Patents

Literature

143results about How to "High environmental value" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Rapid-hardening early-strengthening wearable concrete material for road repair and its preparation method

ActiveCN1699243AHave fast hardening and early strength requirementsSmall shrinkageSolid waste managementSlagMetakaolin

The invention provides a rapid-hardening early-strengthening wearable concrete material for road repair and its preparation, wherein the material mainly comprises the following ingredients, steel slag powdered ore 40-80kg / m3, metakaolin 320-560kg / m3, alkaline exciting agent solution 200-300kg / m3, steel slag fine aggregates 630-1800kg / m3, steel fiber 62-156kg / m3, and polypropylene fiber 1kg / m3.

Owner:WUHAN MUNICIPAL CONSTR GROUP

Production of polymerized ferric-aluminum chloride composite coagulating agent

InactiveCN101074128AReduce manufacturing costLow costWater/sewage treatment by flocculation/precipitationPhosphateChlorate salt

Production of inorganic polymer coagulating agent is carried out by controlling Fe2+ concentration between 75-90g / L in hydrochloric acid pickling effluent, taking it as ferric source, taking calcium aluminate powder as aluminum source with Al2O3 content 47-56 wt%, putting two kinds of raw material into reactor in proportion of calcium aluminate powder: hydrochloric acid pickling effluent=0.05-0.10, reacting while agitating at 50-80 degree for 1-3 hrs, adding into minor chlorate oxidant and phosphate stabilizer, heating, reacting while agitating, and cooling to room temperature to obtain final product. It's simple and can be used for domestic sewage and industrial effluent treatment.

Owner:SHANGHAI UNIV

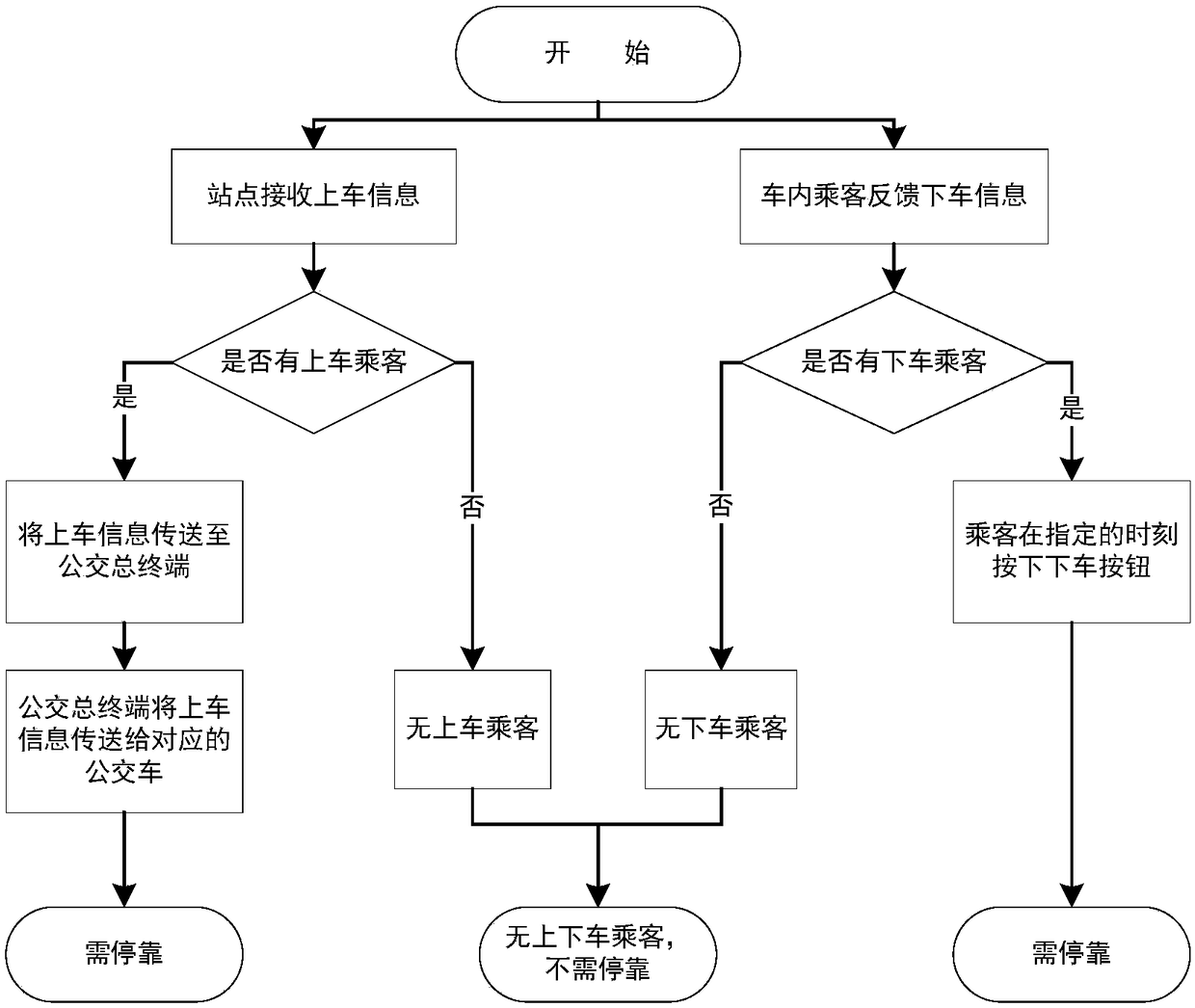

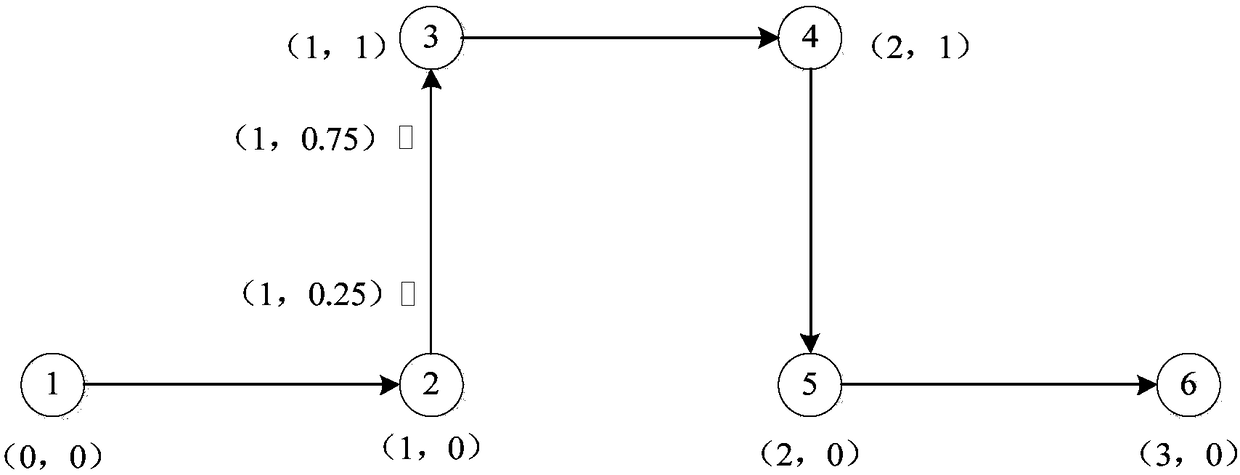

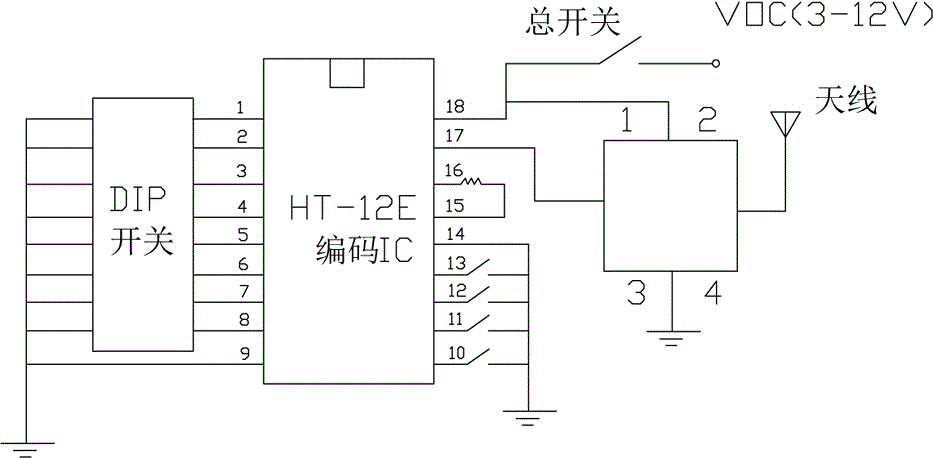

Implementation method and system for bus passing by station where no passengers get on and off without stopping

InactiveCN108335517ASave travel timeImprove ride satisfactionRoad vehicles traffic controlEmbedded systemTotal station

The invention discloses an implementation method and system for a bus passing by a station where no passengers get on and off without stopping. The system comprises a platform input panel, a get-on passenger information indicating lamp, a get-off feedback button, a get-off passenger information indicating lamp, a voice player and an information transmitter are arranged in a bus, and a bus total terminal is arranged on a bus total station; after a passenger inputs a needed bus path through the platform input panel, the station and the bus path are sent to the bus total terminal, and the bus sends the path position of the bus to the bus total terminal in real time; the bus total terminal selects a bus which is closest to the passenger path position to send passenger get-on information according to the received information; after the information transmitter of the bus receives the passenger get-on information, or when the passenger of the bus presses the get-off feedback button, a driverinformation receiving device in the bus can light up the corresponding get-on information indicating lamp and get-off information indicating lamp and plays get-on information and get-off information to a driver through voice, and the driver stops at a front platform. The implementation method and system have the advantages that the bus station-passing efficiency can be improved, energy is saved, the trip time is saved, and the riding satisfaction of the passenger is improved.

Owner:SOUTHEAST UNIV

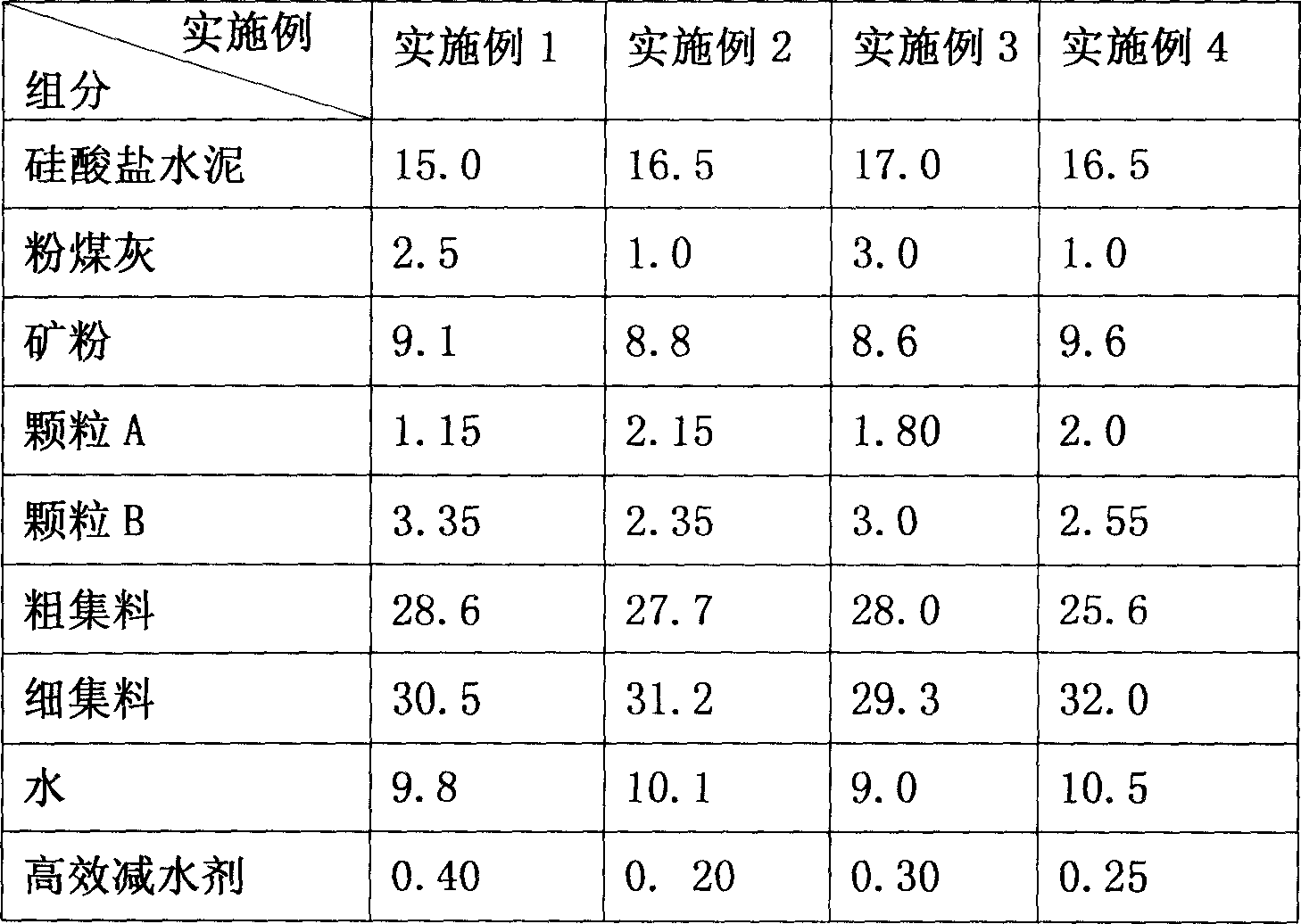

Sound sucking high elasticity concrete material for road

The sound absorbing high elasticity concrete material for road consists of Portland cement 15.0-17.0 wt%ú¼flyash 1.0-3.0 wt%ú¼ calcium carbonate mineral powder 8.6- 9.6 wt%ú¼crushed rubber tyre grain A 1.15-2.15 wt%ú¼ crushed rubber tyre grain B 2.35- 3.35 wt%ú¼ coarse aggregate 25.6-28.6 wt%ú¼ fine aggregate 29.3-32.0 wt%ú¼ water 9.0-10.5 wt% and efficient water reducing agent 0.20-0.40 wt%. The present invention has the advantages of full utilization of waste tyre, reducing environmental pollution, low cost, etc. and the deposited concrete road has high elasticity, high softness, reduces extension joint, less noise and environment friendship.

Owner:SHANGHAI JIAO TONG UNIV

Treatment method of river or lake sediments

InactiveCN104071962AReduce moisture contentPoly Shen YiSludge treatment by de-watering/drying/thickeningSludge treatment by oxidationFiltrationTotal nitrogen

The invention provides a treatment method of river or lake sediments. The treatment method comprises the following steps: (a) removing gravel from the river or lake sediments; (b) mixing the gravel-free sediments obtained in the step (a) with an oxidant for conditioning the sediments to obtain a conditioned product; (c) mixing the conditioned product obtained in the step (b) with a flocculant for coagulation treatment; (d) performing pressure filtration on the sediments subjected to the coagulation treatment. According to the method, the pH values of sediment cakes obtained by treating the sediments with the method provided by the invention as well as residual water, tail water and the like generated in a treatment process are 7, the content of suspended substances (SS) in the water is relatively low, the content of ammonia nitrogen, total nitrogen and total phosphorus is reduced, the waste water and the tail water can be directly discharged back, the obtained sediment cakes can be directly utilized, environmental harm cannot be caused, and relatively high environmental protection values are achieved.

Owner:袁锐 +1

Technology of making paper and paper products by banana fibre

InactiveCN1621611AExtended service lifeQuality improvementCellulose material pulpingBreaking strengthPapermaking

The present invention is the process of making paper and paper product with banana fiber. Unlike common papermaking material, banana fiber is long, fine, soft and easy to separate, and may be beaten into pulp after separating and degluing without needing heating, soaking in alkali solution, etc. During the degluing, pollution-free brine or common bleaching chemical, such as calcium chloride, is used. Therefore, the process is fast and low in cost, and the effluent may be deposited for reuse or drained into fish pond as fish's feed. The paper and the paper product have good physical performance, including high tension strength, high breaking strength, good water tolerance, etc.

