Patents

Literature

228results about How to "Efficient oxidation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

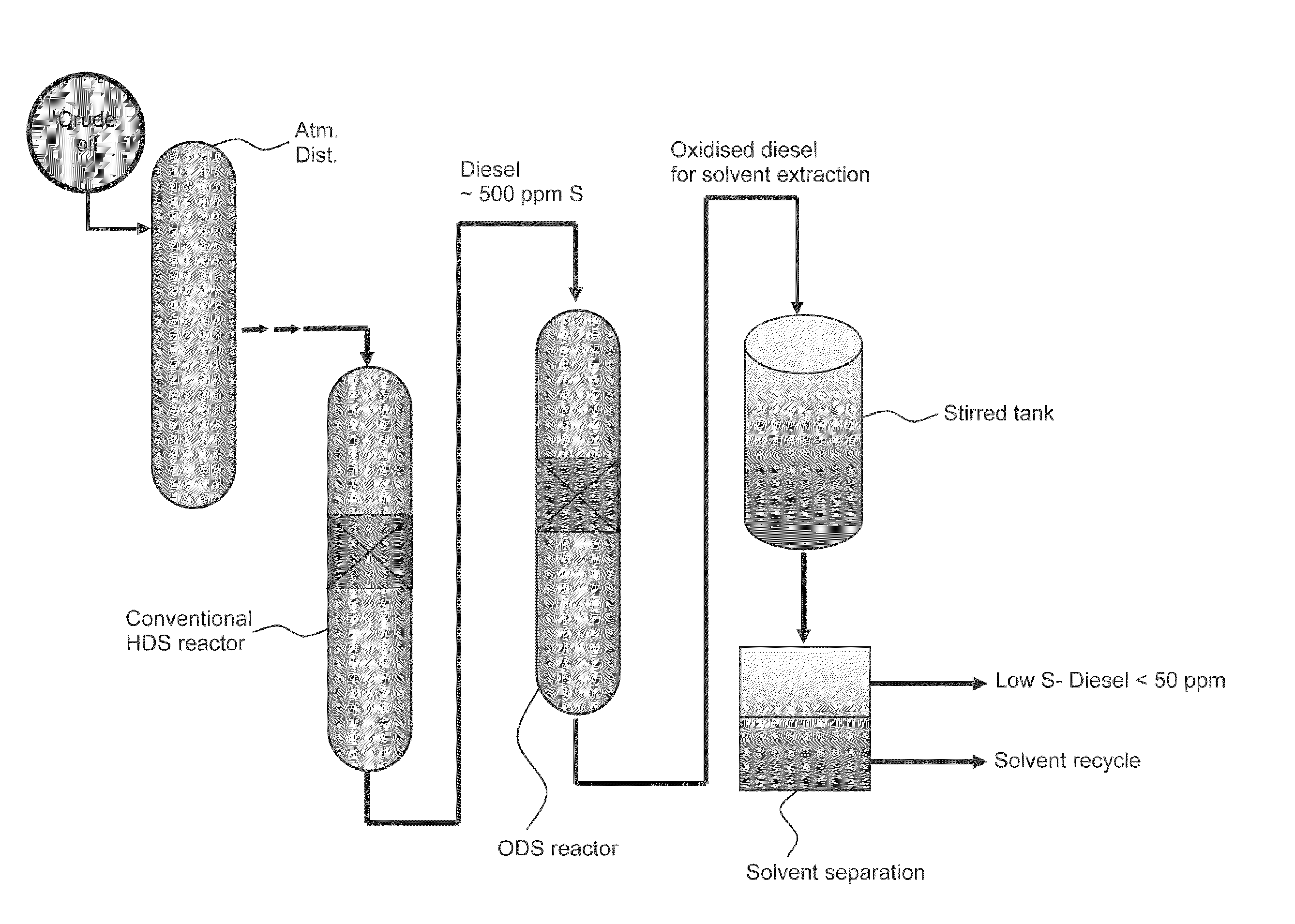

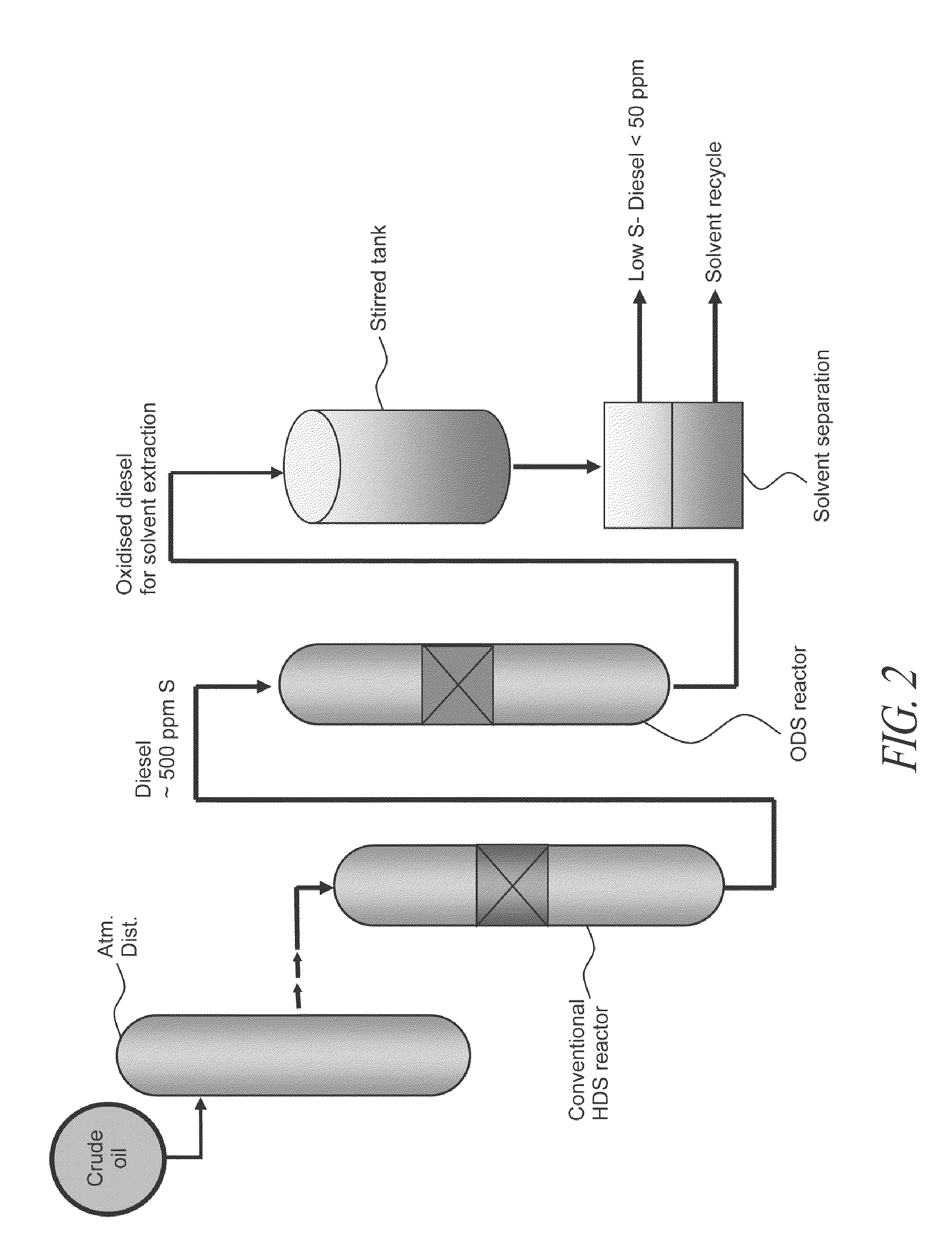

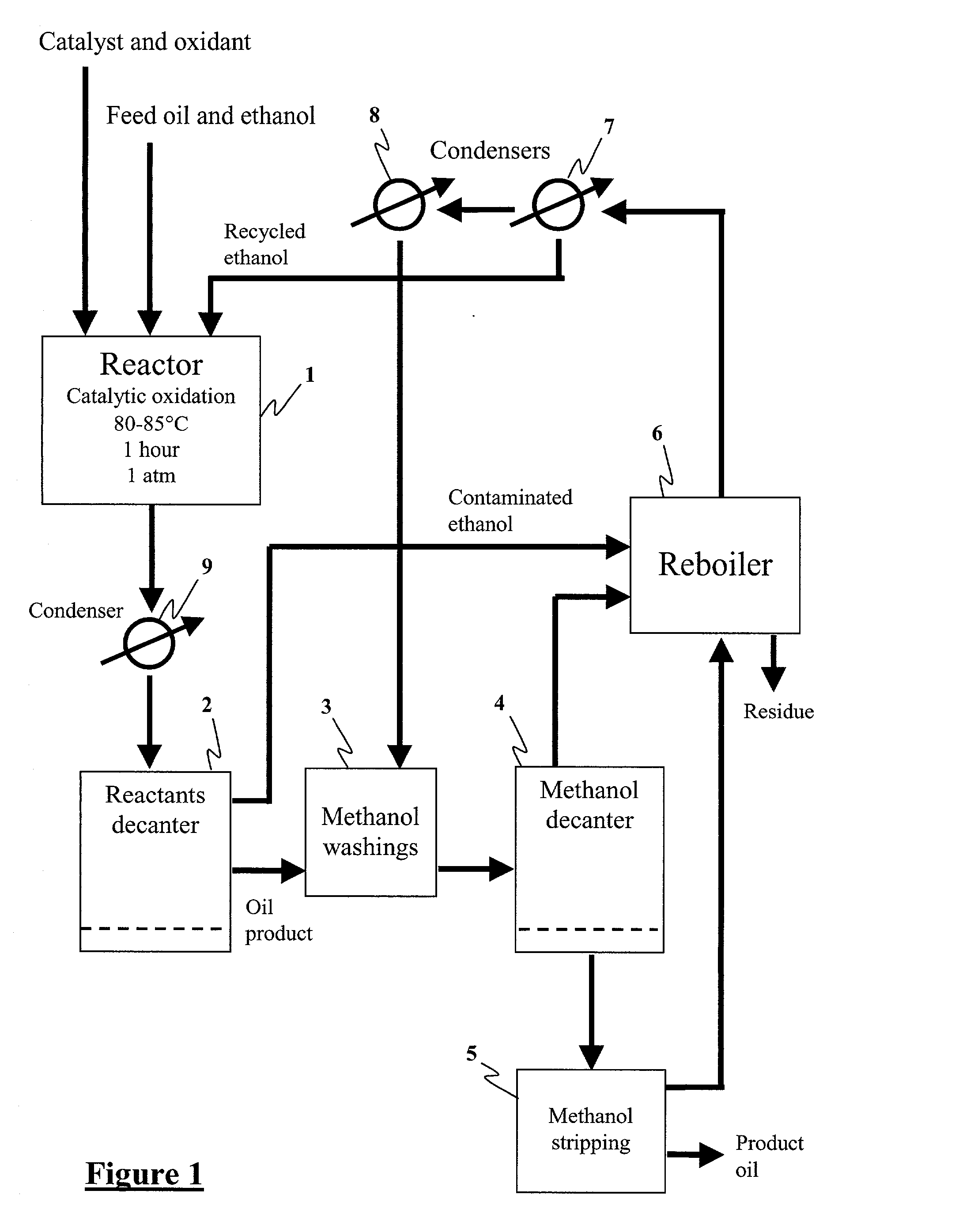

Method for the production of hydrocarbon fuels with ultra-low sulfur content

InactiveUS6673236B2Efficient oxidationReduce sulfur contentRefining with oxygen compoundsCatalytic naphtha reformingAlcoholCatalytic oxidation

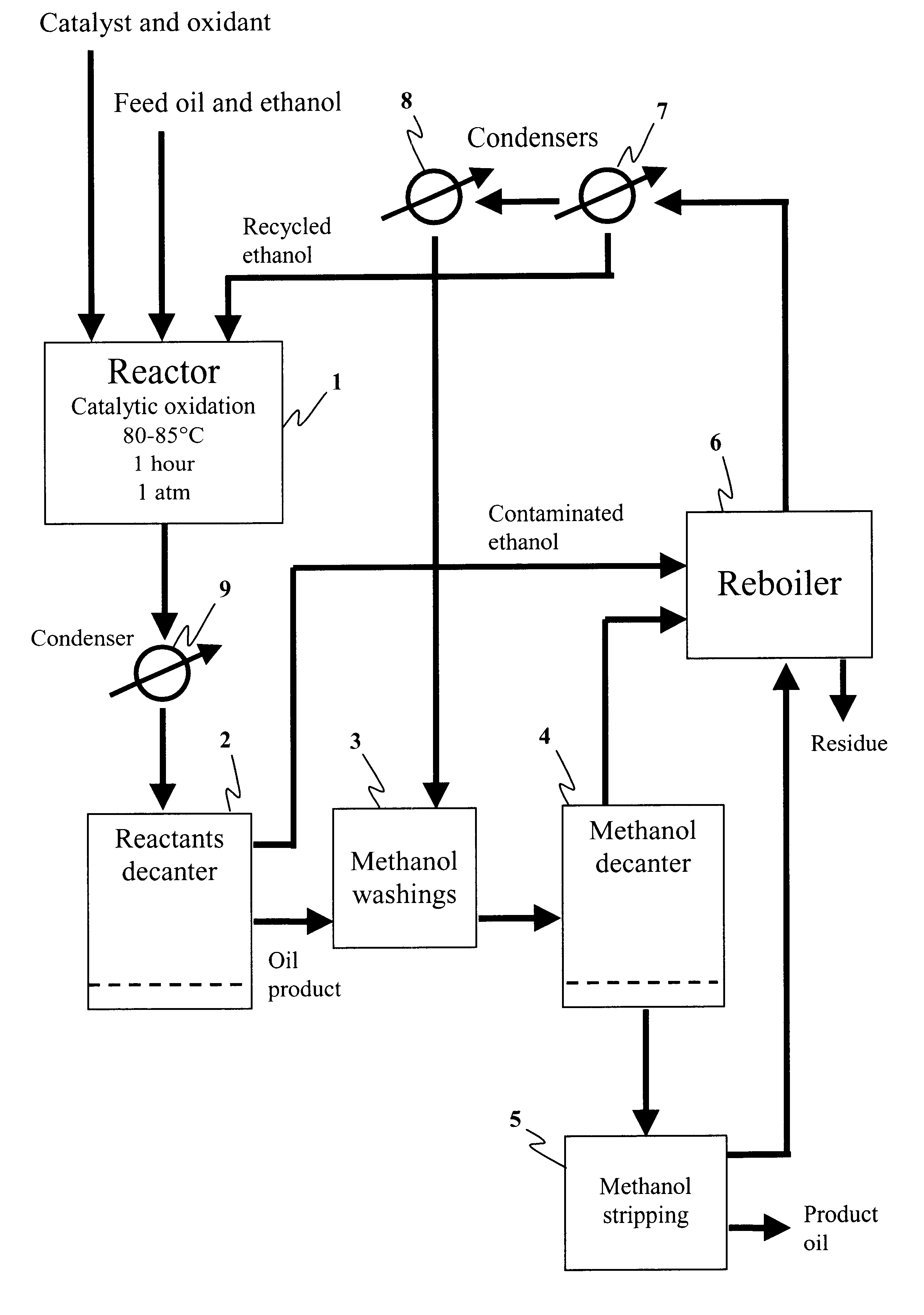

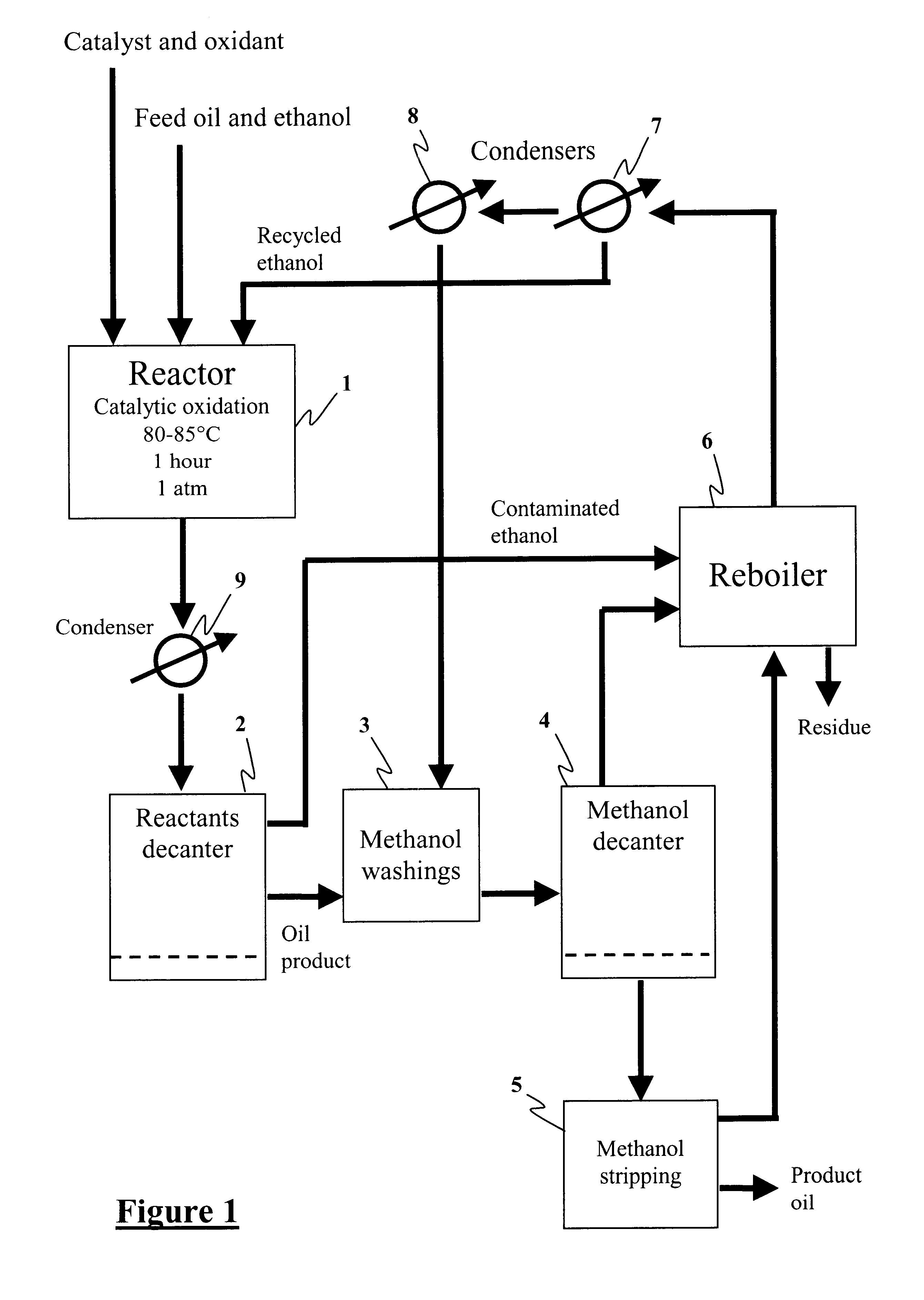

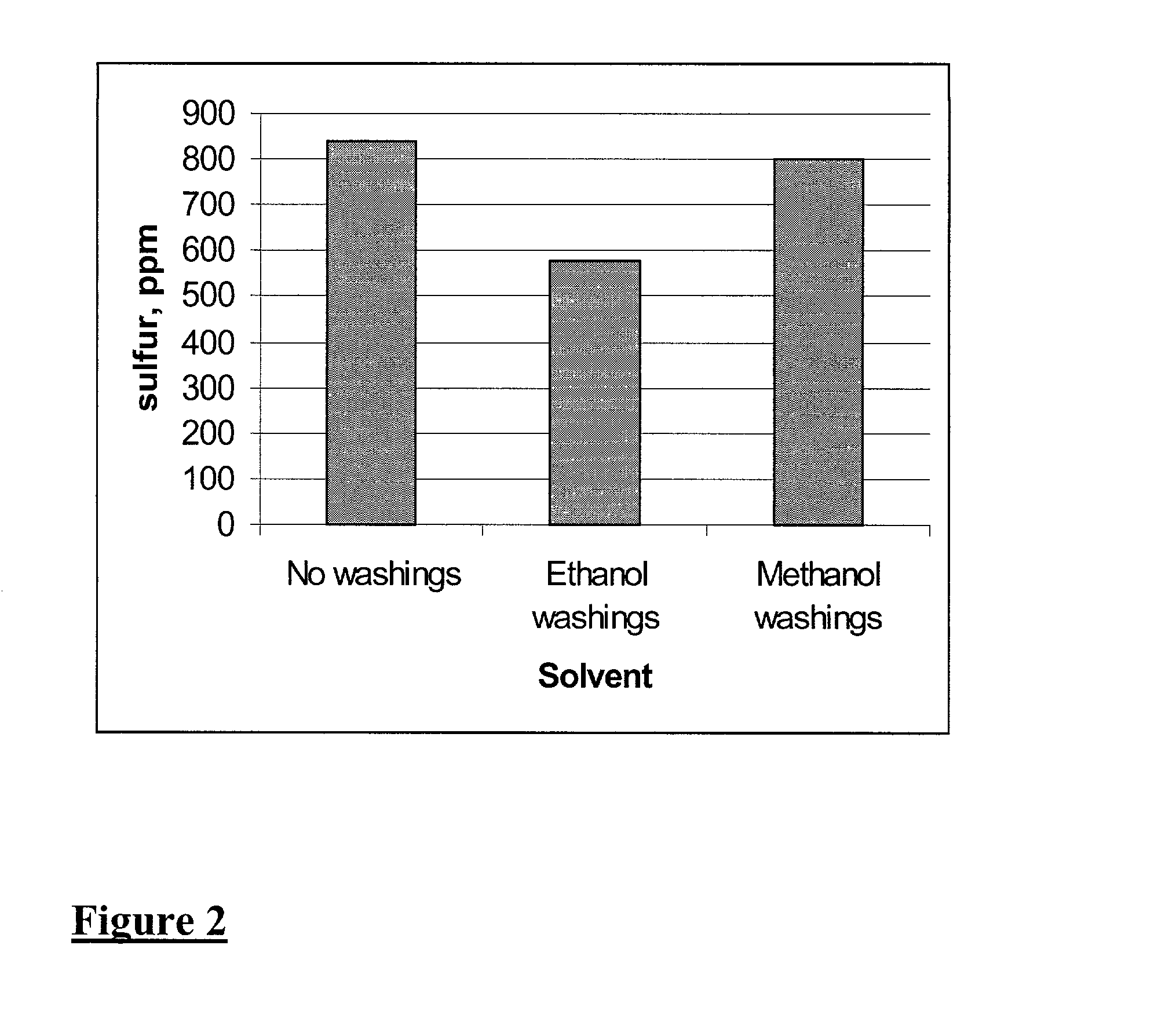

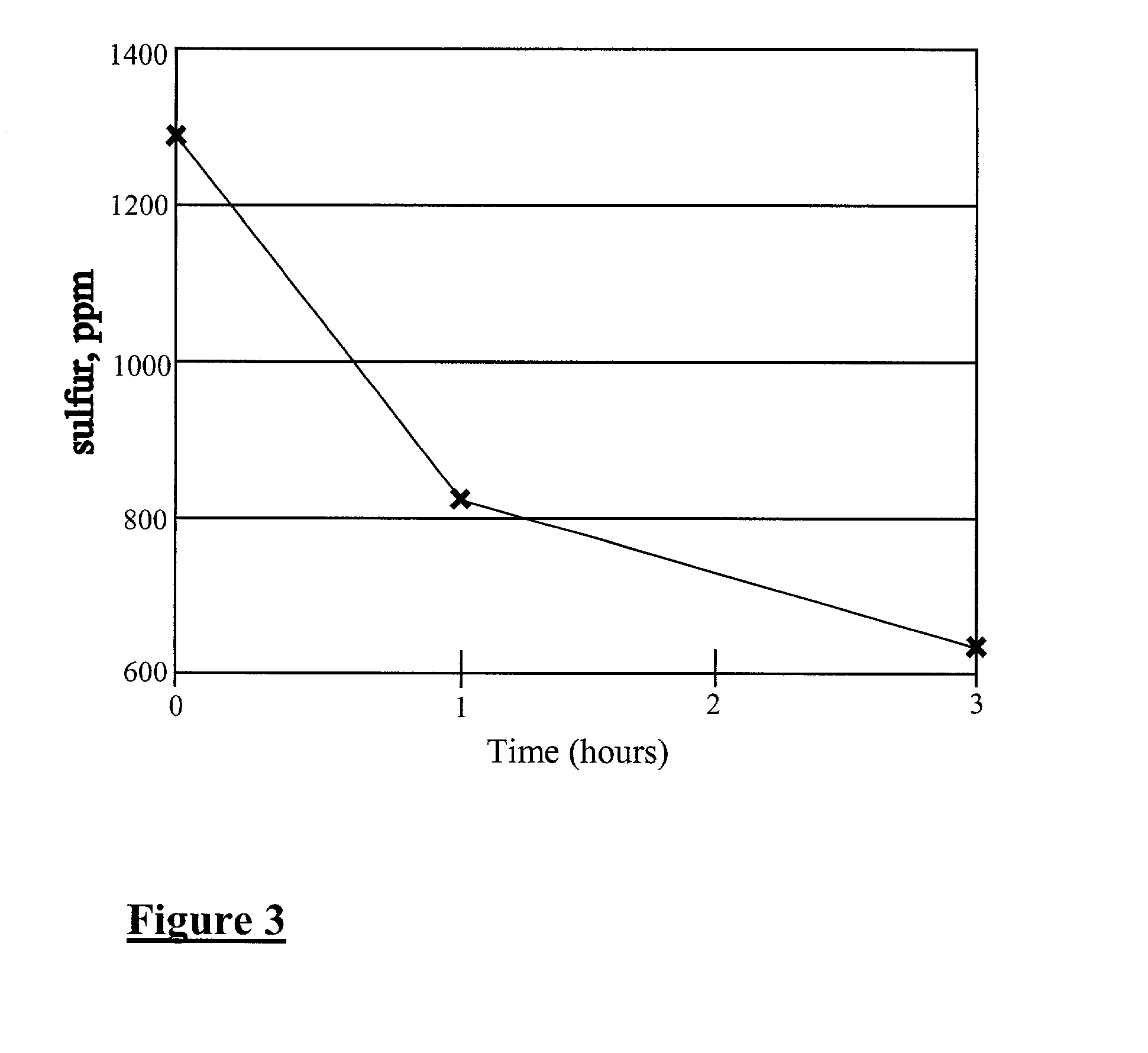

The present invention provides a method for producing hydrocarbon fuels with ultra-low levels of sulfur. The method involves catalytic oxidation of the sulfurous compounds within the hydrocarbon fuel, followed by extraction of the oxidized (and polarized) sulfurous compounds using a polar solvent. The present invention teaches the involvement of ethanol during catalytic oxidation. In this way, the oxidation catalyst has a dual-role in the oxidation process: firstly the catalyst directly oxidizes the sulfurous compounds, and secondly the oxidation catalyst converts of a small portion of the alcohol to the corresponding peroxy acid, which also helps to drive the oxidation process.

