Patents

Literature

59results about How to "Make full use of cooling capacity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

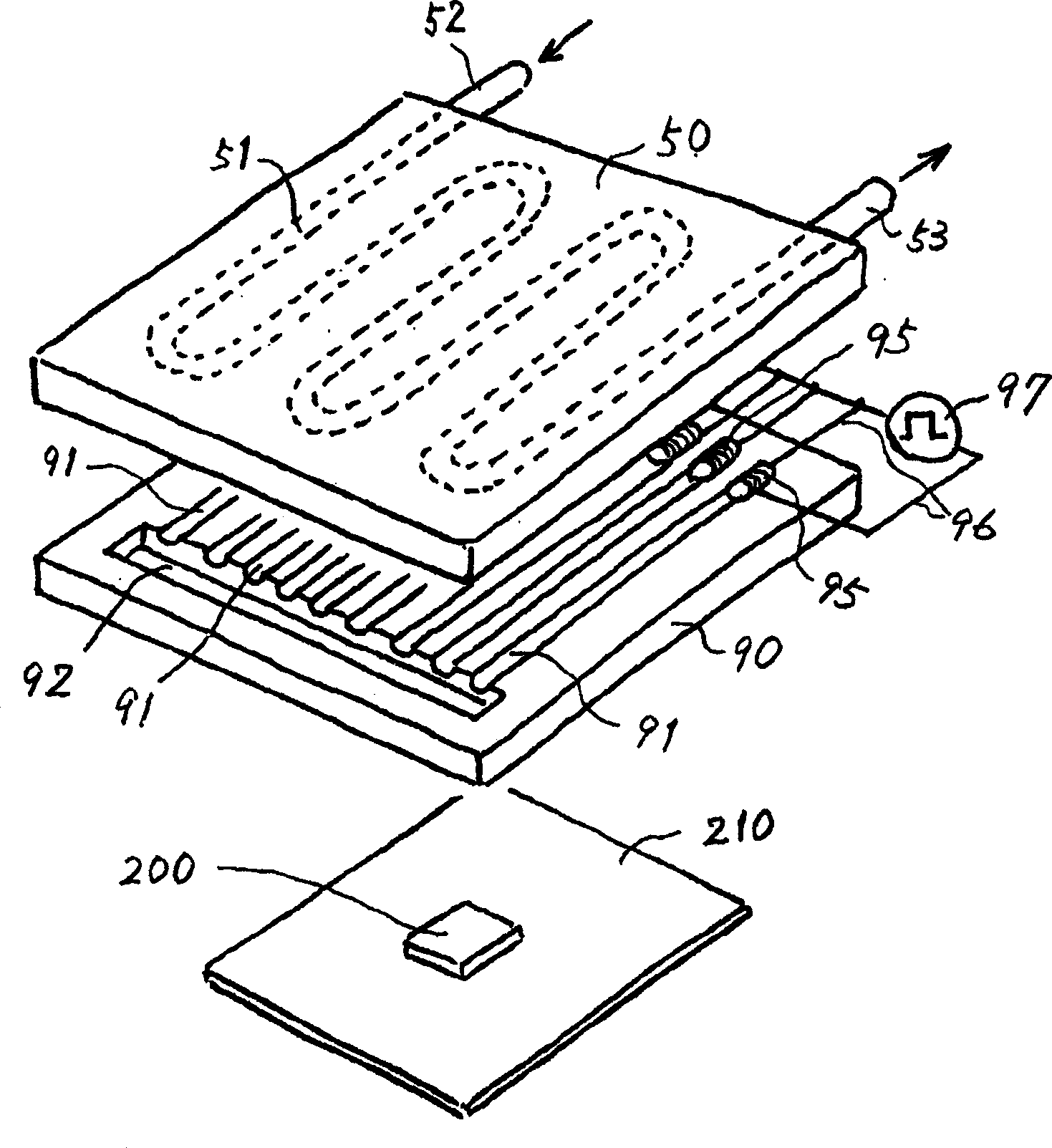

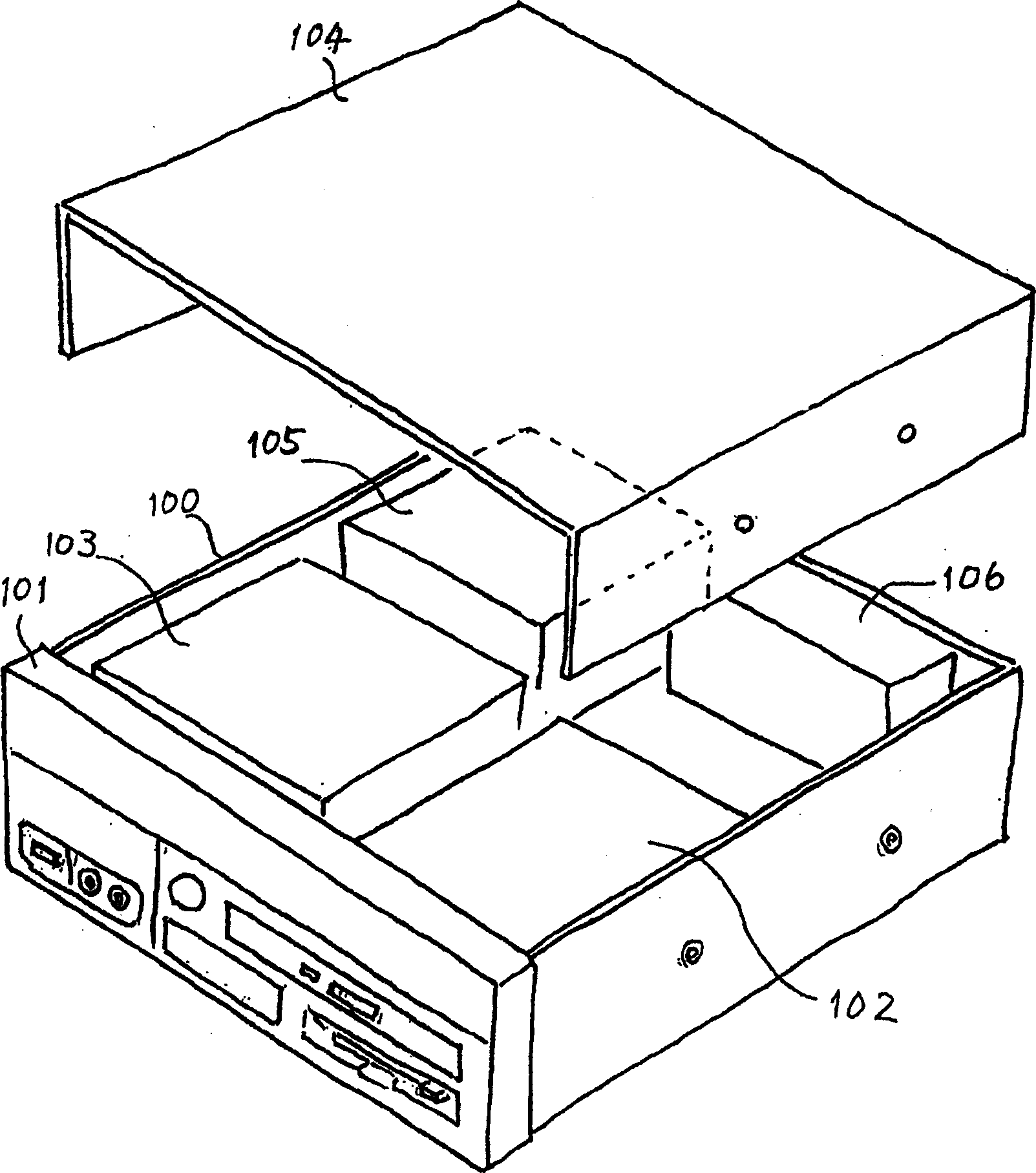

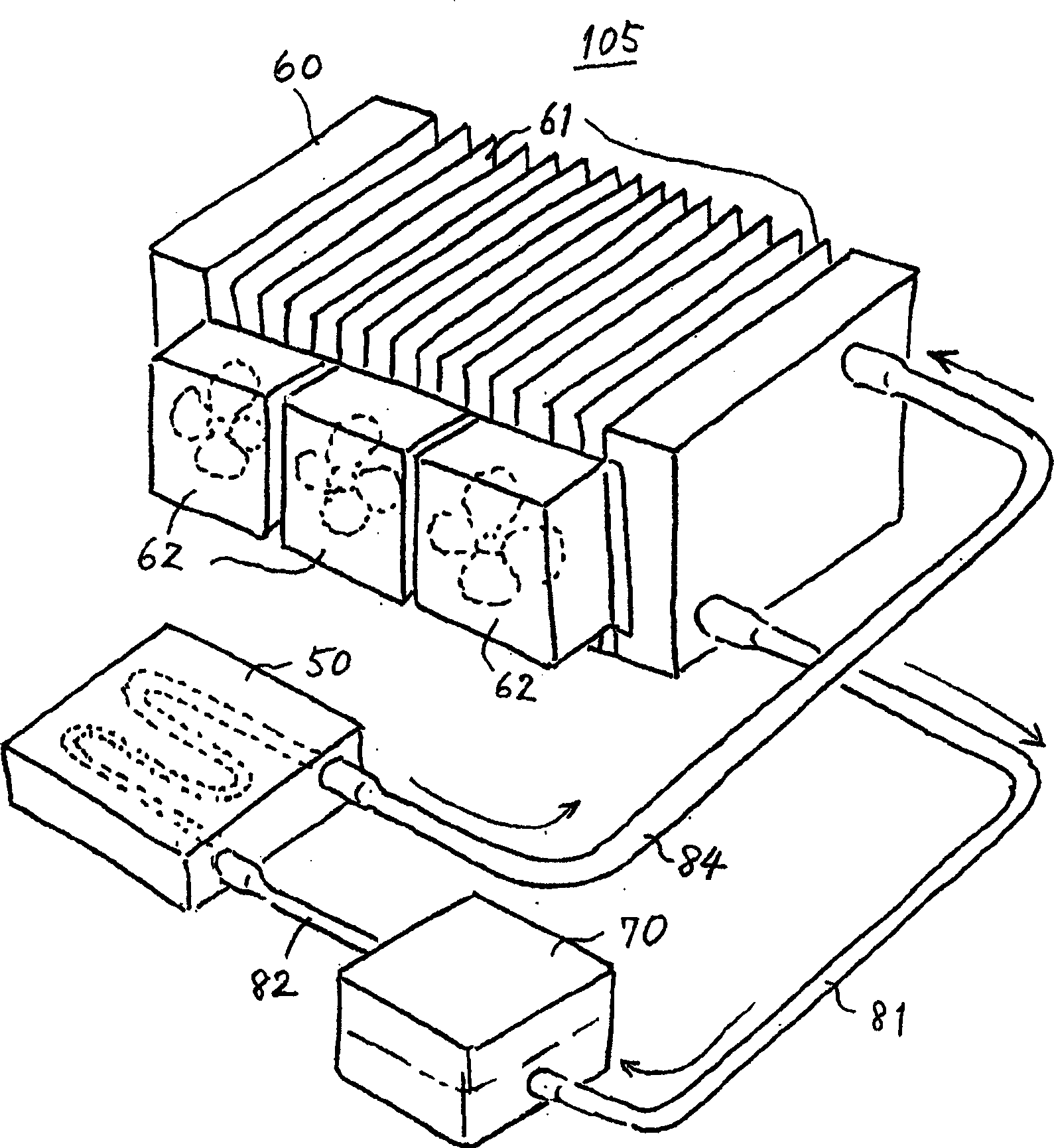

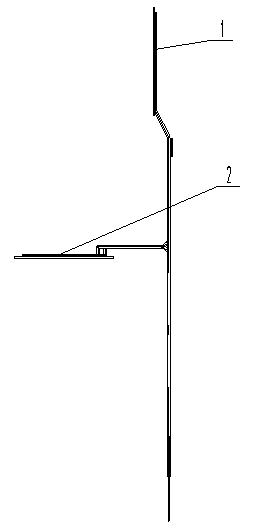

Cooling system for electronic apparatus, and electronic apparatus using the same

InactiveCN1658122AImprove cooling efficiencyLarge transfer areaDigital data processing detailsSemiconductor/solid-state device detailsWorking fluidCoolant flow

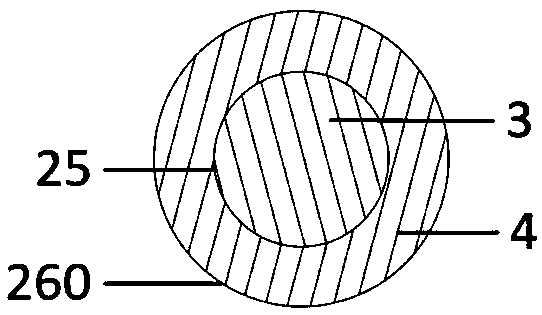

An electronic apparatus, such as, personal computers of so-called a desktop type and a notebook type, as well as, a server, etc., having a cooling system being high in cooling efficiency, wherein a CPU 200 in need of cooling is installed within a hosing 100, and the liquid cooling system for cooling the CPU, comprises: a heat-receiving (cooling) jacket 50; a radiator 60; and a circulation pump 70, wherein the heat-receiving (cooling) jacket 50, for transmitting heat generated from a heat-generation element, i.e., the CPU, into a liquid coolant flowing with in an inside thereof, has a heat diffusion plate 90 attached on the lower surface thereof. This heat diffusion plate encloses an operating fluid 94, such as water, within a space, which is hermetically sealed and formed within an inside thereof, and also has heater elements 95, being provided in contact with a portion the operating fluid. To those heater elements 95 are supplied a pulse-like electric power. With this, a portion of the operating fluid repeats forming / extinguishing, to give vibration to the operating fluid, thereby diffusing the heat over the entire of the diffusion plate, as a whole, thereafter the heat is transmitted to the heat-receiving (cooling) jacket. Or, alternatively, it may be connected with a heat radiation fin 300.

Owner:HITACHI LTD

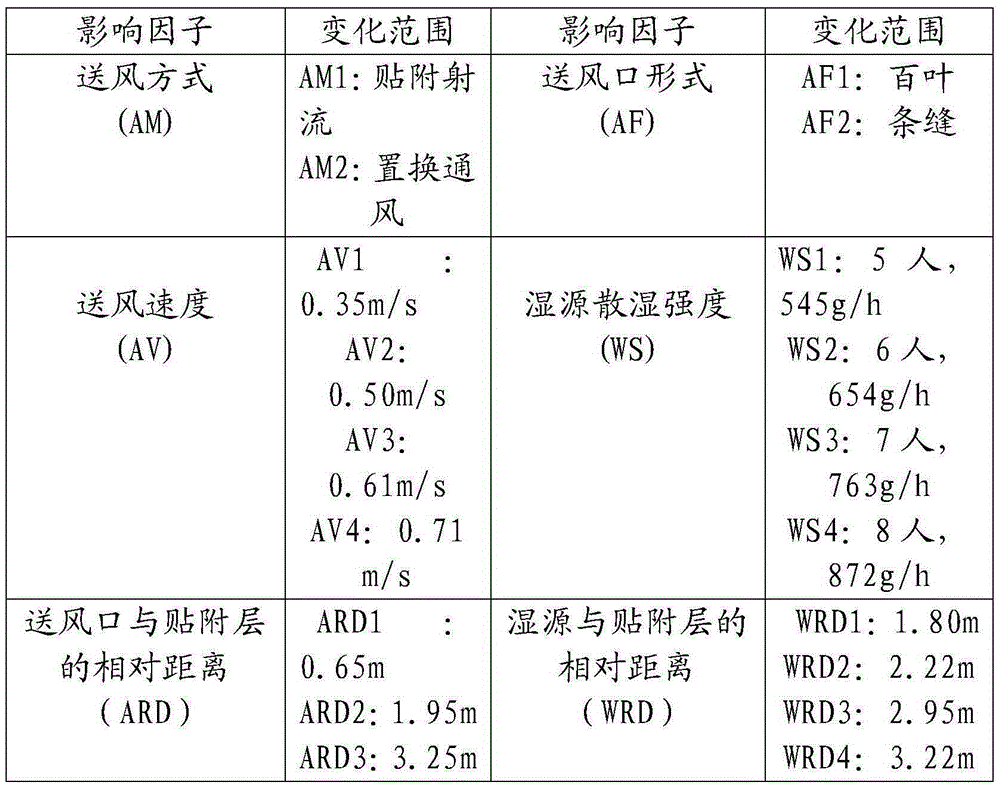

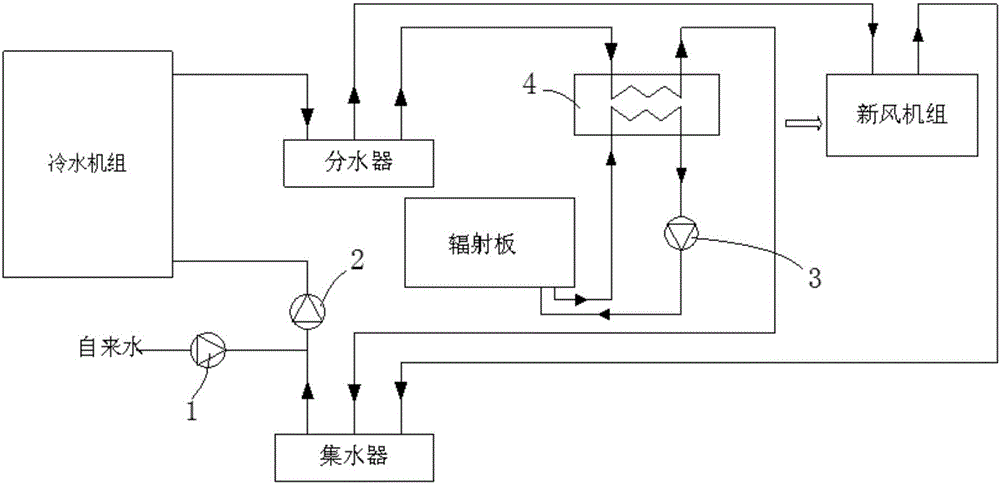

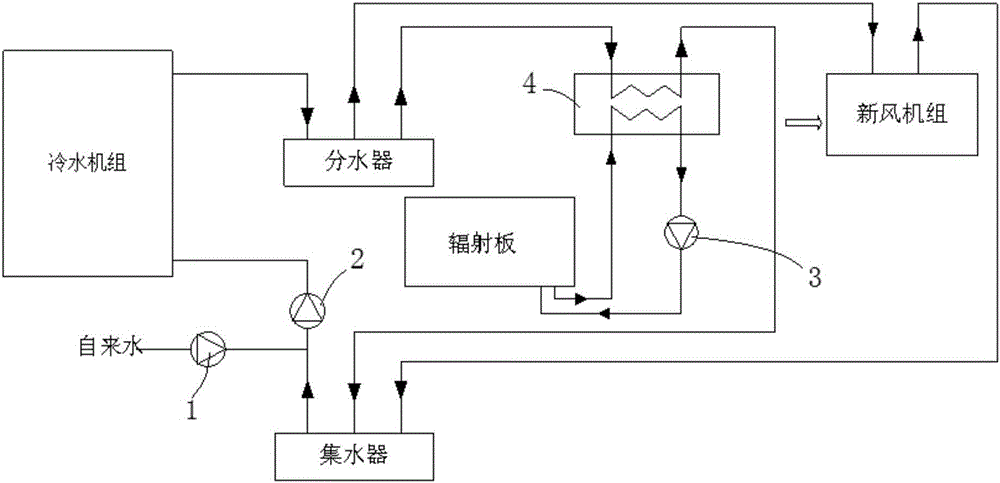

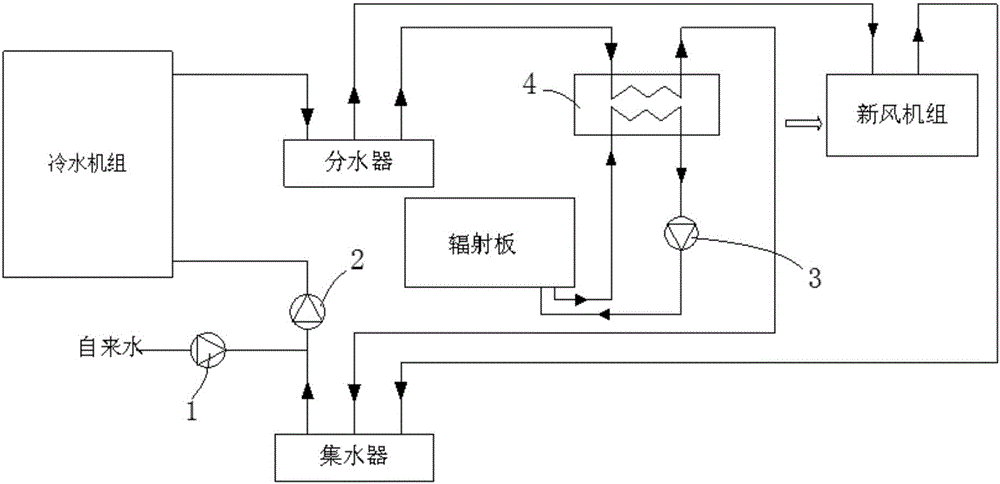

Method for determining dynamic change rule of dew point temperature of attached layer of radiant ceiling

InactiveCN105404771AAvoid condensationMake full use of cooling capacitySpecial data processing applicationsInformaticsRegression analysisFresh air

The invention discloses a method for determining a dynamic change rule of dew point temperature of an attached layer of a radiant ceiling. The method comprises the following specific steps of: firstly, determining influence factors of the dynamic change rule of the dew point temperature of the attached layer; and secondly, performing simulation by utilizing ANSYSY software to obtain sample data, and then based on SAS software, obtaining the dynamic change rule of the dew point temperature of the attached layer with a multivariate regression analysis method: y=12.78891+0.31639xb+0.19712xc-0.12698xd, wherein y is the dew point temperature of the attached layer, b is wet dissipation strength, c is a relative distance between a fresh air inlet and a test point of the attached layer, and d is a relative distance between a wet source and the test point of the attached layer. According to the method, an indoor wet diffusion model is constructed, an interaction relationship among a water supply parameter of a radiant plate, an indoor thermal and humid environment parameter and the dew point temperature of the attached layer is deeply researched, and the dynamic change rule of the dew point temperature of the attached layer is proposed with a statistic analysis method.

