Patents

Literature

82results about How to "Improve the effect of desulfurization and denitrification" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

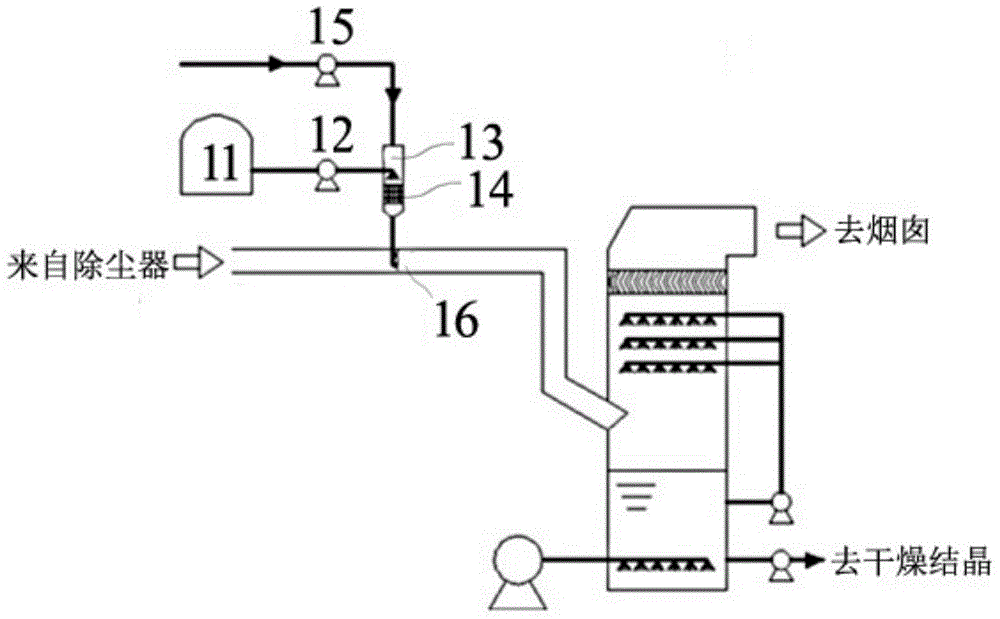

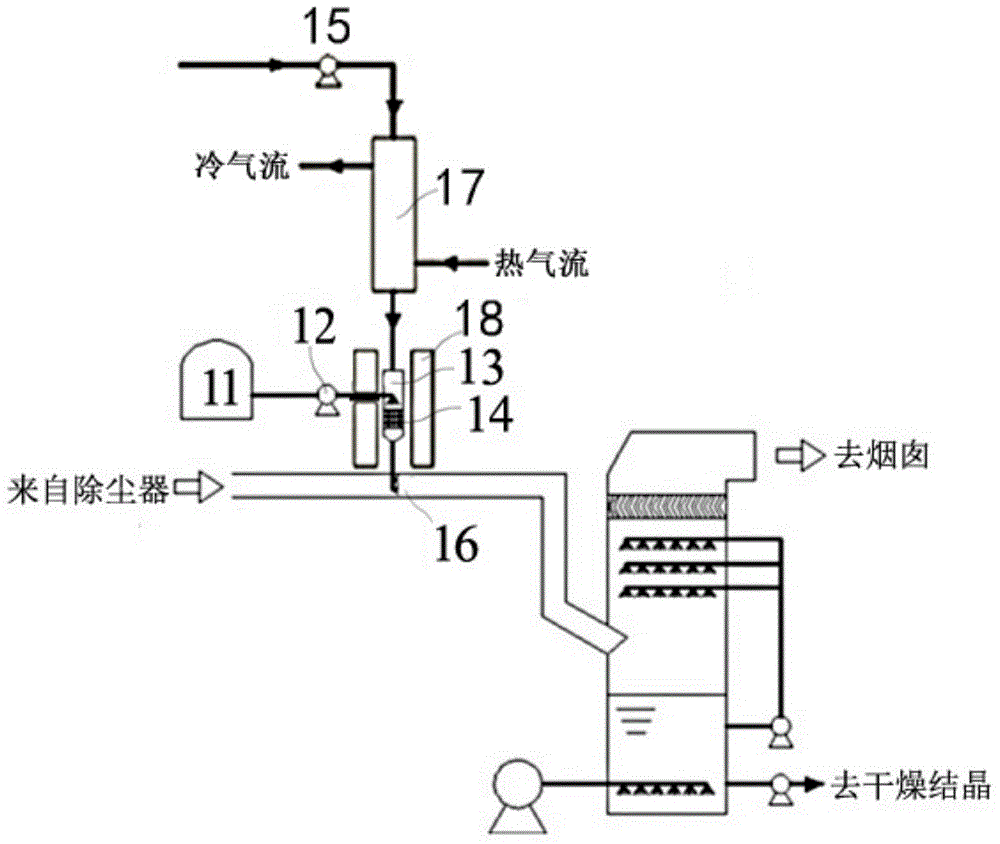

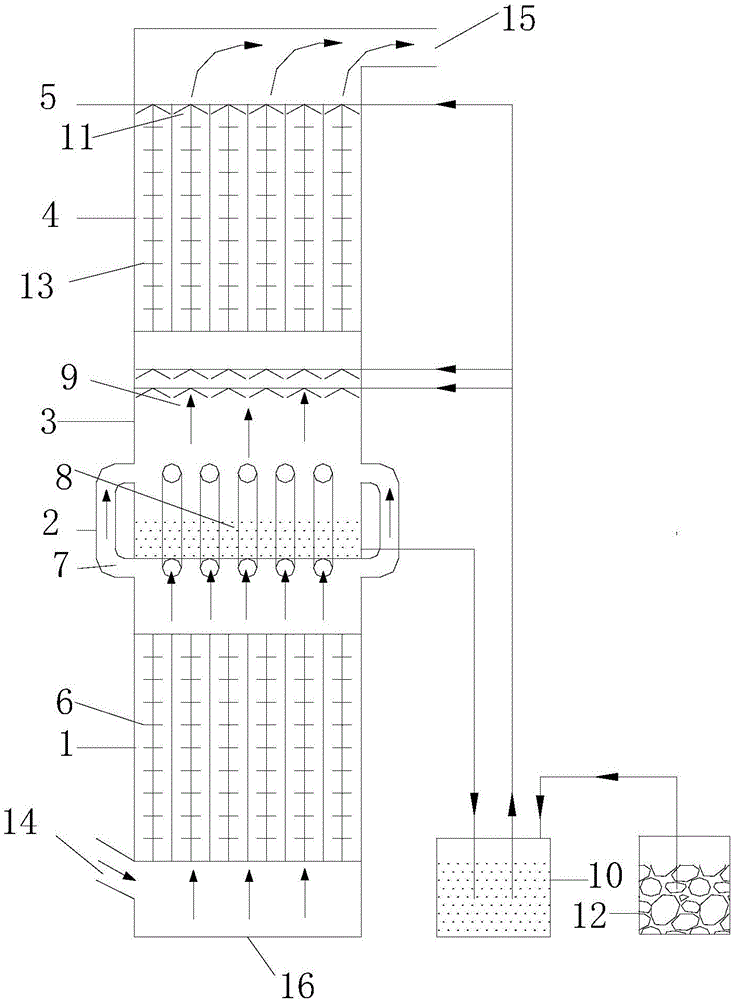

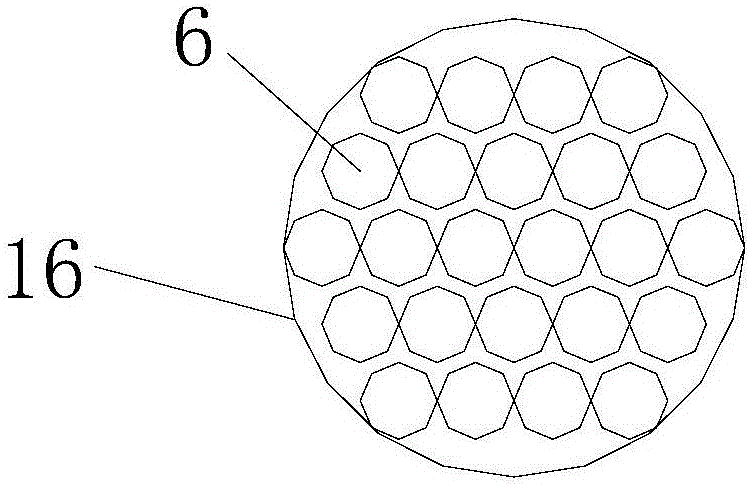

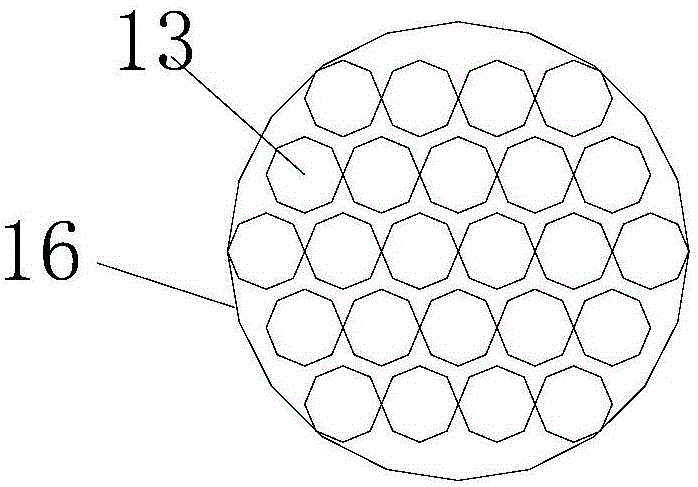

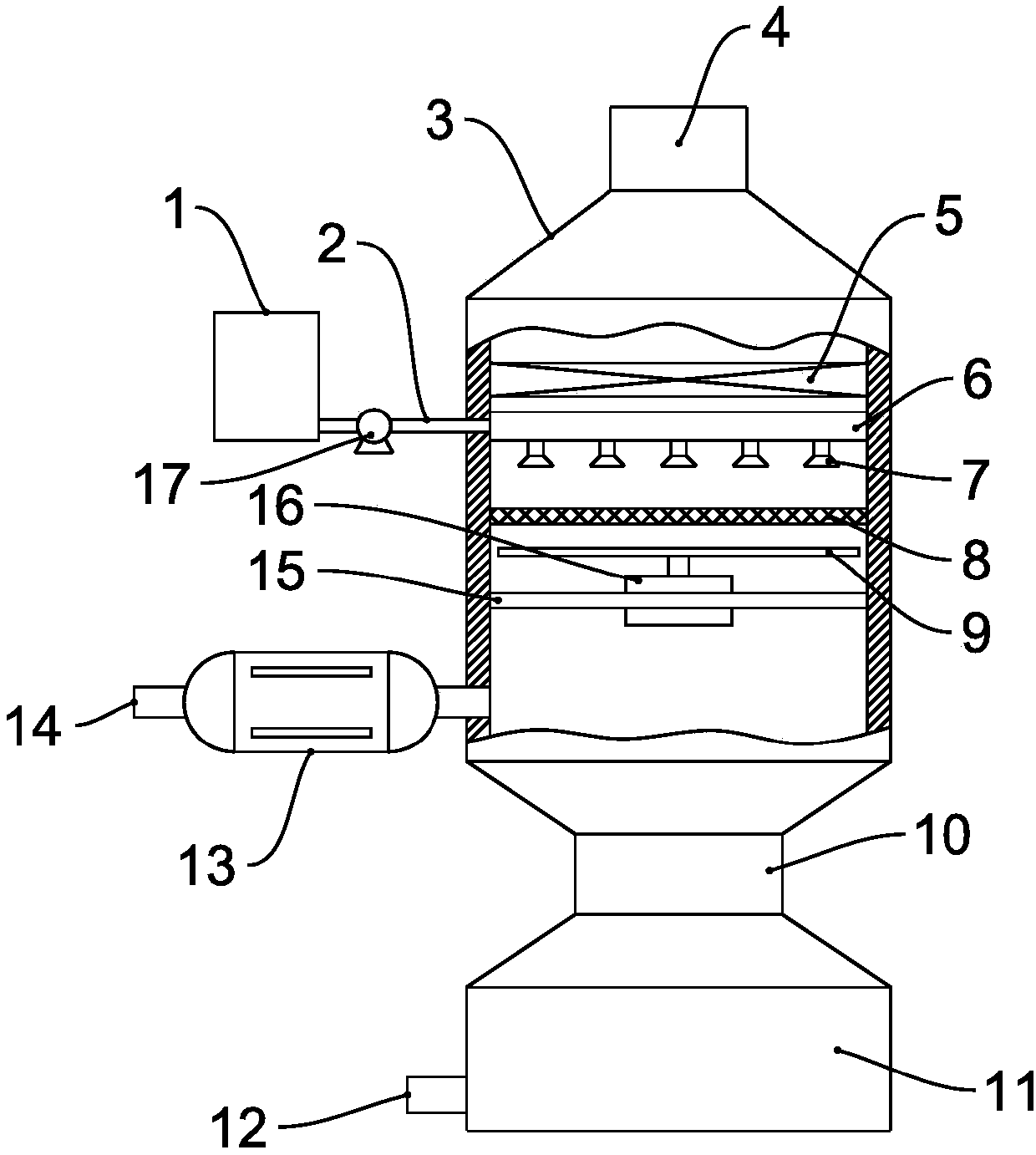

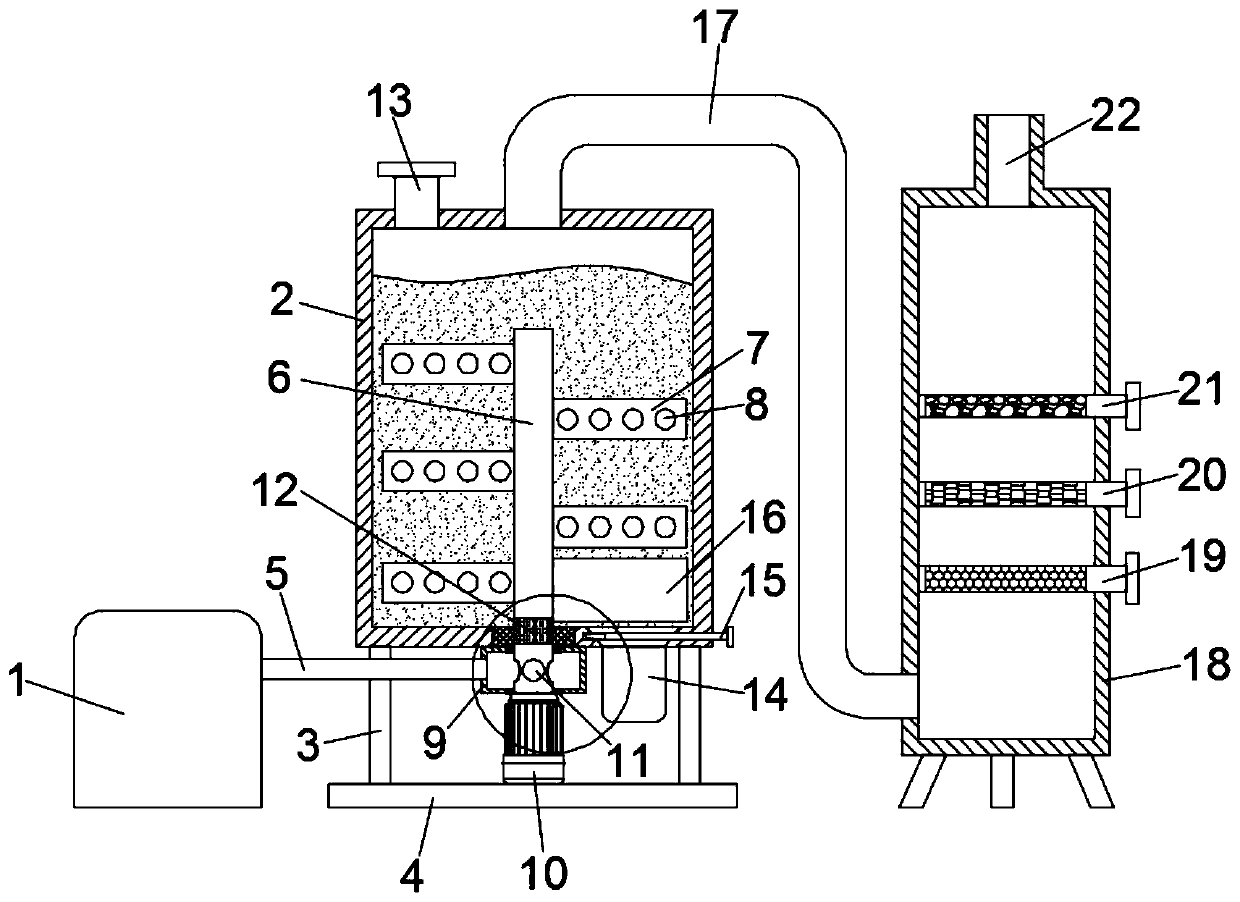

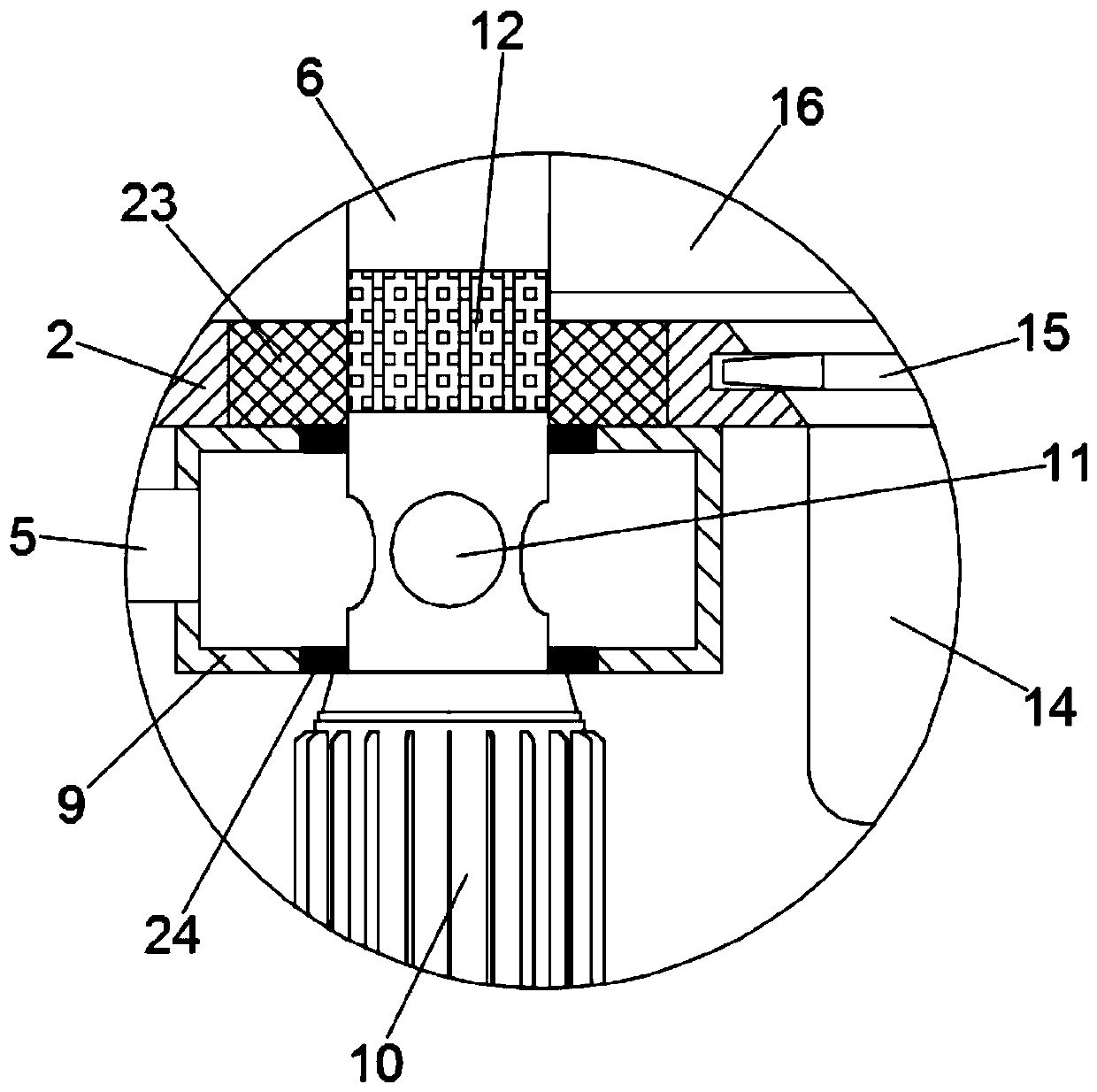

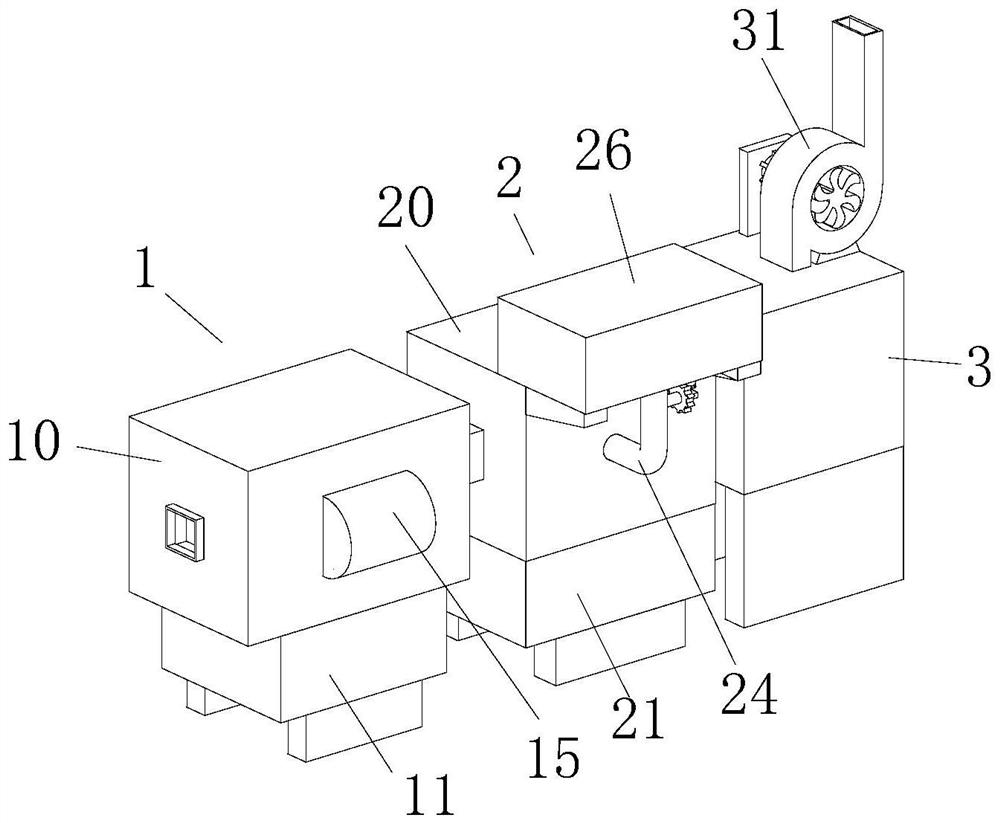

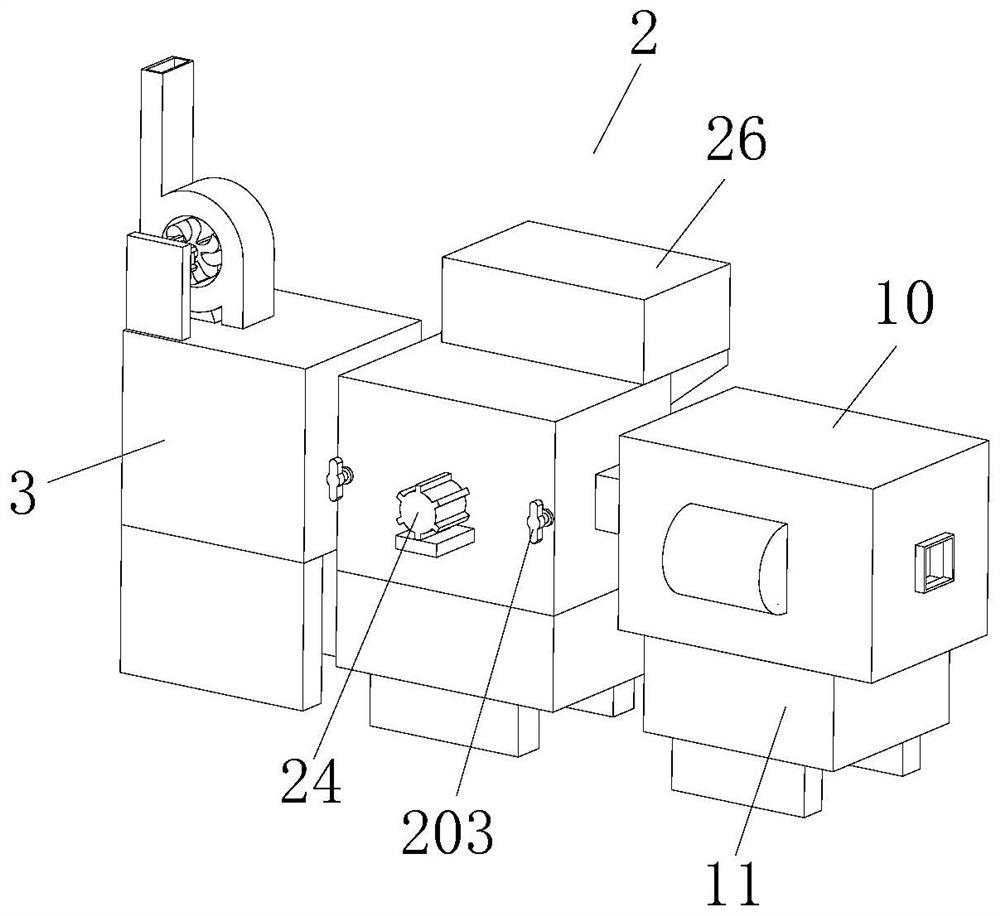

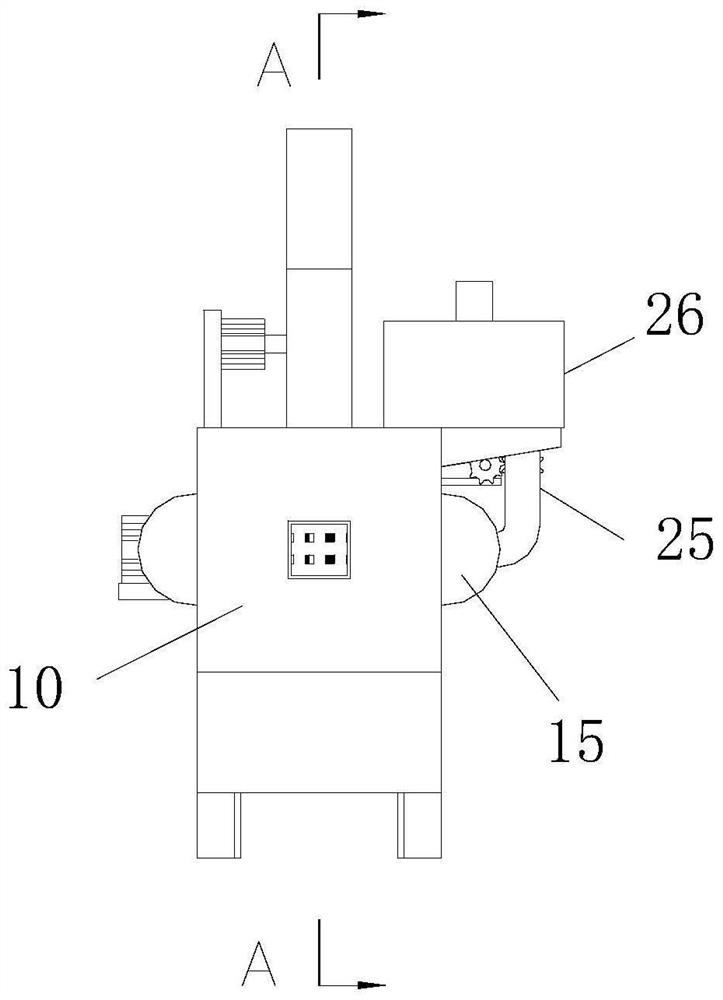

Integrated spray flue gas waste heat recovery and denitration device

InactiveCN104162357ALow flow resistanceFacilitate contact areaLighting and heating apparatusDispersed particle separationContact timeFlue gas

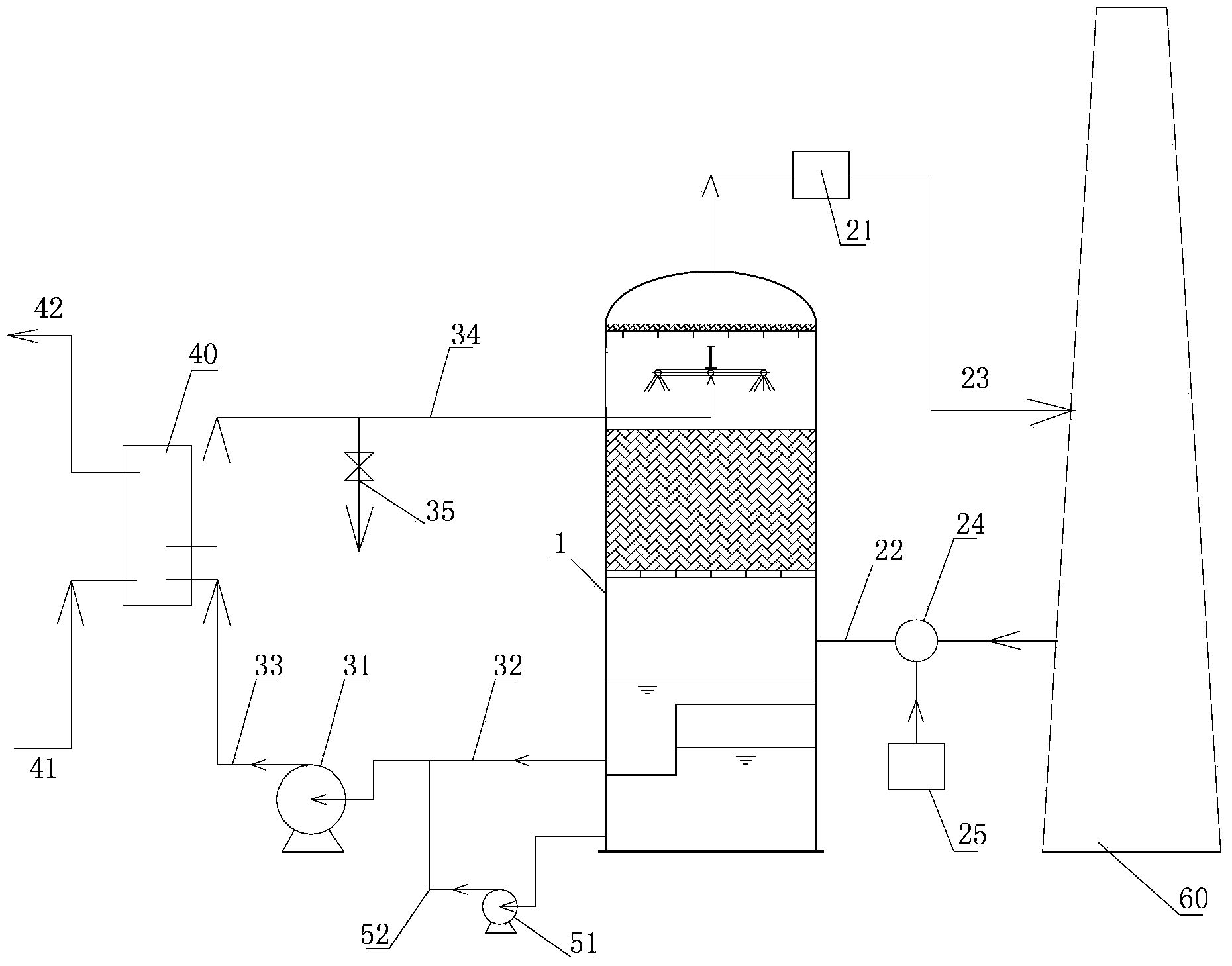

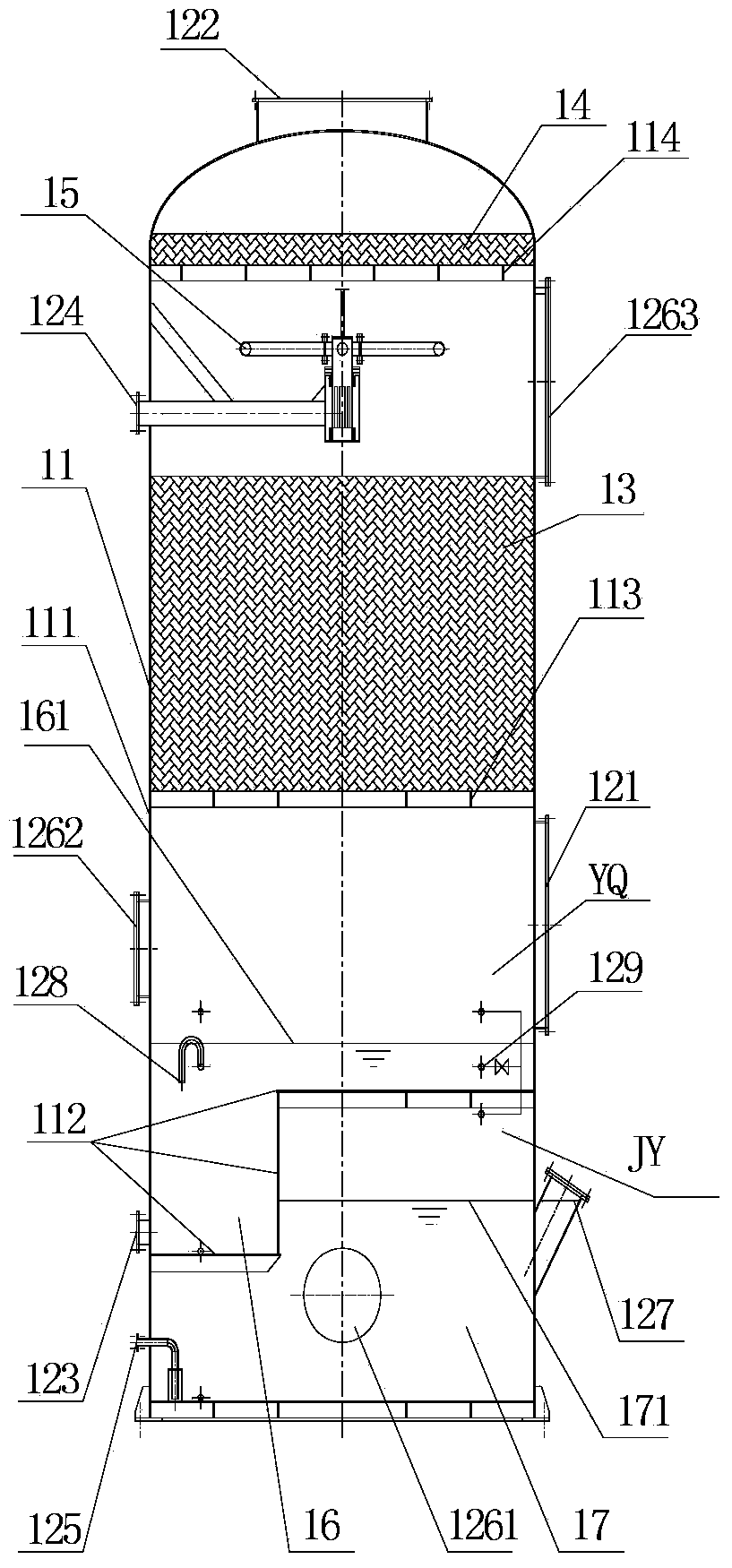

The invention provides an integrated spray flue gas waste heat recovery and denitration device. The device comprises a spray filler and alkali storage tower (1), a flue gas conveying and oxidization loop system, a spray conveying loop system, a heat energy utilization system and an alkalifying neutralization system, wherein the spray filler and alkali storage tower (1) comprises a spray filler and alkali storage tower main body structure part (11), a spray filler and alkali storage tower connector, filler (13), a dehydrator (14) and a spray component (15). According to the device, spray water is in contact with flue gas for heat exchange through the filler with a large specific surface area, the stable contact heat exchange area of gas and liquid phases is remarkably increased, the contact time of gas and liquid phases is remarkably prolonged and the uniformity of gas and liquid phases is remarkably improved, and the performance and the stability of gas liquid heat exchange are remarkably improved, so that the flue gas waste heat recovery efficiency and the denitration / desulfurization effect are remarkably improved.