Owner:HER MAJESTY THE QUEEN & RIGHT OF CANADA REPRESENTED BY THE MIN OF NATURAL RESOURCES

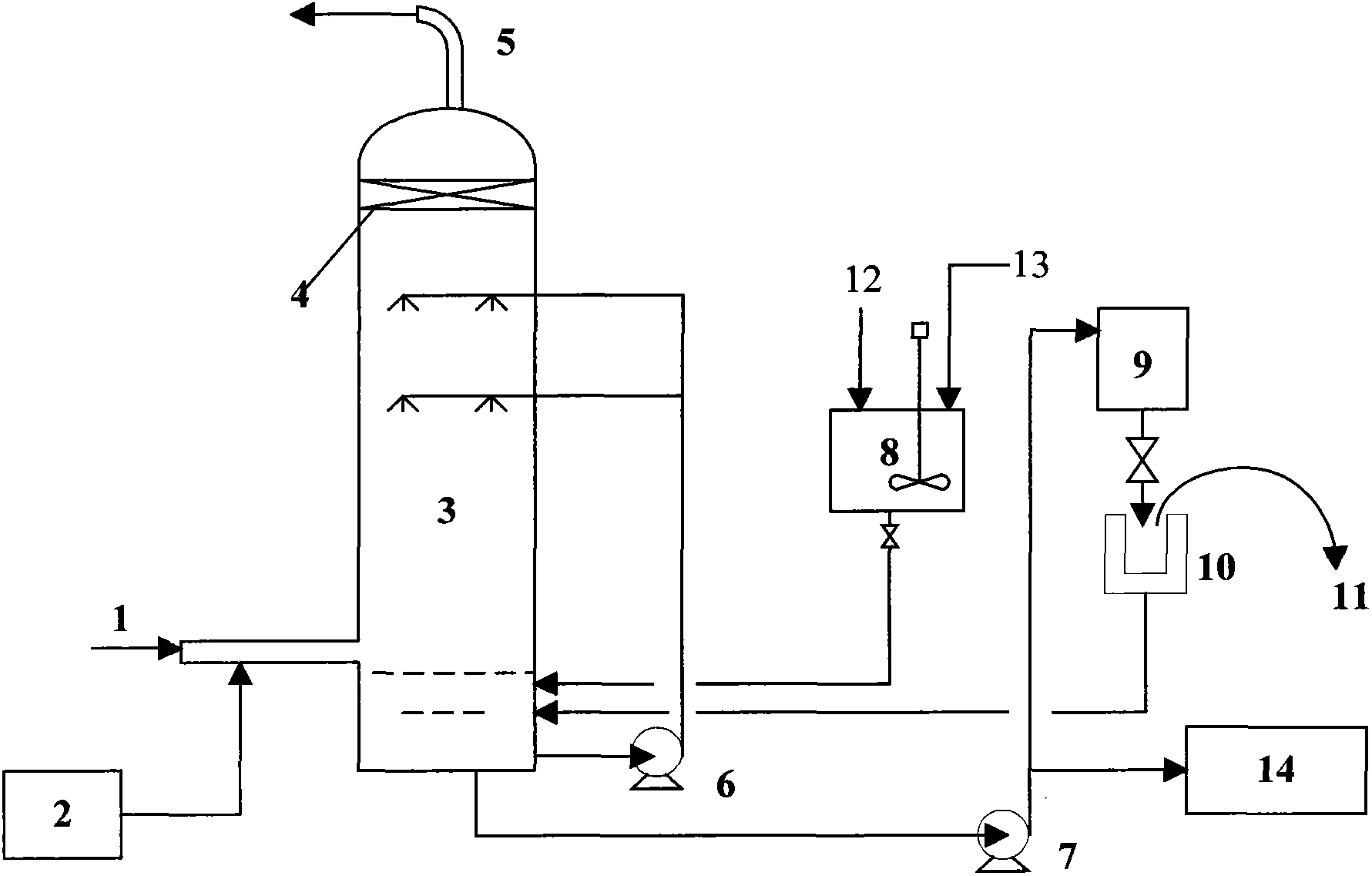

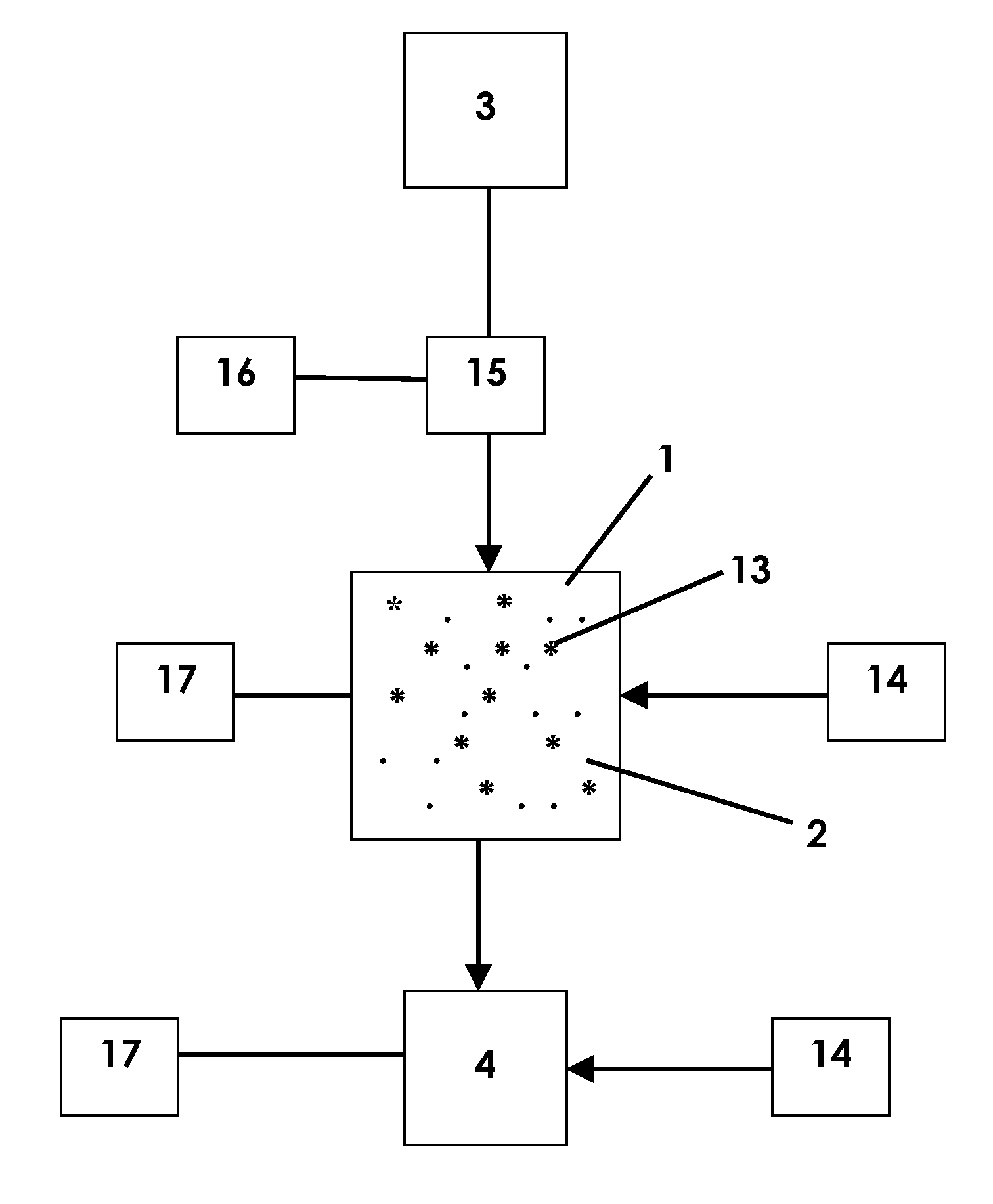

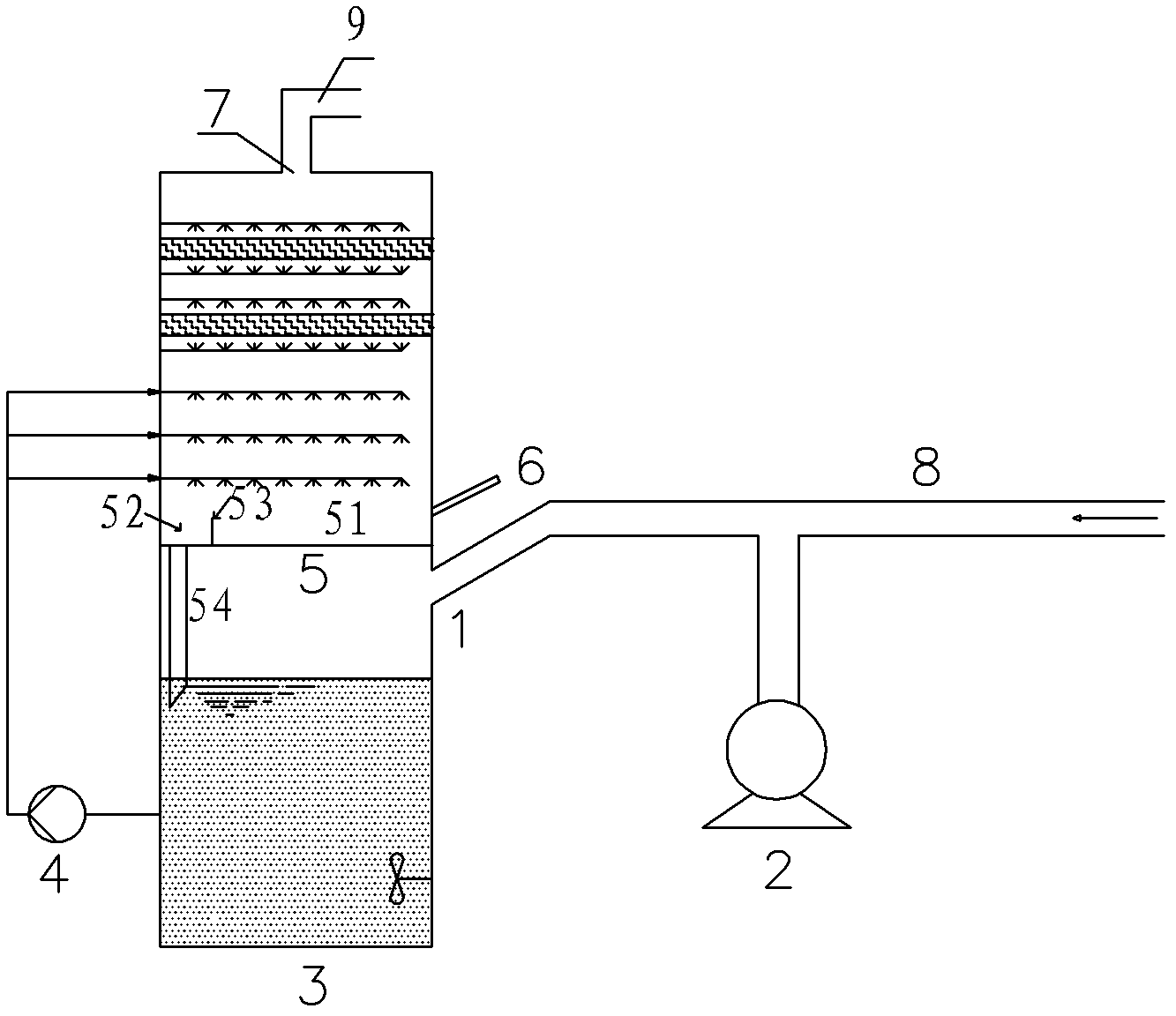

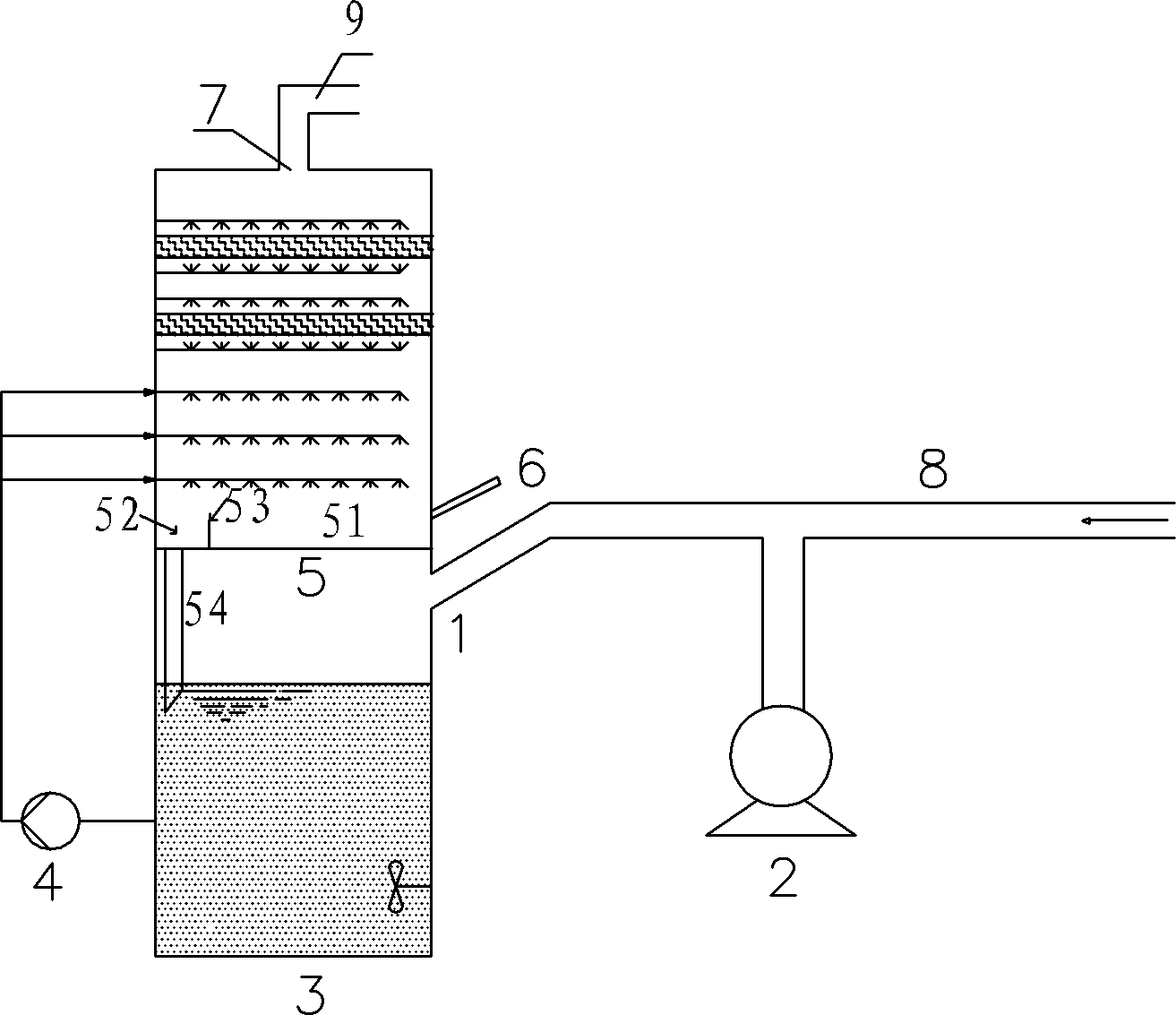

Device and method for simultaneously desulfurizing and denitrifying flue gas by ozone catalytic oxidation process

InactiveCN102247750AEfficient oxidationDispersed particle separationSulfur-trioxide/sulfuric-acidCatalytic oxidationAbsorption of water

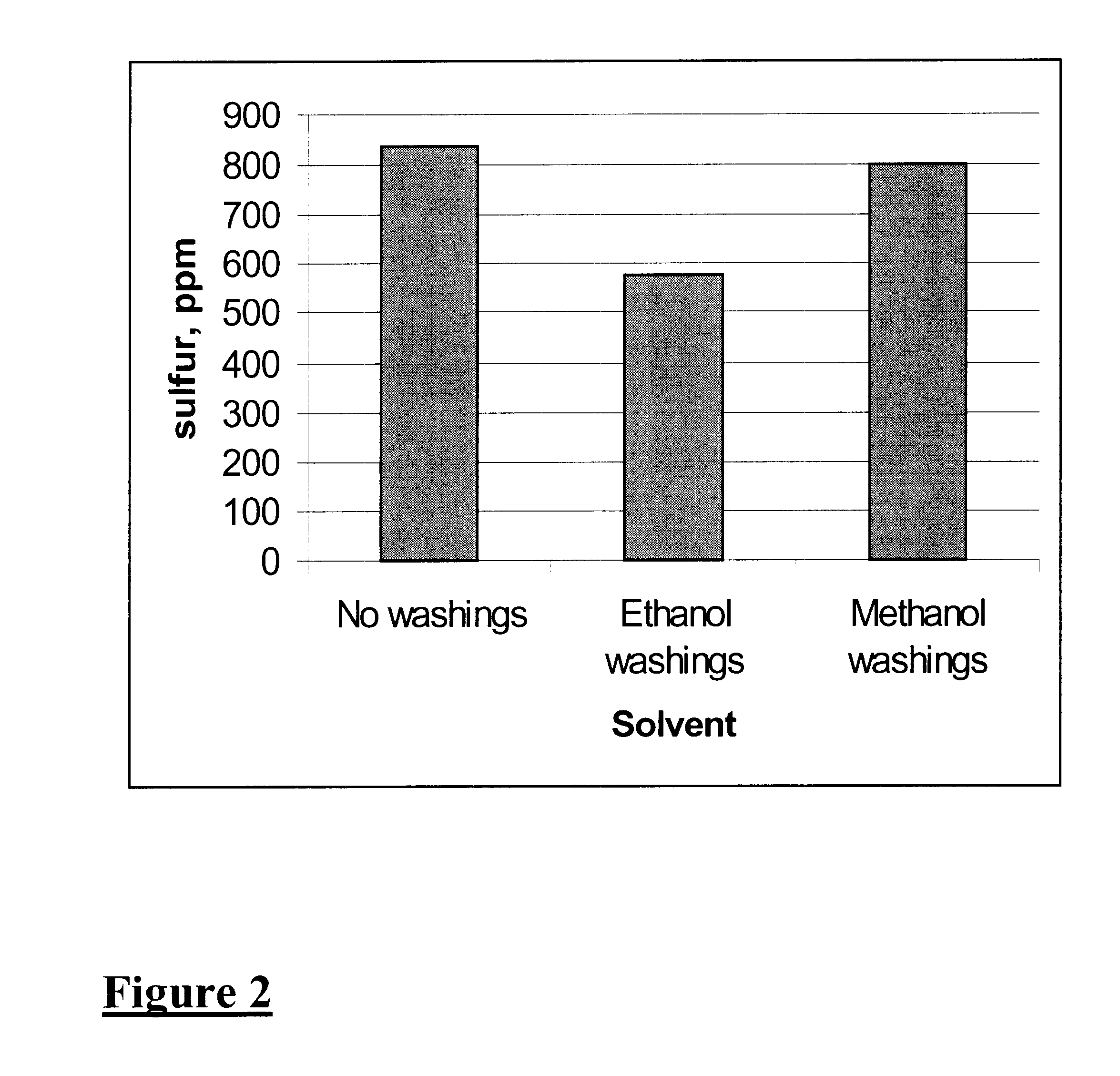

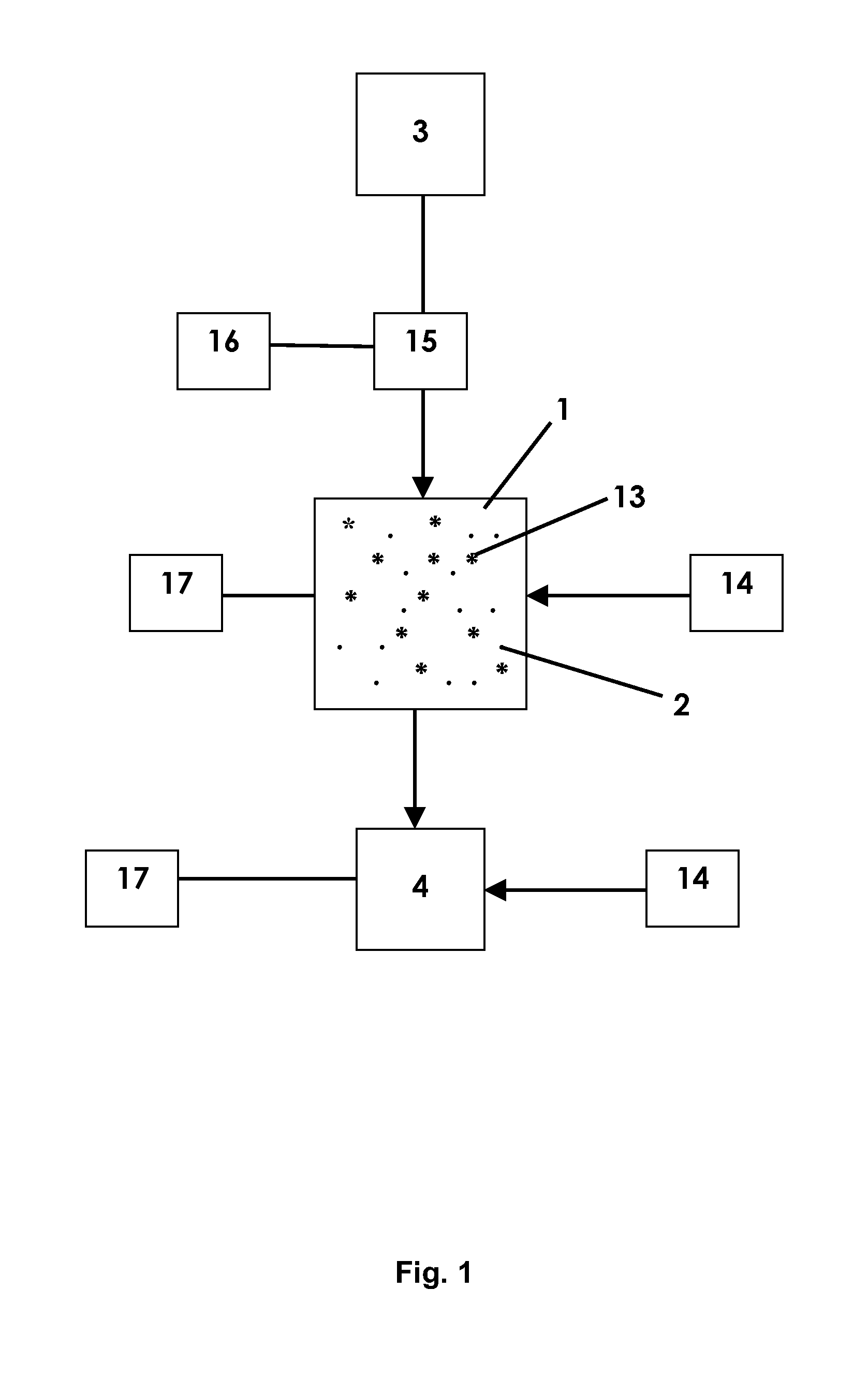

The invention relates to a flue gas pollutant treatment process and aims to provide a device and method for simultaneously desulfurizing and denitrifying a flue gas by ozone catalytic oxidation process. The device comprises a desulfurization and denitrification tower, an ozone generator, absorption liquid circulating equipment and desulfurization and denitrification by-product post-treatment equipment. Ozone enters from a flue or the lower part of the desulfurization and denitrification tower, a catalyst is added to an absorption liquid, and the absorption liquid is injected in from the upper part of the desulfurization and denitrification tower, so that SO2 and NO in the flue gas are oxidized by ozone with high efficiency under the action of the catalyst, and in combination with the absorption of water or alkaline substances, SO2 and NOx in the flue gas are recovered in the form of high value-added sulfuric acid and nitric acid products, or ammonium sulfate / ammonium nitrate mixed nitrogen fertilizers, potassium sulfate / potassium nitrate mixed potassium fertilizers or ammonium / potassium compound fertilizers respectively, thereby achieving resource recovery and value maximization of the desulfurization and denitrification process. The desulfurization and denitrification process provided by the invention has the advantages of simple structure, low investment and low operation cost. The desulfurization rate and the denitrification rate of the desulfurization and denitrification process provided by the invention can reach more than 96% and more than 90% respectively.

Owner:EAST CHINA UNIV OF SCI & TECH

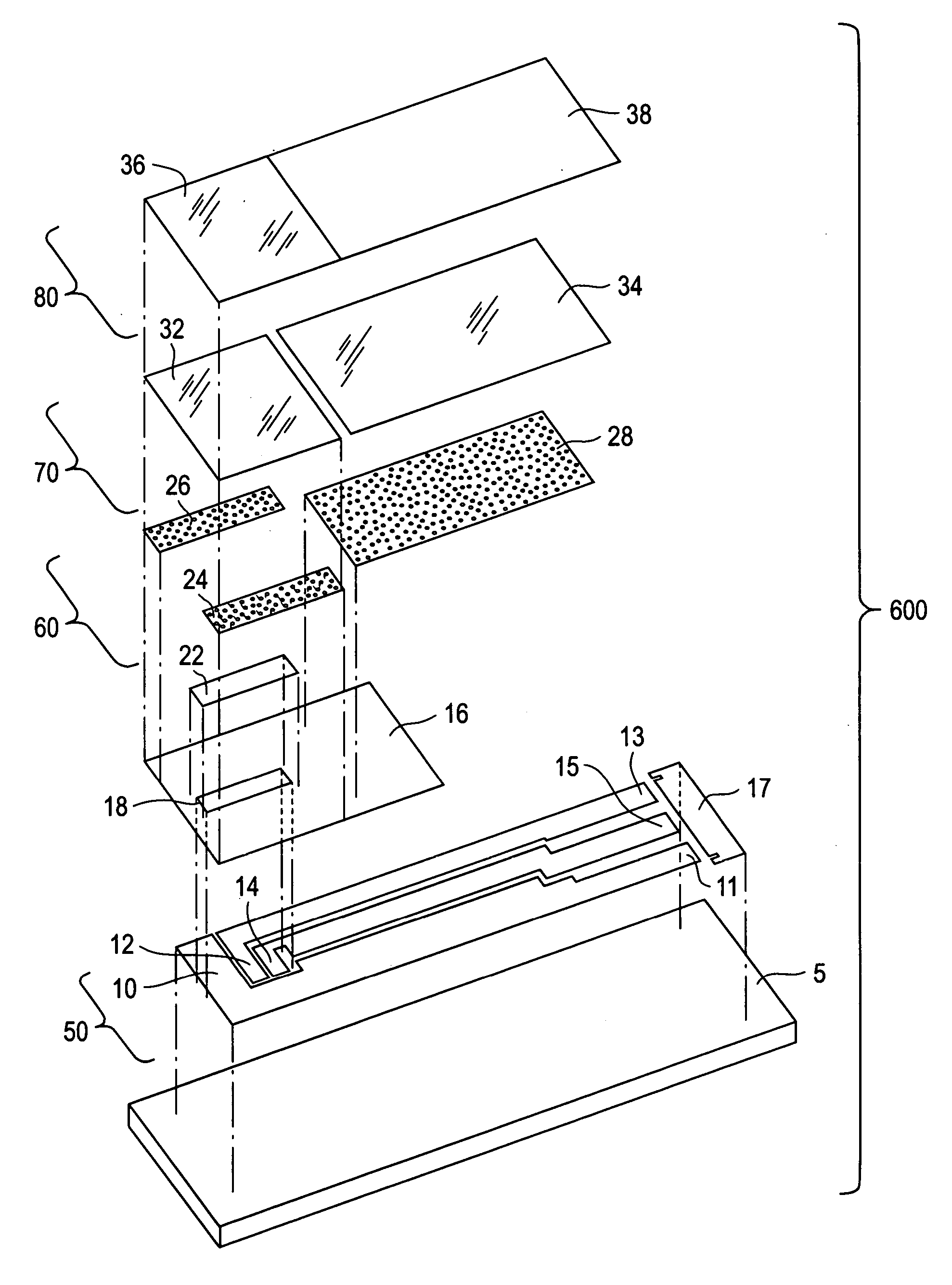

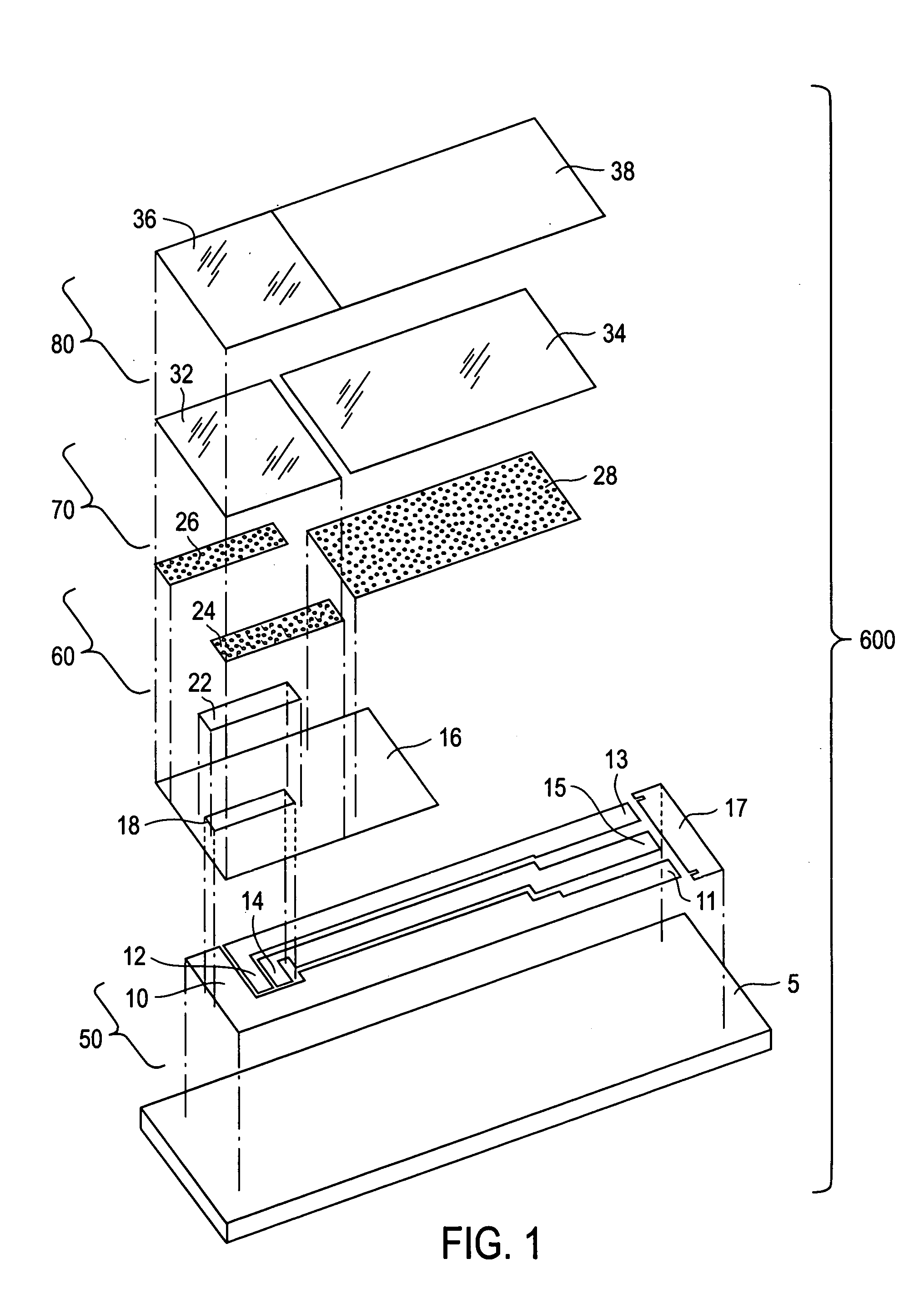

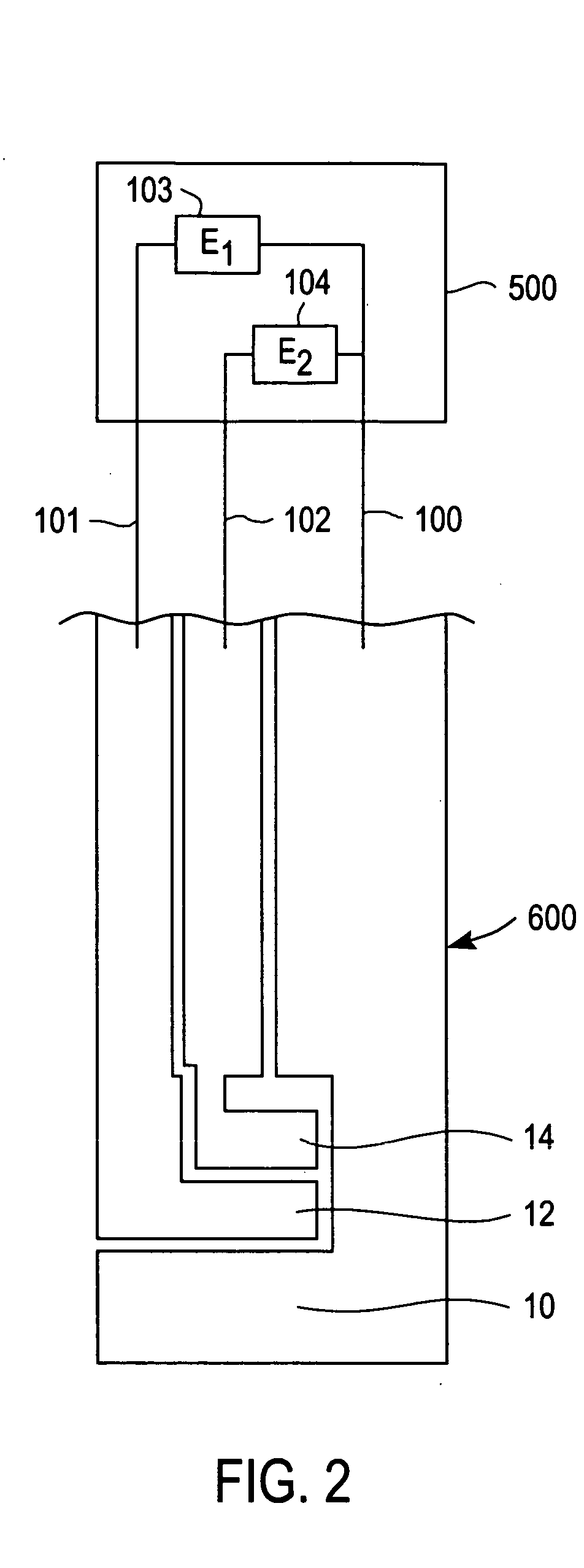

Meter for use in an improved method of reducing interferences in an electrochemical sensor using two different applied potentials

InactiveUS20050109618A1Promote oxidationReduce the impactImmobilised enzymesBioreactor/fermenter combinationsAnalyteElectrical polarity

The present invention is directed to an improved meter that utilizes a method of reducing the effects of interfering compounds in the measurement of analytes and more particularly to a method of reducing the effects of interfering compounds in a system wherein the test strip utilizes two or more working electrodes. In one embodiment of the present invention, a meter is described which applies a first potential to a first working electrode and a second potential, having the same polarity but a greater magnitude than the first potential, is applied to a second working electrode. The meter then measures the generated current and utilizes a predetermined algorithm to correct the measured current to compensate for the presence of interfering compounds in the sample.

