Modified zinc borate and preparation method thereof

A zinc borate and modification technology, applied in the field of flame retardant materials, can solve the problems of deterioration of mechanical properties of materials, less modification and application of zinc borate, and difficulty of uniform dispersion of materials, so as to reduce surface potential energy, improve mechanical properties and flame retardant. Performance, effect of narrow particle size distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

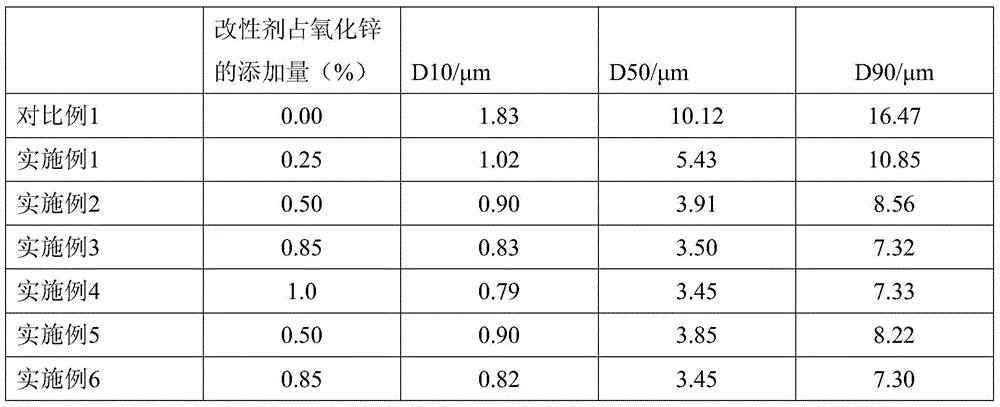

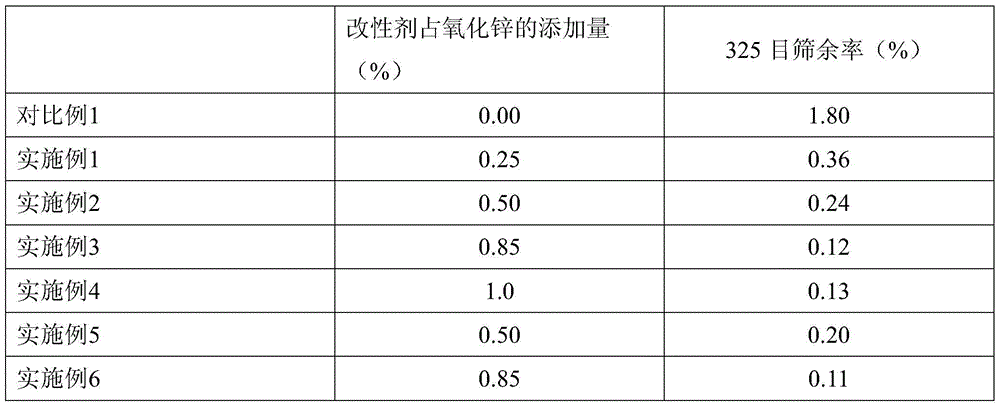

Embodiment 1

[0020] The modifier is made by mixing polydimethylsiloxane and silane coupling agent (KH550) at a mass ratio of 3:1.

[0021] Add 1061g boric acid to 2400g water, add 475g zinc oxide after dissolving, stir, keep stirring at 55°C for 30 minutes, then add 1.18g modifier, keep warm at 60°C for 6 hours, centrifuge while hot after the reaction, then add 50°C Wash twice with water, dry at 105°C, and pulverize to obtain modified zinc borate with a yield of 98.30%.

Embodiment 2

[0023] The modifier is made by mixing polydimethylsiloxane and silane coupling agent (KH550) at a mass ratio of 3:1.

[0024] Add 1080g boric acid to 2800g water, add 475g zinc oxide after dissolving, stir, keep stirring at 55°C for 30 minutes, then add 2.38g modifier, keep warm at 60°C for 6 hours, centrifuge while hot after the reaction, then add 50°C Wash twice with water, dry at 105°C, and pulverize to obtain modified zinc borate with a yield of 97.87%.

Embodiment 3

[0026] The modifier is made by mixing polydimethylsiloxane and silane coupling agent (KH550) at a mass ratio of 3:1.

[0027] Add 1080g boric acid to 2800g water, add 475g zinc oxide after dissolving, stir, keep stirring at 55°C for 30 minutes, then add 4.04g modifier, keep warm at 60°C for 6 hours, centrifuge while hot after the reaction, then add 50°C Wash twice with water, dry at 105°C, and pulverize to obtain modified zinc borate with a yield of 98.26%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com