Low-friction-coefficient MoS2 based metal composite solid lubricating film

A low friction coefficient, solid lubrication technology, applied in metal material coating process, vacuum evaporation plating, coating and other directions, can solve the problems of large surface roughness, poor wear resistance, film peeling failure, etc. Improved overall wear resistance and moisture resistance, enhanced overall mechanical properties, and low processing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

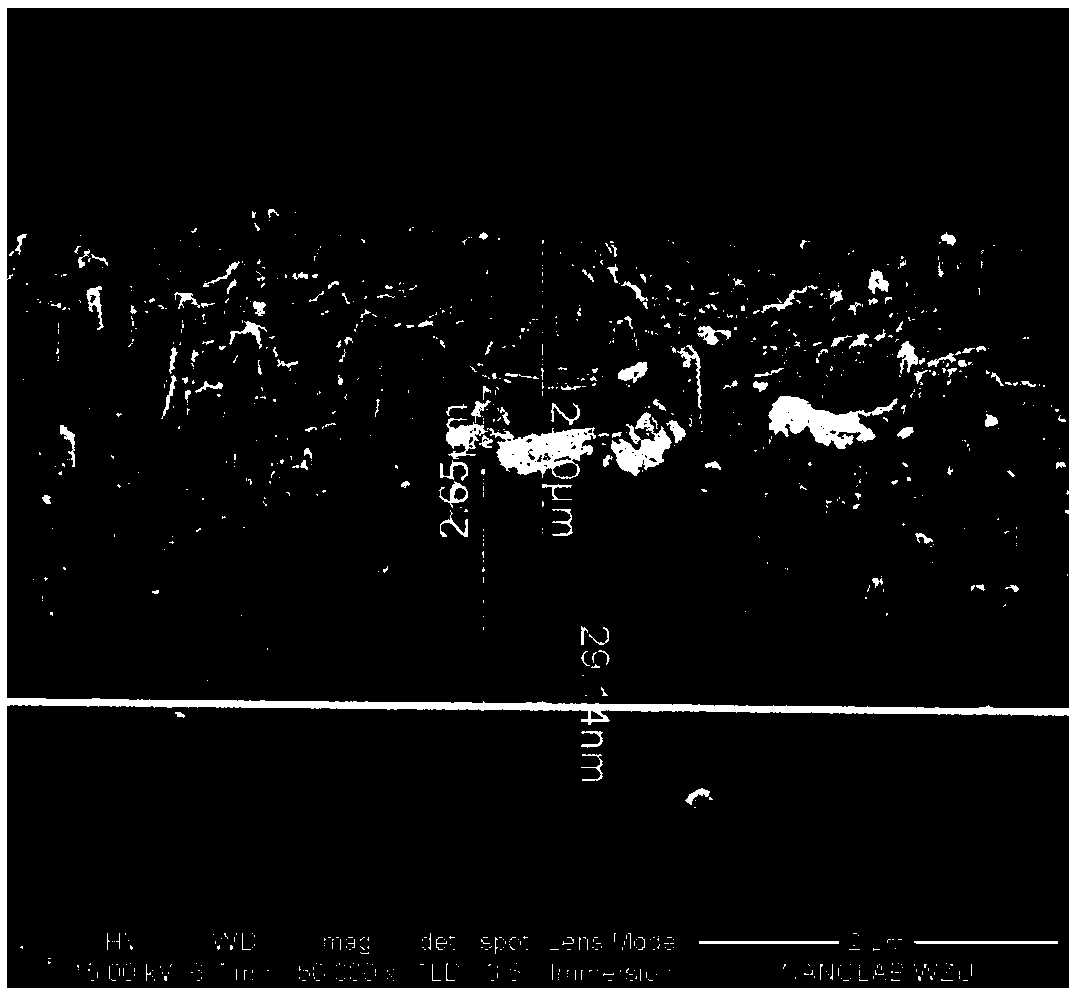

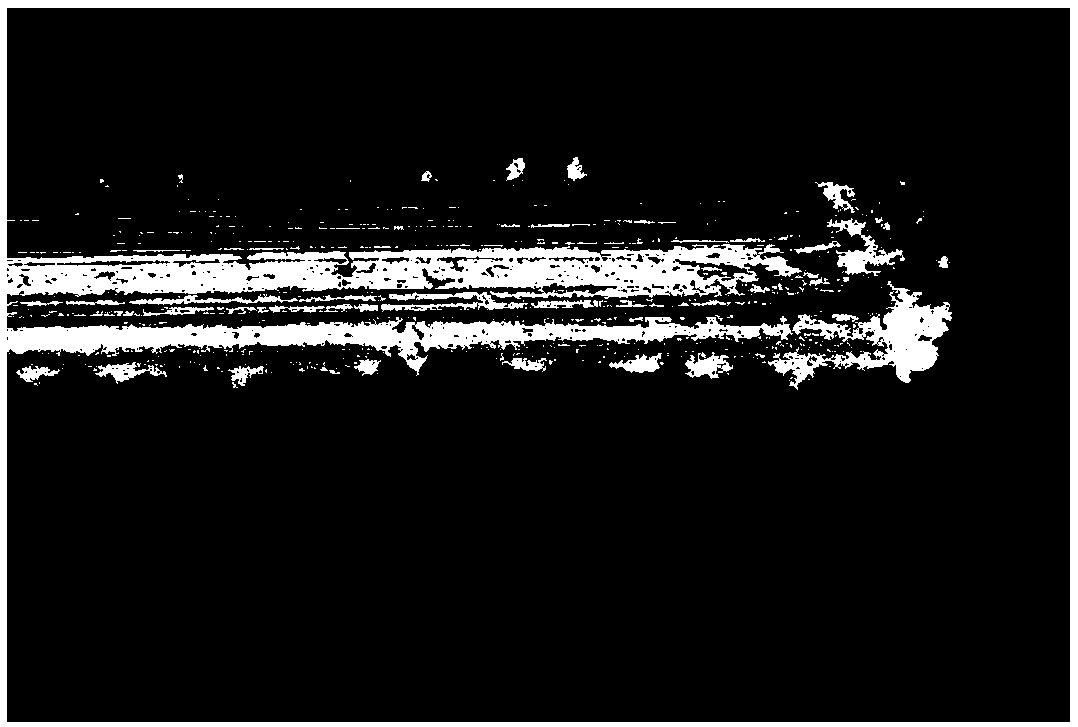

[0042] A low friction coefficient MoS 2 Base metal composite solid lubricating film, its composition is: Cu13.74at%, MoS 2 margin. The film thickness was 2.6 μm.

[0043] The prepared composite solid lubricating film has a compact structure and looks like a mirror surface when observed by naked eyes. The microscopic morphology of the film is as figure 1 As shown, the surface of the film is about 10-100nm granular without cracks; the cross-sectional morphology of the film is as follows figure 2 As shown in , the cross-section is in the shape of a compact columnar column with a certain growth direction.

[0044] The film was passed through Cu metal target and MoS 2 Target co-sputtering, the preparation method is:

[0045] (1) Carry out surface polishing, acetone and alcohol ultrasonic cleaning and drying to the monocrystalline silicon substrate;

[0046] (2) Set the process parameters, the background vacuum is 5×10 -4 Pa, the protective gas is argon, the working pressur...

Embodiment 2

[0051] A low friction coefficient MoS 2 The metal-based composite solid lubricating film has the same composition as in Example 1, and the film thickness is 0.3 μm.

[0052] The preparation method is the same as that of Example 1 except that the Cu metal target in step (3) uses a 20W DC sputtering target power supply, and the thickness of the pre-bonding layer is 29nm.

Embodiment 3

[0054] A low friction coefficient MoS 2 The metal-based composite solid lubricating film has the same composition as in Example 1, and the film thickness is 2 μm.

[0055] The preparation method is the same as that of Example 1 except that the Cu metal target in step (3) uses a 40W DC sputtering target power supply, and the thickness of the pre-bonded layer is 31nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com