Ecological cement high-strength grouting material and preparation method thereof

A technology of ecological cement and grouting materials, applied in the field of building materials, can solve the problems of late strength impact, increased production costs, and non-compliance with national sustainable development strategy requirements, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

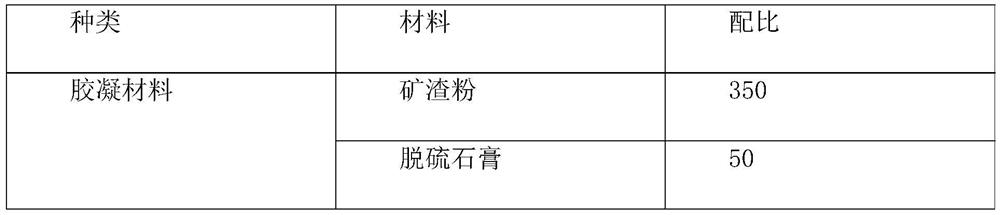

Embodiment 1

[0040] A method for preparing ecological cement high-strength grouting material, comprising the following steps:

[0041] (1) Accurately weigh the gelling material, aggregate and admixture of the specified amount according to the proportioning in Table 1;

[0042] (2) Mix the cementitious material, aggregate and admixture evenly, pour it into a standard mortar mixer, add water of specified quality (12% of the total material), stir at 140±5r / min for 60s, and stir at 280±5r / min Stir at 10r / min for 30s, let stand for 90s, shovel the material on the pot wall into the pot, and then stir at 280±10r / min for 60s;

[0043] (3) Use the grouting material flow cone funnel to measure the initial, 30min, and 60min fluidity of the grouting material, put the evenly stirred grouting material into a 40*40*160 standard triple test mold evenly coated with butter, vibrate evenly, and wipe flat;

[0044] (4) Leave the mold at room temperature for 24 hours, put it into a standard constant temperat...

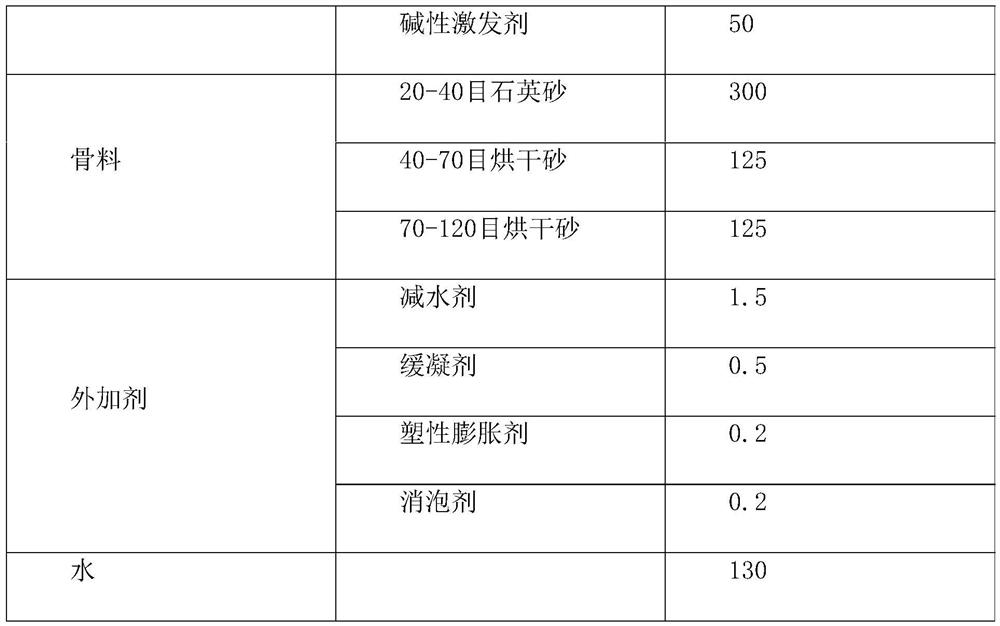

Embodiment 2

[0051] A method for preparing ecological cement high-strength grouting material, comprising the following steps:

[0052] (1) Accurately weigh the specified amount of cementitious material, aggregate and admixture according to the ratio in Table 3;

[0053] (2) Mix the cementitious material, aggregate and admixture evenly, pour it into a standard mortar mixer, add water of specified quality (12% of the total material), stir at 140±5r / min for 60s, and stir at 280±5r / min Stir at 10r / min for 30s, let stand for 90s, shovel the material on the pot wall into the pot, and then stir at 280±10r / min for 60s;

[0054] (3) Use the grouting material flow cone funnel to measure the initial, 30min, and 60min fluidity of the grouting material, put the evenly stirred grouting material into a 40*40*160 standard triple test mold evenly coated with butter, vibrate evenly, and wipe flat;

[0055] (4) Leave the mold at room temperature for 24 hours, put it into a standard constant temperature cur...

Embodiment 3

[0062] A method for preparing ecological cement high-strength grouting material, comprising the following steps:

[0063] (1) Accurately weigh the specified amount of cementitious material, aggregate and admixture according to the ratio in Table 5;

[0064](2) Mix the cementitious material, aggregate and admixture evenly, pour it into a standard mortar mixer, add water of specified quality (12% of the total material), stir at 140±5r / min for 60s, and stir at 280±5r / min Stir at 10r / min for 30s, let stand for 90s, shovel the material on the pot wall into the pot, and then stir at 280±10r / min for 60s;

[0065] (3) Use the grouting material flow cone funnel to measure the initial, 30min, and 60min fluidity of the grouting material, put the evenly stirred grouting material into a 40*40*160 standard triple test mold evenly coated with butter, vibrate evenly, and wipe flat;

[0066] (4) Leave the mold at room temperature for 24 hours, put it into a standard constant temperature curi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com