Owner:颜小平 +1

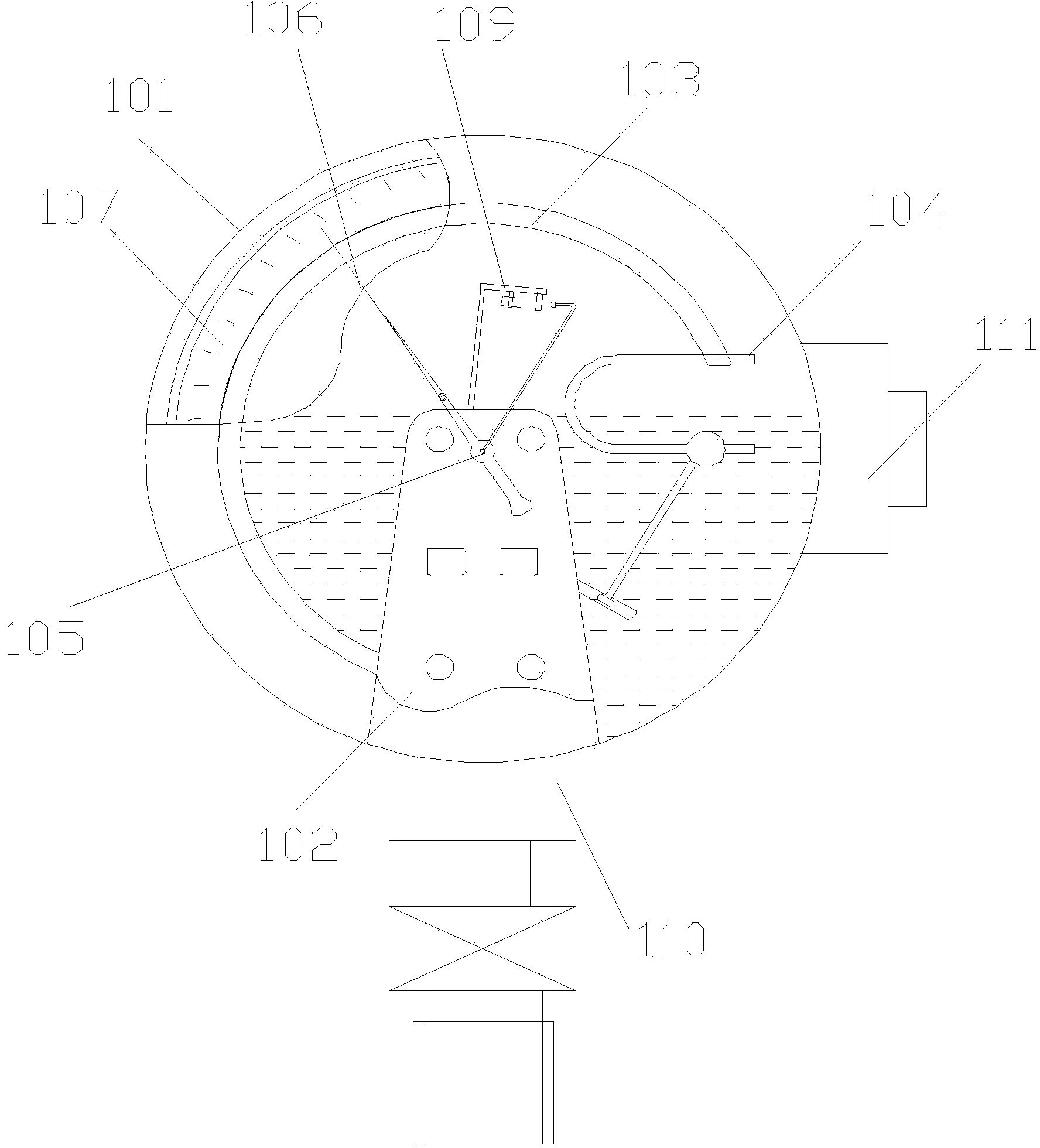

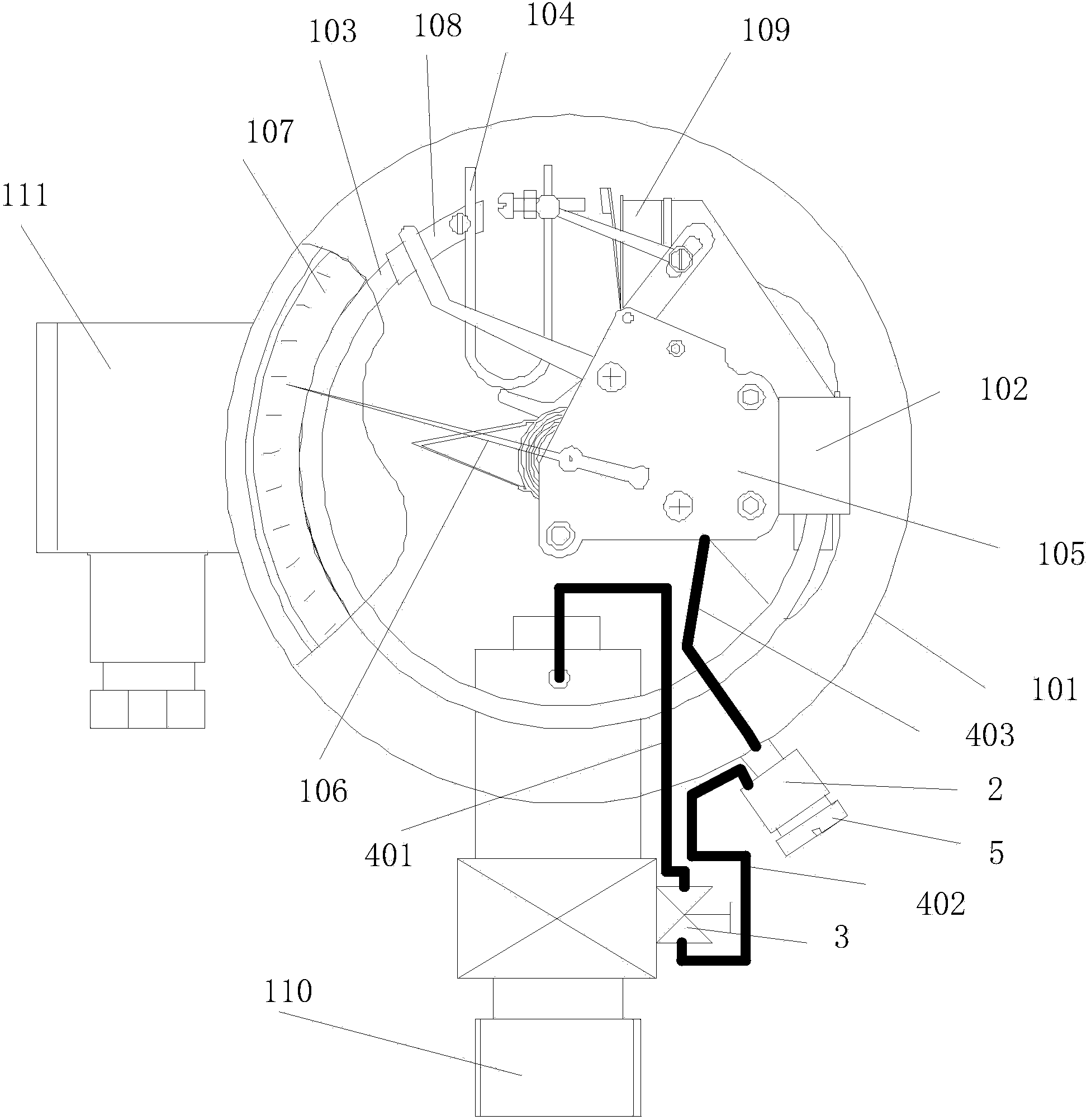

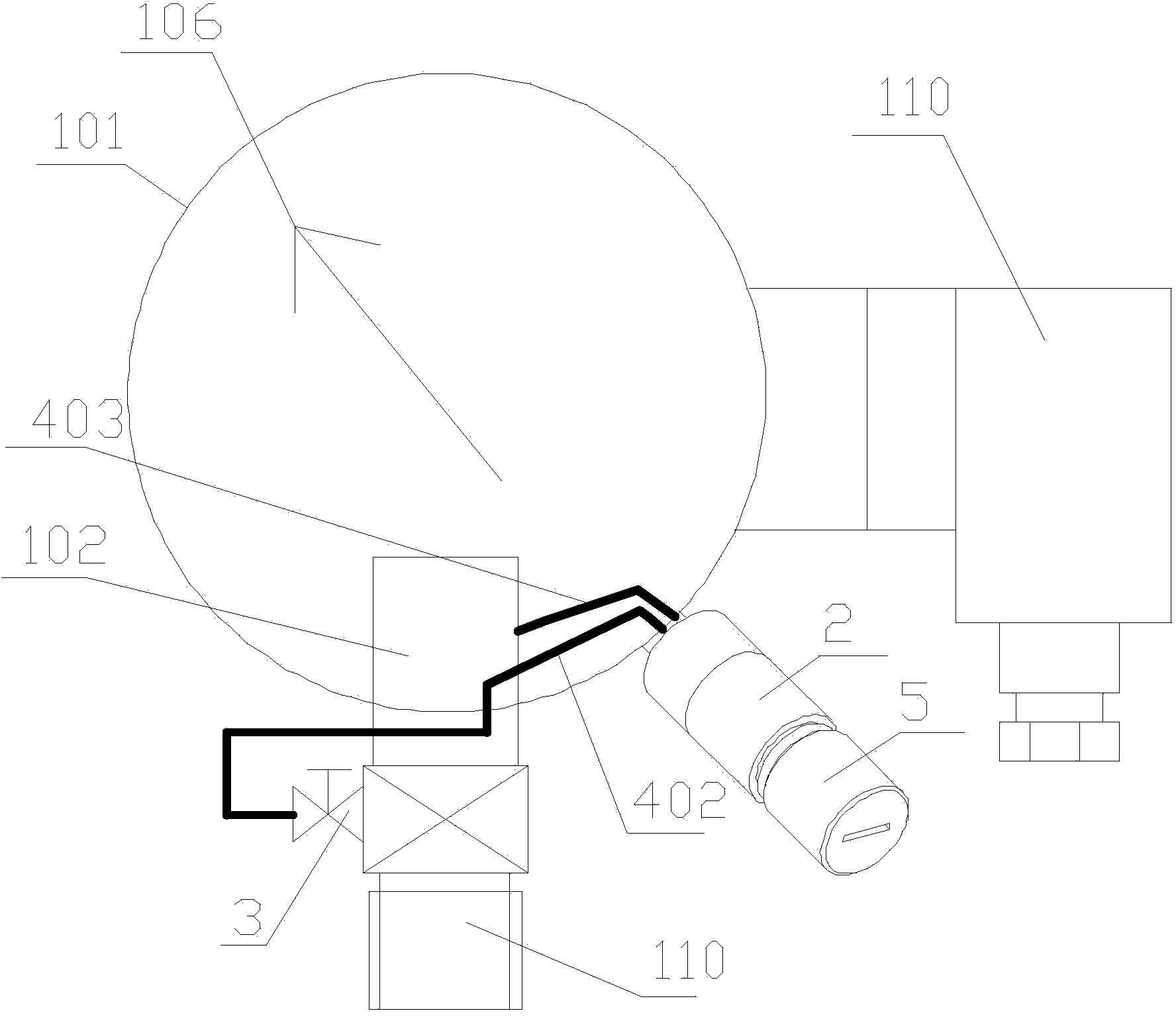

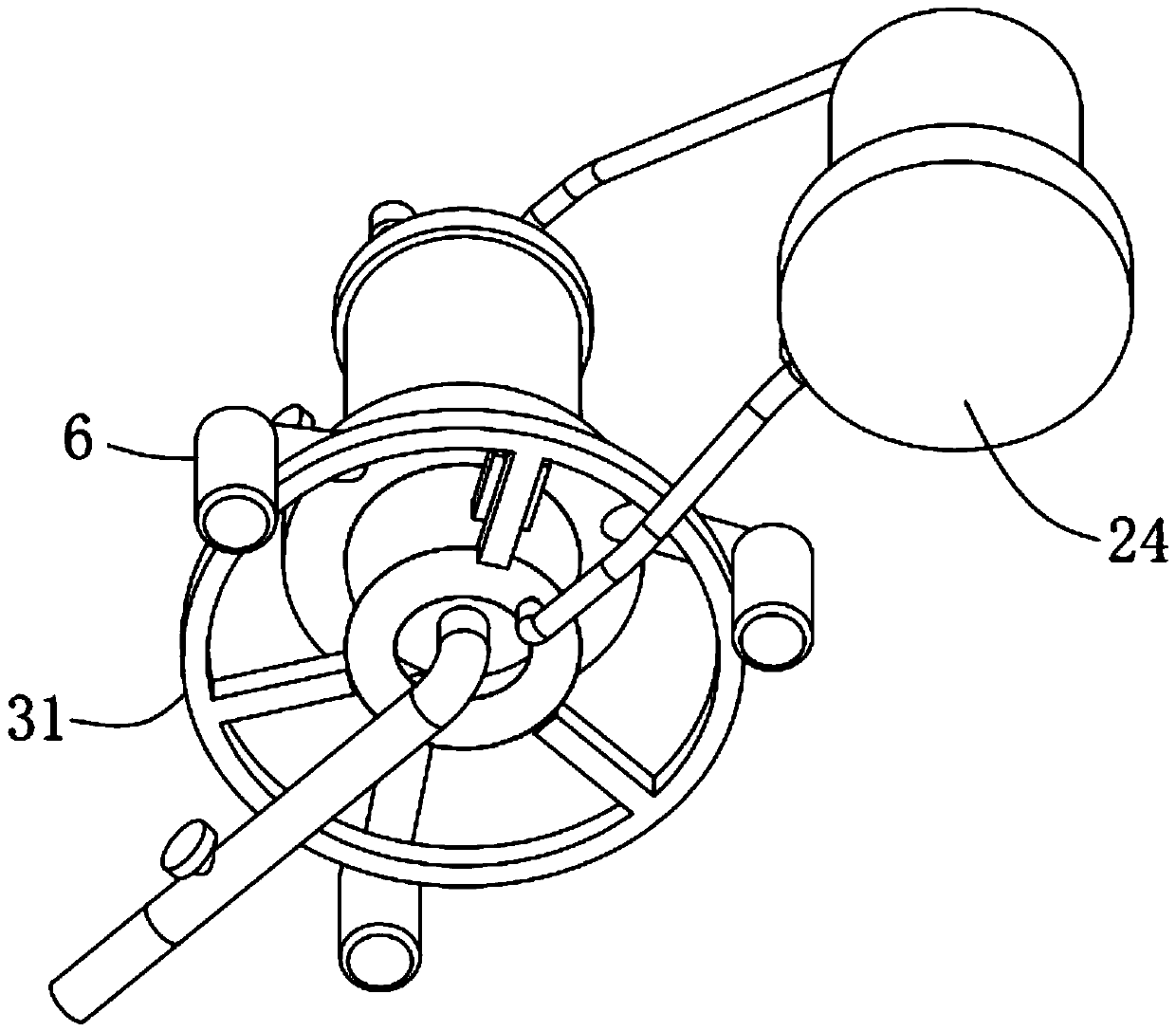

Gas density relay free of detachment in verification process

ActiveCN104299843AOvercome the problem of large size and cannot be installed in many placesSave installationElectric switchesEmergency protective devicesEngineeringSignal generator

The invention discloses a gas density relay free of detachment in the verification process. The gas density relay comprises a shell, a base, a pressure detector, a temperature compensation element, a machine core, a pointer, a dial, a plurality of signal generators and a device connection connector, wherein the base, the pressure detector, the temperature compensation element, the machine core, the pointer, the dial, the signal generators and the device connection connector are arranged in the shell. The gas density relay further comprises a verification connector and a valve, wherein one end of the valve is communicated with the device connection connector, the other end of the valve is communicated with the verification connector, and the verification connector is communicated with the pressure detector through the base. The gas density relay has the advantages that basically like an ordinary density relay, the gas density relay can be installed on any occasion, and the problem that due to the fact that the size of a valve connector is large, the gas density relay can not be installed in many places is thoroughly solved; an additionally-arranged valve type three-way connector can be omitted, materials are greatly saved, the gas density relay has quite high environmental protection value, and meanwhile the gas density relay saves cost and is beneficial to application and popularization; the gas density relay is good in sealing performance, high in safety coefficient, simple in structure and small in size.

