Gradient adjustment method of limestone content in wet desulphurization circulating liquid

A limestone and circulating fluid technology, applied in separation methods, chemical instruments and methods, and separation of dispersed particles, can solve problems such as increased manufacturing costs and operating costs, complex structures, etc., and achieve reduced equipment costs and operating costs, simple operation, Easy to run effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

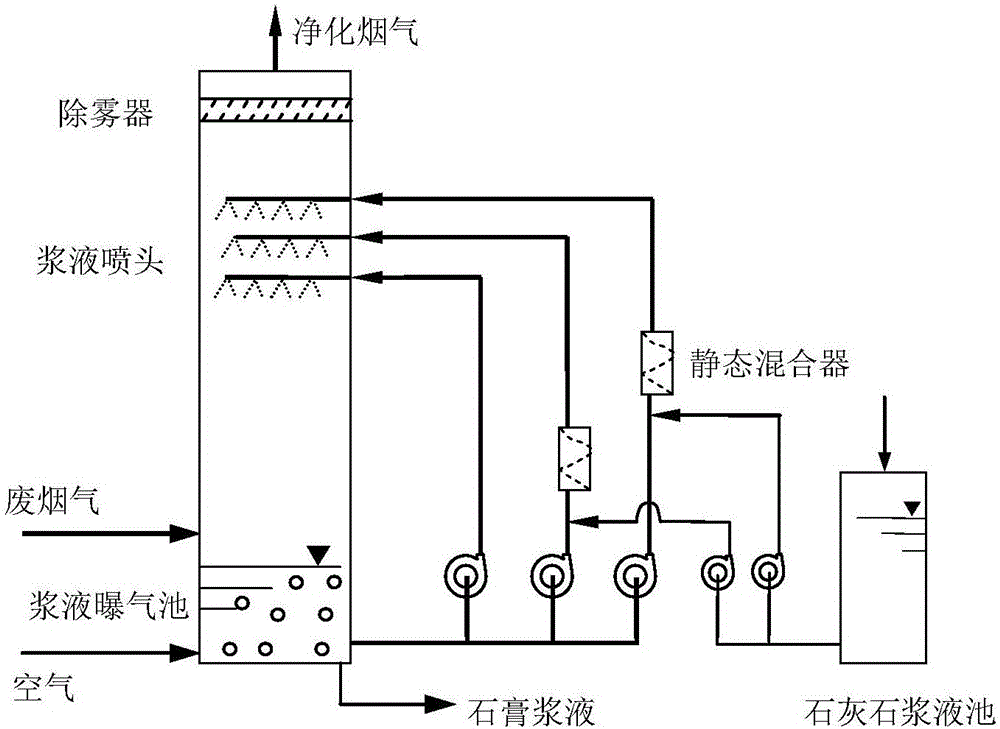

[0019] Such as figure 1 As shown, the gradient adjustment method of limestone content in the wet desulfurization circulating fluid of the present invention adopts the existing conventional desulfurization tower, the bottom of the desulfurization tower is provided with an aeration tank, and the top of the desulfurization tower is provided with multi-layer (2-5 layers) The slurry nozzle forms a multi-layer spray layer. The internal components of the desulfurization tower do not need to be changed or modified. In addition, an independent limestone slurry tank is set up.

[0020] The bottom layer of the desulfurization tower is directly connected to the slurry aeration tank through the desulfurization circulating pump, and directly transfers the desulfurization circulating liquid in the aeration tank (the original desulfurization limestone slurry in the aeration tank and the flue gas desulfurization that falls from the spray layer) The final slurry) forms a circulation in the de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com