Patents

Literature

565 results about "Absorption of water" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

The absorption of water by plants is essential for various metabolic activities. Terrestrial plants get their water supply from the leaves and use the roots as a passage for the water to move through to the plant which serves as the source of water and [minerals]. The way in which water from soil enters roots, particularly to the root xylem, is called "mechanism of water absorption". Both active and passive absorption have been proposed for mechanism of water absorption.This process is known as Conduction...

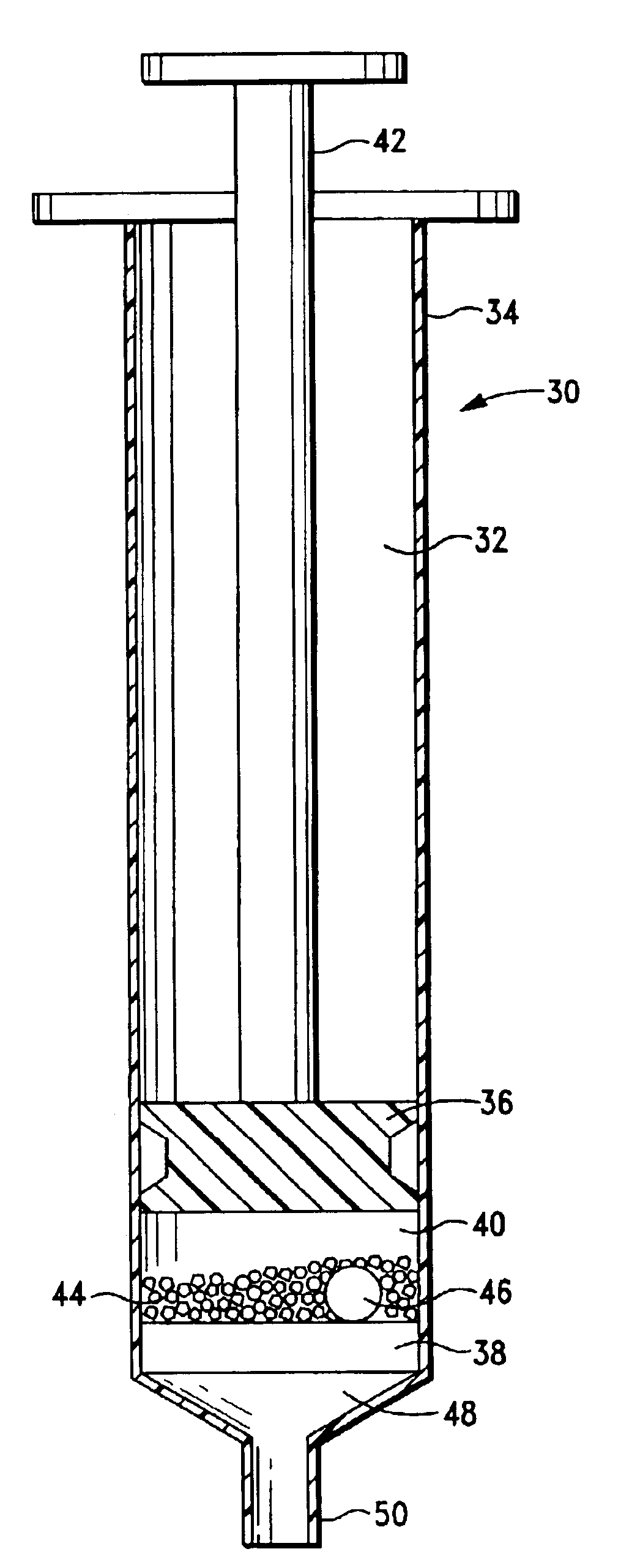

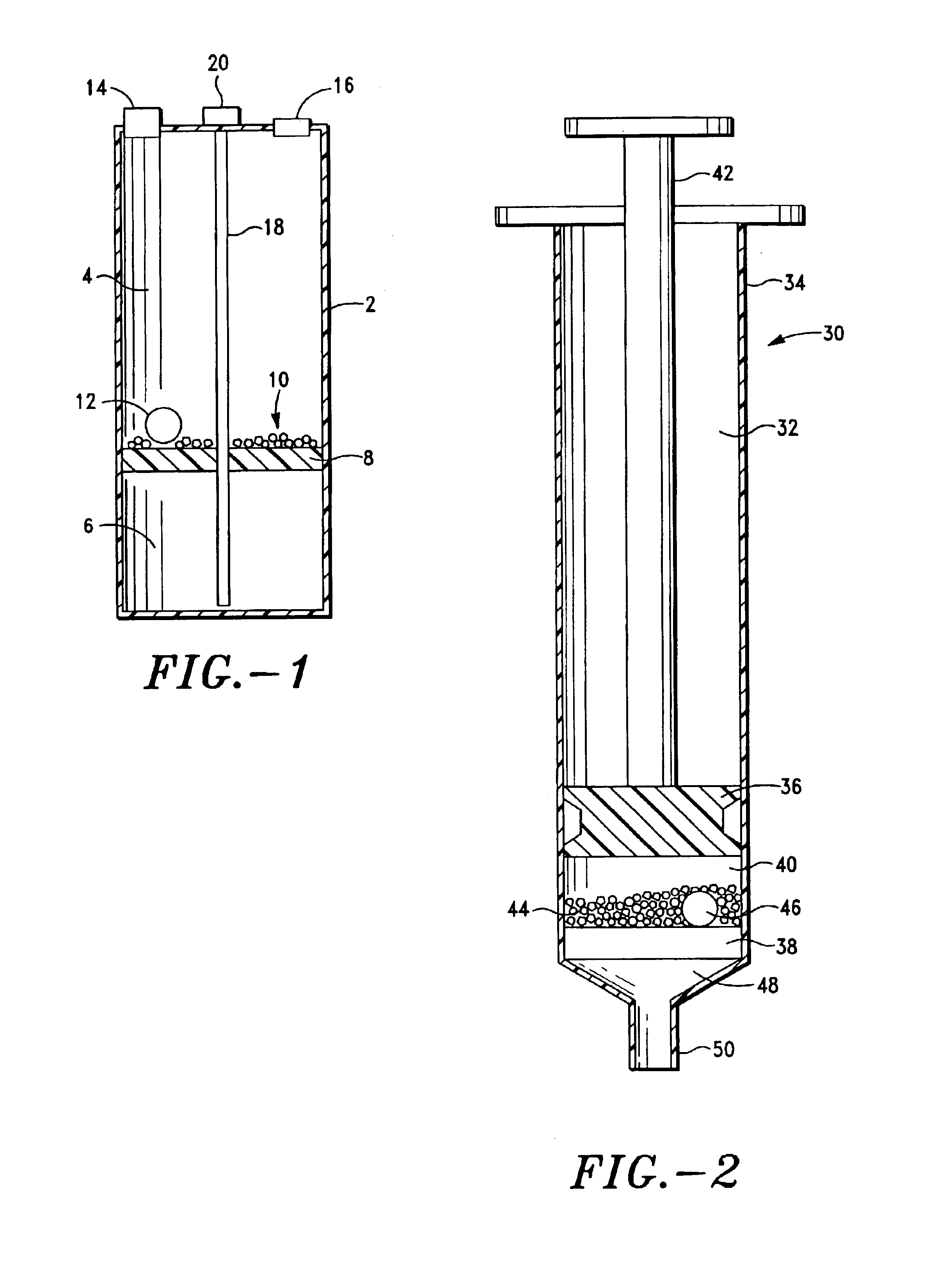

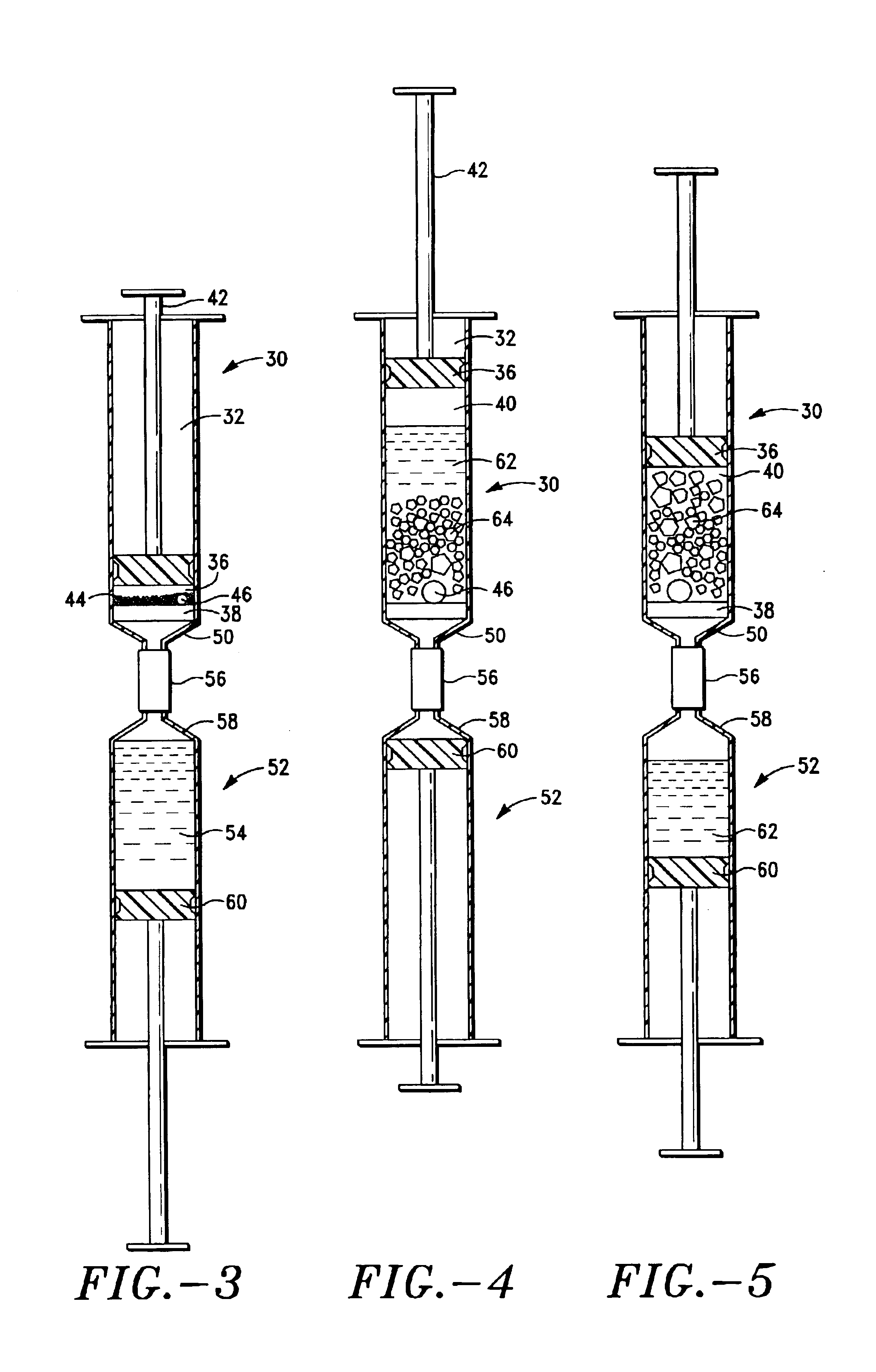

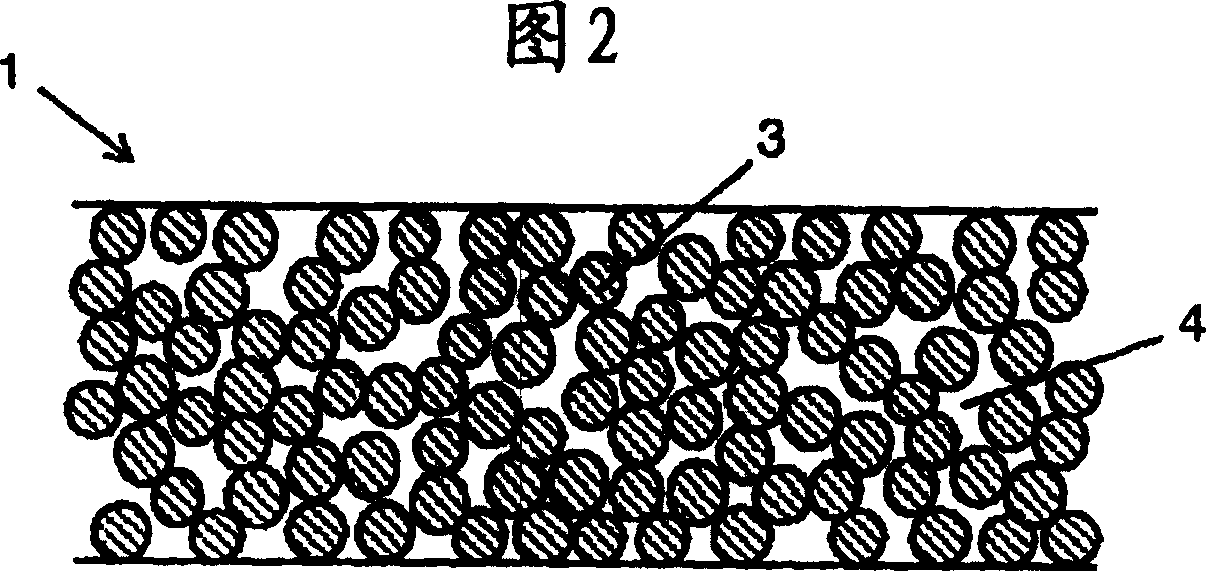

Plasma concentrate apparatus and method

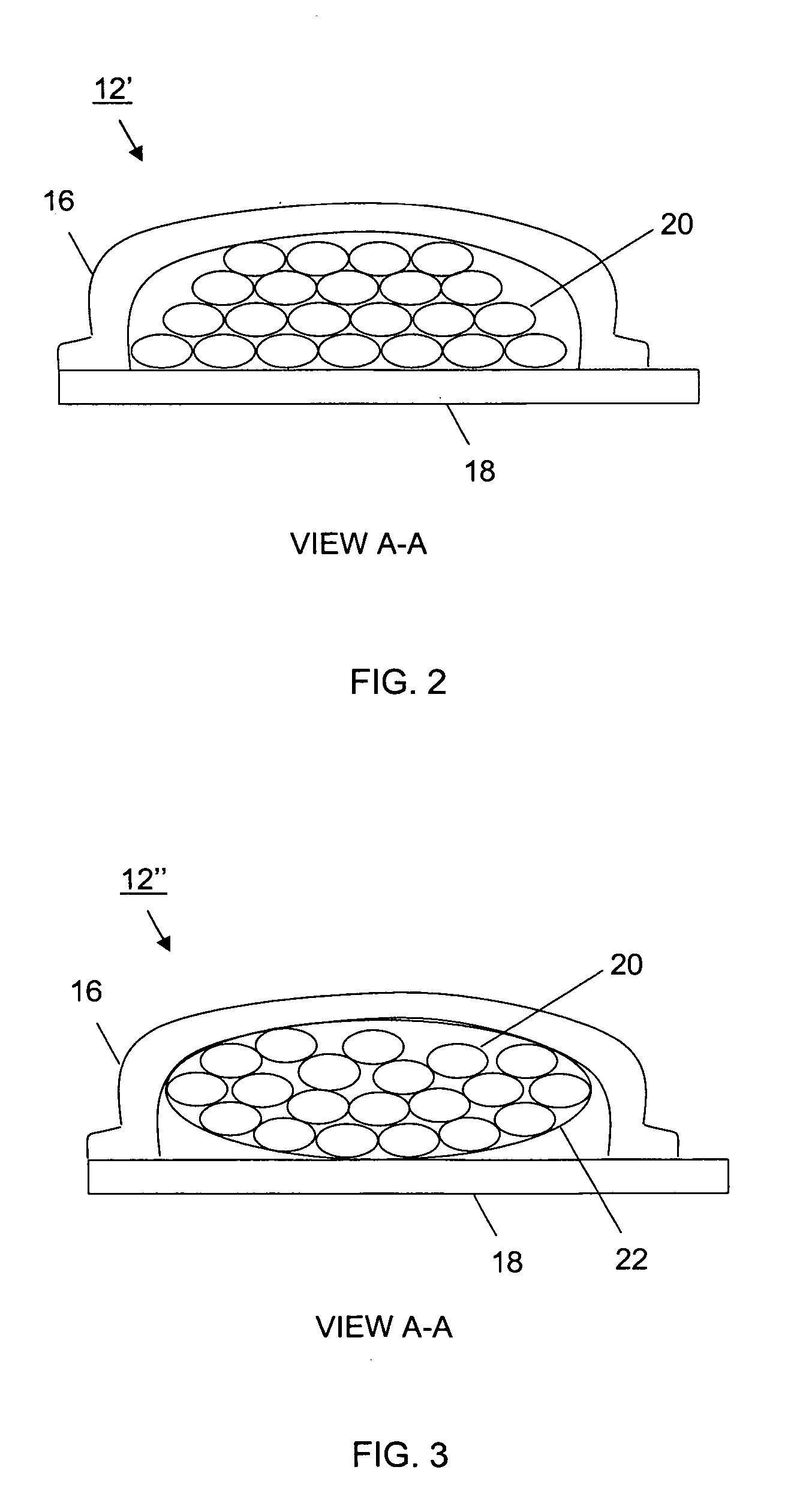

ActiveUS6905612B2Effective absorptionPromote absorptionMixing methodsDead animal preservationRed blood cellAbsorption of water

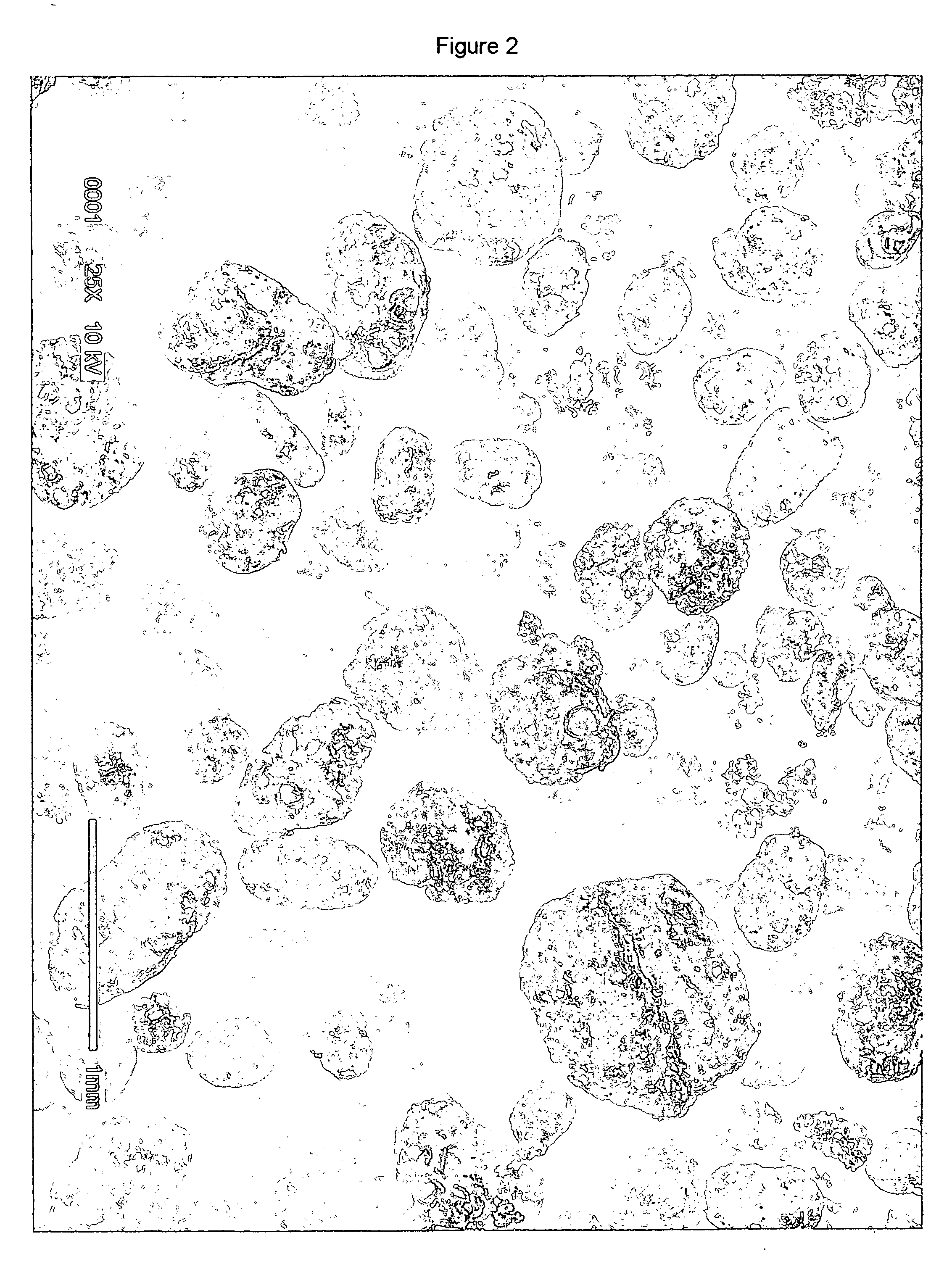

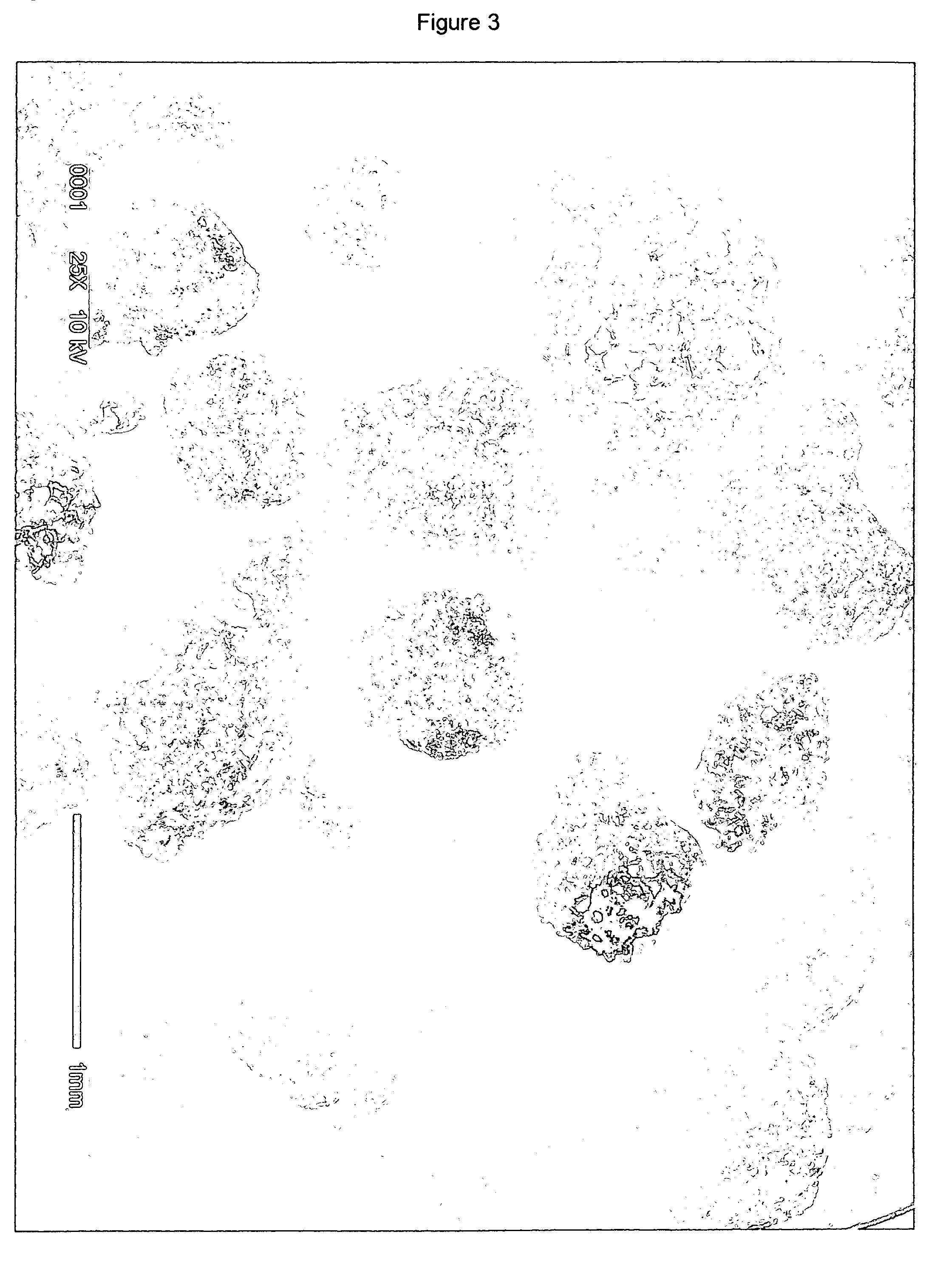

A plasma concentrator for producing plasma concentrate from a plasma from which erythrocytes have been substantially removed. The device comprises a concentrating chamber having an inlet port and an concentrate outlet, the concentrating chamber containing hydrogel beads and at least one inert agitator; and a concentrate chamber having an inlet communicating with the concentrator outlet through a filter, and having an plasma concentrate outlet port. A process for producing plasma concentrate from plasma from which erythrocytes have been substantially removed, comprising the steps of a) moving the plasma into a concentrating chamber containing hydrogel beads and an agitator to form a hydrogel bead-plasma mixture; b) causing the agitator to stir the hydrogel bead-plasma mixture, facilitating absorption of water by the beads from the plasma, until a hydrogel bead-plasma concentrate is formed; and c) separating the plasma concentrate from the hydrogel beads by passing the plasma concentrate through a filter. The concentrator can be one or more syringe devices coupled for multiple concentrations.

Owner:HANUMAN

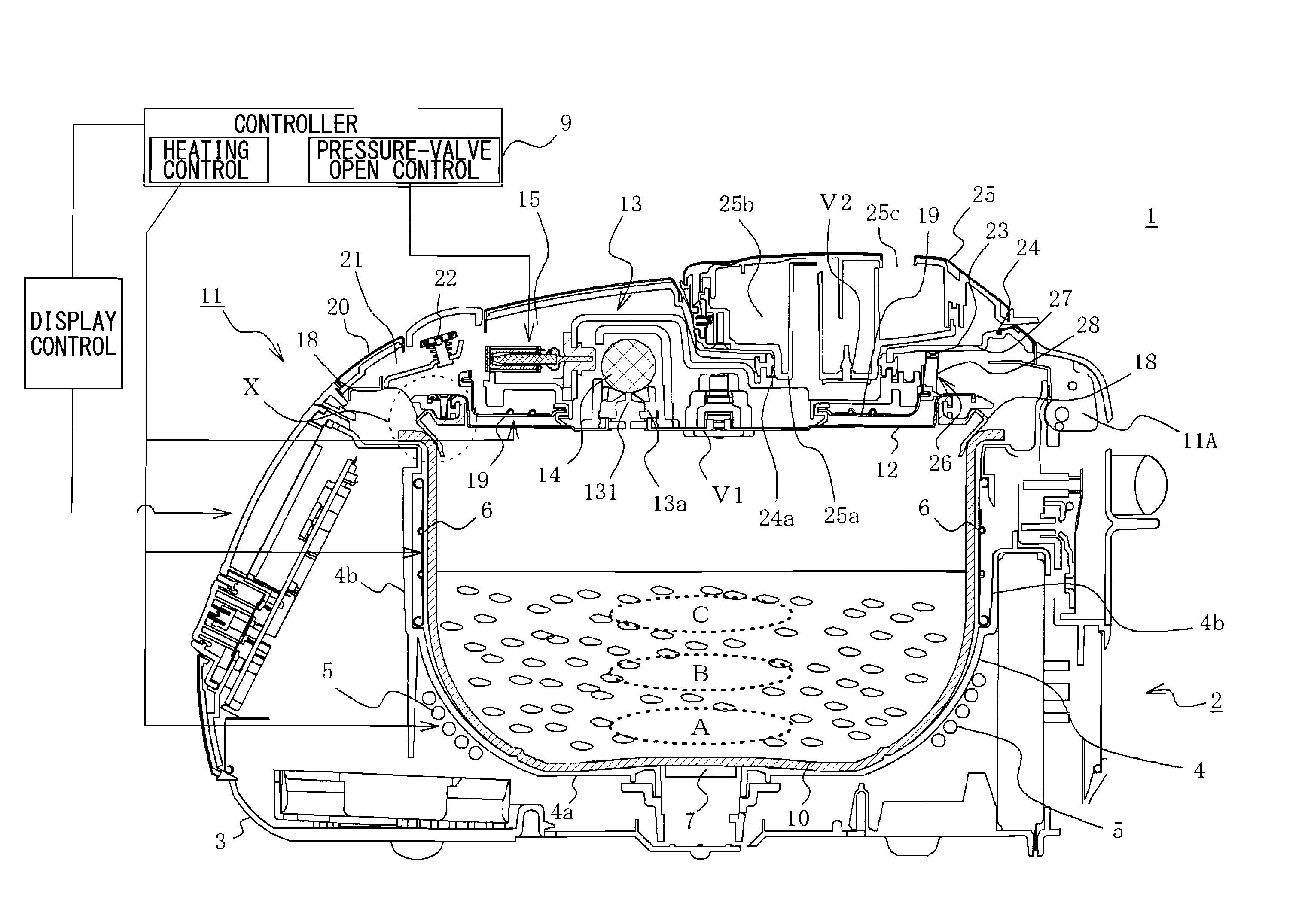

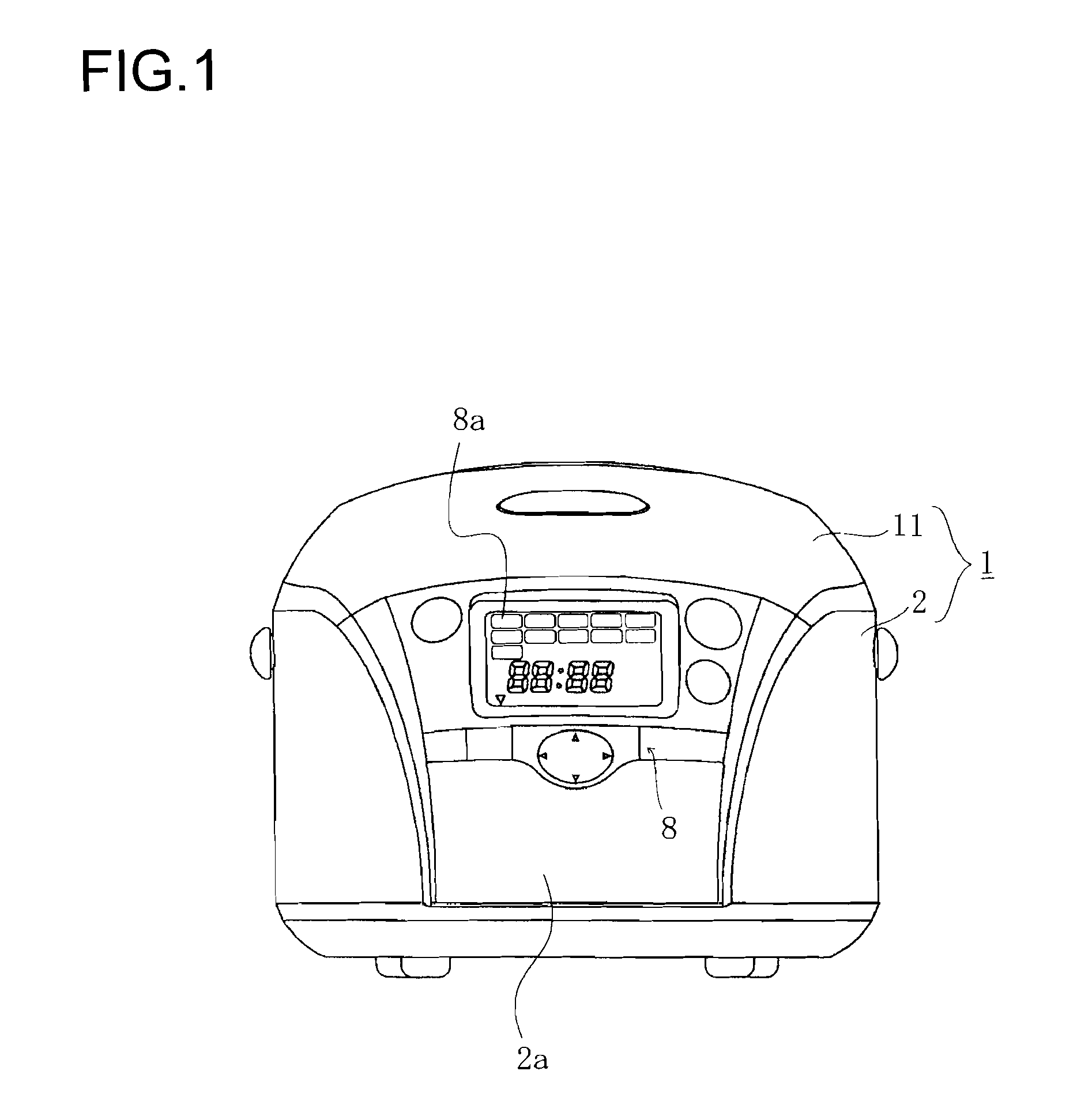

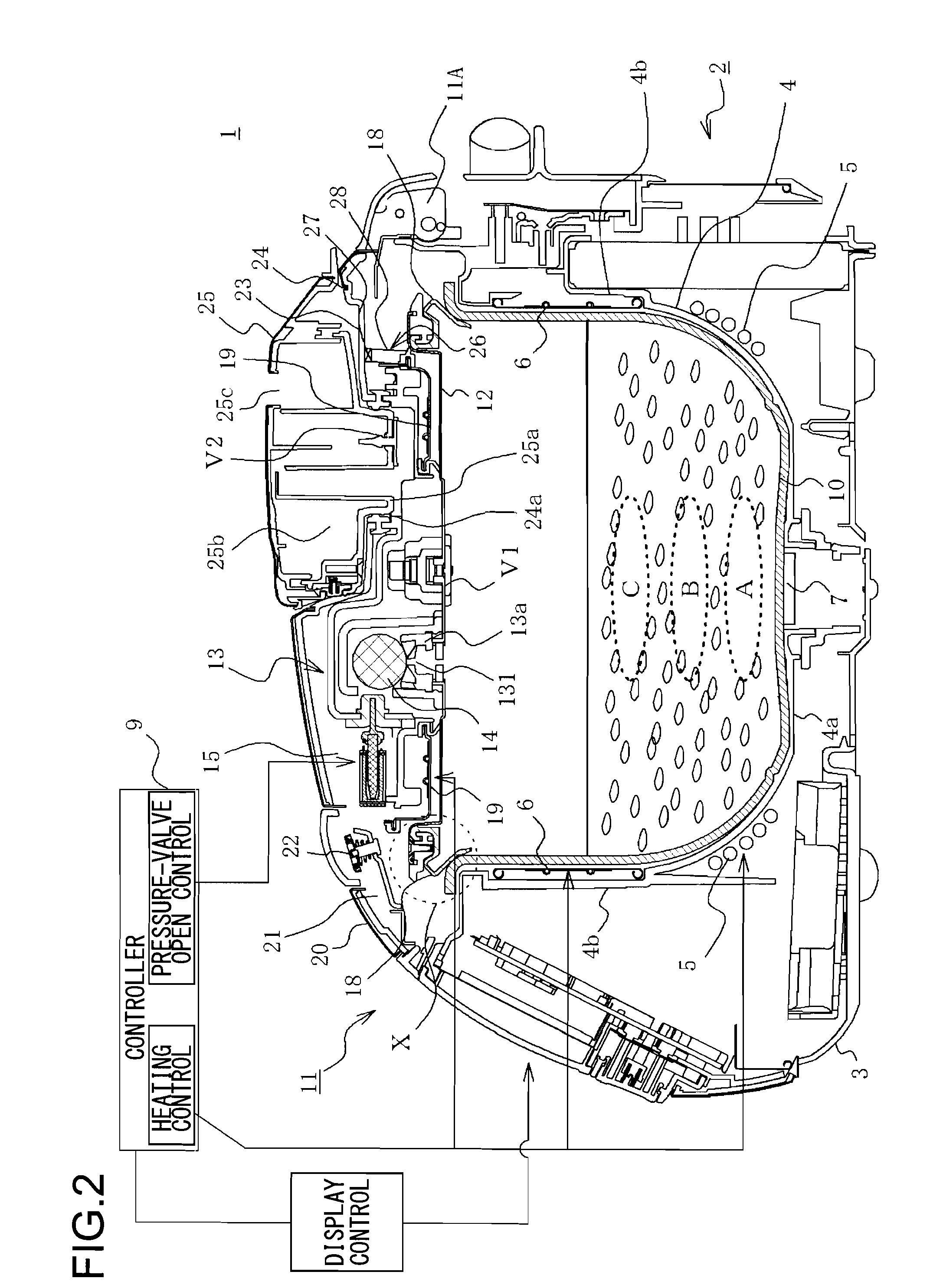

Electric rice cooker and method of cooking rice

InactiveUS20110003048A1Increase moistureUneven water absorptionBoiling over preventionMilk treatmentInternal pressureEngineering