Owner:BEIJING YUANSHEN ENERGY SAVING TECH

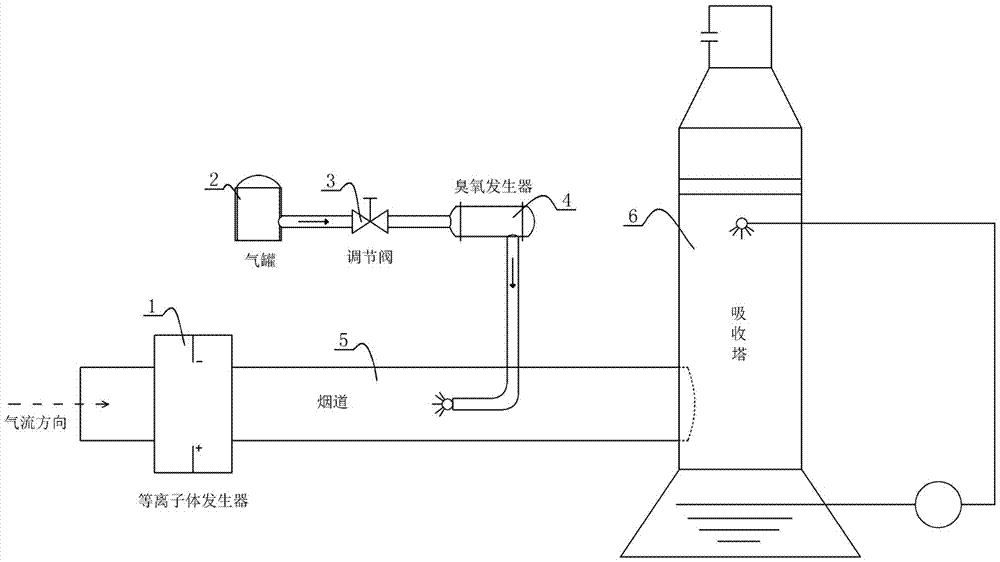

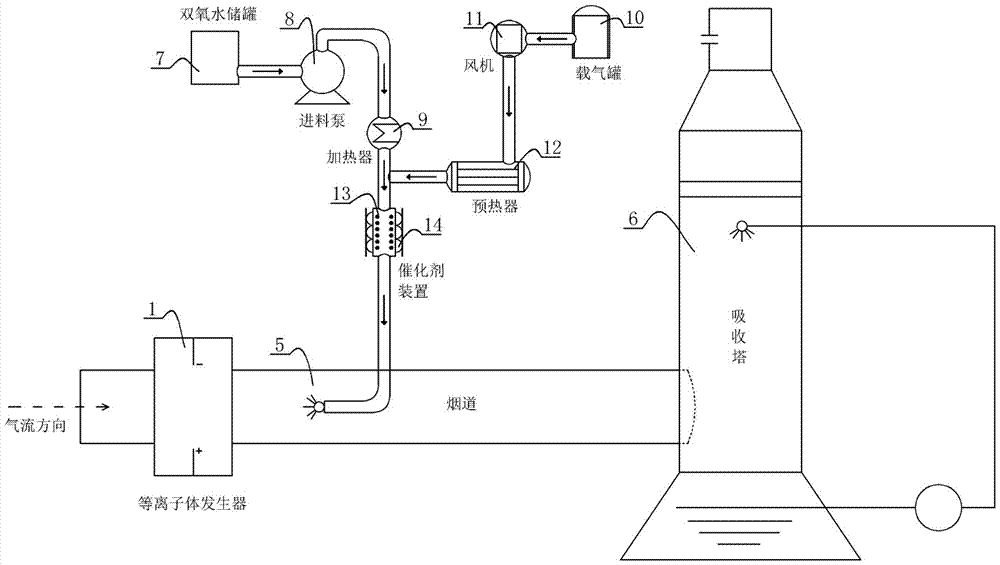

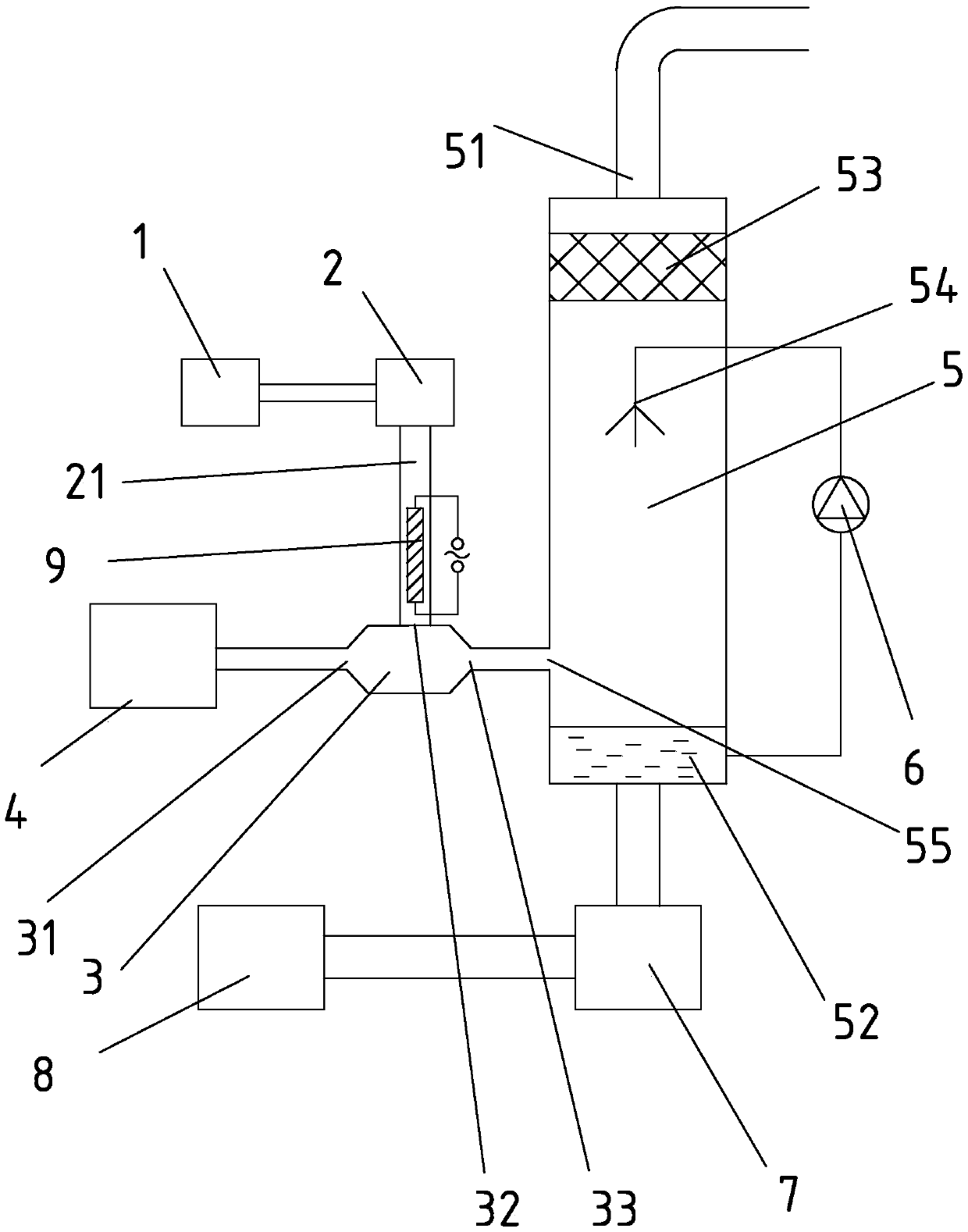

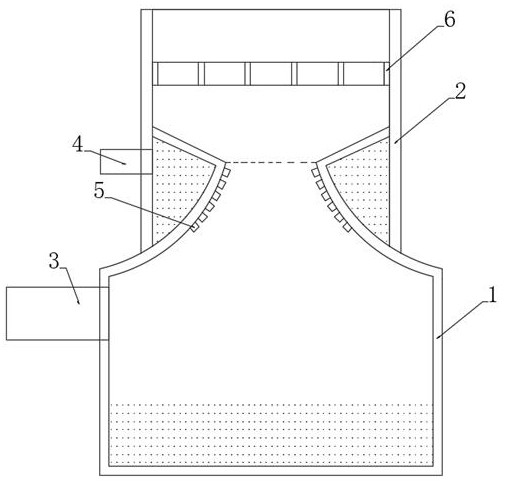

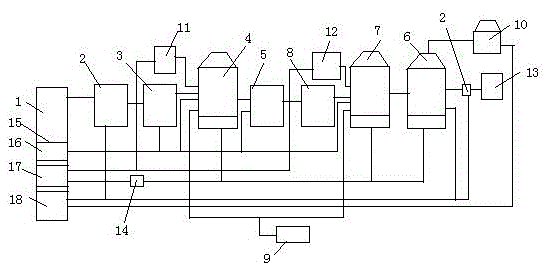

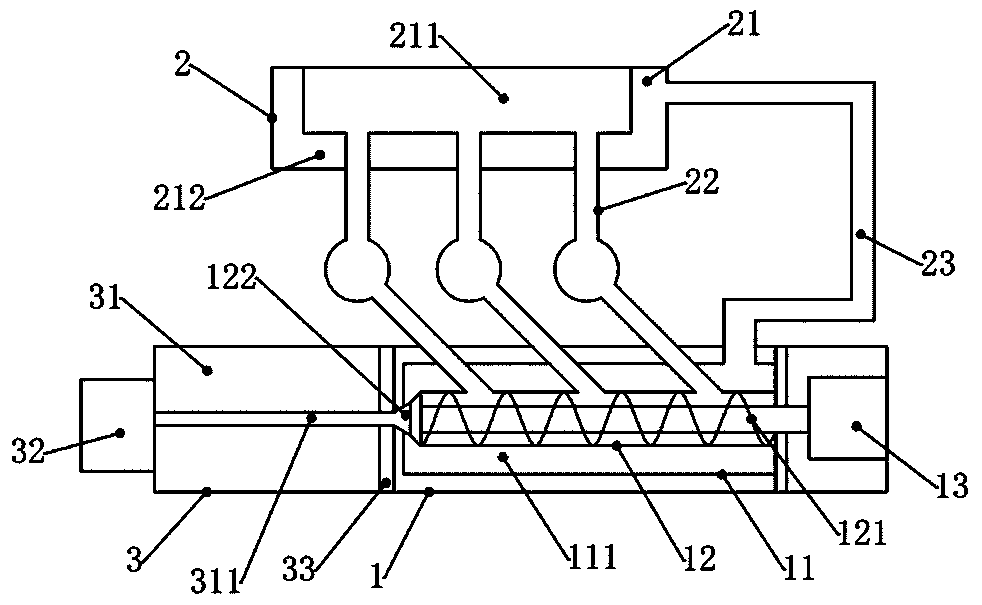

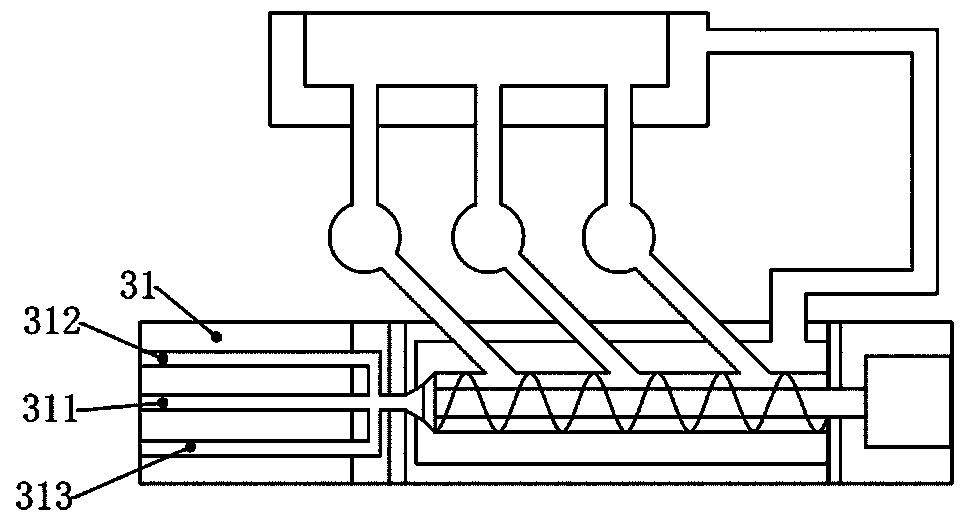

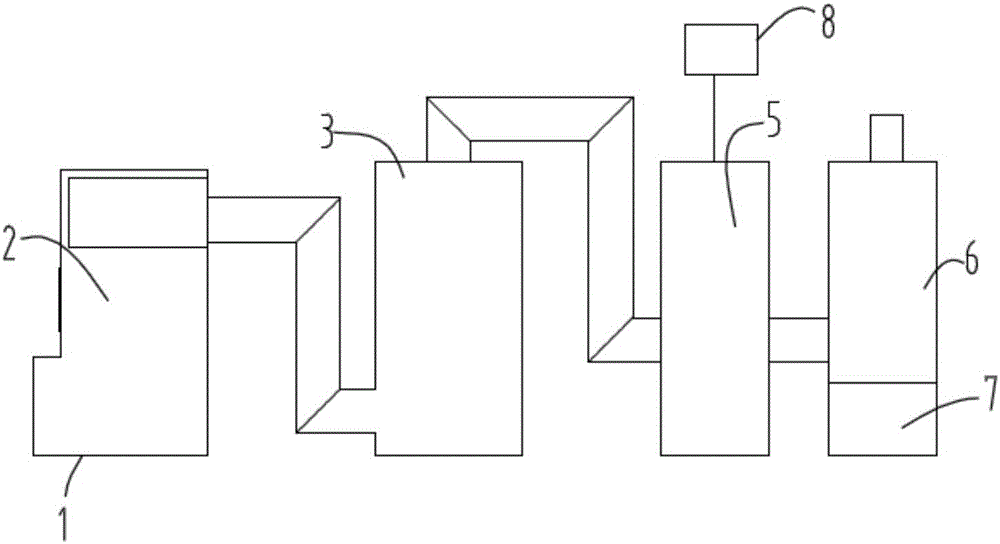

Pulse corona plasma reaction and absorption catalysis desulfurization denitration method and device

InactiveCN101422692AGood economic valueImprove the effect of desulfurization and denitrificationNitrous oxide captureDispersed particle separationFlue gasTower

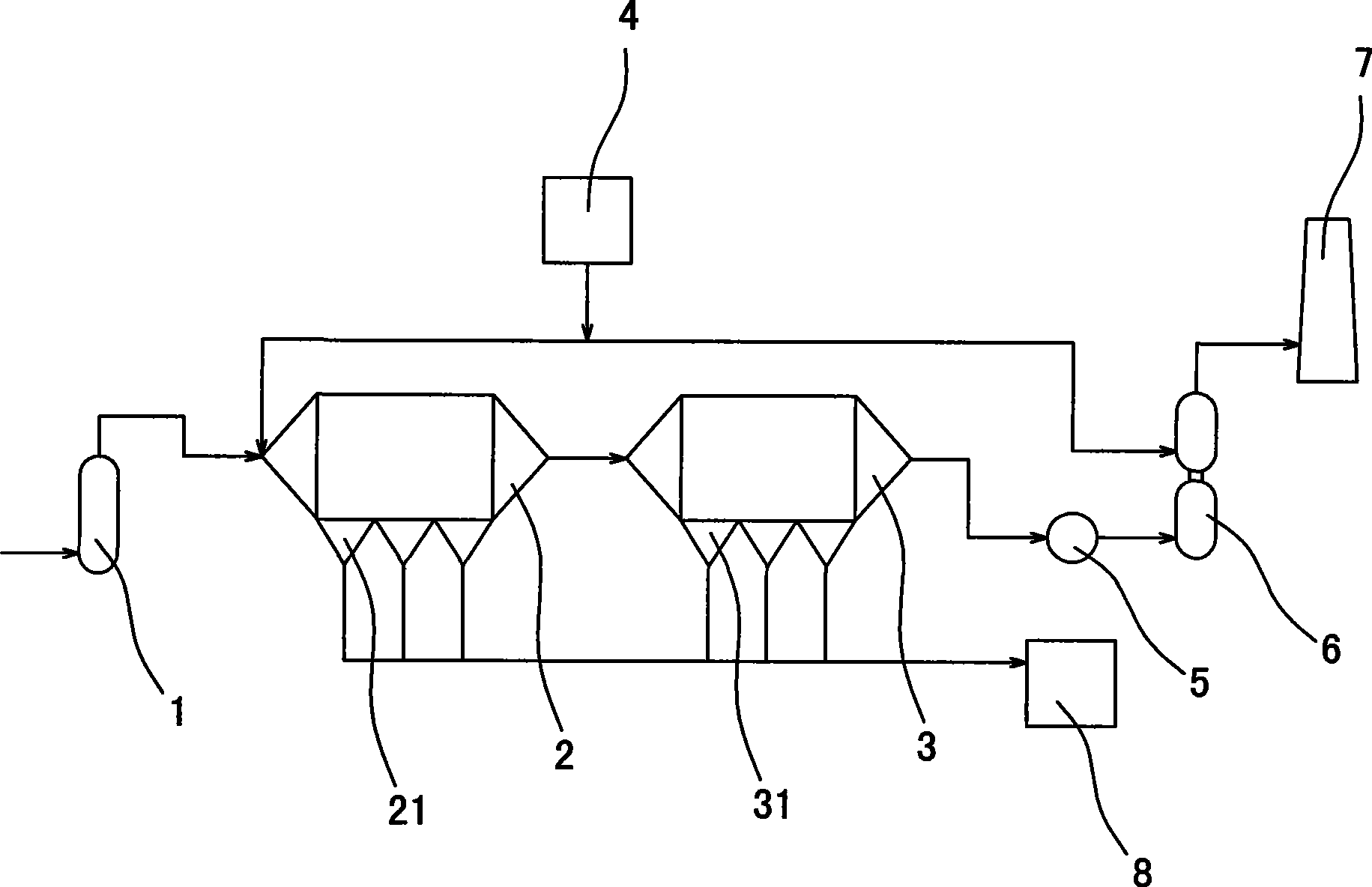

The invention discloses a desulfurization and denitration method of the reaction, adsorption and catalysis of pulse corona plasma. Flue gas enters a quenching and tempering tower (1); the flue gas after being regulated enters a plasma reactor (2); simultaneously, additive ammonia is added for the desulfurization and denitration; then the flue gas enters a material collector (3) to be collected; the flue gas discharged from the material collector (3) is preheated; and then the flue gas enters an adsorption and catalysis system (6) for the adsorption and catalysis, desulfurization and denitration. The device using the method comprises the quenching and tempering tower (1), the plasma reactor (2), the material collector (3) and an ammonia supplying system (4); the device also comprises a pre-heater (5) and the adsorption and catalysis system (6); and the pre-heater (5) is communicated with an air outlet of the material collector (3) and an air inlet of the adsorption and catalysis system (6). The desulfurization and denitration method of the reaction, adsorption and catalysis of pulse corona plasma enhances the threshing performance without secondary pollution, has simple structure and less investment, and can greatly enhance the capability of domestic dry desulfurization and denitration method of the reaction, adsorption and catalysis of pulse corona plasma.

Owner:袁宝春

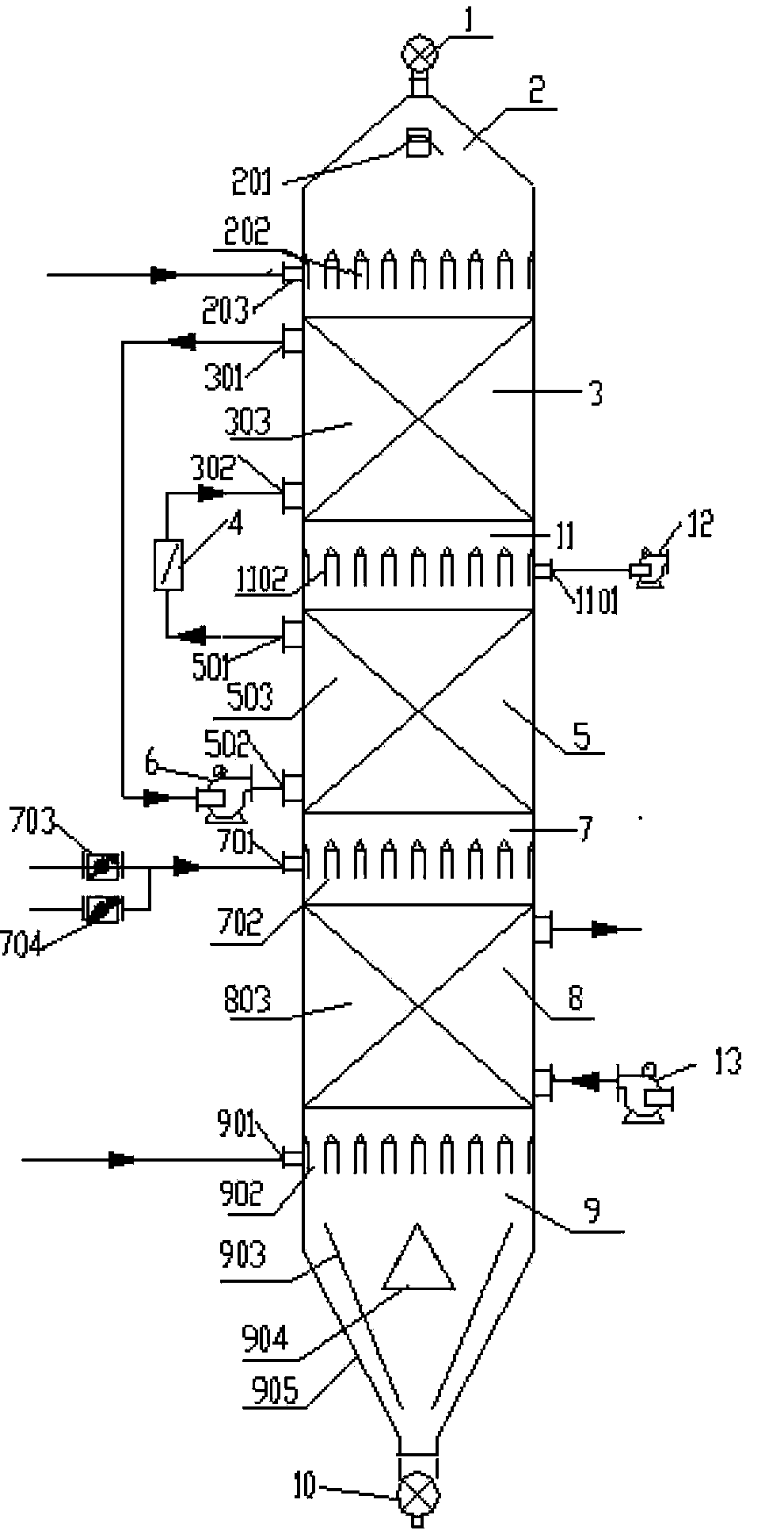

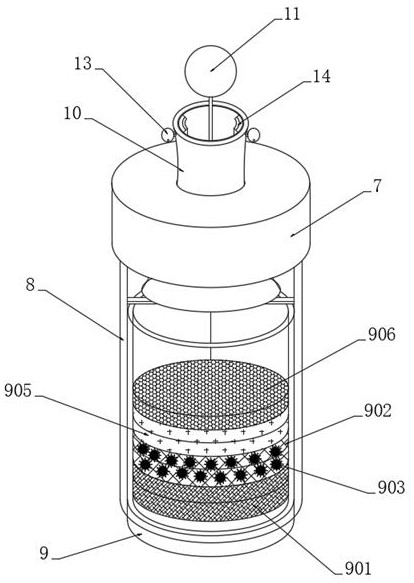

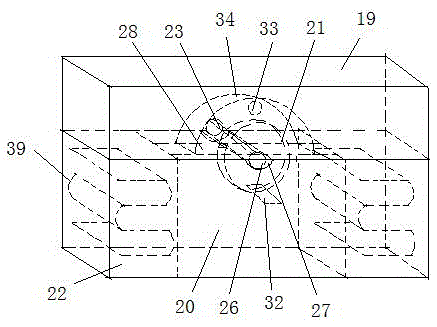

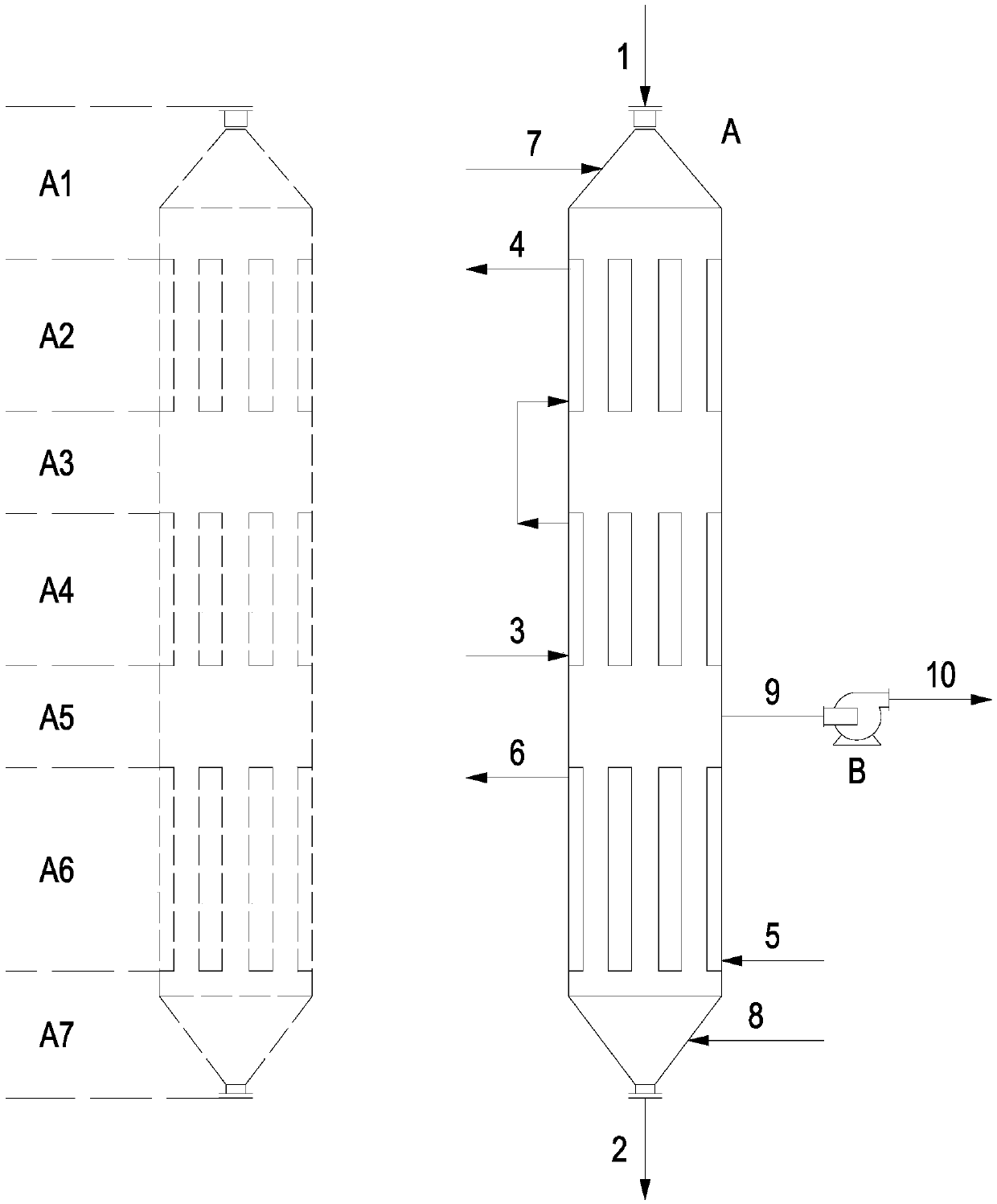

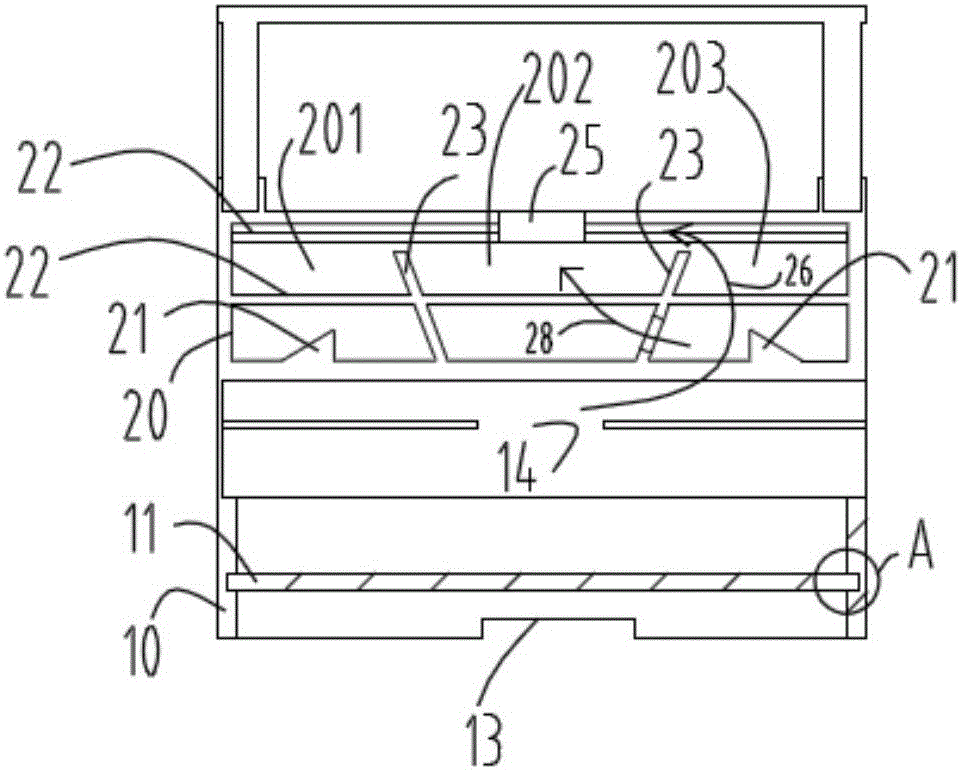

Regenerative device and method for desulfurized and denitrified active coke

ActiveCN103418360ARealize online modificationImprove the effect of desulfurization and denitrificationOther chemical processesDispersed particle separationBlocked valvesProcess engineering