Owner:SHANGHAI ROYE ELECTRICAL CO LTD

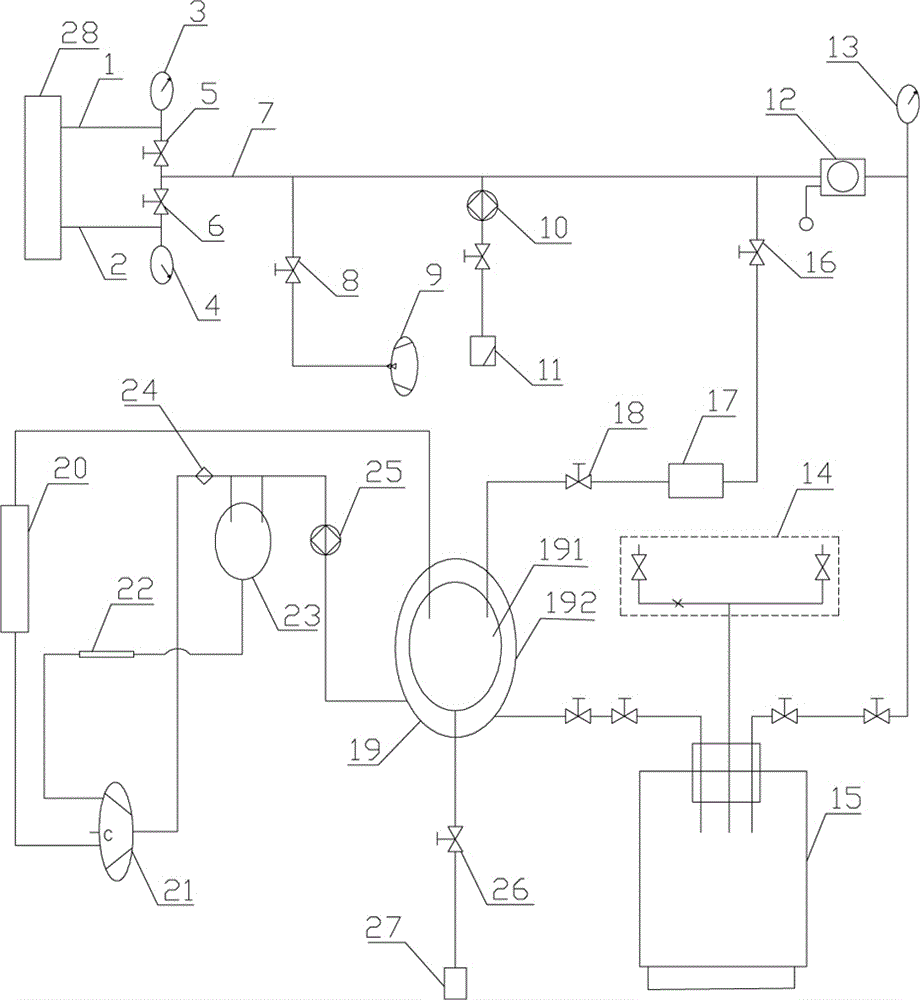

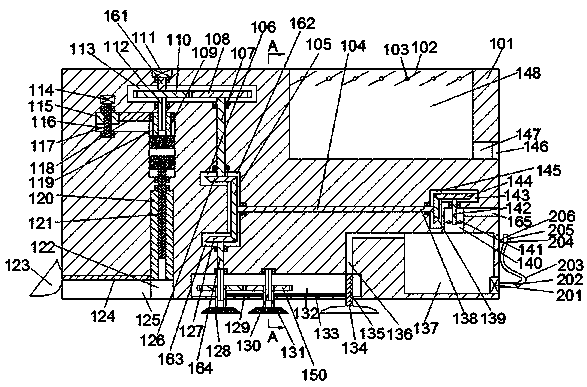

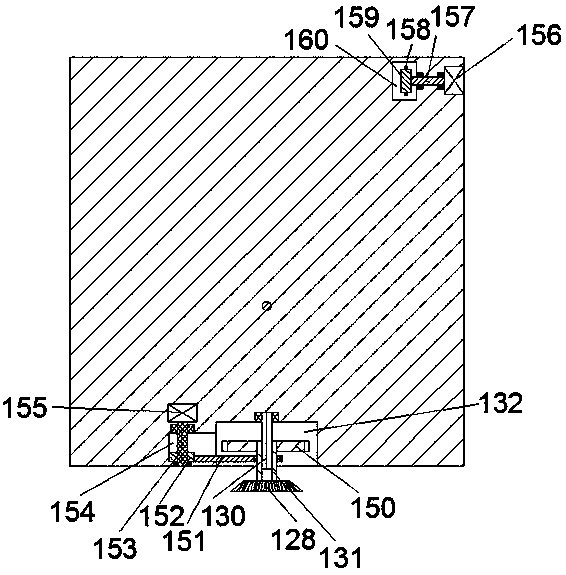

Intelligent refrigerant charging and recovering device

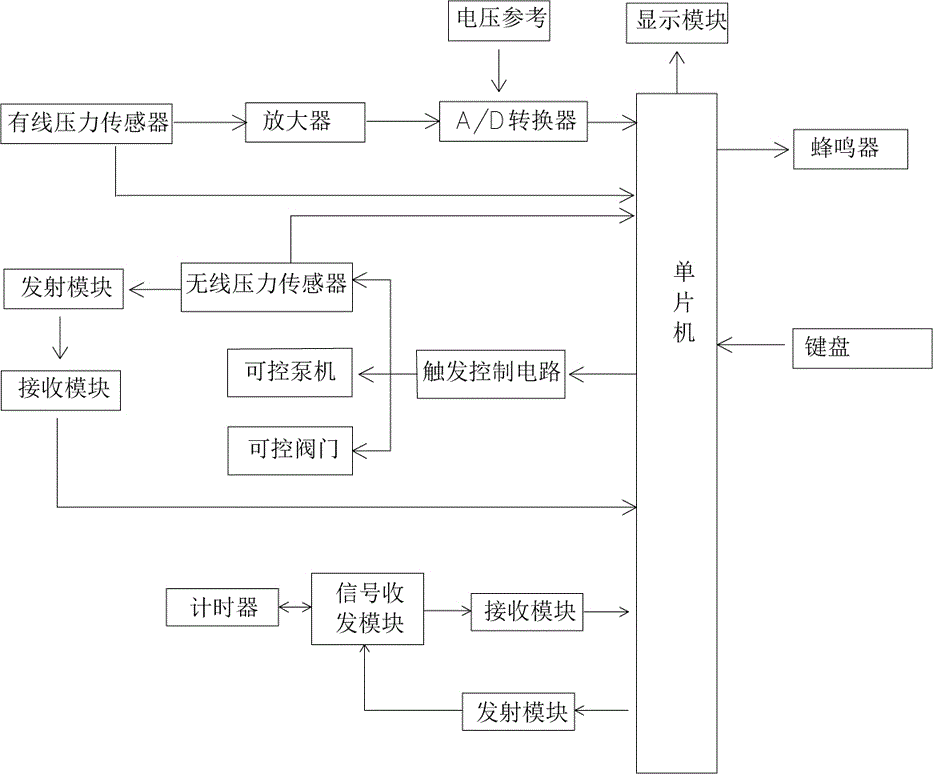

InactiveCN106338166AReduce operational complexityLow maintenanceRefrigerantsElectricitySolenoid valve

The invention discloses an intelligent refrigerant charging and recovering device which comprises a control circuit, a high-pressure manifold, a low-pressure manifold, a first pipeline valve, a second pipeline valve, a first pipeline, a vacuum valve, a vacuum pump, a first check valve, an oil filling cup, a refrigerant recovery unit, an electromagnetic valve and a liquid storage tank; the first end of the first pipeline valve is connected with a high-pressure pipeline of a vehicle air conditioning system; the second end of the first pipeline valve is connected with the first end of the electromagnetic valve, the second end of the second pipeline valve, the first end of the vacuum valve, the inlet of the refrigerant recovery unit and the first end of the first check valve; the second end of the electromagnetic valve is connected to the liquid storage tank; the first end of the second pipeline valve is connected to a low-pressure pipeline of the vehicle air conditioning system; the second end of the vacuum valve is connected with the vacuum pump; the second end of the first check valve is connected with the oil filling cup; the outlet of the refrigerant recovery unit is connected with the liquid storage tank; and the refrigerant recovery unit and the valves are all electrically connected with the control circuit. According to the technical scheme of the invention, an old refrigerant can be separated and reused and is suitable for maintaining an air conditioning of a vehicle or a house.

Owner:ZHEJIANG GEELY HLDG GRP CO LTD +1

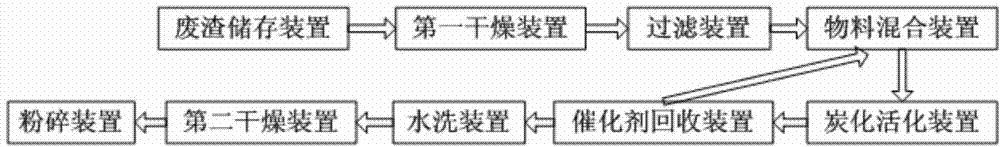

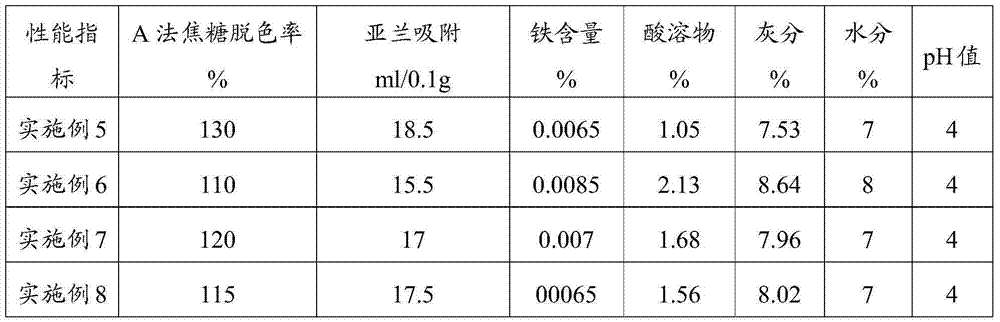

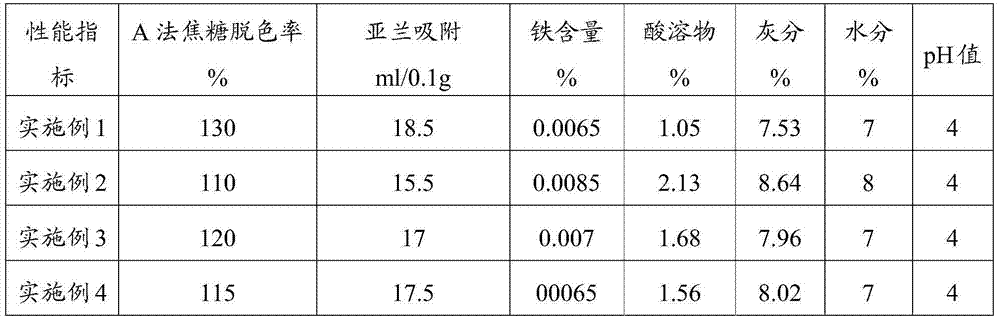

Active carbon preparation method and device

The invention provides an active carbon preparation method. The method comprises providing waste residue which is waste residue obtained by hemicellulose extraction from a biomass raw material, and carrying out charing activation on the waste residue in the presence of a catalyst so that active carbon is obtained. The active carbon preparation method utilizes a waste residue raw material such as furfural residue and / or corn cob residue obtained by hemicellulose extraction from a biomass raw material and utilizes a chemical method to prepare active carbon. Compared with the prior art, the active carbon preparation method utilizes a waste residue raw material obtained by hemicellulose extraction from biomass, realizes residue recovery and recycle, prevents environmental protection caused by residue and has a high environmental protection value. The active carbon preparation method can be used for active carbon preparation and has large economic benefits.

Owner:JINAN SHENGQUAN GROUP SHARE HLDG

River mud factorization solidification treatment method

InactiveCN104988897AEffective dredgingQuick clean upSoil-shifting machines/dredgersSoil preservationRiver regulationMaterials science

The invention discloses a river mud factorization solidification treatment method, and belongs to the technical field of river regulation. The method comprises the following steps of 1, mud collection, 2, solid and liquid separation and 3, mud and sand solidification. According to the technical scheme, river mud can be rapidly cleaned out and solidified through an efficient treatment device, so that a river is dredged efficiently, various excellent effects are obtained, the technical problems that the mud treatment cost is high in the existing river dredging process and the environment is affected in the mud and sand conveying process are solved, industrial operation can be achieved, and the method is widely applied to large-scale factorization mud treatment.

Owner:JIANGSU LVCHUANG ROAD SURFACE NEW MATERIAL CO LTD

Organic wheat straw complex fertilizer

InactiveCN101747099AReduce pollutionHigh environmental valueBio-organic fraction processingOrganic fertiliser preparationLivestock breedingOrganic manure

The invention discloses organic complex fertilizer, in particular organic wheat straw complex fertilizer made of wheat straw and pig manure as the main raw material. The organic complex fertilizer comprises the following components with weight parts as units: 40 parts of wheat straw, 40 parts of pig manure, 2 parts of deodorant, 3 parts of fermenting agent, 10 parts of adsorbent, and 5 parts of microelement. The organic complex fertilizer made of the wheat straw and the pig manure is an environment-friendly efficient organic fertilizer made in the steps such as material crushing, deodorization, fermentation, drying, sieving, impurity removal, packaging and the like. The organic complex fertilizer fully utilizes the waste material of agriculture and livestock breeding as the raw material to reduce the environmental pollution caused by the secondary fermentation of the material, reduce the cost for agriculture fertilization and improve a soil structure and the quality of crops. Furthermore, the organic complex fertilizer has higher promotional value in the northern rural areas.

Owner:梁超君

Road cleaning device and method of use thereof

InactiveCN108999129AFunction increaseAdaptableGeneral water supply conservationRoad cleaningEngineeringMechanical engineering

The invention discloses a road cleaning device including a base body.A first cavity is arranged inside the base body, A rotating motor is arranged in the upper end wall of the first cavity, An upper end wall of that first cavity is rotatably mount with a first rotating shaft which is dynamically connected with the rotating motor and extends downward through a bearing, A low end of that first rotating shaft is fixedly connected with a first toothed disk located in the first cavity, A low end of that right side of the first cavity is provided with a second cavity, A second rotating shaft extending vertically is rotatably mounted between the first cavity and the second cavity through a bearing, An upper end of that second rotate shaft extends into the first cavity and is fixedly connected with a second toothed disk meshed with the first toothed disk, and a low end of the second rotating shaft extends into the second cavity and is fixedly connected with a first bevel gear.

Owner:叶波

Fish feed and preparation method thereof

InactiveCN105995201AImprove palatabilityReasonable ratioFood processingClimate change adaptationSodium bicarbonateAnimal science

The invention relates to the technical field of fish feed preparation, in particular to fish feed and a preparation method thereof. The proportional design is performed through fermented cow mature, corn, wheat bran, common salt, mineral supplements, sodium bicarbonate and fermented pasture, so that the mixture ratio of all raw materials is reasonable; the nutrition structures can be mutually improved; particularly, the palatability of fermented cow manure can be improved; the eating quantity of the feed fed for feeding the fish is increased; the bringing of harmful pathogenic bacteria is avoided; the culture risk is prevented; the safety coefficient is improved.

Owner:SONGTAO TIANNONG FARMS

High-temperature dry-membrane lubricant

InactiveCN104403739AHigh environmental valueImprove antioxidant capacityLubricant compositionHexamethylenetetraminePhosphoric acid

The invention relates to a dry membrane lubrication technology, and concretely relates to a high-temperature dry-membrane lubricant. The high-temperature dry-membrane lubricant mainly comprises graphite micro powder, hexagonal structure boron nitride, ethanol, phenolic resins, urotropine, phosphoric acid and a nonionic surfactant. The high temperature lubricant can be used for coating on surface of a mold after fully mixing, the high temperature lubricant enables solidification treatment under 200-250 DEG C, and the high temperature lubricant has good adherence effect, and can be used for lubrication under high temperature. In addition, the high-temperature dry-membrane lubricant has nontoxic component, less influence on worker, and high environmental protection value.