Owner:LIFESCAN IP HLDG LLC

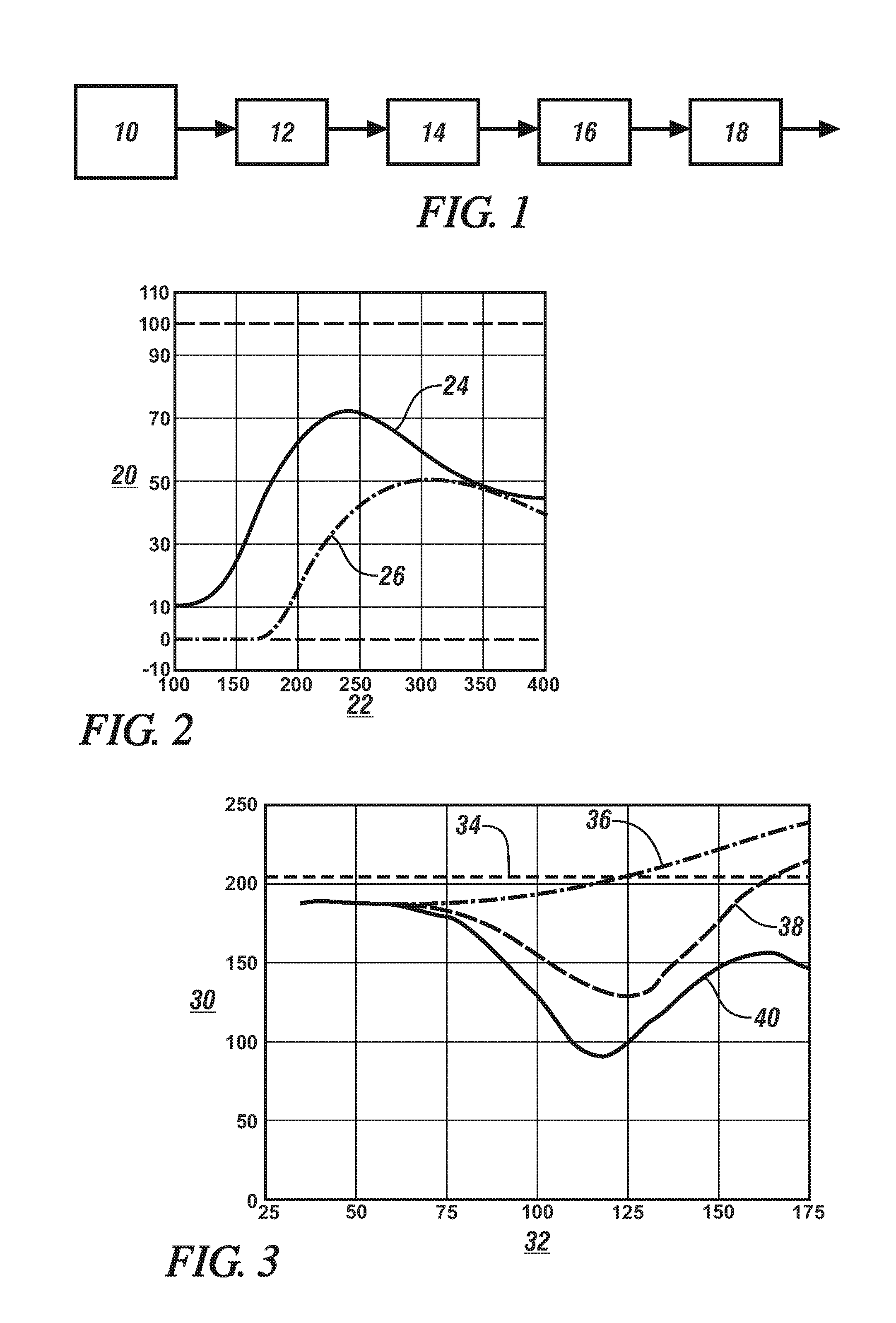

Nitric oxide oxidation over silver-based catalysts

InactiveUS20130294989A1Reduce tailpipe emission of NOxEfficient oxidationCombination devicesNitrogen compoundsHydrogenNitrogen

Ag / Al2O3 materials may be packaged in a suitable flow-through reactor, close coupled to the exhaust manifold of a diesel engine, and upstream of other exhaust gas treatment devices, such as a diesel oxidation catalyst and a selective reduction catalyst for NOx. The silver / alumina catalyst material uses hydrogen in a cold-start engine exhaust and serves to oxidize NO to NO2 in the relatively low temperature, hydrocarbon-containing, exhaust during a short period following the engine cold start, and to temporarily store NOx during the start-up period. After the exhaust has heated downstream catalytic devices, the silver yields its nitrogen oxides for conversion to nitrogen by the then-operating devices before NOx is discharged to the atmosphere.

Owner:GM GLOBAL TECH OPERATIONS LLC

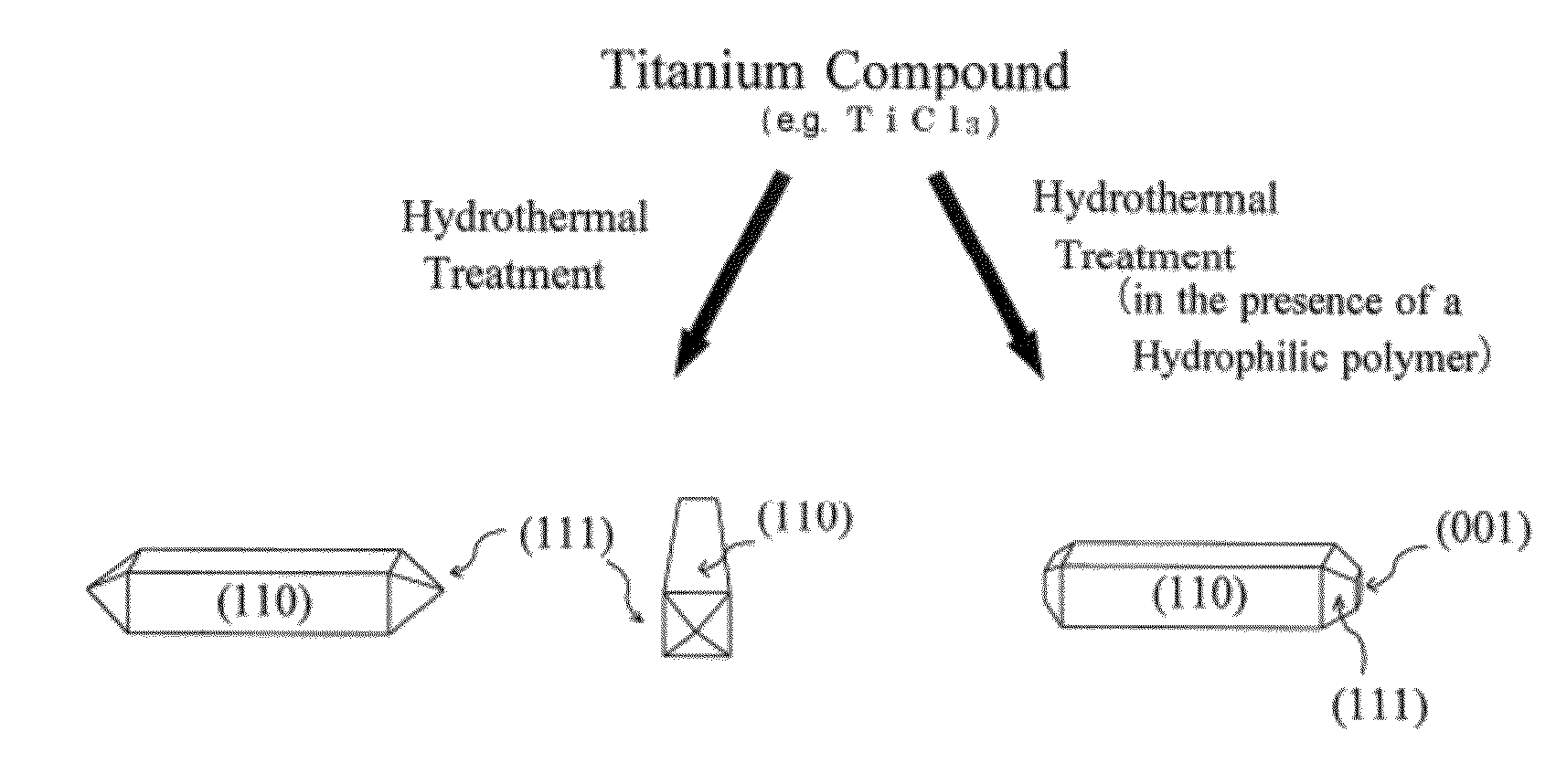

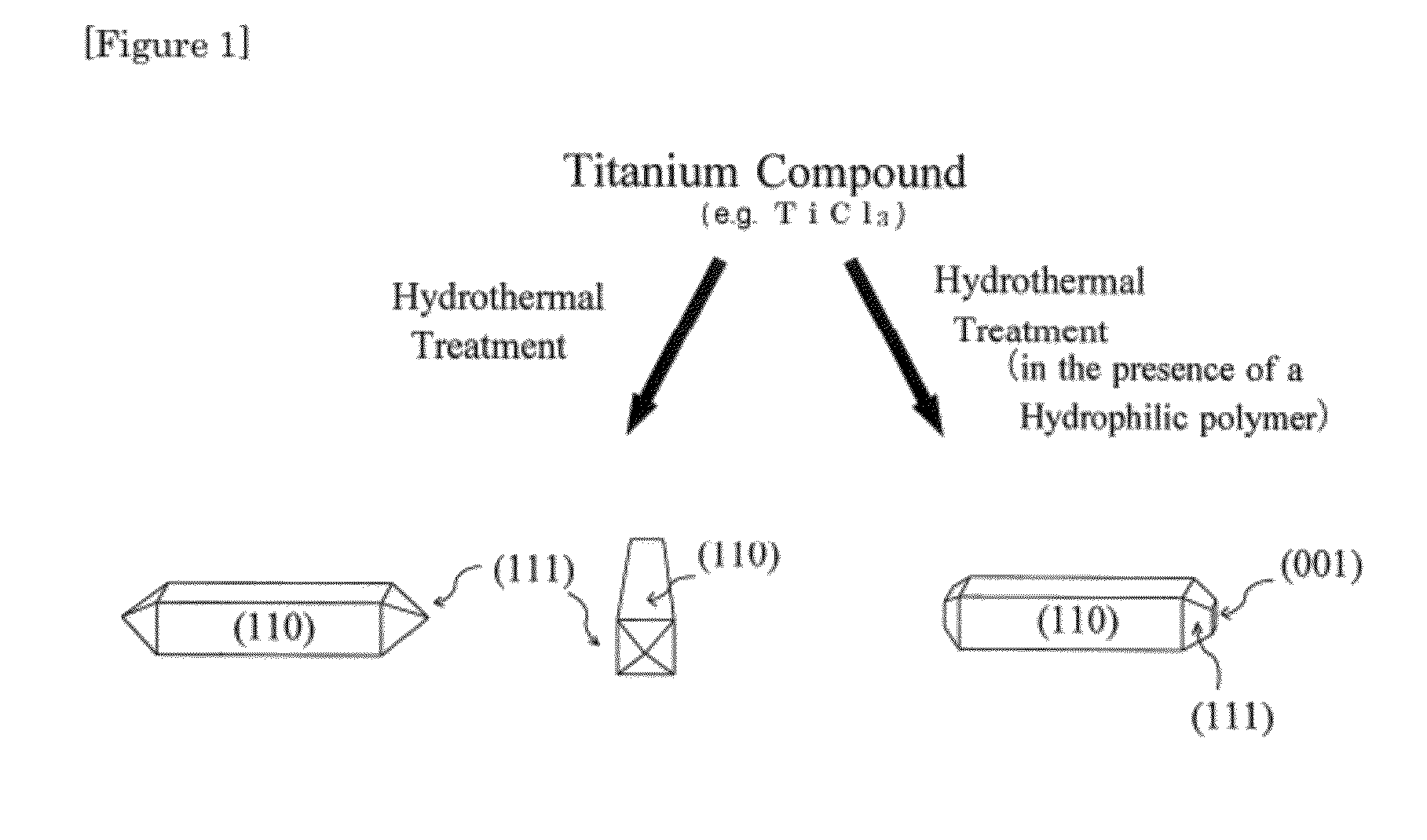

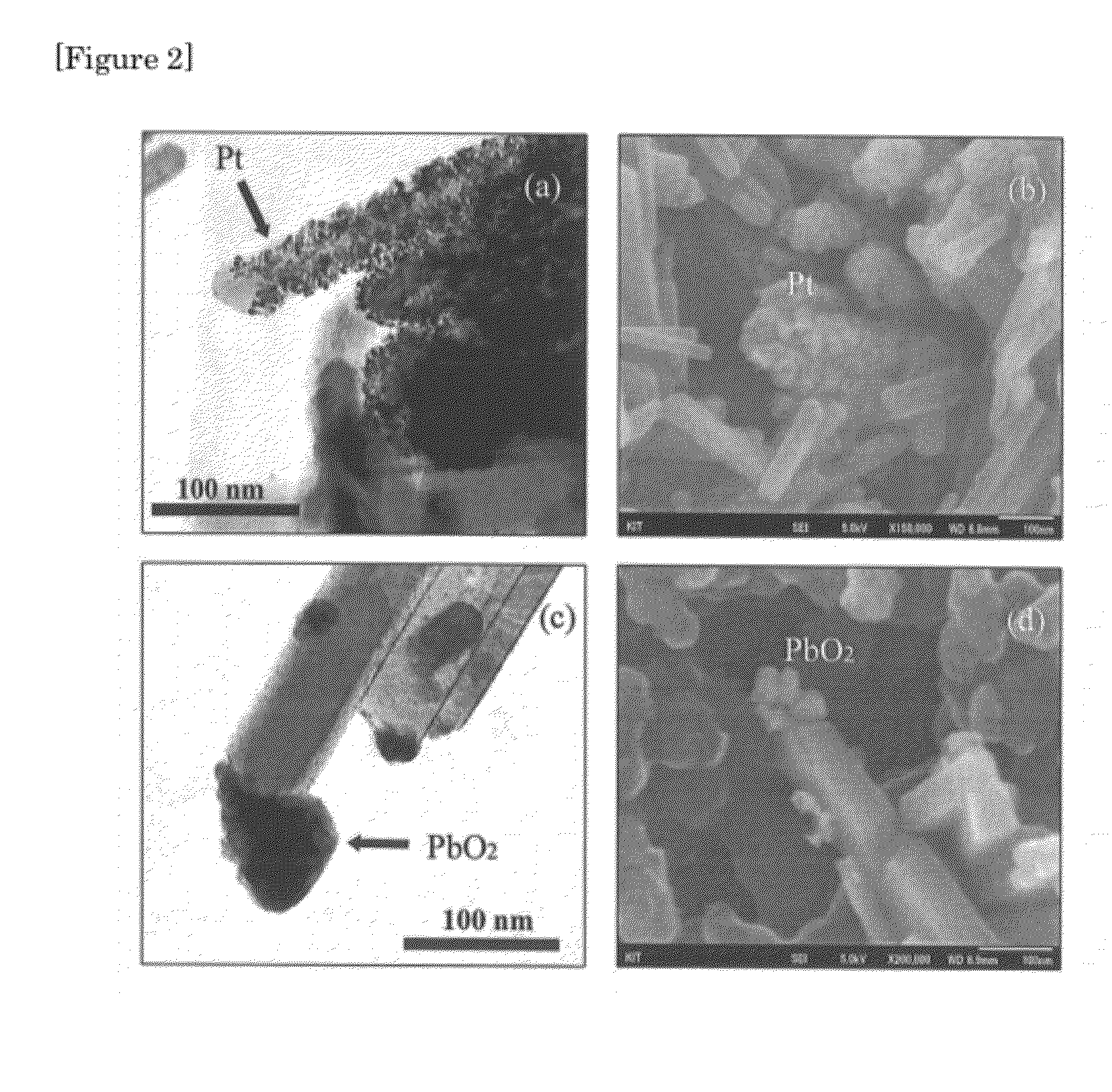

Rutile titanium dioxide nanoparticles each having novel exposed crystal face and method for producing same

InactiveUS20120132515A1Strong oxidation abilityEfficient of substanceMaterial nanotechnologyOrganic oxidationHydrophilic polymersOrganic compound

Provided are: novel rutile titanium dioxide nanoparticles each having a high photocatalytic activity; a photocatalyst including the rutile titanium dioxide nanoparticles; and a method for oxidizing an organic compound using the photocatalyst. The rutile titanium dioxide nanoparticles each have an exposed crystal face (001). The rutile titanium oxide nanoparticles may be produced by subjecting a titanium compound to a hydrothermal treatment in an aqueous medium in the presence of a hydrophilic polymer. A polyvinylpyrrolidone, for example, is used as the hydrophilic polymer. An organic compound having an oxidizable moiety can be oxidized with molecular oxygen or a peroxide under photoirradiation in the presence of the photocatalyst including the rutile titanium oxide nanoparticles.

