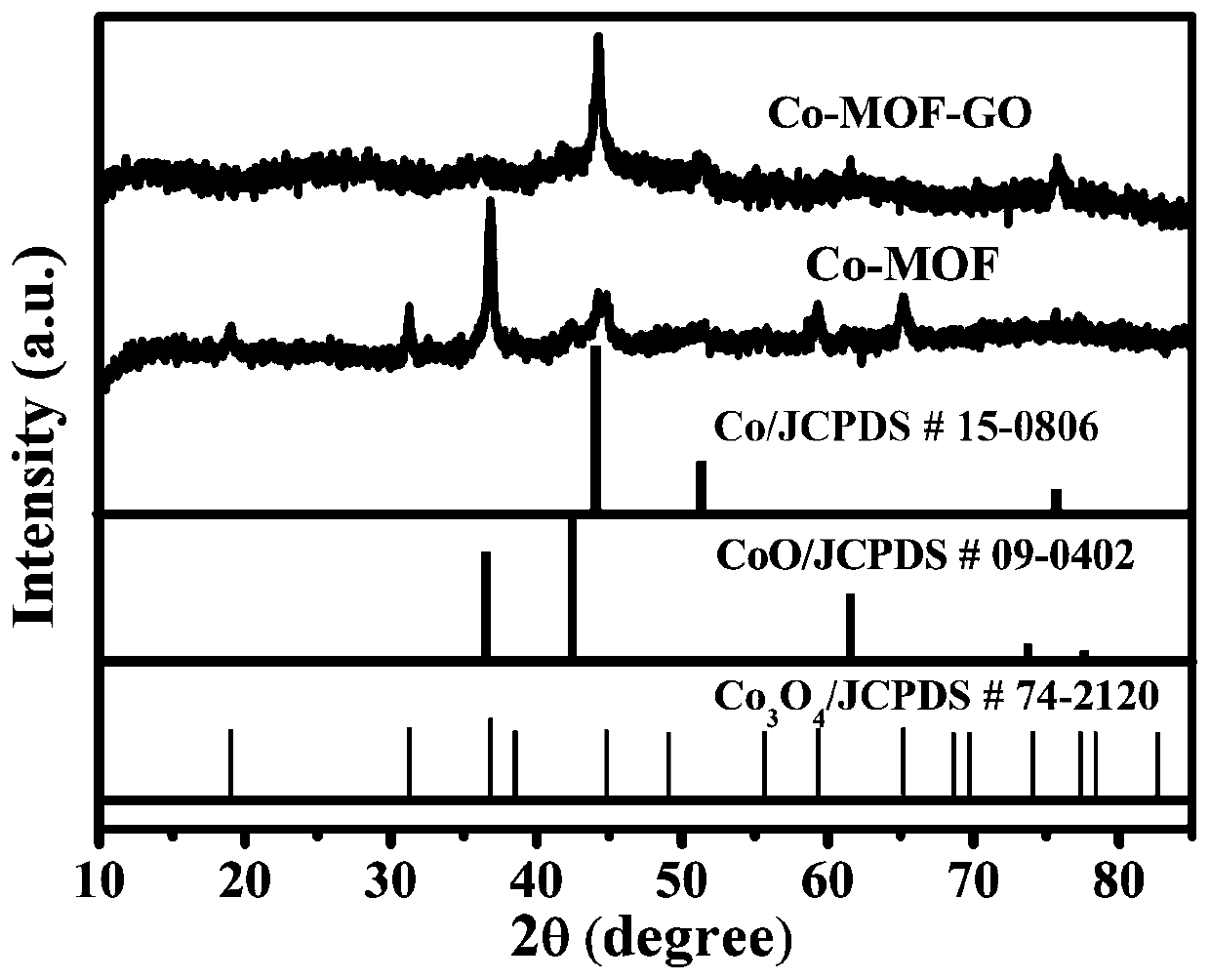

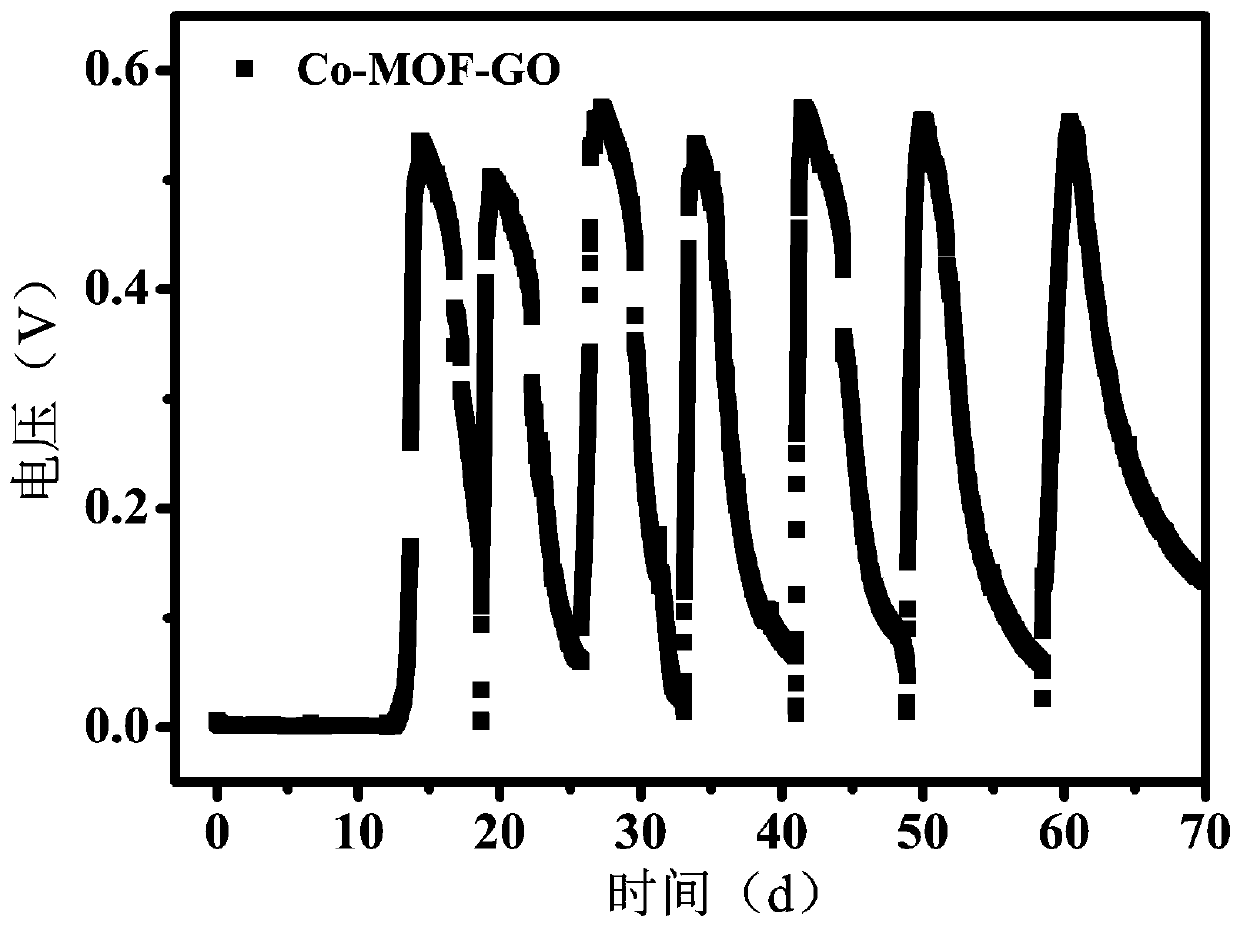

Preparation method of Co-MOF-GO film for microbial fuel cell and MFCs constructed by preparation method

ActiveCN109962228AHigh degree of graphitizationReduce transfer resistanceCell electrodesBiochemical fuel cellsVacuum dryingChemistry

The invention discloses a preparation method of a Co-MOF-GO film for microbial fuel cell and MFCs constructed by the preparation method, and belongs to the technical field of microbial fuel cells. Theinvention aims at solving the problems that an existing MFC anode is high in potential, low in power, short in period and the like. The preparation method comprises the following steps: 1, adding GOto water, performing uniform mixing, sequentially adding cobaltous nitrate hexahydrate and dimethyl imidazole, performing magnetic stirring, performing centrifuging, performing cleaning, and carryingout vacuum drying to obtain nanoparticles; 2, carrying out heat preservation heating under inert gas, and performing cooling to room temperature; 3, adding isopropyl alcohol and Nafion solution, and enabling the solution to uniformly disperse; 4, coating two sides of the carbon cloth with the mixture, and naturally drying the mixture. The constructed microbial electrolytic cell is an H-type double-chamber MECs. The maximum voltage of the MFCs is 0.56 V, the period is long, the COD removal rate reaches 79.195% + / -3.4766%, the coulombic efficiency reaches 9.3151% + / -0.5416%, and the maximum power density is 2303mV / m<2>.