An electric rice cooker capable of increasing the water content of rice by a simple structure. The electric rice cooker (1) has a pot (10) in which food substances to be cooked including water and rice are contained, heating device (5, 6, 19) for heating the food substances to be cooked in the pot, a lid (11) for closing the opening of the pot, and a controller (9) for performing rice cooking steps including a water absorption step for allowing the rice to absorb the water by controlling the heating devices. The controller (9) raises the internal pressure of the pot (10) to 1.05-1.18 atm in the water absorbing step to allow the rice to absorb the water.

Owner:SANYO ELECTRIC CO LTD +1

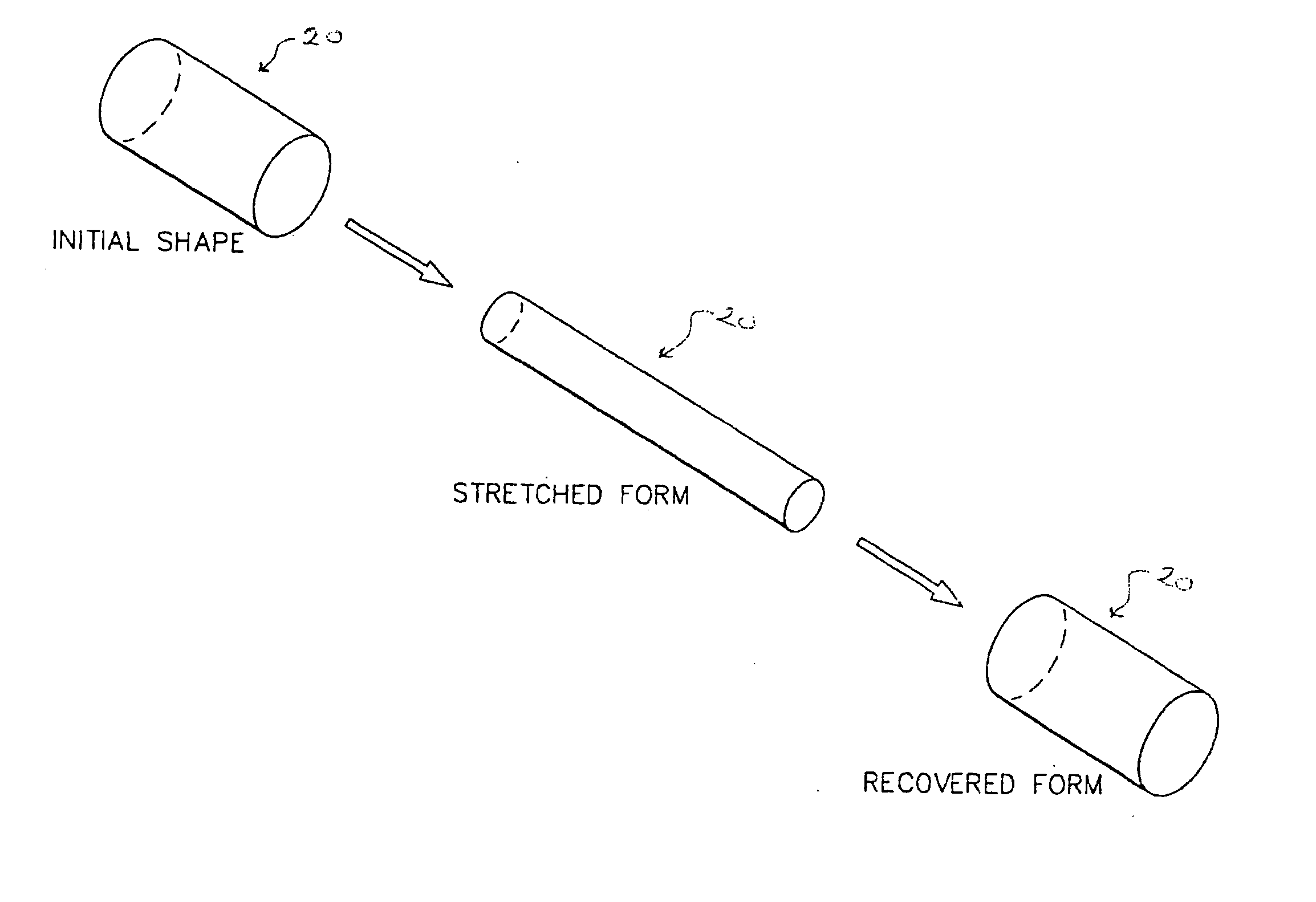

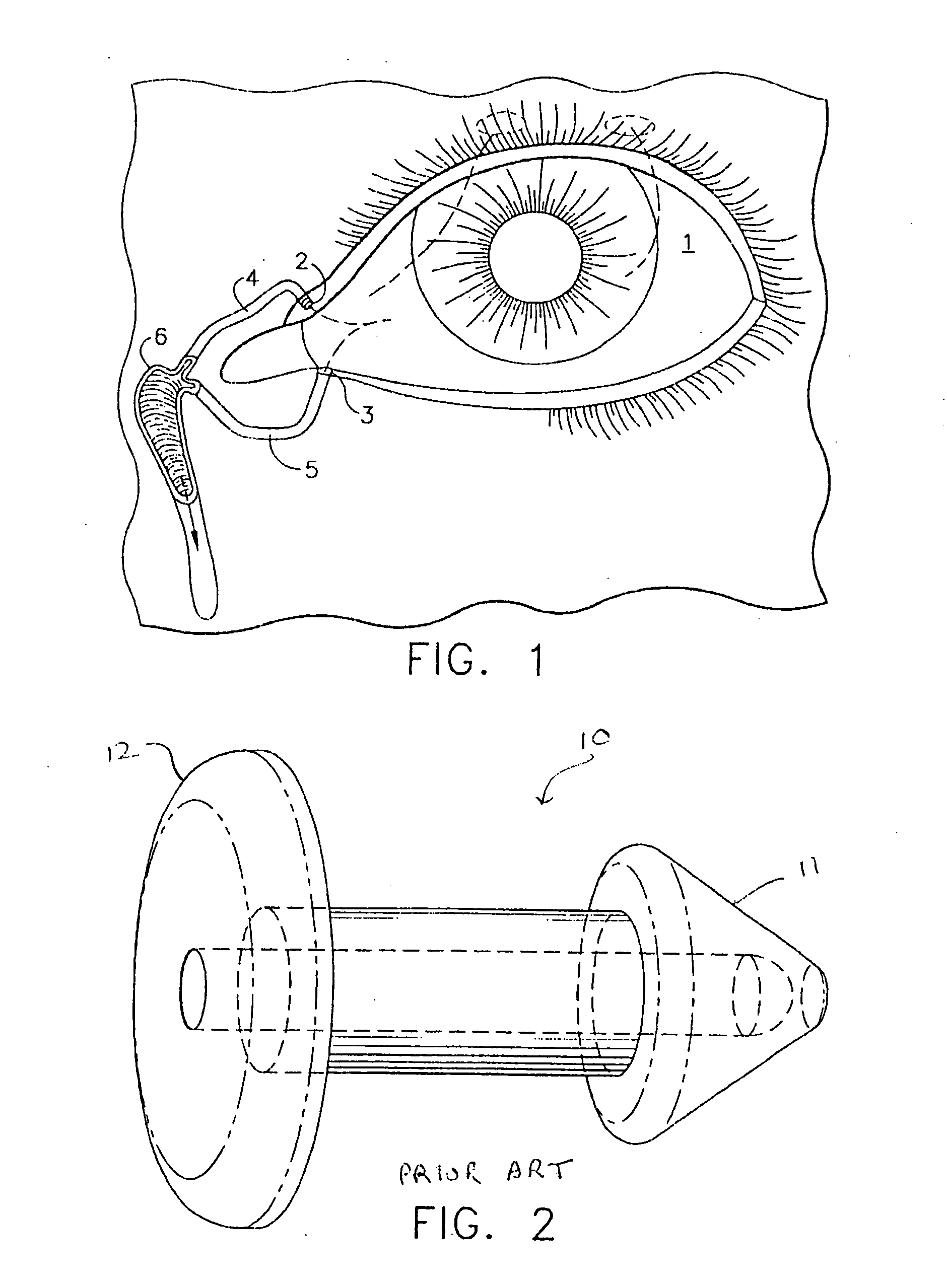

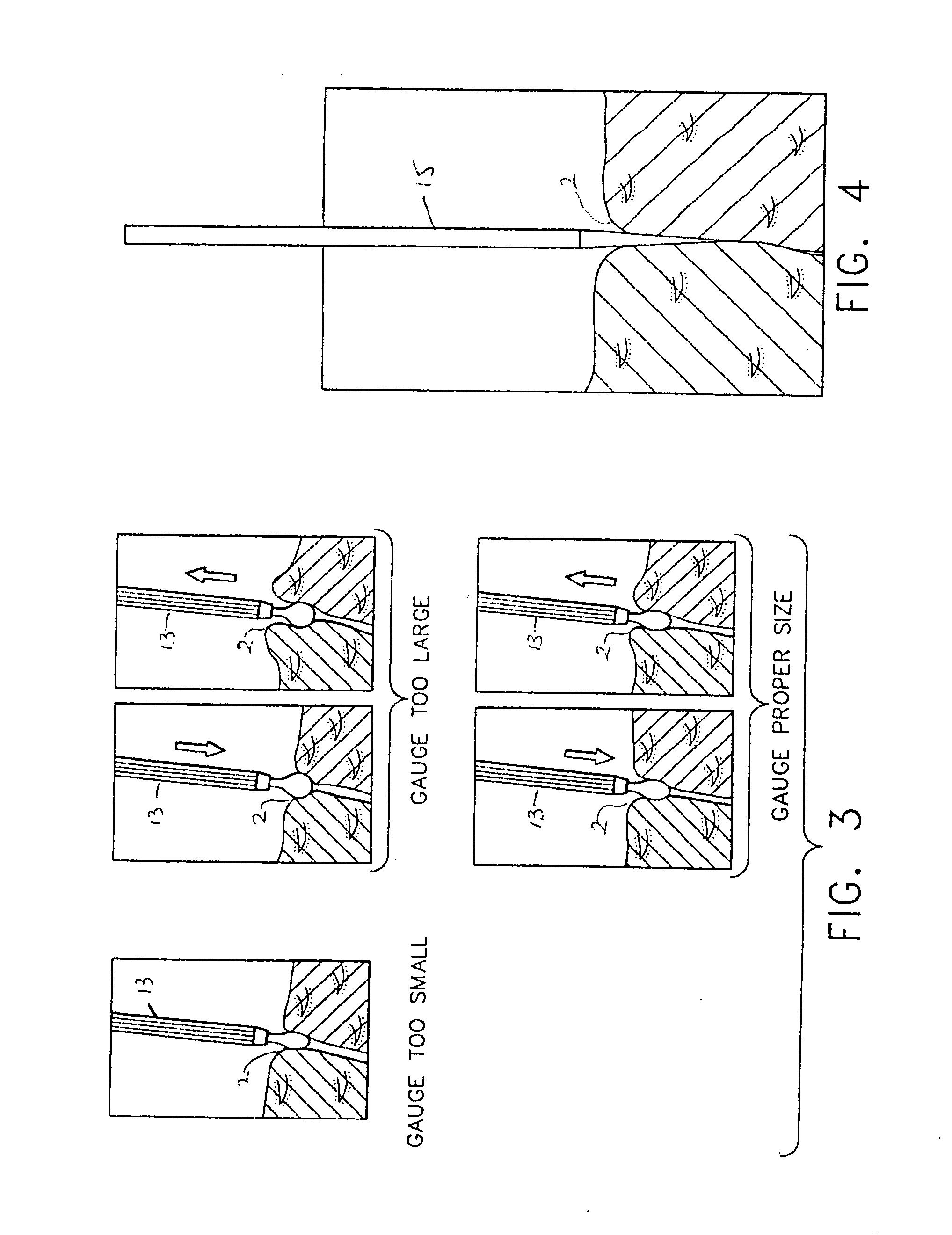

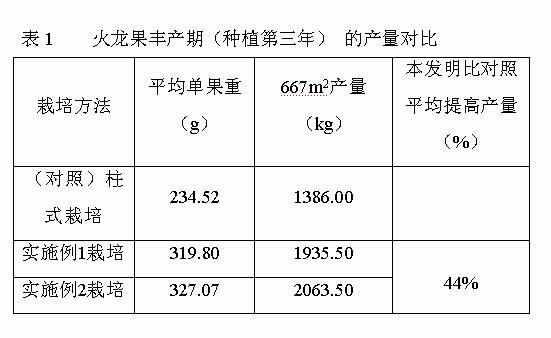

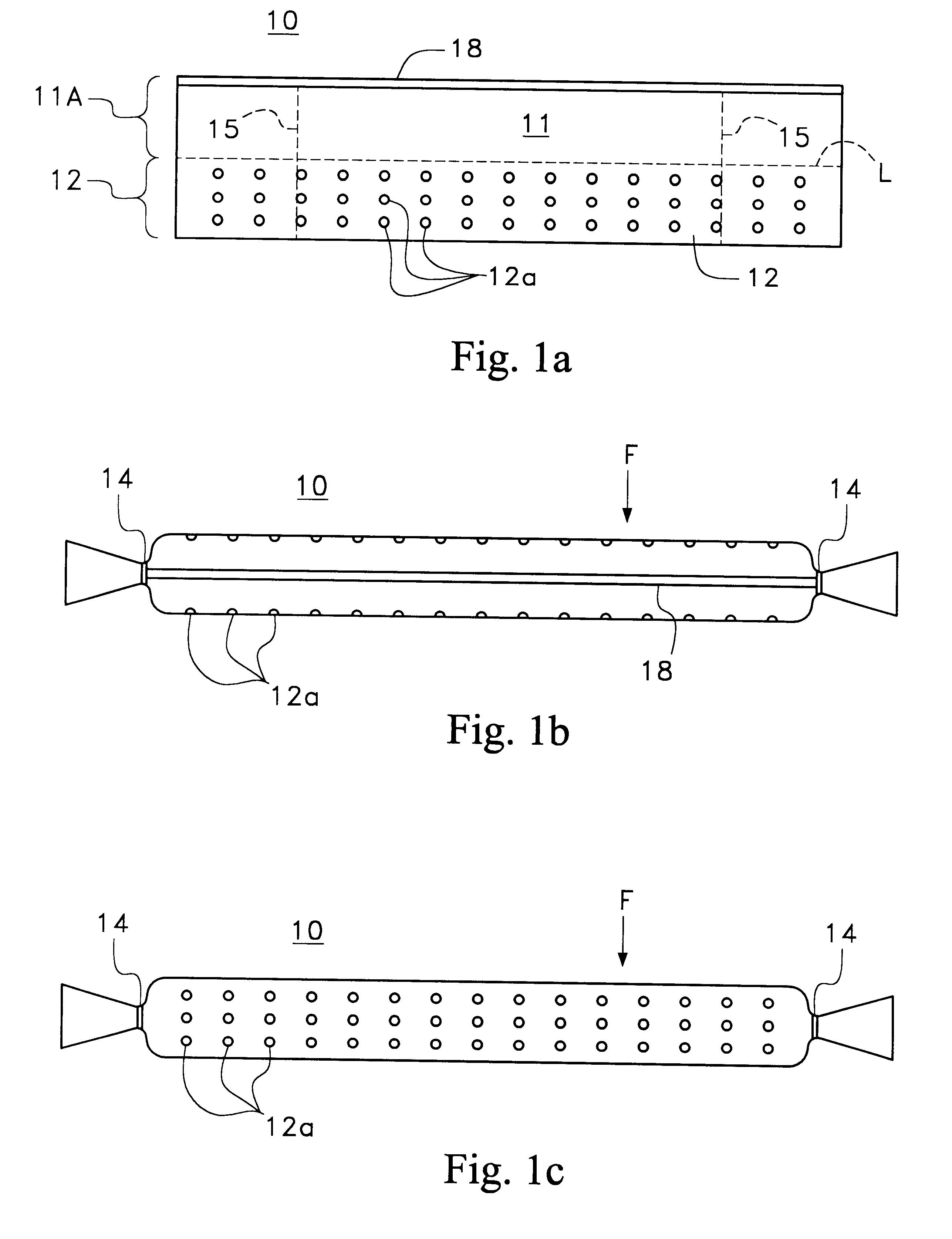

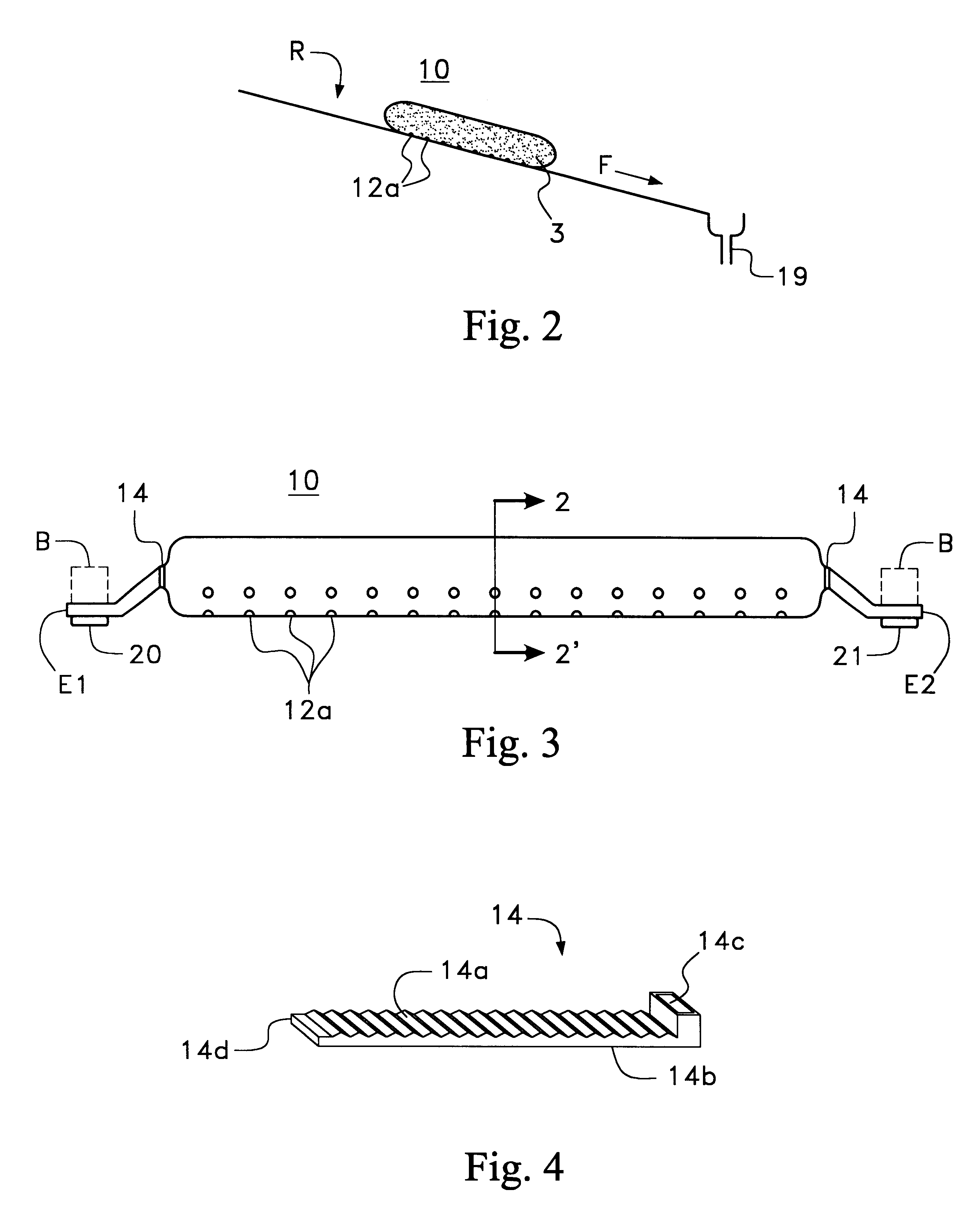

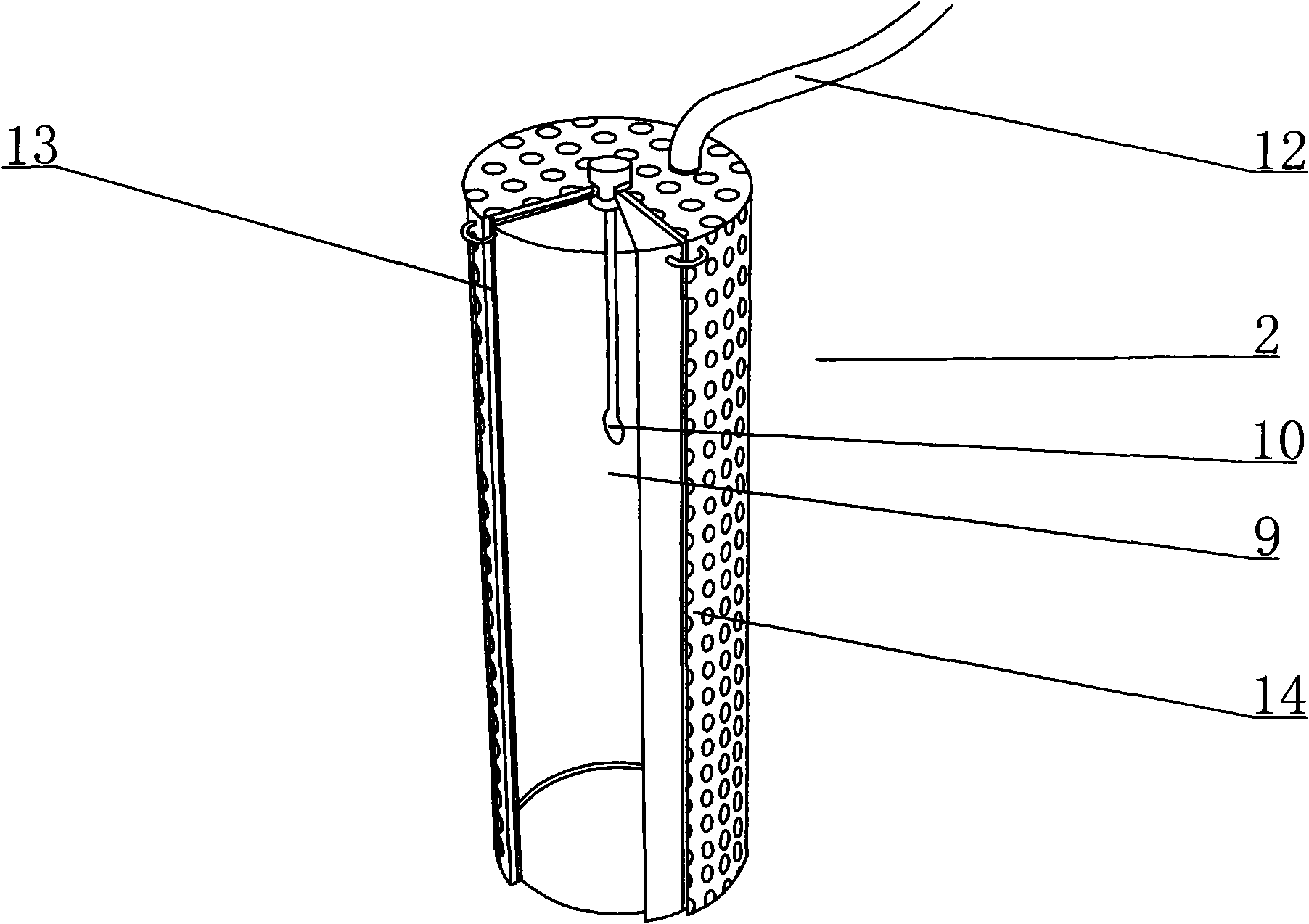

Ocular occluder and method of insertion

InactiveUS20060074370A1Shorten the timeSmall inventoryEye surgeryIntravenous devicesCylindromaOcular occluder

An ocular plug design and method of insertion is described for the treatment of dry eye. This ocular plug is generally a narrow rod-like cylinder of appropriate diameter, which may be tapered at one end, for insertion into an ocular channel, such as the punctum or the canaliculus. The plug is prepared from a hydrophilic polymeric material which forms a hydrogel upon absorption of water, but is rigid in its nonhydrated form. The plug is hydrated, formed into a length and diameter which is appropriate for insertion into an ocular channel (i.e., it is elongated), and dried so as to become frozen in its elongated state prior to insertion into the ocular channel. Once inserted into the ocular channel, the plug absorbs water, thereby becoming a hydrogel which is soft and pliable, and it expands to adapt to the size and shape of the patient's punctum or canaliculus. Once the plug expands to the size of a particular ocular channel, the plug is met with resistance from the surrounding tissue. At that point, expansion of the plug ceases and the plug can effectively block tear drainage through the ocular channel.

