Refining device and vacuum refining process for use in non-oriented silicon steel production

A technology of oriented silicon steel and refining equipment, which is applied in the field of steelmaking and refining, can solve the problems of limiting the performance of silicon steel products and high sulfur content, and achieve the effects of reducing production costs and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

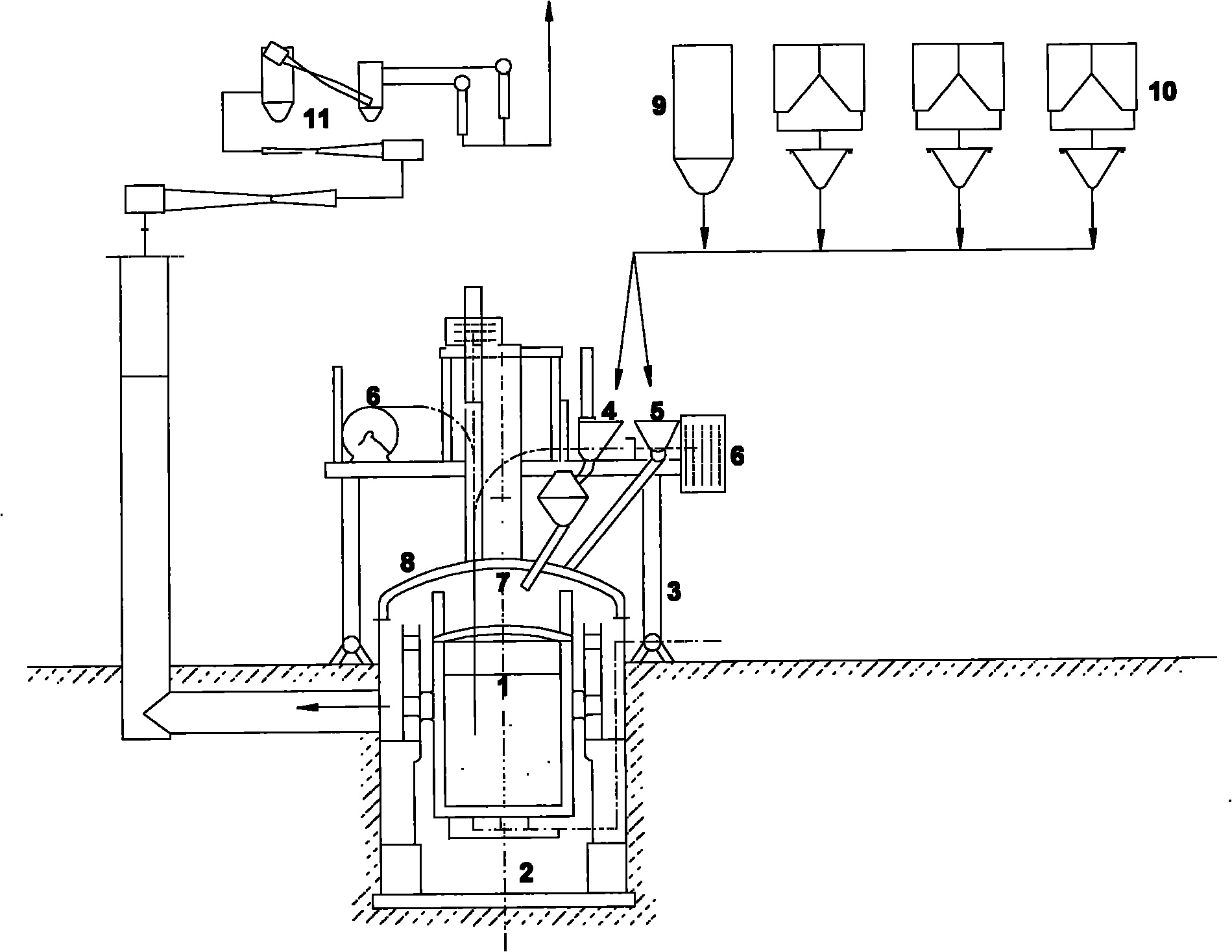

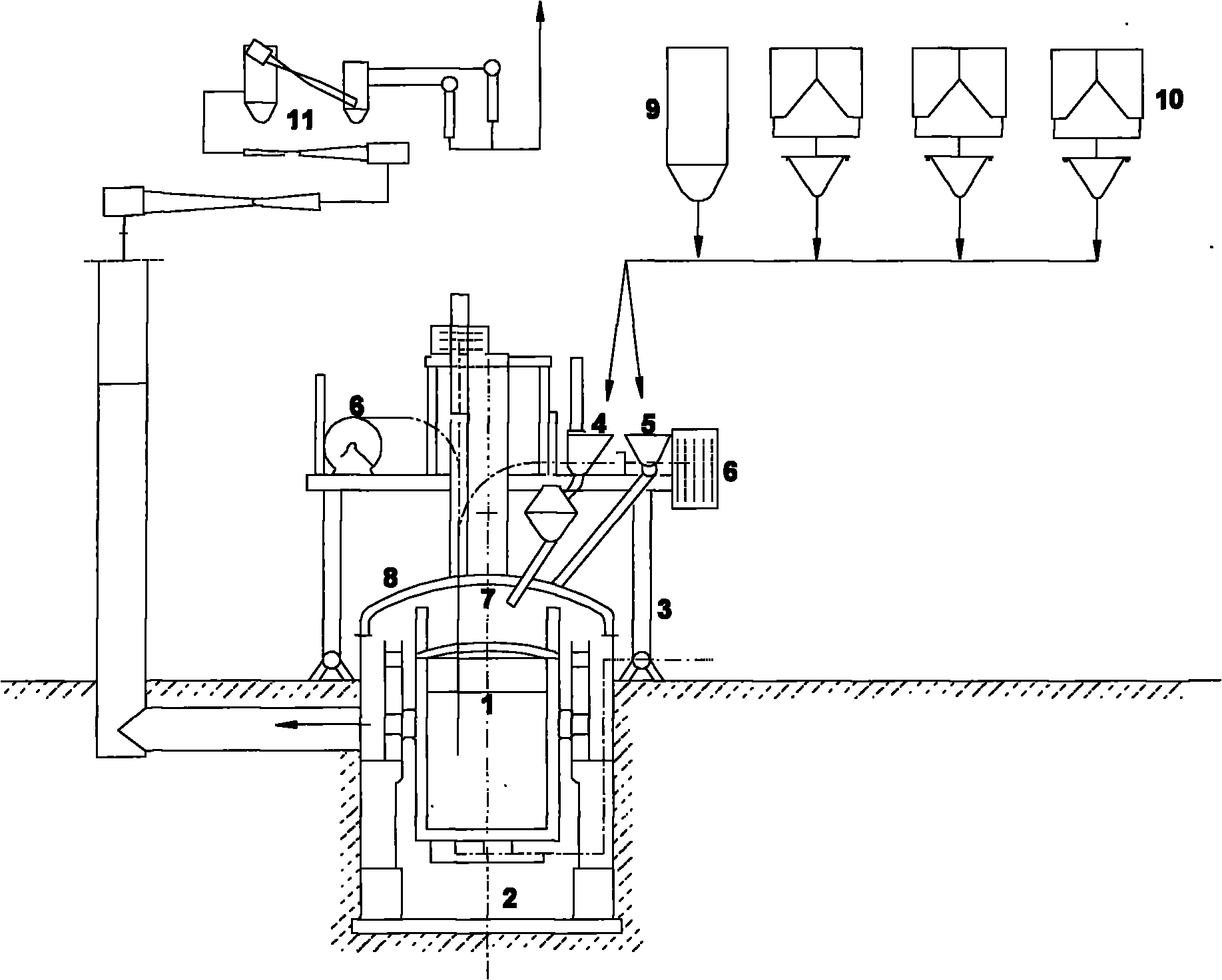

[0032] Using the refining device for the production of non-oriented silicon steel, adopt the vacuum refining process described in the present invention to produce non-oriented silicon steel W600

[0033] (1) Control the carbon content in the steel at 0.03-0.04% when tapping the converter, and the dissolved oxygen in the steel is greater than 600ppm.

[0034] (2) The VD vacuum chamber 2 uses forced oxygen blowing to decarburize, reducing the carbon in the steel to below 0.0025%.

[0035] (3) After decarburization finishes, add ferrosilicon, Al, lime and other slag materials in ladle 1 through line feeding device 6, adjust [Si], [Al] content in molten steel to target value, and control the content of slag in slag (FeO+MnO)≤1.0%.

[0036] (4) After the ladle is covered, vacuum is started, and at the same time, argon gas is blown in three ways from the breathable brick at the bottom of the ladle for stirring. The argon flow rate of each channel is 600Nl / min, and the total flow r...

Embodiment 2

[0040] The non-oriented silicon steel W800 is produced by using the refining device for producing non-oriented silicon steel and adopting the vacuum refining process described in the present invention.