Owner:TIANJIN UNIV OF COMMERCE

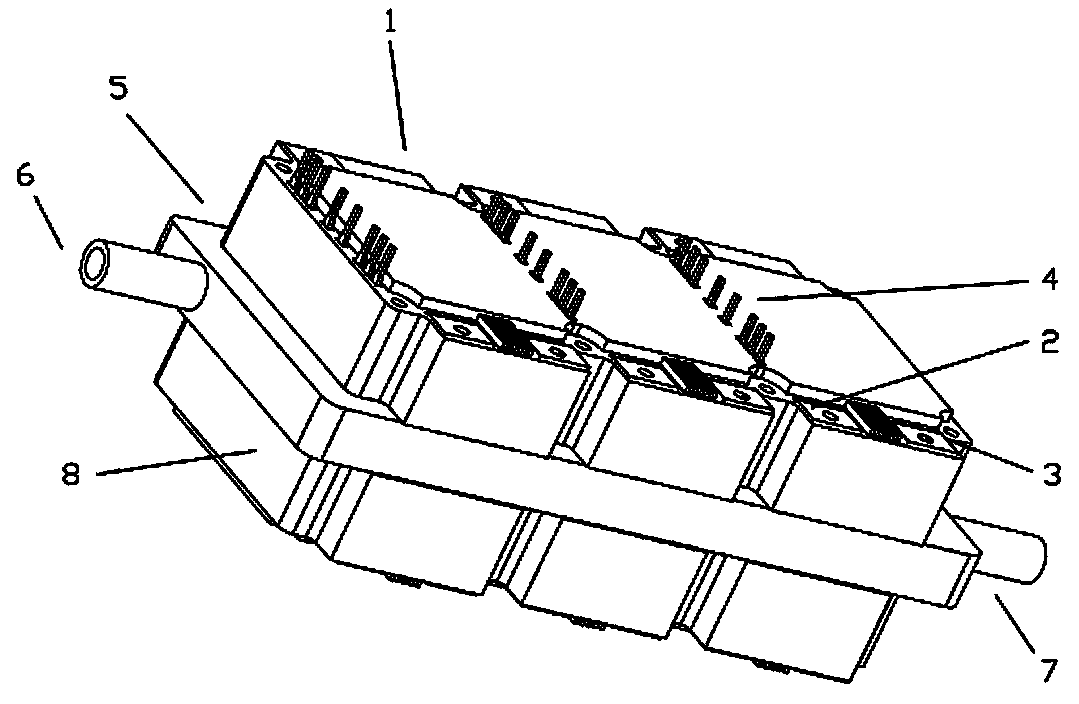

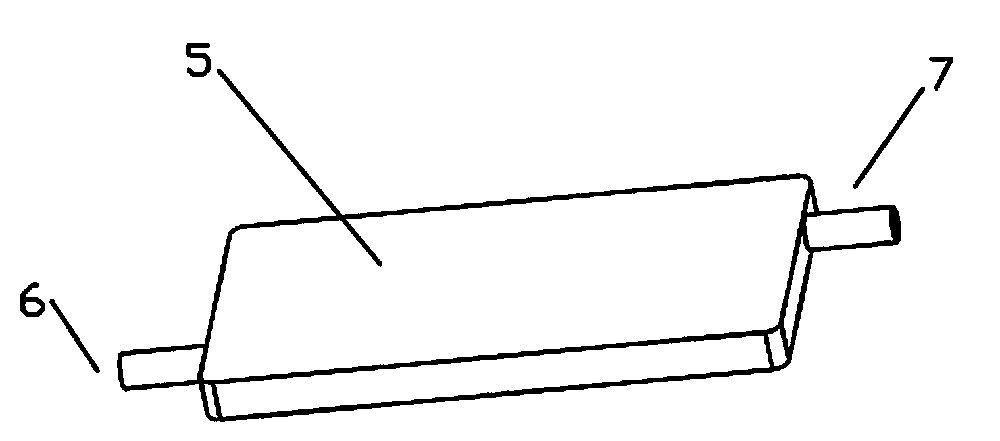

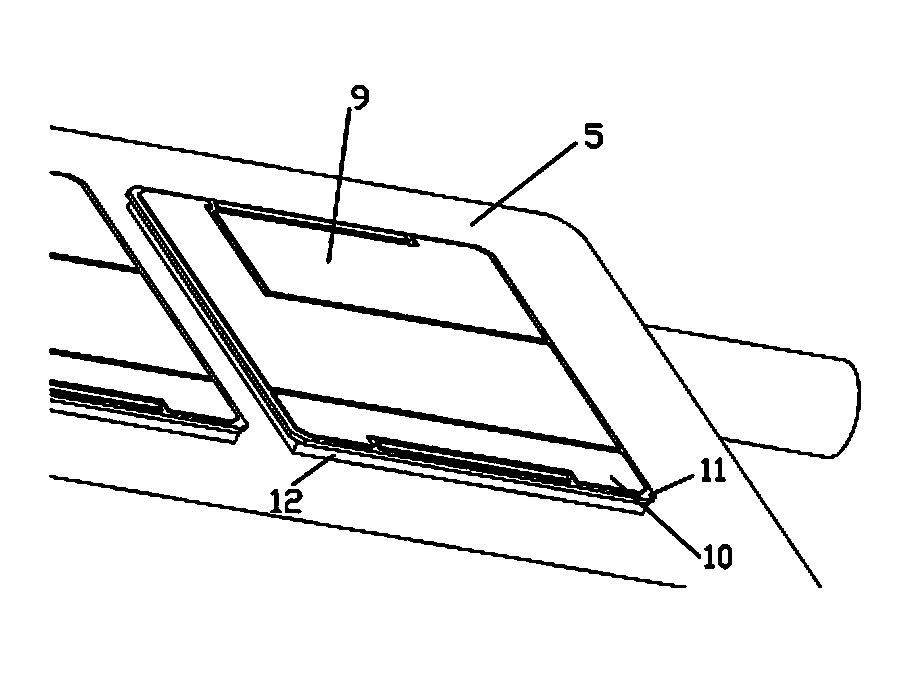

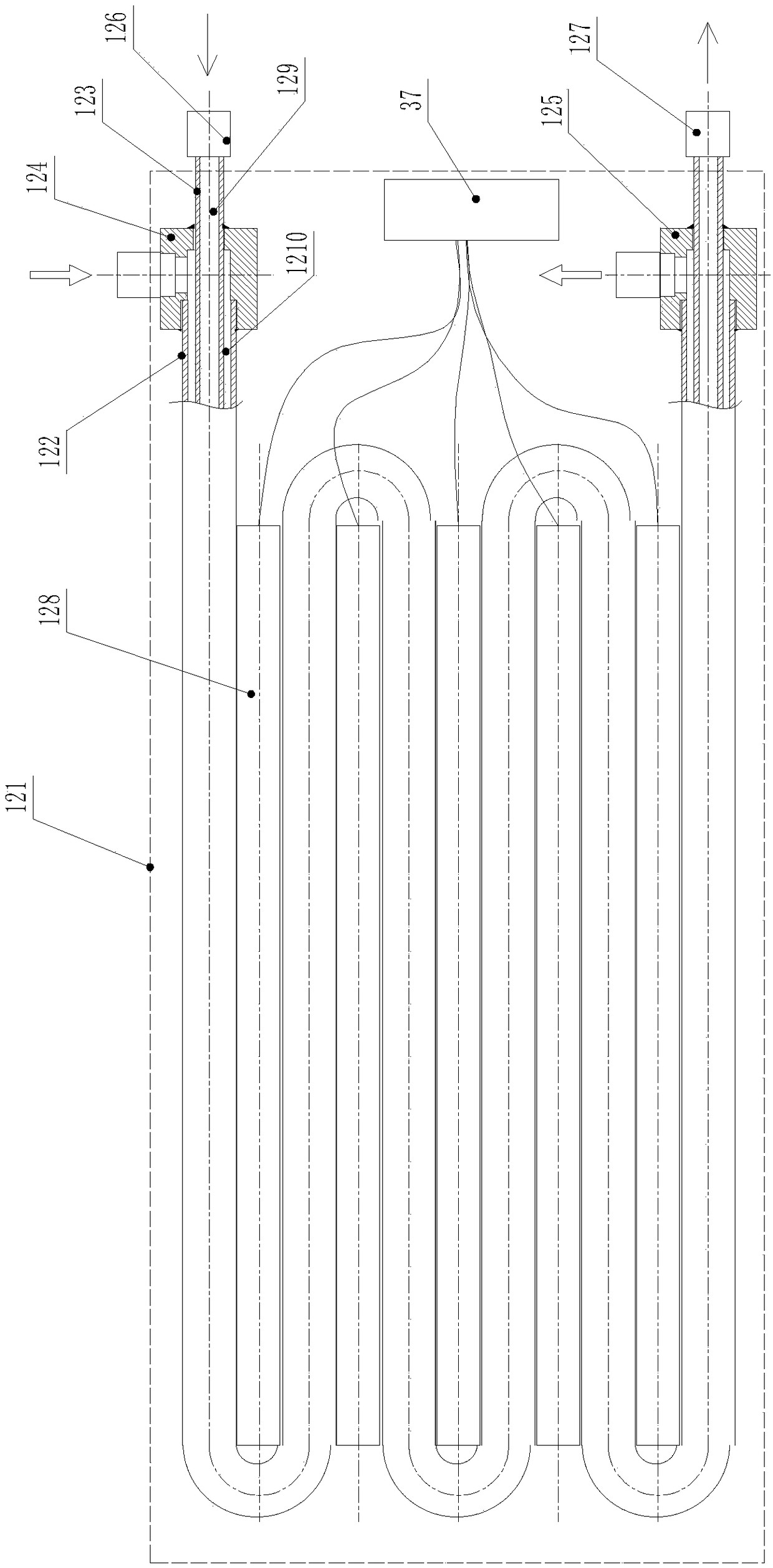

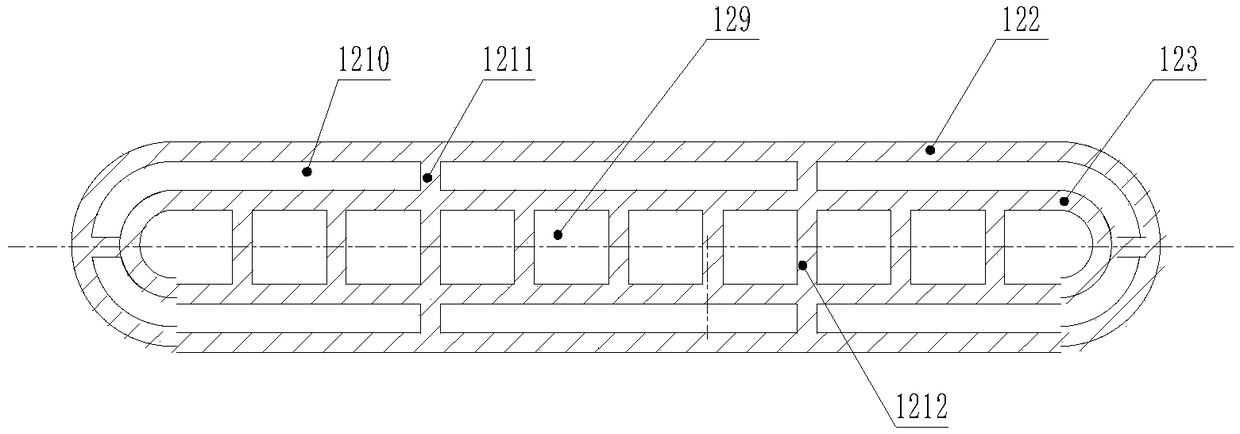

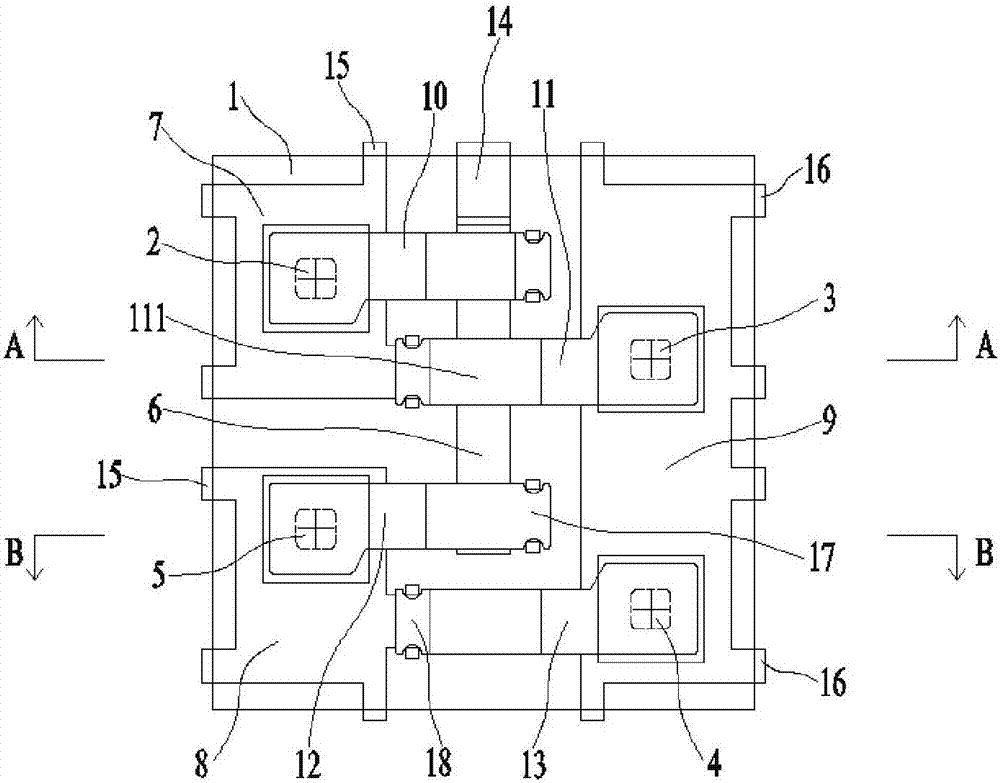

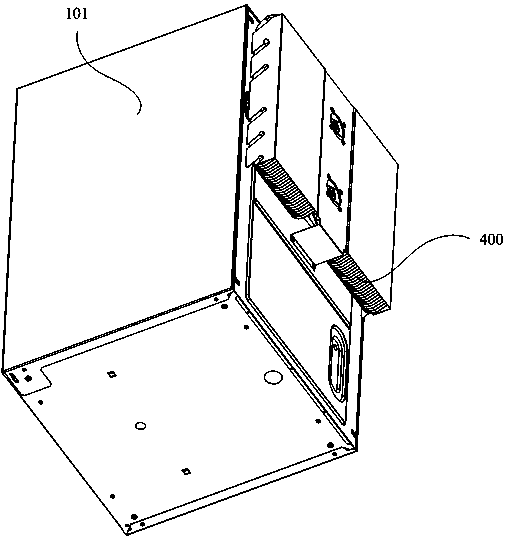

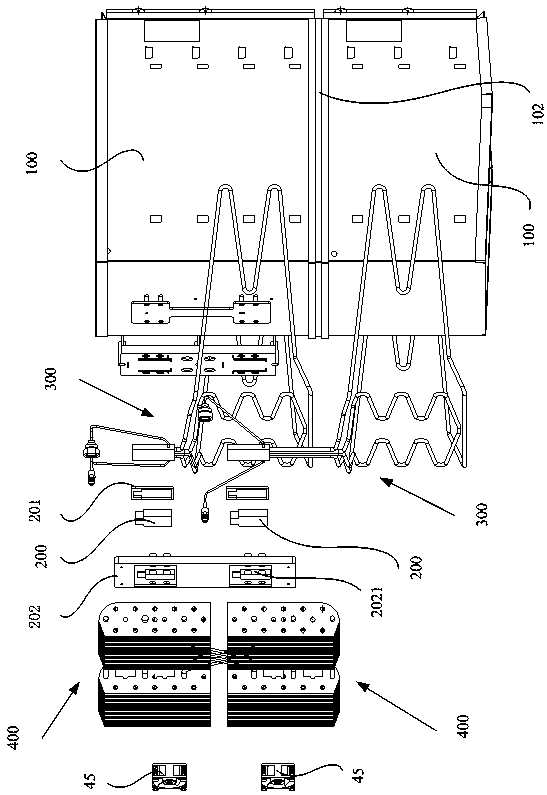

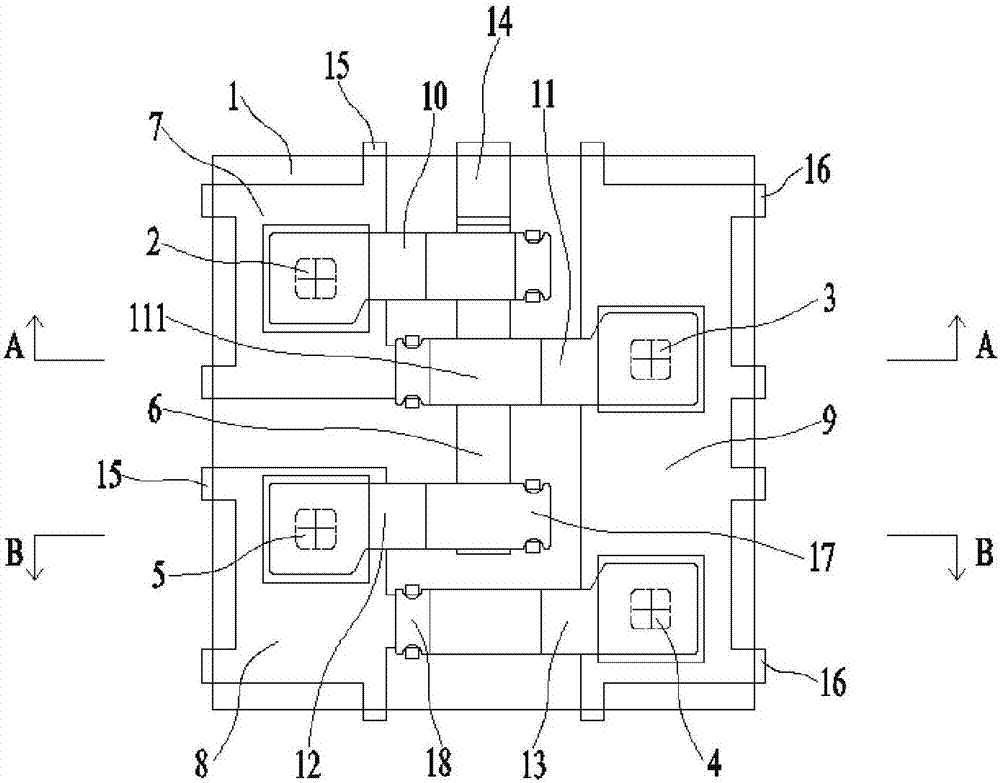

Power module packaging structure with water-cooled heat sink used for two-sided cooling

InactiveCN103779294AMaximize Power DensityMake full use of cooling capacitySemiconductor/solid-state device detailsSolid-state devicesCushioningUltrasonic welding

Provided is a power module packaging structure with a water-cooled heat sink used for two-sided cooling. The power module packaging structure comprises the tabular water-cooled heat sink with a water inlet and a water outlet. Power device units are packaged on the upper surface of the water-cooled heat sink and the lower surface of the water-cooled heat sink, a power terminal located on the surface of a shell is made into a shape by which a nut can be fixed conveniently, and a signal terminal located on the surface of the shell is specially made into a shape which has good welding performance and facilitates fixing and clamping of a PCB. The water-cooled heat sink is fixedly connected with insulating substrates of the power device units directly or through a cushioning material layer, and the power terminal and the signal terminal are directly welded to surface metal layers of the insulating substrates in an ultrasonic welding mode. The shell is fixedly connected with the heat sink, and the signal terminal and the power terminal are directly fixed onto the shell in an injection molding mode. The power module packaging structure has the advantages of being reasonable in structure and convenient to use and install, making full use of the cooling capacity of the water-cooled heat sink, obtaining maximum power density and the like.