Owner:MEDENNIUM

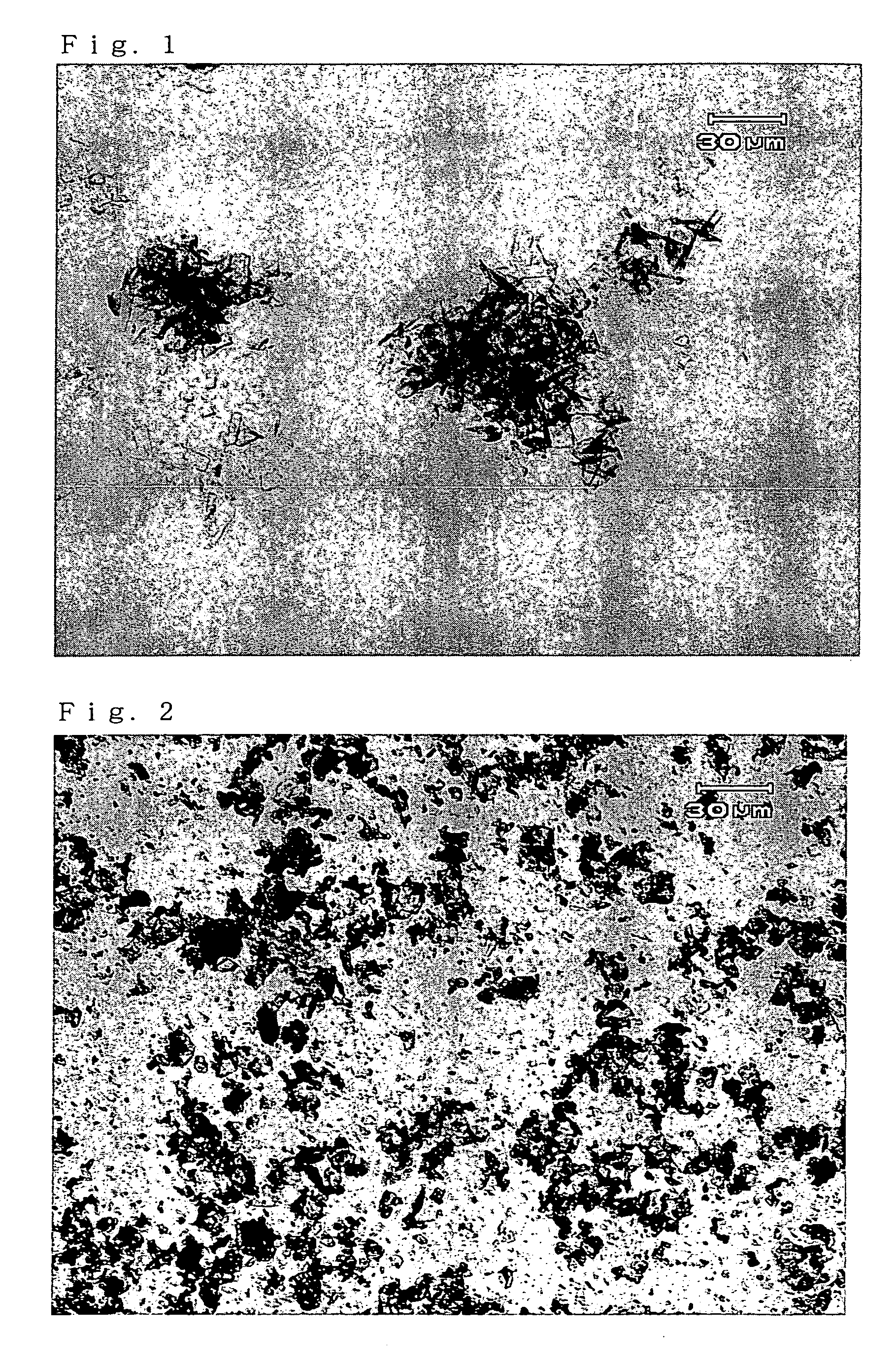

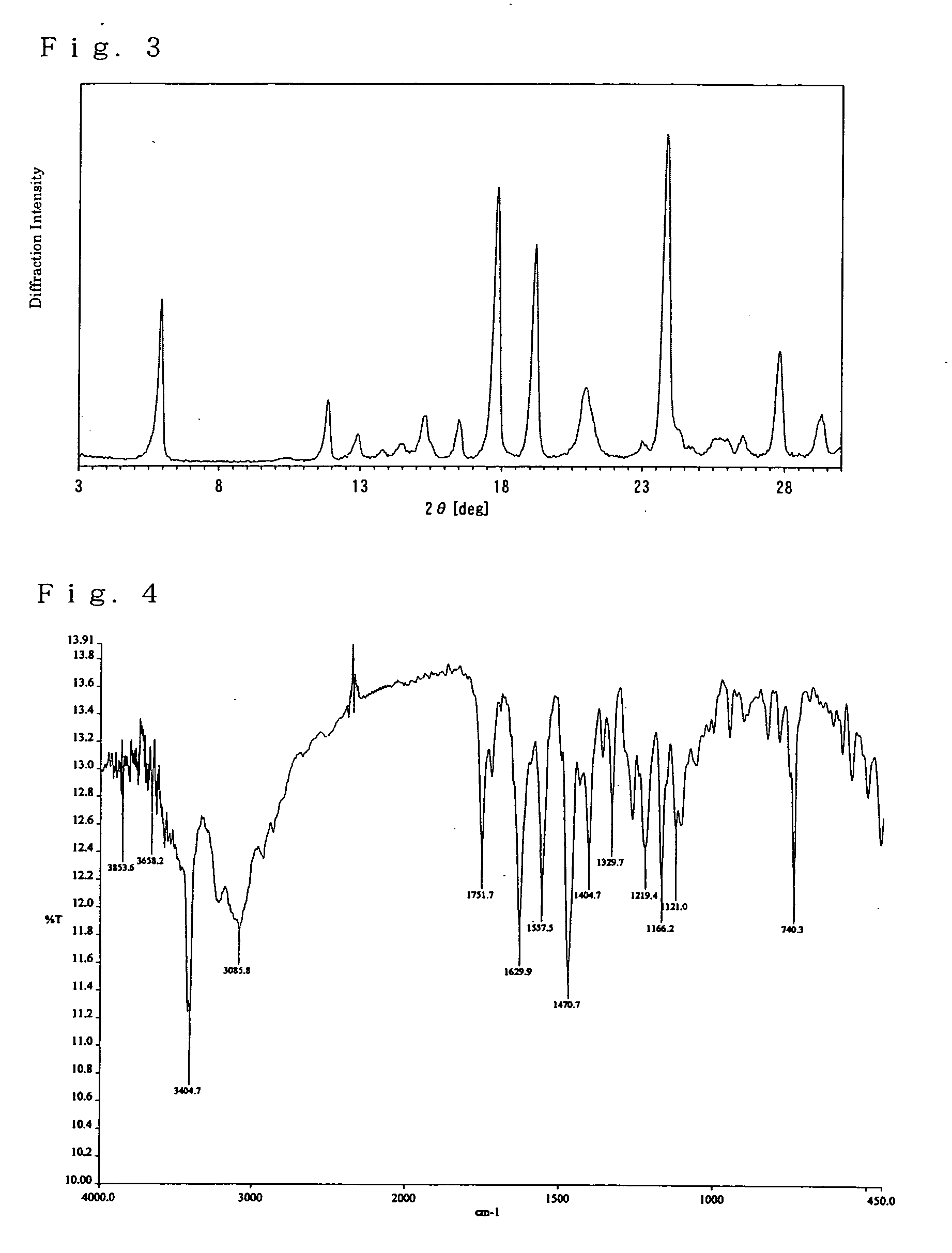

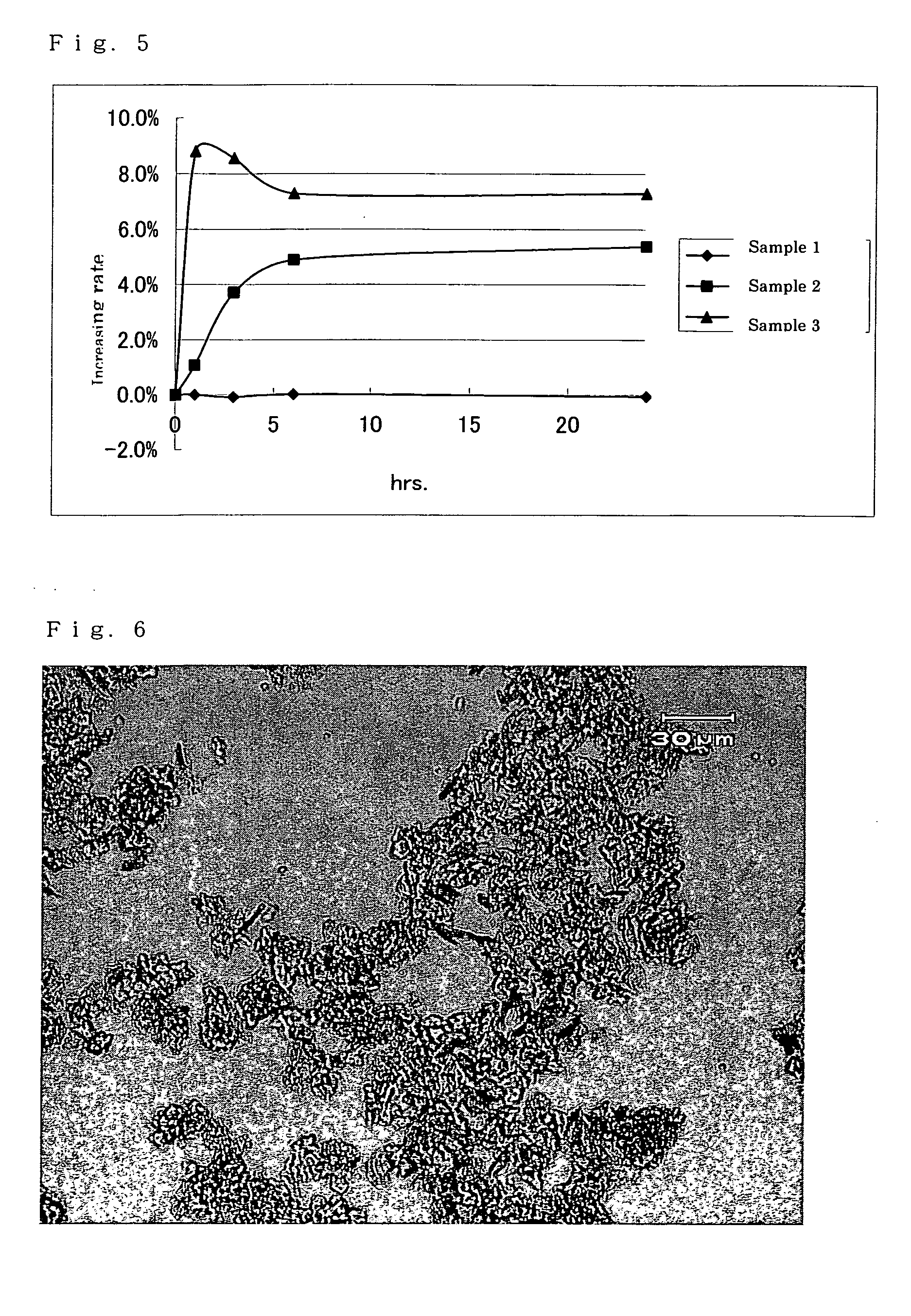

Crystals of free (2R, 4R)-monatin and use thereof

InactiveUS20050272939A1Superior in pointSuperior in sweetness intensityBiocideOrganic chemistryHigh humidityAdditive ingredient

A crystal of free (2R,4R)-monatin is useful as a sweet substance. The crystals resist absorption of water even under high humidity, are stable and exhibit a high degree of sweetness. Thus, such crystals may used as a sweetening agent or an ingredient thereof, and as an ingredient for imparting sweetness to foods and beverages.

Owner:AJINOMOTO CO INC

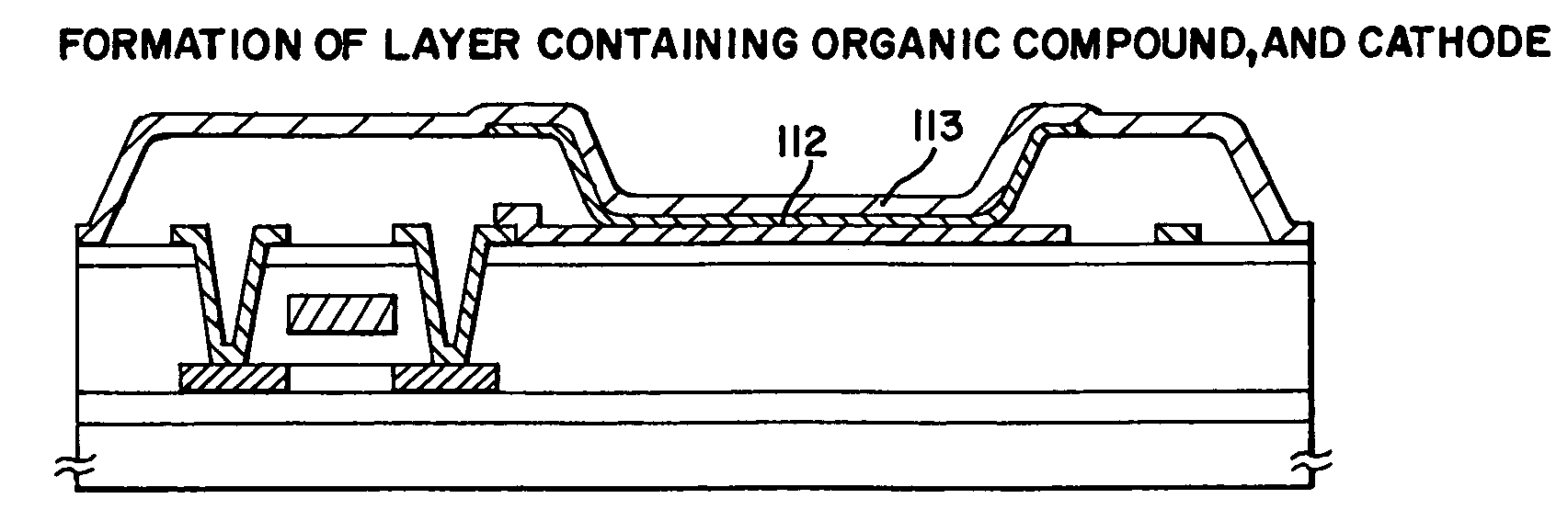

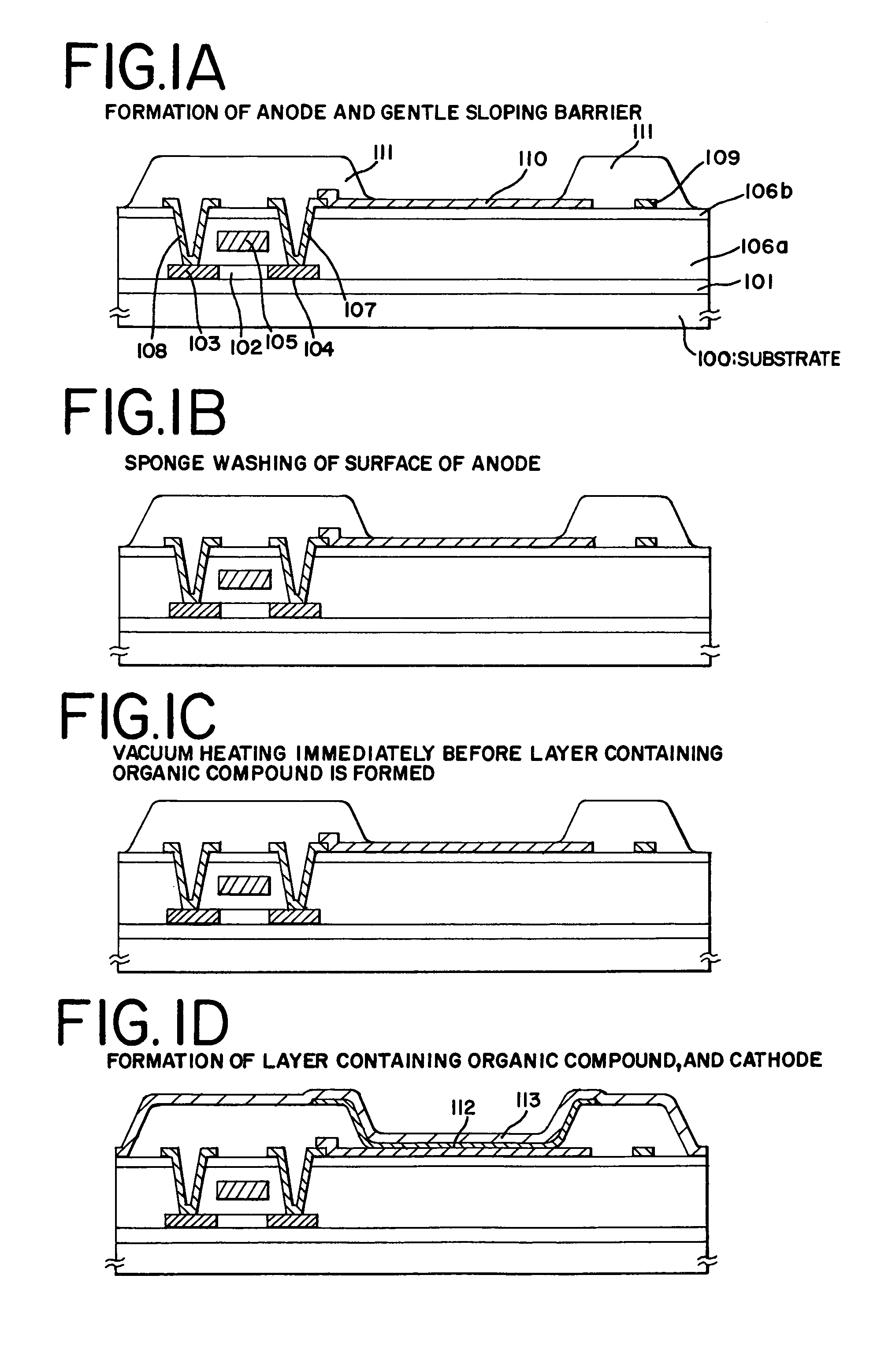

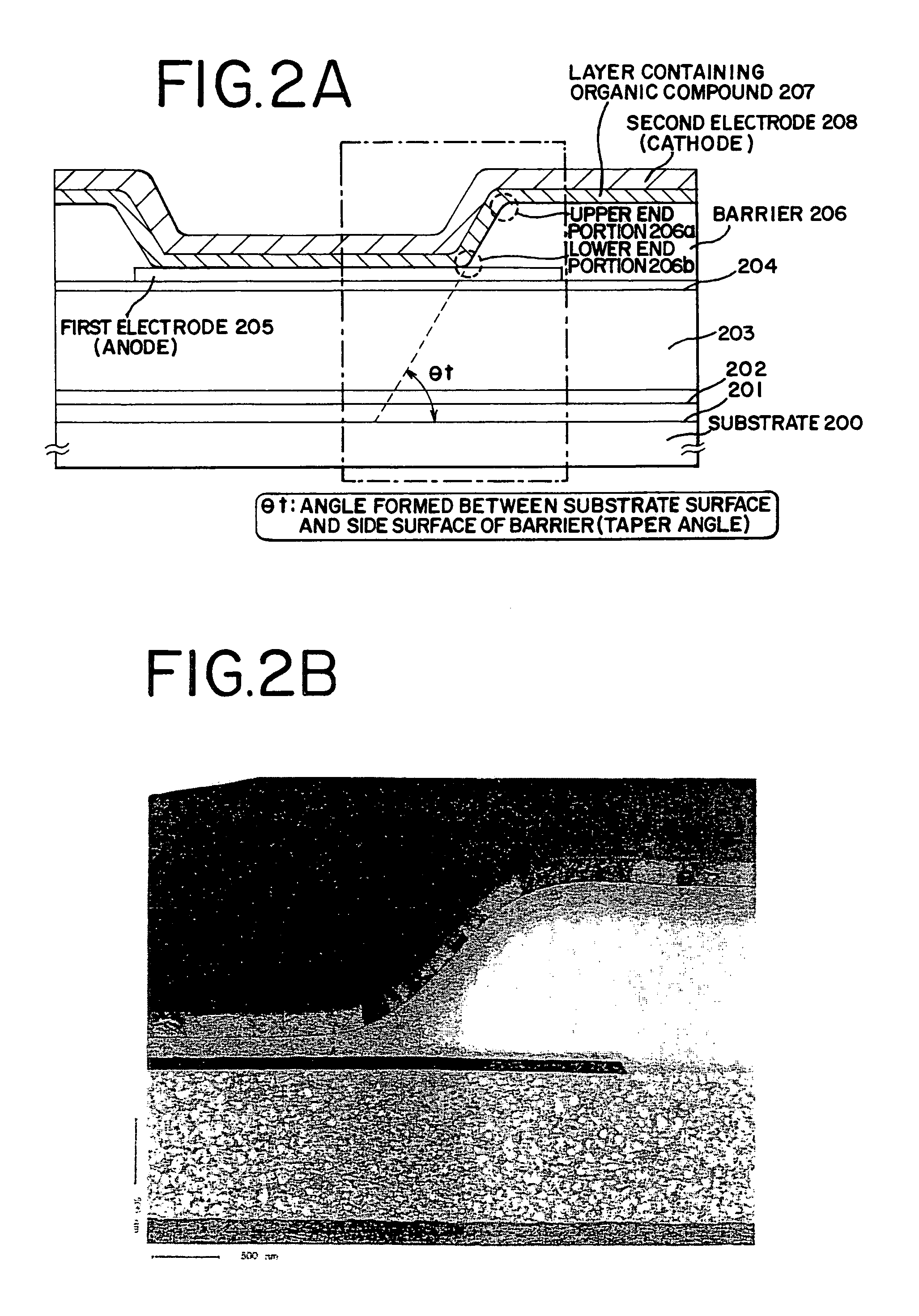

Method of fabricating light emitting device

InactiveUS7037157B2Reduce in quantityElectroluminescent light sourcesSolid-state devicesAbsorption of waterOrganic compound

Owner:SEMICON ENERGY LAB CO LTD

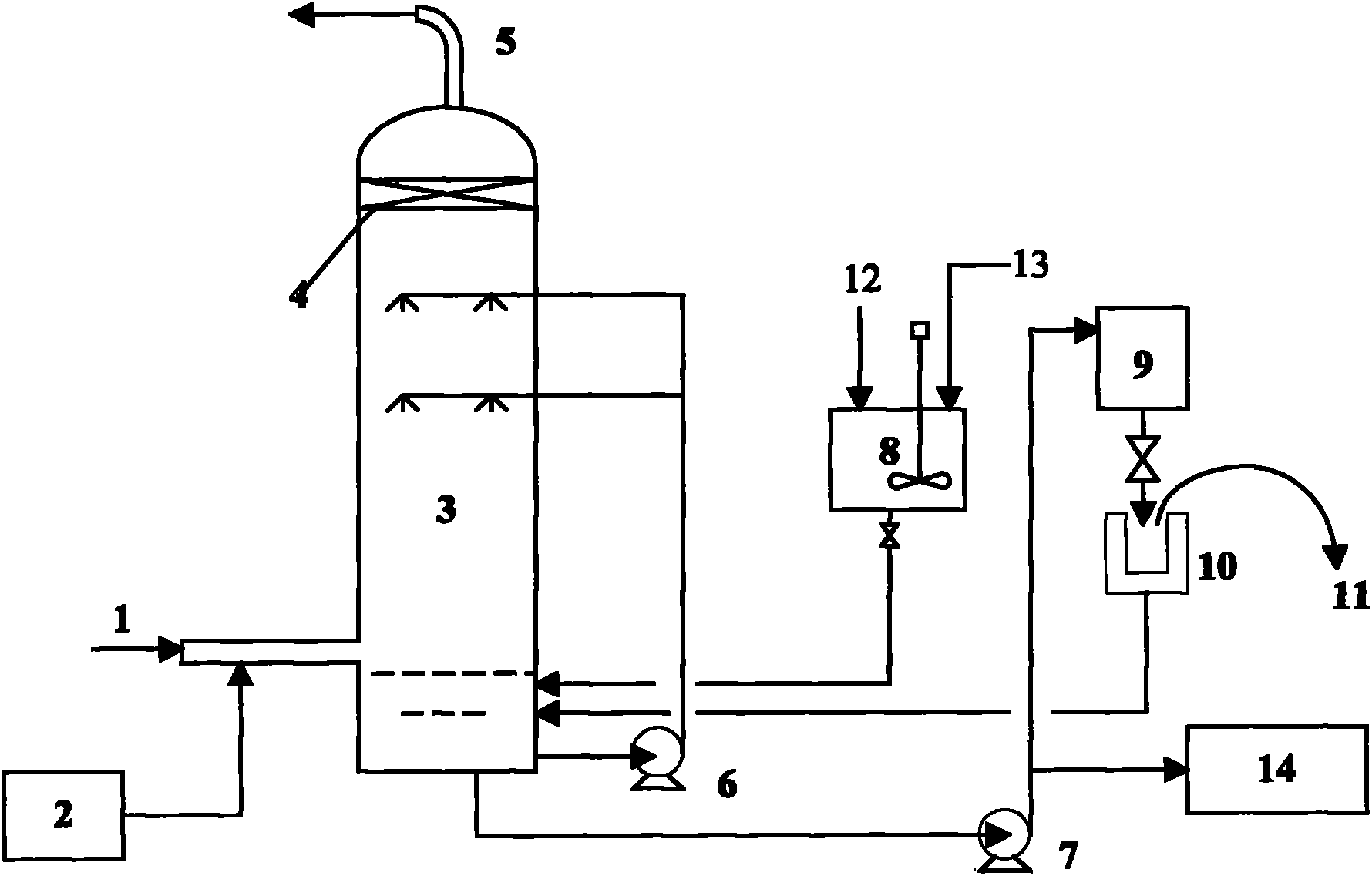

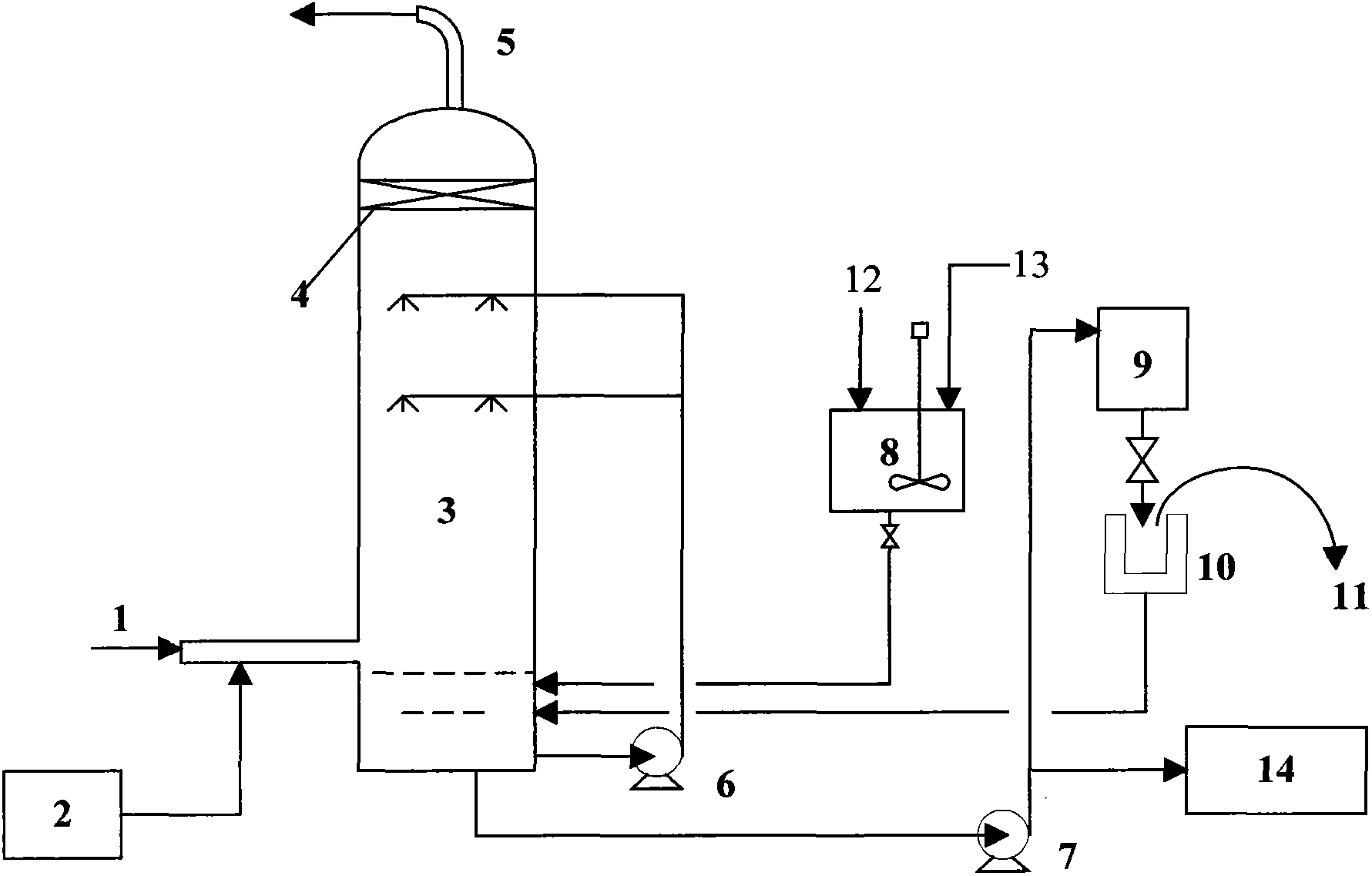

Device and method for simultaneously desulfurizing and denitrifying flue gas by ozone catalytic oxidation process

InactiveCN102247750AEfficient oxidationDispersed particle separationSulfur-trioxide/sulfuric-acidCatalytic oxidationAbsorption of water

The invention relates to a flue gas pollutant treatment process and aims to provide a device and method for simultaneously desulfurizing and denitrifying a flue gas by ozone catalytic oxidation process. The device comprises a desulfurization and denitrification tower, an ozone generator, absorption liquid circulating equipment and desulfurization and denitrification by-product post-treatment equipment. Ozone enters from a flue or the lower part of the desulfurization and denitrification tower, a catalyst is added to an absorption liquid, and the absorption liquid is injected in from the upper part of the desulfurization and denitrification tower, so that SO2 and NO in the flue gas are oxidized by ozone with high efficiency under the action of the catalyst, and in combination with the absorption of water or alkaline substances, SO2 and NOx in the flue gas are recovered in the form of high value-added sulfuric acid and nitric acid products, or ammonium sulfate / ammonium nitrate mixed nitrogen fertilizers, potassium sulfate / potassium nitrate mixed potassium fertilizers or ammonium / potassium compound fertilizers respectively, thereby achieving resource recovery and value maximization of the desulfurization and denitrification process. The desulfurization and denitrification process provided by the invention has the advantages of simple structure, low investment and low operation cost. The desulfurization rate and the denitrification rate of the desulfurization and denitrification process provided by the invention can reach more than 96% and more than 90% respectively.

