Preparation method of air electrode and aluminum air battery

A technology of air electrodes and metal-air batteries, which is applied in battery electrodes, circuits, fuel cell half-cells and primary battery half-cells, etc., and can solve complex electrode production processes, difficult mass production, and complicated preparation processes, etc. problem, to achieve the effect that the preparation process is simple and feasible, the preparation process is simple and practical, and the preparation process is simple

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

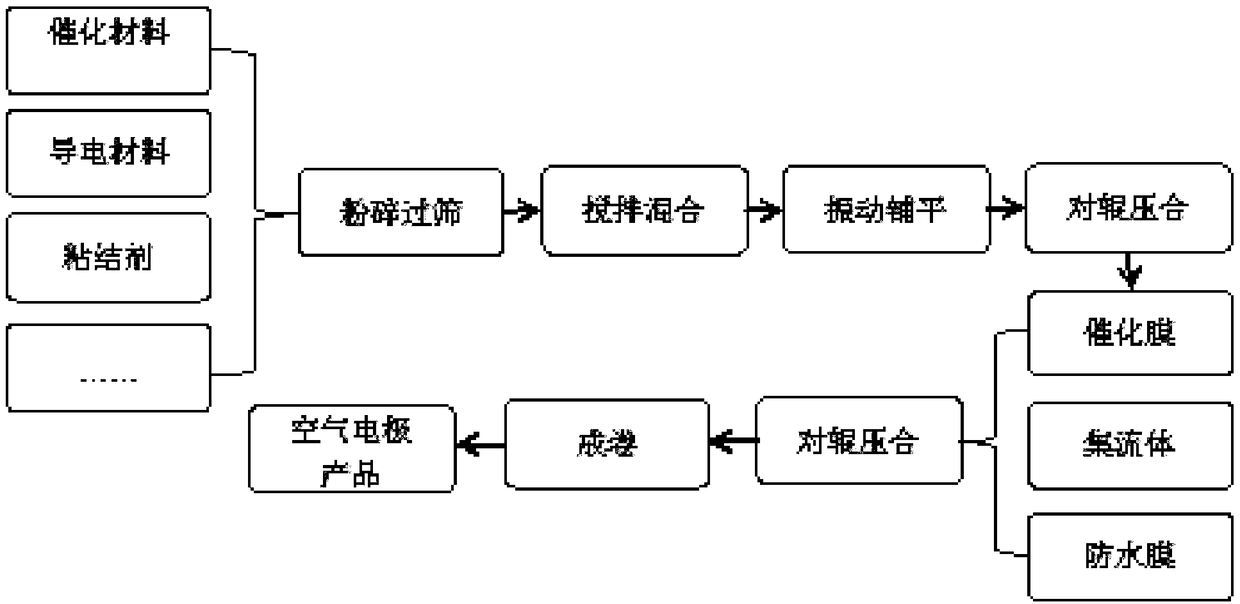

Embodiment 1

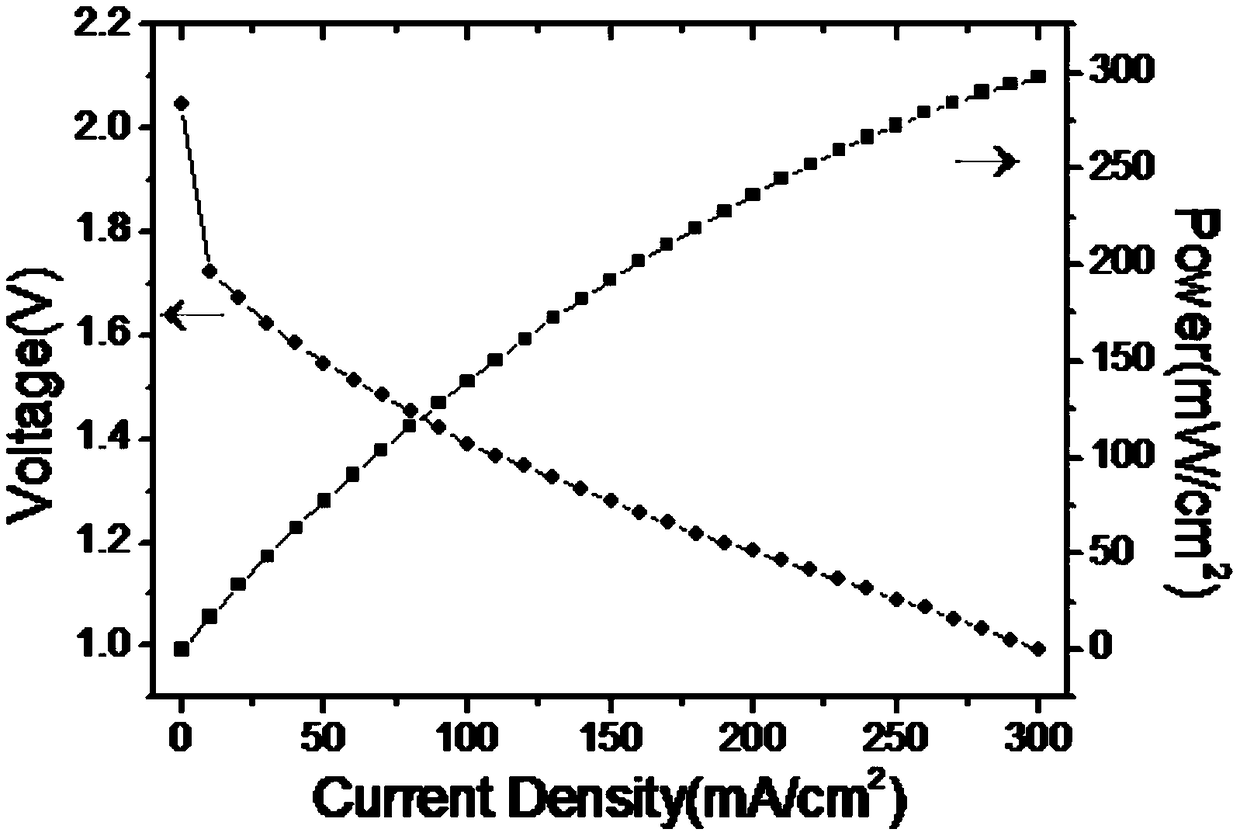

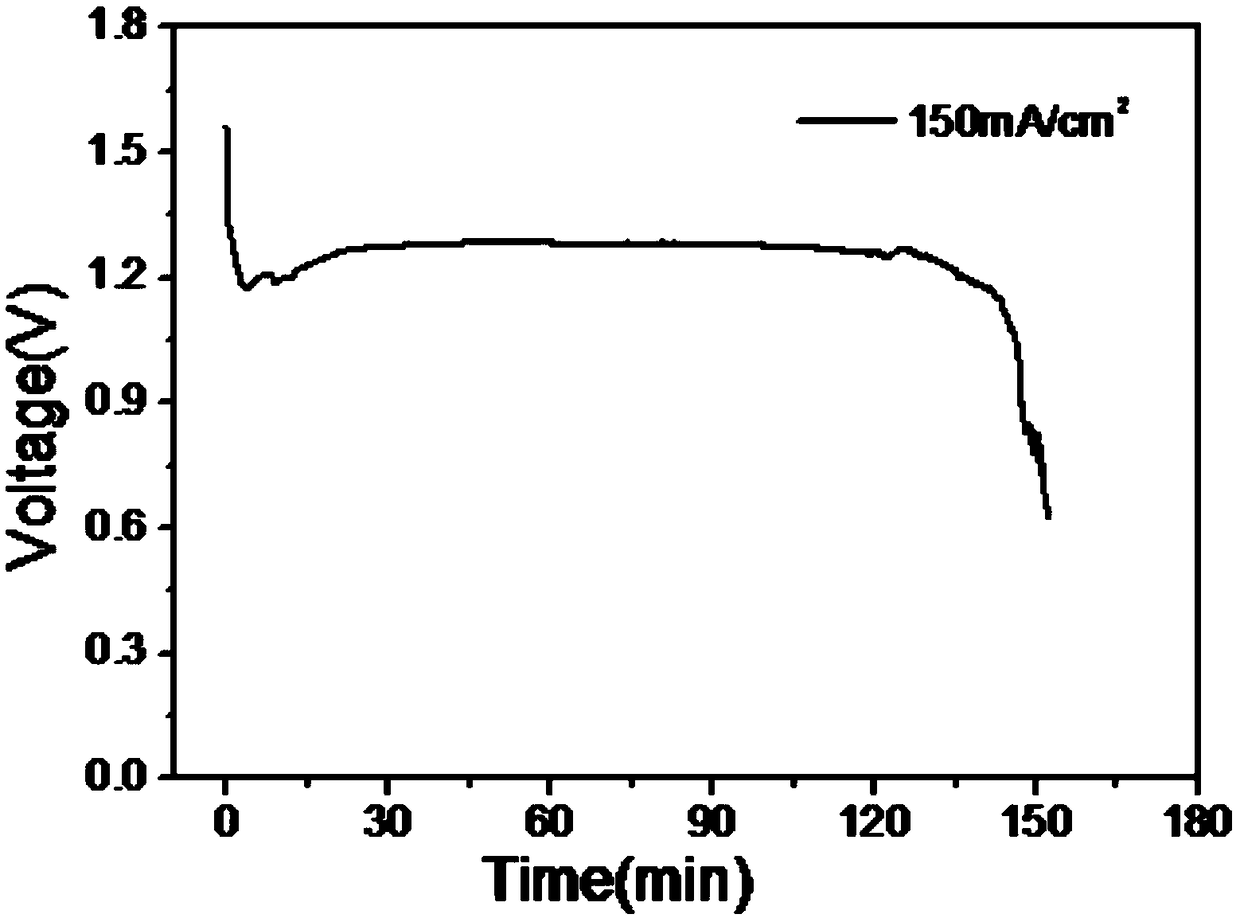

[0035] The mass ratio of manganese dioxide powder, acetylene black, activated carbon, and polytetrafluoroethylene powder is 20:35:30:15, weighed, processed in a pulverizer for 1 min, passed through a 100-mesh sieve, and then put the mixed powder into a vacuum mixer In, add a small amount of alcohol, mix and stir for 4h. The processed material is fed into the feed port, passed through the three-way vibrating equipment to make it completely