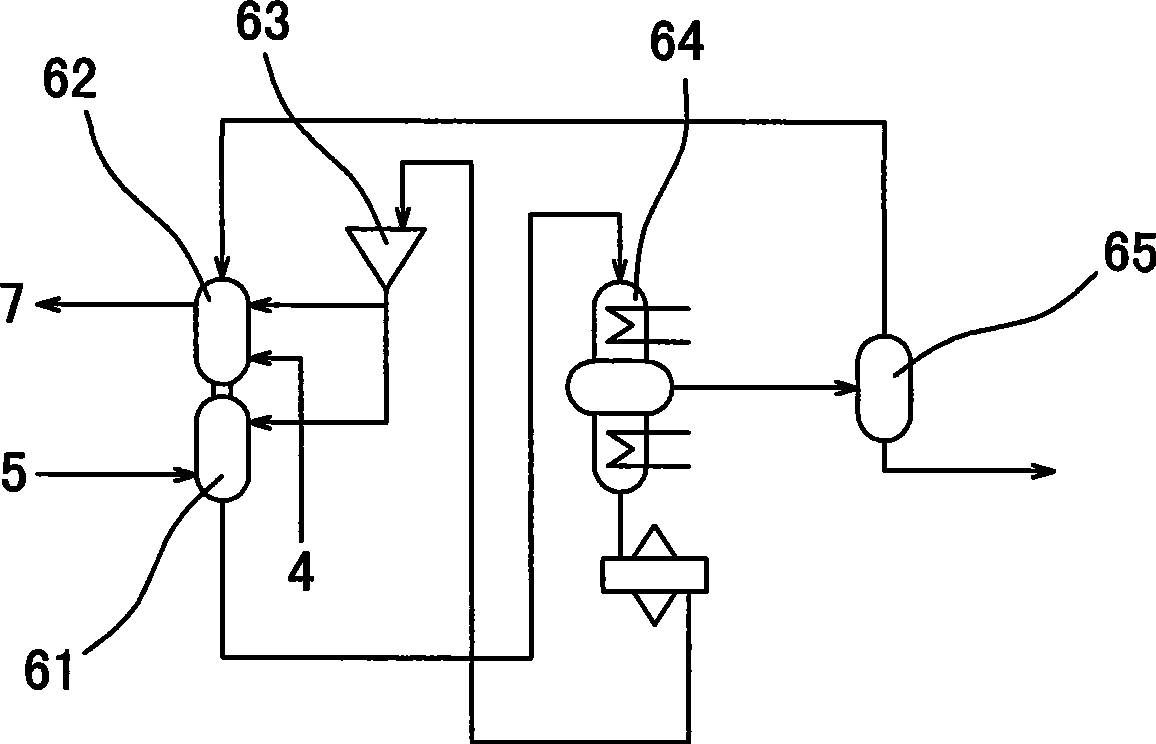

The invention discloses a regenerative device and method for desulfurized and denitrified active coke. The regenerative device comprises a regenerative reactor, wherein the regenerative reactor is composed by the connection of an inlet blocking valve, a feeding bin, a heating bin, a regenerative bin, a precooling bin, a cooling bin, a discharging bin, and an outlet blocking valve in sequence; a heating heat exchanger component is arranged in the heating bin; a precooling heat exchanger component is arranged in the precooling bin; a cooling heat exchanger component is arranged in the cooling bin; a nitrogen carrying bin for inletting ammonia nitrogen gas to improve the desulfurization and denitrification performances of regenerated active coke during regeneration process is arranged between the precooling bin and the cooling bin. The regenerative method adopts the regenerative device to conduct the regeneration of the active coke. According to the invention, more reasonable utilization of energy can be realized in the regeneration process to allow the desulfurization and denitrification performance of the regenerated active coke to obtain further improvement; on-line modification can be conducted on the active coke through the nitrogen carrying bin to keep high desulfurization and denitrification performance of the active coke.

Owner:SHANGHAI CLEAR ENVIRONMENTAL PROTECTION SCI & TECH

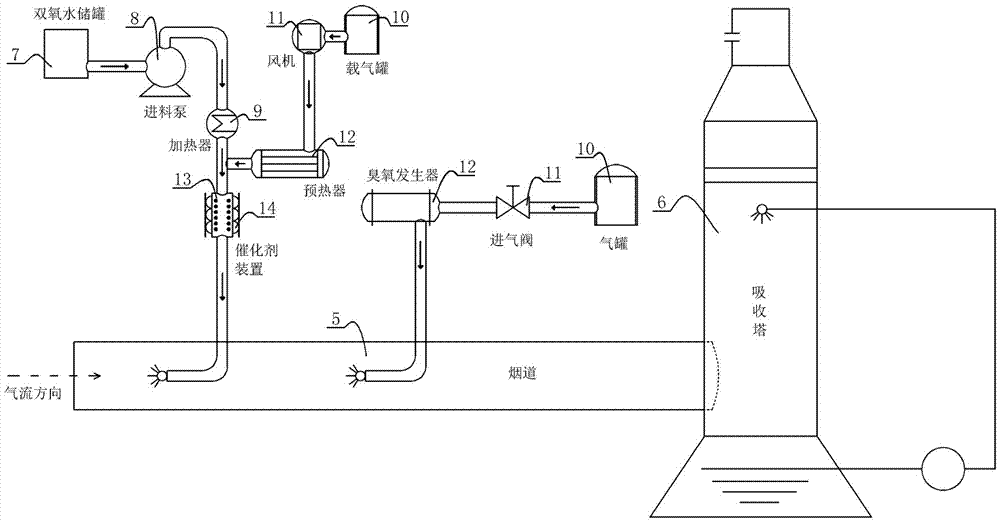

Desulphurization-denitration integrated method and apparatus for low temperature flue gas

ActiveCN106853327AImprove removal efficiencyReduce desulfurization and denitration operating costsGas treatmentDispersed particle separationFlue gasEngineering

The invention provides a desulphurization-denitration integrated method for low temperature flue gas. Two or three apparatuses selected from a group consisting of a plasma desulphurization-denitration apparatus, a hydrogen-peroxide catalytic-activation desulphurization-denitration apparatus and an ozone oxidation desulphurization-denitration apparatus are integrated onto a to-be-treated flue. In a scheme which employs the plasma desulphurization-denitration apparatus, the plasma desulphurization-denitration apparatus is arranged at the forefront of the flue; and in the condition that the hydrogen-peroxide catalytic-activation desulphurization-denitration apparatus and the ozone oxidation desulphurization-denitration apparatus both exist, the hydrogen-peroxide catalytic-activation desulphurization-denitration apparatus is located at the front end. According to the method provided by the invention, two or three technologies selected from a group consisting of a plasma desulphurization-denitration technology, a H2O2 catalytic-activation desulphurization-denitration technology and an ozone advanced-oxidation desulphurization-denitration technology are applied in one scheme, and the three desulphurization-denitration technologies can be cooperated and adjusted according different conditions of flue gas, so the removal efficiency of NOx is improved, and desulphurization-denitration operation cost is reduced.

Owner:UNIV OF JINAN

Desulphurization and denitration device and method

InactiveCN104941431AHigh removal rateReduce injection volumeDispersed particle separationAir quality improvementReaction layerSlurry

The invention discloses a desulphurization and denitration device and method. The desulphurization and denitration device comprises desulphurization and denitration equipment, slurry cyclic delivery equipment and hydrogen peroxide supplement equipment. A spraying and absorption zone, a hydrogen peroxide spray oxidation reaction layer and a slurry storage zone are arranged in the desulphurization and denitration equipment. The hydrogen peroxide spray oxidation reaction layer is arranged in the spraying and absorption zone. The device and method realize combination of magnesium desulfurization and hydrogen peroxide oxidation denitration, improve an arrangement position of a hydrogen peroxide spray oxidation reaction layer in the existing device, provide the optimal hydrogen peroxide excitation conditions, improve nitrogen oxide and sulfur dioxide remove rates, reduce a H2O2 injection amount, save a cost, and prevent an explosion risk caused by superfluous H2O2 and a high temperature. Compared with the existing device and method, the device and method simplify equipment and greatly reduce desulphurization and denitration early stage construction investment, floor space and operation cost.

Owner:ZHONGJING ENVIRONMENTAL TECH CO LTD

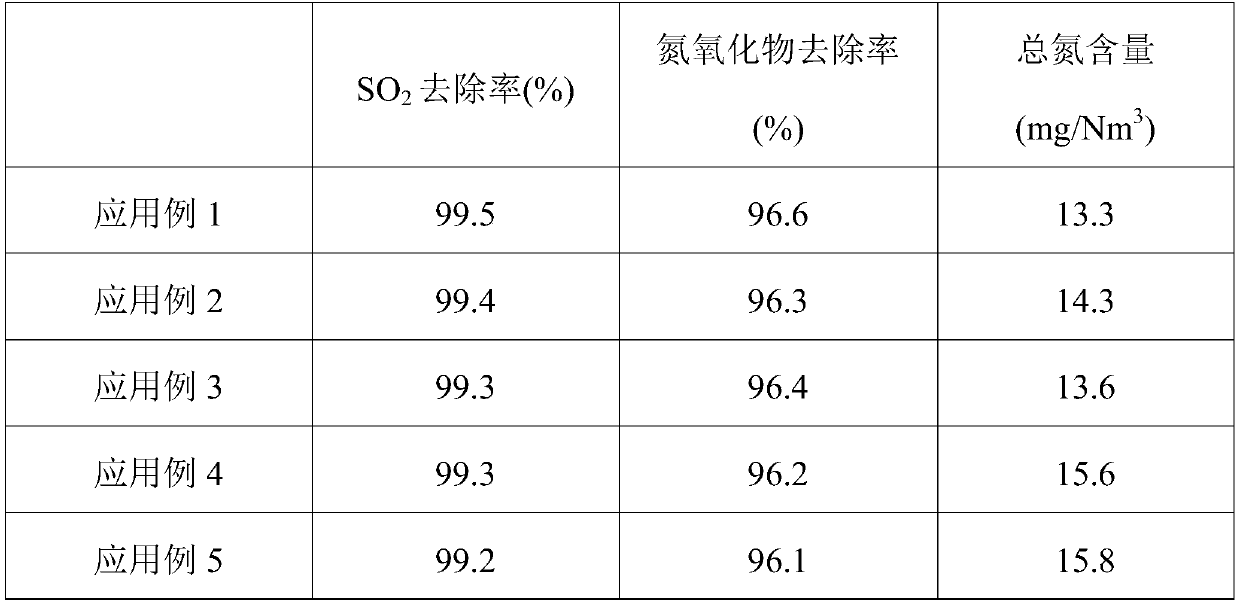

Integrated flue gas desulfurization and denitrification agent and application method thereof

ActiveCN106731783AImprove out-of-stock efficiencyIncrease chance of contactGas treatmentDispersed particle separationChemistryFlue gas

The invention relates to an integrated flue gas desulfurization and denitrification agent and an application method thereof. The invention is characterized in that the flue gas desulfurization and denitrification agent comprises the following ingredients: a desulfurizing agent, an iron-based denitration catalyst, an activator and a suspending agent. By using an alkaline substance as a desulfurizing agent, using the desulfurization product sulfite as a reducing agent and using the iron-based denitration catalyst as an active reaction factor, simultaneous removal of sulfur dioxide and nitrogen oxide in flue gas is realized in a the gas-liquid-solid three-phase homogenization suspension state, wherein NOx is reduced into nitrogen; and a reacted absorption liquid is activated by the use of an acid solution and a suspending agent is supplemented and then the mixture is sent by a circulating pump into a reaction tower for recycling. The method is simple to operate. By the method, desulphurization efficiency is 99% and above, denitration efficiency is 90% and above, and the desulfurization and denitrification effect is good. The materials are recycled, thus greatly reducing the operating cost of desulfurization and denitrification. The product has obvious economic advantages and can be used for treatment of flue gas or tail gas of various industrial boilers and industrial furnaces.

Owner:GUIZHOU BRANCH CHINA ALUMINUM IND

Multilevel plasma ultralow intensified smoke emission control system and multilevel plasma ultralow intensified smoke emission control method

InactiveCN106390701AImprove oxidation effectDirect addition of oxidizing agent is effectiveGas treatmentUsing liquid separation agentEmission standardPlasma generator

The invention discloses a multilevel plasma ultralow intensified smoke emission control system and a multilevel plasma ultralow intensified smoke emission control method. The multilevel plasma ultralow intensified smoke emission control system comprises a reaction tower with a smoke inlet and a smoke outlet, the reaction tower is internally separated into a plasma dry oxidization section, a smoke path switching section, a spraying absorption section and a plasma oxidization absorption section, the smoke inlet is formed below the plasma dry oxidization section, a corona discharge plasma generator is arranged in each of the plasma dry oxidization section and the plasma oxidization absorption section, a pole plate sprayer is arranged above the plasma oxidization absorption section, a liquid collection device for stopping smoke from passing through is arranged in the smoke path switching section and is externally connected with a liquid cycling tank, a smoke lifting device allowing the smoke to pass through is arranged on the outer side of the smoke path switching section, and the spraying absorption section is provided with a spraying absorption layer. The multilevel plasma ultralow intensified smoke emission control system and the multilevel plasma ultralow intensified smoke emission control method have the advantages that NO (nitric oxide) can be oxidized to NO2 (nitrogen dioxide), SO2 (sulfur dioxide), the NO2 and dust in the smoke can be absorbed totally and then held in a desulfurization and denitration dedusting liquid tank, and finally the outlet smoke can reach an ultralow emission standard.