Owner:DAICEL CHEM IND LTD

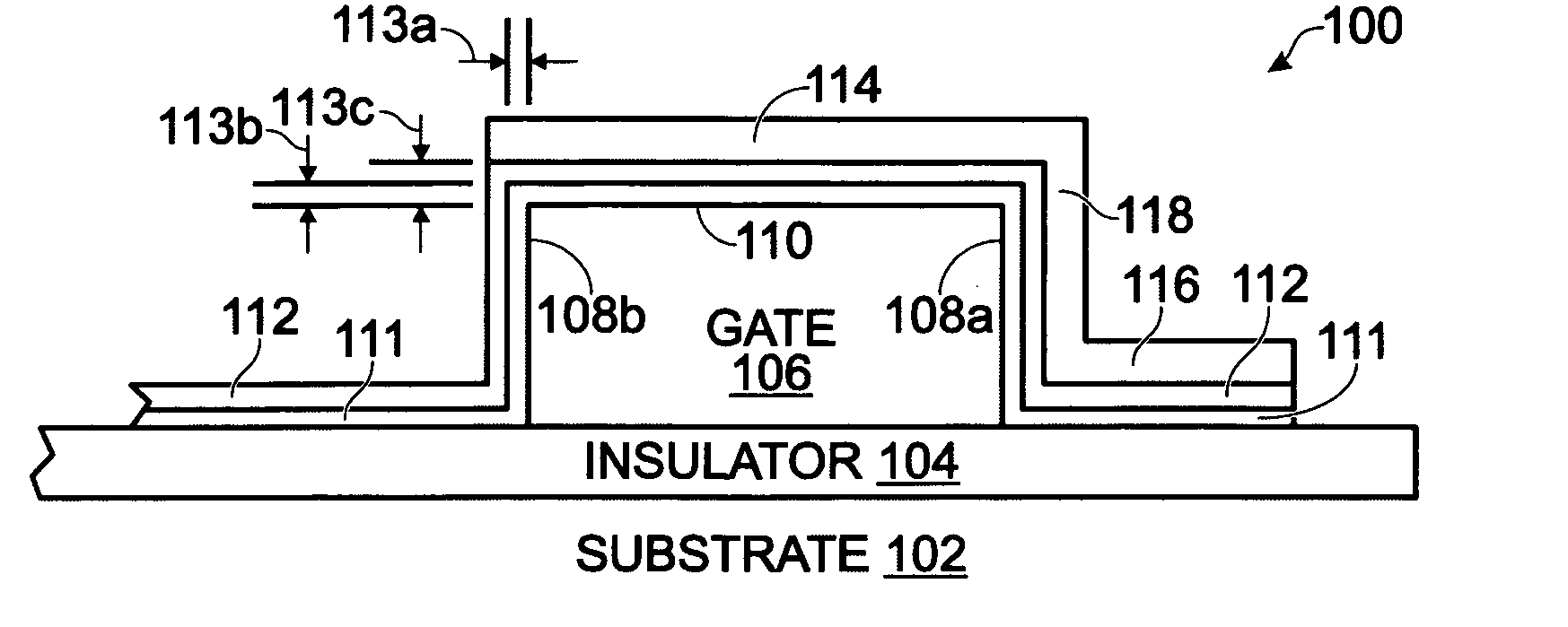

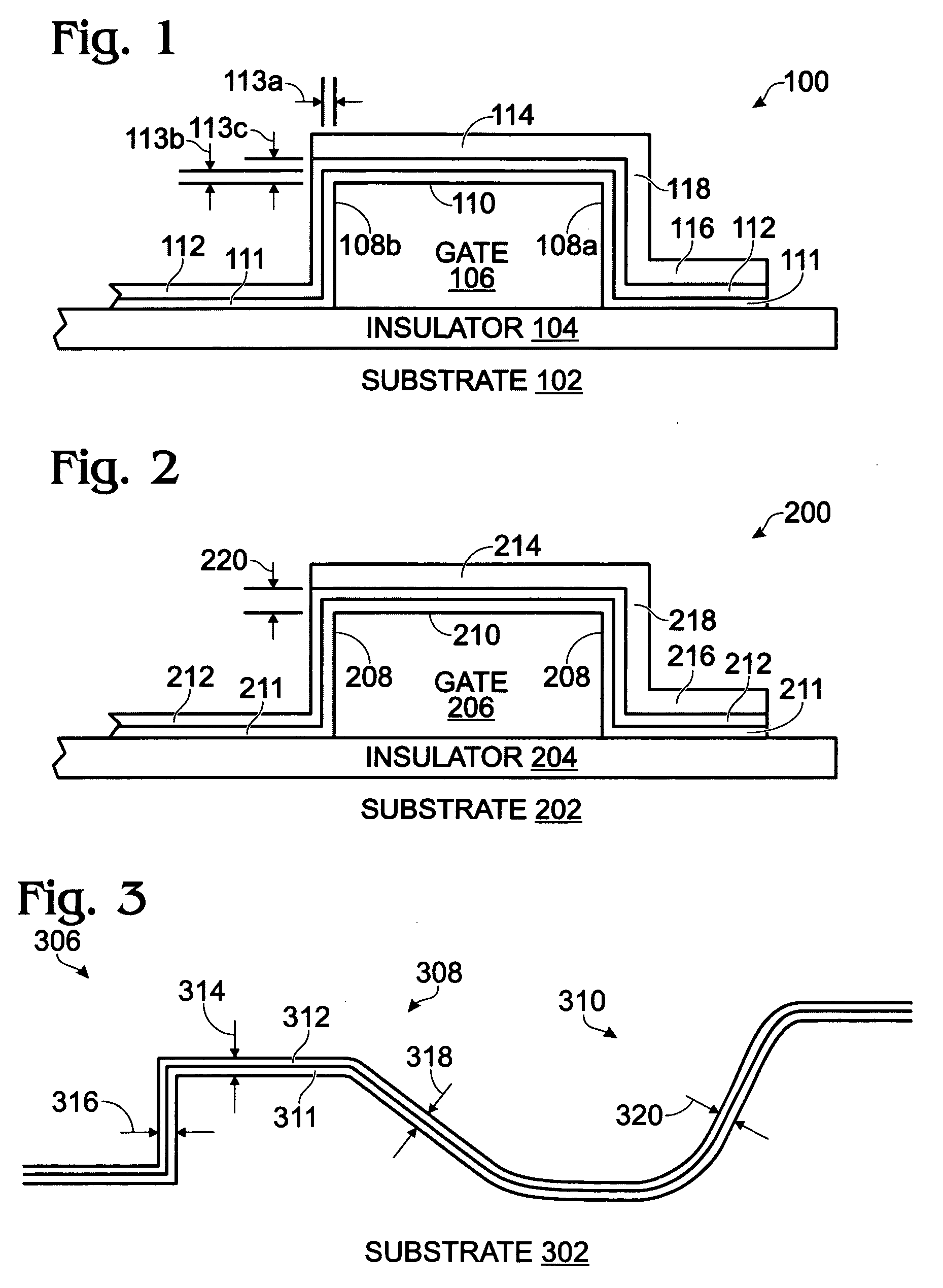

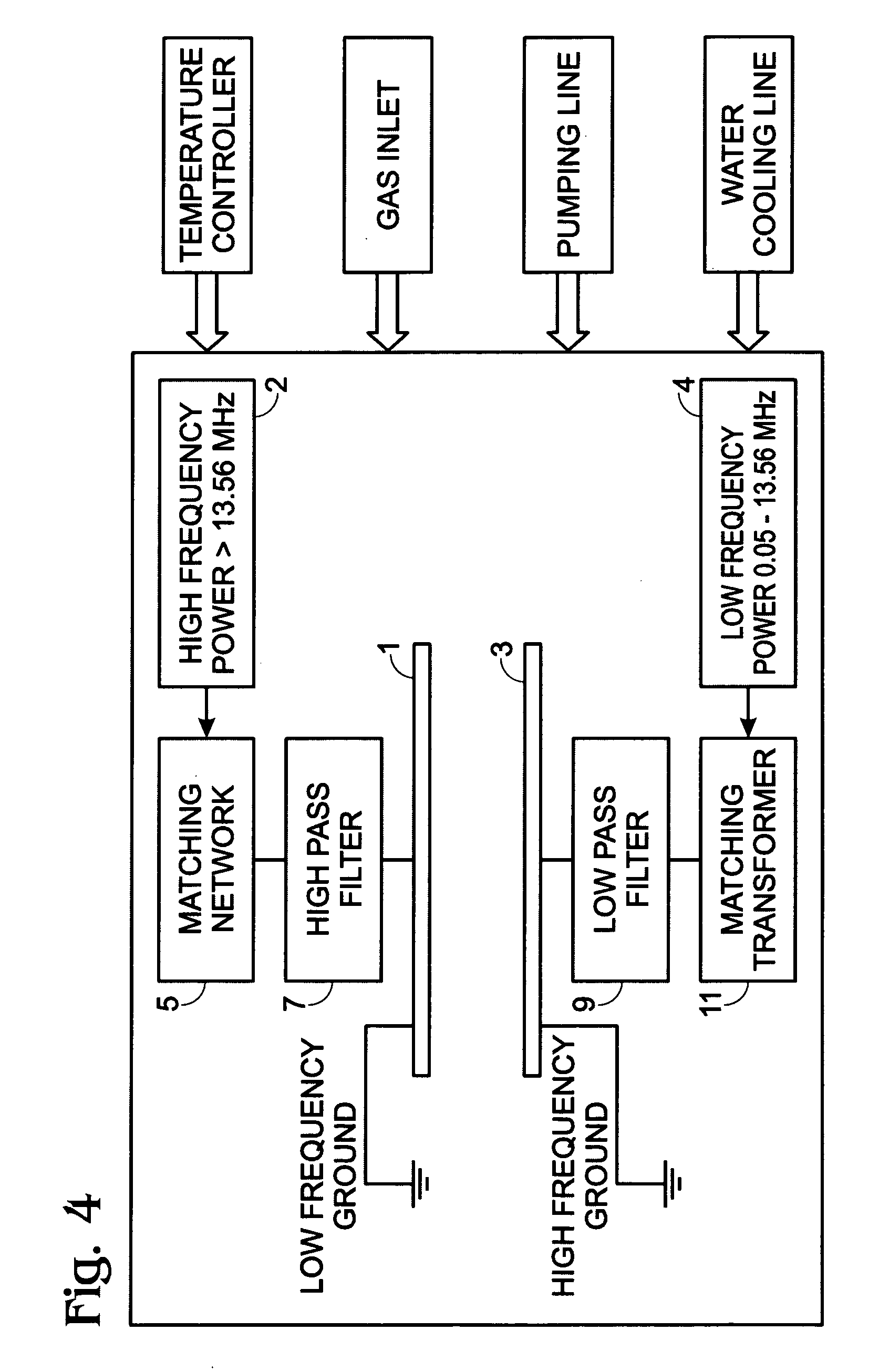

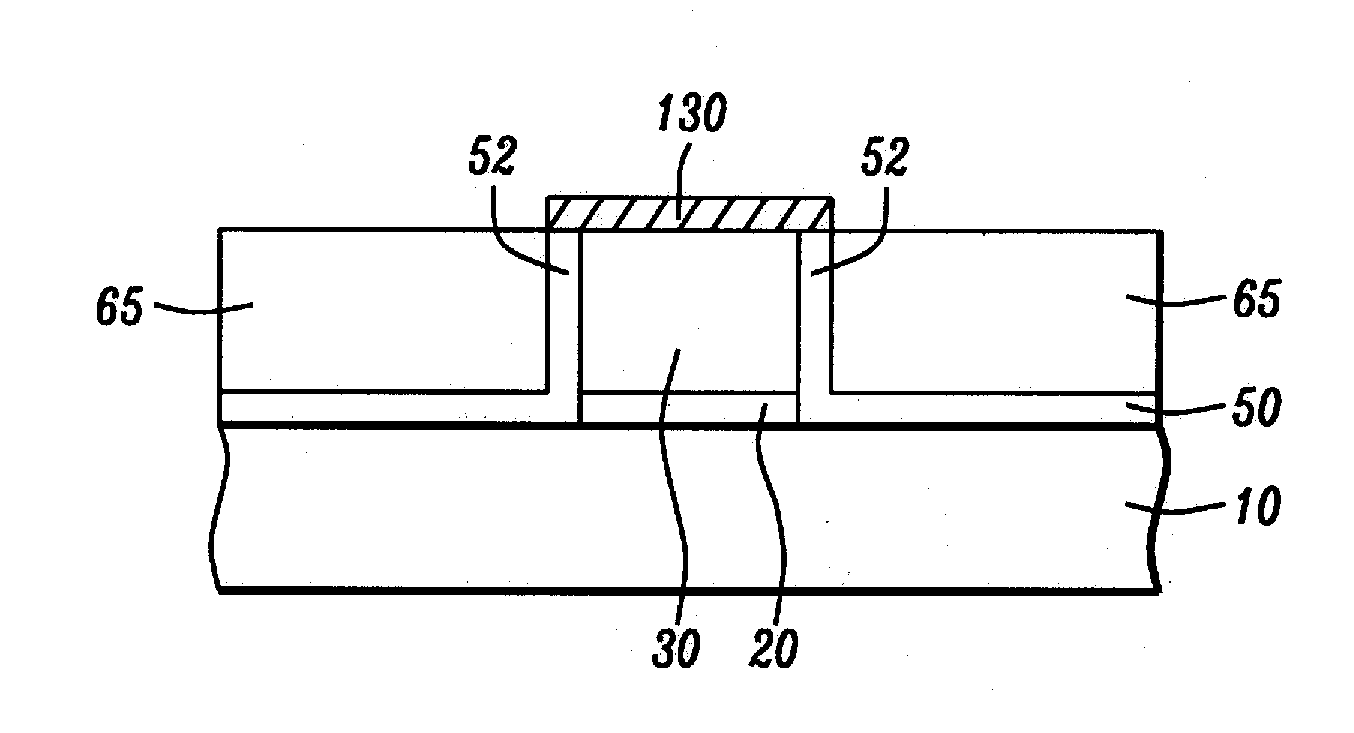

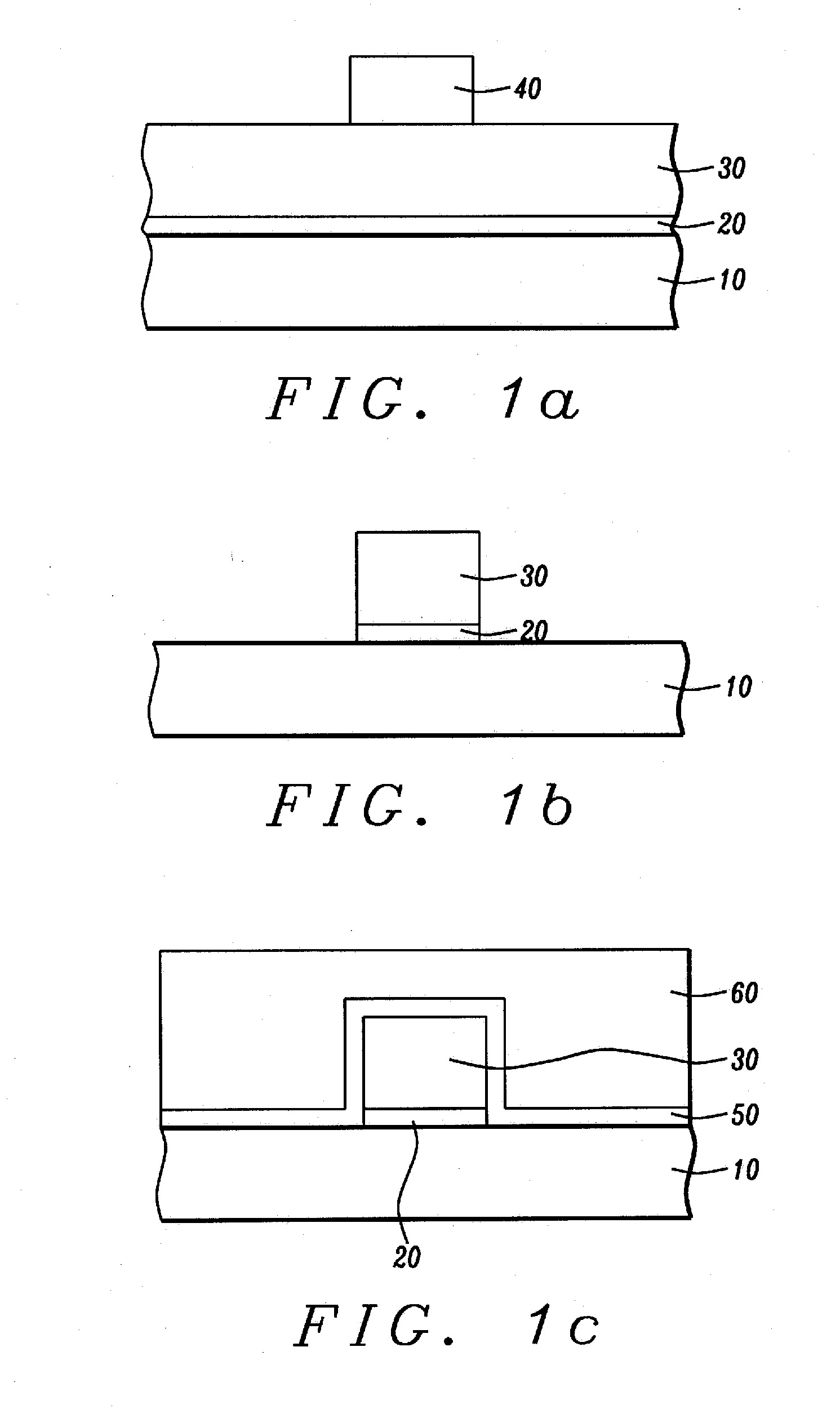

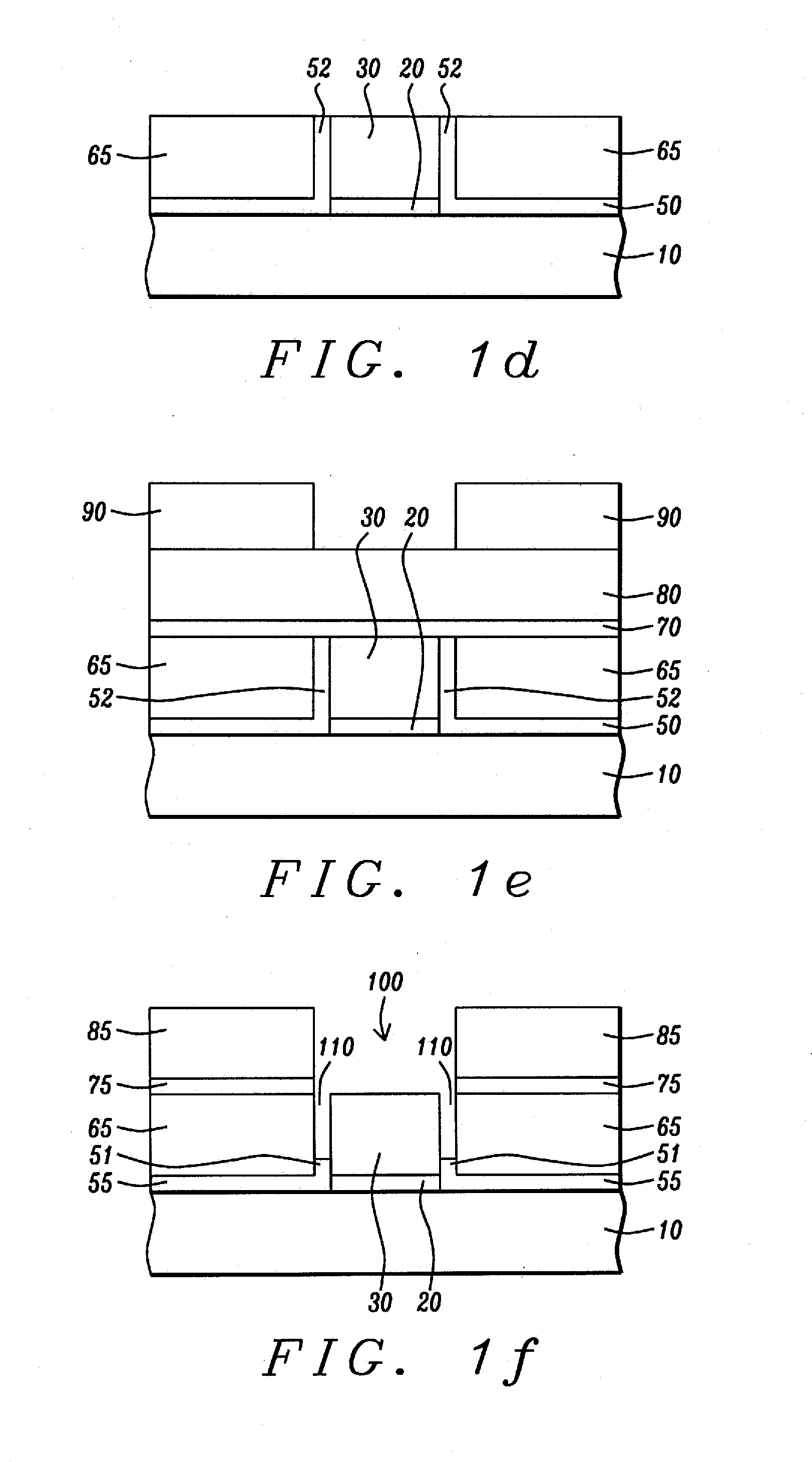

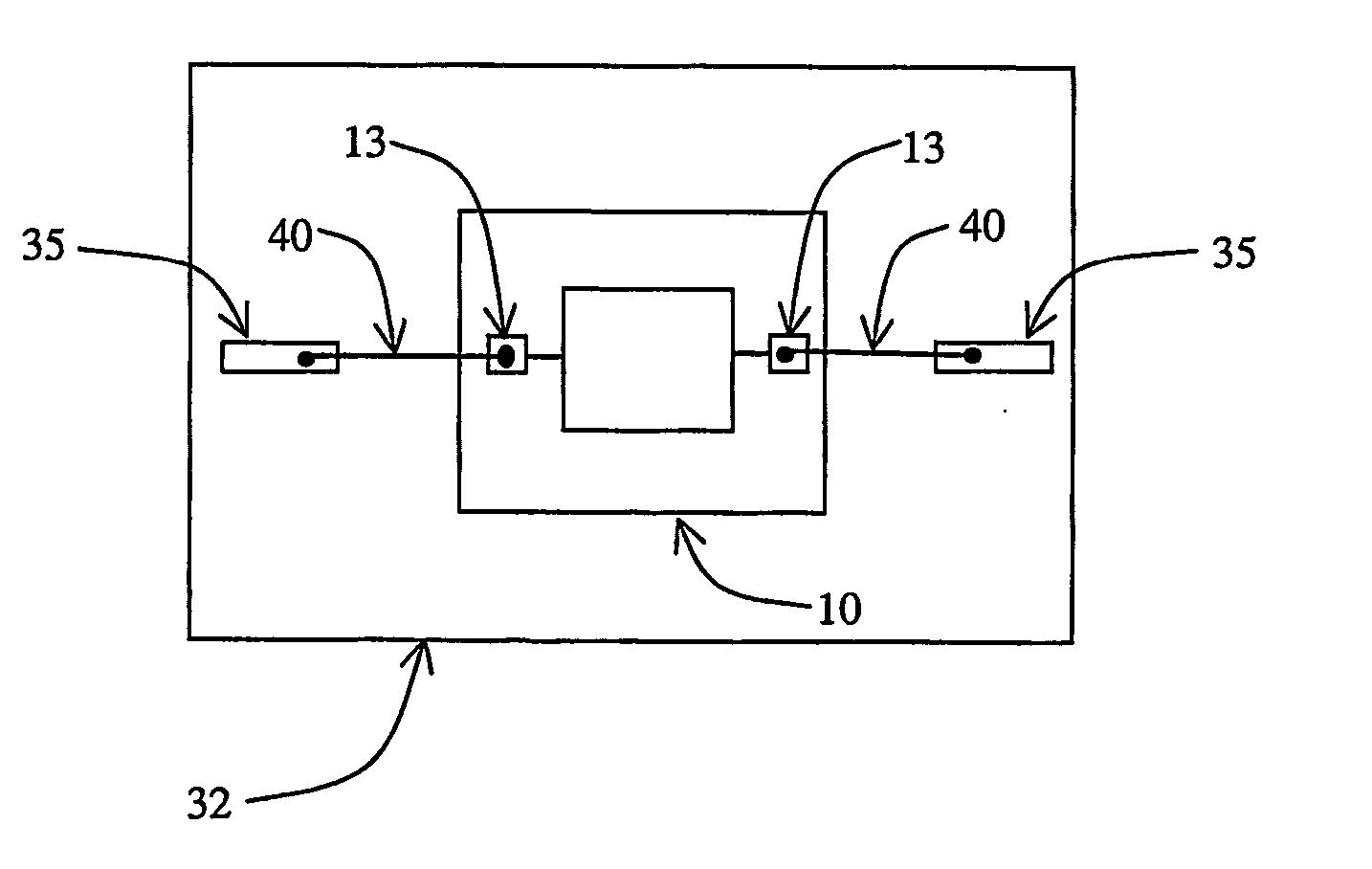

High-density plasma multilayer gate oxide

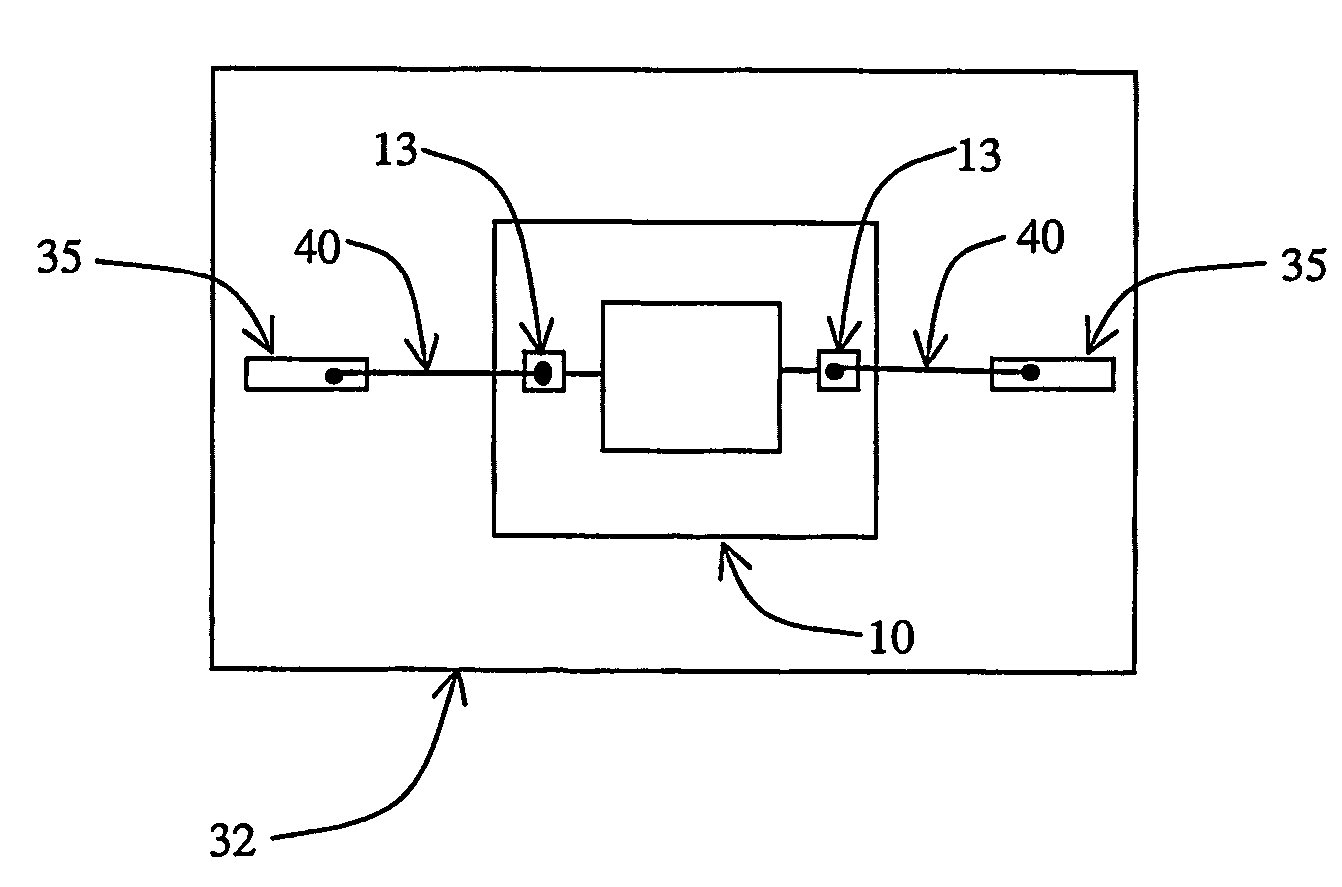

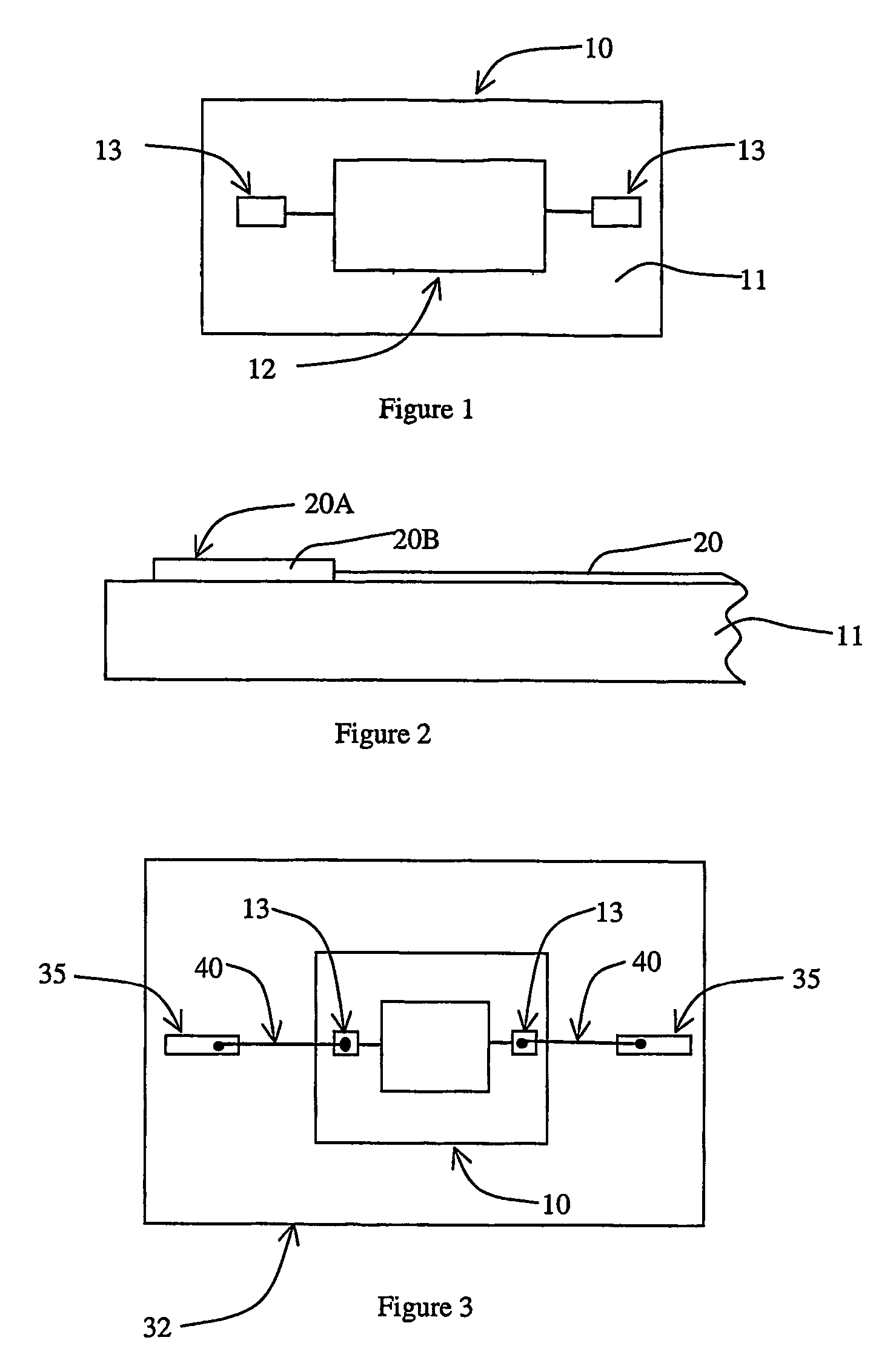

InactiveUS20060060859A1Improve bulk and interfacial qualityEfficient oxidationTransistorSolid-state devicesHigh densityGate insulator

A thin-film transistor (TFT) with a multilayer gate insulator is provided, along with a method for forming the same. The method comprises: forming a channel, first source / drain (S / D) region, and a second S / D region in a Silicon (Si) active layer; using a high-density plasma (HDP) source, growing a first layer of Silicon oxide (SiOx) from the Si active layer, to a first thickness, where x is less than, or equal to 2; depositing a second layer of SiOx having a second thickness, greater than the first thickness, overlying the first layer of SiOx; using the HDP source, additionally oxidizing the second layer of SiOx, wherein the first and second SiOx layers form a gate insulator; and, forming a gate electrode adjacent the gate insulator. In one aspect, the second Si oxide layer is deposited using a plasma-enhanced chemical vapor deposition (PECVD) process with tetraethylorthosilicate (TEOS) precursors.

Owner:SHARP KK

Metal alloy for electrochemical oxidation reactions and method of production thereof

InactiveUS20040101718A1Easy to handleMinimize formationActive material electrodesCatalyst activation/preparationPlatinumFuel cells

A binary platinum-ruthenium alloy suitable as the active component of a direct methanol fuel cell anode and use thereof in a fuel cell and the method of forming a catlyst therefrom.

Owner:BASF FUEL CELL

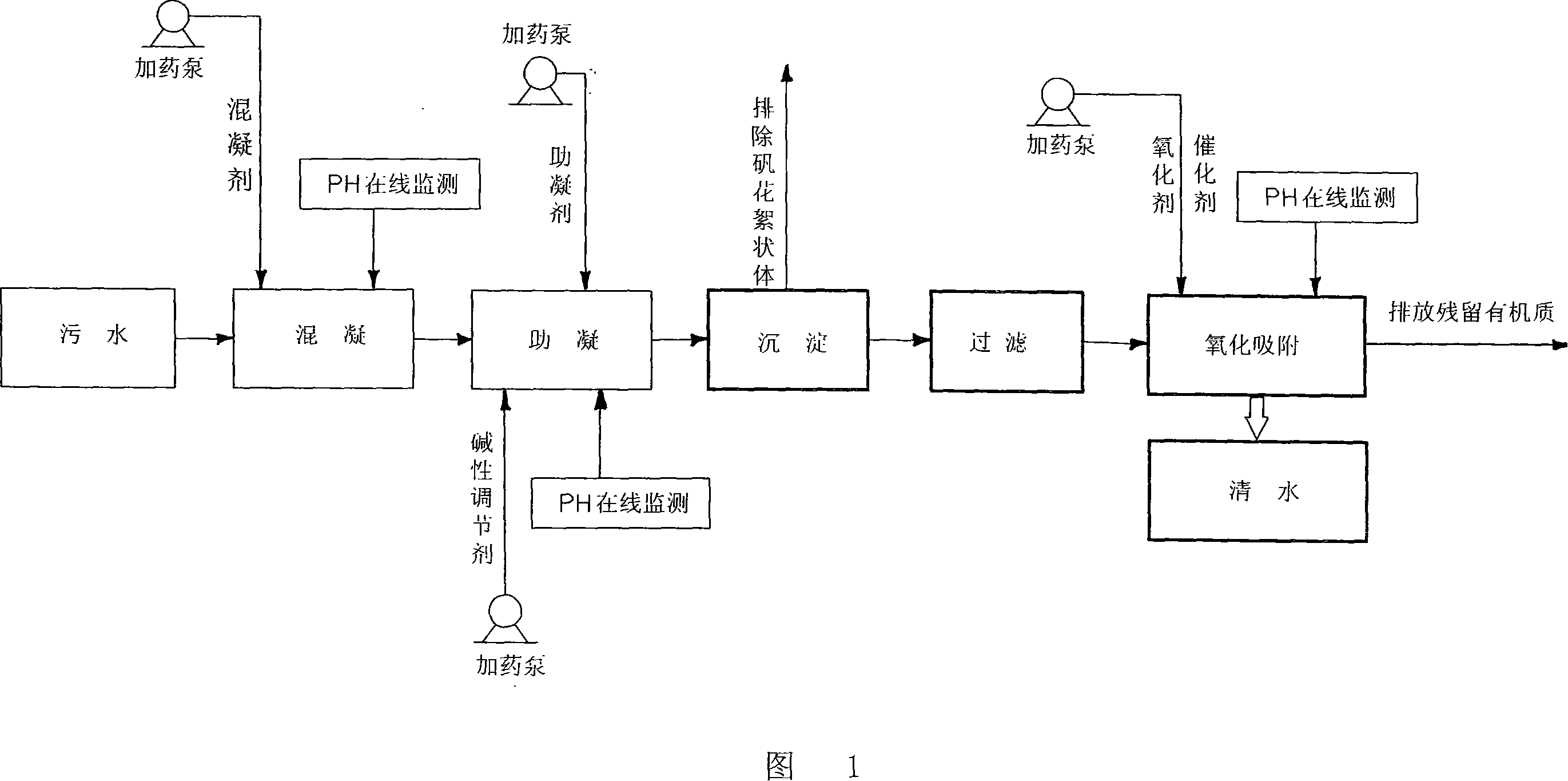

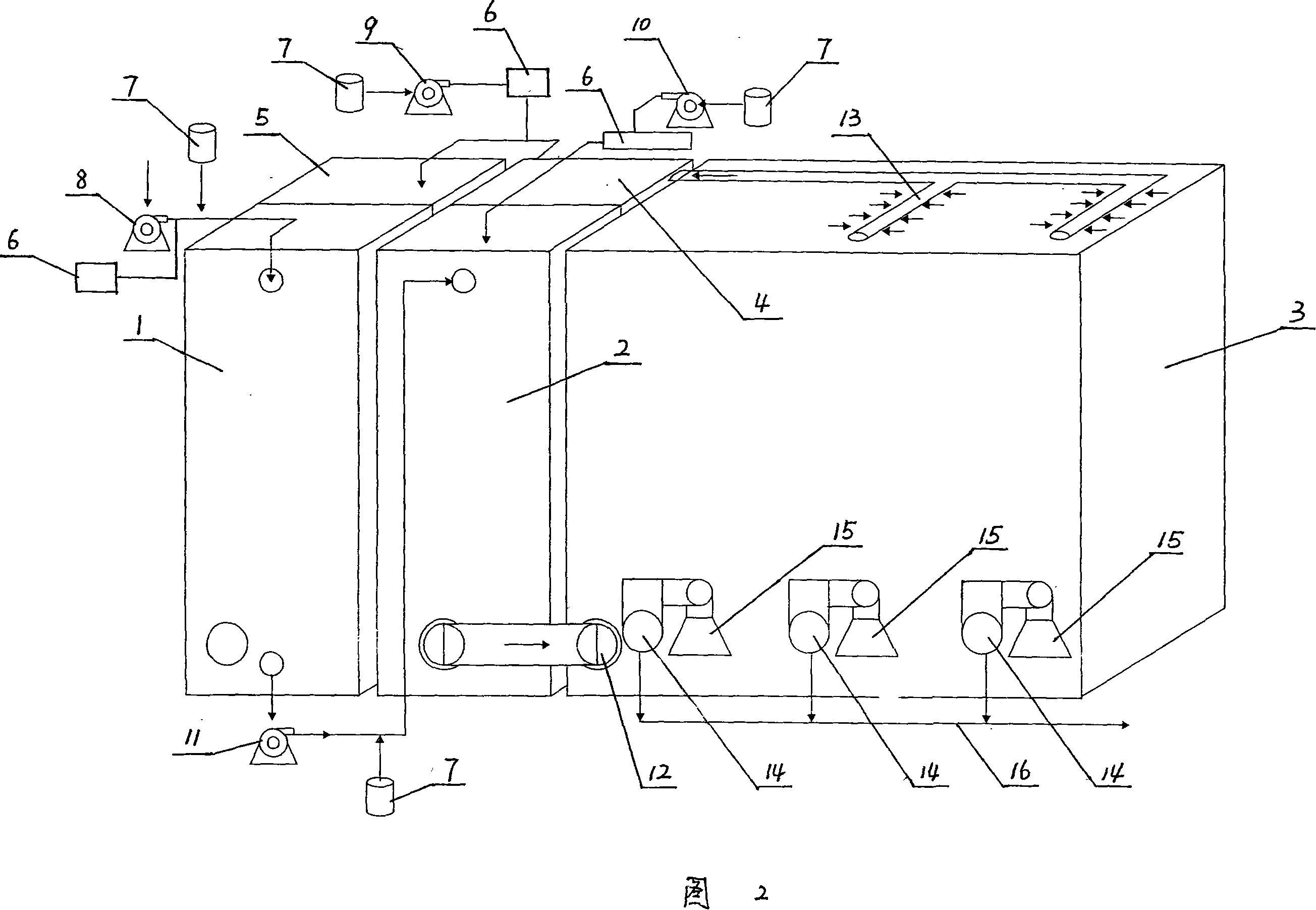

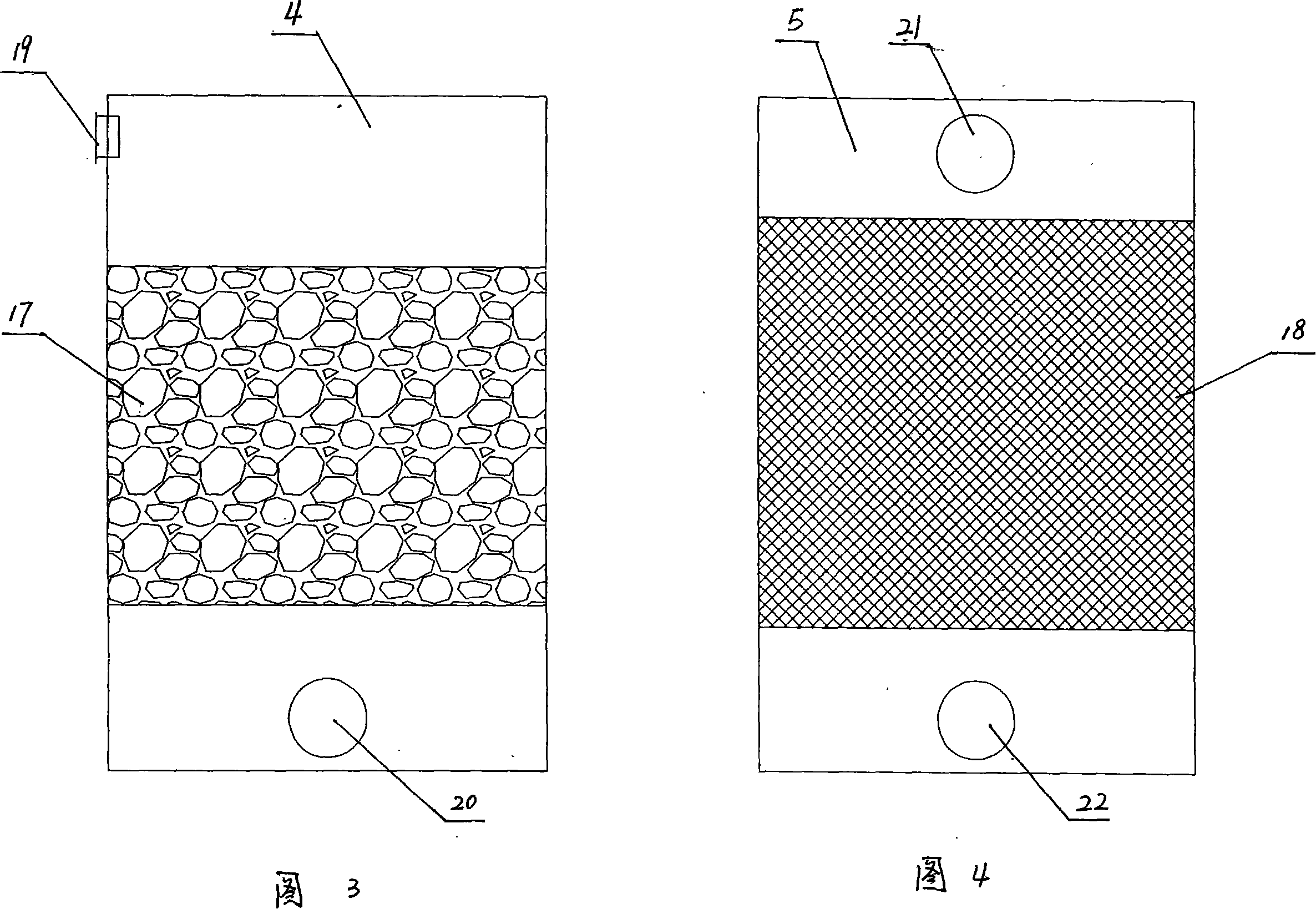

Stone oil well drilling sullage continuous processing technique

ActiveCN101139147AEfficient oxidationHarmlessMultistage water/sewage treatmentWater/sewage treatment by flocculation/precipitationChemistryPollutant

