Method for preparing composite negative electrode on cerium-based electrolyte isolation layer through low-temperature sintering

A composite cathode and electrolyte technology, applied in solid electrolyte fuel cells, battery electrodes, circuits, etc., can solve the problems of low battery performance, difficult powder uniform dispersion, and reduction of effective reactive sites in the cathode, etc., to achieve large specific surface area, Avoid the effect of non-uniform distribution of the two phases

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Co-synthesized by the ammonium citrate method

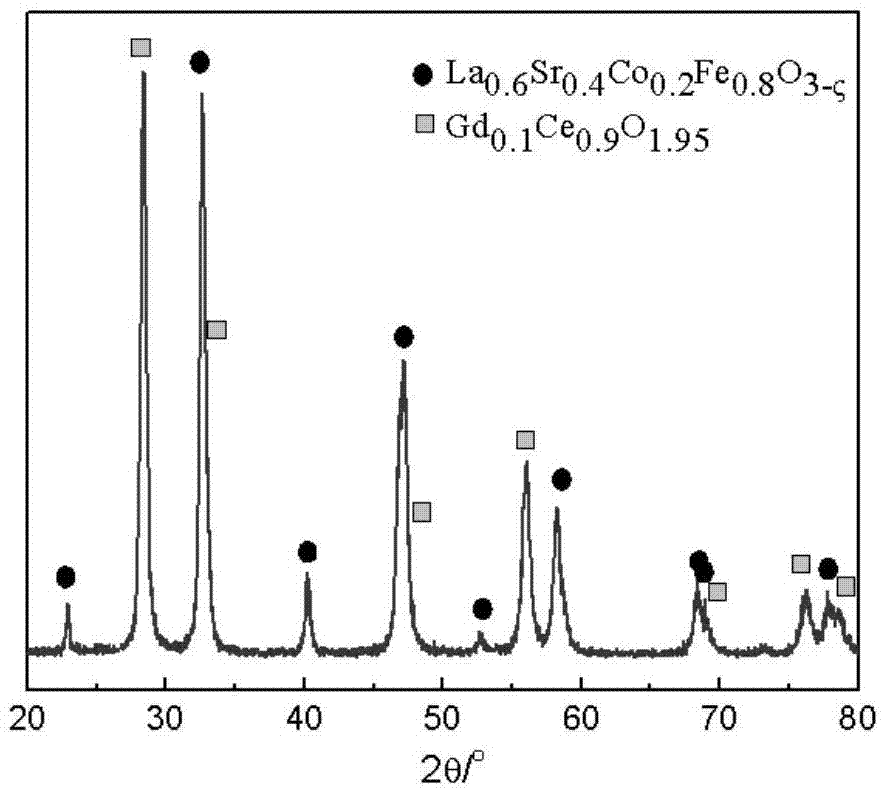

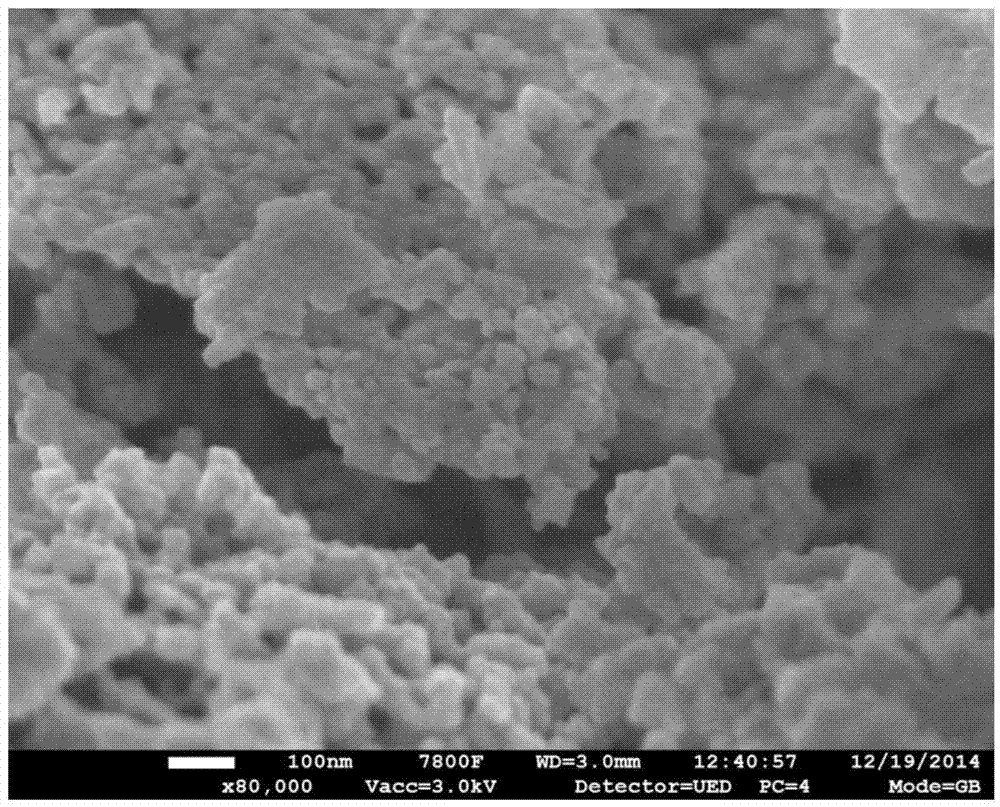

[0024] La 0.6 Sr 0.4 co 0.2 Fe 0.8 o 3-ζ / Gd 0.1 Ce 0.9 o 1.95 =60:40wt% composite cathode material, where La 0.6 Sr 0.4 co 0.2 Fe 0.8 o 3-ζ Take 0.05mol. Weigh 0.7783gGd 2 o 3 Powder (analytically pure), in a 500ml beaker, add HNO 3 (analytical pure) after stirring to dissolve completely, weigh 16.7817gCe(NO 3 ) 3 ·6H 2 O,12.9872gLa(NO 3 ) 3 ·6H 2 O (analytical pure), 4.2325gSr (NO 3 ) 2 (analytical pure), 2.9105gCo(NO 3 ) 2 ·6H 2 O,16.16gFe(NO 3 ) 3 9H 2 O (analytical pure) was added into a beaker with deionized water and stirred to dissolve it completely. Then add 52.1496g of ammonium citrate (analytical pure) according to the ratio of ammonium citrate: metal ion molar ratio of 1.5:1, adjust the pH=9 of the solution with ammonia water (analytical pure) to make the solution clear and transparent, then heat and stir to evaporate the solvent Pour the solution into an evaporating dish until the...

Embodiment 2