Owner:ZHEJIANG FUCHUNJIANG ENVIRONMENTAL THERMOELECTRIC CO LTD +1

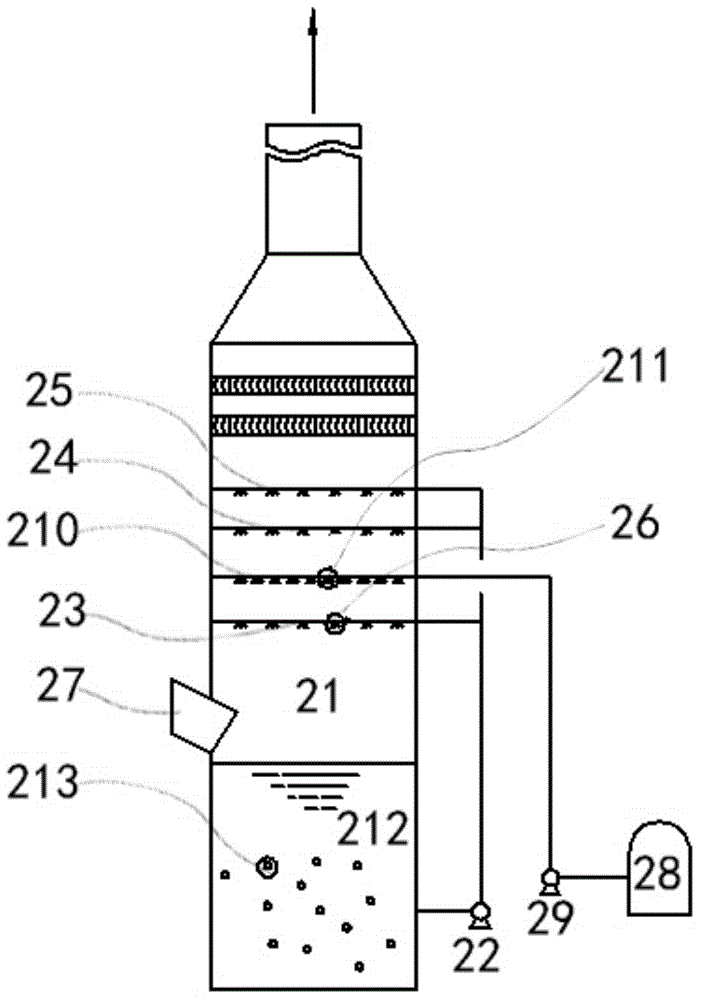

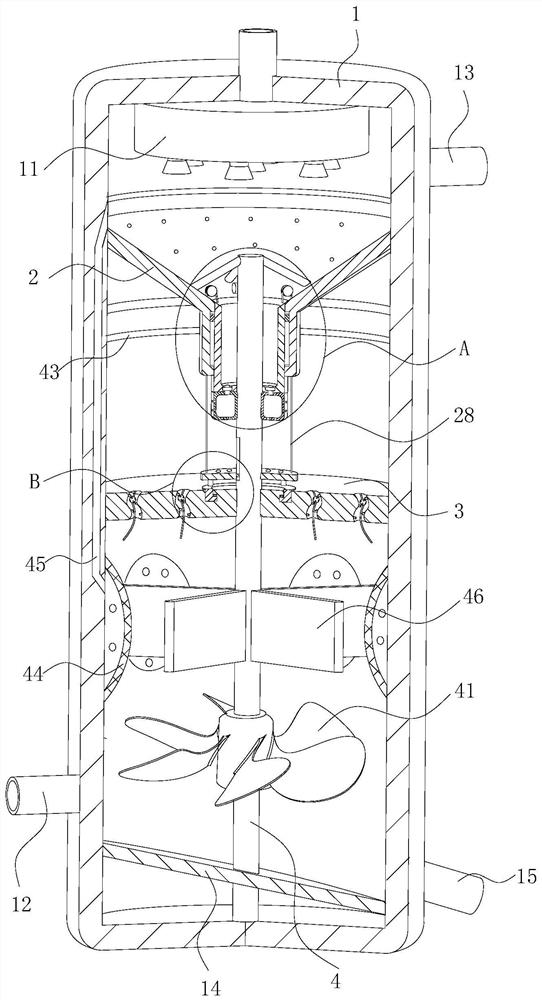

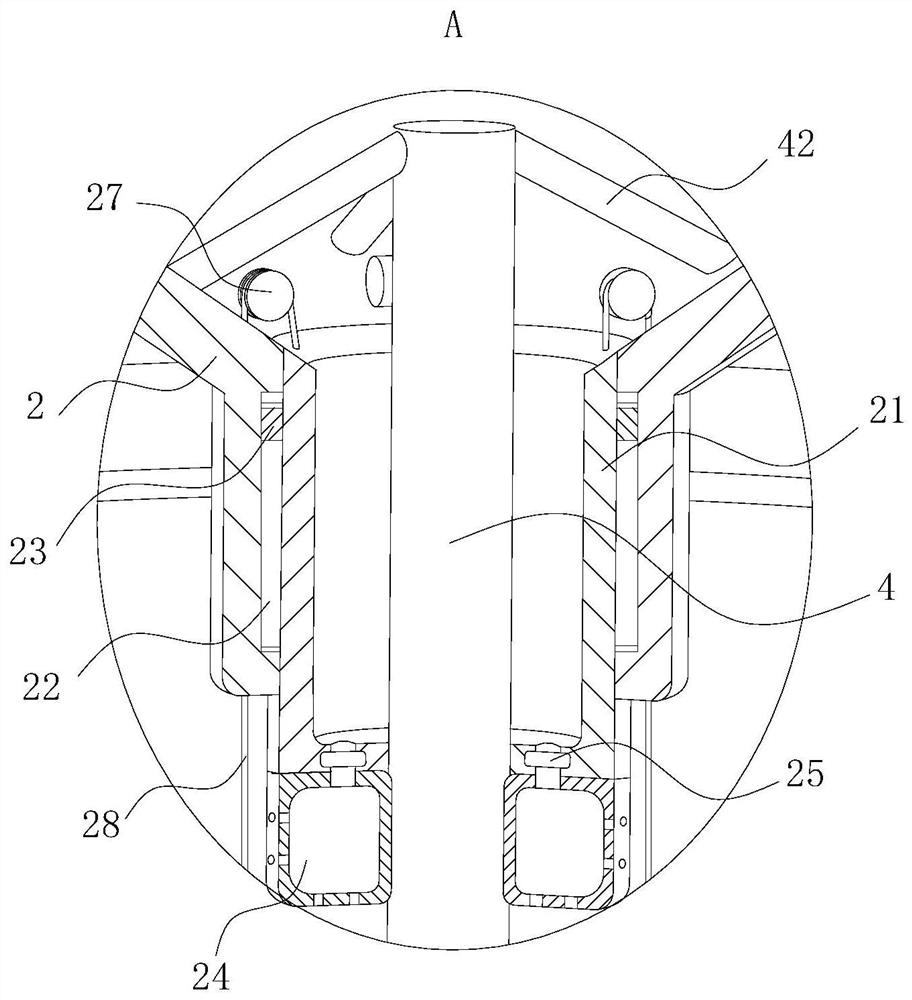

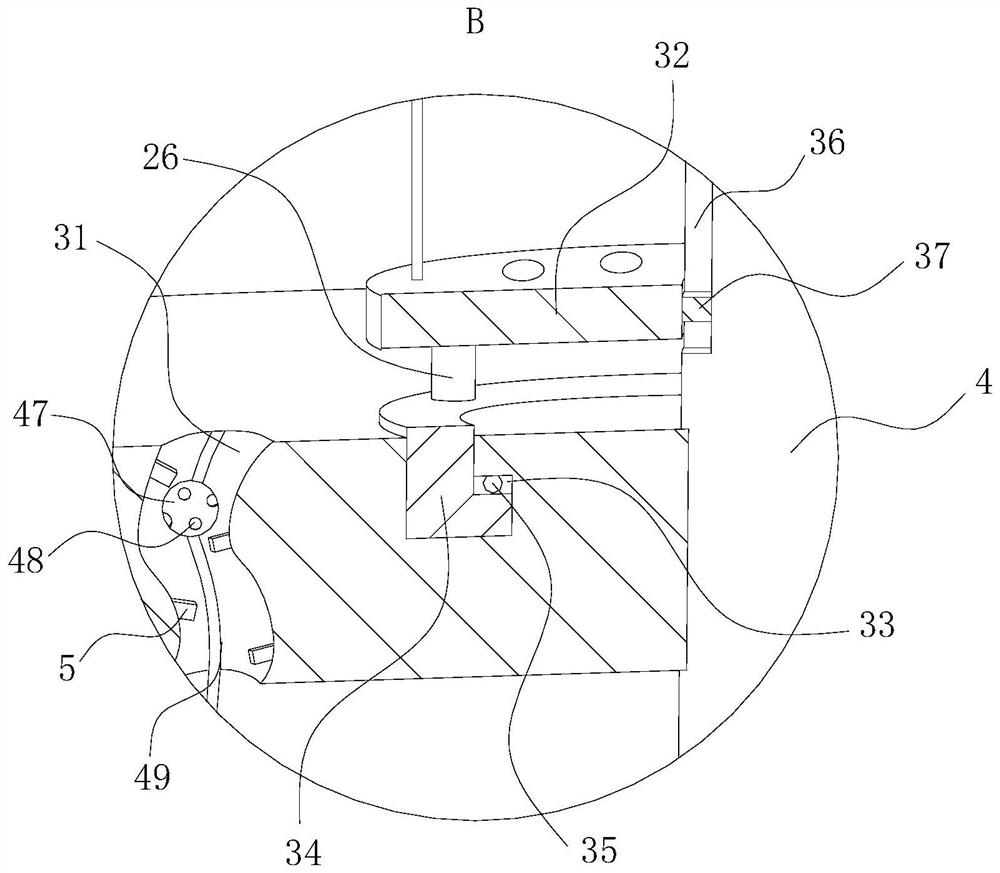

Chemical waste gas integrated treatment device

InactiveCN107670443AImprove dust removalImprove the effect of desulfurization and denitrificationCombination devicesGas treatmentElectrostatic precipitatorAqueous solution

The invention discloses a chemical waste gas integrated treatment device, comprising a desulfurization and denitrification dedusting box; the bottom of the desulfurization and denitrification dedusting box is connected with a setting tank through a communicating pipe, a demister is arranged on the upper side of the interior of the desulfurization and denitrification dedusting box, and a liquid distribution device is arranged on the lower side of the demister and is provided with a liquid inlet tube; the liquid inlet tube is provided with a booster pump, and the other end of the liquid inlet tube is connected with a desulfurization aqueous solution tank; a plurality of atomizers are installed on the lower side of the liquid distribution device, and a silk screen is arranged on the lower side of the liquid distribution device; a variable frequency motor is installed on the middle part of a motor rack at the lower side of the silk screen, a baffle plate is installed on the upper side output shaft of the variable frequency motor, a flue gas inlet pipe is also arranged on the lower part of the left side of the desulfurization and denitrification dedusting box and is provided with a wetelectrostatic precipitator. The chemical waste gas integrated treatment device is simple in structure, low in manufacture and running cost, good in flue gas desulfurization and denitrification effect,high in efficiency and easy to popularize.

Owner:龙里县逸轩生产力促进中心

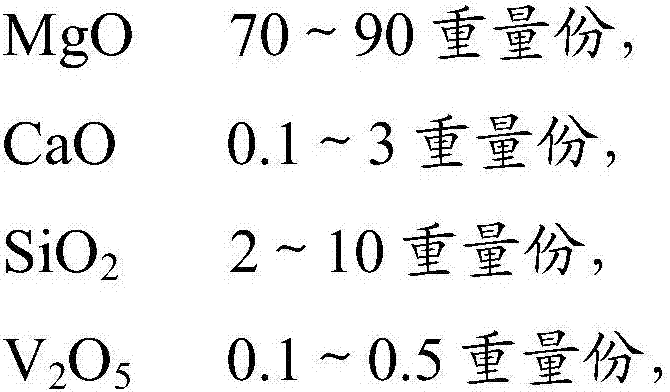

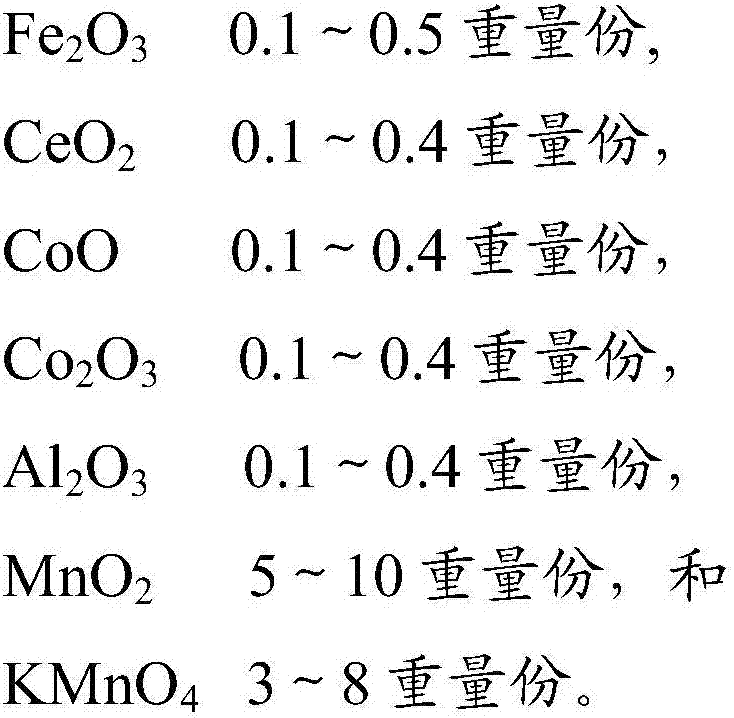

Desulfurization denitrification agent for flue gas, production method and application thereof

InactiveCN107485990AImprove removal efficiencyImprove removal rateGas treatmentDispersed particle separationFlue gasDenitrification

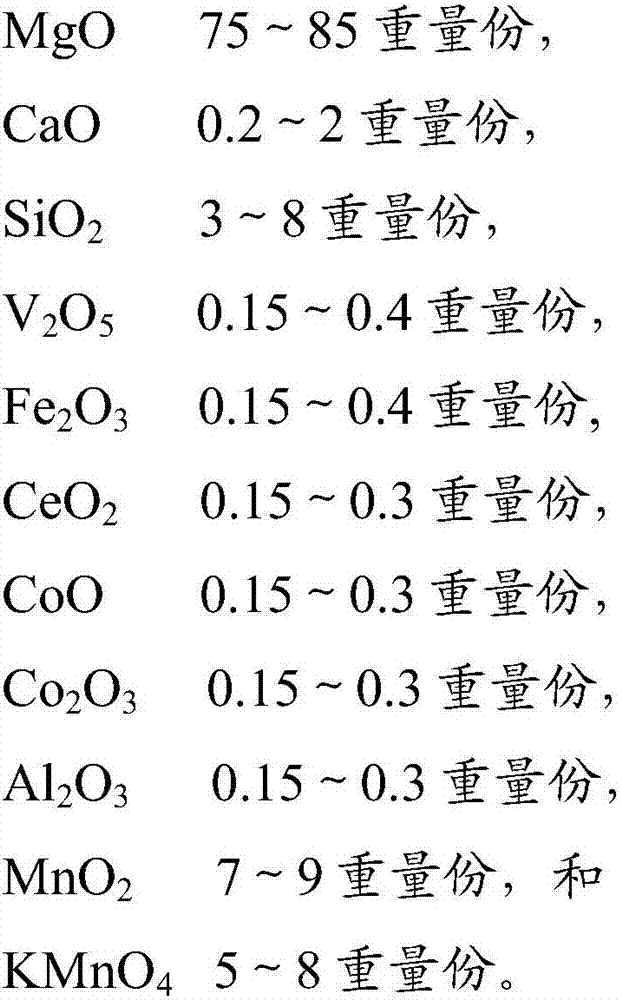

The invention discloses a desulfurization denitrification agent for flue gas, a production method and an application thereof. On the basis of 100 parts by weight, the desulfurization denitrification agent contains the following components: 70-90 parts of MgO, 0.1-3 parts of CaO, 2-10 parts of SiO2, 0.1-0.5 part of V2O5, 0.1-0.5 part of Fe2O3, 0.1-0.4 part of CeO2, 0.1-0.4 part of CoO, 0.1-0.4 part of Co2O3, 0.1-0.4 part of Al2O3, 5-10 parts of MnO2 and 3-8 parts of KMnO4. The desulfurization denitrification efficiency of the desulfurization denitrification agent for flue gas, disclosed by the invention, is ultrahigh.

Owner:中晶昆仑实业集团有限公司

Preparation method of flue gas denitration catalyst

InactiveCN101767041AIncrease oxygen contentLow degree of coalificationDispersed particle separationCatalyst activation/preparationInorganic saltsFlue gas

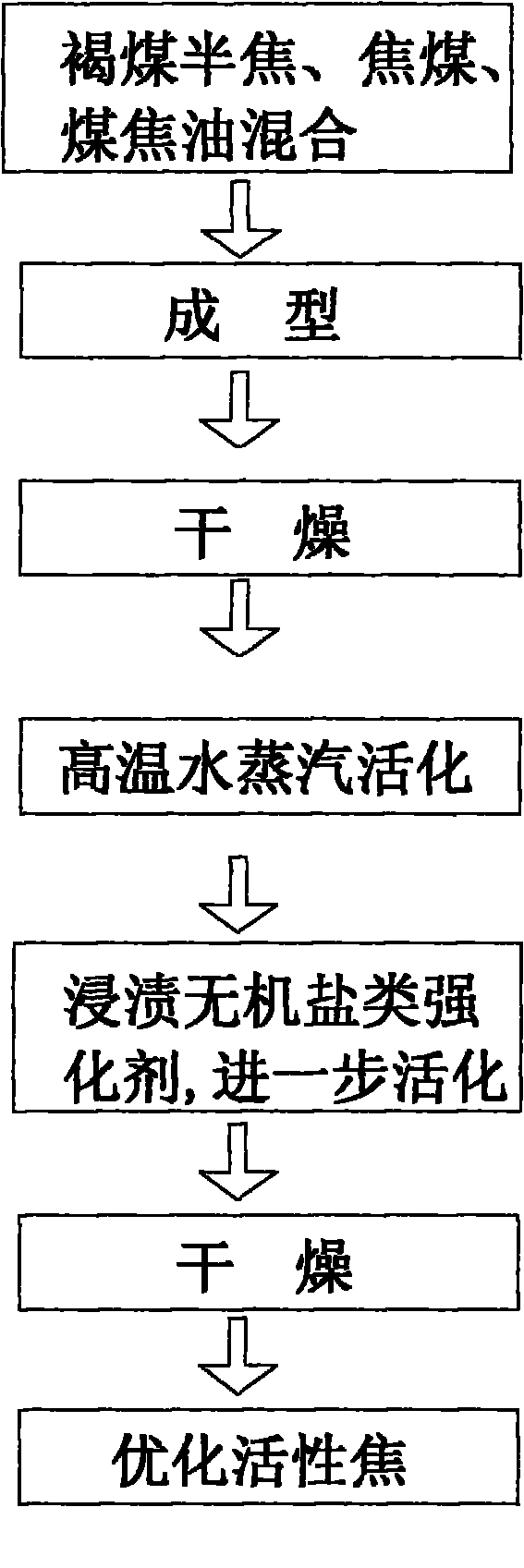

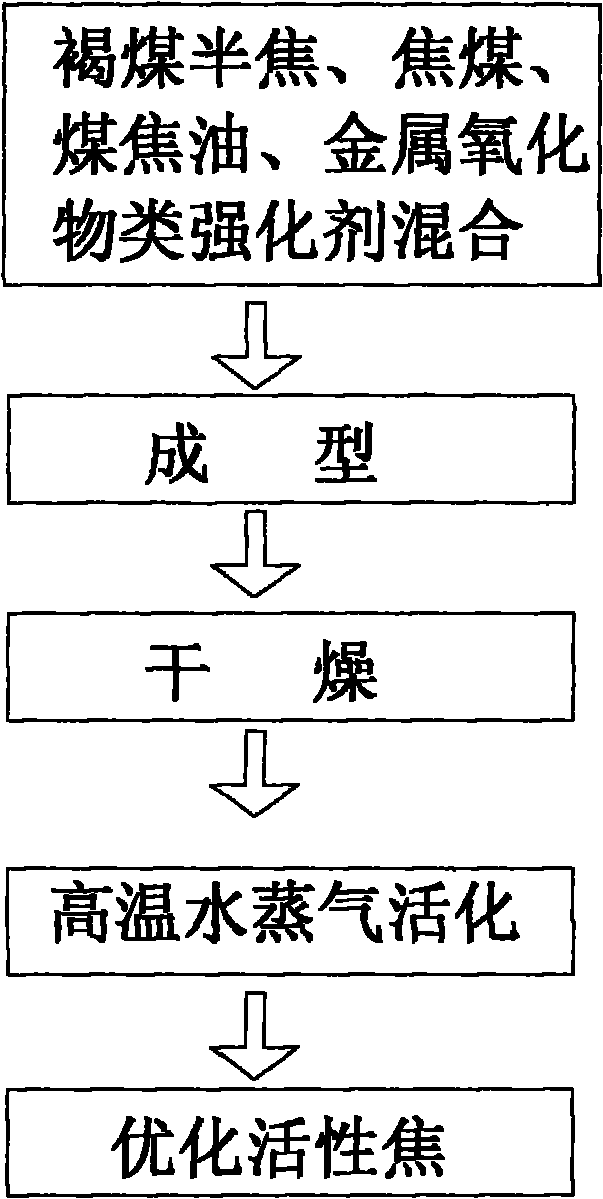

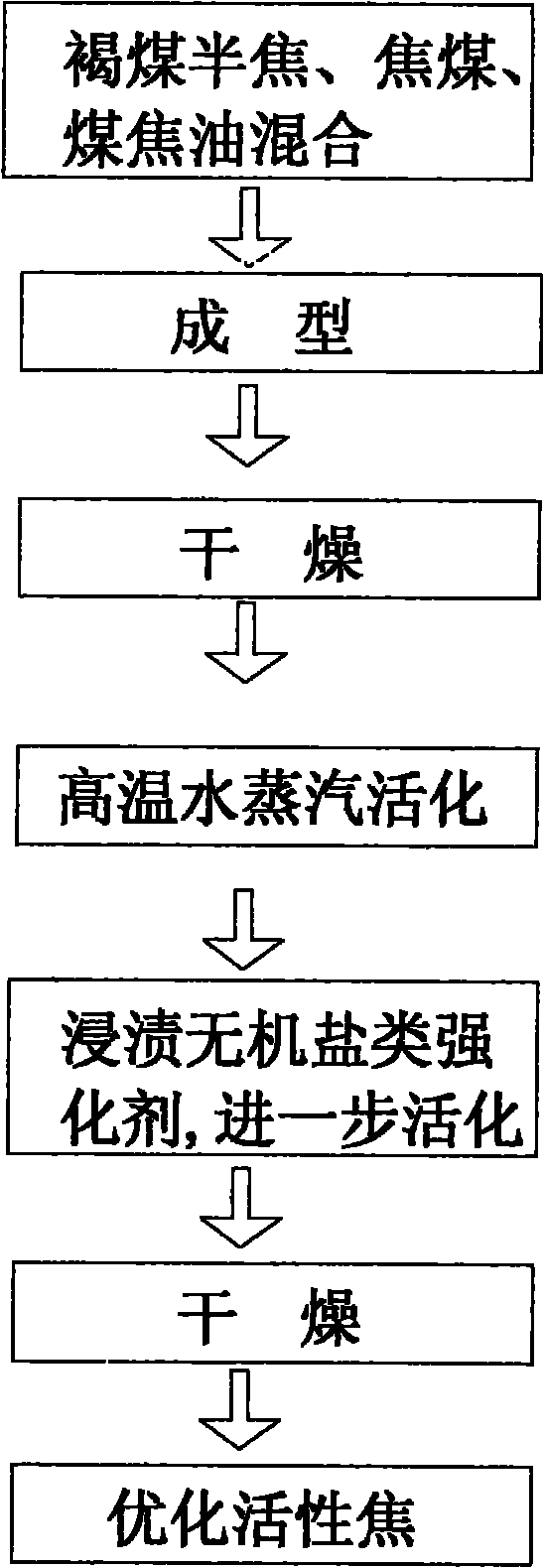

The invention discloses a preparation method of flue gas denitration catalyst, which solves the problem of expensive denitration catalyst and low denitration efficiency in the prior art. The adopted technical scheme is as follows: the method comprises the processing process and method of lignite char, which comprise the following steps and sequence: preparing the lignite char through using lignite as raw material, according to weight percentage of 47-75% :10-35%:5-24%, mixing, forming, drying the lignite char, the lignite, and the coal tar to prepare active coke, adding the enhancer to the active coke for further activation, in order to prepare the optimized active coke. The invention uses the lignite as main raw material, uses the inorganic salt or metal oxide as the enhancer; the advantages of the invention are as follows: the manufacturing cost is low, and the product catalytic effect is good.

Owner:王向明

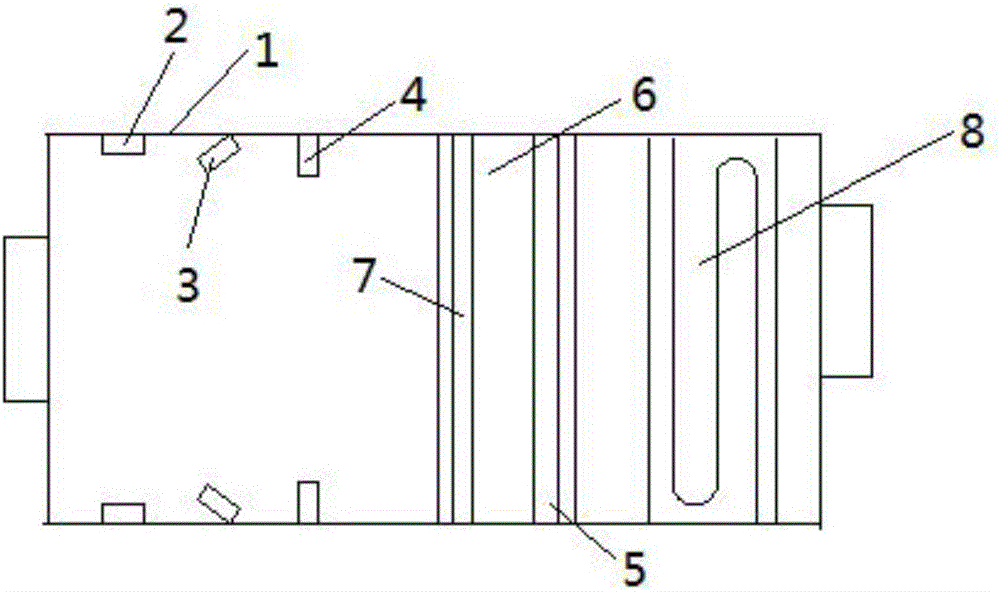

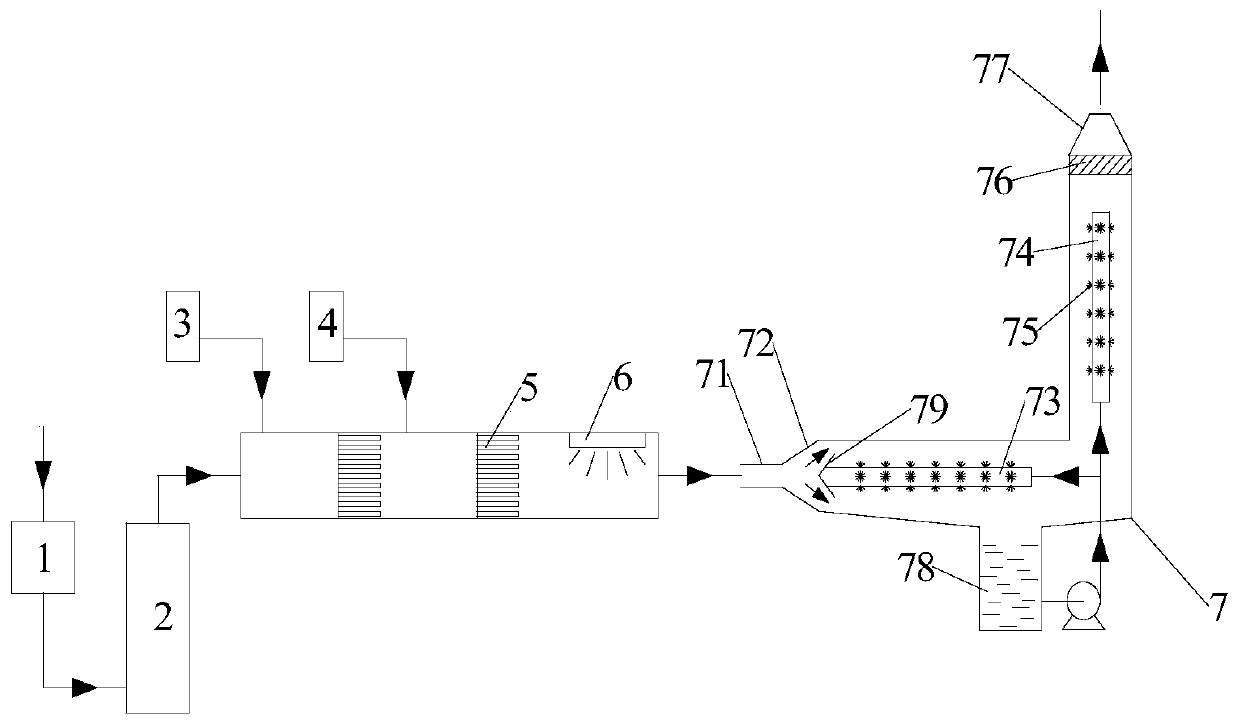

Ultraviolet radiation enhancement based method and device for simultaneous desulfurization, denitrification and particulate removal of pypocholoride

ActiveCN105498480AImprove the effect of desulfurization and denitrificationReduce dosageCombination devicesGas treatmentParticulatesHypochlorite

The invention discloses an ultraviolet radiation enhancement based method for simultaneous desulfurization, denitrification and particulate removal of pypocholoride. The method comprises steps as follows: atomized aerosol formed by an aqueous pypocholoride solution is subjected to ultraviolet radiation, pypocholoride in the atomized aerosol has a photolysis reaction, ROS (reactive oxygen species) free radicals with a strong oxidizing property are generated, the atomized aerosol containing the ROS free radicals with the strong oxidizing property is sufficiently mixed with flue gas, the treated flue gas and the atomized aerosol after reaction are subjected to wet washing treatment, and the treated flue gas is discharged into atmosphere after water mists in the flue gas are removed by a demister. The invention further discloses an ultraviolet radiation enhancement based device for simultaneous desulfurization, denitrification and particulate removal of pypocholoride. According to the method and the device, desulfurization and denitrification effects of pypocholoride are remarkably enhanced with the ultraviolet radiation method, the atomized aerosol and harmful gas in the flue gas are mixed and react, so that the gas-liquid contact area is greatly increased, and gas-liquid mass transfer efficiency is improved; by means of an ultraviolet reactor, the systematic complexity and the mounting operation difficulty are reduced, and the initial investment cost of the system is reduced.