Owner:HARBIN UNIV OF SCI & TECH

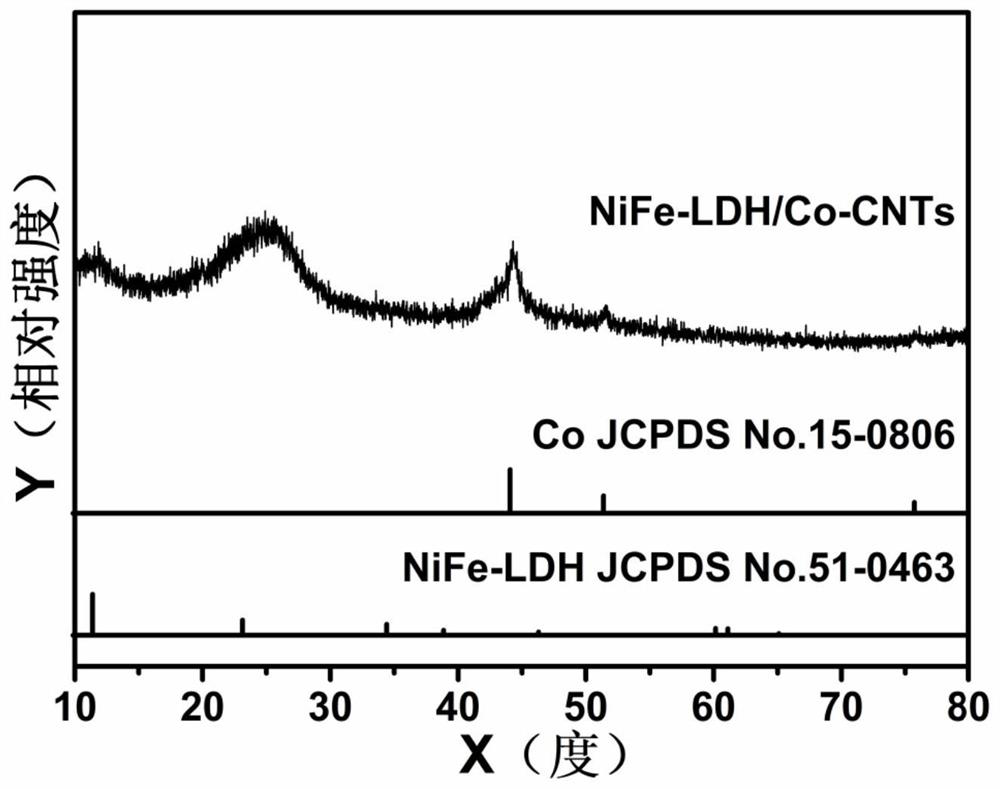

NiFe-LDH/Co-CNTs nano composite material and preparation method and application thereof

ActiveCN113113615AGood OER performanceExcellent OER performanceFuel and secondary cellsCell electrodesNanocompositeNanomaterials

The invention relates to the technical field of preparation of air electrode materials of rechargeable zinc-air batteries, in particular to a NiFe-LDH / Co-CNTs nanocomposite and a preparation method and application thereof. The method comprises the following steps: taking cobalt salt and 2-methylimidazole as reaction raw materials, taking carbon cloth as a substrate, growing to obtain a Co-ZIF nanosheet, and carbonizing to obtain a Co-CNTs / CC nano material; and then carrying out a hydrothermal reaction in a nickel salt and iron salt mixed solution, and obtaining the NiFe-LDH / Co-CNTs nano composite material with the surfaces of the Co-CNTs wrapped with NiFe-LDH. The material has high bifunctional activity, high power density and high stability; when the material is applied to a rechargeable zinc-air battery, the power density is 194mWcm <-2 >, the material has relatively high energy conversion efficiency and cycling stability, and when the material is used as an integrated air electrode for assembling a flexible zinc-air battery, the maximum power density of 142mWcm <-2> is achieved.