flattened into the roller equipment to be pressed into a catalytic membrane with a thickness of 0.2mm, and then pressed with copper mesh and waterproof membrane polytetrafluoroethylene (PTFE) membrane Synthetic air electrodes. The prepared air electrode, aluminum plate, and potassium hydroxide electrolyte (concentration of 4mol / L) were used to assemble an aluminum-air battery and conduct electrical performance tests.

Embodiment 2

[0037] According to the mass ratio of manganese dioxide powder, acetylene black, activated carbon, carbon nanotubes, and polytetrafluoroethylene powder, respectively 20:35:25:5:15, process it in a pulverizer for 1.5 minutes, and pass through a 100-mesh sieve. Then add the mixed powder into a vacuum mixer, add a small amount of alcohol, and mix and stir for 3 hours. The processed material is fed into the feed port, passed through the three-way vibrating equipment to make it completely flattened into the roller equipment to be pressed into a catalytic membrane with a thickness of 0.2mm, and then pressed with copper mesh and waterproof membrane polytetrafluoroethylene (PTFE) membrane Synthetic air electrodes. The prepared air electrode, aluminum plate, and potassium hydroxide electrolyte (concentration of 4mol / L) were used to assemble an aluminum-air battery and conduct electrical performance tests.

Embodiment 3

[0039]According to the mass ratio of manganese dioxide nanowires, acetylene black, activated carbon, and polytetrafluoroethylene powder, respectively 20:40:25:15, weigh them in a pulverizer for 1 minute, pass through a 100-mesh sieve, and then add the mixed powder into the vacuum In the blender, add a small amount of alcohol, mix and stir for 4h. The processed material is fed into the feed port, passed through the three-way vibrating equipment in turn to make it completely flattened into the counter-roller equipment to be pressed into a catalytic membrane with a thickness of 0.2mm, and then pressed with copper mesh and waterproof membrane polytetrafluoroethylene (PTFE) membrane. Synthetic air electrodes. The prepared air electrode, aluminum plate, and potassium hydroxide electrolyte (concentration of 4mol / L) were used to assemble an aluminum-air battery and conduct electrical performance tests.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com