Fine coal powder recombustion denitrificating method

A fine coal powder and denitrification technology, which is applied in the field of boiler combustion, can solve the problems of unreachable NOx emissions, high construction and operation costs, and low denitrification efficiency, and achieve low NOx combustion, small installation and transformation workload, and high denitrification efficiency high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

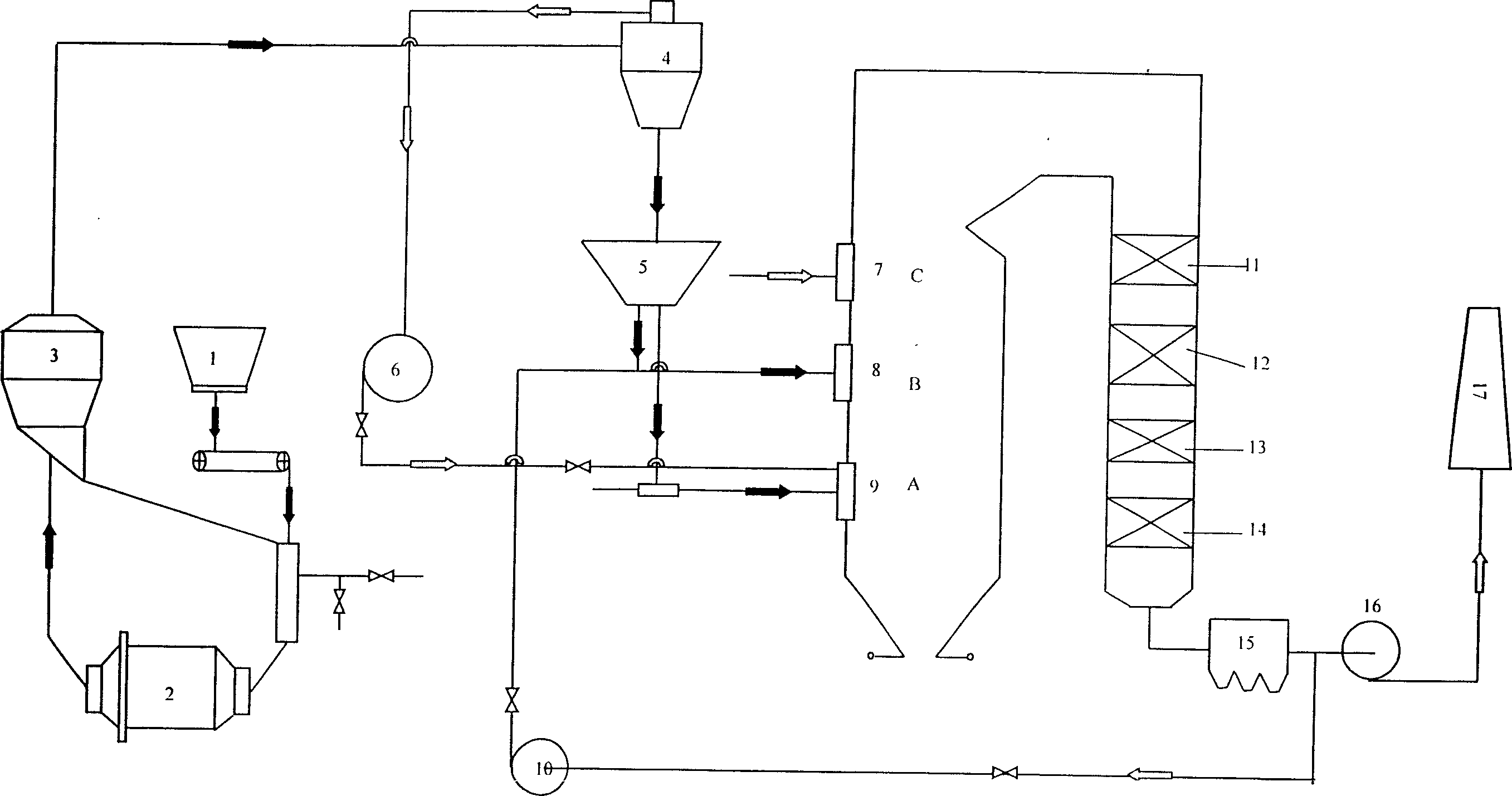

[0041] Such as figure 1 Shown is a schematic diagram of the structure and system of the coal burning device for realizing the present invention. The device adopts the method of denitrification by reburning fine coal powder. The device mainly includes a coal feeder 1, a coal mill 2, a coarse powder separator 3, a fine powder separator 4, a pulverized coal bin 5, a powder exhaust fan 6, a furnace smoke fan 10, economizers 11 and 13, and an air preheater. Heater 12 and 14, dust remover 15, induced draft fan 16 and connecting pipes between each equipment. The main combustion zone A of the pulverized coal furnace is equipped with a horizontal thick-lean burner 9, a reburning fuel nozzle 8 is installed in the reduction zone B, and an overburning air nozzle 7 is installed in the burnout zone C. The raw coal enters the coal mill 2 through the coal feeder 1, and after grinding, it enters the coarse powder separator 3 for coarse and fine separation. The qualified fine coal powder is c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com