Owner:ZHEJIANG NORMAL UNIVERSITY

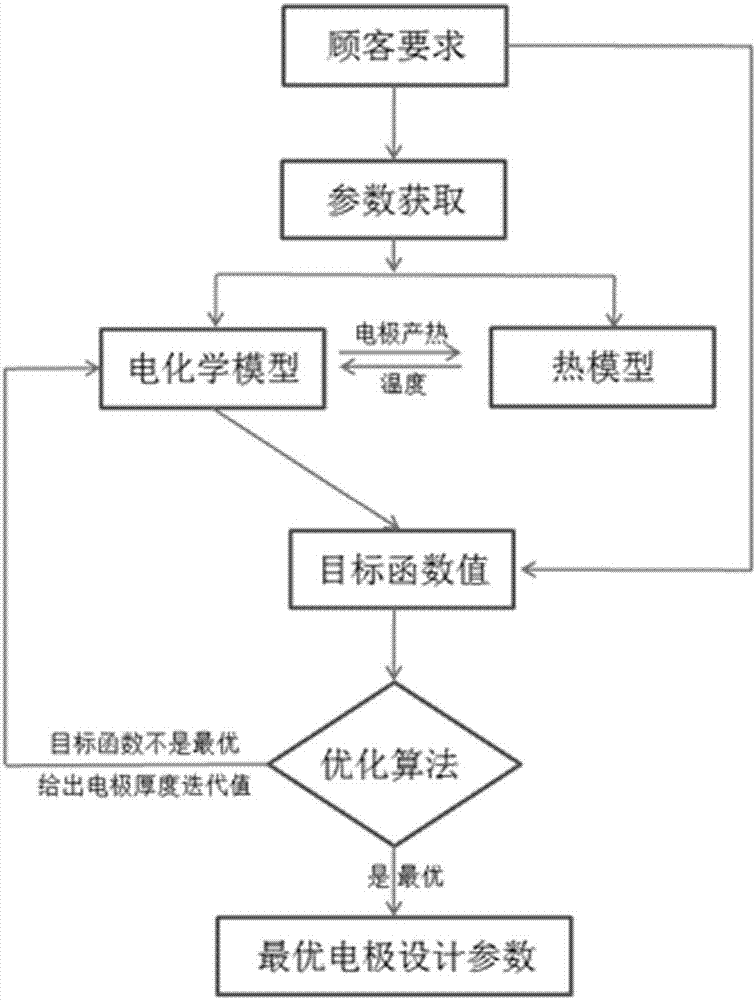

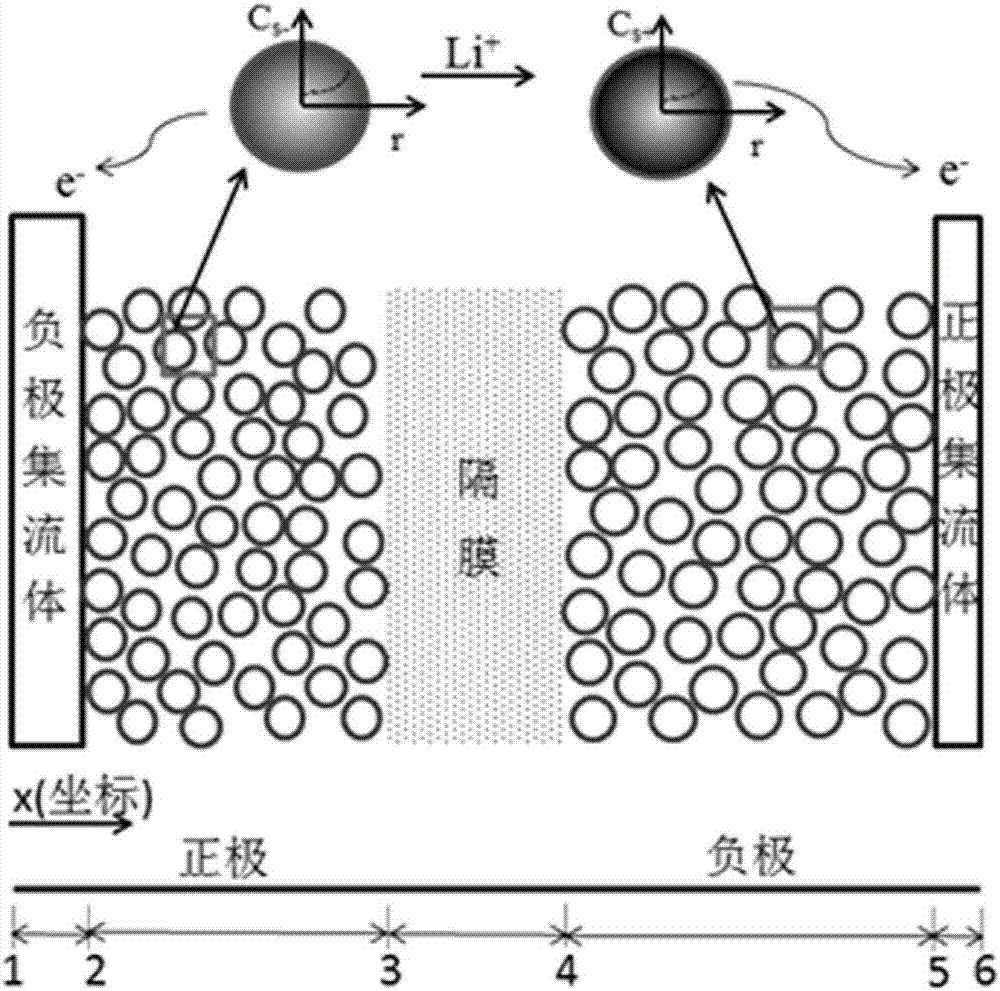

Method for optimizing thickness of battery electrode

InactiveCN107145629AShorten the development cycleReduce development costsDesign optimisation/simulationSpecial data processing applicationsCouplingEngineering

The present invention discloses a method for optimizing the thickness of a battery electrode. The method comprises the following steps: 1) taking the maximum energy density E or the maximum power density P as the optimization target of the method; 2) obtaining electrode structure design parameters, and electrode material kinetic parameters and thermophysical parameters of the base battery specification; 3) establishing an electrochemical thermo-coupling model, wherein the electrochemical thermo-coupling model is the coupling of a quasi-two-dimensional electrochemical model and a three-dimensional thermal model; 4) verifying the validity of the model; and 5) obtaining the optimized thickness of the battery electrode. According to the method disclosed by the present invention, the development period of new materials or new products can be effectively shortened, the development cost is reduced, and the certain guiding significance is offered for the development of new materials or new products.

