Device and method for simultaneously desulfurizing and denitrifying flue gas by ozone catalytic oxidation process

An ozone catalytic oxidation, desulfurization and denitrification technology, applied in industrial boilers, industrial kilns, and power plants, can solve the problems of secondary pollution, desulfurization by-products such as calcium sulfate, low value, and difficulty in large-scale development.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

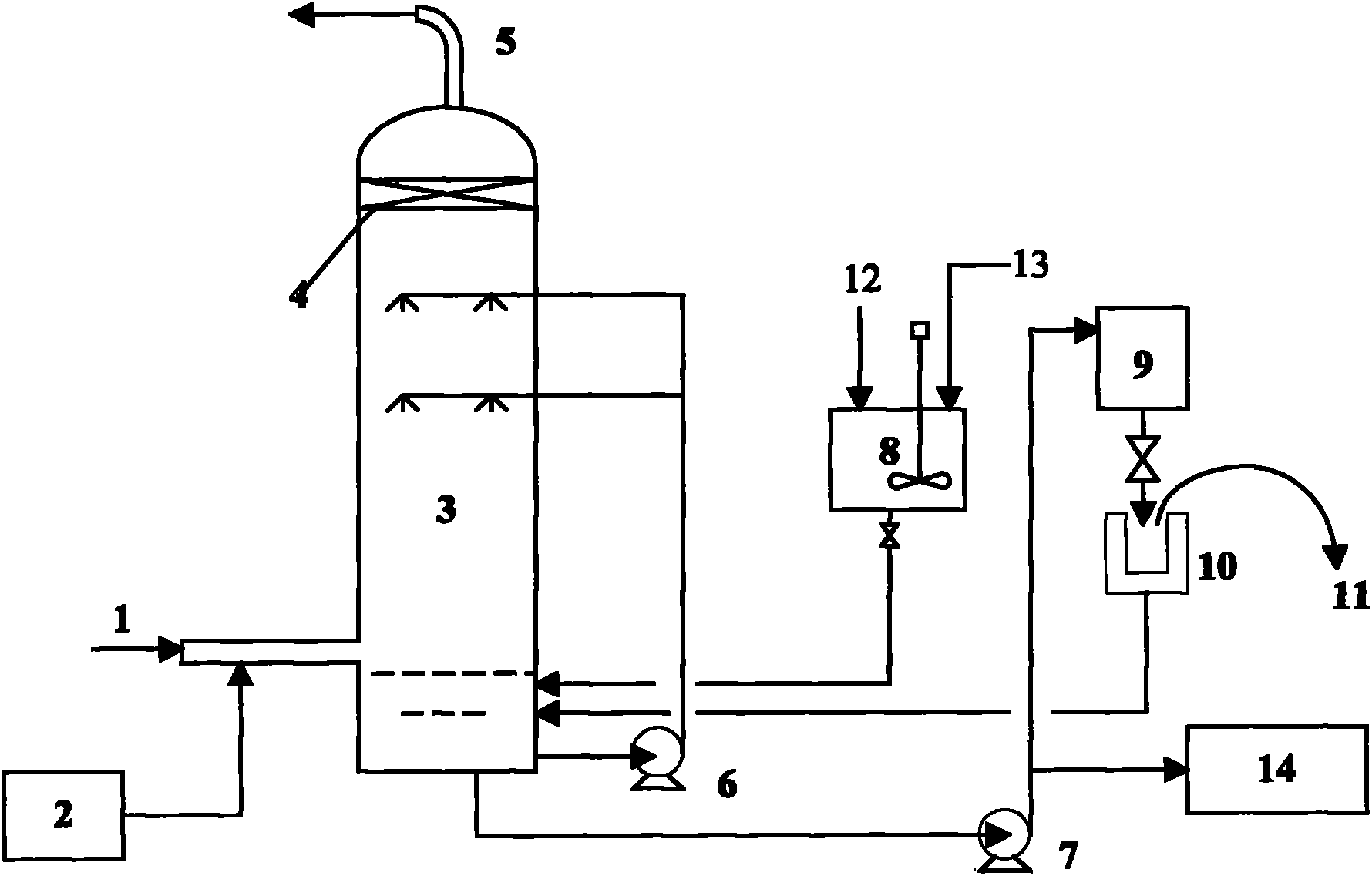

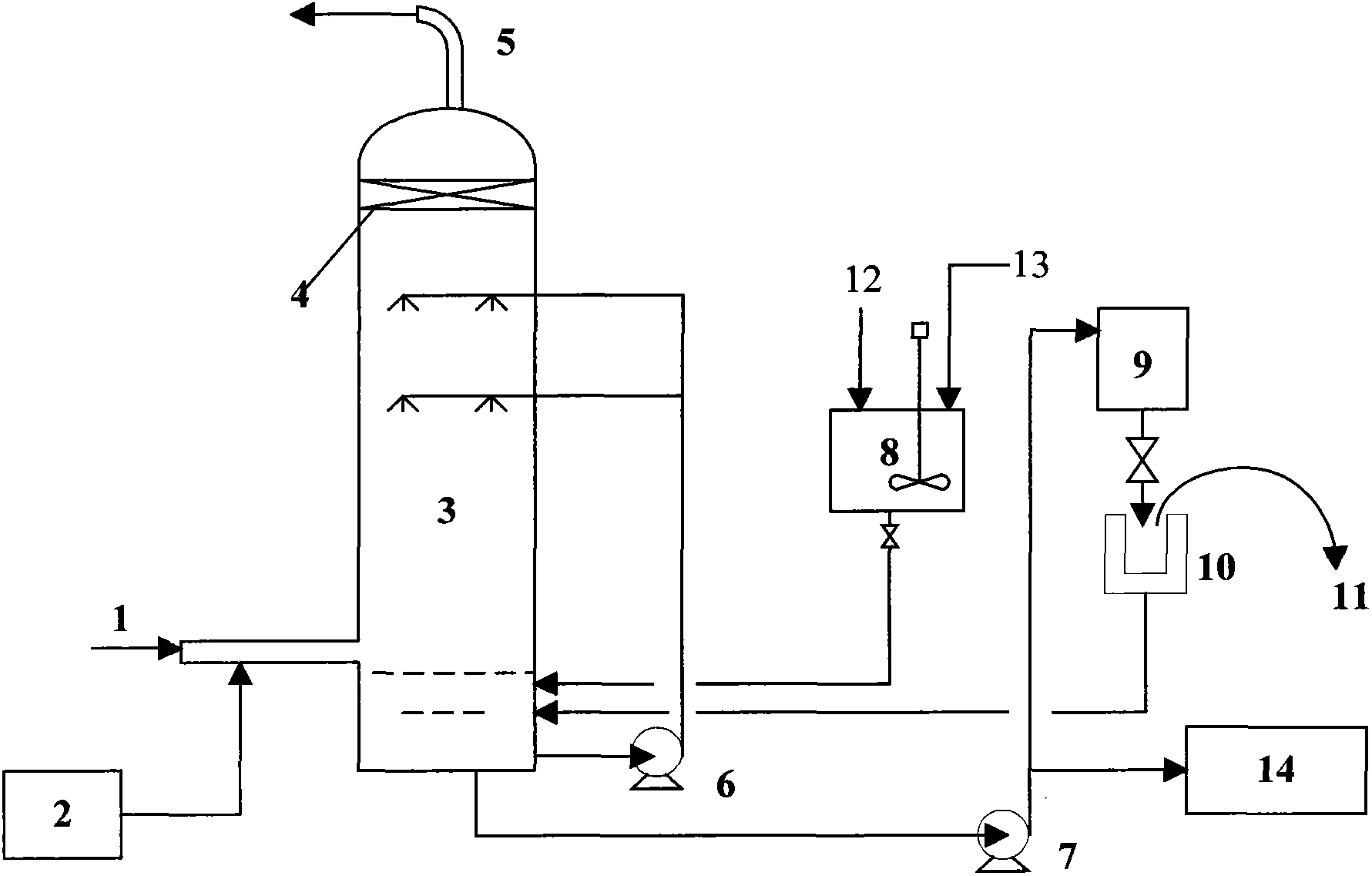

[0049] Flue gas condition: 15000Nm 3 / h, SO 2 Concentration 1200ppm (3428mg / Nm 3 ), NO concentration 460ppm (616mg / Nm 3 ), the temperature is 150°C.

[0050] The flue gas enters the desulfurization tower (the desulfurization tower is a plate corrugated structured packing tower), the amount of ozone added is 53.4kg / h, and the absorption liquid (the concentration of potassium permanganate is 100ppm) is sprayed into the tower from the upper part of the tower, and the flow rate is 10t / h h. SO in the flue gas exiting the top of the tower 2 The content is 116mg / Nm 3 , NO concentration is 49.3mg / Nm 3 , the desulfurization rate is 96.6%, and the denitrification rate is 92%. After desulfurization and denitrification, the flue gas enters the chimney from the top of the tower after demisting by the demister. After 40 hours, 10 tons of mixed acid containing 30.4% sulfuric acid and 7.1% nitric acid were obtained.

Embodiment 2

[0052]Flue gas condition: 6500Nm 3 / h, SO 2 Concentration 450ppm (1286mg / Nm 3 ), NO concentration 230ppm (308mg / Nm 3 ), the temperature is 140°C.

