Alumina-based lean NOx trap system and method of use in dual-mode HCCI engines

a technology of nox traps and nox gas, which is applied in the direction of machines/engines, electrical control, separation processes, etc., can solve the problems of difficult operation of the engine in hcci mode, ineffective reduction of no/sub>x/sub>, co and hc, and the very lean exhaust gas, etc., to achieve efficient desulphurization and prolong the effect of us

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

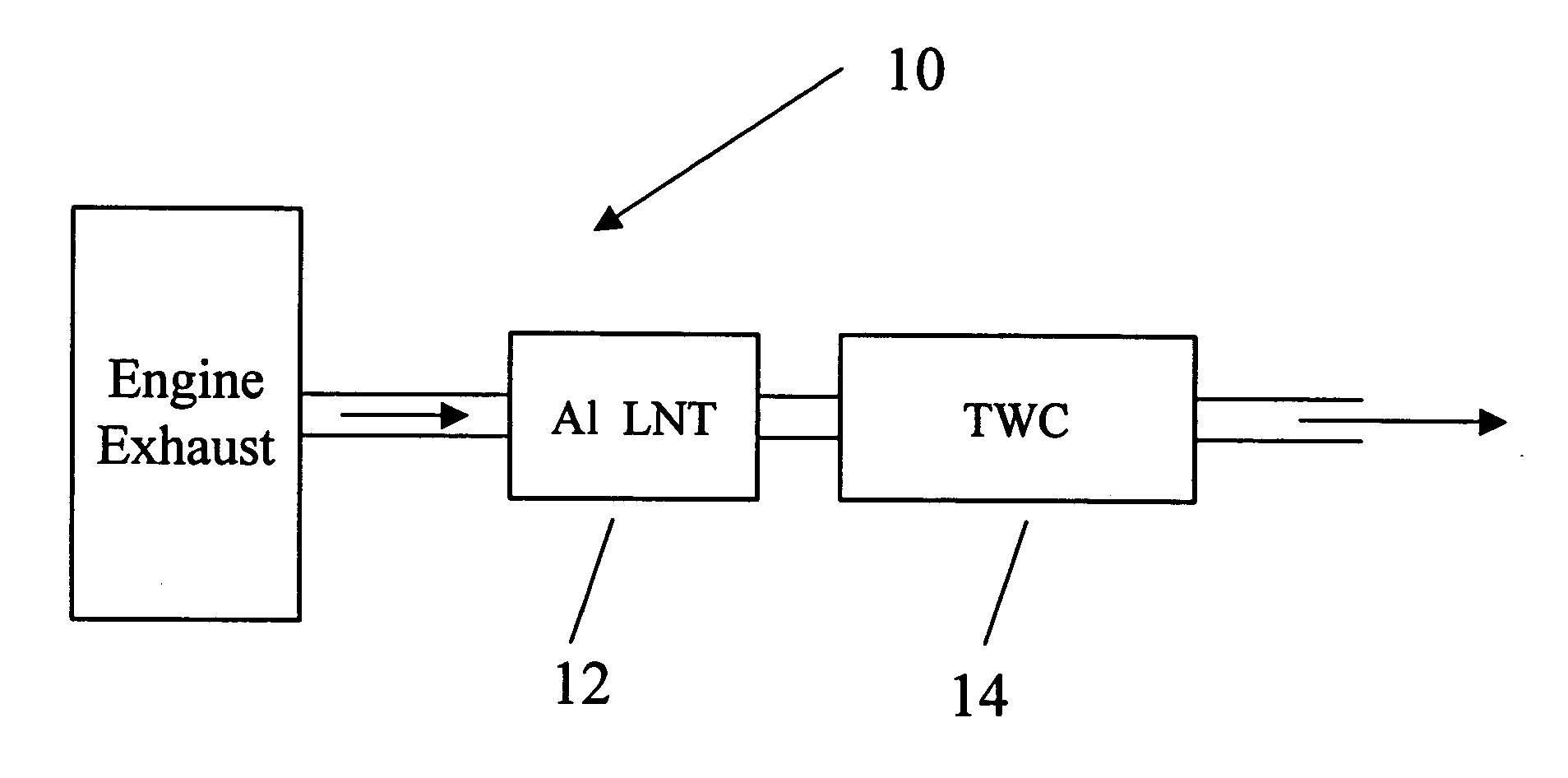