Owner:CENT SOUTH UNIV

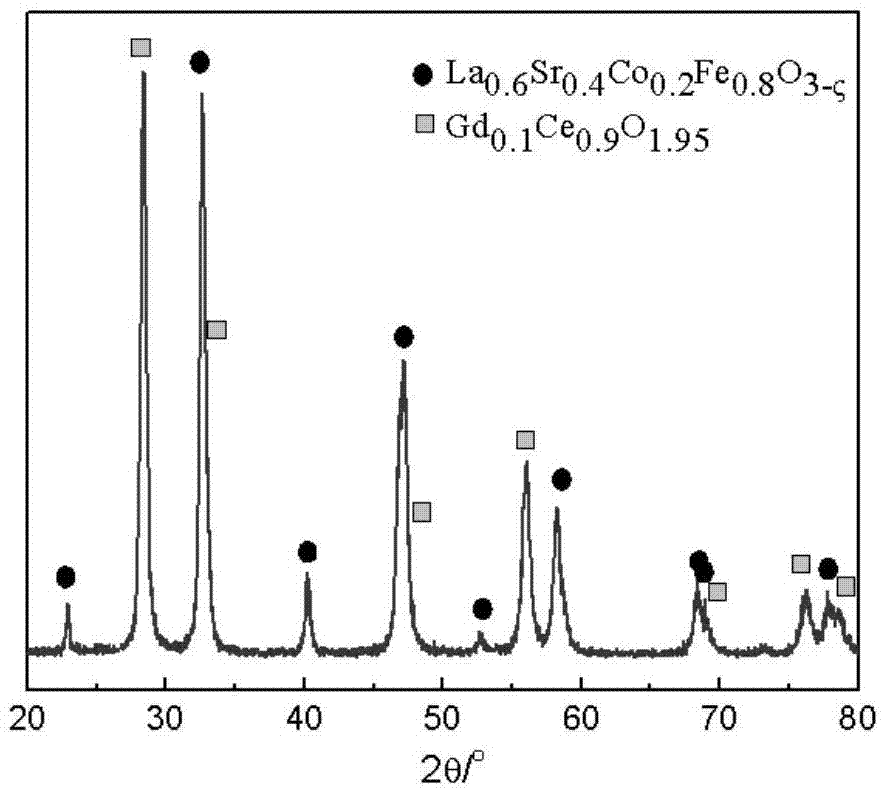

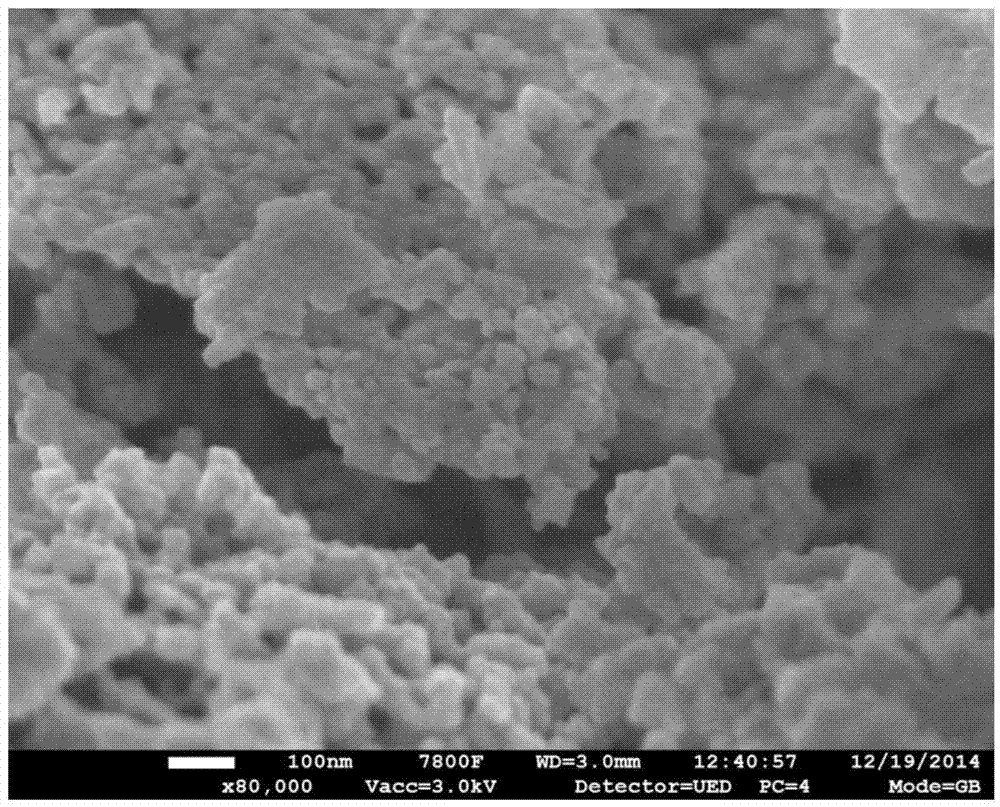

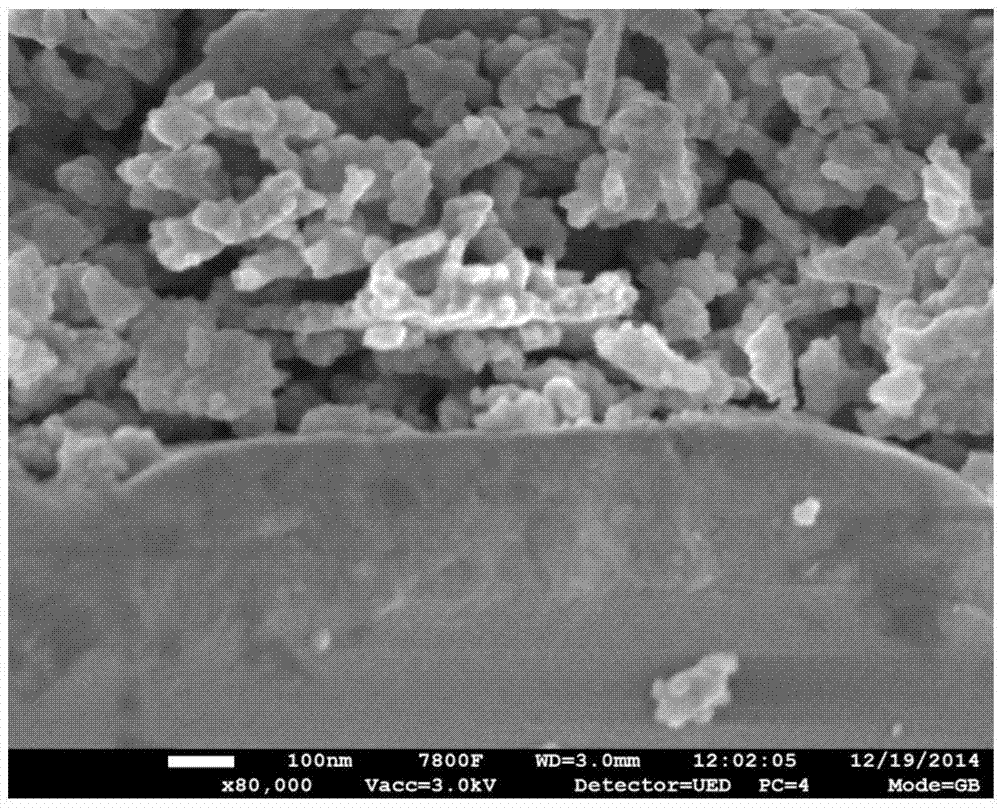

Method for preparing composite negative electrode on cerium-based electrolyte isolation layer through low-temperature sintering

ActiveCN106876755AEvenly distributedElectrochemically active sites decreaseCell electrodesSolid electrolyte fuel cellsSynthesis methodsCerium

The invention provides a method for preparing a composite negative electrode on a cerium-based electrolyte isolation layer through low-temperature sintering. According to the method, an ammonium citrate co-synthesis method is adopted to prepare battery negative electrode powder; roasted and phased powder is configured into negative electrode paste, and a three-in-one positive electrode / / electrolyte / cerium-based electrolyte isolation layer is coated with the paste; and the obtained product is sintered at a temperature of 700-800 DEG C to obtain the battery negative electrode. The composite negative electrode has perovskite and cubic fluorite phase at the same time, and the composite negative electrode is a mixed ion-electron conductor and has small and uniform particle sizes and large specific surface area; and compared with the negative electrode prepared by a conventional mechanical mixing method, the highest power density of the negative electrode prepared by the invention at a temperature of 700 DEG C is improved by about 20%, and stable operation of the battery can be achieved.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

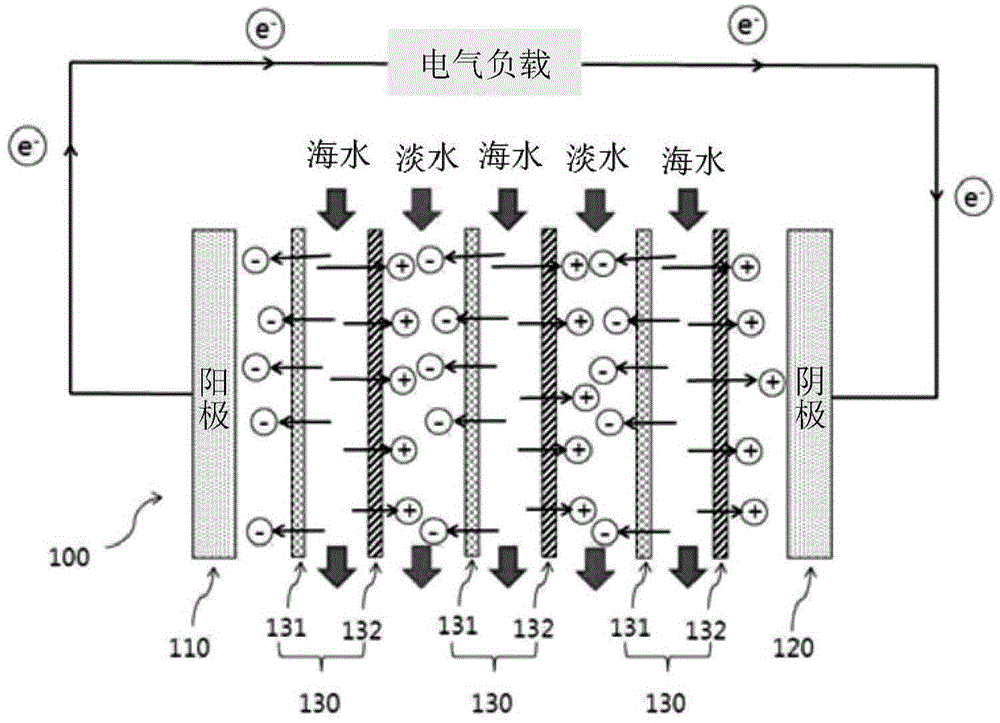

Ion exchange membrane for reverse electrodialysis device and reverse electrodialysis device including same

ActiveCN104437090AIncreased maximum output densityImprove water resistanceSolid electrolytesGeneral water supply conservationPolymer electrolytesPolymer substrate