Owner:北京优材百慕航空器材有限公司

Preparation method for slope protection concrete

InactiveCN104891880AImprove deformation abilityLow elastic modulusSolid waste managementExcavationsCrack resistanceToughness

The invention discloses a preparation method for slope protection concrete. The method includes the steps of: (1) adding equal mass water into rubber particles to fully moisten the rubber particles; (2) pouring stone and medium sand into the moist rubber particles, and stirring the mixture evenly, wherein the crumb rubber accounts for 20-30 parts by weight, the stone accounts for 110-180 parts by weight, and the medium sand accounts for 40-67 parts by weight; and (3) pouring 45-75 parts by weight of cement and 10-20 parts by weight of water into the moist rubber particles, stand and medium sand, and then stirring the materials fully into concrete, with the maximum particle size of stone not exceeding 25mm. Compared with traditional slope protection concrete, the rubber concrete provided by the invention has strong deformability, flexural ultimate strain up to over 500*10<-6>, elastic modulus lower than 2*10<5>MPa, and greatly increased bending toughness, fatigue resistance and crack resistance.

Owner:长春市中路建筑工程有限公司 +1

Alkali slag water-retaining agent and preparation method and application thereof

The invention discloses an alkali slag water-retaining agent and a preparation method and application thereof. The alkali slag water-retaining agent is composed of dechlorination alkali slag and a mixed material. The method for preparing the alkali slag water-retaining agent comprises the steps of evenly mixing the dechlorination alkali slag and the mixed material by mass percentage, adding the dechlorination alkali slag and the mixed material into a grinding device, performing grinding treatment to mixed powder with 0.30 mm residue on sieve smaller than 10 wt%, and obtaining the alkali slag water-retaining agent. The alkali slag water-retaining agent is good in water-retaining property, can be used for improving water-retaining property of mortar and contractibility of concrete, and is economical and environmentally friendly.

Owner:SOUTH CHINA UNIV OF TECH

Fracturing flowback fluid recovery treatment reusing process method

InactiveCN104418450AAvoid emissionsShort processMultistage water/sewage treatmentWater/sewage treatment by flocculation/precipitationFiltrationElectrochemistry

The present invention provides a fracturing flowback fluid recovery treatment reusing process method. The technical scheme comprises that: a precipitating agent is added to fracturing flowback fluid wastewater, and filtration is performed to remove harmful components unsuitable for fluid re-preparation, such that the harmful components can not affect the reuse and the fluid re-preparation, wherein the precipitating agent can be one or a plurality of materials selected from sodium hydroxide, sodium carbonate, aluminum sulfate, aluminum ferric sulfate silicate, polyacrylamide and polymeric aluminum ferric chloride; the precipitated flowback fluid is subjected to an electrochemical treatment so as to be subjected to actions such as oxidation, reduction, air flotation and flocculation; and the electrochemically-treated flowback fluid is subjected to an active carbon felt filtration treatment, such that the purpose of the reuse and the fluid re-preparation are achieved. According to the present invention, the useful components and the harmless components are not destroyed, the process is shortened, the cost is low, the operation is easy, and the high promotion application value is provided; and the method is based on the fracturing flowback fluid recycling and the fluid re-preparation, the sewage emission is avoided, the fresh water is saved, and the high environmental protection value is provided.

Owner:DONGYING TUOPU INFORMATION IND

Method for quickly preparing arc spraying mother plate substrate

The invention discloses a rapid preparation method for an arc-sprayed female die matrix. The female die matrix belongs to a magnesium oxychloride composite material, and contains 41.2 to 57.7 percent of light burned magnesia, 15.9 to 36.1 percent of industrial magnesium chloride, less than or equal to 2.0 percent of chopped carbon fiber, and the balance being water. During the use, raw materials are prepared into an uniform sizing agent, a prototype of a part to be sprayed is used to reclaim a female die made of magnesium oxychloride composite material, the female die is dried and finely machined, and finally hydrochloric acid is used to perform surface treatment on the female die to finish the rapid preparation of the sprayed female die. The sprayed female die produced by the method has low cost and high strength, is high temperature resistant, does not need high temperature baking during the production, can be machined, and is particularly suitable for middle-low melting point and high melting point electric arc spraying rapid molding technologies.

Owner:XI AN JIAOTONG UNIV +1

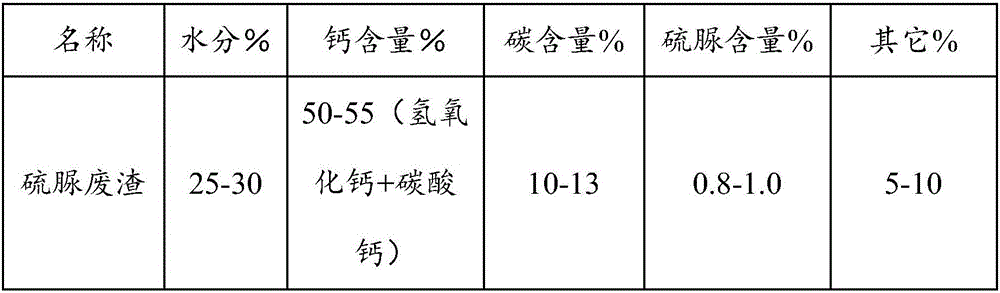

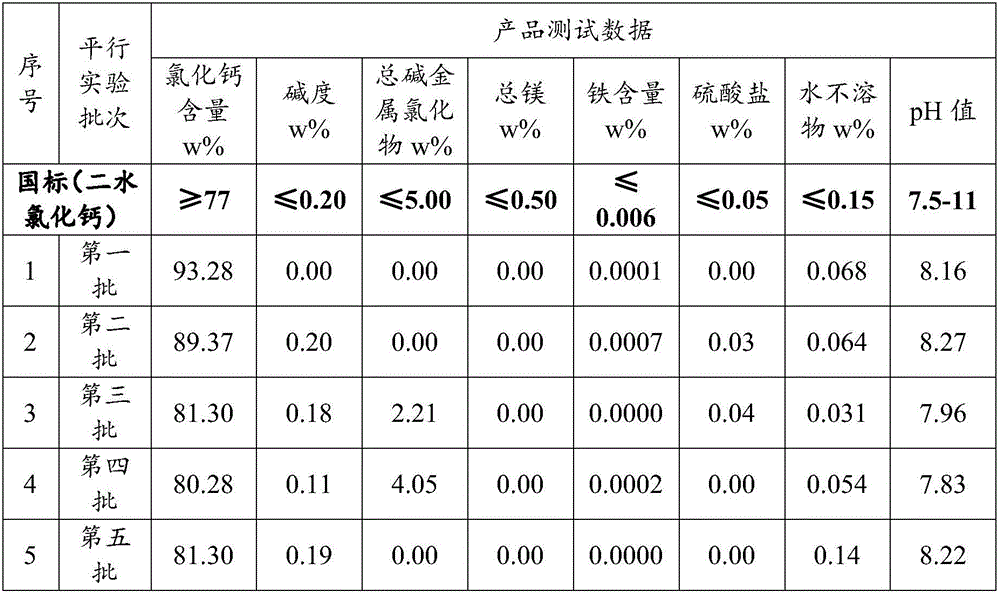

Method for preparing industrial calcium chloride from thiourea waste residues

InactiveCN105883884ASolve processingSolve the accumulationCalcium/strontium/barium chloridesCalcium hydroxideEnvironmental resistance

The invention discloses a method for producing industrial calcium chloride from raw materials including thiourea waste residues and technical hydrochloric acid. Calcium hydroxide in the thiourea waste residues and hydrochloric acid are subjected to an acid-base neutralization reaction, and industrial calcium chloride products are obtained. With the adoption of the method, the problem that industrial solid waste of thiourea is difficult to treat is solved, the production capacity of thiourea is no longer limited by the solid waste, the industrial calcium chloride products meeting market requirements are obtained, new three wastes are no longer generated, comprehensive utilization of the thiourea residues is realized, the industrial added value of thiourea is increased, and the method has greater economic value and environment protection value.

Owner:CHAMBROAD CHEM IND RES INST CO LTD

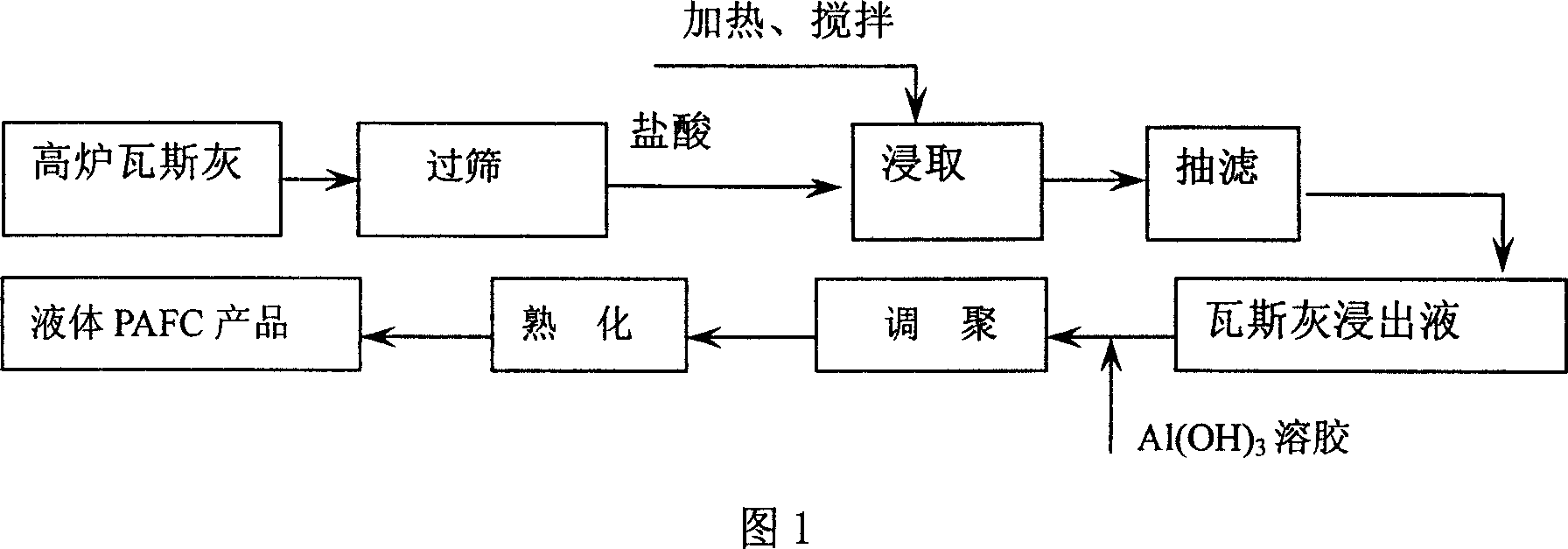

Method for preparing aluminium iron polychloride floculant

InactiveCN1935684ASimple methodProcess innovationWater/sewage treatment by flocculation/precipitationCompound organicIron salts

The invention discloses a polyaluminium iron chloride flocculant preparing method, comprising the steps of: selecting raw materials, preparing blast furnace gas dust solution, preparing Al(OH)3 sol, and preparing polyaluminium iron chloride flocculant; and the prepared product is a compound organic high molecular flocculant and has characters of aluminum and iron salts, and has excellent water purifying performance and wide application range. And it provides a feasible way of synthetically utilizing the wastes of the steel mills and provides a process route with cheap raw materials for flocculant production, achieving the purpose of processing wastes with wastes, and obtaining good economic, social and environmental benefits.

Owner:SHANDONG UNIV

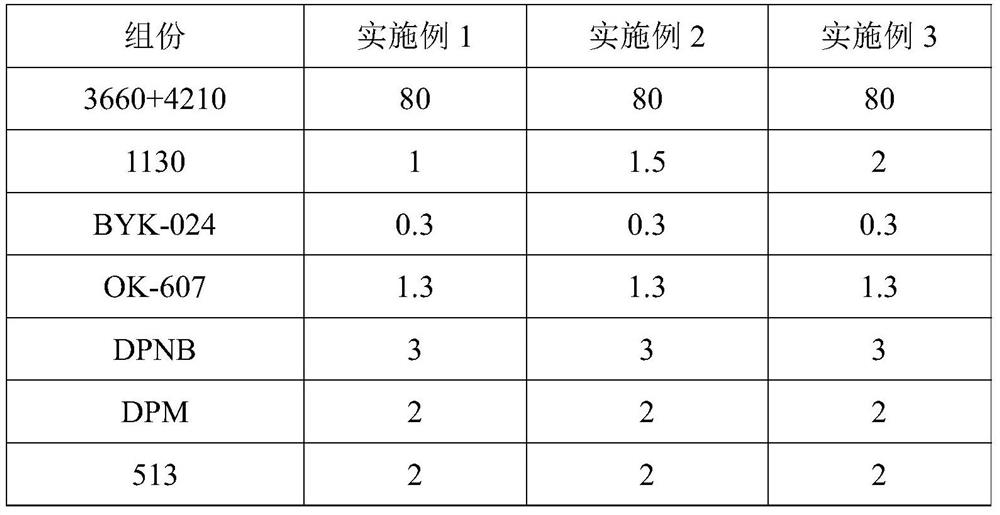

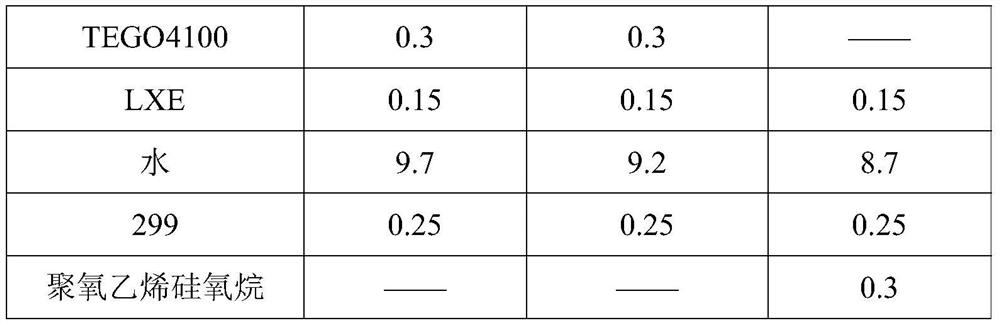

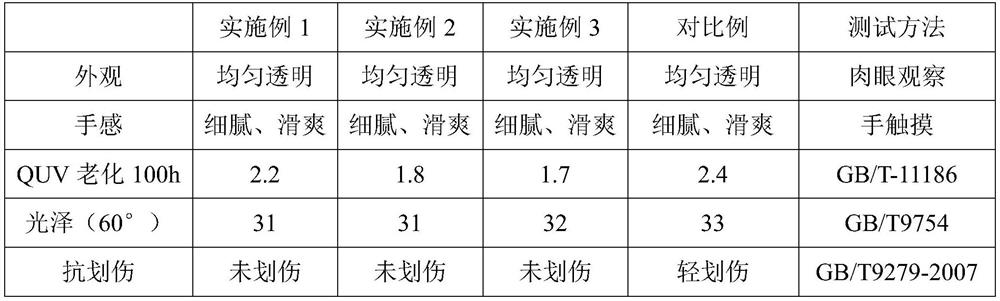

Water-based color-changing-resistant varnish and coating process thereof

PendingCN111808488ANot easy to change colorGood weather resistanceLiquid surface applicatorsPolyurea/polyurethane coatingsUltraviolet lightsVarnish

The invention discloses a water-based color-changing-resistant varnish and a coating process thereof. The varnish is prepared from, by weight, 70-85 parts of water-based resin, 0.2-1 part of a defoaming agent, 0.2-0.8 part of a thickening agent, 4-7 parts of a coalescing agent, 0.5-3 parts of extinction powder, 0.1-0.8 part of a base material wetting agent, 0.1-0.4 part of a sterilization mildew preventive, 1-3 parts of an ultraviolet light absorber, 1-3 parts of a wax emulsion and / or polishing powder and 5-10 parts of water. During construction, 0.2-3 wt% of a water-based color paste is addedinto a primer. According to the water-based color-changing-resistant varnish for the African redwood woodenware, and the coating process thereof, the varnish has excellent discoloration resistance, adhesion, water resistance, transparency, hand feeling and scratch resistance after being dried at room temperature, has extremely low VOC, has relatively high environmental protection value, obviouslyprolongs the service life of a product and obviously improves the grade of the product.