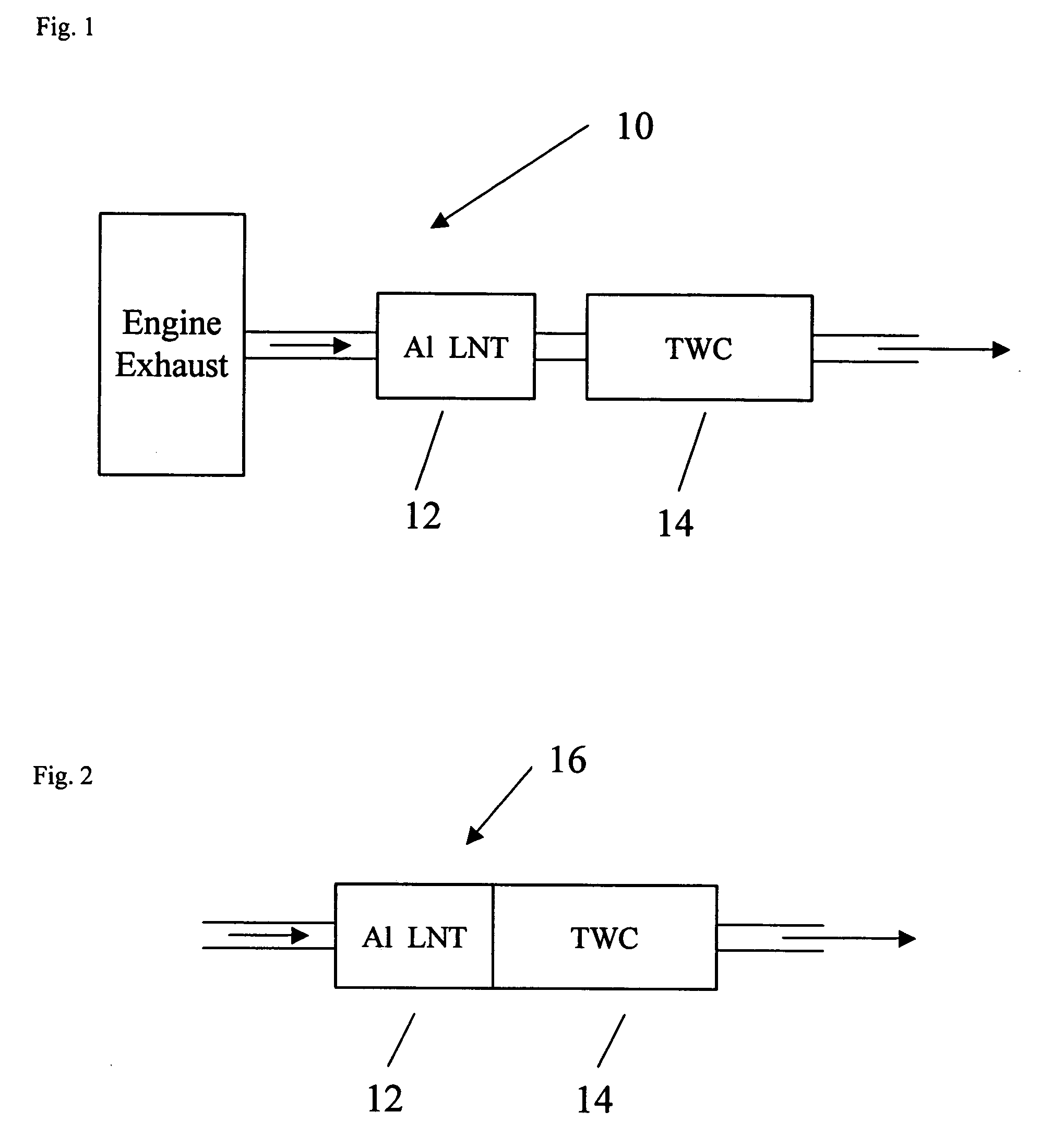

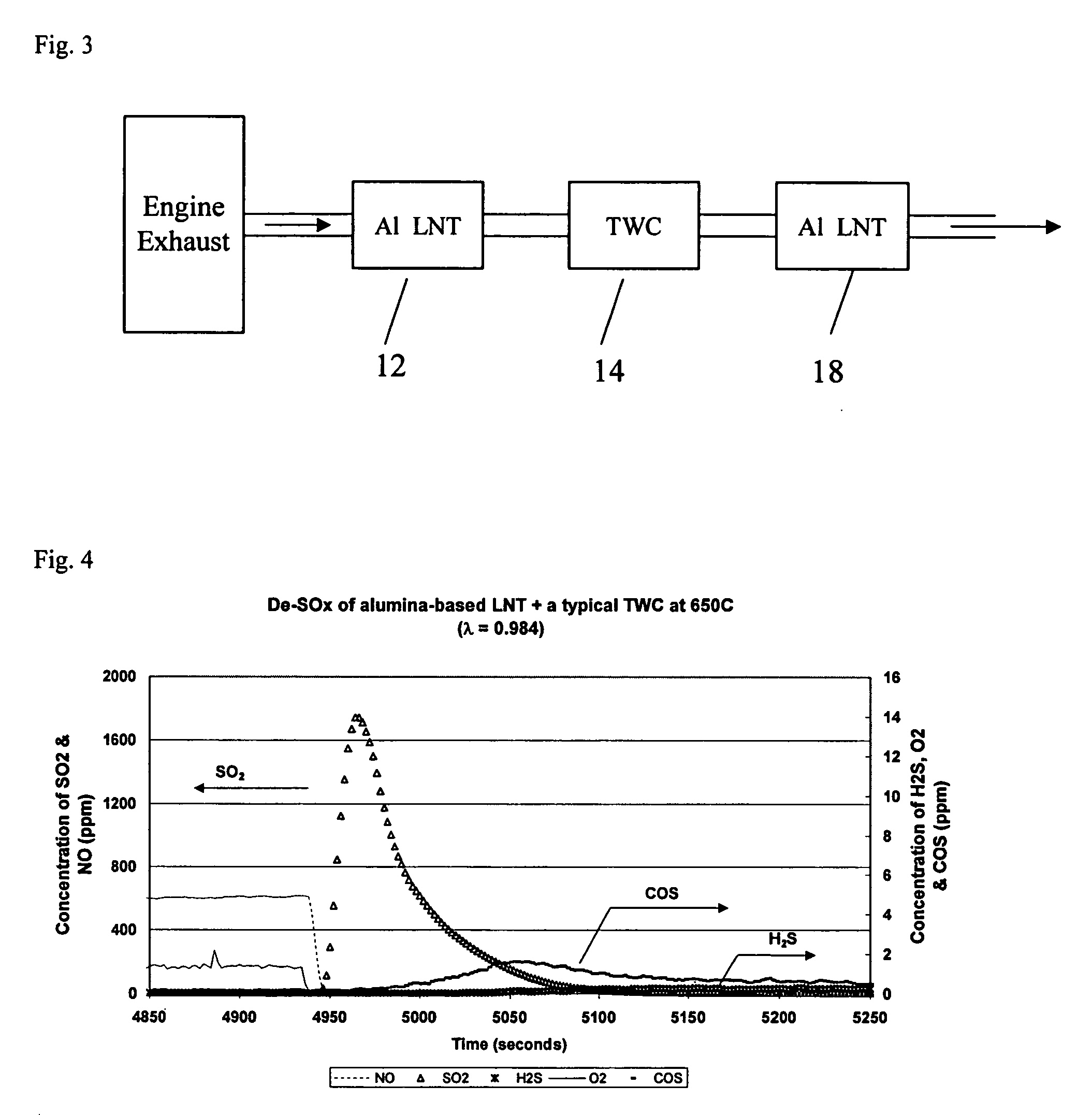

[0049] A lean NOx trap system in accordance with the present invention comprising an alumina-based LNT and a three-way catalyst was applied to simulated dual mode HCCI exhaust gases in a laboratory reactor to verify the efficiencies of the system in converting the pollutants in various engine operation modes. Table 1 below lists the emission data and exhaust gas temperatures from a single cylinder dual mode HCCI engine at different engine modes (#1 to #5), and the emission results after the alumina-based LNT and three way catalyst.

TABLE 1Data from a single cylinder HCCI engine and laboratory emission results aftertreatmentEngine Operation ModeEngine out emissionAfter catalyst (Lab results)#1 - HCCIAF ratio = 94T catalyst inlet = 150° C.T engine out = 190° C.NOx = 0 ppm; HC = 0 ppmNOx = 3 ppm; HC = 1100 ppmCO = 0.001 ppmCO = 4400 ppm#2 - HCCIAF ratio = 36T catalyst inlet = 180° C.T engine out = 240° C.lean / rich (30 / 4)NOx = 140 ppm; HC = 3500 ppmNOx = 4.04 ppm; HC = 150 ppmCO = 400 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com