[0026] Co-synthesized by citric acid-EDTA method

[0027] La 0.6 Sr 0.4 co 0.2 Fe 0.8 o 3-ζ / Gd 0.1 Ce 0.9 o 1.95 =60:40wt% composite cathode material, where La 0.6 Sr 0.4 co 0.2 Fe 0.8 o 3-ζ Take 0.05mol. Weigh 0.7783gGd 2 o 3 Powder (analytically pure), in a 500ml beaker, add HNO 3(analytical pure) after stirring to dissolve completely, weigh 16.7817gCe(NO 3 ) 3 ·6H 2 O,12.9872gLa(NO 3 ) 3 ·6H 2 O (analytical pure), 4.2325gSr (NO 3 ) 2 (analytical pure), 2.9105gCo(NO 3 ) 2 ·6H 2 O,16.16gFe(NO 3 ) 3 9H 2 O (analytical pure) was added into a beaker with deionized water and stirred to dissolve it completely. Then according to citric acid: EDTA: the ratio of metal ion mol ratio is 1.2:1.2:1 to add 36.0454g citric acid (analytical pure), 50.1281gEDTA (analytical pure), adjust the pH=9 of solution with ammonia water to make solution become clear and transparent, Then heat and stir to evaporate the solvent until the solution becomes viscous and sol-lik...

Embodiment 3

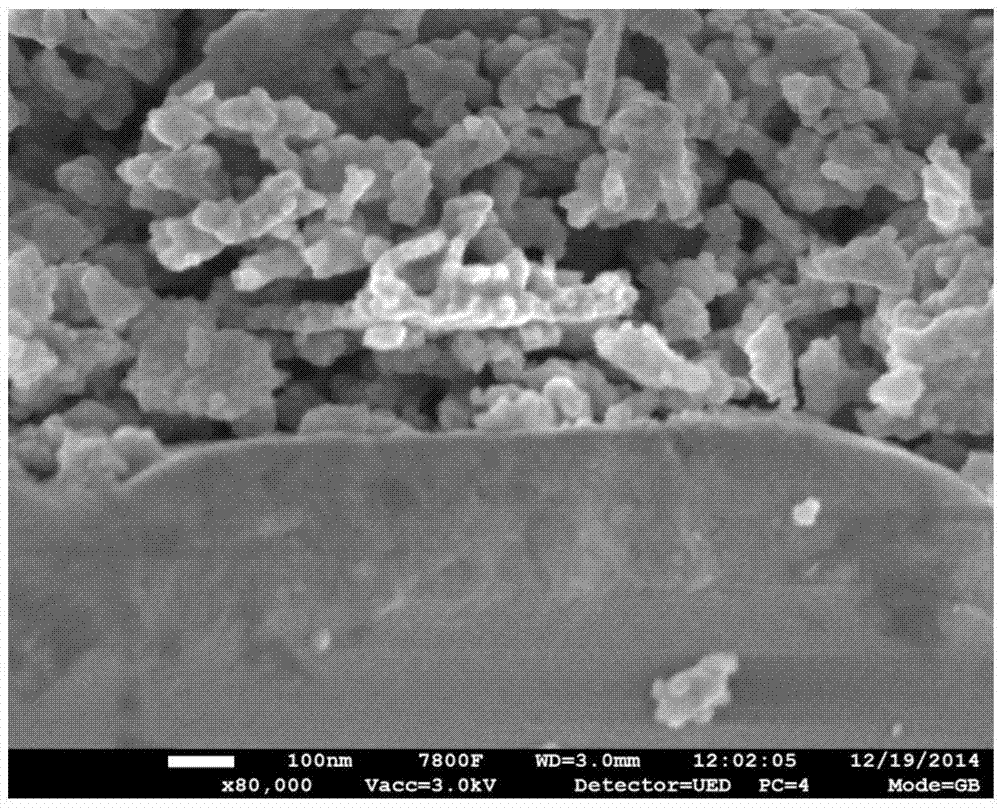

[0029] Prepare La as in Example 1 0.6 Sr 0.4 co 0.2 Fe 0.8 o 3-ζ / Gd 0.1 Ce 0.9 o 1.95 =60:40wt% composite cathode material, after grinding evenly, add 40wt% cathode glue (the composition of adding glue is the terpineol (90wt%) solution that dissolves ethyl cellulose (10wt%)) configuration cathode slurry, coating 0.0100 g to Gd 0.1 Ce 0.9 o 1.95 Tested on the self-assembled battery evaluation device after sintering at 700°C for 2 hours on the interlayer, and tested the I-V curve after polarizing at 700°C for 18 hours, the results are as follows Figure 4 shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com