Dry-wet purifying recovery treatment process of smoke gas

A recovery treatment, dry and wet method technology, applied in the field of flue gas purification, can solve the problems of inconspicuous industrial application, immaturity, and inconspicuous treatment efficiency, and achieve the effects of improving treatment efficiency, maintaining activity, and good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

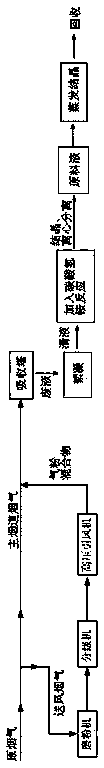

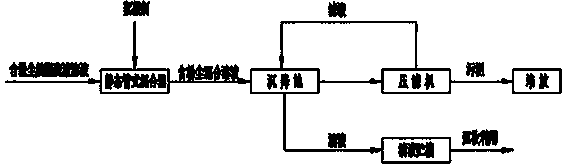

[0075] A dry-wet purification and recycling process for flue gas. The air-supply flue gas and dry powder absorbent enter the pulverizer along with the high-pressure induced draft fan for crushing treatment. The pulverized absorbent is then sent to the classifier with the airflow. The gas-powder mixture enters the main flue and reacts with the flue gas in the main flue to realize the preliminary purification of the flue gas. The flue gas after preliminary purification enters the absorption tower from the main flue and is directly discharged after wet purification; the waste in the absorption tower After the liquid is flocculated, the clear liquid enters the reactor to react with ammonium bicarbonate. After the reaction is completed, the obtained solid is used as an absorbent to be reused in the flue gas purification section. After the liquid is cooled and crystallized, the clear liquid is evaporated and crystallized to obtain ammonium salt crystals and recovered use.

Embodiment 2

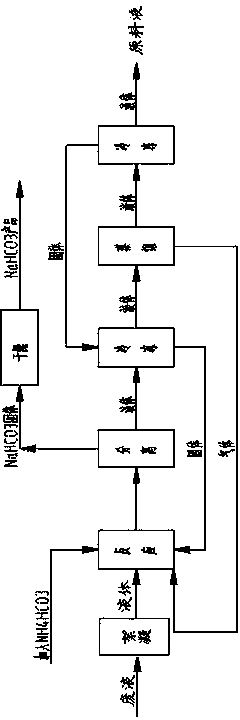

[0077] This embodiment is basically the same as Embodiment 1, on this basis:

[0078] The dry powder absorbent is NaHCO 3 , the absorbent of the wet purification is NaHCO 3 of aqueous solution.

Embodiment 3

[0080] This embodiment is basically the same as Embodiment 1, on this basis:

[0081] The dry powder absorbent is KHCO 3 , the wet purification absorbent is KHCO 3 of aqueous solution.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Graininess | aaaaa | aaaaa |

| Graininess | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com