Owner:EAST CHINA UNIV OF SCI & TECH

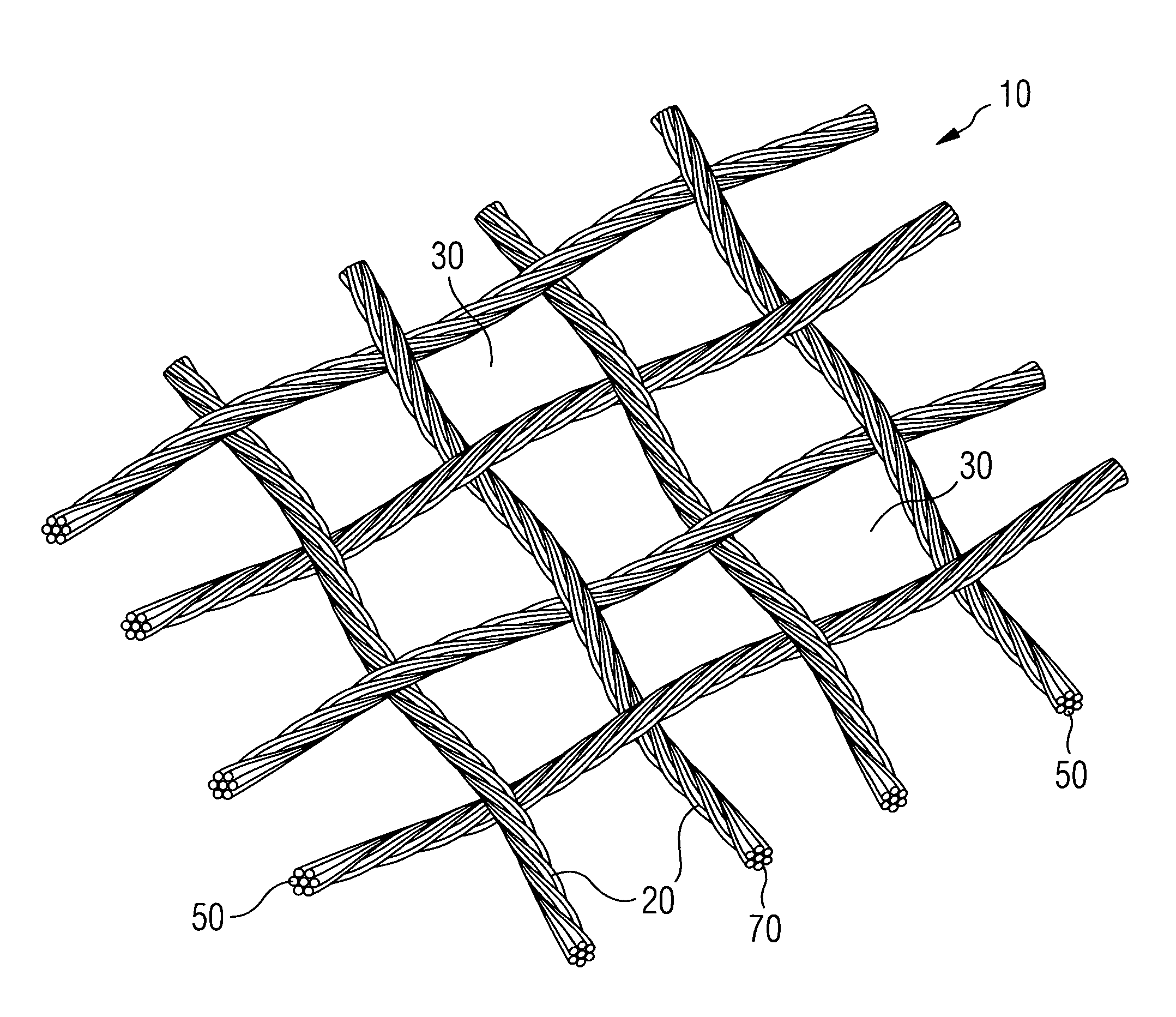

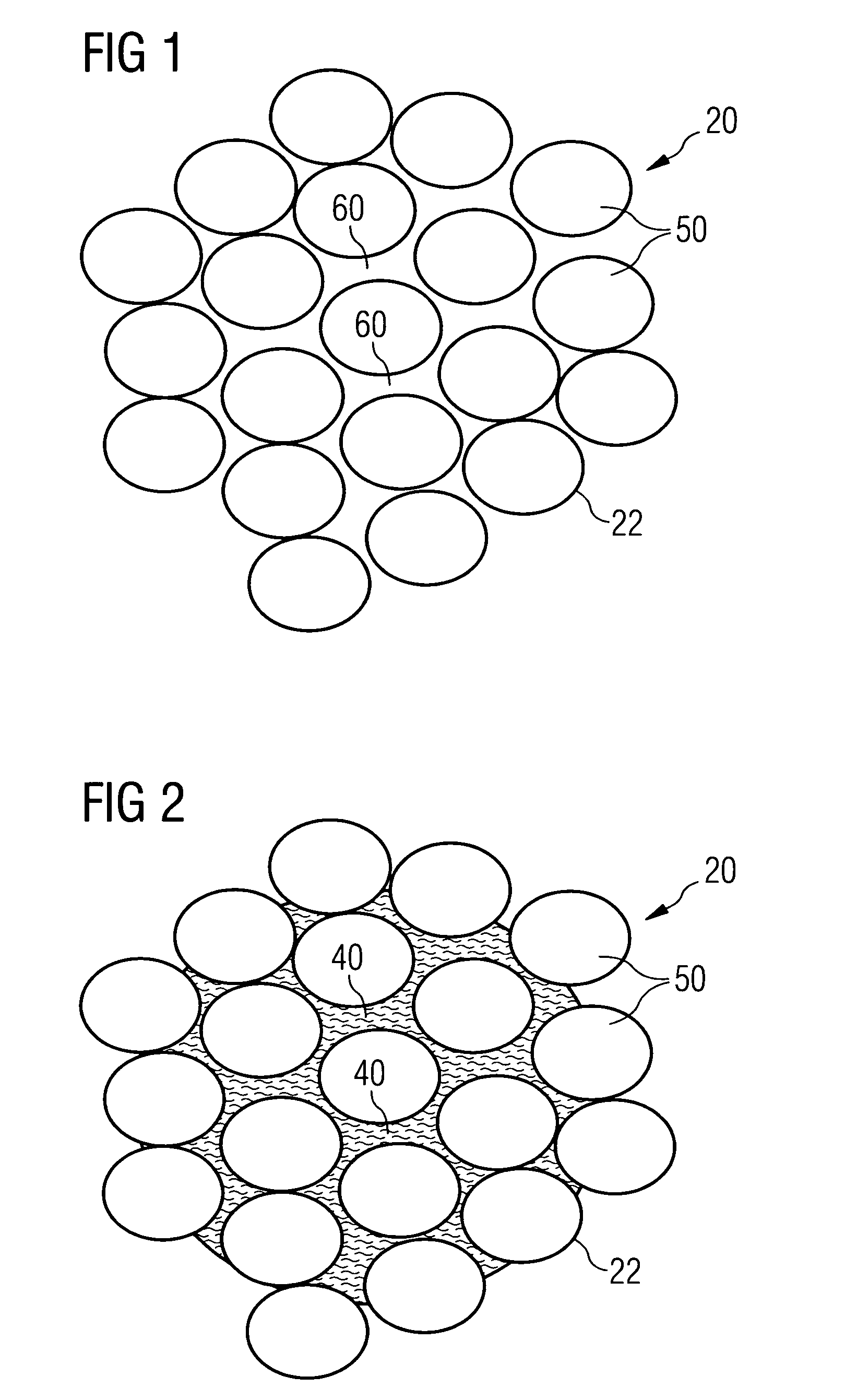

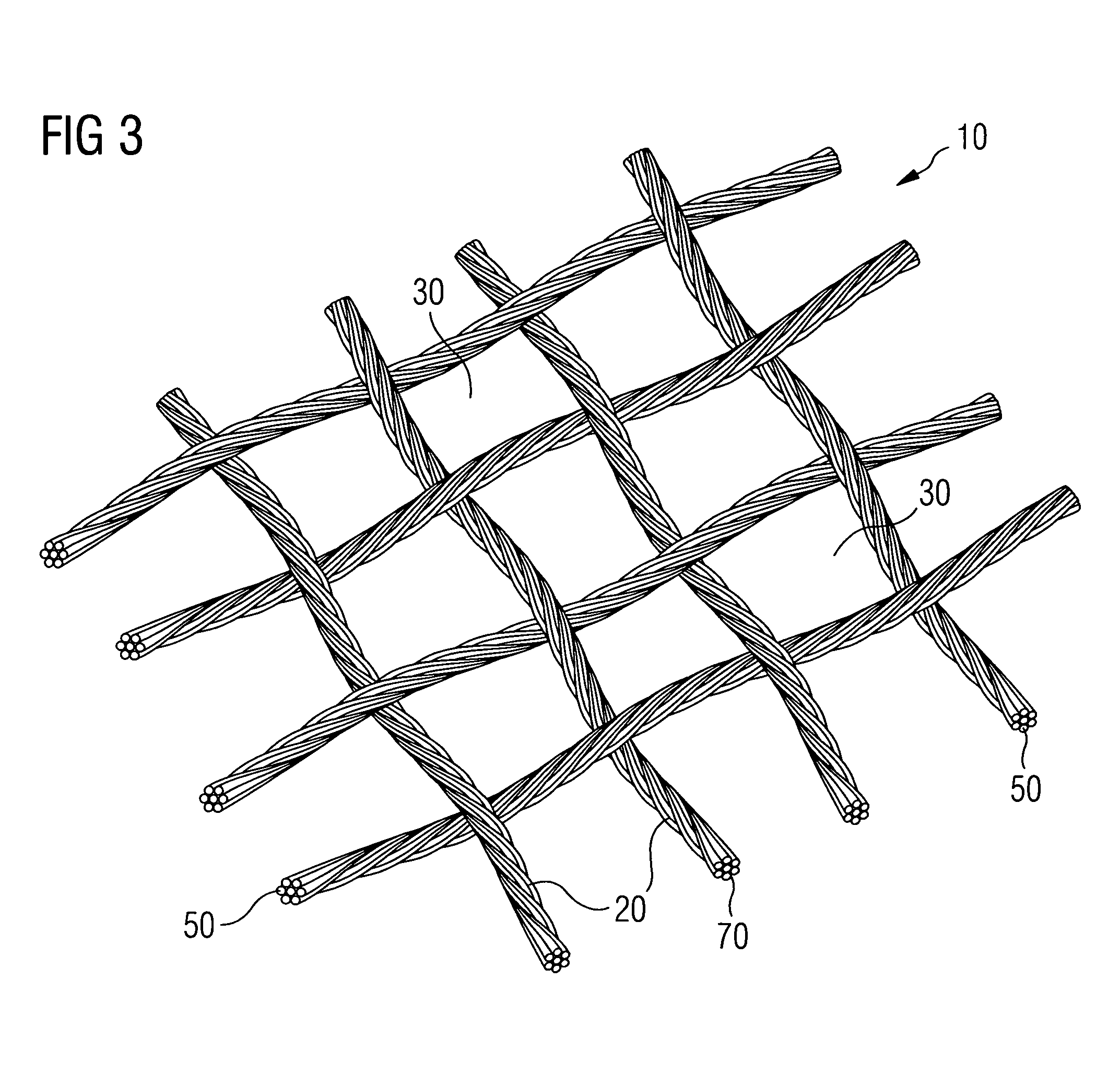

Fabric and Fabric Laminate

InactiveUS20100255270A1Feel goodImprove gripNatural cellulose pulp/paperPretreated surfacesYarnFiber

The present invention provides a fabric and a fabric structure made of yarns with reduced water absorption. The fabric comprises yarns and interstices between the yarns, the interstices between the yarns having an average width of greater than 100 μm. At least one of the yarns is comprised of multiple fibers. Said at least one yarn has voids between the fibers wherein the voids are filled up with a polymer material. The interstices remain open and the size of the interstices is the same as before the treatment. The filling of the voids between the fibers with the polymer material prevents the absorption of water into said voids and therefore leads to reduced water absorption of the fabric. The polymer material is substantially only located within the voids of the yarn and has embedded the fibers within the outer surface of said yarn.

Owner:STUEBIGER WERNER

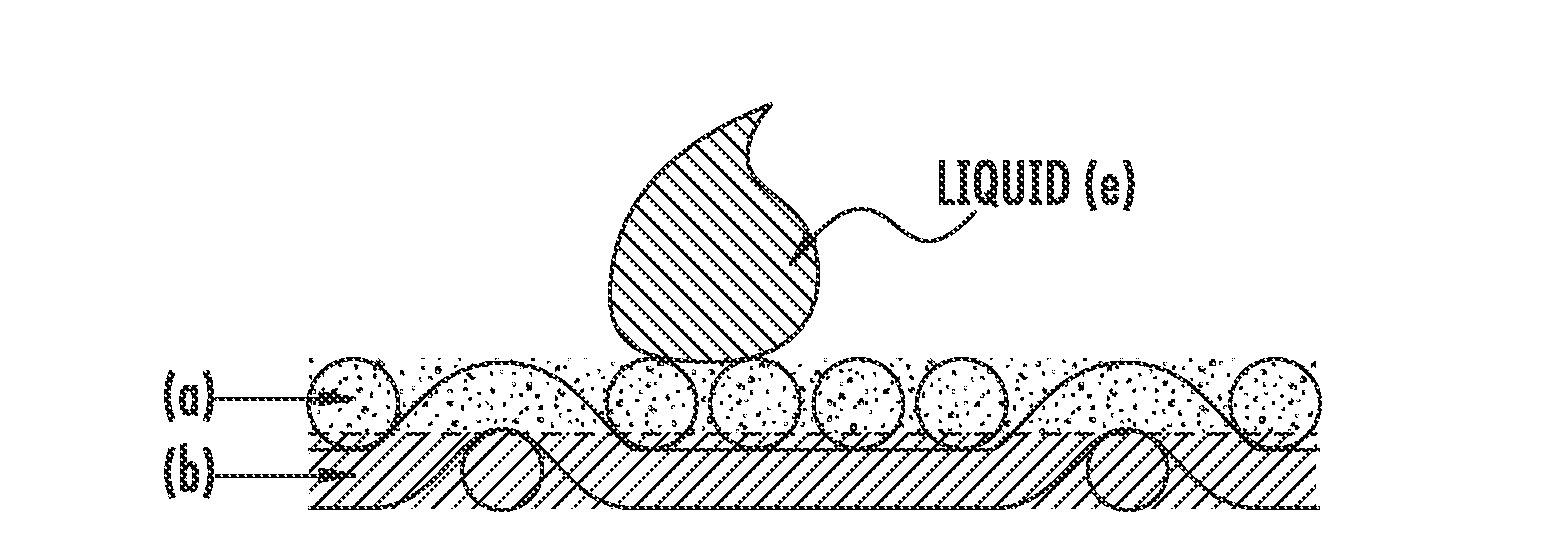

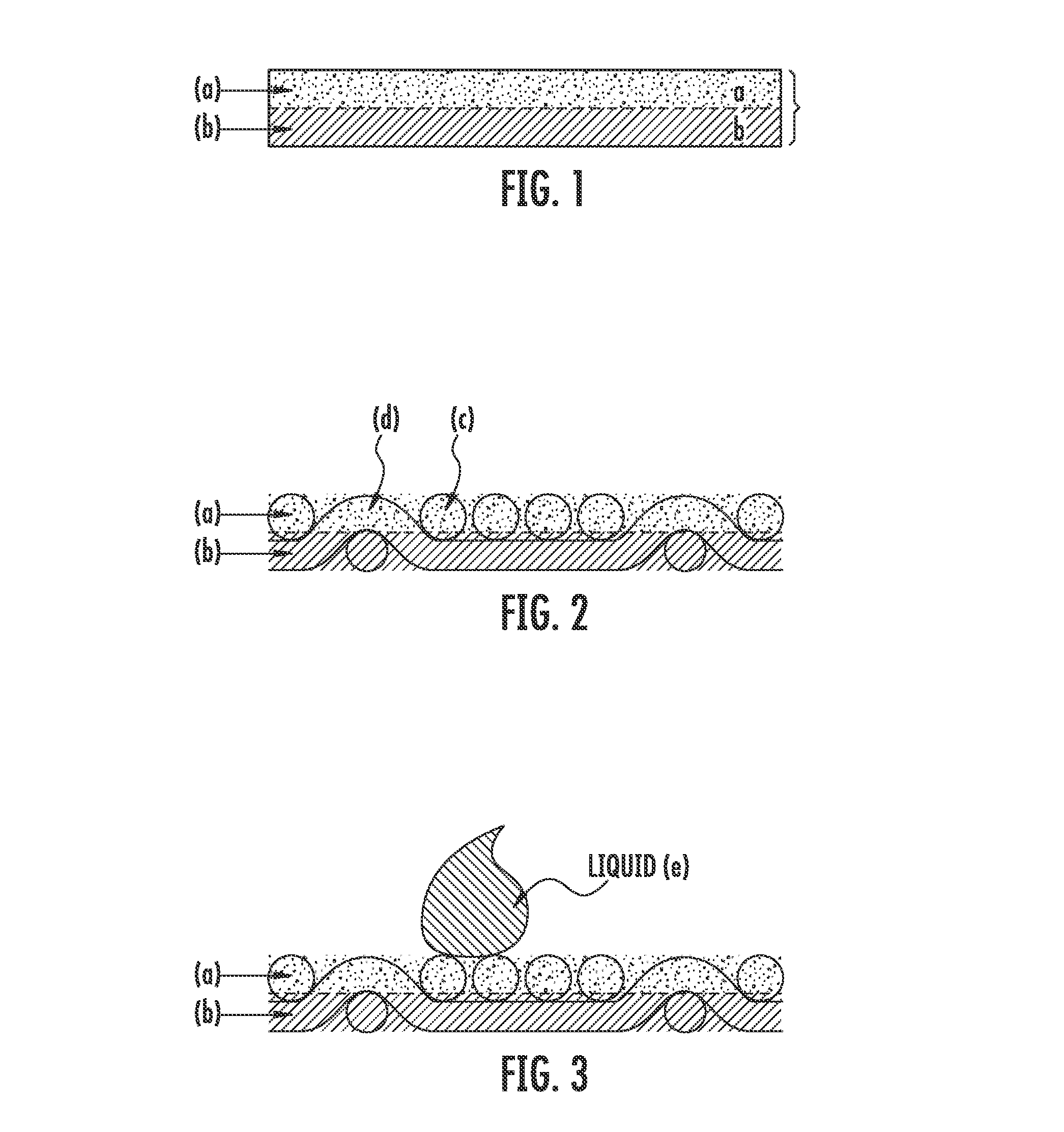

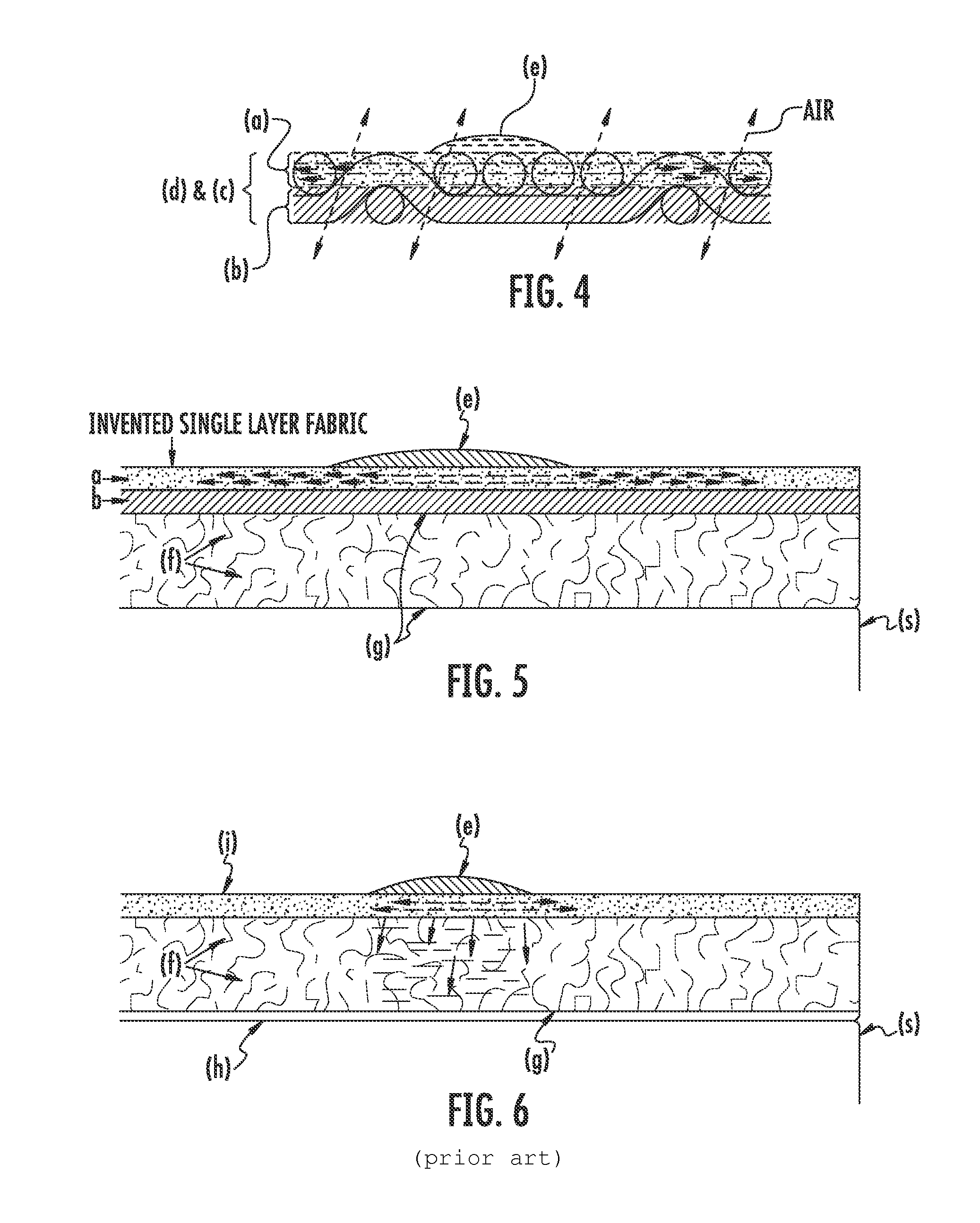

Semi-absorbent, semi-resistant, breathable fabric

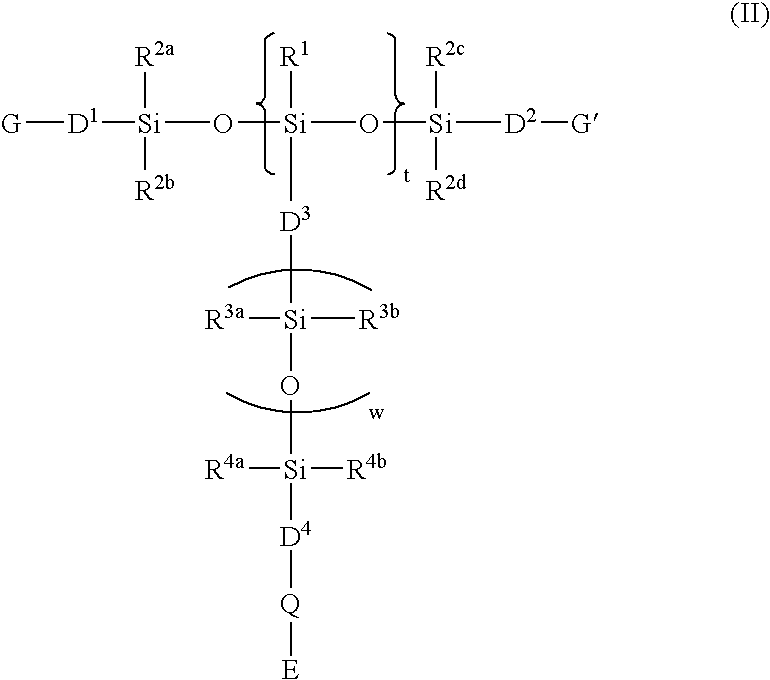

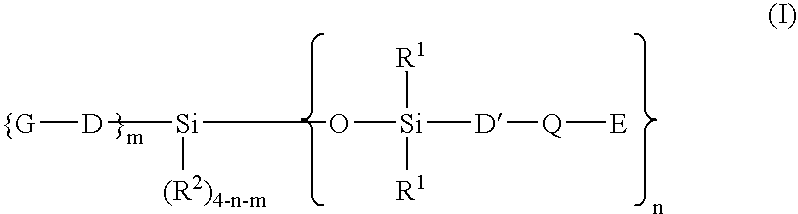

A semi-absorbent, semi-resistant, breathable fabric includes a single-layer having a first, hydrophilic side that absorbs water, and a second, hydrophobic side; wherein the first, hydrophilic side of the single-layer fabric quickly spreads out a liquid that is absorbed laterally to a wider area such that the absorbed liquid does not seep or pass through to the second, hydrophobic side of the single-layer fabric under gravitational force. A method of making a semi-absorbent, semi-resistant, breathable fabric includes: subjecting a first side of a single-layer fabric to a hydrophilic amino functional polysiloxane softener; treating a second opposite side of the fabric with a fluorocarbon compound under low pressure such that the fluorocarbon compound penetrates no more than half of the fabric thickness; and drying and curing the fabric, preferably at a temperature of about 145° C. to 155° C. for about three minutes to about five minutes.

Owner:WELSPUN INDIA LTD

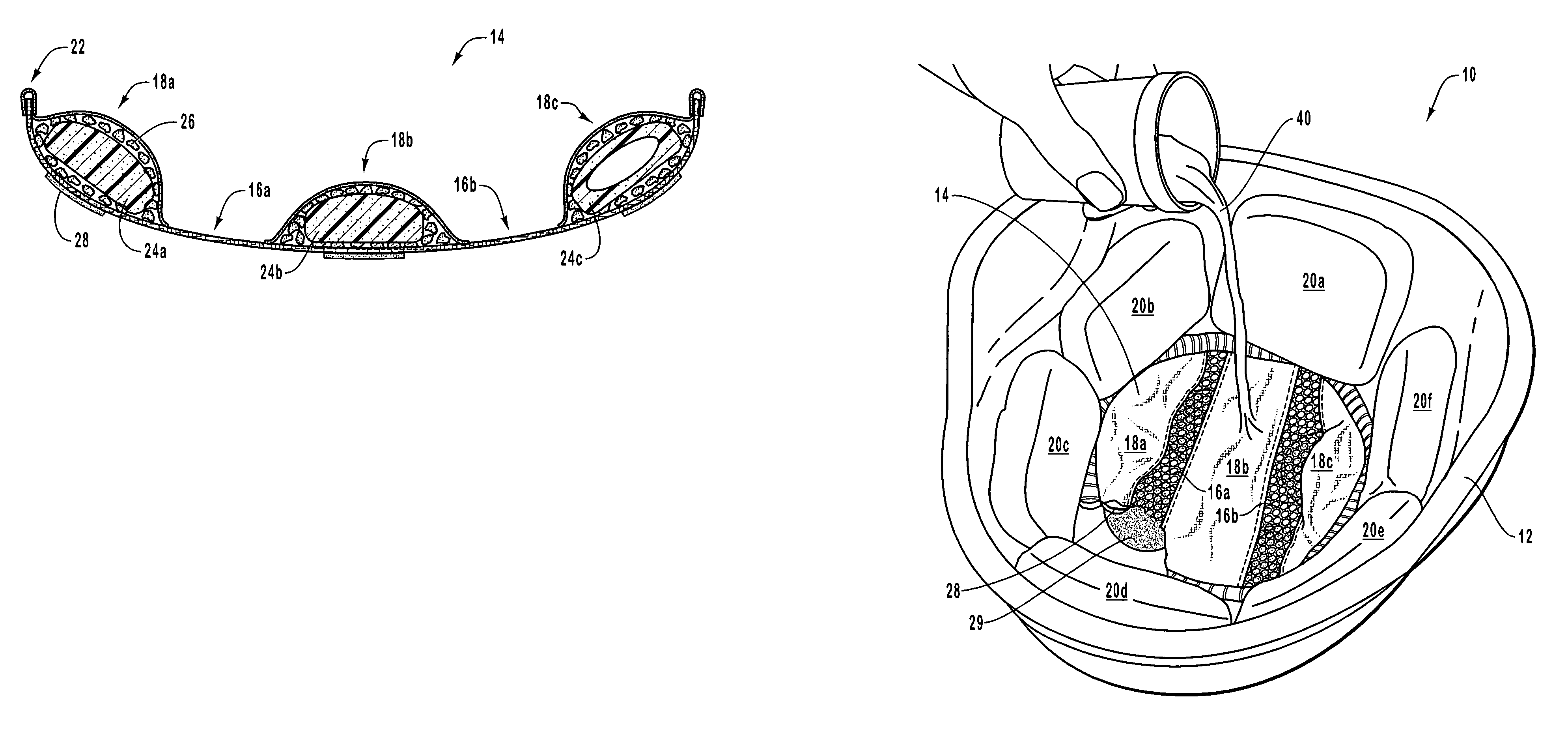

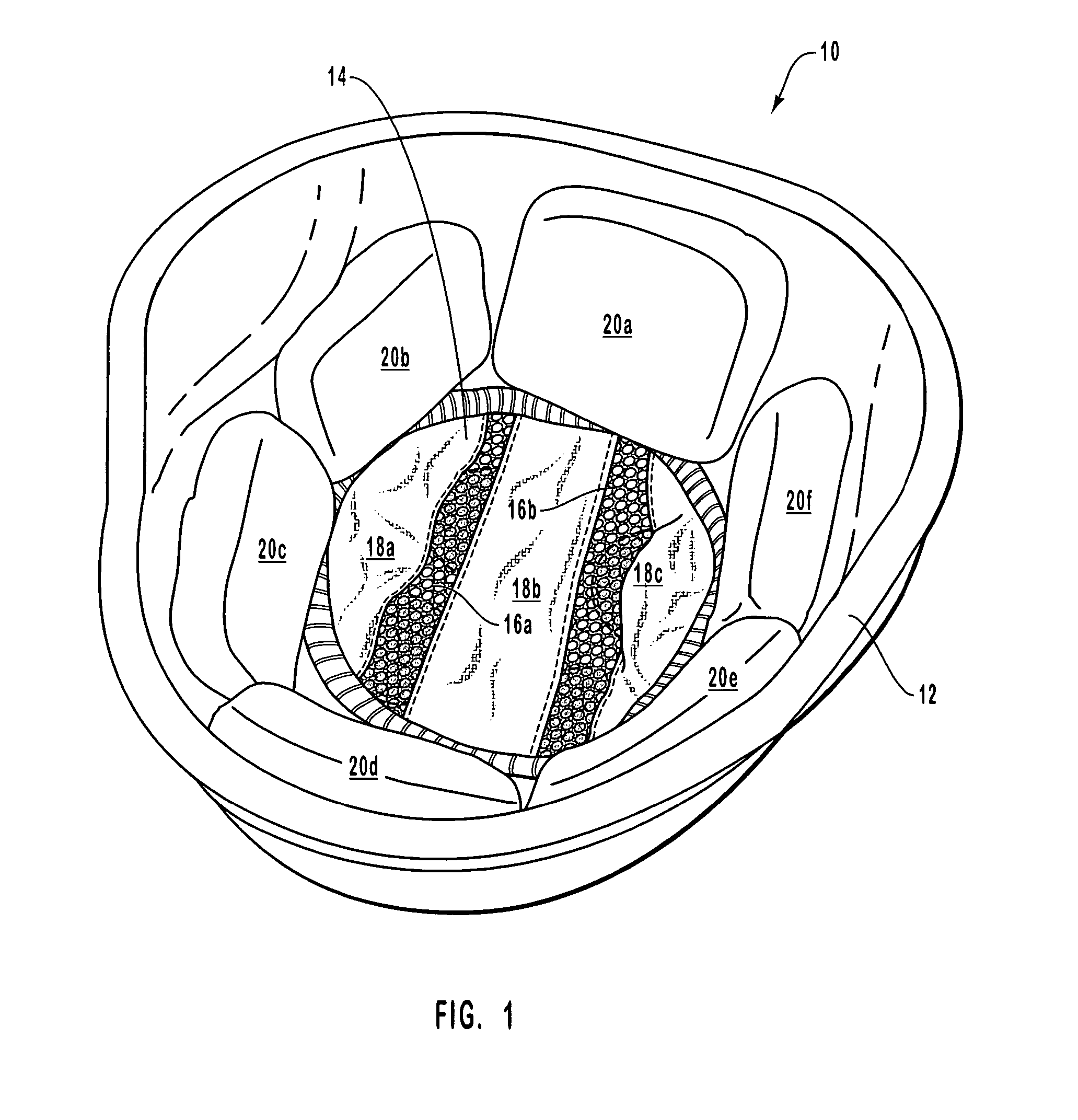

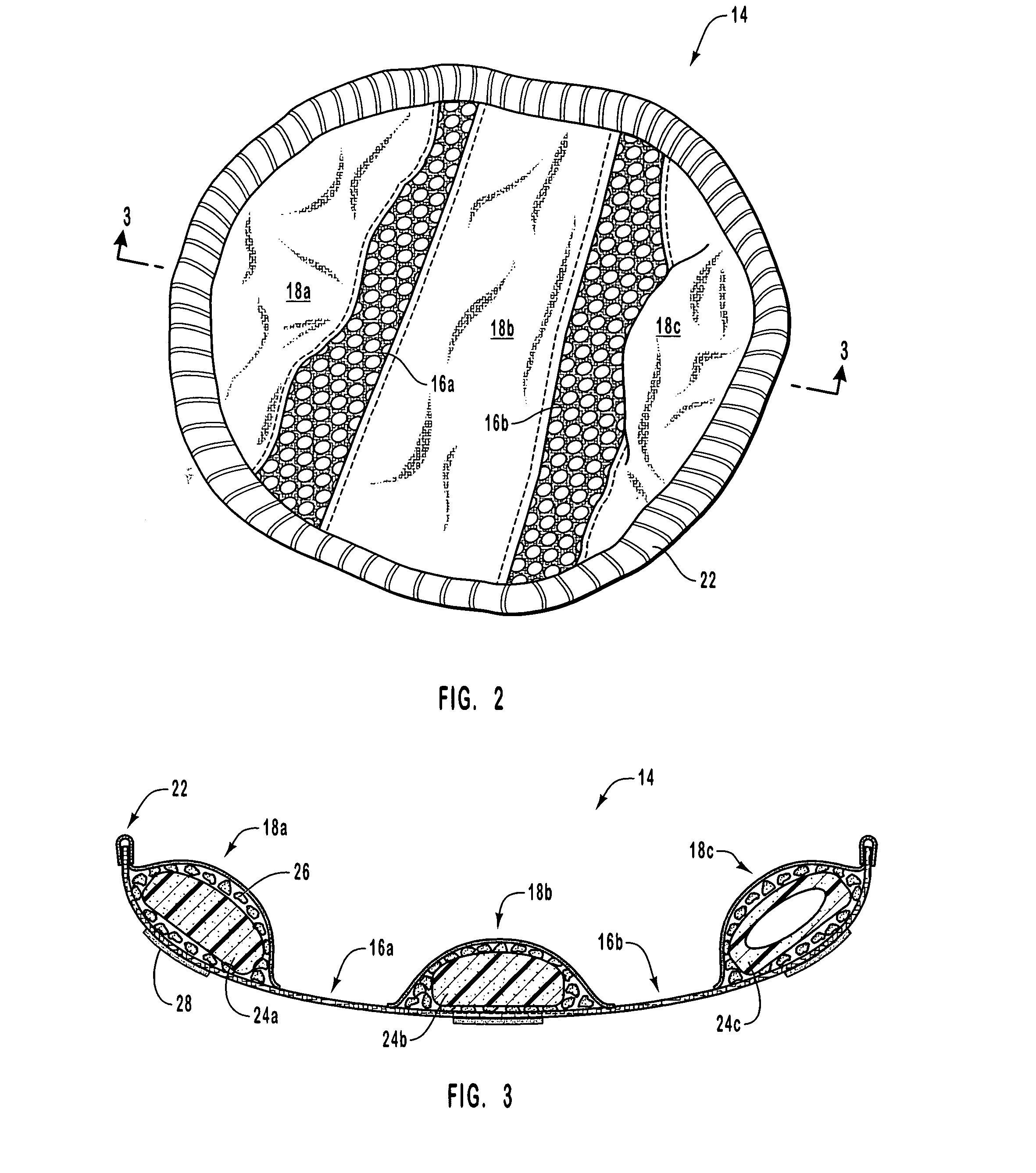

Systems and methods for providing a headgear cooling liner

InactiveUS7028344B2Facilitate natural evaporationDomestic cooling apparatusEye treatmentPerspirationEvaporation

Systems and methods for providing an article associated with headgear that keeps the wearer's head both cool and cushioned from the interior harness of the headgear. The article is a system, liner or pad that is inserted into the headgear or coupled to the headgear harness for cooling and comfort, and includes a water absorbent polymer or other material contained within non-impervious pocket partitions attached to a concave disk of mesh fabric. The mesh fabric provides ventilation portions, which allow for the free flow of air and breathing of the wearer's scalp to facilitate the natural evaporation of perspiration. The article provides a cushion to the wearer's scalp from the abrasive effect of the webbing of the headgear harness. As the pocket partitions swell due to absorption of water by the polymer material, the pockets function as gel-like cushions or pads that protect the wearer's scalp. The article is held in place with small straps, Velcro® tabs, or other retention devices.