The present invention discloses a continuous processing treatment for petroleum drilling, and the sewage continuous processing treatment for petroleum drilling includes the following steps: mixed coagulation, assistant coagulation, filter, oxidation absorption and drainage standard. The present invention has effectively solved the problem of difficult combination of unit treatment, bad treatment effect and inconsecutive sewage treatment of sewage of petroleum drilling. The present invention not only reduces the sewage chroma and other pollutants, in particular able to remove the pollutants dissolved in the sewage, but also applies chemical mixed coagulation, catalytic oxidation and physical adsorption to a set of flows to realize drainage standard of sewage after consecutive and deep treatment.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

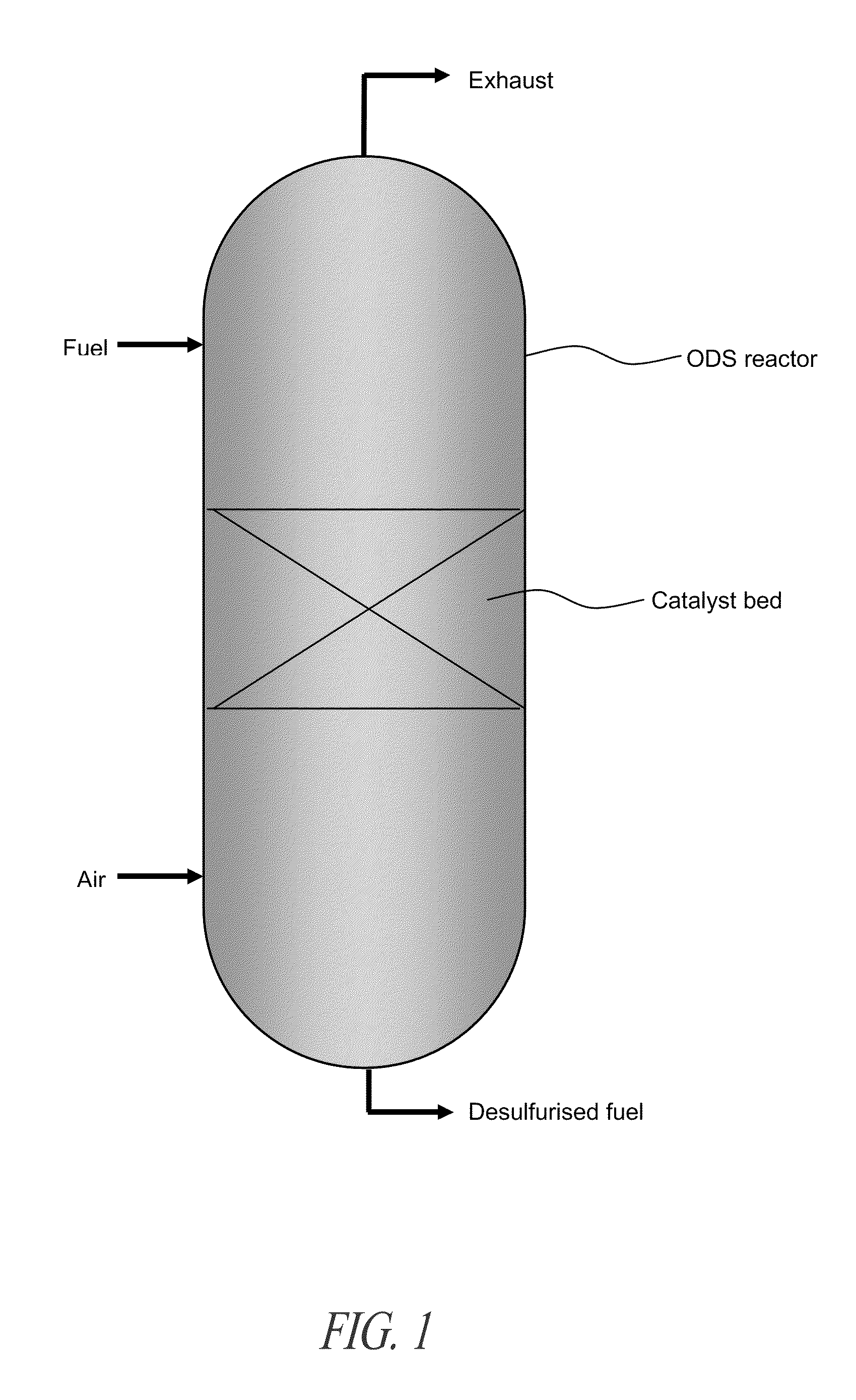

Novel process for removing sulfur from fuels

InactiveUS20100025301A1Carry out economicallyLow energy consumptionRefining with oxygen compoundsTreatment with plural serial refining stagesManganese oxideOxide

A process for removing sulfur-containing compounds from fuel, said process comprising contacting the fuel in liquid phase with air to oxidize the sulfur-containing compounds, said contacting being carried out in the presence of at least one transition metal oxide catalyst, wherein the catalyst is supported on a porous support and wherein the porous support comprises a support material selected from the group consisting of a titanium oxide, a manganese oxide and a nanostructured material of the aforementioned support materials.

Owner:AGENCY FOR SCI TECH & RES

Comprehensive recovery method of complex molybdenum sulphide ores

ActiveCN103526013AEfficient oxidationEnvironmentally friendlyProcess efficiency improvementAmmonium molybdateMineralogy

The invention provides a comprehensive recovery method of complex molybdenum sulphide ores. The comprehensive recovery method is characterized that a pressurized oxidization method is used for treating complex molybdenum-containing sulfide comprising 5-45% of molybdenum, a right amount of activating agent is added, the conversion rate of the molybdenum reaches above 98% under the conditions that the temperature is 105-200 DEG C, the ratio of ore pulp to solid is (2-15):1, the oxygen partial pressure is 100-800kPa, and the reaction time is 1-8 hours, rhenium and molybdenum are recycled from a pressurized oxidization solution step by step by adopting an extraction method, and finally products such as ammonium rhenate and ammonium molybdate are produced. The comprehensive recovery method can be used for treating complex raw materials, is low in reaction temperature and pressure and is a simple high-efficiency and environment-friendly technology.

Owner:BEIJING GENERAL RES INST OF MINING & METALLURGY

Method for the production of hydrocarbon fuels with ultra-low sulfur content

InactiveUS20030075483A1Efficient oxidationReduce sulfur contentRefining with oxygen compoundsCatalytic naphtha reformingAlcoholCatalytic oxidation

The present invention provides a method for producing hydrocarbon fuels with ultra-low levels of sulfur. The method involves catalytic oxidation of the sulfurous compounds within the hydrocarbon fuel, followed by extraction of the oxidized (and polarized) sulfurous compounds using a polar solvent. The present invention teaches the involvement of ethanol during catalytic oxidation. In this way, the oxidation catalyst has a dual-role in the oxidation process: firstly the catalyst directly oxidizes the sulfurous compounds, and secondly the oxidation catalyst converts of a small portion of the alcohol to the corresponding peroxy acid, which also helps to drive the oxidation process.

Owner:HER MAJESTY THE QUEEN & RIGHT OF CANADA REPRESENTED BY THE MIN OF NATURAL RESOURCES

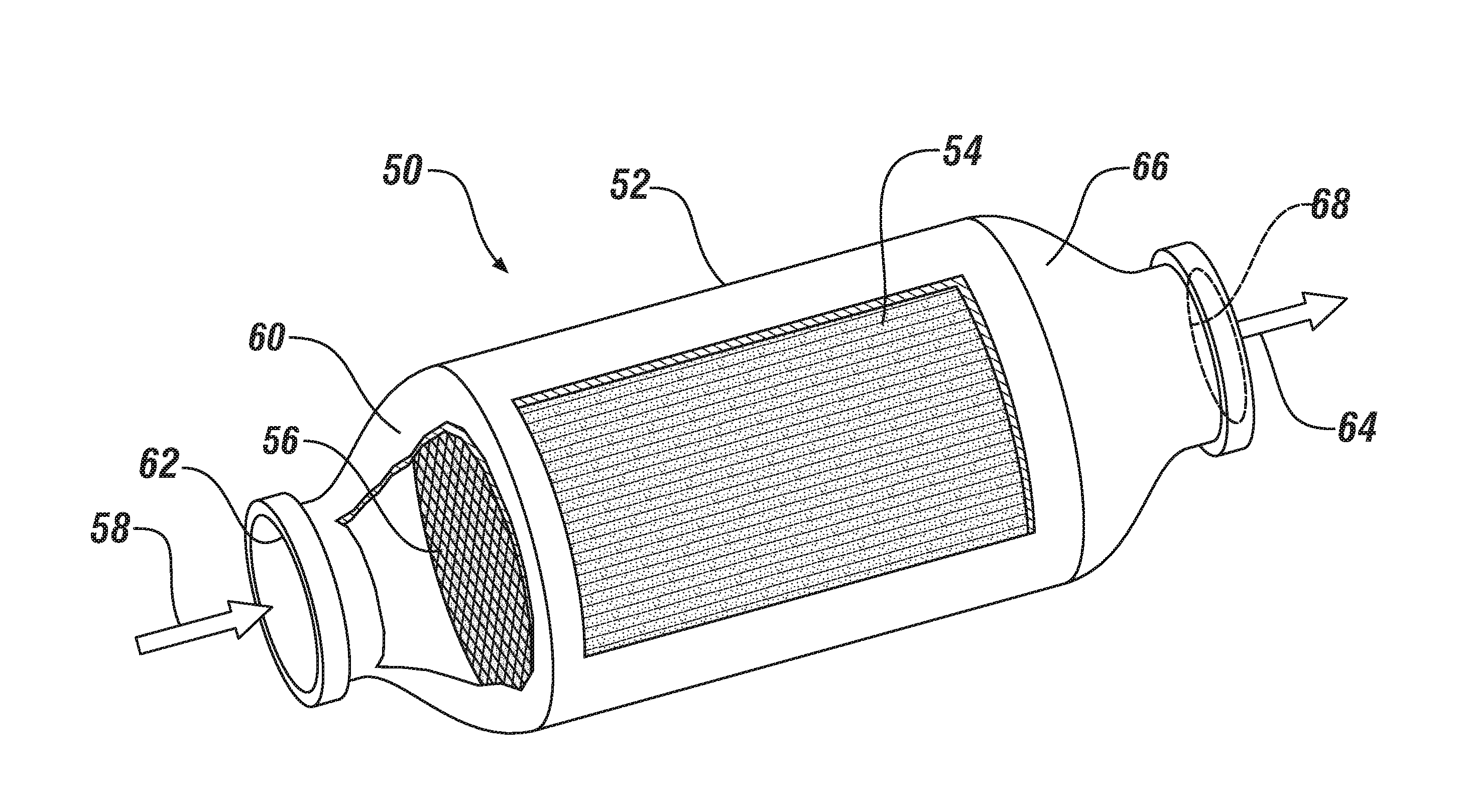

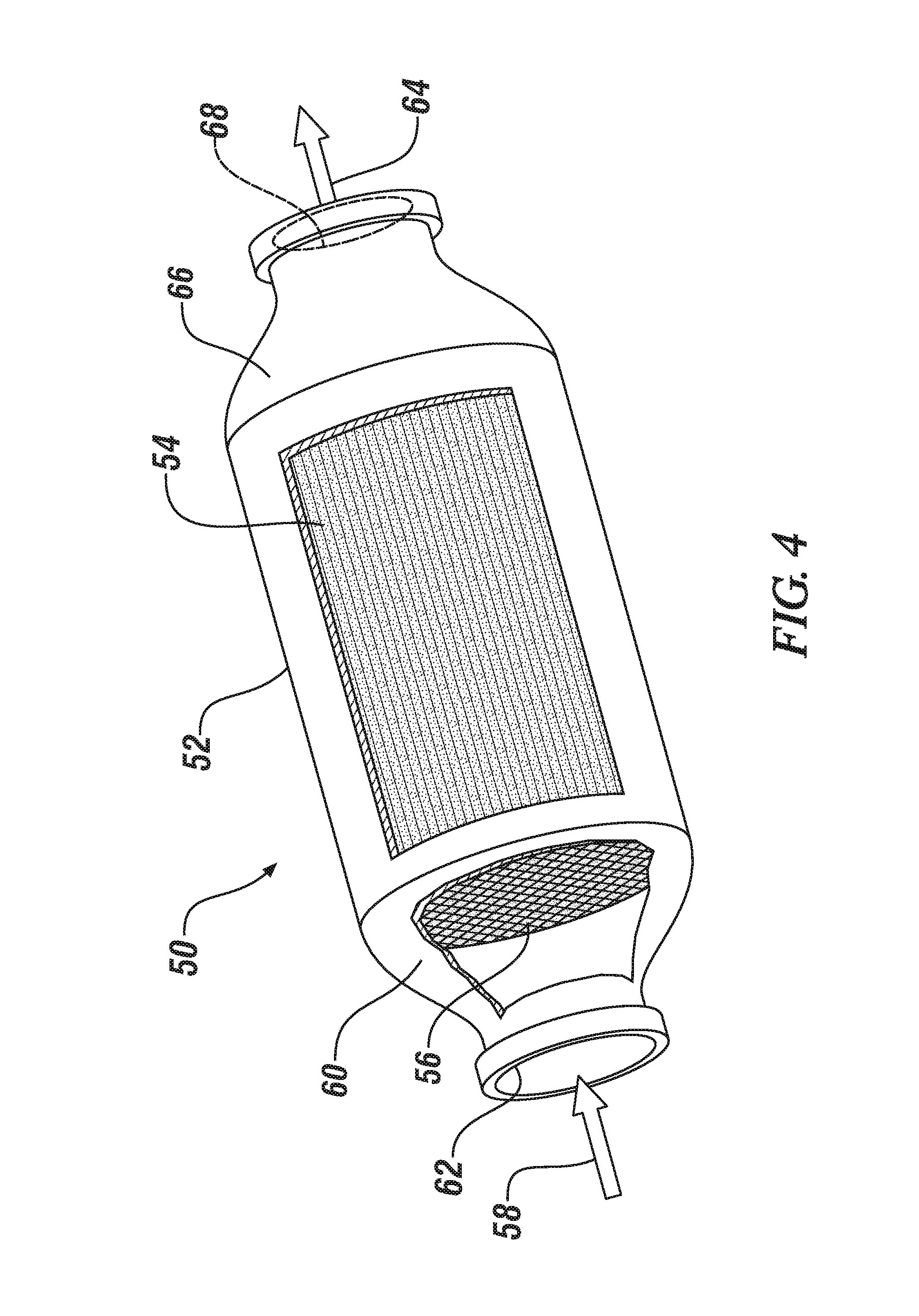

Exhaust cleaner for internal combustion engine

InactiveUS20090120070A1Efficient oxidationReduce the temperatureGas treatmentInternal combustion piston enginesExhaust gasInternal combustion engine

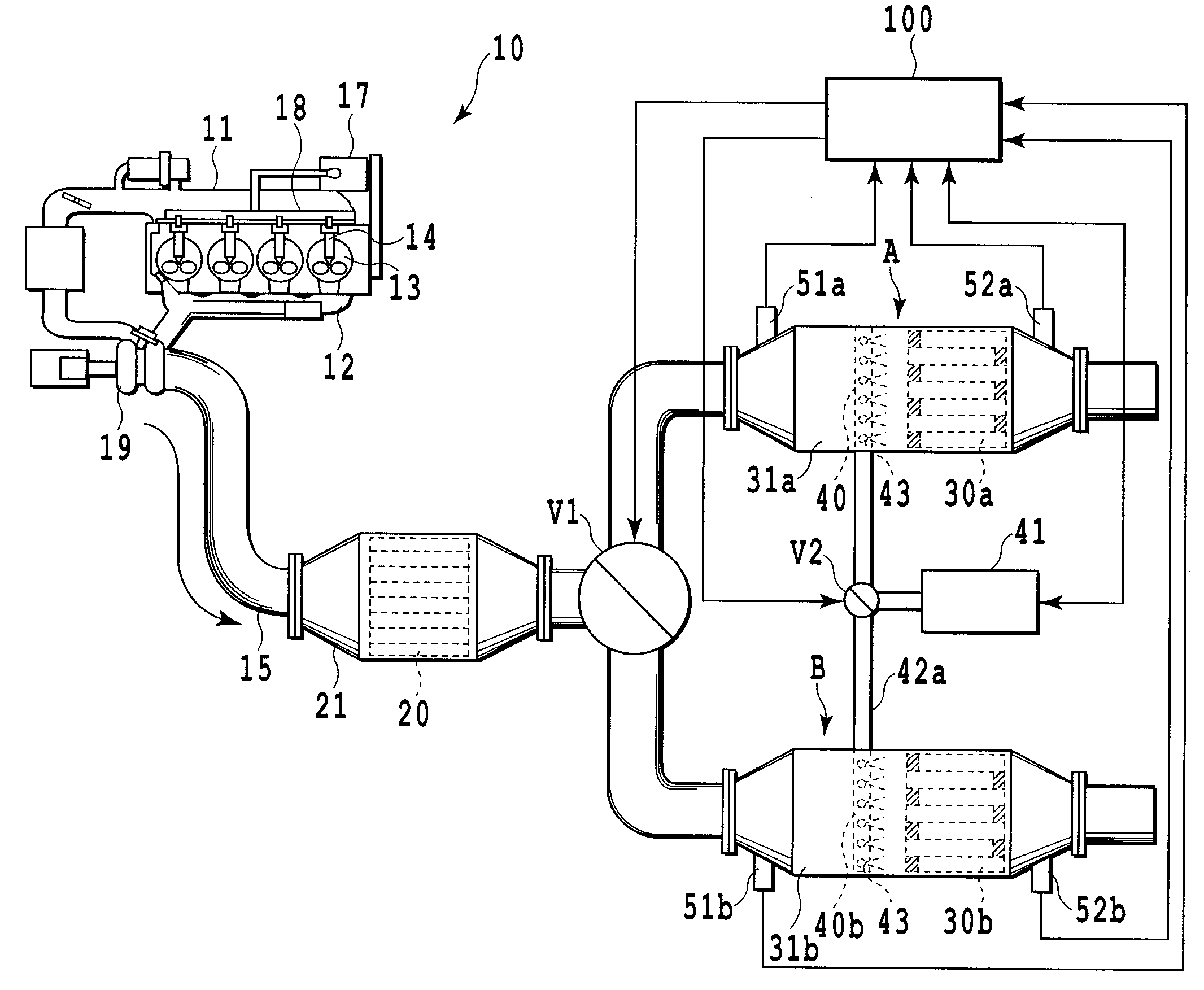

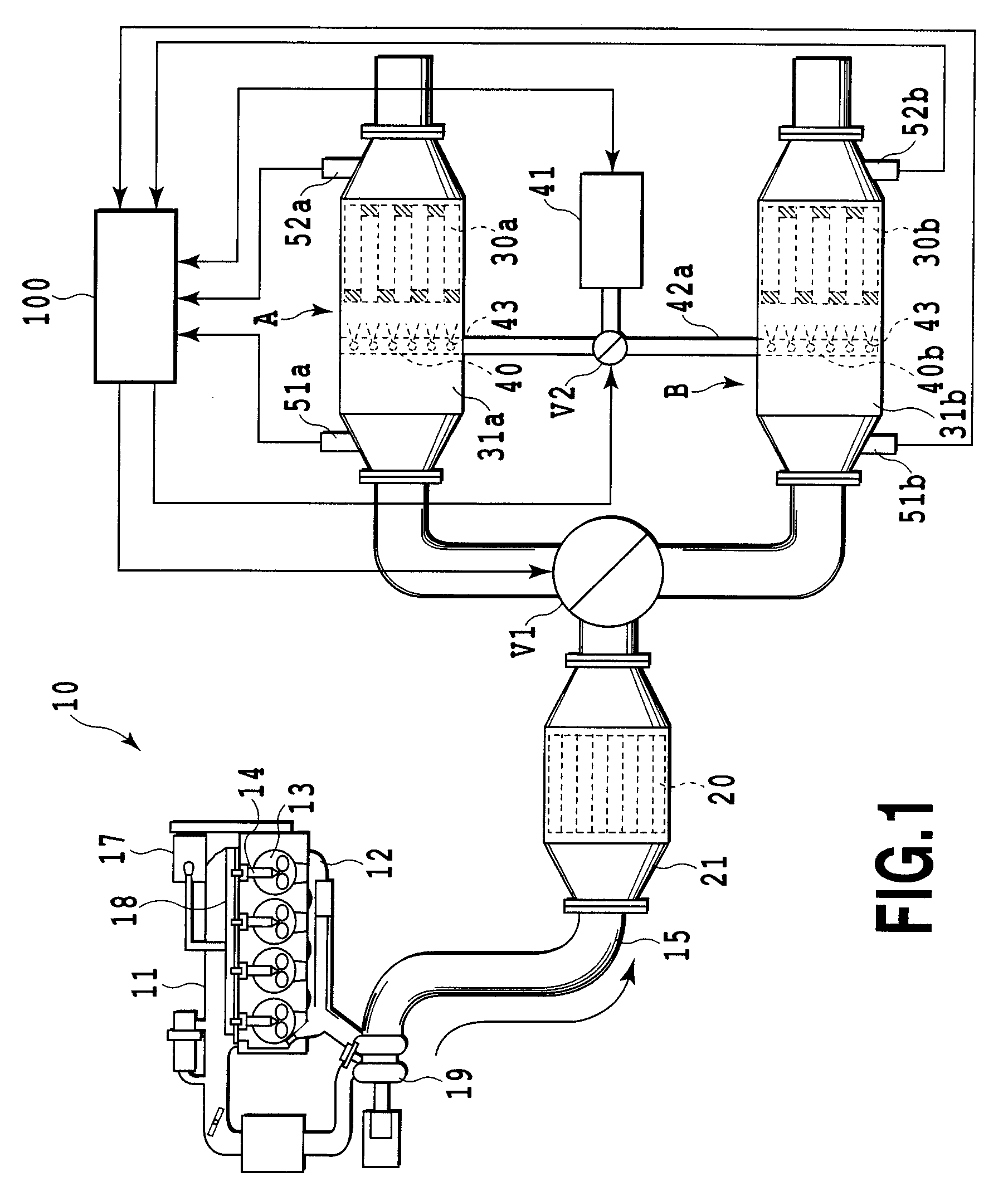

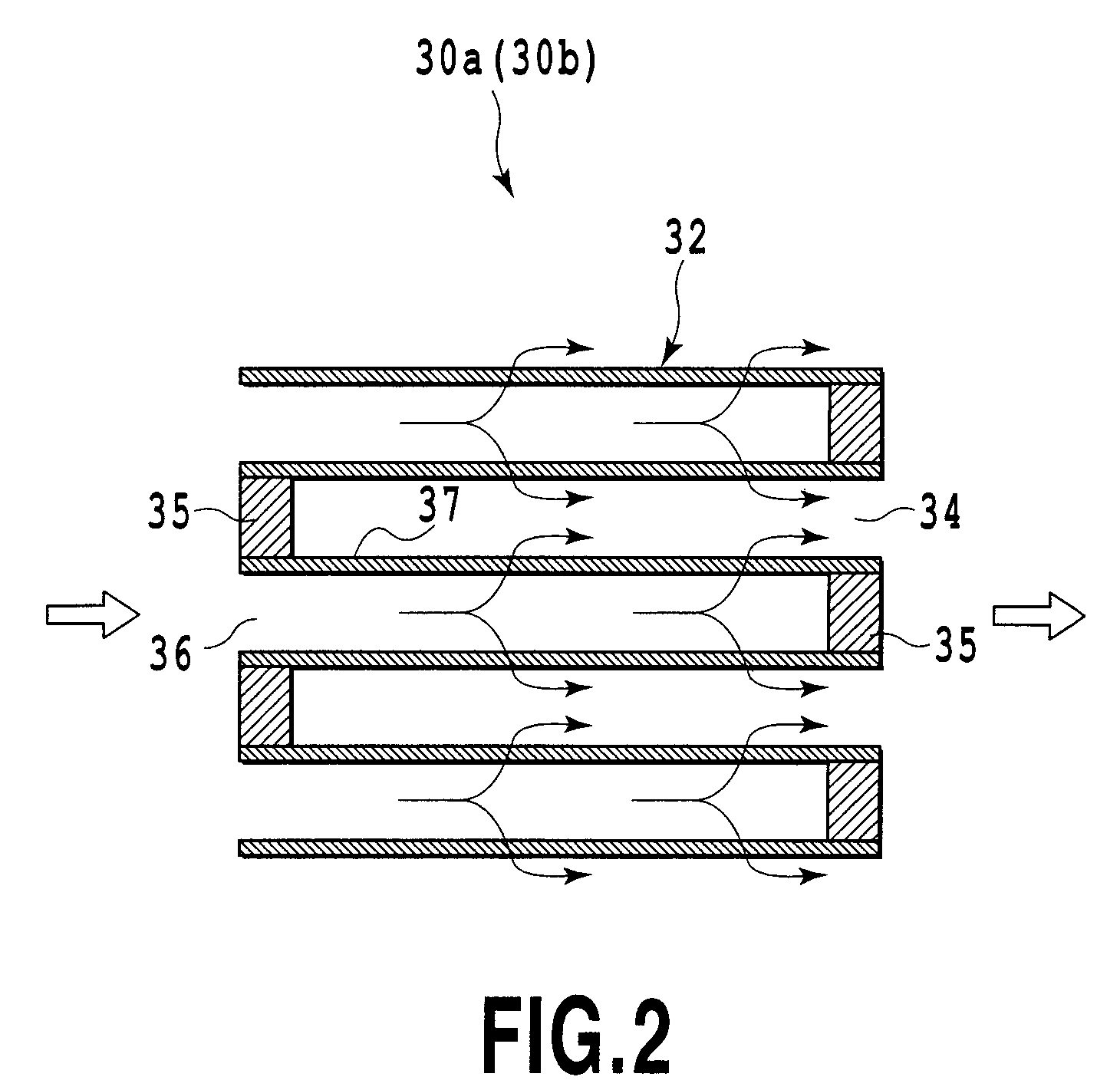

An exhaust purifying system for an internal combustion engine is provided with a plurality of DPFs (30a and 30b) branched and connected to an exhaust passage (15) for collecting particulate matter in an exhaust gas and an ozone supplier for supplying ozone to the upstream side of each of the plurality of DPFs (30a and 30b). The system respectively changes a ratio of a supply amount of the exhaust gas and a ratio of a supply amount of the ozone between the plurality of DPFs (30a and 30b).

Owner:TOYOTA JIDOSHA KK

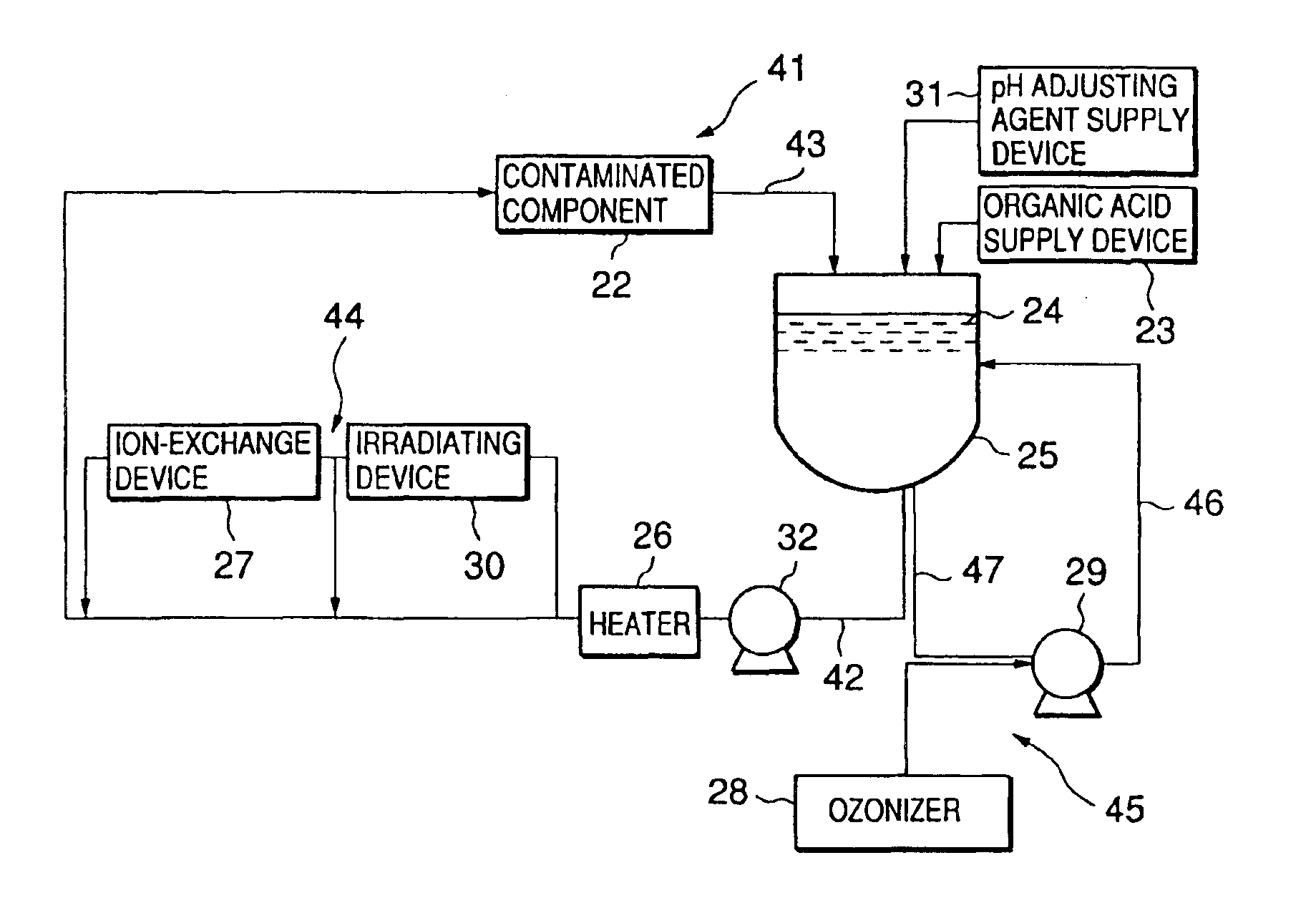

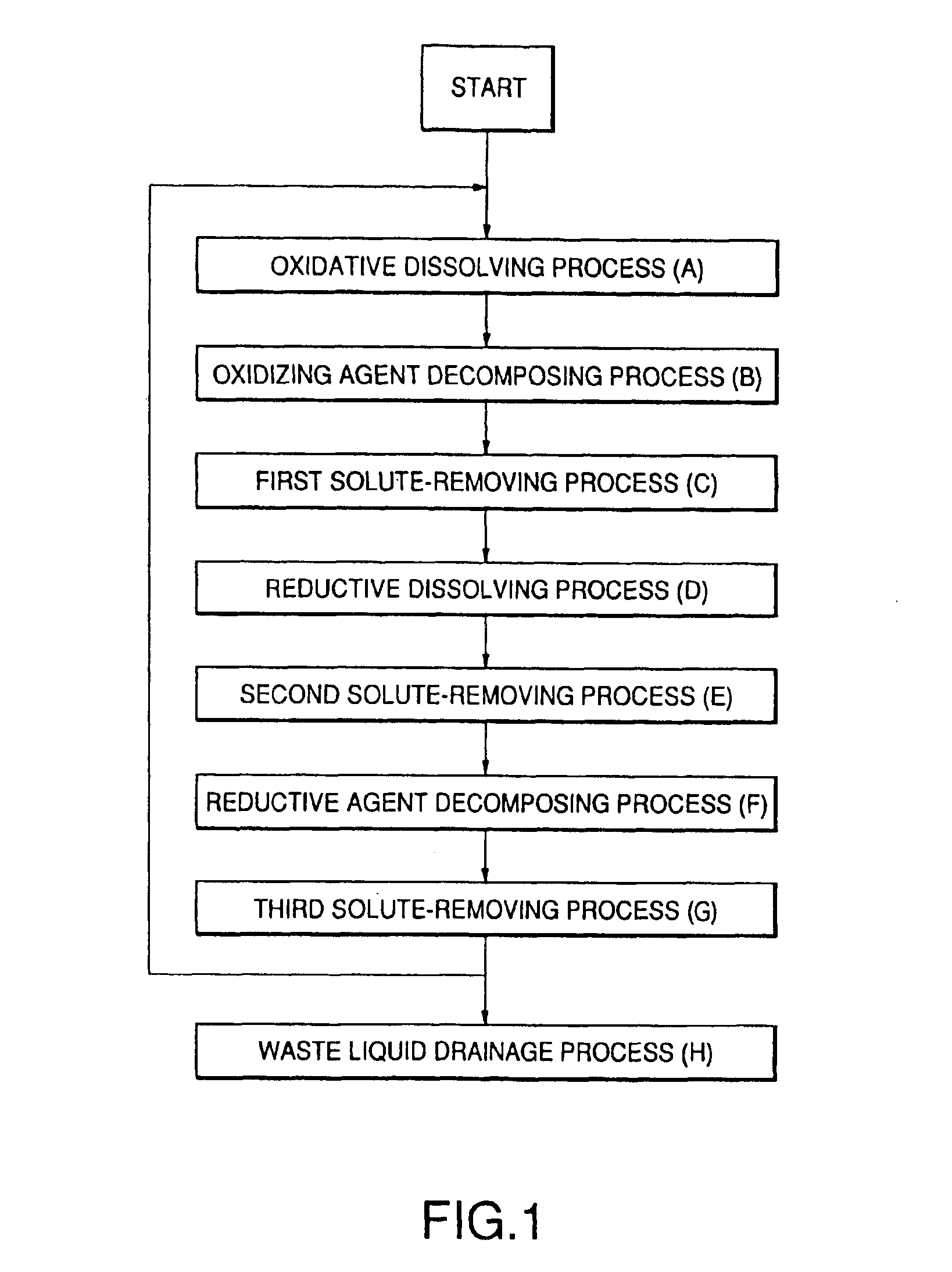

Method of chemically decontaminating components of radioactive material handling facility and system for carrying out the same

