Piezoelectric element and method for manufacturing the same

A technology for piezoelectric elements and manufacturing methods, which is applied to the manufacture/assembly of electrical elements, piezoelectric/electrostrictive devices, piezoelectric devices/electrostrictive devices, etc., and can solve the problems of reduced tensile strength, reduced resistance, complex Detect problems such as circuits to achieve the effect of inhibiting moisture absorption and maintaining electrical characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

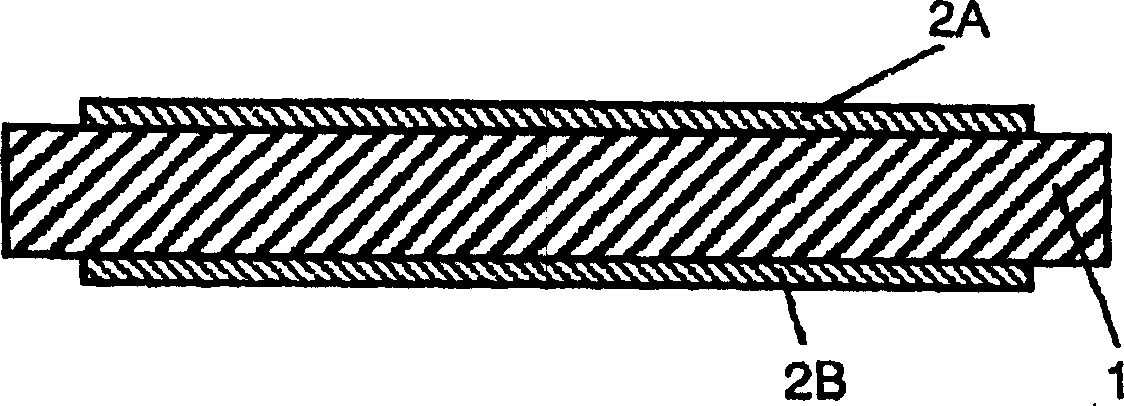

[0036] figure 1 It is a cross-sectional view of the chip piezoelectric element according to Embodiment 1 of the present invention. In the piezoelectric element, an electrode 2A as a first electrode and an electrode 2B as a second electrode are formed on both surfaces of a sheet-shaped piezoelectric composition pressure sensitive body (hereinafter referred to as pressure sensitive body) 1 . The electrode 2A and the electrode 2B are insulated from each other.