Owner:TOTH GREGORY T

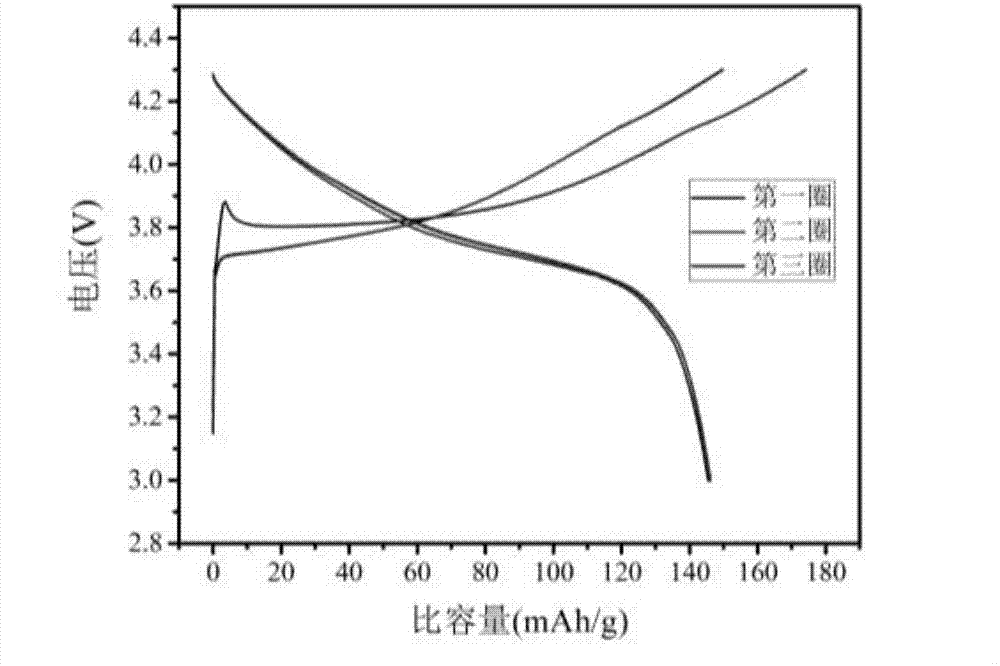

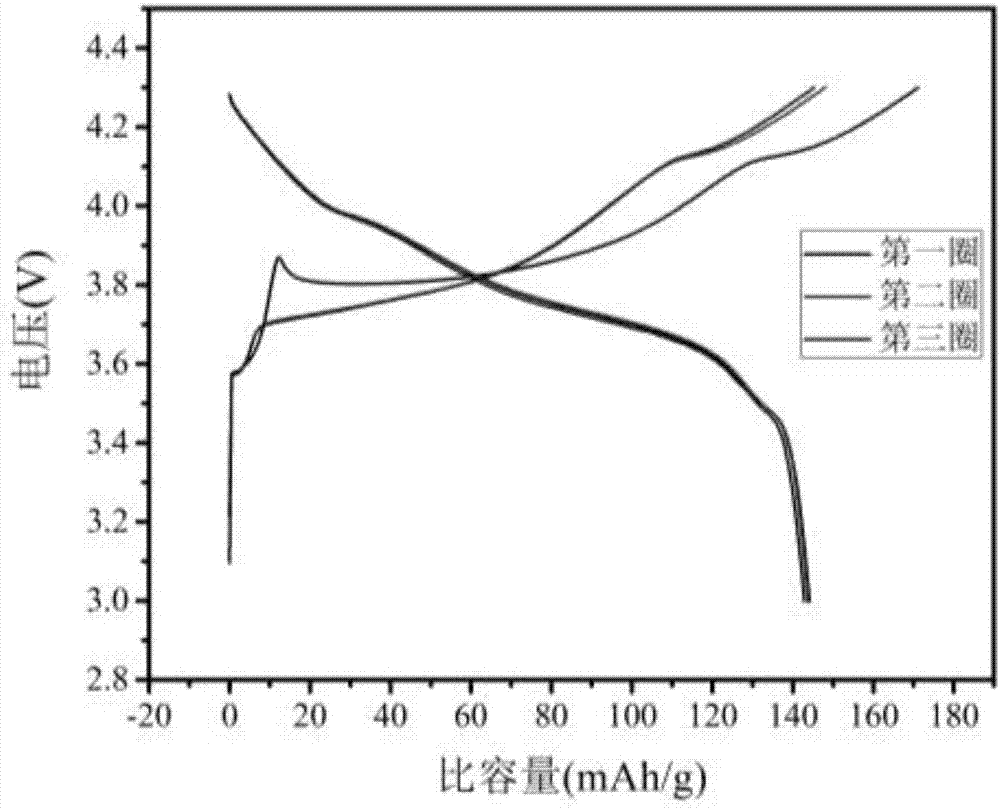

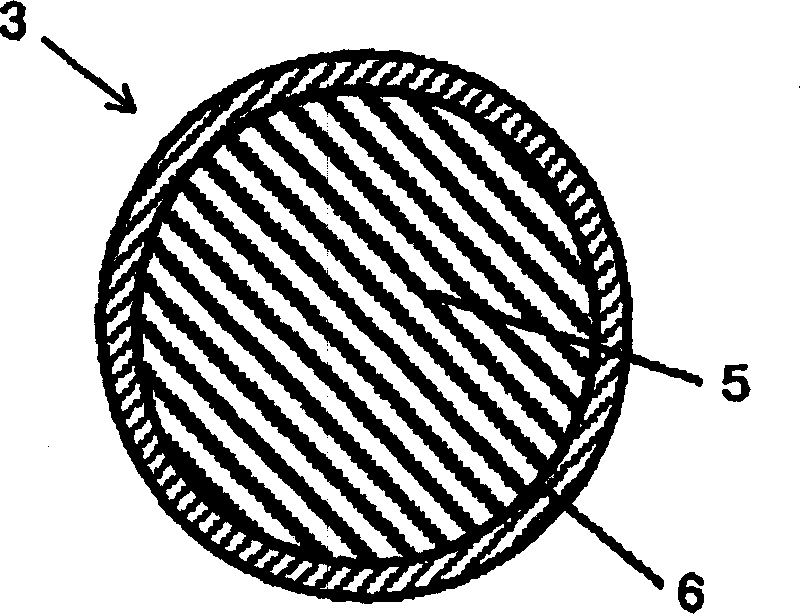

Lithium manganese ferric phosphate-ternary material composite positive electrode material and preparation method therefor

ActiveCN107546379AImprove stabilityImprove cycle performanceCell electrodesSecondary cellsPhosphateManganese

The invention discloses a lithium manganese ferric phosphate-ternary material composite positive electrode material and a preparation method therefor. Lithium manganese ferric phosphate nanoparticlesare fixed on the surfaces of the ternary material granules through a mechanical fusion method to form a tight porous coating layer; therefore, the problem of easy segregation caused by different densities of the ternary material and the lithium manganese ferric phosphate positive electrode material when the mixed paste of the ternary material and the lithium manganese ferric phosphate positive electrode material is needed in the paste mixing stage in the use process of the ternary material and the lithium manganese phosphate positive electrode material can be solved; and by virtue of tight coating of the lithium manganese ferric phosphate on the surface of the ternary material, a stable core-shell structure can be obtained, so that the surface of the ternary material (particularly a high-nickel ternary material) can be protected by the lithium manganese ferric phosphate material, degradation of the ternary material caused by absorption of water contents in the environments can be prevented, direct contact between the ternary material and an electrolyte in the battery can be lowered, and the stability and cyclicity of the ternary material are improved.

Owner:中科致良新能源材料(浙江)有限公司

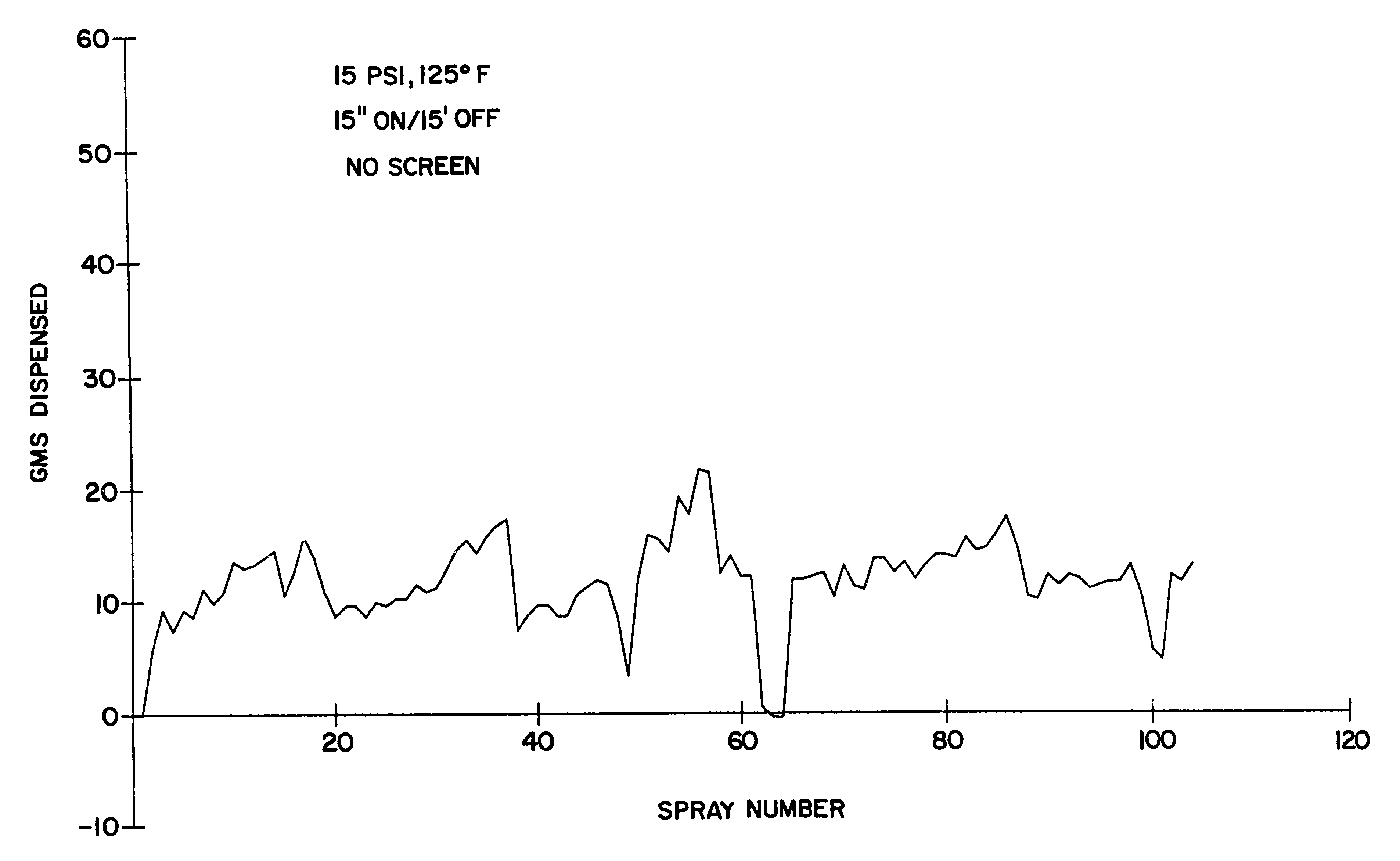

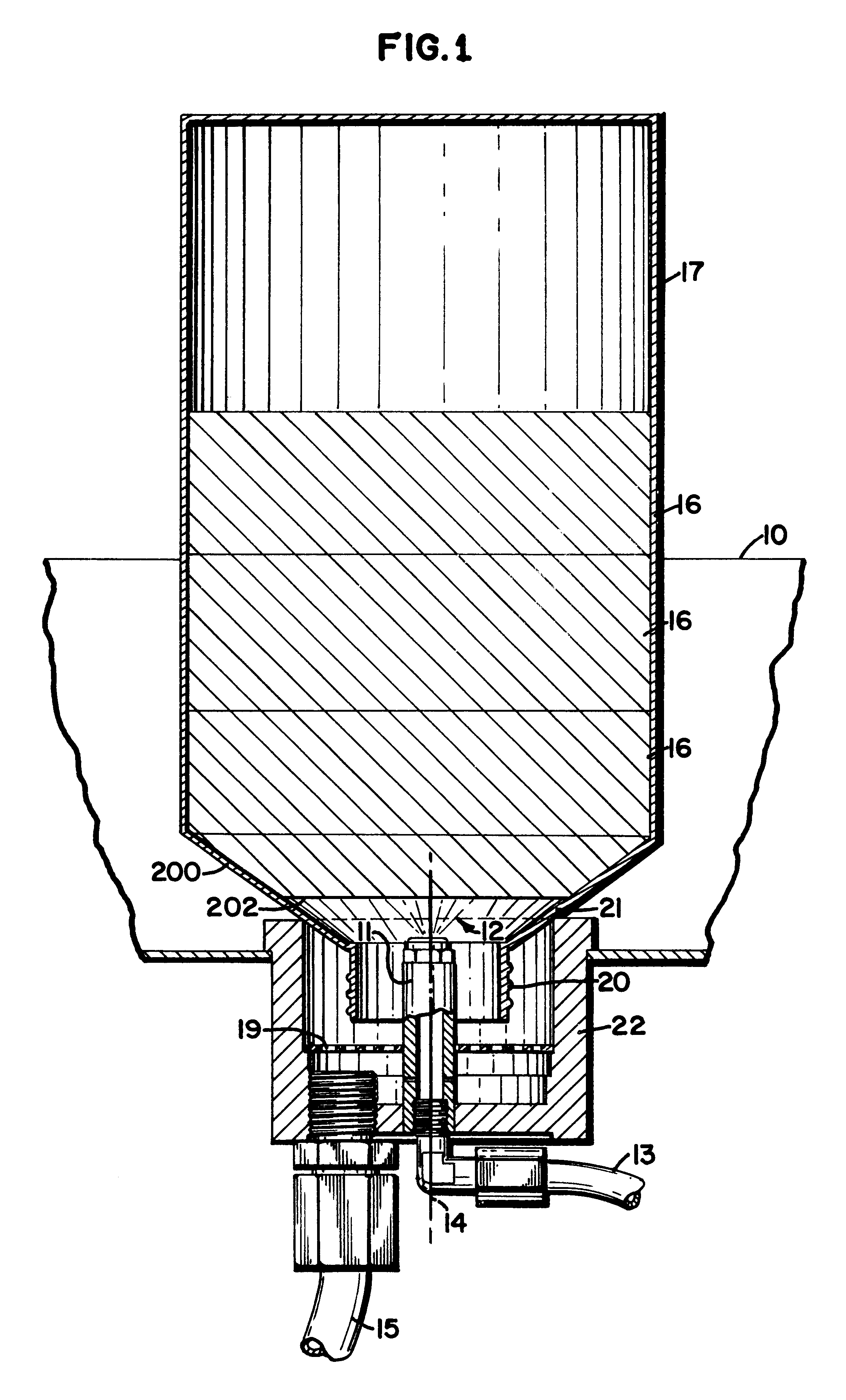

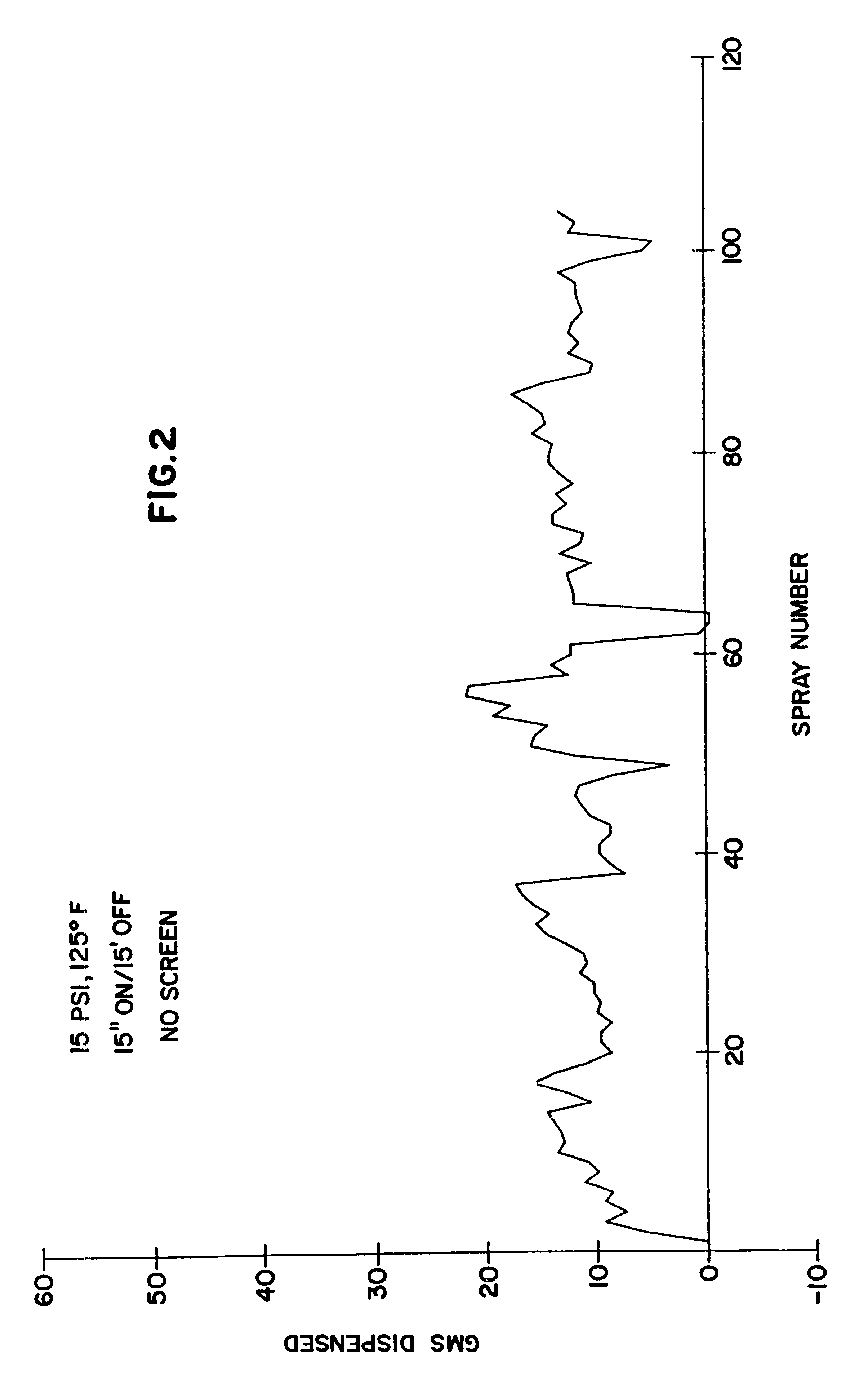

Shaped solid comprising oxidant bleach with encapsulate source of bleach

InactiveUS6589443B1Trend downReduce harmful effectsOxygen/ozone/oxide/hydroxideOther chemical processesParticulatesBrick

Aqueous bleach solutions can be made by directing a spray of water onto a bulk or shaped solid (brick, tablet, block, etc.) comprising a continuous solid phase of an encapsulated source of an active halogen bleach or a solid comprising a source of an oxidizing active halogen bleach, and an encapsulated oxidizing halogen bleach source. Such shaped solids can be used to dispense uniform quantities of an aqueous bleach concentrate to bleaching locus such as a washing machine. The tablets can be made from the encapsulated bleach or from a powder mixture of a particulate, granulated or powdered unencapsulated source of active oxidizing bleach and an encapsulated source of active oxidizing bleach by forming the powder mixture into a desired shape. Such a shaped solid bleach can be packaged in a container and can then be contacted with an aqueous spray in a dispenser to create a solution of active bleach for cleaning bleaching processes. The presence of the encapsulate in the solid with the powder reduces the tendency of the solid to absorb water which can be wicked through the solid to pass water through the solid into adjacent solids. Substantial proportions of absorbed water can cause the tablets to crack, crumble and to periodically dispense uneven, substantially large and undesirable concentrations of active bleach into a wash or bleach cycle. Such large amounts of halogen can cause corrosion of metal machine or dispenser parts, clothing damage, can cause pinholing or other fabric damage, can result in color loss or change, or can result in other undesirable effects in either the dispenser, washing machine or the cleaned item.

Owner:ECOLAB USA INC

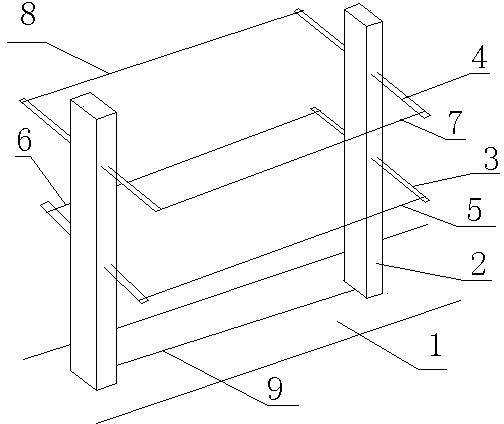

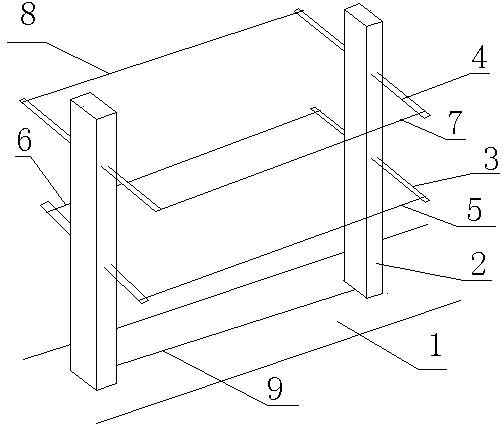

Method for cultivating pitaya

The invention discloses a method for cultivating pitaya. The method comprises the following steps: a planting ditch is dug; decayed farm manure and soil are mixed at a mass ratio of 1:2 is backfilled in the planting ditch; cement pillars are set up in the center of the planting ditch and at an interval of 2 m, a position of 70 cm above the ground and a position of 140cm above the ground on each cement pillar are perforated and penetrated by two cross beams, the cross beams are as long as 70 cm, and horizontal steel ropes are fixed between the cross beams between each two cement pillars; and 4 pitaya stalks are cut on furrow surface among the cement pillars, two left primary branches are drawn onto two steel ropes on the first layer through pull ropes, three left secondary branches are separately bound to steel ropes on the second layer, five tertiary branches are kept, and the other new branches are cut and removed. The method provided by the utility model has the advantages that orchard space is fully utilized; the absorption of water, fertilizer and light by the whole orchard is increased; the weight of a single fruit is improved; and after three years, the average yield can reach 1999.5 kg per mu, increasing by 44% over a conventional yield.

Owner:RES INST OF TROPICAL ECO AGRI SCI YUNAN ACAD OF AGRI SCI

Roof drain de-icer apparatus

InactiveUS6282846B1Prevent ice and water build-upEasy to assembleAnimal feeding devicesAnimal feeding stuffAdhesive beltEngineering

A sleeve-like container fabricated from a waterproof material, comprising an upper and lower surface with a hollow interior filled with salt. At least a portion of the lower surface is perforated with a plurality of openings and is positioned with the lower perforated surface in contact with the upper surface of a flat, sloped roof to provide wicking absorption of water flowing down the roof into the salt. Absorption of water by the salt and leads to release of the resulting saline solution through the perforated openings to the surface of the roof, preventing formation of ice on the roof downstream of the plastic sleeve and in the roof drain. The waterproof container with the packed salt is, preferably, secured to the surface of the roof by an adhesive tape, or a weight attached to or lying upon opposite ends of the container. In another embodiment, the de-icer is a solid block of a pressed, granulated salt having a top portion water-proofed to prevent rapid deterioration due to precipitation.

Owner:BILL PATTON SKYLIGHTS INC T A ERICK IND

Composition for decreasing lost circulation during well operation

InactiveUS20060079408A1Reduce circulationIncrease in sizeFluid removalFlushingLost circulationAbsorption of water

A method is provided for reducing lost circulation when aqueous, oil, or synthetic based drilling fluid is used. The method includes injecting two fluids into the well bore and lost circulation zone. The first fluid is an aqueous liquid containing at least one polymer capable of absorbing water in an alkaline environment. The aqueous liquid has a pH that inhibits at least one polymer from absorbing water. The second fluid contains a hardening composition in a base fluid having a pH sufficient to increase the pH in situ to allow at least one polymer to absorb water and expand with the absorbed water and substantially increase in size to close off the lost circulation zone and allow the hardening composition to create a plug in the well bore and set up.

Owner:TURBO CHEM INT

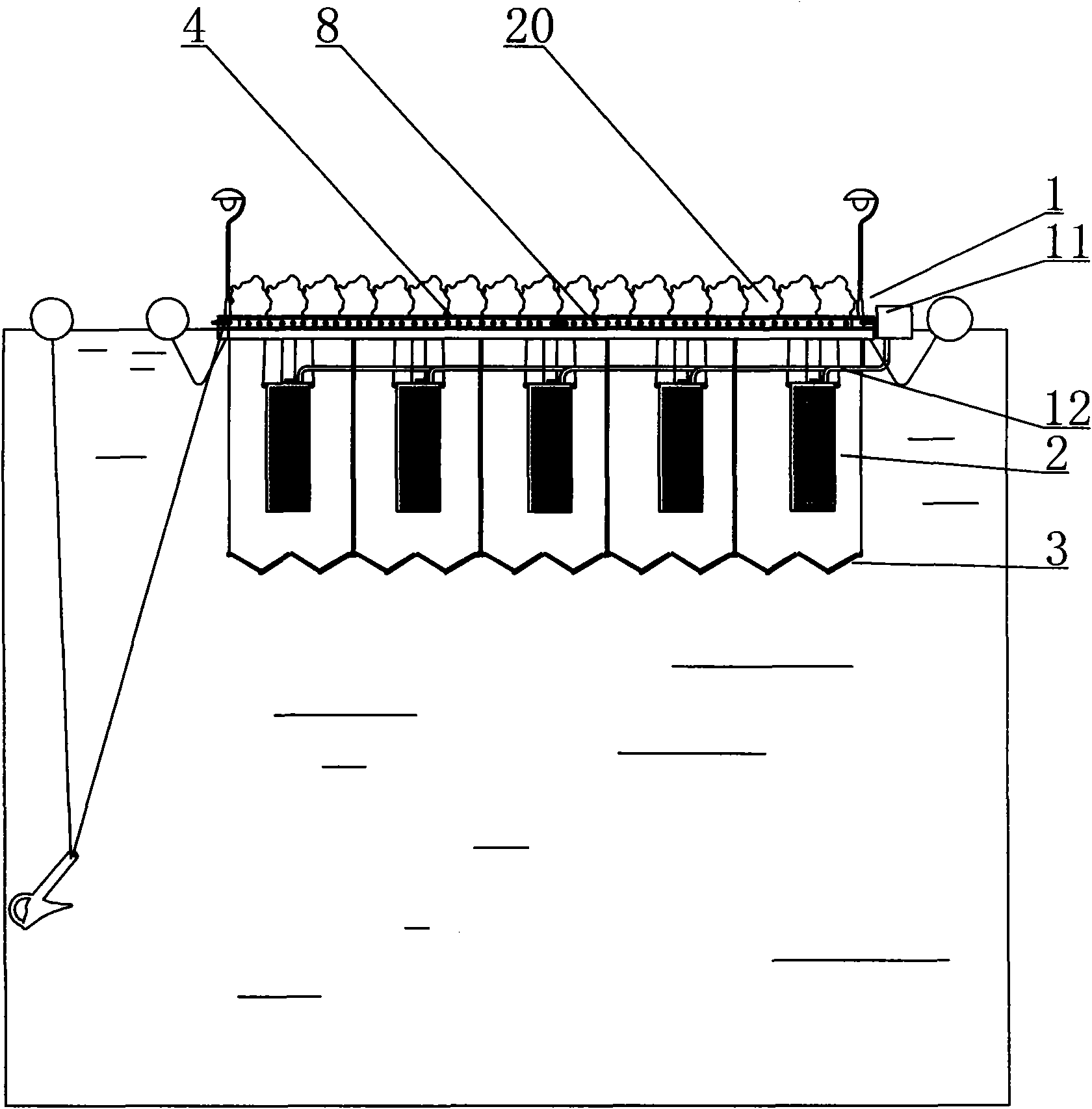

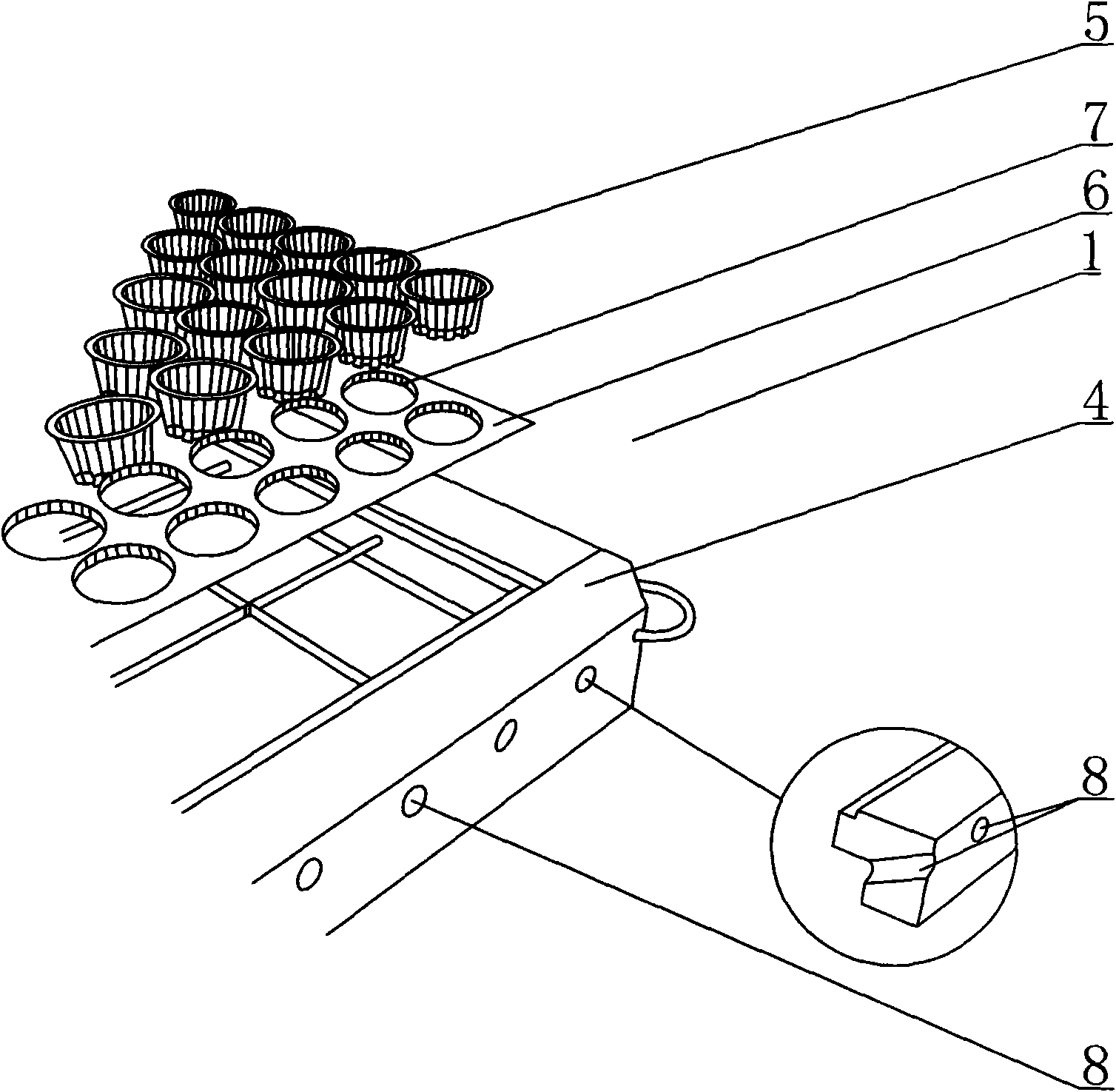

Device and realization method capable of efficiently recycling aquiculture

InactiveCN101830561AImprove digestion and absorptionImprove meat qualityClimate change adaptationEnergy based wastewater treatmentHuman wasteAquatic product

The invention discloses a device and a realization method capable of efficiently recycling aquiculture. The device comprises a plant growing floating bed, a microbial cultivation middle layer and a bottom layer sounding board, wherein the plant growing floating bed is arranged on a water surface and can absorb excrement of fishes, nitrogen and phosphorus in water; the microbial cultivation middle layer is arranged in water below the plant growing floating bed and can purify sewage; and the bottom layer sounding board is arranged below the microbial cultivation middle layer, is matched with the microbial cultivation middle layer and effectively degrades various contaminants in the sewage. The device and the realization method capable of efficiently recycling the aquiculture have good water purifying effect and low cost in the aquiculture, well take advantages of a large amount of harmful substances, ammonia and hydrogen sulfide generated in the water, improve the digestibility of aquatic products, reduce diseases and death rate, and improve the growth rate and meat quality of the aquatic products.