Owner:山东巴德士新材料有限公司

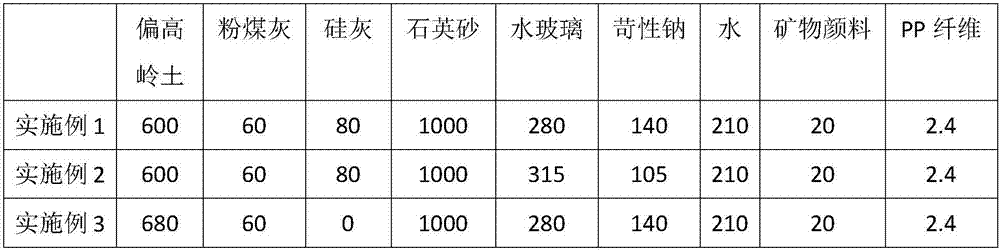

Waterproof and anti-alkali decorating mortar and preparation method thereof

The invention belongs to the technical field of building materials and particularly relates to waterproof and anti-alkali decorating mortar and a preparation method thereof. The decorating mortar is prepared from the following raw materials in percentage by mass: 20%-30% of metakaolin, 2%-3% of coal ash, 3%-5% of silica fume, 40%-55% of quartz sand, 5%-15% of water glass, 3%-7% of caustic soda, 6%-15% of water, 0.2%-1.2% of an inorganic mineral pigment and 0.1%-0.3% of PP fiber. The waterproof and anti-alkali decorating mortar is low in whiskering risk, high in structural compactness and strength, good in water resistance and excellent weather resistance.

Owner:CHINA MINGSHENG DRAWIN TECH INVESTMENT CO LTD

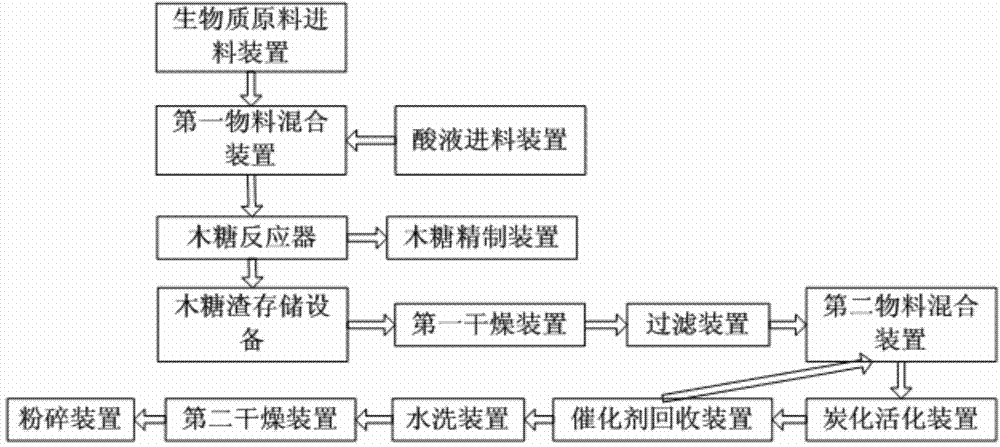

Method and apparatus for preparation of xylose and combined production of active carbon

InactiveCN104745734AAchieve recyclingAvoid pollutionCarbon compoundsXylose productionActivated carbonEconomic benefits

The invention provides a method for preparation of xylose and combined production of active carbon. The method comprises the following steps: hydrolyzing a biomass raw material so as to obtain xylose and xylose residue; and charing and activating the xylose residue under the action of a catalyst so as to obtain active carbon. According to the method provided by the invention, the biomass raw material is hydrolyzed to obtain the xylose and the xylose residue; then the xylose residue is used as a raw material for preparation of active carbon via a chemical method. Compared with the prior art, the invention has the following advantages: since the xylose residue is used as the raw material, recycling of waste residue in production of xylose is realized, pollution to the environment caused by direct discharge of the waste residue is avoided, and a high environmental protection value is achieved; and the method realizes combined production of active carbon, so immense economic benefits are obtained.

Owner:JINAN SHENGQUAN GROUP SHARE HLDG

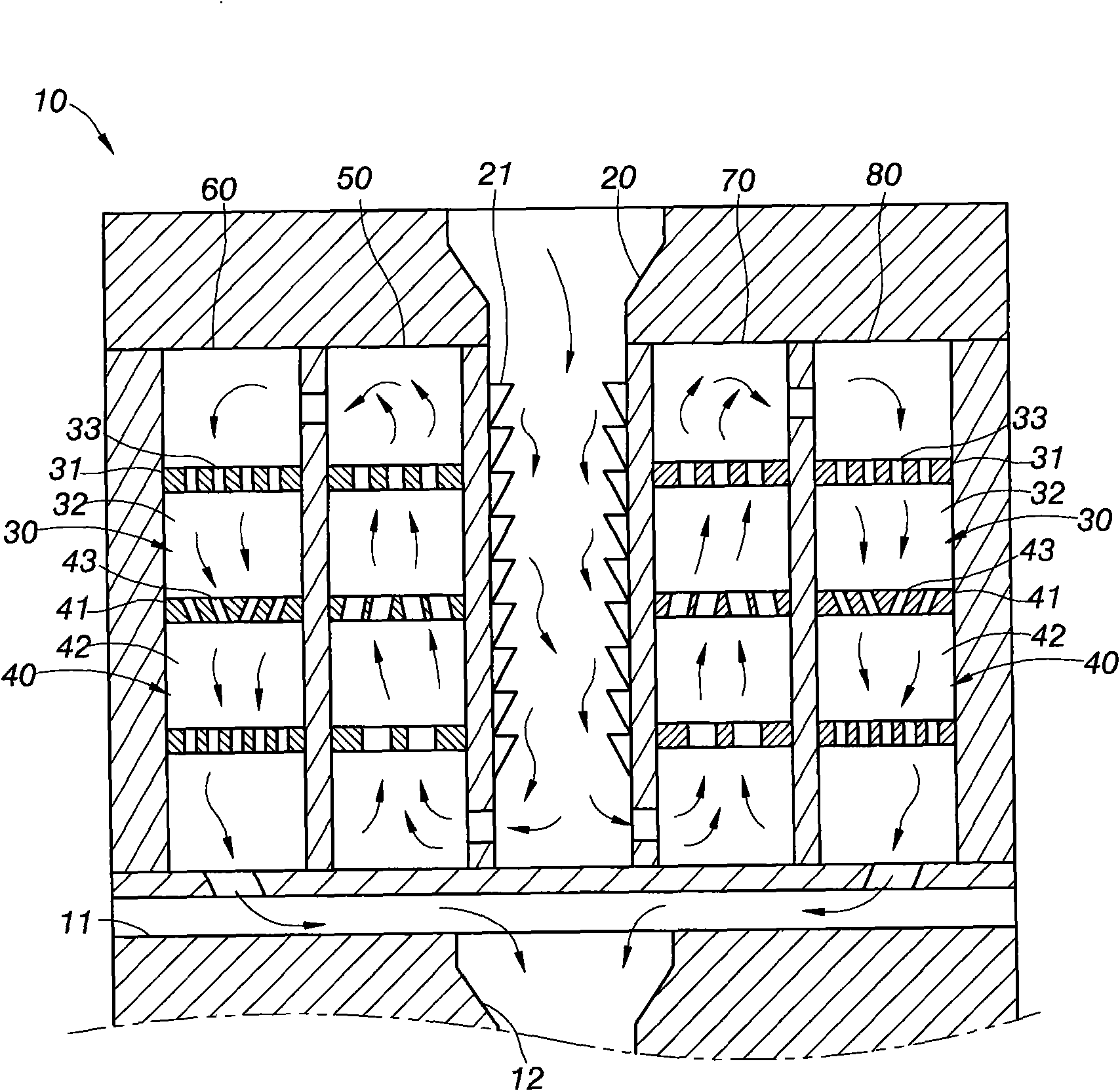

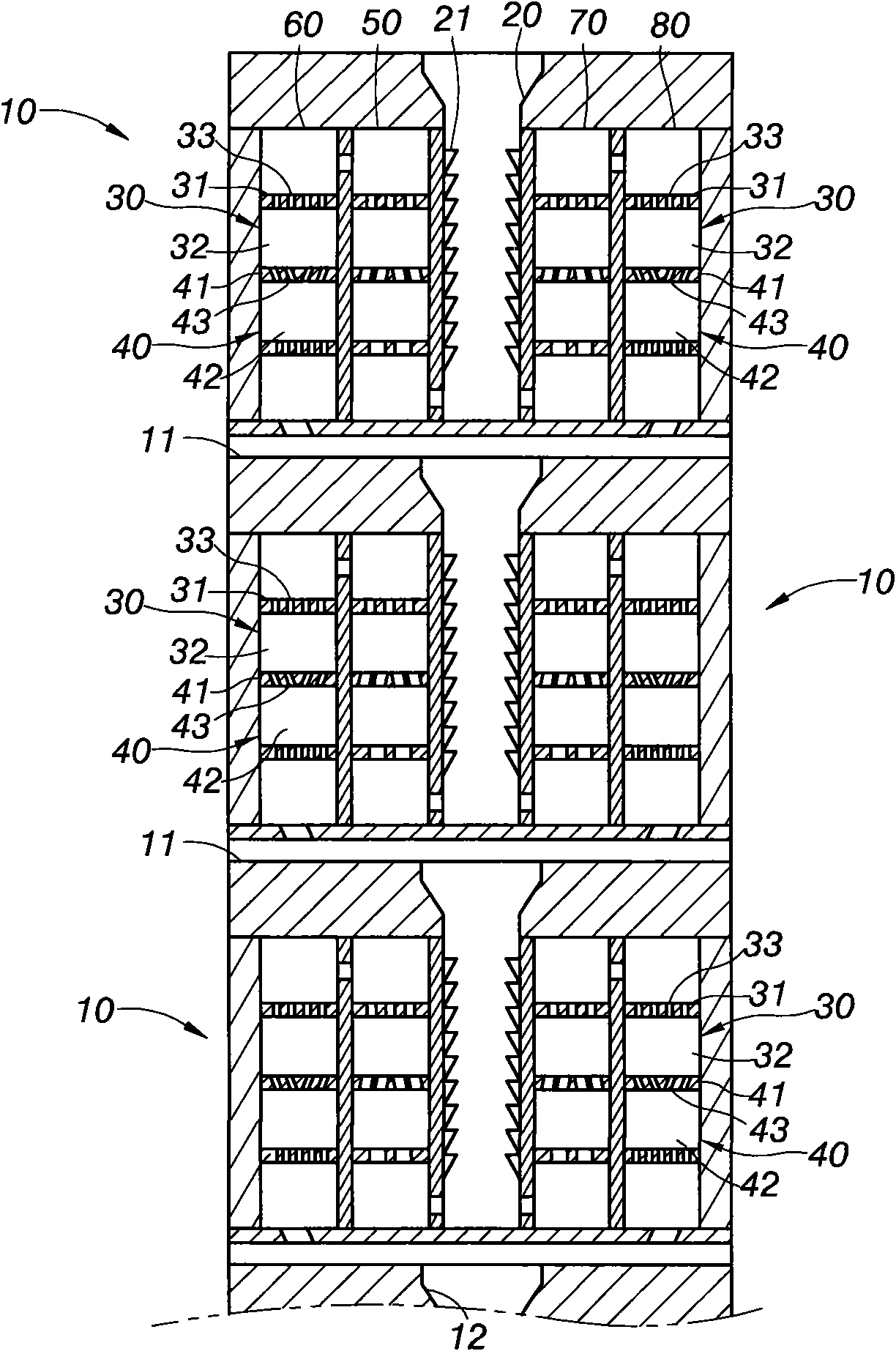

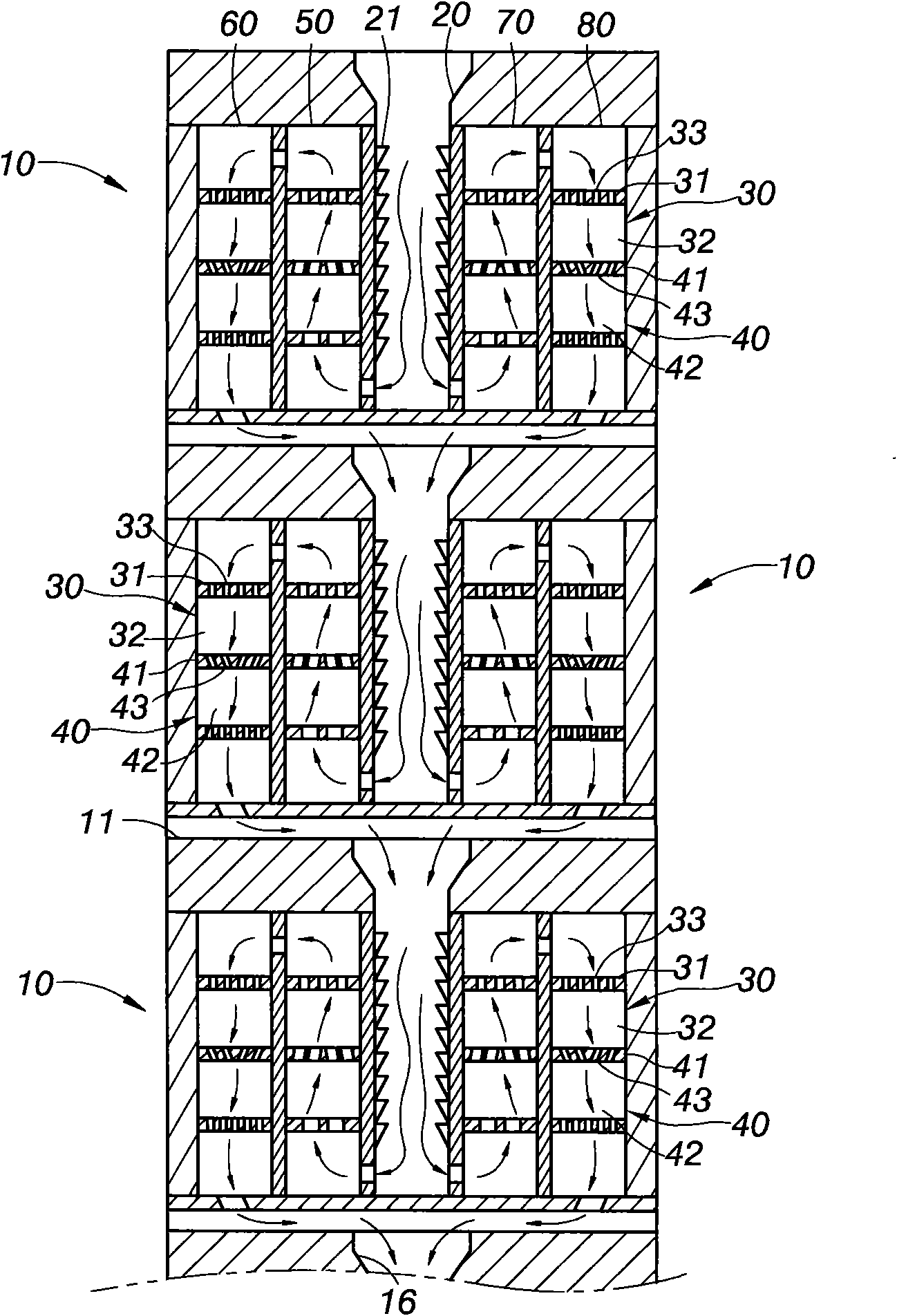

Spiral-flow sectional tube type liquid stirring device

InactiveCN101992038APrecise control of particle sizeImprove qualityLiquid fuel feeder/distributionFlow mixersParticulatesActive agent

The invention discloses a spiral-flow sectional tube type liquid stirring device. A rectifying tube is arranged in an accommodating groove; and a plurality of turbulent flow layers and a rectifying and mixing layer are arranged on the sides of the rectifying tube. After flowing through the turbulent flow layers and the rectifying and mixing layer, fluid can be stirred to form a particulate structure. When the stirring device is used for materials with relatively high viscosity, such as heavy oil, rubber and the like, particles can be relatively uniformly distributed under the condition of not adding an expensive interface active agent (an emulsifier), so that the material cost is saved and the problems of environmental pollution and acid corroded pipelines probably cause by the interface active agent are solved. Particularly, the proportion of the aperture size to the total area on the turbulent flow layers and the rectifying and mixing layer can be calculated to precisely control refining grain diameter. The device has the advantage of improving quality and contributing to automatic mass production.

