Device for desulfurization and recovery of seawater by industrial flue gas

A technology for desulfurization of seawater and industrial flue gas, which is applied in the fields of oxidized water/sewage treatment, separation of dispersed particles, chemical instruments and methods, etc., and can solve problems that restrict the development of desulfurization and environmental protection industries, secondary pollution, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

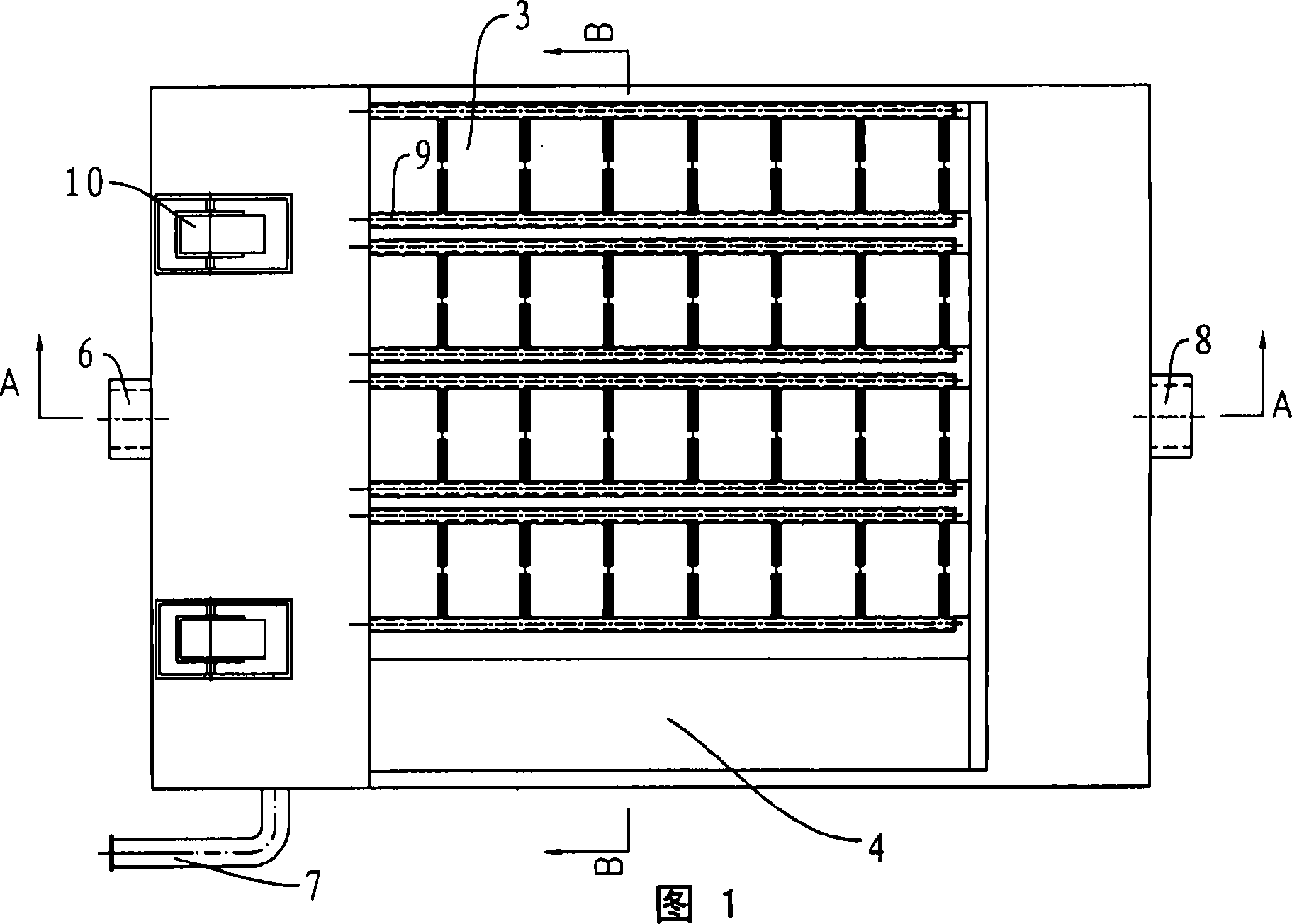

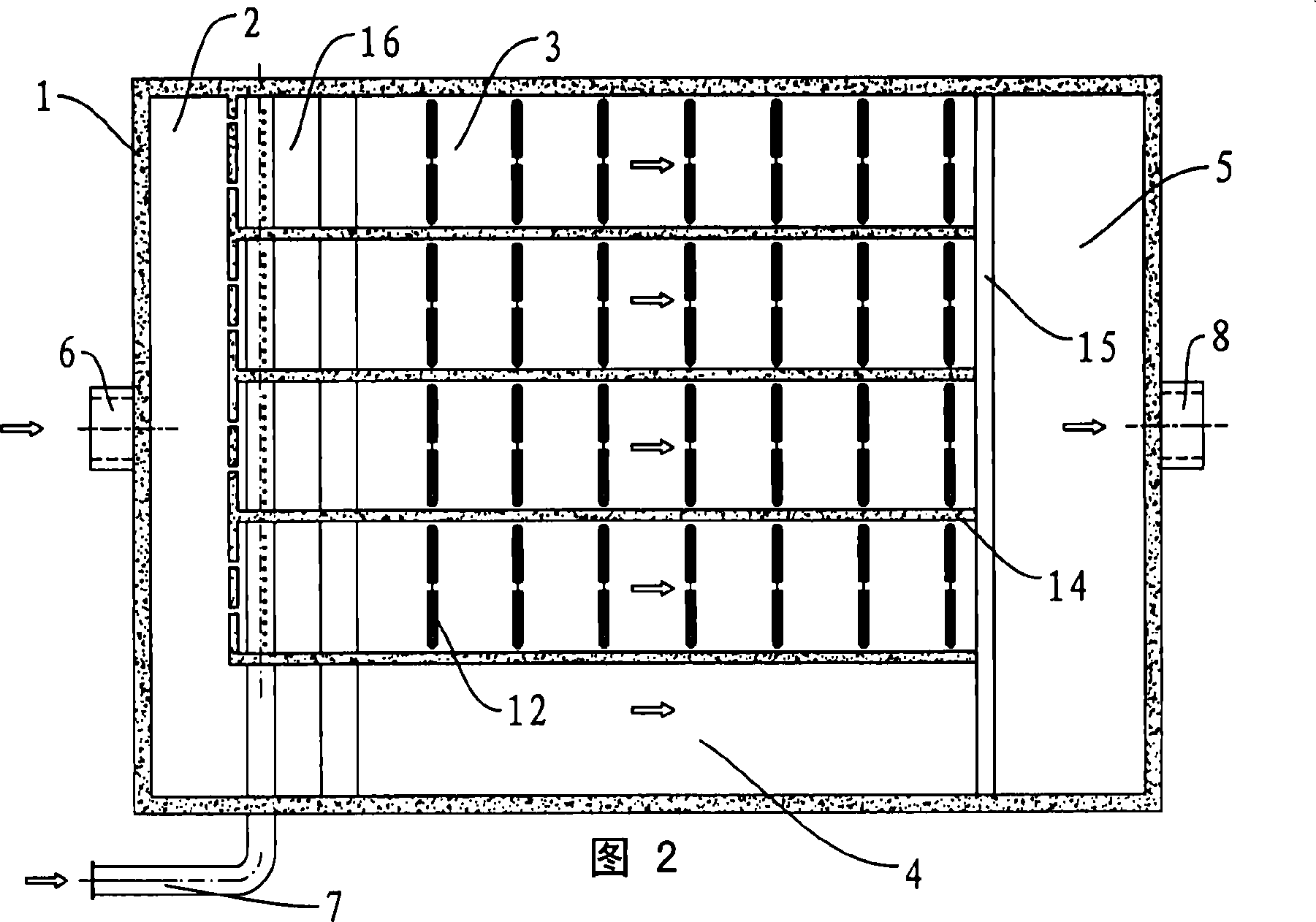