Owner:江声

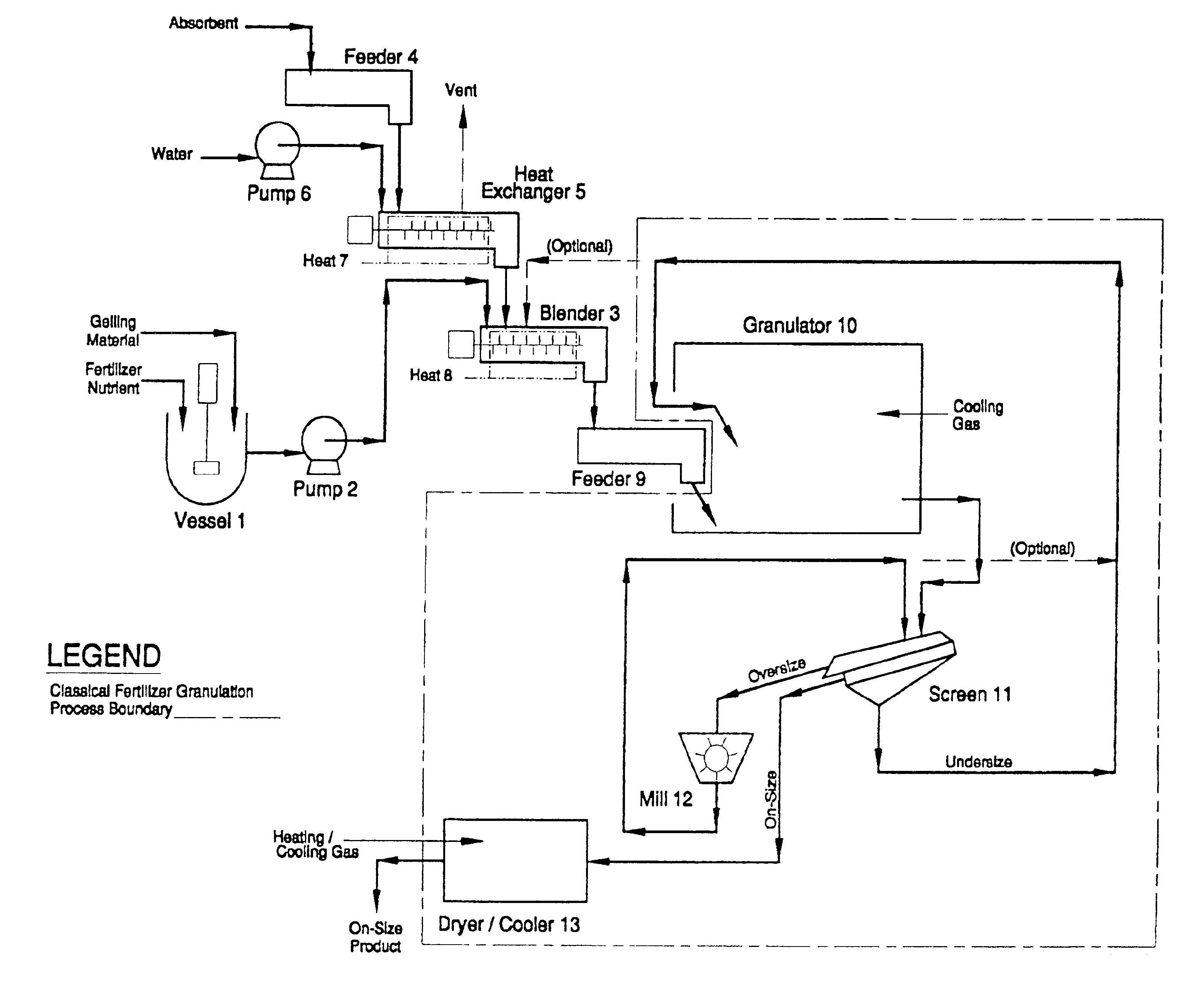

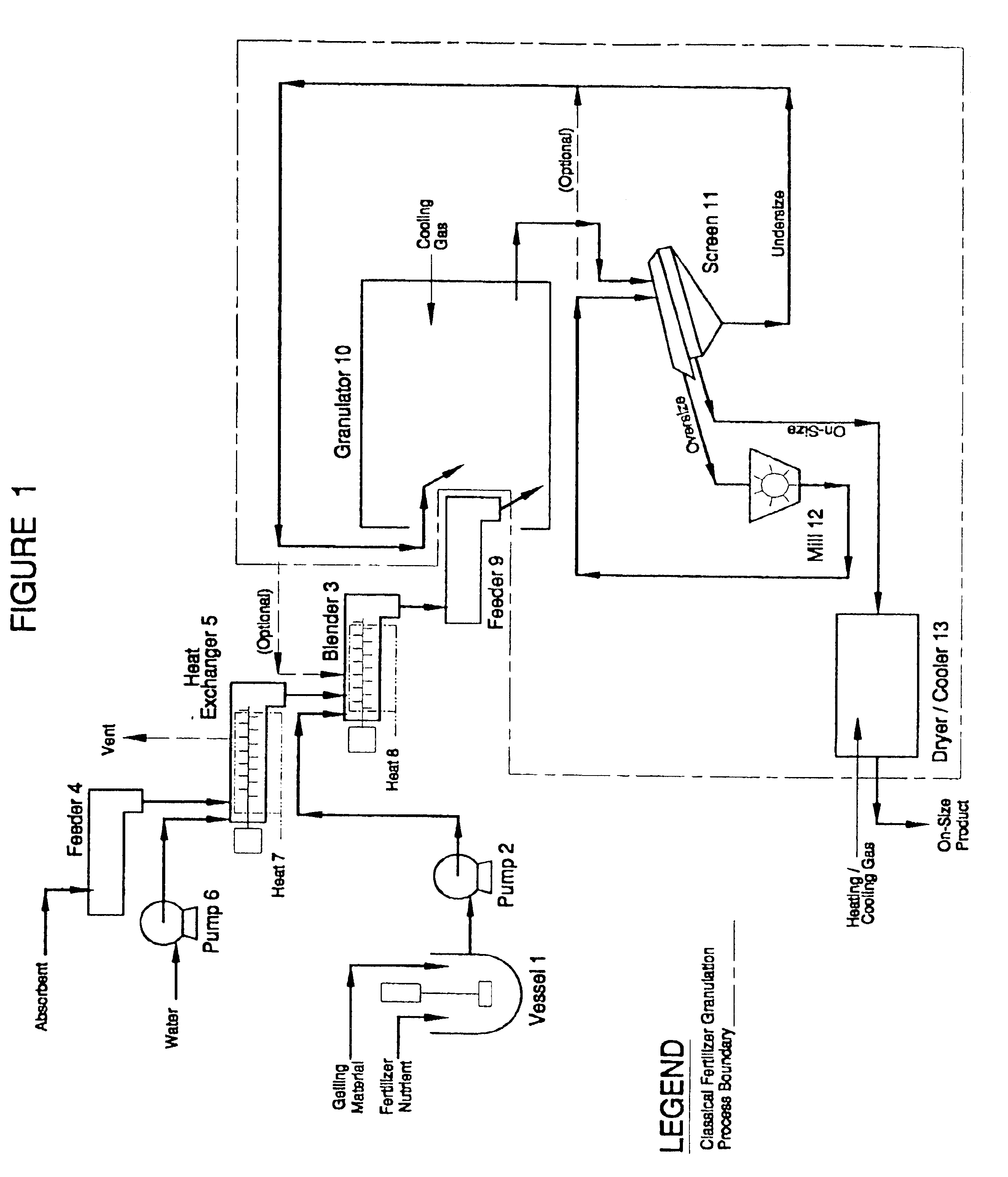

Controlled release agricultural products and processes for making same

Owner:NEW FERTILIZER TECH LLC

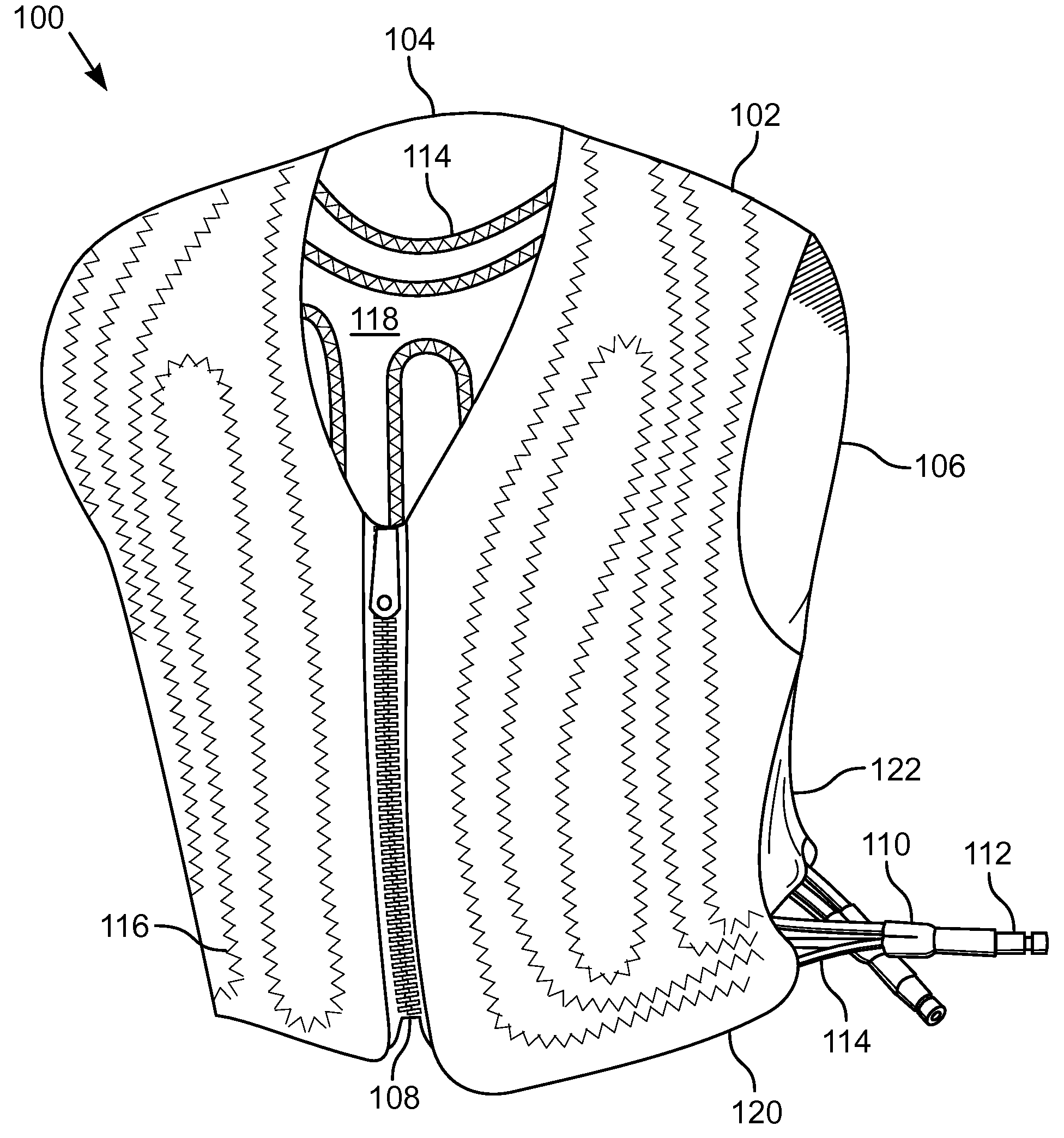

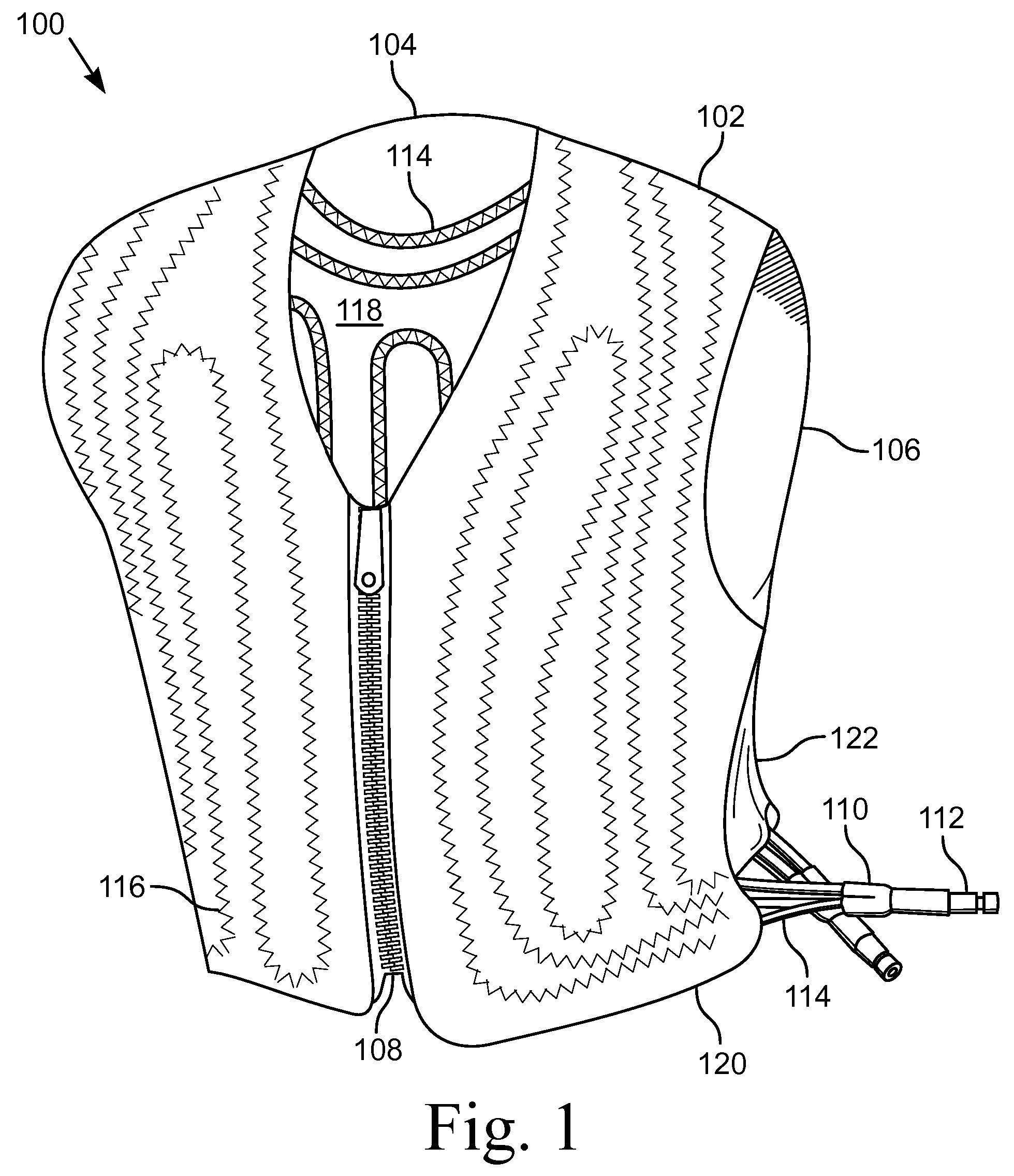

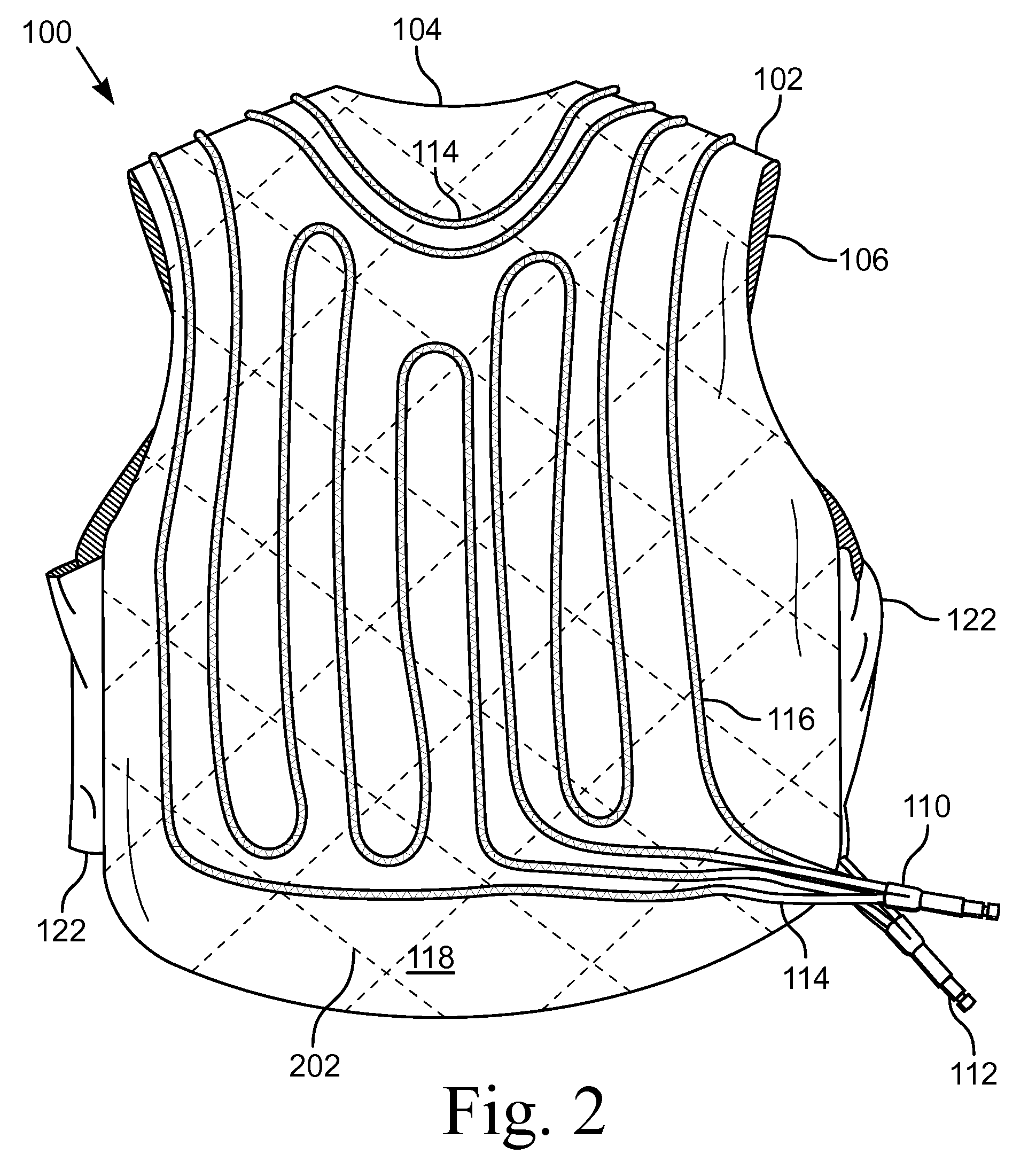

Multi-mode cooling garment

InactiveUS20090264969A1Longer lasting and more rapid cooling of a personReduce temperature differenceTherapeutic coolingTherapeutic heatingLiquid waterEvaporation

Apparatus for cooling a person in extreme environments. The apparatus includes a garment having a vest with attached tubing. The vest includes an evaporative cooling device and the tubing is configured to circulate chilled water. The vest includes a material that is able to receive and absorb an amount of liquid water with a mass greater than the material. When liquid water is applied to the vest, the vest absorbs the water for later evaporation. The tubing enables the garment to have a lower differential temperature between the inside surface and the outside surface, thereby reducing the rate of evaporation, which enables the passive cooling to be operable for an extended period of time. When the heat load does not permit the differential temperature to be reduced, the tubing removes additional heat, thereby providing additional heat removing capacity beyond the passive cooling.

Owner:ADROIT MEDICAL SYST

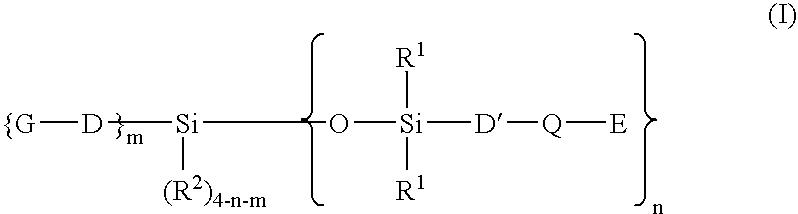

High refractive-index, hydrophilic, arylsiloxy-containing macromonomers and polymers, and ophthalmic devices comprising such polymers

Owner:BAUSCH & LOMB INC

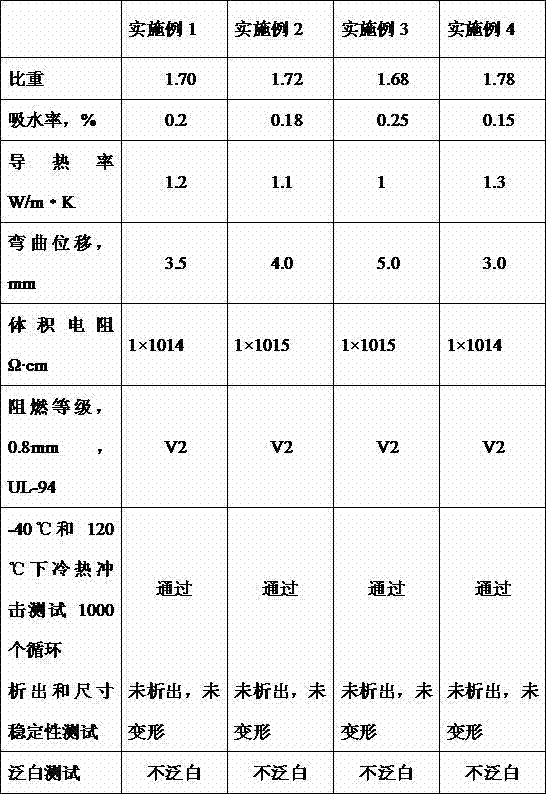

Long-carbon-chain heat-conducting nylon composite material and preparation method thereof

The invention relates to the technical field of macromolecular composite materials, particularly to a long-carbon-chain heat-conducting nylon composite material. The material mainly comprises the following raw materials in percentage by mass: 20-40% of long-carbon chain nylon resin, 30-50% of heat-conducting filler, 5-20% of reinforcing filler, 5-20% of a halogen-free flame retardant, 0.1-0.5% of a coupler, 0.4-1.0% of a lubricant, 0.1-0.5% of an antioxidant and 0.1-5% of toner. A preparation method comprises the following steps: weighing the raw materials in percentage by mass according to the formula; mixing the long-carbon-chain nylon resin with the coupler in a mixed cylinder; then, adding the antioxidant and mixing again; then adding the heat-conducting filler, the halogen-free flame retardant, the lubricant and the toner and mixing again; and finally fusing and extruding. The prepared composite material can pass a thermal shock test over 1000 hours at (-40)-120 DEG C, is low in specific gravity, low in absorption of water, high in toughness, free of separation, stable in dimension and relatively low in viscosity, and the equipment wear is reduced; particularly, when the material is used for manufacturing a gray workpiece, the surface of the workpiece is not whitened.

Owner:GUANGDONG SILVER AGE SCI & TECH CO LTD

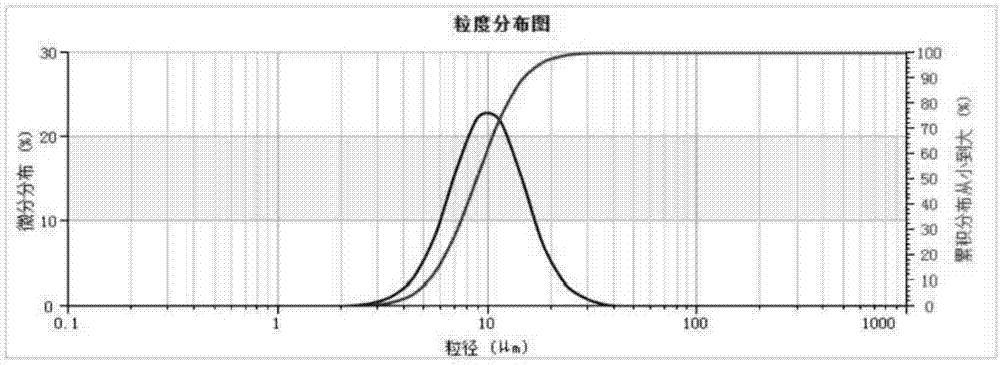

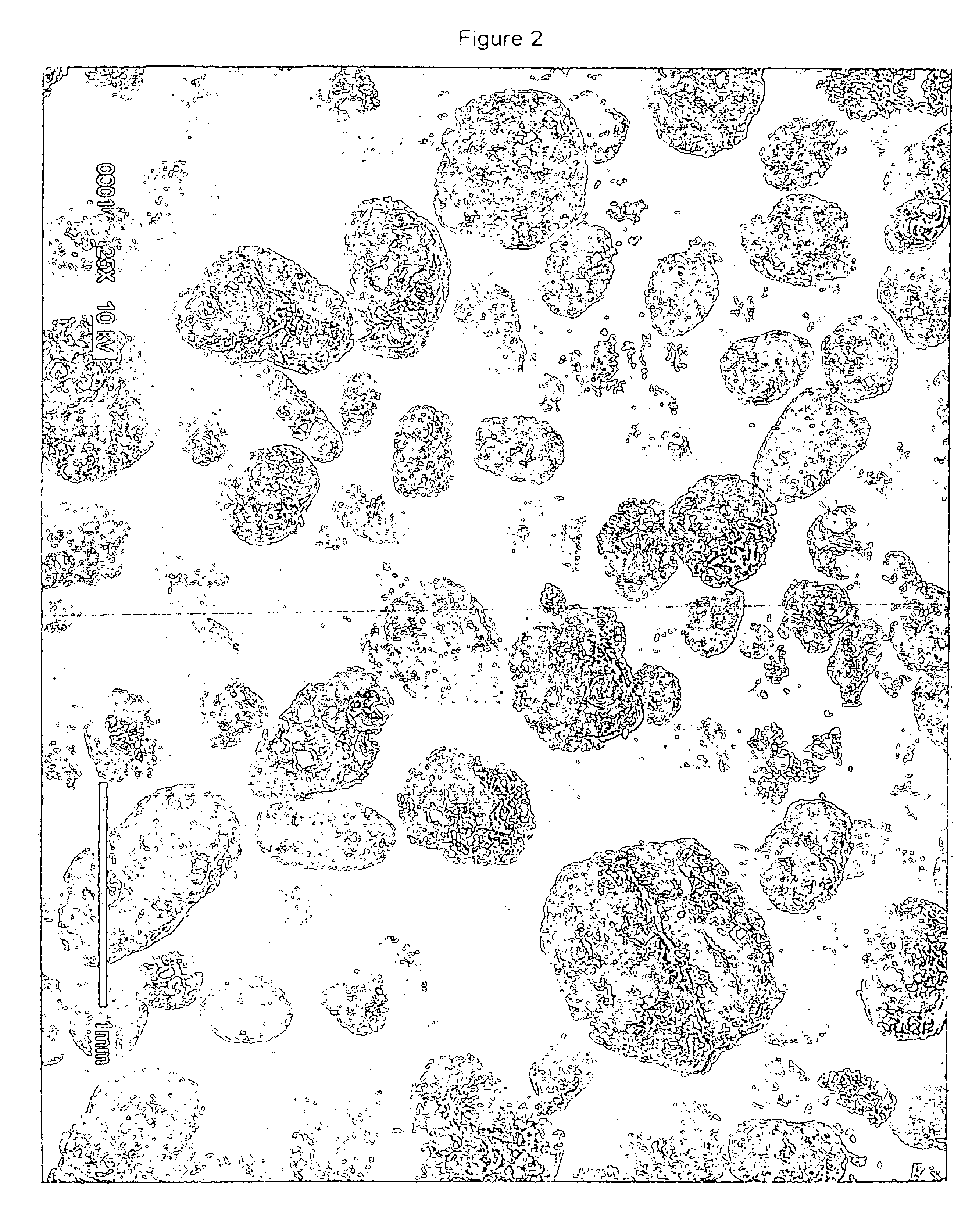

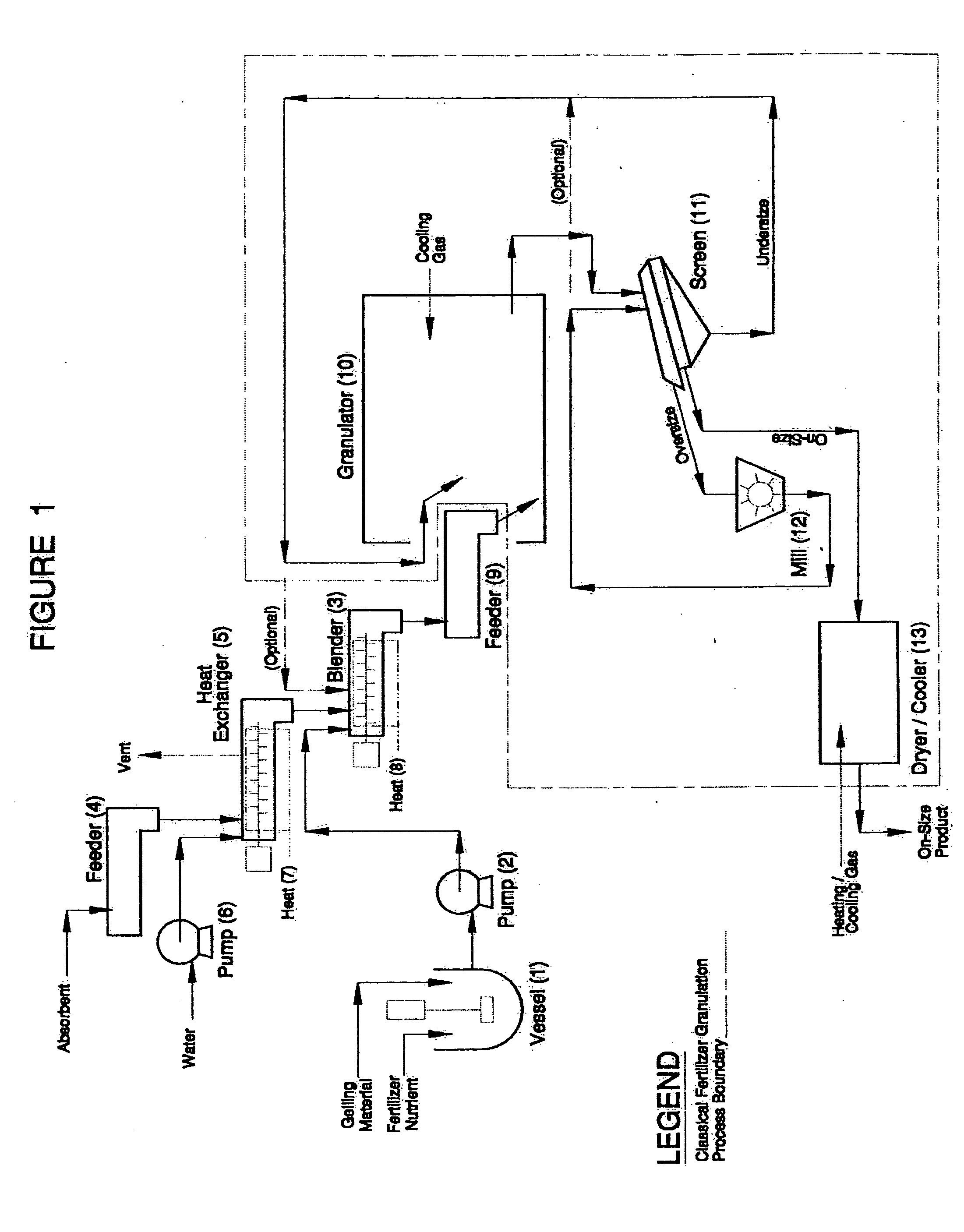

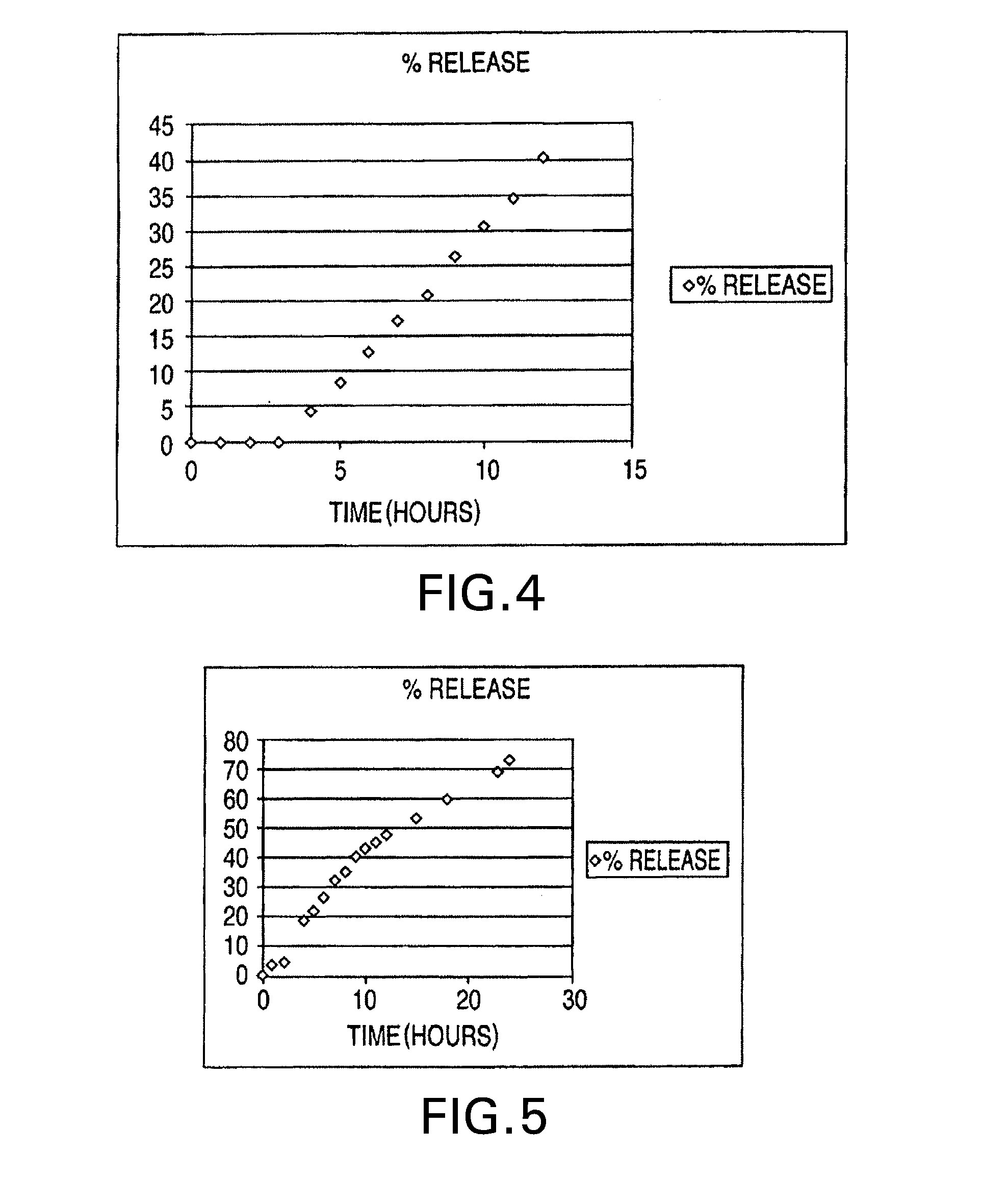

Controlled release fertilizers employing ureaform compounds and processes for making same

A controlled release agricultural absorbent based product including particles of an absorbent material containing capillaries / voids between 10-200 microns in cross-sectional diameter which is impregnated in an amount of 40-95% of the capillaries / voids volume with an agriculturally beneficial material, at least including ureaform, and said beneficial material being selected from the group consisting of fertilizers, insecticides, herbicides and fungicides, being produced by a process including steps of 1) introducing water to particles of absorbent material to result in absorption of water within the absorbent material, 2) heating the absorbent particles and water to transform the water within the absorbent particles to steam, 3) introducing the absorbent particles to an agriculturally beneficial material, at least including ureaform, to saturate the beneficial material, 4) granulating the beneficial material and saturated absorbent particles to solidify and harden the mixture, resulting in the agglomeration of absorbent particles into granules, and drying the granules.