[0041] (1) Control the carbon content in the steel at 0.03-0.04% when the converter is tapping the steel, and the dissolved oxygen in the steel is greater than 600ppm.

[0042] (2) The VD vacuum chamber 2 uses forced oxygen blowing to decarburize, reducing the carbon in the steel to 0.0020%.

[0043] (3) After decarburization finishes, add ferrosilicon, Al, lime and other slag materials in ladle 1 through line feeding device 6, adjust [Si], [Al] content in molten steel to target value, and control the content of slag in slag (FeO+MnO)≤0.8%.

[0044] (4) After the ladle is covered, vacuum is started, and at the same time, argon gas is blown into 3 ways from the breathable brick at the bottom of the ladle for stirring. The argon flow rate of each channel is 600Nl / min, and the ...

Embodiment 3

[0047] Using the refining device for the production of non-oriented silicon steel, adopt the vacuum refining process described in the present invention to produce non-oriented silicon steel W500

[0048] (1) Control the carbon content in the steel at 0.04-0.05% when tapping the converter, and the dissolved oxygen in the steel is greater than 600ppm.

[0049] (2) The VD vacuum chamber 2 uses forced oxygen blowing to decarburize, reducing the carbon in the steel to below 0.0030%.

[0050] (3) After decarburization finishes, add ferrosilicon, Al, lime and other slag materials in ladle 1 through line feeding device 6, adjust [Si], [Al] content in molten steel to target value, and control the content of slag in slag (FeO+MnO)≤1.0%. (4) After the ladle is covered, vacuum is started, and at the same time, argon gas is blown in three ways from the breathable brick at the bottom of the ladle for stirring. The argon flow rate of each channel is 600Nl / min, and the total flow rate can r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com