Self-volatilization system of evaporator condensation water

A technology of condensate water and evaporator, applied in the direction of preventing condensate water, etc., can solve the problems of drainage pipes affecting the environment, wasting energy, and increasing energy consumption in operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

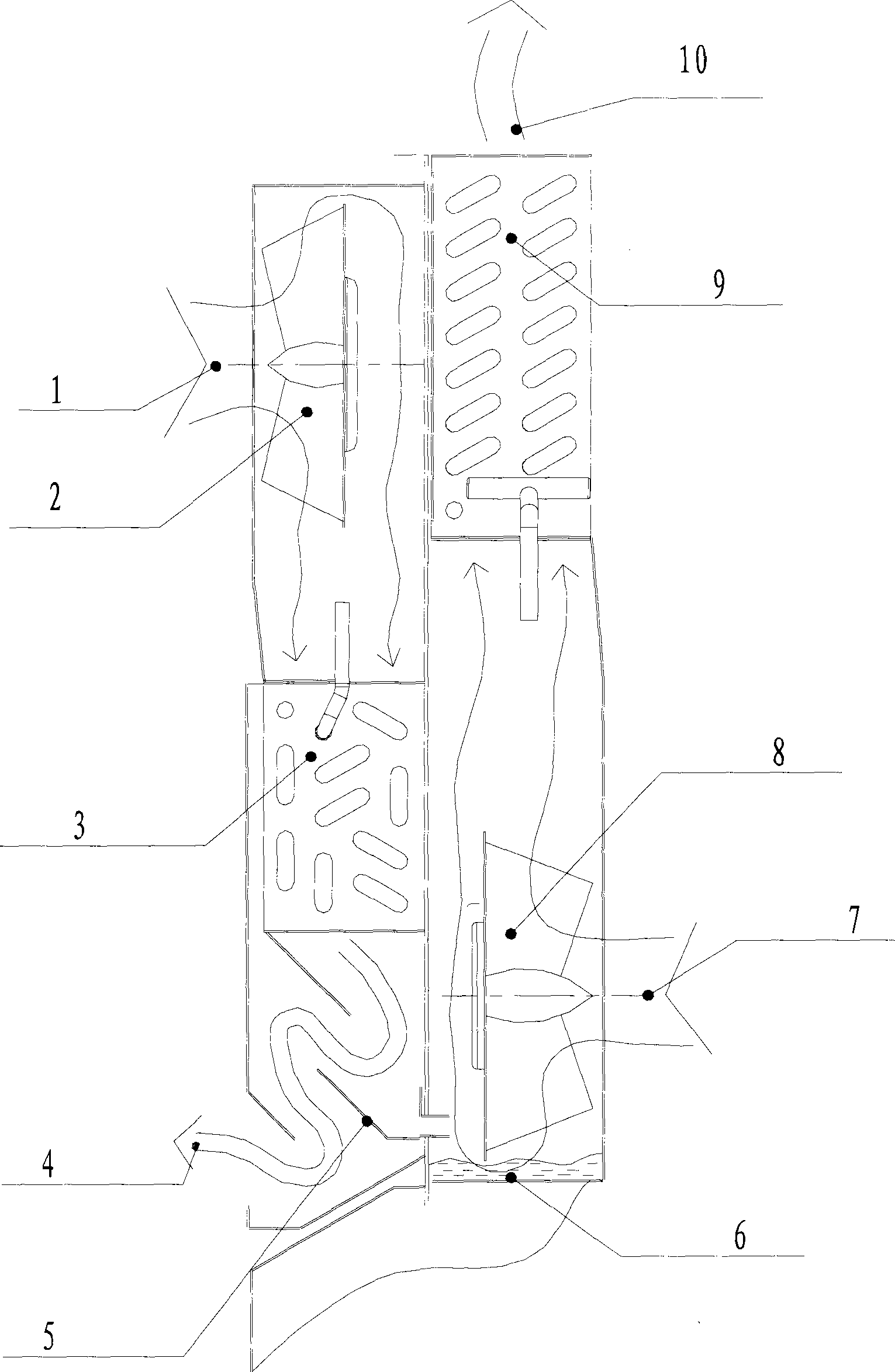

[0012] In the implementation of Fig. 1, when the refrigeration cycle is working, the evaporator fan (2) circulates, and the air in the cooled space is forced to be sucked from the evaporator air inlet (1), and the heat is exchanged through the evaporator (3). The heat is transferred to the refrigerant to complete the gasification process of the refrigerant. At the same time, the moisture in the air condenses into water on the surface of the evaporator. The cooling air returns to the cooled space from the air outlet (4) of the evaporator, and the condensed water passes through the The plate (5) flows into the water accumulation tray (6) at the bottom of the condenser fan (8), and the circulation of the condenser fan fan (8) forces external air to be sucked in from the condenser air inlet (7), and the air passes through the accumulation of water Part of the condensed water evaporates on the water surface of the pan, and after lowering the temperature, it mixes with the tiny water...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com