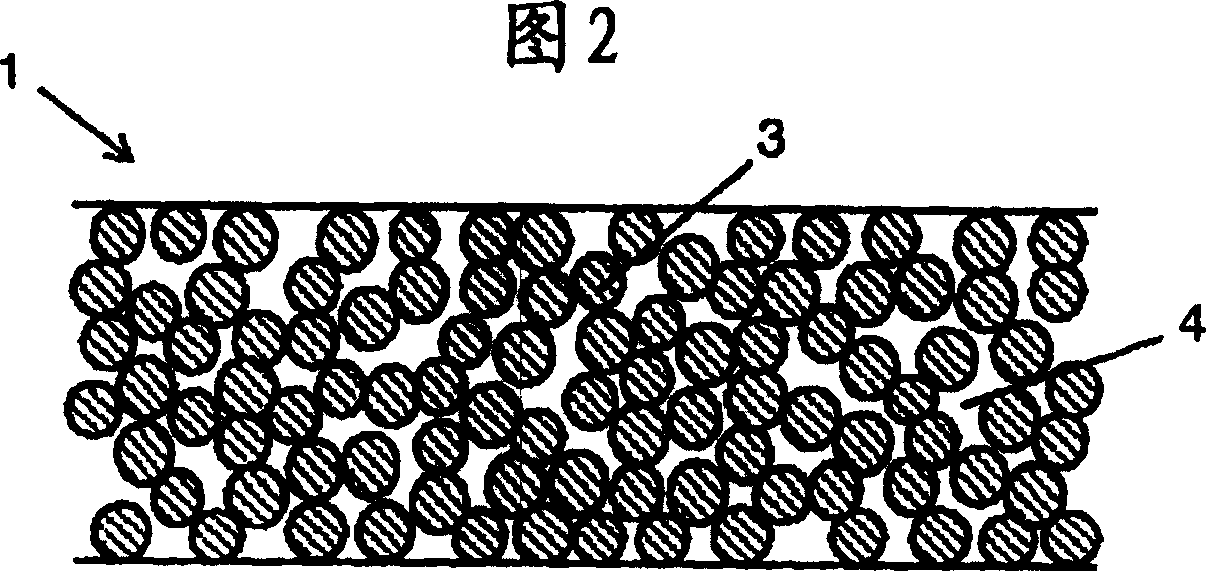

[0037] FIG. 2 is a schematic diagram showing a cross-sectional structure of the pressure sensitive body 1 . The pressure sensitive body 1 includes waterproof piezoelectric ceramic powder 3 and flexible organic polymer 4 . The piezoelectric ceramic powder 3 and the organic macromolecule 4 treated with waterproofing are in a uniformly dispersed state.

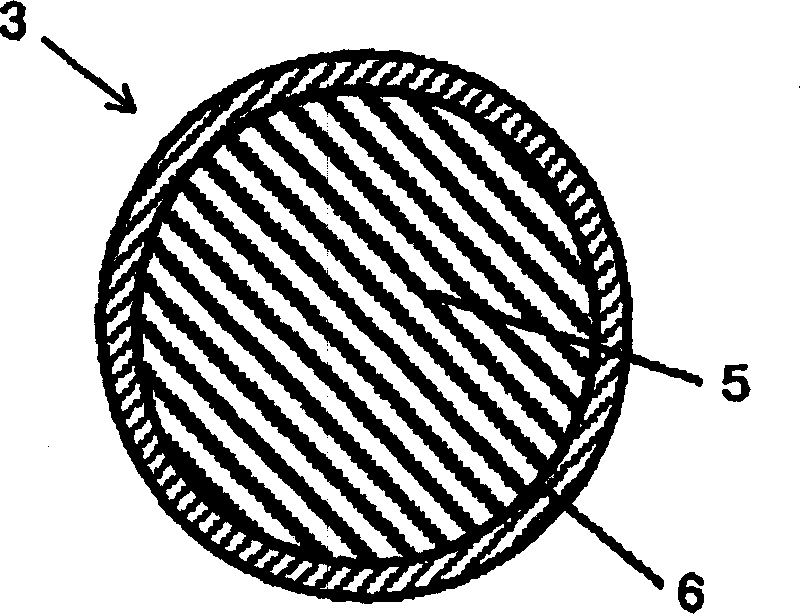

[0038] image 3 It is a schematic cross-sectional view of a particle of the waterproof-treated piezoelectric ceramic powder 3 . The waterproof-treated piezoelectric cer...

Embodiment approach 2

[0166] 7 is a cross-sectional view of a chip piezoelectric element according to Embodiment 2 of the present invention. The piezoelectric element shown in FIG. 7 is different from the piezoelectric element of Embodiment 1 in that a piezoelectric composition pressure sensitive body (hereinafter referred to as pressure sensitive body) 7 is provided with a covering layer 8 made of a waterproof material. .

[0167] The sheet pressure sensitive body 7 has the piezoelectric ceramic powder 5 and the flexible organic polymer 4 described in the first embodiment. Among them, the piezoelectric ceramic powder 5 has not been treated for waterproofing. The cover layer 8 is formed by subjecting the surface of the pressure-sensitive body 7 to waterproof treatment. Electrodes 2A and 2B are formed on the surface of cover layer 8 as in the first embodiment. In FIG. 7, the cover layer 8 is provided on the surface where the electrodes 2A, 2B are formed. That is, the cover layer 8 covers at leas...

Embodiment approach 3

[0175] 9 is a cross-sectional view of a chip piezoelectric element according to Embodiment 3 of the present invention. The difference between the piezoelectric element shown in FIG. 9 and the piezoelectric element of Embodiment 1 lies in that a waterproof material is provided on the surface of the piezoelectric composition pressure sensitive body (hereinafter referred to as the pressure sensitive body) 7 and the electrodes 2A, 2B. The covering layer 9 formed of material is provided with a protective layer 10 covering and protecting them.

[0176] The sheet-shaped pressure sensitive body 7 has the piezoelectric ceramic powder 5 described in the first embodiment and the flexible organic polymer 4 . Covering layer 9 is formed by subjecting the surfaces of electrodes 2A and 2B and part of the surface of pressure sensitive body 7 to water repellent treatment. Furthermore, a protective layer 10 covering the pressure-sensitive body 7 , the electrodes 2A, 2B, and the covering layer 9...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com