Composite desulfurization and denitration agent

A desulfurization, denitrification, and surfactant technology, which is used in the separation of dispersed particles, air quality improvement, chemical instruments and methods, etc., can solve the problems of ammonia escape, difficult to standard discharge, hidden dangers, etc., and achieve fast absorption and high efficiency. Effect

Inactive Publication Date: 2014-05-28

SHANDONG AMETHYST PHOTOELECTRIC NEW MATERIAL

View PDF3 Cites 8 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0003] The shortcomings of the above-mentioned denitrification process are: selective non-catalytic reduction method: the efficiency of nitrogen oxide removal by spraying ammonia in the furnace is low (30%-50%), ammonia escape is serious, and it is difficult to standardize emissions; selective catalytic reduction method uses Catalyst, the efficiency is relatively high and can reach 80% efficiency, but the investment is high, the catalyst layer needs to be replaced every 2-3 years, and the operating cost is high

At the same time, the ammonia gas that the system participates in the reaction needs to be obtained through methods such as liquid ammonia evaporation, ammonia water evaporation, and urea pyrolysis, which poses a great safety hazard

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment

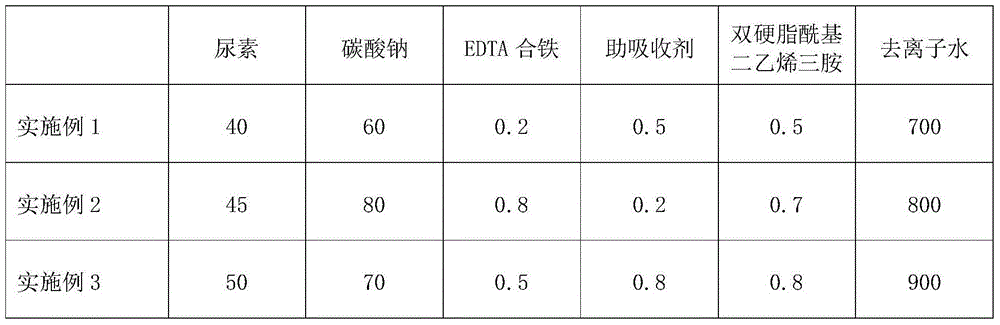

[0016] Embodiment: unit: g

[0017]

[0018] In the formulation of Examples 1-3, an appropriate amount of sodium hydroxide is added to adjust the pH to 10-12 to obtain the alkaline denitrification absorbent of the present invention.

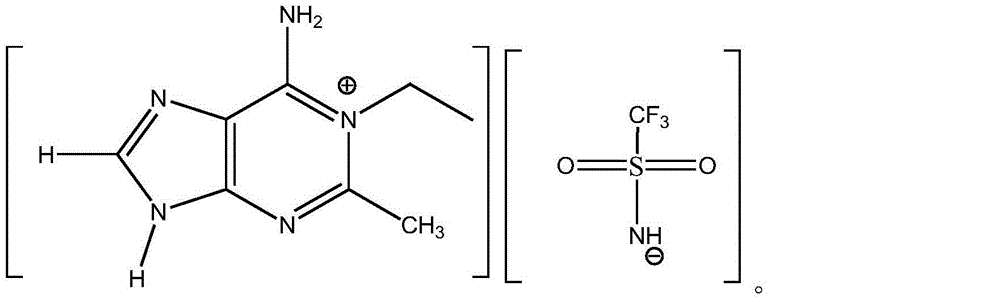

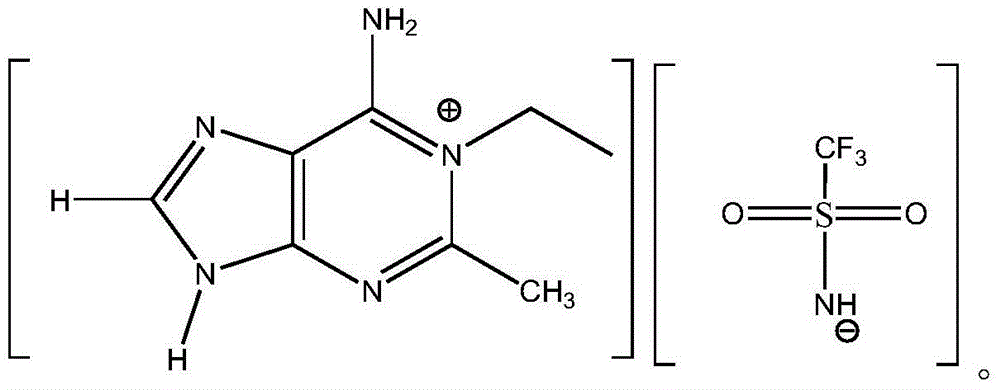

[0019] The absorption aid is a mixture of compounds of the following chemical formula in a molar ratio of 1:1:

[0020] and

[0021]

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention provides a composite desulfurization and denitration agent, and belongs to the technical field of industrial gas purification. The composite desulfurization and denitration agent is characterized by being prepared through the following steps: mixing the following raw materials in parts by weight: 40 to 50 parts of urea, 60 to 80 parts of sodium carbonate, 0.2 to 0.8 part of EDTA-Fe, 0.2 to 0.8 part of absorption enhancer, and 0.5 to 0.8 part of distearoyl diethylenetriamine, wherein the total parts by weight of the EDTA-Fe, absorption enhancer, and surfactant are more than 1.2 parts by weight; adding 700 to 900 parts by weight of water into the mixture, evenly mixing, and adding a proper amount of sodium hydroxide to adjust the pH value to a range of 10 to 12. The composite desulfurization and denitration agent is used to remove high-valence oxynitride and sulfur dioxide at a normal temperature and under a normal pressure; the nitrogen dioxide absorption rate of the agent is 95% or more, the sulfur dioxide absorption rate of the agent is 90% or more, and the agent has the advantages of rapid absorption speed and high efficiency.

Description

technical field [0001] The invention relates to a compound desulfurization and denitrification agent, which belongs to the technical field of industrial gas purification. Background technique [0002] At present, the main denitrification processes are SNCR (selective non-catalytic reduction) and SCR (selective catalytic reduction) technologies. By adding ammonia or ammonia water to the flue gas and controlling the reaction conditions, the nitrogen oxides and ammonia undergo a redox reaction to generate nitrogen to achieve the purpose of denitrification. [0003] The shortcomings of the above-mentioned denitrification process are: selective non-catalytic reduction method: the efficiency of nitrogen oxide removal by spraying ammonia in the furnace is low (30%-50%), ammonia escape is serious, and it is difficult to standardize emissions; selective catalytic reduction method uses Catalyst, the efficiency is relatively high and can reach 80% efficiency, but the investment is hig...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): B01D53/14B01D53/78B01D53/60

CPCY02A50/20

Inventor 李瑞莲

Owner SHANDONG AMETHYST PHOTOELECTRIC NEW MATERIAL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com