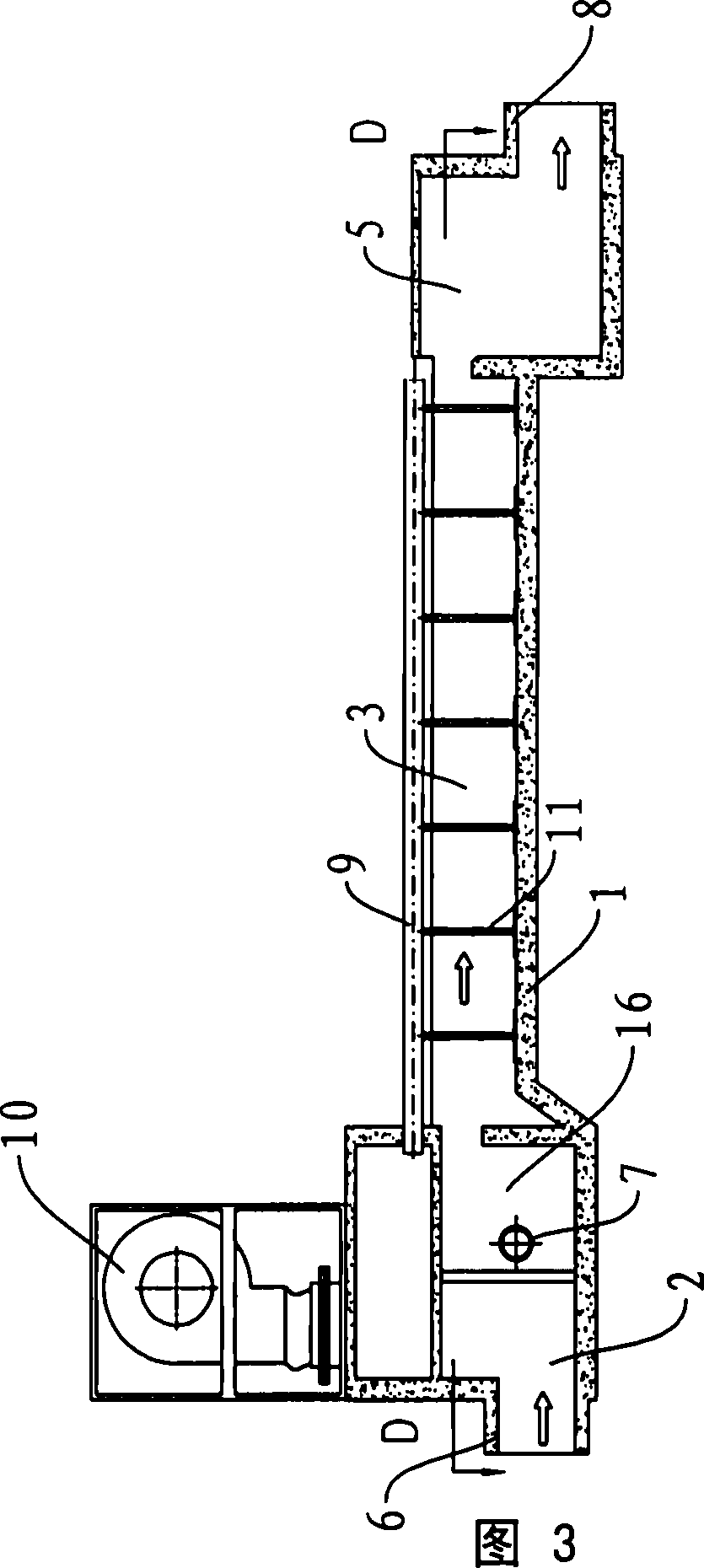

[0023] From Figure 1, Figure 2, Figure 3, Figure 4 As shown, the industrial flue gas seawater desulfurization water quality recovery device of the present invention is specifically a kind of thermal power station coal-fired boiler flue gas seawater desulfurization water quality recovery device, comprising a rectangular pool body 1 made of reinforced concrete, the pool body length is 34m, 47m wide and 3m deep, the horizontal partition wall made of reinforced concrete is divided into interconnected water distribution area 2, mixing area 16, aeration area 3, bypass area 4, and discharge area 5. The partition wall between the water distribution area 2 and the mixing area 16 has 8 slits that allow seawater to pass through. The mixing zone 16 and the aeration zone 3 are respectively divided into four parts by three longitudinal partition walls 14 parallel to the side walls on both sides of the tank body. A fresh seawater inlet 6 is provided on the front wall of the pool body, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com