[0053] The flue gas enters the desulfurization tower (the desulfurization tower is an empty tower), the amount of ozone added is 9.49kg / h, and the absorption liquid (wherein the concentration of potassium permanganate is 30ppm) is sprayed into the tower from the upper part of the tower, and the flow rate is 5t / h. Add 20% ammonia water 26.9kg / h to the absorption liquid. SO in the flue gas exiting the top of the tower 2 The content is 38.6mg / Nm 3 , NO concentration is 18.5mg / Nm 3 , the desulfurization rate is 97%, and the denitrification rate is 94%. After the flue gas is desulfurized and denitrified, the flue gas enters the chimney from the top of the tower after demisting by the demister. After 90 hours, the ammonium sulfate concentration reached 30% and the ammonium nitrate concentration reached 9% in the 5 tons of absorpt...

Embodiment 3

[0055] Flue gas condition: 45000Nm 3 / h, SO 2 Concentration 620ppm (1771mg / Nm 3 ), NO concentration 340ppm (455mg / Nm 3 ), the temperature is 160°C.

[0056] The flue gas enters the desulfurization tower (the desulfurization tower is an empty tower), the amount of ozone added is 94.1kg / h, and the absorption liquid (the concentration of potassium permanganate is 50ppm) is sprayed into the tower from the upper part of the tower, and the flow rate is 30m 3 / h, add potassium carbonate 213.1kg / h in the absorption solution. SO in the flue gas exiting the top of the tower 2 The content is 35.4mg / Nm 3 , NO concentration is 22.7mg / Nm 3 , the desulfurization rate is 98%, and the denitrification rate is 95%. After the flue gas is desulfurized and denitrified, the flue gas enters the chimney from the top of the tower after demisting by the demister. After 21 hours, the concentration of potassium sulfate in the 30 tons of absorption liquid reached 15%, and the concentration of potas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com