Owner:聚方(大连)环保技术有限公司

Coal-fired flue gas denitration and desulfurization method

InactiveCN105879642AImprove the effect of desulfurization and denitrificationAchieve full coverageNitrous oxide captureGas treatmentAmmonium sulfateChemistry

The invention discloses a coal-fired flue gas denitration and desulfurization method, performing treatment through a following desulfurization apparatus. The desulfurization apparatus comprises a desulfurization pipeline that includes a primary filter pipe, an adsorption filter pipe and a photocatalytic purifying pipe connected in sequence, the inner wall of the primary filter pipe is provided with a sodium hypochlorite solution atomizing nozzle, an oxygen nozzle and an ammonium persulfate solution atomizing nozzle sequentially from a flue gas inlet to a flue gas outlet, the sodium hypochlorite solution atomizing nozzle is mounted parallel to the inner wall of the primary filter pipe, the oxygen nozzle is mounted obliquely down and is 35-55 degrees angled to the inner wall of the primary filter pipe, the ammonium persulfate solution atomizing nozzle is mounted perpendicular to the inner wall of the primary filter pipe, and a plate provided with cellular holes is arranged in the adsorption filter pipe. The method enables denitration to be completed during desulfurization, removal rate of sulfur dioxide is up to above 99%, and removal rate of nitrogen oxides is up to above 90%.

Owner:沈阳汇川环境工程有限公司

Flue gas desulfurization and denitrification method

InactiveCN109499326AHigh removal rateHigh sulfur capacityGas treatmentDispersed particle separationFlue gasFlue-gas desulfurization

The invention relates to a flue gas desulfurization and denitrification method. Preparation raw materials are selected and a removal method comprises the following steps of S1, selecting materials: selecting distilled water and boiling the water; S2, selecting; selecting an FeCl3 solution; S3, dropwise adding the FeCl3 solution into the boiled water; continually boiling until reddish brown liquidis generated, so as to obtain a desulfurization agent; S4, cooling flue gas to 50 to 100 DEG C through a heat exchanger and introducing the flue gas into the obtained desulfurization agent; S5, introducing the flue gas into the obtained denitrification agent and carrying out denitrification reaction; S6, carrying out ultraviolet irradiation and electron beam irradiation on primary desulfurizationand denitrification flue gas at the same time, so as to obtain secondary desulfurization and denitrification flue gas; S7, carrying out water spraying treatment; S8, discharging denitrified coke ovenflue gas through an induced draft fan. By adopting two times of the desulfurization and denitrification method, the removal efficiency is high and pollutants including SO2, NOx and the like in the flue gas can be removed, so that pollutions to the air are reduced, damage to humans is reduced and the humans are healthier.

Owner:ZHEJIANG FEIDA ENVIRONMENTAL SCI & TECH CO LTD

Anti-blocking type particle adsorber for high-temperature waste gas

ActiveCN111659218AImprove adsorption capacityEasy to replaceCombination devicesThermodynamicsEngineering

The invention discloses an anti-blocking type particle adsorber for high-temperature waste gas, and belongs to the technical field of waste gas treatment. A gas adsorption device and an embedded plateare installed in an embedded mode. Waste gas which is led out upwards passes through the adsorption layer group in an adsorption cylinder, multiple set adsorption operations are performed, and the adsorption effect of the waste gas is effectively improved; the adsorption layer group reaches a saturated state after being used for a certain time, the gas conduction is difficult to realize continuously; the floating ball which floats upwards is supported by matching with the impact force generated by the conduction gas, when the buoyancy generated by the amount of gas led out upwards is smallerthan the gravity of the floating ball, the floating ball floats upwards, the floating ball sinks and abuts against the top end part of the conical eduction tube, and the outer side wall of the floating ball makes contact with the blockage alarm mechanism to achieve alarm display so that technicians can more easily and visually perceive which adsorption layer set in the adsorption cylinder reachesthe saturation state, the gas adsorption mechanism at the position can be replaced, and replacement by the technicians is facilitated by the embedded installation.

Owner:龙杰机械装备(太仓)有限公司

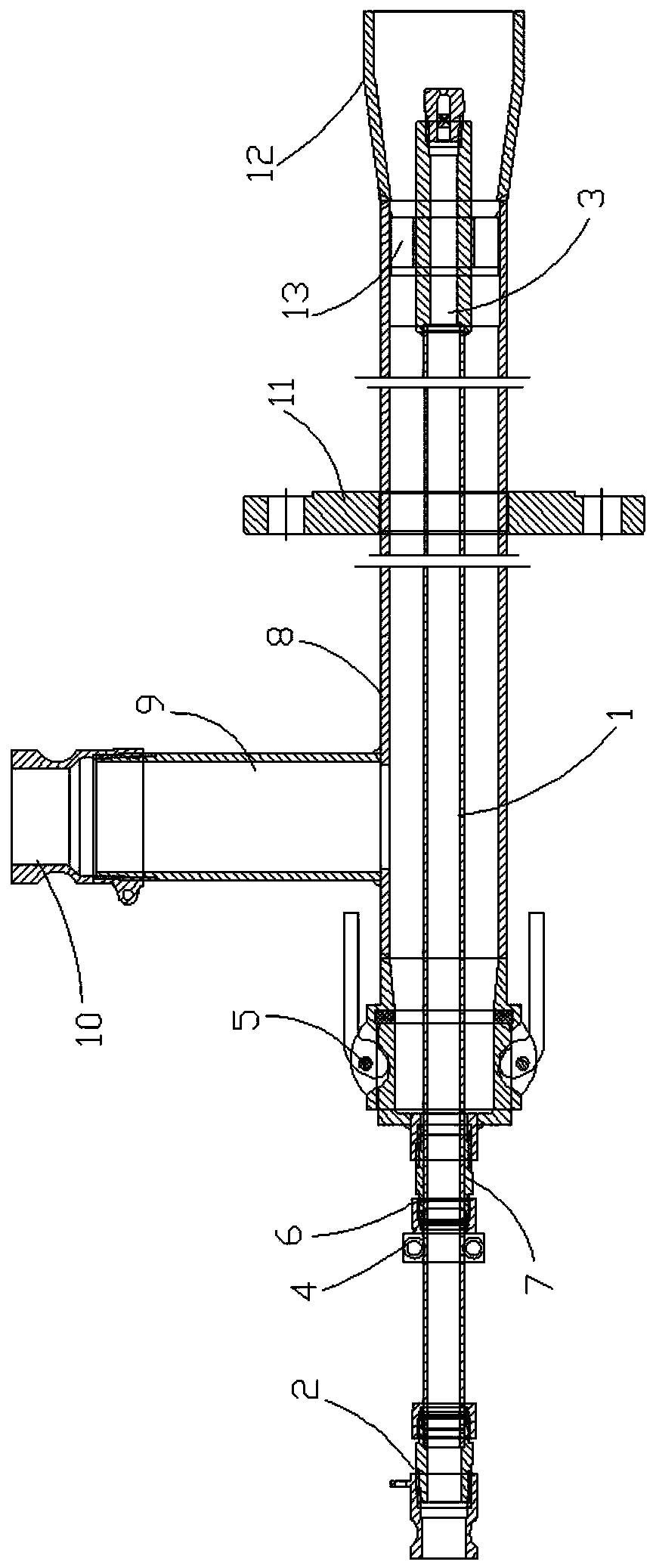

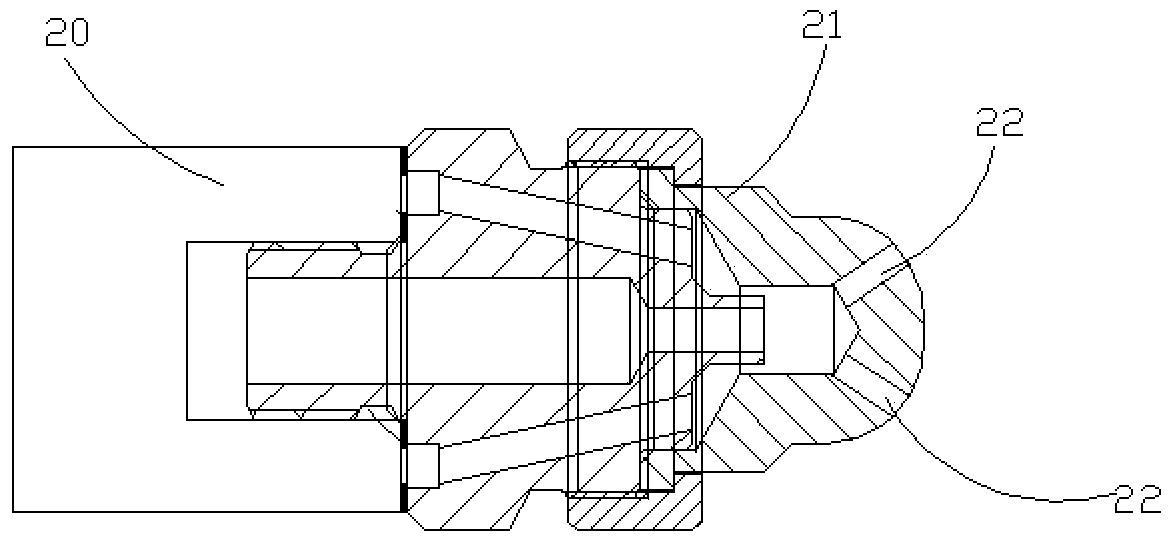

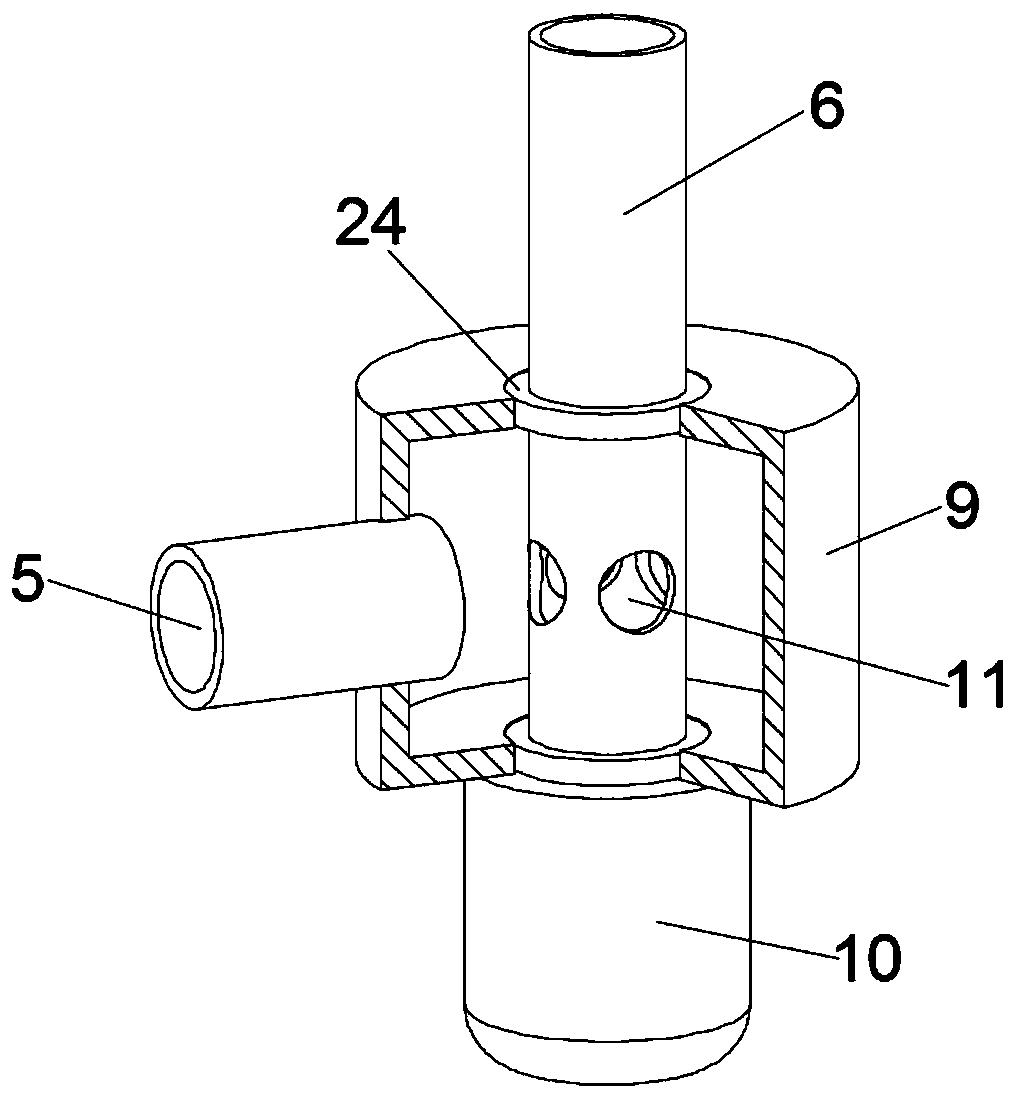

Novel spray gun for desulfurization and denitrification

InactiveCN104001635AWell mixedIncrease air pressureDispersed particle separationCouplingsEngineeringCooling pipe

The invention discloses a novel spray gun for desulfurization and denitrification. The novel spray gun comprises a spray gun inner pipe. One end of the spray gun inner pipe is welded to a connector, and the other end of the spray gun inner pipe is welded to a welding gun head. The outer wall of the spray gun inner pipe is provided with a bayonet and a quick connector, and a small metal sealing ring is arranged between the bayonet and the wall of the spray gun inner pipe. A large metal sealing ring is arranged between the fast connector and the wall of the spray gun inner pipe, and the fast connector is further connected with a spray gun casing pipe. An inlet pipe is arranged on the spray gun casing pipe, and the inlet pipe is provided with a cooling pipe. A flange is arranged on the outer wall of the spray gun casing pipe, and the end opening position of the spray gun casing pipe is provided with a circular-truncated-cone-shaped spray head flared opening. A diversion part is arranged between the inner wall of the spray gun casing pipe and the spray gun head. The novel spray gun for desulfurization and denitrification is convenient to install and capable of improving the desulfurization and denitrification working efficiency, and meanwhile prolonging service life.

Owner:姜建勇

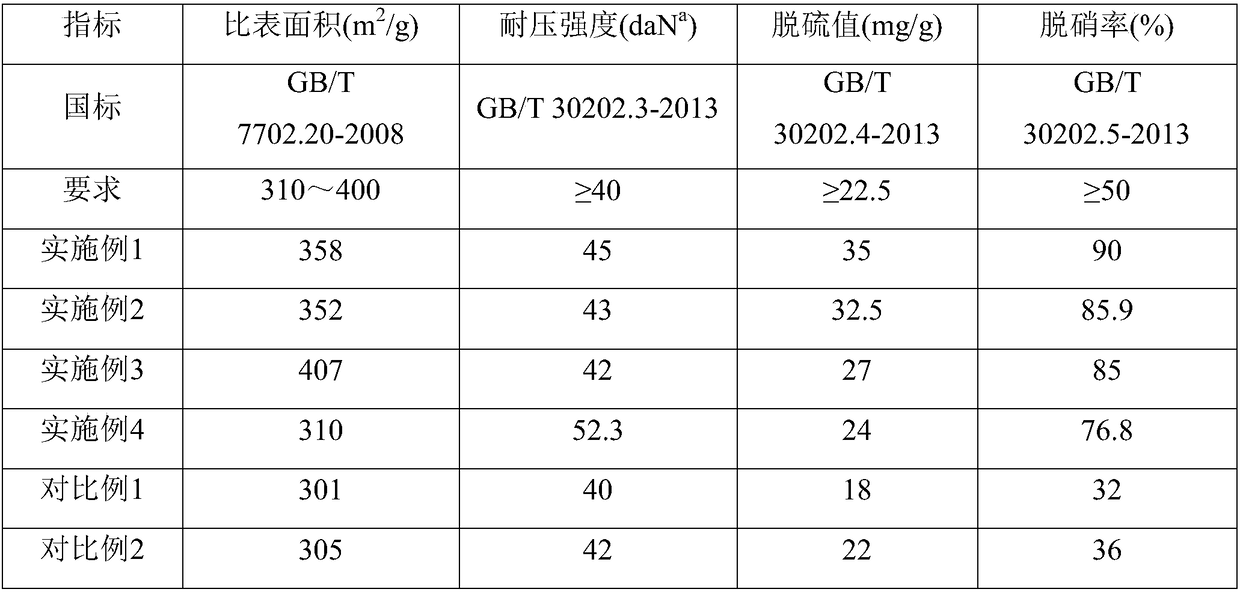

Preparation method of activated coke

ActiveCN109806839AHigh strengthIncrease oxygen contentCarbon compoundsOther chemical processesChemistryMolten steel

The embodiment of the invention provides a preparation method of activated coke. The preparation method comprises the following several steps of burdening, powder milling, kneading, pelleting, carbonizing, activating and post oxidizing. According to the preparation method provided by the invention, the step of post oxidizing is also added to an activated material after activation, the step of postoxidizing is used for introducing an oxygen-containing mixed gas to a post oxidizing chamber, oxygen is enabled to react with the surface of carbon in the activated material to form a layer of denseoxidizing film, t not only the strength of the organizational structure of the carbon can be increased, but also the oxygen content in the activated coke is increased, so that the desulfurization anddenitrification abilities of the activated coke in molten steel can be increased.