Owner:嘉兴斯达微电子有限公司

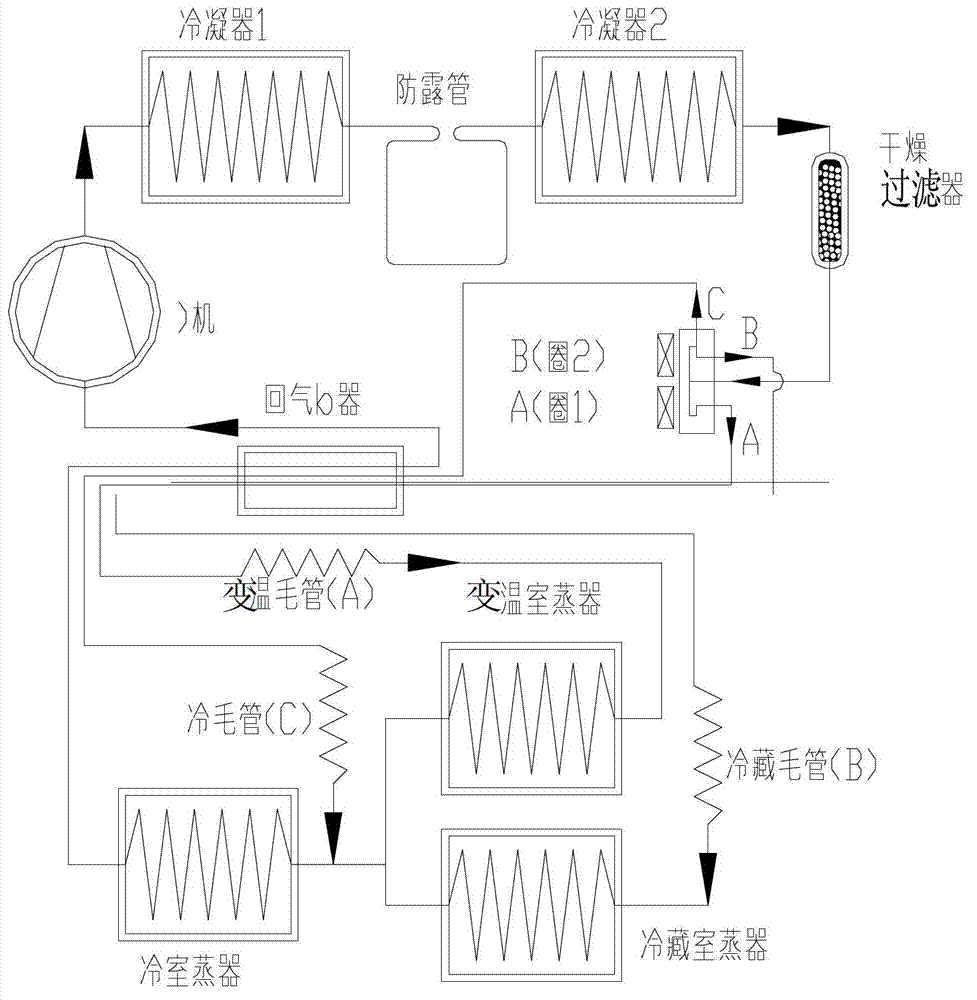

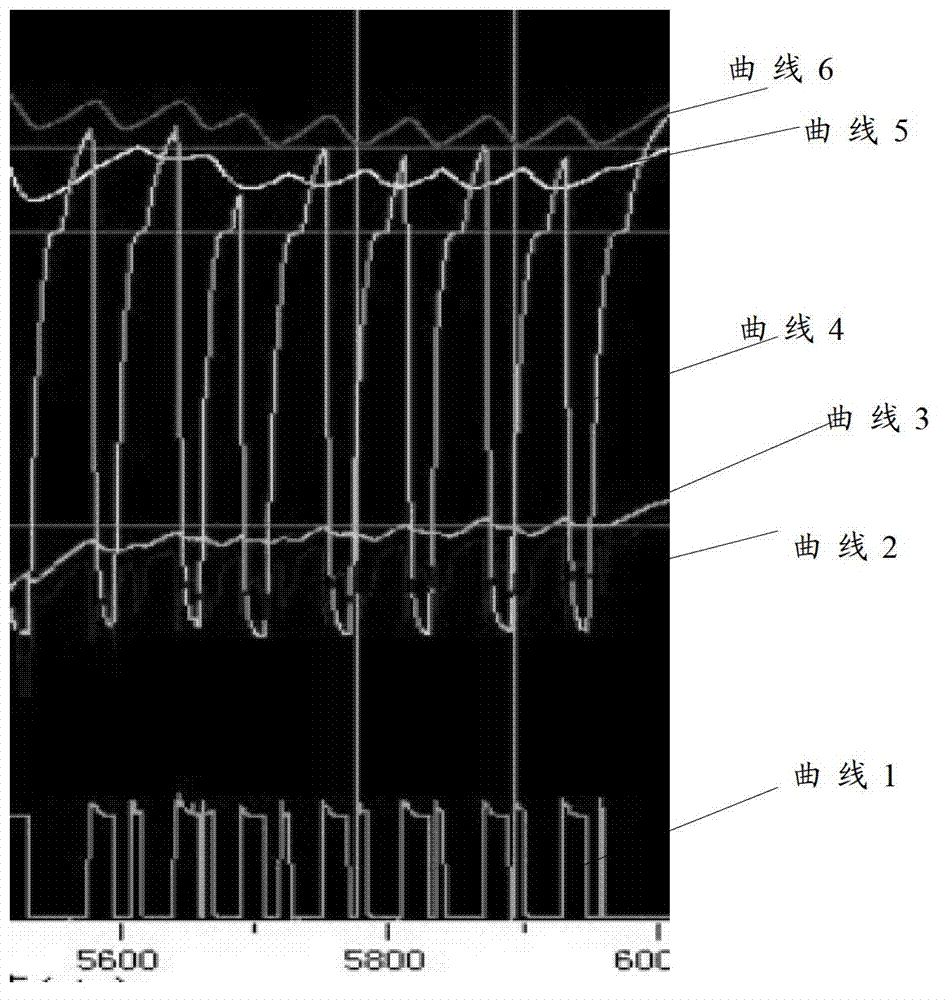

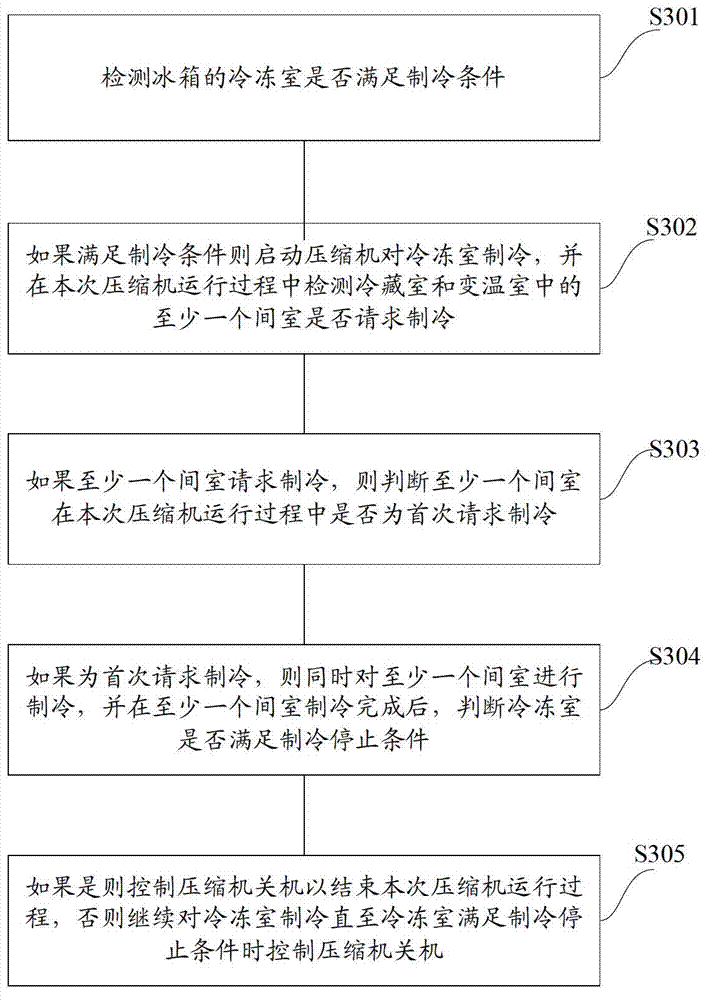

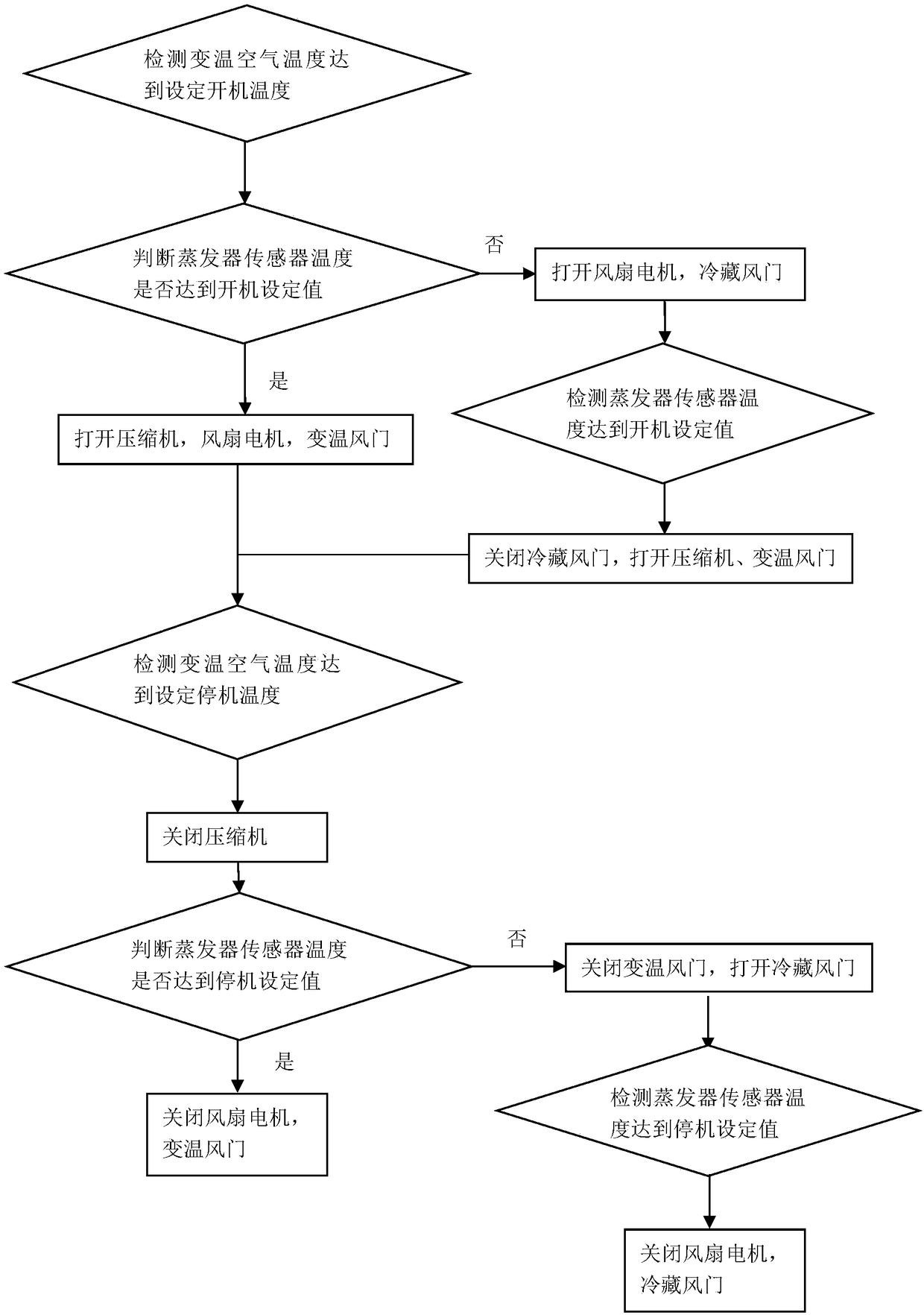

Refrigeration control method of refrigerator

ActiveCN103115476AExtended service lifeReduce energy consumptionDomestic cooling apparatusLighting and heating apparatusEngineeringCold store

The invention provides a refrigeration control method of a refrigerator. The refrigeration control method comprises the following steps of: detecting whether a freezing chamber of the refrigerator meets a refrigeration condition, if so, starting a compressor for refrigerating in the freezing chamber, detecting whether at least one of a refrigerating chamber and a temperature varying chamber requests refrigeration in the current running process of the compressor; if at least one chamber requests refrigeration, judging whether at least one chamber requests refrigeration for the first time in the current running process of the compressor, if so, simultaneously refrigerating at least one chamber, and judging whether the freezing chamber meets a refrigeration stop condition after finishing of refrigerating for the at least one chamber; and if so, controlling the compressor to shut down so as to finish the current running process of the compressor, if not, unceasingly refrigerating the freezing chamber until that the freezing chamber meets the refrigeration stop condition, and controlling the compressor to shut down. The method provided by the embodiment of the invention can meet the refrigerator refrigeration requirement, meanwhile, the home using ratio of the compressor is reduced, and the method provided by the invention has the advantages that the energy consumption is low and the service life of the compressor is prolonged.

Owner:HEFEI MIDEA REFRIGERATOR CO LTD

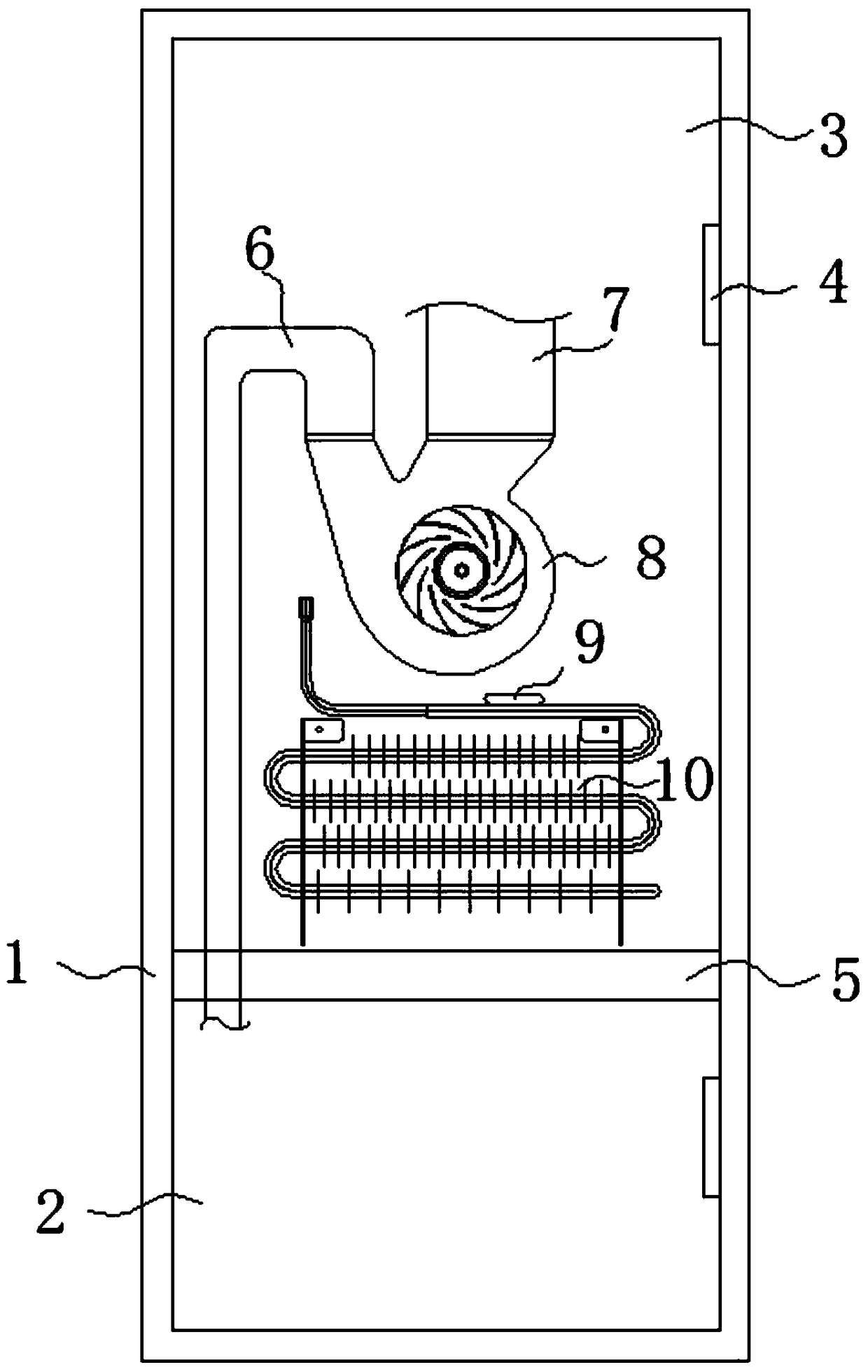

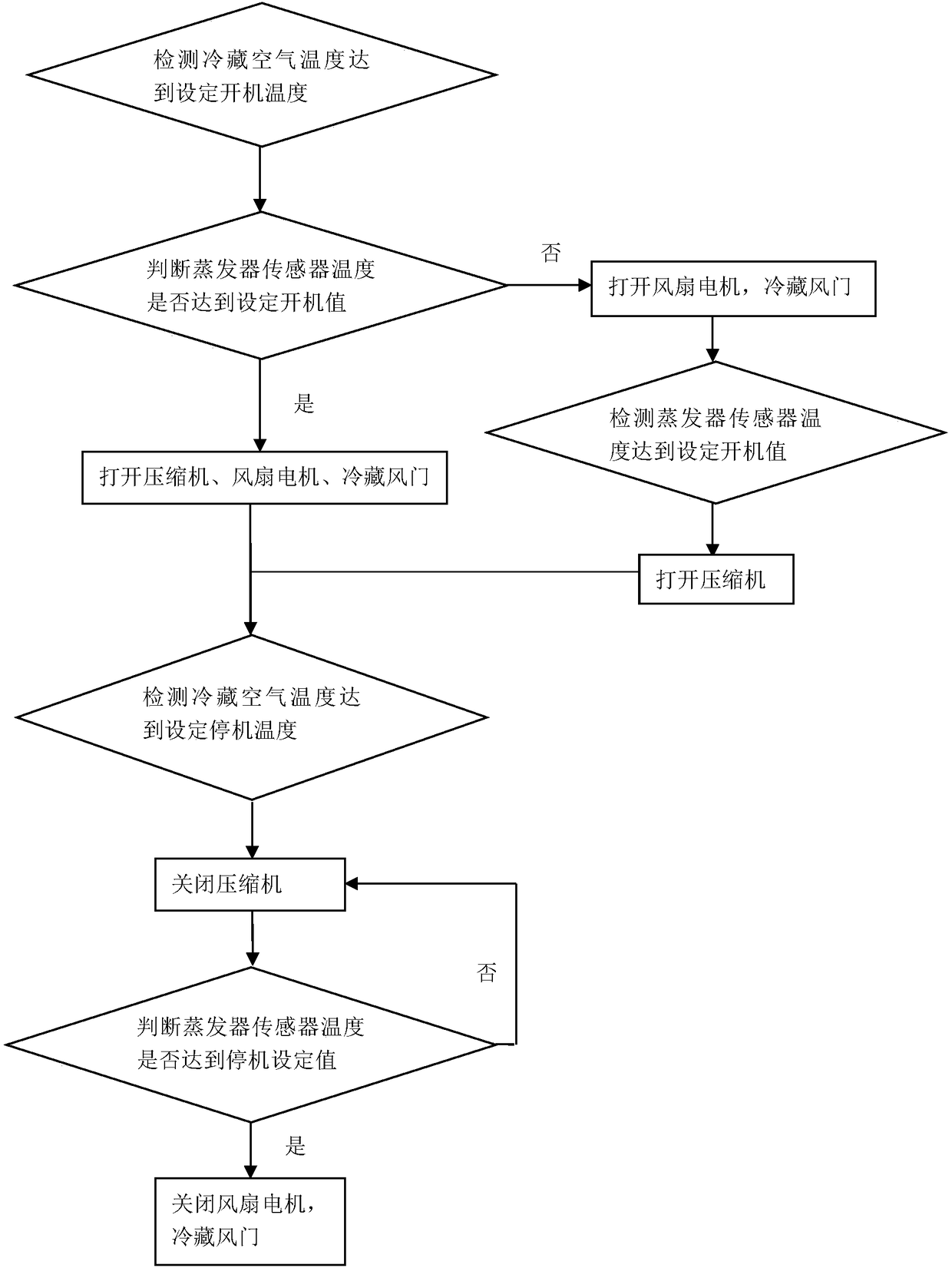

Natural-defrosting refrigerator with temperature changing function and defrosting control method

PendingCN108548366ALower storage temperatureReduce power consumptionLighting and heating apparatusDefrostingEngineeringCooling energy

The invention discloses a natural-defrosting refrigerator with a temperature changing function and a defrosting control method, and belongs to the technical field of refrigerators. The natural-defrosting refrigerator comprises a cooling system used for controlling the temperature of a refrigerating compartment and a temperature changing system used for controlling the temperature of the temperature changing compartment, wherein the refrigerating compartment and the temperature changing compartment are subjected to air supply refrigeration through an evaporator, and the two compartments share one set of refrigeration device for refrigeration, and the temperature requirements of each compartment of the refrigerator are realized by judging the temperature of the evaporator, the temperature ofthe refrigerating compartment and the temperature of the temperature changing compartment in real time and controlling opening and closing of the a refrigerating ventilation door, a temperature changing ventilation door and a compressor on a refrigerating system according to control logic preset by the system. According to the natural-defrosting refrigerator, a defrosting heater on the evaporatoris discarded, the production cost of the refrigerator is reduced, and the evaporator is naturally frosted through the operational characteristic of the refrigerating compartment above 0 DEG C, the normal operation of the refrigerator is ensured, at the same time the energy consumption for the operation of the refrigerator is reduced, and air heat and cool energy in the refrigerator are fully used.

Owner:CHANGHONG MEILING CO LTD

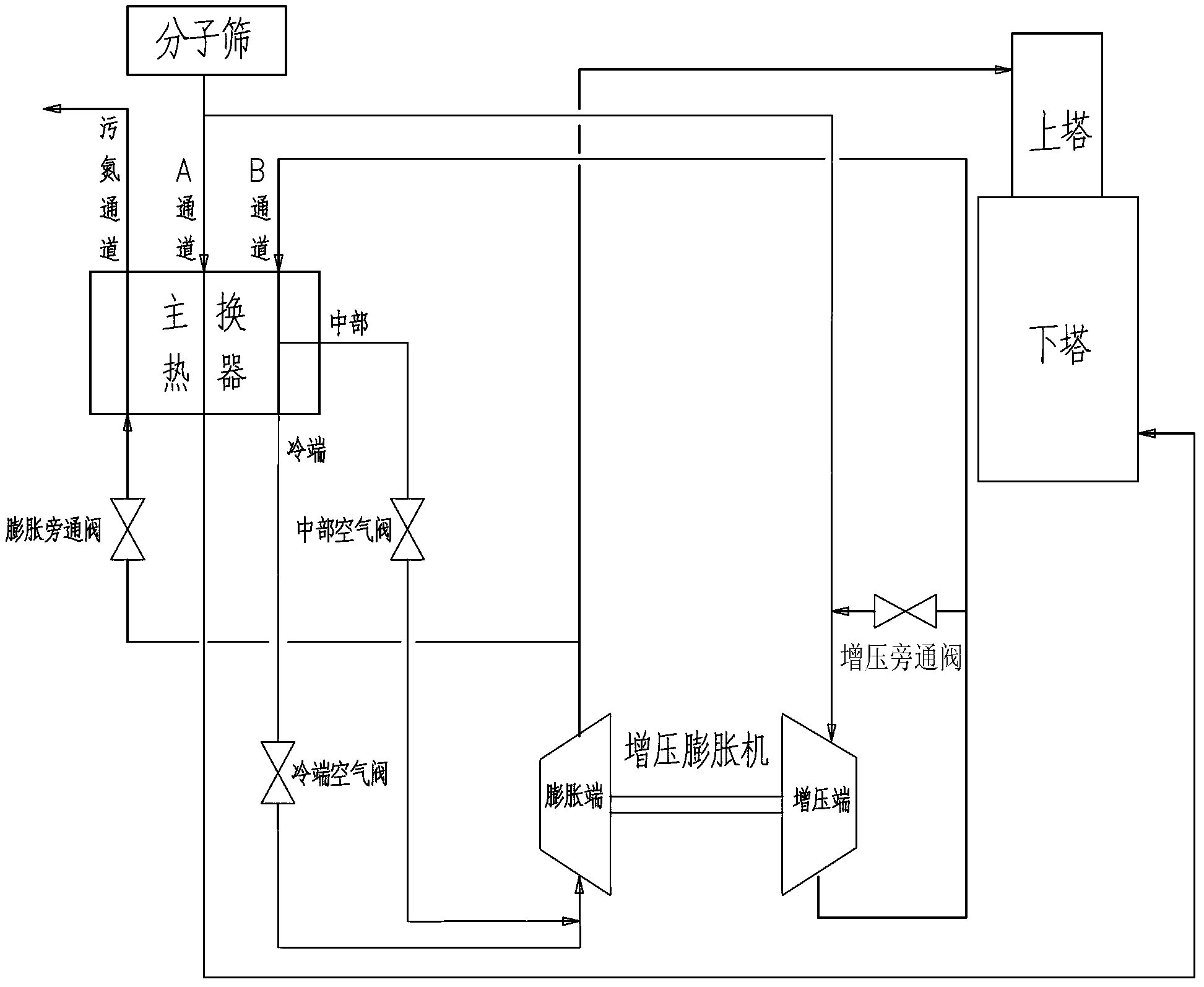

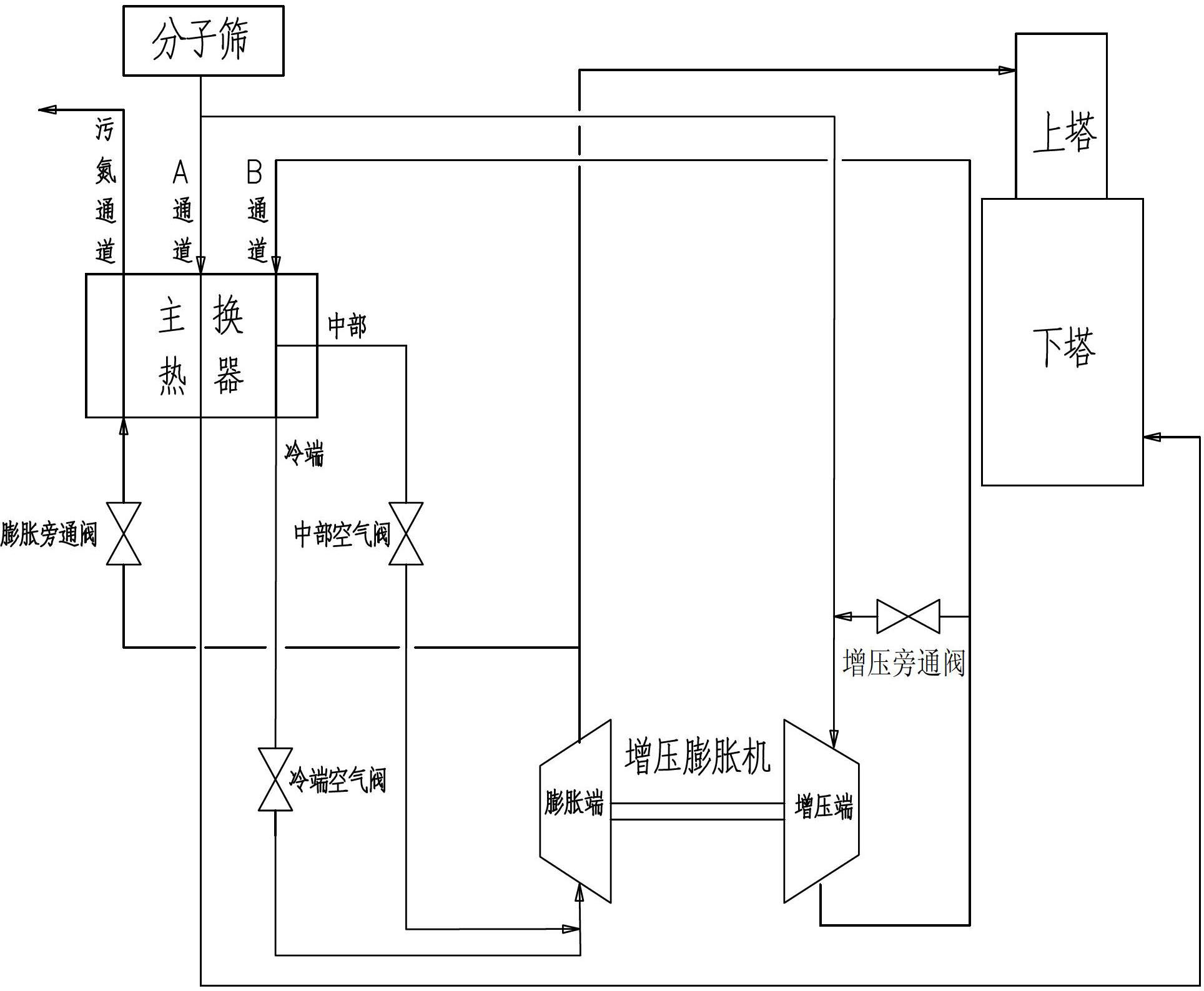

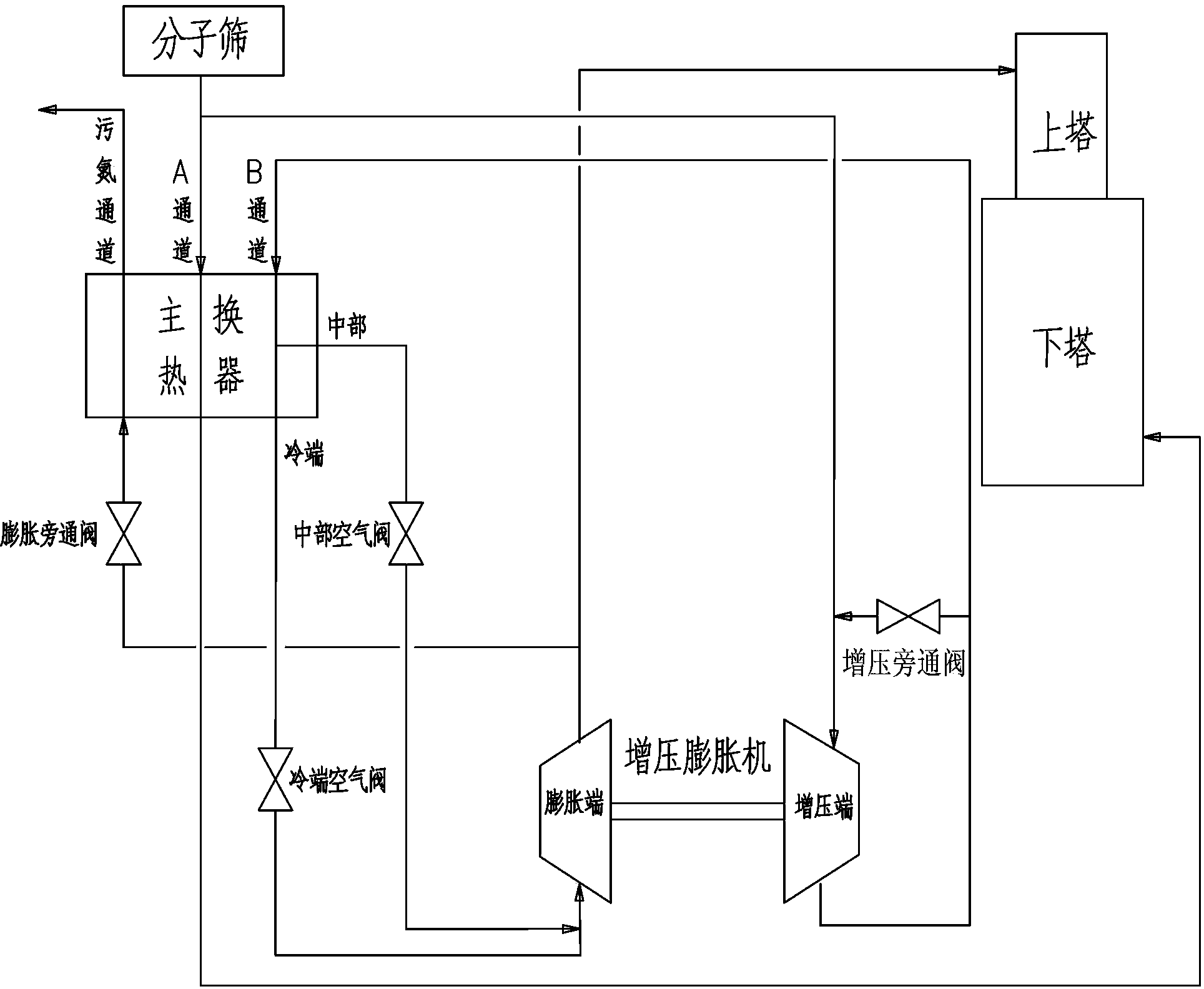

Hot start method for boost expander

ActiveCN102706098AReduce hot start timeMake full use of cooling capacitySolidificationLiquefactionFully developedNitrogen