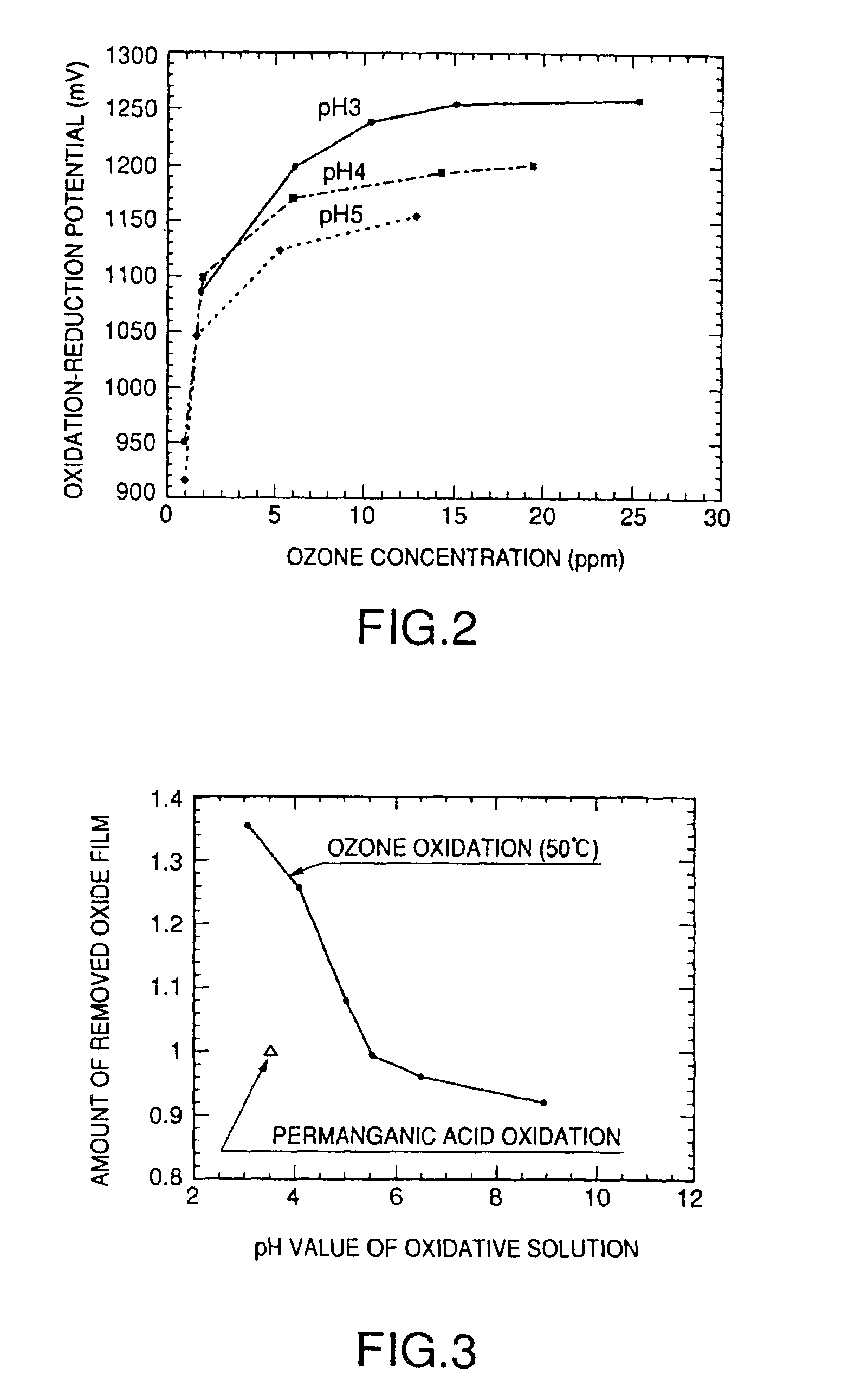

Ozone gas having a high ozone concentration is generated by a solid electrolyte electrolytic process. An ozone solution is prepared by injecting the ozone gas into an acidic solution of pH 6 or below. The ozone solution heated at a temperature in the range of 50° to 90° C. is supplied to a contaminated object to oxidize and dissolve a chromium oxide film by an oxidizing dissolving process. The ozone solution used in the oxidizing dissolving process is irradiated with ultraviolet rays to decompose ozone contained in the ozone solution, the ozone solution is passed through an ion-exchange resin to remove ions contained in the ozone solution. An oxalic acid solution is supplied to the contaminated object to dissolve an iron oxide film by a reductive dissolving process. Oxalic acid remaining in the oxalic acid solution after the reductive dissolving process is decomposed by injecting ozone into the oxalic acid solution and irradiating the oxalic acid solution with ultraviolet rays, and ions contained in the oxalic acid solution is removed by an ion-exchange resin.

Owner:KK TOSHIBA

Method for treating phthalate wastewater by means of catalyzing persulfate by utilization of supported activated carbon in microwave inducement manner

ActiveCN105565465AGood stabilitySimple process operationWater/sewage treatment by irradiationWater contaminantsActivated carbonEnvironmental chemistry

The invention relates to a method for treating phthalate wastewater by means of catalyzing persulfate by utilization of supported activated carbon in a microwave inducement manner, belonging to the technical field of phthalate wastewater treatment. The method comprises the following steps of adding a sodium persulfate solution with a concentration of 0.3 to 0.4 mM into phthalate wastewater with a concentration of 1500 to 3500 (mu)g / L according to a volume ratio of 0.5 to 1 percent, adjusting a pH value of the solution to be 6.0 to 9.0, then adding an activated carbon supported metal catalyst according to a proportion of 1 to 2 permillage, uniformly stirring, putting in a frequency conversion microwave reactor, setting a temperature of 70 to 80 DEG C, continuously reacting for 25 to 30 minutes, and taking a mixed solution to measure a phthalate concentration, wherein the phthalate removal rate reaches above 90 percent. The method disclosed by the invention has the advantages that microwave, supported activated carbon and persulfate act synergistically; the thermal effect and non-thermal effect of the microwave, the strong oxidation effect of the persulfate as well as the adsorptive catalysis and heat sensitization effects of the supported activated carbon are sufficiently exerted; the effects of simplicity and high efficiency in technological operation, easiness in implementation, freeness from secondary pollution, high oxidation efficiency and good removal effect are achieved.

Owner:广州中德环境技术研究院有限公司

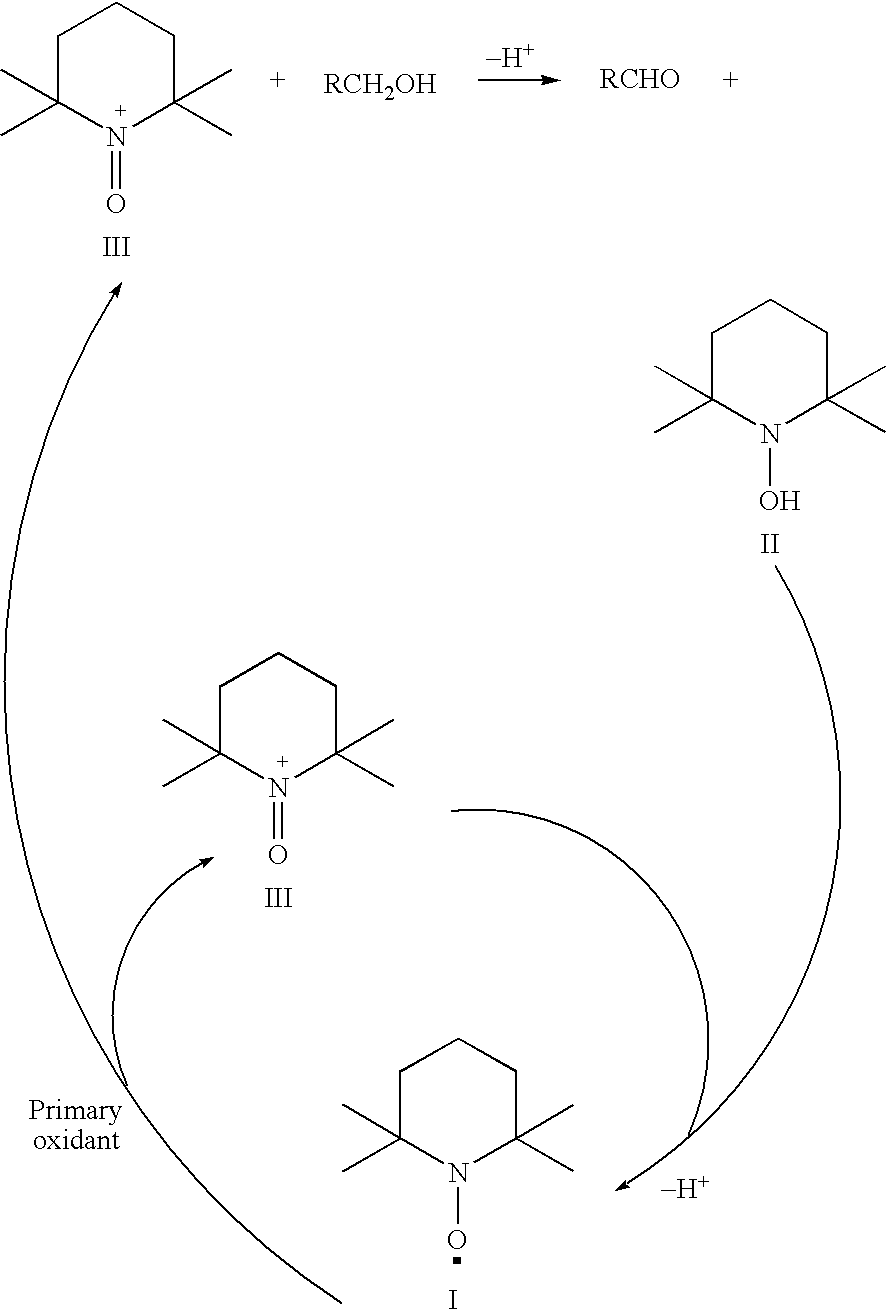

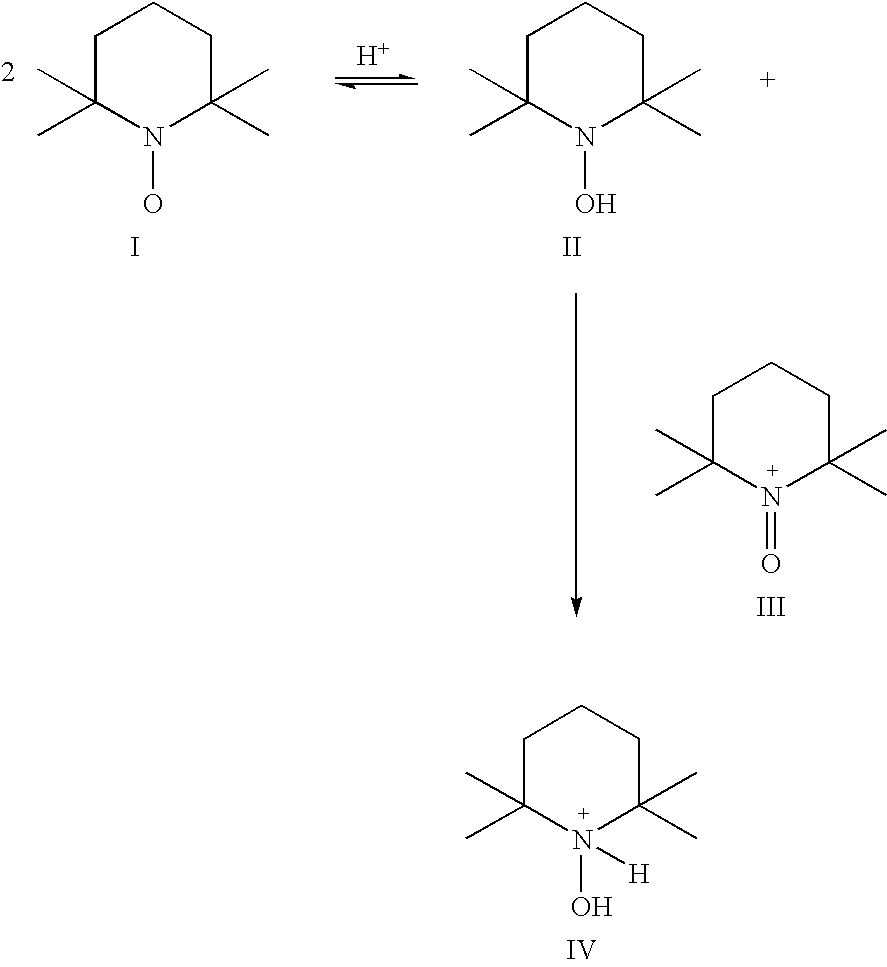

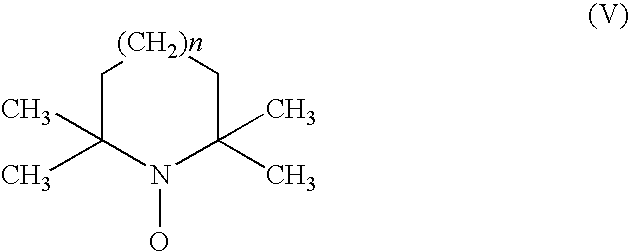

Process for the oxidation of hydroxy compounds by means of nitroxy compounds

InactiveUS20050121159A1Efficient oxidationWithout substantial material lossPulp properties modificationPulping with acid salts/anhydridesCompound aProtonation

A process for the oxidation of a hydroxy compound comprising the steps of: a) providing a first mixture containing an organic protonated hydroxylamine compound, b) oxidizing the protonated hydroxylamine compound to the corresponding nitrosonium compound, c) reacting the nitrosonium compound obtained thereby with a second mixture containing a hydroxy compound, and d) oxidizing the hydroxy compound with the nitrosonium compound, thereby generating the hydroxylamine.

Owner:SCA HYGIENE PROD AB

In-situ contaminant remediation systems and methods

ActiveUS8628659B1Efficient oxidationOrganic chemistryTreatment using aerobic processesIn situ remediationOrganic compound

The present invention provides systems and methods for in-situ remediation of soil and groundwater having contaminants such as but not limited to organic compounds perhaps providing adsorption, chemical oxidation, and even biodegradation of contaminants with novel treatments such as but not limited to mixtures of granular activated carbon, calcium peroxide, sodium persulfate, and nitrate perhaps in various concentrations.

Owner:TAYLOR III JESSE CLINTON

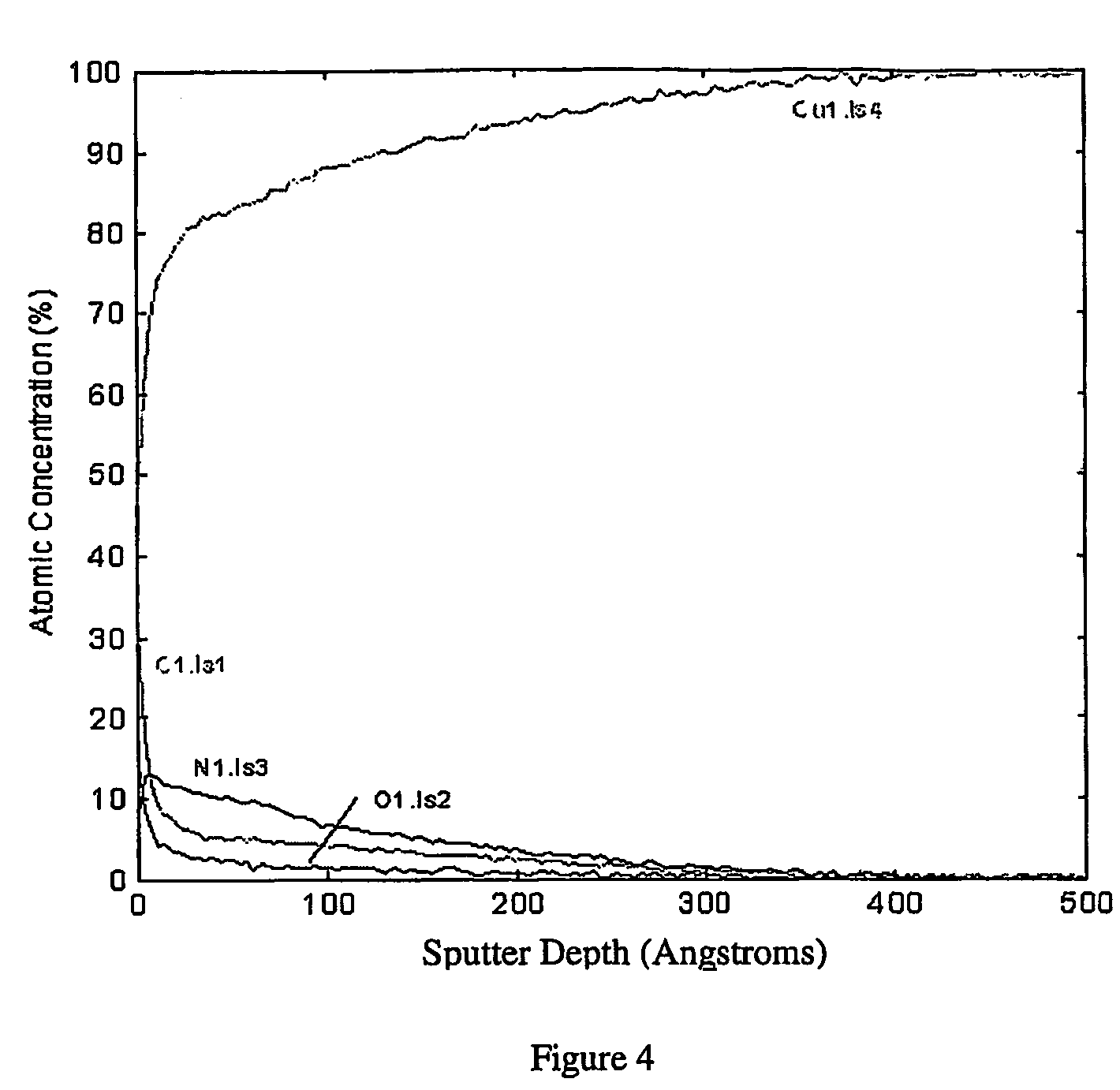

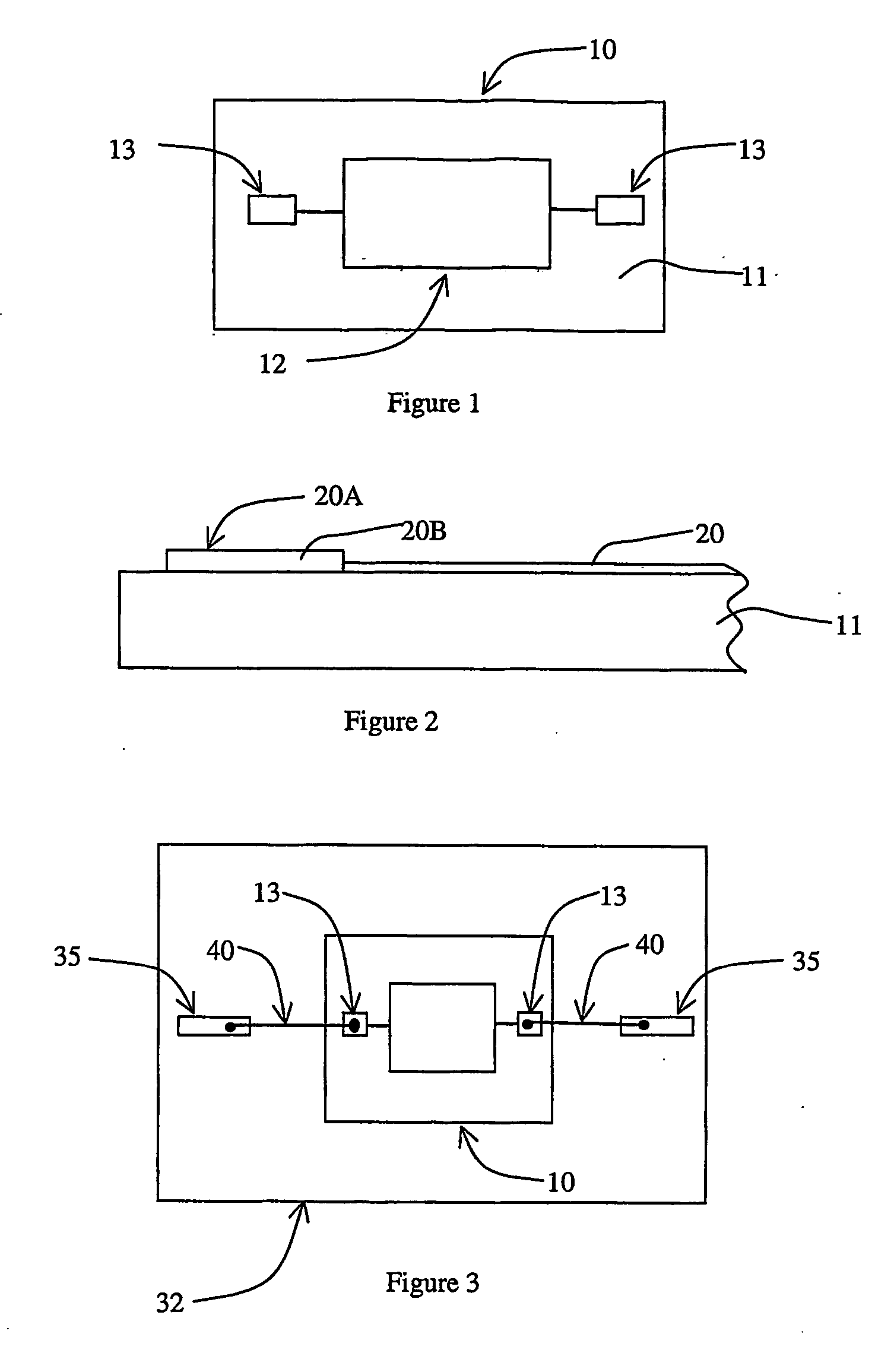

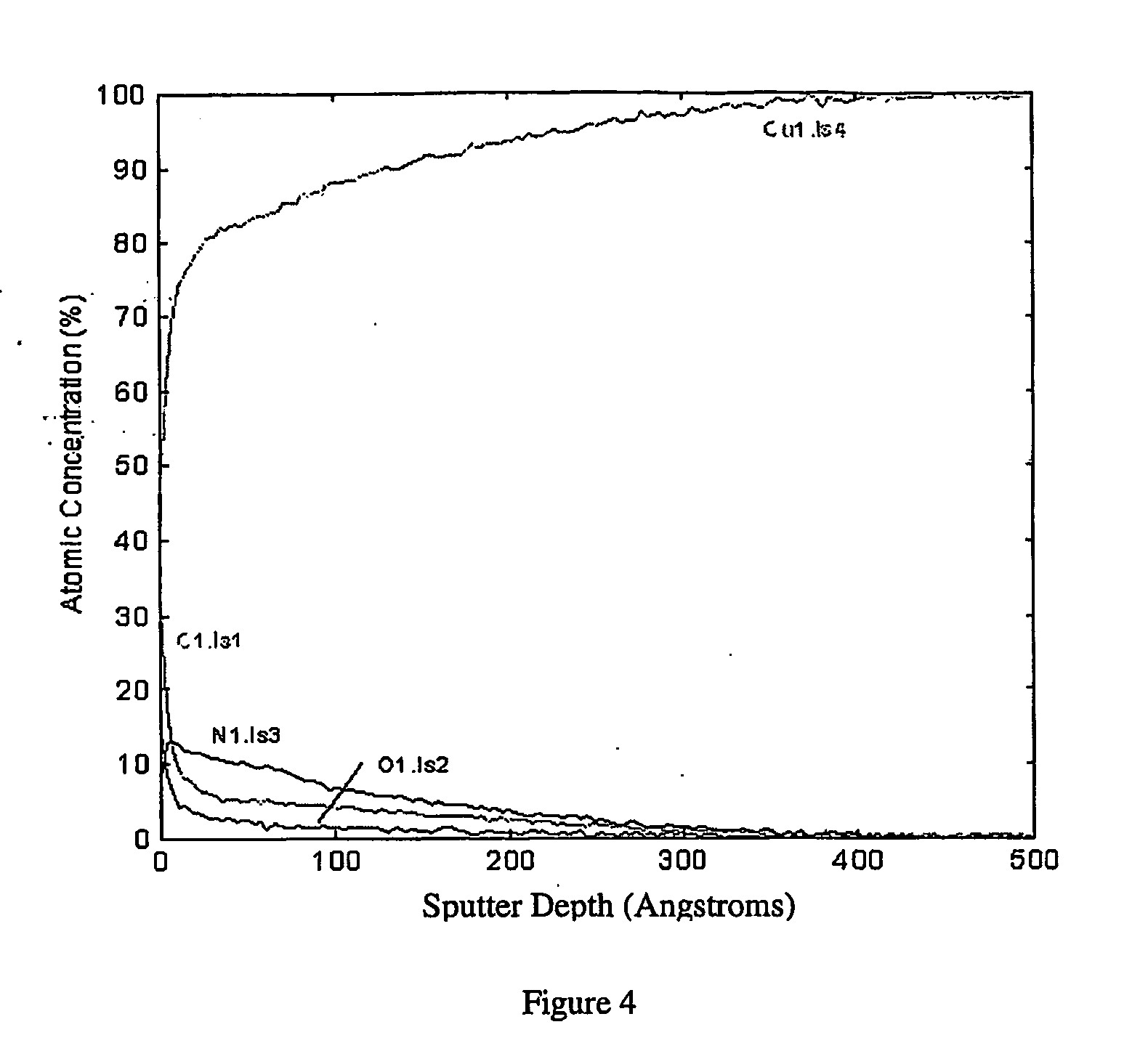

Electrical interconnect structures for integrated circuits and methods of manufacturing the same

InactiveUS7294217B2Effective of materialEfficient oxidationContact member manufacturingSemiconductor/solid-state device detailsConductive materialsCopper

Disclosed are interconnect structures and methods which utilize a bonding surface comprising copper nitride. The interconnect structures include a bonding surface comprising copper nitride which is effective at preventing oxidation and / or other unwanted corrosion of the underlying conductive material while providing the basis for a high conductivity bond. The copper nitride bonding surface provides a relatively non-conductive, corrosion-resistant bonding surface while at the same time being readily transformed into a conductive layer at or just prior to the time of bonding.