Owner:平罗县国宁活性炭有限公司

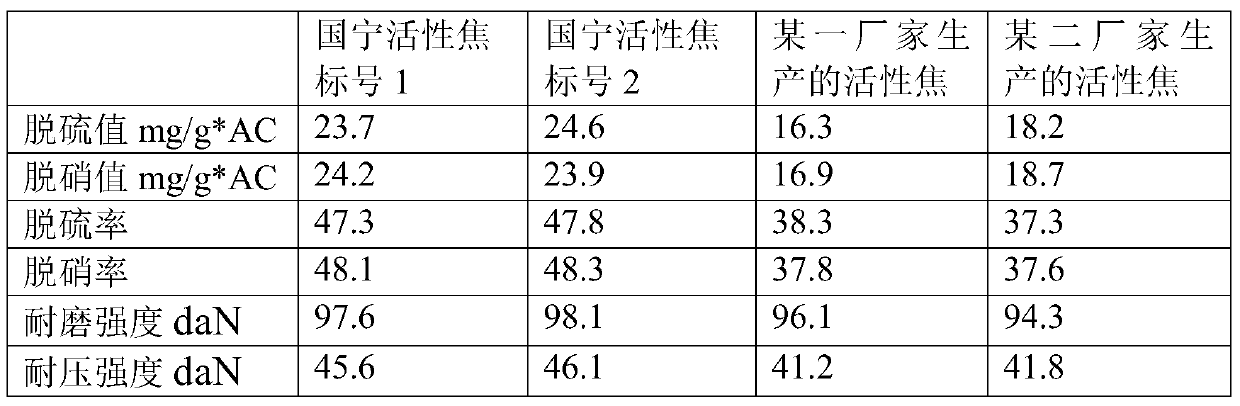

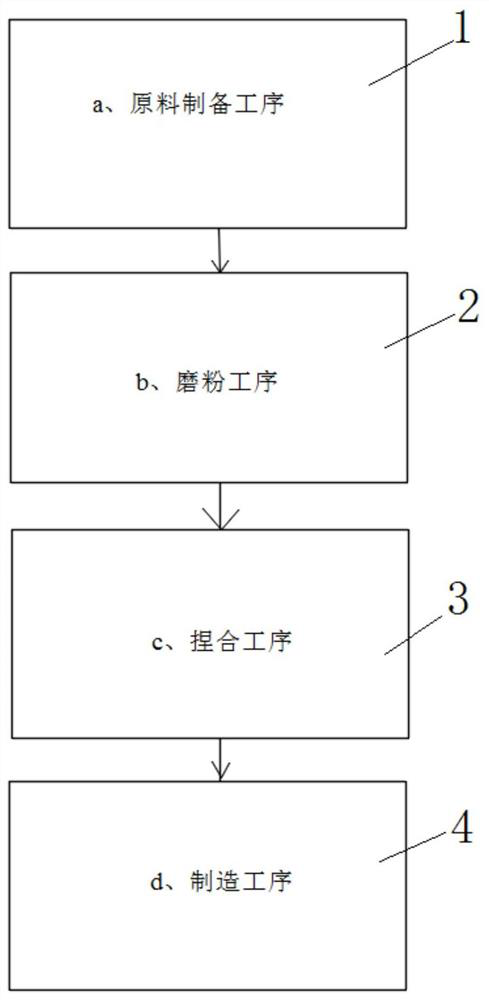

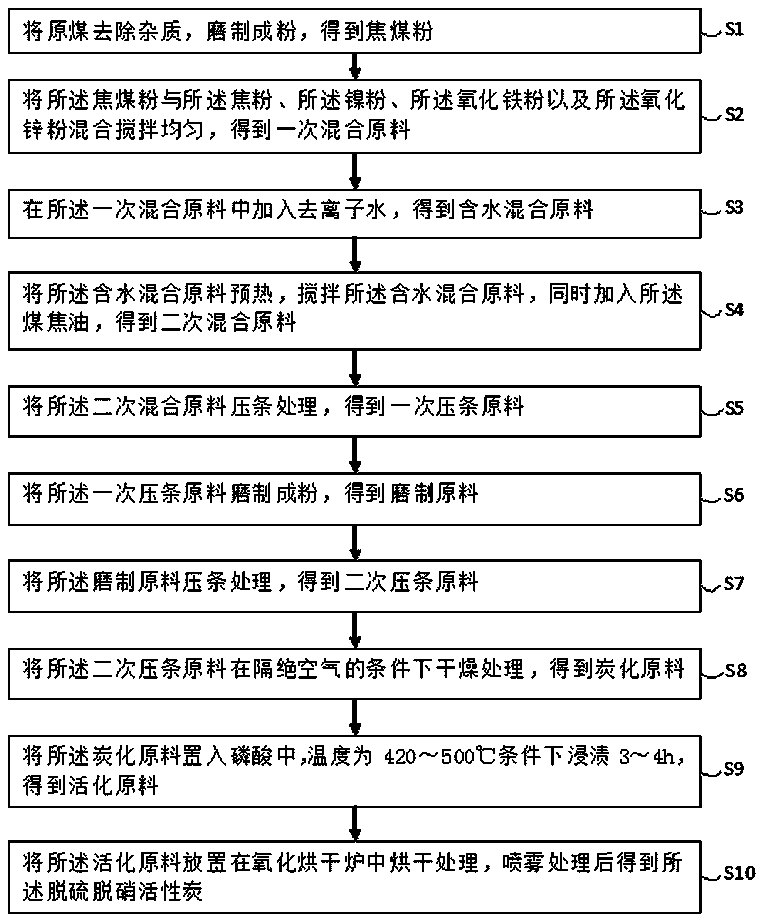

Production method of desulfurization and denitrification active coke catalyst

PendingCN111804339AWell mixedUniform particle sizeOrganic-compounds/hydrides/coordination-complexes catalystsDispersed particle separationCokeCarbonization

The invention discloses a production method of a desulfurization and denitrification active coke catalyst. The production method comprises the following steps: a, preparing raw materials: uniformly mixing 2-4 parts by weight of semi-coke, 1-3 parts by weight of Shenmu coal, 2-4 parts by weight of coking coal, 0.5-1.5 parts by weight of anthracite, and 10.5-1.5 parts by weight of a catalyst; b, grinding: grinding the uniformly mixed raw materials to enable 85% or above of the raw materials to pass through a 200-mesh sieve; c, kneading: adding 25-30 parts by weight of a binder and 8-12 parts byweight of water into the ground raw materials, and kneading at 65-90 DEG C; d, manufacturing: sequentially carrying out granulation, first screening, carbonization, second screening, activation, thirdscreening and packaging on the kneaded raw material which is coal paste. According to the prepared sulfur denitration active coke catalyst, the desulfurization value is increased to 25-30 mg / g, and the denitration rate is increased to 50-55%.

Owner:宁夏乐天碳素有限公司

Metallurgical solid waste based pressed active carbon for desulfurization and denitrification of flue gas and preparation method of pressed active carbon

ActiveCN108745282AIncrease the secondary added value of comprehensive utilizationImprove mechanical propertiesNitrous oxide captureGas treatmentActivated carbonFlue gas

The invention discloses a metallurgical solid waste based pressed active carbon for desulfurization and denitrification of flue gas, the pressed active carbon comprises the following various components by mass percent: 65-80% of powdered activated carbon and 20-35% of forming agent, wherein the forming agent is compounded from a steel slag, a mineral waste residue and desulfurized fly ash. A gelatinizer prepared on the basis of the metallurgical waste residues like the steel slag is used to form and adsorb saturated granular active carbon or powdered activated carbon, the steel slag, the mineral waste residue and the desulfurized fly ash are compounded, the combining property of the forming agent and the powdered activated carbon is good, the mechanical property, the desulfurization and denitrification performances and the like of the obtained activated carbon are effectively improved, the problems like low specific surface of the inorganic forming activated carbon is effectively solved, meanwhile, the additional value of the comprehensive utilization of the metallurgical waste residue is improved, and the activated carbon has important economic and environmental benefits.

Owner:武汉钢铁有限公司

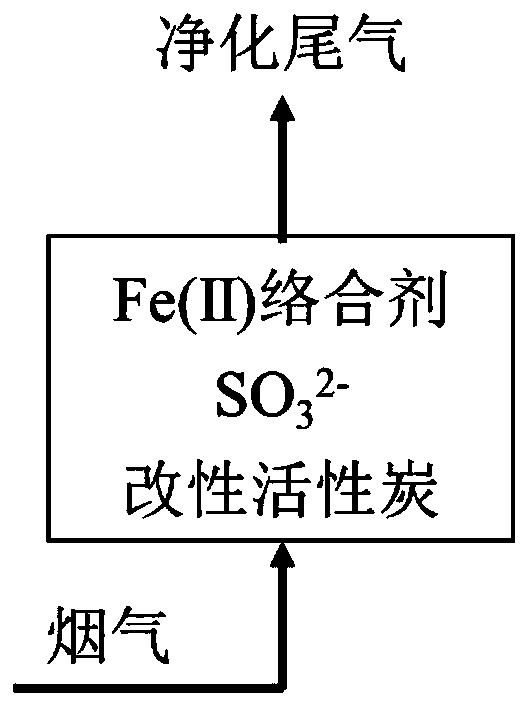

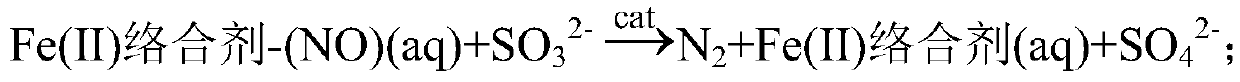

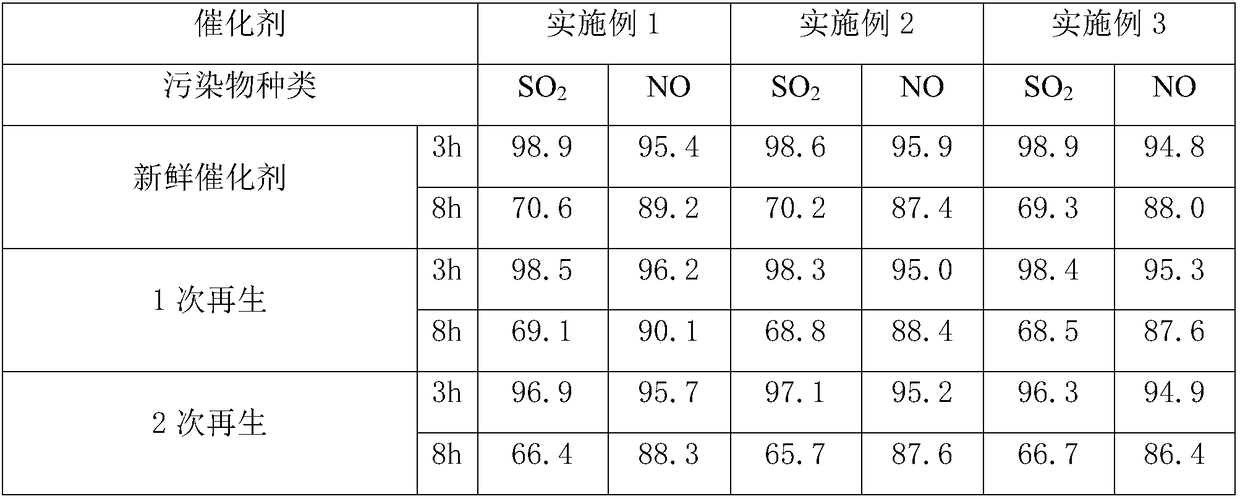

Method for enhancing wet complexing desulfurization and denitrification by modified activated carbon

PendingCN109821381AImprove desulfurization and denitrification efficiencyImprove the effect of desulfurization and denitrificationDispersed particle separationAir quality improvementActivated carbonHydrogen

The invention relates to a method for enhancing wet complexing desulfurization and denitrification by modified activated carbon. The method includes the steps: adding sulfite and activated carbon intoferrous ion complexing agent solution, adjusting a pH (potential of hydrogen) value to reach 3.5-7.5 to obtain wet complexing absorption liquid; leading flue gas to be treated into an absorption reaction device, performing contact reaction on the flue gas and the wet complexing absorption liquid, and discharging the flue gas after NOx and SO2 in the flue gas are absorbed and purified. According to the method, the NOx and the SO2 in the flue gas to be treated and the wet complexing absorption liquid are absorbed, catalyzed, oxidized and reduced, and the modified activated carbon serves as a catalyst in the reaction process. According to the method, wet complexing desulfurization and denitrification efficiency of ferrous ion complexing agents can be enhanced, the removal rate of sulfur dioxide is higher than or equal to 98%, the removal rate of nitrogen oxide is 65%-95% before and after the flue gas is purified, flue gas absorption and regeneration of complexing liquid are integrated, the method is simple, catalyst is easily separated and recyclable, and dust collection efficiency can be improved.

Owner:BEIJING SPC ENVIRONMENT PROTECTION TECH

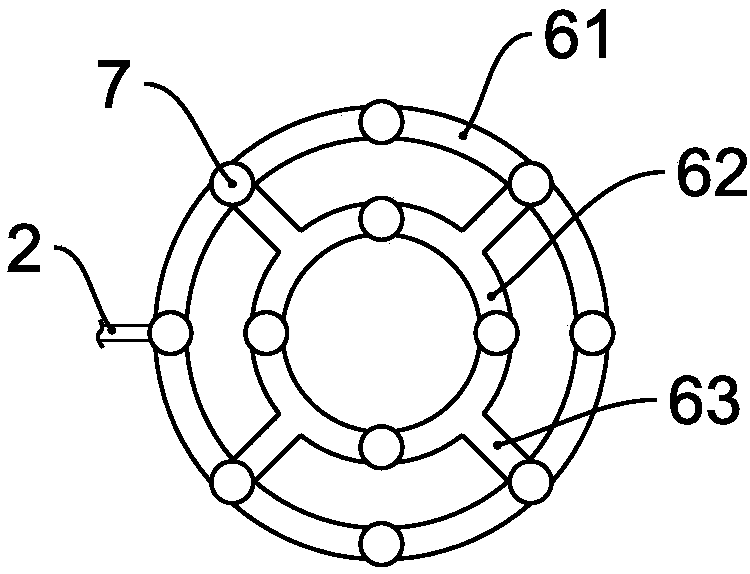

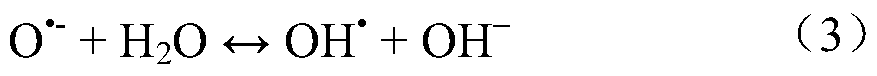

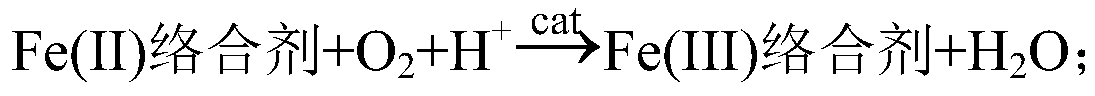

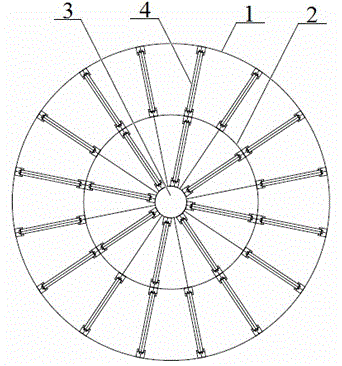

Photocatalyst reactor, photocatalyst reaction tower and flue gas purification system

ActiveCN104984661AOptimize layoutImprove support strengthDispersed particle separationReaction layerFlue gas

The invention relates to a photocatalyst reactor. The photocatalyst reactor comprises a support pillar, an annular partition board and a shell which are coaxially arranged in sequence from inside to outside, and the space between the support pillar and the shell are divided into an inner ring space and an outer ring space by the annular partition board; a first flue gas inlet is formed in one end of the shell, and a first flue gas outlet is formed in the other end of the shell; the inner ring space and the outer ring space are each internally provided with multiple reaction layers in the flue gas circulation direction, each reaction layer is composed of multiple photocatalyst reaction units which are arranged in an annular pattern, and each photocatalyst reaction unit is arranged to be perpendicular to the flue gas circulation direction. In addition, a photocatalyst reaction tower and a flue gas purification system are further provided. By means of each of the photocatalyst reactor, the photocatalyst reaction tower and the flue gas purification system, the desulfuration and denitration can be achieved simultaneously, the photocatalysis efficiency and reaction homogenization degree are high, and a good desulfuration and denitration effect is achieved.

Owner:WISDRI ENG & RES INC LTD

Novel integrated apparatus for conditioning and desulphurizing flue gas by dry method

ActiveCN105642092ASimple structureSimple designCombination devicesGas treatmentFlue gasLiquid storage tank

The invention relates to a novel integrated apparatus for conditioning and desulphurizing flue gas by a dry method. The apparatus comprises the following components: a glass melting cellar, a first cooling device, an adsorption and dust collection device, a first desulphurization apparatus, a centrifugal dust collector, a denitration apparatus, a second desulphurization apparatus, an atomizer, a waste residue processing apparatus, a chimney, a first liquid storage tank, a second liquid storage tank, a third liquid storage tank, an air tank and a heat exchange device, wherein the heat exchange device is internally provided with a high temperature heat exchange apparatus, a middle temperature heat exchange apparatus, and a low temperature heat exchange apparatus from up to bottom in order; and the glass melting cellar is connected to the adsorption and dust collection device by the first cooling device, the adsorption and dust collection device is connected to the centrifugal dust collector by the first desulphurization apparatus, the centrifugal dust collector is connected to the second desulphurization apparatus by the atomizer, and the second desulphurization apparatus is connected to the chimney by the denitration apparatus. Waste heat of flue gas is absorbed, and the absorbed heat is stored and supplied for the devices, so that resource is effectively saved, loss of heat is avoided, and production cost is effectively reduced.

Owner:JIANGSU CTIEC ENVIRONMENTAL PROTECTION RES INST

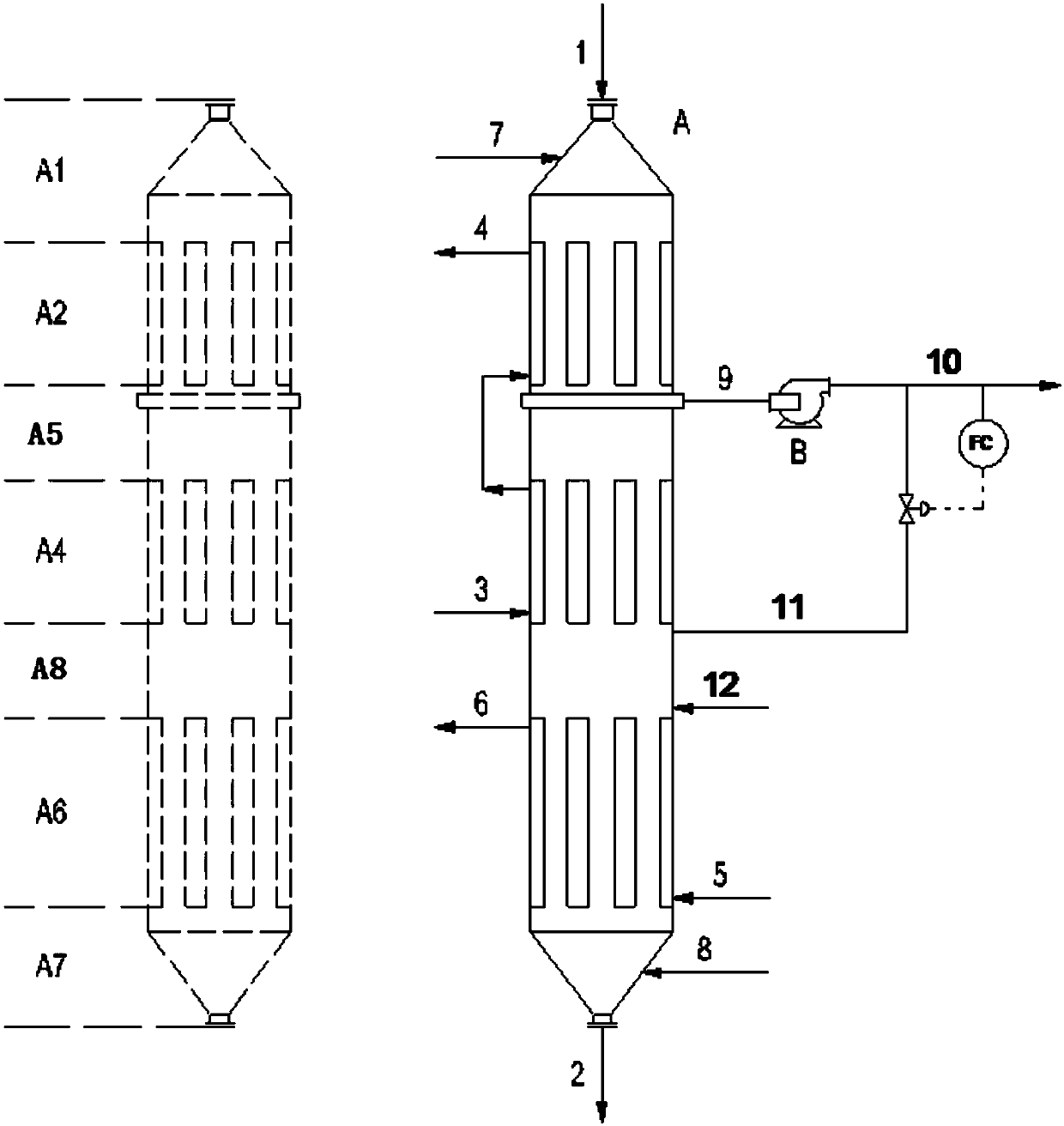

System and method for regenerating active coke

ActiveCN110624525AReduce contentStable flowGas treatmentDispersed particle separationDeposition temperatureEngineering

The invention belongs to the field of chemical engineering, and discloses a system and a method for regenerating active coke. The system for regenerating active coke comprises a regeneration tower anda regeneration fan, and the regeneration tower is sequentially provided with a feeding distribution section, a preheating section, a regeneration tail gas extraction section, a heating section, a redistribution and activation section, a cooling section and an outlet collection section from top to bottom. A process flow of circulating the regeneration tail gas to the bottom of the heating sectionis adopted to generate new oxygen-containing and nitrogen-containing functional groups on the surface of the active coke and improve the desulfurization and denitrification performance of the active coke; the flow and composition stability of regeneration tail gas can be guaranteed, the flow and the SO3 content of the regeneration tail gas can be reduced, the SO2 concentration is improved, the salt deposition temperature of a regeneration tail gas system is reduced, and the salt deposition tendency is reduced, so stable operation of a downstream regeneration tail gas treatment system is facilitated; and the process flow is simple, and is safe and reliable to operate, so the stability and reliability of the active coke regeneration technology are improved.

Owner:SINOPEC ENG +1

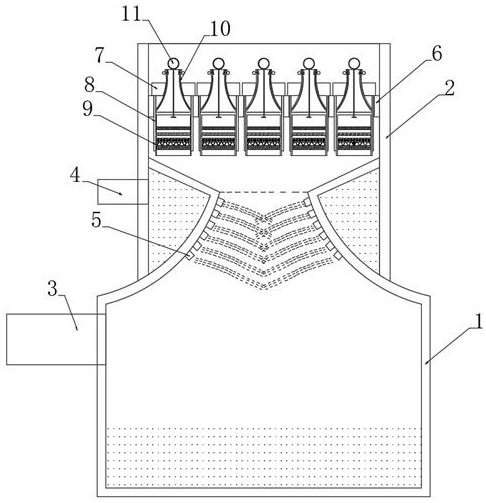

Desulfurization, denitrification and dust removal device

InactiveCN111229003AIncrease contact areaPrevent backflowCombination devicesDust controlEnvironmental engineering

The invention discloses a desulfurization, denitrification and dust removal device. The device comprises a reaction box, a desulfurization and denitrification cylinder and a dust removal tower, a hollow rotating shaft is rotatably mounted in the desulfurization and denitrification cylinder, a fixed pipe is mounted on the hollow rotating shaft, an air hole is formed in the fixed pipe, a fixed sleeve is mounted at the bottom of the desulfurization and denitrification cylinder, a first connecting pipe is communicated between the fixed sleeve and a reaction box, a through hole is formed in the hollow rotating shaft in the fixed sleeve, a first-stage filter plate, a second-stage filter plate and a drying plate are respectively arranged in the dust removal tower from bottom to top, a valve is installed at the bottom of the desulfurization and denitrification cylinder, a collecting box is movably installed below the valve, and a scraper is installed on the hollow rotating shaft. According tothe desulfurization, denitrification and dust removal device, waste gas generated in the reaction box is introduced into the hollow rotating shaft to form spirally ascending bubbles, so that the contact area of the waste gas and desulfurization and denitrification liquid is increased, meanwhile, the desulfurization and denitrification liquid is disturbed, so that the desulfurization and denitrification effect is improved, and a detachable collecting box is convenient for regular cleaning of impurities.