The invention relates to the field of refrigeration process of boost expanders, in particular to a hot start method for a boost expander, wherein the method is characterized in that in a hot start initial stage, all gases exhausted from an expansion end enter a waste nitrogen channel of a main heat exchanger to bypass and quicken decrease of temperature of the main heat exchanger, simultaneously, air exhausted from a cold end of the main heat exchanger flows into the expansion end at the first, then air in the middle of the main heat exchanger gradually flows into the expansion end after the temperature of the air exhausted from the expansion end is reduced to a designed value to enable the expander to run at the highest secure rotation speed all the time, and to fully develop maximum refrigerating capacity to shorten space division hot start time. Compared with the prior art, beneficial effects of the method are as follows: after the method is utilized, hot start time of the expander is shortened from former 48 h to 42 h, a bypass operation period is crossed fast in relatively shorter time, and refrigerating capacity of the expander is fully developed to further reduce power consumption for start.

Owner:ANGANG STEEL CO LTD

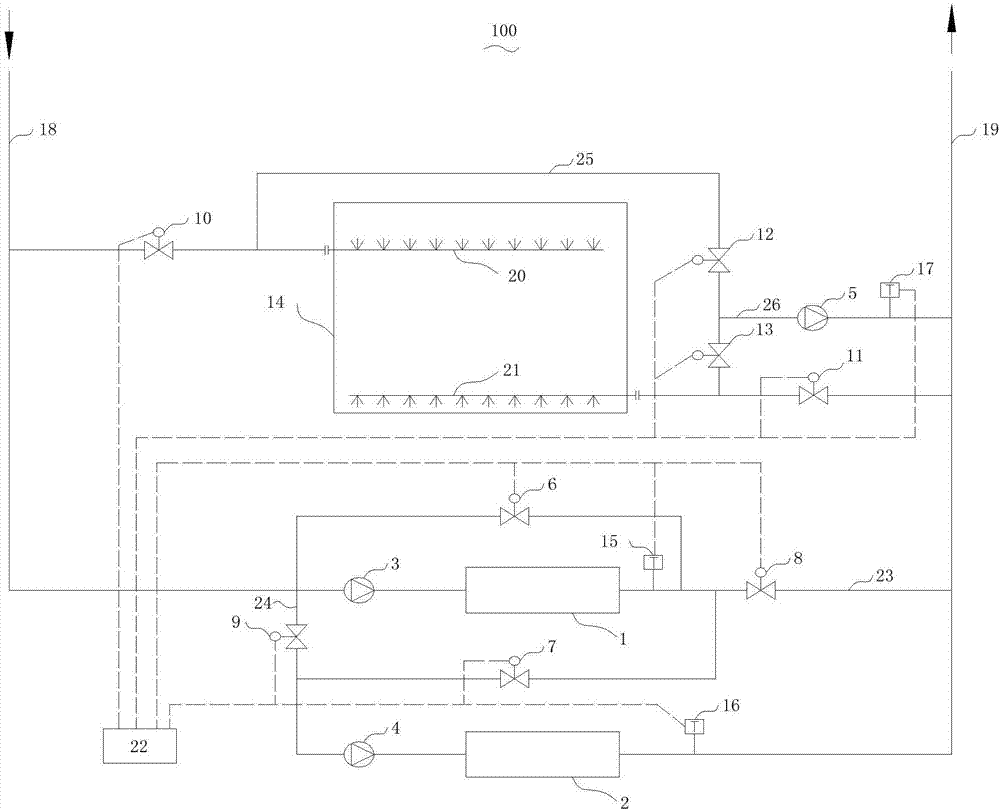

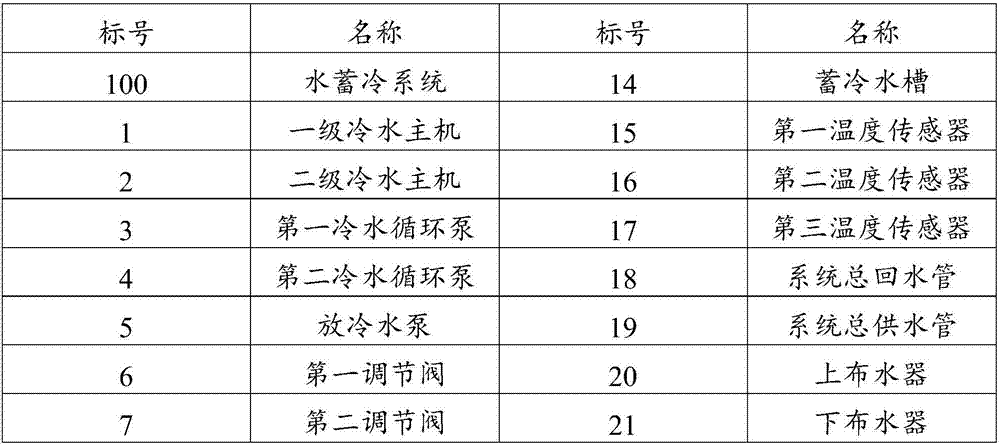

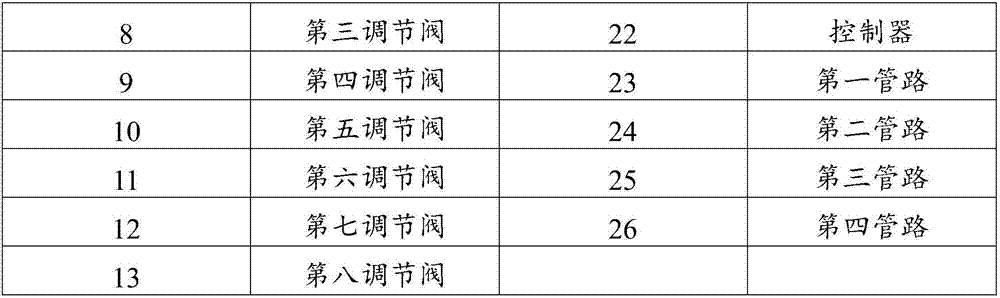

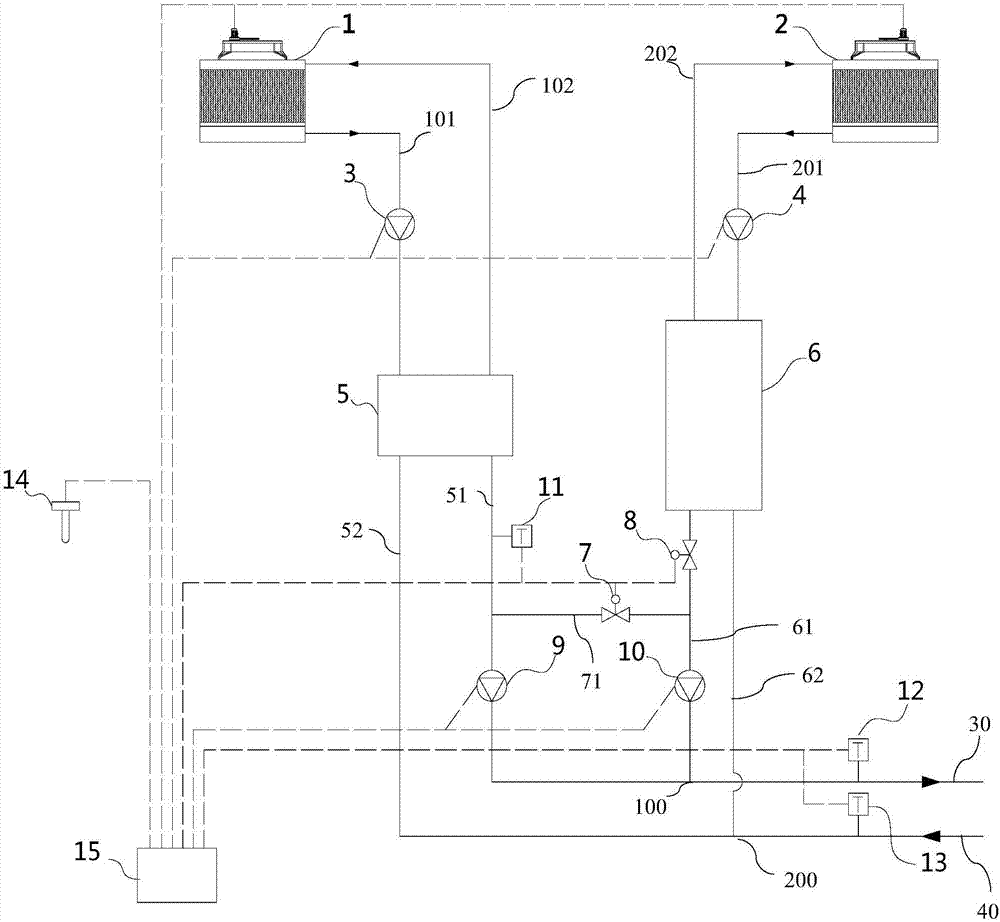

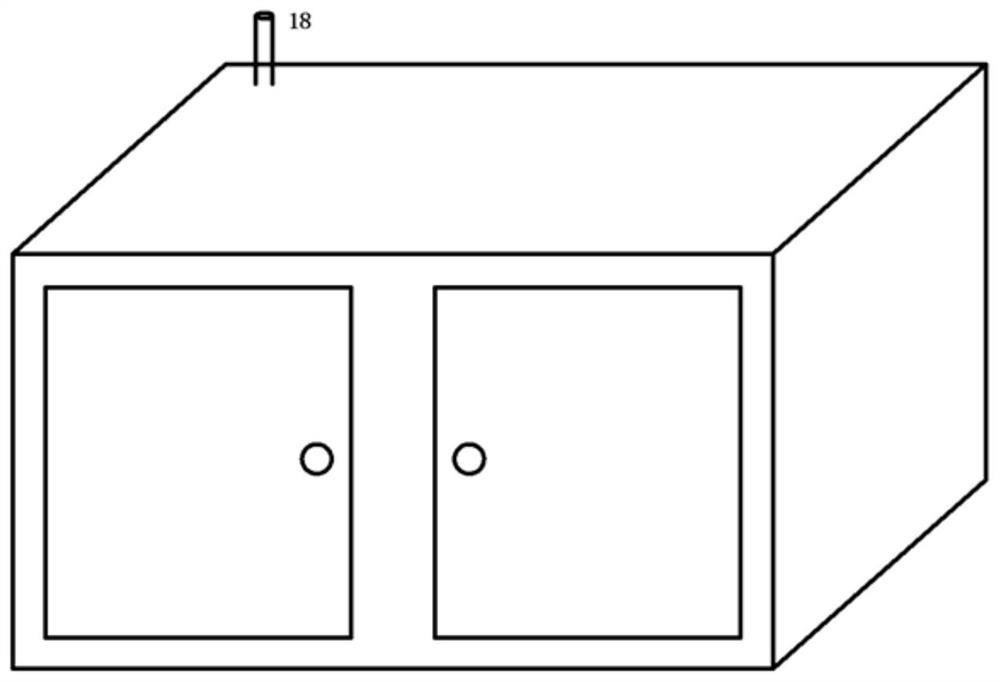

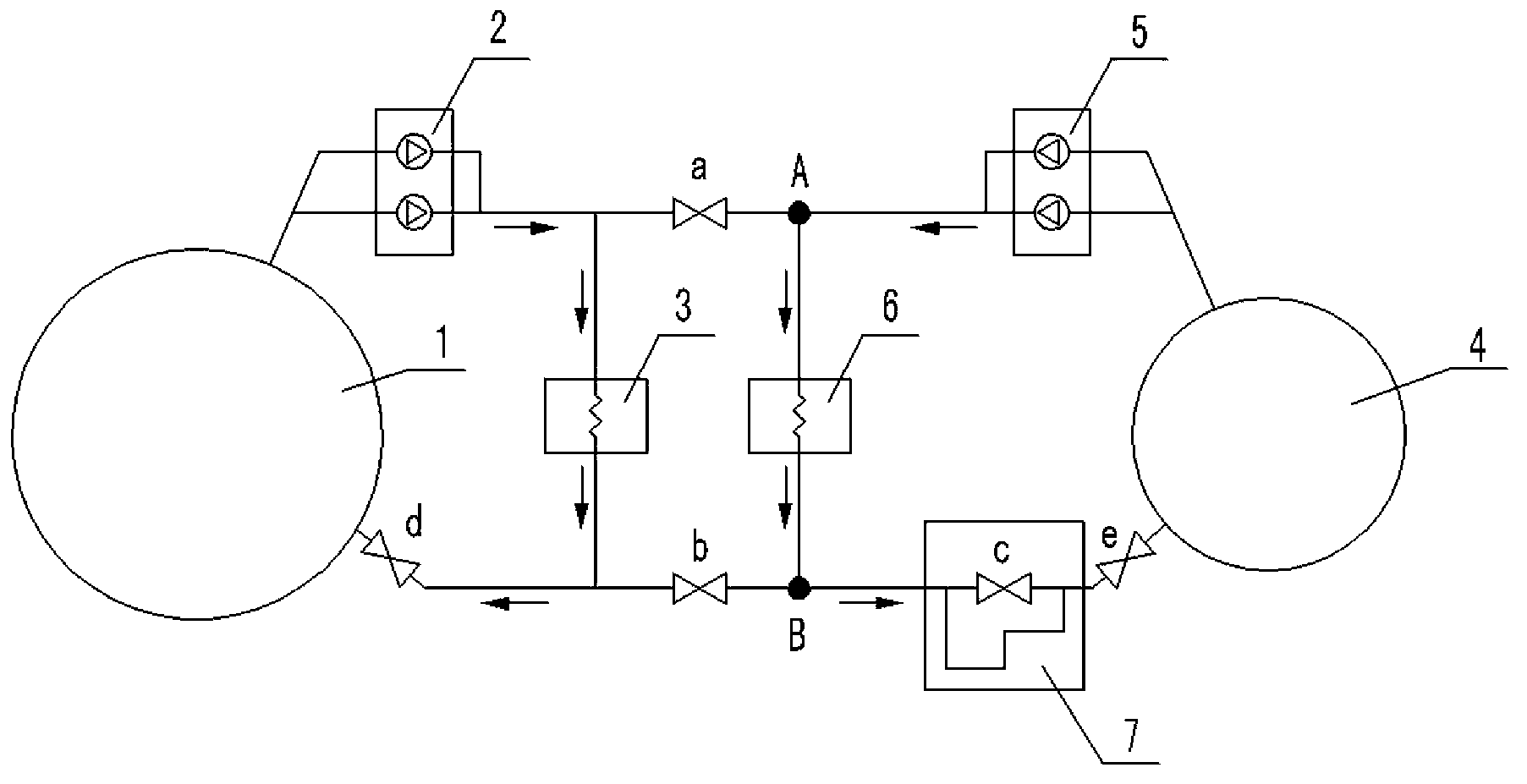

Water cold storage system

InactiveCN107477735ABenefit maximizationMake full use of cooling capacitySpace heating and ventilation safety systemsLighting and heating apparatusElectricityEngineering

The invention discloses a water cold storage system which comprises a controller and a refrigerating unit. The refrigerating unit comprises a primary cold water main machine. The inlet end and the outlet end of the primary cold water main machine are connected with a bypass loop in parallel. A first adjusting valve is arranged on the bypass loop. A first temperature sensor is arranged at the outlet end of the primary cold water main machine. The primary cold water main machine, the first adjusting valve and the first temperature sensor are all electrically connected with the controller. According to the technical scheme, the inlet end and the outlet end of the primary cold water main machine are connected with the bypass loop in parallel, and therefore water can circulate back to the primary cold water main machine through the bypass loop to be cyclically cooled till the set cold storage temperature is achieved, and large-temperature-difference cold storage can be achieved; and the first adjusting valve is arranged on the bypass loop, and the recirculation bypass water quantity of the primary cold water main machine is controlled by the controller by adjusting the opening degree of the first adjusting valve according to the water temperature detected by the first temperature sensor so that it is guaranteed that the primary cold water main machine can fully achieve the refrigerating capacity.

Owner:SHENZHEN DAS INTELLITECH CO LTD

High-efficiency refrigerating system and refrigerating method thereof

ActiveCN107327993AMake full use of cooling capacityExtend cooling timeSpace heating and ventilation safety systemsLighting and heating apparatusCooling towerFully developed

The invention relates to a high-efficiency refrigerating system and a refrigerating method thereof. The high-efficiency refrigerating system comprises a first free cooling tower circulating device, tail end equipment and a second free cooling tower circulating device, wherein the first free cooling tower circulating device is used for natural cooling and refrigerating, and the tail end equipment is refrigerated. A heat exchanger is arranged between the first free cooling tower circulating device and the tail end equipment, a water cooling main engine is arranged between the second free cooling tower circulating device and the tail end equipment, and a first water outlet pipe is connected with the heat exchanger; a second water outlet pipe is connected with the water cooling main engine, a first water freezing circulating pump and a second water freezing circulating pump are arranged on the first water outlet pipe and the second water outlet pipe correspondingly, and a branching pipe is arranged between the first water outlet pipe and the second water outlet pipe in a communicating mode; and a first regulating valve is arranged on the branching pipe, and a second regulating valve is further arranged on the second water outlet pipe. According to the high-efficiency refrigerating system and the refrigerating method thereof, the cooling capacity of a cooling tower is fully developed, the cooling efficiency of a whole air-conditioning system is improved, and the operating energy consumption of the air-conditioning system is saved.

Owner:SHENZHEN DAS INTELLITECH CO LTD

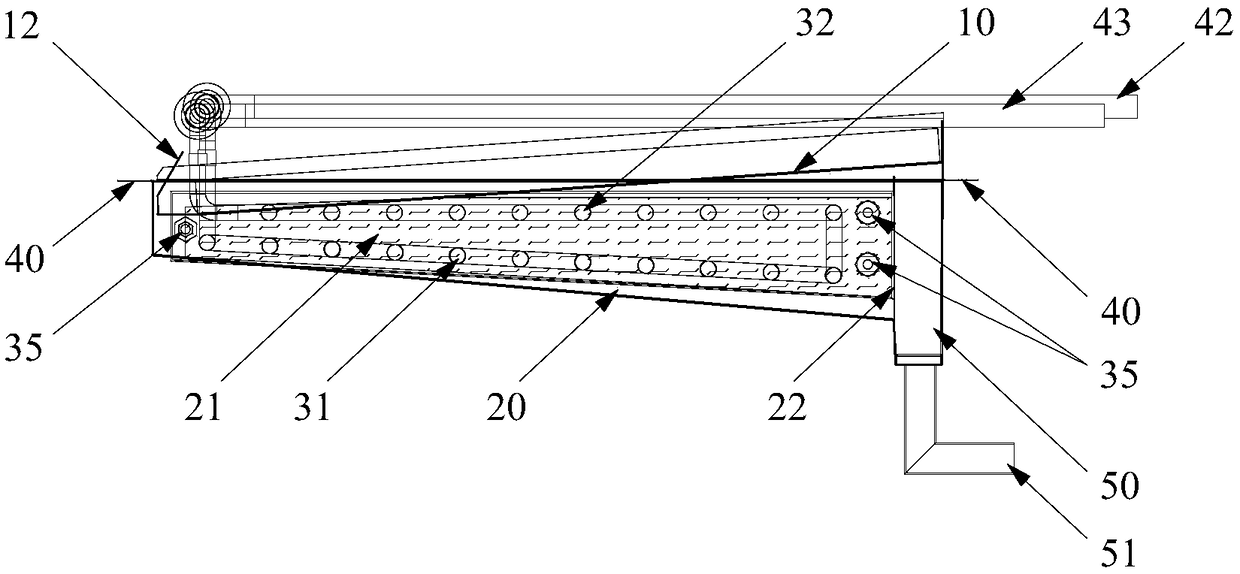

Mixed refrigeration system and quick freezing method thereof

PendingCN112815596AChange cooling rateEasy to storeMechanical apparatusDomestic refrigeratorsQuick FreezeCrystallization temperature

Provided are a mixed refrigeration system and a quick freezing method thereof. The mixed refrigeration system mainly comprises a freezing chamber (16), a contact type cascade heat exchanger (21), a contact type quick freezing system and a carbon dioxide quick freezing circulating system, wherein a tray is arranged in the freezing chamber (16), a contact type cascade heat exchanger (21) is arranged below the tray, the contact type cascade heat exchanger (21) is formed by overlapping an evaporator of a contact type quick-freezing system and a condenser of a carbon dioxide quick-freezing circulating system and serves as a tray support, and the tray is placed on the support. According to the invention, objects to be frozen in different temperature zones are frozen, so that the cooling rate of the objects to be frozen in the cooling zone and the crystallization temperature zone is changed, and the quality of the objects to be frozen is better preserved. The contact type quick-freezing system and the carbon dioxide spraying type quick-freezing system are overlapped, the condensation pressure of carbon dioxide is reduced, and the requirement for high pressure resistance of condensation equipment is lowered.