This invention relates to an ion exchange membrane for a reverse electrodialysis (RED) device, a manufacturing method thereof and a reverse electrodialysis device including the ion exchange membrane, wherein the ion exchange membrane includes a porous polymer substrate; and a polymer electrolyte incorporated into pores of the porous polymer substrate. According to this invention, cation and anion exchange membranes for a reverse electrodialysis device have superior ion conductivity and thus can minimize membrane resistance, thereby remarkably improving maximum power density of the reverse electrodialysis device, and also have high water resistance and heat resistance, making it possible to stably operate the reverse electrodialysis device.

Owner:TORAY ADVANCED MATERIALS KOREA

Preparation method and application of supercapacitor material

InactiveCN106935417AIncrease energy densityIncreased maximum power densityHybrid capacitor electrodesHybrid/EDL manufacturePhosphateCharge discharge

The invention discloses a preparation method and application of a supercapacitor material. The process comprises the steps of mixing and heating acetylene black, sulfuric acid and sodium p-styrenesulfonate, and performing a series of operation such as heat preservation, cooling, dilution, centrifugal separation and washing to obtain a modified carbon black compound; adding lithium dihydrogen phosphate and nickel chloride in a reaction kettle for reaction, and performing acid processing after drying; mixing the product and a reactant obtained through high-temperature reaction of acrylonitrile power, dimethyl sulfoxide and tetraethyl orthosilicate, and adding distilled water for ultrasonic dispersion, adding waterborne polyurethane emulsion, cobaltosic sulfide, stannous chloride, a triethanolamine salt and a silane coupling agent for high-temperature reaction; and finally, performing washing and vacuum drying to obtain a finished product. The supercapacitor material obtained by preparation is high in energy density, maximum power density and charge-discharge efficiency, and has relatively good application prospect. Meanwhile, the invention also discloses application of the supercapacitor material prepared by the process in preparation of a supercapacitor.