Owner:NEW FERTILIZER TECH LLC

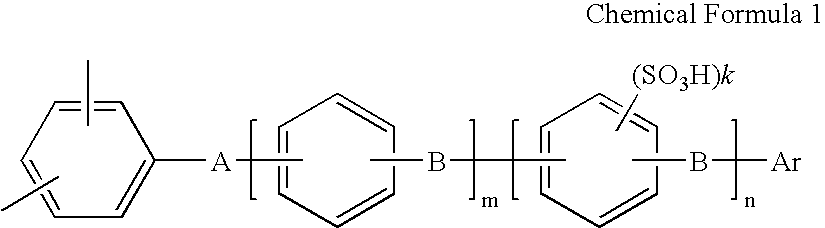

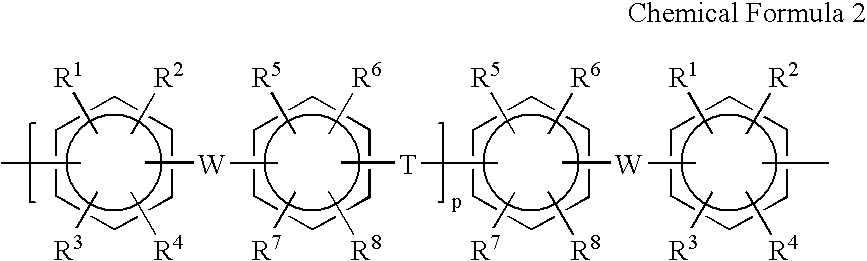

Membrane electrode assembly and polymer electrolyte fuel cell therewith

ActiveUS20050186460A1Improve power generation effectImprove featuresFinal product manufactureCell electrodesPolymer electrolytesFuel cells

A membrane electrode assembly for a polymer electrolyte fuel cell has superior power generation characteristics under low humidity conditions and superior starting characteristics under low temperature conditions. In the membrane electrode assembly for a polymer electrolyte fuel cell in which a polymer electrolyte membrane is disposed between a pair of electrodes containing a catalyst, the polymer electrolyte membrane has a polymer segment A having an ion conductive component and a polymer segment B not having an ion conductive component. Furthermore, in the case in which the polymer electrolyte membrane is immersed in water at 90° C. for 30 minutes, absorbed water which exhibits a thawing temperature of from −30 to 0° C. is in a range from 0.01 to 3.0 g per 1 g of the polymer.

Owner:HONDA MOTOR CO LTD

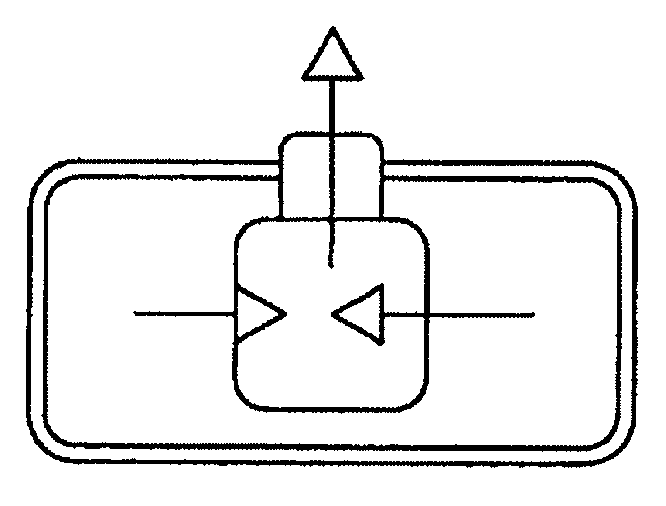

Drug delivery system for zero order, zero order biphasic, ascending or descending drug delivery of methylphenidate

InactiveUS20100151020A1Slow drug releaseEasy to reachBiocideNervous disorderMethylphenidate HydrochlorideControlled release

The invention is directed to a drug delivery device for controlled release of a drug, such as methylphenidate hydrochloride. The drug deliver device has a drug core, having a plug embedded therein, and at least a first coating that at least partially surrounds the core. The plug may be hollow or solid, and swells upon absorption of water, bursting through the first coating. The drag delivery device enables zero-order drug release profiles as well as more complicated release profiles to be obtained.

Owner:TEVA PHARM USA INC

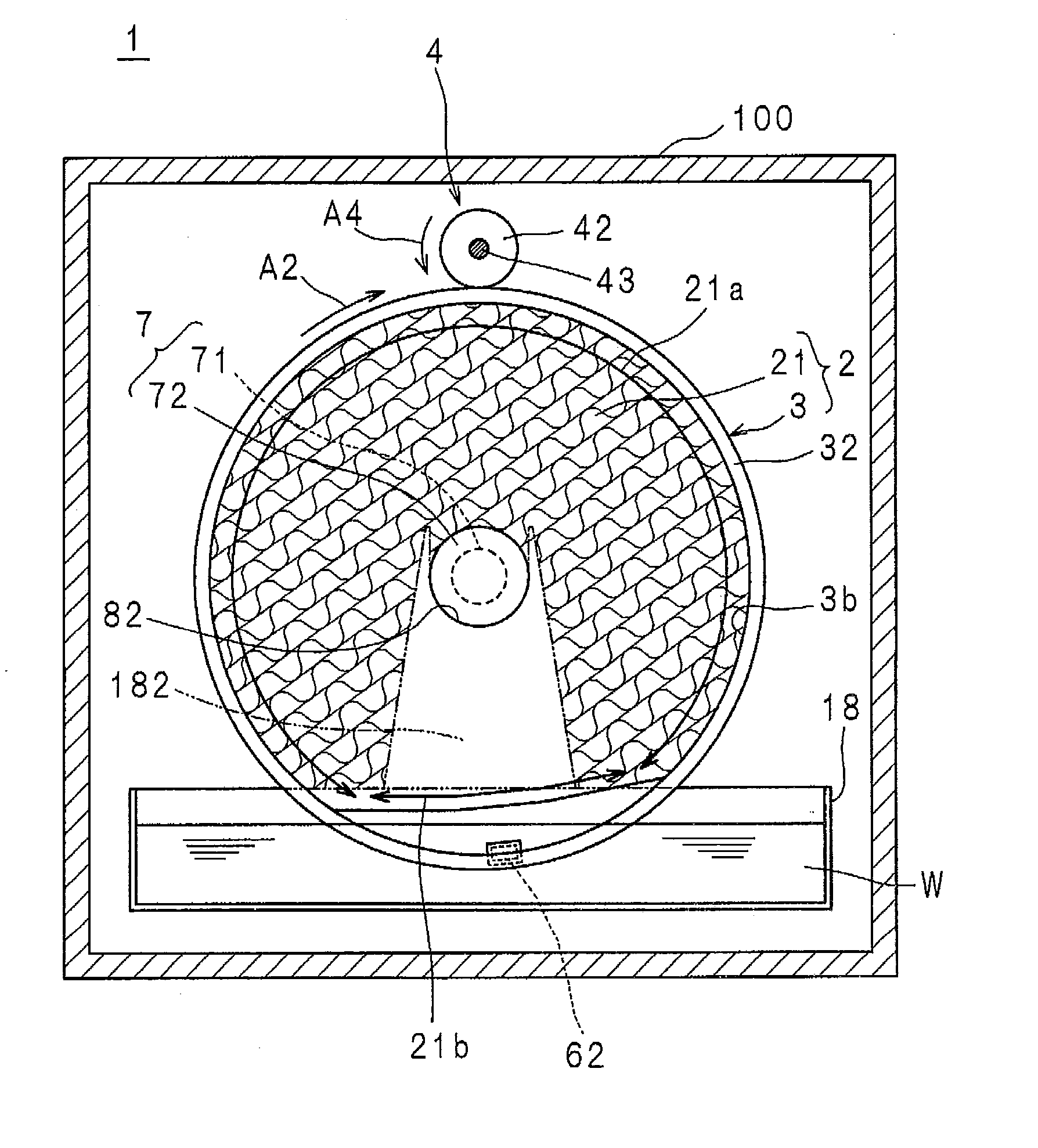

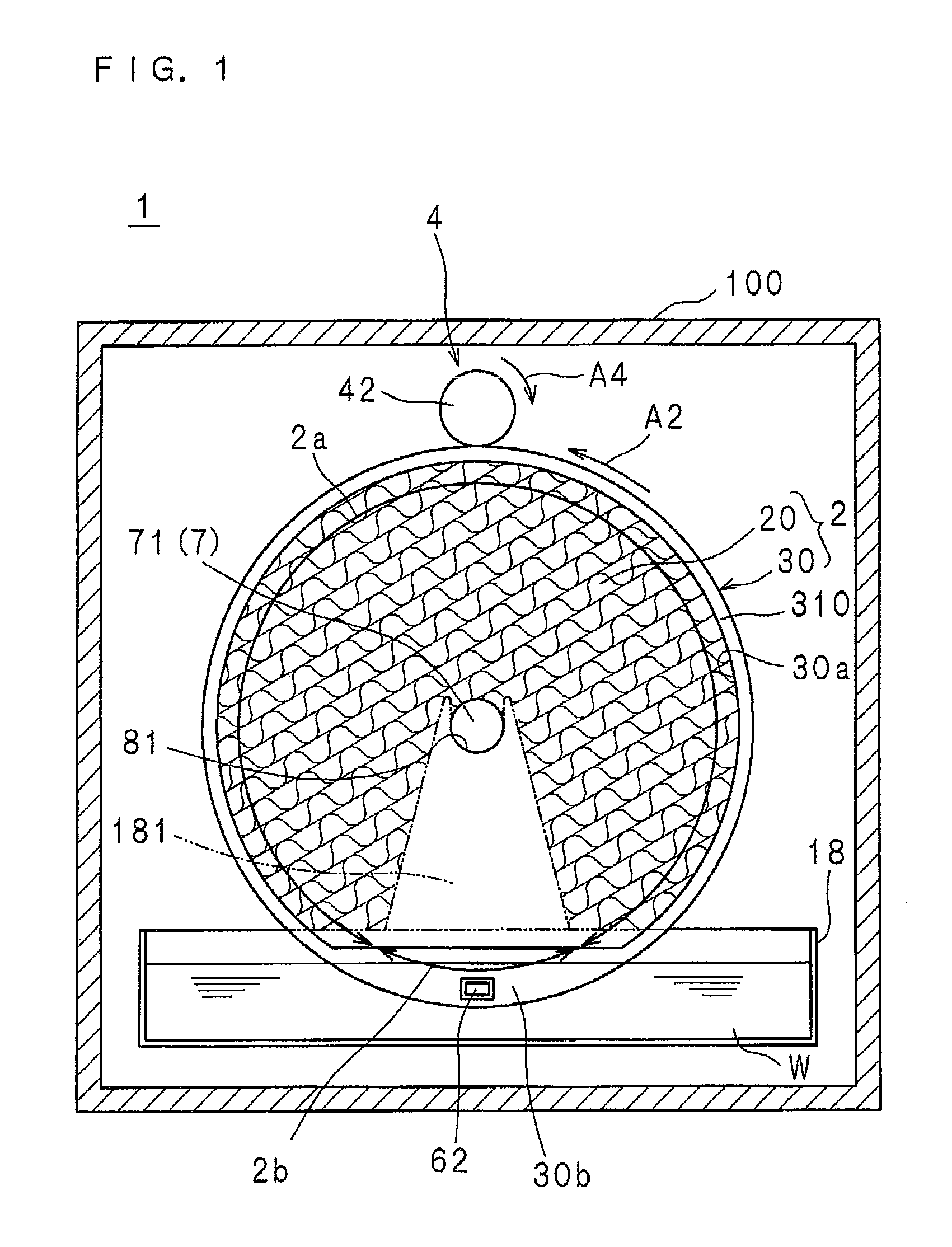

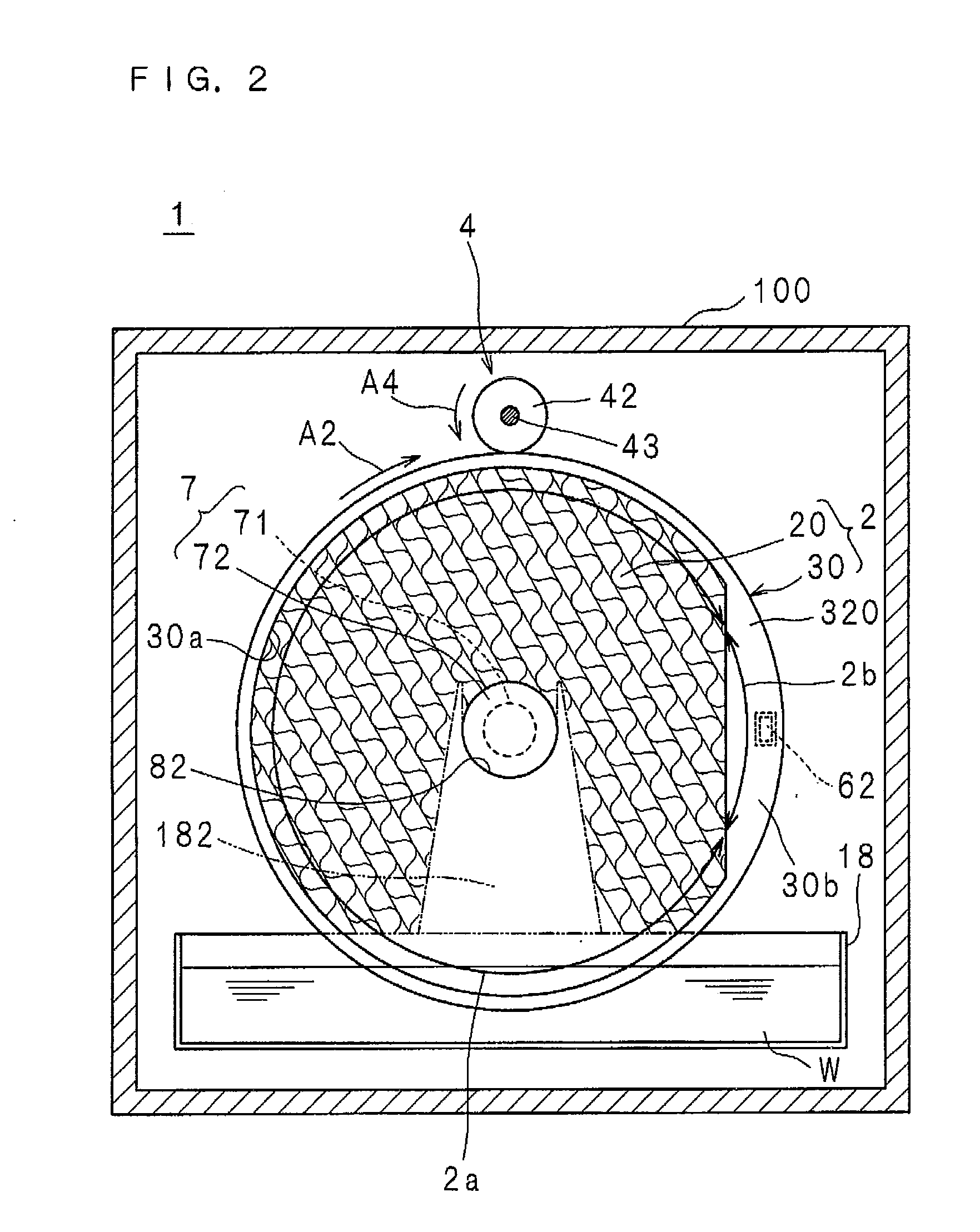

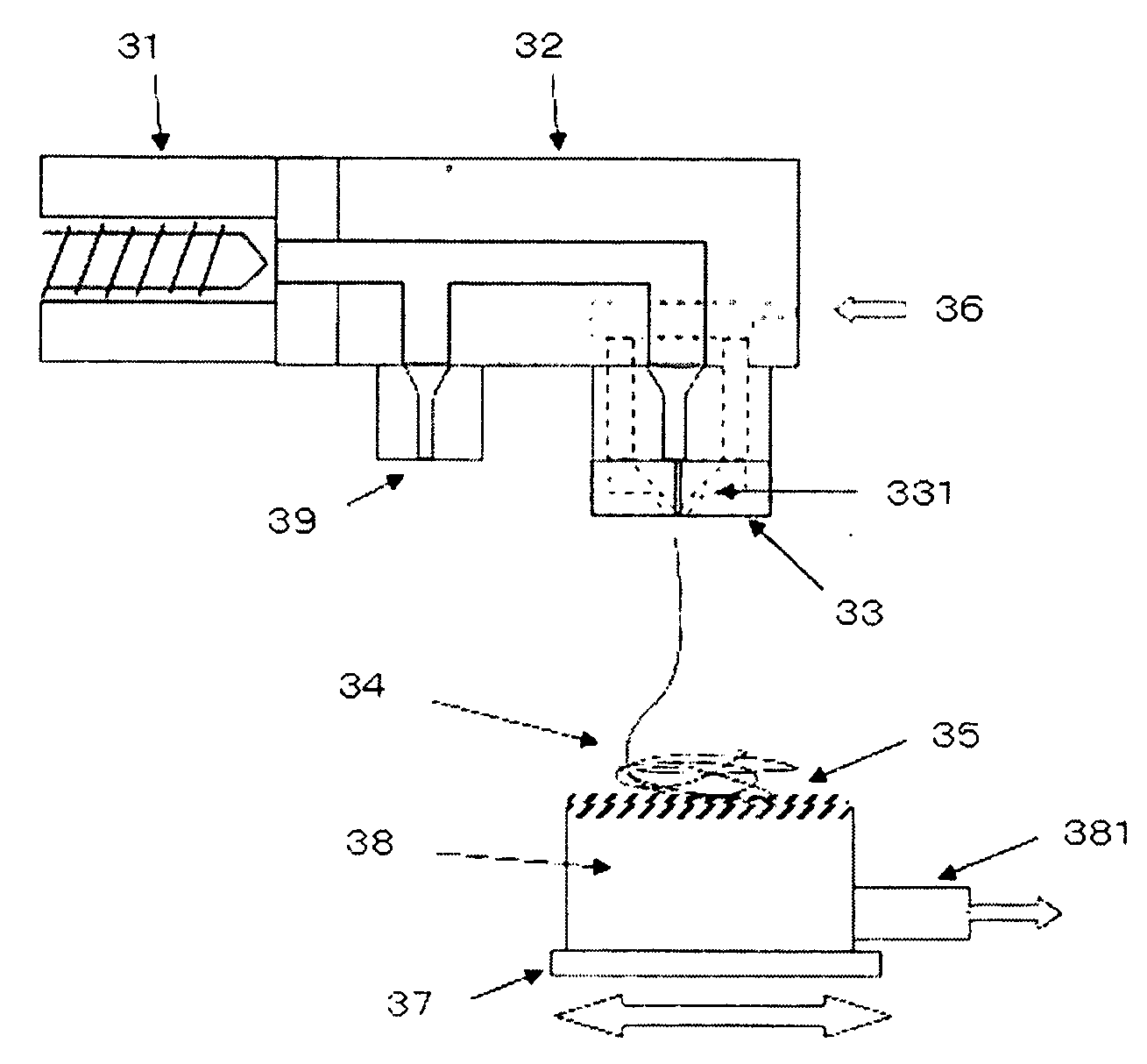

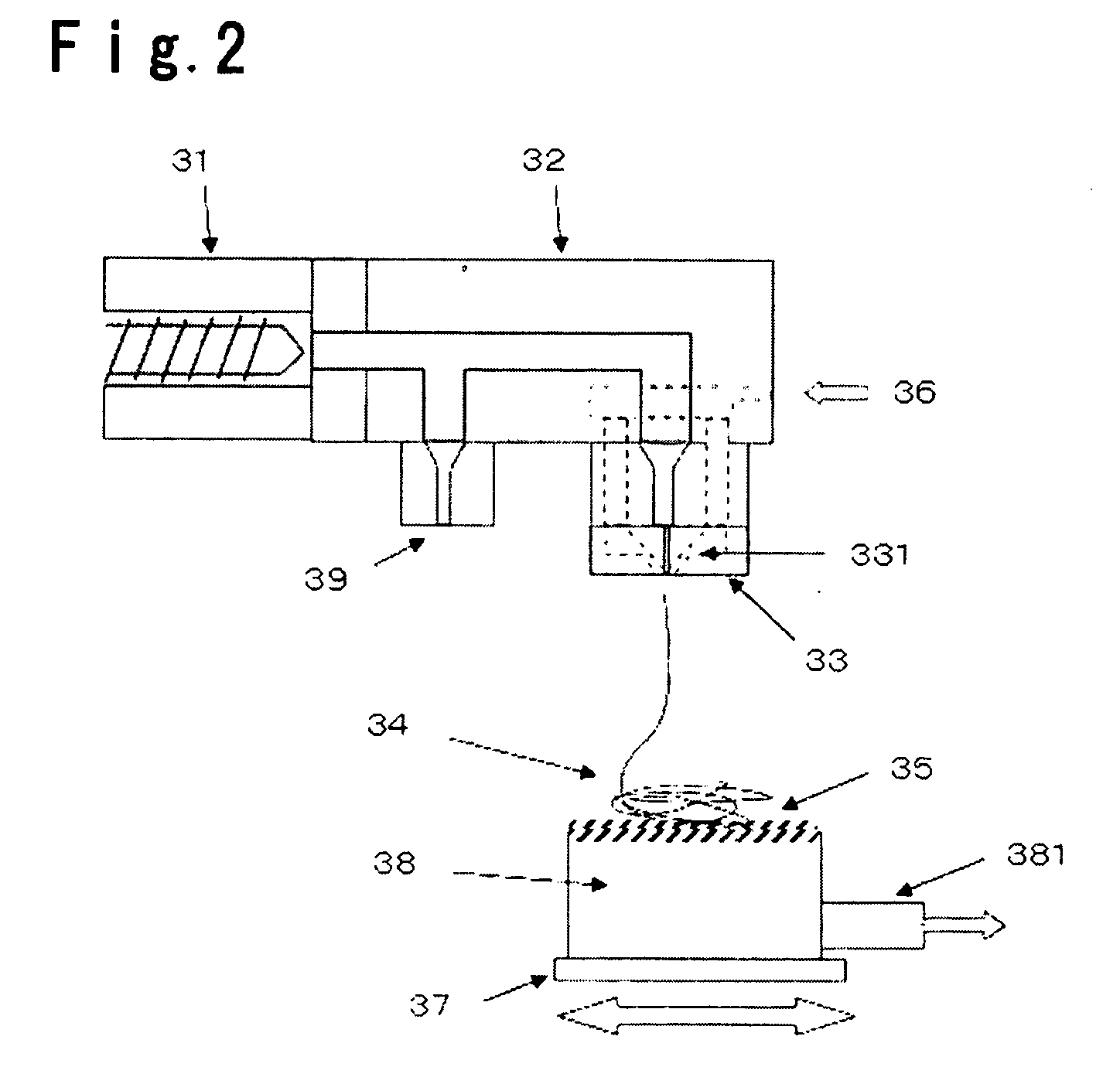

Humidifier, filter unit and rotation drive structure

ActiveUS20100201007A1Prevent water absorptionSimple structureLighting and heating apparatusMixing methodsAbsorption of waterWaste management

A disc-shaped filter unit including a filter main body having a water absorbability and a holder having a non water absorbability is disposed in a vertical orientation, with a part of a circumferential portion thereof immersed in water reserved in a water tank, and is rotated by a rotation drive mechanism in a circumferential direction. The filter unit has an absorptive region and a non-absorptive region arranged adjacent to each other in the circumferential direction. Therefore, in accordance with rotation of the filter unit in the circumferential direction, a state where the absorptive region is immersed and the filter main body of the filter unit absorbs water through a water-conduction hole and a state where the non-absorptive region is immersed and water absorption of the filter main body is prevented by a watertight section having a non water absorbability are continuously alternated.

Owner:SHARP KK

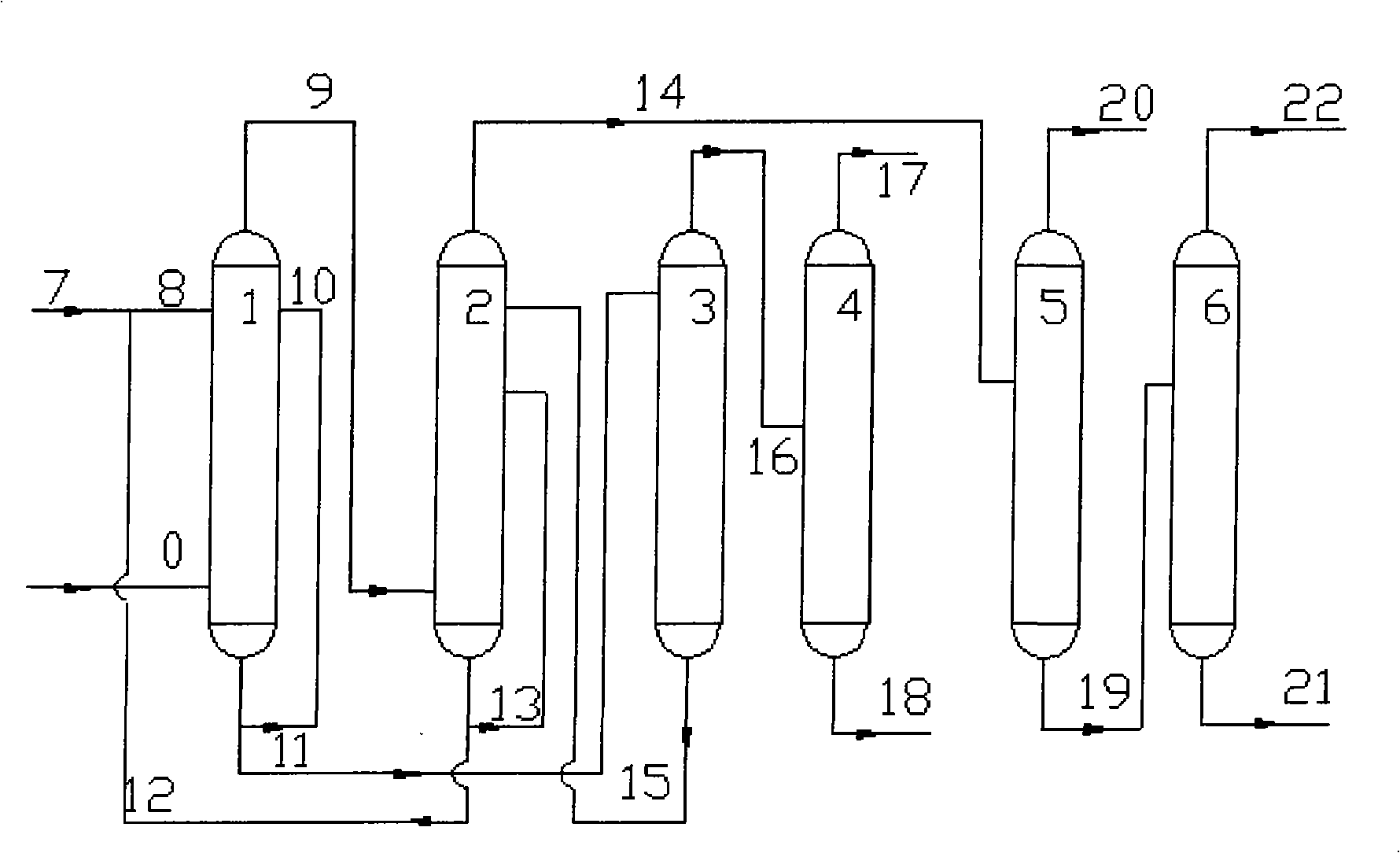

Refining device for preparing high-pure isobutene by cracking methyl tertiary butyl ether and technique thereof

InactiveCN101260016AHigh purityImprove mass transfer efficiencyHydrocarbon from oxygen organic compoundsWater dischargeTower

The invention discloses a refining device and a technical method used to make high-purity isobutene through the cracking of methyl tert-butyl ether. The technical method contains a six-tower continuous rectification technical process, and comprises a cooling absorption double tower system, a methanol dehydrating tower system, a methanol refining tower system, an isobutene light fraction-removal tower system and an isobutene heavy fraction-removal tower system, wherein the water discharged from the methanol dehydrating tower system is cooled down and then is returned to a cooling absorption tower to undergo cooling absorption operation once again; therefore, the refining process realizes zero release of cooling absorption water; moreover, the internal top of a cooling absorption tower 2 is provided with a foam destroyer which catches the liquid droplets carried in gas, thereby ensuring the purity of isobutene product. All internal parts of each rectification tower device adopt efficient regular filler and multi-row hole distribution, which ensures that the purity of high-purity isobutene product is more than 99.7 percent.