Owner:PEKING UNIV

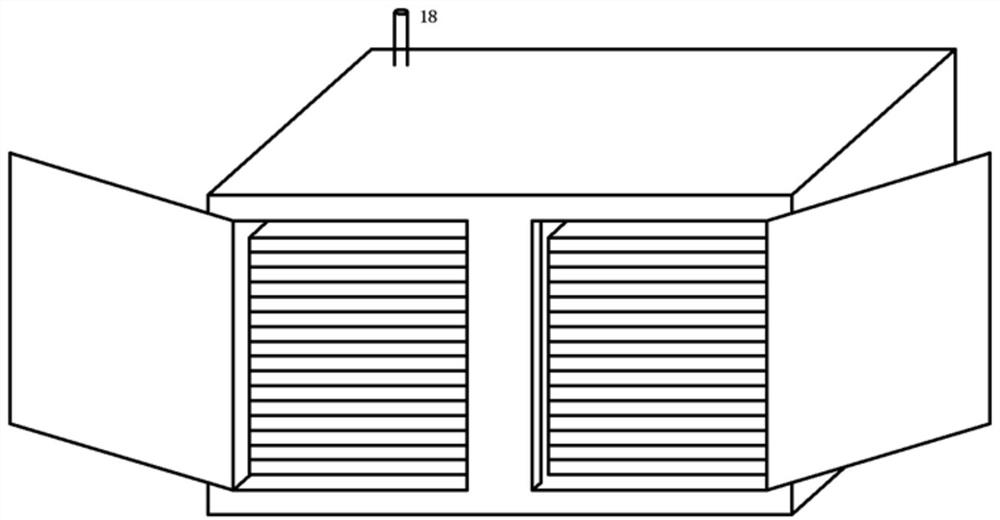

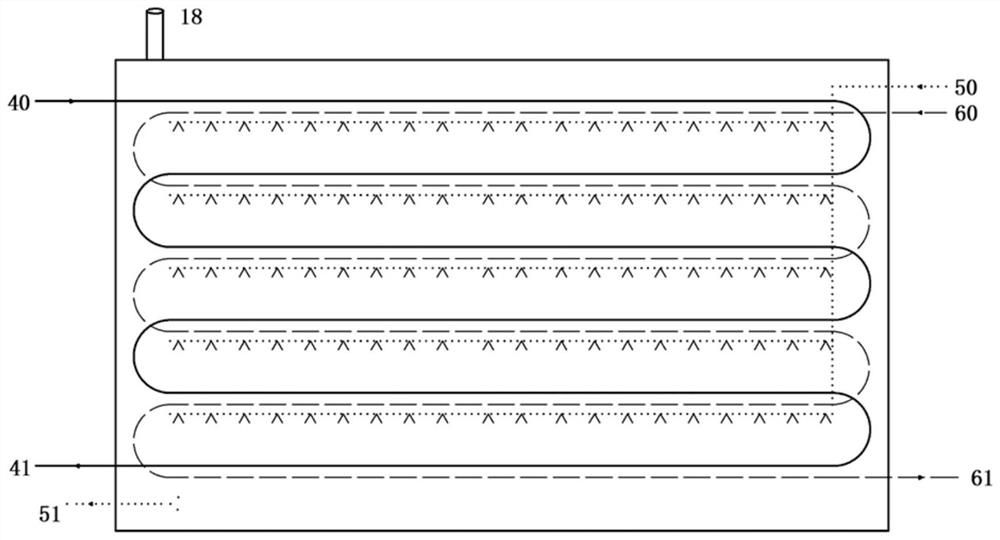

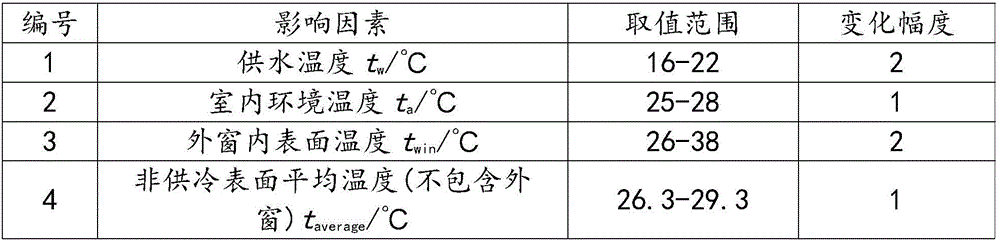

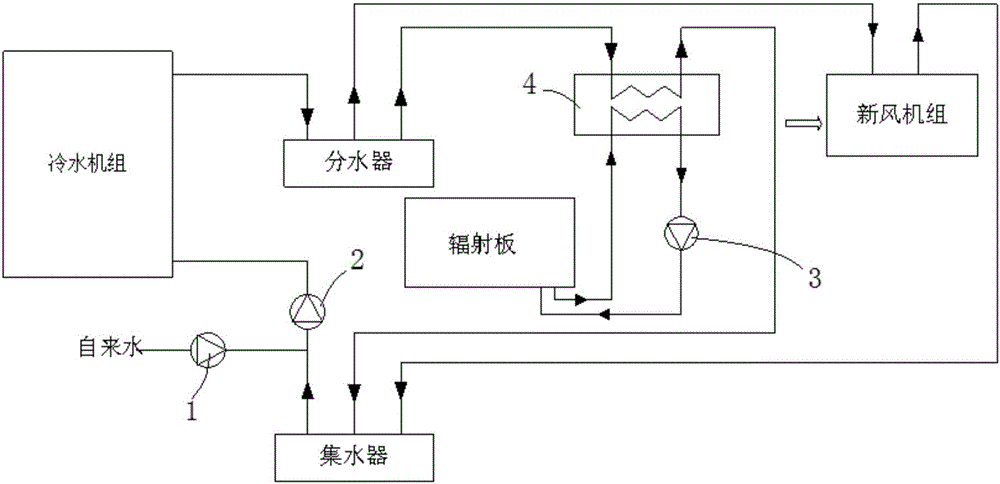

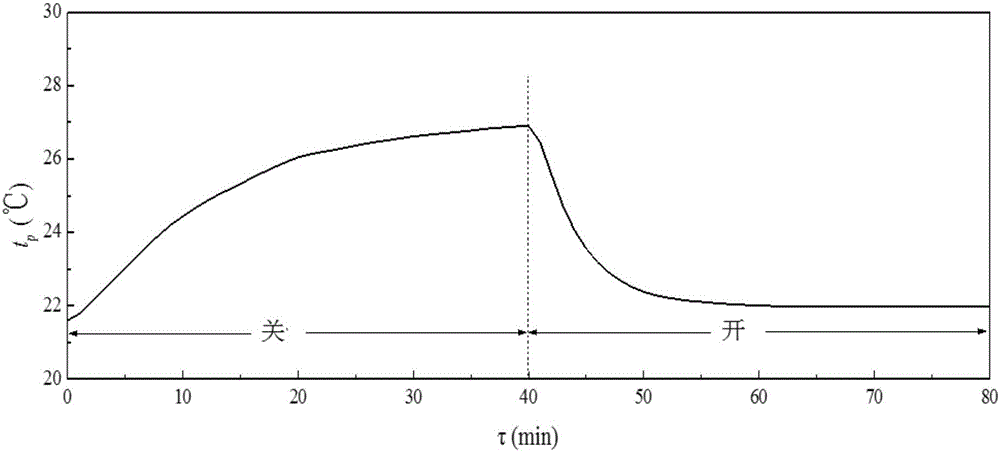

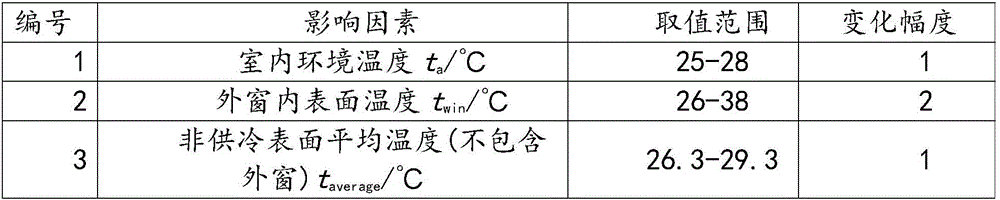

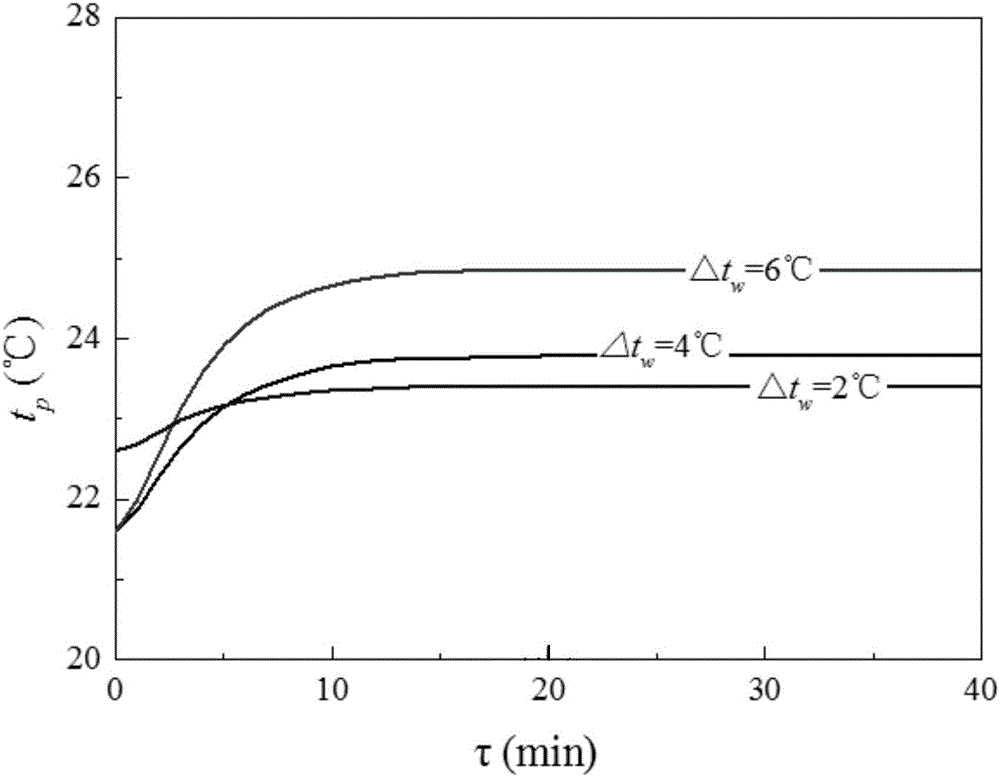

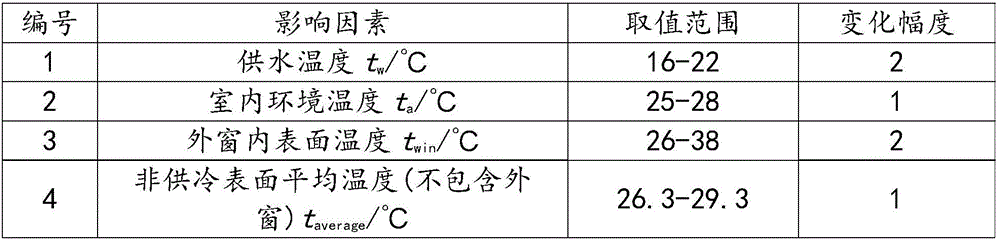

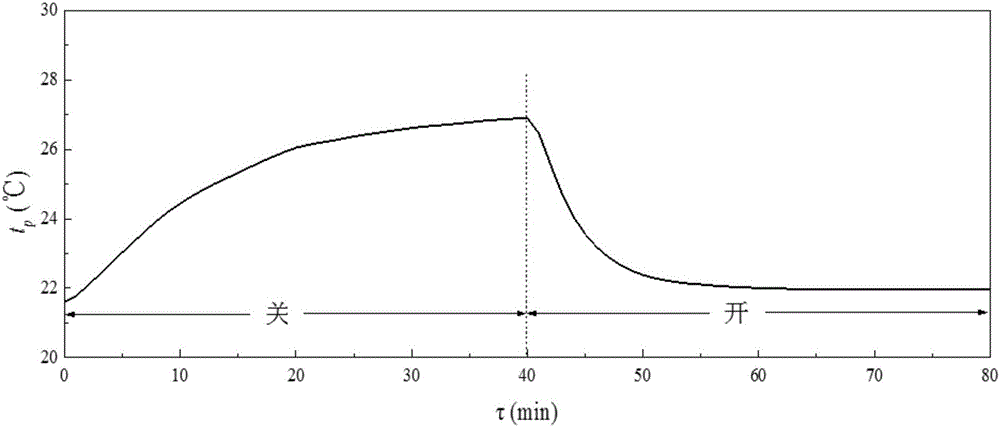

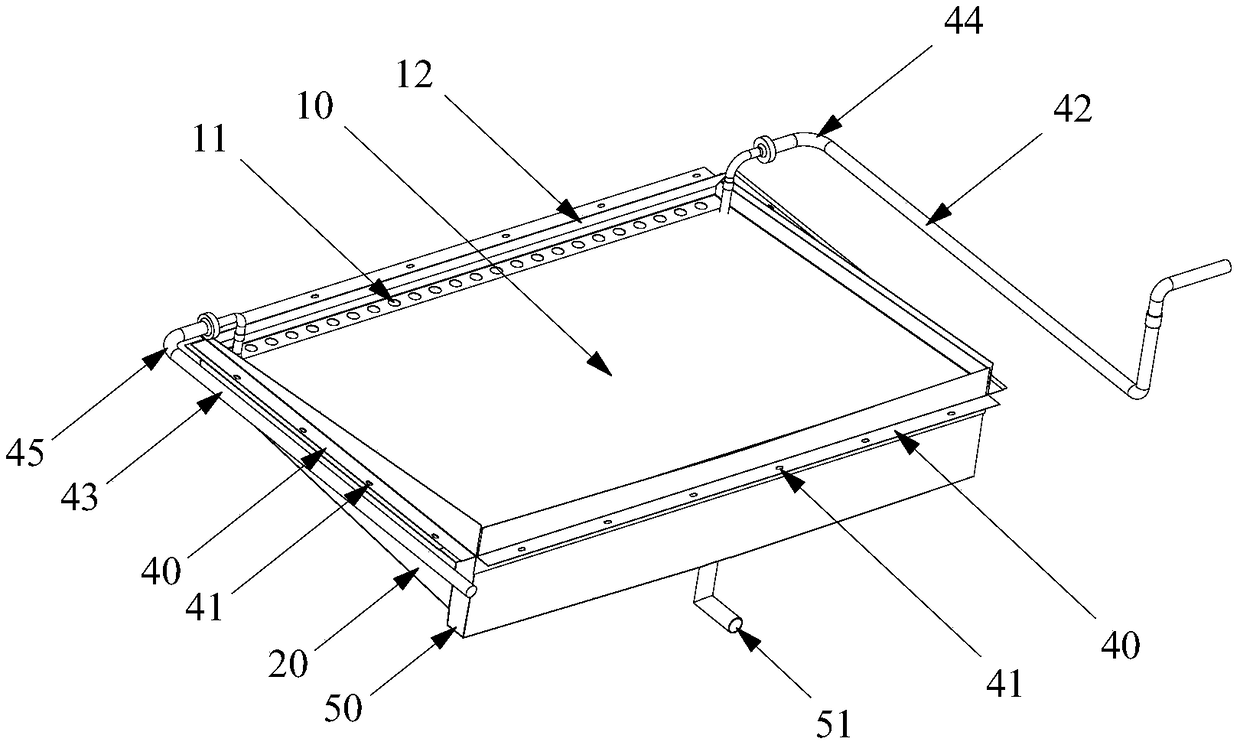

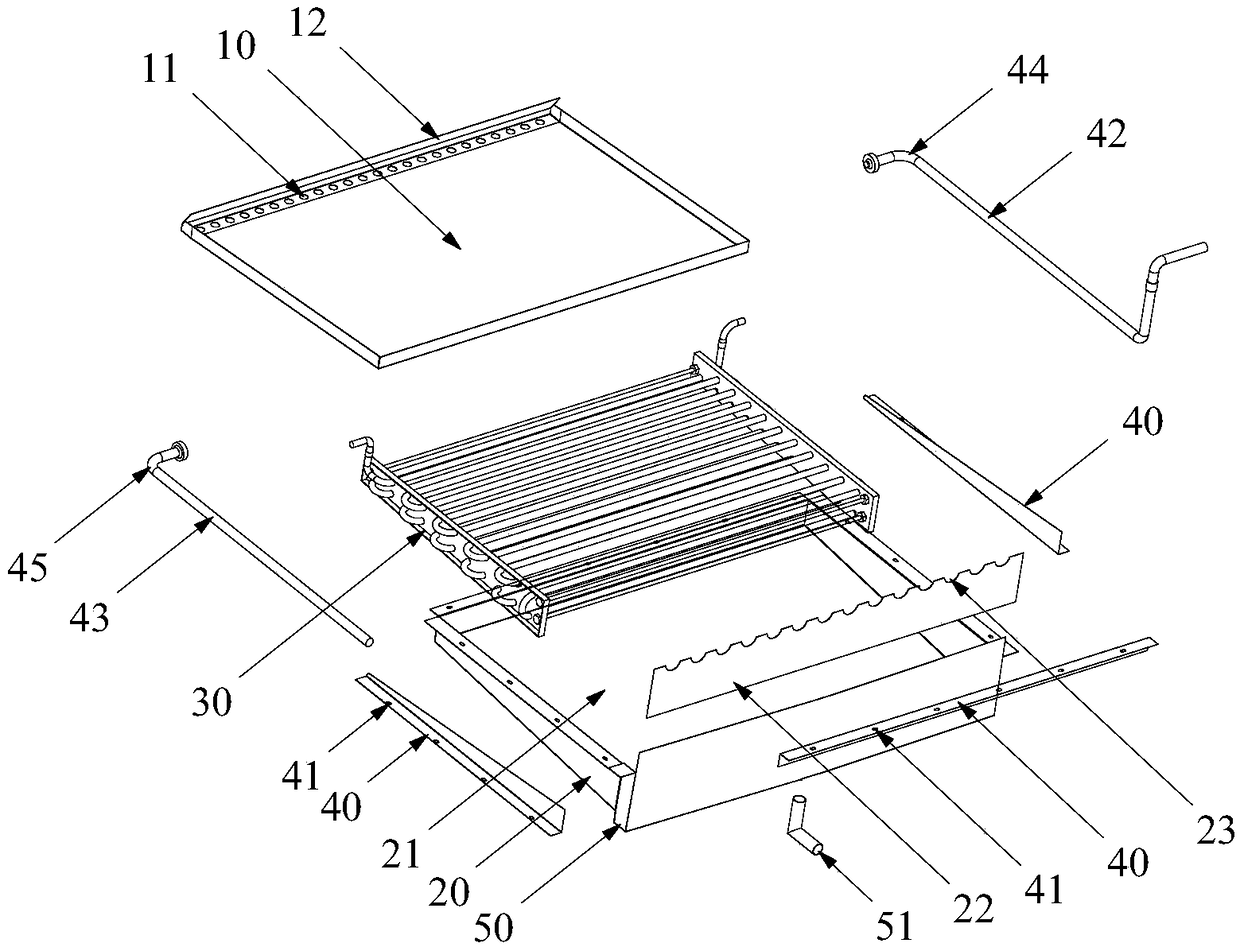

Method for determining surface temperature change of radiation plate of radiation cold supply system in water supply cooling

InactiveCN106765744AMake full use of cooling capacityImprove accuracySpace heating and ventilation safety systemsLighting and heating apparatusControl systemRegression analysis

The invention relates to a method for determining surface temperature change of a radiation plate of a radiation cold supply system in water supply cooling. The method comprises the following steps: influence factors of the surface temperature change of the radiation plate and change ranges of all factors are determined according to actual operation conditions of a radiation cold supply air conditioning system; according to the determined influence factors of the surface temperature change rules of the radiation plate and the change ranges of all the factors, ANSYS software is applied to simulate the surface temperature change conditions of the radiation plate in water supply cooling under different influence factors to obtain sample data; and based on SAS software, a statistic analysis program is applied to perform regression analysis for the sample data to obtain a surface temperature change prediction model of the radiation plate in water supply cooling. The method is higher in accuracy of the prediction result obtained by the regression analysis, is simple in control system, can realize real-time control, and is suitable for residential building heating system control.