Owner:KULICKE & SOFFA IND INC

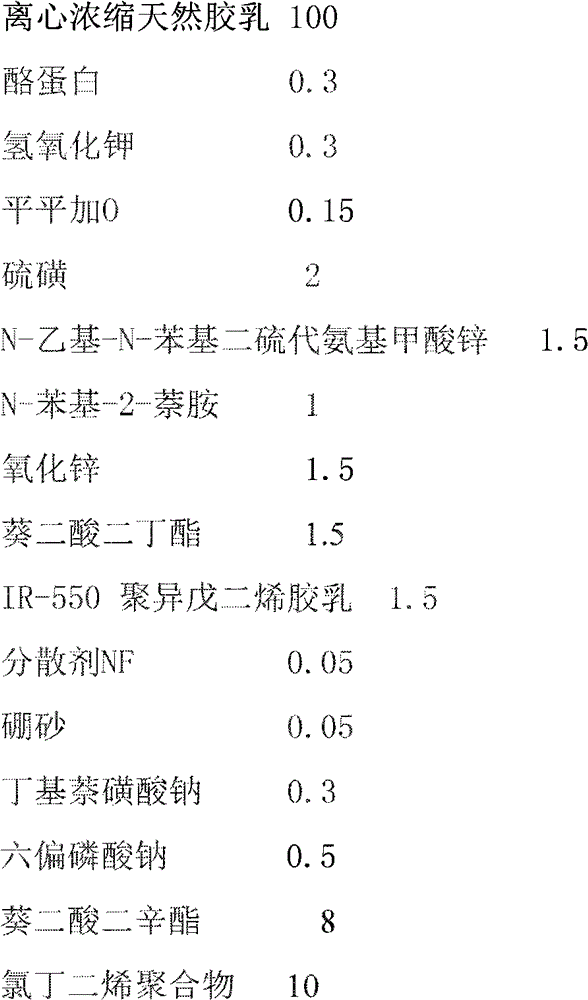

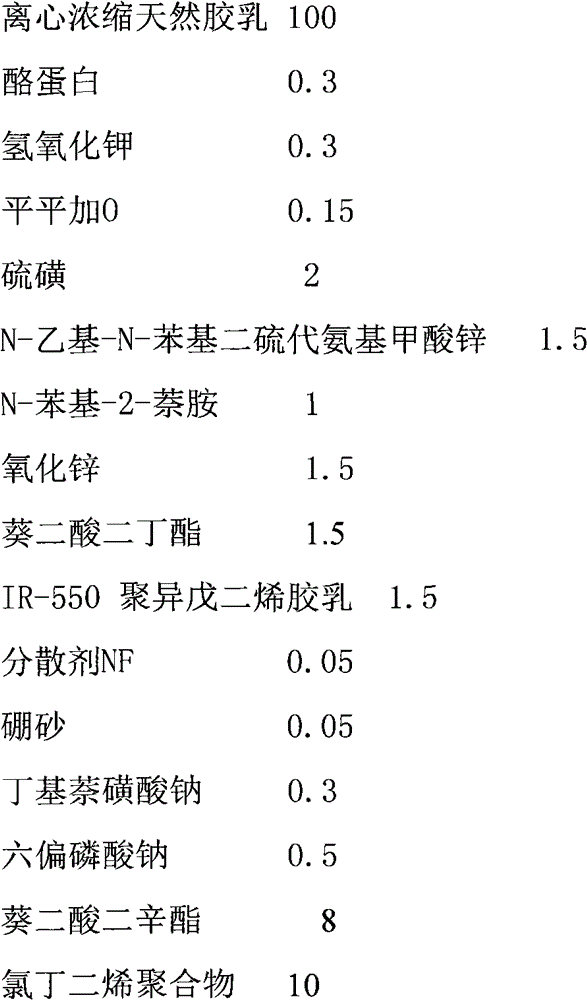

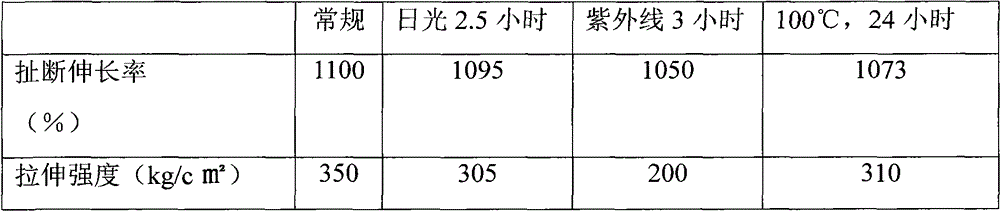

Weather monitoring device and application thereof

ActiveCN102718994AGood dispersionSame plasticizing effectBalloon aircraftsInstrumentsDibutyl sebacateDIETHYL SEBACATE

The invention relates to a weather monitoring device, in particular to a new weather balloon, which comprises the following components by weight percent: 100 of centrifugal concentrated natural latex, 0.3 of casein, 0.3 of potassium hydroxide, 0.15 of peregal 0, 2 of sulphur, 1.5 of N-ethyl-N-phenyl dithiocarbamate zinc, 1 of N-phenyl-2-naphthylamine, 1.5 of zinc oxide, 1.5 of dibutyl sebacate, 1.5 of IR-550 polyisoprene latex, 0.05 of dispersing agent NF, 0.05 of borax, 0.3 of sodium butylnaphthalenesulfonate, 0.5 of sodium hexametaphosphate, 8 of dioctyl sebacate and 10 of chloroprene polymer. The new weather balloon provided by the invention has the advantages of high sounding altitude, long sounding time and wide application prospect.

Owner:南通市通州区新志浩实业有限公司

Metal Protection Layer over SiN Encapsulation for Spin-Torque MRAM Device Applications

InactiveUS20140061827A1Efficient oxidationImprove etch selectivityMagnetic measurementsSemiconductor/solid-state device manufacturingBit lineSpins

A magnetic thin film deposition is patterned and protected from oxidation during subsequent processes, such as bit line formation, by an oxidation-prevention encapsulation layer of SiN. The SiN layer is then itself protected during the processing by a metal overlayer, preferably of Ta, Al, TiN, TaN or W. A sequence of low pressure plasma etches, using Oxygen, Cl2, BCl3 and C2H4 chemistries provide selectivity of the metal overlayer to various oxide layers and to the photo-resist hard masks used in patterning and metal layer and thereby allow the formation of bit lines while maintaining the integrity of the SiN layer.

Owner:HEADWAY TECH INC

Encapsulated oxo-bridged organometallic cluster catalyst and a process for the preparation thereof

InactiveUS20030008770A1High activityEasy to separateMolecular sieve catalystsOrganic compound preparationMolecular sieveManganese

The present invention relates to a novel encapsulated organometallic cluster complex catalyst and to a process for the preparation thereof. The oxo-bridged organometallic cluster complex of the invention has at least one atom of cobalt and manganese encapsulated in micro and mesoporous porous solids like aluminosilicate zeolites, aluminophosphates, carbon molecular sieves, silica and is particularly effective for oxidation of aromatic alkyl groups to the carboxyl groups in high yields.

Owner:COUNCIL OF SCI & IND RES

Interconnect apparatus and methods

InactiveUS20070026574A1Effective of materialEfficient oxidationContact member manufacturingSemiconductor/solid-state device detailsConductive materialsCopper

Disclosed are interconnect structures and methods which utilize a bonding surface comprising copper nitride. The interconnect structures include a bonding surface comprising copper nitride which is effective at preventing oxidation and / or other unwanted corrosion of the underlying conductive material while providing the basis for a high conductivity bond. The copper nitride bonding surface provides a relatively non-conductive, corrosion-resistant bonding surface while at the same time being readily transformed into a conductive layer at or just prior to the time of bonding.

Owner:KULICKE & SOFFA IND INC

Boiler flue gas ozonation and denitration method

InactiveCN109224820AImprove absorption efficiencyEfficient oxidationDispersed particle separationNitrogen monooxideFlue gas

The invention belongs to the technical field of environmental protection, and particularly relates to a boiler flue gas ozonation and denitration method which comprises the following steps: spraying oxygen into a boiler flue; when the temperature of the boiler flue is reduced to 200-250 DEG C, spraying ozone into the boiler flue, wherein the ozone experiences an oxidation reaction with nitrogen monoxide in the flue to generate a mixed gas of NO2, NO3 and N2O5; feeding the mixed gas into a denitration absorption tower from the bottom of the denitration absorption tower; adding absorption liquidinto a tower kettle of the denitration absorption tower; pumping the absorption liquid to the upper part of the denitration absorption tower by a circulating pump; performing spray circulation absorption to realize denitration of the mixed gas; discharging the denitrated flue gas through a chimney. With a high denitration rate, the method provided by the invention greatly reduces air pollution and realizes harmless treatment of the flue gas and thus completely satisfies current discharge standard.

Owner:实友化工(扬州)有限公司

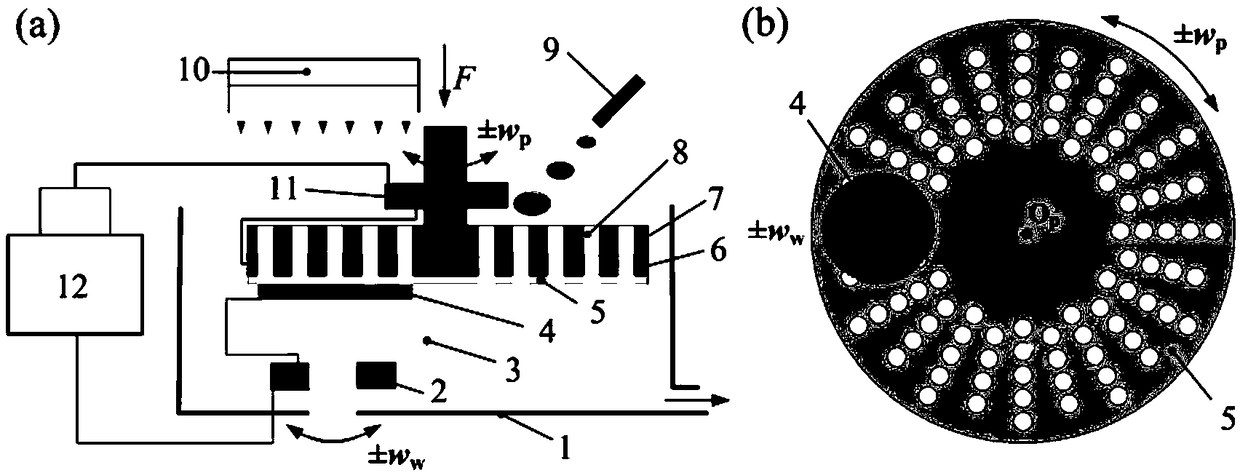

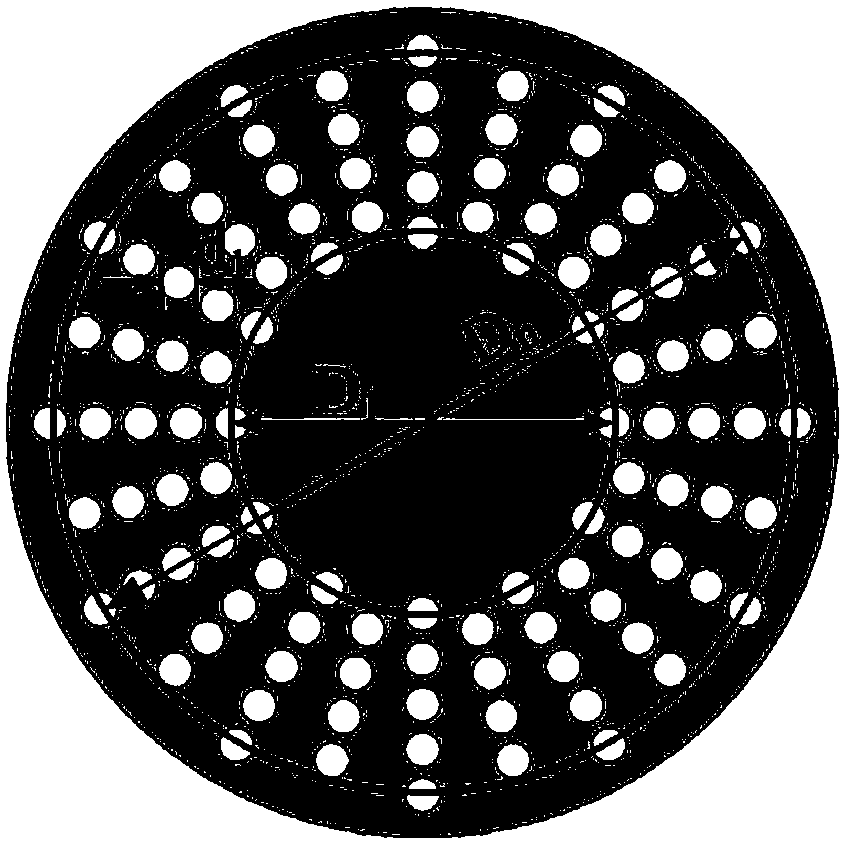

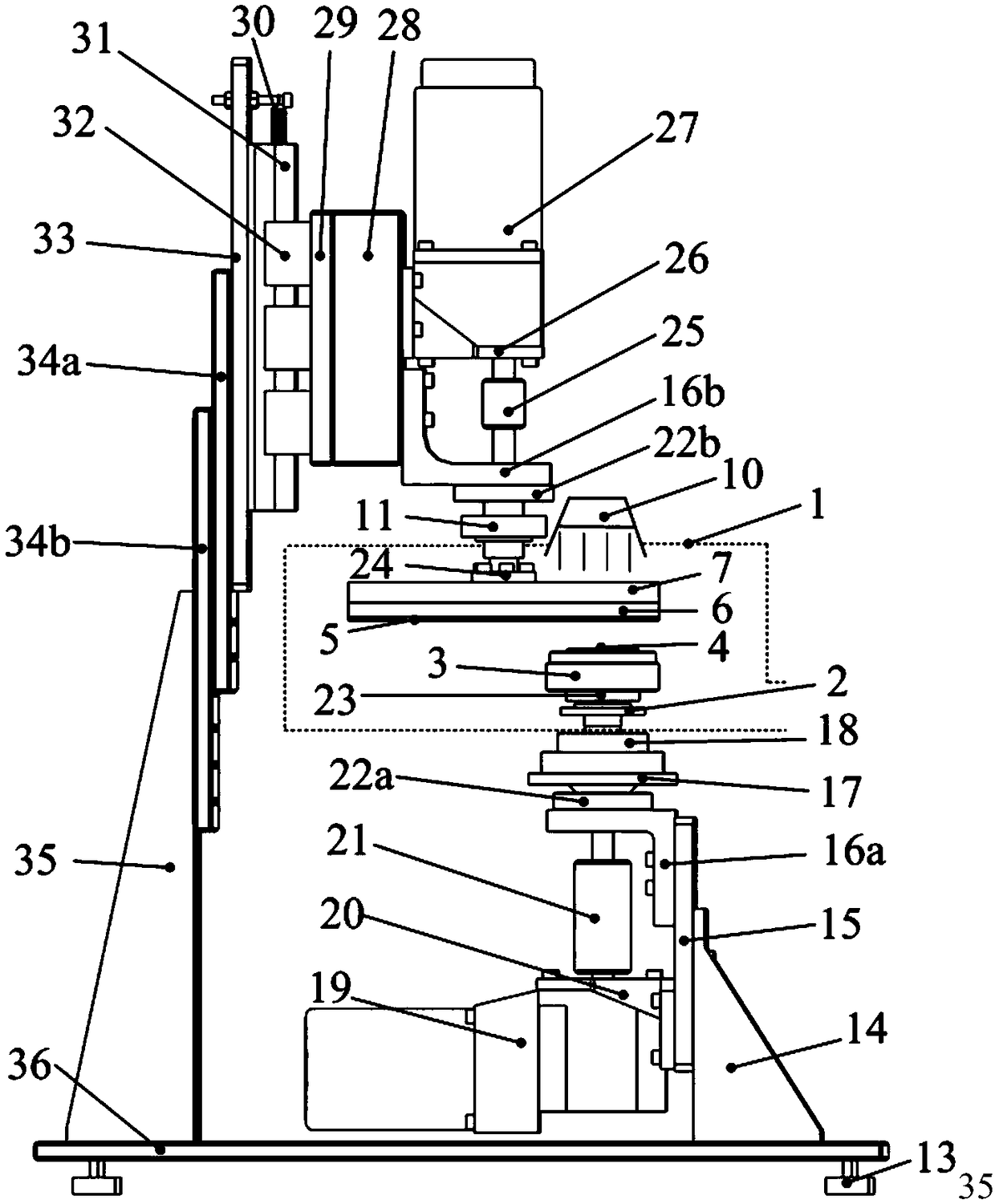

Semiconductor chip photo-electro-chemical mechanical polishing machining device

ActiveCN109465739AReduce roughnessFast removal rateGrinding machine componentsLapping machinesUltraviolet lightsSemiconductor chip

The invention discloses a semiconductor chip photo-electro-chemical mechanical polishing machining method and device. A chip is fixedly bonded to a polishing head through electrically-conductive adhesive. The lower portion of the chip is connected with a positive pole of an external power source through wires at an inner ring and an outer ring of an electrically-conductive sliding ring. A polishing pad is bonded to the bottom of a counter electrode disc. The counter electrode disc is fixed to the bottom of a polishing disc, and a through hole is machined in the position, corresponding to the polishing disc, of the counter electrode disc. The counter electrode disc is connected with a negative pole of the external power source through wires at the inner ring and the outer ring of an electrically-conductive sliding ring located above the counter electrode disc. Ultraviolet light transmitted by an ultraviolet light source can be cast to the surface of the chip through the through hole. Apolishing solution can be sprayed into the through hole and enter the contact area of the chip and the polishing pad. By means of the photo-electro-chemical mechanical polishing machining device, themachining method can be well implemented; the machining device has the advantages that the device is easy to operate and implement, and technological parameters can be flexibly adjusted; and the effects that in the practical machining process of the gallium nitride chip, the removal rate is high, and the surface quality achieved after machining is high are achieved.

Owner:DALIAN UNIV OF TECH

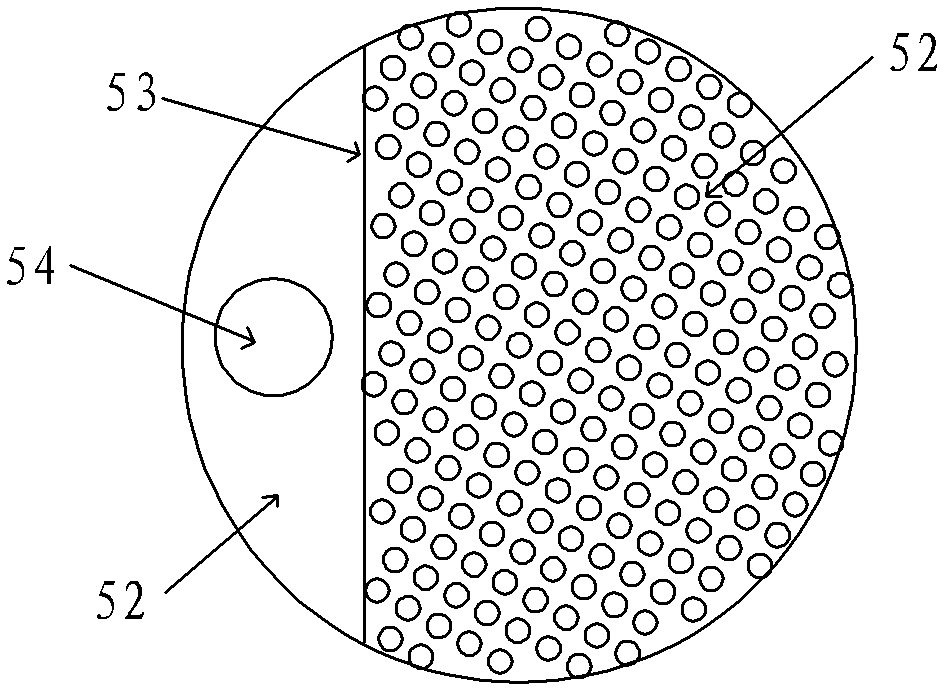

Sieve-plate tower used for sintering machine flue gas desulfurization and desulfurization process thereof

InactiveCN102512939ALarge specific surface areaImprove absorption efficiencyDispersed particle separationFlue gasSlurry

The invention discloses a sieve-plate tower used for sintering machine flue gas desulfurization and a desulfurization process thereof, and belongs to the field of resource and environment protection. The device comprises an absorption tower, wherein the absorption tower is provided with a flue gas inlet, a flue gas outlet and a desulfurizer inlet, a demisting layer, a spraying layer, a sieve plate and a pulp chest are sequentially arranged in the absorption tower from top to bottom, the desulfurizer inlet is positioned above the flue gas inlet, the sieve plate is positioned between the desulfurizer inlet and the flue gas inlet, an overflow weir is arranged above the sieve plate, the sieve plate is divided into an overflow area and a gas liquid contact area by the overflow weir, sieve pores of the sieve plate are arranged in the gas liquid contact area, the gas liquid contact area is positioned at one side of the sieve plate close to the desulfurizer inlet, and an overflow pipe is arranged under the overflow area. The desulfurization process comprises the following steps that: sintering machine flue gas enters the absorption tower to be reacted with the desulfurizer at the gas liquid contact area and then is discharged after sulfur dioxide is removed, and desulfurized pulp generated by the reaction of the flue gas and the desulfurizer overflows into the pulp chest of the absorption tower. The invention is used for removing the sulfur dioxide in the sintering machine flue gas, the flue gas desulfurization efficiency is improved, and the desulphurization energy consumption is reduced.

Owner:ZHEJIANG TIANLAN ENVIRONMENTAL PROTECTION TECH

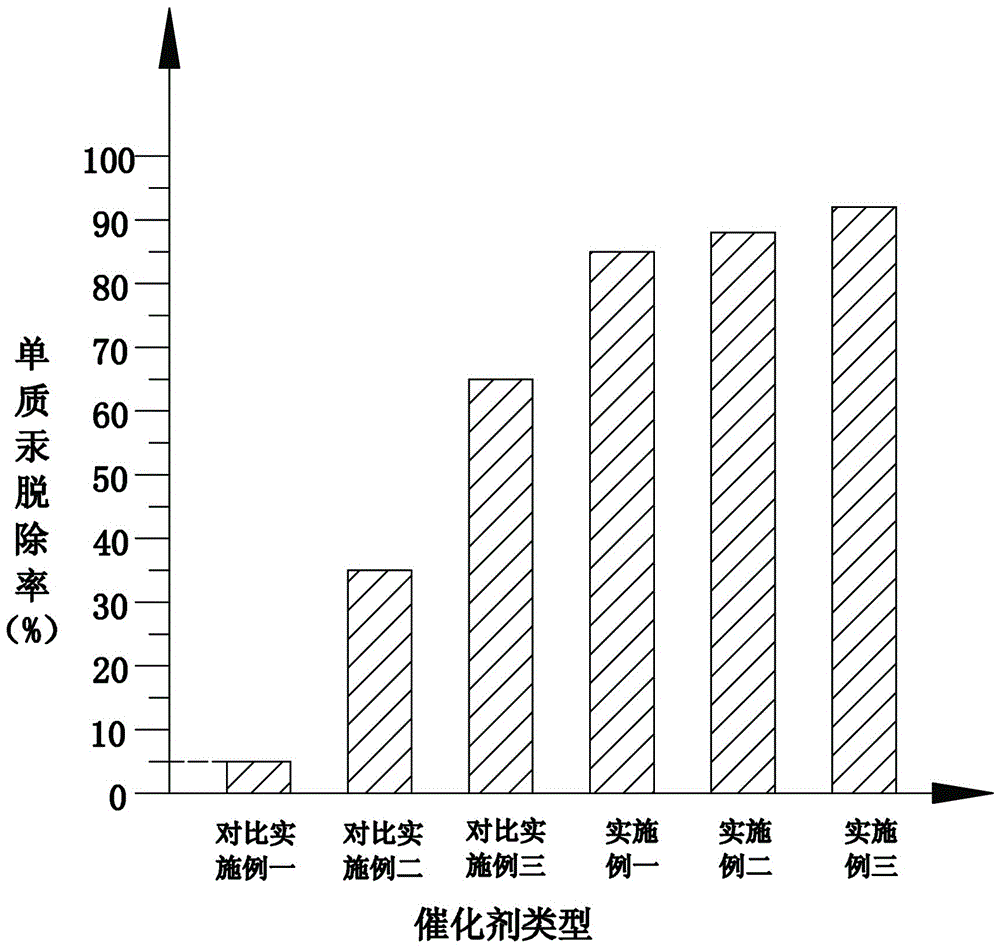

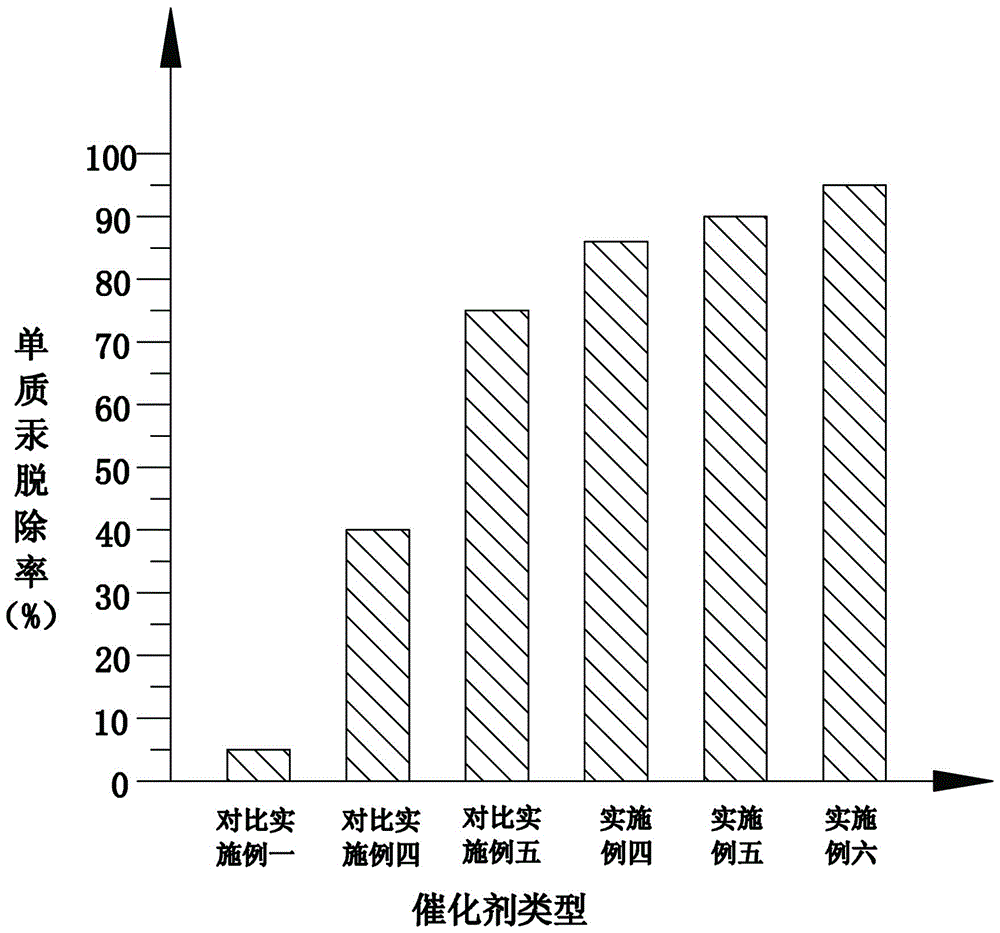

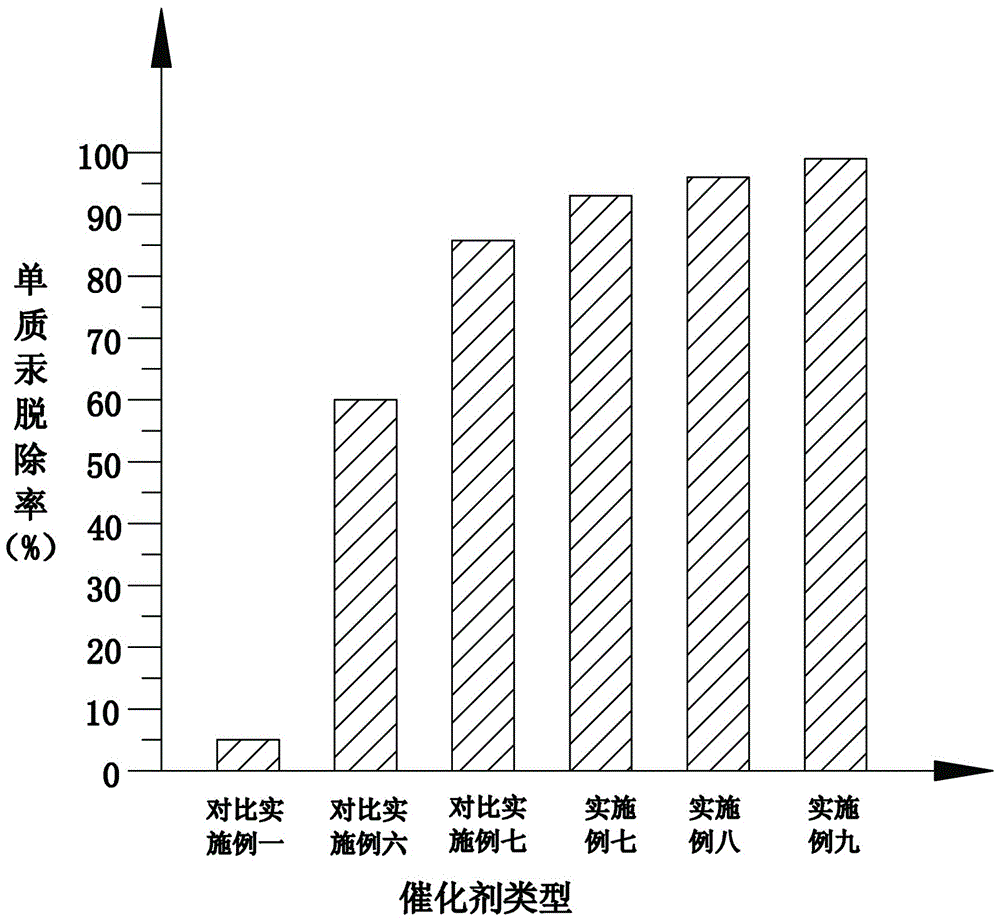

Composite magnetic visible light photocatalyst silver-silver halide-bismuth oxyhalide-cobalt ferrite and preparation method thereof

ActiveCN106732688AEfficient separationStrong oxidation abilityGas treatmentPhysical/chemical process catalystsElectron holeAdditive ingredient

The invention provides a composite magnetic visible light photocatalyst silver-silver halide-bismuth oxyhalide-cobalt ferrite and a preparation method thereof. The invention provides a recoverable magnetic visible light photocatalyst Ag-AgX-BiOX-CoFe2O4 (X is Cl or Br or I); the catalyst is formed by compounding simple substances Ag, AgX (X is Cl or Br or I), BiOX (X is Cl or Br or I) and CoFe2O4. Multiple ingredients are coupled, so that the effective separation of photo-induced electron hole pairs is facilitated; many strong oxidizing substances can be generated, so that the oxidization activity of the visible light photocatalyst can be enhanced; through the doping of a magnetic carrier of CoFe2O4, the visible light photocatalyst has the sufficient strong magnetic recovery capability; the multi-time circulation use can be realized, so that the smoke gas demercuration cost can be reduced; the environment-friendly performance of the visible light photocatalyst is improved.

Owner:HENAN POLYTECHNIC UNIV

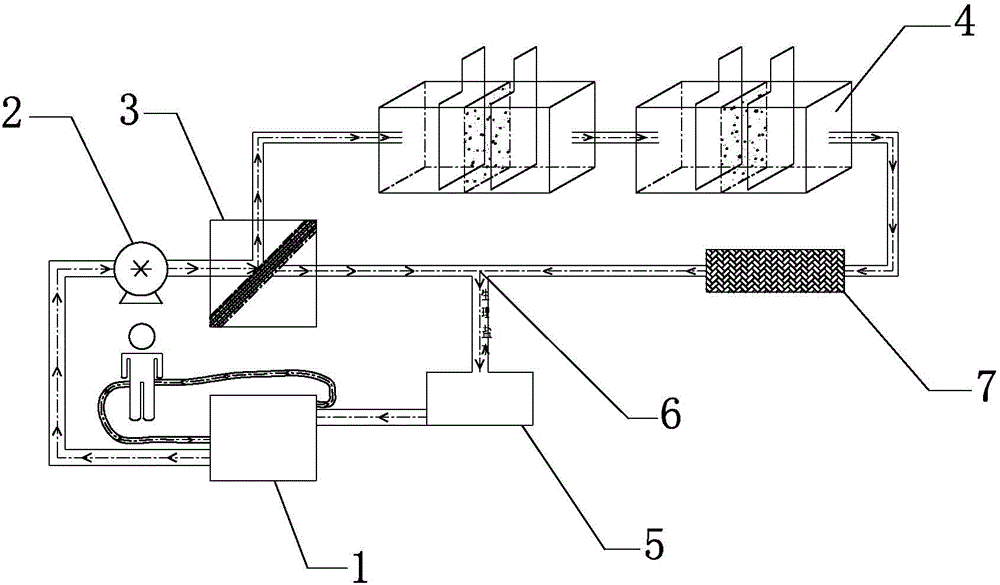

Dialysate regeneration device

InactiveCN104826185AImprove electrochemical stabilityWill not polluteDialysis systemsMedicineReverse osmosis

The present invention relates to a dialysate regeneration device capable of continuously regenerating dialyzate in a dialysis treatment process, or regenerating the dialysate after dialysis, which can greatly reduce the amount of dialysate and clean water used in the dialysate process, The dialysate regeneration device is particularly suitable for dialysate in an emergent condition. The dialysate regeneration device comprises a pump, a reverse osmosis component, an electric catalysis reactor based on BDD electrode and a dialysate water tank. An upstream of the reverse osmosis component is communicated with a liquid outlet of a dialysis machine via the pump; the downstream of the reverse osmosis component comprises two branches, one branch (concentrated water) converges the other branch (clean water) through two groups of electric catalysis reactors and is communicated with a liquid inlet of the dialysate water tank via the confluence port ; a liquid outlet of the dialysate water tank is communicated with the liquid inlet of the dialyzate machine; a filter and air emission component are arranged on a communication channel between the outlet of the electric catalysis reactors and the confluence port.