Owner:SUZHOU HAILINGDA EIECTRONIC TECH CO LTD

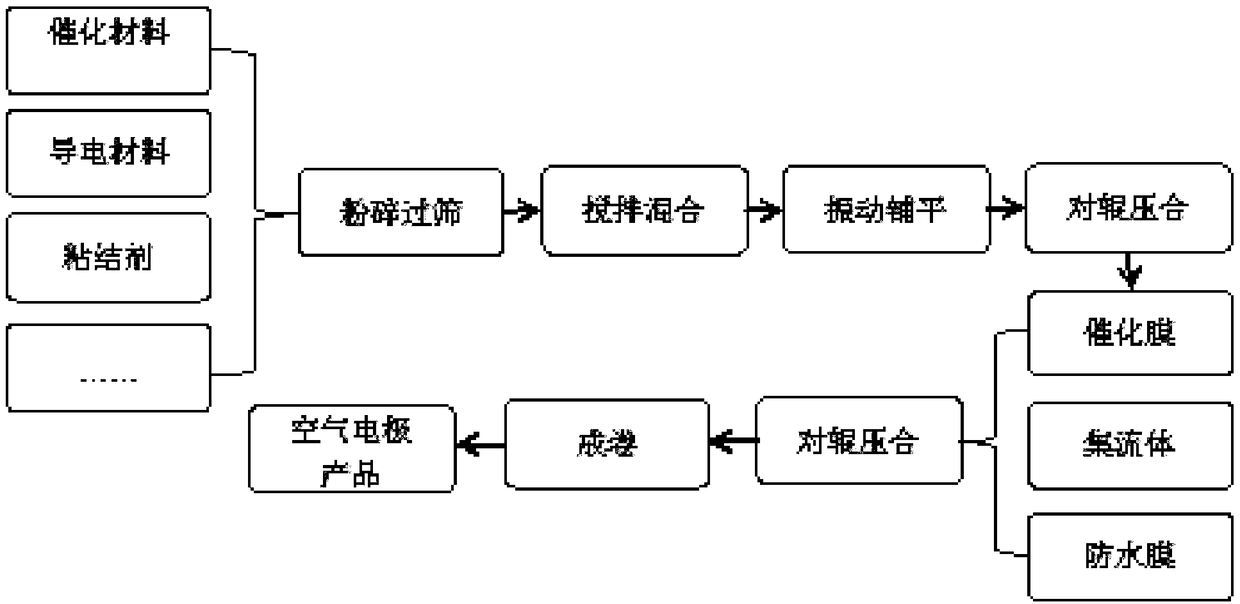

Preparation method of air electrode and aluminum air battery

InactiveCN108878901AEvenly distributedIncreasing the thicknessFuel and primary cellsCell electrodesMass ratioConductive materials

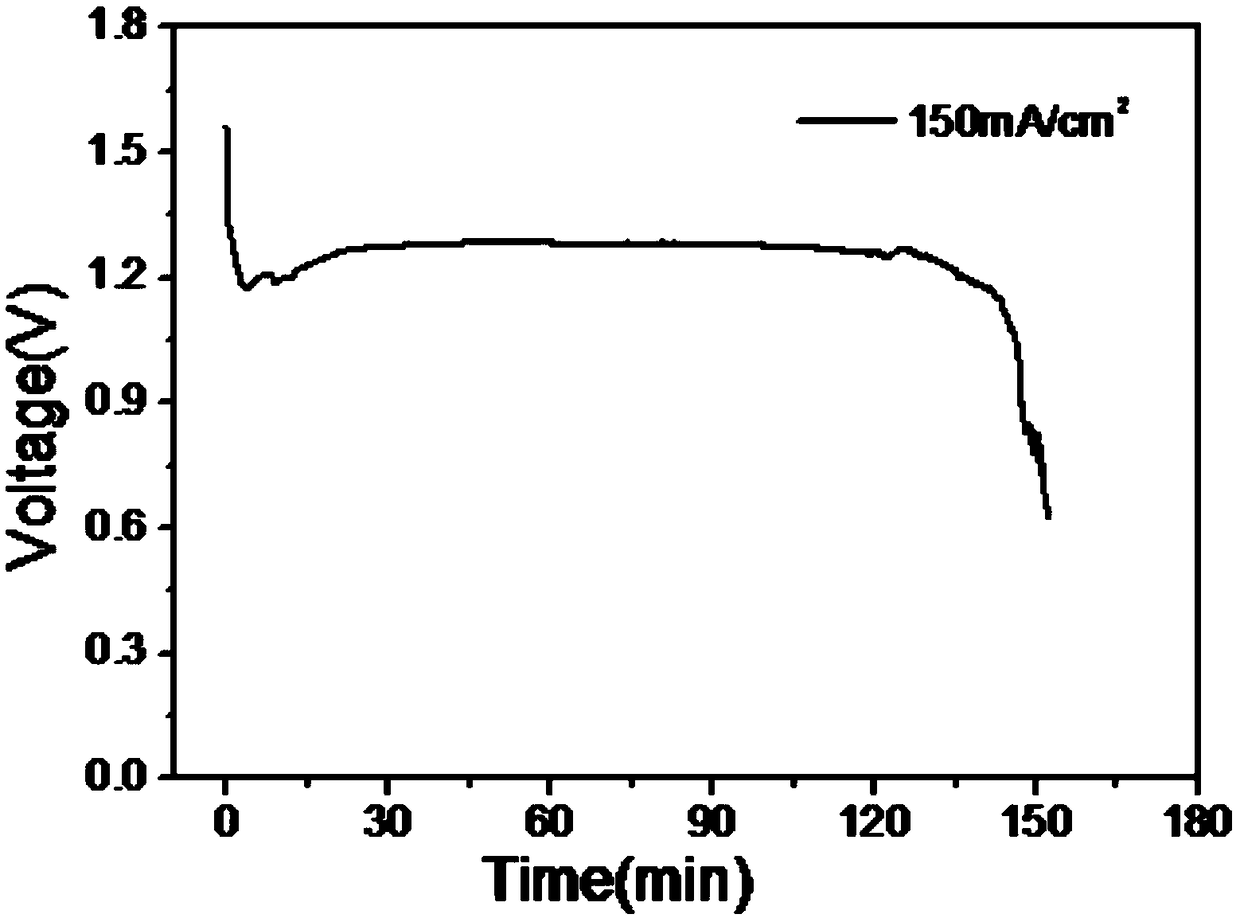

The invention discloses a preparation method of an air electrode and an aluminum air battery and relates to the technical field of batteries. The air electrode is prepared through the steps of mixingcatalyst material powder, conductive material powder and binder powder evenly through mixing equipment at a mass ratio of (10-40):(40-80):(10-30); directly pressing the mixture into a catalytic membrane through rolling equipment and directly laminating the catalytic membrane, a current collector and a waterproof membrane. The preparation technology method disclosed by the invention is simple, massproduction of the air electrode can be achieved, and the consistency of the air electrode is ensured through improving uniform distribution of materials in the electrode. The air electrode prepared by adopting the method is assembled into the aluminum air battery, the maximum power density can reach 300mW / cm<2>, the curve of the battery is stable in a constant-current discharge test (150mA / cm<2>), the utilization rate of negative electrode aluminum can reach 89% and the aluminum air battery has good electric property.

