Dry method combined desulfurization and denitration technology and device for activated coke

A desulfurization, denitrification, and activated coke technology, applied in the field of flue gas pollution control, can solve the problems of insufficient utilization of active coke active sites and low desulfurization efficiency, and achieve the effects of improving desulfurization and denitrification efficiency, reducing investment costs, and reducing adsorption reaction steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

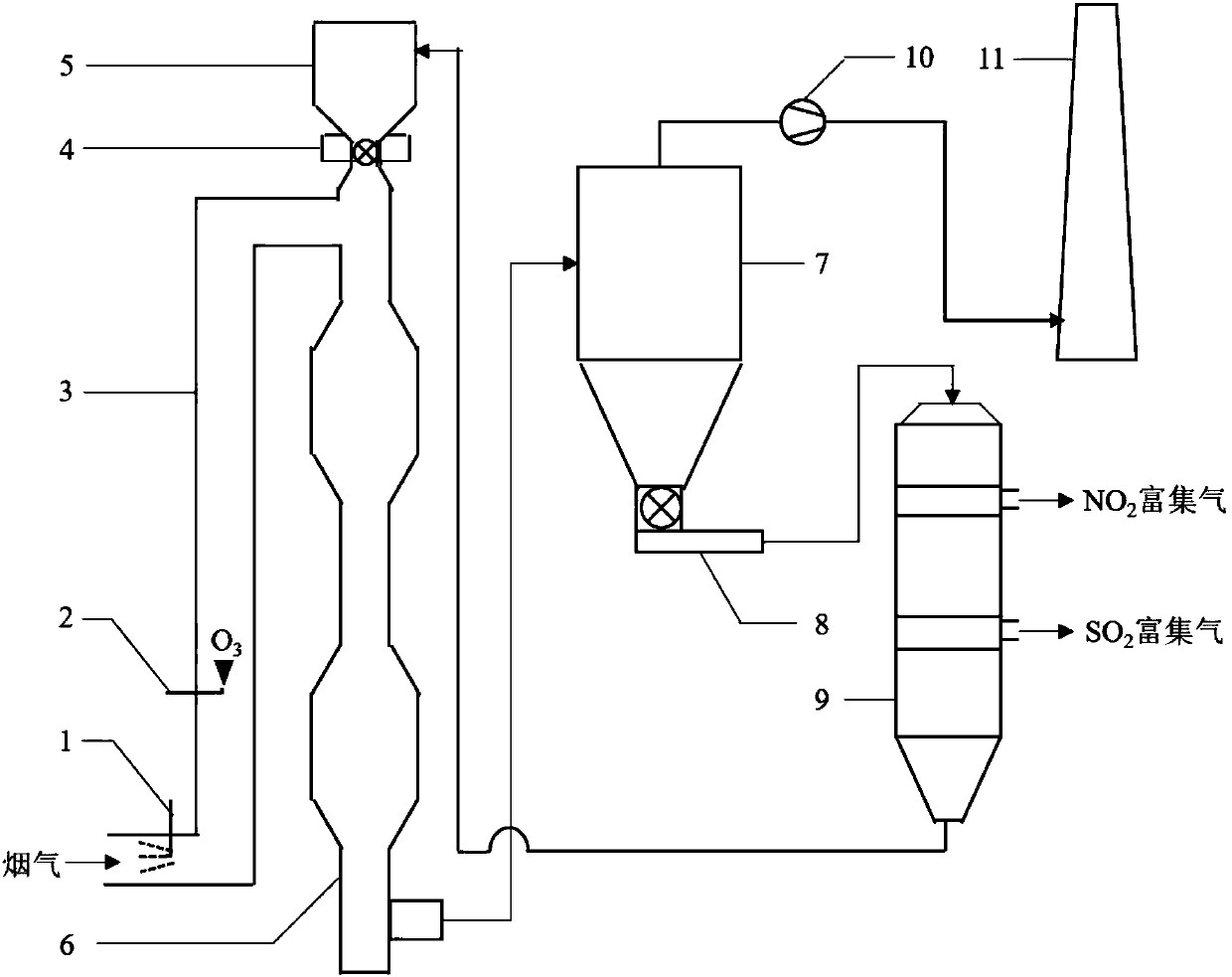

[0026] Attached below figure 1 To further illustrate the present invention, the water atomization nozzle 1 is placed at the inlet end of the upward flue 3; the ozone injection device 2 is located behind the water atomization nozzle 1; the outlet of the upward flue 3 is connected to the upper inlet of the fluidized bed 6; the fluidized bed 6. The top is connected to the powder bin 5 through the feeding device 4, and the outlet at the bottom is connected to the gas-solid separation device 7; It is connected with the inlet of the segmental analysis tower 9; the outlet of the segmental analysis tower 9 is connected to the powder bin 5. The specific implementation method is as follows:

[0027] (1) The flue gas enters the upward flue 3 at the front end of the fluidized bed 6 under the suction of the induced draft fan 10, humidifies and cools the flue gas through the water atomizing nozzle 1, and adjusts the flue gas temperature within the range of 70-80°C , the ozone is sprayed i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com