General halogen-free and flame-retardant low-smoke cable material for sheath and insulation materials and preparation method of cable material

A flame-retardant cable material and sheath technology, which is applied in the direction of insulators, organic insulators, plastic/resin/wax insulators, etc., can solve the problems of not meeting the requirements of low-smoke, halogen-free flame-retardant insulating materials, loss of electrical properties, etc., and achieve maintenance Effect of improving mechanical properties and flame retardancy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

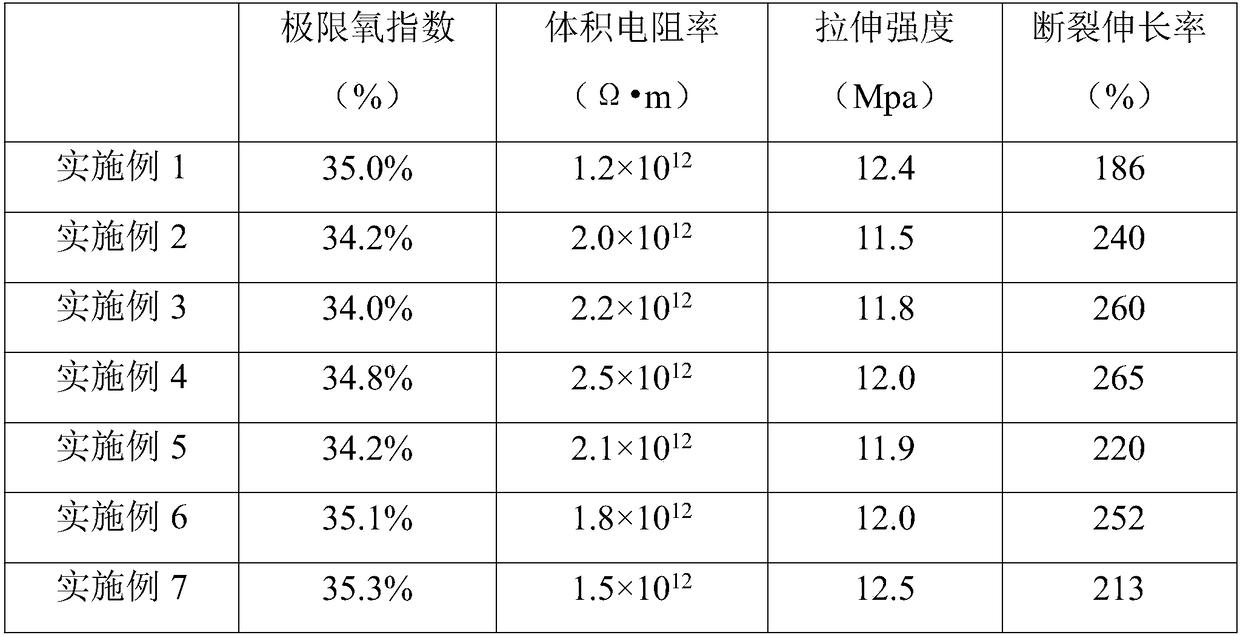

Examples

preparation example Construction

[0024] The embodiment of the present invention also provides a method for preparing a universal low-smoke halogen-free flame-retardant cable material for sheath and insulation, which includes the following steps:

[0025] Add the main flame retardant, auxiliary flame retardant and surface activation treatment agent to the high mixer respectively, and activate the treatment at 80-140 ° C for 5-40 minutes to obtain high-activity flame-retardant fillers;

[0026] Mix and granulate the highly active flame retardant filler together with polyethylene, ethylene-vinyl acetate copolymer, ethylene-octene copolymer and processing aids on a mixing device to obtain the general low-smoke sheath and insulation Halogen-free flame retardant cable compound.

[0027] Wherein, the mixing equipment is a single-screw extruder or a two-stage extruder.

Embodiment 1

[0030] The general low-smoke halogen-free flame-retardant cable material for sheath and insulation in this embodiment includes the following components by weight: 6 parts of polyethylene, 13 parts of ethylene-vinyl acetate copolymer, 4 parts of ethylene-octene copolymer, 32 parts 1 part of main flame retardant, 8 parts of auxiliary flame retardant, 2 parts of surface active treatment agent and 3 parts of processing aid.

[0031] Wherein, the polyethylene is linear low density polyethylene, the main flame retardant is hydromagnesite, the auxiliary flame retardant is magnesium hydroxide, and the surface activation treatment agent is a silane coupling agent.

[0032] The preparation method comprises the steps of:

[0033] Add the main flame retardant, auxiliary flame retardant and surface activation treatment agent into the high mixer respectively, and activate the treatment at 90°C for 10 minutes to obtain highly active flame retardant fillers;

[0034] Mix and granulate the hi...

Embodiment 2

[0036] The general low-smoke halogen-free flame-retardant cable material for the sheath and insulation in this embodiment includes the following components in parts by weight: 7 parts of polyethylene, 15 parts of ethylene-vinyl acetate copolymer, 5 parts of ethylene-octene copolymer, 45 parts 1 part of main flame retardant, 5 parts of auxiliary flame retardant, 3 parts of surface active treatment agent and 4 parts of processing aid.

[0037] Wherein, the polyethylene is metallocene polyethylene, the main flame retardant is hydromagnesite, the auxiliary flame retardant is aluminum hydroxide, and the surface activation treatment agent is an aluminate coupling agent.

[0038] The preparation method comprises the steps of:

[0039] Add the main flame retardant, auxiliary flame retardant and surface activation treatment agent into the high mixer respectively, and activate it at 100°C for 15 minutes to obtain highly active flame retardant fillers;

[0040] Mix and granulate the hig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com