Owner:北京创能惠通新能源科技有限公司

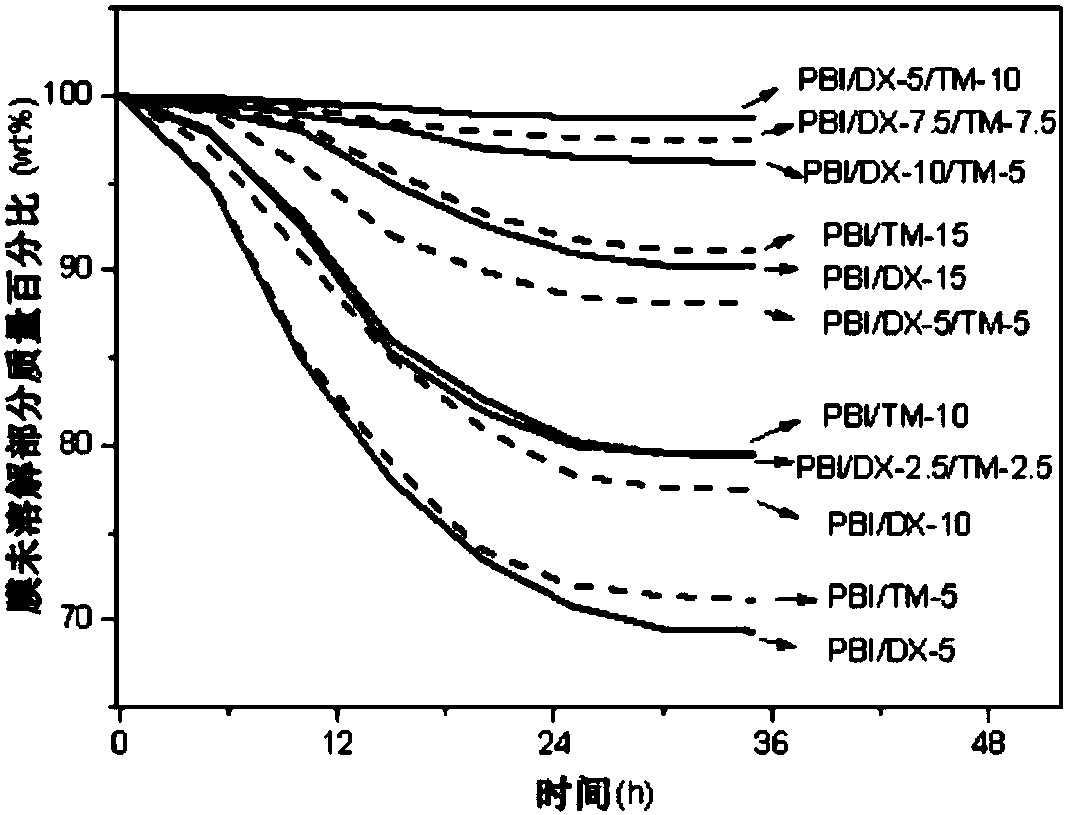

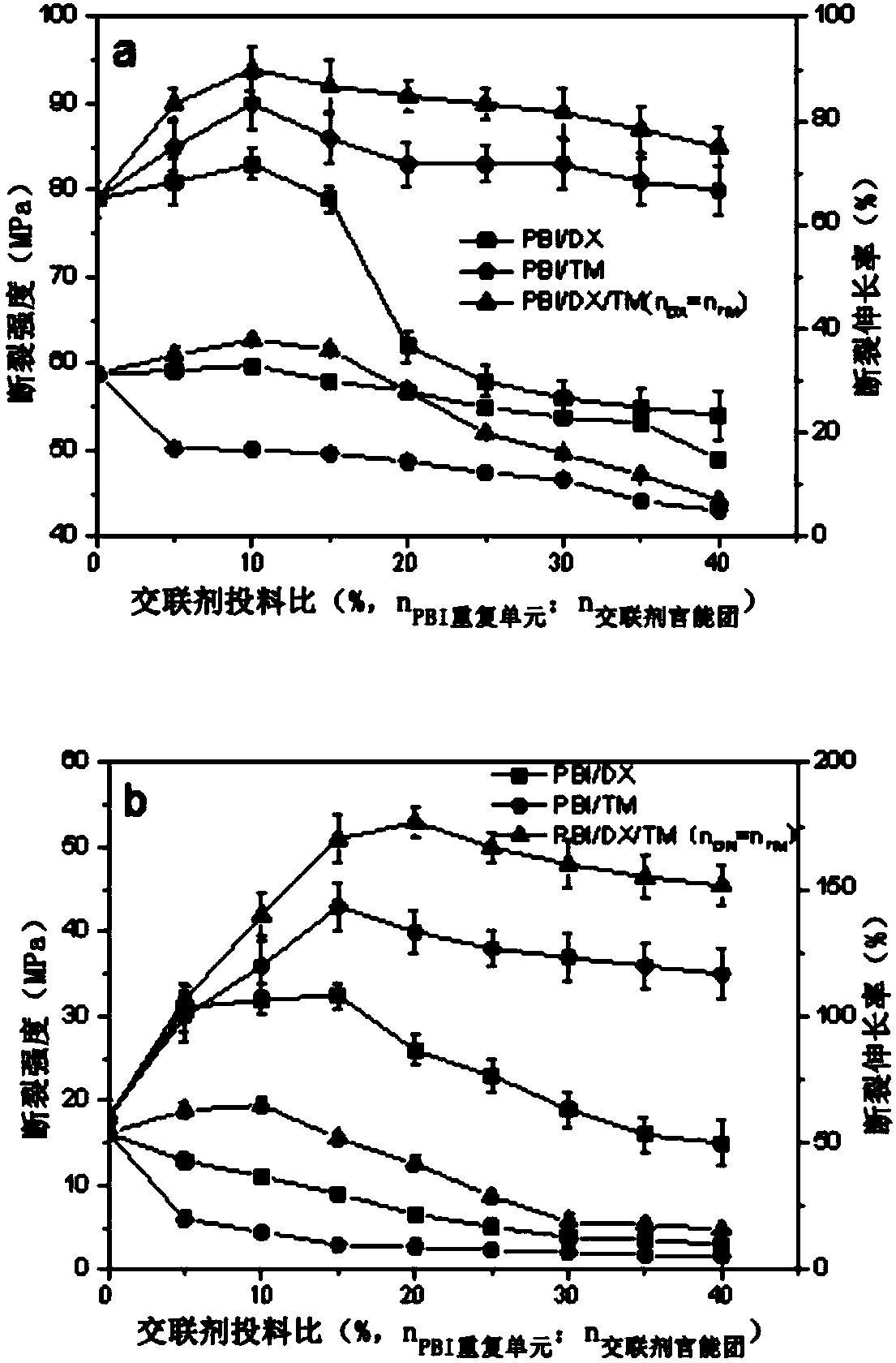

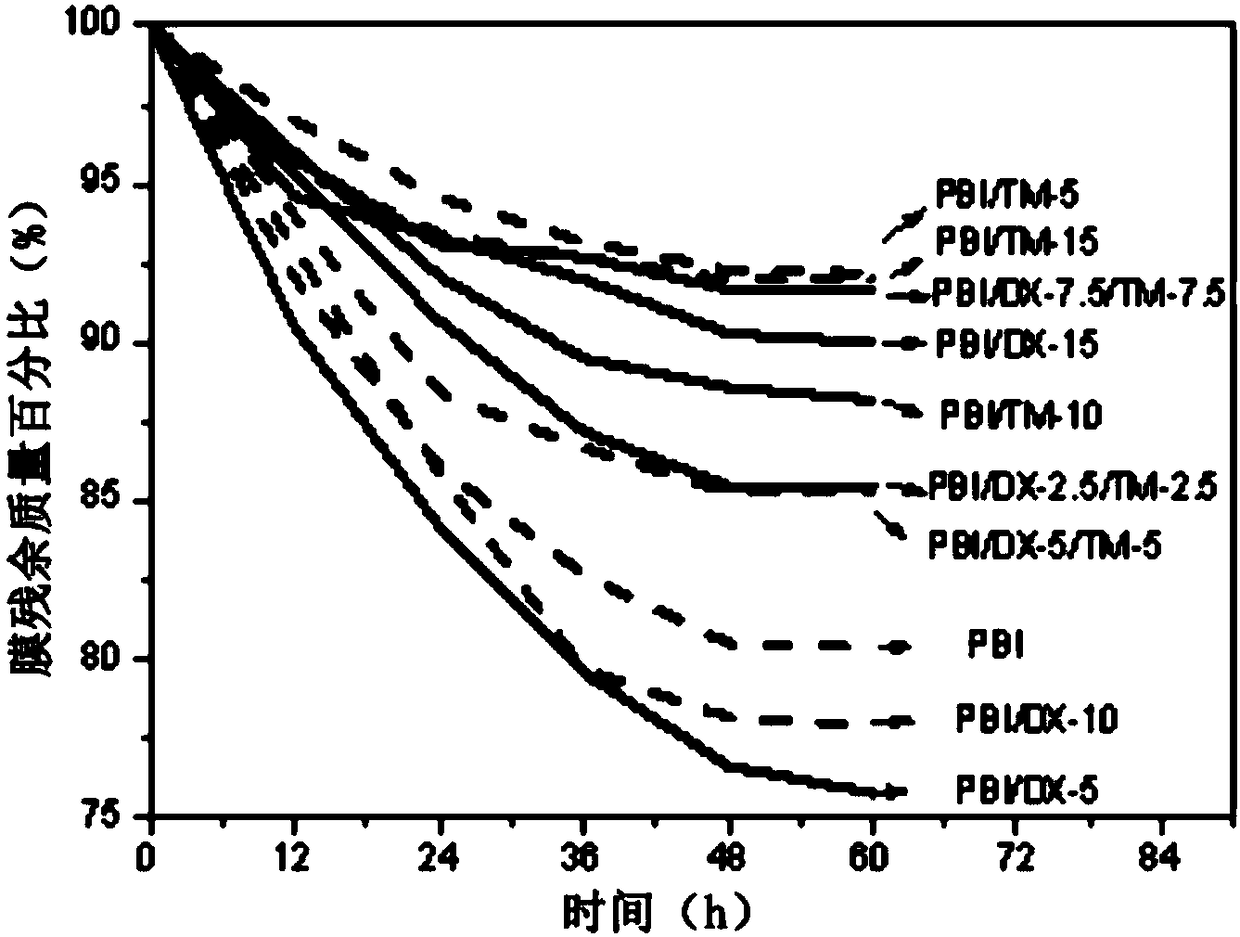

Polybenzimidazole proton conducting membrane with double-network structure and preparation method thereof

InactiveCN108539235ATo overcome the shortcomingsOvercome deficienciesFuel cellsCross-linkPhosphoric acid

The invention belongs to the technical field of functional materials, and particularly relates to a polybenzimidazole proton conducting membrane with a double-network structure and a preparation method thereof. By using two cross-linking agents with different reaction temperatures to perform twice crosslinking on a linear PBI under different temperature conditions, the PBI membrane which has a double-network structure and can be used for a high-temperature fuel cell proton exchanging membrane is prepared. The test shows that when the modified membrane reaches the same gelling rate, the consumption of the cross-linking agent for the double-network structural membrane is reduced by 40 to 60 percent compared with that of the single-network structural membrane; and moreover, the cross-linkinggrid density is more uniform, the methanol permeability / air permeability / phosphoric acid migration rate is lower, the mechanical performance is better after the phosphoric acid is doped, and the chemical stability and thermal stability of the double-network membrane are higher than that of the non-modified PBI membrane; and meanwhile, the proton conducting rate (the proton conducting rate is 10<2>S.cm<1> scale with the linear PBI / phosphoric acid system) and the single cell performance (the maximum power density is 350 mW.cm<2>, and the current density is 1150mA.cm<2>) are high.

Owner:TONGJI UNIV

Formulation of nano-scale electrolyte suspensions and its application process for fabrication of solid oxide fuel cell-membrane electrode assembly (SOFC-MEA)

