Flue gas treatment device of printing and dyeing setting machine

A technology for flue gas treatment and shaping machine, applied in gas treatment, combined device, membrane technology and other directions, can solve the problems of high pressure of electrostatic precipitator, insufficient dust removal, poor flue gas treatment effect, etc. The effect of improving work efficiency and reducing load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

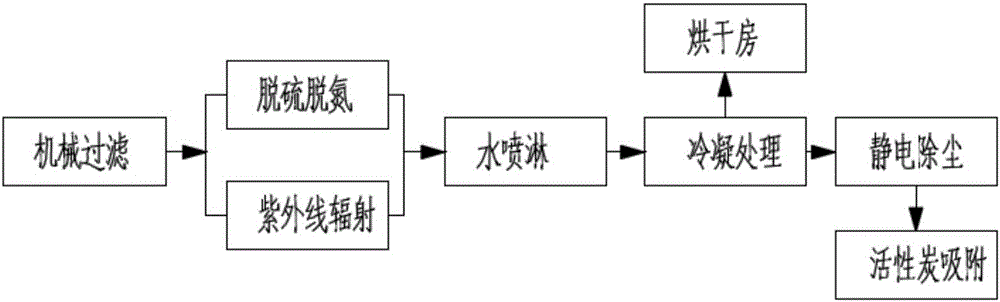

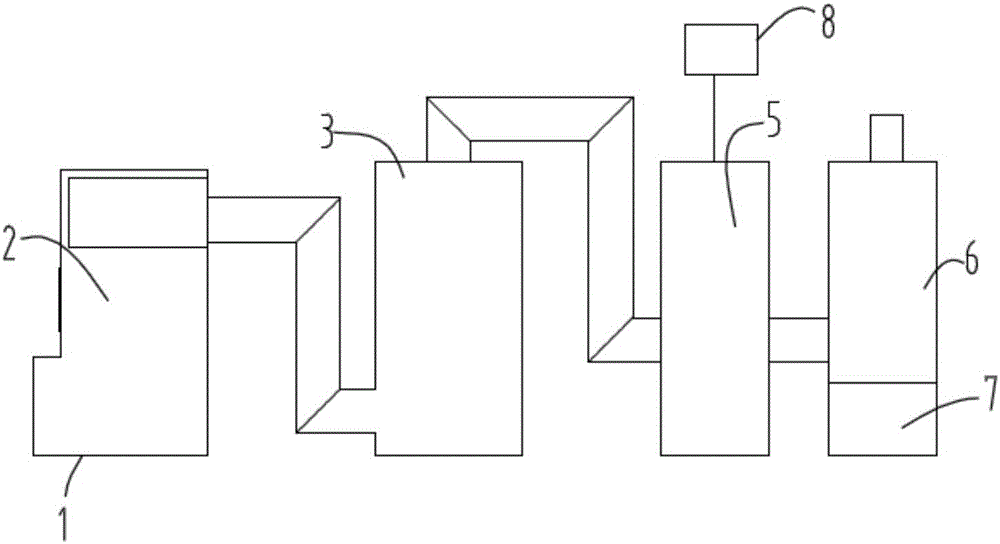

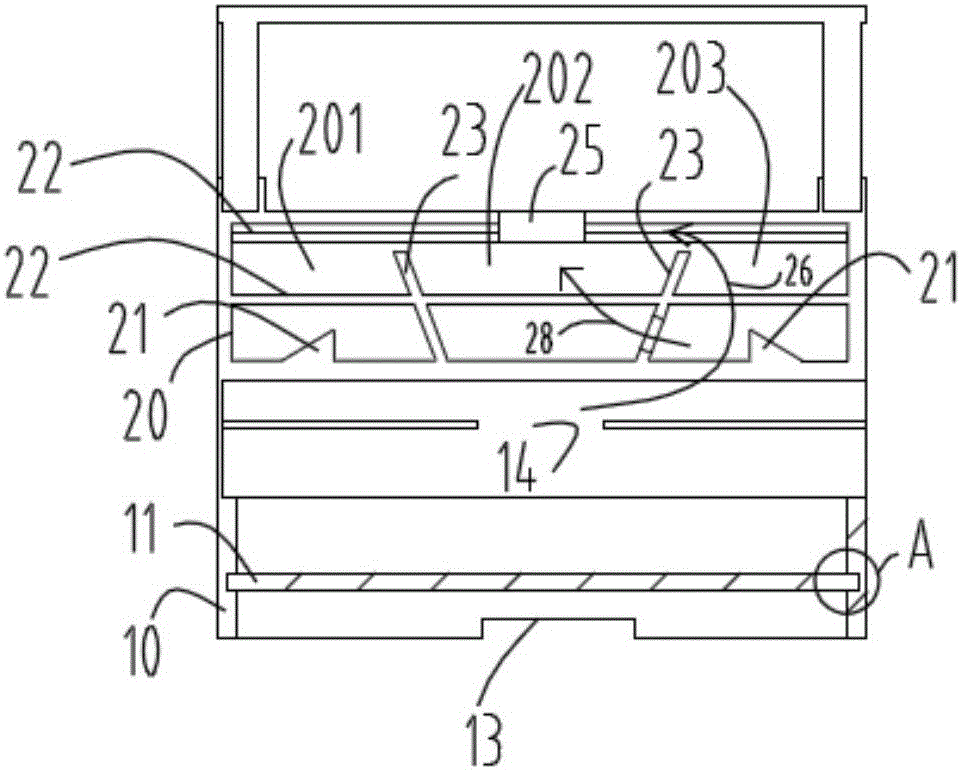

[0036] A flue gas treatment device for a printing and dyeing setting machine, including a mechanical filter box 1, an ultraviolet treatment box 2, a water spray tower 3, a heterogeneous dehumidification tower 5, an electrostatic dust removal tower 6, an activated carbon adsorption tower 7, and a drying room 8; The mechanical filter box 1 includes a filter box 10 and a first filter plate 11 disposed inside and penetrating the filter box 10, the first filter plate 11 is provided with filter holes 12 for gas to pass through, the filter The bottom of the box body 10 is provided with a first flue gas inlet 13, and the top is provided with a first flue gas outlet 14; the ultraviolet treatment box 2 is located above the mechanical filter box 1, and the ultraviolet treatment box 2 includes a box body 20. The second flue gas inlet 21, which is located on both sides of the bottom of the box body 20 and has a triangular opening cross section, two rows of ultraviolet lamp tubes 22 horizont...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com