Owner:SCI RES TRAINING CENT FOR CHINESE ASTRONAUTS

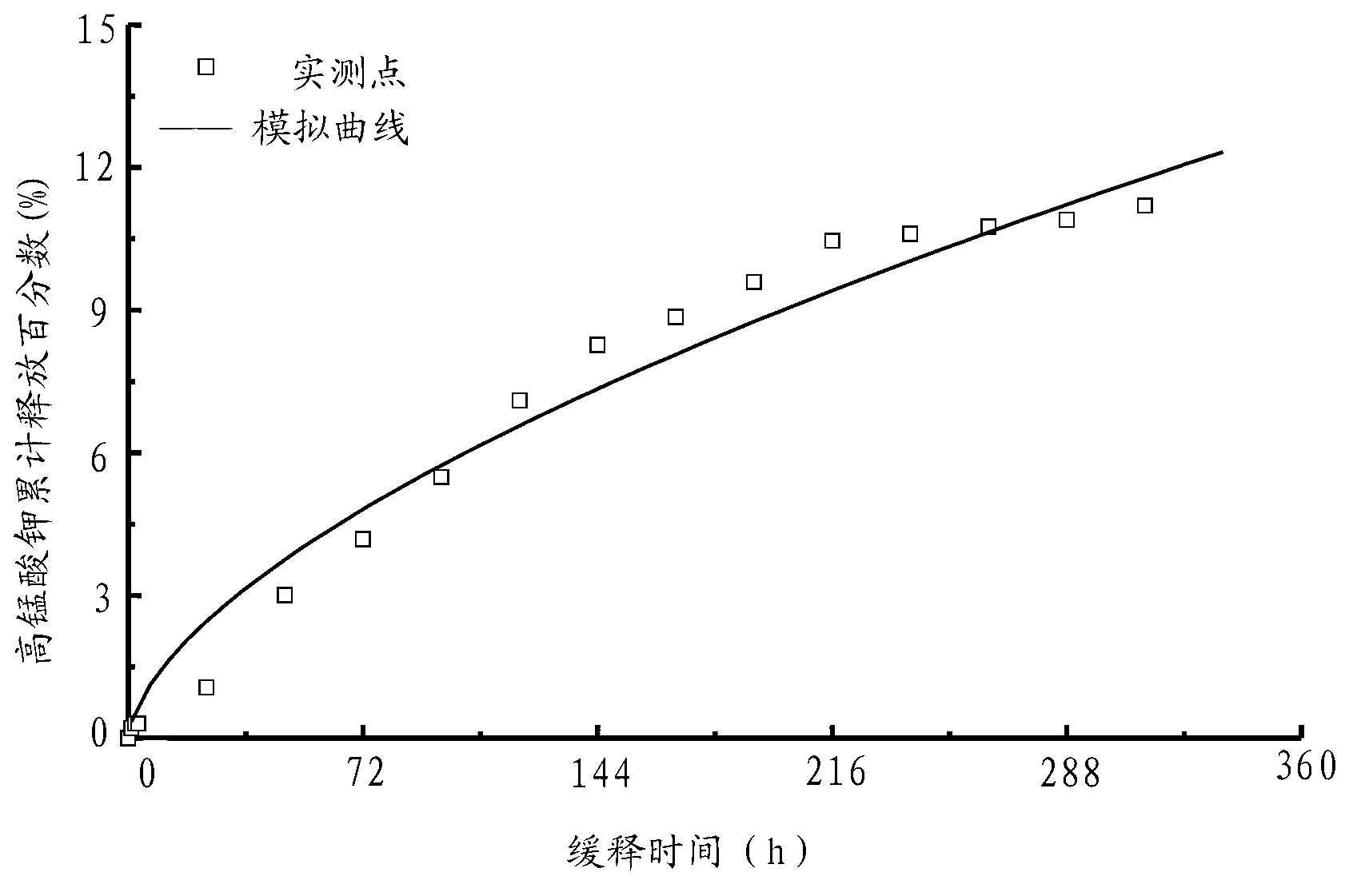

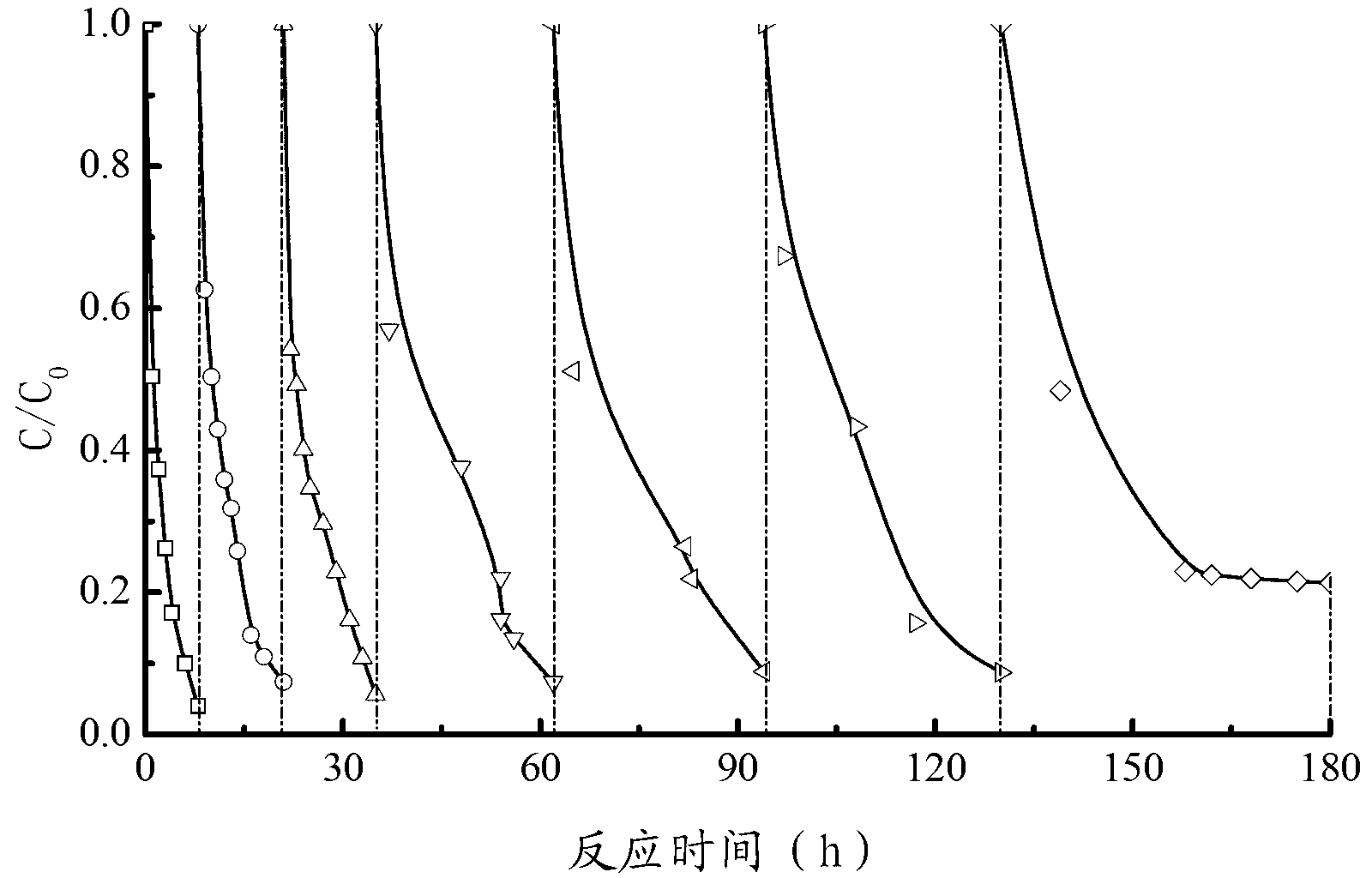

Preparation method for sustained release potassium permanganate microcapsule

InactiveCN103071436AIncrease reachImprove utilizationMicroballoon preparationWater/sewage treatment by oxidationWater bathsPolyethylene glycol

The invention discloses a preparation method for a sustained release potassium permanganate microcapsule, comprising the following steps that (1), stearic acid is arranged in a reactor, absolute ethyl alcohol is added to the reactor, the reactor is heated in water bath, the solution in the reactor is sufficiently stirred until the stearic acid is completely dissolved; (2), polyethylene glycol 4000 and potassium permanganate are added to the reactor, potassium permanganate is homogeneously dispersed in the solution through ultrasound, the ultrasound is stopped, the solution is stirred and naturally cooled to the temperature of below 35 DEG C, and the reaction is finished after solid is completely dissolved out; and the mass ratio of potassium permanganate to stearic acid is 1:1-1:3. The preparation method for the sustained release potassium permanganate microcapsule solves the problems of low utilization rate of oxidant, high non-preference consumption and mass transfer of oxidant in the process of removing underground water pollutants by the in-situ chemical oxidation of liquid and powder potassium permanganate, and realizes the purposes of sustained release, effective transmission and efficient oxidation of the oxidant.

Owner:HUAQIAO UNIVERSITY

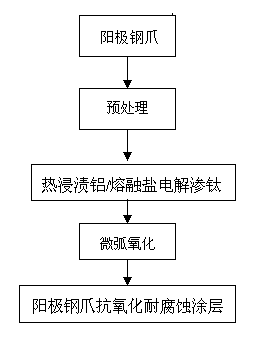

Preparation method for coating on electrolytic aluminum prebaked anode steel claw

InactiveCN103526212AImprove mechanical propertiesReduce consumption costMicro arc oxidationPlasma electrolytic oxidation

The invention relates to a preparation method for a coating on an electrolytic aluminum prebaked anode steel claw, which belongs to the technical field of metallurgical materials. The method comprises the following steps: removing dirt on the surface of the electrolytic aluminum prebaked anode steel claw through polishing, cleaning and drying the electrolytic aluminum prebaked anode steel claw and successively removing oil by using an oil removal agent and removing rust by using acid; subjecting the pretreated electrolytic aluminum prebaked anode steel claw to hot dip aluminum plating or fused salt electrolysis titanizing; and finally, carrying out micro-arc oxidation on the electrolytic aluminum prebaked anode steel claw treated by any method in a NaSiO3 solution, NaOH solution, NaH2PO4 solution or Na2SiO3 solution by using constant-current electrolysis so as to prepare the oxidation-resistant corrosion-resistant electrolytic aluminum prebaked anode steel claw treated by using a hot dip aluminum plating or fused salt electrolysis titanizing method and a micro-arc oxidation method. The preparation method provided by the invention overcomes the problems of high-temperature oxidation consumption of the anode steel claw and corrosion of electrolyte cryolite.

Owner:KUNMING UNIV OF SCI & TECH

Low-friction-coefficient MoS2 based metal composite solid lubricating film

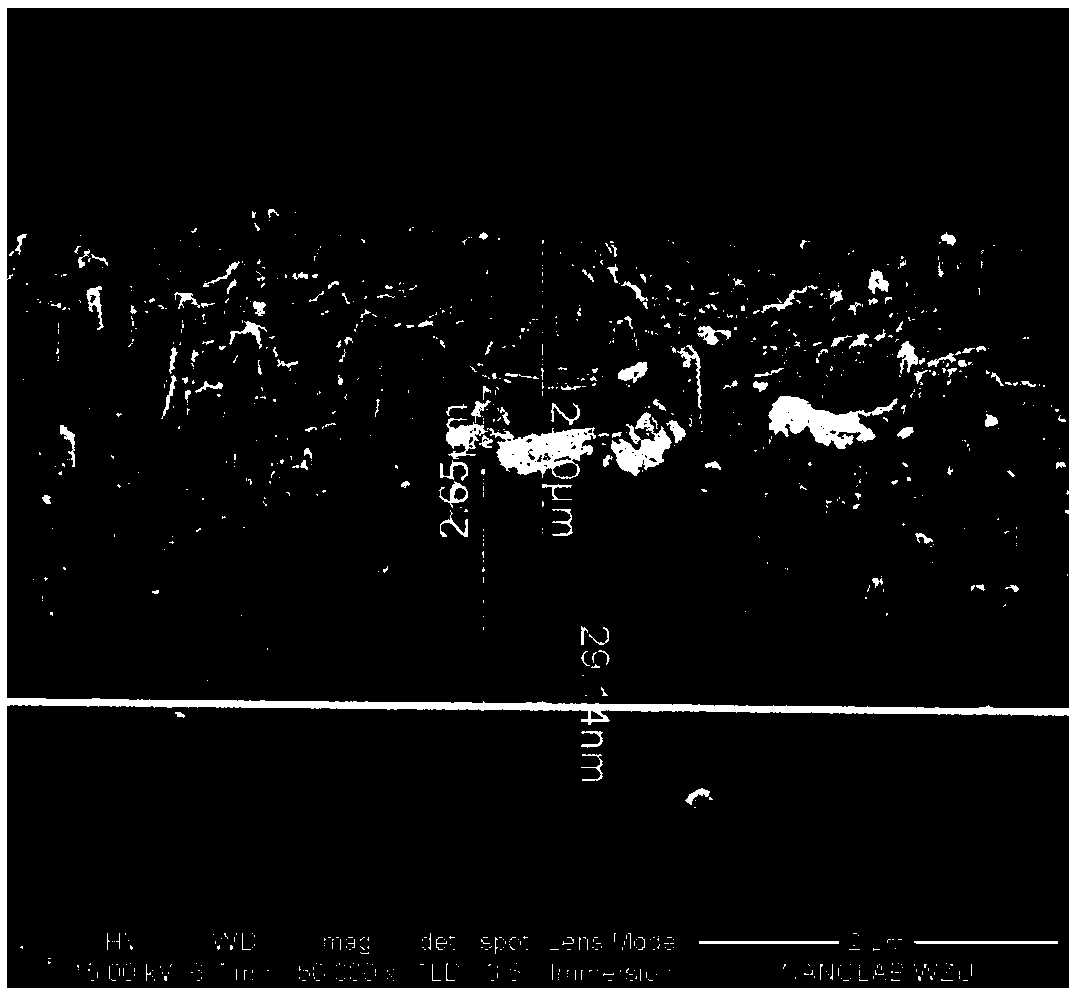

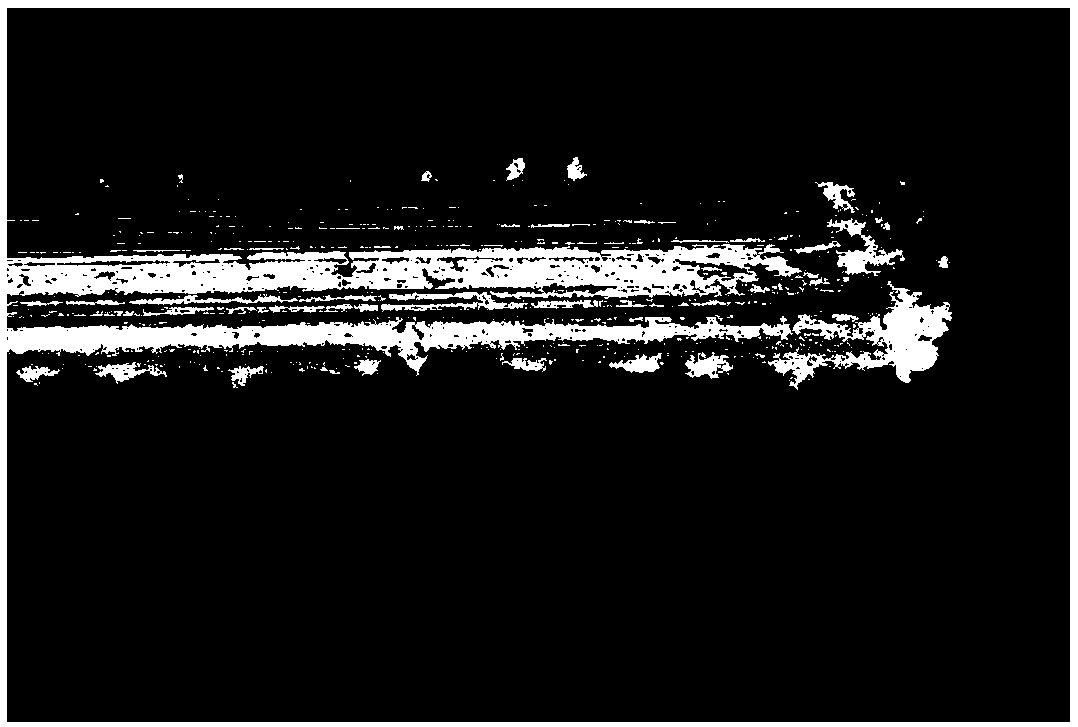

InactiveCN107815645AImprove performanceReduce processing costsVacuum evaporation coatingSputtering coatingSputteringWear resistance

The invention discloses a low-friction-coefficient MoS2 based metal composite solid lubricating film. The low-friction-coefficient MoS2 based metal composite solid lubricating film consists of the following components in atomic percentage: 2at%-38at% of Cu, 0-12at% of Al and the balance of MoS2. A preparation method for the low-friction-coefficient MoS2 based metal composite solid lubricating filmcomprises the following steps of: pre-depositing a Ti or Al pre-combined layer on the surface of a substrate before magnetron sputtering and coating; and performing magnetron sputtering on a metal target and a MoS2 target, thereby obtaining the low-friction-coefficient MoS2 based metal composite solid lubricating film. The low-friction-coefficient MoS2 based metal composite solid lubricating filmdisclosed by the invention improves a composition system of combining a molybdenum disulfide solid lubricating film and a metal additive, solves the problem that the molybdenum disulfide solid lubricating film is relatively poor in wear resistance and is harsh in operating environment in use of the molybdenum disulfide solid lubricating film, provides multi-occasion using possibility of the molybdenum disulfide based film, and prolongs the service life of the film.

Owner:JILIN UNIV

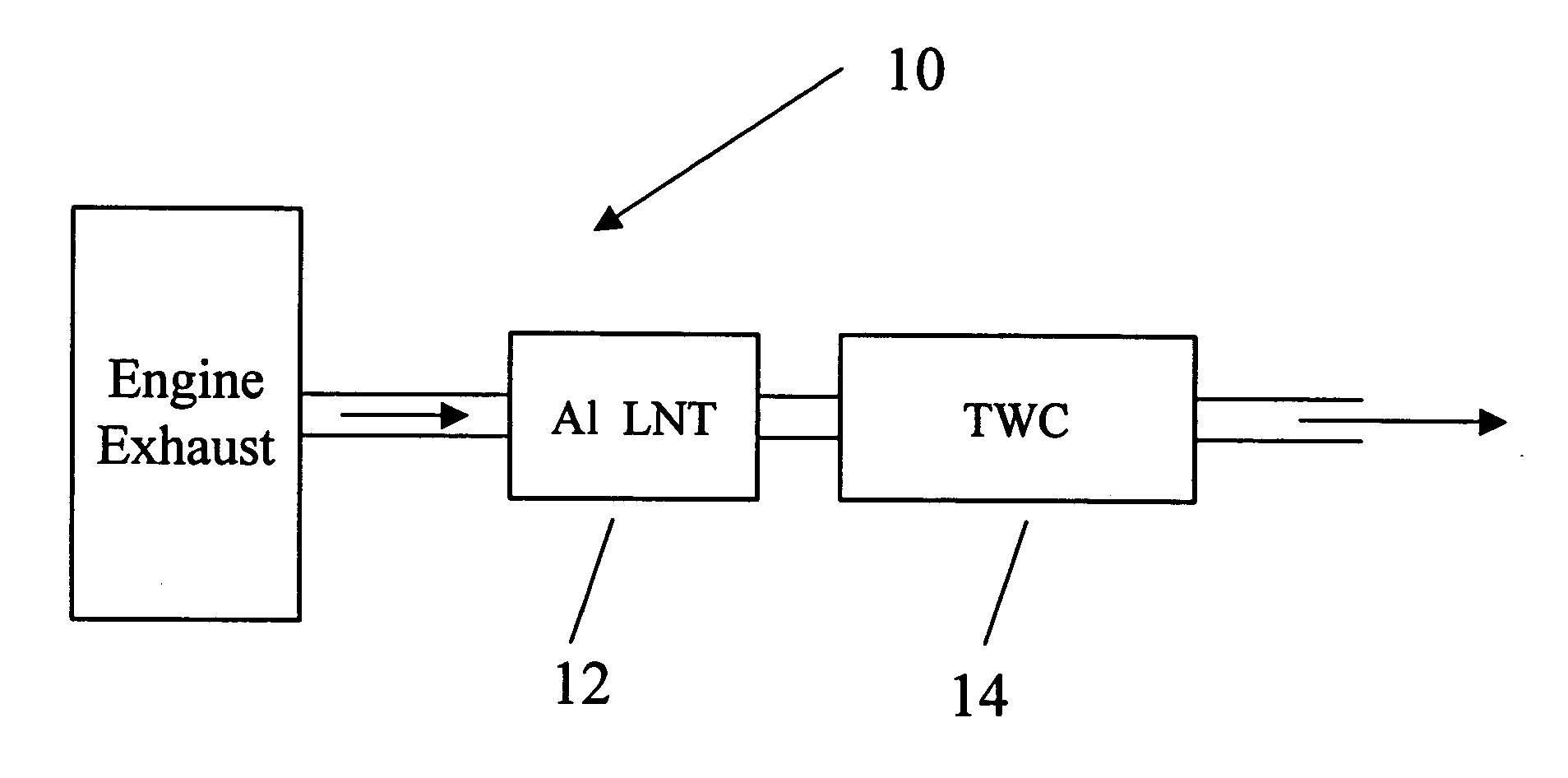

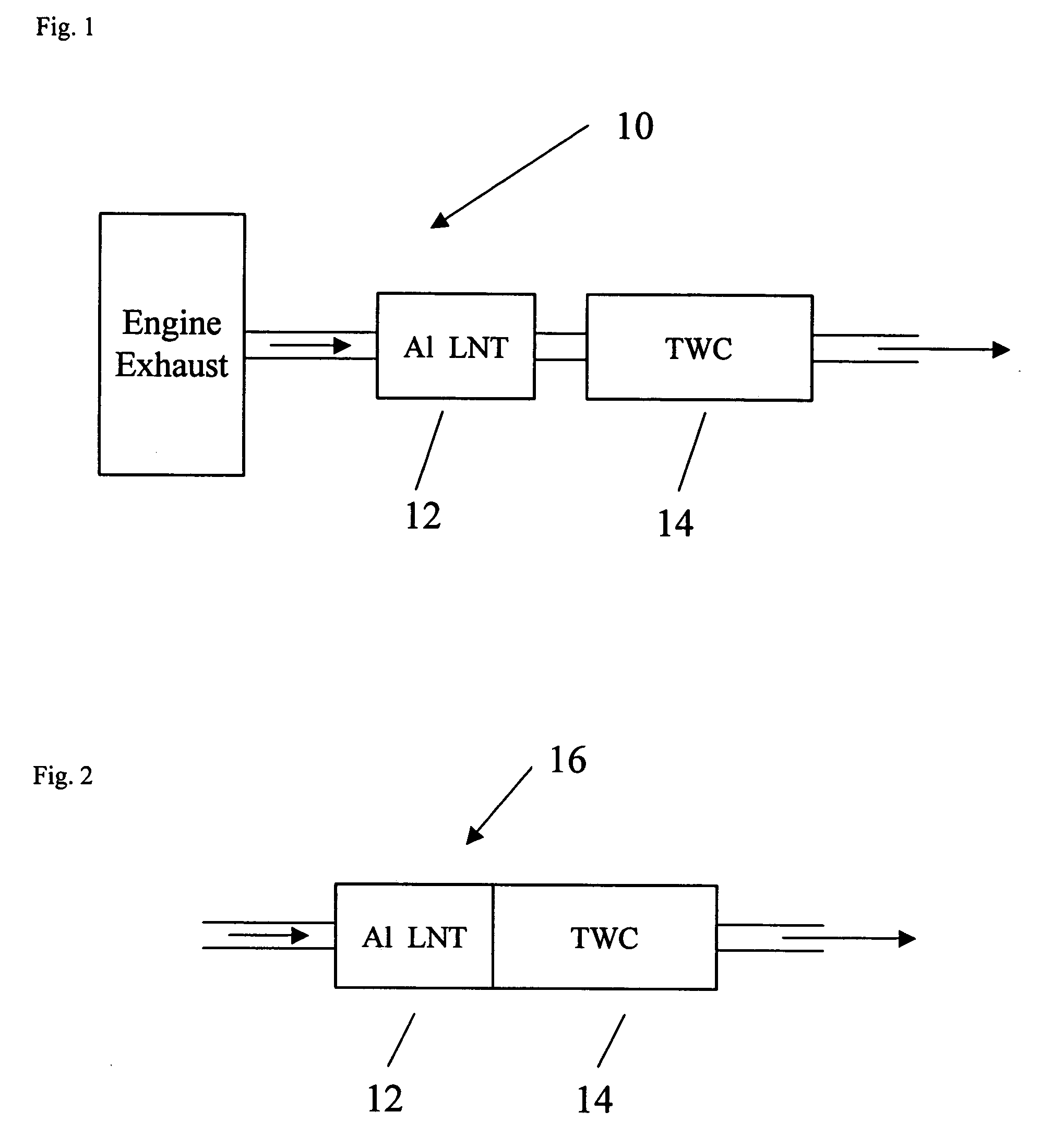

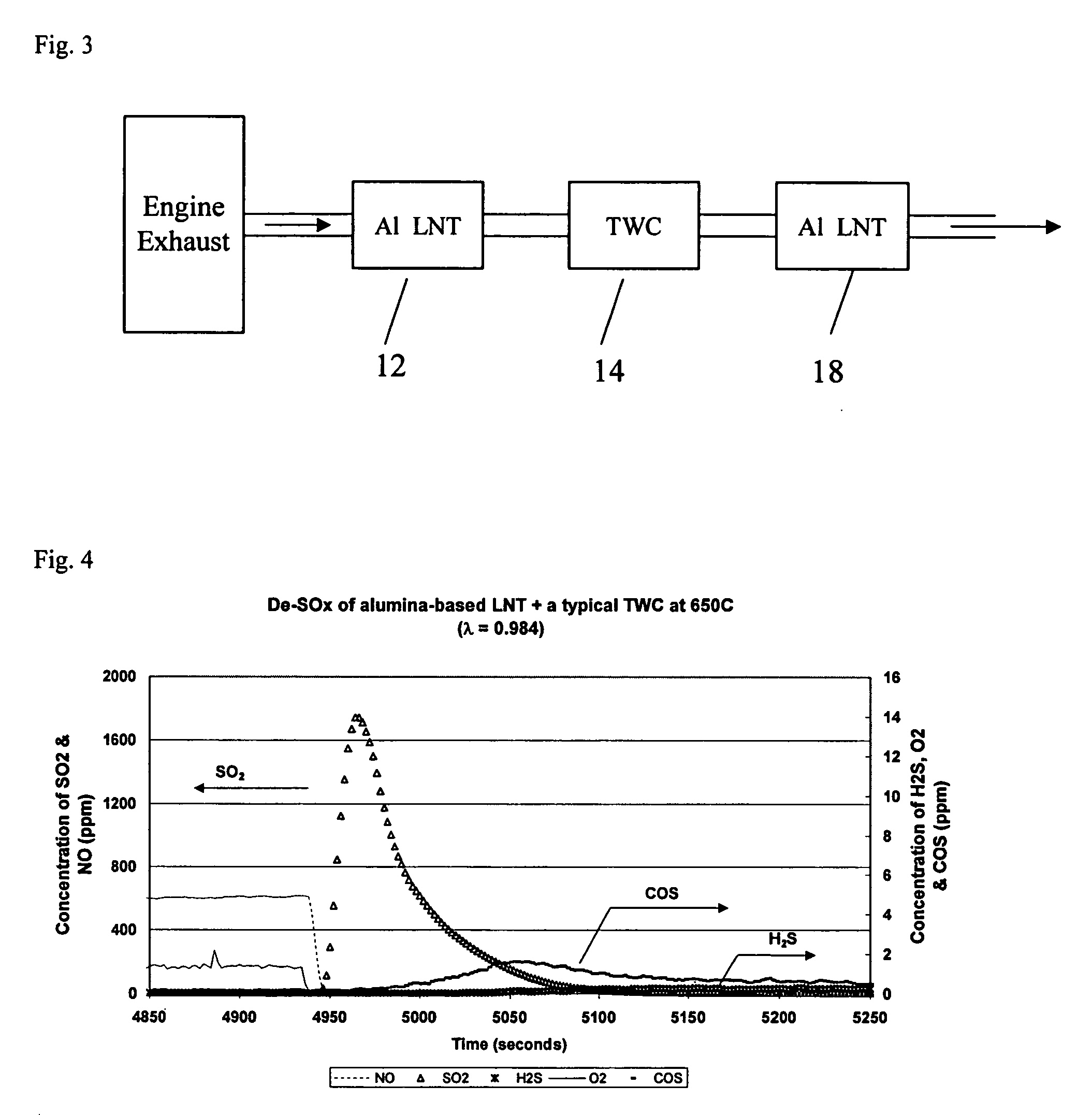

Alumina-based lean NOx trap system and method of use in dual-mode HCCI engines

InactiveUS20060168949A1Efficient desulfurizationEasy to useElectrical controlInternal combustion piston enginesDual modeAbsorbent material

An alumina-based lean NOx trap system for use in a HCCI engine exhaust is provided which includes at least one alumina-based lean NOx trap comprising a catalyst, an alumina NOx absorbent material, and optionally, from 0 to about 4 wt % of an alkaline earth metal oxide; and a conventional three-way catalyst. The lean NOx trap system substantially oxidizes HC and CO and converts at least a portion of NOx contained in the exhaust gas to N2 at a temperature between about 150° C. to about 250° C. in HCCI mode. The system also effectively removes HC, CO and NOx at high temperature when the engine is in SI mode (stoichiometric conditions). The alumina-based lean NOx trap in the system also undergoes efficient desulphurization and maintains its activity with extended use.

Owner:FORD GLOBAL TECH LLC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com