Owner:TIANJIN UNIV OF COMMERCE

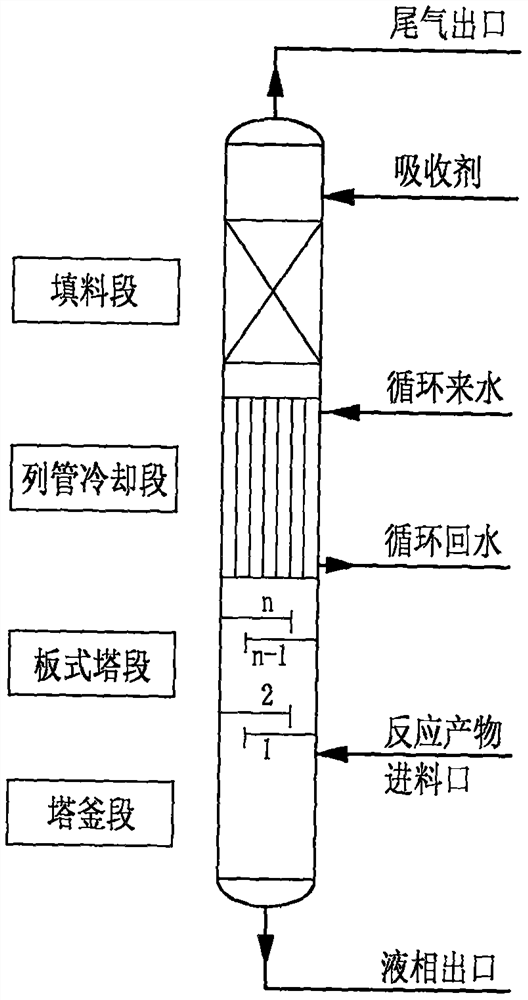

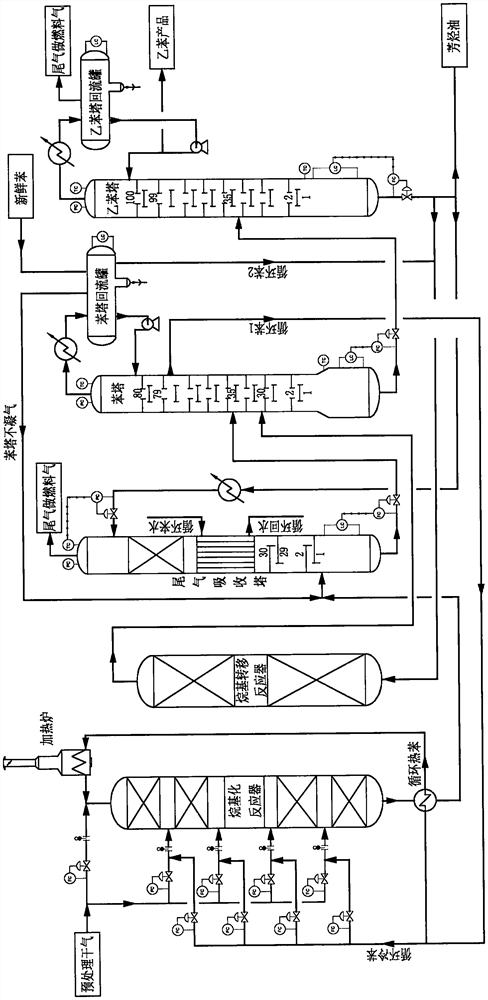

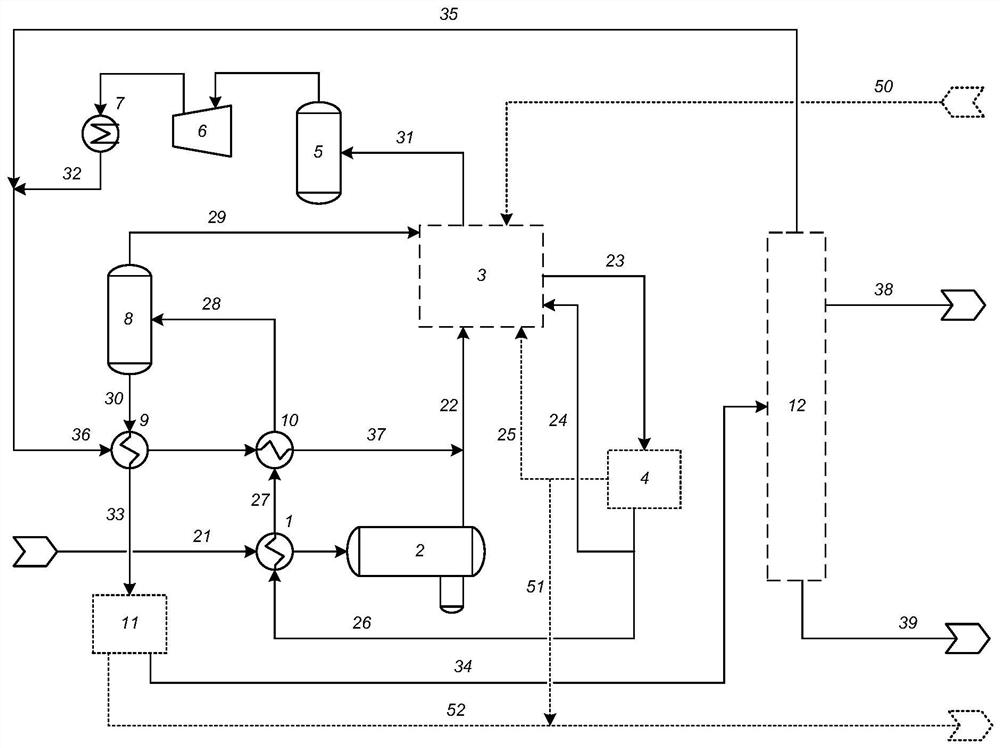

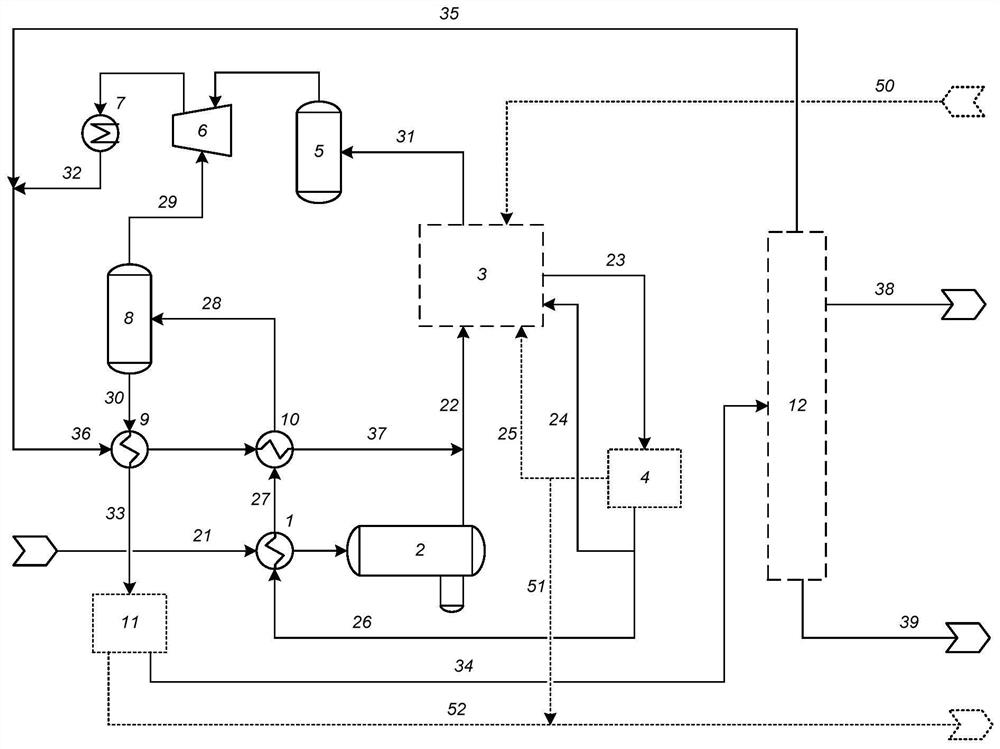

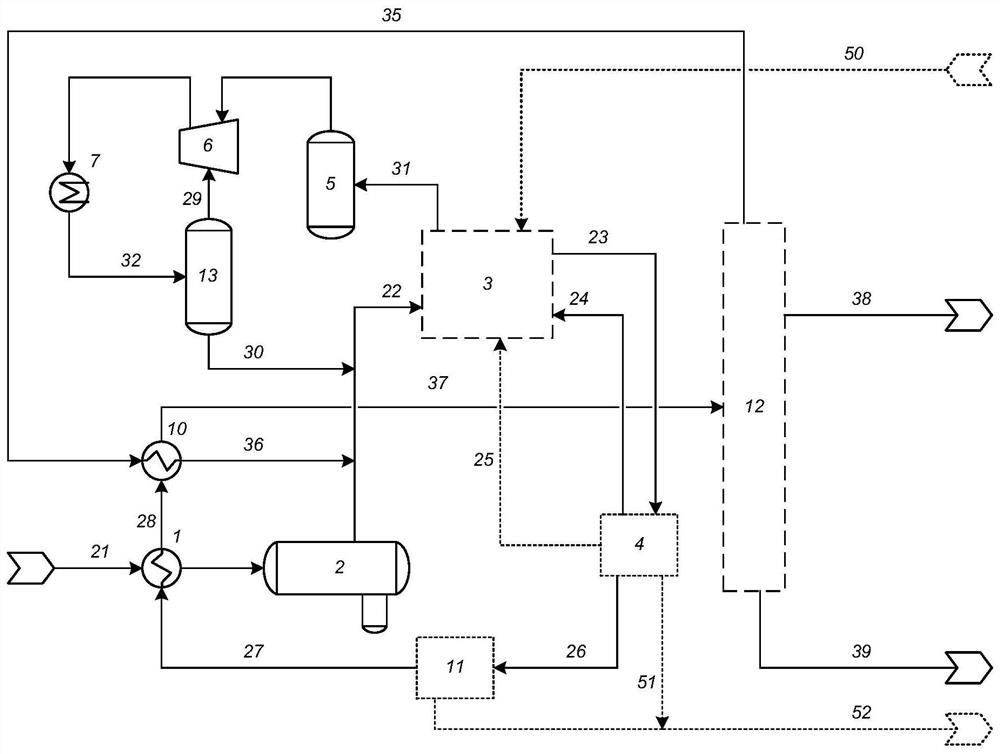

Energy-saving and environment-friendly method for preparing ethylbenzene from dry gas

ActiveCN112321379ATake advantage ofHigh recovery rateMolecular sieve catalystCatalystsPlate columnEnvironmental geology

The invention provides an energy-saving and environment-friendly method for preparing ethylbenzene from dry gas. The method is mainly used for gas-liquid separation and tail gas debenzolization of a reaction product of preparing ethylbenzene from dry gas. The method is characterized in that gas-liquid separation and tail gas absorption of a reaction product of ethylbenzene preparation from dry gasare carried out in a same tower, an absorption and separation tower is divided into four sections, a tower upper section is a packing section, a tower middle section is a tube nest cooling section, atower lower section is a plate type tower, and a tower bottom section is a tower kettle. The reaction product enters from the upper part of the tower kettle and an absorbent enters from the top of the packing section; after the tail gas is absorbed and separated by the absorption and separation tower, the tail gas enters a fuel gas pipe network from the tower top, and rich absorption liquid is mixed with condensed liquid in the reaction product and flows out from the bottom of the tower kettle to enter a benzene tower. Non-condensable gas at the top of the benzene tower returns to the absorption and separation tower, circulating benzene 1 is extracted from the upper section of the benzene tower and enters an alkylation reactor, circulating benzene 2 at the bottom of a benzene tower refluxtank enters an alkyl transfer reactor, materials at the bottom of the benzene tower enter an ethylbenzene tower to obtain a product ethylbenzene at the top of the ethylbenzene tower, and tower bottomliquid of the ethylbenzene tower is divided into three parts, one stream returns to the absorption and separation tower as an absorbent, one stream is sent to the transalkylation reactor, and the other stream is aromatic hydrocarbon oil. The separation process is simple and reliable, tower equipment is reduced while reaction heat is fully utilized, equipment investment and subsequent operation cost are saved, and energy consumption of the device is reduced. According to the separation method, the recovery rate of benzene carried by the tail gas is greater than 99.9%, and the purity of an ethylbenzene product is greater than 99.8%.

Owner:北京惠尔三吉绿色化学科技有限公司

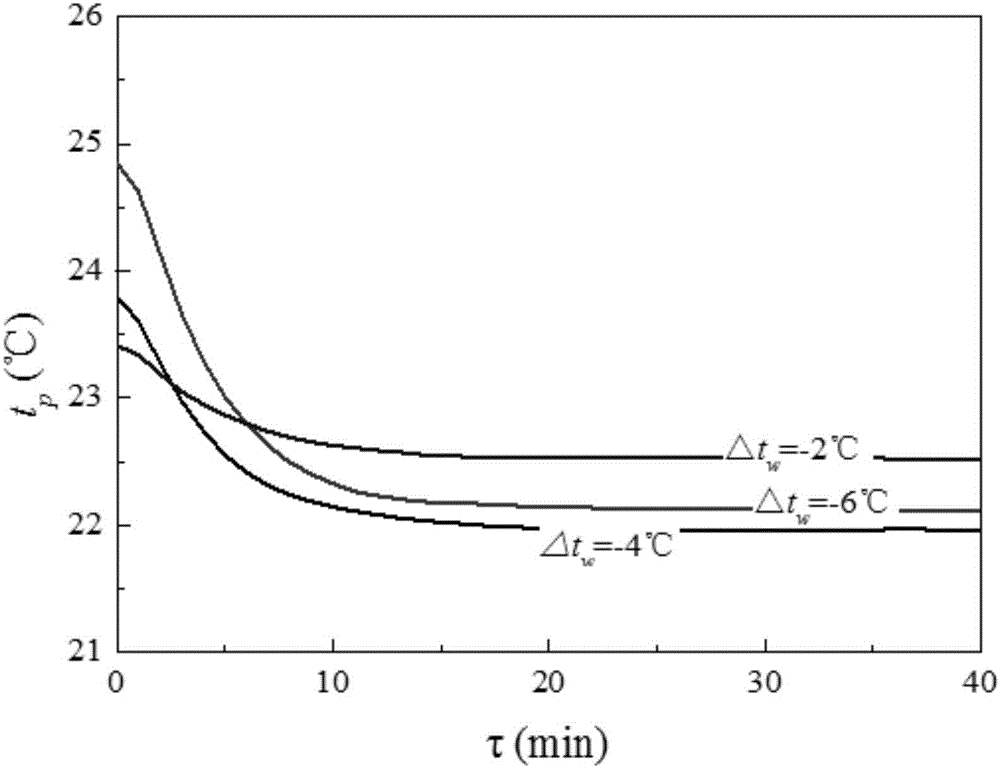

Method for determining radiant panel surface temperature change of radiant cooling system when water supply is started

InactiveCN106765880AImprove accuracySimple control systemGeometric CADMechanical apparatusHeating systemRegression analysis

The invention relates to a method for determining the radiant panel surface temperature change of a radiant cooling system when water supply is started. The method comprises the following steps: determining the influence factors of the radiant panel surface temperature change and the change range of each factor according to actual operating conditions of the radiant cooling air conditioner system; using an ANSYS software to simulate the radiant panel surface temperature change condition when the water supply is started under different influence factors according to the determined influence factors of the radiant panel surface temperature change and the determined change range of each factor, and obtaining sample data; based on an SAS software, carrying out regression analysis by utilizing statistic analysis program sample data, and obtaining a prediction model for the radiant panel surface temperature change when the water supply is started. According to the method, the prediction result obtained through regression analysis is relatively high in accuracy, the control system is simple, real-time control can be realized, and the method is applicable in residential building heating system control.

Owner:TIANJIN UNIV OF COMMERCE

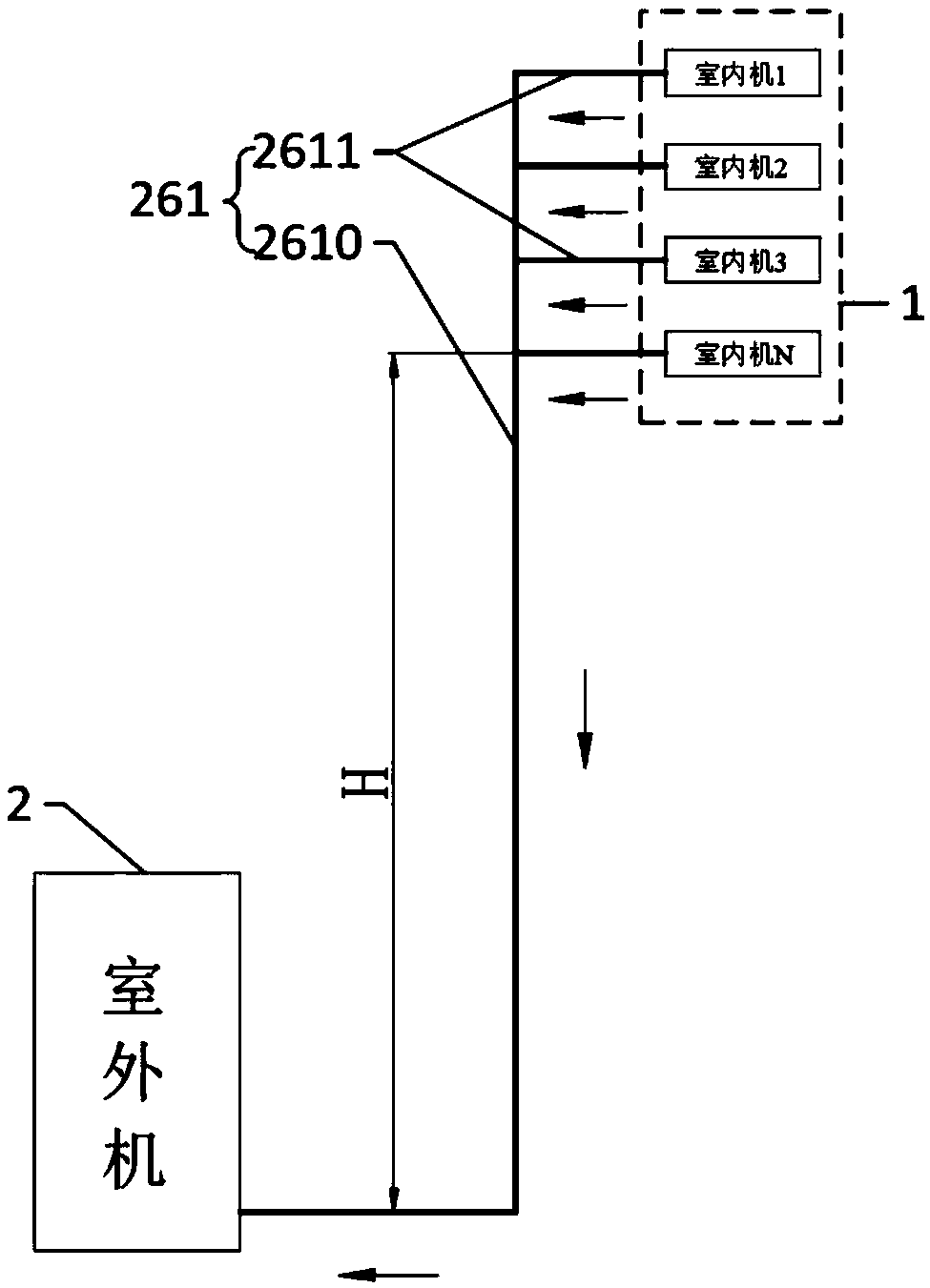

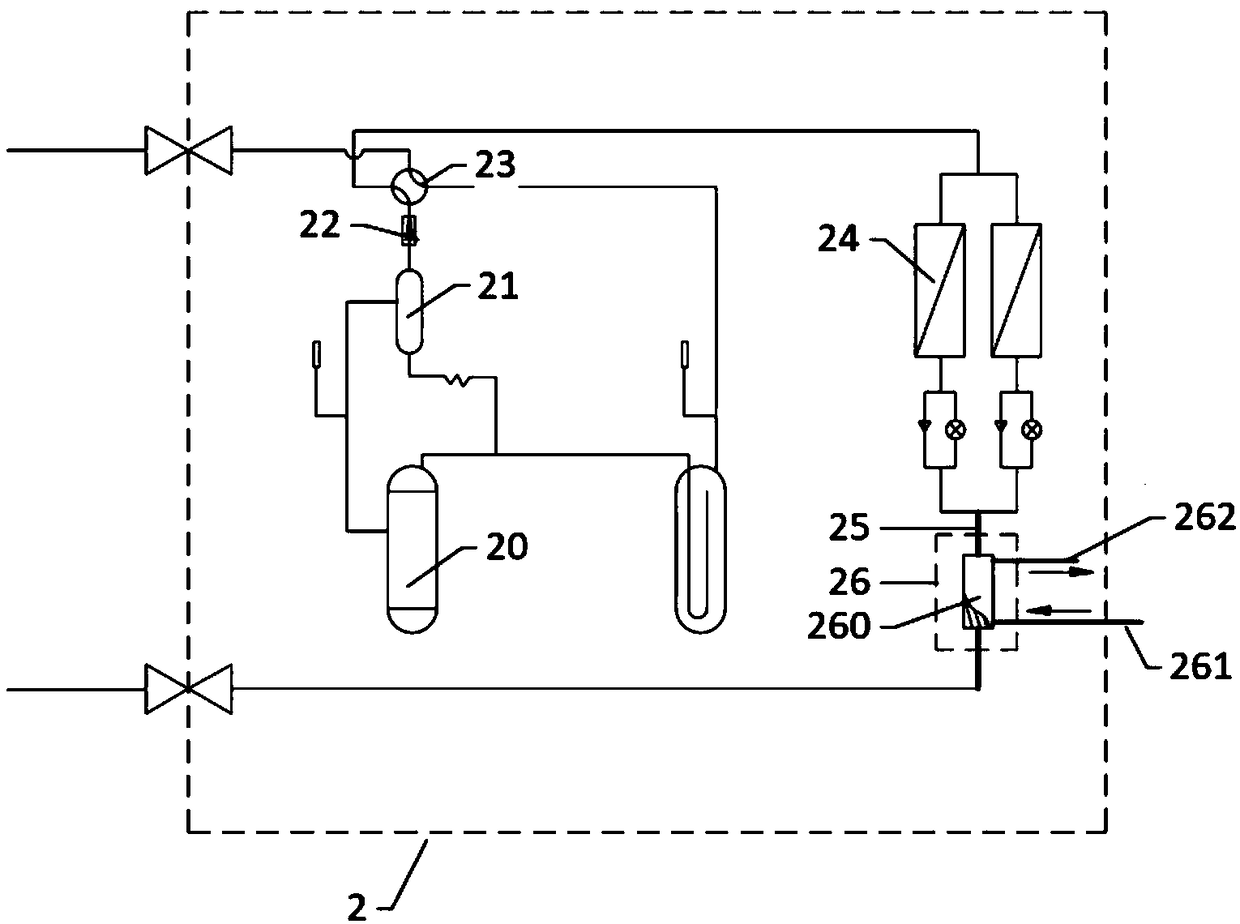

Supercooling device for air conditioner and air conditioner

PendingCN109373644AIncrease subcoolingAvoid flickeringSubcoolersAir conditioning systemsWater circulationEngineering

The invention relates to the technical field of air conditioners, and provides a supercooling device for an air conditioner and the air conditioner in order to solve the problems of high cost and easyloss of refrigerant energy of an existing supercooling device for the air conditioner. The air conditioner comprises a condenser and a water receiving tray. An outlet of the condenser is connected with a refrigerant main pipeline. The water receiving tray is used to collect condensate water produced in the refrigeration process of the air conditioner. The supercooling device comprises a condensate water circulation pipeline. The condensate water circulation pipeline comprises a heat exchange pipe section. The heat exchange pipe section is arranged to enable the condensate water to exchange heat with refrigerant in the refrigerant main pipeline to improve the supercooling degree of the refrigerant. The supercooling device can improve the supercooling degree of the refrigerant by utilizingthe heat exchange between the low temperature condensate water and the refrigerant, so that the flash phenomenon of the refrigerant is avoided, the uniformity of refrigerant flow distribution in eachinternal machine is improved, the refrigeration efficiency of the air conditioner is greatly improved, and the power consumption of a system is reduced. The supercooling device has simple structure and convenient installation, and contributes to providing a more stable and uniform refrigeration effect.

