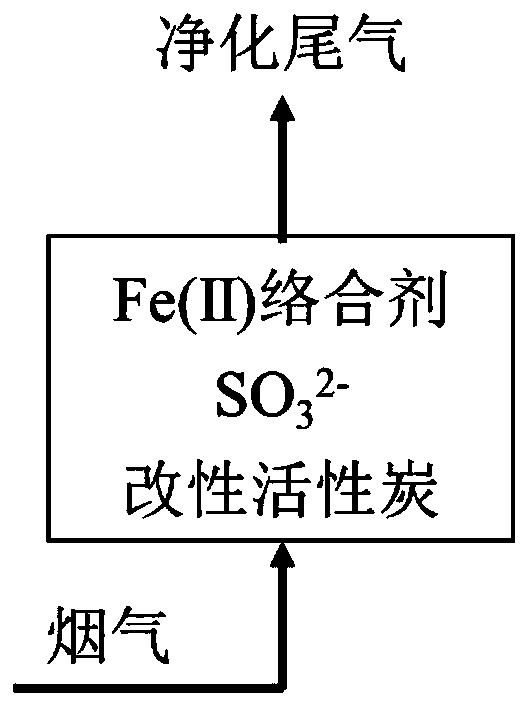

Method for enhancing wet complexing desulfurization and denitrification by modified activated carbon

A technology of desulfurization and denitrification and activated carbon, which is applied in the direction of separation methods, chemical instruments and methods, air quality improvement, etc., can solve the problems of failure to apply, increase the operating cost of iron filings, etc., achieve enhanced desulfurization and denitrification capabilities, and improve desulfurization and denitrification efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0036] Step 1 (preparation of modified activated carbon)

[0037] The carbon-containing raw materials are mechanically crushed and screened, and the carbon-containing raw materials with a particle size of 30-500 μm are selected, and then carbonized at 200-850 °C for 0.3-8 hours, and then physically activated at 600-950 °C for 0.4 ~24 hours to obtain an activated carbon material; wherein, the carbon-containing raw material is selected from one or more of lignite, bituminous coal and semi-coal;

[0038] The activated carbon material is subjected to modification treatment, and the modification treatment is selected from one or more of alkali treatment, metal loading and metal oxide loading to obtain modified activated carbon.

[0039] In a further embodiment of the present invention, the particle size of the modified activated carbon is 30-500 μm, and the BET specific surface area is 150-1000 m 2 / g, the floating rate is 1%-5%, the ignition point is 400-580°C, the isoelectric po...

Embodiment 1

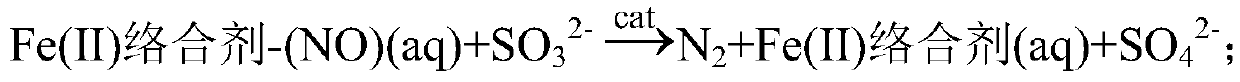

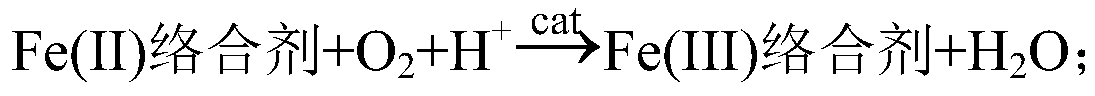

[0054] This embodiment provides a method for enhanced wet complexation desulfurization and denitrification with modified activated carbon, comprising the following steps:

[0055] The carbon-containing raw material lignite is mechanically crushed and sieved, and the carbon-containing raw material with a particle size of 30-500 μm is selected, and then carbonized at 200-700 ° C for 1 hour. The starting temperature of this process is 200 ° C, and the temperature is programmed to 700°C. The programmed temperature rise time is the specified carbonization time; and then the water vapor activation treatment is performed at 700-850°C for 0.75 hours. The initial temperature of this process is 700°C, and the temperature is programmed to rise to 850°C. The temperature program heating time is the specified carbonization time, and the activated carbon material is obtained. The particle size is 30-500 μm, the BET specific surface area is 472m2 / g, the floating rate is 1.5%, the ignition poi...

Embodiment 2

[0063] This embodiment provides a method for enhanced wet complexation desulfurization and denitrification with modified activated carbon, comprising the following steps:

[0064]The carbon-containing raw material lignite is mechanically crushed and screened, and the carbon-containing raw material with a particle size of 30-500 μm is selected, and then carbonized at 700 ° C for 1.5 hours, and then activated with water vapor at 850 ° C for 2 hours to obtain activated carbon materials Add 5mol / L potassium hydroxide solution to the activated carbon material, soak at 45°C for 12 hours; filter after soaking, wash with deionized water until neutral, then dry at 120°C for 4 hours to obtain modified activated carbon; the particle size is 30-500μm, BET specific surface area is 515m2 / g, floating rate is 2.3%, ignition point is 445°C, isoelectric point is 8.3, ash specific gravity is 6.04%, metal loading rate is 0%.

[0065] Dissolve the complexing agent and ferrous salt in deionized wat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com