Owner:陈黄传

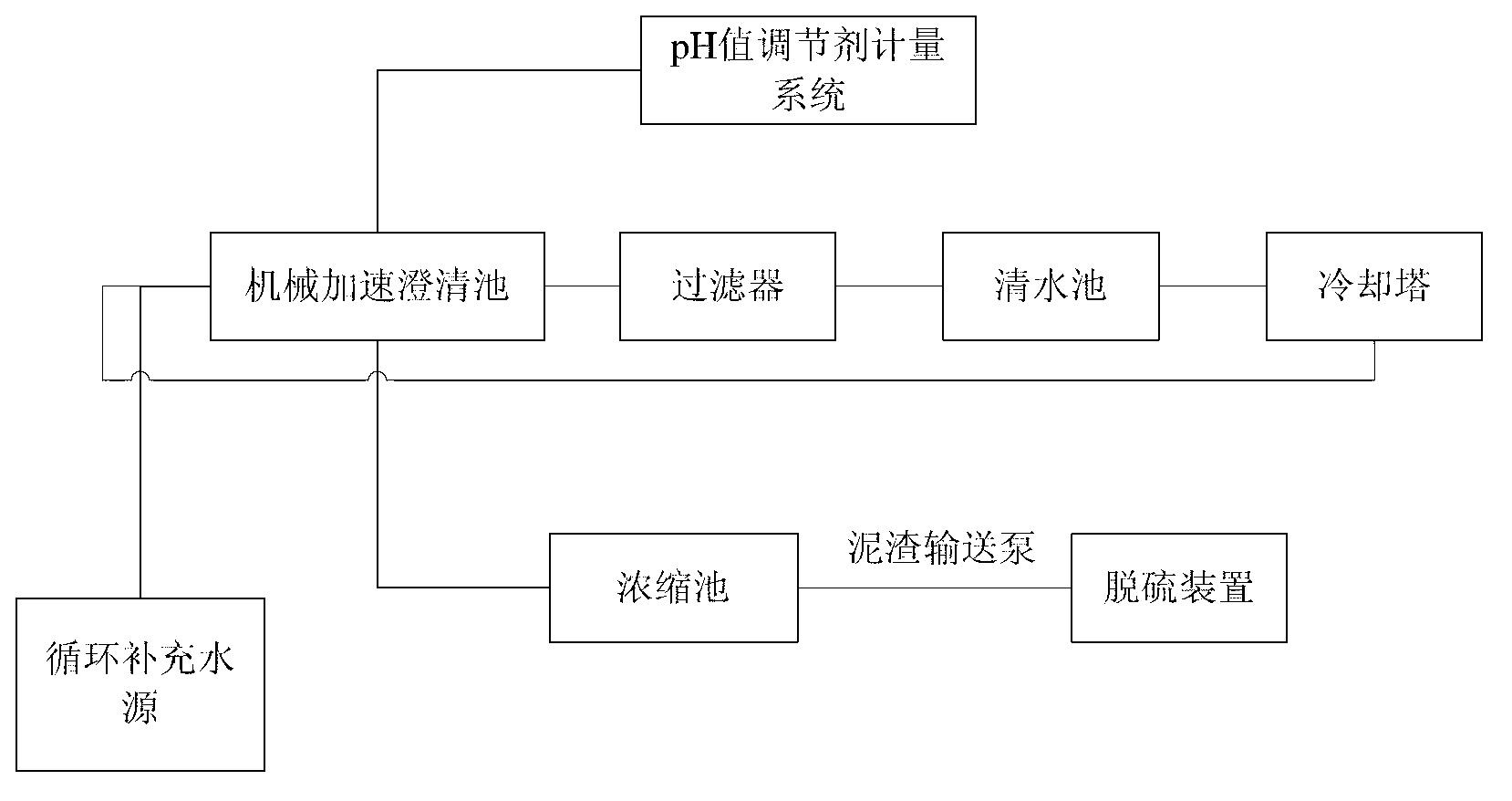

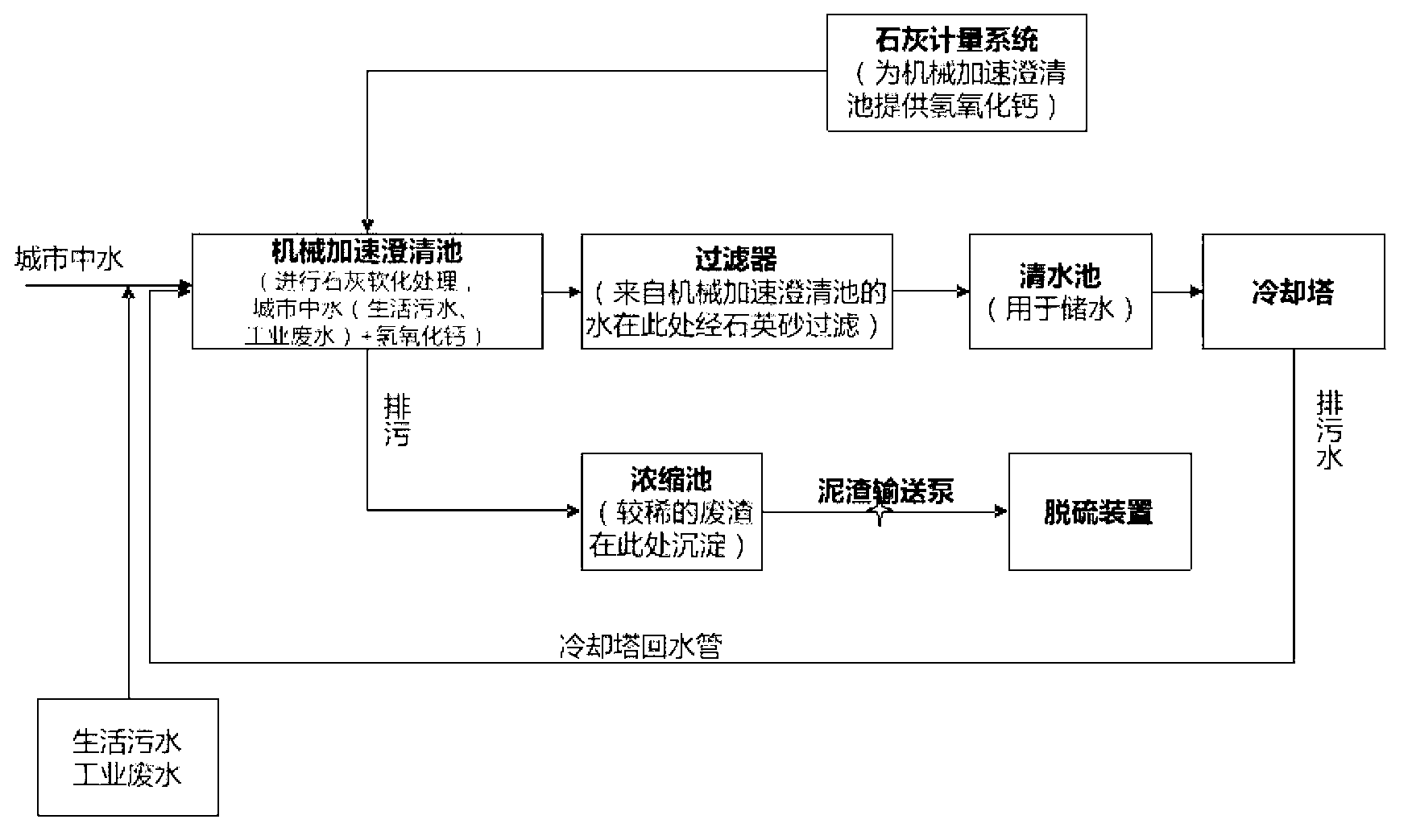

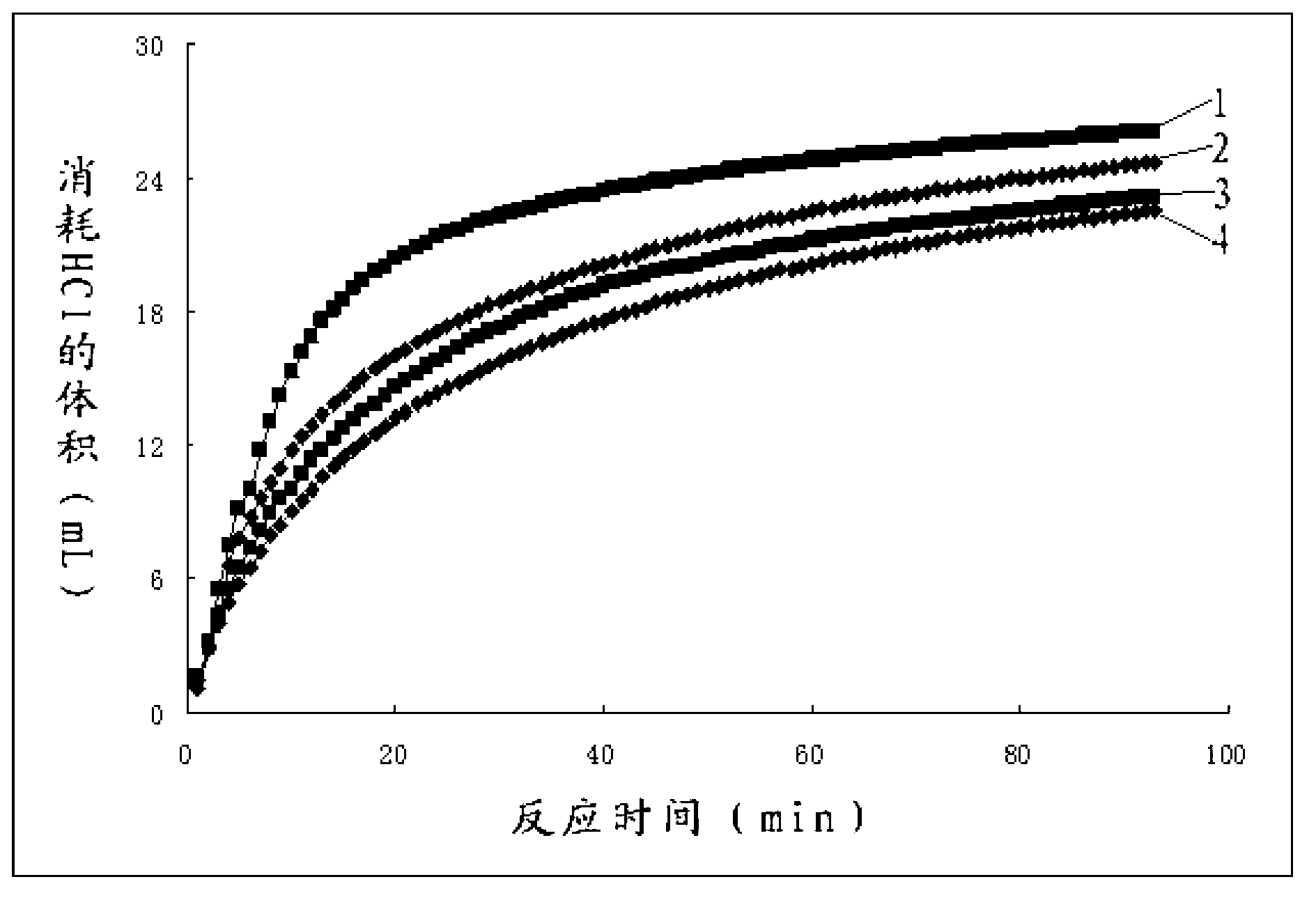

Device and method for treating waste residues of circulating make-up water by reutilizing lime softening method of power plant

ActiveCN103011462AImprove desulfurization efficiencyHigh environmental valueMultistage water/sewage treatmentWater sourceEnvironmental engineering

The invention provides a method for treating waste residues of circulating make-up water by reutilizing a lime softening method of a power plant. The method comprises the following steps of: a), mixing a circulating make-up water source with a pH value regulating agent for regulating the pH value of the circulating make-up water source to 9.9-10.3 on the condition of not adding a flocculant and a coagulant aid; and b), stewing the mixed solution with the pH value of 9.9-10.3 obtained in the step a) and using the obtained filter residue as a desulfurizing agent. According to the method provided by the invention, the flocculant and the coagulant aid are not added while the circulating make-up water is treated by the lime softening method, and the treated water also satisfies the water standard of the circulating make-up water; the obtained filter residue can form into dry solid gypsum, so that high desulfurizing efficiency can be achieved; and moreover, according to the method provided by the invention, the pH value of the circulating make-up water source is regulated to 9.9-10.3 by adopting the pH value regulating agent, so that the obtained filter residue can directly serve as the desulfurizing agent and has high desulfurizing efficiency.

Owner:CHINA RESOURCES POWER HENAN SHOUYANGSHAN

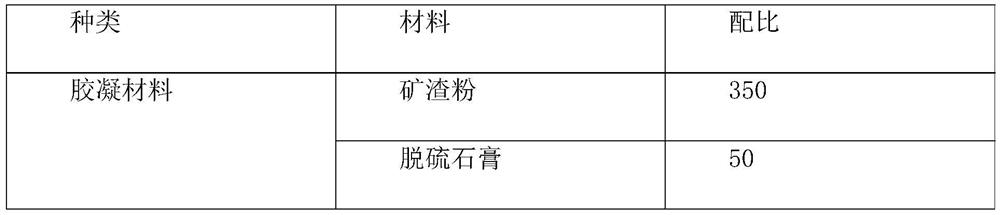

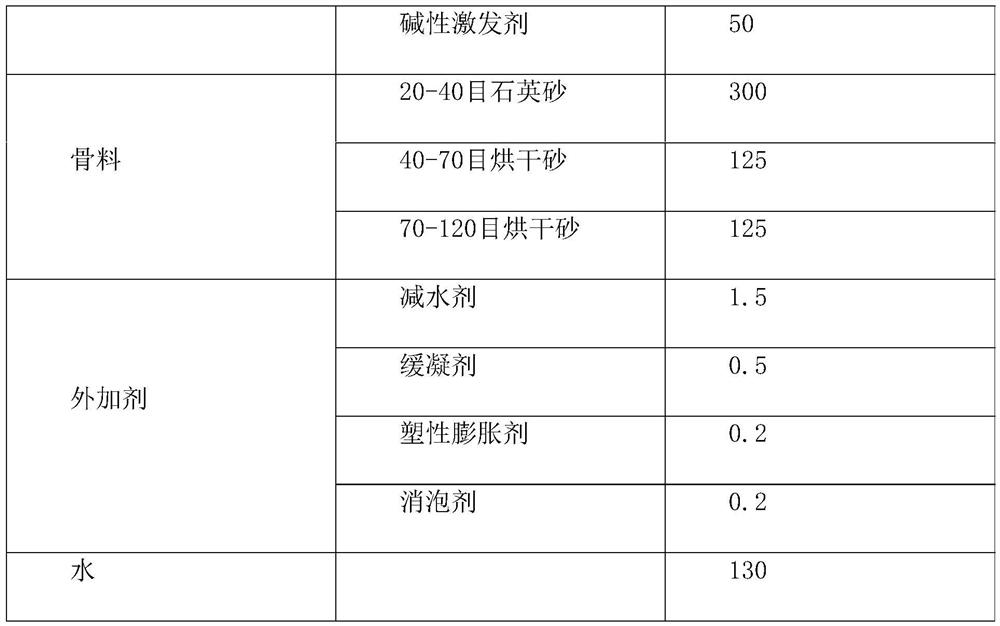

Ecological cement high-strength grouting material and preparation method thereof

The invention provides an ecological cement high-strength grouting material and a preparation method thereof. The ecological cement high-strength grouting material has the advantages of high flowability, favorable constructability, long operable time and smooth and flat surface after completion, and can perform self-remaining leveling. The ecological cement high-strength grouting material comprises a cementing material, aggregate and an additive, wherein the cementing material comprises slag powder, desulfurized gypsum and an alkaline activator; the aggregate is prepared from, by weight, 250-300 parts of 20-40-mesh quartz sand, 100-150 parts of 40-70-mesh dried sand and 100-150 parts of 70-120-mesh dried sand; and the additive comprises, by weight, 1-2 parts of a water reducing agent, 0.1-0.6 part of a retarder, 0.1-0.3 part of a plastic expanding agent and 0.1-0.3 part of a defoaming agent.