Owner:黄延兵

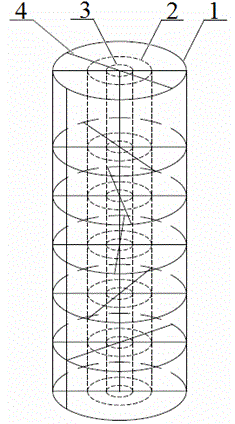

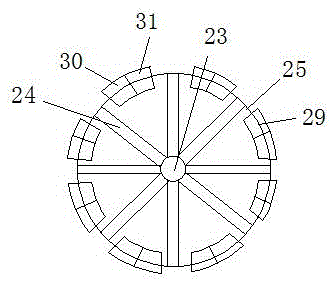

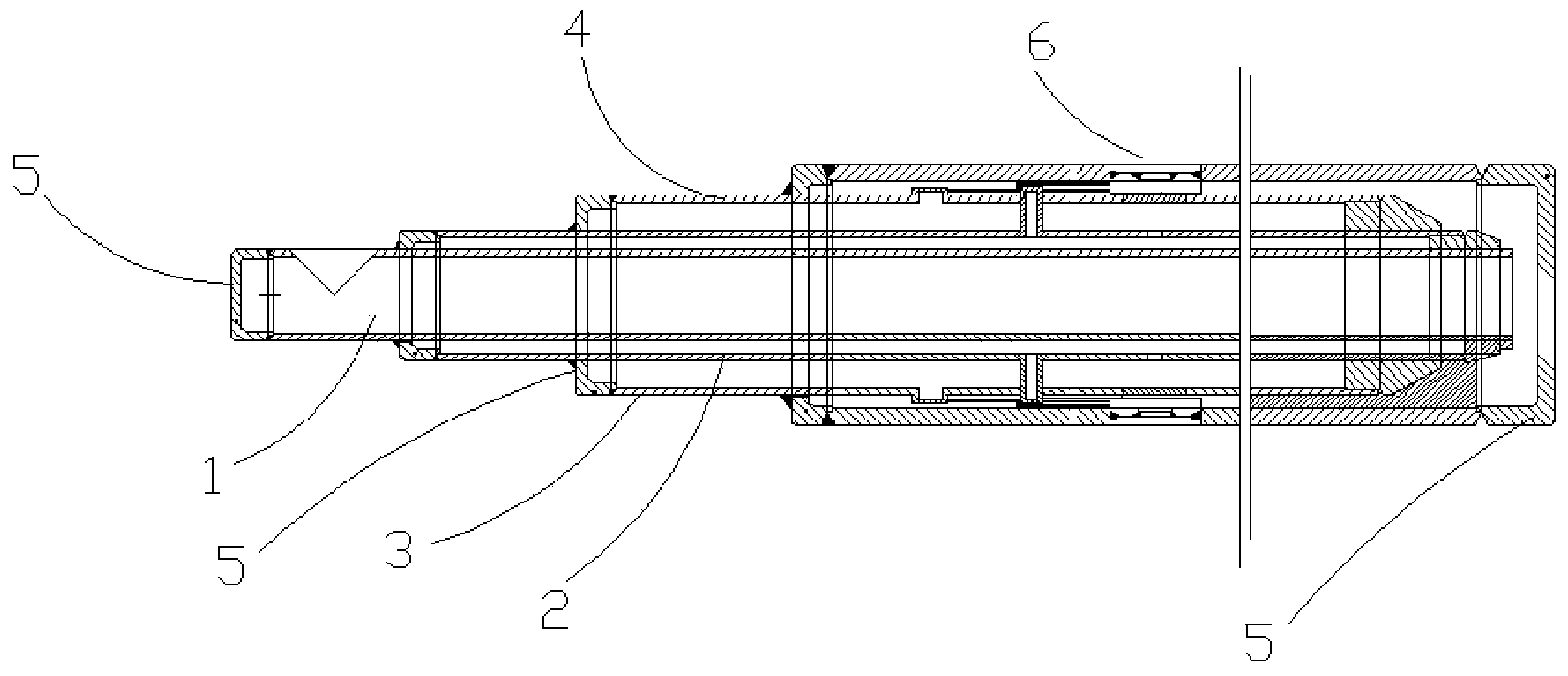

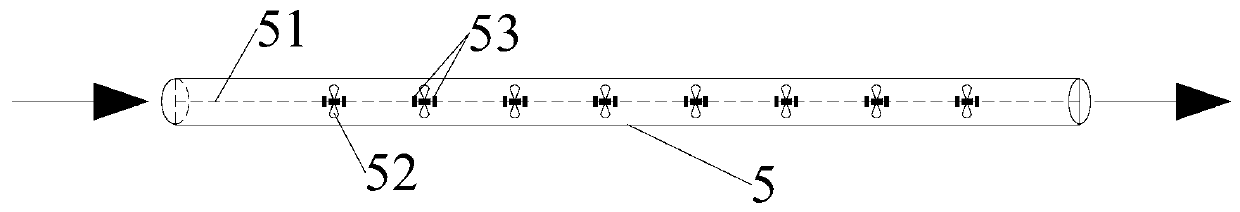

Improved type desulfurization and denitrification spray gun

InactiveCN104001418AReduce manufacturing costExtended service lifeDispersed particle separationEngineeringElectrical and Electronics engineering

The invention discloses an improved type desulfurization and denitrification spray gun which comprises a first tube, a second tube, a third tube and a fourth tube which are arranged in sequence from inside to outside and are connected at intervals through support rings, wherein one end of the first tube is blocked by an end plug for sealing; a through hole is formed in the other end of the first tube; the part between each of two ends of the second tube and the outer wall of the first tube is sealed by using an end seal; the part between each of two ends of the third tube and the outer wall of the second tube is sealed by using an end seal; the part between one end of the fourth tube and the outer wall of the third tube is sealed by using another end seal; the other end of the fourth tube is sealed by using another end seal; a plurality of nozzle components which are arranged at intervals in the radial direction and the axial direction are arranged on the wall of the fourth tube; a plurality of second connectors which face outwards are formed on the wall of the second tube; the second connectors penetrate through the wall of the third tube; urea tubes are arranged among the second connectors and the nozzle components; a plurality of convex third connectors are formed on the wall of the third tube; air tubes are arranged among the third connectors and the nozzle components. By adopting the spray gun, the desulfurization and denitrification working efficiency is improved, meanwhile the service life is prolonged, and the use cost is lowered for companies.

Owner:姜建勇

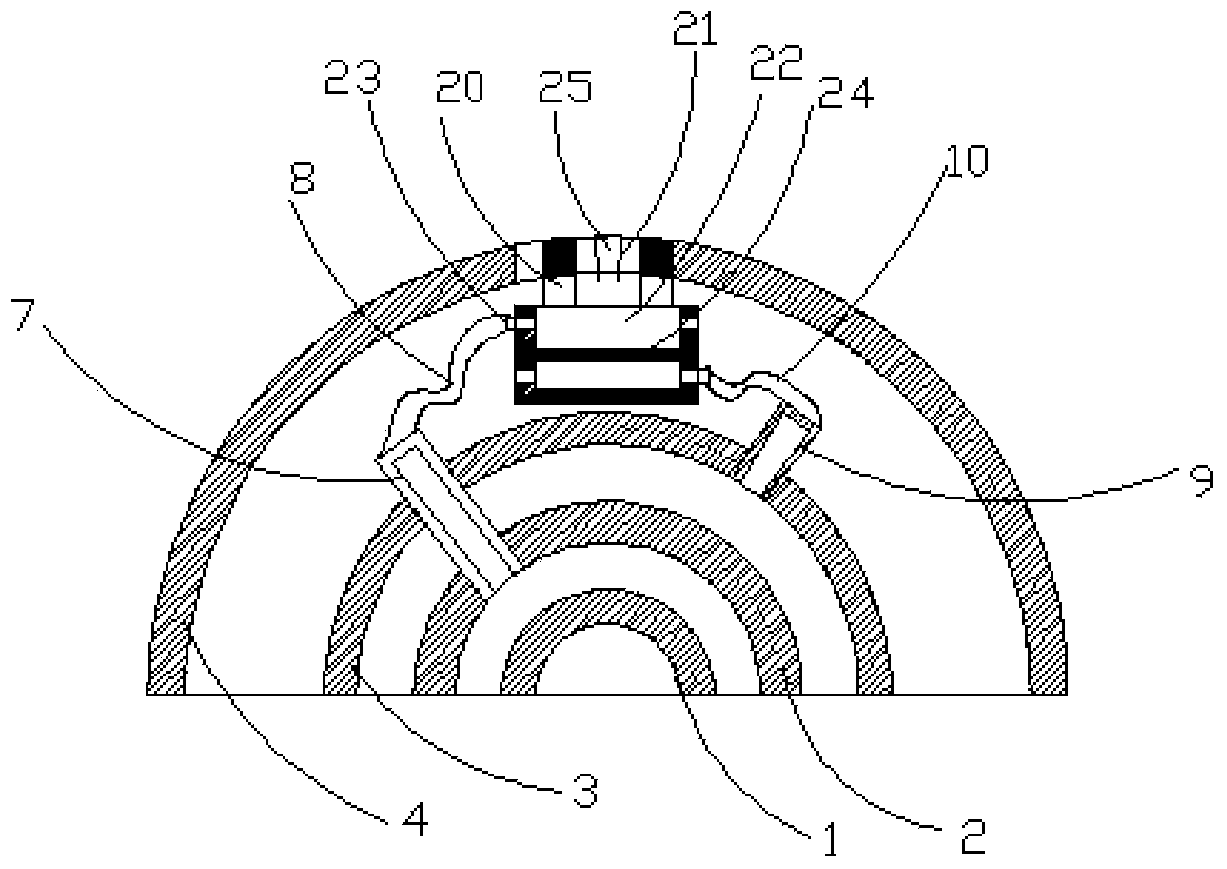

Desulfurization and denitrification active carbon and preparation method and device thereof

InactiveCN108975324AImprove the effect of desulfurization and denitrificationCarbon compoundsPhosphoric acidActivated carbon

The invention discloses desulfurization and denitrification active carbon and a preparation method and device thereof. The active carbon is prepared from the following raw materials: raw coal, coke powder, coal tar, nickel powder, ferric oxide powder, zinc oxide powder and deionized water; the preparation method comprises the following steps that the raw materials are blended and stirred to be uniform and then subjected to bar depression treatment, a first bar depression raw material is obtained, the first bar depression raw material is ground to be powder, the ground raw material is obtained,the ground raw material is subjected to bar depression treatment, a secondary bar depression raw material is obtained, the secondary bar depression raw material is subjected to drying treatment underthe condition of air isolation, a carbonized raw material is obtained, the carbonized raw material is dipped in phosphoric acid, an activated raw material is obtained, the activated raw material is dried and subjected to spray treatment, and the desulfurization and denitrification active carbon is obtained. The preparation device comprises a stirring device, a feeding device and a pressing device. The desulfurization and denitrification active carbon and the preparation method and device thereof increase the sulfur capacity of the active carbon and the oxygen-containing groups on the surface,and remarkably improve the desulfurization and denitrification effect of the active carbon.

Owner:DATONG XINCHENG NEW MATERIAL CO LTD

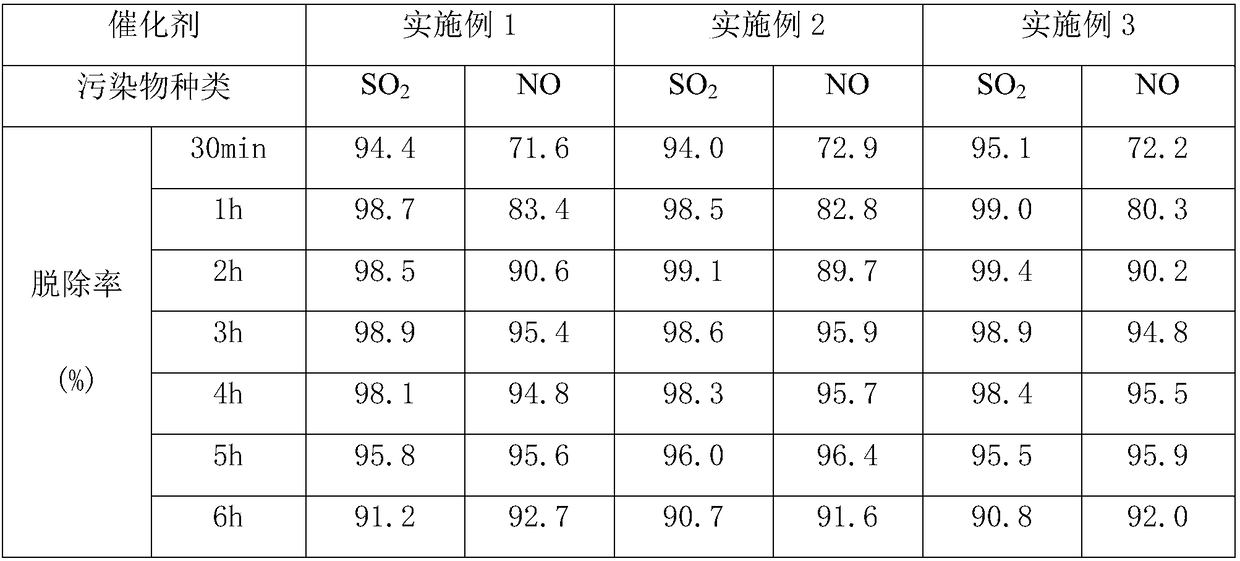

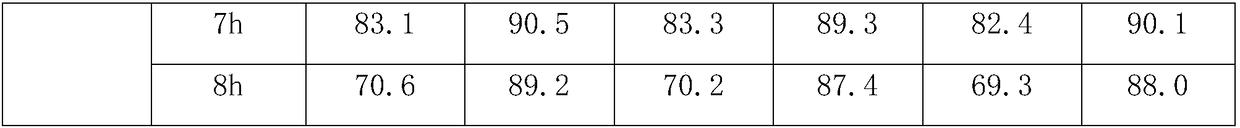

A low-temperature desulfurization and denitrification catalyst and flue gas low-temperature integrated desulfurization and denitrification method

ActiveCN107597140BImprove the effect of desulfurization and denitrificationOptimized areaDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsNitrateSulfur

The invention relates to a low-temperature desulfurization and denitrification catalyst and a flue gas low-temperature integrated desulfurization and denitrification method. The catalyst is prepared by the following method: 1) mixing semi-coke particles and calcium oxide powder to obtain a mixture; 2) continuously passing the mixture into water Under the condition of mixed gas of steam and CO2, activate the carrier at high temperature; 3) Prepare the precursor solution containing copper nitrate, manganese nitrate and sodium chloride; 4) Use the equal volume impregnation method to impregnate the activated carrier with the precursor solution to The total loading mass of CuO and MnO2 on the activated carrier reaches 4.0%-6.0%, that is, it is obtained. The present invention uses a variety of activation modes to act synergistically, which greatly improves the specific surface area and pore volume of the semi-coke; in the presence of NaCl, CuO and MnO2 are loaded on the activation carrier, and the adsorption activity of the activated semi-coke cooperates with CuO and MnO2, and the obtained The catalyst has high desulfurization and denitrification efficiency, sulfur capacity and long catalytic activity period.

Owner:广东立伟达矿业有限公司

Flue gas desulfurization and denitrification treatment system

InactiveCN114159902AImplement the cleanup functionImprove the situation where the vibration amplitude is not largeGas treatmentDispersed particle filtrationFlue gasDust control

The invention relates to a flue gas desulfurization and denitrification treatment system, which comprises a dust removal device, a desulfurization and denitrification device, a box body and flue gas through pipes, the right end of the dust removal device is sequentially provided with the desulfurization and denitrification device and the box body, and the flue gas through pipes are arranged between the dust removal device and the desulfurization and denitrification device and between the desulfurization and denitrification device and the box body. The lower end of the box body is connected with the existing ground through a bearing plate, and a smoke exhaust port is formed in the upper end of the box body, the dust removal plate in the dust removal device improves the situation that the vibration amplitude of the dust removal plate is not large due to the fact that only one side of the dust removal plate is knocked in an existing desulfurization and denitrification treatment system, and the cleaning effect on the dust removal plate is enhanced; the desulfurization and denitrification device provided by the invention can realize the function of spraying a medicament to flue gas in all directions, improves the desulfurization and denitrification rate, can also realize the function of intermittently conveying a desulfurization and denitrification agent, and achieves the effects of saving the desulfurization and denitrification agent and reducing the cost.

Owner:徐荣俊

Biomass fuel desulfurization and denitrification system

PendingCN113318583AIncrease contact areaExtension of timeDispersed particle separationExhaust fumesEngineering

The invention belongs to the technical field of waste gas purification, and particularly relates to a biomass fuel desulfurization and denitrification system which comprises a tower body, a guide cylinder and a filler plate, a spraying box is arranged in the upper end of the tower body, the guide cylinder in a funnel-shaped design is arranged below the spraying box, and a sliding cylinder is arranged in the middle of the guide cylinder; first liquid bags which are uniformly distributed are arranged on the lower surface of the sliding cylinder; a filler plate is arranged below the guide cylinder; an extrusion plate is arranged between the filler plate and the liquid bags, and first connecting rods which are uniformly distributed are arranged between the extrusion plate and the filler plate; and fixed pulleys which are evenly distributed are arranged on the inner wall of the guide cylinder, pull ropes which are evenly distributed are fixedly connected to the upper surface of the sliding cylinder, and one ends of the pull ropes penetrate through the fixed pulleys and the side wall of the guide cylinder to be fixedly connected with the upper surface of an extrusion plate. An absorbent is collected, the wall flow effect is prevented, the absorbent is evenly dispersed on the filler plate, the gas-liquid contact area is increased, the gas-liquid contact time is prolonged, and the mass transfer separation efficiency and the flue gas desulfurization and denitrification effect are improved.

Owner:郭建成

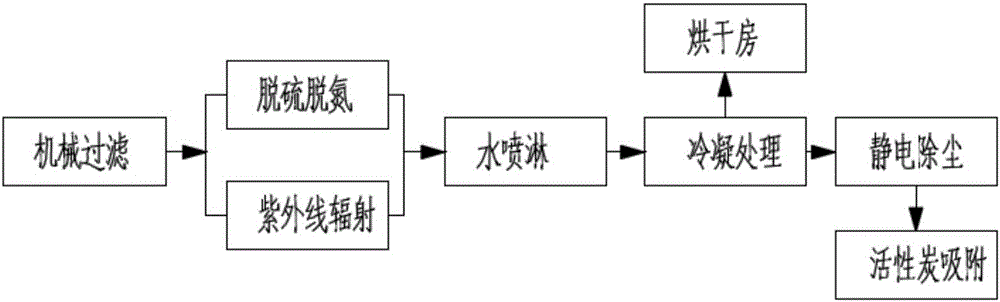

Flue gas treatment device of printing and dyeing setting machine

PendingCN105944555AReduce the temperatureReduce moisture contentCombination devicesGas treatmentActivated carbonHazardous substance

The invention relates to a flue gas treatment device of a printing and dyeing setting machine. The flue gas treatment device comprises mechanical filter tank (1), an ultraviolet treatment tank (2), a water spray tower (3), a shaped energy-gathering dehumidification tower (5), an electrostatic precipitation tower (6), an activated-carbon adsorption tower (7) and a drying chamber (8); the irradiation time of ultraviolet rays in the ultraviolet treatment tank (2) is shorter than or equal to 2 s, and the wavelength of the ultraviolet rays is 184.9 nm. By means of the treatment, hazardous substances in flue gas can be treated harmlessly and thoroughly, and the electrostatic precipitation load can be reduced meanwhile, therefore, the work efficiency is improved.

Owner:湖州荣大环境科技有限公司

Electron beam-oxygen synergistic desulfurization and denitrification system and method

PendingCN111359412APlay a limiting roleExtended service lifeCombination devicesGas treatmentFlue gasDust control

The invention relates to an electron beam-oxygen synergistic desulfurization and denitrification system and method. The system comprises a dust removal device, a spraying device, a mixed reaction device, an absorption device, an oxygen supply device and an ammonia supply device, wherein the mixed reaction device comprises at least two gas distribution pipe plates which are sequentially arranged inthe shell in a flue gas flowing direction and an electron beam generation device which is arranged behind the last gas distribution pipe plate; flue gas sequentially flows through the dust removal device, the spraying device, the mixed reaction device and the absorption device; an ammonia gas inlet is formed between a flue gas inlet of the mixed reaction device and the first gas distribution pipeplate, and is connected with the ammonia gas supply device; and an oxygen inlet is formed between the first gas distribution pipe plate and the last gas distribution pipe plate and connected with theoxygen supply device. The system can reduce the emission of ammonia gas and is beneficial for improving the desulfurization and denitrification effects of flue gas and reducing the influence of purified gas on the environment.

Owner:GUANGDONG J TECH ENVIRONMENT SCI CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com