Owner:TIANJIN UNIV

Piezoelectric element and method for manufacturing the same

InactiveCN1879230AMaintain electrical propertiesMaintain piezoelectric propertiesPiezoelectric/electrostrictive device manufacture/assemblyForce measurement using piezo-electric devicesMetallurgyAbsorption of water

A piezoelectric element is provided with a piezoelectric composition pressure sensitive body, a first electrode, a second electrode and a coat layer. The piezoelectric composition pressure sensitive body includes a piezoelectric ceramic powder and a flexible organic polymer. The first electrode and the second electrode are connected with the piezoelectric composition pressure sensitive body and are insulated from one another. The coat layer is provided on the outer side of the piezoelectric ceramic powder and suppresses absorption of water into the piezoelectric ceramic powder.

Owner:PANASONIC CORP

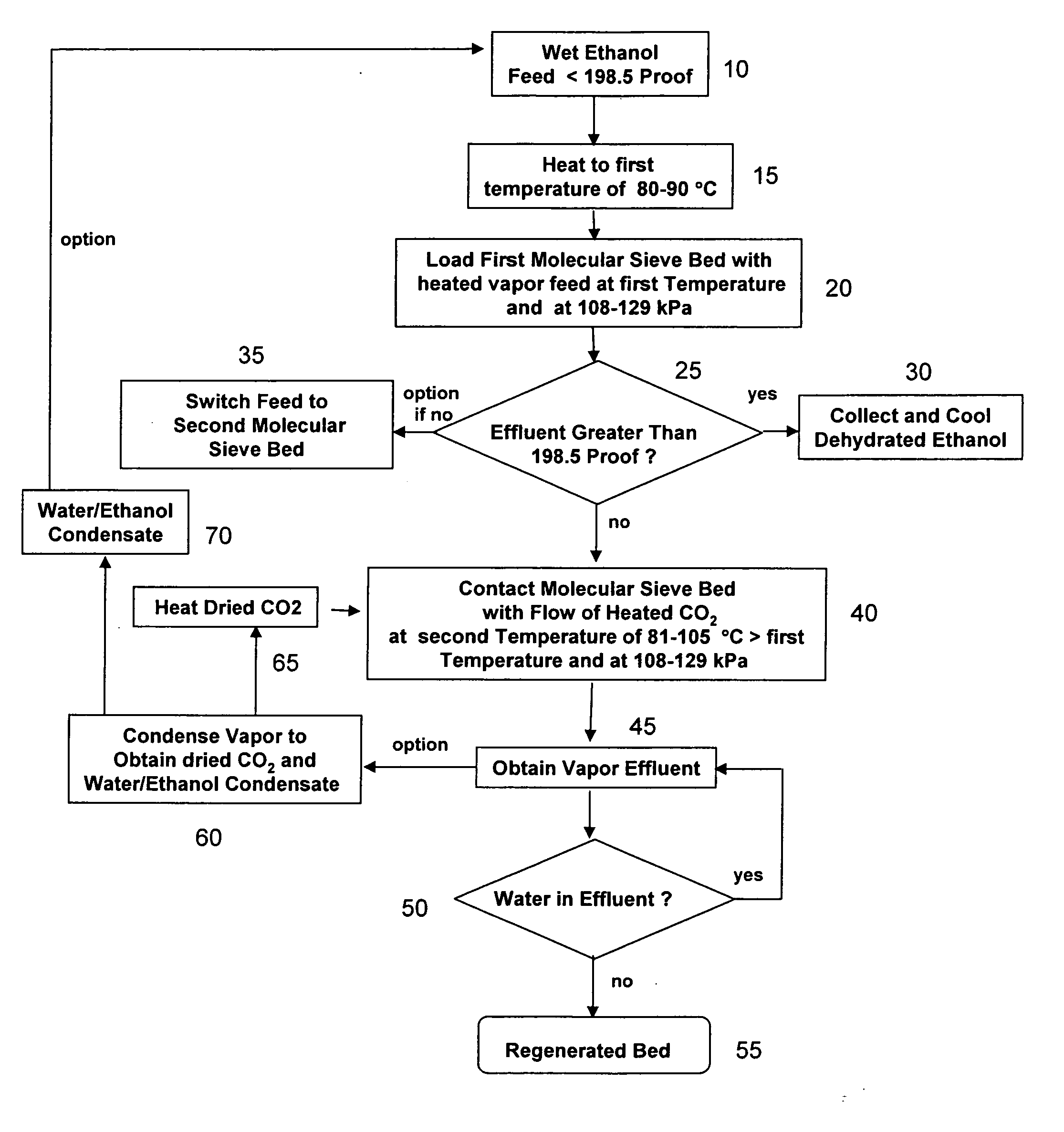

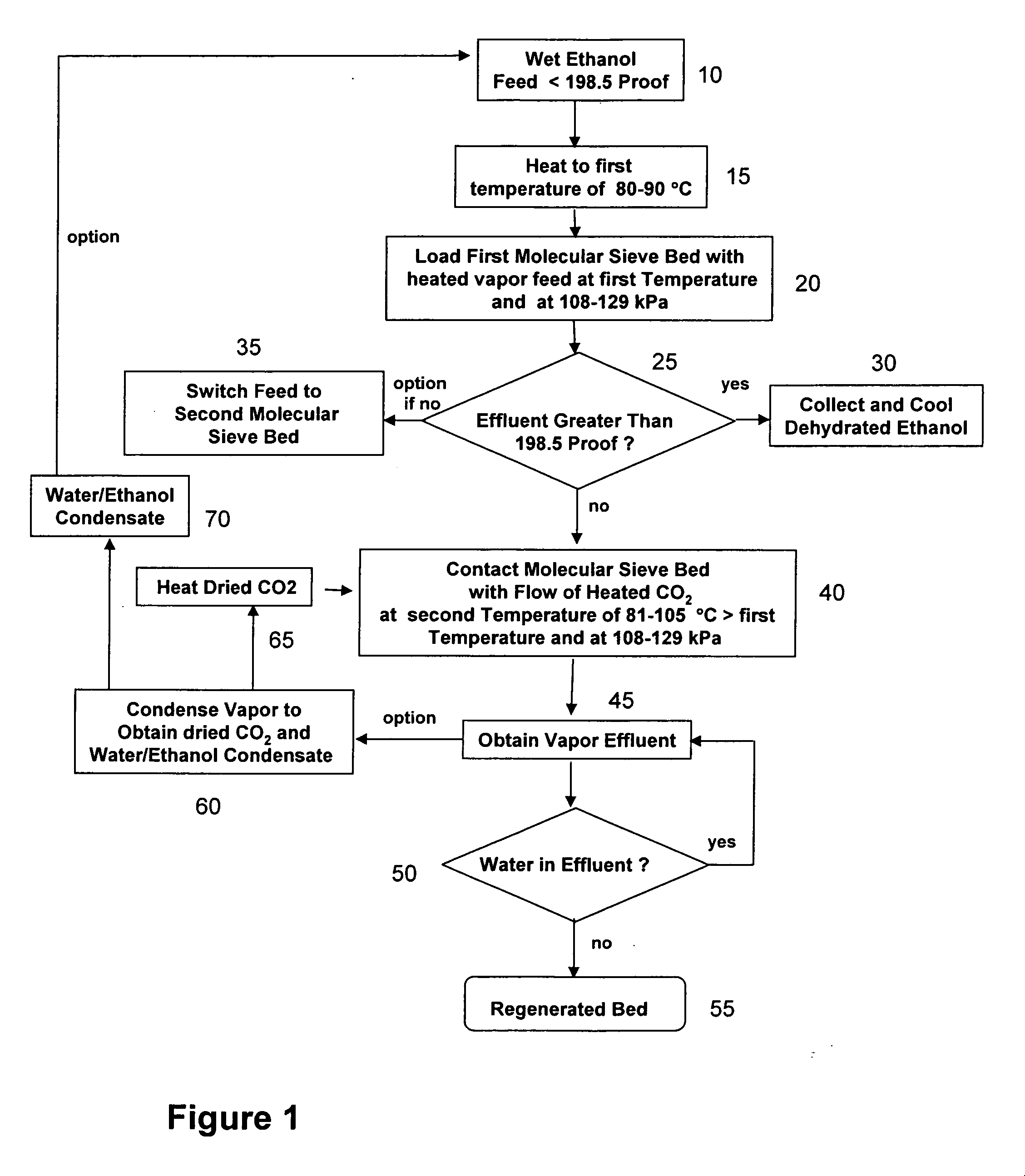

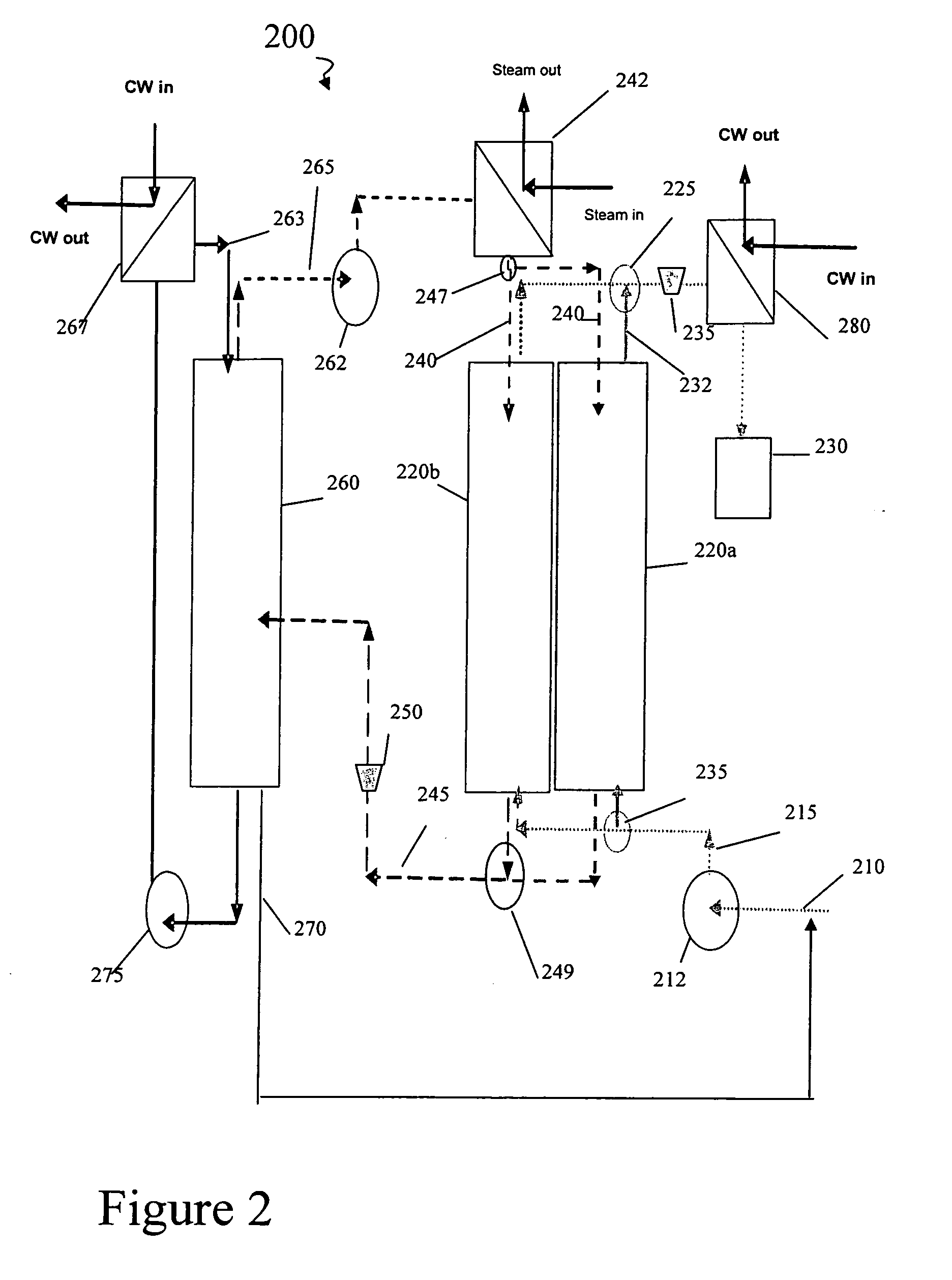

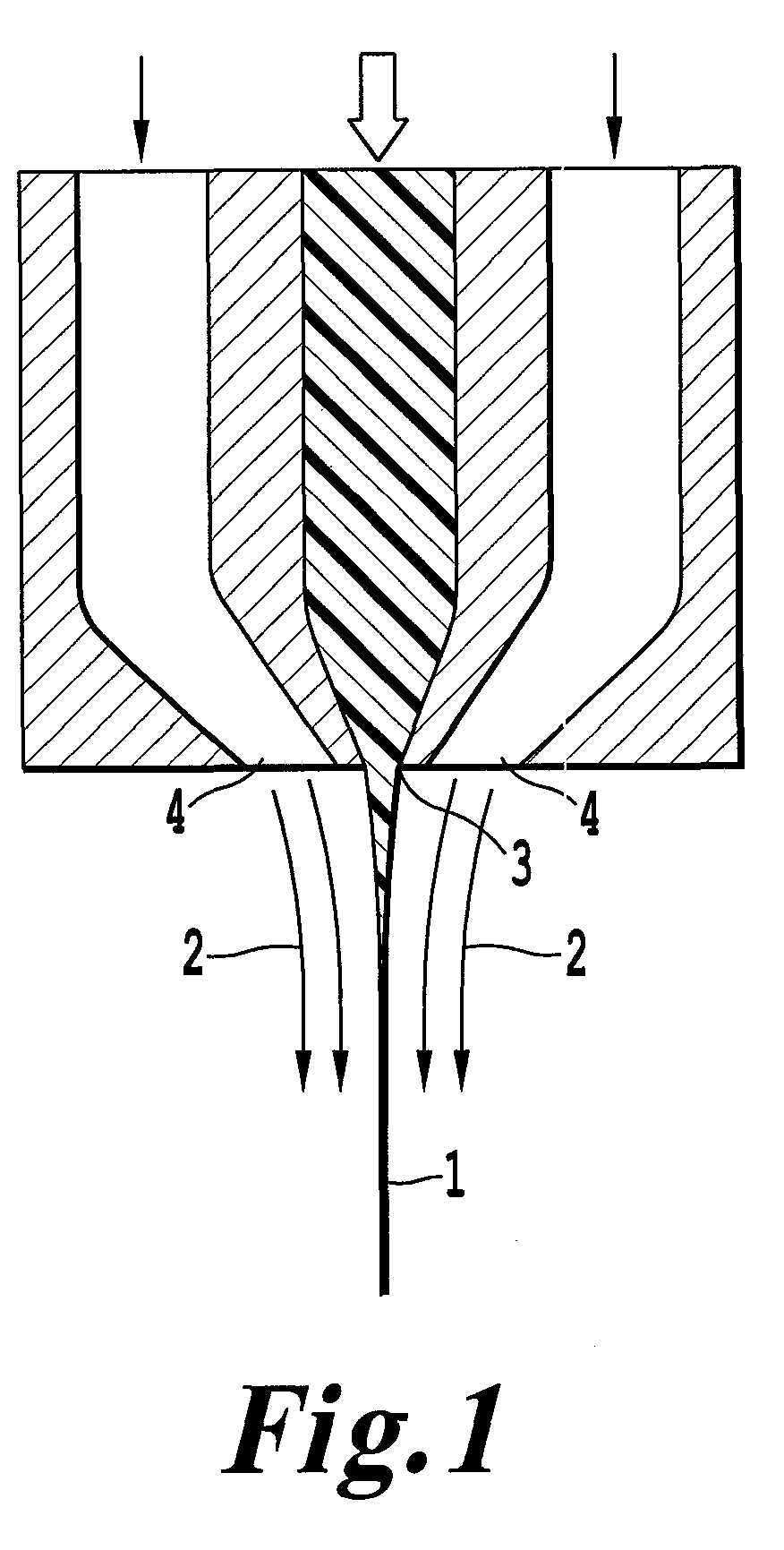

Regenerating molecular sieve absorbents used for alcohol dehydration

ActiveUS20070088182A1Accelerates the removal of moistureReduce the amount requiredMolecular sieve catalystsOrganic compound preparationMolecular sieveOrganic solvent

A process for regenerating a molecular sieve absorbent bed used for dehydrating an organic solvent is disclosed. The process is illustrated by regenerating a molecular sieve bed used for dehydrating ethanol, which includes a dehydrating cycle where an ethanol / water vapor mixture is loaded onto the molecular sieve bed at a first temperature to absorb water and recover a substantially dehydrated ethanol vapor effluent. In a regeneration cycle, the bed is subjected to a temperature swing technique whereby a dried gas, such as dried CO2, heated to at a second temperature greater than the first temperature, is passed over the molecular sieve bed, optimally in a counter current directional flow with respect to the dehydrating cycle. The process obviates the need for applying a vacuum pressure swing to regenerate the molecular sieve bed. Water and residual ethanol are removed with the CO2 effluent and can optionally be condensed and combined with a feed input for a subsequent dehydrating cycle.

Owner:ARCHER DANIELS MIDLAND CO

Weighted-edge overlay article

InactiveUS20060024471A1Resistant to stainsSecurely holdTravelling rugLayered productsPolyvinyl chlorideEngineering

An overlay article for overlaying an object surface is provided. In one embodiment, the overlay article includes: a first material panel and at least one weighted portion. The first material panel has a lower surface and an upper surface that define a perimeter region. Each weighted portion is disposed along the perimeter region. Each weighted portion is a closed cavity formed by securing a second material panel to the upper surface of the first material panel to hold a weighted material captive between the first and second material panels during normal use and maintenance of the overlay article. The weighted material is resistant to absorption of water, resistant to corrosion, and resistant to staining the first and second material panels. In another embodiment, the weighted material may be polyethylene or polyvinylchloride pellets. The overlay article may, for example, be a beach towel or a beach blanket.

Owner:CUNNINGHAM DAWN

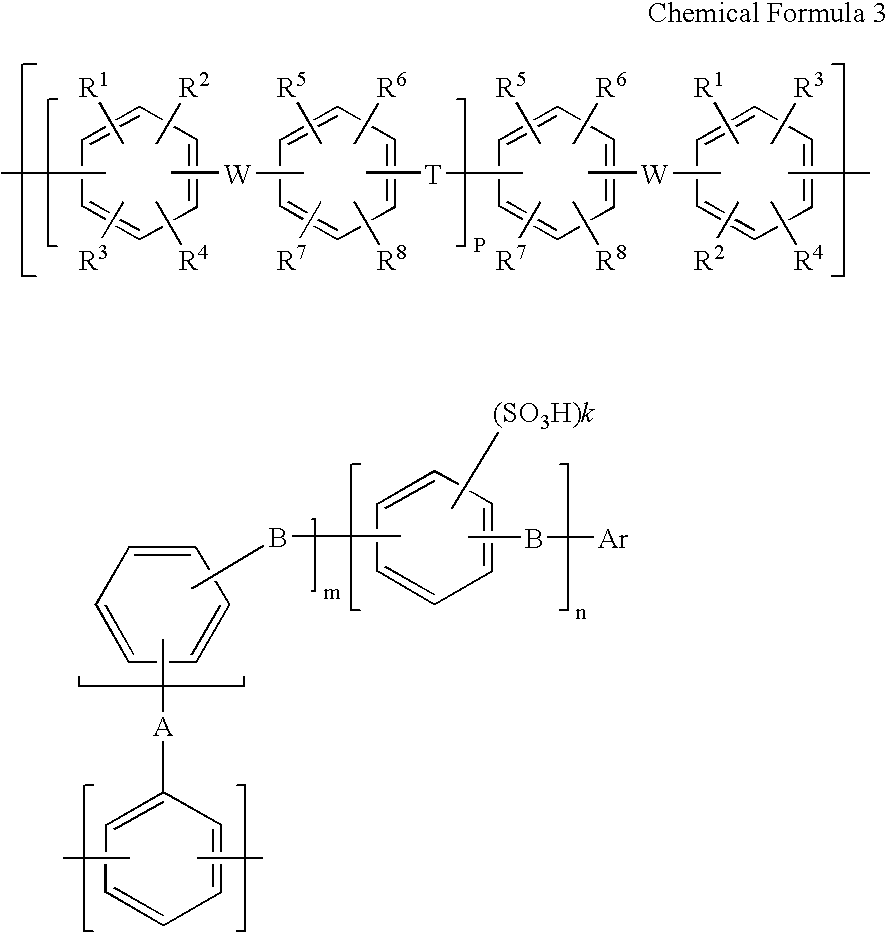

Electrolyte membrane for polymer electrolyte fuel cells, process for its production and membrane-electrode assembly for polymer electrolyte fuel cells

InactiveUS20090239123A1Good dimensional stabilityImprove proton conductivityIon-exchanger regenerationFinal product manufactureAbsorption of waterNonwoven fabric

To provide an electrolyte membrane having excellent dimensional stability even upon absorption of water, a high proton conductance and high power generation performance; and a process for producing the electrolyte membrane with a high productivity.An electrolyte membrane for polymer electrolyte fuel cells, which is made mainly of an ion exchange resin and reinforced with a nonwoven fabric made of fiber of a fluororesin wherein at least some of intersecting points of the fiber are fixed, and which has, as the outermost layer on one side or each side, a layer not reinforced, made of an ion exchange resin which may be the same as or different from the above ion exchange resin, wherein the fluororesin is an ethylene / tetrafluoroethylene copolymer having a melting point of at most 240° C., and the above fixing is fixing by fusion of the fiber.

Owner:ASAHI GLASS CO LTD

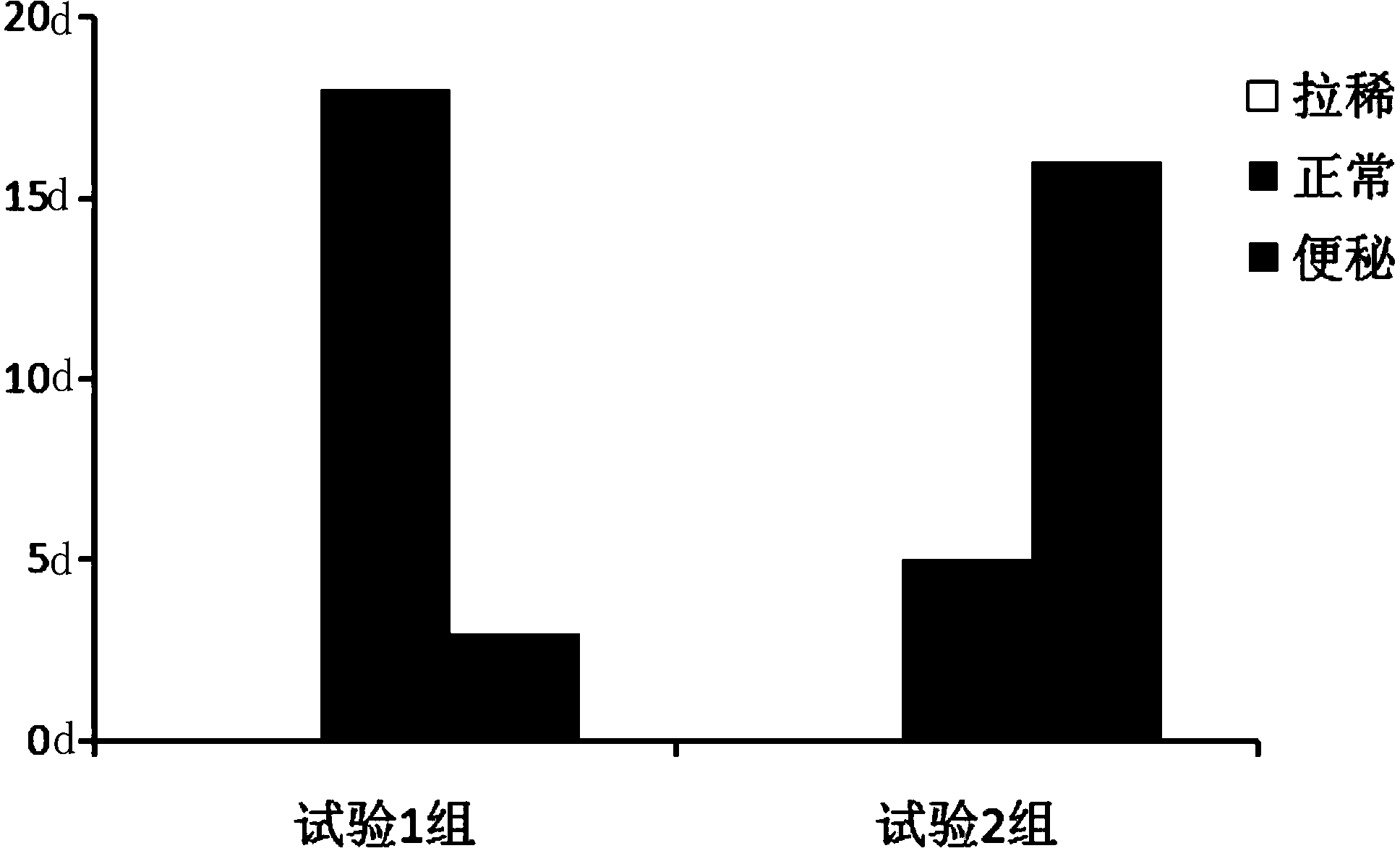

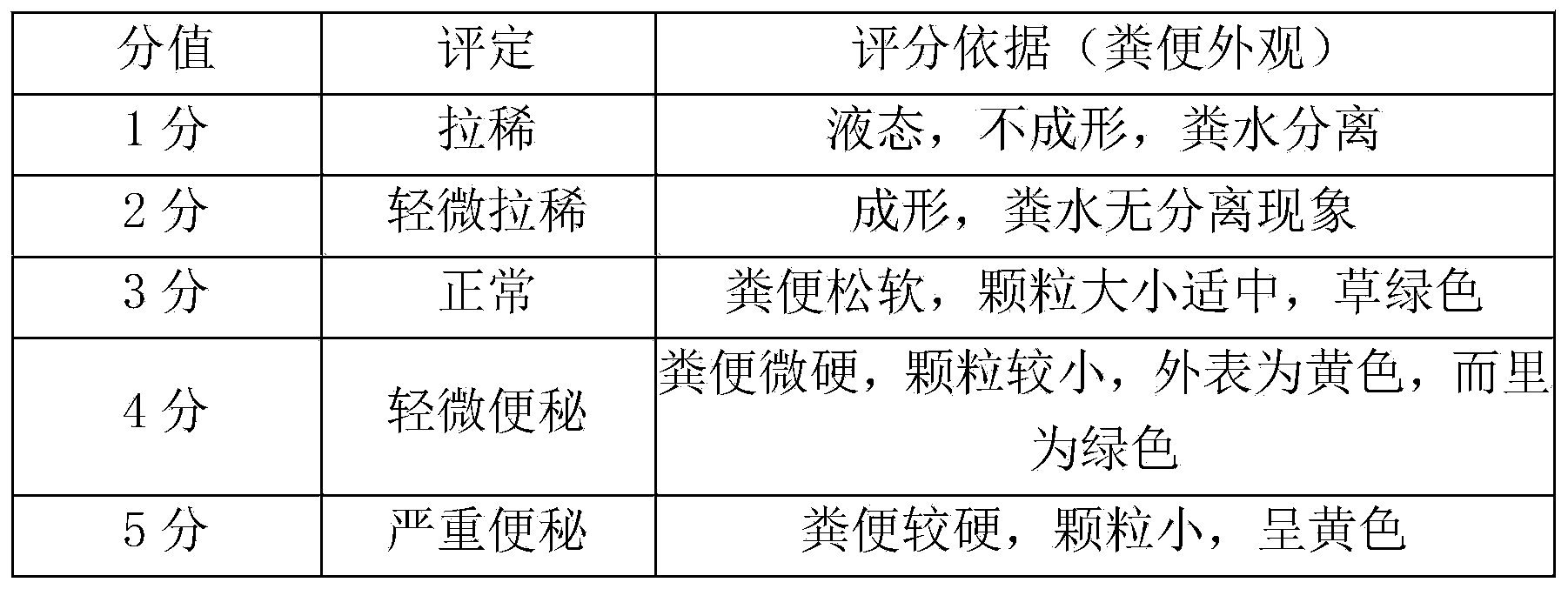

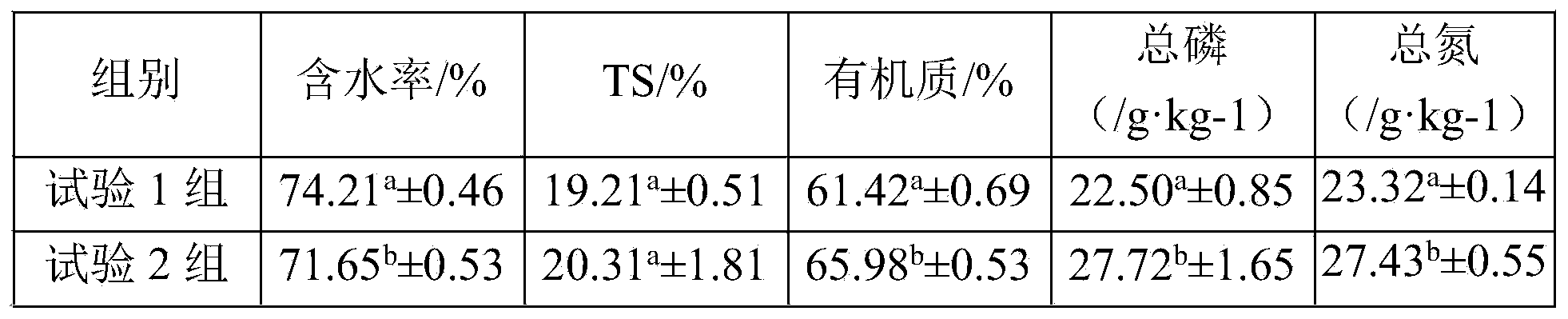

Constipation-resisting complete formula feed for sows at latter half of gestation

InactiveCN104366089AImprove digestibilityEase the burden on digestionFood processingAnimal feeding stuffL-threonineGestation

The invention provides a constipation-resisting complete formula feed for sows at the latter half of gestation. The complete formula feed is prepared from the following components: 19%-21% of corn, 10%-12% of soybean meal, 1.9%-2.5% of soybean peel, 28%-32% of wheat, 8%-12% of alfalfa powder, 13%-18% of barley, 1.5%-1.8% of soybean oil, 3%-8% of rice bran, 0.4%-0.7% of L-lysine sulfate, 0.20%-0.40% of L-threonine, 0.15%-0.20% of glycine betaine, 1.5%-2.0% of calcium hydrophosphate, 0.85%-1% of calcium carbonate, 0.01%-0.05% of sodium butyrate, 0.3%-0.5% of table salt, 0.5% of a vitamin premix, 0.3% of a microelement premix, 0.03% of a compound enzyme preparation, 0.02% of high-temperature-resisting phytase and the balance being other auxiliary additives. According to the constipation-resisting complete formula feed, the digestible rate of the feed can be increased and the digestion load of intestinal tracts is reduced; and high-quality fiber components and micro-ecological preparations are added so that the excessive absorption of water, caused by the fact that the digestion function is reduced, is avoided and the constipation of the sows at the latter half of gestation can be reduced.

Owner:SICHUAN TEQU INVESTMENT

Process for production of water-absorbent resin

A purpose of the present invention is to reduce odor of a water-absorbent resin during absorption of water. Such the invention is attained by a process for production of a water-absorbent resin by subjecting a water-soluble ethylenically unsaturated monomer to reversed-phase suspension polymerization. The process comprises the following steps (A) to (C): (A) adding an aqueous solution of water-soluble ethylenically unsaturated monomer to a petroleum hydrocarbon dispersion medium to disperse the aqueous solution in the dispersion medium; (B) adding a surfactant to the emulsion to further disperse the emulsion; and (C) performing the reversed-phase suspension polymerization using a water-soluble radical polymerization initiator, optionally in the presence of an internal-crosslinking agent.

Owner:SUMITOMO SEIKA CHEM CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com