Owner:山东华迪建筑科技有限公司 +1

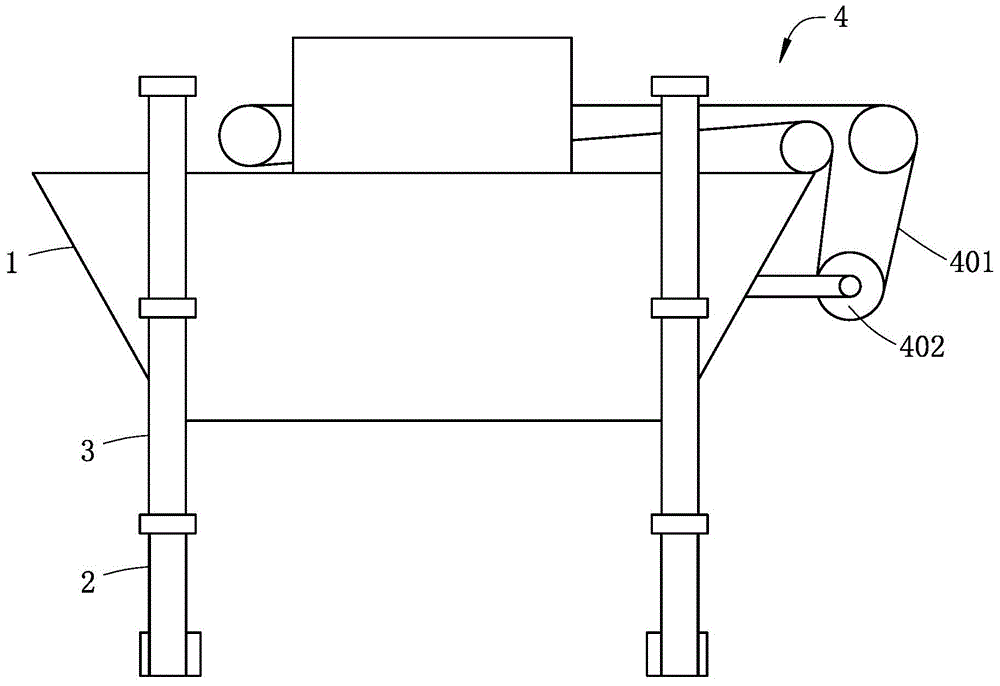

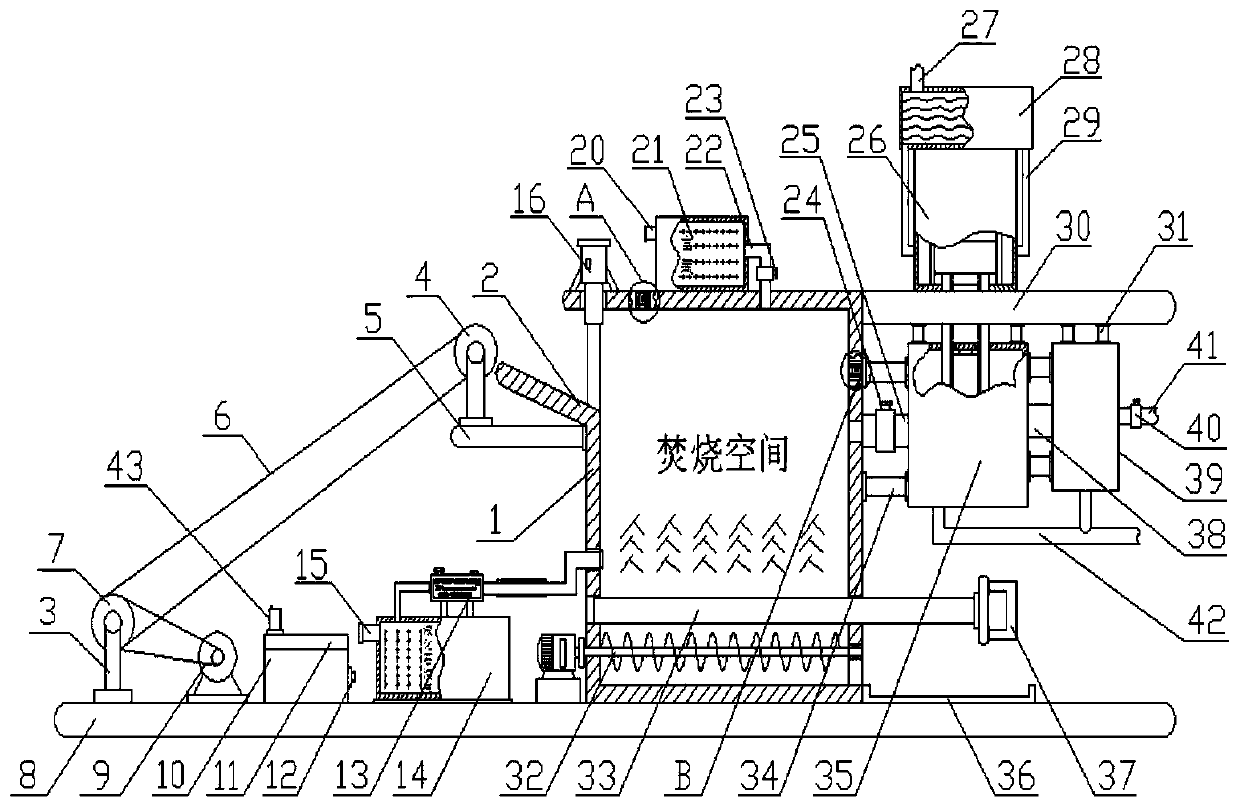

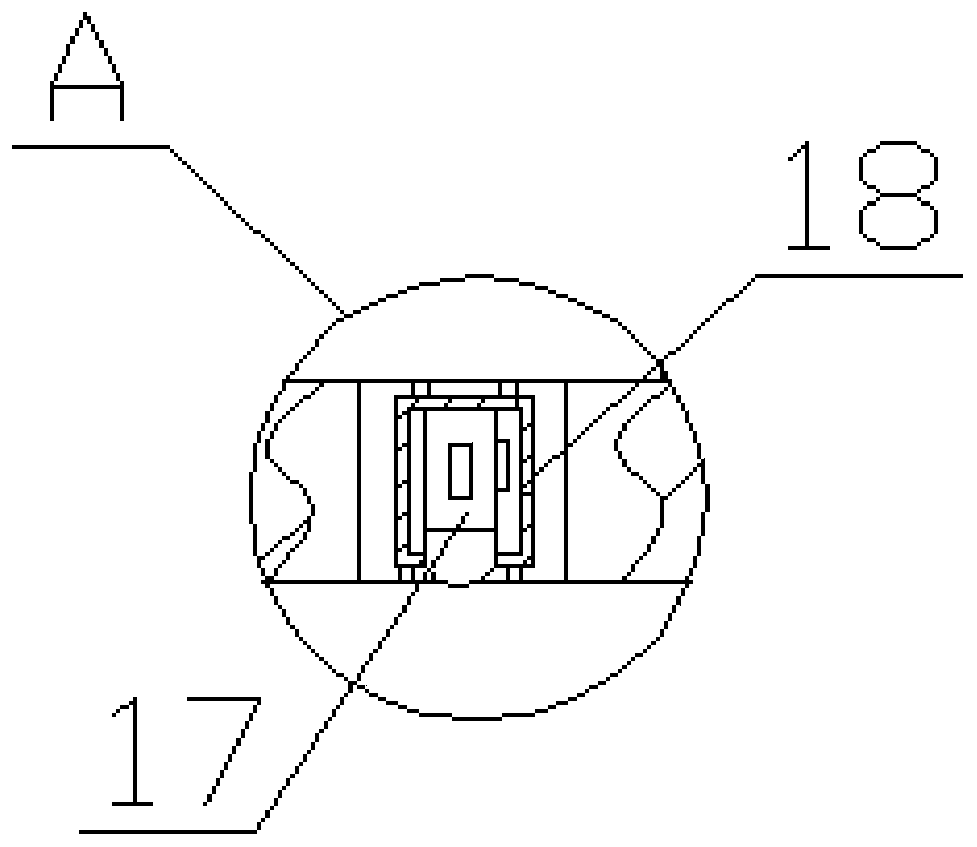

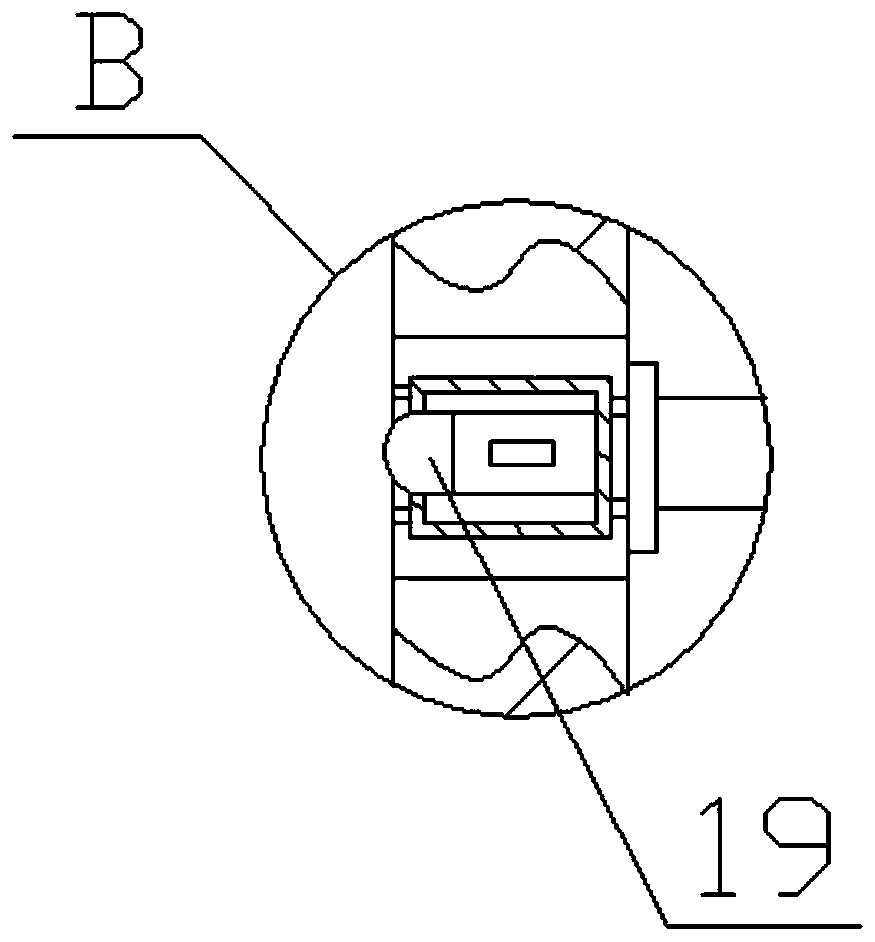

Environment-friendly type dry refuse incineration and waste gas treatment system

ActiveCN110345493ARealize automatic reciprocating movementLabor savingDispersed particle filtrationEmission preventionEnvironmental resistanceEngineering

The invention provides an environment-friendly type dry refuse incineration and waste gas treatment system comprising an incinerator wall, a material guiding inclined plate, supporting frames, a firsttransmission wheel, a support plate, a conveyer belt, a second transmission wheel, a base plate, a material guiding motor and other structures. A reciprocating cleaning mechanism is installed on theupper portion of the installation plate through bolts. A discharging mechanism is installed at the bottom in the incinerator wall and located on the lower side of the incinerator plate. A waste gas filtering box is arranged on the lower portion of the installation plate. The reaction chamber is installed on the lower portion of the installation plate through a stabilizing column and located on oneside of the waste gas filtering box. By means of the reciprocating cleaning mechanism, the filtering mechanism, the waste gas filtering box and a reaction chamber, dry garbage can be effectively incinerated, generated gas is filtered and purified, the filtering portion can be cleaned in a reciprocating manner so as to improve the purifying effect, the national requirements for refuse environmental protection treatment are further met, the incinerated refuse discharging process is environmentally friendly and free of pollution, and the whole system has great environmental protection value.