Owner:QINGDAO HAIER AIR CONDITIONING ELECTRONICS CO LTD

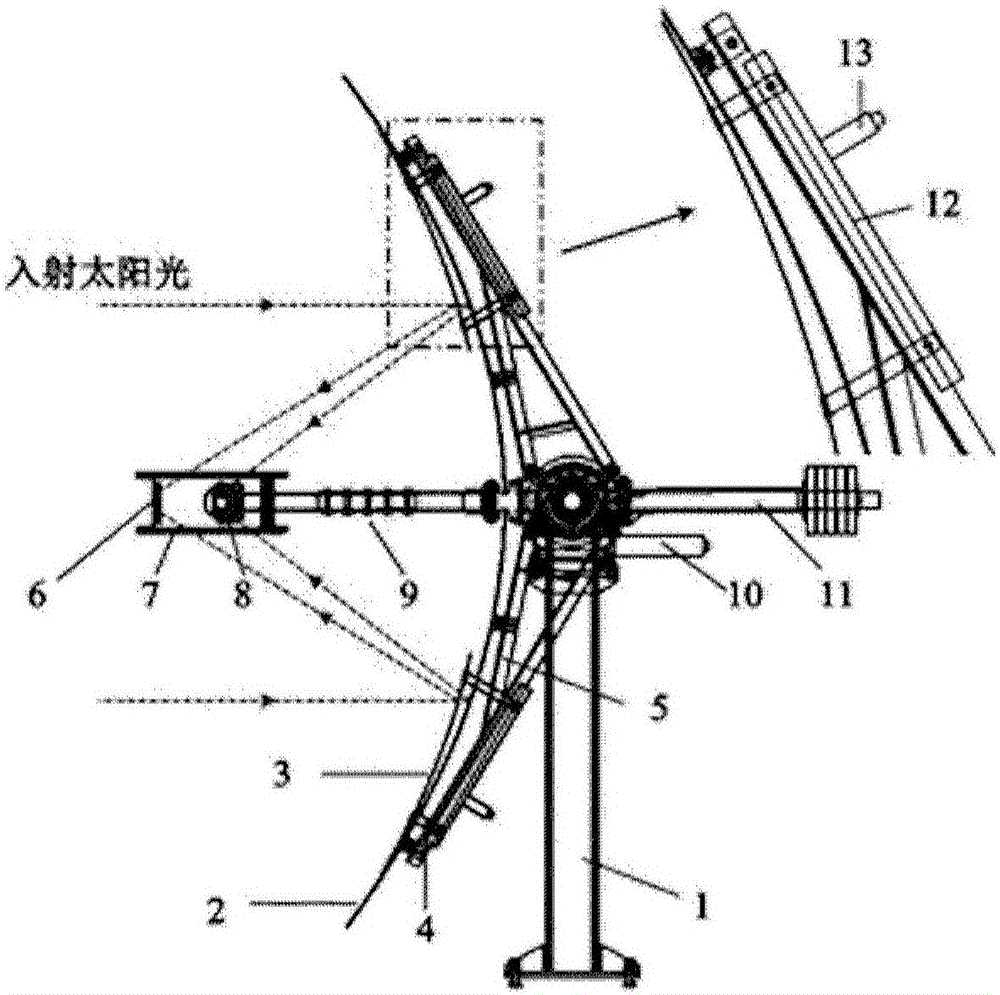

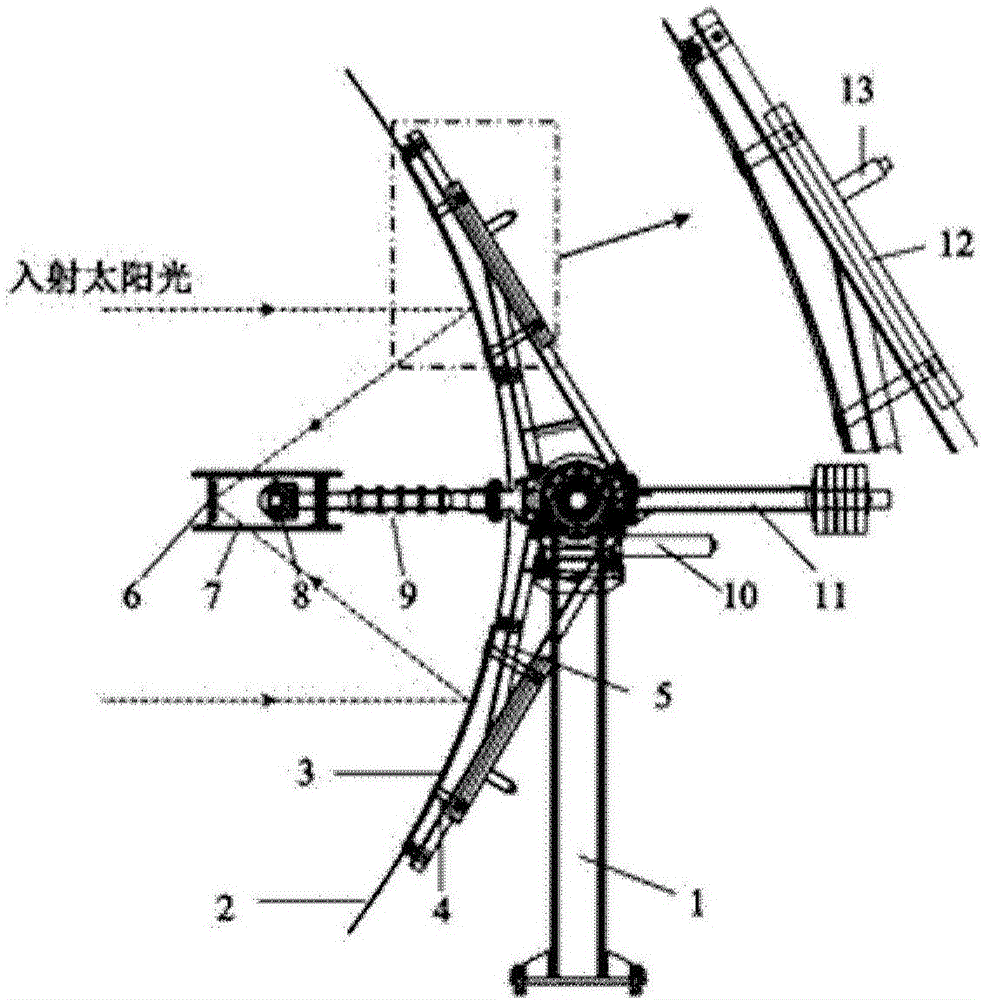

Gradient utilization device of line focusing concentrating photovoltaic-photothermal full spectrum

ActiveCN106788236AReduce heat productionImprove photoelectric conversion efficiencyPhotovoltaicsPhotovoltaic energy generationWavelength rangeConcentrator photovoltaic

The invention provides a gradient utilization device of a line focusing concentrating photovoltaic-photothermal full spectrum. Compared with the traditional concentrating photovoltaic technology, the device has the advantages that an upper layer collecting lens is provided, as only sunlight within an operating wavelength range of a concentrating photovoltaic battery but not all sunlight is subjected to photovoltaic utilization, the heat yield of the photovoltaic battery is reduced, and meanwhile the photoelectric conversion efficiency of the photovoltaic battery is enhanced; through medium temperature photothermal utilization, the photovoltaic-photothermal utilization grade is enhanced, so that the solar radiation utilization ratio is improved, full spectrum utilization of solar energy is realized, and irreversible loss during solar utilization is reduced.

Owner:INST OF ENGINEERING THERMOPHYSICS - CHINESE ACAD OF SCI

Method for determining surface temperature change of radiant panel of radiant cooling system in water temperature rise

InactiveCN106765745AAvoid condensationExtension of timeSpace heating and ventilation safety systemsLighting and heating apparatusRegression analysisControl system

The invention relates to a method for determining the surface temperature change of a radiant panel of a radiant cooling system in water temperature rise. The method comprises the following steps: determining influence factors of the surface temperature change of the radiant panel and the change range of each factor according to the actual running condition of the radiant cooling air-conditioning system; simulating the surface temperature change situation of the radiant panel in water temperature rise under different influence factors by applying ANSYS software according to the determined influence factors of the surface temperature change rule of the radiant panel and the change range of each factor, and acquiring sample data; and, based on the SAS software, performing regression analysis on the sample data by applying a statistic analysis program to acquire a surface temperature change prediction model of the radiant panel in water temperature rise. A prediction result acquired by regression analysis has a relatively high accuracy, the control system is simple, and real-time control can be realized. The method is applicable to control of residential building warming systems.

Owner:TIANJIN UNIV OF COMMERCE

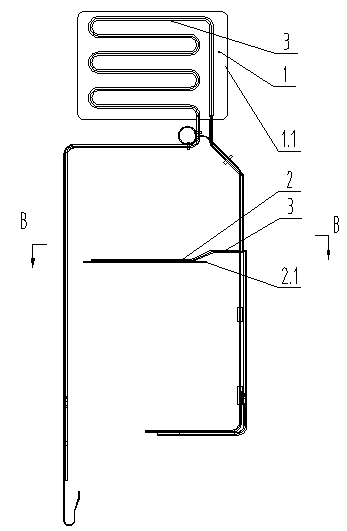

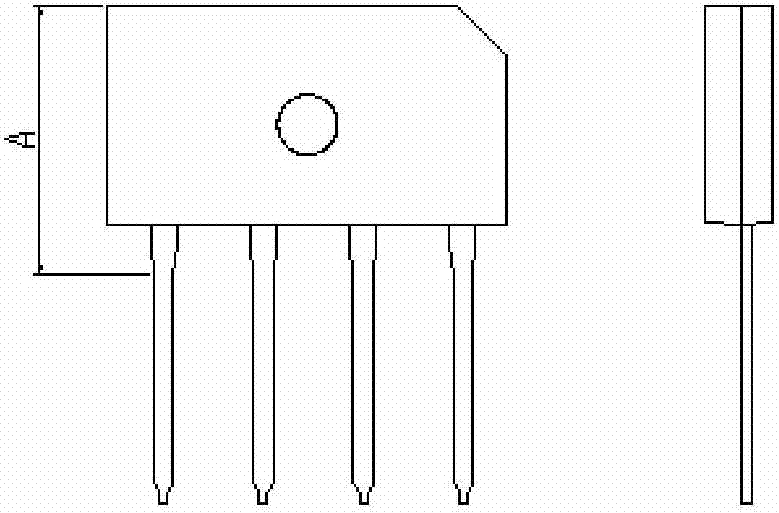

Radiating fin structure surface-mount rectifier bridge device

ActiveCN105185757AShort cooling pathMake full use of cooling capacitySemiconductor/solid-state device detailsSolid-state devicesMetal stripsSurface mounting

The invention discloses a radiating fin structure surface-mount rectifier bridge device. The radiating fin structure surface-mount rectifier bridge device comprises a first diode chip, a second diode chip, a third diode chip, a fourth diode chip and a cathode metal strip all coated by an epoxy packaging body, and a first metal substrate, a second metal substrate and an E-shaped metal substrate are respectively located at left side and right side of the bottom of the epoxy packaging body; a first connecting sheet, a second connecting sheet, a third connecting sheet and a fourth connecting sheet are arranged in parallel along a front-to-back direction; the front end of the cathode metal strip, located between the first metal substrate and the E-shaped metal substrate, comprises a bending part, and the bottom of the bending part and the bottom of each of the first metal substrate, the second meal substrate and the E-shaped metal substrate are in the same horizontal plane and are all naked outside the epoxy packaging body; the first metal substrate and the second metal substrate are used as alternating current input ends, the cathode metal strip is used as a direct current cathode end, and the E-shaped metal substrate is used as a direct current anode end. According to the invention, a radiating path between the chips and a PCB is shortest, radiating fins are metal material and have excellent heat conductivity coefficient, own radiating capacity of the PCB is used fully, and defects of the existing product, such as poor epoxy heat conduction capability caused by radiating through air convection in a case, are avoided.

Owner:SUZHOU GOODARK ELECTRONICS CO LTD

Refrigerating device

InactiveCN106642916AReduce contentReduce the intensity of aerobic respirationLighting and heating apparatusDomestic refrigeratorsNitrogenEngineering

The invention provides a refrigerating device. The refrigerating device comprises a case body, an air-adjusted film assembly, an oxygen exhausting pipeline and a gas pumping device. Storage space and a compressor room are arranged in the case body in limited modes, a storage container is arranged in the storage space, and air-adjusted freshness retaining space is arranged in the storage container. The air-adjusted film assembly is configured in a mode that compared with nitrogen in peripheral space airflow of the air-adjusted film assembly, and more oxygen in the peripheral space airflow of the air-adjusted film assembly penetrates an air-adjusted film and enters an enriched oxygen collecting cavity. An inlet of the oxygen exhausting pipeline communicates with the oxygen-rich gas collecting cavity, and an outlet of the oxygen exhausting pipeline is towards a condenser so as to enable gas flowing out of the oxygen-rich gas collecting cavity to blow towards the condenser. The gas pumping device is arranged on the oxygen exhausting pipeline, so that the gas penetrated into the oxygen-rich gas collecting cavity is pumped and exhausted outside the storage container. According to the refrigerating device, not only is the freshness retaining effect good, but also cold energy in the gas flowing out of the oxygen-rich gas collecting cavity is fully utilized so as to conduct cooling on the condenser, and the energy efficiency of the refrigerating device is improved.

Owner:HAIER SMART HOME CO LTD

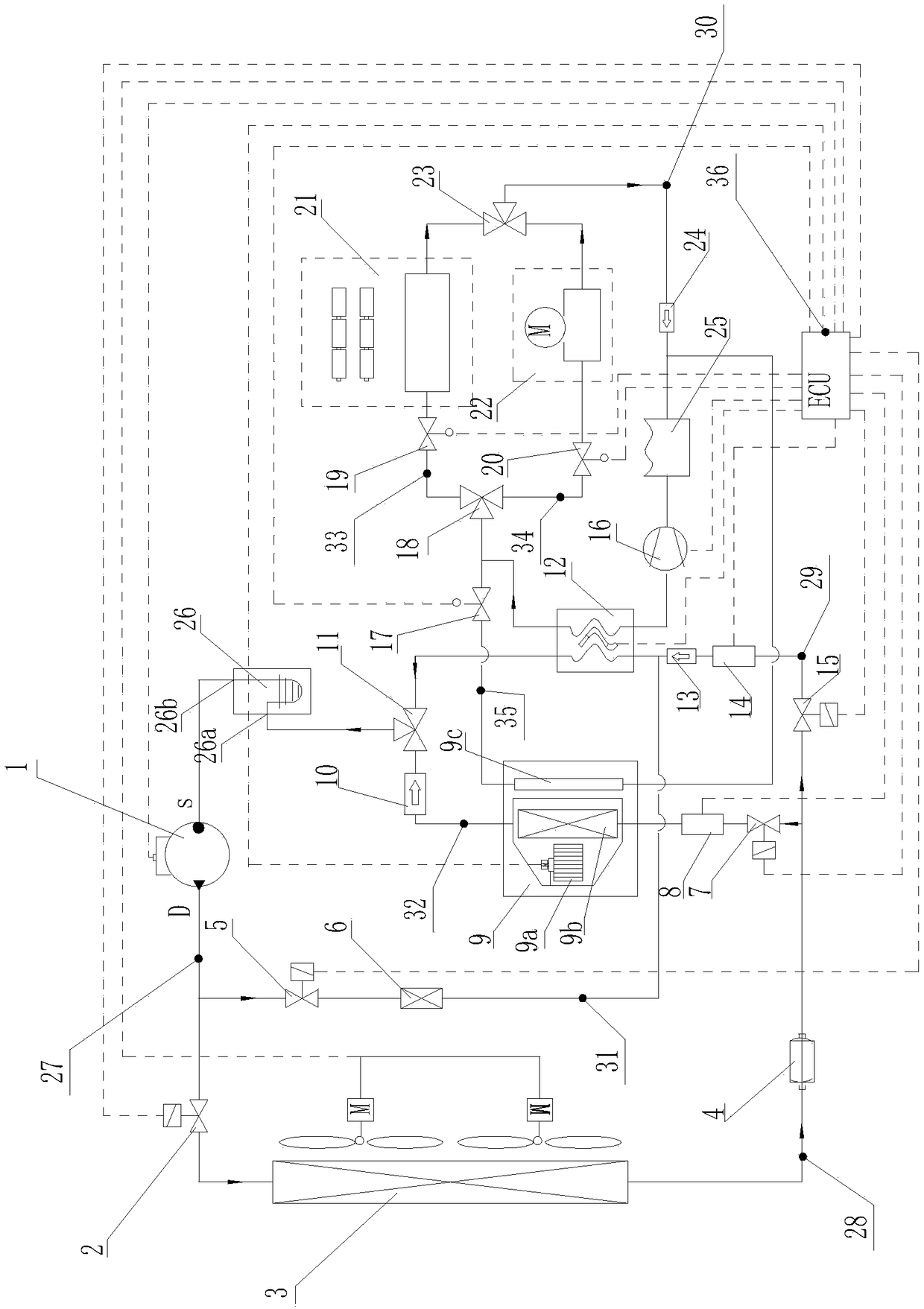

Heat management system for new energy automobile

PendingCN108715125ARealize heat dissipationAdjustable temperatureAir-treating devicesVehicle heating/cooling devicesNew energyEngineering

The invention discloses a heat management system for a new energy automobile. The heat management system comprises a compressor, a condenser, an expansion valve, HVAC (High Voltage Alternating Current), a gas-liquid separator, a heat exchange module and an ECU (Electronic Control Unit), wherein the heat exchange module comprises a water flow pipeline and a refrigerant flow pipeline capable of mutually performing heat exchange; the refrigerant flow pipeline is communicated with an outlet of the condenser by virtue of a low-temperature refrigerant shunt pipeline; an electric auxiliary heating device is arranged on the outer part of the water flow pipeline; and after heat exchange is performed between the cooling capacity of the refrigerant or heating capacity and water, water is fed into a battery temperature control assembly, a motor electrically controlled heat dissipation assembly and an HVAC heating core, so that electrically controlled refrigerating or heating of the battery pack and the motor can be realized, and HVAC heating is also realized. According to the heat management system, the structure is simplified, in-vehicle temperature regulation, battery temperature regulationand electrically controlled motor temperature regulation can be simultaneously met, temperature regulation response is rapid, and the energy efficiency ratio is high.

Owner:苏州赛普瑞新能源科技有限公司

Hot start method for boost expander

ActiveCN102706098BReduce hot start timeMake full use of cooling capacitySolidificationLiquefactionFully developedNitrogen

The invention relates to the field of refrigeration process of boost expanders, in particular to a hot start method for a boost expander, wherein the method is characterized in that in a hot start initial stage, all gases exhausted from an expansion end enter a waste nitrogen channel of a main heat exchanger to bypass and quicken decrease of temperature of the main heat exchanger, simultaneously, air exhausted from a cold end of the main heat exchanger flows into the expansion end at the first, then air in the middle of the main heat exchanger gradually flows into the expansion end after the temperature of the air exhausted from the expansion end is reduced to a designed value to enable the expander to run at the highest secure rotation speed all the time, and to fully develop maximum refrigerating capacity to shorten space division hot start time. Compared with the prior art, beneficial effects of the method are as follows: after the method is utilized, hot start time of the expander is shortened from former 48 h to 42 h, a bypass operation period is crossed fast in relatively shorter time, and refrigerating capacity of the expander is fully developed to further reduce power consumption for start.

Owner:ANGANG STEEL CO LTD

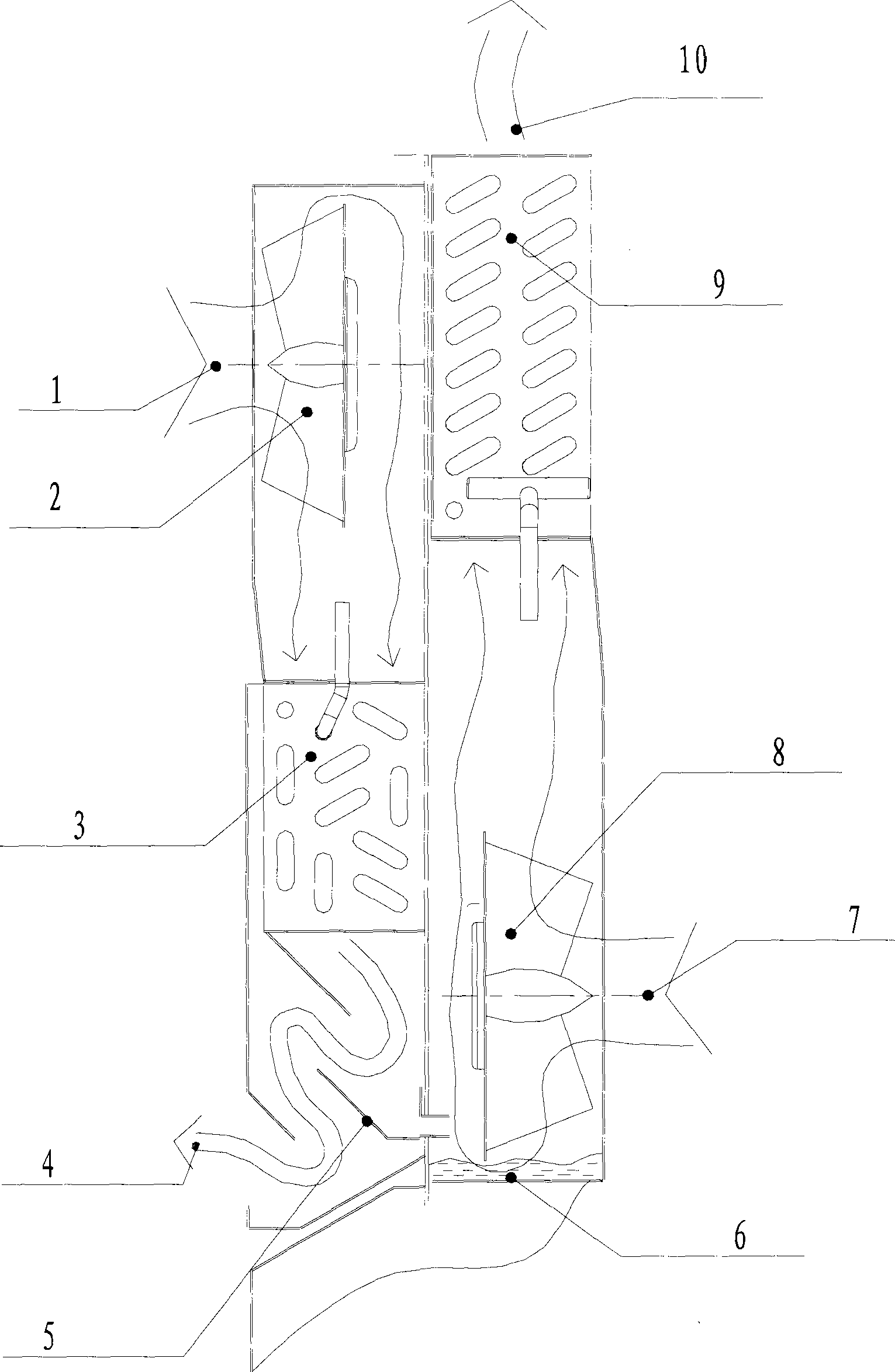

Self-volatilization system of evaporator condensation water

InactiveCN101373096AOvercome the shortcomings of the processing methodAvoid defectsCondensate preventionEvaporationEngineering

The invention provides a self-volatilization system of a condensation water of a steam compression type refrigeration and air-conditioning device. The self-volatilization system is based on the synchronous working principle that in the steam compressor type refrigeration process, the operation of a compressor, the operation of a condensation blower fan (8) and the condensed water of an evaporator (3) generate three states. The condensed water of the evaporator is introduced to a water accumulating disk (6) through a water deflector (5); the water accumulating disk (6) is installed on an air suction flow passage on the side of a condenser (9). When a device works, the condensed water leaves the water accumulating disk through high-speed rotating circulation centrifugal fan impellers of the condensation blower fan (8), and is mixed with the air sucked on the side of the condenser, and the mixture passes through the radiating surface of the condenser (9), so as to synchronously achieve the evaporation of the condensed water and the condensation of a refrigerant. In the invention, devices for assisting heating or assisting the fan do not need to be added to the water accumulating disk, and a pipeline for discharging water to the outside do not need to be installed. The invention overcomes the shortcoming of the prior condensed water processing method, effectively utilizes the cold energy of the condensed water of the evaporator, reduces the cost, saves the energy resource and protects the environment.

