Preparation method of low-platinum catalytic layer for proton exchange membrane fuel cell

A proton exchange membrane, fuel cell technology, applied in battery electrodes, circuits, electrical components, etc., can solve problems such as unfavorable mass transfer, inability to ensure uniformity, poor battery performance, etc., and achieve good pore structure, which is conducive to gas mass transfer. , the effect of large porosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with example

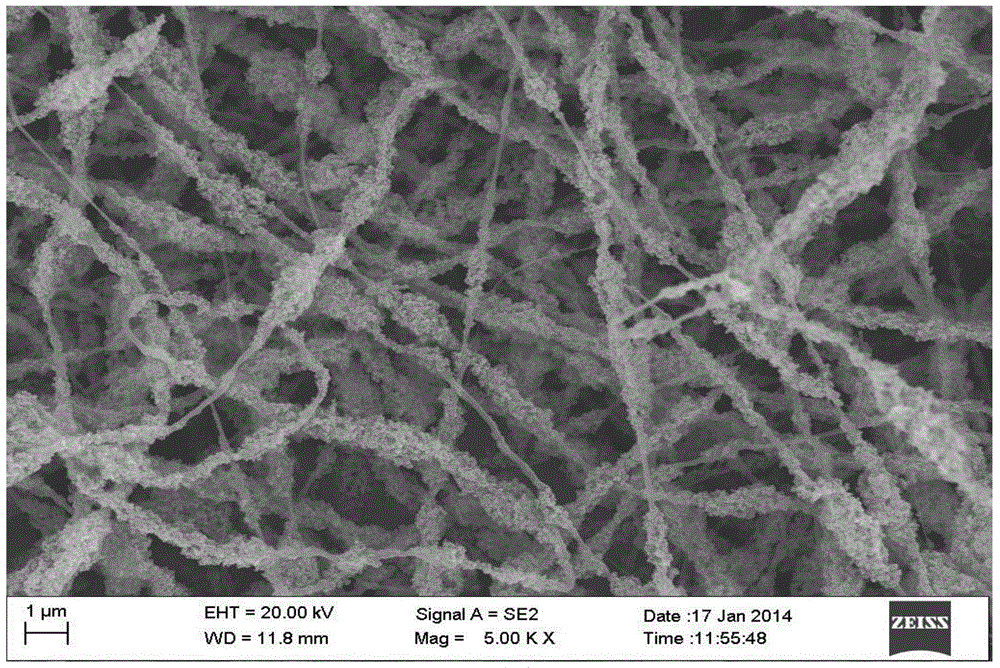

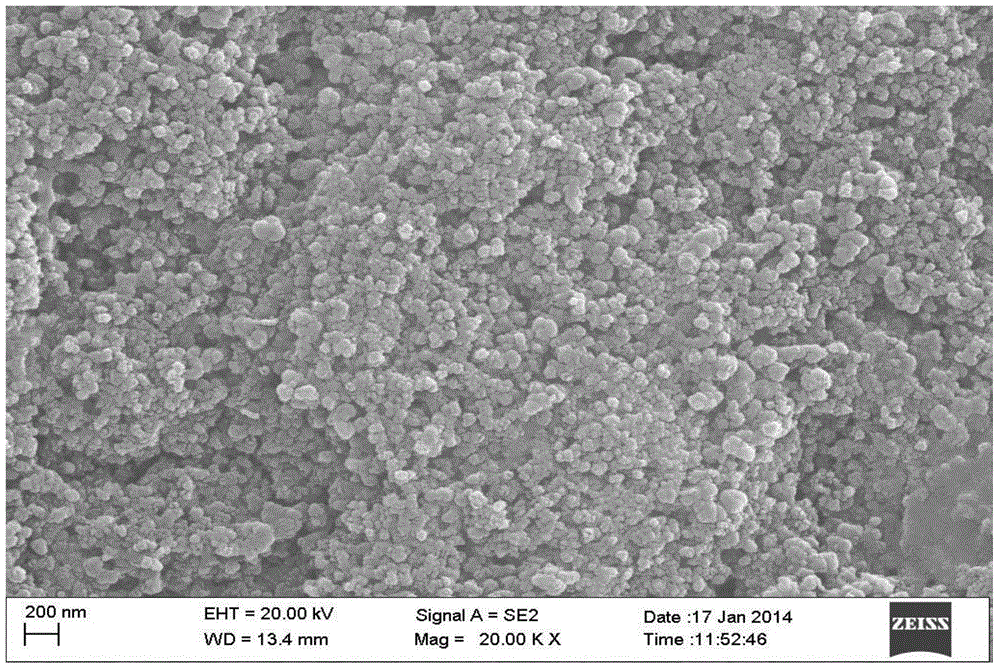

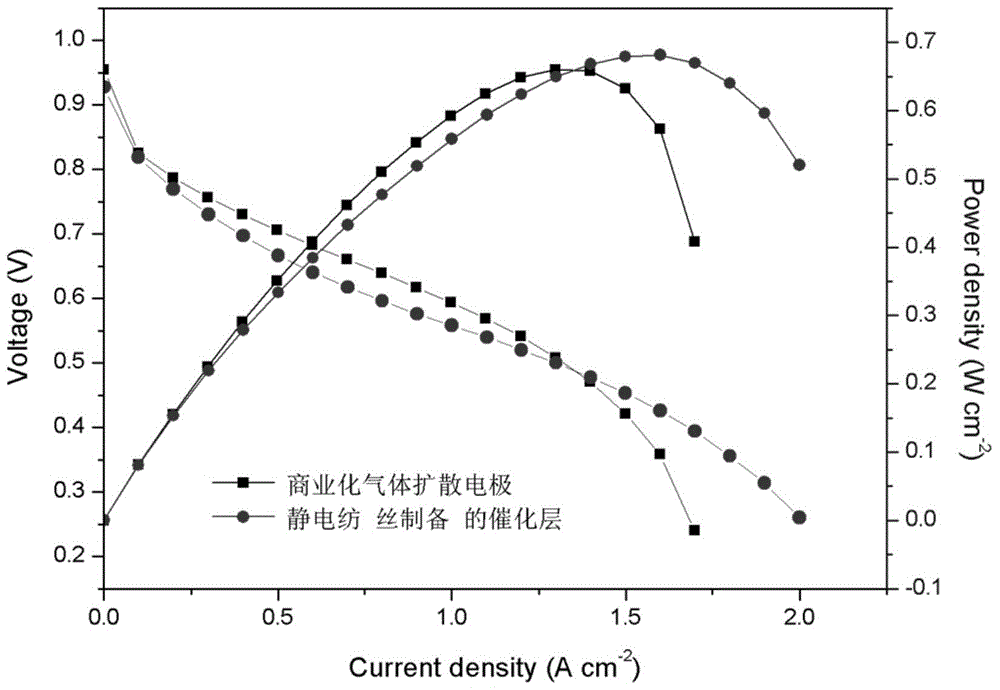

[0028] Weigh 1 g of polymer polymer, dissolve and mix 6 g of isopropanol and 1 g of water, and stir for 24 hours to prepare a 12.5% solution. Weigh 0.1g of 40% P / C catalyst, 0.6g of Nafion solution (5%), mix well, add 0.2g of polymer solution after ultrasonic for a while, and stir for 36h. Then adopt the electrospinning technique to prepare the catalytic layer, the condition parameters are: the liquid flow rate is 0.8mlh -1 , the distance between the needle tip and the receiving plate was 10cm, and the voltage was 10kV. By controlling different receiving times, the catalytic layers with different Pt loadings were prepared. Finally, transfer the prepared catalytic layer to the surface of Nafion with hot pressing at 140°C, hot pressing pressure 0-2Mpa, and hot pressing time 2-4min to prepare a single-sided membrane electrode. The anode uses a commercial gas diffusion electrode , the el...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com