Owner:HEZE UNIV

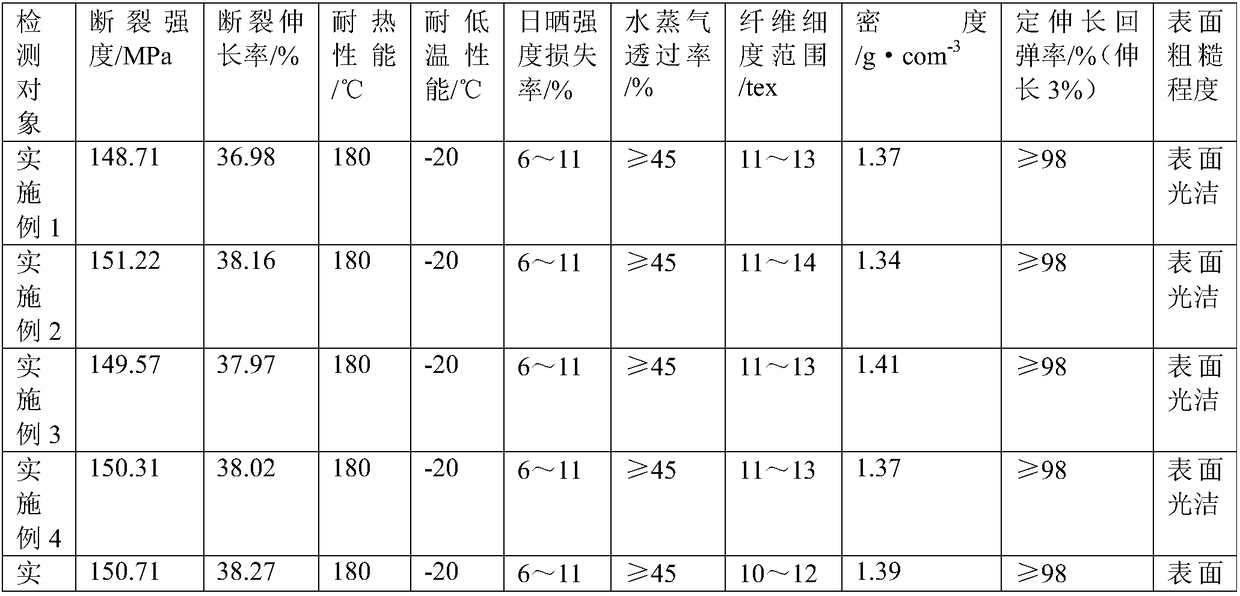

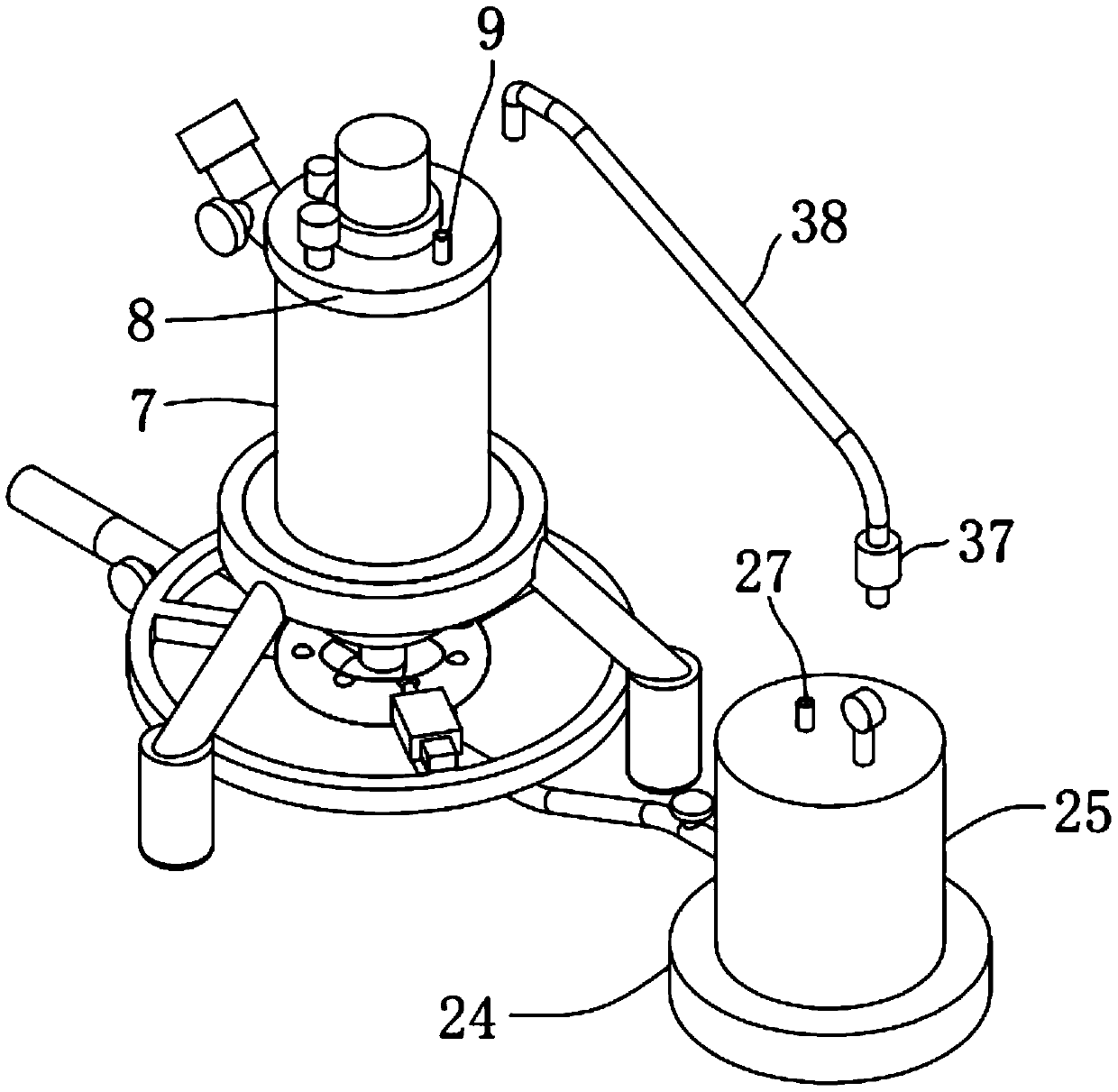

Flexible, temperature-resistant and environment-friendly fiber and preparation technology thereof

InactiveCN108360087AAbundant and renewable sourcesNaturally degradable digestibleFlame-proof filament manufactureConjugated cellulose/protein artificial filamentsFiberNatural degradation

The invention relates to a flexible, temperature-resistant and environment-friendly fiber with excellent mechanical performance, high flame retardance, temperature resistance, corrosion resistance andlighter texture and a preparation technology of the fiber. Most of used raw materials are green, environment-friendly and pollution-free biomaterials, the raw materials are widely sourced and renewable, part of solutions used as solvents can be repeatedly recycled, the prepared fiber material has the characteristics of natural degradation and digestion besides excellent mechanical performance, cannot cause pollution to the environment and has very high environmental protection value, excellent high-temperature resistance and low-temperature resistance and good balance in temperature resistance period, the preparation process is very environmentally friendly, and quick temperature change exerts smaller influences on the fiber.

Owner:HUZHOU KEBO INFORMATION TECH CO LTD

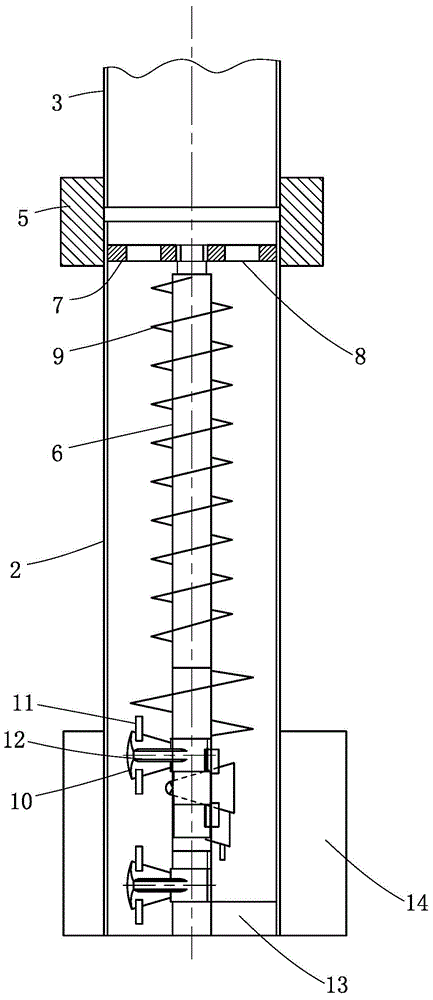

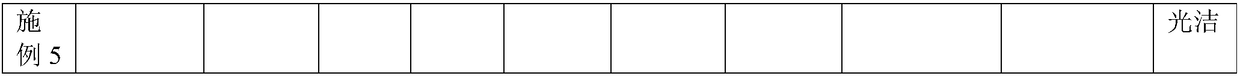

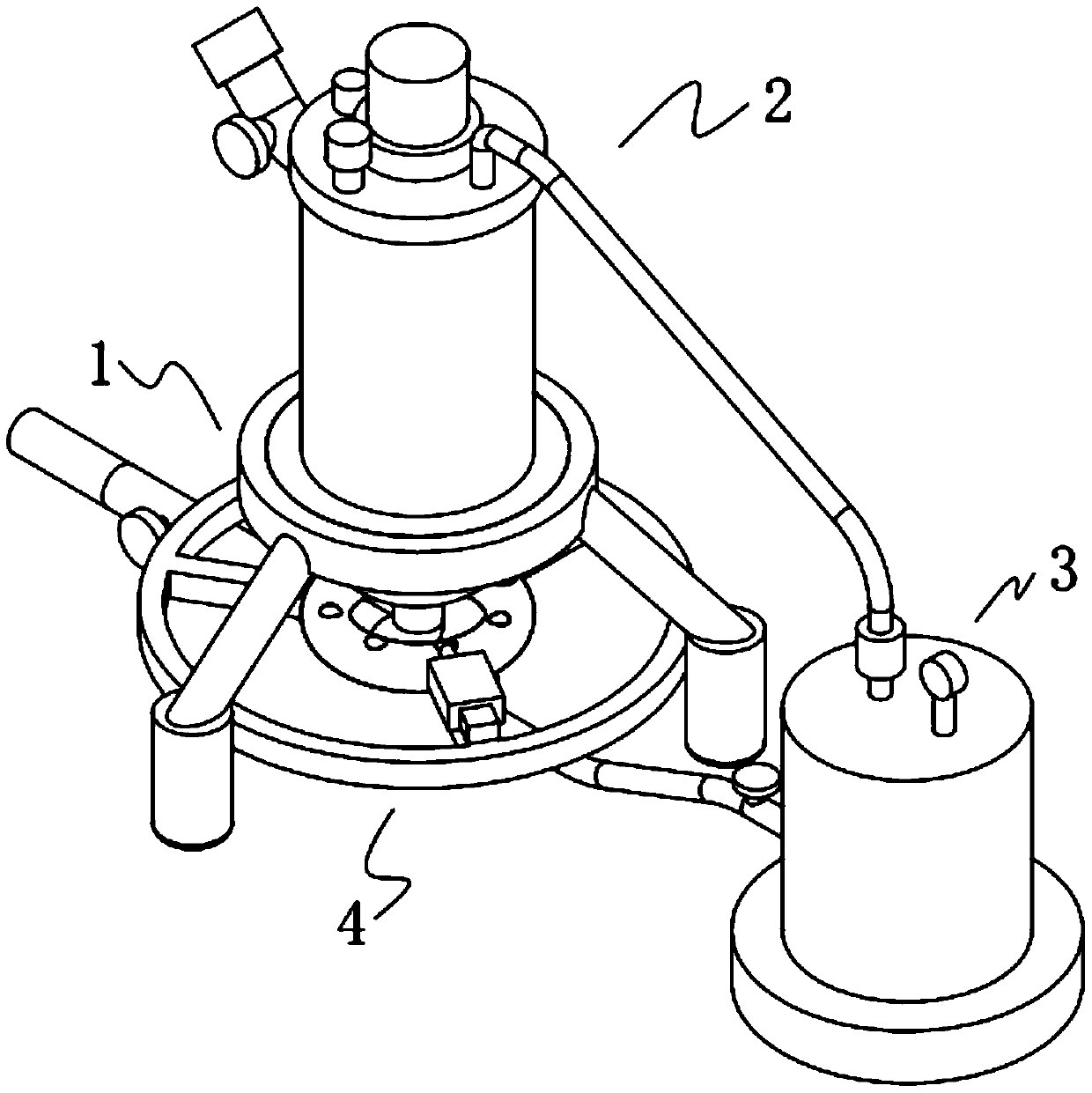

Harmless treatment device for sludge

ActiveCN110835217ARealize comprehensive utilizationHigh environmental valueSludge treatment by thermal conditioningBiological sludge treatmentSludgeHazardous substance

The invention discloses a harmless treatment device for sludge. The device comprises a bottom fixing unit, and further comprises a harmless sludge treatment unit, a gas storage unit and a combustion heating unit, the harmless sludge treatment unit is fixedly mounted on the bottom fixing unit, the gas storage unit is communicated with the harmless sludge treatment unit, the combustion heating unitis communicated with the gas storage unit, and the combustion heating unit is fixedly mounted inside the bottom of the bottom fixing unit. The device has the advantages of reasonable design, novel structure, achieving the effects of effectively increasing the sludge treatment efficiency and effectively reducing the harmless treatment cost of sludge by effectively using biogas generated in the harmless treatment process of the sludge for self use, no generation or discharge of toxic and harmful substances in the treatment process, good treatment quality, high environmental protection values, non-blockage, smoothness in discharge of harmlessly treated sludge, and avoiding of adhesion of a large amount of sludge in the device on use.

Owner:江苏环保产业技术研究院股份公司

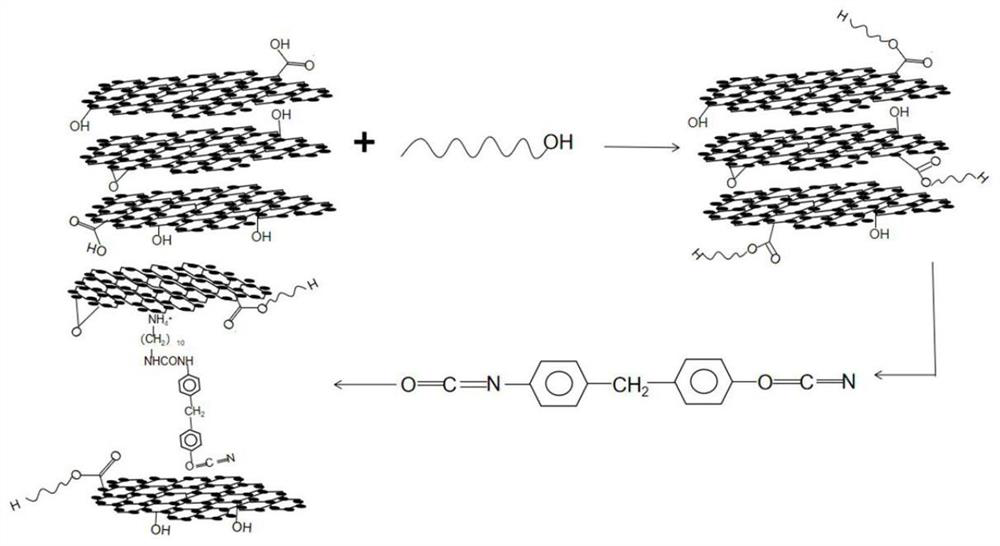

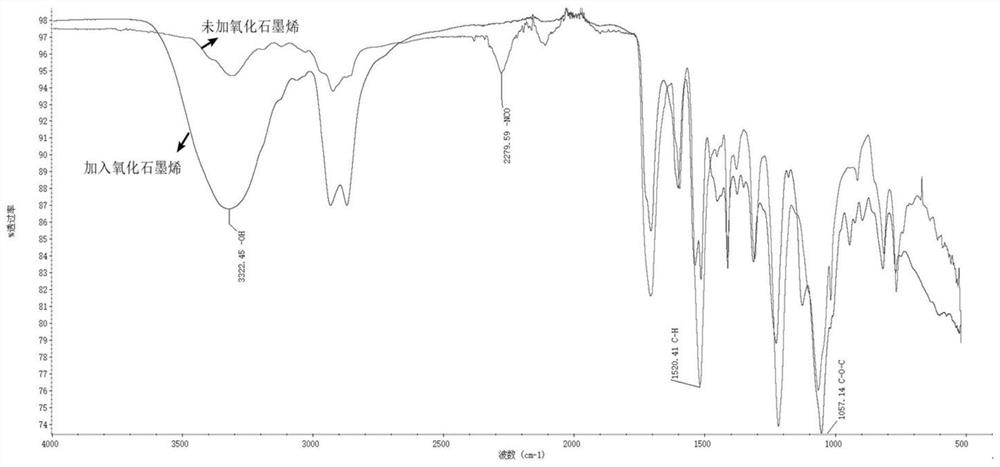

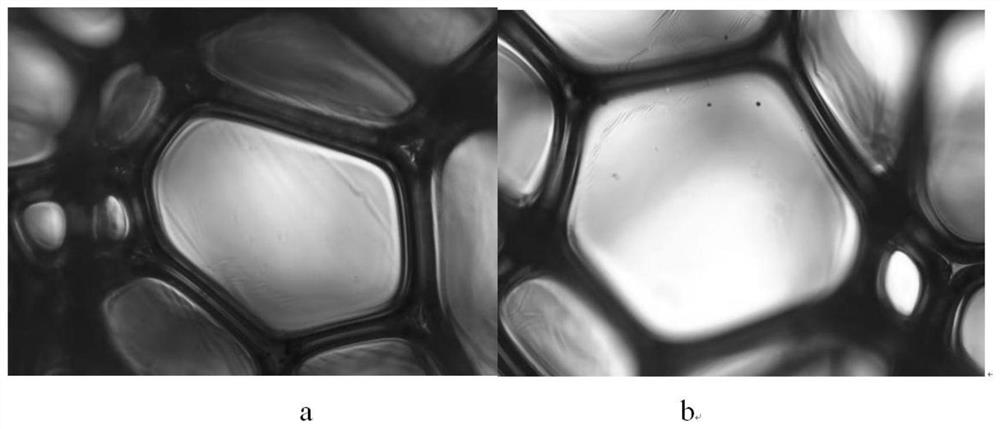

Preparation method of graphene/waste polyurethane composite material

The invention belongs to the technical field of waste polyurethane recovery and reutilization, and particularly relates to a preparation method of a graphene / waste polyurethane composite material. According to the method disclosed by the invention, the waste polyurethane rigid foam subjected to crushing and a polyol, graphene oxide and additive blending system meeting different functional requirements are degraded and recycled according to a certain proportion for reutilization, and the graphene oxide / waste polyurethane composite material with excellent performance is prepared by utilizing a degradation product. The material has good thermal stability, thermal insulation performance and the like, and the apparent density, the compression strength, the water absorption rate and the like are all higher than national standards. In the recovery process, three wastes are not discharged, the method is green and environment-friendly, the recovery utilization rate of the waste polyurethane is close to 100%, and the degradation product can be directly utilized without subsequent treatment, so that the cost of the polyurethane rigid foam product is greatly reduced.

Owner:山东东特环保科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com