Owner:上海上菱科技开发有限公司

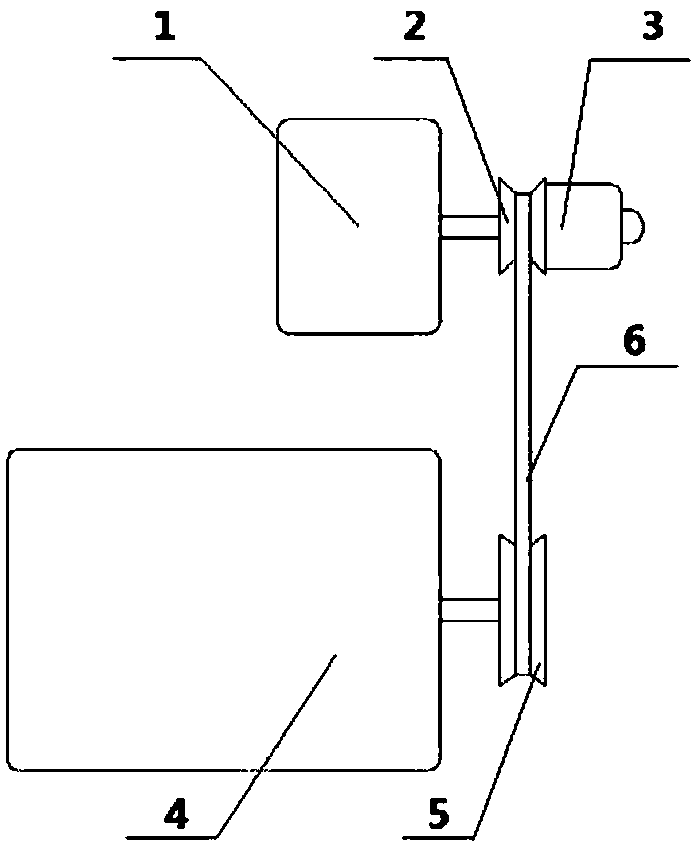

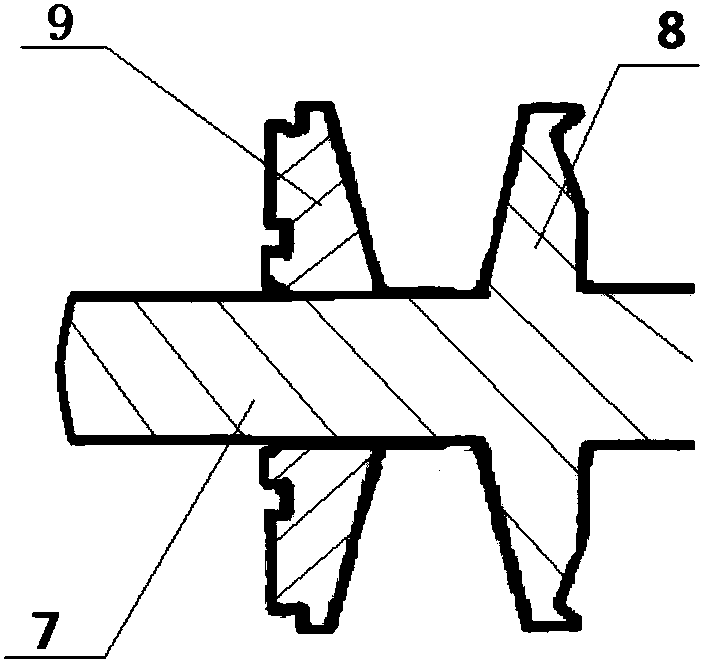

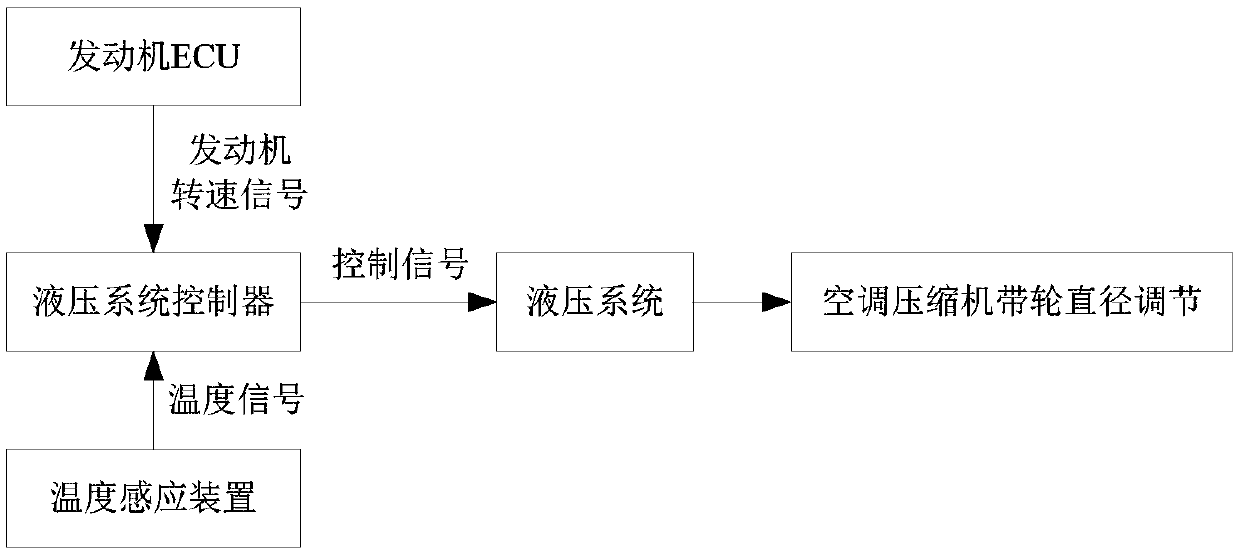

Vehicle air conditioning refrigeration adjustment method and device

InactiveCN109927508ALarge transmission ratioReduce cooling capacityAir-treating devicesVehicle heating/cooling devicesOperational costsAir conditioning

The invention relates to a vehicle air conditioning refrigeration adjustment method and device. Temperature in a vehicle is collected when the vehicle is judged to be in a normal operation state; andthe transmission ratio of an air conditioning compressor is controlled to increase when the temperature in the vehicle is reduced. The method is simple and reliable without increasing complex structures, and can reduce the refrigeration capabilities of an air conditioner under the premise of meeting the refrigeration capabilities, so that the occurrence of surplus can be avoided, and therefore, the energy consumption of the air conditioner can be decreased, the oil consumption of the whole vehicle can be reduced, the influences on environments can be decreased, and the purpose of energy savingand emission reduction can be achieved; and the method can reduce the operation costs of clients.

Owner:ZHENGZHOU YUTONG BUS CO LTD

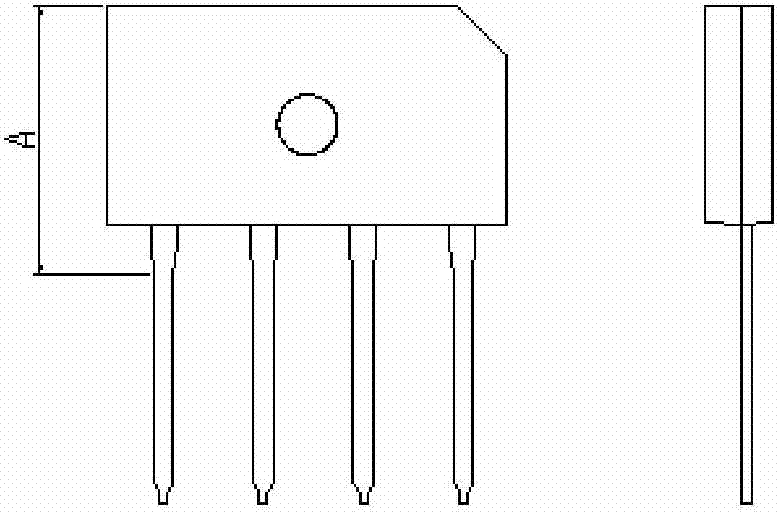

High-reliability rectifier bridge device

ActiveCN107887353AShort cooling pathMake full use of cooling capacitySemiconductor/solid-state device detailsSolid-state devicesMetal stripsAlternating current

Owner:SUZHOU GOODARK ELECTRONICS CO LTD

Parallel operation system of cooling towers with different areas

InactiveCN103162573AMake full use of cooling capacitySave engineering investmentHeat exchange apparatusCooling towerNuclear engineering

The invention discloses a parallel operation system of cooling towers with different areas. The parallel operation system of the cooling towers with the different areas is characterized in that a first cooling tower and a second cooling tower are together arranged in the system, and the cooling area of the first cooling tower is less than the cooling area of the second cooling tower. According to the parallel operation system of the cooling towers with the different areas, a coil pipe resistance piece is arranged so that the cooling towers with the different areas are enabled to be put under an associated operating state, cooling capacity of the cooling towers which are originally needed to be wasted is fully used, and therefore construction investment of a newly-built power plant is saved.

Owner:ANHUI ELECTRIC POWER DESIGN INST CEEC

Sulfuric acid alkylation reaction method and device and heat removal method for sulfuric acid alkylation reaction

PendingCN114085682AIncrease the alkene ratioReduce the amount of circulating light hydrocarbonsTreatment with alkylationIsobutaneButane

The invention relates to a sulfuric acid alkylation reaction method, a sulfuric acid alkylation reaction device and a sulfuric acid alkylation reaction heat removal method, and the sulfuric acid alkylation reaction method comprises the following steps: a C4 raw material enters an alkylation reactor, isobutane and butylene are subjected to an alkylation reaction under the action of a sulfuric acid catalyst, a reaction material flow is subjected to gas-liquid separation to obtain light hydrocarbon and a liquid phase material flow, the light hydrocarbon enters a gas compressor system to serve as a refrigerant, a liquid-phase material flow enters an acid-hydrocarbon first-stage separator, separated sulfuric acid returns to the alkylation reactor to be recycled, separated crude reaction products enter a product fractionation unit after being subjected to acid-hydrocarbon second-stage separation to remove trace acid, and iso-butane, n-butane and alkylated oil products are obtained through further separation; wherein the separated isobutane returns to the alkylation reactor for continuous reaction. According to the sulfuric acid alkylation reaction method, the sulfuric acid alkylation reaction device and the heat extraction method, the total energy consumption of the alkylation reaction device is remarkably reduced, and the equipment investment is reduced.

Owner:CHINA PETROLEUM & CHEM CORP +1

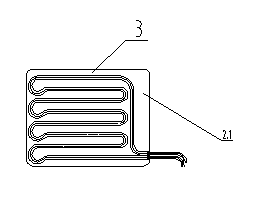

Refrigerating evaporator with auxiliary refrigeration evaporator

InactiveCN103983050AMake full use of cooling capacityImprove cooling effectEvaporators/condensersRefrigeration devicesCurve shapeCooling effect

The invention discloses a refrigerating evaporator with an auxiliary refrigeration evaporator. The refrigerating evaporator comprises a first evaporator and a second evaporator, wherein the first evaporator is a plate tube structure, and comprises a first aluminum plate and an evaporating tube which is fixedly arranged on the first aluminum plate after being bent in a multi-round way, and the second evaporator is arranged below the first evaporator and consists of an evaporating tube arranged below the first evaporator and a second aluminum plate, thereby forming the evaporator for auxiliary refrigeration of a refrigerator. Further improvement is as follows: the evaporating tube is bent into a coil structure that the adjacent evaporating tubes are arranged in parallel and are fixedly connected onto the second aluminum plate, and the end parts of the adjacent evaporating tubes arranged in parallel are connected in a 9-shaped curve shape; the first evaporator and the second evaporator are vertically arranged. The refrigerating evaporator provided by the invention has the advantages that the cooling effect of a freezer can be significantly improved, and the energy consumption is reduced; the refrigeration capacity of the refrigerating evaporator is fully utilized, and the waste is avoided; the sealing performance is good, and the manufacturing cost is low.

Owner:JIANGSU XINCHENG ELECTRICAL APPLIANCE GENERAL FACTORY

Heat sink and semiconductor refrigeration equipment

ActiveCN105716317BReduce energy consumptionMake full use of cooling capacityIndirect heat exchangersMachines using electric/magnetic effectsEngineeringRefrigeration

The invention provides a cooling device and semiconductor refrigeration equipment. The cooling device comprises a plurality of radiators. Each radiator comprises a heat conductor, a plurality of heat pipes, a cooling fin set and a fan, wherein the heat pipes are connected to the heat conductor, the cooling fin set is connected to the heat pipes, and the fan and the cooling fin set are arranged side by side. An auxiliary heat pipe is further connected to each heat conductor, and the auxiliary heat pipe in any radiator is further connected with at least one cooling fin set in the rest of the radiators. Heat at the heat ends of semiconductor refrigeration modules is absorbed by means of the heat conductors, the heat conductors can transmit the heat to the cooling fin sets with large cooling areas through the heat pipes for automatic cooling, and the requirement for powering on the fans all the time for air cooling is avoided; and in addition, the heat conductors can conduct cooling by utilizing the cooling fin sets in the multiple radiators at the same time, so that the multiple cooling fin sets are in the cooling state all the time, and accordingly the cooling capacity of the multiple cooling fin sets is brought into full play, the cooling capacity of the semiconductor refrigeration equipment is improved, and energy consumption of the semiconductor refrigeration equipment is reduced.

Owner:QINGDAO HAIER SPECIAL ICEBOX

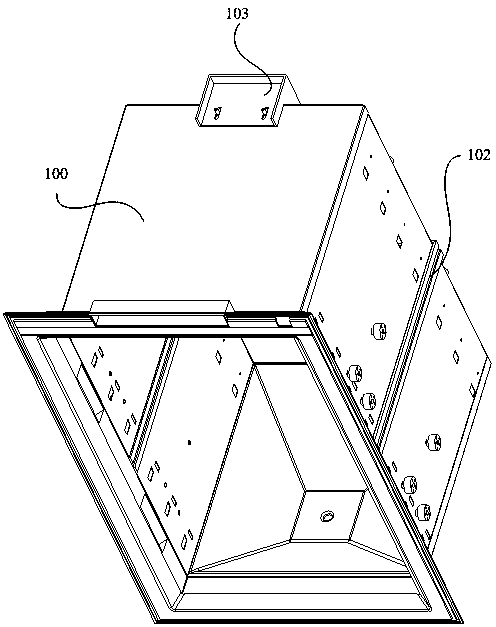

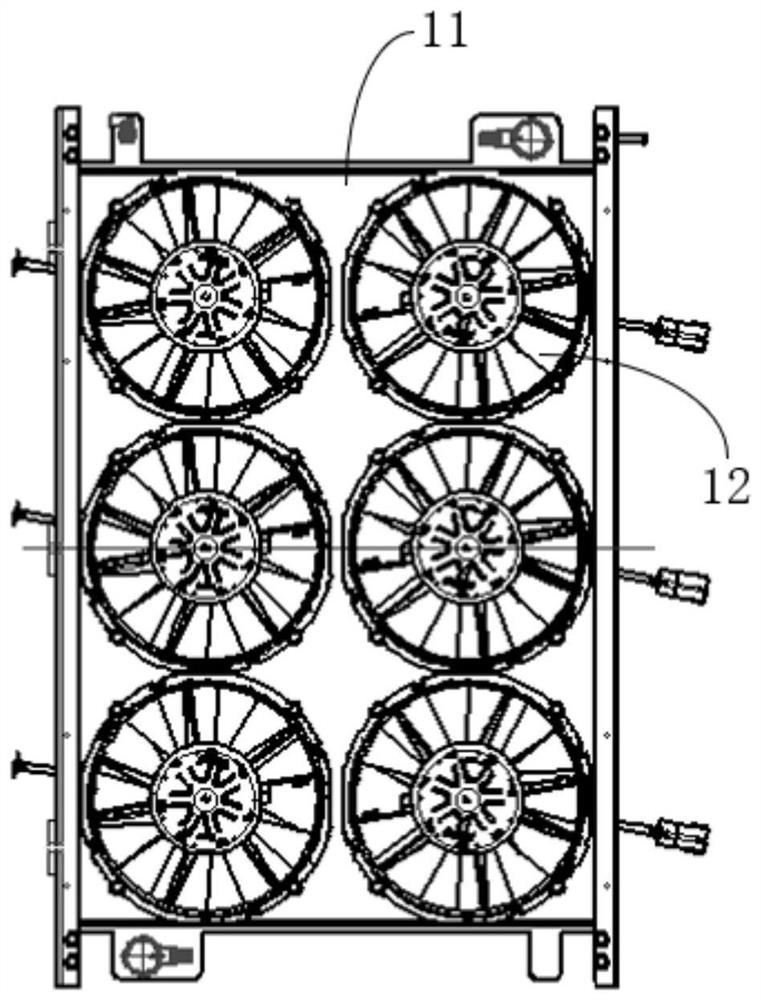

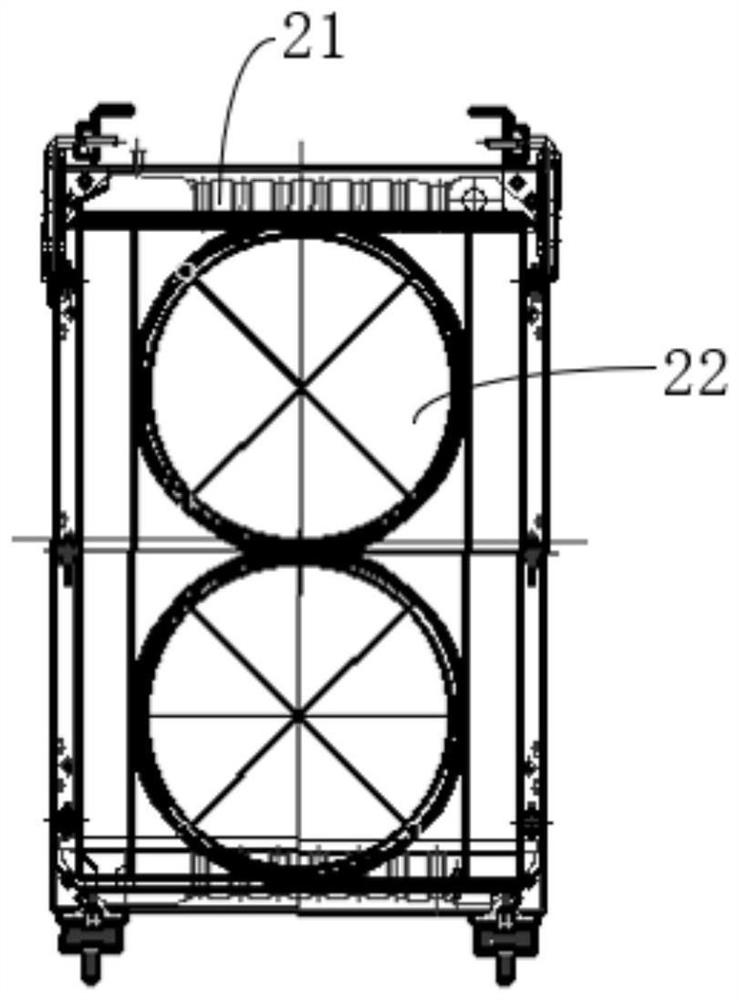

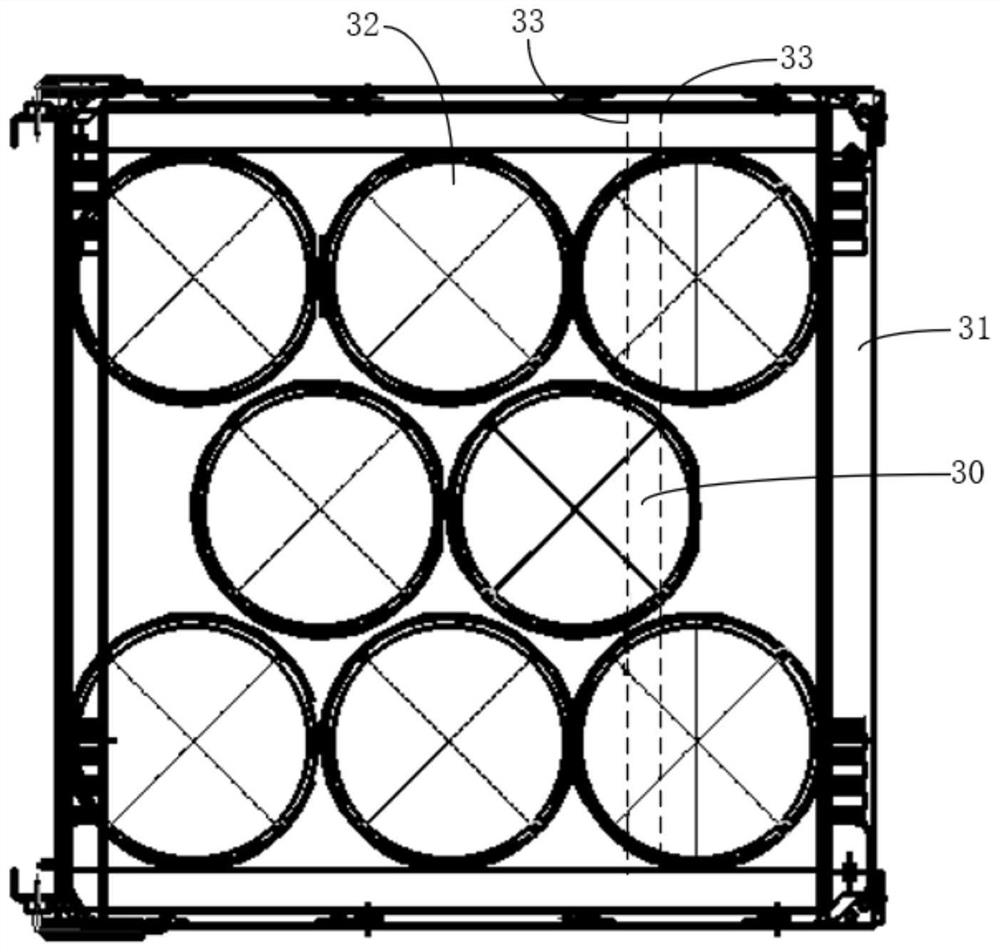

Radiator and radiating system of fuel cell and vehicle

ActiveCN111653804AMake full use of cooling capacityImprove utilization efficiencyFuel cell heat exchangeMotive system fuel cellsAutomotive engineeringThermal circuit

The invention relates to a radiator and a radiating system of a fuel cell and a vehicle. The radiator of the fuel cell comprises a radiator shell (31) and a plurality of fans (32) integrated and fixedon the radiator shell. A first heat dissipation loop (111) and a second heat dissipation loop (112) which are separated by an isolation cavity (30) are arranged in the radiator shell (31). The firstheat dissipation loop is used for heat dissipation of a fuel cell stack (4), and the second heat dissipation loop (112) is used for heat dissipation of a fuel cell accessory (5). A radiator for a fuelcell stack and a radiator for a fuel cell accessory are integrally designed into one radiator; namely, the heat dissipation of the fuel cell stack and the heat dissipation of the fuel cell accessories are connected in parallel and share one group of fans, and the heat dissipation of the fuel cell stack and the heat dissipation of the accessories are respectively completed through two independentheat dissipation loops, so that the heat dissipation capability of the parallel radiator can be fully utilized, the maximization of the heat dissipation efficiency is ensured, and the utilization efficiency of space is improved.

Owner:BEIQI FOTON MOTOR CO LTD

Miniature bridge rectifier

ActiveCN107887367AMake full use of cooling capacityShort cooling pathSemiconductor/solid-state device detailsSolid-state devicesElectricityMetal strips

The invention relates to a miniature bridge rectifier. According to the miniature bridge rectifier, a first metal substrate, a second metal substrate and an E-shaped metal substrate are located at thebottom of an epoxy packaging body and are distributed at the left side and right side of the epoxy packaging body; a negative pole metal strip is located between the first metal substrate, the secondmetal substrate and the E-shaped metal substrate; two ends of a first connecting sheet are electrically connected with the negative pole end of a first diode chip and the upper surface of the negative pole metal strip respectively; and the middle portion of a second connecting sheet is provided with a protruding portion which is isolated from the negative pole metal strip through the epoxy packaging body; a second positioning mechanism is composed of protruding points at two sides of the first metal substrate and two sides of the second metal substrate, and recessed portions at two sides of the tail end of the second connecting sheet and two sides of the tail end of a fourth connecting sheet, wherein the protruding points are embedded into the recessed portions; the thickness of the epoxypackaging body is smaller than 2 mm; and an end surface of the E-shaped metal substrate, which is located at the edge of the epoxy packaging body, is provided with four second pin outward-protrudingportions. An existing product dissipates heat through air convection in a chassis, as a result, the area of heat dissipation sheets can be 50% of the length*width area of the product, while, with theminiature bridge rectifier adopted, such kind of situation in the prior art can be avoided.

Owner:SUZHOU GOODARK ELECTRONICS CO LTD

Method for determining surface temperature change of radiant panel of radiant cooling system during water supply shutdown

InactiveCN106500220AImprove accuracyReduce wasteMechanical apparatusSpace heating and ventilation safety systemsControl systemRegression analysis

The invention relates to a method for determining the surface temperature change of a radiant panel of a radiant cooling system during water supply shutdown. The method comprises steps as follows: influence factors for the surface temperature change of the radiant panel and change ranges of the various factors are determined according to actual running conditions of the radiant cooling air-conditioning system; according to the determined influence factors for the surface temperature change rule of the radiant panel and the determined change ranges of the various factors, surface temperature change conditions of the radiant panel during water supply shutdown under different influence factors are simulated with ANSYS software, and sample data are acquired; and on the basis of SAS software, a prediction model for the surface temperature change of the radiant panel during water supply shutdown is obtained through regression analysis of the sample data with a statistical analysis procedure. With the method, the accuracy of a prediction result obtained through regression analysis is relatively high, a control system is simple, real-time control can be realized, and the method is suitable for application to control of heating systems of residential buildings.

Owner:TIANJIN UNIV OF COMMERCE

Water pan and heat pump dryer comprising same

PendingCN109307388AReduce energy consumptionSpeed up the flowEvaporators/condensersHeating arrangementWater flowPulp and paper industry

The invention relates to a water pan and a heat pump dryer comprising same. The water pan comprises an upper pan and a lower pan, and the upper pan is positioned above the lower pan; the upper pan isused for receiving condensed water separated out by the dryer, the rear end of the upper pan is provided with a water falling hole, and the bottom surface of the upper pan is inclined downwards towards the rear; the lower pan is used for receiving condensate water flowing out of the water falling hole, and the bottom surface of the lower pan is inclined downwards towards the front; a containing cavity capable of storing condensed water is formed in the lower pan, and a heat exchange tube is arranged in the containing cavity. According to the water pan and the heat pump dryer comprising the same, the latent cooling capacity of the condensed water can be fully utilized, so that the purpose of reducing the energy consumption of the dryer is achieved.

Owner:GUANGDONG SHENLING ENVIRONMENT SYST CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com