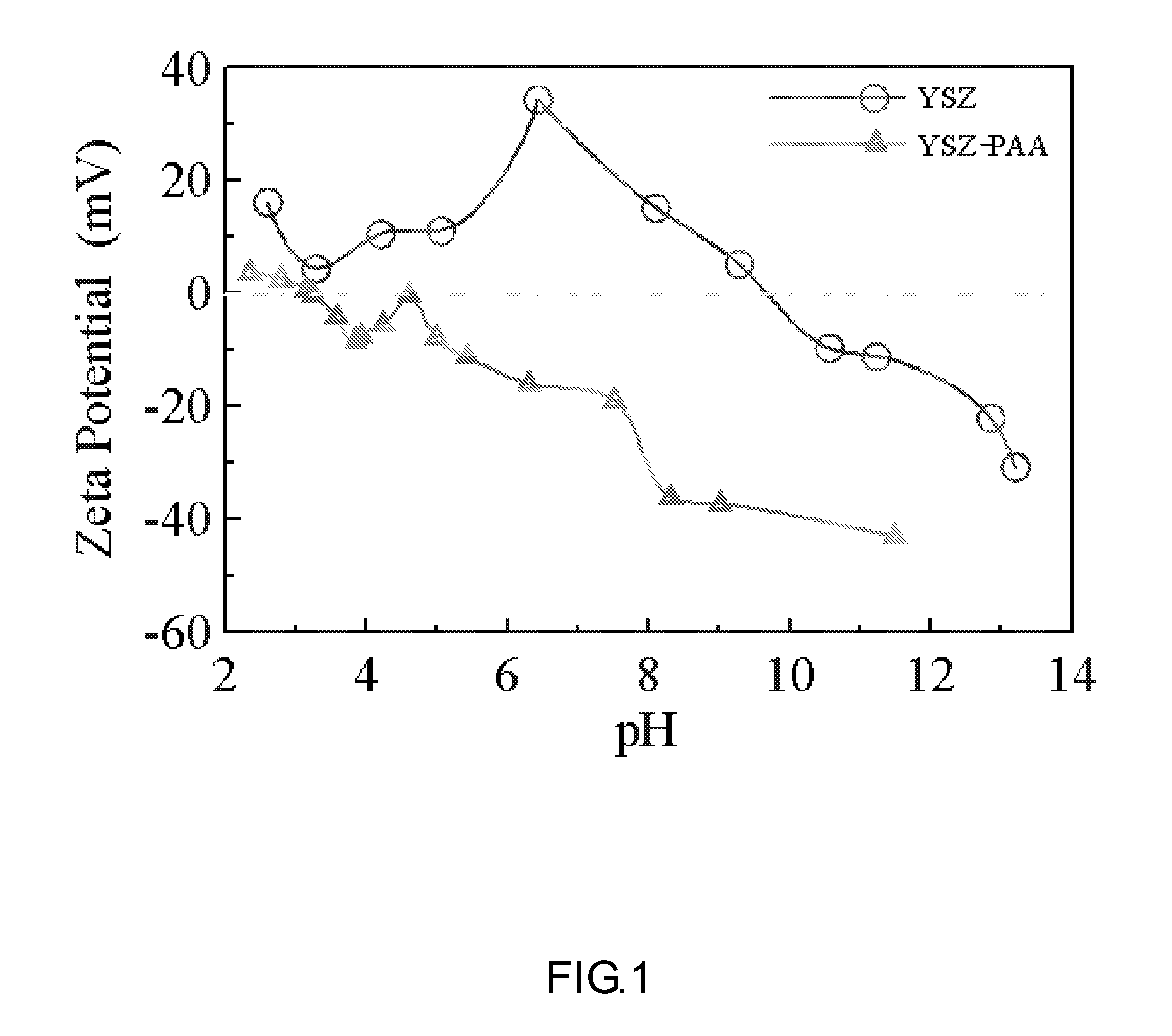

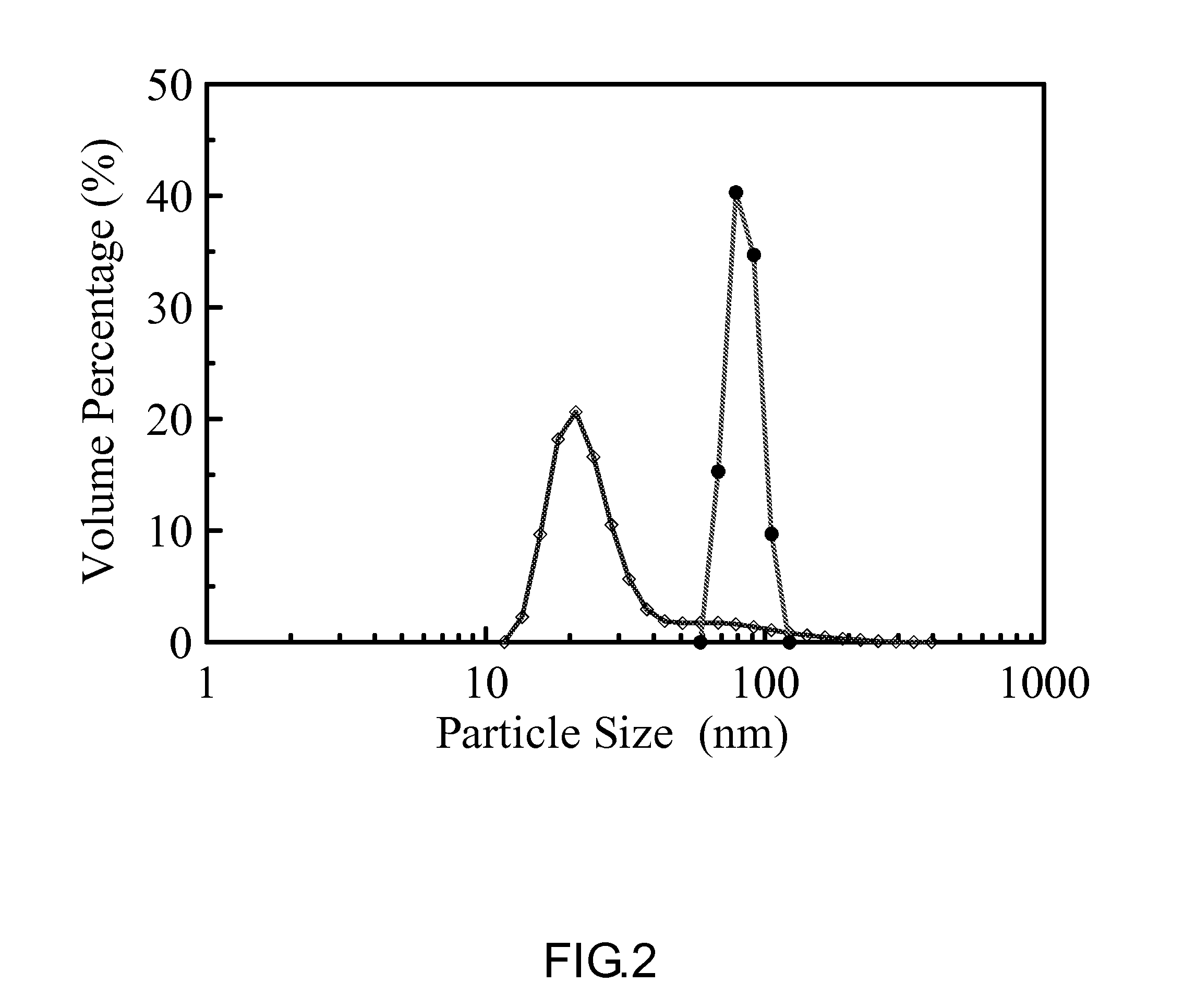

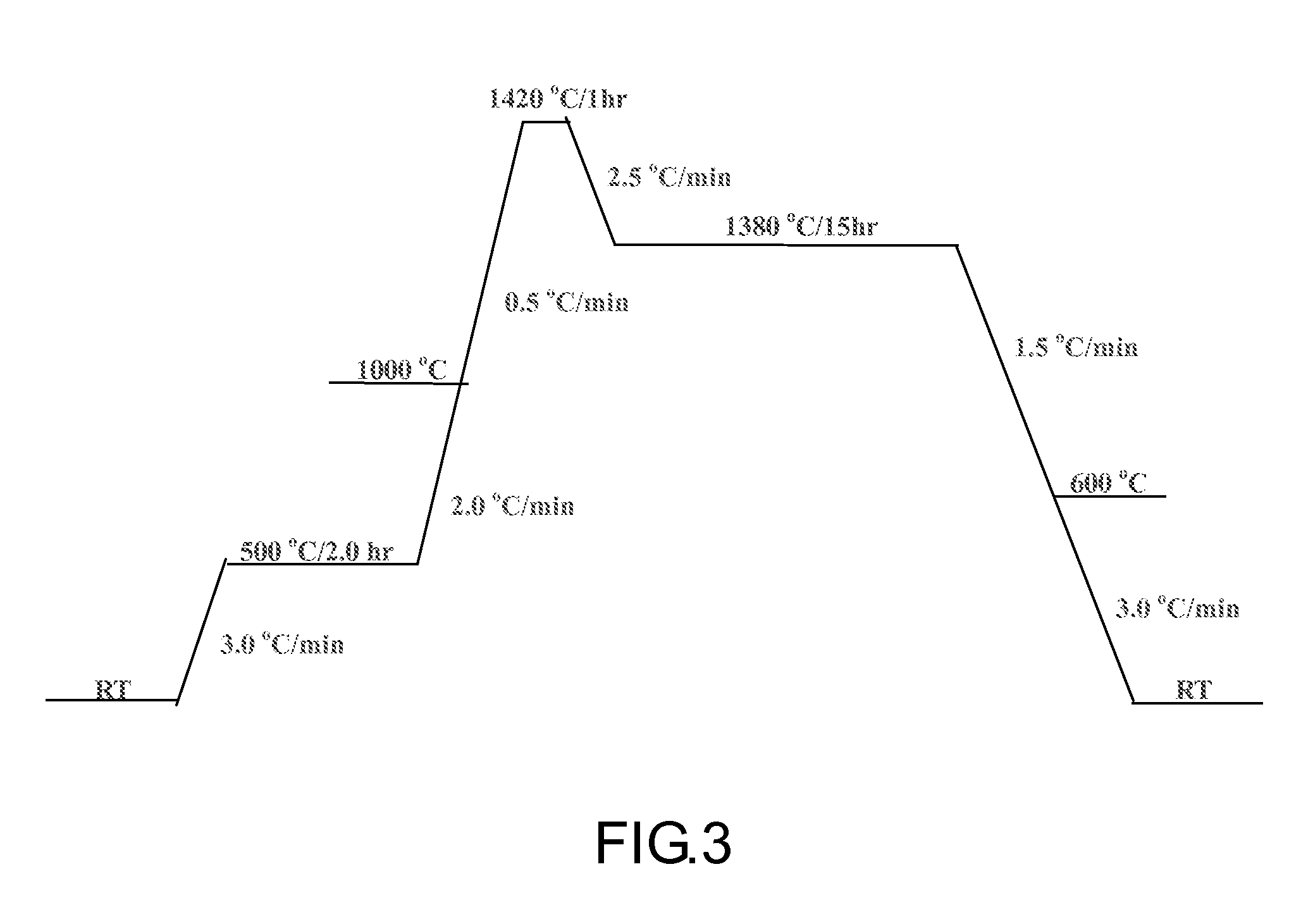

ActiveUS20100018036A1Improve electrochemical performanceIncreased durabilityFinal product manufacturePrimary cellsPolyvinyl alcoholOctanol

This invention describes the recipe and preparation process of nano-scale electrolyte suspension and its application via a spin coating process for fabrication of airtight / fully dense electrolyte layers composed in solid oxide fuel cell-membrane electrode assembly with high performance characteristics. The recipe of nano-scale electrolyte suspension includes 10˜50 wt % nano-scale electrolyte powder, 0.01˜1 wt % poly acrylic acid (PAA as dispersant), 0.1˜5 wt % poly vinyl alcohol (PVA as binder), 0.005˜1 wt % octanol as defoamer, and deionized water as solvent. Solid oxide fuel cell fabricated via this recipe and process exhibits that the open-circuit voltage (OCV) is over 1 Volt, and maximum power density is 335 mW / cm2 at 800° C.

Owner:INST NUCLEAR ENERGY RES ROCAEC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com